Page 1

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

1 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

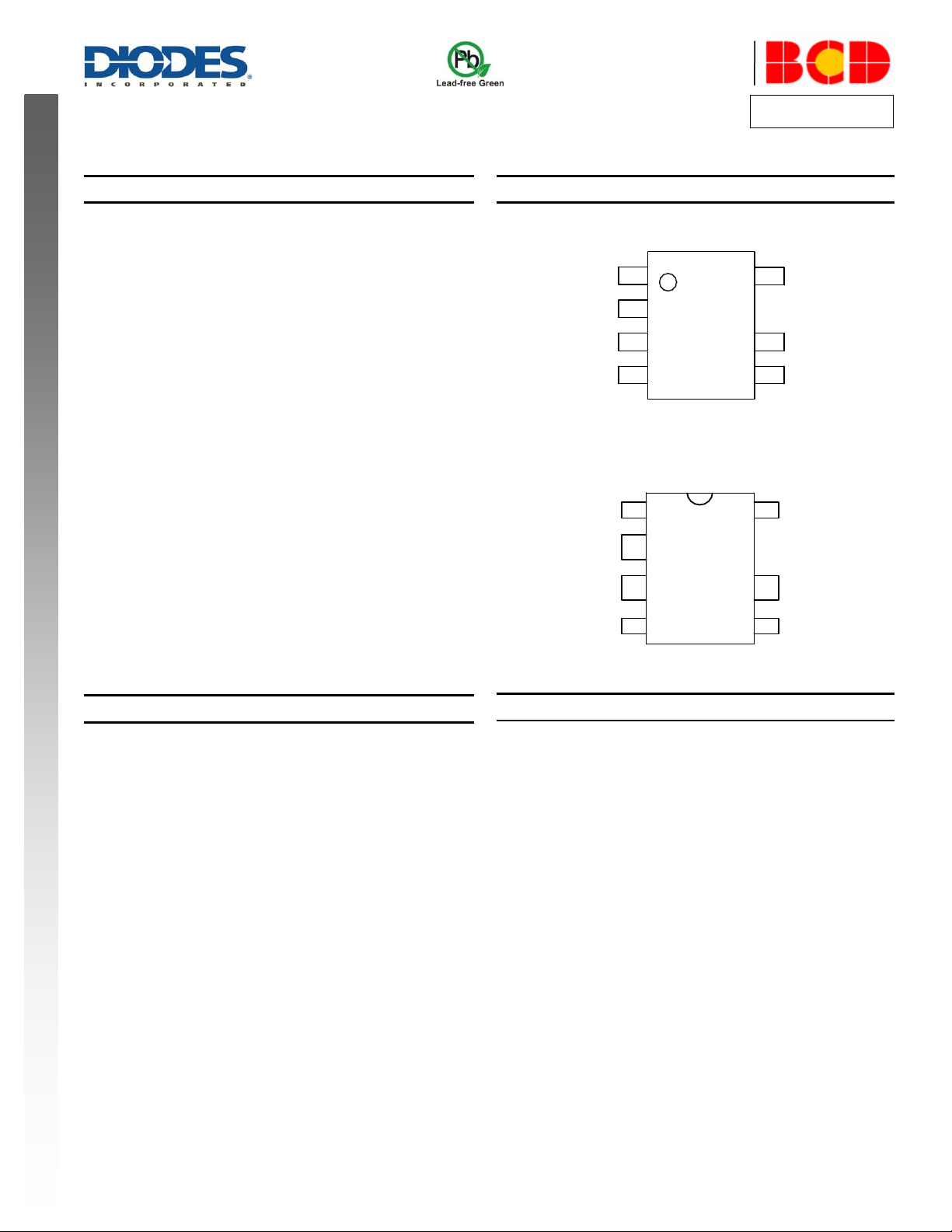

CPC

FB

VCC

CS

C

C

GND

1

2

3

4

7

6

5

Description

The AP3988/89/90 is a performance enhanced power switcher for

power supplies with better conversion efficiency, better voltage &

current accuracy, and improved protection functions. Typical

applications include charger, adapter for ADSL, home appliance

power supply, LED lighting power supply and PC auxiliary power

supplies. The controller regulates the output voltage and current in

the primary side by piece-wise Pulse Frequency Modulation (pPFM) in discontinuous conduction mode (DCM). The system

operating frequency reduces linearly from heavy load to light load

in each interval of the p-PFM, and enters constant current mode

when the load current equals to the maximum system output

current.

