Dodge BR, BE Repair Manual

BR/BE ENGINE SYSTEMS 8F - 1

ENGINE SYSTEMS

TABLE OF CONTENTS

page page

BATTERY SYSTEM ......................... 1

CHARGING .............................. 25

BATTERY SYSTEM

TABLE OF CONTENTS

page page

BATTERY SYSTEM

DESCRIPTION ..........................1

OPERATION ............................2

DIAGNOSIS AND TESTING - BATTERY

SYSTEM .............................2

CLEANING .............................5

INSPECTION ...........................6

SPECIFICATIONS

BATTERY ............................6

SPECIAL TOOLS ........................7

BATTERY

DESCRIPTION ..........................7

DIAGNOSIS AND TESTING - BATTERY .......7

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING ...........................8

STANDARD PROCEDURE - BUILT-IN

INDICATOR TEST .....................10

STANDARD PROCEDURE - HYDROMETER

TEST ...............................11

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST .......................12

STANDARD PROCEDURE - LOAD TEST ....12

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST .........................13

STANDARD PROCEDURE - USING

MIDTRONICS ELECTRICAL TESTER.......15

STARTING............................... 31

REMOVAL .............................16

INSTALLATION .........................16

BATTERY HOLDDOWN

DESCRIPTION .........................17

OPERATION ...........................17

REMOVAL .............................17

INSTALLATION .........................18

BATTERY CABLE

DESCRIPTION .........................18

OPERATION ...........................18

DIAGNOSIS AND TESTING - BATTERY

CABLES ............................19

REMOVAL

POSITIVE CABLE REMOVAL - GASOLINE

ENGINE.............................21

NEGATIVE CABLE REMOVAL - GASOLINE

ENGINE.............................22

INSTALLATION

POSITIVE CABLE INSTALLATION -

GASOLINE ENGINE....................22

NEGATIVE CABLE INSTALLATION -

GASOLINE ENGINE....................22

BATTERY TRAY

DESCRIPTION .........................23

OPERATION ...........................23

REMOVAL .............................23

INSTALLATION .........................24

BATTERY SYSTEM

DESCRIPTION

A single 12-volt battery system is standard factoryinstalled equipment on gasoline engine equipped

models. Models equipped with a diesel engine utilize

two 12-volt batteries connected in parallel. All of the

components of the battery system are located within

the engine compartment of the vehicle. The service

information for the battery system in this vehicle

covers the following related components, which are

covered in further detail elsewhere in this service

manual:

8F - 2 BATTERY SYSTEM BR/BE

BATTERY SYSTEM (Continued)

• Battery - The storage battery provides a reli-

able means of storing a renewable source of electrical

energy within the vehicle.

• Battery Cable - The battery cables connect the

battery terminal posts to the vehicle electrical system.

• Battery Holddown - The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

• Battery Tray - The battery tray provides a

secure mounting location in the vehicle for the battery and an anchor point for the battery holddown

hardware.

For battery system maintenance schedules and

jump starting procedures, see the owner’s manual in

the vehicle glove box. Optionally, refer to Lubrication

and Maintenance for the recommended battery maintenance schedules and for the proper battery jump

starting procedures. While battery charging can be

considered a maintenance procedure, the battery

charging procedures and related information are

located in the standard procedures section of this service manual. This was done because the battery must

be fully-charged before any battery system diagnosis

or testing procedures can be performed. Refer to

Standard procedures for the proper battery charging

procedures.

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle accessory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging system for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING - BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be tested

as a complete system. In order for the engine to start

and the battery to maintain its charge properly, all of

the components that are used in these systems must

perform within specifications. It is important that

the battery, starting, and charging systems be thoroughly tested and inspected any time a battery needs

to be charged or replaced. The cause of abnormal battery discharge, overcharging or early battery failure

must be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it easier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interdependency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmmeter, a battery charger, a carbon pile rheostat (load

tester) and a 12-volt test lamp may be required. All

OBD-sensed systems are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trouble Code (DTC). The PCM will store a DTC in electronic memory for any failure it detects. Refer to

Charging System for the proper charging system onboard diagnostic test procedures.

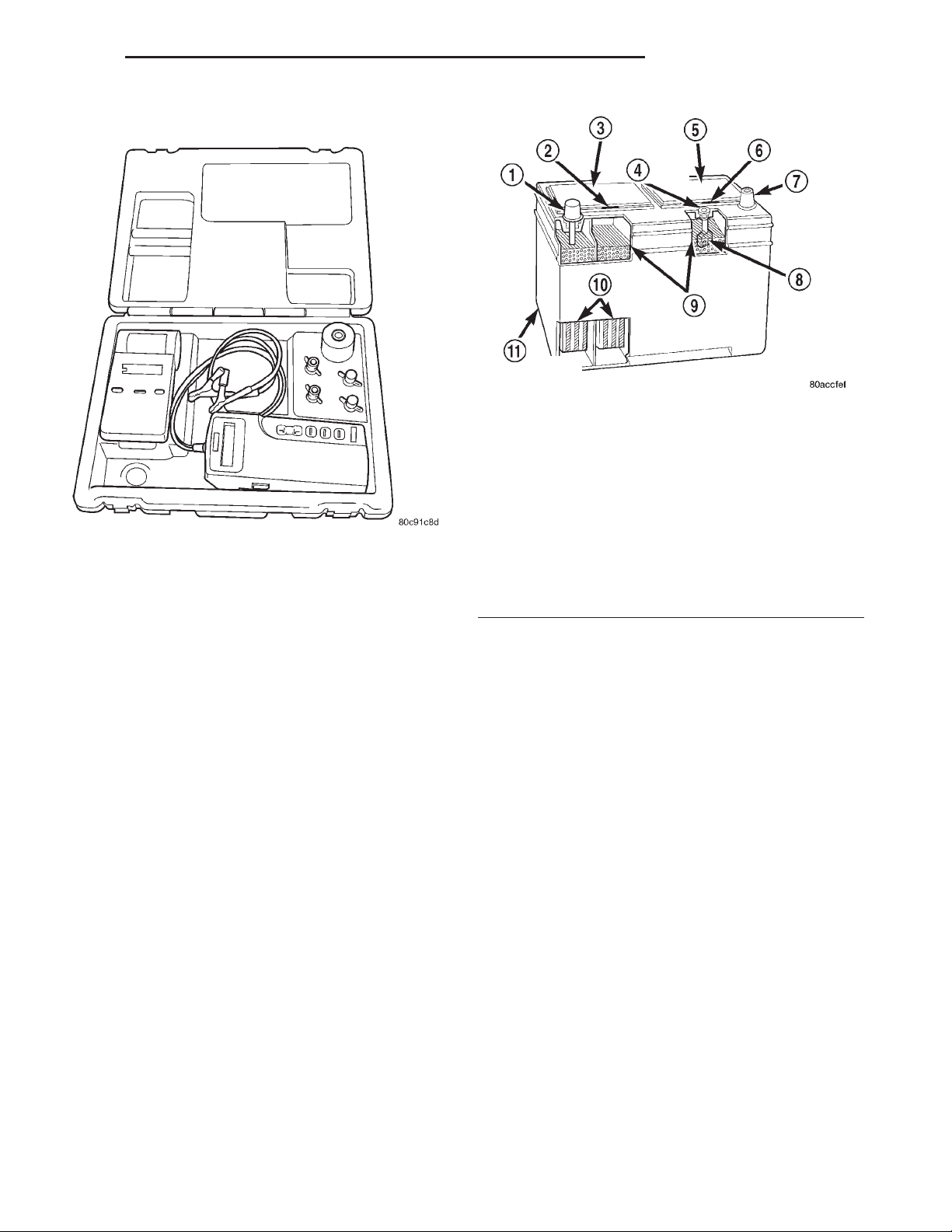

MIDTRONICS ELECTRICAL SYSTEM TESTER

The Midtronicst automotive battery and charging

system tester is designed to help the dealership technicians diagnose the cause of a defective battery or

charging system. Follow the instruction manual supplied with the tester to properly diagnose a vehicle. If

the instruction manual is not available refer to the

standard procedure in this section, which includes

the directions for using the midtronics electrical system tester.

