Page 1

A

f

Product Line o

Diodes Incorporated

PAM8124

Description

The PAM8124 is a 15W efficient, Class-D audio power amplifier for

driving stereo speakers in a single-ended configuration; or a mono

speaker in a bridge-tied-load configuration. The PAM8124 can drive

stereo speakers (SE) as low as 4Ω. Due to the low power dissipation

and high efficiency, up to 95%, the device can be used without any

external heat sink when playing music.

The gain of the amplifier is controlled by 2 gain selectable pins,

offering 20dB, 26dB, 32dB, and 36dB gain selections.

The PAM8124 is available in a TSSOP-24-EP package.

NEW PRODUCT

Features

• 30W/Ch into 8Ω BTL Load from 22V Supply

• 15W/Ch into 4Ω SE Load from 22V Supply

• 10W/Ch into 8Ω SE Load from 24V Supply

• Operate from 10V to 26V

• Single-Ended Analog Inputs

• Supports Multiple Output Configurations:

2-Ch Single-Ended (SE, Half-Bridge)

1-Ch Bridge-Tied Load (BTL, Full-Bridge)

• Four Selectable Fixed-gain Settings

• No Pop Noise for Start-up and Shut-down Sequences

• Internal Oscillator (No External Components Required)

• High Efficient Class-D Operation Eliminates Need for Heat Sinks

• Thermal and Short-Circuit Protection with Auto Recovery

• Space-Saving Surface-Mount TSSOP-24EP Package

• Pb-Free Package

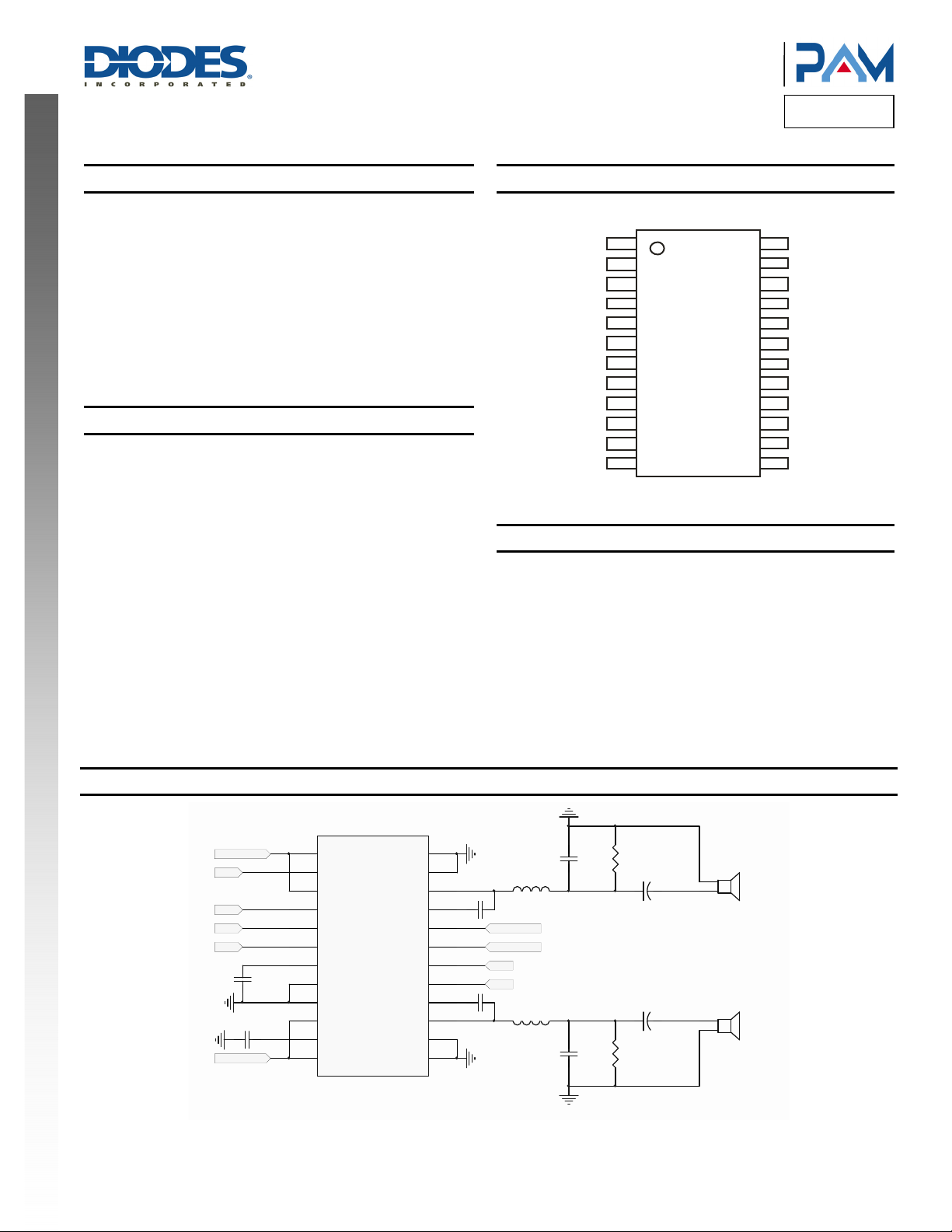

Pin Assignments

PVCCL

SDN

PVCCL

MUTE

LIN

RIN

VCM

AGND

AGND

PVCC R

VCLAMP

PVCCR PGNDR

Applications

• Televisions

• Home Sound Systems

• Active Speakers

HIGH POWER AUDIO

TSSOP-24-EP

1

2

3

4

XXXYWWLL

PAM8124

5

6

7

8

9

10

11

12 13

24

23

22

21

20

19

18

17

16

15

14

PGNDL

PGNDL

LOUT

BSL

AVCC

SE_BTL

GAIN 0

GAIN1

BSR

ROUT

PGNDR

Typical Applications Circuit

U1

10V_to_26V

SD

Mute

L_in

R_i n

10V_to_26V

1

PVCCL

2

SDN

3

PVCCL

4

MUTE

5

LIN

6

RIN

7

C1

1uF

C3

1uF

VCM

8

AGND

9

AGND

10

PVCCR

11

