DoAll DC-330NC User Manual

Instruction Manual

By

Models:

DC-280NC

DC-330NC

DC-420NC

DC-460NC

DC-500NC

DC-560NC

Band Sawing Machine

DAMAGE CLAIM PROCEDURES

VISIBLE DAMAGE AT THE TIME OF DELIVERY:

1.Note damage on carrier’s delivery receipt. Accept the shipment. It can be returned later if repairs are not possible in the field.

2.Request a “damage inspection” from the delivery carrier:

a.The carrier will send his own people or contract an independent agency to make the inspection.

b.The inspector will request a signature on the report and leave a copy.

c.The carrier “damage inspection” report is not final. If additional damage is found when repairs are started, contact the carrier for another inspection; or at least give them the details of the damage.

3.Do not move the equipment from the receiving area and keep all shipping materials until carrier “damage inspection” report is complete.

4.If possible, take photographs of the damage and keep them for your files. Photos could possibly prove a claim at a later time.

5.Keep a record of all expenses and be sure they are documented.

6.Repair damage in the field whenever possible. Carriers encourage this to keep expenses down.

7.You have nine (9) months to file a claim.

CONCEALED DAMAGE:

1.You have fourteen (14) days to report damage not noted at time of delivery.

a.Report damage as soon as possible. This makes it easier to prove that it did not happen at cosignee’s plant.

b.Inspect machine(s) carefully before moving from the receiving area. Again, if machine is not moved, it is easier to prove your case.

2.Request a “damage inspection” from the delivery carrier:

a.The carrier will send his own people or contract an independent agency to make the inspection.

b.The inspector will request a signature on the report and leave a copy.

c.The carrier “damage inspection” report is not final. If additional damage is found when repairs are started, contact the carrier for another inspection; or at least give them the details of the damage.

3.Do not move the equipment from the receiving area and keep all shipping materials until carrier “damage inspection” report is complete.

4.If possible, take photographs of the damage and keep them for your files. Photos could possibly prove a claim at a later time.

5.Keep a record of all expenses and be sure they are documented.

6.Repair damage in the field whenever possible. Carriers encourage this to keep expenses down.

7.You have nine (9) months to file a claim.

OPERATOR'S INSTRUCTION MANUAL

METAL CUTTING BAND SAW

For your information and future reference, pertinent data concerning your machine should be written in the spaces provided above. This information is stamped on a plate attached to your machine. Be sure to provide machine model and serial numbers with any correspondence or parts orders.

Specifications contained herein were in effect at the time this manual was approved for printing. The DoALLCompany, whose policy is one of continuous improvement, reserves the right, however, to change specifications or design at any time without notice and without incurring obligations.

PLEASE READ THIS MANUAL CAREFULLY BEFORE OPERATING THE MACHINE! For Sales, Parts and Service, call 1-888-362-5572

For general information, visit our web site at: www.doallsawing.com

DoALL SAWING PRODUCTS

2375B TOUHY AVENUE

ELK GROVE, ILLINOIS 60007 U.S.A.

The following registered trademarks of the DoALL Company are used in this manual: DoALL.