BR/BE BATTERY SYSTEM 8F - 3

BATTERY SYSTEM (Continued)

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY SEEMS

WEAK OR DEAD WHEN

ATTEMPTING TO START

THE ENGINE.

1. The electrical system

ignition-off draw is excessive.

2. The charging system is

faulty.

3. The battery is discharged. 3. Determine the battery state-of-charge using the

4. The battery terminal

connections are loose or

corroded.

5. The battery has an

incorrect size or rating for

this vehicle.

6. The battery is faulty. 6. Determine the battery cranking capacity using

7. The starting system is

faulty.

8. The battery is physically

damaged.

1. Refer to the IGNITION-OFF DRAW TEST

Standard Procedure for the proper test

procedures. Repair the excessive ignition-off

draw, as required.

2. Determine if the charging system is performing

to specifications using the Midtronics battery and

charging system tester. Refer to Charging System

for additional charging system diagnosis and

testing procedures. Repair the faulty charging

system, as required.

Midtronics battery and charging system tester.

Refer to the Standard Procedures in this section

for additional test procedures. Charge the faulty

battery, as required.

4. Refer to Battery Cables for the proper battery

cable diagnosis and testing procedures. Clean

and tighten the battery terminal connections, as

required.

5. Refer to Battery System Specifications for the

proper size and rating. Replace an incorrect

battery, as required.

the Midtronics battery and charging system tester.

Refer to the Standard Procedures in this section

for additional test procedures. Replace the faulty

battery, as required.

7. Determine if the starting system is performing

to specifications. Refer to Starting System for the

proper starting system diagnosis and testing

procedures. Repair the faulty starting system, as

required.

8. Inspect the battery for loose terminal posts or a

cracked and leaking case. Replace the damaged

battery, as required.

8F - 4 BATTERY SYSTEM BR/BE

BATTERY SYSTEM (Continued)

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY STATE OF

CHARGE CANNOT BE

MAINTAINED.

1. The battery has an

incorrect size or rating for

this vehicle.

2. The battery terminal

connections are loose or

corroded.

3. The electrical system

ignition-off draw is excessive.

4. The battery is faulty. 4. Test the battery using the Midtronics battery

5. The starting system is

faulty.

6. The charging system is

faulty.

7. Electrical loads exceed the

output of the charging

system.

8. Slow driving or prolonged

idling with high-amperage

draw systems in use.

1. Refer to Battery System Specifications for the

proper specifications. Replace an incorrect

battery, as required.

2. Refer to Battery Cable for the proper cable

diagnosis and testing procedures. Clean and

tighten the battery terminal connections, as

required.

3. Refer to the IGNITION-OFF DRAW TEST

Standard Procedure for the proper test

procedures. Repair the faulty electrical system, as

required.

and charging system tester. Refer to Standard

Procedures for additional test procedures.

Replace the faulty battery, as required.

5. Determine if the starting system is performing

to specifications. Refer to Starting System for the

proper starting system diagnosis and testing

procedures. Repair the faulty starting system, as

required.

6. Determine if the charging system is performing

to specifications using the Midtronics battery and

charging system tester.. Refer to Charging

System for additional charging system diagnosis

and testing procedures. Repair the faulty charging

system, as required.

7. Inspect the vehicle for aftermarket electrical

equipment which might cause excessive electrical

loads.

8. Advise the vehicle operator, as required.

THE BATTERY WILL NOT

ACCEPT A CHARGE.

1. The battery is faulty. 1. Test the battery using the Midtronics battery

and charging system tester.. Charge or replace

the faulty battery, as required.

BR/BE BATTERY SYSTEM 8F - 5

BATTERY SYSTEM (Continued)

ABNORMAL BATTERY DISCHARGING

Any of the following conditions can result in abnor-

mal battery discharging:

• A faulty or incorrect charging system component. Refer to Charging System for the proper charging system diagnosis and testing procedures.

• A faulty or incorrect battery. Refer to Standard

Procedures for the proper battery diagnosis and testing procedures. Refer to Battery System Specifications for the proper specifications.

• A faulty circuit or component causing excessive

ignition-off draw.

• Electrical loads that exceed the output of the

charging system. This can be due to equipment

installed after manufacture, or repeated short trip

use.

• A faulty or incorrect starting system component.

Refer to Starting System for the proper starting system diagnosis and testing procedures.

• Corroded or loose battery posts and terminal

clamps.

• A loose or worn generator drive belt.

• Slow driving speeds (heavy traffic conditions) or

prolonged idling, with high-amperage draw systems

in use.

