Page 1

Pag.1

Instruction Manual

Edition A

INSTRUCTION MANUAL

Band Saw Machine

type

C-530 NC

March 2003

Page 2

Pag.2

Instruction Manual

Edition A

INDEX..................................................................................ERRORE. IL SEGNALIBRO NON È DEFINITO.

CE DECLARATION.........................................................................................................................5

GENERAL WARNINGS ..................................................................................................................6

1. GENERAL INFORMATION.................................................................................................................7

1.1. Goal of this manual...................................................................................................................7

1.2. Regulations to refer...................................................................................................................7

1.3. Manual description....................................................................................................................7

2. MACHINE IDENTIFICATION DATA....................................................................................................8

2.1 Main costructive characteristics.................................................................................................9

2.2. Blade speed...............................................................................................................................9

2.3. Working surface........................................................................................................................9

2.4. Indexing ....................................................................................................................................9

2.5. Vises........................................................................................................................................10

OW TO USE THE INSTRUCTION MANUAL.....................................................................................11

3. H

3.1. Who should read the instruction manual ?..............................................................................11

3.2. Where to keep this manual......................................................................................................11

3.3. Strength of this manual...........................................................................................................11

3.4. Manual update.........................................................................................................................11

3.5. How to obtain more copies .....................................................................................................12

3.6. If the machine change owner .................................................................................................12

3.7. Suggestions.............................................................................................................................12

4. L

IABILITY LIMITS..........................................................................................................................13

4.1 Inappropriate use of the machine.............................................................................................13

5. TYPE OF USE ALLOWED.................................................................................................................14

5.1. Machine addressee.................................................................................................................14

5.2. Operator ..................................................................................................................................14

5.3. Regulation...............................................................................................................................14

5.4 Typical use...............................................................................................................................14

5.5. Limits using the saw ...............................................................................................................15

5.6. Workable materials.................................................................................................................15

5.7. Work area...............................................................................................................................15

5.8. Work place..............................................................................................................................15

5.9. Command modes, stop, emergency stop and out of service..................................................16

5.9.1 Command modes ..............................................................................................................16

5.9.1.1. Stop...............................................................................................................................16

5.9.1.2. Emergency stop.............................................................................................................16

5.9.1.3. Out of service................................................................................................................16

5.9.1.4. Safety precautions.........................................................................................................16

6. TECHNICAL DESCRIPTION.............................................................................................................17

6.1. Machine structure....................................................................................................................17

6.1.1. Base frame........................................................................................................................17

6.1.2. Chip conveyor.................................................................................................................17

6.1.3. Indexing ...........................................................................................................................17

6.1.4. Vises.................................................................................................................................18

6.2. Cutting bridge .........................................................................................................................18

6.2.1 Cutting bridge frame.........................................................................................................18

6.2.2 Guiding columns...............................................................................................................18

Page 3

Pag.3

Instruction Manual

6.2.3 Columns connection..........................................................................................................18

6.2.4 Lifting cylinder..................................................................................................................19

6.2.5 Blade tension assembly.....................................................................................................19

6.2.6 Band drive assembly.........................................................................................................19

6.2.7 Band brush assembly.........................................................................................................19

6.2.8 Left and right band guides.................................................................................................19

6.2.9 Cutting servo-control ........................................................................................................19

6.2.10 Wheels............................................................................................................................20

6.2.11 Band drive motor (Exhibit A07).....................................................................................20

6.3. Hydraulic power unit...............................................................................................................20

6.3.1 Motor-pump assembly ......................................................................................................20

6.3.2 Oil reservoir ......................................................................................................................20

6.3.3 Solenoid valves.................................................................................................................20

6.4. Electrical system....................................................................................................................21

6.4.1 Control console.................................................................................................................21

6.4.2 Control enclosure..............................................................................................................21

7. MACHINE PROTECTIONS ...............................................................................................................22

8. HOW TO MOVE THE MACHINE.......................................................................................................23

9. HOW TO INSTALL THE MACHINE...................................................................................................24

10. WHAT TO DO TO PREPARE THE MACHINE TO OPERATE .............................................................25

11. SAFETY DEVICES..........................................................................................................................26

11.1 Limit switches and segnalation devices.................................................................................26

11.1.1. Limit switches................................................................................................................26

11.1.2. speed reducer..................................................................................................................26

11.1.3. Mechanical extra stroke .................................................................................................26

11.1.4. Signals............................................................................................................................26

11.1.5. Led, indicators and signals to avoid danger situations...................................................26

11.1.6. Protection devices..........................................................................................................26

11.2. Fix protections ......................................................................................................................26

11.3. Moveable protections............................................................................................................27

11.4. Safety features set-up............................................................................................................27

12. USE OF THE MACHINE..................................................................................................................28

12.1. How to use the machine – The Saw 3 control.......................................................................28

12.1.1 What the Saw 3 is ...........................................................................................................28

12.1.2 Switching the Saw 3 ON.................................................................................................28

12.1.3 Machine status icons.......................................................................................................29

12.1.4 Status icons .....................................................................................................................29

Edition A

12.1.5 Manual cycle .......................................................................................................29

12.1.5.1 Manual operation with the material handling (option) ...............................31

12.1.6 Semi automatic cycle

12.1.7 Automatic cycle

12.1.7.1 Programs directory ..........................................................................................31

12.1.7.2 Create a new cutting program ......................................................................32

12.1.7.2.1 How proceed to create your working list (only for material handling).................32

...........................................................................................31

....................................................................................................31

Page 4

Pag.4

Instruction Manual

12.1.7.3 Running a program.......................................................................................................33

12.1.7.4 How to modify the current cutting program (PGM function)......................................33

12.1.8. How to select the type of coolant (for machine which applies mist lubricator units)....33

12.1.9 General information concerning parameters setup .................................................33

12.1.10 Select your country language .............................................................................36

12.1.11 Inputs & outputs testing screen ..........................................................................36

12.1.12 Software update.............................................................................................................36

12.1.13 Help function.................................................................................................................37

12.2. Head feed control..................................................................................................................37

12.2.1 How to select the feed system (option)...........................................................................37

12.3. Automatic workstop (option)................................................................................................37

12.3.1 How to reset the automatic workstop sensor ..................................................................38

12.4. Band deviation monitor (option)...........................................................................................38

13. HOW TO DISMANTLE THE MACHINE............................................................................................39

14. ORDINARY PROBLEMS..................................................................................................................40

14.1. Base.......................................................................................................................................40

14.1.1. Base (Exhibit A02).........................................................................................................40

14.1.2 Chip conveyor.................................................................................................................40

14.1.3. Index...............................................................................................................................40

14.2. Cutting bridge .......................................................................................................................40

14.2.1 Columns..........................................................................................................................40

14.2.2 Connection bar................................................................................................................41

14.2.3 Lifting cylinder................................................................................................................41

14.2.4 Blade tension assembly...................................................................................................41

14.2.5 Band drive assembly.......................................................................................................41

14.2.6 Guide arms......................................................................................................................41

14.2.7 Band brush assembly.......................................................................................................41

14.2.8 Wheels.............................................................................................................................41

14.2.9 Servo-cutting device .......................................................................................................42

14.2.10 Rapid approach .............................................................................................................42

14.3 Coolant system.......................................................................................................................42

14.4 Hydraulic power unit..............................................................................................................42

14.5 Electric control panel .............................................................................................................42

MAINTENANCE .............................................................................................................................43

15.

15.1 Lubrication.............................................................................................................................43

15.2. Problems ...............................................................................................................................44

15.3. Blade replacement.................................................................................................................44

16.

REMAINING DANGERS ..................................................................................................................46

17. PERSONEL TRAINING...................................................................................................................47

18. MACHINE DISMANTLE .................................................................................................................48

PROOF OF TEST............................................................................................................................49

SPARE PARTS LIST......................................................................................................................50

ELECTRICAL AND HYDRAULIC SCHEMATICS..................................................................72

Edition A

Page 5

Pag.5

Instruction Manual

Edition A

CE DECLARATION

We declare that the product “Band saw machine type C-530NC”:

Serial number 23151 Year of production 2003

referred to in this declaration is in compliance with :

• CEI EN 60204-1

• UNI EN 292/1

• UNI EN 292/2

and :

1. EEC Machine Directive 89/332 dated June 14, 1989 and amendments ;

2. EEC Low Voltage Directive 73/23 and amendments ;

3. EEC Directive 89/336 and amendments.

This product uses only tested and certified components, which meet the CE requirements, unless

otherwise specified.

Vanzago, March 2003 SEGATRICI S.R.L.

