Page 1

C-8056SA

Metal Cutting

Band Sawing Machine

Version 20-8-2014

Utility Line

Instruction Manual

Page 2

Page 3

Page 4

2

PREFACE

Ever since it was established, SINGULAR MACHINERY has always followed the company's

policy of "Specialized Manufacturing, Customers First and Business Perpetuity". Oriented by

market demands, we have dedicated ourselves to technological innovation and produce the best

quality of hydraulic band saws to serve the industry. We always look forward to any advice given

by our customers.

We appreciate very much for your choosing Singular hydraulic band saws for your production.

To ensure correct operation and safety, the operator must thoroughly read the operation manual

before attempting to operate the machine.

Please fill in the basic information in the spaces below:

(1) MACHINE MODEL: ____________________

(2) SERIAL NUMBER: ____________________

(3) SHIPPING DATE: ____________________

(4) OTHERS: ____________________

C-8056SA

SAW BLADE

6800 × 54 × 1,6mm

MAIN DRIVE BELT

3V530X2

STEEL BRUSH BELT

M56

ITEMS

MODEL

Page 5

3

CONTENTS

1. SAFETY RULES ..................................................................... 6

2. MACHINE SPECIFICATIONS ................................................. 7

3. USER'S PREPARATION ........................................................ 9

4. MOVING AND INSTALLING THE MACHINE ....................... 11

5. OPERATION INSTRUCTIONS ............................................. 14

6. MACHINE REPAIR AND MAINTENANCE ........................... 20

7. TROUBLE SHOOTING ......................................................... 25

8. HYDRAULIC CIRCUIT DIAGRAM ........................................ 26

Page 6

4

1. SAFETY RULES

1.1 CLOTHING

To protect the operator from entangling or clamping by the machine, the operator must

remove gloves and beware of loose clothing. Before operating the machine, wear safety

shoes to avoid foot injury by waste material.

1.2 INSTALLATION

The machine must be properly grounded to avoid danger by electric shock. Use durable

insulating material to cover the power wires placed on the floor to avoid electric shock.

1.3 Be sure to tighten all guards before operating the machine.

1.4 While the machine is running, never try to touch the saw blade. Failure to comply may result

in accident by entangling.

1.5 During operation, if you need to check the interior of the machine, wait until the machine

has come to a complete stop before opening any guards.

1.6 Do not enter into the workpiece moving area. Lifting of the work pieces to the work piece

supporting is done by using an electric hoist, which is to be operated only by qualified

personnel.

1.7 Do not try to touch the circuit breaker, switches or buttons with wet hands.

1.8 Turn power off before maintaining or cleaning the machine.

1.9 Wear gloves for replacing saw blade, removing chips, replacing cutting fluid and moving

work pieces. Do not touch the teeth of the saw blade.

1.10 The coolant is not edible. If any should accidentally enter the mouth, spit it out immediately

and rinse mouth.

1.11 Do not operate the machine, maintain or check the machine under the influence of alcohol

or medication.

1.12 The machine will stop when safety guard is opened. While the machine is running, opening

the guard will cause the power to shut off but the running parts do not stop immediately and

can still cause danger. Be sure to open the safety guard only when the machine has come

to a complete stop.

1.13 Do not stand on the front or rear supporting rollers to avoid accident by slipping.

1.14 Be sure to perform a machine check before starting and check periodically. After the job is

finished, clean both the machine and the working area thoroughly.

1.15 The machine operator must be well trained. The training course takes one week, including

machine operation, workpiece lifting, saw blade replacement, and machine maintenance.

1.16 The machinery maintenance personnel must have knowledge of electric control and must

be well trained.

1.17 Do not apply the machine for cutting work pieces such as food, wood, plastic, poisonous

material, magnesium or magnesium alloy. This machine is designed for cutting steel bars

and profiled steel tubes only.

Page 7

5

2. MACHINE SPECIFICATIONS

2.1 SPECIFICATIONS

MODEL

C-8056SA

Cutting capacity

●

100 ~ 560 mm

100 (W) × 100 (H) to 300 (W) × 280 (H) mm

Bundle Cutting

Max.

560 (W) x 270 (H) mm

Min.

