Page 1

A

f

Description

The PAM2846 is a high-efficiency boost type LED driver. It is

designed for large LCD panel that employs an array of LEDs as back

light source.

The PAM2846 employs a current-mode step-up converter that drives

six parallel strings of LEDs connected in multiple series. This built-in

string current-control circuit achieves ±1% typical current matching

between strings, which ensures even brightness for all LEDs. The

device is able to adapt to different numbers of LEDs in each string or

different forward voltage for different types of LEDs and keep the

string current constant.

Separate feedback loops limit the output voltage if one or more LEDs

open or short. The limit voltage of over voltage protection is

adjustable by changing the feedback resistor ratio. The PAM2846 has

features cycle-by-cycle current limit to provide consistent operation

and soft-start capability. A thermal-shutdown circuit provides another

level of protection.

The PAM2846 has a wide +4.8V to +28V input voltage range and

provides adjustable full-scale LED current. The switching frequency of

this device can be selected among 500kHz, 1MHz and 1.6 MHz

according to the application requirements.

Features

Product Line o

Diodes Incorporated

PAM2846

INTEGRATED 6 STRING LED BOOST TYPE DRIVER

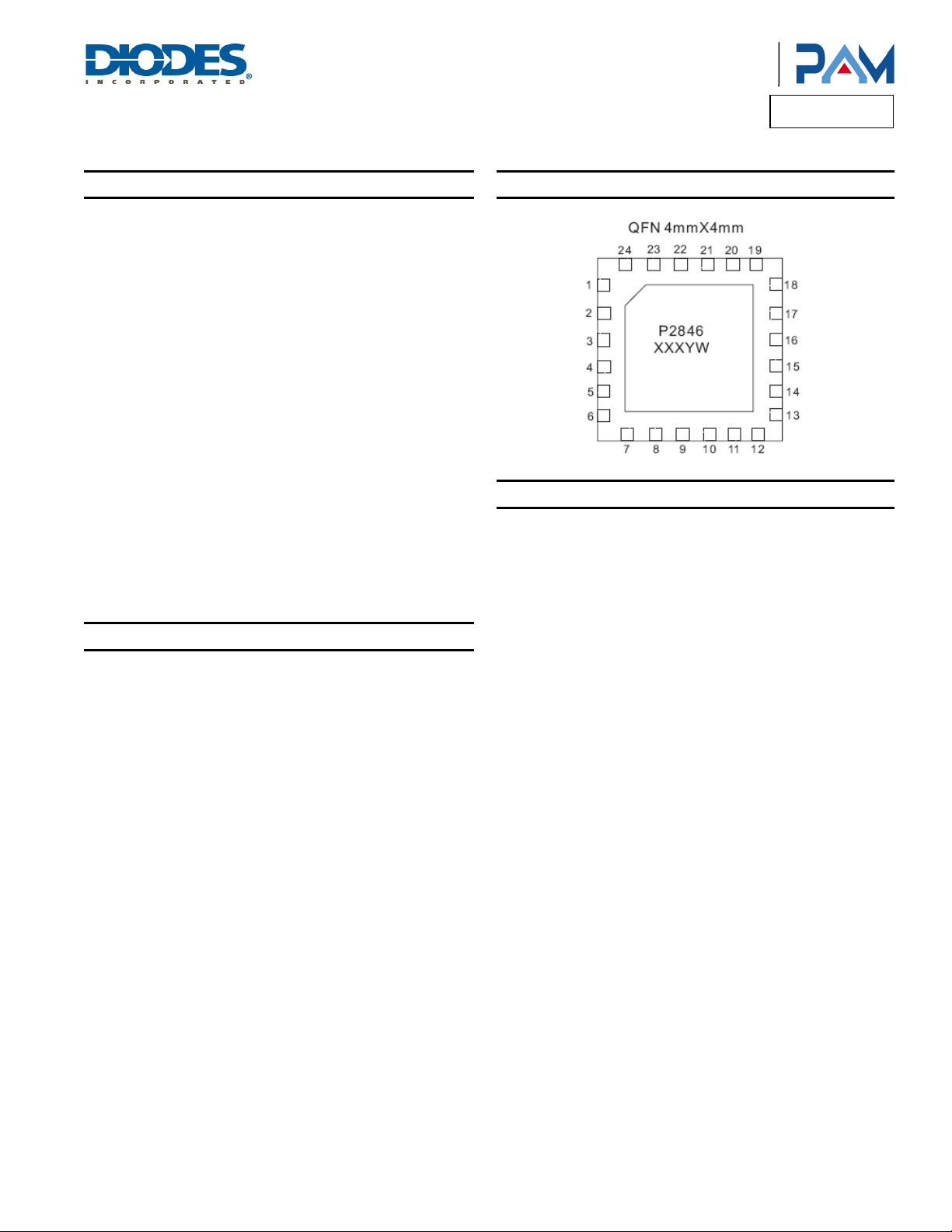