Via Ferrario 13

20010 Vanzago – MI

Alessandro Rescaldani

(Amministratore)

Page 6

Pag.6

Instruction Manual

Edition A

GENERAL WARNINGS

This machine was design and built using the state of the art techniques, and with respect of the machine tools European

Laws.

Notwithstanding what above, it is implicit that working underestimating or forgiving the dangers which this kind of machine can generate, the operator could cause a serious injury to him/herself.

Therefore, the operator should carefully read the entire instruction manual, and respect strictly what in it prescribed.

In particular, please pay attention to the following suggestions :

1. Keep always your working area clean.

2. Avoid to keep in your working area pieces of material, chips, cans, or other things which could reduce the possibility of movement for t he operator or even generate risks of inj ury.

3. Be always cautious using the machine, because, even if it is protected in every dangerous spot, it can be a dangerous equipment, and thus it has to be use being particularly careful and aware .

4. Give immediately notice to your supervisor if the machine needs to be maintained or serviced, even if the problem is caused by inexperience. An incorrect use of the machine can be dangerous and can cause injuries.

5. Do not try to repair the problem if you are not sure of what caused it.

6. Never service or m aintain the machine when it is running. Always turn it off.

7. Never leave the machine working without respecting the safety rules or removing the safety devices.

8. Remove electrical power when the machine is not working.

9. Always wear protective cloths, especially when replacing the blade.

10. Never do anything imprudent.

11. Never touch the unprotected part of the blade .

12. Never cut any piece shorter than the shortest possible length.

13. Never start cutting if the material is not firmly clamped by the vises.

14. Move the material only if the cutting bridge is completely up.

Page 7

Pag.7

Instruction Manual

Edition A

1. GENERAL INFORMATION

1.1. GOAL OF THIS MANUAL.

This manual wants to explain instructions about how to operate safely, using texts, drawings, pictures and diagrams used by

themselves or combined to instruct the operator to use the machine.

1.2. REGULATIONS TO REFER.

This manual was written to comply to the European Machine Directive UNI-EN 89/392 and following modifications, and

based on UNI-EN 292/1 e 292/2 concerning a safe use of the machine.

1.3. MANUAL DESCRIPTION

This document contains information needed to :

• install and make the machine work

• normal use of the saw

• how to maintain the machine

• how to service the machine

• how to dismantle the machine

Page 8

Pag.8

Name

Instruction Manual

Edition A

2. MACHINE IDENTIFICATION DATA

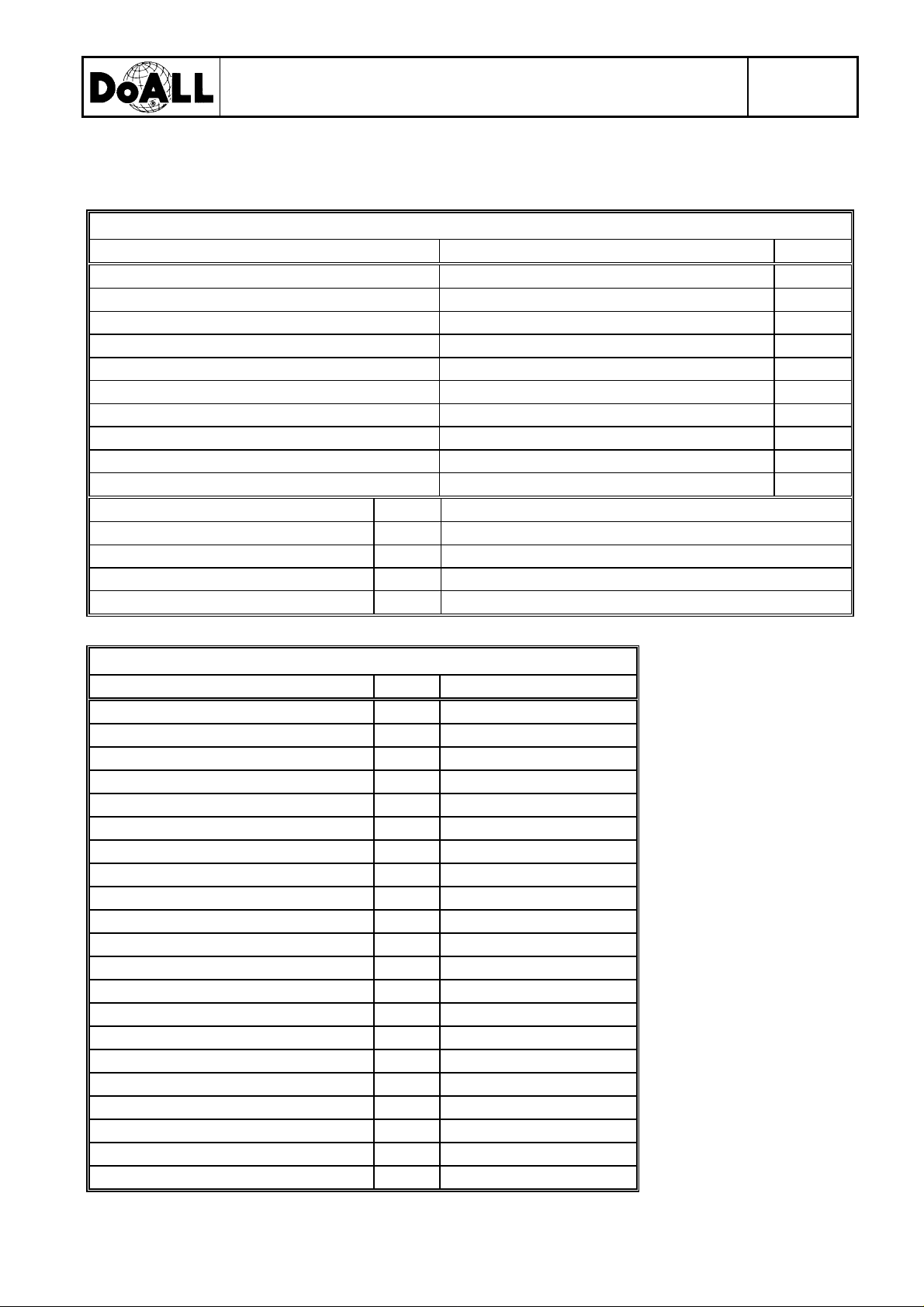

TAB 2.1

Identification data

Description

Type C-530 NC Yes

Serial number 23151 Yes

Year 2003 Yes

Voltage and frequency 400 V 3ph+N+GND ±10% 50 Hz ±1% Yes

Hydraulic power unit Yes

Control circuit 24Vdc 50 Hz

Dangerous area Area around the machine (1.5meters)

Working place Machine control panel

Type of tool Band saw blade

Machine

Description Band saw machine, type C-530 NC

Total amperage A 28

Maximum power kW 12.5

Approximate weight Kg 4.000

Band Saw machine

Denomination or value

Plate

TAB 2.2

Technical Characteristics

Description C-530 NC

Round cutting capacity mm 530

Square cutting capacity mm 530x530

Index stroke mm 500

Band drive motor kW 7.5

Blade dimension mm 6400x54x1.6

Blade speed m/1’ 20-100

Hydraulic pump motor kW 4

Coolant pump motor kW 0.25

Hydraulic pump capacity l/1’ 27

Voltage of motors V 400 c.a.

Control circuit voltage V 24 dc

Cutting kerf mm 1.8

Hydraulic reservoir l 50

Coolant reservoir l 70

Working height mm 770

Machine overall dimension mm

Shipping dimension mm

Color RAL DoALL Roy al blue

Moving components color RAL Beige 1001

Maximum noise level dB 80

Weight (Approximate) Kg 4.000

2800x2500x2800 H

same

Page 9

Pag.9

Instruction Manual

Edition A

AIN COSTRUCTIVE CHARACTERISTICS .

2.1 M

The machine uses :

• Cutting programmer SAWIII

• Trouble shutting control panel “Check Panel”

• Automatic feeding control device

• Blade speed controlled by an AC motor and a variable frequency drive.

• Working surface with non-wearable materials.

• Ball precision screws to control index movements.

• Vises with tempered inserts.

• Pressure reducer valves on vises.

• Self-positioning band guides.

• Carbide inserts mounted inside the band guides.

• Band brush powered by hy draulic motor.

• Chip conveyor powered by hydraulic motor.

• Cutting bridge mounted on chromate columns.

• Welded frame.

• Castings in gray iron C26

• Hydraulic band tension.

The saw is built to work in automatic also without an operator. A special design in the rear vise and working surface area allows the machine to cut slightly irregular bars.

2.2. BLADE SPEED

The blade speed is controlled by an AC motor and a variable frequency drive, which allow to regula te the blade speed within

a range of 0- 100 m/1’. In this way the machine can cut both hard steels and aluminum. A digital reader constantly shows the

blade speed .