VCL A M P

12

PVCCR

PAM8124

PGNDL

PGNDL

LOUT

BSL

AVCC

SE_BT L

GAIN0

GAIN1

BSR

ROUT

PGNDR

PGNDR

24

23

22

21

C2 1uF

20

19

18

17

16

C4 1uF

15

14

13

L1

33uH

10V_to_26V

SE_BT L

G0

G1

L2

33uH

C5

220nF

C6

220nF

R1

4.7K

R2

4.7K

C7

470uF

C8

470uF

L_out1

8ohm

8ohm

R_out1

PAM8124

Document number: DS36627 Rev. 1 - 2

1 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Page 2

A

f

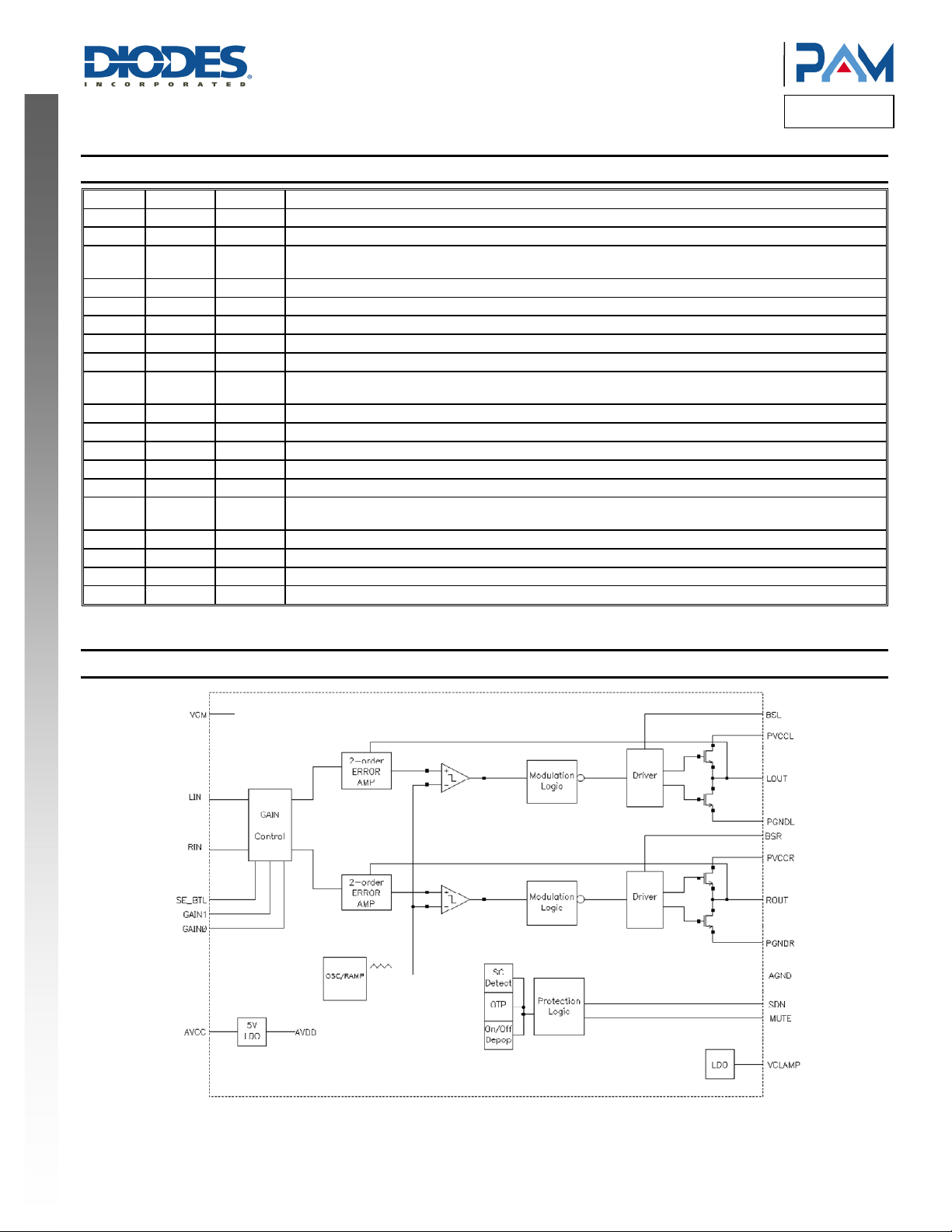

Pin Descriptions

Pin Name I/O/P Function

1, 3 PVCCL P Power supply for left channel H-bridge, not connected to PVCCR or AVCC

2 SDN I Shutdown signal for IC (low = shutdown, high = operational). TTL logic levels with compliance to AVCC

4 MUTE I

5 LIN I Audio input for left channel

6 RIN I Audio input for right channel

7 VCM O Reference for analog cells

8, 9 AGND P Analog ground for digital/analog cells in core

10, 12 PVCCR P Power supply for right channel H-bridge, not connected to PVCCL or AVCC

NEW PRODUCT

11 VCLAMP P

13, 14 PGNDR P Power ground for right channel H-bridge

15 ROUT O Class-D H-bridge output for right channel

16 BSR I/O Bootstrap I /O for right channel H-bridge

17 GAIN1 I Gain select most-significant bit. TTL logic levels with compliance to AVCC

18 GAIN0 I Gain select least-significant bit. TTL logic levels with compliance to AVCC

19 SE_BTL I

20 AVCC P High-voltage analog power supply

21 BSL I/O Bootstrap I /O for left channel H-bridge

22 LOUT O Class-D H-bridge output for left channel

23, 24 PGNDL P Power ground for left channel H-bridge

Functional Block Diagram

Product Line o

Diodes Incorporated

PAM8124

A logic high on this pin disables the outputs. A low on this pin enables the outputs. TTL logic levels with

compliance to AVCC

Internally generated voltage supply for bootstrap. Not to be used as a supply or connected to any

component other than the decoupling capacitor.