Pin Assignments

Applications

White or RGB Backlighting for LCD TV, LCD Monitor, Notebook,

Handy Terminals, and Avionics Displays Panels

LED Lighting Devices

Six Constant-Current Output Channels

Parallel Channels Allow Higher Current per LED String

Maximum 40V Continuous Voltage Output Limit for Each

Channel

Self-adaptive V

Adjustable Constant LED Current

Drives 10 or more LEDs Each String as Long as the String

Voltage Less Than 40V

Internal 2.5A Power MOSFET

Low 400mV Feedback Voltage at Full Current Improves

Efficiency

Allows Digital PWM and Analog Dimming

Wide (100:1) PWM Dimming Range without Color Shift

Independent Dimming and Shutdown Control of the LED Driver

Open LED Protection: Adjustable Clamp Voltage

Short LED Protection

3 Frequencies Selection: 1.6MHz/1MHz/500kHz

Wide Input Voltage Range: 4.8V to 28V

Over Temperature Protection

Available in 24-pin 4mmx4mm QFN Package

Pb-free Package

to Fit Different LED Number

OUT

PAM2846

Document number: DSxxxxx Rev. 1 - 2

1 of 14

www.diodes.com

November 2012

© Diodes Incorporated

Page 2

A

f

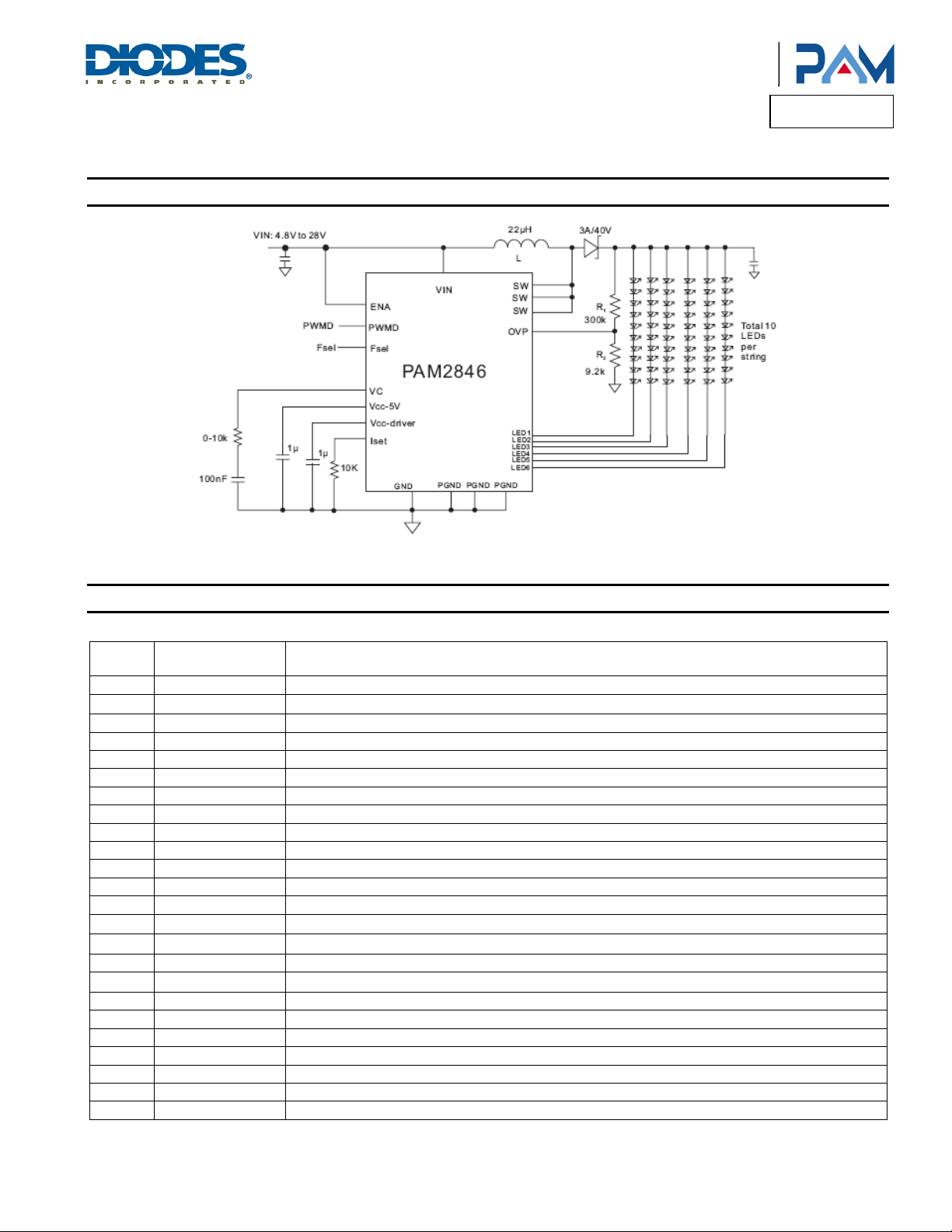

Typical Applications Circuit

Product Line o

Diodes Incorporated

PAM2846

Pin Descriptions

Pin

Number

1 VIN Supply Input

2

3 GND Ground

4 ENA Enable Input

5 PWMD PWM Dimming Control

6 LED1 LED1 Cathode Terminal