The blade speed can be adjusted :

• in automatic cyc le during the editing ;

• in manual using a rotary potentiometer mounted on the control panel.

2.3. WORKING SURFACE

The material that has to be cut lays on a roller way that covers the entire stroke of the machine. The distance between the rollers is studied to avoid that short pieces can fall.

2.4. INDEXING

The material is fed by an index with hydraulic vises, which clamp the piece and move it under the blade. The index moves

on round chrome guides located underneath the roller table, and it is controlled by a tempered steel precision ball screw . The

index has two speeds : fast to move and slow to precisely position the piece. A rotary encoder (with a precision of a tenth of

a millimeter) controls the position of the index.

Page 10

Pag.10

Instruction Manual

Edition A

2.5. VISES

The saw vises are hydraulic. The clamping part of them have a tempered insert bolted. Besides, the hy draulic circuit that controls the vises has a pressure reducer valve with a gauge to avoid to clamp with too much strength the material and deform it.

Page 11

Pag.11

Instruction Manual

Edition A

3. HOW TO USE THE INSTRUCTION MANUAL

3.1. WHO SHOULD READ THE INSTRUCTIO N MANUAL ?

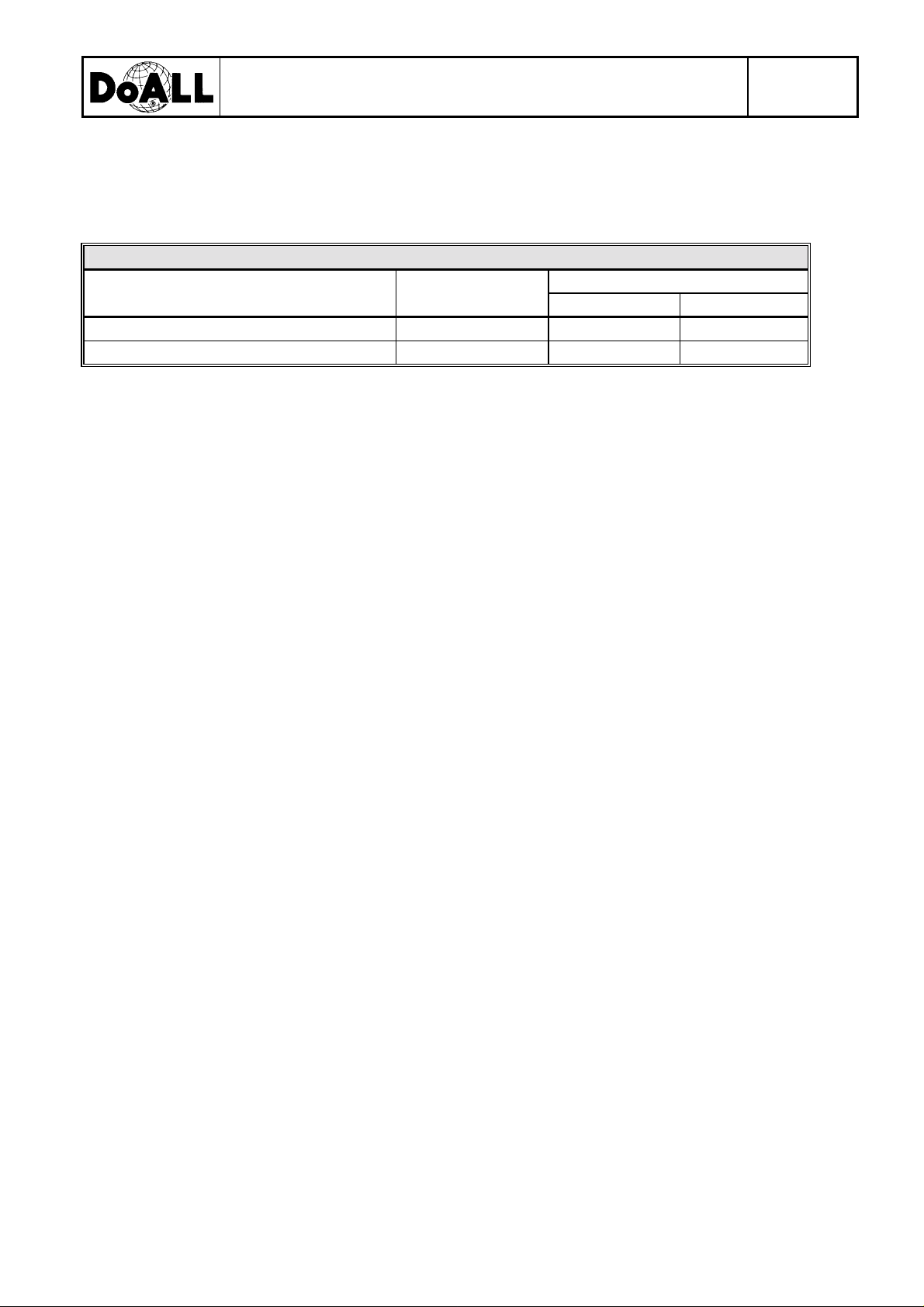

TAB 3.1 Who should read the manual

Description Operator Internal service

Mechanical Electrical

Instruction Manual Yes Yes No

Electrical Schematic No No Yes

The electrical schematic is included in this manual and cannot be supplied separately.

HERE TO KEEP THIS MANUAL

3.2. W

This manual, that is provided along the machine in one copy, should be kept where the machine is located, in a safe and protected place, to be consulted if necessary.

TRENGTH OF THIS MANUAL

3.3. S

1. This manual reflects the state of the art at the time the machine was built, and cannot be considered replaceable by a

newer version.

2. This manual has full force for all the life of the machine it goes along.

3. The customer is not allowed to copy totally or partially this manua l to reach goals different tha n the one of the orig inal manual, and to avoid that a partial documentation replaces the original one.

ANUAL UPDATE

3.4. M

The manufacturer does not have to update this manual if improvements are adopted on newer machines of the same kind of

the one this manual make reference to.

This manual will be updated by the manufacturer only if :

• this manual contains mistakes, errors, or something is missing;

• the original machine is modified by the manufacturer.

Marginal errors or missing e lements, if considered important for the correct work of the machine and its safe use will be immediately notified through an “Errata Corrige”.

To modify this manual the manufacturer will bring all the copy of the sa me edition back and then new copies will be sent to

the customer.

The latest version is marked with higher letter (A, B....). The first edition is called “Edition A”.

Page 12

Pag.12

Instruction Manual

Edition A

3.5. HOW TO OBTAIN MORE COPIES

If necessary , the customer ca n obtain new copie s of this manual simply making a written request a nd mentioning on it the

machine serial number.

If copies are requested, the manufacturer has the right to be paid to issue them.

F THE MACHINE CHANGE OWNER

3.6. I

If the original customer sales the machine, he/she should notify the manufacturer that the machine changed ownership, so to

allow the manufacturer to inform the new use r on the dangers and limits of liability.

3.7. SUGGESTIONS

The customer should notify the manufacturer if improvements are necessary and where they are to increase an easy understanding of this manual/

Page 13

Pag.13

Instruction Manual

Edition A

4. LIABILITY LIMITS

The manufacturer cannot be responsible if the machine if used in one following ways , which are classified as inappropriate :

4.1 INAPPROPRIATE USE OF THE MACHINE

It has to be considered inappropriate the use of the machine if :

• the safety ru les are partially are completely unattended ;

• what the manufacturer prescribed is not done ;

• the a danger or injury is due to an incorrect installation or assembly of the machine, and it was not done by the customer

or under his surveillance ;

• wrong installation of protective equipment after maintenance or service ;

• hydraulic or electrical problems due to the producer of the component and not to the producer of the machine ;

• big deficiency in maintenance ;

• modifications or maintenance on the machine without authorization of the manufacturer ;

• use of atypical tools, other than the ones suggested by the manufacturer ;

• use of non-original spare parts, other than the one suggested by the manufacturer ;

• Partial or complete non-observance of the instructions ;

• machine used by uninstructed operators without control of an expert operator ;

• movement or machining of non-typical materials, or oversize and overweight materials compared to the ones indicated ;

• natural calamities, including earthquakes, floods or others which could provoke danger or faults to the machine or its

structures easy to be identified ;

• if electrical , pneumatic or mechanical safety features were partially or completely removed ;

• maintenance while the machine is working ;

• when parts of the machine are tensioned using temporary connections, without protection or using faulty materials ;

• a person without experience is within the danger area while the machine is running ;

• a person with experience is within the danger area while the machine is running with the automatic cycle.

