Page 1

V

Description

A PRODUCT LINE OF

DIODES INCORPORATED

PAM8013/PAM8015

3W MONO CLASS D AUDIO AMPLIFIER

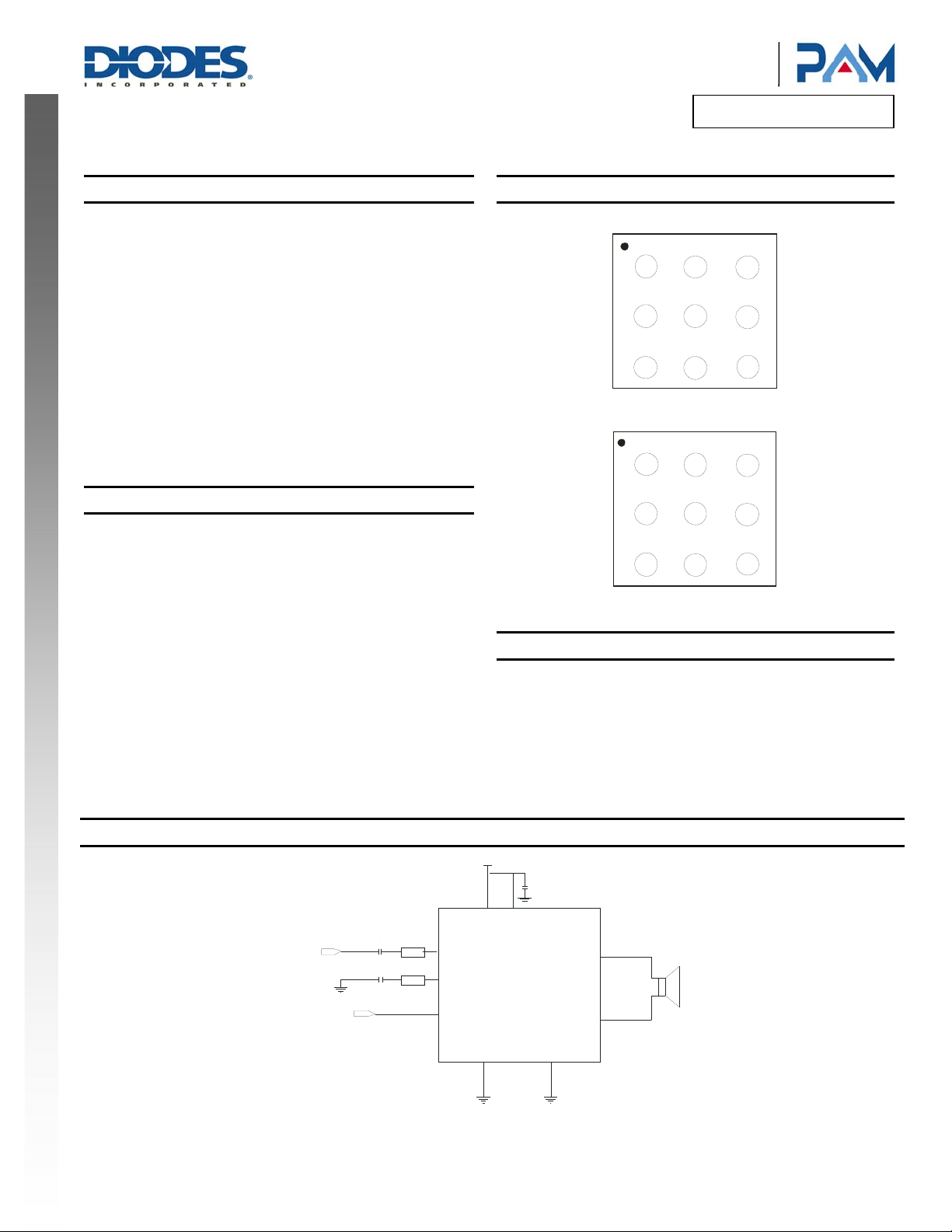

Pin Assignments

The PAM8013/PAM8015 is a 3W mono filter-less class-D amplifier

with high PSRR and differential input that eliminate noise and RF

rectification.