PRINTED IN U.S.A. |

PB-560 (10-13) |

|

i |

TABLE OF CONTENTS

SAFETY RULES ................................................ |

1 |

MACHINE SPECIFICATIONS ..................... |

2 |

MACHINE DIMENSIONS |

|

Installation Dimensions ......................................... |

3 |

DC-280NC Dimensions ......................................... |

4 |

DC-330NC Dimensions ......................................... |

5 |

DC-420NC Dimensions ......................................... |

6 |

DC-460NC Dimensions ......................................... |

7 |

DC-500NC Dimensions ......................................... |

8 |

DC-560NC Dimensions ......................................... |

9 |

MACHINE FEATURES .................................. |

10 |

INSTALLATION |

|

Location ................................................................. |

11 |

OSHA Notice!! ....................................................... |

11 |

Unpacking ............................................................. |

11 |

Lifting ..................................................................... |

11 |

Cleaning ................................................................ |

12 |

Floor Installation .................................................... |

12 |

Electrical Installation ............................................. |

12-13 |

Preparation for Use ............................................... |

13 |

OPERATION |

|

Selecting Band Speed and Cutting Rate ............... |

14 |

Control Console .................................................... |

15- |

Saw Band Preparation .......................................... |

15-16 |

Left Hand Guide Arm Adjustment .......................... |

16 |

Band Speed Adjustments ...................................... |

16 |

Feed Force Adjustments ....................................... |

16-17 |

Saw Head Positioning and Approach .................... |

17 |

Automatic Head Elevation and Sensing Arm ........ |

17-18 |

Stock Indexing Handwheel and Readout .............. |

18-19 |

Minimum Bar End/Split Front Vise ........................ |

19 |

Hydraulic System .................................................. |

19 |

Coolant System ..................................................... |

19 |

Chip Removal ........................................................ |

19-20 |

Positioning Stock ................................................... |

20-21 |

Typical Operating Procedures ............................... |

21-22 |

LUBRICATION |

|

Lubrication Chart ................................................... |

24 |

Lubrication Diagrams ............................................ |

25 |

MAINTENANCE |

|

Replacing Saw Guide and Back-Up Inserts .......... |

26 |

Replacing Saw Band Anti-Squeal Rollers ............. |

26 |

Band Drive Belt Replacement ............................... |

26 |

Hydraulic System .................................................. |

26-27 |

Coolant System ..................................................... |

27 |

Machine Cleaning ................................................. |

27 |

Machine Alignment ................................................ |

27 |

Band Brush ........................................................... |

28 |

Band Tension Measurement ................................. |

28 |

Wear Plate Replacement ...................................... |

28 |

Band Drive Worm Gear Reducer .......................... |

28 |

Bandwheels ........................................................... |

29 |

Cleaning Chip Box or Chip Conveyor ................... |

29 |

Cut Counter Self-Test ............................................ |

29 |

TROUBLE SHOOTING ................................. |

30-33 |

ACCESSORIES |

|

Roller Stock Conveyor .......................................... |

34 |

Vertical Guide Rollers ............................................ |

34 |

Nesting Fixture ...................................................... |

34-35 |

Vertical Guide Rollers (For Nesting) ...................... |

35 |

Discharge Tray Side Fences ................................. |

36 |

Variable Vise Pressure .......................................... |

36 |

Band Lubricator ..................................................... |

36 |

Laser Line Option .................................................. |

36 |

Chip Conveyor ...................................................... |

36-37 |

Band Twist Indicator .............................................. |

37-38 |

Material Handling Equipment ................................ |

38 |

ii

SAFETY RULES

1.CLOTHING. To protect the operator from entanglement or being pulled by a clamped vise, the operator should not wear loose fitting clothing or wear gloves while operating the machine. Wear safety shoes to protect against foot injury.

2.INSTALLATION. The machine must be properly grounded to protect against electric shock. Use durable insulating material to protect power lines that lie on the floor.

3.DO NOT defeat the purpose of any guards or any other safety devises. THEY ARE THERE FOR YOUR PROTECTION!

4.Keep hands away from moving saw band while the machine is running.

5.If the operator needs to check the interior of the machine during operation, turn the machine off and wait until the machine come to a complete stop.

6.Do not enter the index vise moving area. Lifting of workpieces to the feeding table is done by overhead hoist.

7.Do not touch the circuit breakers, switches or buttons with wet hands.

8.Turn power off before servicing, cleaning or maintenance.

9.Wear gloves when replacing the saw band, removing chips, replacing cutting fluid and/or moving material.

10.Coolant is not edible. If swallowed, immediately spit it out and rinse the mouth thoroughly.

11.Do not operate, maintain or check the machine while under the influence of alcohol or medication.

12.The machine will stop when a door or guard is opened. Wait until the machine come to a complete stop before entering the area.

13.Do not stand on the front or rear supporting rollers.

14.Periodically perform a machine check before starting. After completing a job, clean both the machine and the work area thoroughly.

15.The machine operator must be trained and must understand the operation, lifting, saw band replacement and maintenance of the machine.

16.Maintenance personnel must be trained and knowledgeable of electrical controls systems.

17.This machine is designed to cut steel bars and profiled tubes only. Do not cut food, wood, plastic, poisonous material, magnesium or magnesium alloys.

1

MACHINE SPECIFICATIONS

English Std.

