Page 1

A

f

Description

The PAM2842 is a high power LED driver, capable of driving up to 10

high power LEDs in series. The PAM2842 supports buck, boost and

sepic topology.

The PAM2842 features over current protection, over voltage

protection, under voltage lockout and over temperature protection,

which prevent the device from damage.

LED dimming can be done by using a PWM signal to the COMP pin.

The PAM2842 is available in TSSOP-20 packages.

Features

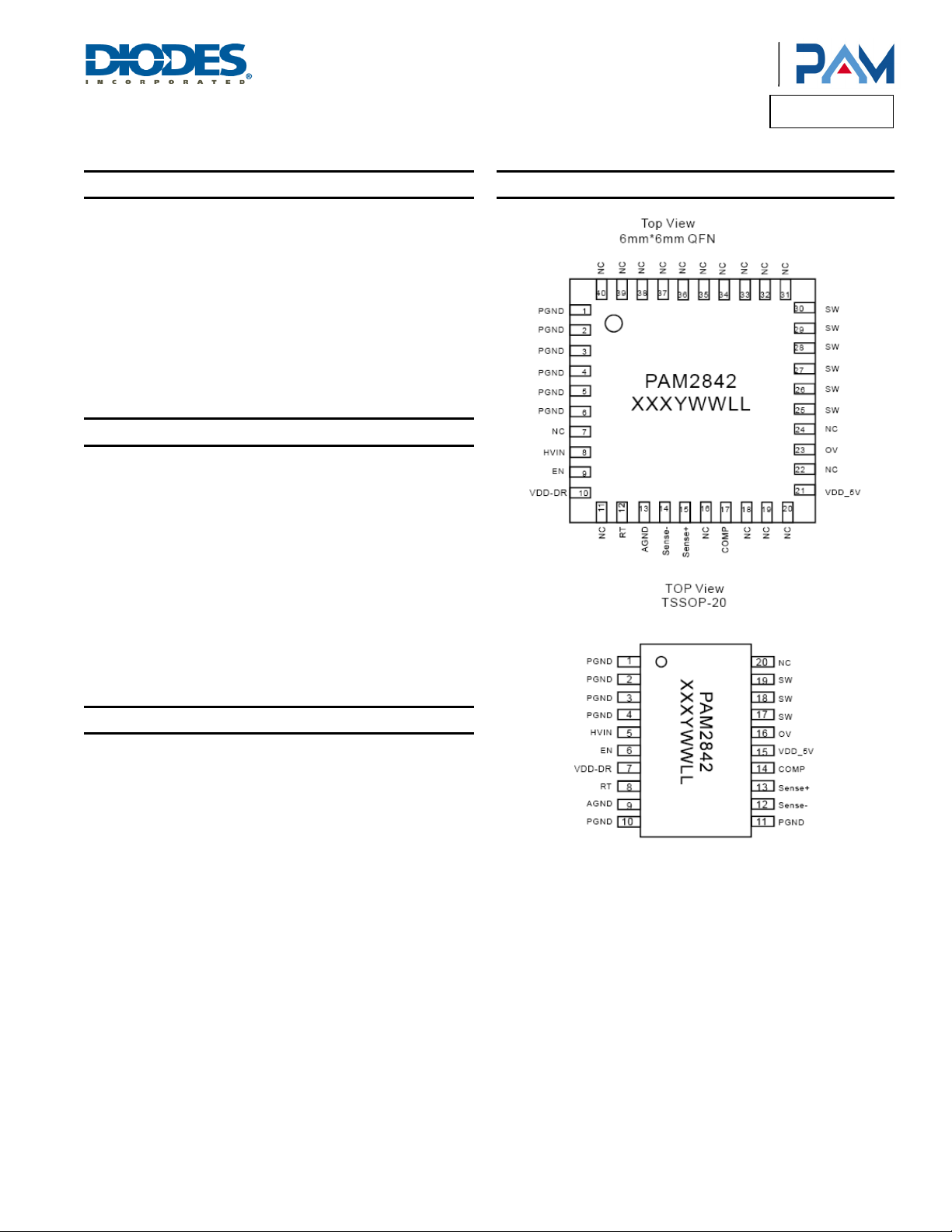

Pin Assignments

Product Line o

Diodes Incorporated

PAM2842

HIGH POWER LED DRIVER

• Output Power up to 30W

• Chip Enable with Soft-start

• Analog and PWM Dimming

• Peak Efficiency up to 97%

