Page 1

A

f

Product Line o

Diodes Incorporated

AP3585A/B/C

SINGLE PHASE SYNCHRONOUS BUCK PWM CONTROLLER

Description

The AP3585A/B/C is a compact synchronous-rectified buck controller

specifically designed to operate from 4.5V to 13.2V supply voltage

and deliver high-quality output voltage as low as 0.8V (AP3585A) or

0.6V (AP3585B/C). This SO-8EP device operates at fixed

300kHz/200kHz frequency and provides an optimal level of

integration to reduce size and cost of the power supply.

This controller integrates internal MOSFET drivers that support

12V+12V bootstrapped voltage for high- efficiency power conversion.

The bootstrap diode is built-in to simplify the circuit design and

minimize external part count.

This controller provides single feedback loop, voltage-mode control

with fast transient response. The error amplifier features a 10MHz

gain-bandwidth product and 6V/μs slew rate which enables high

converter bandwidth for fast transient performance.

Other features include internal soft-start, under voltage protection,

over current protection and shutdown function. With afore mentioned

NEW PRODUCT

functions, this part provides customers a compact, high efficiency,

well-protected and cost-effective solution.

The AP3585A/B/C is available in SO-8 and SO-8EP packages.

Features

Supply Voltage: 4.5V to 13.2V

Input Range: 3.3V to 12V

V

IN

0.8V/0.6V to 80% of V

Internal Reference: 0.8V/0.6V

Simple Single-loop Control

Voltage-mode PWM Control

Duty Cycle: 0% to 80%

Fast Transient Response

10MHz High-bandwidth Error Amplifier with 6V/μs Slew Rate

Fixed Oscillator Frequency: 300kHz/200kHz

Lossless, Programmable Over Current Protection

(Uses Lower MOSFET R

Start-up into Pre-biased Load

Built-in Thermal Shutdown

Built-in Soft-start

Over Current Protection

Over Voltage Protection

Under Voltage Protection

Integrated Boot Diode

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

Output Range

IN

)

DS(ON)

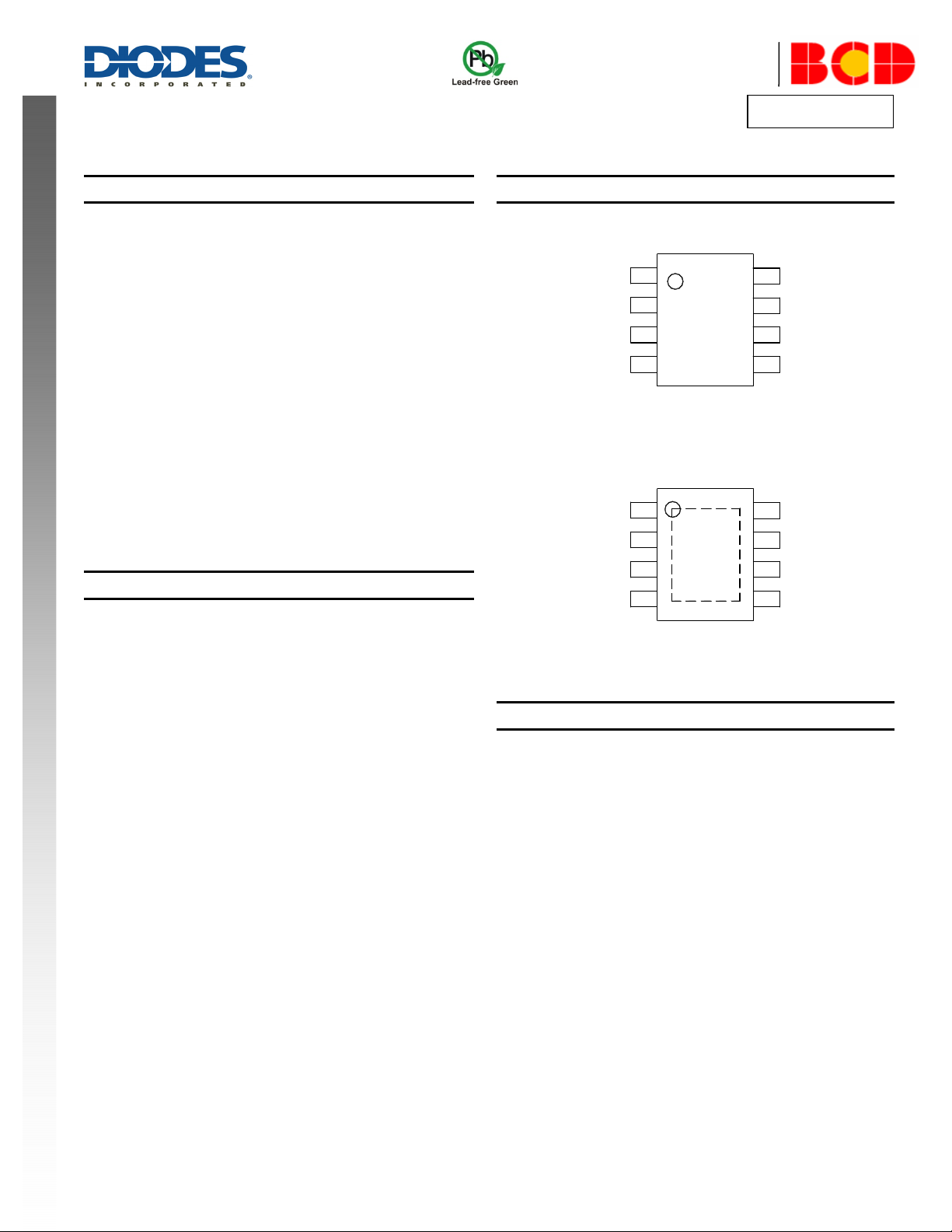

Pin Assignments

BOOT

UGATE

GND

LGATE/OCSET

(Top View)

1

2

3

4

8

PHASE

7

COMP/EN

6

FB

5

VCC

(SO-8/ M Package)

(Top View)

BOOT

UGATE

GND

LGATE/OCSET

1

2

3

4

Exposed

Pad

9

8

7

6

5

PHASE

COMP/EN

FB

VCC

(SO-8EP/ MP Package)