7 LED2 LED2 Cathode Terminal

8 LED3 LED3 Cathode Terminal

9 GND Ground

10 GND Ground

11 LED4 LED4 Cathode Terminal

12 LED5 LED5 Cathode Terminal

13 LED6 LED6 Cathode Terminal

14

15

16 VC Boost Stage Compensation Pin

17

18 FB Feedback

19 PGND Power Ground

20 PGND Power Ground

21 PGND Power Ground

22 SW Power MOS Drain

23 SW Power MOS Drain

24 SW Power MOS Drain

PAM2846

Document number: DSxxxxx Rev. 1 - 2

Pin Name

QFN4x4-24

V

-Driver

CC

I

SET

V

-5V

CC

F

SEL

5V Linear Regulator Output for Power MOS Driver

LED Current Adjustment Pin

5V Linear Regulator

Oscillator Frequency Selection Pin

2 of 14

www.diodes.com

Function

November 2012

© Diodes Incorporated

Page 3

A

f

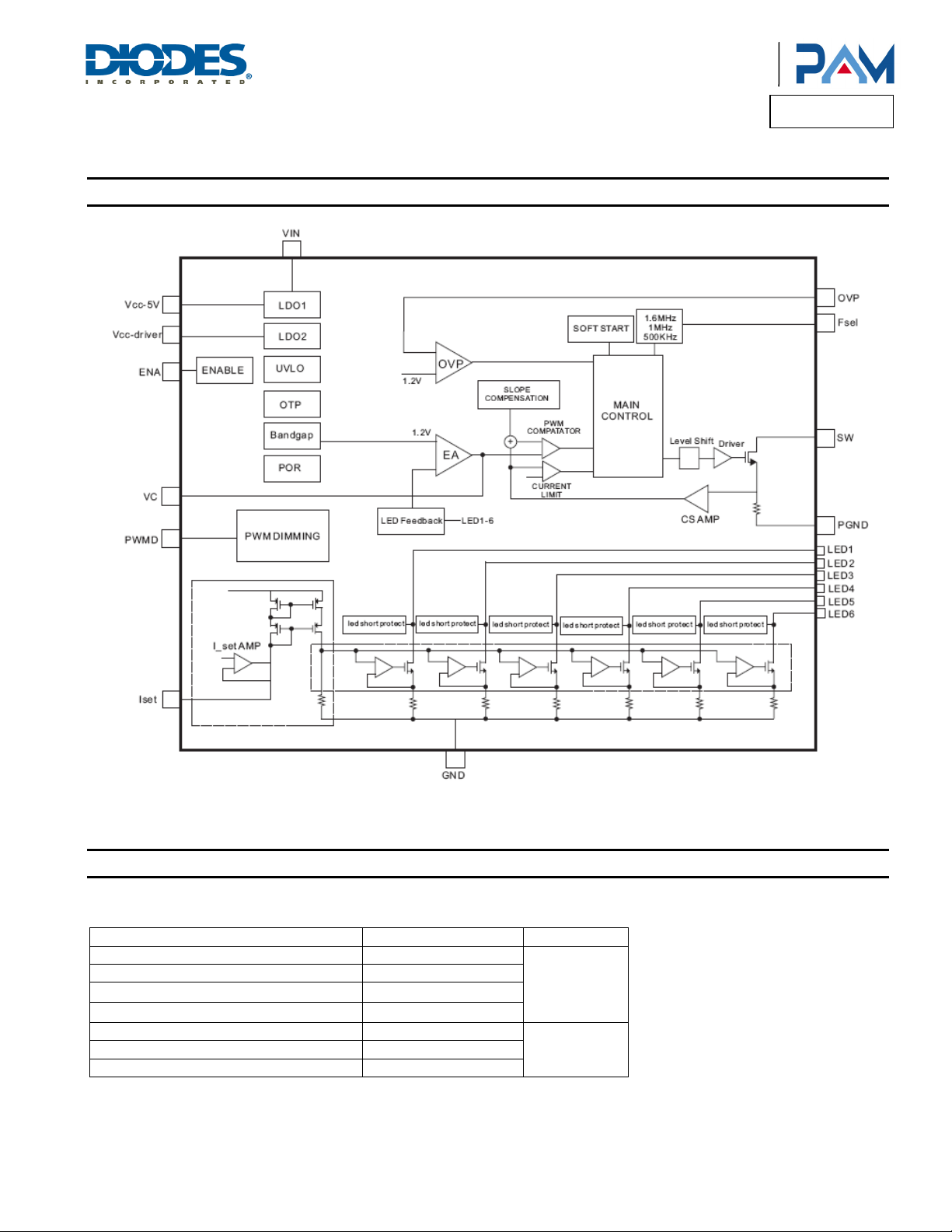

Functional Block Diagram

Product Line o

Diodes Incorporated

PAM2846

Absolute Maximum Ratings (@T

These are stress ratings only and functional operation is not implied. Exposure to absolute maximum ratings for prolonged time periods may

affect device reliability. All voltages are with respect to ground.

Parameter Rating Unit

VIN, ENA -0.3 to +30

SW, LED -0.3 to +40

VCC -5V, VCC–Driver, VC

PWMD. F

Storage Temperature -65 to +170

Maximum Junction Temperature 170

Soldering Temperature 300, 5sec

PAM2846

Document number: DSxxxxx Rev. 1 - 2

SEL

, OVP, I

SET

= +25°C, unless otherwise specified.)