A logic low on this pin enables one single-ended input in BTL configuration. A logic high on this pin

enables two inputs in SE/BTL configuration. TTL logic levels with compliance to AVCC

PAM8124

Document number: DS36627 Rev. 1 - 2

2 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Page 3

A

f

Product Line o

Diodes Incorporated

PAM8124

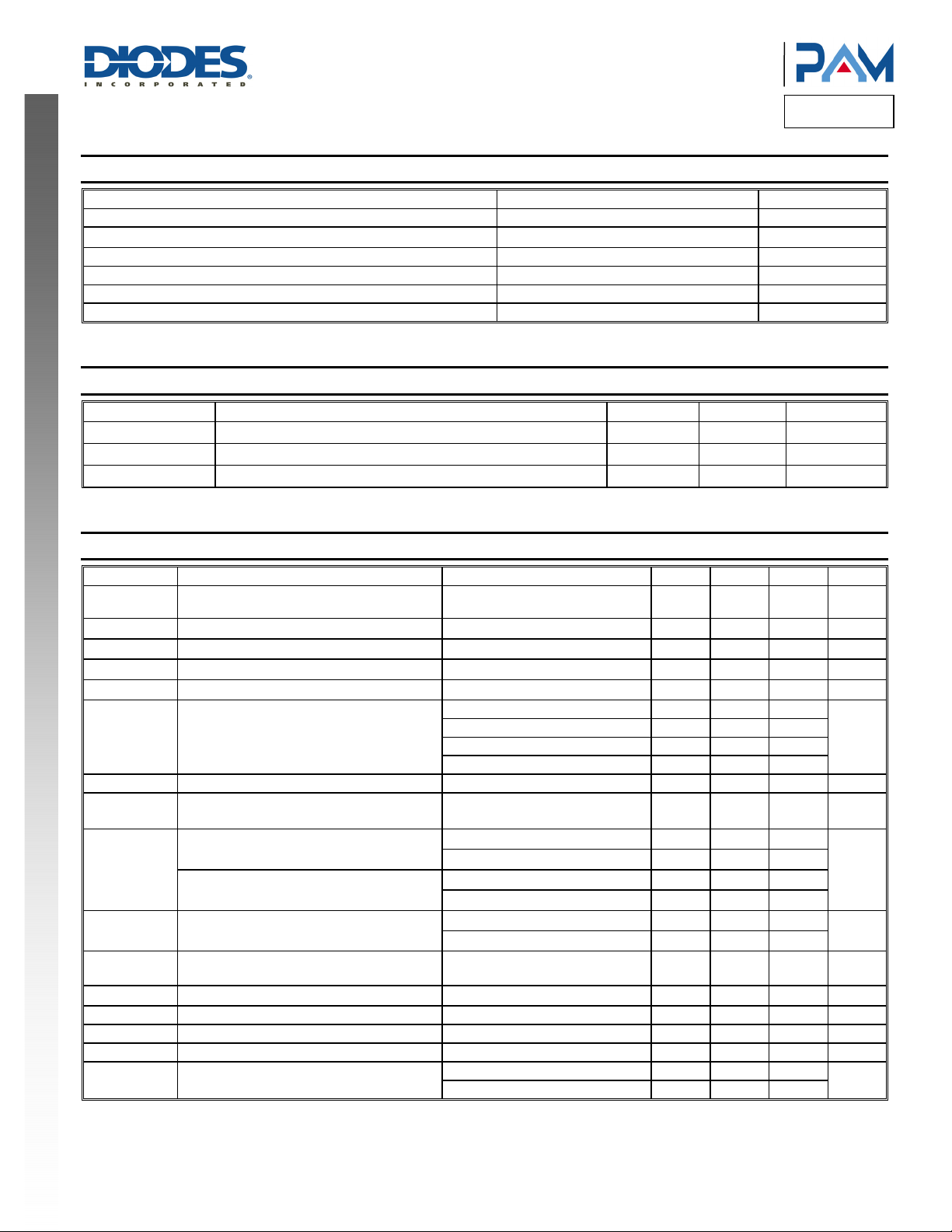

Absolute Maximum Ratings (@T

Parameter Rating Unit

Supply Voltage (VCC) 28 V

Logic Input Voltage (SDN, MUTE, GAIN0, GAIN1, SE_BTL)

Analog Input Voltage (LIN, RIN) -0.3 to +5.5 V

Storage Temperature -65 to +150 °C

Maximum Junction Temperature 150 °C

Junction to ambient thermal resistance 40 °C/W

Recommended Operating Conditions (@T

NEW PRODUCT

Symbol Parameter Min Max Unit

VCC

TA

TJ

Operating Ambient Temperature Range

Electrical Characteristics (@T

Symbol Parameter Test Conditions Min Typ Max Units

|VOS|

I

CC(q)

I

CC(MUTE)

I

CC(SDN)

R

DS(ON)

G Gain

Mute Attenuation Vi = 1Vrms -60 dB

PSRR Power Supply Rejection Ratio

PO

THD+N Total harmonic distortion + noise

Vn Output integrated noise floor

Cs Crosstalk

SNR Signal-to-noise ratio THD+N<1%, f = 1kHz, Gain = 20dB 92 dB

OTP Thermal trip point 160 °C

OTH Thermal hysteresis 60 °C

fosc Oscillator frequency

PAM8124

Document number: DS36627 Rev. 1 - 2

Class-D output offset voltage(measured

differently)

Quiescent supply current SDN = 2.5V, MUTE = 0V, No Load 25 40 mA

Quiescent supply current in mute mode MUTE = 2.5V, No load 25 40 mA

Quiescent current in shutdown mode SDN = 0.8V, No load 30 60 µA

Drain-source on-state resistance

Output Power at 1% THD+N

Output Power at 10% THD+N

= +25°C, unless otherwise specified.)

A

-0.3 to V

= +25°C, unless otherwise specified.)

A

Supply Voltage 10 26 V

Junction Temperature Range

= +25°C, VCC = 24V, Gain = 20dB, RL = 8Ω unless otherwise specified.)

