Page 1

AP5002

PWM CONTROL 2A STEP-DOWN CONVERTER

Features

• Input voltage: 3.6V to 20V

• Output voltage: 0.8V to V

• Duty ratio: up to 100% PWM control

• Oscillation frequency: 500KHz typical

• Soft-start Current Limit, Enable function

• Thermal Shutdown function

• Built-in internal SW P-channel MOS

• Low ESR output capacitor (MLCC, multi-layer ceramic

capacitor) support

• Efficiency 90%

• SOP-8L: Available in “Green” Molding Compound

(No Br, Sb)

• Lead Free Finish / RoHS Compliant (Note 1)

CC

Applications

• PC Motherboard

• LCD Monitor

• Graphic Card

• DVD-Video Player

• Telecom Equipment

• ADSL Modem

• Printer and other Peripheral Equipment

• Microprocessor core supply

• Networking power supply

General Description

AP5002 consists of step-down switching regulator with

PWM control. These devices include a reference voltage source,

oscillation circuit, error amplifier, internal PMOS.

AP5002 provides low-ripple power, high efficiency, and excellent

transient characteristics. The PWM control circuit is able to vary

the duty ratio linearly up to 100%. This converter also contains

an error amplifier circuit as well as a soft-start circuit that prevents

overshoot at startup. An enable function, an over current protect

function and a short circuit protect function are built inside, and

when OCP or SCP happens, the operation frequency will be

reduced from 500KHz to 50KHz. Also, an internal compensation

block is built in to minimum external component count.

With the addition of an internal P-channel Power MOS, a coil,

capacitors, and a diode connected externally, these ICs can

function as step-down switching regulators. They serve as ideal

power supply units for portable devices when coupled with the

SOP–8L mini-package, providing such outstanding features as

low current consumption. Since this converter can accommodate

an input voltage up to 22V, it is also suitable for the operation via

an AC adapter.

Ordering Information

AP5002 S G - 13

Package

S : SOP-8L

Device

AP5002SG-13 S SOP-8L 2500/Tape & Reel -13

Notes: 1. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied. Please visit our website at

http://www.diodes.com/products/lead_free.html

2. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

http://www.diodes.com/datasheets/ap02001.pdf

AP5002 Rev. 8 1 of 10 FEBRUARY 2009

Package

Code

Packaging

(Note 2)

.

.