The AP3988/89/90 provides operating frequency dithering function

to improve EMC performance of power supply. The AP3988/89/90

also has built-in fixed cable voltage drop compensation (5% of

nominal system output voltage) and adjustable line voltage

compensation.

The AP3988/89/90 solution has fewer component number, smaller

size, and lower total cost.

The AP3988 is packaged in SO-7. The AP3989/90 is packaged in

PDIP-7.

Features

Primary Side Control for Eliminating Opto-coupler and

Secondary CV/CC Control Circuitry

Built-in NPN Transistor with 700V

CBO

Low Start-up Current: 0.2A (Typ.)

Internal Output Cable Voltage Drop Compensation

Hiccup Function to Improve Short Circuit Protection

Better Over Voltage Protection

Better Over Temperature Protection

Low Total Cost Solution

Output Power Range (Note 1):

AP3988 for 5.5W Adapter

AP3989 for 8W Adapter

AP3990 for 12W Adapter

Totally Lead-free & Fully RoHS Compliant (Note 2 & 3)

Halogen and Antimony Free. “Green” Device (Note 4)

Pin Assignments

(Top View)

SO-7 (M Package) For AP3988

(Top View)

PDIP-7 (P7 Package) For AP3989/90

Applications

Adapters

Set Top Boxes

Auxiliary Supplies

Appliances

1

2

3

4

7

6

5

CPC

FB

VCC

CS

C

C

GND

PRIMARY SIDE POWER SWITCHER FOR OFF-LINE SMPS

Notes: 1. Typical continuous power in a non-ventilated enclosed adapter measured at +50°C ambient.

3. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

4. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

2. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

Page 2

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

2 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

+

J1

AC 90-264V

D1 to D4

C2

Rf1

+

C1

D6

L1

T1

FB

C

VCC

CS

+

C3

U1

CPC

C8

R5

C11

Np

Ns

Nfb

D5

C5

R6

Vo+

Vo-

C10

GND

D12

+

C12

R11

R12

C13

+

R10

R3

R8

R9

R7

L2

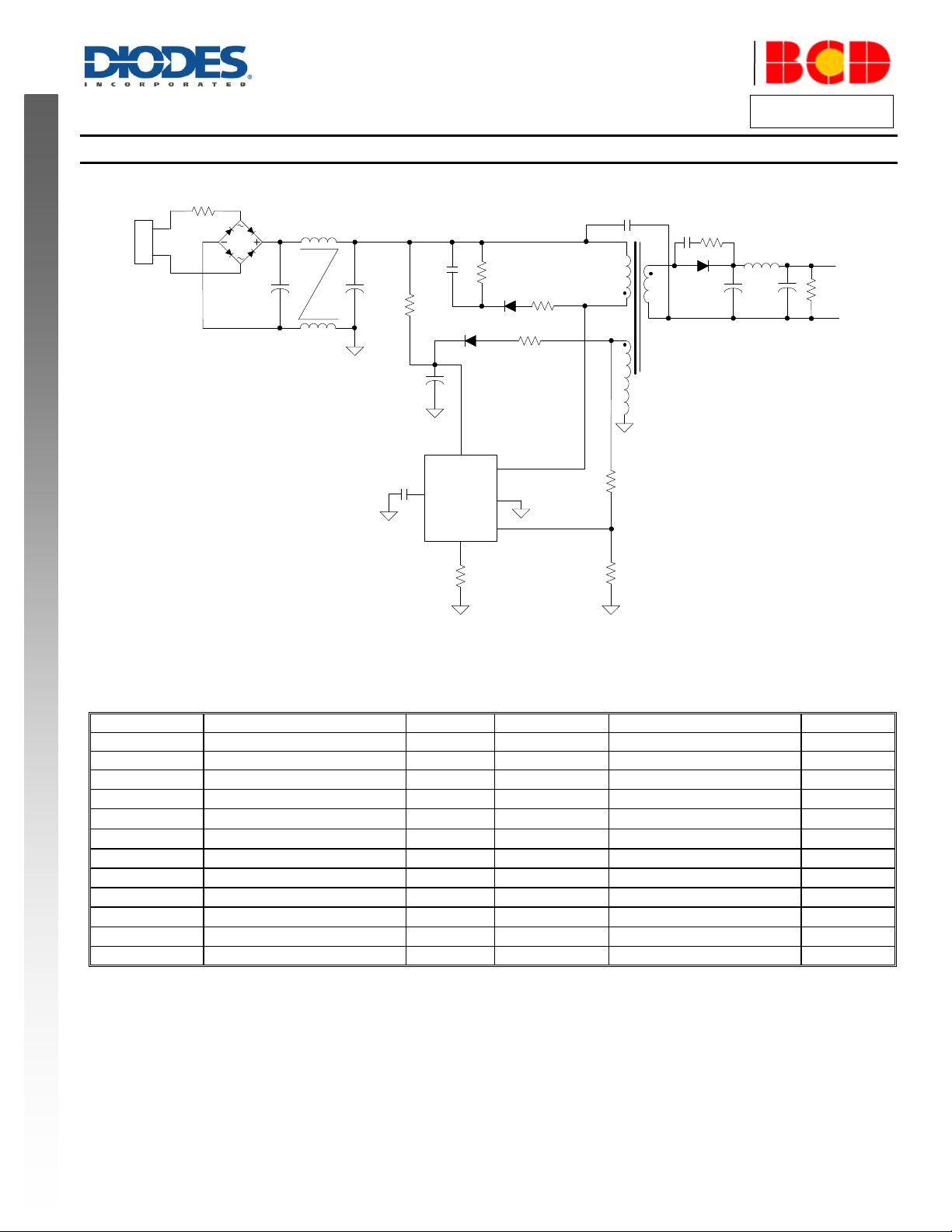

Item

Function

QTY

Item

Function

QTY

C1,C2

10µF/400V, electrolytic

2

U1

AP3990, PDIP-7

1

C3

4.7µF/50V, electrolytic

1

Rf1

2A/250V, fuse

1

C5

1nF/250V, ceramic

1

R3

3.3M/0.25W

1

C8

0.1µF, 0805

1

R5

3.9, 0805

1

C10

1nF/250VAC, Y1 capacitor

1

R6

150k, 0.25W

1

C11

1nF, 0805

1

R7

0.62, 1206

1

C12, C13

470µF/16V

2

R8

31k, 0805

1

D1 to D6

1N4007, rectifier diode

6

R9

13k, 0805

1

D12

MBR3100, Schottky diode

1

R10

360, 0805

1

L1

15mH, Common inductor, EE10

1

R11

27, 0805

1

L2

10µH/1A, inductor, 0805

1

R12

1.2k, 0805

1

– – –

T1

EE20 core, PC40, transformer

1

Typical Applications Circuit

For AP3990 (12V/1A)

Page 3

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

3 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

Pin Number

Pin Name

Function

1

CPC

This pin connects a capacitor to GND for output cable compensation

2

FB

The voltage feedback from auxiliary winding

3

VCC

This pin receives rectified voltage from the auxiliary winding of the transformer