(Metric)

Specification |

DC-280NC |

DC-330NC |

DC-420NC |

||||

|

|

Rounds |

.38 - 11.00" |

.38 - 13.00" |

.38 - 16.50" |

||

Cutting |

|

(10 mm - 280 mm) |

(10 mm - 330 mm) |

(10 mm - 420 mm) |

|||

|

|

|

|

||||

Capacity |

|

Rectangles |

|

|

11.75" x 11.00" |

15.75" x 13.00" |

16.50" x 16.50" |

|

|||||||

|

|

(W x H) |

|

|

(300 mm x 280 mm) |

(400 mm x 330mm) |

(420 mm x 420 mm) |

|

|

|

|||||

|

|

Minimum (W x H) |

6.50" x .63" |

6.50" x 2.00" |

6.50" x 3.25" |

||

Bundle |

|

(165 mm x 15 mm) |

(165 mm x 50 mm) |

(165 mm x 80 mm) |

|||

|

|

|

|

||||

Cutting |

|

Maximum (W x H) |

9.75" x 4.00" |

14.50" x 6.63" |

14.50" x 7.88" |

||

|

|

(250 mm x 100 mm) |

(370 mm x 170 mm) |

(370 mm x 200 mm) |

|||

|

|

|

|

|

|||

Band Saw Blade |

|

|

|

1.25" x 150" |

1.25" x 167" |

1.50" x 192" |

|

|

|

|

(32 mm x 3820 mm) |

(32 mm x 4242 mm) |

(38 mm x 4880 mm) |

||

|

|

|

|

|

|||

Band Speed |

|

|

|

50 - 400 fpm |

50 - 400 fpm |

50 - 400 fpm |

|

|

|

|

(15 - 120 m/min.) |

(15 - 120 m/min.) |

(15 - 120 m/min.) |

||

|

|

|

|

|

|||

Band Drive Motor |

|

|

|

5 HP (3.7 kW) |

5 HP (3.7 kW) |

7.5 HP (5.5 kW) |

|

Hydraulic Pump Motor |

|

|

|

1 HP (.75 kW) |

1 HP (.75 kW) |

2 HP (1.5 kW) |

|

Coolant Pump Motor |

|

|

|

1/6 HP (.12 kW) |

1/6 HP (.12 kW) |

1/4 HP (.2 kW) |

|

Band Drive Gearbox Capacity |

1.2 Gal. (4.5 liters) |

1.9 Gal. (7 liters) |

3.0 Gal. (11.5 liters) |

||||

Hydraulic Tank Capacity |

|

|

|

16 Gal. (60 liters) |

16 Gal. (60 liters) |

22 Gal. (85 liters) |

|

Coolant Tank Capacity |

|

|

|

20 Gal. (80 liters) |

24 Gal. (90 liters) |

26 Gal. (100 liters) |

|

Indexing Length |

|

Single |

15.75 (400 mm) |

19.68 (500 mm) |

19.68 (500 mm) |

||

|

Multiple |

141.73 (3600 mm) |

177.16 (4500 mm) |

177.16 (4500 mm) |

|||

|

|

||||||

Net Weight |