• Low Quiescent Current

• Switching Frequency Adjustable

• Support Buck/Boost/Sepic Toplogy

• Over Current Protection

• Over Voltage Protection

• Thermal Protection

• UVLO

• Tiny Pb-Free Packages: 40-Pin QFN6x6 and TSSOP-20

Applications

• Home Lighting

• Automotive Lighting

• Monitor Backlighting

PAM2842

Document number: DSxxxxx Rev. 1 - 2

1 of 17

www.diodes.com

October 2012

© Diodes Incorporated

Page 2

A

f

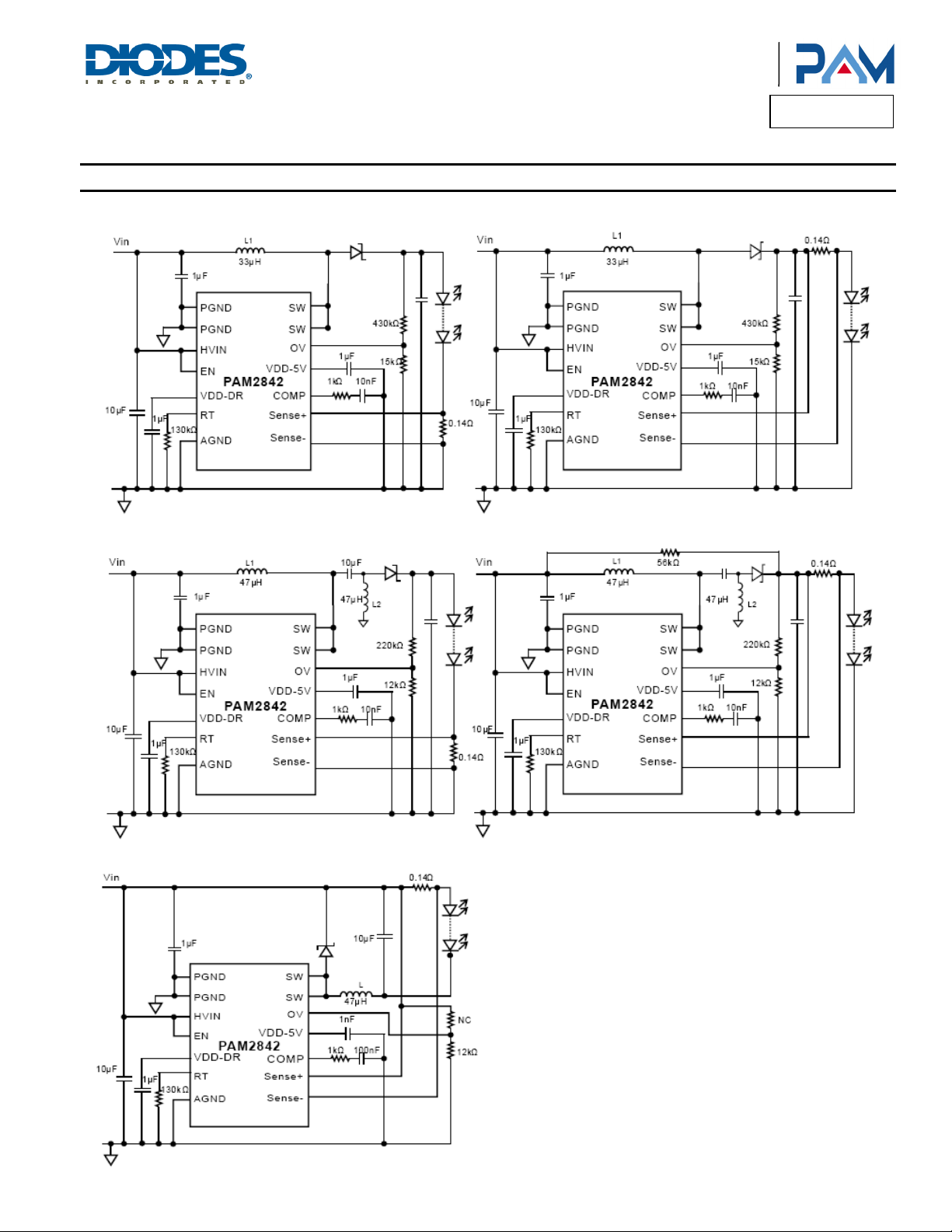

Typical Applications Circuit

Boost with Low Side Current Sense Boost with High Side Current Sense

Product Line o

Diodes Incorporated

PAM2842

Buck/Boost (Sepic) with Low Side Current Sense Buck/Boost (Sepic) with High Side Current Sense