4

CS

Current sense for primary side of transformer

5, 6

C

This pin is connected with an internal power BJT’s collector

7

GND

This pin is the signal reference ground

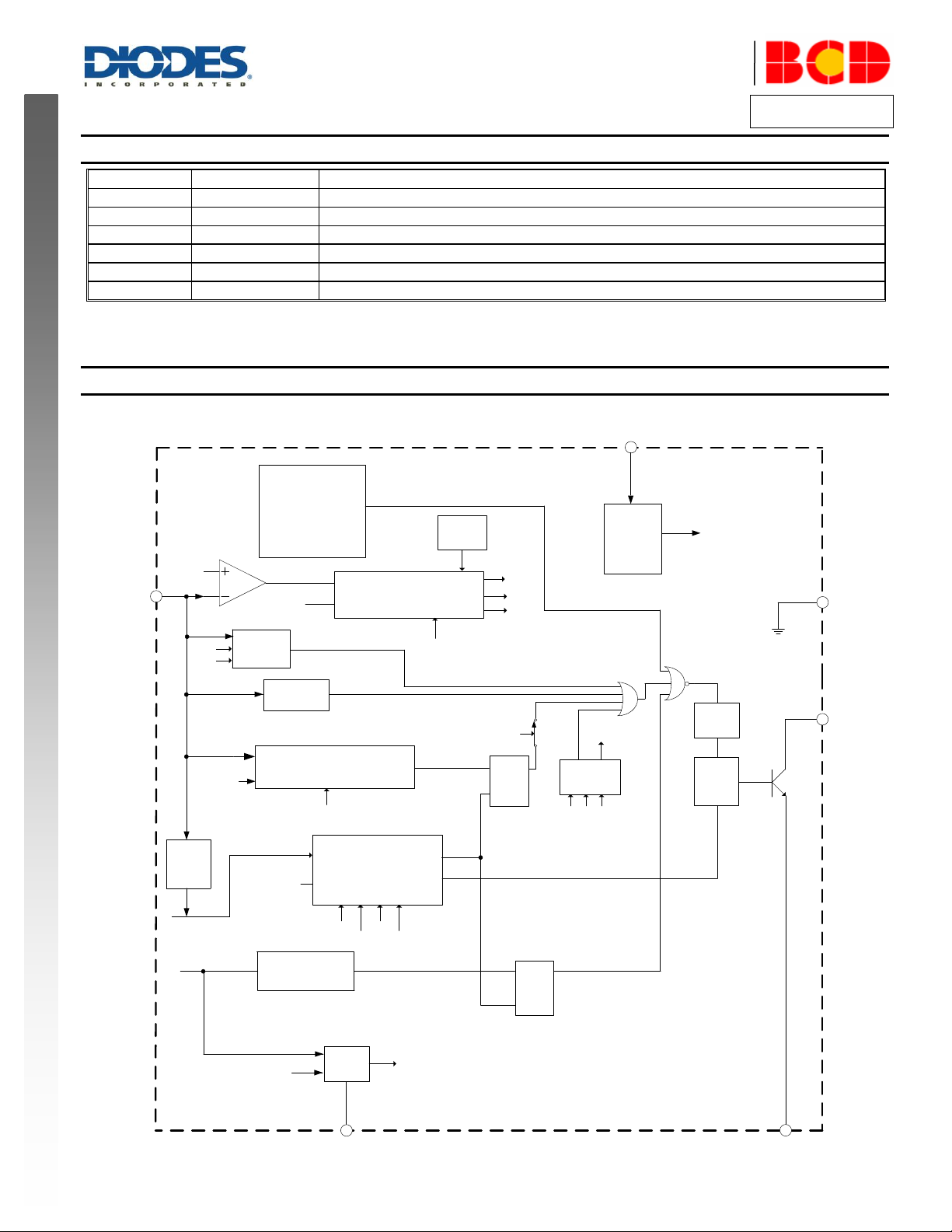

Regulator

&

Bias

OVP

OCkP

OTP

PFM

UVLO

CV_ctrl

PFM

Driver

R

Q

S

R

Q

S

FB

CS

CPC

VCC

CS

GND

Constant Voltage Control

Cable Compensation

Constant Current

Control

0.05V

V

FB_ref

3

4

7

1

2

V

CSN(N=1,2,3)

COMP

Peak Current Control

LEB

Frequency Dither

V

CSN

Select

Dynamic

Response

Pro

Dyn

Shutdown

Pre_Shutdown

Line

Comp.