www.diodes.com © Diodes Incorporated

Green

G : Green

Packing

13 : Tape & Reel

13” Tape and Reel

Quantity Part Number Suffix

Page 2

(

AP5002

PWM CONTROL 2A STEP-DOWN CONVERTER

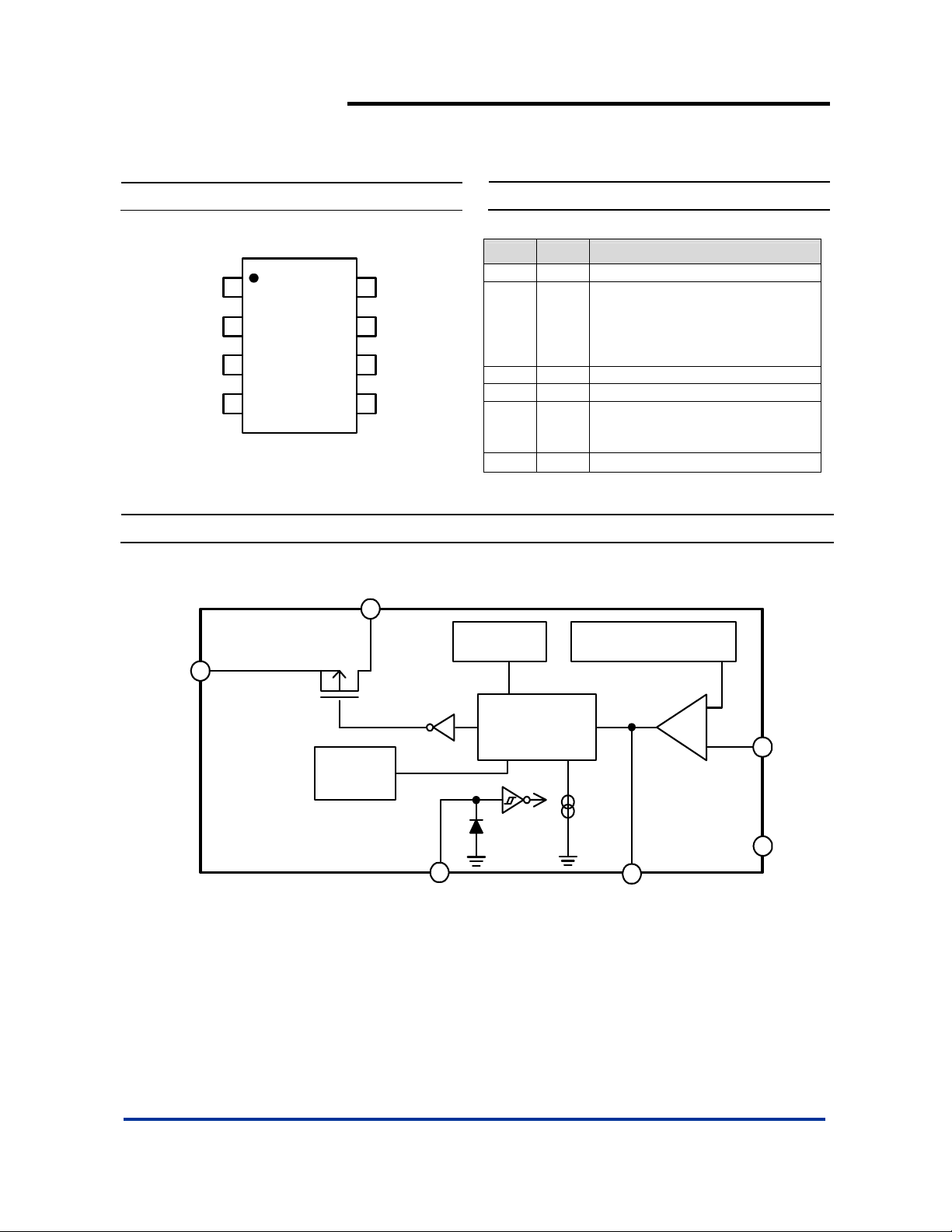

Pin Assignments

( Top View )

1

FB

2

EN

Comp

CC

V

AP5002

3

4

SOP-8L

Block Diagram

Vcc

8

7

6

5

Vss

Vss

Output

Output

Output

Pin Descriptions

Name Pin Description

FB 1 Feedback pin

Power-off pin

H: Normal operation

EN 2

Comp 3 Compensation pin

VCC 4 IC power supply pin

Output

VSS

Oscillation

Circuit

(Step-down operation)

L: Step-down operation stopped

All circuits deactivated)

Switch Pin. Connect external

5、6

inductor/diode here. Minimize trace

area at this pin to reduce EMI.