Buck with High Side Current Sense

PAM2842

Document number: DSxxxxx Rev. 1 - 2

2 of 17

www.diodes.com

October 2012

© Diodes Incorporated

Page 3

A

f

Pin Descriptions

Pin

Name

QFN6x6-40 TSSOP-20

Pin Number

PGND 1 – 6 1, 2, 3, 4, 10, 11

HVIN 8 5

EN 9 6

VDD-DR 10 7

RT 12 8

AGND 13 9

Sense- 14 12

Sense+ 15 13

COMP 17 14

VDD_5V 21 15

OV 23 16

SW 25 – 30 17, 18, 19

NC

7, 11, 16, 18-20,

22, 24, 31-40

20

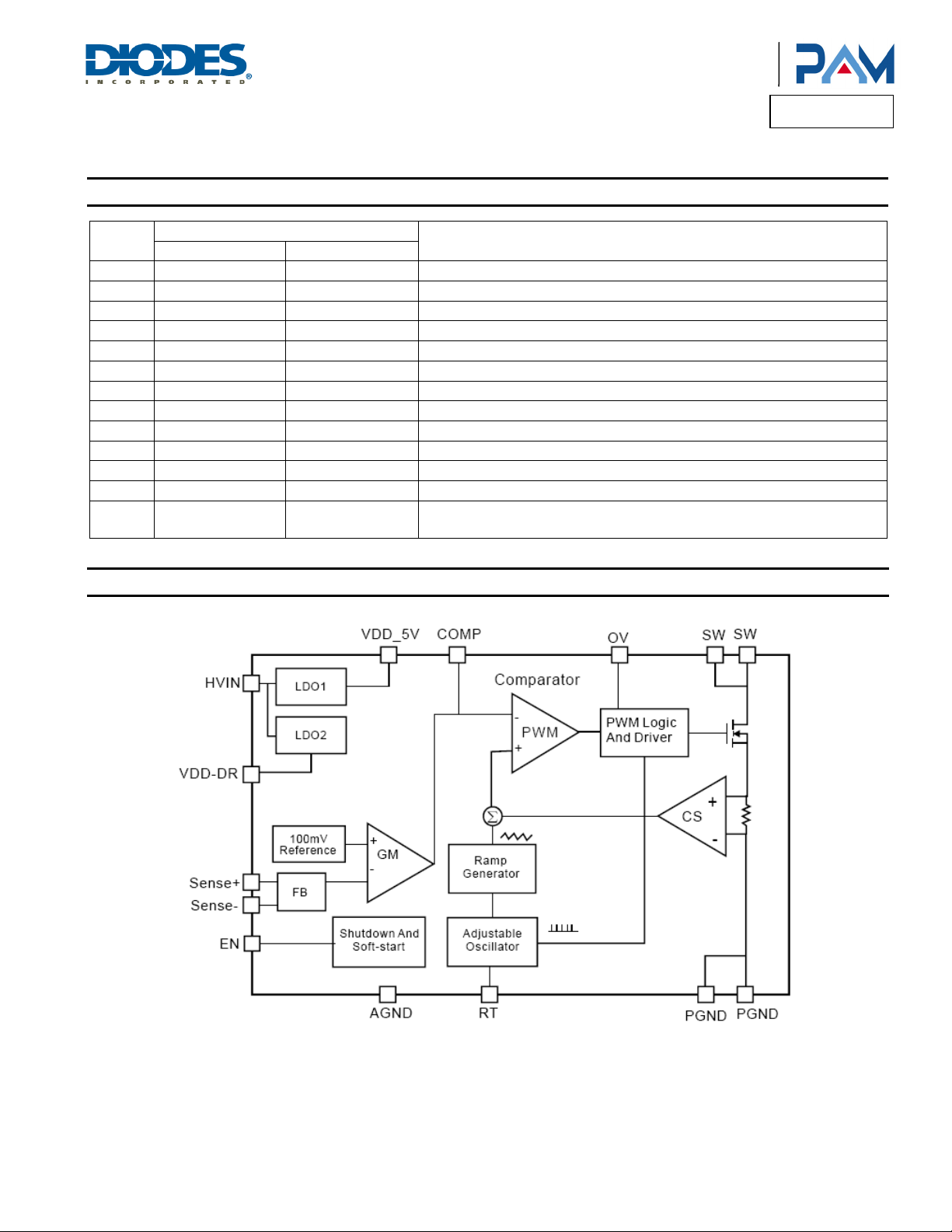

Functional Block Diagram

Product Line o

Diodes Incorporated

PAM2842

Function

Power Ground

Input

Chip Enable, Active High

Internal LDO Output

Frequency Adjustment Pin

Analog Ground

Sense Resistor -

Sense Resistor+

Compensation Node

Internal LDO Output

Over Voltage

Drain of Main Switch

Not Connected

PAM2842

Document number: DSxxxxx Rev. 1 - 2

3 of 17

www.diodes.com

October 2012

© Diodes Incorporated

Page 4

A

f

Product Line o

Diodes Incorporated

PAM2842

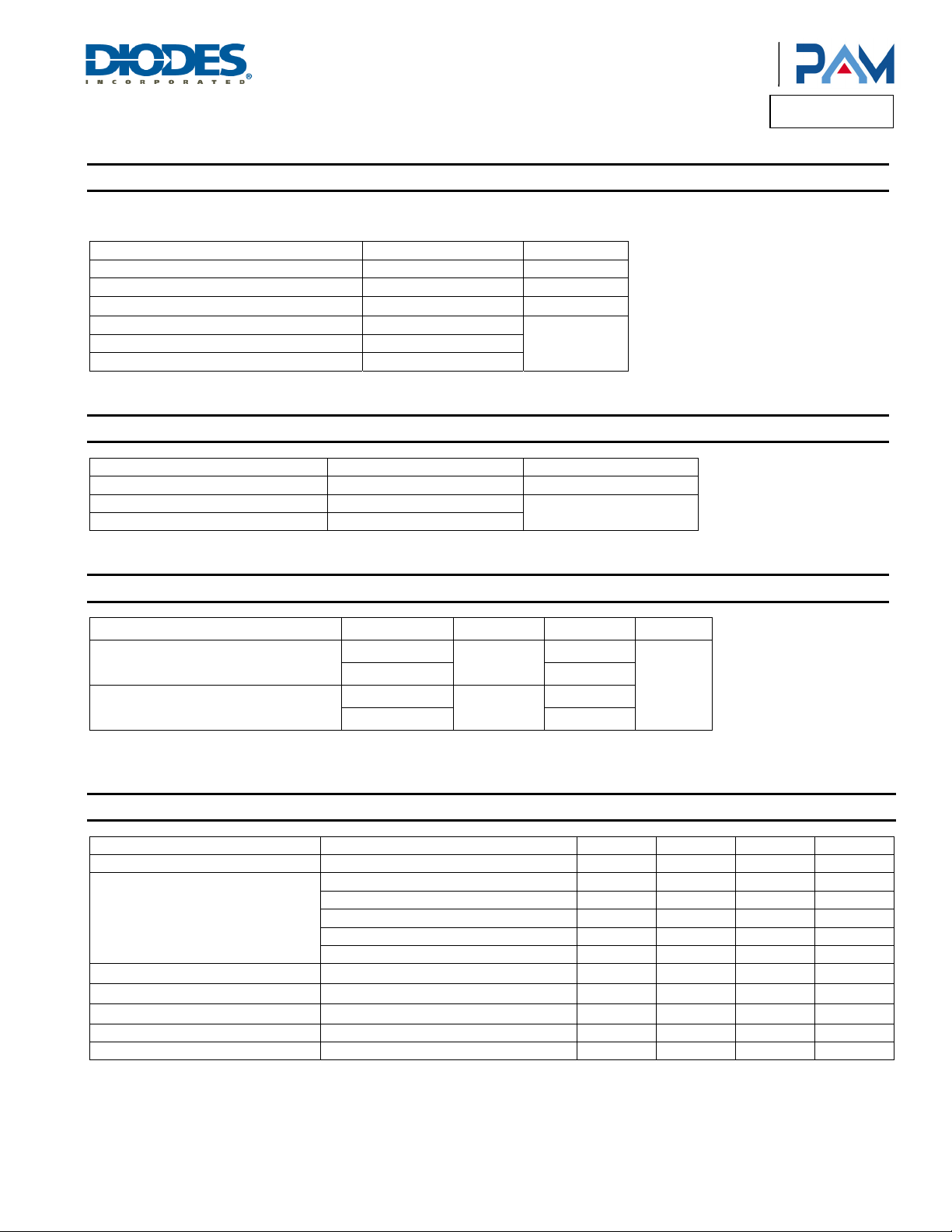

Absolute Maximum Ratings (@T

These are stress ratings only and functional operation is not implied. Exposure to absolute maximum ratings for prolonged time periods may

affect device reliability. All voltages are with respect to ground.