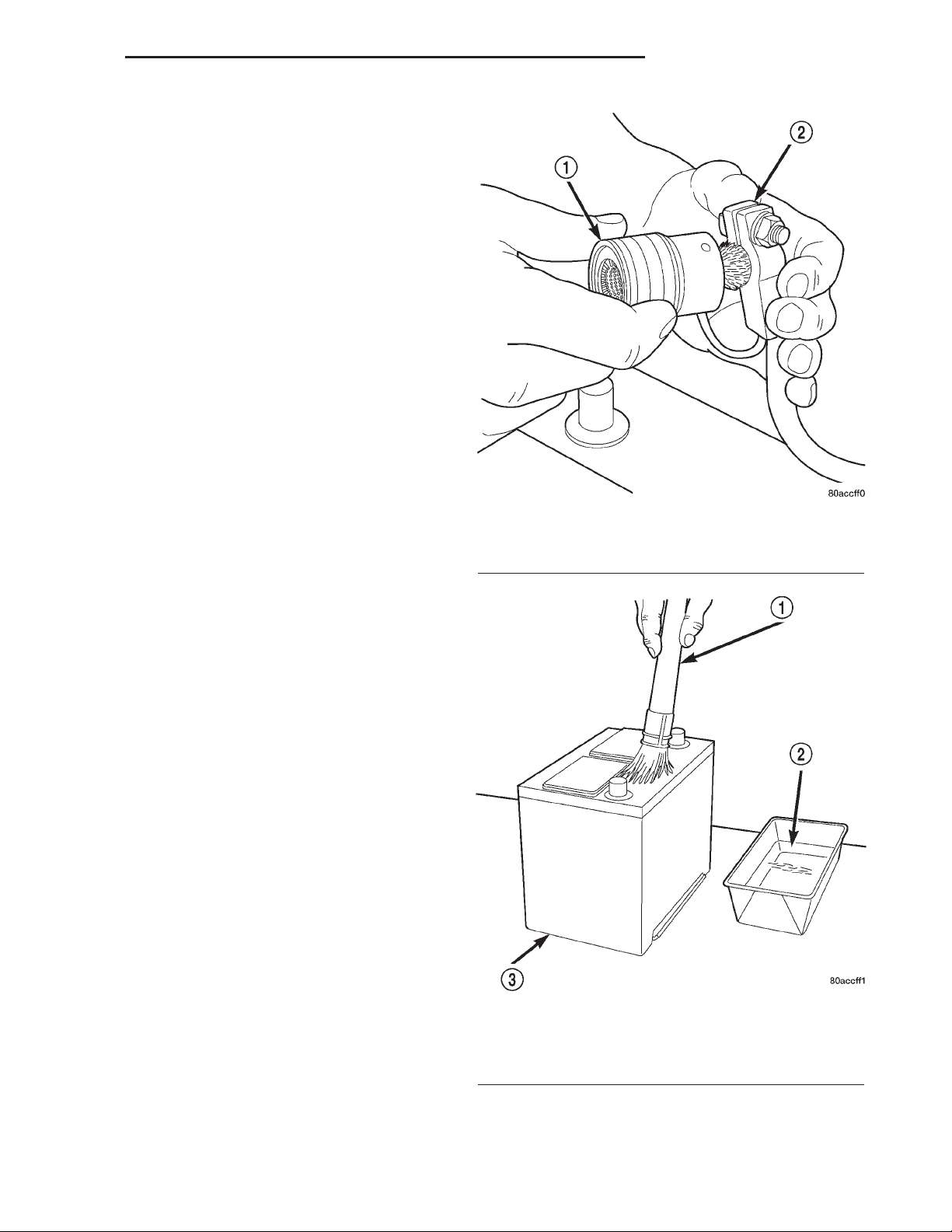

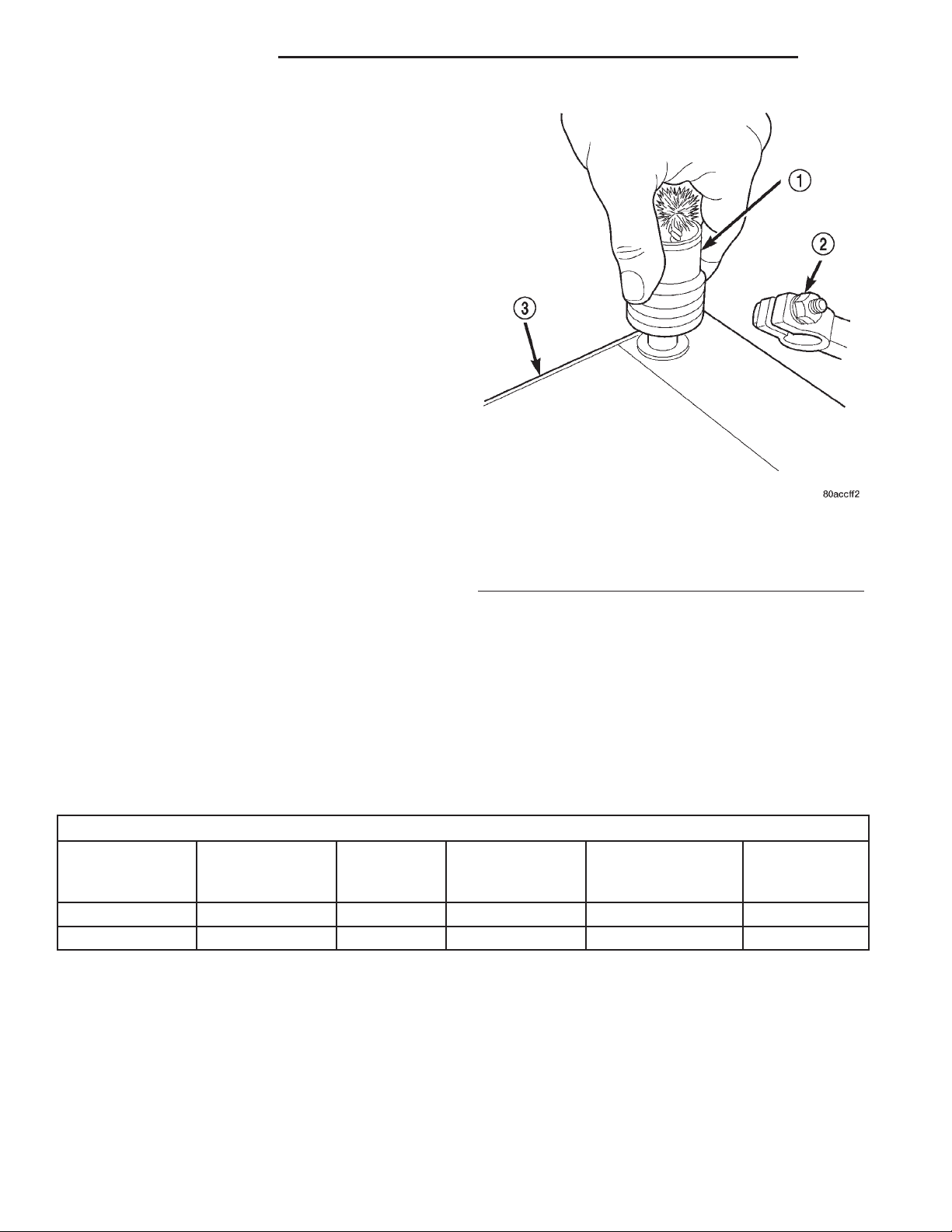

Fig. 1 Clean Battery Cable Terminal Clamp - Typical

1 - TERMINAL BRUSH

2 - BATTERY CABLE

CLEANING

The following information details the recommended

cleaning procedures for the battery and related components. In addition to the maintenance schedules

found in this service manual and the owner’s manual, it is recommended that these procedures be performed any time the battery or related components

must be removed for vehicle service.

(1) Clean the battery cable terminal clamps of all

corrosion. Remove any corrosion using a wire brush

or a post and terminal cleaning tool, and a sodium

bicarbonate (baking soda) and warm water cleaning

solution (Fig. 1).

(2) Clean the battery tray and battery holddown

hardware of all corrosion. Remove any corrosion

using a wire brush and a sodium bicarbonate (baking

soda) and warm water cleaning solution. Paint any

exposed bare metal.

(3) If the removed battery is to be reinstalled,

clean the outside of the battery case and the top

cover with a sodium bicarbonate (baking soda) and

warm water cleaning solution using a stiff bristle

parts cleaning brush to remove any acid film (Fig. 2).

Rinse the battery with clean water. Ensure that the

cleaning solution does not enter the battery cells

through the vent holes. If the battery is being

replaced, refer to Battery System Specifications for

the factory-installed battery specifications. Confirm

that the replacement battery is the correct size and

has the correct ratings for the vehicle.

Fig. 2 Clean Battery - Typical

1 - CLEANING BRUSH

2 - WARM WATERAND BAKING SODA SOLUTION

3 - BATTERY

8F - 6 BATTERY SYSTEM BR/BE

BATTERY SYSTEM (Continued)

(4) Clean the battery thermal guard with a sodium

bicarbonate (baking soda) and warm water cleaning

solution using a stiff bristle parts cleaning brush to

remove any acid film.

