Page 1

AP65550

Document number: DS36336 Rev. 2 - 2

1 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

Description

The AP65550 is an adaptive constant on-time mode synchronous

buck converter providing high efficiency, excellent transient response

and high DC output accuracy for low-voltage regulation in digital TV

and monitor.

The constant-on-time control scheme handles wide input/output

voltage ratios and provides low external component count. The

internal proprietary circuit enables the device to adopt both low

equivalent series resistance (ESR) output capacitors, such as SPCAP or POSCAP and ultra-low ESR ceramic capacitors.

The adaptive on-time control supports seamless transition between

continuous conduction mode (CCM) at higher load conditions and

discontinuous conduction mode (DCM) at lighter load conditions.

DCM allows AP65550 maintain high efficiency at light load conditions.

The AP65550 also features programmable soft-start, UVLO, OTP and

OCP to protect the circuit.

This IC is available in SO-8EP package.

Features

Fixed Frequency Emulated Constant On-time Control

Good Stability Independent of the Output Capacitor ESR

Fast Load Transient Response

Synchronous Rectification: 65mΩ Internal High-side Switch and

36mΩ Internal Low-side Switch

Wide Input Voltage Range: 4.5V to 18V

Output Voltage Range: 0.76V to 6V

5A Continuous Output Current

650kHz Switching Frequency

Built-in Over Current Limit

Built-in Thermal Shutdown Protection

Programmable Soft-start

Pre-biased Start-up

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

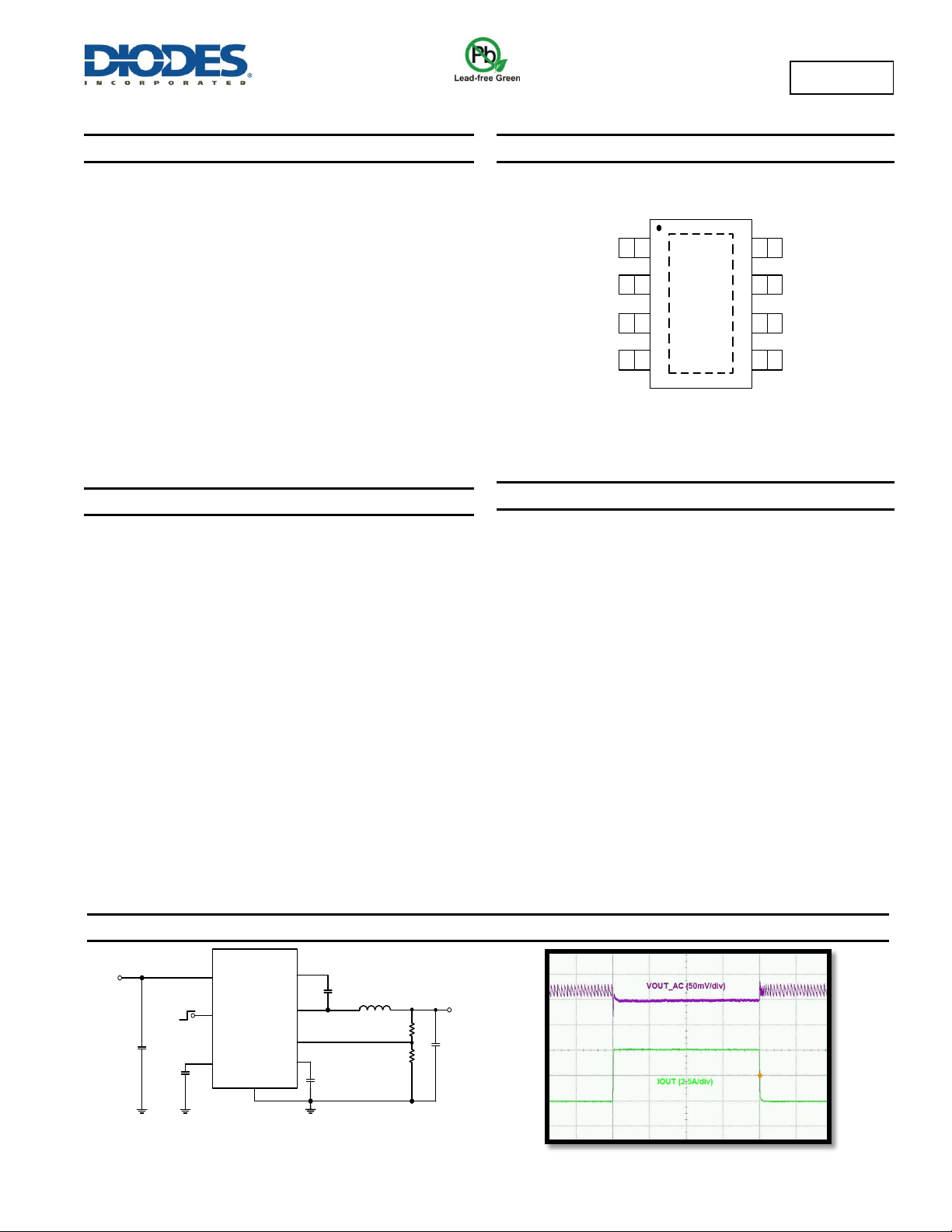

Pin Assignments

SW

VREG5

SS

EN

BS

GND

VIN

( Top View )

