Page 1

EXTRACTIVE GAS DETECTOR

OPERATION MANUAL

Model PS-7

For Administrators

• Operate this unit only after reading and fully understanding the content of this manual.

• This Operation Manual was written for administrator use. Instructions for the basic

operations of this unit are provided separately in the standard Operation Manual. Refer

to the Operation Manual when necessary.

740 McArdle Drive, Unit C – Crystal Lake, IL 60014

815-788-5200 Phone 815-788-5300 Fax www.dodtec.com

Page 2

Some of the settings on this unit (alarm settings, etc.) are password protected.

This Operation Manual explains the following items:

•

Passwords

•

Changing settings

1 Passwords

1-1 Password-protected Settings

• Span adjustment (Refer to 2-1 Span Adjustment)

•

21vol% adjustment (Refer to

•

The values of various settings (Refer to 2-3 Changing Setting Values)

•

The values of alarm settings (Refer to 2-4 Changing the Alarm Settings)

1-2 Releasing the Password Lock

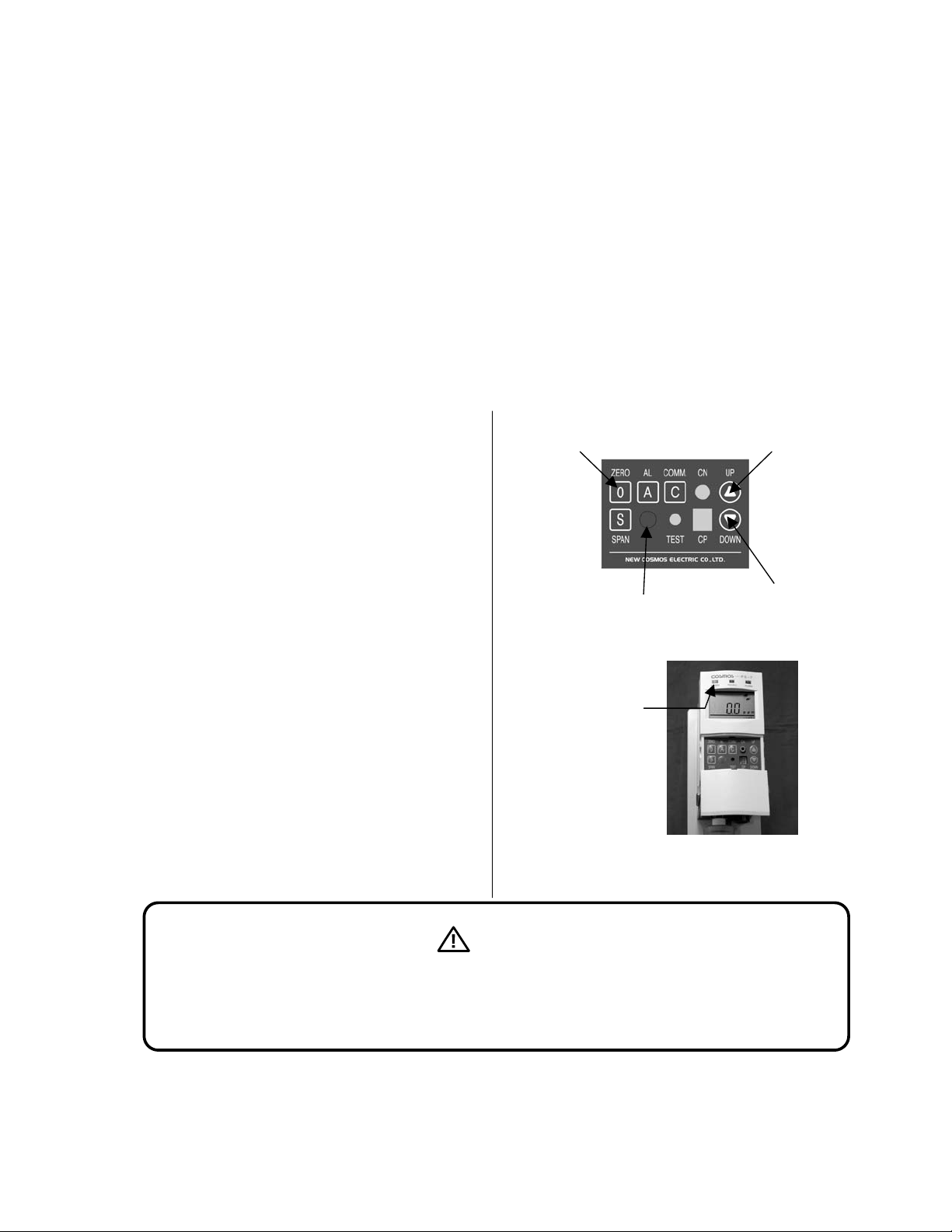

(1) Press these key switches in the following order.