A

= 0V, AV = 36dB

V

i

IO = 0.5A

GAIN1 = 0.8V, GAIN0 = 0.8V 18 20 22

GAIN1 = 0.8V, GAIN0 = 2.5V 24 26 28

GAIN1 = 2.5V, GAIN0 = 0.8V 30 32 34

GAIN1 = 2.5V, GAIN0 = 2.5V 34 36 38

V

= 200mVpp,

RIPPLE

f = 1kHz,gain = 20dB

= 4Ω, f = 1kHz

R

L

RL = 8Ω, f = 1kHz

= 4Ω, f = 1kHz

R

L

RL = 8Ω, f = 1kHz

=4Ω, f = 1kHz, Po = 10W

R

L

RL = 8Ω, f = 1kHz, Po = 5W

20Hz to 22kHz, A-weighted,

Gain = 20dB

P

= 1W, f = 1kHz, Gain = 20dB

O

SE_BTL = 2.5V 250 300 350

SE_BTL = 0.8V 360

3 of 15

www.diodes.com

+0.3

CC

-40 +85 °C

-40 +125 °C

20 100 mV

150 mΩ

-52 dB

14

8

18

10

0.15

0.08

200 µV

-70 dB

V

dB

W

%

kHz

October 2013

© Diodes Incorporated

Page 4

A

f

Product Line o

Diodes Incorporated

PAM8124

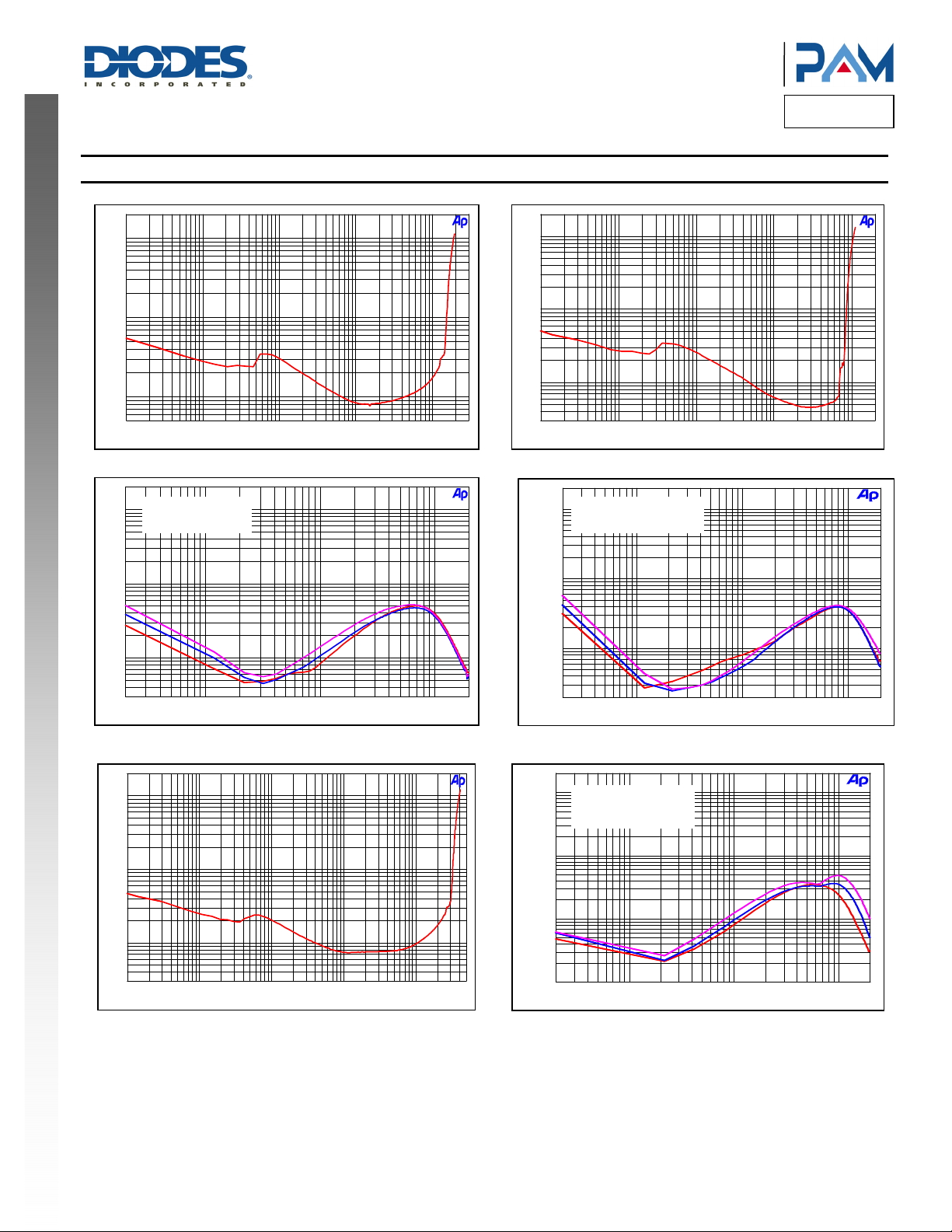

Performance Characteristics (@T

20

10

5

2

1

%

0.5

0.2

NEW PRODUCT

0.1

0.06

1m 302m 5m 10m 20m 50m 100m 200m 500m 1 2 5 10 20

20

10

5

2

1

%

0.5

0.2

0.1

0.05

0.03

20 20k50 100 200 500 1 k 2k 5k 10k

20

10

5

2

1

%

0.5

0.2

0.1

0.05

0.03

1m 502m 5m 10m 20m 50m 100m 200m 500m 1 2 5 10 20

PAM8124

Document number: DS36627 Rev. 1 - 2

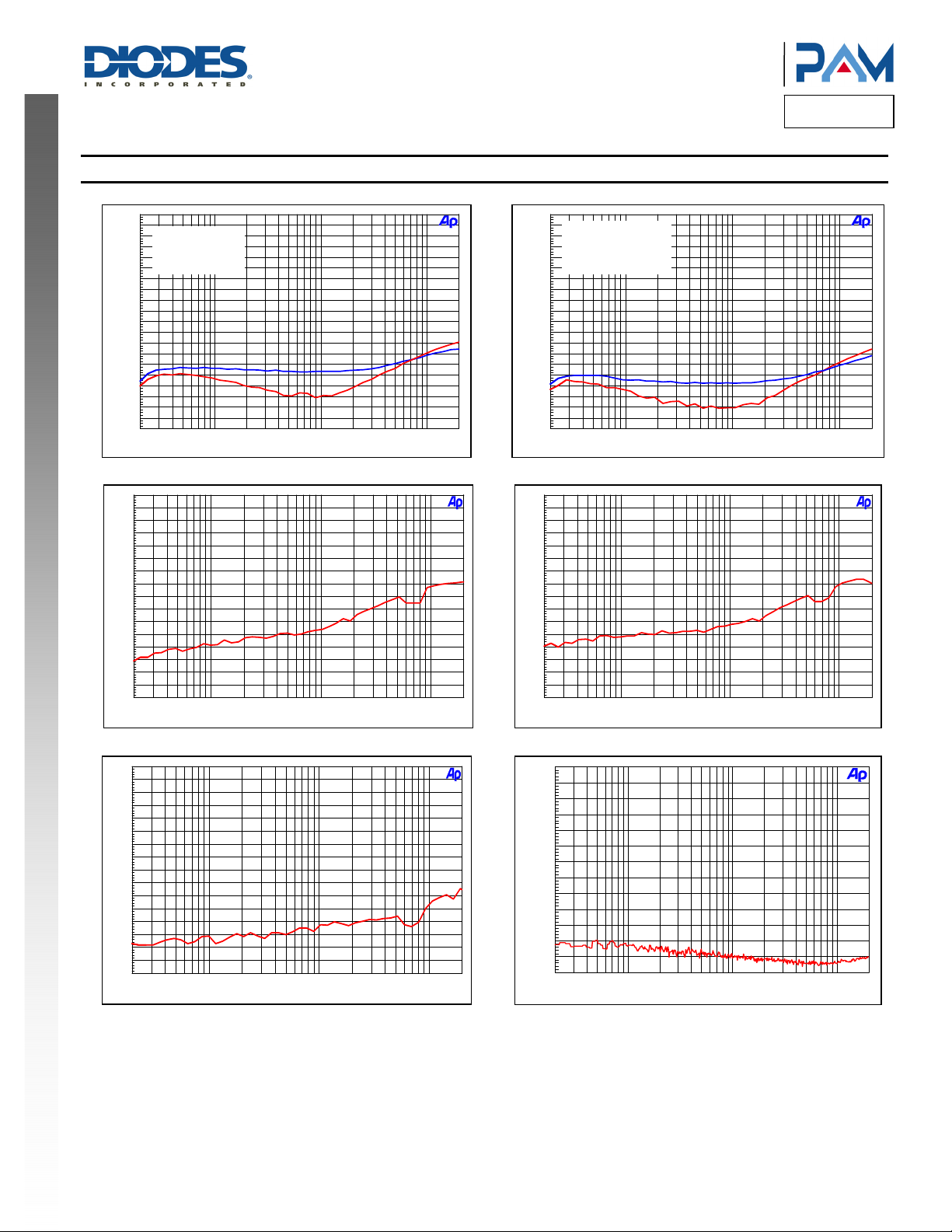

THD+N vs. Output Power (RL = 4Ω, SE)

W

THD+N vs. Frequency (R

L

PO = 2W/ 5W/ 8W

(Red / Blue/ Pink)

Hz

THD+N vs. Output Power (R