Parameter Rating Unit

Supply Voltage 40 V

Buck Application Maximum Output Current 3 A

I/O Pin Voltage Range

Maximum Junction Temperature 150

Storage Temperature -40 to +150

Soldering Temperature 300, 5sec

Recommended Operating Conditions (@T

Parameter Rating Unit

Supply Voltage Range 5.5 to 40 V

Operation Temperature Range -40 to +85

Junction Temperature Range -40 to +125

= +25°C, unless otherwise specified.)

A

GND -0.3 to V

A

+0.3

DD

= +25°C, unless otherwise specified.)

V

°C

°C

Thermal Information

Parameter Package Symbol Max Unit

Thermal Resistance (Junction to Case)

Thermal Resistance (Junction to Ambient)

Note: 1. The exposed PAD must be soldered to a thermal land on the PCB.

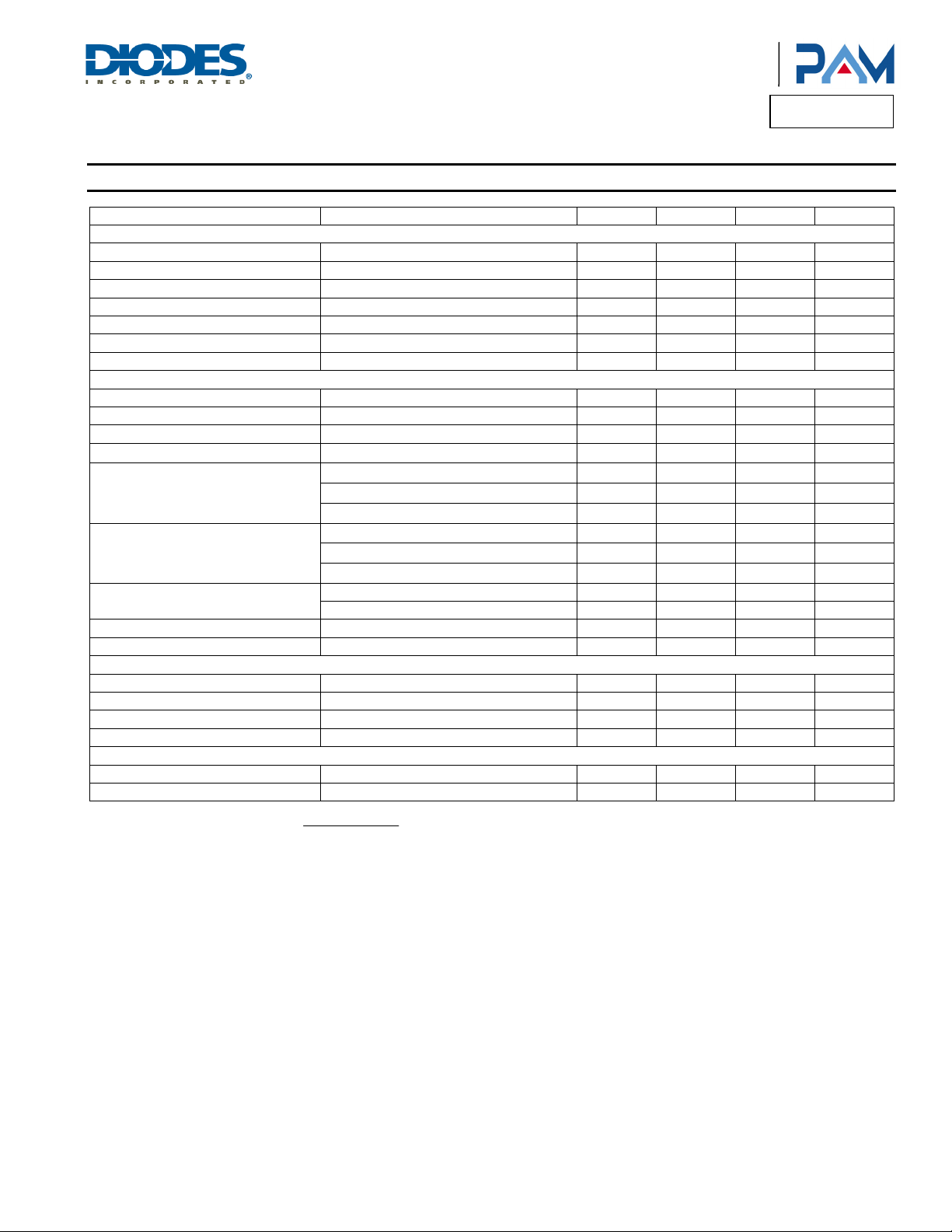

Electrical Characteristics (@T

Parameter Test Conditions Min Typ Max Units

Input Voltage Range 5.5 40 V

Quiescent Current

Feedback Voltage, Low Side

Feedback Voltage, High Side

LED Current Line Regulation

LED Current Load Regulation 1.0 %

VDD_DR UVLO Hysteresis No Switching 200 mV

PAM2842

Document number: DSxxxxx Rev. 1 - 2

TSSOP-20

QFN6x6-40 7.6 (Note 1)

TSSOP-20

QFN6x6-40 18.1 (Note 1)

= +25°C, VEN = VDD = 24V, 1W x 10 LEDs, unless otherwise specified.)