1. ZERO switch

2. UP switch

3. Special command switch

4. DOWN switch

(2) The password lock is released when the

POWER lamp (green) blinks once.

2-2 21Vol% Adjustment

1

3

POWER lamp (green)

Blinks once

)

2

4

(3) The password lock is automatically reactivated

10 minutes after it has been released.

Important tasks, such as changing alarm settings, span adjustment, etc., can be carried out once

the password lock is released. Take the utmost care regarding confidentiality of the password.

Warning

Page 3

2 Changing Settings

g

2-1 Span Adjustment

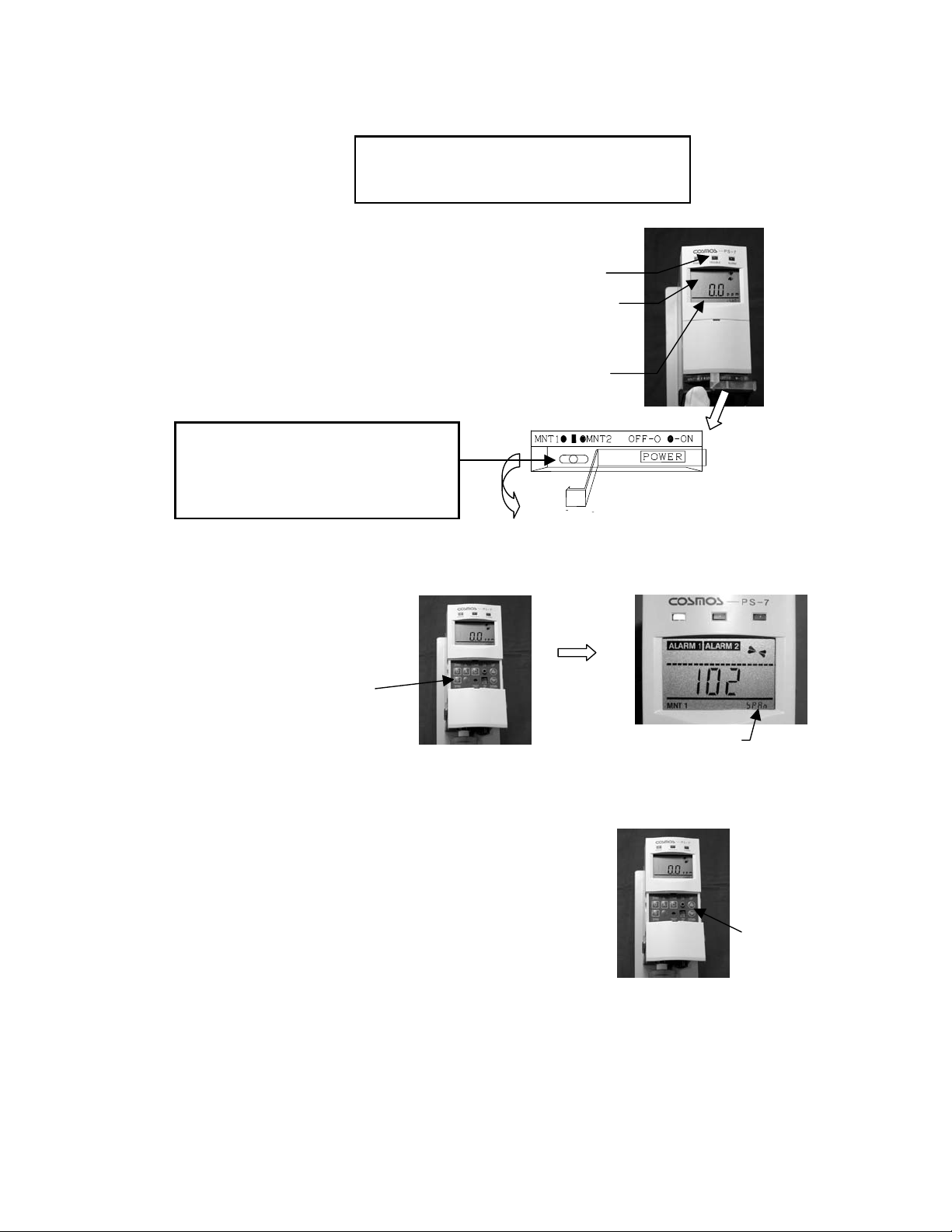

(1) Set to maintenance mode

(2) Release the password lock. (Refer to 1-2 Releasing the Password Lock.)