1

2

3

4

8

7

6

5

FB

SO-8EP

Applications

Gaming Consoles

Flat Screen TV sets and Monitors

Set Top Boxes

Distributed power systems

Home Audio

Consumer electronics

Network Systems

FPGA, DSP and ASIC Supplies

Green Electronics

AP65550

L1

1.5μH

R1

8.25kΩ

R2

22.1kΩ

C5

0.1µF

C2

44μF

C1

20μF

C4

8.2nF

ON

OFF

8

IN

4

SS

1

EN

3

VREG5

6

SW

7

BST

2

FB

C3

1µF

5

GND

INPUT

OUTPUT

V

OUT

1.05V

VIN

12V

Figure 1. Typical Application Circuit

5A, 18V, 650kHz ADAPTIVE COT STEP-DOWN CONVERTER

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

Typical Applications Circuit

Page 2

AP65550

Document number: DS36336 Rev. 2 - 2

2 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

Pin

Name

Pin Number

Function

SO-8EP

EN

1

Enable input. EN is a digital input that turns the regulator on or off. Drive EN high to turn on the

regulator, drive it low to turn off. Pull up with 100kΩ resistor for automatic startup.

FB

2

Feedback Input. FB senses the output voltage and regulates it. Drive FB with a resistive voltage

divider connected to it from the output voltage.

VREG5

3

Internal power supply output pin to connect an additional capacitor. Connect a 1μF (typical) capacitor

as close as possible to the VREG5 and GND. This pin is not active when EN is low.

SS

4

Soft-start control input pin. SS controls the soft start period. Connect a capacitor from SS to GND to

set the soft-start period.

GND

5

Ground pin is the main power ground for the switching circuit.

SW

6

Power Switching Output. SW is the switching node that supplies power to the output. Connect the

output LC filter from SW to the output load. Note that a capacitor is required from SW to BS to power

the high-side switch.

BS

7

Bootstrap pin. A bootstrap capacitor is connected between the BS pin and SW pin. The voltage across

the bootstrap capacitor drives the internal high-side NMOS switch. A 0.1μF (typical) capacitor is

required for proper operation

VIN

8

Supply input pin. A capacitor should be connected between the VIN pin and GND pin to keep the DC

input voltage constant.