(5) Clean any corrosion from the battery terminal

posts with a wire brush or a post and terminal

cleaner, and a sodium bicarbonate (baking soda) and

warm water cleaning solution (Fig. 3).

INSPECTION

The following information details the recommended

inspection procedures for the battery and related

components. In addition to the maintenance schedules found in this service manual and the owner’s

manual, it is recommended that these procedures be

performed any time the battery or related components must be removed for vehicle service.

(1) Inspect the battery cable terminal clamps for

damage. Replace any battery cable that has a damaged or deformed terminal clamp.

(2) Inspect the battery tray and battery holddown

hardware for damage. Replace any damaged parts.

(3) Slide the thermal guard off of the battery case,

if equipped. Inspect the battery case for cracks or

other damage that could result in electrolyte leaks.

Also, check the battery terminal posts for looseness.

Batteries with damaged cases or loose terminal posts

must be replaced.

(4) Inspect the battery thermal guard for tears,

cracks, deformation or other damage. Replace any

battery thermal guard that has been damaged.

Fig. 3 Clean Battery Terminal Post - Typical

1 - TERMINAL BRUSH

2 - BATTERY CABLE

3 - BATTERY

(5) Inspect the battery built-in test indicator sight

glass for an indication of the battery condition. If the

battery is discharged, charge as required. (Refer to 8

- ELECTRICAL/BATTERY SYSTEM/BATTERY STANDARD PROCEDURE).

SPECIFICATIONS

BATTERY

Battery Classifications and Ratings

Part Number

56028375AA 27 600 120 Minutes 66 300

56028376AA 27 750 150 Minutes 75 375

BCI Group Size

Classification

Cold

Cranking

Amperage

Reserve

Capacity

Ampere-Hours

Load Test

Amperage

BR/BE BATTERY SYSTEM 8F - 7

BATTERY SYSTEM (Continued)

SPECIAL TOOLS

Fig. 4 Low-Maintenance Battery - Typical

1 - POSITIVE POST

2 - VENT

3 - CELL CAP

4 - TEST INDICATOR

5 - CELL CAP

6 - VENT

7 - NEGATIVE POST

MIDTRONICS BATTERY AND CHARGING SYSTEM

TESTER - Micro420

BATTERY

8 - GREEN BALL

9 - ELECTROLYTE LEVEL

10 - PLATE GROUPS

11 - LOW-MAINTENANCE BATTERY

DESCRIPTION

A large capacity, low-maintenance storage battery

(Fig. 4) is standard factory-installed equipment on

this model. Refer to Battery System Specifications for

the proper specifications of the factory-installed batteries available on this model. Male post type terminals made of a soft lead material protrude from the

top of the molded plastic battery case to provide the

means for connecting the battery to the vehicle electrical system. The battery positive terminal post is

physically larger in diameter than the negative terminal post to ensure proper battery connection. The

letters POS and NEG are also molded into the top of

the battery case adjacent to their respective positive

and negative terminal posts for identification confirmation. Refer to Battery Cables for more information

on the battery cables that connect the battery to the

vehicle electrical system.

The battery is made up of six individual cells that

are connected in series. Each cell contains positively

charged plate groups that are connected with lead

straps to the positive terminal post, and negatively

charged plate groups that are connected with lead

straps to the negative terminal post. Each plate consists of a stiff mesh framework or grid coated with

lead dioxide (positive plate) or sponge lead (negative

plate). Insulators or plate separators made of a nonconductive material are inserted between the positive

and negative plates to prevent them from contacting

or shorting against one another. These dissimilar

metal plates are submerged in a sulfuric acid and

water solution called an electrolyte.

The factory-installed battery has a built-in test

indicator (hydrometer). The color visible in the sight

glass of the indicator will reveal the battery condition. Refer to Standard Procedures for the proper

built-in indicator test procedures. The factory-in-

stalled low-maintenance battery has non-removable battery cell caps. Water cannot be added

to this battery. The battery is not sealed and has

vent holes in the cell caps. The chemical composition

of the metal coated plates within the low-maintenance battery reduces battery gassing and water

loss, at normal charge and discharge rates. Therefore, the battery should not require additional water

in normal service. Rapid loss of electrolyte can be

caused by an overcharging condition. Be certain to

diagnose the charging system before returning the

vehicle to service. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND TESTING).

DIAGNOSIS AND TESTING - BATTERY

The battery must be completely charged and the

top, posts and terminal clamps should be properly

cleaned and inspected before diagnostic procedures

are performed. Refer to Battery System Cleaning for

8F - 8 BATTERY SYSTEM BR/BE

BATTERY (Continued)

the proper cleaning procedures, and Battery System

Inspection for the proper battery inspection procedures. Refer to Standard Procedures for the proper

battery charging procedures.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING OR LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BATTERY. PERSONAL INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

A battery that will not accept a charge is faulty,

and must be replaced. Further testing is not

required. A fully-charged battery must be load tested

to determine its cranking capacity. A battery that is

fully-charged, but does not pass the load test, is

faulty and must be replaced.

NOTE: Completely discharged batteries may take

several hours to accept a charge. Refer to Standard

Procedures for the proper battery charging procedures.

A battery is fully-charged when:

• All battery cells are gassing freely during charg-

ing.

• A green color is visible in the sight glass of the

battery built-in test indicator.

• Three corrected specific gravity tests, taken at

one-hour intervals, indicate no increase in the specific gravity of the battery electrolyte.

• Open-circuit voltage of the battery is 12.4 volts

or greater.

STANDARD PROCEDURE

The condition of a battery is determined by two cri-

teria:

• State-Of-Charge - This can be determined by

checking the specific gravity of the battery electrolyte

(built-in indicator test or hydrometer test), or by

checking the battery voltage (open-circuit voltage

test).

• Cranking Capacity - This can be determined

by performing a battery load test, which measures

the ability of the battery to supply high-amperage

current.

First, determine the battery state-of-charge. This

can be done in one of three ways. If the battery has a

built-in test indicator, perform the built-in indicator

test to determine the state-of-charge. If the battery

has no built-in test indicator but does have removable cell caps, perform the hydrometer test to determine the state-of-charge. If the battery cell caps are

not removable, or a hydrometer is not available, perform the open-circuit voltage test to determine the

state-of-charge. Refer to open-circuit voltage test in

the Standard Procedures section of this group.

Second, determine the battery cranking capacity by

performing a load test. The battery must be charged

before proceeding with a load test if:

• The battery built-in test indicator has a black or

dark color visible.

• The temperature corrected specific gravity of the

battery electrolyte is less than 1.235.

• The battery open-circuit voltage is less than 12.4

volts.

STANDARD PROCEDURE - BATTERY

CHARGING

Battery charging can be performed fast or slow, it

terms of time. Slow battery charging is the best

means of restoring a battery to full potential. Fast

battery charging should only be performed when

absolutely necessary due to time restraints. A battery

is fully-charged when:

• All of the battery cells are gassing freely during

battery charging.

• A green color is visible in the sight glass of the

battery built-in test indicator.

• Three hydrometer tests, taken at one-hour intervals, indicate no increase in the temperature-corrected specific gravity of the battery electrolyte.

• Open-circuit voltage of the battery is 12.65 volts

or above.

WARNING: NEVER EXCEED TWENTY AMPERES

WHEN CHARGING A COLD (-1° C [30° F] OR

LOWER) BATTERY. THE BATTERY MAY ARC INTERNALLY AND EXPLODE. PERSONAL INJURY AND/OR

VEHICLE DAMAGE MAY RESULT.