t

ONS

t

ONS

, NL and LL

Detector

OSC

UV

UV

Vload

Vally

ON

Vload

CC_ctrl

Max Tonp

Rcs Short

Output Short

t

ONS

LL

NL

CPC

t

OSC

Detect

Pulse

(LL+NL)Bar

NL

Vload

UV

CV_M

DetectON

DetectON

LL

Vload

V

CSN(N=1,2,3)

tosc

NL LL

C

5, 6

Pin Descriptions

Functional Block Diagram

Page 4

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

4 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

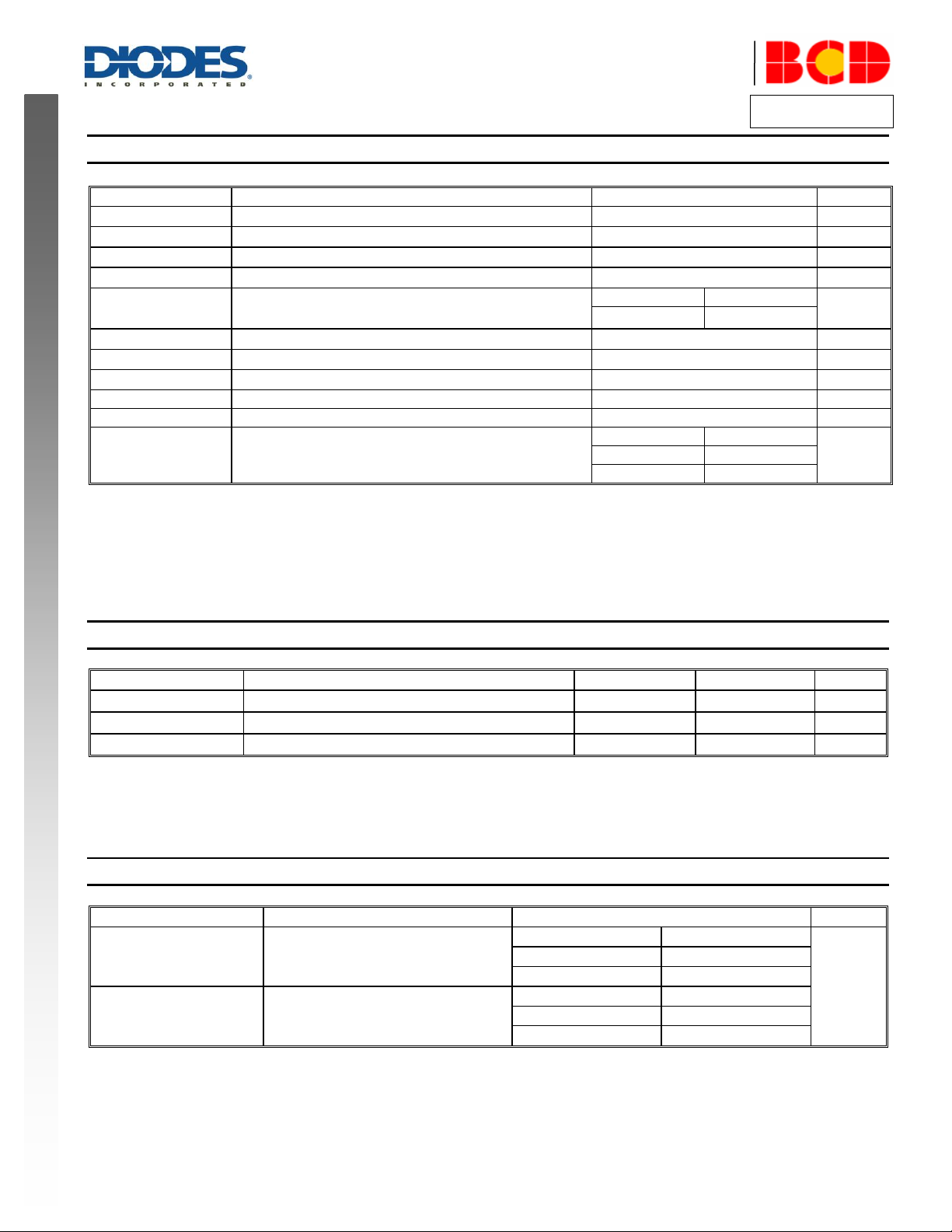

Symbol

Parameter

Rating

Unit

VCC

Supply Voltage

-0.3 to 30

V

VCS, V

CPC

Voltage on CS, CPC Pin

-0.3 to 7

V

VFB

FB Input Voltage

-0.3 to 8

V

V

CBO

Collector-emitter Voltage

700

V

I

CDC

Collector DC Current

AP3988/89

1.5

A

AP3990

4

TJ

Operating Junction Temperature

+150

°C

T

STG

Storage Temperature

-65 to +150

°C

T

LEAD

Lead Temperature (Soldering, 10 sec)