7、8

GND Pin

Reference Voltage Source

+

FB

-

Vss

Thermal

Shutdown

EN

PWM-Switched

Control Circuit

V

EN

100uA

Comp

AP5002 Rev. 8 2 of 10 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 3

AP5002

PWM CONTROL 2A STEP-DOWN CONVERTER

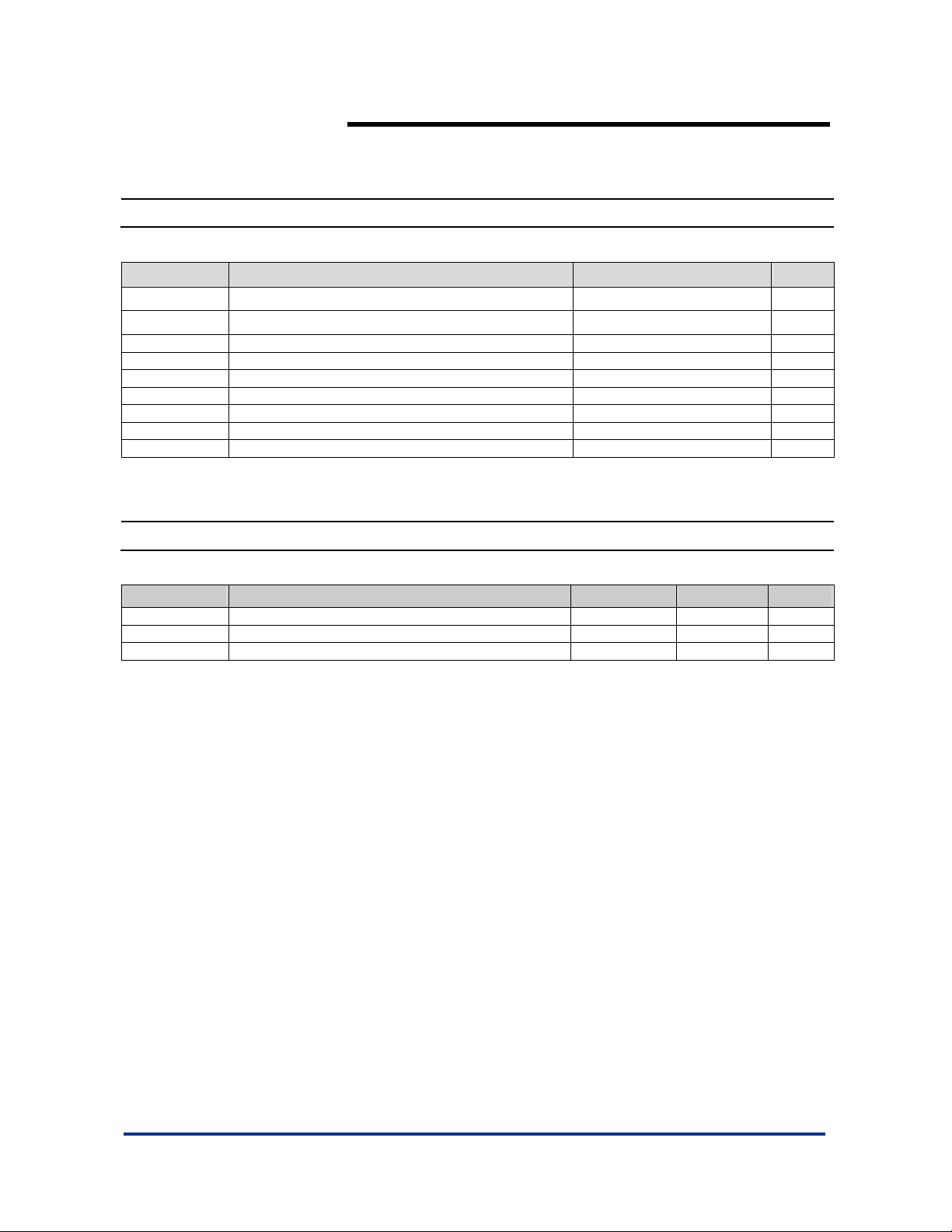

Absolute Maximum Ratings

Symbol Parameter Rating Unit

ESD HBM Human Body Model ES D Protection

5

ESD MM Machine Model ESD Protection 200 V

VCC VCC Pin Voltage VSS - 0.3 to VSS + 22 V

VFB Feedback Pin Voltage VSS - 0.3 to VCC V

VEN EN Pin Voltage VSS - 0.3 to VIN V

V

Switch Pin Voltage VSS- 0.3 to VIN V

OUTPUT

PD Power Dissipation 1000 mW

TJ Operating Junction Temperature Range -20 to +125

T

Storage Temperature Range -65 to +150

ST

Caution: The absolute maximum ratings are rated values exceeding which the product could suffer physical damage. These values must therefore not be

exceeded under any conditions.