Left: Maintenance 1 (MNT1)

Center: Normal mode

Right: Maintenance 2 (MNT2)

Toxic gas sensor unit : CDS-7

Combustible gas sensor unit : CHS-7

(MNT1 or MNT2).

TROUBLE lamp (yellow) blinks.

The “__” indication and the

concentration value of the detected

as blink alternately.

MNT1 or MNT2 is displayed at the

bottom of the LCD screen.

Pull back to open

(3) Press the SPAN switch.

SPAN switch

(4) Let the calibration gas through.

SPAN is displayed at the bottom

right of the LCD screen.

(5) Use the UP/DOWN switch to adjust the concentration indication on the screen to that of the calibration

gas concentration.

(6) Once adjustments have been done, press the SPAN

switch again. The SPAN indication in the bottom right of the LCD

screen will go off, and the span adjustment will be completed.

UP/DOWN switch

(7) Remove the calibration gas, check that the detected gas concentration is under that of the alarm value,

and restore to the normal mode (by switching the maintenance switch to the center).

Page 4

2-2 21Vol% Adjustment

Oxygen sensor unit: COS-7

(1) Set to maintenance mode

(MNT1 or MNT2).

TROUBLE lamp(yellow)blinks.

The “__” indication and the concentration

value of the Oxygen blink alternately.

MNT1 or MNT2 is displayed at the

bottom of the LCD screen.

Left: Maintenance 1 (MNT1)

Center: Normal mode

Right: Maintenance 2 (MNT2)

Pull back to open

(2) Release the password lock. (Refer to 1-2 Releasing the Password Lock.)

(3) Press the SPAN switch.

SPAN switch

SPAN is displayed at bottom of the

LCD screen

(4) Let the calibration gas through.

(5) Use the UP/DOWN switch to adjust the concentration indication on the screen to that of the calibration

gas concentration.

(6) When the adjustment is completed, press the SPAN switch again. The SPAN indication in the bottom

right corner of the LCD screen will then disappear, and the 21vol% adjustment is complete.

(7) Remove the calibration gas and confirm that no alarm is displayed(

ALARM 1 , ALARM 2 is not shown). Then,

restore to the normal mode by switching the maintenance switch to the center.

Page 5

2-3 Changing Setting Values

Some of the setting values of the unit can be changed. Those that can be changed are listed in the table

below. The method for changing them is explained here.

(1) Release the password lock. (Refer to 1-2 Releasing the Password Lock.)

(2) Press the UP/DOWN switch (“U” or “V”)

until the setting you wish to

change ( “LCD Screen Indication” in the

table below ) is displayed at the bottom right of

the LCD display.

(3) Then press the special command switch, and the

setting to be changed ( “LCD Screen Indication”

in the table below ) and “—“ will flash alternately.

UP/DOWN switch

Setting to be changed

- - - - - d1 0

Special command switch

Page 6

(4) Change the value by using the UP/DOWN switches (“U” or “V”). When you are done, press the special

command switch again, and the alternating display in the bottom right corner of the LCD display will

become constant. The process is now finished.

LCD

Screen

The function

Indication

Each time the UP switch is pressed, it will move down the table to the next item.

d1 **

Time delay 1

d2 ** Time delay 2

az

as

zs *

Analog output

(base)

Analog output

(span)

Zero

suppression, or

21vol%

suppression

to be set

Remarks

Time delay (secs.) of the gas

alarm contact (1st level)

Time delay (secs.) of the gas

alarm contact (2nd level)

(*For our maintenance purposes only)

(*For our maintenance purposes only)

Displays the percentage of the full

scale value (rounded to the

percent)

1st: upper limit, 2nd : upper limit

H-H

L-L

When the DOWN switch is pressed, it will move up one.