300 (W) x 120 (W) mm

Saw

Blade

Size

6.800 x 54 x 1,6 mm

Speed

16 to 85 m/min

Tension

Hydraulic

Motors

Output

Saw Blade

7,5 KW (10 HP)

Hydraulic Pump

2,2 KW (3 HP)

Coolant Pump

0,2 KW (1/4 HP)

Tanks

Hydraulic

130 L

Coolant

140 L

Working height

850 mm

Dimensions

3390 (W) × 2140 (H) × 1600 (L) mm

Net Weight

3800 kg

Page 8

6

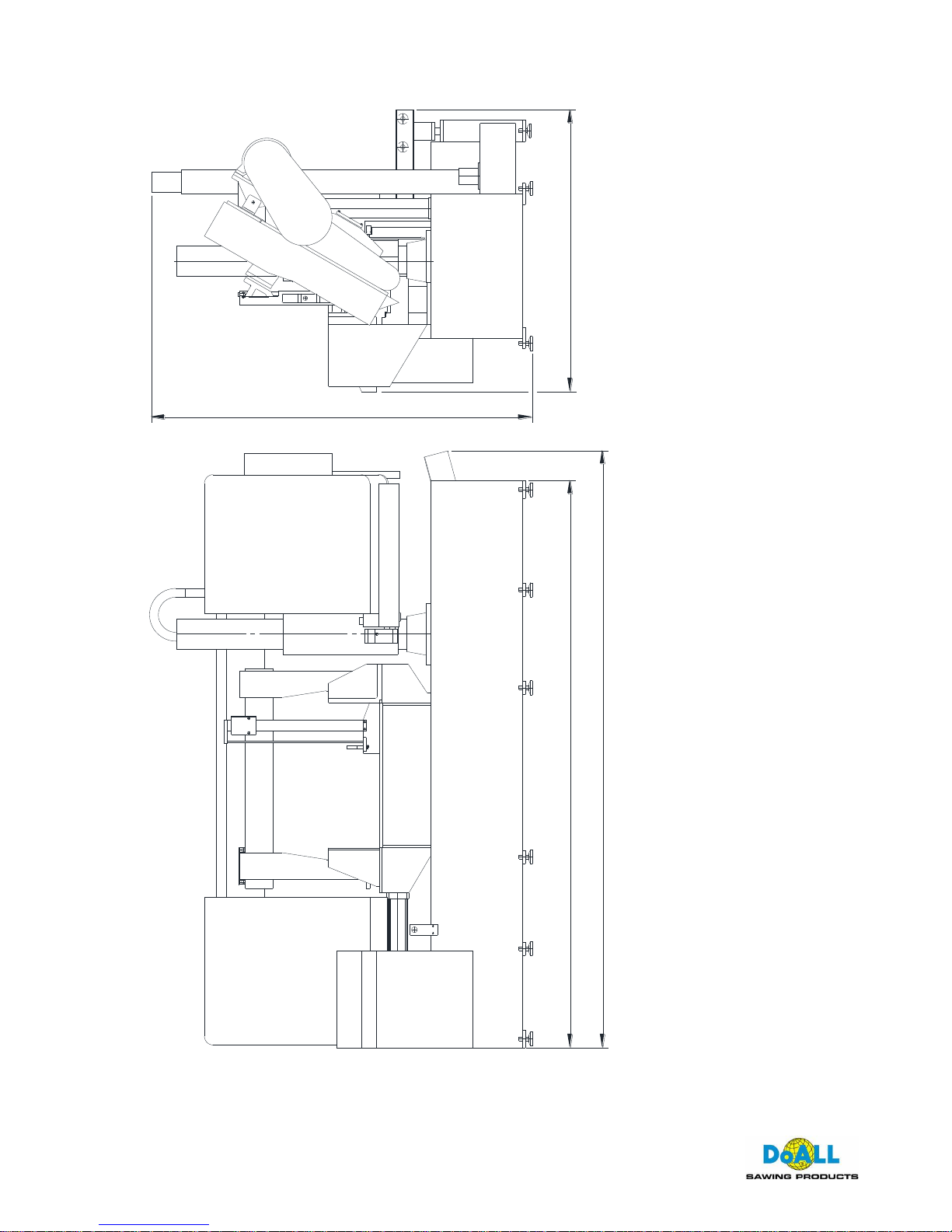

2.2 DIMENSIONAL DRAWINGS

2160

3220

3390

1600

DIMENSIONAL DRAWINGS OF THE C-8056SA

Page 9

7

3. USER'S PREPARATION

3.1 INSTALLATION SPACE REQUIRED

When installing the machine, the installation space should be considered as the figures shown

below:

1. Operator's working area

2. Workpiece collection area

3. Chip tank installation and maintenance area

4. Hydraulic unit checking area

INSTALLATION SPACE OF SH-8056SA

OPERTROR'S WORKING AREA

PARTS COLLECTION AREA

CHIP TANK INSTALLATION

AND MAINTENANCE AREA

CHECKING AREA

HYDRAULIC UNIT

600

4960

1600

1450

2500

Page 10

8

3.2 FOUNDATION REQUIRED

The thickness should be over 200mm. The foundation work must comply with local

regulations of construction. It is not suggested to install the machine in an upstairs area.

3.3 INSTALLATION ENVIRONMENT

※ Do not install the machine or controller at a location with direct sunlight and keep

the machine free from pollution of chips, water or oil from other machines.

※ The machine installation location should be free of vibration. Do not install the

machine in an area where there may be potential danger of explosion.

3.4 POWER SOURCE REQUIRED

Do not connect the machine to a power source with serious power interference caused

by welding machines or electric discharge machines. Keep the power source from

being affected by other machines. Avoid voltage drop resulting from insufficient power

capacity of the factory. Connect the machine to an independent power source.

C-8056 SA Input power: 12 KW

* Allowable input power tolerance: local voltage ±10%

3.5 GROUNDING

3.5.1 Do not use a grounding wire together with that of electric welding machines or electric

discharge machines.

3.5.2 Use a short and big grounding wire as possible.

3.5.3 Connect the grounding wire independently. Make sure the machine has been properly

grounded.

Page 11

9

4. MOVING AND INSTALLING THE MACHINE

4.1 MOVING THE MACHINE

The machine and roller stand are moved separately as shown in the figure below:

F

HOIST CAPACITY

The figure shows the lifting positions and steel wire rope is used.

5 T0N

C-8056SA

Page 12

10

F

FORKLIFT CAPACITY

The figure shows the machine being lifted by a forklift

C-8056SA

5 T0N

4.2 INSTALLING THE MACHINE

4.2.1 Once the machine has been moved to the worksite, you need to make the machine leveling

adjustment using the leveling adjustment bolts and pads. Use the bracket in front of the vise

as a reference plane for leveling adjustments. Leveling accuracy is shown as below:

(a) The front side of the machine should be about 0,2 / 100mm lower than the backside.

(b) The movable vise should be about 0,2 / 100mm higher than the fix vise.

4.2.2 Once the machine has been properly installed, you then need to install the roller stand at the

backside of the machine. The height of roller is the same as bed.

4.2.3 Then fix the machine and roller stand to avoid their unexpected shifting.

4.3 CONNECTING THE POWER WIRES

4.3.1 The machine is coated with rust-preventative oil before shipment. You are requested to

thoroughly remove all rust-preventative oil before using the machine to avoid damaging the

machine parts during operation.

CAUTION: Use a mild cleanser to remove rust-preventative oil. Do not use volatile solvents

to remove rust-preventative oil such as benzene and gasoline.

Page 13

11

4.3.2 REMOVING FIX OBJECTS

To avoid machine parts vibration during transportation, some objects are applied to keep the

machine parts fixed. Be sure to remove all these objects before connecting the power wires.

Otherwise, machine damage may occur once the power is turned on.

4.3.3 Before connecting power wires, make sure the machine voltage is in compliance with that of

your factory power source. The electric information of the machine is indicated on a name

plate attached to the front side of the machine.

4.3.4 Once the power wires have been connected, turn the power on and check if all motors run to

the correct directions.

4.3.5 PROPERLY MAKE GROUNDING WORK

Make sure the current supplied to PLC and frequency inverter are stable. Connect grounding

wire properly to prevent the control system from damage by instant current.

Page 14

12

5. OPERATION INSTRUCTIONS

5.1 CONTROL PANEL

1 2 3 4

965

7 8 10 12

11

1. POWER LAMP

When the power switch is turned on, this power lamp lights up.

2. WORKING LIGHT SWITCH

Switch to right for turning on the light. Switch to left for turning off the light.

3. BED VISE RETRACTING SWITCH

Press the switch for retracting the table vise. When this switch released, the retracting

motion stops.

4. BED VISE FORWARD MOTION SWITCH

Press this switch for moving the bed forward. When this switch released, the forward

motion stops. The right indicating lamp lights up when vises clamping.