Recommended Operating Conditions

Symbol Parameter Min Max Unit

VIN Input Voltage 3.6 20 V

I

Output Current 0 2 A

OUT

TA Operating Ambient Temperature -20 85 oC

AP5002 Rev. 8 3 of 10 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

KV

o

C

o

C

Page 4

T

AP5002

PWM CONTROL 2A STEP-DOWN CONVERTER

Electrical Characteristics (VIN = 12V, T

= 25°C, unless otherwise specified)

A

Symbol Parameter Conditions Min Typ. Max Unit

VFB Feedback Voltage I

IFB Feedback Bias Current I

I

Quiescent Current VFB= 1.2 force drive off - 3 5 mA

CCQ

= 0.1A 0.784 0.8 0.816 V

OUT

= 0.1A - 0.1 0. 5 µA

OUT

ISW Switch Current -- 3.5 - - A

ISD Shutdown Supply Current VEN = 0V - 10 - µA

∆V

OUT

/V

∆V

/V

Line Regulation V

OUT

OUT

Load Regulation I

OUT

f

Oscillation Frequency Measure waveform at SW pin 400 500 600 KHz

OSC

VSH

EN Pin Input Voltage

VSL Evaluate oscillation stop at SW pin - - 0.8

ISH

EN Pin Input Leakage

Current

ISL Ven = 0.8V -10 - 10 µA

= 4V~20V, I

IN

= 0.1 to 2A - 0.5 1 %

OUT

Evaluate oscillation at SW pin 2. 0 - -

= 0.2A - 1 2 %

OUT

V

Ven = 2V -10 - 10 µA

TSS Soft-Start Time -- - 3 - ms

= 5V, V

V

R

Internal MOSFET Rdson

DSON

Notes: 3. Test condition: Device mounted on 2oz copper, minimum recommended pad layout, FR-4 PCB.

Thermal shutdown 140

Minimum Duty Cycle

Thermal Resistance

θ

JA

Junction-to-Ambient

θ

hermal Resistance

JC

Junction-to-Case

IN

V

= 12V, V

IN

6.5 %

SOP-8L (Note 3) 124

SOP-8L (Note 3) 25

= 0V - 110 150

FB

= 0V - 70 100

FB

mΩ

o

o

C/W

o

C/W

C

AP5002 Rev. 8 4 of 10 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 5

Typical Application Circuit

AP5002

PWM CONTROL 2A STEP-DOWN CONVERTER

VIN+12V

Notes: 4. V

VIN+12V

U1

C2

22uF

C3

0.1uF

R5

100K

C6

0.1uF

ON/OFF

1

FB

2

EN

3

COMP

4 5

VCC Output

AP5002

R4

0.8~2K

VSS

VSS

Output

C7

0.1uF

8

7

6

Compensation Capacitor Selection(MLCC)

VIN VOUT R4 C7

12V 5/ 3.3/ 2.5/ 1.8/ 1.5V 0.8~2K 0.1µF

5V 3.3/ 2.5/ 1.8/ 1.5V 0.8~2K 27nF

C2

470uF

OUT

C3

0.1uF

= V

U1

FB

1

ON/OFF

R5

100K

C6

0.1uF

R1

)

FB

(1 +×

R2

2

3

4

R4

4.7~6.8K

EN

COMP

VCC

AP5002

VSS

VSS

Output

Output

C7

33nF

8

7

6

5

L1-(WURTH S05100104)

10uH

1 2

D1

Dii 723

B340A

L1-(WURTH S05100104)

10uH

1

D1

Dii 723

B340A

VOUT = 3.3V

C1

3.8K

1.2K

R1

R2

330pF

C8

0.1uF

C4

22uF

C1

330pF

330pF

VOUT = 3.3V

2

R1

3.8K

R2

1.2K

C1

330pF

C8

0.1uF

C4

470uF

AP5002 Rev. 8 5 of 10 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 6

PWM CONTROL 2A STEP-DOWN CONVERTER

Typical Performance Characteristics

AP5002 Vin vs. Frequency

570

560

550

540

530

Frequency(KHZ)