Features like greater than 90% efficiency and small PCB area make

the PAM8013/PAM8015 Class-D amplifier ideal for portable

applications. The output uses a filter-less architecture minimizing the

number of external components and PCB area whilst providing a high

performance, simple and lower cost system.

The PAM8013/PAM8015 features short circuit protection and thermal

shutdown.

The PAM8013/PAM8015 is available in U-FLGA1515-9 packages.

NEW PRODUCT

Features

Ultra Low EMI, -20dB Better Than FCC Class-B @ 300MHz

High Efficiency up to 90% @1W with an 8Ω Speaker

Shutdown Current <1μA

3W@10% THD Output with a 4Ω Load at 5V Supply

Demanding Few External Components

Superior Low Noise without Input

Supply Voltage from 2.8V to 5.5 V

Short Circuit Protection

Thermal Shutdown

Available in Space Saving U-FLGA1515-9 Packages

Pb-Free Package

U-FLGA1515-9

GND

IN+

A1 A2

VDD

PVDD PGND

B1 B2 B3

IN-

C1 C2 C3

SD

PAM8013

PVDD

IN+

A1 A2

GND GND PGND

B1 B2 B3

IN- SD OUT+

C1 C2 C3

PAM8015

Applications

Cellular Phones/Smart Phones

MP4/MP3

GPS

Digital Photo Frame

Electronic Dictionary

Portable Game Machines

OUT-

A3

OUT +

OUT-

A3

Typical Applications Circuit

DD

1Fμ

VDD(PAM8013)