A

-0.3 to +6.0

-0.3 to +6.0

3 of 14

www.diodes.com

V

°C

November 2012

© Diodes Incorporated

Page 4

A

f

Product Line o

Diodes Incorporated

PAM2846

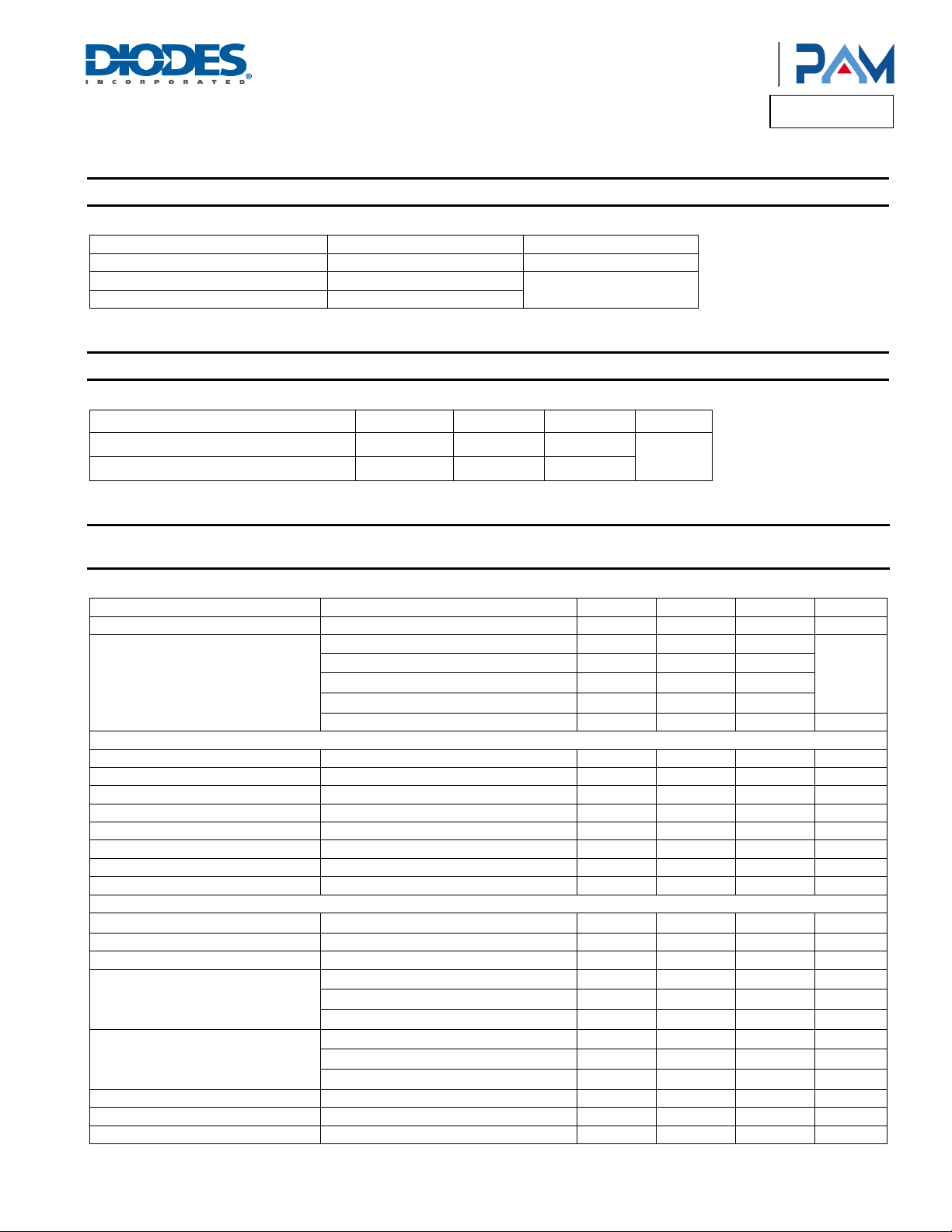

Recommended Operating Conditions (@T

Parameter Rating Unit

Supply Voltage Range 4.8 to 28V V

Junction Temperature Range -40 to +150

Ambient Temperature Range -40 to +85

= +25°C, unless otherwise specified.)

A

°C

Thermal Information

Parameter Package Symbol Max Unit

Thermal Resistance (Junction to Case)

Thermal Resistance (Junction to Environment)