Applications

Subsystem Power Supplies

PCI, AGP, Graphics Cards, Digital TV

SSTL-2 and DDR/2/3 SDRAM Bus Termination Supply

Cable Modems, Set Top Boxes, and DSL Modems

Industrial Power Supplies and General Purpose Supplies

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

1 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 2

A

f

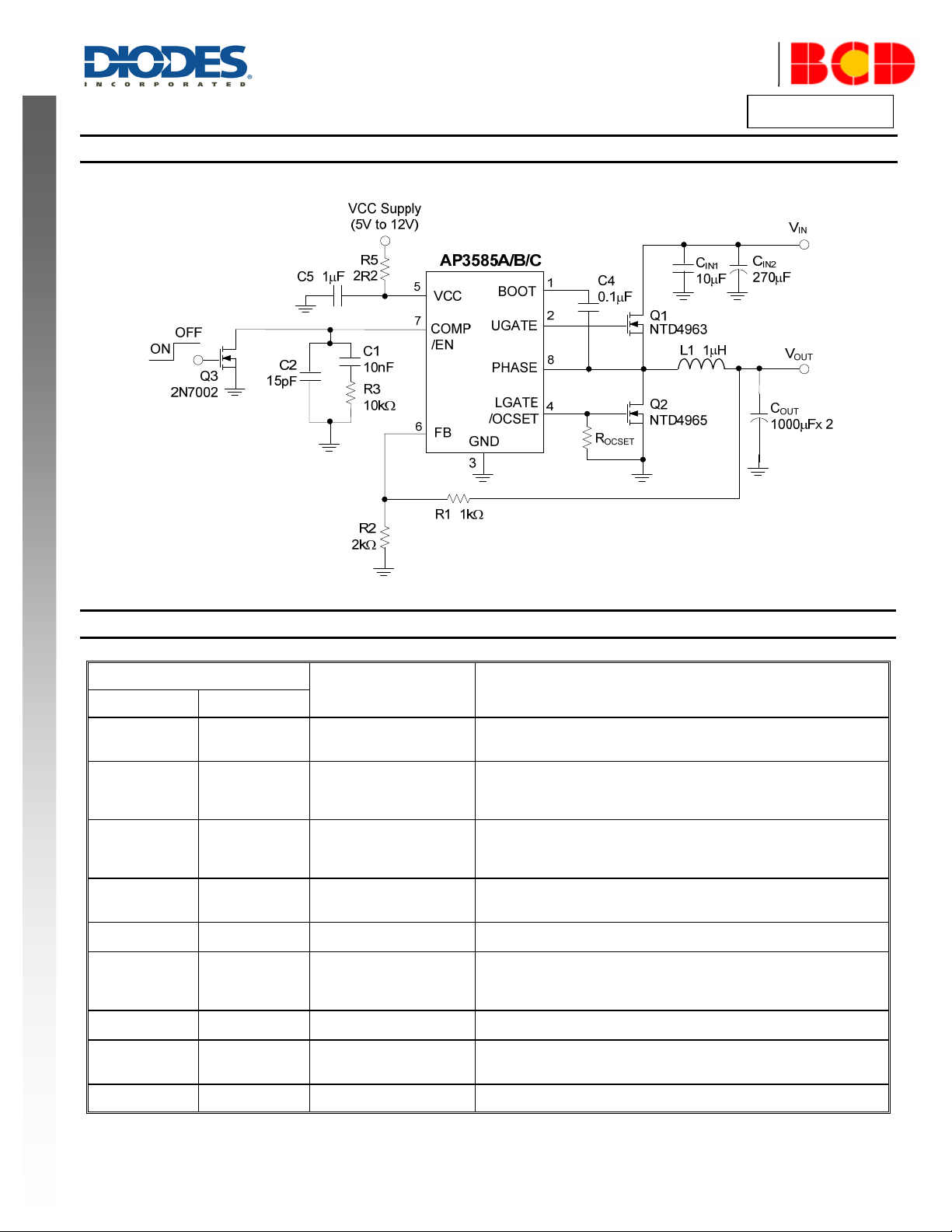

Typical Applications Circuit

Product Line o

Diodes Incorporated

AP3585A/B/C

NEW PRODUCT

Pin Descriptions

SO-8 SO-8EP

1 1 BOOT

2 2 UGATE

3 3 GND

4 4 LGATE/OCSET

5 5 VCC

6 6 FB

7 7 COMP/EN

8 8 PHASE

– 9 Exposed Pad

Pin Number

Pin Name Function

Bootstrap pin. Connect a bootstrap capacitor from this pin to PHASE for

creating a BOOT voltage suitable to drive a standard N-Channel

MOSFET.

Upper-gate drive pin. Connect this pin to the upper MOSFET gate

providing the gate drive. This pin is monitored by the adaptive shootthrough protection circuitry to determine when the upper MOSFET has

turned off.

Ground for the IC. All voltage levels are measured with respect to this pin.

Connect this pin directly to the low side MOSFET source and ground

plane with the lowest impedance. The exposed pad must be soldered to a

large PCB and connected to GND for maximum power dissipation.

Low-side Gate Driver Output and Over-Current Setting Input. This pin is

the gate driver for low-side MOSFET. It is also used to set the maximum

inductor current. Refer to the section in “Function Description” for detail.

Bias supply pin. Provides a 4.5V to 13.2V bias supply for the chip from this

pin. The pin should be bypassed with a capacitor to GND.

Feedback pin. This pin is the inverting input of the internal error amplifier.

Use FB pin, in combination with the COMP pin, to compensate the voltage

control feedback loop of the converter. A resistor divider from output to

GND is used to set the output voltage.

Compensation and disable pin. This pin is the output of the Error Amplifier.

Pull COMP pin low will shut down the IC.

This pin connects to the source of the upper MOSFET and the drain of the

lower MOSFET. This pin is also monitored by the adaptive shoot-through

protection circuitry to determine when the upper MOSFET has turned off.

Exposed Pad as ground pin.