W

= +25°C, VCC = 24V, f = 1kHz, Gain = 20dB unless otherwise specified.)

A

THD+N vs. Output Power (R

20

10

5

2

1

%

0.5

0.2

0.1

0.05

0.03

1m 202m 5m 10m 20m 50m 100m 200m 500m 1 2 5 10

= 4Ω, SE)

%

0.5

0.2

0.1

0.05

0.02

THD+N vs. Frequency (R

20

10

PO = 1W/ 2W/ 6W

(Red / Blue/ Pink)

5

2

1

20 20k50 100 200 500 1k 2k 5k 10k

= 8Ω, BTL)

L

20

10

0.5

%

0.2

0.1

0.05

0.02

0.01

THD+N vs. Frequency (R

PO = 5W/ 10W/ 15W

5

(Red / Blue/ Pink)

2

1

20 20k50 100 200 500 1k 2k 5k 10k

4 of 15

www.diodes.com

W

Hz

L

= 8Ω, SE)

L

Hz

= 8Ω, BTL)

L

= 8Ω, SE)

October 2013

© Diodes Incorporated

Page 5

A

f

(

Performance Characteristics (@T

Crosstalk vs. Frequency (RL = 4Ω, SE)

PO = 1W

L to R/ R to L

Red /Blue)

20 20k50 100 200 500 1k 2k 5k 10k

PSRR vs. Frequency (R

TT

PSRR vs. Frequency (R

NEW PRODUCT

+0

-5

-10

-15

-20

-25

-30

-35

-40

-45

d

-50

B

-55

-60

-65

-70

-75

-80

-85

-90

-95

-100

+0

-5

-10

-15

-20

-25

-30

-35

d

-40

B

-45

-50

-55

-60

-65

-70

-75

-80

20 20k50 100 200 500 1k 2k 5k 10k

+0

TTT TT T

-5

-10

-15

-20

-25

-30

-35

d

-40

B

-45

-50

-55

-60

-65

-70

-75

-80

20 20k50 100 200 500 1k 2k 5k 10k

Hz

Hz

L

Hz

= +25°C, VCC = 24V, f = 1kHz, Gain = 20dB unless otherwise specified.)