QFN4x4-24

QFN4x4-24

θ

JC

θ

JA

12

30

°C/W

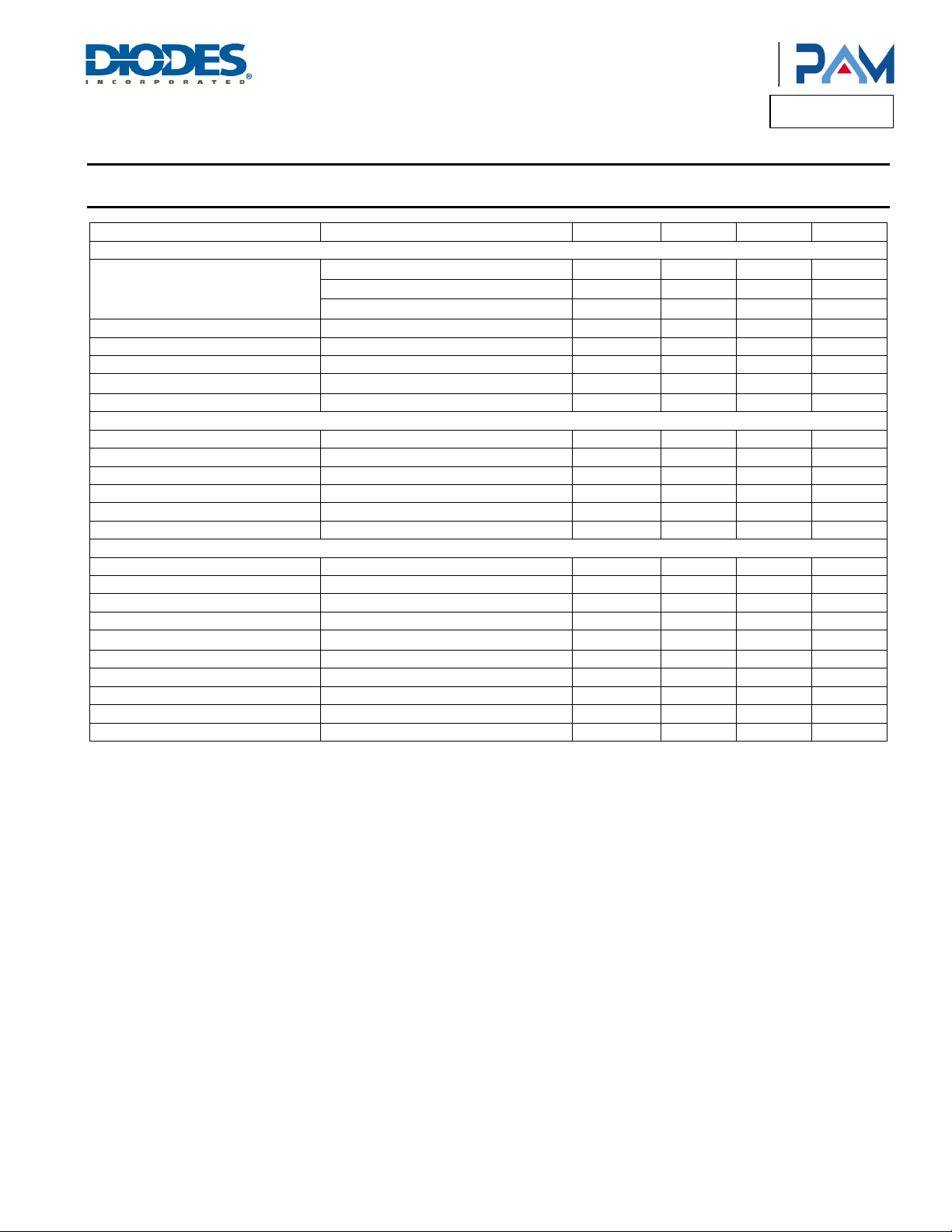

Electrical Characteristics

(@TA = +25°C, VIN = ENA = 12V, R

Parameter Test Conditions Min Typ Max Units

Input Voltage Range 4.8 28 V

Quiescent Current

VDD_5V No switching 4.7 5.0 5.5 V

VDD_5V Current Limit No switching 14 74 90 mA

VDD_5V UVLO Threshold No switching 3.9 4.2 4.5 V

VDD_5V UVLO Hysteresis No switching 70 mV

VDD_Driver No switching 4.7 5.0 5.5 V

VDD_Driver Current_Limit No switching 14 74 90 mA

VDD_Driver UVLO Threshold No switching 3.9 4.2 4.5 V

VDD_Driver UVLO Hysteresis No switching 70 mV

Switch RDS(ON)

Switch Current Limit 2.5 A

Switch Leakage Current 1 µA

Switching Frequency

Minimum Duty Cycle

Maximum Duty Cycle 90 %

VC Source Current 60 µA

VC Sink Current 60 µA

PAM2846

Document number: DSxxxxx Rev. 1 - 2

= 10kΩ, L = 22µH, unless otherwise specified.)

SET

E NA = high (no switching frequency) 1 2

F

= high (1.6M switching frequency)

SEL

F

= high (1M switching frequency)

SEL

F

= high (500k switching frequency)

SEL

E NA = low 5 20 µA

LDO Stage

Boost Stage

V

_5V = 5V

CC

= VCC_5V

F

SEL

F

= Open

SEL

F

= GND

SEL

= VCC_5V

F

SEL

F

= Open

SEL

F

= GND

SEL

4 of 14

www.diodes.com

10

6

3

0.2 Ω

1.6 MHz

1.0 MHz

500 kHz

20 %

10 %

5 %

mA

November 2012

© Diodes Incorporated

Page 5

A

f

Product Line o

Diodes Incorporated

PAM2846

Electrical Characteristics (cont.)

(@TA = +25°C, VIN = ENA = 12V, R