EP

—

Connect the exposed thermal pad to GND on the PCB

Pin Descriptions

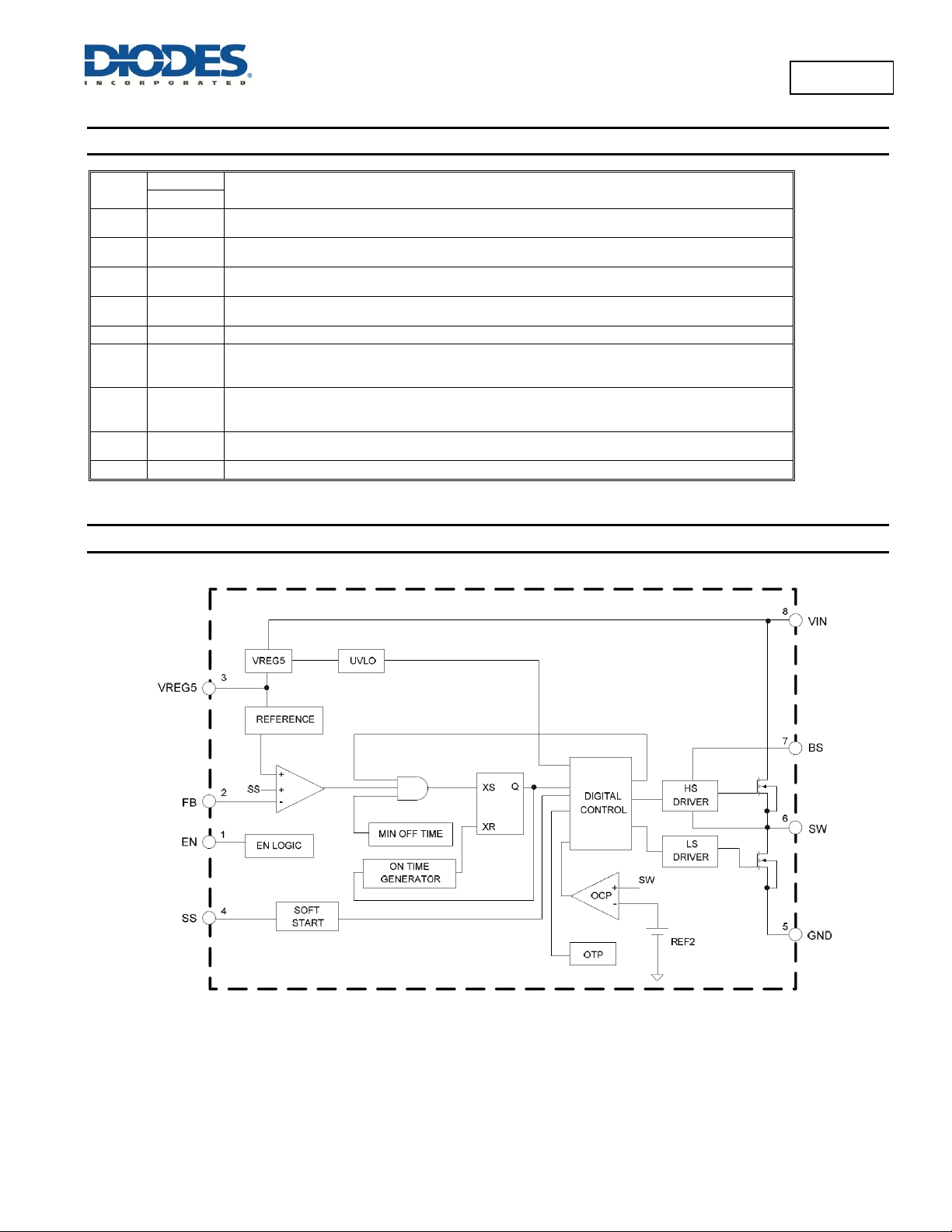

Functional Block Diagram

Figure 2. Functional Block Diagram

Page 3

AP65550

Document number: DS36336 Rev. 2 - 2

3 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

Symbol

Parameter

Rating

Unit

VIN

Supply Voltage

-0.3 to 20

V

V

REG5

VREG5 Pin Voltage

-0.3V to +6.0

V

VSW

Switch Node Voltage

-1.0 to V

IN

+0.3

V

VBS

Bootstrap Voltage

-0.3 to VSW +6.0

V

VFB

Feedback Voltage

-0.3V to +6.0

V

VEN

Enable/UVLO Voltage

-0.3V to +6.0

V

VSS

SoftStart PIN

-0.3V to +6.0

V

V

GND

GND Pin Voltage

-0.3 to 0.3

V

TST

Storage Temperature

-65 to +150

°C

TJ

Junction Temperature

+160

°C

TL

Lead Temperature

+260

°C

ESD Susceptibility (Note 5)

HBM

Human Body Model

2

kV

MM

Machine Model

200

V

Symbol

Parameter

Rating

Unit

θ

JA

Junction to Ambient

SO-8EP

70

°C/W

θ

JC

Junction to Case

SO-8EP

30

°C/W

Symbol

Parameter

Min

Max

Unit

VIN

Supply Voltage

4.5

18.0

V

TJ

Operating Junction Temperature Range

-40

+125

°C

TA

Operating Ambient Temperature Range

-40

+85

°C

Absolute Maximum Ratings (Note 4) (@T

= +25°C, unless otherwise specified.)

A

Notes: 4. Stresses greater than the 'Absolute Maximum Ratings' specified above may cause permanent damage to the device. These are stress ratings only;

functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device reliability may

be affected by exposure to absolute maximum rating conditions for extended periods of time.

5. Semiconductor devices are ESD sensitive and may be damaged by exposure to ESD events. Suitable ESD precautions should be taken when

handling and transporting these devices.

Thermal Resistance (Note 6)

Note: 6. Test condition: SO-8: Device mounted on 1"x1" FR-4 substrate PCB, 2oz copper, with minimum recommended pad layout.

Recommended Operating Conditions (Note 7) (@T

Note: 7. The device function is not guaranteed outside of the recommended operating conditions.

= +25°C, unless otherwise specified.)

A

Page 4

AP65550

Document number: DS36336 Rev. 2 - 2

4 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

Parameter

Symbol

Conditions

Min

Typ

Max

Unit

SUPPLY VOLTAGE (VIN PIN)

Input Voltage

V

IN

—

4.5 — 18

V

Quiescent Current

IQ

VFB=0.85V

—

0.9 — mA

Shutdown Supply Current

I

SHDN

VEN=0V

—

3.6

10

μA

UNDER VOLTAGE LOCKOUT

UVLO Threshold

V

UVLO

VIN Rising Test VREG5

Voltage

3.45

3.75

4.05

V

UVLO Hysteresis

V

HYS

VIN Falling Test VREG5

Voltage

0.19

0.32

0.45

V

ENABLE (EN PIN)

EN High-level Input Voltage

V

ENH

—

1.9 — —

V

EN Low-level Input Voltage

V

ENL

— — —

0.6

V

VOLTAGE REFERENCE (FB PIN)