CAUTION: Always disconnect and isolate the battery negative cable before charging a battery. Do

not exceed sixteen volts while charging a battery.

Damage to the vehicle electrical system components may result.

BR/BE BATTERY SYSTEM 8F - 9

BATTERY (Continued)

CAUTION: Battery electrolyte will bubble inside the

battery case during normal battery charging. Electrolyte boiling or being discharged from the battery

vents indicates a battery overcharging condition.

Immediately reduce the charging rate or turn off the

charger to evaluate the battery condition. Damage

to the battery may result from overcharging.

CAUTION: The battery should not be hot to the

touch. If the battery feels hot to the touch, turn off

the charger and let the battery cool before continuing the charging operation. Damage to the battery

may result.

NOTE: Models equipped with the diesel engine

option are equipped with two 12-volt batteries, connected in parallel (positive-to-positive and negativeto-negative). In order to ensure proper charging of

each battery, these batteries MUST be disconnected

from each other, as well as from the vehicle electrical system, while being charged.

Some battery chargers are equipped with polaritysensing circuitry. This circuitry protects the battery

charger and the battery from being damaged if they

are improperly connected. If the battery state-ofcharge is too low for the polarity-sensing circuitry to

detect, the battery charger will not operate. This

makes it appear that the battery will not accept

charging current. See the instructions provided by

the manufacturer of the battery charger for details

on how to bypass the polarity-sensing circuitry.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine the battery

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures. If the battery

will endure a load test, return the battery to service.

If the battery will not endure a load test, it is faulty

and must be replaced.

Clean and inspect the battery hold downs, tray,

terminals, posts, and top before completing battery

service. Refer to Battery System Cleaning for the

proper battery system cleaning procedures, and Battery System Inspection for the proper battery system

inspection procedures.

CHARGING A COMPLETELY DISCHARGED

BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless this procedure is properly followed, a good battery may be

needlessly replaced.

(1) Measure the voltage at the battery posts with a

voltmeter, accurate to 1/10 (0.10) volt (Fig. 5). If the

reading is below ten volts, the battery charging cur-

rent will be low. It could take some time before the

battery accepts a current greater than a few milliamperes. Such low current may not be detectable on the

ammeters built into many battery chargers.

Fig. 5 Voltmeter - Typical

(2) Disconnect and isolate the battery negative

cable. Connect the battery charger leads. Some battery chargers are equipped with polarity-sensing circuitry. This circuitry protects the battery charger and

the battery from being damaged if they are improperly connected. If the battery state-of-charge is too

low for the polarity-sensing circuitry to detect, the

battery charger will not operate. This makes it

appear that the battery will not accept charging current. See the instructions provided by the manufacturer of the battery charger for details on how to

bypass the polarity-sensing circuitry.

(3) Battery chargers vary in the amount of voltage

and current they provide. The amount of time

required for a battery to accept measurable charging

current at various voltages is shown in the Charge

Rate Table. If the charging current is still not measurable at the end of the charging time, the battery

is faulty and must be replaced. If the charging current is measurable during the charging time, the battery may be good and the charging should be

completed in the normal manner.

CHARGE RATE TABLE

Voltage Hours

16.0 volts maximum up to 4 hours

14.0 to 15.9 volts up to 8 hours

13.9 volts or less up to 16 hours

CHARGING TIME REQUIRED

The time required to charge a battery will vary,

depending upon the following factors:

• Battery Capacity - A completely discharged

heavy-duty battery requires twice the charging time

of a small capacity battery.

8F - 10 BATTERY SYSTEM BR/BE

BATTERY (Continued)

• Temperature - A longer time will be needed to

charge a battery at -18° C (0° F) than at 27° C (80°

F). When a fast battery charger is connected to a cold

battery, the current accepted by the battery will be

very low at first. As the battery warms, it will accept

a higher charging current rate (amperage).

• Charger Capacity - A battery charger that

supplies only five amperes will require a longer

charging time. A battery charger that supplies

twenty amperes or more will require a shorter charging time.

• State-Of-Charge - A completely discharged bat-

tery requires more charging time than a partially

discharged battery. Electrolyte is nearly pure water

in a completely discharged battery. At first, the

charging current (amperage) will be low. As the battery charges, the specific gravity of the electrolyte

will gradually rise.

The Battery Charging Time Table gives an indication of the time required to charge a typical battery

at room temperature based upon the battery state-ofcharge and the charger capacity.

BATTERY CHARGING TIME TABLE

Charging

Amperage

Open Circuit

Voltage

12.25 to 12.49 6 hours 3 hours 1.5

12.00 to 12.24 10 hours 5 hours 2.5

10.00 to 11.99 14 hours 7 hours 3.5

Below 10.00 18 hours 9 hours 4.5

5 Amps

Hours Charging @

10

Amps

21° C (70° F)