5. HYDRAULIC ON/OFF SWITCH

Press the upper switch for starting the hydraulic system. Press the lower switch for

stopping hydraulic system.

6. COOLANT SWITCH

Press this switch for turning on the cooling system. Press it again for turning off the cooling

system.

Page 15

13

7. EMERGENCY STOP SWITCH

When this switch is pressed, the control power is turned off.

8. BLADE START/STOP SWITCH

When the clamping indication lamp for the table lights up, press the upper switch for

starting the saw blade. Press the lower switch for stopping the saw blade.

9. SAW ARM RAISE SWITCH

Press this switch for raising saw arm. When this switch is released, the raising motion

stops.

10. SAW ARM LOWER SWITCH

Press this switch for lowering the saw arm. When this switch is released, the lowering

motion stops.

11. LIFTING ROLLER UPWARD/DOWNWARD SWITCH

Switch to right for roller upward and switch to left for roller downward.

12. SAW BOW STOP POSITION SWITCH

Switch to right: Saw head raises to the highest position and stops after the cutting

finished. Then the saw blade stops.

Switch to left: The saw blade stop without upward moving of saw head after the

cutting finished.

5.2 REPLACING AND ADJUSTING SAWBLADE

5.2.1 REPLACING SAWBLADE

(1) Press the "SAW ARM RAISE" key to raise the saw above the workpiece or the vise.

(2) Open the right and left wheel guards.

(3) Shift the tension lever to position, then the driven wheel will move toward the driving

wheel for loosening the blade tension.

(4) Loosen the screw that tightens the guide seats for loosening the tungsten plate.

(5) Remove the original blade.

CAUTION: Wear gloves for safety when removing the blade.

(6) Place the new blade on the two saw wheels. Twist the blade to place it between the tungsten

plate and auxiliary bearing of the guide seats and let the back of blade touches the upper

tungsten plate. Then, slightly tighten the screw of guide seats.

(7) Shift the tension lever to position to tighten the blade tension. Then return it to the

middle position.

Page 16

14

(8) Have the back side of the blade come into contact with the saw wheel edge.

(9) Shift the tension lever to position to tighten the blade tension.

(10) Adjust the steel brush position so that it just touches the gullet of blade tooth.

5.2.2 ADJUSTING SAW ARM POSITION

The saw arm position should be properly adjusted according to the workpiece width. Keep the

saw arm as close to the clamping position as possible. Make adjustments according to the

following procedures:

(1) Loosen the lock screw on the guide seats for loosening the tungsten plate. If it is clamped by

the hydraulic system, loosen it from the control panel.

(2) Loosen the fix handle on the left saw arm.

(3) Move the left saw arm to suitable position. A scale is attached on saw guide indicating the

work piece width.

(4) Tighten the fix handle on the left saw arm.

(5) Tighten the lock screw on the guide seats. If it is clamped by the hydraulic.

5.3 OPERATION INSTRUCTIONS:

(1) Select the correct saw blade according to the work piece type.

(2) Install the saw blade.

(3) Properly adjust the saw arm position according to the work piece width.

(4) PLACING THE WORKPIECE

a. Select a suitable speed of saw blade and adjust the position of belt on belt pulley.

b. Open the vise according to the work piece width.

c. Place the work piece on the roller stand.

d. Lower the saw arm until the saw blade is about 15mm above the work piece.

e. Move the work piece into the vise by using the lifting roller or manual. Then, set the

cutting length.

f. Press the "BED VISE CLAMPING SWITCH" to clamp the work piece until the

indication lamp at the right side lights up.

(5) Press the "BLADE START/STOP" switch. At this time the coolant system also starts

running. The coolant will flush out from the right and left tungsten plates and coolant nozzle.

You need to adjust the coolant flow properly.

(6) Adjust the blade speed according to actual cutting condition.

(7) Slowly turn the flow control valve and the pressure valve and check the cutting condition.

NOTE: When the job is finished, remove the work piece and clean the machine.

Page 17

15

5.4 NOTICES FOR OPERATION

(1) The "EMERGENCY STOP" should be used at a proper time. Except for an emergent damage

to the machine or operator occurs, normally stopping the machine by pressing the SAW ARM

RAISE SWITCH is suggested. During cutting, when the "EMERGENCY STOP" button is

pressed, the power will be shut off immediately. At this time, the hydraulic system still has

remaining power to feed the blade but no power on the blade which may result in breaking of

the blade teeth.