A

= 4Ω, SE)

L

= 8Ω, BTL)

Product Line o

Diodes Incorporated

+0

-5

-10

-15

-20

-25

-30

-35

-40

-45

d

-50

B

-55

-60

-65

-70

-75

-80

-85

-90

-95

-100

20 20k50 100 200 500 1k 2k 5k 10k

TT

PO = 1W

L to R/ R to L

(Red / Blue)

PSRR vs. Frequency (R

Crosstalk vs. Frequency (R

+0

TTT

-5

-10

-15

-20

-25

-30

-35

d

-40

B

-45

-50

-55

-60

-65

-70

-75

-80

20 20k50 100 200 500 1k 2k 5k 10k

Noise Floor (RL = 8Ω, SE)

+0

-10

-20

-30

-40

-50

d

-60

B

r

-70

A

-80

-90

-100

-110

-120

-130

20 20k50 100 200 500 1k 2k 5k 10k

Hz

Hz

Hz

= 8Ω, SE)

L

= 8Ω, SE)

L

PAM8124

PAM8124

Document number: DS36627 Rev. 1 - 2

5 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Page 6

A

f

Performance Characteristics (@T

NEW PRODUCT

Frequency Response (RL = 8Ω, SE)

+24

+23

L

= 33µH

FILT

+22

+21

+20

+19

d

+18

B

+17

g

+16

A

+15

+14

+13

+12

+11

+10

20 20k50 100 200 500 1k 2k 5k 10k

C

FILT

C

DC

= 0.22µF

= 470µF

Efficiency vs. Output Power (R

Product Line o

Diodes Incorporated

PAM8124

= +25°C, VCC = 24V, f = 1kHz, Gain = 20dB unless otherwise specified.)

A

Frequency Response (R

+24

+23

+22

+21

+20

+19

d

+18

B

+17

g

+16

A

+15

+14

+13

+12

+11

+10

Hz

20 20k50 100 200 500 1k 2k 5k 10k

= 4Ω)

L

Efficiency vs. Output Power (R

Hz

= 8Ω, BTL)

L

= 8Ω)

L

Quiescent Current vs. Supply Voltage

OSC Frequency vs. Supply Voltage

PAM8124

Document number: DS36627 Rev. 1 - 2

6 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Page 7

A

f

Performance Characteristics (@T

Case Temperature vs. Output Power (RL = 4Ω) Case Temperature vs. Output Power (RL = 8Ω)

Product Line o

Diodes Incorporated

= +25°C, VCC = 24V, f = 1kHz, Gain = 20dB unless otherwise specified.)

A

PAM8124

NEW PRODUCT

Two Channels Driving

Two Channels Driving

Application Information

Input Capacitors (Ci)

In the typical application, an input capacitor Ci, is required to allow the amplifier to bias the input signal to the proper DC level for optimum

operation. In this case, Ci and the minimum input impedance Ri form is a high-pass filter with the corner frequency determined in the follow

equation:

1

f

C

=

2RiCi

π

()

It is important to consider the value of Ci as it directly affects the low frequency performance of the circuit. For example, when Ri is 40kΩ and the

specification calls for a flat bass response are down to 20Hz. Equation is reconfigured as followed:

Ci

=

When input resistance variation is considered Ci is 200nF, so one would likely choose a value of 220nF. A further consideration for this capacitor

is the leakage path from the input source through the input network (Ci, Ri + Rf) to the load. This leakage current creates a DC offset voltage at

the input to the amplifier that reduces useful headroom, especially in high gain applications. For this reason, a low-leakage tantalum or ceramic

capacitor is the best choice.

Gain Setting Control

The gain of the PAM8124 is set by two input terminals, GAIN0 and GAIN1.

The gains listed in following table are realized by changing the taps on the input resistors inside the amplifier. This causes the input impedance to

be dependent on the gain setting. The actual gain settings are controlled by ratios of resistors, so the gain variation from part-to-part is small.

However, the input impedance from part-to-part at the same gain may shift by ±20% due to shifts in the actual resistance of the input resistors.

Table 1: Gain Setting

PAM8124

Document number: DS36627 Rev. 1 - 2

1

2Rf

ic

π

()

Gain1 Gain0

0 0 20 40

0 1 26 20

1 0 30 10

1 1 36 6.67

Amplifier Gain (dB),

Typical

7 of 15

www.diodes.com

Input Impedance (kΩ),

Typical (Ri)

October 2013

© Diodes Incorporated

Page 8

A

f

Product Line o

Diodes Incorporated

PAM8124

Application Information (cont.)

Input Resistance

Changing the gain setting can vary the input resistance of the amplifier from its smallest value (6.67kΩ ±20%) to the largest value (40kΩ ±20%).

As a result, if a single capacitor is used in the input high-pass filter, the –3dB cutoff frequency may change when changing gain steps.

The –3dB frequency can be calculated using the following Equation. Use the Ri values given in Table 1.

1

f

C

=

2RiCi

π

()

NEW PRODUCT

Single-Ended Output Capacitor

In single-ended (SE) applications, the dc blocking capacitor forms a high-pass filter with the speaker impedance. The frequency response rolls off

with decreasing frequency at a rate of 20dB/decade. The cutoff frequency is determined by:

1

=

f

coh

π

2

Table 2 shows some common component values and the associated cutoff frequencies:

Table 2: Common Filter Responses

-Speaker Impedance (Ω)

R

L

4 680 1000 2200

6 470 680 1500

8 330 470 1000

fc = 60Hz (-3dB) fc = 40Hz (-3dB) fc = 20Hz (-3dB)

CSE-DC Blocking Capacitor (µF)

CR

SEL

Output Filter and Frequency Response

For the best frequency response, a flat pass band output filter (second-order Butterworth) may be used. The output filter components consist of

the series inductor and capacitor to ground at the LOUT and ROUT pins. There are several possible configurations, depending on the speaker

impedance and whether the output configuration is single-ended (SE) or bridge-tied load (BTL). Table 3 lists the recommended values for the filter

components. It is important to use a high-quality capacitor in this application. A rating of at least X7R is required.

Table 3: Recommended Filter Output Components

Output Configuration Speaker Impedance(Ω) Filter Inductor(µH) Filter Capacitor(nF)

Single Ended (SE)

Bridge Tied Load (BTL) 8 22 680

4 22 680

8 33 220

PAM8124

Document number: DS36627 Rev. 1 - 2

8 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Page 9

A

f

Application Information (cont.)