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

2 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 3

A

f

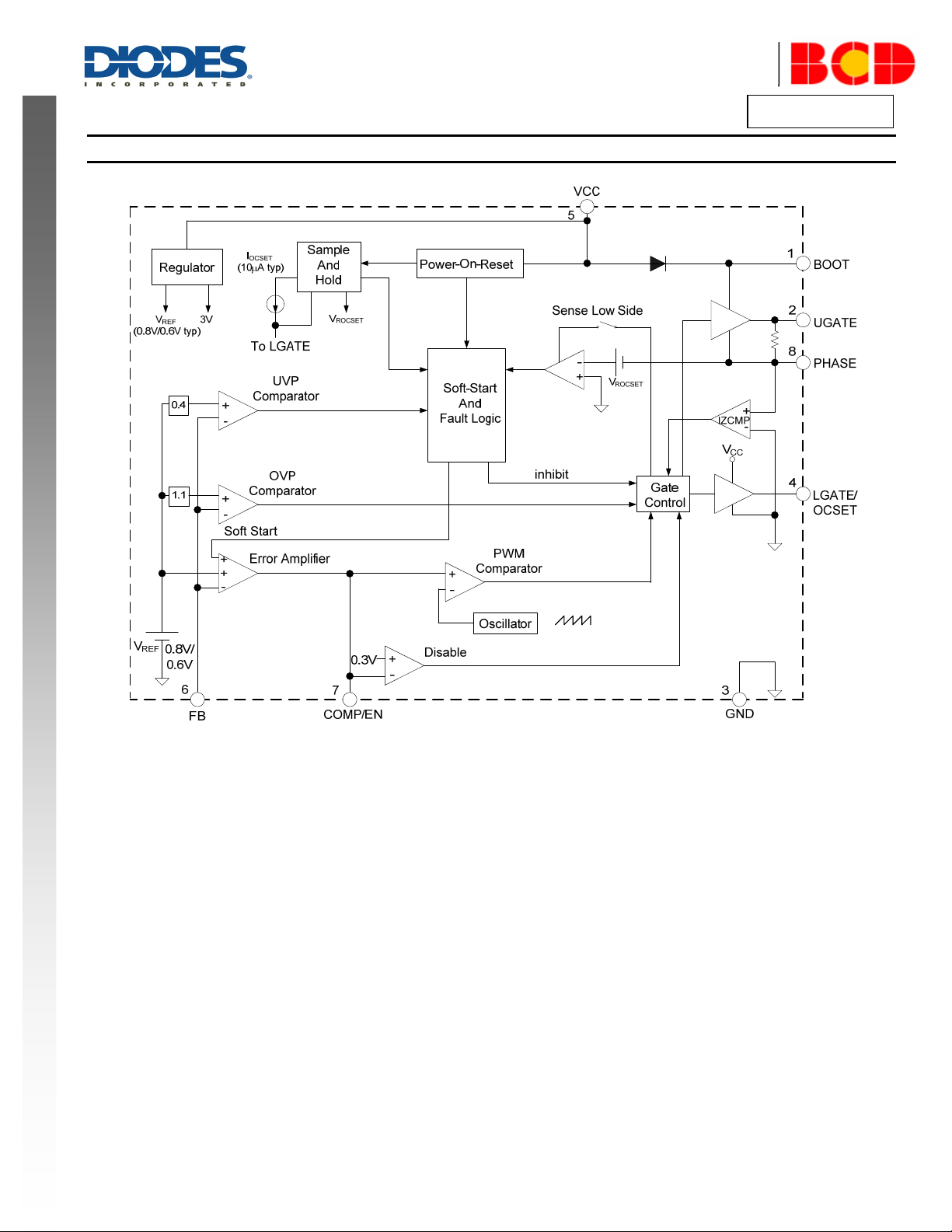

Functional Block Diagram

Product Line o

Diodes Incorporated

AP3585A/B/C

NEW PRODUCT

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

3 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 4

A

f

Product Line o

Diodes Incorporated

AP3585A/B/C

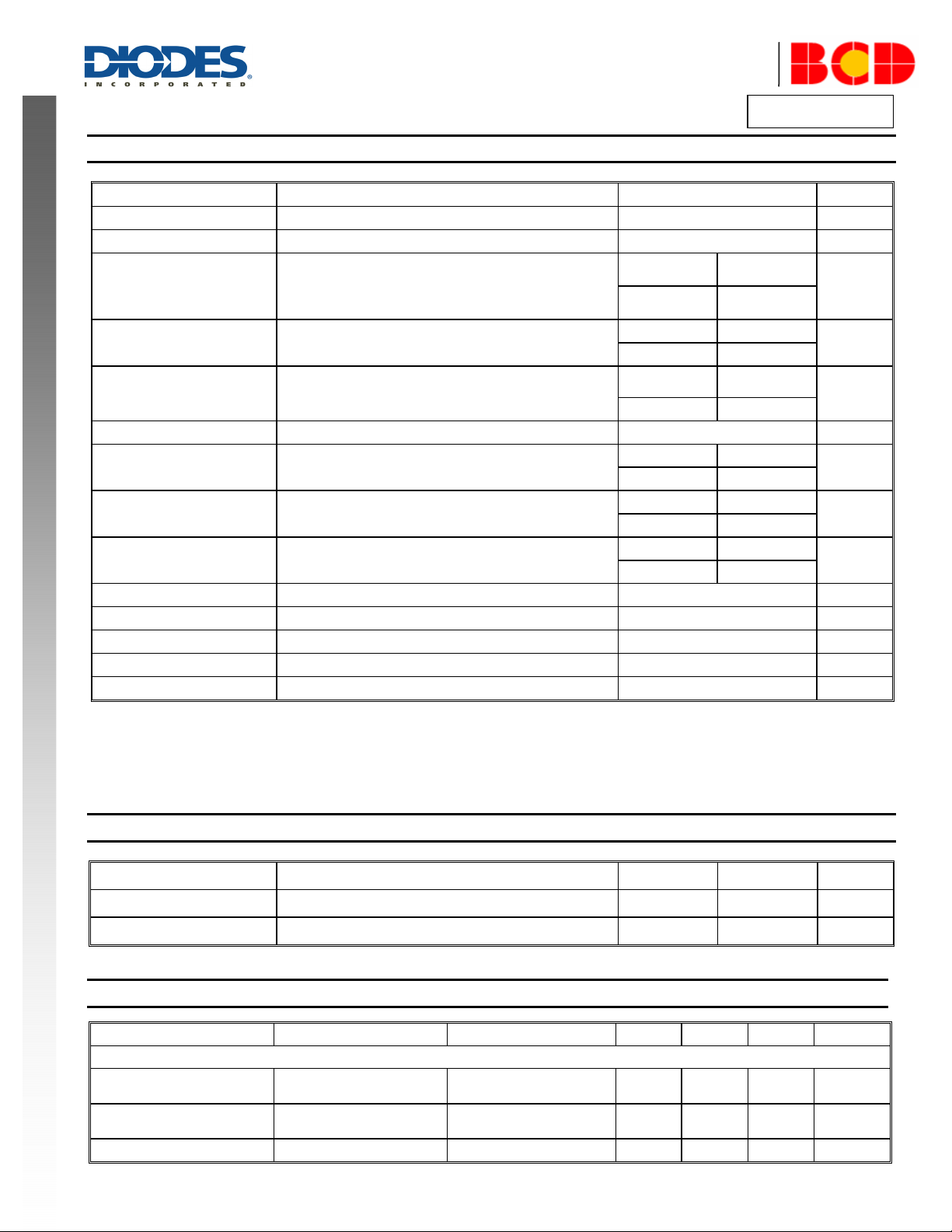

Absolute Maximum Ratings (Note 4)

Symbol Parameter

VCC

V

BOOT-PHASE

V

V

V

UGATE

PHASE

LGATE

Other Pin Voltage -0.3 to 6 V

PD

NEW PRODUCT

θJA

θJC

TJ

T

STG

T

LEAD

– ESD (Human Body Model) (Note 5) 2000 V

– ESD (Machine Model) (Note 5) 200 V

Notes: 4. Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and

5. Devices are ESD sensitive. Handling precaution is recommended.

functional operation of the device at these or any other conditions beyond those indicated under “Recommended Operating Conditions” is not implied.

Exposure to “Absolute Maximum Ratings” for extended periods may affect device reliability.