20 Amps

hours

hours

hours

hours

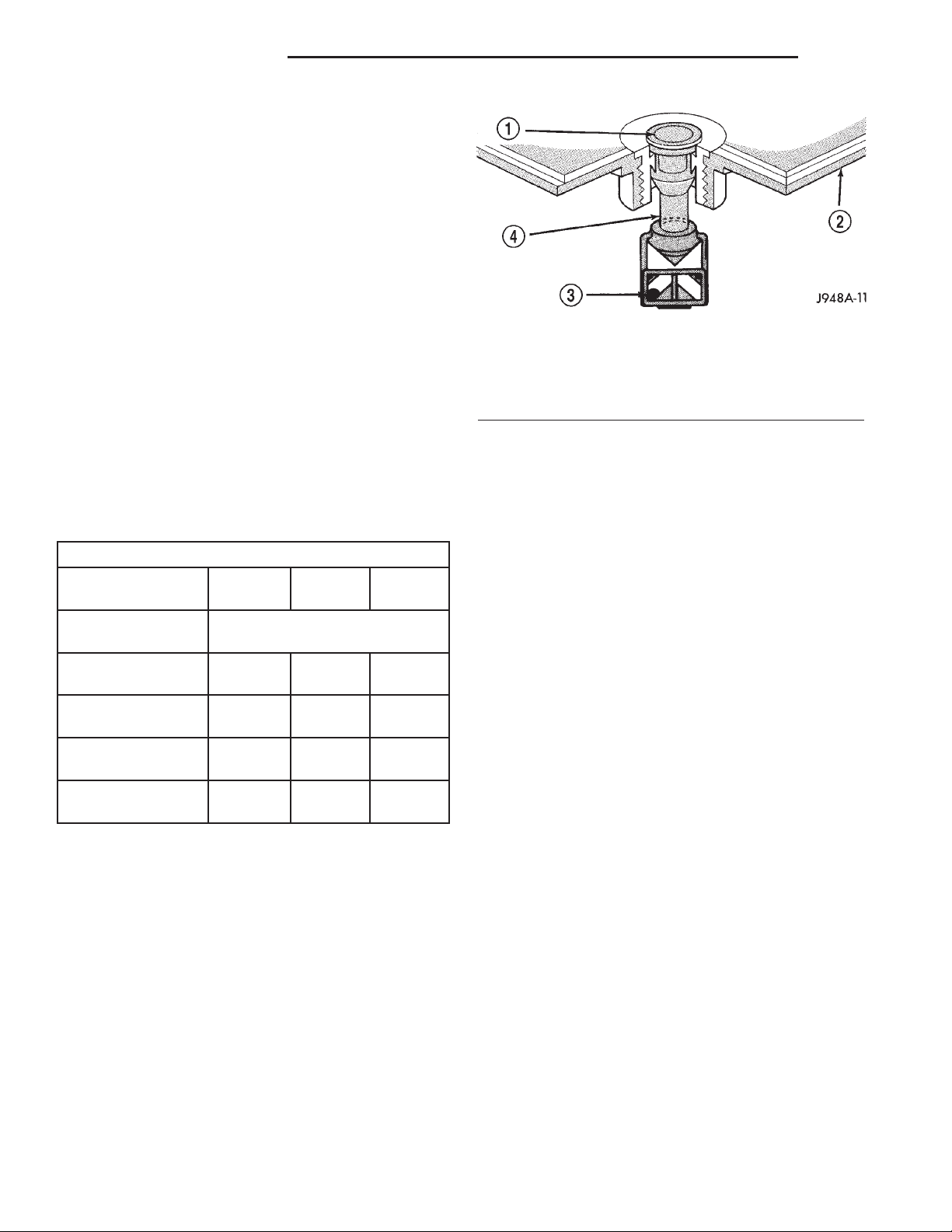

STANDARD PROCEDURE - BUILT-IN

INDICATOR TEST

An indicator (hydrometer) built into the top of the

battery case provides visual information for battery

testing (Fig. 6). Like a hydrometer, the built-in indicator measures the specific gravity of the battery

electrolyte. The specific gravity of the electrolyte

reveals the battery state-of-charge; however, it will

not reveal the cranking capacity of the battery. A load

test must be performed to determine the battery

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures.

Before testing, visually inspect the battery for any

damage (a cracked case or cover, loose posts, etc.)

that would cause the battery to be faulty. In order to

obtain correct indications from the built-in indicator,

it is important that the battery be level and have a

1 - SIGHT GLASS

2 - BATTERY TOP

3 - GREEN BALL

4 - PLASTIC ROD

clean sight glass. Additional light may be required to

view the indicator. Do not use open flame as a

source of additional light.

To read the built-in indicator, look into the sight

glass and note the color of the indication (Fig. 7). The

battery condition that each color indicates is

described in the following list:

• Green - Indicates 75% to 100% battery state-of-

charge. The battery is adequately charged for further

testing or return to service. If the starter will not

crank for a minimum of fifteen seconds with a fullycharged battery, the battery must be load tested.

Refer to Standard Procedures for the proper battery

load test procedures.

• Black or Dark - Indicates 0% to 75% battery

state-of-charge. The battery is inadequately charged

and must be charged until a green indication is visible in the sight glass (12.4 volts or more), before the

battery is tested further or returned to service. Refer

to Standard Procedures for the proper battery charging procedures. Also refer to Diagnosis and Testing

for more information on the possible causes of the

discharged battery condition.

• Clear or Bright - Indicates a low battery elec-

trolyte level. The electrolyte level in the battery is

below the built-in indicator. A maintenance-free battery with non-removable cell caps must be replaced if

the electrolyte level is low. Water must be added to a

low-maintenance battery with removable cell caps

before it is charged. Refer to Standard Procedures for

the proper battery filling procedures. A low electrolyte level may be caused by an overcharging condition. Refer to Charging System for the proper

charging system diagnosis and testing procedures.

Fig. 6 Built-In Indicator

BR/BE BATTERY SYSTEM 8F - 11

BATTERY (Continued)

Fig. 7 Built-In Indicator Sight Glass Chart

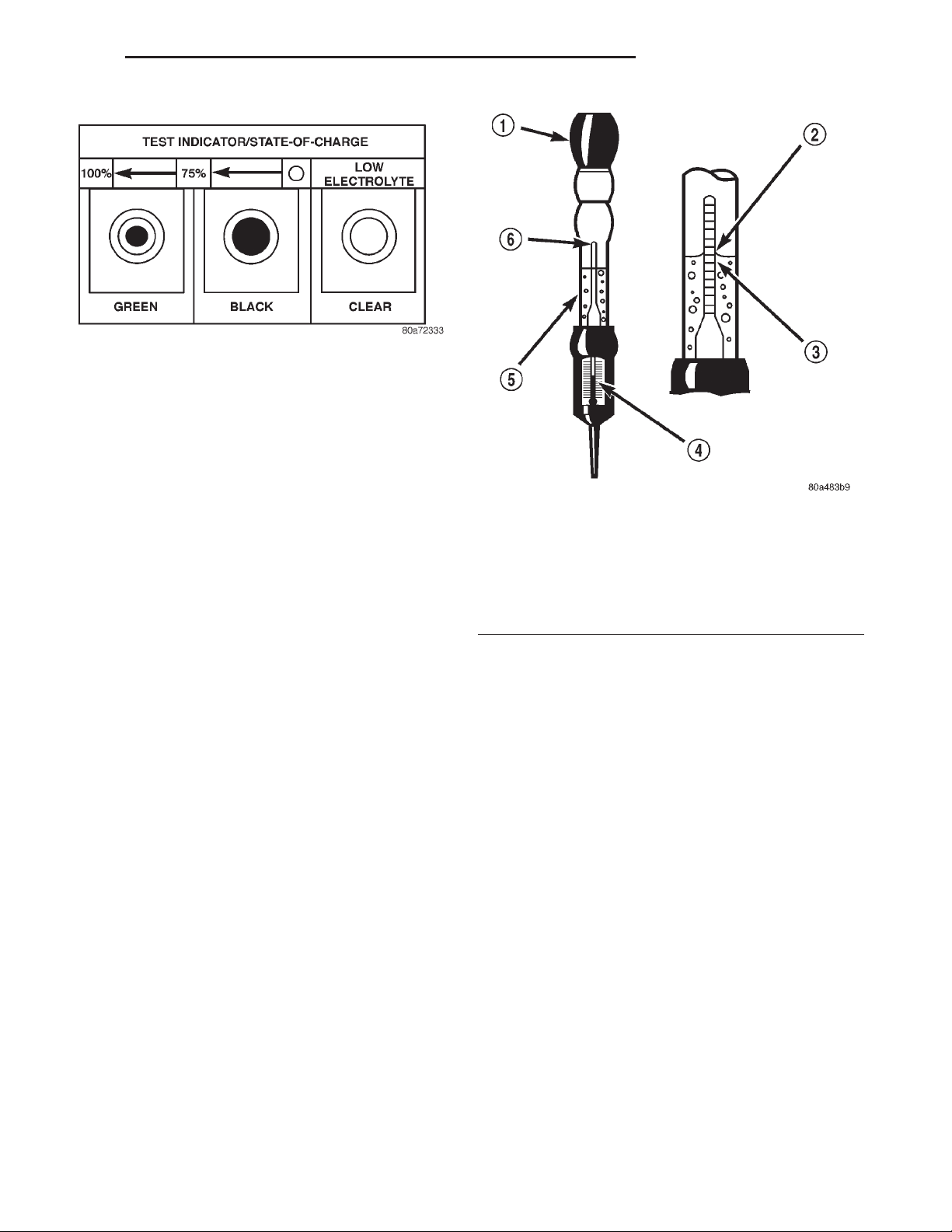

STANDARD PROCEDURE - HYDROMETER TEST

The hydrometer test reveals the battery state-ofcharge by measuring the specific gravity of the electrolyte. This test cannot be performed on

maintenance-free batteries with non-removable

cell caps. If the battery has non-removable cell caps,

refer to Diagnosis and Testing for alternate methods

of determining the battery state-of-charge.