Feedback Voltage

VFB

V

OUT

=1.05V

0.753

0.765

0.777

V

Feedback Bias Current

IFB

VFB=0.8V

-0.1

0

0.1

μA

VREG5 OUTPUT

VREG5 Output Voltage

V

VREG5

6.0V<VIN<18V 0<I

VREG5

<5mA

4.7

5.1

5.5

V

Source Current Capability

—

VIN=6V, V

VREG5

=4V

—

110 — mA

Load Regulation

—

0<I

VREG5

<5mA

— — 60

mV

Line Regulation

—

6.0V<VIN<18V I

VREG5

=5mA

—

—

20

mV

MOSFET

High-side Switch On-resistance

R

DSONH

—

—

0.065 — Ω

Low-side Switch On-resistance

R

DSONL

—

—

0.036 — Ω

CURRENT LIMIT

High Level Current Limit

I

LIM-H

L=1.5μH

5.6

6.4

7.9

A

ON-TIME TIMER

On Time

tON

VIN=12V, VOUT=1.05V

—

150 — ns

Minimum Off Time

t

OFF-MIN

VFB=0.7V

—

260

310

ns

THERMAL SHUTDOWN

Thermal Shutdown

T

OTSD

— — +160 — °C

Thermal Shutdown Hysteresis

T

HYS

— — +30 — °C

SOFT START (SS PIN)

Soft-start Source Current

I

SS-SOURCE

VSS=1V

4.2

6.0

7.8

μA

Soft-start Discharge Current

I

SS-DISCHARGE

VSS=0.5V

0.1

0.2 — mA

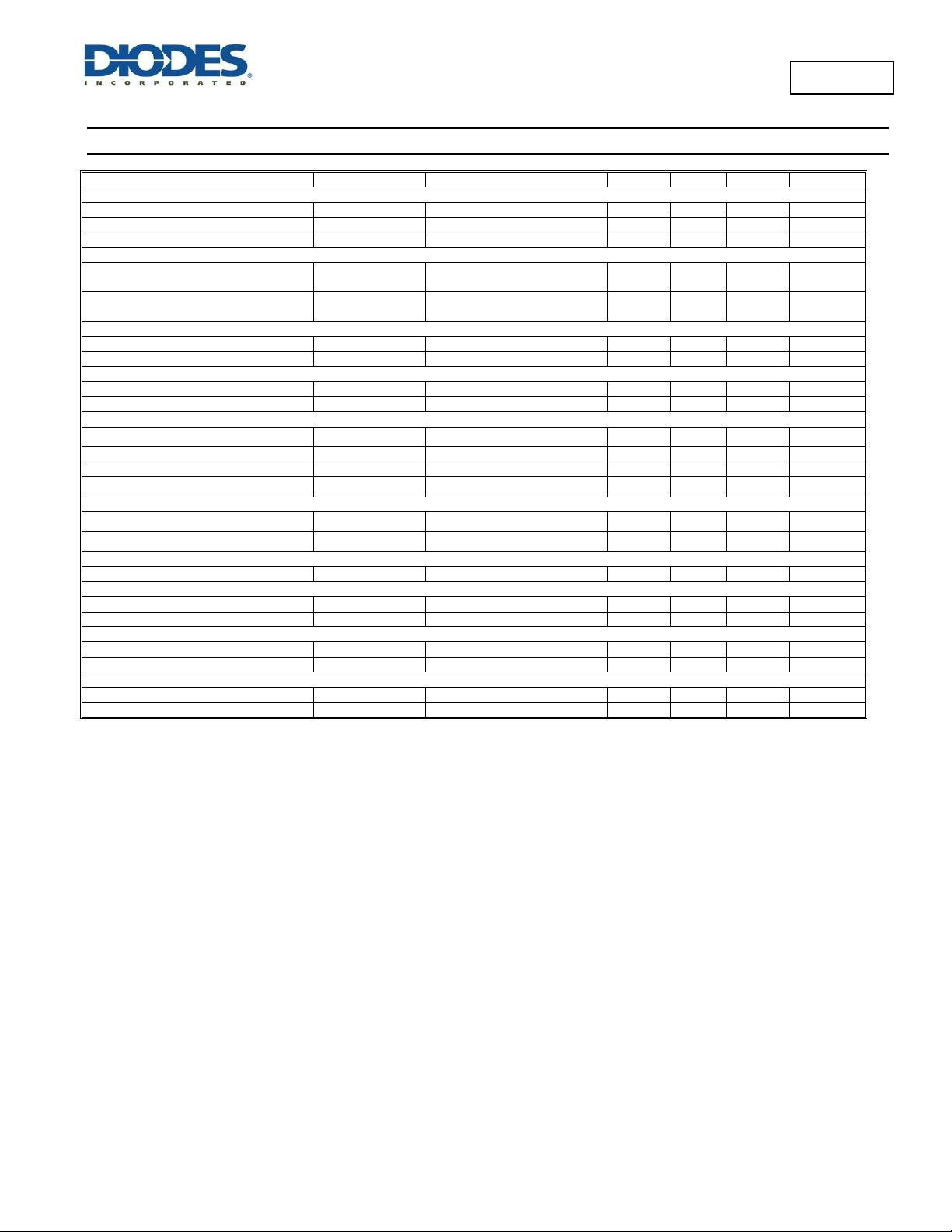

Electrical Characteristics (@T

= +25°C, VIN = 12V, unless otherwise specified.)