|

|

|

3859 lbs. (1750 kg) |

4410 lbs. (2000 kg) |

5402 lbs. (2450 kg) |

|

Specification |

DC-460NC |

DC-500NC |

DC-560NC |

||||

|

|

Rounds |

.38 - 18.00" |

.38 - 19.50" |

.38 - 22.00" |

||

Cutting |

|

(10 mm - 460 mm) |

(10 mm - 500 mm) |

(10 mm -560 mm) |

|||

|

|

|

|

||||

Capacity |

|

Rectangles |

|

|

19.50" x 18.00" |

22.00" x 19.50" |

24.00" x 22.00" |

|

|||||||

|

|

(W x H) |

|

|

(500 mm x 460 mm) |

(560 mm x 500mm) |

(610 mm x 560 mm) |

|

|

|

|||||

|

|

Minimum (W x H) |

9.38" x 3.12" |

9.38" x 3.12" |

NA |

||

Bundle |

|

(240 mm x 80 mm) |

(240 mm x 80 mm) |

||||

|

|

|

|

|

|||

Cutting |

|

Maximum (W x H) |

18.88" x 9.75" |

18.88" x 9.75" |

NA |

||

|

|

(480 mm x 240 mm) |

(480 mm x 240 mm) |

||||

Band Saw Blade |

|

|

|

1.50" x 209" |

1.50" x 215" |

2.00" x 260" |

|

|

|

|

(41 mm x 5300 mm) |

(41 mm x 5450 mm) |

(54 mm x 6605 mm) |

||

|

|

|

|

|

|||

Band Speed |

|

|

|

50 - 400 fpm |

50 - 400 fpm |

50 - 400 fpm |

|

|

|

|

(15 - 120 m/min.) |

(15 - 120 m/min.) |

(15 - 120 m/min.) |

||

|

|

|

|

|

|||

Band Drive Motor |

|

|

|

7.5 HP (5.5 kW) |

7.5 HP (5.5 kW) |

10 HP (7.5 kW) |

|

Hydraulic Pump Motor |

|

|

|

2 HP (1.5 kW) |

2 HP (1.5 kW) |

3 HP (2.2 kW) |

|

Coolant Pump Motor |

|

|

|

1/4 HP (.2 kW) |

1/4 HP (.2 kW) |

1/4 HP (.2 kW) |

|

Band Drive Gearbox Capacity |

4.8 Gal. (18 liters) |

6.1 Gal. (23 liters) |

7.4 Gal. (28 liters) |

||||

Hydraulic Tank Capacity |

|

|

|

22 Gal. (85 liters) |

22 Gal. (85 liters) |

34 Gal. (130 liters) |

|

Coolant Tank Capacity |

|

|

|

29 Gal. (110 liters) |

29 Gal. (110 liters) |

37 Gal. (140 liters) |

|

Indexing Length |

|

Single |

19.68 (500 mm) |

19.68 (500 mm) |

15.75 (400 mm) |

||

|

Multiple |

177.16 (4500 mm) |

177.16 (4500 mm) |

141.73 (3600 mm) |

|||

|

|

||||||

Net Weight |

|

|