Specific gravity is a comparison of the density of

the battery electrolyte to the density of pure water.

Pure water has a specific gravity of 1.000, and sulfuric acid has a specific gravity of 1.835. Sulfuric acid

makes up approximately 35% of the battery electrolyte by weight, or 24% by volume. In a fully-charged

battery the electrolyte will have a temperature-corrected specific gravity of 1.260 to 1.290. However, a

specific gravity of 1.235 or above is satisfactory for

the battery to be load tested and/or returned to service.

Before testing, visually inspect the battery for any

damage (a cracked case or cover, loose posts, etc.)

that would cause the battery to be faulty. Then

remove the battery cell caps and check the electrolyte

level. Add distilled water if the electrolyte level is

below the top of the battery plates. Refer to Battery

System Cleaning for the proper battery inspection

procedures.

See the instructions provided by the manufacturer

of the hydrometer for recommendations on the correct use of the hydrometer that you are using.

Remove only enough electrolyte from the battery cell

so that the float is off the bottom of the hydrometer

barrel with pressure on the bulb released. To read

the hydrometer correctly, hold it with the top surface

of the electrolyte at eye level (Fig. 8).

CAUTION: Exercise care when inserting the tip of

the hydrometer into a battery cell to avoid damaging the plate separators. Damaged plate separators

can cause early battery failure.

1 - BULB

2 - SURFACE COHESION

3 - SPECIFIC GRAVITY READING

4 - TEMPERATURE READING

5 - HYDROMETER BARREL

6 - FLOAT

Hydrometer floats are generally calibrated to indicate the specific gravity correctly only at 26.7° C.

When testing the specific gravity at any other temperature, a correction factor is required. The correction factor is approximately a specific gravity value

of 0.004, which may also be identified as four points

of specific gravity. For each 5.5° C above 26.7° C, add

four points. For each 5.5° C below 26.7° C, subtract

four points. Always correct the specific gravity for

temperature variation.

EXAMPLE: A battery is tested at -12.2° C and has

a specific gravity of 1.240. Determine the actual specific gravity as follows:

(1) Determine the number of degrees above or

below 26.7° C: 26.7° C + -12.2° C = 14.5° C below

the 26.7° C specification

(2) Divide the result from Step 1 by 5.5° C: 14.5°

C ÷ 5.5° C = 2.64

(3) Multiply the result from Step 2 by the temperature correction factor (0.004): 2.64 X 0.004 = 0.01

(4) The temperature at testing was below 26.7° C;

therefore, the temperature correction factor is subtracted: 1.240 - 0.01 = 1.23

(5) The corrected specific gravity of the battery cell

in this example is 1.23.

Fig. 8 Hydrometer - Typical

8F - 12 BATTERY SYSTEM BR/BE

BATTERY (Continued)

Test the specific gravity of the electrolyte in each

battery cell. If the specific gravity of all cells is above

1.235, but the variation between cells is more than

fifty points (0.050), the battery should be replaced. If

the specific gravity of one or more cells is less than

1.235, charge the battery at a rate of approximately

five amperes. Continue charging the battery until

three consecutive specific gravity tests, taken at onehour intervals, are constant. If the cell specific gravity variation is more than fifty points (0.050) at the

end of the charge period, replace the battery.

When the specific gravity of all cells is above 1.235,

and the cell variation is less than fifty points (0.050),

the battery may be load tested to determine its

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures.

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used in place of the hydrometer test

when a hydrometer is not available, or for maintenance-free batteries with non-removable cell caps.

Before proceeding with this test, completely charge

the battery (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE).

(1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, negative cable first.

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufacturer of the voltmeter), measure the open-circuit voltage (Fig. 9).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

STANDARD PROCEDURE - LOAD TEST

A battery load test will verify the battery cranking

capacity. The test is based on the Cold Cranking

Amperage (CCA) rating of the battery. To determine

the battery CCA rating, see the label affixed to the

battery case or refer to Battery Specifications for the

proper factory-installed specifications.

Before proceeding with this test, completely charge

the battery (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE).

(1) Disconnect and isolate both battery cables, negative cable first. The battery top and posts should be

clean (Refer to 8 - ELECTRICAL/BATTERY SYSTEM

- CLEANING).