It has to be considered inappropriate also when the machine runs without enough surveillance to assure the operator

safety or to assure that the machine can run properly .

Page 14

Pag.14

Instruction Manual

Edition A

5. TYPE OF USE ALLOWED

5.1. MACHINE ADDRESSEE

This machine was design and built to comply a professional use, meaning that, besides the technical knowledge required, it is

necessary to have a specific knowledge to operate the saw to obtain the required goals.

5.2. OPERATOR

The saw operator should have experience on similar type of machine. People with low or none experience must be educated,

followed and watched by a supervisor with enough experience and ability .

Therefore, the operator must be aware about dangers related to the use of this machine, and dangers due to normal handling

of metallic materials, similar, or he avy .

This machine cannot be used by people with handicaps or disables.

5.3. REGULATION

Designing and building this machine we respected the following laws and rules :

• UNI rules

• CEI rules

and more in detail, concerning the safety features (ty pe A and B rules):

• European Community Machine directive 89/392;

• CEI-EN 60204-1 and related rules concerning electric’s, with respect of EC directive 73/23 ;

• EN 292/1

• EN 292/2

If not clearly specified, every component used on this machine was UNI and CEI approved at the time it was bought or

made.

YPICAL USE

5.4 T

This machine was designed and built to cut metallic materials fed by automatic sy stems and with overall size non larger than

the ones listed in the chart below (5.4). The saw can move :

1. movement of the material before and after each cut ;

2. vertical movement of the cutting bridg e ;

3. blade rotation.

All these movements could take place at the same time.

The saw has the following performance :

Page 15

Instruction Manual

Tab. 5.4

Characteristic MIN MAX

Cutting speed cmq/m 5 140

Material feeding speed Mt./m 30 300

Cutting bridge falling r ate (w/o material) Mt./m 3 30

Bars size mm

Bar weight kg. 1.336 3.528

5.5. LIMITS USING THE SAW

The machine has two limits of use due to :

• operator’s inexperience

• material size and weight

1. The operator’s experience is particularly necessary when the saw runs in manual cy cle ;

2. material size and weight must be within the ones above shown.

∅ 10 (manual) ∅ 520

Pag.15

Edition A

5.6. WORKABLE MATERIALS

This machine can cut only me tallic bars, pipe s and tubing . Eve ry other use will is considered inappr opria te use of the ma chine.

5.7. WORK AREA

This machine has to work in industrial environment. It is design to make mechanical machining under human control, but

the operator presence is not required continuously.

It is recommended to keep clean and free of interference the area close to the machine.

This machine use a mixture of oil and water as coolant liquid. Thus, the working area could be slippery and dirty .

THIS AREA MUST BE MARKED BY AN APPROPRIATE SIGNAL.

5.8. WORK PLACE

The machine has one work place in front of the control panel.

A second temporary work place is aside the vises, the register them, and to change the blade.

Each work place must be easy to reach when necessary, without interference, even temporary. The machine can work

automatically without operator, who must be present during the manual operations of loading and unloading, and control the

control panel operations.

Page 16

Pag.16

Instruction Manual

No specific illumination is required, but the work place must be well illuminated to respect the requirements set by present

safety rules.

Only authorized people and maintenance personnel should be allowed to reach the saw work place.

The operator must be equipped with personal protection instruments, like gloves and safety glasses.

Edition A

5.9. COMMAND MODES, STOP, EMERGENCY STO P AND OUT OF SERVICE.

5.9.1 Command modes

The saw can be controlled in two different ways:

1. Automatic mode, all automatic commands are enable.

2. Manual mode, all the commands are switched to the control panel push-button and switches.

5.9.1.1. Stop

The saw stops when the cutting cy cle is over.

5.9.1.2. Emergency stop

The emergency stop stops the machine removing tension from the control circuit.

5.9.1.3. Out of service

The saw can be turned out of service removing tension from the control circuit, switching off the main disconnect switch located on the front face of the enclosure. A signal saying “Out of service” must be placed on the machine, and it is operator’s

duty to verify that the machine cannot generate danger situations.

5.9.1.4. Safety precautions

The machine cannot generate danger situation when it is completely without electric or hy draulic power.

Concerning the electrical power, the machine must be completely disconnected from electrical sources, turning of the electrical socket on the building electrical panel. The machine cannot be considered completely safe if the only main disconnect

switch of the machine is turned off.

Page 17

Instruction Manual

6. TECHNICAL DESCRIPTION

6.1. MACHINE STRUCTURE

This saw is manly made by :

1. Base frame

2. Cutting bridge

3. Hydraulic power unit

4. Control Panel

5. Coolant system

Pos. Tab 6.1. Base frame

6.1.1. Base frame

6.1.2. Chip conveyor

6.1.3. Indexing (Only for automatic machines)

6.1.4. Vises (Only for automatic machines)

Pag.17

Edition A

6.1.1. Base frame

The machine frame is welded and machined. The material used is Fe 37. In the weldment there are two reservoirs, one for

the coolant liquid, and the second for the hydraulic oil.

The frame is machined to avoid corners or abrasive points that could be dangerous. It is painted with two layers of paint, the

first of which prevent corrosion.

It is machined to be assembled with other machine components.

6.1.2. Chip conveyor

It is standard on automatic ma chines and optional on semi-automatic machines, and it is made by :

• Bended and welded frame with Fe37 steel.

• Hydraulically powered chip screw.

• Protective brackets.

• Chip tank

• Coolant reservoir

The chip conveyor removes chips coming from the band brush and from the cut, taking them outside the machine.

6.1.3. Indexing

Used only for automa tic machines, it includes :

• Index frame welded and machined , and made using Fe37 steel.

• Precision ball bearing screw, to move backward and forward the index frame.

• Steel vises to clamp the material, controlled by hy draulic cylinders.

Page 18

Pag.18

Instruction Manual

Two limit switches are mounted on the index, the first to set the zero, and the second to control when the index is out of material.

6.1.4. Vises

It includes :

• clamping vises made with a gray iron casting G26, machined. Vises are controlled by hydraulic cy linders.

Edition A

UTTING BRIDGE

6.2. C

Pos. Tab 6.2 Cutting bridge

6.2.1 Cutting bridge frame

6.2.2 Guiding columns

6.2.3 Columns connection

6.2.4 Lifting cylinder

6.2.5 Blade tension assembly

6.2.6 Blade drive assembly

6.2.7 Band brush assembly

6.2.8 Left and right band guide

6.2.9 Cutting servo-control

6.2.10 Wheels

6.2.11 Bland drive motor

6.2.1 Cutting bridge frame

The cutting bridge frame is a steel Fe37 weldment ; it is machined to be assembled with other machine components.

The bridge was design and built to endure the cutting strength, keeping enoug h sturdiness.

The frame is mechanically machined and painted with anti-corrosion a gents and with nitro paint.

The blade is completely protected where it does not work. Covering the wheels, there are two doors that can be opened to

change the blade. Two safety switches are mounted on these doors, so to stop the machine if the covers are not in position.

The blade rotates on the wheels, one of which is driven, and the other one is idler.

6.2.2 Guiding columns

The columns guide vertically the cutting bridge movement. They are made with chrome bars, hardene d and grinded.

6.2.3 Columns connection

Made using a Fe52 steel square tube, the columns connection connects and makes the guiding columns sturdy. I t is fastened

to the columns through two locknuts. The lifting cylinder is fastened to the center of the connection tube.

Page 19

Pag.19

Instruction Manual

6.2.4 Lifting cylinder

This is an hydraulic cylinder, with chrome rod and lapped cy linder. The lifting cylinder is a double effect cy linder. The head is

fastened to the columns connection, and the final end of the rod is fastened to the cutting bridge using a locknut.

6.2.5 Blade tension assembly

This assembly has to keep the blade at the right tension when the machine is running. There is a steel slide which support the

idler wheel shaft. An hydraulic cy linder, that works on the slide, keeps the band in tension. A limit switch protects the machine turning immediately off the machine if the blade brakes.

6.2.6 Band drive assembly

The band is powered by a n AC motor which automatically reg ulates the rotation speed. Using two pulley s and three V-be lts,

the motor makes the speed reducer turning. On the other end of the reducer there is the drive wheel, that is fastened to the reducer using a collet locking .

Edition A

6.2.7 Band brush assembly

A band brush is powered by an hy draulic motor, and it cleans the teeth removing the chips.

6.2.8 Left and right band guides.

The band guides have to :

• straighten the blade coming out the wheel, and keep it vertical helping the blade insertion between the inserts.

• protect the part of the blade that is not cutting .

Left guide arm : Moves horizontally on guides machined on the bridge, and it is moved by the movement of the vise.

Right guide arm : Fixed on the cutting bridge. It supports the cutting servo control.