Parameter Test Conditions Min Typ Max Units

Full-Scale LED_Output Current

LED Current Matching -3 1 +3 %

ISET Voltage 1.2 V

Minimums LED Voltage 400 mV

Analog Dimming Range

PWM Dimming Frequency 100 1k Hz

LED_Overvoltage Threshold 4.6 4.9 5.1 V

LED_Overvoltage Hysteresis 1 V

Overvoltage Threshold 1.2 V

Overvoltage Hysteresis 80 mV

Thermal-Shutdown 150 °C

Thermal-Shutdown Hysteresis 30 °C

EN High 1.5 V

EN Low 0.4 V

PWMD High 1.5 V

PWMD Low 0.4 V

FSEL High

FSEL Midlevel 1 2 V

FSEL Low 0.5 V

EN Min Pulse Width Single Wire Dimming Low Level 0.5 µs

EN Max Pulse Width Single Wire Dimming Low Level 10 µs

EN Off Delay Single Wire Dimming Low Level 200 µs

PAM2846

Document number: DSxxxxx Rev. 1 - 2

= 10kΩ, L = 22µH, unless otherwise specified.)

SET

LED Controller Stage

I = 190*1.2V/R

I = 190*1.2V/R

I = 190*1.2V/R

I = 190*1.2V/R

, R

ISET

ISET

ISET

ISET

= 7.68k

ISET

, R

= 11.3k

ISET

, R

= 22.6k

ISET

Fault Protection

Control Interface

5 of 14

www.diodes.com

30 mA

20 mA

10 mA

I/32 I mA

V

CC

_5V -0.5

V

November 2012

© Diodes Incorporated

Page 6

A

f

Typical Performance Characteristics

(@TA = +25°C, VIN = ENA = 12V, R

= 10kΩ, L = 22µH, FSW = 500kHz, 10x6 LEDs, unless otherwise specified.)

SET

Product Line o

Diodes Incorporated

PAM2846

PAM2846

Document number: DSxxxxx Rev. 1 - 2

6 of 14

www.diodes.com

November 2012

© Diodes Incorporated

Page 7

A

f

Typical Performance Characteristics (cont.)