Product Line o

Diodes Incorporated

PAM8124

NEW PRODUCT

BTL Filter Configuration SE Filter Configuration

Power and Heat Dissipation

Choose speakers that are able to stand large output power from the PAM8124. Otherwise, speaker may suffer damage.

Heat dissipation is very important when the device works in full power operation. Two factors affect the heat dissipation, the efficiency of the

device that determines the dissipation power, and the thermal resistance of the package that determines the heat dissipation capability.

Generally, class-D amplifiers are high efficiency and need no heat sink. Operating at higher powers a heat sink still may not be necessary if the

PCB is carefully designed to achieve good thermal dissipation.

How to Reduce EMI

Most applications require a ferrite bead filter for EMI elimination shown at Figure 1. The ferrite filter reduces EMI around 1MHz and higher. When

selecting a ferrite bead, choose one with high impedance at high frequencies, but low impedance at low frequencies.

OUT+

OUT-

Ferrite Bead

200pF

Ferrite Bead

200pF

Figure 1. Ferrite Bead Filter to Reduce EMI

Dual-Side PCB

To achieve good heat dissipation, the PCB's copper plate should be thicker than 35um and the copper plate on both sides of the PCB should be

utilized for heat sink. The thermal pad on the bottom of the device should be soldered to the plate of the PCB, and via holes, usually 9 to 16,

should be drilled in the PCB area under the device and deposited copper on the vias should be thick enough so that the heat can be dissipated to

the other side of the plate. There should be no insulation mask on the other side of the copper plate. It is better to drill more vias on the PCB

around the device if possible.

PAM8124

Document number: DS36627 Rev. 1 - 2

9 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Page 10

A

f

Product Line o

Diodes Incorporated

PAM8124

Application Information (cont.)

MUTE Operation

The MUTE pin is an input for controlling the output state of the PAM8124. A logic high on this pin causes the outputs to run at a constant 50%

duty cycle. A logic low on this pin enables the outputs. This pin may be used as a quick disable or enable of the outputs.

Shutdown Operation

The PAM8124 employs a shutdown operation mode to reduce supply current to the absolute minimum level during periods of non-use to save

power. The SDN input terminal should be pulling high during normal operation when the amplifier is in use. Pulling SDN low causes the outputs to

mute and the amplifier to enter a low-current state. SDN should never be left unconnected to prevent the amplifier from unpredictable operation.

For the best power-off pop performance, the amplifier should be set in shutdown mode prior to removing the power supply voltage.

For the best start-up pop performance, the amplifier should be set in mute mode prior to restarting the amplifier.

NEW PRODUCT

Internal Bias Generator Capacitor Selection

The internal bias generator (VCM) provides the internal bias for the preamplifier stage. The external input capacitors and this internal reference

allow the inputs to be biased within the optimal common-mode range of the input preamplifiers.

The selection of the capacitor value on the VCM terminal is critical for achieving the best device performance. During startup or recovery from

shutdown state the VCM capacitor determines the rate at which the amplifier starts up. The startup time is not critical for the best de-pop

performance since any heard pop sound is the result of the class-D output switching-on other than that of the startup time. However, at least a

0.47µF capacitor is recommended for the VCM capacitor.

Another function of the VCM capacitor is to bypass high frequency noise on the internal bias generator.

Power Supply Decoupling, CS

The PAM8124 is a high-performance CMOS audio amplifier that requires adequate power supply decoupling to ensure the output total harmonic

distortion (THD) as low as possible. Power supply decoupling also prevents oscillations caused by long lead between the amplifier and the

speaker. The optimum decoupling is achieved by using two capacitors of different types that target different types of noise on the power supply

leads. For higher frequency transients, spikes, or digital hash on the line, a good low equivalent-series-resistance (ESR) ceramic capacitor of

0.1µF is typically recommended, placed as close as possible to the device's PVCC lead. To filter lower-frequency noises a large aluminium

electrolytic capacitor of 470µF or greater is recommended, placed near the audio power amplifier. The 10µF capacitor also serves as a local

storage capacitor for supplying current during large signal transients on the amplifier outputs.

BSL and BSR Capacitors

The half H-bridge output stages use NMOS transistors therefore requiring bootstrap capacitors for the high side of each output to turn on correctly.

A ceramic capacitor 220nF or more rated for over 25V must be connected from each output to its corresponding bootstrap input. Specifically, one

220nF capacitor must be connected from LOUT to BSL and another 220nF capacitor from ROUT to BSR. It is recommended to use 1μF BST

capacitor to replace 220nF for lower than 100Hz applications.

VCLAMP Capacitors

To ensure that the maximum gate-to-source voltage for the NMOS output transistors is not exceeded, an internal regulator is used to clamp the

gate voltage. A 1µF capacitor must be connected from VCLAMP to ground and must be rated for at least 25V. The voltages at the VCLAMP

terminals vary with VCC and may not be used to power any other circuitry.

Using Low-ESR Capacitors

Low-ESR capacitors are recommended throughout this application section. A real (with respect to ideal) capacitor can be modeled simply as a

resistor in series with an ideal capacitor. The voltage drop across this resistor minimizes the beneficial effects of the capacitor in the circuit. The

lower the equivalent value of this resistance the more the real capacitor behaves as an ideal capacitor.

Short-Circuit Protection

The PAM8124 has short circuit protection circuitry on the outputs to prevent damage to the device when output-to-output shorts (BTL mode),

output-to-GND shorts, or output-to-VCC shorts occur. Once a short-circuit is detected on the outputs, the output drive is immediately disabled.

This is not a latched fault. If the short was removed, the normal operation is restored.

PAM8124

Document number: DS36627 Rev. 1 - 2

10 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Page 11

A

f

Product Line o

Diodes Incorporated

PAM8124

Application Information (cont.)

Thermal Protection

Thermal protection on the PAM8124 prevents damage to the device when the internal die temperature exceeds 160°C. There is a ±15 degree

tolerance on this trip point from device to device. Once the die temperature exceeds the set thermal point, the device enters into the shutdown

state and the outputs are disabled. This is not a latched fault, the thermal fault is cleared once the temperature of the die is reduced by 60°C. The

device begins normal operation at this point without external system intervention.