Supply Input Voltage -0.3 to 15 V

BOOT to PHASE Voltage -0.3 to 15 V

UGATE to PHASE Voltage

<200ns

PHASE to GND Voltage

LGATE to GND Voltage

Power Dissipation

Thermal Resistance (Junction to Ambient)

Thermal Resistance (Junction to Case)

Junction Temperature -40 to +150 ºC

Storage Temperature -65 to +150 ºC

Lead Temperature (Soldering, 10 sec) +260 ºC

<200ns -5 to 30

<200ns

SO-8EP 1.43

SO-8EP 70

SO-8EP 22

Rating

DC

DC -0.3 to 15

DC

SO-8 0.87

SO-8 115

SO-8 22

-0.3 to V

PHASE

-5 to V

PHASE

-0.3 to

V

CC

-5 to V

BOOT-

+0.3

BOOT-

+5

+0.3

CC

+5

Recommended Operating Conditions

Symbol Parameter Min Max Unit

VCC

Supply Input Voltage 4.5 13.2 V

Unit

V

V

V

W

ºC/W

ºC/W

TA

Operating Ambient Temperature -40 +85

C

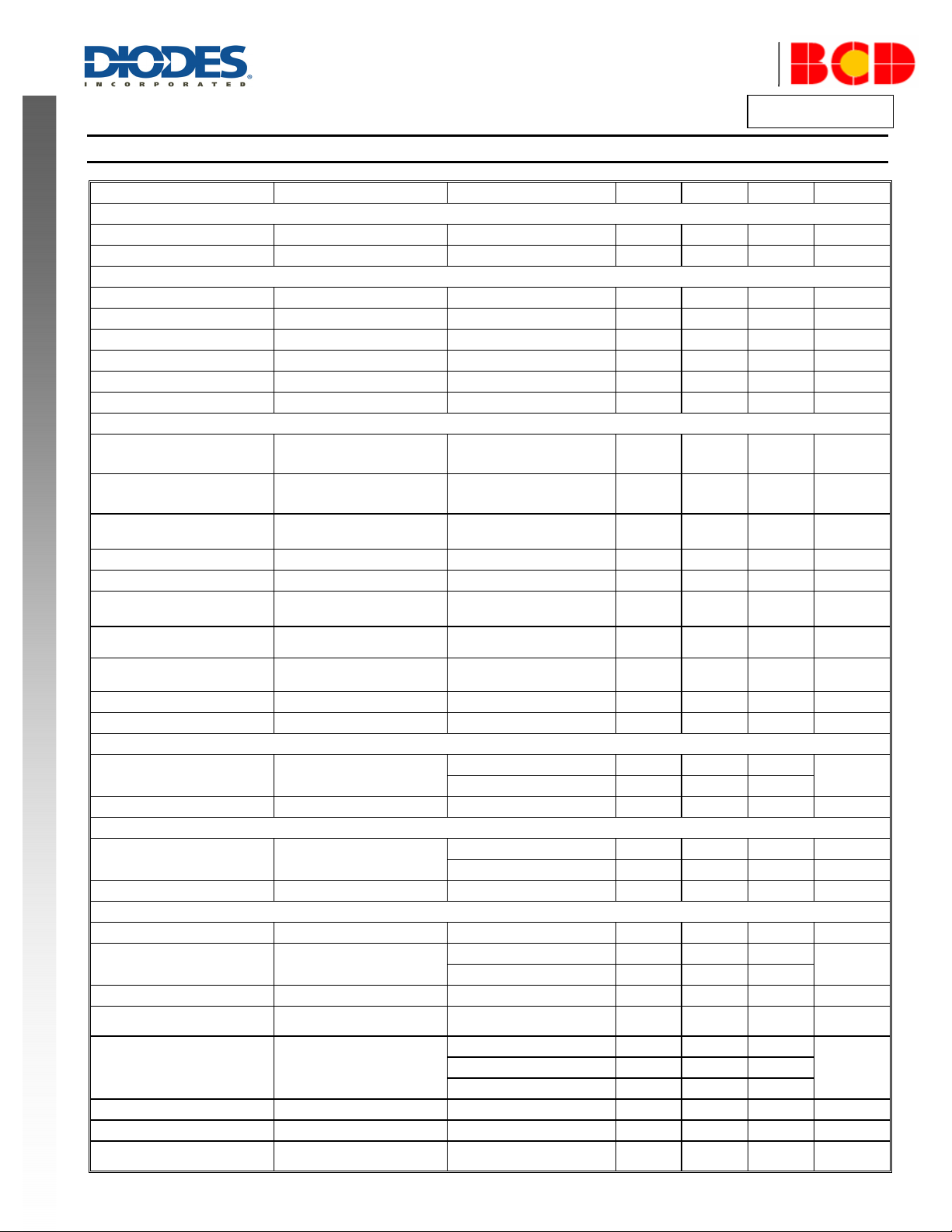

Electrical Characteristics (V

Symbol Parameter Conditions Min Typ Max Unit

SUPPLY INPUT

ICC

I

CC_Q

VIN

Supply Current

Quiescent Supply Current

Power Input Voltage – 3.0 – 13.2 V

= 12V, TA = +25oC, unless otherwise specified.)