(2) Use proper flow and density of cutting fluid. Too much flow and density are not helpful for

cutting and cause environmental pollution.

(3) The blade speed adjustment can be identified by the cutting sound. A smooth cutting sound

means correct blade speed. A "rushed" or "impact" cutting sound means incorrect blade

speed.

(4) When using a new blade, it is suggested to reduce the blade speed and sawbow downward

speed to perform blade friction about 3-5 cuttings. Then, set at normal speed to ensure the

blade life.

5.5 CUTTING INFORMATION

5.5.1 SELECTING THE BLADE TEETH PER INCH

To ensure the economical, fast and accurate cutting, the blade teeth number and speed must be

properly selected according to work piece sizes and material.

A correct cutting rate must also be considered.

SAWBLADE SPECIFICATIONS

WIDTH

TEETH NUMBER

mm INCH

0.75/1.25

1.4/2

2/3

3/4

4/6

5/8

6/10

8/12

10/14

20×0,90 3/4× .035

* * * * *

27×0,90 1 × .035

* * * * * * *

34×1,10 11/4 × .042

* * * * *

*

41×1,30 11/2 × .050

* * * * *

*

54×1,30 2 × .050

*

* * *

*

54×1,60 2 × .062

*

* * *

*

67×1,60 25/8 × .062

*

* * *

80×1,60 3 × .062

*

* * *

SAWBLADE SPECIFICATIONS TABLE

Page 18

16

TYPE

TPI

SINGLE (SOLID)

BUNDLE

(SOLID)

SINGLE (PIPE)

BUNDLE (PIPE)

5/8

Thickness under

4 mm

Single thickness

under 4 mm

4/6

Under 80 mm

Thickness 4~10

mm

Single thickness 4~8

mm

3/4

60~150 mm

Single piece 20

mm

Thickness over

15 mm

Single thickness

8~15 mm

2/3

150~250 mm

Single piece 25

mm

Thickness over

25 mm

Single thickness over

15 mm

1.4/2

250~400 mm

0.75/1.25

400~1000 mm

SAWBLADE TEETH SELECTION TABLE

5.5.2 SELECTING BLADE SPEED AND CUTTING RATE

To ensure the machine and the blade fully extend their performance, the blade speed and cutting

rate must be selected properly according to the cutting material. The below table provides a

reference for selection.

Page 19

17

STEEL MATERIAL CUTTING DATA

CODE

DESCRIPTION

JIS

AISI

DIN

BLADE

SPEED

M/MIN

CUTTING

RATE

CM2/MIN

Low Carbon Steel

SS41

S10C

S15C

A570

1010

1015

St44-2

C10

C15

60~70

75~80

75~80

50~60

55~65

55~65

Mild Carbon Steel

S45C

S55C

1045

1055

C45

CK55

50~60

50~60

40~50

40~50

Cr Mo Steel

Nickel

Cr Mo Steel

Cr Mo Steel

Nickel

Cr Mo Steel

SCM440

SNCM8

SCM21

SNCM21

4140

4340

4118

8620

42CrMo4

34CrNiMo8

15CrMo5

21NiCrMo2

45~50

40~45

50~60

56~60

30~40

30~40

35~45

35~45

Tool Steel

Alloy Tool Steel

SK2

SKS3

W1

D1

C125W

105WCr6

30~45

30~35

30~35

25~30

Alloy Tool Steel

(15) Alloy Tool Steel

SKD1

SKD11

D3

D2

X210Cr12

X155CrVMo12

1

30~35

30~35

25~30

25~30

Alloy Tool Steel

SKD61

H13

X40CrMoV51

20~30

8~12

Stainless Steel

SUS304

SUS316

SUS430

304

316

430

X5CrNi1810

X5CrNiMo171

21

X6Cr17

35~40

25~30

30~35

25~30

15~20

20~25

Bearing Steel

SUJ2

52100

100Cr6

35~45

25~35

The above information is for reference only. Correct data should be dependent on the actual

cutting condition.

Page 20

18

6 MACHINE REPAIR AND MAINTENANCE

6.1 QUALIFICATION OF MACHINE PERSONNEL

MACHINE MAINTENANCE PERSONNEL: The person must have enough knowledge of

machinery and have been well trained.