A

Page 5

AP65550

Document number: DS36336 Rev. 2 - 2

5 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

85˚C

-40˚C

25˚C

85˚C

25˚C

-40˚C

85˚C

25˚C

-40˚C

IO=5A

IO=2A

IO=3A

IO=4A

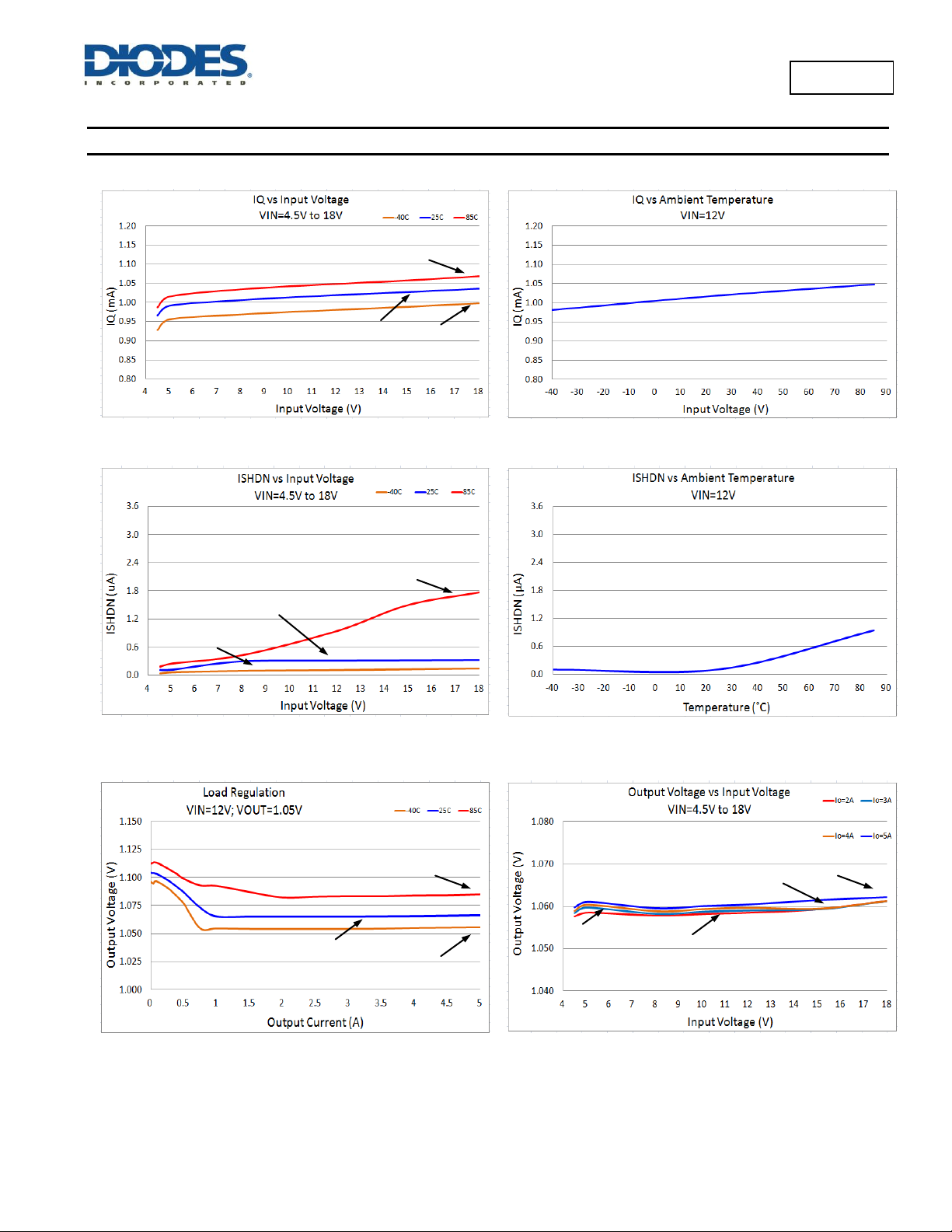

Typical Performance Characteristics (@T

= +25°C, VIN = 12V, V

A

= 3.3V, unless otherwise specified.)

OUT

Page 6

AP65550

Document number: DS36336 Rev. 2 - 2

6 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

VO=3.3V

VO=5V

VO=3.3V

VO=2.5V

VO=1.05V

VO=1.2V

VO=1.5V

VO=1.8V

VO=2.5V

VO=1.8V

VO=1.05V

IO=10mA

IO=1A

Typical Performance Characteristics (cont.) (@T

= +25°C, VIN = 12V, V

A

= 3.3V, unless otherwise specified.)