CC

UGATE and LGATE Pins

Open; Switching

= V

REF

+0.1V,

V

FB

No Switching

– 5 – mA

– 4 – mA

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

4 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 5

A

f

Product Line o

Diodes Incorporated

AP3585A/B/C

Electrical Characteristics (Cont. V

= 12V, TA = +25oC, unless otherwise specified.)

CC

Symbol Parameter Conditions Min Typ Max Unit

POWER ON RESET

V

V

POR

V

V

POR_HYS

ERROR AMPLIFIER

G

DC_OL

GBW

SR Slew Rate – 3 6 – V/µs

– Transconductance – – 800 1100 µA/V

– Output Source Current

– Output Sink Current

PWM CONTROLLER GATE DRIVERS

I

UG_SRC

NEW PRODUCT

I

UG_SNK

R

UGATE

I

LG_SRC

I

LG_SNK

R

LGATE

–

–

– Minimum Duty Cycle – – 0 – %

– Maximum Duty Cycle – 75 82 89 %

OSCILLATOR

f

OSC

∆V

OSC

REFERENCE VOLTAGE

VFB

IFB

PROTECTION

V

FB_UVP

V

FB_OVP

I

OCSET

V

OCP_MAX

tSS

V

COMP/EN

T

OTSD

T

HYS

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

Rising Threshold VCC Rising

CC

Threshold Hysteresis

CC

–

4.0 4.2 4.4 V

– 500 – mV

Open Loop DC Gain – 55 70 – dB

Gain-bandwidth Product – – 10 – MHz

< V

REF

> V

REF

LGATE

= 6V

< 1.2V to V

< 1.2V to

= 5V

= 6V

= 12V,

= 6V

= 12V,

= 6V

LGATE

) > 1.2V

80 120 – µA

80 120 – µA

– -1.0 – A

– 1.5 – A

– 2 4 Ω

– -1 – A

– 1.5 – A

– 1 2 Ω

>

– 30 – ns

– 30 – ns

kHz

V

P-P

– 10 50 nA

0.3 0.4 0.5 V

V

9 10 11 µA

– 0.375 – V

V

FB

V

FB

V

Upper Gate Source Current

Upper Gate Sink Current

Upper Gate Sink

Resistance

Lower Gate Source Current

Lower Gate Sink Current

Lower Gate Sink

Resistance

PHASE Falling to LGATE

Rising Delay

LGATE Falling to UGATE

Rising Delay

Oscillator Frequency

BOOT-VPHASE

V

BOOT-VUGATE

V

BOOT-VPHASE

V

BOOT-VUGATE

50mA Source Current

VCC-V

V

LGATE

50mA Source Current

V

PHASE

1.2V

V

LGATE

(V

UGATE-VPHASE

AP3585A/B 270 300 330

AP3585C 180 200 220

Ramp Amplitude – – 1.4 –

Feedback Voltage

Feedback Bias Current

Under Voltage Protection

Over Voltage Protection

OC Current Source

Built-in Maximum OCP

Voltage

AP3585A 0.788 0.8 0.812 V

AP3585B/C 0.591 0.6 0.609 V

V

FB

–

AP3585A – 1.1 –

AP3585B/C – 0.8 –

–

–

AP3585A – 2 –

Soft-start Interval

Enable Threshold

Thermal Shutdown

Thermal Shutdown

Hysteresis

AP3585B – 1.5 –

AP3585C

–

–

–

– 2.4 –

0.25 0.30 0.35 V

– +160 – ºC

– +20 – ºC

5 of 18

www.diodes.com

ms

January 2014

© Diodes Incorporated

Page 6

A

f

Product Line o

Diodes Incorporated

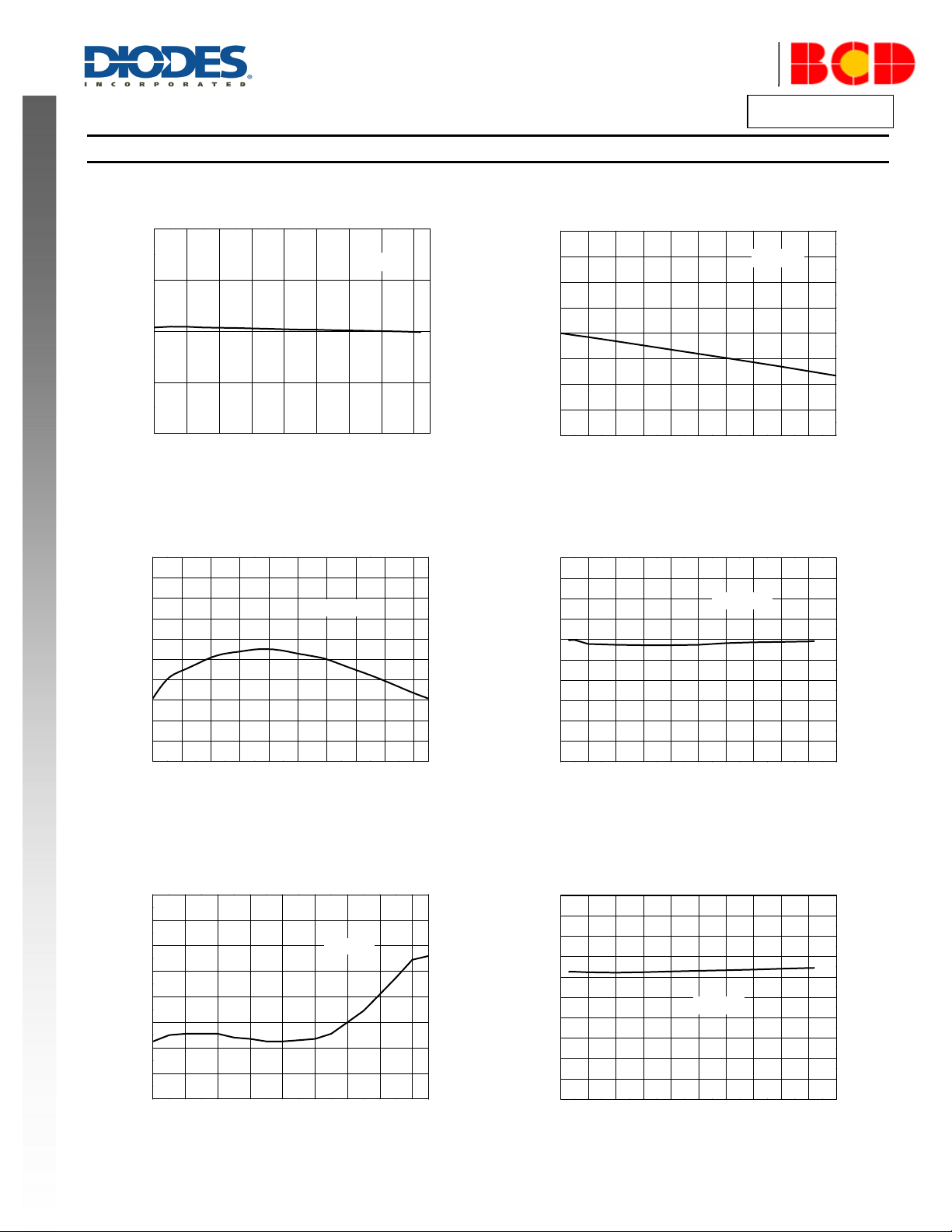

Performance Characteristics

Line Regulation Load Regulation

1.0

0.5

0.0

-0.5

Output Voltage Variation (%)

-1.0

5 6 7 8 9 10111213

NEW PRODUCT

Switching Frequency vs. Temperature Switching Frequency vs. Input Voltage

320

315

310

305

300

295

290

285

Switching Frequency (kHz)

280

275

270

-40-20 0 20406080100120140

Temperature (oC)

Reference Voltage vs. Temperature Reference Voltage vs. Input Voltage

0.816

0.814

0.812

0.810

0.808

0.806

Reference Voltage (V)

0.804

0.802

0.800

-40 -20 0 20 40 60 80 100 120

Temperature (oC)

Input Voltage (V)

AP3585A/B

V

AP3585A

OUT

=1.5V

4

3

2

1

0

-1

-2

Output Voltage Variation (%)

-3

-4

0 2 4 6 8 101214161820

320

315

310

305

300

295

290

285

Switching Frequency (kHz)

280

275

270