ELECTRIC MAINTENANCE PERSONNEL: The person must have enough knowledge of

electronics and have been well trained.

6.2 MACHINE REPAIR

During operation, the machine may suffer from damage caused by personnel or other factors. In

case of any abnormal motion occurs, the operator needs to perform trouble shooting. If the

problem cannot be corrected, contact an experienced service technician for trouble shooting

assistance.

※CAUTION: Except for experienced maintenance personnel, do not dismantle any parts of the

machine without authorization to do so.

6.3 MACHINE MAINTENANCE

The machine must be operated under normal conditions and maintained periodically to upgrade its

performance and life.

The table below gives instructions for routine checks of the machine.

ROUTINE CHECK ITEMS FOR THE MACHINE

CHECK CYCLE

CHECK ITEMS

DAILY

1. Pressure gauge on hydraulic systems.

2. Coolant amount.

3. Steel brush condition.

4. Check if the saw blade is properly located on the right and left saw

wheel and between the front and rear tungsten plates.

WEEKLY

1. Check oil amount in hydraulic power unit.

2. Check lubrication oil amount in gearbox.

3. Shoot grease to the parts below:

※Tension slide ※Driven wheel ※Gear box base

4. Remove deposited chips under the chip collection tank.

Page 21

19

EVERY THREE MONTHS

1. Replace the oil in spindle gearbox.

(Replace oil after initial 3 months, then, every 6 months)

※Suggested gear oil: SAE 90 (ISO 220)

2. Check all lock screws. Tighten them if necessary.

3. Check main drive belt tension.

4. Check steel brush belt tension.

YEARLY

Replace oil in hydraulic oil tank.

(Suggested hydraulic oil: ISO-VG grade No.32)

6.3.1 CHANGE OIL IN GEARBOX

Remove the plug at the bottom of the oil tank. Place a container under the gearbox for collecting

the used oil. Wrap tape seal around the plug then tighten it securely. Fill oil through the oil inlet

port located at the top of the gearbox until the oil amount is over the red line on the oil level gauge.

6.3.2 CHANGE HYDRAULIC OIL

Remove the plug. Use a container for collecting the used oil. Wrap tape seal around the plug, then

tighten it securely. Fill oil through the oil tank until the oil amount is over the red line of the oil level

gauge.

Page 22

20

6.4 LUBRICATION

GREASE

NIPPLE

TENSIONING UNIT

Page 23

21

GREASE

NIPPLE

DRIVEN WHEEL

GREASE

NIPPLE

SIDE GUARD OF GEAR BOX

Page 24

22

GREASE

NIPPLE

WORM BEARING IN GEARBOX

Page 25

23

7. MACHINE TROUBLE SHOOTING

During operation, the machine may fail in operation due to personal or other factors. At this time,

the trouble must be solved as shown below:

SA Series

No.

ERROR MESSAGE

CORRECTION

1

Hydraulic system does not start

1. Release the EMERGENCY STOP

2. Check if the electric overload

2

Saw blade does not start

1. Check if the clamping indicating lamp

lights on.

2. Check if blade stalling or breakage

3. Check the overload relay

4. Check the electrical line

3

Saw bow does not move upward

Check if the limit switch damaged

4

Saw bow does not move downward

1. Check if chip jam under the guide

holder

2. Check if the solenoid valve of lifting

cylinder damaged

5

Cutting fluid abnormal

1. Check the amount of coolant tank

2. Check if the line clogged

3. Check if the pump damaged

4. Check the electrical line

6

Vise does not move

1. Check connection of the line

2. Check if the solenoid valve damaged

7

Seriously noisy when cutting

1. Adjust touching situation of blade and

the wheel edge

2. Check if guide holder damaged

3. Check if the upper tungsten insert or

bearing damaged or improper

touching with the blade

4. Check if the bearing of driven wheel

damaged.

5. Check if the bearing in gear box

damaged or bad lubrication

Page 26

24

8. HYDRAULIC CIRCUIT DIAGRAM

70kg/cm

2

M

2.5

11A

CRD063

CPF063

TENSION

LIFT

UNIT

VISE

CHIP REMOVING

70kg/cm

2

M

CRD063

2B3

INSERT

CARBIDE

ROLLER

FREED

HYDRAULIC CIRCUIT DIAGEAM FOR SH-8056SA

2

100kg/cm

Loading...

Loading...