(@TA = +25°C, VIN = ENA = 12V, R

= 10kΩ, L = 22µH, FSW = 500kHz, 10x6 LEDs, unless otherwise specified.)

SET

Product Line o

Diodes Incorporated

PAM2846

PAM2846

Document number: DSxxxxx Rev. 1 - 2

7 of 14

www.diodes.com

November 2012

© Diodes Incorporated

Page 8

A

f

Typical Performance Characteristics (cont.)

(@TA = +25°C, VIN = ENA = 12V, R

= 10kΩ, L = 22µH, FSW = 500kHz, 10x6 LEDs, unless otherwise specified.)

SET

Product Line o

Diodes Incorporated

PAM2846

PAM2846

Document number: DSxxxxx Rev. 1 - 2

8 of 14

www.diodes.com

November 2012

© Diodes Incorporated

Page 9

A

f

Product Line o

Diodes Incorporated

PAM2846

Application Information

The inductance, peak current rating, series resistance, and physical size should all be considered when selecting an inductor. These factors

affect the converter's operating mode, efficiency, maximum output load capability, transient response time, output voltage ripple, and cost.

The maximum output current, input voltage, output voltage, and switching frequency determine the inductor value. Very high inductance

minimizes the current ripple, and therefore reduces the peak current, which decreases core losses in the inductor and I

power path. However, large inductor values also require more energy storage and more turns of wire, which increases physical size and I

copper losses in the inductor. Low inductor values decrease the physical size, but increase the current ripple and peak current. Finding the best

inductor involves the compromises among circuit efficiency, inductor size, and cost.

When choosing an inductor, the first step is to determine the operating mode: continuous conduction mode (CCM) or discontinuous conduction

mode (DCM). When CCM mode is chosen, the ripple current and the peak current of the inductor can be minimized. If a small-size inductor is

required, DCM mode can be chosen. In DCM mode, the inductor value and size can be minimized but the inductor ripple current and peak

current are higher than those in CCM.

Capacitor Selection

An input capacitor is required to reduce the input ripple and noise for proper operation of the PAM2846. For good input decoupling, low ESR

(equivalent series resistance) capacitors should be used at the input. At least 2.2µF input capacitor is recommended for most applications. A

minimum output capacitor value of 10µF is recommended under normal operating conditions, while a 22µF or higher capacitor may be required

for higher power LED current. A reasonable value of the output capacitor depends on the LED current. The total output voltage ripple has two

components: the capacitive ripple caused by the charging and discharging on the output capacitor, and the ohmic ripple due to the capacitor's

equivalent series resistance. The ESR of the output capacitor i s the important parameter to determine the output voltage ripple of the converter,

so low ESR capacitors should be used at the output to reduce the output voltage ripple. The voltage rating and temperature characteristics of the

output capacitor must also be considered. So a value of 10µF, voltage rating (50V) capacitor is chosen.

Diodes Selection

PAM2846 is high switching frequency convertor, which demands high speed rectifier. It's indispensable to use a Schottky diode rated at 2A, 60V

with the PAM2846. Using a Schottky diode with a lower forward voltage drop can improve efficiency of the convertor. The voltage rating of the

diode should be greater than the output voltage.

Methods for Setting LED Current

There are three methods for setting and adjusting the LED current outlined here. The methods are:

1) RSET only

2) PWM Input at PWMD

3) Single wire logic signal at ENA

2

R losses in the entire

2

R

PAM2846

Document number: DSxxxxx Rev. 1 - 2

Figure 1. Timing Diagram for EN

9 of 14

www.diodes.com

November 2012

© Diodes Incorporated

Page 10

A

f

Application Information (cont.)

Product Line o

Diodes Incorporated

PAM2846

● Method 1: LED Current Setting with External Resistor R

The most basic means of setting the LED current is connecting a resistor between R

I

= 228/ R

LED

ISET

ISET

and GND. The LED current is decided by I

ISET

Resistor.

SET

● Method 2: LED Current Setting with PWM Signal to PWM Signal to PWMD Pin

This circuit uses resistor R

PWMD pin is logic low. Average LED current is approximately equal to:

I = (t

*I)/(tON+t

ON

Also, the recommended PWM frequency is between 100Hz and 1kHz. Frequency <100Hz can cause the LEDs to blink visibly.

to set the on state current and the average LED current, then proportional to the percentage of on-time when the

ISET

)

OFF

● Method 3: LED Current Setting with Single Wire Logic to ENA Pin

When the LEDs are enabled by high level, the LED current initially goes to I

width). Each pulse reduces the LED current by 1/32, so after one pulse the LED current is 31/32*I

. Figure 1 shows a timing diagram for EN.

to I

LED

. Dimming is done by pulsing ENA low (500ns to 10 s pulse

LED

. The 32th pulse sets the LED current back

LED

Setting the Over Voltage Protection

The OVP pin is connected to the center tap of a resistive voltage divider (R1 and R2 in Typical Application diagram) from the high-voltage output.