A

E NA = high (no switching frequency) 1 2 mA

E NA = high (1M switching frequency) 6 mA

E NA = high (500k switching frequency) 3 mA

E NA = high (200k switching frequency) 1.6 mA

E NA = low 5 10 µA

V

= V

FB

V

= V

FB

I

= 350mA

O

SENSE+

SENSE+

-AGND, V

– V

SENSE-

www.diodes.com

SENSE-

4 of 17

θ

JC

θ

JA

= AGND

20

90

95 100 105 mV

95 100 105 mV

°C/W

0.02 %/V

October 2012

© Diodes Incorporated

Page 5

A

f

Product Line o

Diodes Incorporated

PAM2842

Electrical Characteristics (cont.) (@T

Parameter Test Conditions Min Typ Max Units

VDD_5V No Switching 4.5 5 5.5 V

VDD_5V Current Limit No Switching 14 74 90 mA

VDD_5V UVLO Threshold No Switching 3.7 4.0 4.3 V

VDD_5V UVLO Hysteresis No Switching 200 mV

VDD_DR No Switching 4.5 5 5.5 V

VDD_DR Current_Limit No Switching 14 50 90 mA

VDD_DR UVLO Threshold No Switching 3.7 4.0 4.3 V

Switch RDS(ON) VDD_5V = 5V 0.1 Ω

Switch Current Limit 3.5 A

Switch Leakage Current 50 µA

RT Voltage

Switching Frequency (Note 2)

Min Duty Cycle

Max Duty Cycle

VC Source Current Feedback Voltage = 0 30 µA

VC Sink Current Feedback Voltage = 0 30 µA

OV Threshold Voltage 1.1 1.2 1.3 V

OV Hysteresis 70 mV

Thermal Shutdown 150 °C

Thermal Shutdown Hysteresis 30 °C

EN High 1.5 V

EN Low 0.4 V

Note: 2. Switching frequency

F

SW

PAM2842

Document number: DSxxxxx Rev. 1 - 2

R

RT

R

RT

RRT = 71kΩ

RRT = 180kΩ

F

SW

FSW = 500kHz

FSW = 200kHz

Low Side Sense 95 %

High Side Sense 100 %

10

=

(x24

R

= +25°C, VEN = VDD = 24V, 1W x 10 LEDs, unless otherwise specified.)

A

LDO Stage

Switch Stage

= 71kΩ

= 30kΩ

= 1MHz

12

+

RT

Fault Protection

Control Interface

, reference value.