4 5 6 7 8 9 10 11 12 13 14

0.810

0.808

0.806

0.804

0.802

0.800

0.798

0.796

Reference Voltage (V)

0.794

0.792

0.790

4 5 6 7 8 9 10 11 12 13 14

Output Current (A)

AP3585A/B

Input Voltage (V)

AP3585A

Input Voltage (V)

AP3585A/B/C

V

=1.5V

OUT

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

6 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 7

A

f

Product Line o

Diodes Incorporated

AP3585A/B/C

Performance Characteristics (Cont.)

Power-on Waveform (V

= 12V, V

IN

OUT

= 1.5V, I

= 0A) Enable-on Waveform (V

OUT

= 12V, V

IN

OUT

= 1.5V, I

VIN

10V/div

V

OUT

1V/div

V

COMP

0.5V/div

V

LGATE

5V/div

NEW PRODUCT

(V

= 12V, V

IN

Time 4ms/div

Load Transient Response Load Transient Response

OUT

= 1.5V, I

= 0A to 10A) (V

OUT

V

OUT

1V/div

V

COMP

0.5V/div

V

UGATE

20V/div

V

LGATE

10V/div

Time 4ms/div

= 12V, V

IN

OUT

= 1.5V, I

= 0A to 20A)

OUT

OUT

= 0A)

V

OUT_AC

50mV/div

50mV/div

V

OUT_AC

I

OUT

5A/div

Time 400µs/div

I

OUT

10A/div

Time 400µs/div

Over Current Protection (V

= 12V, V

IN

= 1.5V) Under Voltage Protection (V

OUT

= 12V, V

IN

OUT

= 1.5V)

V

OUT

1V/div

V

PHASE

10V/div

V

COMP

1V/div

I

OUT

50A/div

Time 10ms/div

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

7 of 18

www.diodes.com

20V/div

10V/div

V

OUT

1V/div

V

UGATE

V

LGATE

V

COMP

1V/div

Time 20ms/div

January 2014

© Diodes Incorporated

Page 8

A

f

Performance Characteristics (Cont.)

Over Voltage Protection (V

= 12V, V

IN

V

OUT

1V/div

V

UGATE

20V/div

V

LGATE

10V/div

V

COMP

1V/div

Time 20ms/div

OUT

Product Line o

Diodes Incorporated

AP3585A/B/C

= 1.5V)

NEW PRODUCT

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

8 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 9

A

f

Product Line o

Diodes Incorporated

AP3585A/B/C

Functional Descriptions

The AP3585A/B/C is a voltage-mode single phase synchronous buck controller with embedded MOSFET drivers. This part provides complete

protection functions such as over voltage protection, under voltage protection and over current protection. Inductor current information is sensed

by R

Power on Reset and Chip Enable

A power on reset (POR) circuitry continuously monitors the supply voltage at VCC pin. Once the rising POR threshold is exceeded, the

AP3585A/B/C sets itself to active state and is ready to accept chip enable command. The rising POR threshold is typically 4.2V at VCC rising.

The COMP/EN is a multifunctional pin: control loop compensation and chip enable as shown in Figure 1. An Enable Comparator monitors the

COMP/EN pin voltage for chip enable. A signal level transistor is adequate to pull this pin down to ground and shut down AP3585A/B/C. A 120µA

current source charges the external compensation network with 0.45V ceiling when this pin is released. If the voltage at COMP/EN pin exceeds

0.3V, the AP3585A/B/C initiates its soft start cycle.

The 120µA current source keeps charging the COMP pin to its ceiling until the feedback loop boosts the COMP pin higher than 0.45V according to

the feedback signal. The current source is cut off when V

NEW PRODUCT

of the low side MOSFET. The over current protection threshold can be simply programmed by a resistor.

DS(ON)

is higher than 0.45V during normal operation.