|

6284 lbs. (2850 kg) |

6835 lbs. (3100 kg) |

9923 lbs. (4500 kg) |

|

2

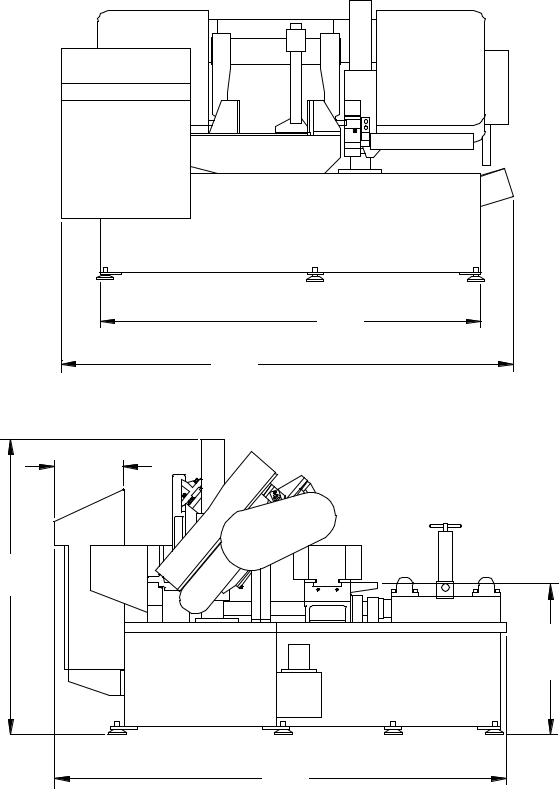

MACHINE DIMENSIONS

|

INCHES (± .03) |

INSTALLATION DIMENSIONS |

MILLIMETERS (± 1 mm) |

Dimension |

DC-280NC |

DC-330NC |

DC-420NC |

DC-460NC |

DC-500NC |

DC-560NC |

A |

108.25" |

117.50" |

117.50" |

118.00" |

118.00" |

112.25" |

(2750 mm) |

(2980 mm) |

(2980 mm) |

(3000 mm) |

(3000 mm) |

(2850 mm) |

|

B |

23.50" |

23.50" |

23.50" |

23.50" |

23.50" |

23.50" |

(600 mm) |

(600 mm) |

(600 mm) |

(600 mm) |

(600 mm) |

(600 mm) |

|

C |

124.50" |

134.50" |

145.00" |

153.50" |

156.50" |

187.50" |

(3160 mm) |

(3420 mm) |

(3680 mm) |

(3900 mm) |

(3980 mm) |

(4760 mm) |

|

D |

41.75" |

46.00" |

50.00" |

53.00" |

54.00" |

63.00" |

(1060 mm) |

(1170 mm) |

(1265 mm) |

(1350 mm) |

(1370 mm) |

(1600 mm) |

|

E |

37.50" |

41.25" |

45.00" |

49.25" |

49.25" |

57.00" |

(950 mm) |

(1050 mm) |

(1150 mm) |

(1250 mm) |

(1250 mm) |

(1450 mm) |

3

MACHINE DIMENSIONS (Continued....) |

|

|

DC-280NC DIMENSIONS |

INCHES (± .03) |

|

MILLIMETERS (± 1 mm) |

||

|

3DVVOLQH

4

MACHINE DIMENSIONS (Continued....) |

|

|

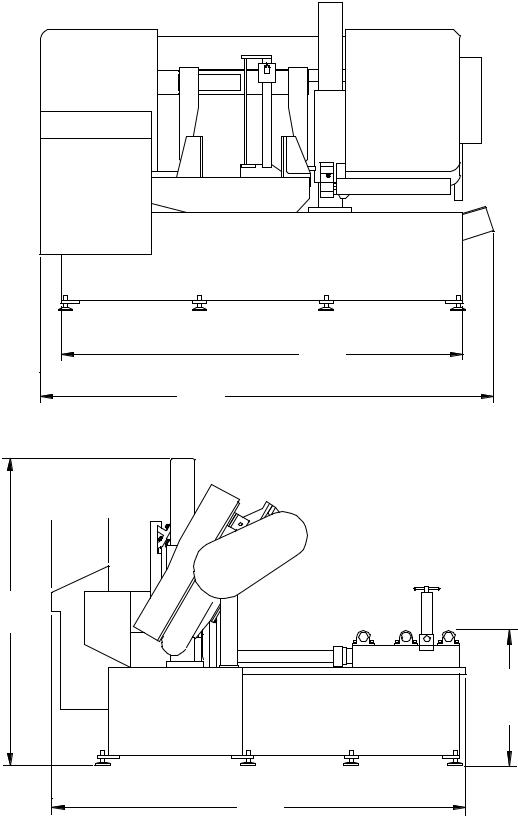

DC-330NC DIMENSIONS |

INCHES (± .03) |

|

MILLIMETERS (± 1 mm) |

||

|

3DVVOLQH

5

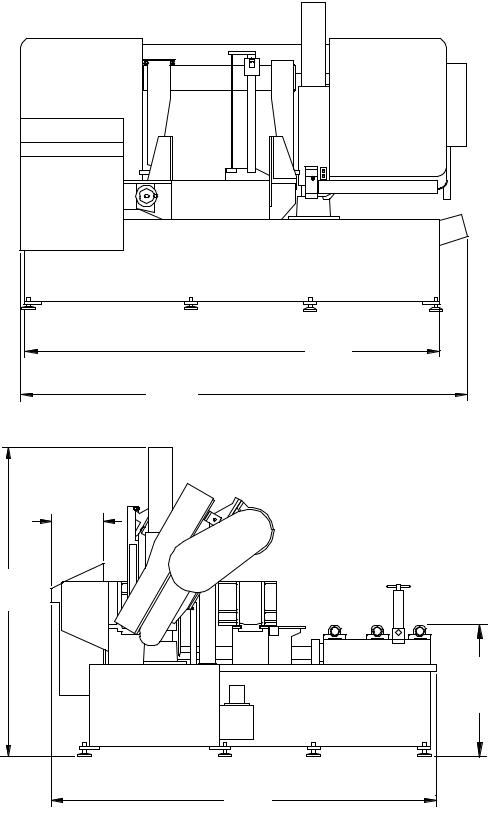

MACHINE DIMENSIONS (Continued....) |

|

|

DC-420NC DIMENSIONS |

INCHES (± .03) |

|

MILLIMETERS (± 1 mm) |

||

|

3DVVOLQH

6

MACHINE DIMENSIONS (Continued....) |

|

|

DC-460NC DIMENSIONS |

INCHES (± .03) |

|

MILLIMETERS (± 1 mm) |

||

|

3DVVOLQH

7

MACHINE DIMENSIONS (Continued....) |

|

|

DC-500NC DIMENSIONS |

INCHES (± .03) |

|

MILLIMETERS (± 1 mm) |

||

|

3DVVOLQH

8

MACHINE DIMENSIONS (Continued....) |

|

|

DC-560NC DIMENSIONS |

INCHES (± .03) |

|

MILLIMETERS (± 1 mm) |

||

|

3DVVOLQH

9

Loading...

Loading...