V

OUT_LIMIT

The recommend procedure is to choose R

= VOV (1 + R2/R1)

= 300kΩ and R1 = 9.2kΩ to set V

2

OUT_LIMIT

= 40V. This OVP pin is used for over voltage protect, not

for output voltage regulate.

LED Short Protection

The PAM2846 uses LED_OVP function to protect devices when one or more LED(s) is/are shorted.

= V

V

Normally V

LED

LED

make sure all LED pins’ voltage is less then 5V. With this function V

– Vf * N

OUT

is around 0.4V and V

is decided by LED numbers. When one or more LED(s) is/are shorted, the PAM2846 will clamp V

OUT

will be clamped at (5V + Vf*N

OUT

MIN

).

OUT

to

Note:

V

V

: LED pin voltage

LED

: Output voltage

OUT

Vf: LED forward voltage

N

: The minimum LED numbers among all strings.

MIN

LED Open Protection

The control loop is related to all six LED sinks. When one or more LED(s) is/are opened, the sink will have no current and the device will work in

unstable open loop state. The V

PAM2846

Document number: DSxxxxx Rev. 1 - 2

voltage will be limited by external resistor divider or 5V + Vf*N

OUT

10 of 14

www.diodes.com

, whichever is lower.

MIN

November 2012

© Diodes Incorporated

Page 11

A

f

Product Line o

Diodes Incorporated

PAM2846

Application Information (cont.)

PCB Layout Guidelines

Careful PCB layout is important for proper operation. Use the following guidelines for good PCB layout:

1) Minimize the area of the high current switching loop of the rectifier diode and output capacitor to avoid excessive switching noise.

2) Connect high-current input and output components with short and wide connections. The high-current input loop goes from the positive

terminal of the input capacitor to the inductor, to the SW pin. The high-current output loop is from the positive terminal of the input capacitor

through the inductor, rectifier diode, and positive terminal of the output capacitors, reconnecting between the output capacitor and input

capacitor ground terminals. Avoid using vias in the high-current paths. If vias are unavoidable, use multiple vias in parallel to reduce

resistance and inductance.

3) Create a ground island (PGND) consisting of the input and output capacitor ground and PGND pin. Connect all these together with short, wide

traces or a small ground plane. Maximizing the width of the power ground traces improves efficiency and reduces output-voltage ripple and

noise spikes. Create an analog ground island (GND) consisting of the output voltage detection-divider ground connection, the I

connections, V

connecting the GND pins directly to the exposed backside pad. Make sure no other connections between these separate ground planes.

4) Place the output voltage setting-divider resistors as close to the OVP pin as possible. The divider's center trace should be kept short. Avoid

running the sensing traces near SW Pin.

5) Place the VIN pin bypass capacitor as close to the device as possible. The ground connection of the VIN bypass capacitor should be

connected directly to GND pins with a wide trace.

6) Minimize the size of the SW node while keeping it wide and short. Keep the SW node away from the feedback node and ground. If possible,

avoid running the SW node from one side of the PCB to the other.

7) Refer to the PAM2846 Evaluation board for an example of proper board layout.

-5V and VCC-driver capacitor connections, and the device's exposed backside pad. Connect the GND and PGND islands by

CC

resistor

SET

PAM2846

Document number: DSxxxxx Rev. 1 - 2

PAM2846 Evaluation Board

11 of 14

www.diodes.com

November 2012

© Diodes Incorporated

Page 12

A

f

Ordering Information

Product Line o

Diodes Incorporated

PAM2846

Part Number Marking Package Type Standard Package

PAM2846KR

P2846

XXXYW

QFN4x4 3000 Units/ Tape & Reel

Marking Information

PAM2846

Document number: DSxxxxx Rev. 1 - 2

12 of 14

www.diodes.com

November 2012

© Diodes Incorporated

Page 13

A

f

Package Outline Dimensions (All dimensions in mm.)

QFN4x4-24

Product Line o

Diodes Incorporated

PAM2846

PAM2846

Document number: DSxxxxx Rev. 1 - 2

13 of 14

www.diodes.com

November 2012

© Diodes Incorporated

Page 14

A

f

Product Line o

Diodes Incorporated

PAM2846

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2012, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

PAM2846

Document number: DSxxxxx Rev. 1 - 2

14 of 14

www.diodes.com

November 2012

© Diodes Incorporated

Loading...

Loading...