PVDD

SD

0.1 Fμ

0.1 Fμ

IN+

IN-

SD

PGND

1 of 9

www.diodes.com

GND

OUT+

OUT-

May 2014

© Diodes Incorporated

VIN

PAM8013/PAM8015

Document number: DS36979 Rev. 2 - 2

Page 2

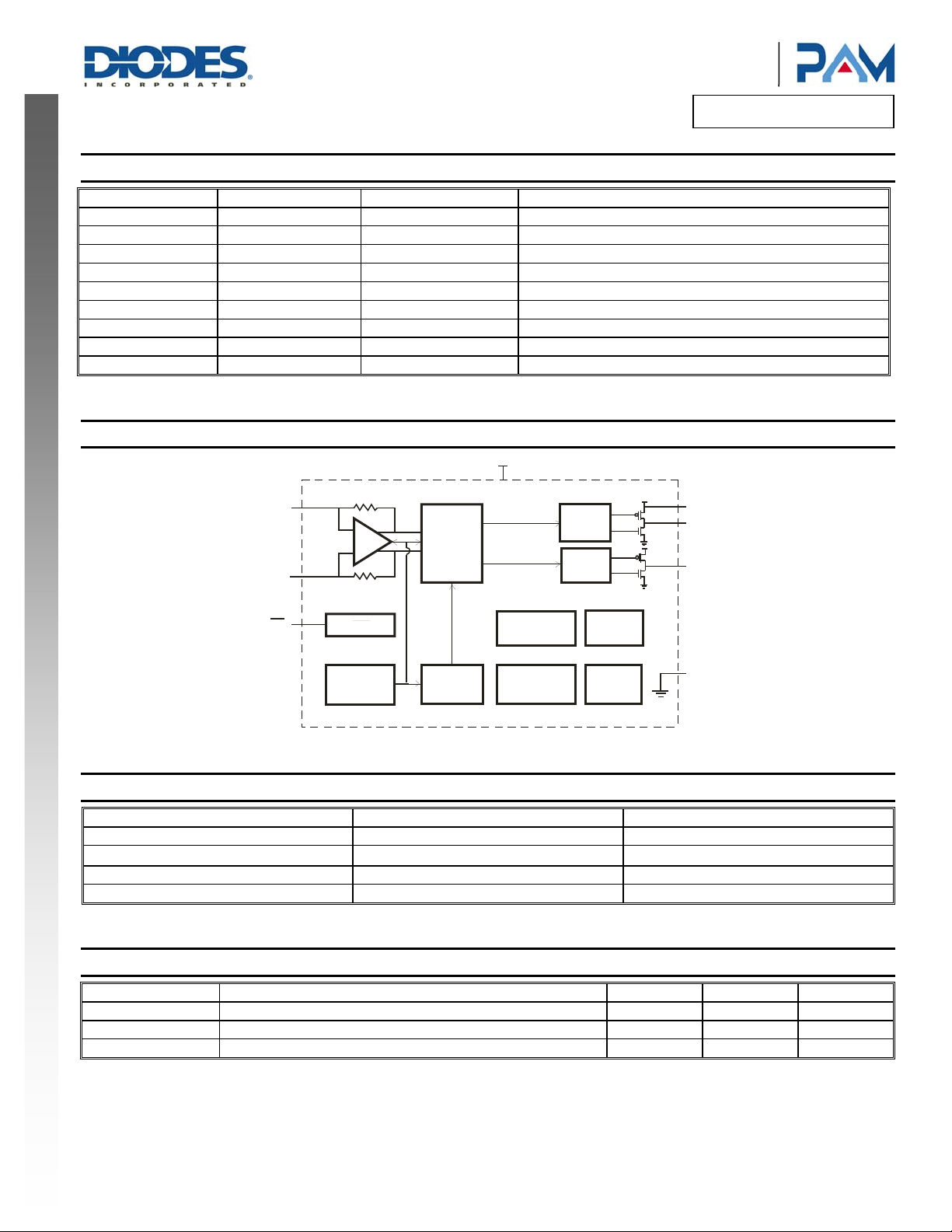

Pin Descriptions

Pin Name PAM8013 PAM8015 Function

IN+ A1 A1 Positive differential input

GND A2 B1/B2 Ground

OUT- A3 A3 Negative BTL output

VDD B1 — Power supply

PVDD B2 A2 Power supply

PGND B3 B3 Power Ground

IN- C1 C1 Negative differential input

SD C2 C2 SD terminal to disable the chip

OUT+ C3 C3 Positive BTL output

Functional Block Diagram

NEW PRODUCT

IN+

IN-

A PRODUCT LINE OF

DIODES INCORPORATED

PAM8013/PAM8015

VDD

(PAM8013)

Gate

-

+

PWM

Modulator

Drive

Gate

Drive

PVDD

OUT +

OUT-

SD

SD

Bias and

Vref

OSC

UVLO

Startup

Protection

SC

Protect

OTP

GND

Absolute Maximum Ratings

Parameter Rating Unit

Supply Voltage (VDD) 6.0 V

Input Voltage(IN+, IN-, SD)

Storage Temperature -65 to +150 °C

Maximum Junction Temperature 150 °C

Recommended Operating Conditions (@T

Symbol Parameter Min Max Unit

VDD Supply Voltage 2.8 5.5 V

TA Operating Ambient Temperature Range -25 85 °C

TJ Junction Temperature -40 +125 °C

(@TA = +25°C, unless otherwise specified.)

-0.3 to V

= +25°C, unless otherwise specified.)