COMP

0.45V

ERROR

120A

0.3V

ENABLE

+

-

ENABLE

COMP

+

-

AMPLIFIER

DISABLE

ENABLE

Figure 1. Chip Enable Function

Soft Start

A built-in Soft Start is used to prevent surge current from power supply input V

error amplifier is a three-input device. Reference voltage V

or the internal soft start voltage SS whichever is smaller dominates the behavior of

REF

the non-inverting inputs of the error amplifier. SS internally ramps up to 0.8V in 2ms for AP3585A (to 0.6V in 1.5ms for AP3585B and 0.6V in

2.4ms for AP3585C) after the soft start cycle is initiated. The ramp is created digitally, so there will be 100 small discrete steps. Accordingly, the

output voltage will follow the SS signal and ramp up smoothly to its target level.

The SS signal keeps ramping up after it exceeds the internal 0.8V for AP3585A (0.6V for AP3585B/C) reference voltage. However, the internal

0.8V for AP3585A (0.6V for AP3585B/C) reference voltage takes over the behavior of error amplifier after SS > V

to its ceiling voltage (4.2V), AP3585A/B/C claims the end of soft start cycle and enables the under voltage protection of the output voltage.

Figure 2 shows a typical start up interval for AP3585A/B/C where the COMP/EN pin has been released from a grounded (system shutdown) state.

The internal 120µA current source starts charge the compensation network after the COMP/EN pin is released from ground at T1. The COMP/EN

exceeds 0.3V and enables the AP3585A/B/C at T2. The COMP/EN continues ramping up the stays at 0.45V before the SS starts ramping at T3.

The output voltage follows the internal SS and ramps up to its final level during T3 and T4. At T4, the reference voltage V

behavior of the error amplifier as the internal SS crosses V

. The internal SS keeps ramping up and stays at 4.2V at T5, where AP3585A/B/C

REF

asserts the end of soft start cycle.

during turn-on (Referring to the Functional Block Diagram). The

IN

. When the SS signal climbs

REF

takes over the

REF

VIN10V/Div

0.5V/Div

V

OUT

CO MP 0. 5V/D iv

LGATE 10V/Div

1ms/Div

Figure 2. Soft Start Behavior of AP3585A/B/C

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

9 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 10

A

f

G

Product Line o

Diodes Incorporated

AP3585A/B/C

Functional Descriptions (Cont.)

Power Input Detection

The AP3585A/B/C detects PHASE voltage for the present of power input V

exceed 2.0V when UGATE turns on, AP3585A/B/C asserts that V

ramping up to V

where V

does not present initially.

IN

. Another soft start is initiated after SS ramps up to VDD. The hiccup period is about 1ms. Figure 3 shows the start-up waveform

DD

VIN10V/Div

I

10A/Div

L

is not ready and stops the soft start cycle. However, the internal SS continues

IN

L

when UGATE turns on the first time. If the PHASE voltage does not

IN

0.5V/Div

V

OUT

AT E 10V/Div

1ms/Div

Figure 3. Soft Start Where VIN Does Not Present Initially

NEW PRODUCT

Over Current Protection (OCP)

A resistor R

connected from LGATE pin sets the threshold. An internal current source I

OCSET

determines the OCP trigger point, which can be calculated using the following equation:

I

LIMIT

DS(ON)

R I

OCSETOCSET

MOSFET sidelowtheofR

If R

Because the R

is absent or larger than 40kΩ, AP3585A/B/C will work in build-in Maximum OCP Mode. Then the current limit will be:

OCSET

/375I

RmV

)(LIMIT

ONDS

of MOSFET increases with temperature, it is necessary to take this thermal effect into consideration in calculating OCP point.

DS(ON)

When OCP is triggered, both UGATE and LGATE will go low to stop the energy transfer to the load. Controller will try to restart in a hiccupped

way. Figure 4 shows the hiccupped over current protection.

(10µA typically), flowing through R

OCSET

OCSET

Figure 4. Hiccupped Over Current Protection

Over Voltage Protection (OVP)

The feedback voltage is continuously monitored for over voltage protection. When OVP is triggered, LGATE will go high and UGATE will go low to

discharge the output capacitor.

The AP3585A/B/C provides full-time over voltage protection whenever soft start completes or not. The typical OVP threshold is 137.5% of the

internal reference voltage V

removed.

Under Voltage Protection (UVP)

The feedback voltage is also monitored for under voltage protection. The under voltage protection has 15µs triggered delay. When UVP is

triggered, both UGATE and LGATE will go low. Unlike OCP, UVP is not a latched protection; controller will always try to restart in a hiccupped way.

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

. AP3585A/B/C provides non-latched OVP. The controller will return to normal operation if over voltage condition is

REF

10 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 11

A

f

Product Line o

Diodes Incorporated

AP3585A/B/C

Functional Descriptions (Cont.)

Thermal Shutdown

If the junction temperature of the device reaches the thermal shutdown limit of +160°C, the PWM and the oscillator are turned off and UGATE and

LGATE are driven low, turning off both MOSFETs. When the junction cools to the required level (+140°C nominal), the PWM initiates soft start as

during a normal power-up cycle.

Output Voltage Selection

The output voltage can be programmed to any level between the 0.8V (for AP3585A) internal reference (0.6V for AP3585B/C) to the 80% of V

supply. The lower limitation of output voltage is caused by the internal reference. The upper limitation of the output voltage is caused by the

maximum available duty cycle (80%). This is to leave enough time for over-current detection. Output voltage out of this range is not allowed.

A voltage divider sets the output voltage (Refer to the typical application circuit). In real applications, choose R1 in 100Ω to 10kΩ range and

choose appropriate R2 according to the desired output voltage.

0.8VV

OUT

0.6VV

NEW PRODUCT

PCB Layout Considerations

High speed switching and relatively large peak currents in a synchronous-rectified buck converter make the PCB layout a very important part of

design. Switching current from one power device to another can generate voltage spikes across the impedances of the interconnecting bond wires

and circuit traces. The voltage spikes can degrade efficiency and radiate noise, which results in over-voltage stress on devices. Careful

component placement layout a printed circuit design can minimize the voltage spikes induced in the converter.

Follow the below layout guidelines for optimal performance of AP3585A/B/C.