520

510

(Vout=3.3V; Iout=0.2A)

0 5 10 15 20 25

Vin(V)

AP5002

AP5002 Tem p eratur e vs. Frequen cy

575

560

545

530

515

Frequency(KHZ)

500

485

-20 0 20 40 60 80 100 120

(Vout=3.3V; Iout=0.2A)

Temperature(℃)

AP5002 V in vs. FB

0.808

0.806

0.804

VFB(V)

0.802

0.8

(Vout=3.3V; Iout=0.2A)

0 5 10 15 20 25

Vin(V)

AP5002 Effici en cy

100

90

Vout=5V

80

70

60

50

40

30

Efficiency(%)

20

10

0

0 0.5 1 1.5 2

Vout=3.3V

Iout(A )

AP5002 Temperature vs. FB

(Vout=3.3V; Iou t=0.2A)

0.82

0.81

0.8

VFB (V)

0.79

0.78

-2030 80130

Temperature(℃)

AP5002 Rev. 8 6 of 10 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 7

PWM CONTROL 2A STEP-DOWN CONVERTER

Typical Performance Characteristics (Continued)

AP5002 Load Regu lation

3.35

AP5002 Line Re gulation

3.35

AP5002

3.34

3.33

Vout(V)

3.32

3.31

3.3

00.511.52

AP5002 V i n vs. I

5

4

3

(mA)

CCQ

2

I

1

0

0 5 10 15 20

Iout( A)

(Vou t=3. 3V)

CCQ

Vin(V)

3.34

3.33

Vout(V)

3.32

3.31

3.3

0 5 10 15 20 25

AP5002 Temperature vs. I

Vin(V)

CCQ

(Vout=3.3V)

5

4.5

4

3.5

3

(mA)

2.5

CCQ

I

2

1.5

1

0.5

0

-20 0 20 40 60 80 100 120

Temperature(℃)

AP5002 Rev. 8 7 of 10 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 8

V

A

PWM CONTROL 2A STEP-DOWN CONVERTER

Typical Performance Characteristics (Continued)

AP5002

(Vin=12V; Vout=5V; Iout=0.2A)

out Ripple

(Vin=12V; Vout=5V; Iout=2A)

AP5002

P5002 Vout Ripple

Test Circuit

A

Enable function test Feedback function test

+

-

22u

1500p

A

Oscillation

+

-

6.8K

+

-

V

1.2K

COMP

EN

open

OUTPUT OUTPUT

COMP

EN

VCC

EN

VSS

OUTPUT

VSS

FB

COMP

open

FBVCC

6.8K

FBVCC

VSS

Operati on function test

AP5002 Rev. 8 8 of 10 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 9

R

Δ

=

AP5002

PWM CONTROL 2A STEP-DOWN CONVERTER

Functional Description

PWM Control

The AP5002 consists of DC/DC converters that employ a

pulse-width modulation (PWM) system.

In converters of the AP5002, the pulse width varies in a range up

to 100%, according to the load current. The ripple voltage

produced by the switch ing can ea sily be re moved t hrough a filter

because the switching frequency remains constant. Therefore,

these converters provide a low-ripple power over broad ranges of

input voltage and load current.

Current Limiting

R

DS(ON)

The current limit threshold is set by the internal circuit.

Setting the Output Voltage

Application cir cuit item shows the basic applic ation circuit with

adjustable output version. The external resistor sets the output

voltage according to the following equation:

V

(V)

OUT

5 6.4 1.2

3.3 3.8 1.2

2.5 2.6 1.2

1.8 3.3 2.6

1.5 3.3 3.7

1.2 3.3 6.5

1 3.3 13

Inductor Selection

For most designs, the operates with inductors of 10µH to

22µH. The inductor value can be derived from the following

equation:

()

=

L

Where is inductor Ripple Current. Large value inductors lower

ripple current and small value inductors result in high ripple

currents. Choose inductor ripple current approximately 15% of the

maximum load current 2A, ∆IL=0.3A. The DC current rating of the

inductor should be at least equal to the maximum load current

plus half the ripple current to prevent core saturation (2A+0.15A).