)k12

www.diodes.com

5 of 17

1.1 1.2 1.3 V

800k 1M 1.2M Hz

400 500 600 kHz

160 200 240 kHz

10 %

5 %

2.5 %

October 2012

© Diodes Incorporated

Page 6

A

f

Diodes Incorporated

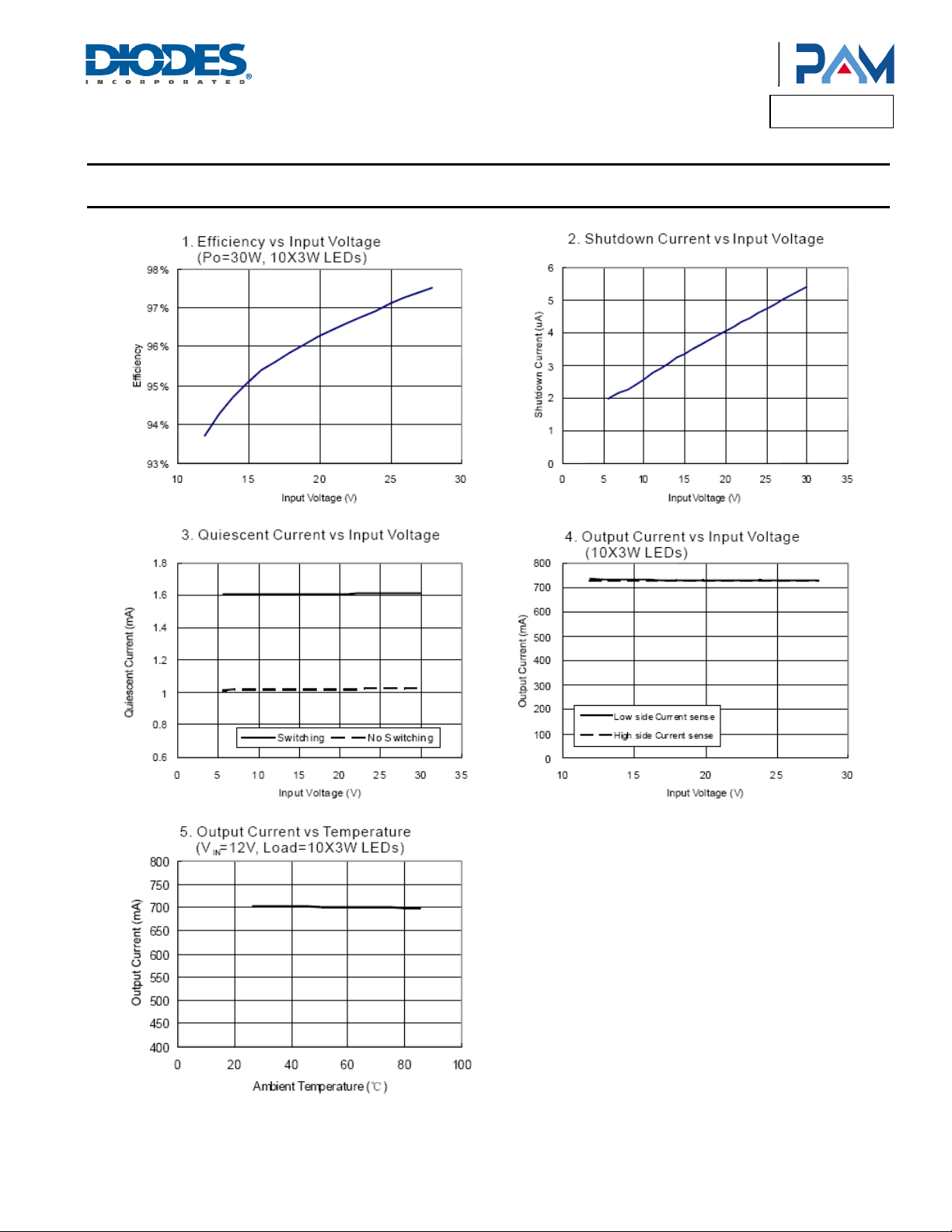

Typical Performance Characteristics

Boost Mode, @TA = +25°C, VEN = VDD = 24V, 3W LEDs, FSW = 200kHz, unless otherwise specified.)

Product Line o

PAM2842

PAM2842

Document number: DSxxxxx Rev. 1 - 2

6 of 17

www.diodes.com

© Diodes Incorporated

October 2012

Page 7

A

f

Typical Performance Characteristics (cont.) @T

Product Line o

Diodes Incorporated

= +25°C, FSW = 300kHz, unless otherwise specified.)

A

PAM2842

PAM2842

Document number: DSxxxxx Rev. 1 - 2

7 of 17

www.diodes.com

© Diodes Incorporated

October 2012

Page 8

A

f

Product Line o

Diodes Incorporated

PAM2842

Application Information

Topology Selection

When maximum power supply voltage is below than minimum load voltage, select the boost topology. When minimum power supply voltage is

high than maximum load voltage, select buck topology. When load voltage range is small and between the power supply voltage, select sepic

topology.

Table 1: Voltage Condition vs. Topology

Condition Topology

V

< V

INMAX

V

> V

INMIN

VO<VIN

OMIN

OMAX

Inductor Selection

The inductance, peak current rating, series resistance, and physical size should all be considered when selecting an inductor. These factors

affect the converter's operating mode, efficiency, maximum output load capability, transient response time, output voltage ripple, and cost.

The maximum output current, input voltage, output voltage, and switching frequency determine the inductor value. Large inductance can

minimizes the current ripple, and therefore reduces the peak current, which decreases core losses in the inductor and I2R losses in the entire

power path. However, large inductor values also require more energy storage and more turns of wire, which increases physical size and I2R

copper losses in the inductor. Low inductor values decrease the physical size, but increase the current ripple and peak current. Finding the best

inductor involves the compromises among circuit efficiency, inductor size, and cost.

When choosing an inductor, the first step is to determine the operating mode: continuous conduction mode (CCM) or discontinuous conduction

mode (DCM). When CCM mode is chosen, the ripple current and the peak current of the inductor can be minimized. If a small-size inductor is

required, DCM mode can be chosen. In DCM mode, the inductor value and size can be minimized but the inductor ripple current and peak

current are higher than those in CCM.

For the large power application, if chose DCM, the peak current will be very large, it will have great electrical stress on the components, so we

chose CCM.

When work in CCM mode, a reasonable ripple current is chosen to

ΔI

For the boost topology,

D: duty cycle, Io: output current, F: switching frequency.

From above equation we can get the inductance:

The inductor's current rating should be higher

than

For the buck topology, I

so

= 0.4IL

L

=

I

L

L−=

+

I

L

=

D

I

Δ

L

L−=

I

O

D

,

D1

−

2

(V5.2

IN

FI

O

I

O

2

= IO

L

V

O

V

IN

(

−

LFV

O

FI

VV

IN

(V5.2

V

O

=

PAM2842

Document number: DSxxxxx Rev. 1 - 2

Boost

Buck

Sepic

−

VV

=

V

O

V

O

INO

,

I

V

VV

2

)

V

OOIN

IN

VV

OIN

2

Δ

O

)

INO

)

(

V

=

L

LF

)

−

VV

INOIN

V

O

www.diodes.com

8 of 17

October 2012

© Diodes Incorporated

Page 9

A

f

Product Line o

Diodes Incorporated

PAM2842

Application Information (cont.)

Inductor Selection (cont.)

For the sepic topology, L1 = L2

I

Chose

so

D

L

Capacitor Selection

An input capacitor is required to reduce the input ripple and noise for proper operation of the PAM2842. For good input decoupling, Low ESR

(equivalent series resistance) capacitors should be used at the input. At least 10µF input capacitor is recommended for most applications. And

close the IC V

A minimum output capacitor value of 10µF is recommended under normal operating conditions, while a 22µF or higher capacitor may be

required for higher power LED current. A reasonable value of the output capacitor depends on the LED current. The total output voltage ripple

has two components: the capacitive ripple caused by the charging and discharging on the output capacitor, and the ohmic ripple due to the

capacitor's equivalent series resistance. The ESR of the output capacitor is the important parameter to determine the output voltage ripple of the

converter, so low ESR capacitors should be used at the output to reduce the output voltage ripple. The voltage rating and temperature

characteristics of the Output capacitor must also be considered. So a value of 10µF, 50V voltage rating capacitor is chosen.

Consider from discharge aspect: I x Δt = C x ΔV

In boost and sepic topology,

In buck topology,

: Output voltage allowable ripple.

V

RIPPLE

Consider from equivalent series resistance:

V

In sepic topology, there is a series capacitor Cs between L1 and L2 (see application schematic), it flows the current:

The ripple voltage is

The voltage rating must be higher than input voltage.

Because the Cs capacitor will flow the large RMS current, so this topology is suitable for small power application.