A

DD

+0.3

V

PAM8013/PAM8015

Document number: DS36979 Rev. 2 - 2

2 of 9

www.diodes.com

May 2014

© Diodes Incorporated

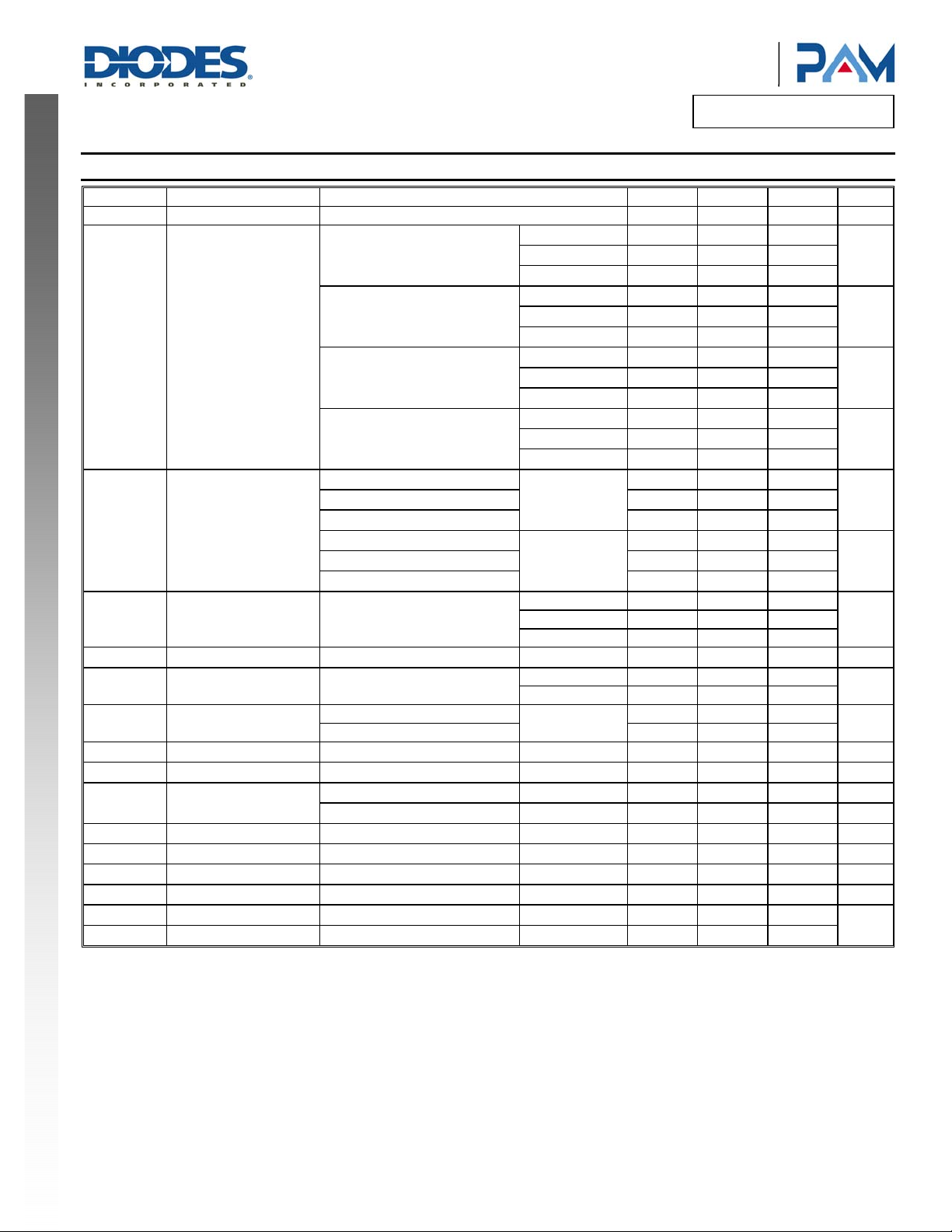

Page 3

A PRODUCT LINE OF

DIODES INCORPORATED

Electrical Characteristics (@TA=25°C, VDD=5V, Gain=18dB, RL=L(33μH)+R+L(33μH), unless otherwise noted.)