Both the guide arms have carbide inserts.

6.2.9 Cutting servo-control

The Cutting servo-control automatically controls the saw feed rate. A servovalve has an extension which touches the blade

back, and registers the efforts to cut the piece. The servovalve modifies the feed rate for :

• shape of piece

• material hardness

• blade wear condition

The operator, reading on the knob, is allowed to change the preferred feed rate.

Page 20

Pag.20

Instruction Manual

6.2.10 Wheels

Made using cast iron G26, and lathe machined. They are fastened as follow :

• the idler wheel is fastened on the band tension a ssembly, and it turns on ball bearings ;

• the band drive wheel is fastened using a collect locking on the reducer shaft.

The wheels diameter is larger the n the maximum material height that can be cut by the saw..

6.2.11 Band drive motor (Exhibit A07)

The machine mounts a self-cooling AC electric motor. On the shaft there is a three throats pulley, on which there are 3 Vbelts to connect motor and reducer

Edition A

6.3. HYDRAULIC POWER UNIT

The power unit has a double location inside the machine frame. Underneath the infeed roller table there is the oil reservoir,

and under the outfeed roller table there are all the solenoid valves. The power unit is made by :

Pos. Tab 6.3. Hydraulic power unit

6.3.1 Motor-pump assembly

6.3.2 Oil reservoir

6.3.3 Solenoid valves

6.3.1 Motor-pump assembly

Electrical motor and pump are connected by an elastic coupling.

6.3.2 Oil reservoir

It is in the machine fra me, and it has a maximum and a minimum level indic ators, and a suc tion filter. On the left side of the

infeed roller table there is a plug which allows to refill the reservoir. The hy draulic system has 2 filter s :

• a 250 micron 45 litres suction filter

• a 60 micron 45 liters outflow filter

These two filters have to be removed when changing the oil for the first time (after 500 working hours), washed using trichloroethylene and dried blowing air.

6.3.3 Solenoid valves

The solenoid valves are mounted on blocks, and the control the hydraulic movements.

Page 21

Pag.21

Instruction Manual

Edition A

6.4. ELECTRICAL SYSTEM

6.4.1 Control console

The control console is on the upper part of the control enclosure, and all the push-buttons and switches are mounted on it.

There is a 5” monitor, which displays the control commands.

6.4.2 Control enclosure

It is made bending metal sheets and it complies the IP55 standards. I nside there is the electrical panel which supports all the

electrical devices (relays, circuit breakers,...) comply ing the CEI 60204.1 standards.

Page 22

Pag.22

Instruction Manual

Edition A

7. MACHINE PROTECTIONS

This machine is entirely protected where it can be dangerous. Despite of this, there are some parts that cannot be protected,

and where the operator must never work. The biggest of these parts is where the blade touches material.

There is a sticker close to every part which is not completely safe, to show to the operator that he should be extremely conscious.

Page 23

Pag.23

Instruction Manual

Edition A

8. HOW TO MOVE THE MACHINE

This machine, when installed and fastened to the ground must be considered a fix equipment.

If it is necessary to move the machine or parts of it (because of maintenance or service), the operator must use a crank or a

fork lift, or a lighter lifter with regards of the weight of the part that have to be lifted.

Page 24

Pag.24

Instruction Manual

Edition A

9. HOW TO INSTALL THE MACHINE

The machine can be installed by :

• the manufacturer/distributor ;

• the customer ;

The machine is shipped completely mounted.

Moving the machine is one of the moment the risk of injuries is higher, thus it is important to make sure that :

• Every operator wears the necessary safety equipment.

• The lifting equipment must be enough big to lift the machine. Always use only one lifting equipment to lift the machine,

never combine more then one.

• Do not use a lift fork if the length and width of the forks are inadequate to lift the machine.

• If using a crank, use metallic ropes and be sure they can support the weig ht of the machine. Put strong cartoon or wood

between the ropes and the machine. Never leave the ropes slide freely on the machine body .

• Do not use metallic ropes if they show wear areas.

• Lift the machine slowly so to have enoug h time to adjust the lifting if necessary or to avoid obstacles.

• In the lifting area there should be enough people to move safely the machine, and do not allow anyone else to stay in the

lifting area during such operation.

• Be sure that every moveable part is well fastened to the machine. Remove or secure ever y part which falling can be dan-

gerous for the people in the work area.

• Move the machine paying attention to the surrounding environment. Be extremely cautious so to avoid hitting anyone or

anything.

• Moving the machine, stay as close as y ou can to the ground to avoid that a rope brake could generate dang ers or serious

machine breaks.

• If necessary, put pieces of wood under the machine base before putting it down.

Page 25

Pag.25

Instruction Manual

Edition A

10. WHAT TO DO TO PREPARE THE MACHINE TO OPERATE

This machine can be installed by :

• the manufacturer;

• a manufacturer representative ;

• the customer.

It is customer duty to get the place ready to install the machine, arranging also the anchor bolts to secure the machine on the

ground.

To installed the machine it is necessary :

• to be sure the place where the machine as to be placed is leveled ;

• prepare the anchor bolts to secure the machine ;

• lift the machine and insert the anchor bolts ;

• Level the machine on the ground working on the leveling screws ;

The machine needs only to be electrically connected.

Before to connect the power :

• check if the operator uses the necessary safety devices ;

• check if the disconnect switch is insulated ;

• check if the control panel is insulate d ;

• check if the fuses and circuit breakers are operative ;

• check the 3 phase electric source ;

• if the machine does not work properly, do not try to fix it, but immediately disconnect the power and ask for a mainte-

nance expert ;

• check the correct electrical connection ;

• check if the necessary protection devices work properly ;

• check if push buttons and select switch work properly ;

• check the mechanical connections ;

The manufacturer cannot be responsible for injuries and/or damages due to the customer electric source, especially if it does not meet the present safety requirements. (In Italy DL SG 94/626)

Check if the following motors rotate c lockwise :

• hydraulic power unit motor

• coolant pump

• band drive motor

Fill completely the oil and the coolant reservoir.

If not ye t mounted, install the blade (make reference to par. 15.4.)

Feed the material and input a cutting program.

Page 26

Instruction Manual

11. SAFETY DEVICES

11.1 LIMIT SWITCHES AND SEGNALATIO N DEVICES

11.1.1. Limit switches

On the machine there are the following limit switches

• Control enclosure open

• Safety interloc k switches (4 )

• Head down

• Head up

• End of material

• Head rapid approach

• Blade break

Pag.26

Edition A

11.1.2. speed reducer

Not necessary

11.1.3. Mechanical extra stroke

• Head down

• Index back

11.1.4. Signals

See 12.1.2

11.1.5. Led, indicators and signals to avoid danger situations

Not necessary

11.1.6. Protection devices

The blade is protected, where uncovered, by two guides that reduce the risk, but that cannot completely cover it.

11.2. FIX PROTECTIONS

The moveable parts of the machine are protected by fix covers, which can be removed using tools.

Page 27

Pag.27

Instruction Manual

Edition A

11.3. MOVEABLE PROTECTIONS

The wheels are covered by two removable doors which can be opened to inspect or replace the blade. Two safety interlock

switches automatically stop the machine if the cover is opened while the machine is wor king.

11.4. SAFETY FEATURES SET-UP

The limit switches are set up at the factor y.

Page 28

Pag.28

Instruction Manual

Edition A

12. USE OF THE MACHINE

The manufacturer cannot be liable for any injury caused by errors or mistake using the

machine, as described in the following paragraphs.

The operator must wear all the personal protections equipments, as gloves and ear plugs.

12.1. HOW TO USE THE MACHINE – THE SAW 3 CONTRO L

12.1.1 What the Saw 3 is

The Saw 3 is a PLC & a NC control, specifically designed for cutting machines. All the machine

operations are controlled by the Saw 3: in manual by pressing the pushbuttons correspondent to the

desired operation, and in automatic by the programmed logic.

LCD display Numeric keyboard PGM & RUN pushbuttons

Contrast adjustment

Manual mode pushbuttons

START pushbutton STOP pushbutton

12.1.2 Switching the Saw 3 ON

The Saw 3 automatically switches on when the machine is operated. Therefore, to switch the Saw 3

on is necessary to switch the entire machine ON, by rotating the main switch located on the

electrical enclosure, below the control. After few second in which the welcome logo of DoAll will

appear, the machine will ask if it’s necessary to set the zero on the index axis: press the start

pushbutton ( ) to run the setting process, or press the pushbutton corresponding to NO if you

don’t want to run it.