RIPPLE-ESR

O

=

=

I

L

=

V =Δ

II

=Δ

IN-PIN

CS

O1L

D1

−

=

II

O2L

V

O

+

VV

OIN

VV

OIN

+

I4.0I =Δ

2

V5.2

IN

+

VV

I

O

FV

CO.RIPPLE

V

O)RMS(CS

V

D

S

)

VV

OIN

1LL

)

OIN

C

O

−

RIPPLE

O

IN

=

)D1(

x C

FV

D

I

O

RIPPLE

OESR

(LF

(FI

O

we should add a bypass capacitor, usually use a 1µF capacitor.

=

C

O

= I

=

II

I

O

FC

PAM2842

Document number: DSxxxxx Rev. 1 - 2

9 of 17

www.diodes.com

October 2012

© Diodes Incorporated

Page 10

A

f

Product Line o

Diodes Incorporated

PAM2842

Application Information (cont.)

Diode Selection

PAM2842 is a high switching frequency converter which demands high speed rectifier. It's indispensable to use a Schottky diode rated at 3A,

40V with the PAM2842. Using a Schottky diode with a lower forward voltage drop is better to improve the power LED efficiency.

In boost topology, the voltage rating should be higher than V

I

Δ

L

in sepic topology, the voltage rating should be higher than V

The average current of the diode equals to I

II

L)MAX(D

+=

2

+=

III

)PEAK(2L)PEAK(1L)MAX(D

.

O

Work Frequency Selection

PAM2842 working frequency is decided by resistor connect to the RT pin, it can be calculated by follow equation:

From the equations, we can see when working frequency is high, the inductance can be small. It's important in some size limit application. But

we should know when the working frequency is higher, the switching loss is higher too. We must pay attention to thermal dissipation in this

application.

=

F

SW

10

12

+

)Hz(

)K12RT(x24

Methods for Setting LED Current

There are two methods for setting and adjusting the LED current:

1) R

2) PWM signal with external components

a) Use the COMP pin

b) Use the Sense pin

SENSE

only

● Method 1: LED Current Setting with Resistor R

The most basic means of setting the LED current is connecting a resistor between R

Resistor R

I

For flowing the large current, must pay attention to power dissipation on the resistor.

has two positions to select: high side current sense and low side current sense. In buck topology it just has high side current sense. In

R

SENSE

other topology we recommend use low side current sense for easier PCB layout.

SENSE

LED

.

= 0.1/ R

SENSE

● Method 2: LED Current Setting with PWM Signal Using COMP Pin

This circuit uses resistor Rsense to set the on state current and the average LED current, then proportional to the percentage of off-time when

the COMP pin is logic high. Here use a invert component 2N7002 (Q1) to isolate and invert the PWM signal (See Figure 1).

and in buck topology, the voltage rating higher than VIN, the peak current is

OUT

+V

SENSE

, the peak current is

OUT

SENSE

+ and R

-. The LED current is decided by ISET

SENSE

IN

Figure 1. PWM Dimming Use COMP Pin

Average LED current is approximately equal to:

IT

=

I

AVG

PAM2842

Document number: DSxxxxx Rev. 1 - 2

LEDOFF

+

TT

OFFON

10 of 17

www.diodes.com

October 2012

© Diodes Incorporated

Page 11

A

f

Product Line o

Diodes Incorporated

PAM2842

Also, the recommended PWM frequency is between 100Hz and 200Hz.

Application Information (cont.)

● Method 2: LED Current Setting with PWM Signal Using COMP Pin (cont.)

Frequency <100Hz can cause the LEDs to blink visibly. As the COMP pin connects to a capacitor, it needs rise time. If frequency >200Hz, the

average LED current will have a large error when duty cycle is small (<50%).

It maybe generate the audible noise in this dimming condition.

● Method 3: LED Current Setting with PWM Signal using Sense Pin

This method is turn PWM signal to DC voltage, the output current can be adjusted. Because the LED current is a adjustable DC value, it will

cause LED color drift.

Low side current sense and high side current sense circuit is different. Please see Figure 2 and 3. It use the internal reference voltage, so PWM

dimming signal voltage is not considered, just meet the request of the MOSFET driving voltage.

Figure 2. PWM Dimming Use Sense Pin in Low Side Current Sense Figure 3. PWM Dimming Use Sense Pin in High Side Current

The RC filter (R1,R2,C1,C2) value is decided by dimming frequency, the divider resistor (R3,R4) is decided by dimming range.

Because final adjusted is a DC value, this method can avoid audible noise effectively and achieve better EMI performance than the second

method.

Sense

Setting the Output Limit Voltage

The OV pin is connected to the center tap of a resistive voltage divider from the high-voltage output to ground (see application schematic).

R

UP

R

DOWN

)

OUT_LIMIT

.

IN +VO

11 of 17

www.diodes.com

= 37.2V.

October 2012

© Diodes Incorporated

1(

+=

−

The recommend procedure is to choose R3 = 360K and R4 = 12K to set V

In boost and sepic circuit, when LED open or no load, the circuit will have no feedback, if no other measure be taken the switch voltage will be

very high and damage the switch, so this OV pin must be set carefully.

In buck circuit, the switch voltage is always small than input voltage, so the OV pin setting is not important in this condition.

This OV pin is used to limit output voltage to avoid breakdown of the switch other than to regulate output voltage. The setting value must keep

the switch voltage below 40V.

In sepic circuit, one must notice that the switch voltage equals V

This OV pin has a hysteresis voltage detect function, not latch-up function, so output voltage will have a overshoot when no load or load working

voltage is high than setting limit voltage. If the component parameter not match appropriately, the overshoot voltage will be too high and can

demage the switch.

VV

OVLIMITOUT

PAM2842

Document number: DSxxxxx Rev. 1 - 2

Page 12

A

f

=

+++

+

Application Information (cont.)