OUT

Page 7

AP65550

Document number: DS36336 Rev. 2 - 2

7 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

Steady State Test 5A

Time-1µs/div

Startup Through VIN No Load

Time-500µs/div

Startup Through VIN 5A Load

Time-500µs/div

Steady State Test 5A

Time-50ns/div

Shutdown Through VIN No load

Time-50ms/div

Shutdown Through VIN 5A Load

Time-50ms/div

Startup Through VEN No Load

Time-1ms/div

Startup Through VEN 5A Load

Time-2ms/div

Short Circuit Test

Time-100µs/div

Shutdown Through VEN No load

Time-20ms/div

Shutdown Through VEN 5A Load

Time-20ms/div

Short Circuit Recovery

Time-1ms/div

VIN (12V/DIV)

VOUT (1V/DIV)

IOUT (1A/DIV)

SW (10V/DIV)

VIN (12V/DIV)

VOUT (1V/DIV)

IOUT (5A/DIV)

SW (10V/DIV)

VIN (12V/DIV)

VOUT (1V/DIV)

IOUT (5A/DIV)

SW (10V/DIV)

VIN (12V/DIV)

VOUT (1V/DIV)

IOUT (1A/DIV)

SW (10V/DIV)

VEN (3V/DIV)

VOUT (1V/DIV)

IOUT (1A/DIV)

SW (10V/DIV)

VEN (3V/DIV)

VOUT (1V/DIV)

IOUT (5A/DIV)

SW (10V/DIV)

VEN (3V/DIV)

VOUT (1V/DIV)

IOUT (5A/DIV)

SW (10V/DIV)

VEN (3V/DIV)

VOUT (1V/DIV)

IOUT (1A/DIV)

SW (10V/DIV)

VOUT (500mV/DIV)

IOUT (2A/DIV)

VOUT (500mV/DIV)

IOUT (2A/DIV)

VIN_AC (1V/DIV)

VOUT_AC (50mV/DIV)

ISW (2A/DIV)

SW (10V/DIV)

VIN_AC (1V/DIV)

VOUT_AC (50mV/DIV)

ISW (2A/DIV)

SW (10V/DIV)

Typical Performance Characteristics (cont.)

(@TA = +25°C, VIN = 12V, V

= 1.05V, L = 1.5µH, C1 = 20µF, C2 = 44µF, unless otherwise specified.)

OUT

Page 8

AP65550

Document number: DS36336 Rev. 2 - 2

8 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

DCM Voltage Ripple 30mA

Time-1µs/div

Startup with VREG5 No Load

Time-1ms/div

EN (3V/DIV)

VREG5 (5V/DIV)

VOUT (500mV/DIV)

VOUT_AC (50mV/DIV)

SW (5V/DIV)

Typical Performance Characteristics (cont.)

(@TA = +25°C, VIN = 12V, V

= 1.05V, L = 1.5µH, C1 = 20µF, C2 = 44µF, unless otherwise specified.)

OUT

Page 9

AP65550

Document number: DS36336 Rev. 2 - 2

9 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

EN

FB

VREG5

SS

EP

GND

SW

VIN

BS

8.25KΩ

22.1KΩ

1.5µH

EN

VOUT

VIN

VOUT

AP65550

1

2

3

4 5

6

7

8

8.2nF

1µF

10µF

22µF

0.1µF

R3

R1

C4

C6

L1

C1

10µF

C2 C8

22µF

C5

C9

fV

V

T

IN

OUT

ON

ON

OUTIN

LOAD

T

2L

VV

I

Application Information

Figure 3. Typical Application of AP65550

PWM Operation and Adaptive On-time Control

The AP65550 is synchronous step-down converters with internal power MOSFETs. Adaptive constant on time (COT) control is employed to

provide fast transient response and easy loop stabilization. At the beginning of each cycle, the high-side MOSFET is turned on. This MOSFET is

turned off after internal one shot timer expires. This one shot is set by the converter input voltage(VIN), and the output voltage(V

pseudo-fixed frequency over the input voltage range, hence it is called adaptive on-time control. The output voltage variation is sensed by FB

voltage. The one-shot timer is reset and the high-side MOSFET is turned on again when FB voltage falls below the 0.76V.

AP65550 uses an adaptive on-time control scheme and does not have a dedicated in board oscillator. It runs with a pseudo-constant frequency of

650kHz by using the input voltage and output voltage to set the on-time one-shot timer. The on-time is inversely proportional to the input voltage

and proportional to the output voltage. It can be calculated using the following equation:

) to maintain a

OUT

V

is the output voltage

OUT

VIN is the input voltage

f is the switching frequency

After an ON-time period, the AP65550 goes into the OFF-time period. The OFF-time period length depends on VFB in most case. It will end when

the FB voltage decreases and below 0.76V then the ON-time periods is triggered. If the OFF-time period is less than the minimum OFF time, the

minimum OFF time will be applied, which is about 260ns typical.

Power Save Mode

The AP65550 is designed with Power Save Mode (PSM) at light load conditions for high efficiency. The AP65550 automatically reduces the

switching frequency and change the Ton time to Tmin-on time during a light load condition to get high efficiency and low output ripple. As the

output current decreases form heavy load condition, the inductor current decreases as well, eventually comes close to zero current, which is the

boundary between CCM and DCM. The low side MOSFET is turned off when the inductor current reaches zero level. The load is provided only by

output capacitor, when FB voltage is lower than 0.76V, the next cycle ON cycle is beginning. The on-time is the minimum on time that benefit for

decreasing V

OUT

keep output voltage. The transition point to light load operation can be calculated using the following equation:

TON is on-time

Enable

Above the ‘EN high-level input voltage’, the internal regulator is turned on and the quiescent current can be measured above this threshold. The

enable (EN) input allows the user to control turning on or off the regulator. To enable the AP65550, EN must be pulled above the ‘EN high-level

input voltage’ and to disable the AP65550, EN must be pulled below ‘EN low-level input voltage’.

ripple at light load condition. When the output current increases from light to heavy load, the switching frequency increases to

Page 10

AP65550

Document number: DS36336 Rev. 2 - 2

10 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

SS

FBSS

SS

I

VCt

OC

COMPARATOR

-266mV

Q1

Q2

S

Q

R

1

0.765

V

RR

OUT

21

Figure 5. Feedback Divider Network

Output Voltage (V)

R1 (kΩ)

R2 (kΩ)

1

6.81

22.1

1.05

8.25

22.1

1.2

12.7

22.1

1.5

21.5

22.1

1.8

30.1

22.1

2.5

49.9

22.1

3.3

73.2

22.1 5 124

22.1

Table 1. Resistor Selection for Common Output

Application Information (cont.)

Soft-start

The soft-start time of the AP65550 is programmable by selecting different CSS value. When the EN pin becomes high, the C

current source, generating a ramp signal fed into non-inverting input of the error comparator. Reference voltage V

voltage SS whichever is smaller dominates the behavior of the non-inverting inputs of the error amplifier. Accordingly, the output voltage will follow

the SS signal and ramp up smoothly to its target level. The capacitor value required for a given soft-start ramp time can be expressed as:

Where CSS is the required capacitor between SS pin and GND, tSS is the desired soft-start time and VFB is the feedback voltage.

or the internal soft-start

REF

Over Current Protection (OCP)

Figure 4 shows the over current protection (OCP) scheme of AP65550. In each switching cycle, the inductor current is sensed by monitoring the

low-side MOSFET in the OFF period. When the voltage between GND pin and SW pin is smaller than the over current trip level, the OCP will be

triggered and the controller keeps the OFF state. A new switching cycle will begging when the measured voltage is larger than limit voltage. The

internal counter is incremented when OCP is triggered. After 16 sequential cycles, the internal OCL (Over Current Logic) threshold is set to a

lower level, reducing the available output current. When a switching cycle occurs where the switch current is below the lower OCL threshold, the

counter is reset and OCL limit is returned to higher value.

Because the R

dependency of R

of MOSFET increases with temperature, V

DS(ON)

.

DS(ON)

has xppm/oC temperature coefficient to compensate this temperature

Limit

is charged by a 6μA

SS

Under Voltage Lockout

The AP65550 provides an under voltage lockout circuit to prevent it from undefined status when startup. The UVLO circuit shuts down the device

when VIN drops below 3.45V. The UVLO circuit has 320mV hysteresis, which means the device starts up again when V

latch)

Thermal shutdown

If the junction temperature of the device reaches the thermal shutdown limit of 160°C, the AP65550 shuts itself off, and both HMOS and LMOS will

be turned off. The output is discharge with the internal transistor. When the junction cools to the required level (130°C nominal), the device initiates

soft-start as during a normal power -up cycle.

Setting the Output Voltage

The output voltage can be adjusted from 1.000 to 5V using an external resistor divider. Table 1 shows a list of resistor selection for common

output voltages. Resistor R1 is selected based on a design tradeoff between efficiency and output voltage accuracy. For high values of R1 there

is less current consumption in the feedback network. However the trade off is output voltage accuracy due to the bias current in the error

amplifier. R1 can be determined by the following equation:

Figure 4. Over Current Protection Scheme

rise to 3.75V. (non-

REG

Page 11

AP65550

Document number: DS36336 Rev. 2 - 2

11 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

SWLIN

OUTINOUT

fΔIV

)V(VV

L

L

ΔI

SW

f

2

ΔI

II

L

LOADL(MAX)

Output Voltage (V)

C10(pF)

L1(µH)

C5+C9(µF)

1

—

1.0-1.5

22-68

1.05

—

1.0-1.5

22-68

1.2

—

1.0-1.5

22-68

1.5

—

1.5

22-68

1.8

5-22

1.5

22-68

2.5

5-22

2.2

22-68

3.3

5-22

2.2

22-68

5

5-22

3.3

22-68

Application Information (cont.)

Inductor

Calculating the inductor value is a critical factor in designing a buck converter. For most designs, the following equation can be used to calculate

the inductor value;

Where

And

Choose the inductor ripple current to be 30% of the maximum load current. The maximum inductor peak current is calculated from:

Peak current determines the required saturation current rating, which influences the size of the inductor. Saturating the inductor decreases the

converter efficiency while increasing the temperatures of the inductor and the internal MOSFETs. Hence choosing an inductor with appropriate

saturation current rating is important.

A 1µH to 3.3µH inductor with a DC current rating of at least 25% percent higher than the maximum load current is recommended for most

applications. For highest efficiency, the inductor’s DC resistance should be less than 100mΩ. Use a larger inductance for improved efficiency

under light load conditions.

The phase boost can be achieved by adding a additional feed forward capacitor (C4) in parallel with R1.

is the inductor ripple current.

is the buck converter switching frequency.