Symbol Parameter Test Conditions Min Typ Max Unit

VDD Supply Voltage — 2.8 — 5.5 V

— 3.0 —

— 1.5 —

— 1.2 —

— 2.4 —

— 1.25 —

— 1.0 —

— 1.75 —

— 0.90 —

— 0.70 —

— 1.40 —

— 0.72 —

— 0.60 —

— 0.17 —

— 0.16 —

— 0.14 —

— 0.14 —

— 0.16 —

— 0.17 —

— -68 —

— 95 — dB

— 170 —

— 93 —

— 5 — mA

— —1 μA

— 325 — mΩ

— 200 — mΩ

— 400 kHz

—

28.5 KΩ

— — 20 mV

1.4 — —

— — 1.0

NEW PRODUCT

THD+N = 10%, f = 1kHz, R = 4Ω

THD+N = 1%, f = 1kHz, R = 4Ω

Po Output Power

THD+N = 10%, f = 1kHz, R = 8Ω

THD+N = 1%, f = 1kHz, R = 8Ω

= 5.0V, PO = 1W, R = 8Ω

V

DD

VDD = 3.6V, PO = 0.1W, R = 8Ω

THD+N

Total Harmonic

Distortion Plus

Noise

VDD = 3.2V, PO = 0.1W, R = 8Ω

VDD = 5.0V, PO = 0.5W, R = 4Ω

VDD = 3.6V, PO = 0.2W, R = 4Ω

VDD = 3.2V, PO = 0.1W, R = 4Ω

PSRR

Power Supply Ripple

Rejection

Dyn Dynamic Range

= 3.6V, Inputs ac-grounded

V

DD

with C = 1μF

V

= 5V,THD = 1%, R = 8Ω

DD

Vn Output Noise Inputs AC-grounded

η Efficiency

IQ Quiescent Current

Isd Shutdown Current

Rdson

Static Drain-to Source

On-state Resistor

fsw Switching Frequency

Gv Closed-loop Gain

RIN Input Impedance

Vos Output Offset Voltage

VIH SD Input High Voltage

VIL SD Input Low Voltage

RL= 8Ω, THD = 10%

RL= 4Ω, THD = 10% — 86 —

V

= 5V

DD

V

= 2.8V to 5V SD = 0V

DD

High Side PMOS, I = 500mA

Low Side NMOS, I = 500mA

V

= 2.8V to 5V

DD

V

= 2.8V to 5V

DD

V

= 2.8V to 5V

DD

Input AC-ground, V

V

= 5V

DD

V

= 5V

DD

DD

= 5V

V

= 5.0V

DD

V

= 3.6V

DD

V

= 3.2V

DD

V

= 5.0V

DD

V

= 3.6V

DD

V

= 3.2V

DD

V

= 5.0V

DD

V

= 3.6V

DD

V

= 3.2V

DD

V

= 5.0V

DD

V

= 3.6V

DD

V

= 3.2V

DD

f = 1kHz

f = 1kHz

f = 217Hz

f = 1kHz — -70 —

f = 10kHz — -67 —

f = 1kHz

No A weighting

A-weighting — 130 —

f = 1kHz

No Load

= 5.0V

V

DD

V

= 5.0V

DD

—

—

—

—

—

PAM8013/PAM8015

Document number: DS36979 Rev. 2 - 2

3 of 9

www.diodes.com

PAM8013/PAM8015

W

W

W

W

%

%

dB

μV

%

300K/RIN

— V/V

V

May 2014

© Diodes Incorporated

Page 4

Performance Characteristics (@T

THD+N Vs. Output Power (RL = 4Ω) THD+N Vs. Output Power (RL = 8Ω)

20

10

VDD = 5.0V/3.6V VDD = 5.0V/3.6V

5

2

1

%

0.5

0.2

0.1

0.06

1m 52m 5m 10m 20m 50m 100m 200m 500m 1 2

NEW PRODUCT

THD+N vs. Frequency PSRR vs. Frequency

10

5

VDD = 5.0V/3.6V

= 300mW

P

O

2

1

0.5

%

0.2

0.1

0.05

0.02

0.01

20 20k50 100 200 500 1k 2k 5k 10k

Frequency Response Noise Floor

+24

+22

+20

+18

+16

+14

d

B

+12

g

A

+10

+8

+6

+4

+2

-0

20 20k50 100 200 500 1k 2k 5k 10k

PAM8013/PAM8015

Document number: DS36979 Rev. 2 - 2

A PRODUCT LINE OF

DIODES INCORPORATED

PAM8013/PAM8015

= +25°C, VDD = 5V, Gain = 18dB, RL = L(33μH)+R+L(33μH), unless otherwise noted.)