Over Voltage Protection and Under Voltage Lock-out (OVP and UVLO)

An over voltage protection (OVP) circuit is integrated in PAM8124, when the supply voltage is over 28V the OVP is active and then the output

stage is disabled. The PAM8124 will auto recovery when the supply voltage is lower than the OVP threshold.

The PAM8124 incorporates circuitry designed to detect low supply voltage. When the supply voltage drops to 9V or below, the PAM8124 goes

into a state of shutdown. When the supply voltage is higher than UVLO threshold normal operation is resumed.

NEW PRODUCT

Typical Applications Circuits

C10

L_in

R_i n

C1 1 uF

C2 1 uF

Mute

C7

10uF

0.1uF

U1

1

C9

0.1uF

2

3

4

5

6

7

8

9

10

11

12

C12

10uF

SD

R1

R2

C4

1uF

C3

1uF

PVCCL

SDN

PVCCL

MUTE

LIN

RIN

VCM

AGND

AGND

PVCCR

VCL A MP

PVCCR

C13

470uF

C14

470uF

PAM8124

VCC

PGNDL

PGNDL

LOUT

BSL

AVCC

SE_ BTL

GAIN0

GAIN1

BSR

ROU T

PGNDR

PGNDR

VCC

24

23

22

21

C5 1 uF

20

19

18

17

16

C6 1 uF

15

14

13

L1

33uH

G0

G1

L2

33uH

C8

0.1uF

VCC

C11

10uF

C15

220nF

C16

220nF

R3

4.7K

R4

4.7K

C17

470uF

C18

470uF

L_ou t

8ohm

8ohm

R_ou t

Schematic for Single-Ended (SE) Configuration (8Ω Speaker)

PAM8124

Document number: DS36627 Rev. 1 - 2

www.diodes.com

11 of 15

October 2013

© Diodes Incorporated

Page 12

A

f

Application Information (cont.)

Typical Applications Circuits (cont.)

NEW PRODUCT

IN+

IN-

C1 1uF

C2 1uF

Mute

C3

1uF

Product Line o

Diodes Incorporated

PAM8124

C10

C7

10uF

0.1uF

U1

1

PVCCL

2

SD

R1

R2

C4

1uF

SDN

3

PVCCL

4

MUTE

5

LIN

6

RIN

7

VCM

8

AGND

9

AGND

10

PVCCR

11

VCL A M P

12

PVCCR

C13

470uF

VCC

LOUT

BSL

AVCC

GAIN0

GAIN1

BSR

ROUT

24

23

22

21

C5 1 uF

20

19

18

17

16

C6 1 uF

15

14

13

L1

22uH

C8

0.1uF

G0

G1

L2

22uH

VCC

C11

10uF

C15

680 nF

C16

680 nF

R3

4.7K

R4

4.7K

8ohm

PGNDL

PGNDL

SE_BT L

PAM8124

PGNDR

PGNDR

C9

0.1uF

C12

10uF

C14

470uF

VCC

Schematic for Bridge-Tied-Load (BTL) Configuration with Differential Input (8Ω Speaker)

C10

C7

10uF

0.1uF

U1

1

SD

Mute

C3

1uF

R1

C4

1uF

IN

C1 1uF

2

3

4

5

6

7

8

9

10

11

12

PVCCL

SDN

PVCCL

MUTE

LIN

RIN

VCM

AGND

AGND

PVCCR

VCL A M P

PVCCR

C13

470uF

VCC

LOUT

BSL

AVCC

GAIN0

GAIN1

BSR

ROUT

24

23

22

21

C5 1uF

20

19

18

17

16

C6 1uF

15

14

13

L1

22u H

C8

0.1uF

G0

G1

L2

22u H

VCC

C11

10uF

C15

680nF

C16

680nF

R3

4.7K

R4

4.7K

8ohm

PGNDL

PGNDL

SE_BT L

PAM8124

PGNDR

PGNDR

C9

0.1uF

C12

10uF

C14

470uF

VCC

Schematic for Bridge-Tied-Load (BTL) Configuration with Single-Ended Input (8Ω Speaker)

PAM8124

Document number: DS36627 Rev. 1 - 2

12 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Page 13

A

f

Ordering Information

Part Number Package Standard Package

PAM8124RHR TSSOP-24-EP 3000 Units/Tape&Reel

NEW PRODUCT

Marking Information

PVCCL

SDN

PVCCL

MUTE

LIN

RIN

VCM

AGND

AGND

PVCCR

VCLAMP

PVCCR PGNDR

Product Line o

Diodes Incorporated

PAM8124

PAM8124 X X X

Package Type

R: TSSOP H: 24 Pin R: Tape & Real

1

2

3

4

5

6

7

8

9

10

11

12 13

XXXYWWLL

PAM8124

Package Configuration

PGNDL

24

PGNDL

23

LOUT

22

BSL

21

20

AVCC

19

SE_BTL

18

GAIN0

17

GAIN1

16

BSR

ROUT

15

PGNDR

14

Shipping Package

PAM8124: Product Code

X: Internal Code

Y: Year

W: Week

LL: Internal Code

PAM8124

Document number: DS36627 Rev. 1 - 2

13 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Page 14

A

f

Package Outline Dimensions (All dimensions in mm.)

Package: TSSOP-24-EP

NEW PRODUCT

Product Line o

Diodes Incorporated

PAM8124

PAM8124

Document number: DS36627 Rev. 1 - 2

www.diodes.com

14 of 15

October 2013

© Diodes Incorporated

Page 15

A

f

Product Line o

Diodes Incorporated

PAM8124

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

NEW PRODUCT

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2013, Diodes Incorporated

www.diodes.com

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

IMPORTANT NOTICE

LIFE SUPPORT

PAM8124

Document number: DS36627 Rev. 1 - 2

15 of 15

www.diodes.com

October 2013

© Diodes Incorporated

Loading...

Loading...