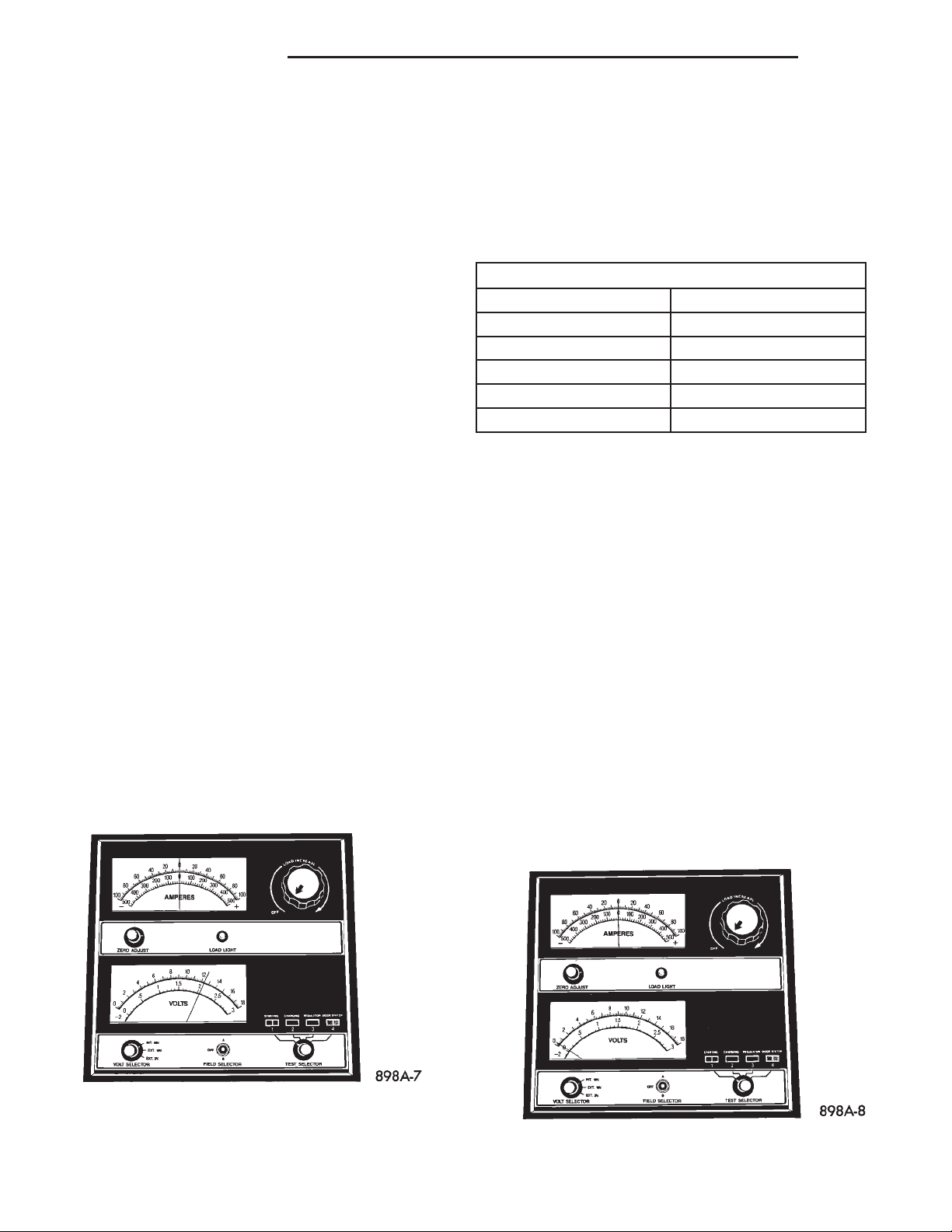

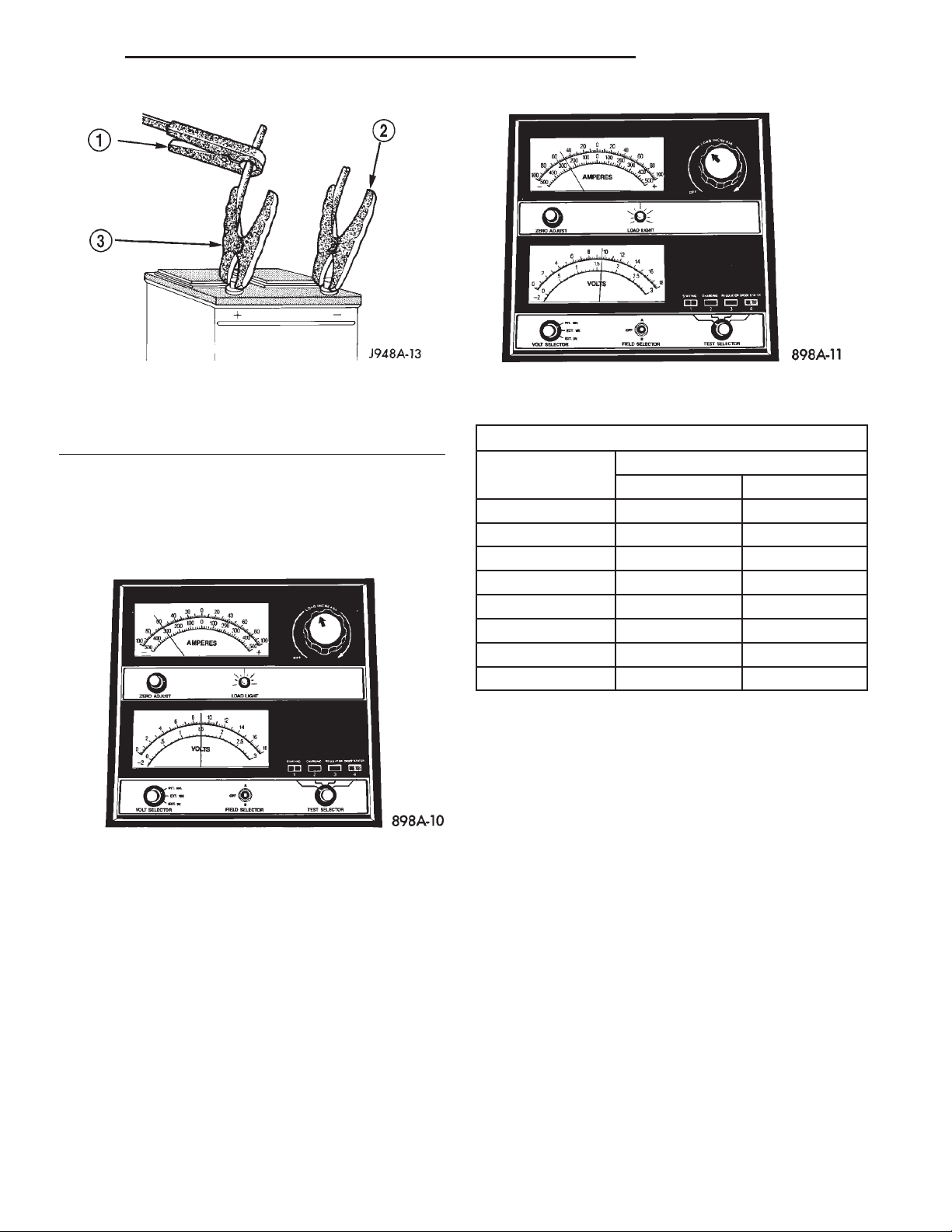

(2) Connect a suitable volt-ammeter-load tester

(Fig. 10) to the battery posts (Fig. 11). See the

instructions provided by the manufacturer of the

tester you are using. Check the open-circuit voltage

(no load) of the battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - STANDARD PROCEDURE). The battery open-circuit voltage must be

12.4 volts or greater.

Fig. 9 Testing Open-Circuit Voltage - Typical

Fig. 10 Volt-Ammeter-Load Tester - Typical

BR/BE BATTERY SYSTEM 8F - 13

BATTERY (Continued)

Fig. 11 Volt-Ammeter-Load

1 - INDUCTION AMMETER CLAMP

2 - NEGATIVE CLAMP

3 - POSITIVE CLAMP

(3) Rotate the load control knob (carbon pile rheostat) to apply a 300 ampere load to the battery for

fifteen seconds, then return the control knob to the

Off position (Fig. 12). This will remove the surface

charge from the battery.

Fig. 12 Remove Surface Charge from Battery

(4) Allow the battery to stabilize to open-circuit

voltage. It may take up to five minutes for the battery voltage to stabilize.

(5) Rotate the load control knob to maintain a load

equal to 50% of the CCA rating of the battery (Fig.

13). After fifteen seconds, record the loaded voltage

reading, then return the load control knob to the Off

position.

(6) The voltage drop will vary with the battery

temperature at the time of the load test. The battery

temperature can be estimated by using the ambient

temperature during the past several hours. If the

battery has been charged, boosted, or loaded a few

minutes prior to the test, the battery will be somewhat warmer. See the Load Test Temperature Table

for the proper loaded voltage reading.

Fig. 13 Load 50% CCA Rating - Note Voltage -

Typical

LOAD TEST TEMPERATURE TABLE

Minimum Voltage

9.6 volts 70° and above 21° and above

9.5 volts 60° 16°

9.4 volts 50° 10°

9.3 volts 40° 4°

9.1 volts 30° -1°

8.9 volts 20° -7°

8.7 volts 10° -12°

8.5 volts 0° -18°

(7) If the voltmeter reading falls below 9.6 volts, at

a minimum battery temperature of 21° C (70° F), the

battery is faulty and must be replaced.

Temperature

°F °C

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a normal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from five

to thirty-five milliamperes (0.005 to 0.035 ampere)

with the ignition switch in the Off position, and all

non-ignition controlled circuits in proper working

order. Up to thirty-five milliamperes are needed to

enable the memory functions for the Powertrain Control Module (PCM), digital clock, electronically tuned

radio, and other modules which may vary with the

vehicle equipment.

A vehicle that has not been operated for approximately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the Junction Block. This will reduce battery discharging.

Loading...

Loading...