After this operation the machine is ready for manual operations. On the display appear all the status

icons, such as the coolant, band speed,…

While in manual mode (the symbol appears at the top left corner of the screen) it is possible to:

1. Have access to all machine configuration parameters;

2. Enable working cycles.

In manual mode the operator can also control each singol machine part by pressing the

correspondant pushbuttong (Please go to paragraph “machine controls”), with the only exception for

the band ON control.

Page 29

Pag.29

Instruction Manual

The allows to get into the machine parameters area (most of them protected by passwords),

and the allows to make all programming & cutting operations.

In this manual will not be trained the operator to use the menu, because this area must be operated only by the manufacturer or its representatives. The customer cannot modify any of the machine parameters, because this might cause severe injuries to the operator and people around the

machine.

12.1.3 Machine status icons

On the left upper corner of the display, it appears the machine status icon, which specify in which

mode or in which status the machine currently is. These icons are:

Icon Description Icon Description

Manual

Normal machine status, and allows to

use machine manually.

Semiautomatic

The saw is making a single cut.

Automatic

The machine is running an automatic

cutting program

Editing

One program is edited at the time

Program directory

The control is in the program directory

area

Zero setting

The machine is setting the index zero

Index positioning

Index is moving to a position.

Edition A

12.1.4 Status icons

The following icons show the status of each machine component during

ICONS DESCRIPTION

0m/m Blade speed control

12.1.5 Manual cycle

The SAW3 NC control has 28 customizable pushbuttons (or function keys) to control the entire machine. The standard version looks like the following:

Band motor ON / OFF

Index movement

Inboard vise open / close / undefined / opening / closing

Index vise open / close / undefined / opening / closing

Hydraulics’ ON / OFF

Head up / down fast / down slow / undefined

Coolant ON / OFF / ON in cycle

Band broken / Band OK

Page 30

Pag.30

Instruction Manual

Above each function key the operator can easily understand what the function of the button is. Following the operator can find the entire list of the function keys available:

F01 !

F02 !

F03 !

F04 !

F05 !

Hydraulics’ ON / OFF

To control the coolant mode

Front vise opening

Front vise closing

Blade speed increase

Edition A

F06 !

F07 !

F08 !

F09 !

F11 !

F12 !

F15 !

F17 !

F18 !

F21 ! Discharge unit to the left (option)

F22 ! Discharge unit to the right (option)

F23 ! Increase head feed (option)

F24 ! Decrease head feed (option)

F27 ! Power conveyor ON (option)

F28 ! ON – OFF – AUTO material handling (option)

All the other function keys are disable in the standard configuration.

Blade speed decrease

Index backward

Index forward

Index positioning control: type the index position you have to reach, then

press START

Head up

Head down. Pressed with SHIFT, the head moves down slowly

SHIFT.

Index vise opening

Index vise closing

Page 31

Pag.31

Instruction Manual

Edition A

12.1.5.1 Manual operation with the material handling (Option)

To access the material handling controls, press the button located on the middle lower part of

the LCD monitor. The following icons will appear:

Second hydraulic power supply – CONTROL DISABLED

Power conveyor backward

Power conveyor forward

Transferring unit forward

Transferring unit rearward – CONTROL DISABLED

High – Low speed for roller conveyor

12.1.6 Semi automatic cycle

The operator can run a semiautomatic cycle when he needs to make only one cut. In fact, after finishing the cut, the machine will stop in this cycle.

To run a semiautomatic cycle is therefore necessary to position the material between the vises, make

sure it is firmly clamped and then press together:

SHIFT +

To stop the cycle, press

12.1.7 Automatic cycle

12.1.7.1 Programs directory

By pushing the (program directory) the operator has full access to all the operations on program editing. It appears a screen like the one below, in which it is possible to:

Nome

ALFA

BETA

= MAKE A NEW PROGRAM

= DELETE THE HIGHLIGHTED PROGRAM

= DELETE ALL THE PROGRAMS

GAMMA

= GO TO THE TO P OF THE PR OGRAM LIST

= GO TO THE BOTTOM OF THE PROGRAM

LIST

Page 32

Pag.32

Instruction Manual

12.1.7.2 Create a new cutting program

The allows to make a new program. To edit a new cutting program it is required to enter the

following programs:

Program name

Crop cut

Material type

Dimension

To move on the editing screen, use the arrows on the top right corner of the SAW 3 control. All the

figures typed must be confirmed by pressing the ENTER button.

The control, when editing the program, gives a numeric name by default to the program. This number follows the last one written in the control memory. By moving with the pointer on the name

field, the operator can modify the program name as he prefers.

The automatic screen gives also other important information’s to the operator, like:

" NECESSARY BAR LENGTH to run the program. The SAW3 adds the cutting lengths, times the

number of cuts, to the blade kerfs and the minimum butt end. I.e.: (30 mm x 50 Pc) + (1,6 mm x

50 pc) = 1580.0

" TOTAL NUMBER OF CUTS TO DO (50 in the example);

" ALREADY DONE CUTS (0 in the example).

Also, the bottom part of the screen shows the following icons which allow to:

Delete the cutting line underlined

Insert a new cutting line where the cursor is at the moment

To delete all the lines of a program

To go to the first page of the program

To go to the last page of the program

To save

12.1.7.2.1 How proceed to create your working list (Only for material handling)

To create the list of programs to execute, it is necessary that the material handling icon would be

on ON or in AUTO mode (on the screen will appear the icon or ). To enable this

icon, press button “F28”.

Select the programs directory( ) and it will appear the entire list of programs stored in the

control. Go to the line showing the first program to execute and press INS button (lower right

corner of the screen), then do the same for the following programs.

Press RUN and it will appear the current job list.

I :10

Len: 1580.0 50 0

Alfa 316L 70m/m

50-100

1 30.0 50

2

27%

Band speed

Feed force

Number of cuts

Cut length

Edition A

Page 33

Pag.33

Instruction Manual

Edition A

12.1.7.3 Running a program

Press the RUN key to prepare the machine for the automatic cycle. On the display will appear the

screen of the current program (in case the program is not the one you wan to run, select from the

program directory the one you need to run).

The automatic cycle will start by pressing simultaneously SHIFT and

To stop the cycle press

Make sure that the cuts counter is set to z ero. If necessary to reset only on program line, move with

the cursor to the desired line and press the button. If the operator wants to reset all the program lines, then it’s necessary to press to button. The cutting lines already executed will be

marked with the symbol “*” at the left side of the line number.

While in automatic the buttons allows to switch the displayed information between the automatic data’s and the machine status icons. Besides, the icon showing the “CLOCK”, gives the cutting times.

12.1.7.4 How to modify the current cutting program (PGM function)

By using the “PGM” pushbutton the operator can modify the active program. It is possible to

change all the program variables, such as name, band speed, cutting lengths and number of cuts. To

make such changes, please proceed as described in paragraph 12.1.7.2

To save the changes, press OK. To exit without saving, press EXIT.

12.1.8. How to select the type of coolant (only for machine which applies mist lubricator units)

In case your band saw machine would be equipped with a second coolant system, it is possible to

switch from standard coolant to mist coolant. To do so, press at the same time SHIFT + COOLANT

buttons (F02+F15). On the display it will appear on the side of the coolant status icon H

O (for stan-

2

dard coolant) or OIL (for mist unit).

12.1.9 General information concerning parameters setup

To avoid that non authorized personnel could change machine setting parameters, the Saw 3 is protected by passwords.

Liv. 1 Liv. 2 Liv. 3 Liv. 4 Liv. 5 Descrittore

To access the machine configuration menus

Zero setting of machine axes

Advanced zero setting s

Static zero setting, axis 2

Static zero setting axis 1

Dinamic zero setting axis 1

Advanced zero setting

Page 34

Pag.34

Instruction Manual

Edition A

Static zero setting axis 1 with band kerf co mpensation

Operator customizable parameters

Axis 1 test

SAW 3 programm ing section

Machine components definition

Machine components parameters

Control type and configuration version

Inputs & outputs list

Hydraulic pum p parameters

Front vise parameters

Index vise parame ters

Axis 1, type A parameters

Axis 1, type B param eters

Parameters for swiveling machines

Axis 2, type A parameters

Axis 2, type B param eters

Saw head parameters

Saw head input parameters

Saw head output parameters

Measurement indexer parameters

Swiveling indexer parameters

Coolant parameters

Chip conveyor parameters

Band drive motor parameters

Band tension parameters

Blade speed proximity

Blade motor amperometer parameters

Page 35

Pag.35

Instruction Manual

Edition A

Band deviation monitor parameters

NC control test section

Language selection. Pay attentio n !!!! Once changed the la nguage the machine must be restarted

Automatic material handling parameters

Automatic discharger parameters

Automatic roller conveyor parameters

Emergencies definition

Warnings definition

Automatic cycle parameters

Manual mode parameters

Saw head parameters for automatic head controlled machines

Nesting parameters

General parameters

PC connection for configuration parameters download and upload

Material library configuration

Cutting parameters

Manual controls for material handling, roller conveyor, transferring units

Second hydraulic power unit

Roller conveyor

Roller conveyor

Transferr i ng unit up

Transferr i ng unit down

Roller conveyor speed

VERY IMPORTANT

Never modify the machine parameters without a DoAll technician present. This could cause

severe injuries to the operator and machine failure. Changing parameters without our written express authorization will immediately inte rrupt machine warranty and will ke ep DoAll armless for any possible injury .