1. The turn-off transition of the upper MOSFET prior to turn-off, the upper MOSFET was carrying the full load current. During turn-off, current stops

flowing in the upper MOSFET and is picked up by the low side MOSFET. Any inductance in the switched path generates a large voltage spike

during the switching interval. Careful component selections, layout of the critical components, and use shorter and wider PCB traces help in

minimizing the magnitude of voltage spikes.

2. The power components and the PWM controller should be placed firstly. Place the input capacitors, especially the high-frequency ceramic

decoupling capacitors, close to the power switches. Place the output inductor and output capacitors between the MOSFETs and the load. Also

locate the PWM controller near MOSFETs.

3. Use a dedicated grounding plane and use vias to ground all critical components to this layer. Use an immediate via to connect the component to

ground plane including GND of AP3585A/B/C.

4. Apply another solid layer as a power plane and cut this plane into smaller islands of common voltage levels. The power plane should support

the input power and output power nodes. Use copper filled polygons on the top and bottom circuit layers for the PHASE node.

5. The PHASE node is subject to very high dV/dt voltages. Stray capacitance between this island and the surrounding circuitry tend to induce

current spike and capacitive noise coupling. Keep the sensitive circuit away from the PHASE node and keep the PCB area small to limit the

capacitive coupling. However, the PCB area should be kept moderate since it also acts as main heat convection path of the lower MOSFET.

6. The PCB traces between the PWM controller and the gate of MOSFET and also the traces connecting source of MOSFETs should be sized to

carry 2A peak currents.

OUT

R2R1

R2

R2R1

R2

AP3585A

AP3585B/C

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

11 of 18

www.diodes.com

January 2014

© Diodes Incorporated

IN

Page 12

A

f

Ordering Information

Diodes IC’s Pb-free products with "G1" suffix in the part number, are RoHS compliant and green.

Temperature

Range

Part Number Marking ID Packing

AP3585AMTR-G1 3585AM-G1 4000/Tape & Reel

AP3585BMTR-G1 3585BM-G1 4000/Tape & Reel

NEW PRODUCT

Package

SO-8

Product Line o

Diodes Incorporated

AP3585A/B/C

-40°C to +85°C

SO-8EP

Marking Information

(1) SO-8

(Top View)

(Top View)

AP3585CMTR-G1 3585CM-G1 4000/Tape & Reel

AP3585AMPTR-G1 3585AMP-G1 4000/Tape & Reel

AP3585BMPTR-G1 3585BMP-G1 4000/Tape & Reel

AP3585CMPTR-G1 3585CMP-G1 4000/Tape & Reel

First and Second Lines: Logo and Marking ID

Third Line: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

th

XX: 7

and 8th Digits of Batch Number

First and Second Lines: Logo and Marking ID

Third Line: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

th

XX: 7

and 8th Digits of Batch Number

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

12 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 13

A

f

Marking Information (Cont.)

(2) SO-8EP

NEW PRODUCT

(Top View)

(Top View)

(Top View)

Product Line o

Diodes Incorporated

AP3585A/B/C

First and Second Lines: Logo and Marking ID

Third Line: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

th

XX: 7

First and Second Lines: Logo and Marking ID

Third Line: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

XX: 7

First and Second Lines: Logo and Marking ID

Third Line: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

XX: 7

First and Second Lines: Logo and Marking ID

Third Line: Date Code

Y: Year

WW: Work Week of Molding

A: Assembly House Code

XX: 7

and 8th Digits of Batch Number

th

and 8th Digits of Batch Number

th

and 8th Digits of Batch Number

th

and 8th Digits of Batch Number

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

13 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 14

A

f

Package Outline Dimensions (All dimensions in mm(inch).)

(1) Package Type: SO-8

4.700(0.185)

5.100(0.201)

7

9

1.350(0.053)

1.750(0.069)

Product Line o

Diodes Incorporated

AP3585A/B/C

0.320(0.013)

TYP

°

NEW PRODUCT

1.000(0.039)

TYP

Option 1

°

7

9

1.270(0. 050)

TYP

0.300(0.012)

0.510(0.020)

0.100(0.004)

0.300(0.012)

3.800(0.150)

4.000(0.157)

0.150(0.006)

0.250(0.010)

0.600(0. 024)

0.725(0. 029)

D

0

°

°

8

1

7

D

:

0

1

2

°

°

0.450(0.017)

0.820(0.032)

5.800(0.228)

6.200(0.244)

0

5

1

.

0

R

°

Option 1

)

6

0

0

.

(

0

Option 2

Note: Eject hole , oriented hole and mold mark is optional

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

14 of 18

www.diodes.com

.

0.350(0.014)

TYP

January 2014

© Diodes Incorporated

Page 15

A

f

Package Outline Dimensions (Cont. All dimensions in mm(inch).)

(2) Package Type: SO-8EP

2.750(0.108)

3.402(0.134)

Product Line o

Diodes Incorporated

AP3585A/B/C

NEW PRODUCT

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

15 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 16

A

f

Suggested Pad Layout

(1) Package Type: SO-8

Product Line o

Diodes Incorporated

AP3585A/B/C

NEW PRODUCT

Dimensions

Value 6.900/0.272 3.900/0.154 0.650/0.026 1.500/0.059 1.270/0.050

Z

(mm)/(inch)

G

(mm)/(inch)

X

(mm)/(inch)

Y

(mm)/(inch)

E

(mm)/(inch)

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

16 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 17

A

f

Suggested Pad Layout (Cont.)

(2) Package Type: SO-8EP

Product Line o

Diodes Incorporated

AP3585A/B/C

NEW PRODUCT

Y1

G

Z

X1

Y

E

X

Dimensions

Value 6.900/0.272 3.900/0.154 0.650/0.026 1.500/0.059 3.600/0.142 2.700/0.106 1.270/0.050

Z

(mm)/(inch) G (mm)/(inch) X (mm)/(inch) Y (mm)/(inch)

X1

(mm)/(inch)

Y1

(mm)/(inch) E (mm)/(inch)

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

17 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Page 18

A

f

Product Line o

Diodes Incorporated

AP3585A/B/C

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

NEW PRODUCT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2012, Diodes Incorporated

www.diodes.com

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

IMPORTANT NOTICE

LIFE SUPPORT

AP3585A/B/C

Document number: DS36819 Rev. 1 - 2

18 of 18

www.diodes.com

January 2014

© Diodes Incorporated

Loading...

Loading...