+300

°C

–

ESD (Machine Model)

200

V

–

ESD (Human Body Model)

2000

V

PD

Total Power Dissipation

AP3988

0.7

W

AP3989

0.9

AP3990

1.1

Symbol

Parameter

Min

Max

Unit

VCC

Supply Voltage

–

25

V

TOP

Operating Temperature Range

-40

+85

°C

f

S(MAX)

Maximum Operating Frequency

–

60

kHz

Symbol

Parameter

Value

Unit

θ

JA

Junction to Ambient

AP3988

100

°C/W

AP3989

80

AP3990

65

θ

JC

Junction to Case

AP3988

50

AP3989

40

AP3990

35

Absolute Maximum Ratings (Note 5)

Note 5: Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating Condi tions” is not implied.

Exposure to “Absolute Maximum Ratings” for extended periods may affect device reliability.

Recommended Operating Conditions

Thermal Impedance (Note 6)

Note 6: When mounted a standard single-sided FR4 board with 300mm2 Cu (at least 35µm thick) connected to all collectors and CS pins.

Page 5

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

5 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

Symbol

Parameters

Conditions

Min

Typ

Max

Unit

STARTUP AND UVLO SECTION

V

TH_ST

Turn-on Voltage

–

13

15

17

V

V

OPR(MIN)

Turn-off Voltage

–

5.2

5.8

6.4

V

STANDBY CURRENT SECTION

IST

Turn-on Current

VCC=V

TH_ST

-1V before

startup

0

0.2

0.6

μA

I

CC_OPR

Operating Current

Static current @ no load

550

650

750

OPERATING FREQUENCY SECTION (5% LOAD TO FULL LOAD)

f

S(MAX)

Operating Frequency in Full Load

Condition

–

– – 60

kHz

Δf/f

Frequency Dithering

5% to 100% of full load

range

4.5 5 5.5

%

OPERATING FREQUENCY SECTION (NO LOAD TO 5% OF I

OUT(MAX)

)

f

S(MIN)

Output Voltage Detection Frequency

–

1.8 2 2.2

kHz

CURRENT SENSE SECTION

V

CS_H

Peak Current Sense Voltage in Heavy

Load

40% to 100% of full load

874

910

946

mV

V

CS_M

Peak Current Sense Voltage in Middle

Load

18% to 40% of full load

581

605

630

mV

V

CS_L

Peak Current Sense Voltage in Light

Load

5% to 18% of full load

390

405

425

mV

V

CS_EL

Peak Current Sense Voltage in ExtraLight Load

0% to 5% of full load

216

225

234

mV

ΔVCS/VCS

V

CS

Modulation for Frequency Dithering

–

–

2.5 – %

t

MOD

VCS Modulation Period

–

14.4

16

17.6

ms

R

LINE

Built-in Line Compensation Resistor

–

260

330

400

Ω

t

LEB

Leading Edge Blanking

@ V

CS_H

and V

CS_M

410

500

575

ns

@ V

CS_EL

155

200

245

ns

CONSTANT VOLTAGE SECTION

VFB

Equivalent Feedback Voltage @ Light

Load

Closed loop test of V

OUT

3.94

4.00

4.06

V

IFB

FB Pin Input Current

VFB=4V

3.36

4.20

5.04

μA

V

CABLE/VOUT

Cable Compensation Ratio

(V

FB@FULLLOAD-VFB

)/VFB

5.65

6.00

6.40

%

CONSTANT CURRENT SECTION

t

ONS/tSW

Secondary Winding Conduction Duty

VFB=2V

–

4/7 – –

POWER TRANSISTOR SECTION

V

CE(SAT)

Collector-emitter Saturation Voltage

AP3988/89: IC=0.5A

AP3990: IC=1A

– – 0.3

V

hFE

DC Current Gain

AP3988/89

14

17 – –

AP3990

17

26 – –

I

CEO

Leakage Current

–

– – 60

μA

PROTECTION FUNCTION SECTION

V

FB(OVP)

Over Voltage Protection

–

–

7.5 – V

V

FB(SCP)

Short Circuit Protection

VFB @ Hiccup

1.4

1.5

1.6

V

T

OTP

Shutdown Temperature

–

+125

+160 – °C

T

HYS

Temperature Hysteresis

–

–

+40 – °C

–

Driver Protection Voltage

–

4 5 6

V

Electrical Characteristics (@V

=15V, TJ=+25°C, unless otherwise specified.)