Material definition

Material enable

Page 36

Pag.36

Instruction Manual

Edition A

12.1.10 Select your country language

To change the display language, press the buttons , and then . Type 123456 and confirm it by

pressing ENTER. Then select:

For ITALIAN

1

For ENGLISH

2

For SPANISH

5

For FRENCH

6

12.1.11 Inputs & outputs testing screen

This menu allows to test inputs, outputs and other machine functionalities.

* C H E C K *

1 1 1 1 1 1 1 1 1 1 2

1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 0

I : O O O O O O O OOOOOOOOOOO O O

O : O O O O O O O OOOOOOOOOOO O O

K E Y : D I P : OOOO L C D : 1 8

D : 0 D : 0 D : - - - -

A : 0 A : 0 A : 0

E : z 0 0 0 0 E : z 0 0 0 0 H z : 0

12.1.12 Software update

Plug a serial cable, type RS-232, from the serial port of your PC to the

serial connector in the electrical cabinet of the machine

To update the machine software, you should start the machine having

pressed the soft key below the display 1 & 3. It will appear this screen

and the machine will be ready for connection to a remote PC Press the

button

application that allows to updated the software. The command that has

to be input is:

C

:\>SAWFLASH -X -Ffilename.X02

When the operation is complete, restart the machine. If any mistake happens during the operation, start the upload

newly.

. The communication software SAWFLASH is a DOS

Parameters update

SAWUTIL is the DOS application that upload or download the machine configuration. To run the application, press

the button

When the connection will be reached, it will appear

and . On the screen it will appear:

Page 37

Pag.37

Instruction Manual

Edition A

UPLOAD COMMANDS:

SAWUTIL

LINK

GET filename

UNLINK

QUIT

Type this command to run the application

This command allows to link the PC to the NC control

It Uploads the parameter file on the PC

The command unlinks Pc and NC control

To quit the application

DOWNLOAD COMMANDS:

SAWUTIL

LINK

PUT nomefile

SAVE

QUIT

Type this command to run the application

This command allows to link the PC to the NC control

It downloads the parameter file on the PC

To save the new parameters

To quit the application

12.1.13 Help function

The Saw3 controls has an Help on line function, that gives to the operator all the necessary information to run the machine.

To use this function, move the cursor on the field you want to request help on, then press the HELP

button. Will appear a window in which the operator will read all the necessary instructions.

12.2. HEAD FEED CONTROL

The Cutting servo-control automatically controls the saw feed rate. A servovalve has an extension

which touches the blade back, and registers the efforts to cut the piece. The servovalve automatically modifies the feed rate for :

• shape of piece

• material hardness

• blade wear condition

12.2.1 How to select the feed system (option)

Same machines are equipped with two separated feed systems: the standard servo control and the

metered feed. It is suggestible to use the servo when cutting structural or soft & medium hardness

materials, and the use the metered feed when cutting hard materials.

T

YPE OF FEED CONTROL

SERVO

METERED

HOW TO SET THE CONTROL MACHINE REACTION

Position the feed handle on this

symbol and adjust the cutting

pressure to the desired value

Position the feed handle on this

symbol and adjust the servo

pressure to the max allowed

pressure.

Adjust cutting speed on the metered control.

Machine will cut faster with

small section and slower

with higher section

Machine will always at the

same speed, regardless of the

cross section.

12.3. AUTOMATIC WORKSTOP (OPTION)

Position the bar to cut on the machine, paying attention that its front edge doesn’t cover the photo

electric workstop sensor, positioned near the zero position of the index stroke.

Page 38

Pag.38

Instruction Manual

Prepare the program to execute and operate like explained in “Running a program” paragraph. The

control will ask if you want to make the crop cut or no. When it will displayed the message, press

YES to make a crop cut or NO to start directly with the first cutting length.

12.3.1 How to reset the automatic workstop sensor

If the first cut is too short or too long, then it is required to reset the automatic workstop sensor. To

do so:

123456 Enter the password and press OK

Parameter 13 gives the distance between the sensor and the blade. If the cut is too short,

Press the SET button

Press the button

reduce the set value of the difference in length (i.e. if 298 instead of 300, reduce the set

value by 2 mm). If the cut is to long, increase the set value of the difference in length.

Exit the parameter area by pressing OK, then EXIT

Edition A

12.4. BAND DEVIATION MONITOR (OPTION)

To set the band deviation monitor:

123456 Enter the password and press OK

Set the parameter #14 “Max deviation” to the desired value

Press the SET button

Press the button

Exit the parameter area by pressing OK, then EXIT

LOADING THE MATERIAL ONTO THE MACHINE

Moving bars, especially if they are in bundles, it is necessary to pay attention to the security rules for the movement of heavy loads.

Keep the bundle with steel strips until it is in the vises, then remove the strap before starting the cutting cycle.

Page 39

Instruction Manual

13. HOW TO DISMANTLE THE MACHINE

Only experts can dismantle the machine.

Pag.39

Edition A

Page 40

Pag.40

Instruction Manual

Edition A

14. ORDINARY PROBLEMS

warning

It is defined as ordinary service the maintenance due to breaks or wear of parts. Even in these circumstances, only expert operators should service the saw. They have to be able to work safely knowing which are the machine dangers, and avoiding

unnecessary risks.

WHEN SERVICING THE SAW, ALWAYS DISCONNECT THE ELECTRIC SOURCE. THE OPERATOR

MUST USE THE ENTIRE SAFETY EQUIPMENT (GLOVES, GLASSES AND BOOTS).

The manufacturer can not be judged liable for injuries or damages due to unattended safety rules by the

user.

14.1. B

14.1.1. Base (Exhibit A02)

Vise wear status 06-012

Replace vise inserts 06-012

Vise guide 06-008

14.1.2 Chip conveyor

Chip conveyor 11-004 none

Clean chip conveyor 11-004 any

14.1.3. Index

No special service is needed 09-003

ASE

Base dwg. 01-001-0

Chip conveyor dwg. 11-001-0

Vertical vise dwg. 09-001-0

Pos.

Pos.

Pos.

Tool

Tool

Tool

14.2. CUTTING BRIDGE

14.2.1 Columns

Column dwg. 01-024-0 Pos. Tool

Check locknuts 01-025 Spanner

Page 41

Instruction Manual

14.2.2 Connection bar

Connection bar. /01-032-0

Check hydraulic hoses none

14.2.3 Lifting cylinder

Lifting cylinder dwg. 12

Check locknuts 12-017 Spanner

Check gaskets None

14.2.4 Blade tension assembly

Blade tension assembly Dwg. 16 Pos. Tool

Adjust the guide track Spanner

Check locknut 03-052

Do not regulate the central screw of the blade tension guide

Pos.

Pos.

Tool

Pag.41

Edition A

Tool

14.2.5 Band drive assembly

Band drive assembly dwg. 03 Pos. Tool

Check the electrical motor 03-001

Check the collect locking that connect the wheel to the reducer shaft 03-043

Check belts 03-019

14.2.6 Guide arms

Check guide arms dwg. 05 Pos. Tool

Check carbide inserts 05-045

When changing the blade, clean the inserts with gasoline

Check, and if necessary replace, the guiding ball bearing s and the guide-arm inserts 05-023

05-026-029

Check and rotate the carbide backer 17-003

14.2.7 Band brush assembly

Band brush assembly dwg. 20 P os. Tool

Check and if necessary replace the band brush 20-014 Spanner

Register the brush so to keep the blade teeth always clean

14.2.8 Wheels

Wheel. /03-042-0 Pos. Tool

Check the wheel adjustment

Check the blade position on the wheel. If the blade back touches the wheel, call the manufacturer.

Check and keep clean the wheel grooves 03-042

03-042 Manufacturer

Page 42

Instruction Manual

Be sure the blade is not cutting the machine frame 03-042 Manufacturer

Keep lubricated all the bearings 03-051

14.2.9 Servo-cutting device

Servo cutting assembly Dwg. 066/17 Pos. Tool

Check the servo-v alve adjusting the cutting pressure. Turn the knob

Open the servo-valv e cover and check the vertical movem ent of the unit. Spanner

14.2.10 Rapid approach

Check that the rapid approach limit switch is in working properly

COOLANT SYSTEM

14.3

Check the reservoir level and, if necessary, add oil ty pe OSO46.