H-L

Alarm mode

warning

1st : lower limit, 2nd : lower limit

warning

1st : upper limit, 2nd: lower limit

warning

Pyroletic

Con *

converter

0: Off 1: On

failure alarm

Calibration

CG **

gas

(*For our maintenance purposes only)

concentration

The existence

nEt *

F ***

FL ***

P ***

At *

×××

of a DeviceNet

unit

Display off

value

Displays rate

of flow

Sensor unit

output

Auto 21vol%

adjustment

0

: Non-existent 1: Existent

Calibration gas type in lower right of

LCD

f value in center of LCD

Shows the current rate of flow

(mL/min)

(*For our maintenance purposes)

0

: Off 1: On

Type of sensor unit (Normal display) (Depending on the sensor unit)

-- A t 1 0

Default value

To xi c :

CDS-7

Combustible

: CHS-7

Oxygen:

COS-7

Adjustable

Range

d1 0 d1 0 0 to 99 sec

d2 0 d2 0 0 to 99 sec

zs 5 zs 2 0 to 30%

H-H

H-H L-L

L-L

H-L

Con 0 Con 0 0 or 1

CG 40 CG 84

nEt 0 nEt 0 0

(Depending on the sensor unit)

(Depending on the rate of flow)

or 1

--

1

or

Page 7

2-4 Changing the Alarm Settings

A

A

The values of alarm settings on this unit can be changed. The method for changing them is explained

here.

(1) Release the password lock. (Refer to 1-2 Releasing the Password Lock.)

(2) Press the AL switch until the alarm setting

to be changed is displayed on the LCD display.

(The bottom right of the screen, as in the table below.)

The alarm setting for the actual gas concentration is

displayed in the middle of the screen, and the

percentage of the full scale value is displayed in the

bottom right corner

LCD Display

Indication

(Lower right)

A1 **

Tox i c : C D S-7

Comb. : CHS-7

Default value

A1 10

Oxygen: COS-7 A2 72

L switch

Explanation of

the default value

10% F.S.

72% F.S.

Gas concentration

The percentage of the full scale value

Adjustable

Range

0 to 100% F.S.

A2 **

Tox i c : C D S-7

Comb. : CHS-7

Oxygen: COS-7

A2 20

A2 76

20% F.S.

76% F.S.

0 to 100% F.S.

* Pressing the AL switch changes to 1st level Æ 2nd levelÆ Normal display.

* The A2 value should be greater than the A1 value in any case.

(3) Press the special command switch.

The setting to be changed and the “—“

indication will then flash alternately.

- - - - -

Special

command

switch

UP/DOWN switches

(4) Change the value by using the UP/DOWN key “U” and”V”.

When you are done, press the special command switch again, and the alternating display in the lower

right corner of the LCD display will become constant. The process is now finished.

1 10

(5) When this is finished, press the UP/DOWN switches (“U” or”V”) again to return to the normal display.

Note

The relationship between 1st level and 2nd level alarm values of each alarm mode is as follows:

Page 8

st

A

A

nd

A

A

nd

A

A

A

A

A

A

A

A

H – H mode (1

st

level: Upper limit, 2nd level: Upper limit)

Full Scale

0ppm

level gas alarm : ALARM 1 , ALARM 2 is displayed.

2

larm contacts ZA1 and ZA2 are activated

larm value is set by entering A2 **

st

level gas alarm : ALARM 1 is displayed.

1

larm contact ZA1 is activated

larm value is set by entering A1 **

L – L mode (1

st

level: Lower limit, 2nd level: Lower limit)

Normal state (No gas is detected)

Normal state

25vol%

21vol%

0 vol%

1

level alarm : ALARM 1 is displayed.

larm contact ZA1 is activated.

larm value is set by entering A2 **

2

level alarm : ALARM 1 , ALARM 2 is displayed.

larm contact ZA1 and ZA2 are activated.

larm value is set by entering A1 **

H – L mode (Upper limit, Lower limit)

Normal state

50vol%

21vol%

0 vol%

Upper alarm : ALARM 2 is displayed.

larm contact ZA2 is activated.

larm value is set by entering A2 **

Lower alarm : ALARM 1 is displayed.

larm contact ZA1 is activated.

larm value is set by entering A1 **

* A2 value should be always greater than A1 value.

Page 9

Manual Revision History

Edition No. Date Revisions

GAE-019 July 2004

Additional copies of this Operation Manual are available.

Contact the following address for ordering information.

Manufacturer:

New Cosmos Electric Co., Ltd.

2-5-4 Mitsuya-naka

Yodogawa-ku

Osaka 532-0036, Japan

Phone 81-6-6309-1505

Fax 81-6-6309-1514

Distributor:

DOD Technologies, Inc

740 McArdle Drive

Unit C

Crystal Lake, IL 60014

Phone 815-788-5200

Fax 815-788-5200

www.dodtec.com

Loading...

Loading...