A

20

10

5

2

1

%

0.5

0.2

0.1

0.04

W

Hz

Hz

1m 32m 5m 10m 20m 50m 100m 200m 500m 1 2

+0

-10

-15

-20

-25

-30

-35

d

-40

B

-45

-50

-55

-60

-65

-70

-75

-80

+0

-10

-20

-30

-40

-50

-60

d

-70

B

r

-80

A

-90

-100

-110

-120

-130

-140

-150

20 20k50 100 200 500 1k 2k 5k 10k

T

-5

20 20k50 100 200 500 1k 2k 5k 10k

4 of 9

www.diodes.com

W

Hz

Hz

May 2014

© Diodes Incorporated

Page 5

A PRODUCT LINE OF

DIODES INCORPORATED

Performance Characteristics

Efficiency vs. Output Power (RL = 4Ω) Efficiency vs. Output Power (RL = 8Ω)

(cont) (@TA = +25°C, VDD = 5V, Gain = 18dB, RL = L(33μH)+R+L(33μH), unless otherwise noted.)

100.00

80.00

60.00

40.00

20.00

0.00

30.1

10.18

50.6

80.09

100.1

200.9

300.5

400.8

501.9

1010

705.6

1300

1601

2000

2500

3000

100.00

80.00

60.00

40.00

20.00

0.00

NEW PRODUCT

Quiescent Current Vs. Supply Voltage OSC Frequency Vs. Supply Voltage

Start-up Response Shutdown Response

PAM8013/PAM8015

PAM8013/PAM8015

Document number: DS36979 Rev. 2 - 2

5 of 9

www.diodes.com

May 2014

© Diodes Incorporated

Page 6

A PRODUCT LINE OF

DIODES INCORPORATED

PAM8013/PAM8015

Application Information

Input Capacitors (Ci )

In the typical application, an input capacitor, Ci, is required to allow the amplifier to bias the input signal to the proper DC level for optimum

operation. In this case, Ci and the minimum input impedance Ri form is a high-pass filter with the corner frequency determined in the follow

equation:

It is important to consider the value of Ci as it directly affects the low frequency performance of the circuit. For example, when Ri is 150kΩ and the

specification calls for a flat bass response are down to 150Hz. Equation is reconfigured as followed:

When input resistance variation is considered, the Ci is 7nF, so one would likely choose a value of 10nF. A further consideration for this capacitor is

the leakage path from the input source through the input network (Ci, Ri + Rf) to the load. This leakage current creates a DC offset voltage at the

input to the amplifier that reduces useful headroom, especially in high gain applications. For this reason, a low-leakage tantalum or ceramic

capacitor is the best choice. When polarized capacitors are used, the positive side of the capacitor should face the amplifier input in most

applications as the DC level is held at VDD/2, which is likely higher than the source DC level. Please note that it is important to confirm the

capacitor polarity in the application.

NEW PRODUCT

Decoupling Capacitor (CS )

The PAM8013/PAM8015 is a high-performance CMOS audio amplifier that requires adequate power supply decoupling to ensure the output total

harmonic distortion (THD) as low as possible. Power supply decoupling also prevents the oscillations causing by long lead length between the

amplifier and the speaker.

The optimum decoupling is achieved by using two different types of capacitors that target on different types of noise on the power supply leads. For

higher frequency transients, spikes, or digital hash on the line, a good low equivalent-series-resistance (ESR) ceramic capacitor, typically 1μF, is

placed as close as possible to the device VDD pin for the best operation. For filtering lower frequency noise signals, a large ceramic capacitor of

10μF or greater placed near the audio power amplifier is recommended.

How to Reduce EMI

Most applications require a ferrite bead filter for EMI elimination shown at Figure 1. The ferrite filter reduces EMI around 1MHz and higher. When

selecting a ferrite bead, choose one with high impedance at high frequencies, but low impedance at low frequencies.

OUT+

Ferrite Bead

1

C

f

2RiCi

Ci

1

ic

2Rf

PAM8013/PAM8015

Document number: DS36979 Rev. 2 - 2

200pF

Ferrite Bead

OUT-

200pF

Figure 1 Ferrite Bead Filter to Reduce EMI

6 of 9

www.diodes.com

May 2014

© Diodes Incorporated

Page 7

A PRODUCT LINE OF

DIODES INCORPORATED

PAM8013/PAM8015

Application Information (cont.)

Shutdown Operation

In order to reduce power consumption while not in use, the PAM8013/PAM8015 contains shutdown circuitry amplifier off when logic low is placed on

the SD pin. By switching the shutdown pin connected to GND, the PAM8013/ PAM8015 supply current draw will be minimized in idle mode.