CC

Page 6

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

6 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

-40 -20 0 20 40 60 80 100 120

4.5

5.0

5.5

6.0

6.5

Turn-off Voltage (V)

Ambient Temperature (oC)

125

-40 -20 0 20 40 60 80 100 120

500

550

600

650

700

750

Operating Current (

A)

Ambient Temperature (oC)

125

+

C1

+

C

O

V

O

D1

R

FB1

R

FB2

R

CS

C

FB

CS

GND

AP3988/89/90

N

S

N

AUX

N

P

I

OUT

V

S

V

AUX

V

IN

L

M

CPC

C

CPC

Q1

V

bulk

-40 -20 0 20 40 60 80 100 120

14.2

14.3

14.4

14.5

14.6

14.7

14.8

Turn on Voltage (V)

Ambient Temperature (oC)

Performance Characteristics

Turn-on Voltage vs. Ambient Temperature Turn-off Voltage vs. Ambient Temperature

Operating Current vs. Ambient Temperature

Operation Description

Figure 1. Simplified Flyback Converter Controlled by AP3988/89/90

Page 7

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

7 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

M

b

L

tV

dt

tdi)()(

ulk

p

ip(t)

0A

See equation 2

I

PK

CS

CS

PK

R

V

I

2

g

2

1

PKM

ILE

SWPKM

fILP

2

2

1

d

S

AUX

AUX

VV

N

N

V

O

See equation 5

V

AUX

0V

Portion of T

ons

T

ons

Operation Description (Cont.)

Constant Primary Peak Current

The primary ip(t) current is sensed by a current sense resistor R

The current rises up linearly at a rate of:

……… (1)

As illustrated in Figure 2, when the current i

………(2)

(t) rises up to I

p

Figure 2. Primary Current Waveform

, the switch Q1 turns off. The constant peak current is given by:

PK

as shown in Figure 1.

CS

The energy stored in the magnetizing inductance LM each cycle is therefore:

………(3)

So the power transferring from input to output is given by:

………(4)

Where fSW is the switching frequency. When the peak current IPK is constant, the output power depends on the switching frequency fSW.

Constant Voltage Operation

The AP3988/89/90 captures the auxiliary winding feedback voltage at FB pin and operates in constant-voltage (CV) mode to regulate the output

voltage. Assuming the secondary winding is master, the auxiliary winding is slave during the D1 on-time. The auxiliary voltage is given by:

………(5)

Where Vd is the diode forward drop voltage, N

is the turns of auxiliary winding, and NS is the turns of secondary winding.

AUX

The output voltage is different from the secondary voltage in a diode forward drop voltage Vd which depends on the current. If the secondary

voltage is always detected at a constant secondary current, the difference between the output voltage and the secondary voltage will be a fixed Vd.

The voltage detection point is portion of T

regulate the output voltage.

Figure 3. Auxiliary Voltage Waveform

after D1 is turned on. The CV loop control function of AP3988/89/90 then generates a D1 off-time to

ons

Page 8

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

8 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

I

s

0A

See equation 7

T

ons

T

offs

I

OUT

3

4

offs

ons

T

T

offsons

ons

PKSOUT

TT

T

II

2

1

PK

S

P

PKS

I

N

N

I

PK

S

P

OUT

I

N

N

I

7

2

Operation Description (Cont.)

Constant Current Operation

The AP3988/89/90 is designed to work in constant current (CC) mode. Figure 4 shows the secondary current waveforms.

In CC operation, the CC loop control function of AP3988/89/90 will keep a fixed proportion between D1 on-time T

discharging or charging the built-in capacitance connected. This fixed proportion is

……… (6)

The relation between the output constant-current and secondary peak current I

At the instant of D1 turn-on, the primary current transfers to the secondary at an amplitude of:

Thus the output constant current is given by:

Leading Edge Blanking (LEB)

When the power switch is turned on, a turn-on spike on the output pulse rising edge will occur on the sense-resistor. To avoid false termination of

the switching pulse, a typical 500ns leading edge blanking is built in. During this blanking period, the current sense comparator is disabled and the

gate driver cannot be switched off.