Pag.42

Edition A

HYDRAULIC POWER UNIT

14.4

Keep the pressure to 55 bar.

ELECTRIC CONTROL PANEL

14.5

Replace, if necessary, broken components.

Page 43

15. MAINTENANCE

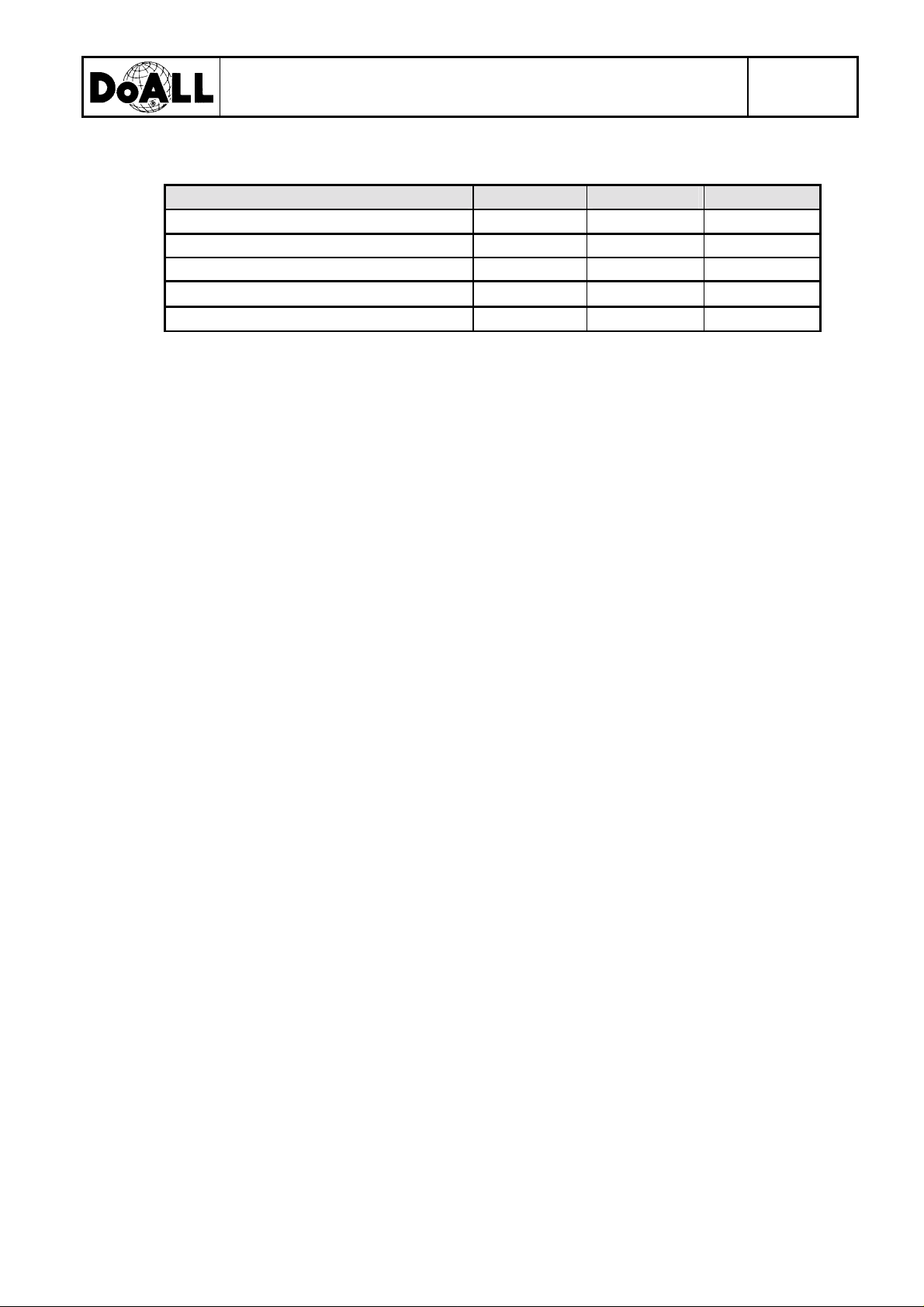

15.1 LUBRICATION

REDUCER

A Loading plug

B Level

C Unloading plug

INDEX

D Loading plug

E Precision ball screw

F Lubrication

COLUMNS

G Loading plug

WHEEL

H Bearings

GUIDE ARM

I Lubrication points

VISE GUIDES

L Lubrification points

Instruction Manual

AGIP BLASI A 150

ESSO SPARTAN EP 150

MOBILGEAR 632

BP ENERGOL GR-XP150

FINA GIRA 150

AGIP EXIDI A 68

BP ENERGOL HP 60-C

TOTAL CARTER EP 68

AGIP GR MU 2

BP MACH-GREASE LT2

TOTAL MULTIS MS

AGIP EXIDI A 68

BP ENERGOL HP 60-C

TOTAL CARTER EP 68

AGIP GR MU 2

BP MACH-GREASE LT2

TOTAL MULTIS MS

AGIP GR MU 2

BP MACH-GREASE LT2

TOTAL MULTIS MS

AGIP GR MU 2

BP MACH-GREASE LT2

TOTAL MULTIS MS

Pag.43

Edition A

Replace oil after 100 hours

Check the level every 2000 hours

Replace after 4000 hours

Control weekly

Control weekly

Control weekly

Control weekly

Control weekly

Page 44

Pag.44

Instruction Manual

Edition A

ROBLEMS

15.2. P

Problems Reasons How to solve the problem

Twisted cut Feed rate

Blade is not perpendicular

The blade looses the sharpnes s

quickly

The blade vibrates

Blade teeth break Feed rate

Blade breaks The guides don’t work properly

Stripes on a side of th e blade Only one guide guides th e blade Regulate the guides

Blade stalls Feed rate Reduce the feed rate

The motors are off Problems with the electric source

Cutting speed

Wrong teeth

The blade slides on the material

Feed rate

Wrong teeth

Cutting speed

The cut begins on an irregular or thin section

Material unclamped

Blade in tension even w hen work is over

Wrong weldment

Blade installed incorrectly

Wrong circuit breakers

Short circuit

Reduce the feed rate

Register the blade

Reduce the speed

Use a blade with the right teeth

Increase the feed rate

Increase the band tension

Reduce the feed rate

Use a blade with the right teeth

Reduce the speed

Turn the material on the mach ine

Clamp the material

Check the guides and th eir carbide inserts

Remove tension when not working

Return the blade to the supplier

Check the blade

Look for the problem and solve it

15.3. BLADE REPLACEMENT

1. Turn the electric power off, and unplug the source.

2. Wear the protection gloves.

3. Turn the band tension valve handle so to remove tension to the blade.

Page 45

Instruction Manual

4. Open both the band wheel doors.

5. If stalling in a bar, remove the blade slowly.

6. It is suggested to cover the blade using the plastic teeth strip was orig inally on the blade.

7. Take the old blade in a place where no one can be injured.

8. Clean using compressed air the wheel tracks and the band guides.

9. Put the new blade on the wheel paying attention to the teeth orientation.

10. Make sure the blade sits completely on the wheel track.

11. Tension the blade little by little, and check that it sits correctly on the track.

Pag.45

Edition A

Page 46

Pag.46

Instruction Manual

Edition A

16. REMAINING DANGERS

This machine is powered by electrical power. The manufacturer, building the machine, used the state of the art solutions

also meeting the regar ding regulations to assure maximum safety to the operator.

When servicing the machine with power on to check particular electrical components, always respects the basic safety

rules. Reduce as much as possible this type of operations.

The customer is required to provide a suitable power source respecting the CEI 64-8 or other countries special rules

where the machine was installed.

Page 47

Pag.47

Instruction Manual

Edition A

17. PERSONEL TRAINING

This machine was design to be easily operated. I t is not expressly required an expert to operate the saw, but an expert can

set as best as possible the machine so to obtain the ma ximum results.

Therefore, the operator needs a good experience in machine tools, especially in band saw machine.

The internal maintenance personnel should be able to read and understand an electrical and hydraulic schematic, and

work on the machine following the instructions c ontained in the schematics.

Page 48

Pag.48

Instruction Manual

Edition A

18. MACHINE DISMANTLE

This machine was built using only ecological materials. It is necessary to separately recycle only the hydraulic oils and the

coolant liquid.