Setting the Output Limit Voltage (cont.)

Several methods can decrease the overshoot voltage:

(1) Add a small capacitor (<100pF) parallel with the up divider resistor (See Figure 4).

(2) Use external zener to clamp the output peak voltage (See Figure 5).

Product Line o

Diodes Incorporated

PAM2842

Figure 4. Add Forward Capacitor Figure 5. Use External Zener

Note: The output limit voltage must be set higher than working output voltage by a proper value, or it will work abnormal in low temperature or

some other conditions.

Short LED Function

PAM2842 is a constant current driver. When one or more LED shorted, the circuit will still work, the output voltage is decided by LED numbers.

In boost topology, make sure the output voltage is higher than input voltage; otherwise the unlimited current will directly go through supply to

LED and damage the LED.

Power Dissipation

As PAM2842 integrates a power MOSFET, the power dissipation must be considered. To a MOSFET the power loss includes 5 sections, turn on

loss, turn off loss, conduction loss, drive loss and output capacitor Coss loss.

1

P

P

=

Tr: switch rise time. Tf: switch fall time. U

Above description does not consider the IC control power, so the total power will be more than calculated value.

PAM2842 has over-temperature protection. When junction temperature is over +150°C, it will shut down and auto restart when junction

temperature decrease below +120.

In high temperature circumstance application, one must pay attention to heat dissipation, or it will shut down and restart. It is recommended to

use external heat-sink and placed near to the IC surface.

: gate drive voltage. θJA is relative with IC package, heat-sink area and air flow condition etc.

DRIVE

−

PAM2842

Document number: DSxxxxx Rev. 1 - 2

=

2

1

=

2

=

)ON(RDS

P

P

DRIVE

COSS

Q

1

=

C

2

PPP

θ=Δ

T

JA

12 of 17

www.diodes.com

2

RMS

U

G

OSS

ff

P

SWITCH

RIP

DRIVE

2

V

OUT

f

f

TVI

rOUTONTURNONTURN −−

f

TVI

rOUTONTURNOFFTURN −−

)ON(DS

f

PPP

COSSDRIVE)ON(RDSTURNEONTURNSWITCH

October 2012

© Diodes Incorporated

Page 13

A

f

Product Line o

Diodes Incorporated

PAM2842

Application Information (cont.)

PCB Layout Guidelines

Careful PCB layout is important for normal operation. Use the following guidelines for good PCB layout: (BOOST)

1) Minimize the area of the high current switching loop of the rectifier diode and output capacitor to avoid excessive switching noise.

2) Connect high-cur rent input and output components with short and wide connections. The high-current input loop goes from the positive

terminal of the input capacitor to the inductor and the SW pin. The high-current output loop is from the positive terminal of the input capacitor

through the inductor, rectifier diode, and positive terminal of the output capacitors, reconnecting between the output capacitor and input

capacitor ground terminals. Avoid using vias in the highcurrent paths. If vias are unavoidable, use multiple vias in parallel to reduce resistance

and inductance.

3) Create a ground island (PGND) consisting of the input and output capacitor ground and PGND pin. Connect all these together with short, wide

traces or a small ground plane. Maximizing the width of the power ground traces improves efficiency and reduces output-voltage ripple and

noise spikes. Create an analog ground island (AGND) consisting of the output voltage detection-divider ground connection, the Sense-pin

connection, V

connections between these separate ground planes.

4) Place the output voltage setting-divider resistors as close to the OV pin as possible. The divider's center trace should be kept short. Avoid

running the sensing traces near SW Pin.

5) Place the VIN pin bypass capacitor as close to the device as possible. The ground connection of the VIN bypass capacitor should be

connected directly to GND pins with a wide trace.

6) Minimize the size of the SW node while keeping it wide and short. Keep the SW node away from the feedback node. If possible, avoid running

the SW node from one side of the PCB to the other.

7) For the good thermal dissipation, PAM2842 has a heat dissipate pad in the bottom side, it should be soldered to PCB surface. As the copper

area cannot be large in the component side, we can use multiple vias connecting to other side of the PCB.

8) Refer to the example of a PAM2842 Evaluation board layout below.

-5V and VCC-driver capacitor connections. Connect the device's exposed backside pad to PGND. Make sure no other

CC

TSSOP-20 Boost QFN6x6-40 Boost

PAM2842

Document number: DSxxxxx Rev. 1 - 2

PCB Layout Example

13 of 17

www.diodes.com

October 2012

© Diodes Incorporated

Page 14

A

f

Ordering Information

Product Line o

Diodes Incorporated

PAM2842

Part Number Package Type Standard Package

PAM2842RGR TSSOP-20 1000 Units/Tape&Reel

PAM2842TJR QFN6x6-40 1000 Units/Tape&Reel

Marking Information

PAM2842

Document number: DSxxxxx Rev. 1 - 2

14 of 17

www.diodes.com

October 2012

© Diodes Incorporated

Page 15

A

f

Package Outline Dimensions (All dimensions in mm.)

TSSOP-20

Product Line o

Diodes Incorporated

PAM2842

PAM2842

Document number: DSxxxxx Rev. 1 - 2

15 of 17

www.diodes.com

October 2012

© Diodes Incorporated

Page 16

A

f

Package Outline Dimensions (cont.) (All dimensions in mm.)

QFN6x6-40

Product Line o

Diodes Incorporated

PAM2842

PAM2842

Document number: DSxxxxx Rev. 1 - 2

16 of 17

www.diodes.com

© Diodes Incorporated

October 2012

Page 17

A

f

Product Line o

Diodes Incorporated

PAM2842

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2012, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

PAM2842

Document number: DSxxxxx Rev. 1 - 2

17 of 17

www.diodes.com

October 2012

© Diodes Incorporated

Loading...

Loading...