Under Voltage Lock-out (UVLO)

The PAM8013/PAM8015 incorporates circuitry designed to detect low supply voltage. When the supply voltage drops to 2.0V or below, the

PAM8013/PAM8015 goes into a state of shutdown, and the device comes out of its shutdown state and restore to normal function only when VDD

higher than 2.2V.

Short Circuit Protection (SCP)

The PAM8013/PAM8015 has short circuit protection circuitry on the outputs to prevent the device from damage when output-to-output shorts or

output-to-GND shorts occur. When a short circuit occurs, the device immediately goes into shutdown state. Once the short is removed, the device

will be reactivated.

Over Temperature Protection (OTP)

Thermal protection on the PAM8013/PAM8015 prevents the device from damage when the internal die temperature exceeds 150°C. There is a 15°C

NEW PRODUCT

tolerance on this trip point from device to device. Once the die temperature exceeds the set point, the device will enter the shutdown state and the

outputs are disabled. This is not a latched fault. The thermal fault is cleared once the temperature of the die decreased by 40°C. This large

hysteresis will prevent motor boating sound well and the device begins normal operation at this point with no external system interaction.

POP and Click Circuitry

The PAM8013/PAM8015 contains circuitry to minimize turn-on and turn-off transients or “click and pops”, where turn-on refers to either power supply

turn-on or device recover from shutdown mode. When the device is turned on, the amplifiers are internally muted. An internal current source ramps

up the internal reference voltage. The device will remain in mute mode until the reference voltage reach half supply voltage, 1/2 VDD. As soon as the

reference voltage is stable, the device will begin full operation. For the best power-off pop performance, the amplifier should be set in shutdown

mode prior to removing the power supply voltage.

Ordering Information

PAM8013/PAM8015 X X X

Pin Configuration

A: 9 Pin K: U-FLGA1515-9 R: Tape & Real

Part Number Package Standard Package

PAM8013AKR U-FLGA1515-9 3,000Units/Tape&Real

PAM8015AKR U-FLGA1515-9 3,000Units/Tape&Real

PAM8013/PAM8015

Document number: DS36979 Rev. 2 - 2

Package Type

7 of 9

www.diodes.com

Shipping Package

May 2014

© Diodes Incorporated

Page 8

Marking Information

A PRODUCT LINE OF

DIODES INCORPORATED

PAM8013- U-FLGA1515-9

BU

YW

PAM8013/PAM8015

BU: PAM8013 Product Code

Y: Year

W: Week

PAM8015-

U-FLGA1515-9

NEW PRODUCT

BV

YW

Package Outline Dimensions (All dimensions in mm.)

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

A

A

1

A

D

e

E

R

︵

1

.

0

Pin #1 ID

︶

b SQ.

3

Seating Plane

e

Z

BV: PAM8015 Product Code

Y: Year

W: Week

U-FLGA1515-9

Dim Min Max Typ

A 0.55 0.65 0.60

A1 0 0.05 0.02

A3 0.13 BSC

b 0.20 0.30 0.25

D 1.45 1.55 1.50

E 1.45 1.55 1.50

e 0.50 BSC

Z 0.125 BSC

All Dimensions in mm

PAM8013/PAM8015

Document number: DS36979 Rev. 2 - 2

8 of 9

www.diodes.com

May 2014

© Diodes Incorporated

Page 9

A PRODUCT LINE OF

DIODES INCORPORATED

PAM8013/PAM8015

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

Y2Y

NEW PRODUCT

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume all

risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2014, Diodes Incorporated

www.diodes.com

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

1

X

X

1

Y

G

G

1

C

X

2

IMPORTANT NOTICE

LIFE SUPPORT

Dimensions

C 0.587

G 0.150

G1 0.150

X 0.525

X1 0.350

X2 1.700

Y 0.525

Y1 0.350

Y2 1.700

Value

(in mm)

PAM8013/PAM8015

Document number: DS36979 Rev. 2 - 2

9 of 9

www.diodes.com

May 2014

© Diodes Incorporated

Loading...

Loading...