Input Capacitor Selection

EL CAP

This capacitor should be located close to the IC using short leads

and the voltage rating should be approximately 1.5 times the

maximum input volta ge. The RMS current rati ng requirement for

the input capacitor of a buck regulator is approximately 1⁄2 the

DC load current. A low ESR input capacitor sized for maximum

RMS current must be used. A 470µF low ESR capacitor for most

applications is sufficient.

MLCC CAP

A 22µF MLCC capacitor for most applications is sufficient.

Output Capacitor Selection

EL CAP

The output capacitor is required to filter the output voltage and

provides regulator loop stability. The important capacitor

parameters are the 100KHz Equivalent Series Resistance (ESR),

the RMS ripples current rating, voltage rating and capacitance

−

R1 (KΩ) R2 (KΩ)

TVV

ONOUTIN

×Δ×

fI2

oscL

AP5002 Rev. 8 9 of 10 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

value. For the output capacitor, the ESR value is the most

important parameter . The output ripple can be calculated fro m

the following formula.

ES

IV

×

The bulk capacitor’s ESR will determine the output ripple voltage

and the initial voltage drop after a high slew-rate transient.

An aluminum electrolytic capacitor's ESR value is related to the

capacitance and its voltage rating. In most case, higher voltage

electrolytic capacitors have lower ESR values. Most of the time,

capacitors with much higher voltage ratings may be needed to

provide the low ESR values required for low output ripple v oltage .

MLCC CAP

A 22µF MLCC capacitor for most applications is sufficient.

PCB Layout Guide

If you need low T

SW pins(5& 6) and VSS pins(7& 8)on the SOP-8L package are

internally connecte d to die pad, Th e PCB layout s hould all ow for

maximum possible copper area at the SW pins.

1. Connect C3 to VCC and VSS pin as closely as possible to get

good power filter effect.

2. Connect R4 to VCC and OCSET pin as closely as possible.

3. Connect ground side of the C2 & D1 as closely as possible.

Typical PC Board Layout

Top Side Layout Guide

Use vias to conduct the heat into the backside of

PCB layer. The PCB heat sink copper area should be

solder-painted without masked. This approa ches a

“best case” pad heat sink.

Bottom Side Layout Guide

& TJ or large PD(Power Dissipation), The dual

C

LRIPPLE

Page 10

Marking Information

AP5002

PWM CONTROL 2A STEP-DOWN CONVERTER

( Top View )

8

5

Logo

Part Number

AP5002

YY

WW X

X

41

Package Information (All Dimensions in mm)

0.254

0.62/0.82

7°~9°

Gauge Plane

Seating Plane

7°~9°

1.27typ

4.85/4.95

0.3/0.5

3.85/3.95

5.90/6.10

0.10/0.20

Detail "A"

0.35max.

45°

0.15/0.25

1.30/1.50

1.75max.

G : Green

: Year : 08, 09,10~

YY

WW : Week : 01~52; 52

represents 52 and 53 week

: Internal Code

X

Detail "A"

0°/8°

8x-0.60

5.4

6x-1.27

8x-1.55

Land Pattern Recommendation

(Unit: mm)

IMPORTANT NOTICE

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes without further

notice to any product herein. Diodes Incorporated does not assume any liability arising out of the application or use of any product described herein; neither

does it convey any license under its patent rights, nor the rights of others. The user of products in such applications shall assume all risks of such use and will

agree to hold Diodes Incorporated and all the companies whose products are represented on our website, harmless against all damages.

LIFE SUPPORT

Diodes Incorporated products are not authorized for use as critical components in life support devices or systems without the expressed written approval of the

President of Diodes Incorporated.

AP5002 Rev. 8 10 of 10 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Loading...

Loading...