The built-in LEB in AP3988/89/90 has shorter delay time from current sense terminal to output pulse than those IC solutions adopting external RC

filter as LEB.

Built-in Cable Compensation

The AP3988/89/90 has built-in fixed voltage of 0.35V typical to compensate the drop of output cable when the load is changed from zero to full

load. A typical 10nF external capacitor connected to the CPC pin is used to smooth voltage signal for cable compensation.

Over Temperature Protection

The AP3988/89/90 has internal thermal sensing circuit to shut down the PFM driver output when the die temperature reaches 160°C typical. When

the die temperature drops about 40°C, the IC will recover automatically to normal operation.

………(8)

………(9)

………(7)

Figure 4. Secondary Current Waveform

is given by:

PKS

and D1 off-time T

ons

offs

by

Page 9

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

9 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

AP39XX XX XX - G1

Packing

Package

TR : Tape & Reel

M : SO-7

G1 : Green

Product Name

RoHS/Green

Product Version

88 : AP3988

89 : AP3989

90 : AP3990

P7 : PDIP-7

Blank : Tube

Package

Temperature Range

Part Number

Marking ID

Packing

SO-7

-40°C to +85°C

AP3988MTR-G1

3988M-G1

4000/Tape & Reel

PDIP-7

AP3989P7-G1

AP3989P7-G1

50/Tube

AP3990P7-G1

AP3990P7-G1

50/Tube

First and Second Lines: Logo and Marking ID

Third Line: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

XX: 7th and 8th Digits of Batch No.

First Line: Logo and Marking ID

Second Line: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

XX: 7th and 8th Digits of Batch No.

Ordering Information

Diodes IC’s Pb-free products with "G1" suffix in the part number, are RoHS compliant and green.

Marking Information

Page 10

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

10 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

3.800(0.150)

4.000(0.157)

1.270(0.050)

TYP

4.700(0.185)

5.100(0.201)

0.330(0.013)

0.510(0.020)

0.190(0.007)

0.250(0.010)

0.100(0.004)

0.250(0.010)

1.350(0.053)

1.750(0.069)

0.450(0.017)

0.800(0.031)

8

°

0

°

5.800(0.228)

6.200(0.244)

2.54(0.100)

TYP

1.250(0.049)

1.500(0.059)

Note: Eject hole, oriented hole and mold mark is optional.

Package Outline Dimensions (All dimensions in mm(inch).)

(1) Package Type: SO-7

Page 11

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

11 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

8.400(0.331)

9.000(0.354)

0.204(0.008)

0.360(0.014)

7.320(0.288)

9.000(0.354)

9.400(0.370)

3.

710

(0.146)

4.310(0.170)

3.000(0.118)

3.600(0.142)

2.540(0.100)BSC

6.200(0.244)

6.600(0.260)

3.200(0.126)

3.600(0.142)

0.510(0.020)MIN

1

.524(0.060)

BSC

Note: Eject hole, oriented hole and mold mark is optional.

0.380(0.015)

0.570(0.022)

7.920(0.312)

Package Outline Dimensions (cont.) (All dimensions in mm (inch).)

(2) Package Type: PDIP-7

Page 12

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

12 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

Z

G

E1

E

X

Y

Dimensions

Z

(mm)/(inch)

G

(mm)/(inch)

X

(mm)/(inch)

Y

(mm)/(inch)

E

(mm)/(inch)

E1

(mm)/(inch)

Value

6.900/0.272

3.900/0.154

0.650/0.026

1.500/0.059

1.270/0.050

2.540/0.100

Suggested Pad Layout

(1) Package Type: SO-7

Page 13

AP3988/89/90

Document number: DS36722 Rev. 3 - 2

13 of 13

www.diodes.com

March 2014

© Diodes Incorporated

AP3988/89/90

A Product Line of

Diodes Incorporated

NE W P R OD UC T

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2014, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

Loading...

Loading...