Input Capacitor

The input capacitor reduces the surge current drawn from the input supply and the switching noise from the device. The input capacitor has to

sustain the ripple current produced during the on time on the upper MOSFET. It must hence have a low ESR to minimize the losses.

The RMS current rating of the input capacitor is a critical parameter that must be higher than the RMS input current. As a rule of thumb, select an

input capacitor which has RMs rating that is greater than half of the maximum load current.

Due to large dI/dt through the input capacitors, electrolytic or ceramics should be used. If a tantalum must be used, it must be surge protected.

Otherwise, capacitor failure could occur. For most applications, greater than 10µF ceramic capacitor is sufficient.

Output Capacitor

The output capacitor keeps the output voltage ripple small, ensures feedback loop stability and reduces the overshoot of the output voltage. The

output capacitor is a basic component for the fast response of the power supply. In fact, during load transient, for the first few microseconds it

supplies the current to the load. The converter recognizes the load transient and sets the duty cycle to maximum, but the current slope is limited

by the inductor value.

Table 2. Recommended Component Selection

Page 12

AP65550

Document number: DS36336 Rev. 2 - 2

12 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

ESR*ΔIVout

inductorcapacitor

2

out

2

out

2

inductor

out

o

V)V V(Δ

)

2

ΔI

L(I

C

Application Information (cont.)

Output Capacitor (cont.)

Maximum capacitance required can be calculated from the following equation:

ESR of the output capacitor dominates the output voltage ripple. The amount of ripple can be calculated from the equation below:

An output capacitor with ample capacitance and low ESR is the best option. For most applications, a 22µF to 68µF ceramic capacitor will be

sufficient.

WhereΔVis the maximum output voltage overshoot.

Bootstrap Capacitor

To ensure the proper operation, a ceramic capacitor must be connected between the VBST and SW pin. A 0.1µF ceramic capacitor is sufficient.

VREG5 Capacitor

To ensure the proper operation, a ceramic capacitor must be connected between the VREG5 and GND pin. A 1µF ceramic capacitor is sufficient.

PC Board Layout

1. The AP65550 works at 5A load current, heat dissipation is a major concern in layout the PCB. A 2oz Copper in both top and bottom

layer is recommended.

2. Provide sufficient vias in the thermal exposed pad for heat dissipate to the bottom layer.

3. Provide sufficient vias in the Output capacitor GND side to dissipate heat to the bottom layer.

4. Make the bottom layer under the device as GND layer for heat dissipation. The GND layer should be as large as possible to provide

better thermal effect.

5. Make the Vin capacitors as close to the device as possible.

6. Make the VREG5 capacitor as close to the device as possible.

7. The thermal pad of the device should be soldered directly to the PCB exposed copper plane to work as a heatsick. The thermal vias in

the exposed copper plane increase the heat transfer to the bottom layer.

Figure 6. PC Board Layout

Page 13

AP65550

Document number: DS36336 Rev. 2 - 2

13 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

AP65550 XX - 13

Packing

Package

SP : SO-8EP

13 : Tape & Reel

Part Number

Package Code

Part Marking

Identification Code

Tape and Reel

Quantity

Part Number Suffix

AP65550SP-13

SP

SO-8EP

—

2500

-13

( Top View )

AP65550

YY WW X

Logo

Part No

5

8

41

E

WW : Week : 01~52; 52

YY : Year : 08, 09,10~

G : Green

represents 52 and 53 week

E : SO-8EP Blank SO-8

X

X : Internal Code

SO-8EP (SOP-8L-EP)

Dim

Min

Max

Typ A 1.40

1.50

1.45

A1

0.00

0.13 - b

0.30

0.50

0.40

C

0.15

0.25

0.20 D 4.85

4.95

4.90

E

3.80

3.90

3.85

E0

3.85

3.95

3.90

E1

5.90

6.10

6.00 e - - 1.27

F

2.75

3.35

3.05

H

2.11

2.71

2.41 L 0.62

0.82

0.72 N - - 0.35 Q 0.60

0.70

0.65

All Dimensions in mm

Gauge Plane

Seating Plane

E1

E

N

e

b

A

45°

E0

H

F

Exposed Pad

Bottom View

L

Q

C

7°

4° ± 3°

9° (All sides)

A1

D

1 4

8 5

Ordering Information

Note: 8. For packaging details, go to our website at http://www.diodes.com/products/packages.html

Marking Information

(1) SO-8EP

Package Outline Dimensions (All dimensions in mm.)

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

(1) SO-8EP

Page 14

AP65550

Document number: DS36336 Rev. 2 - 2

14 of 14

www.diodes.com

April 2014

© Diodes Incorporated

AP65550

Dimensions

Value (in mm)

C

1.270

X

0.802

X1

3.502

X2

4.612

Y

1.505

Y1

2.613

Y2

6.500

C

Y1

X1

X

Y

Y2

X2

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

(1) SO-8EP

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2014, Diodes Incorporated

www.diodes.com

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

IMPORTANT NOTICE

LIFE SUPPORT

Loading...

Loading...