Page 1

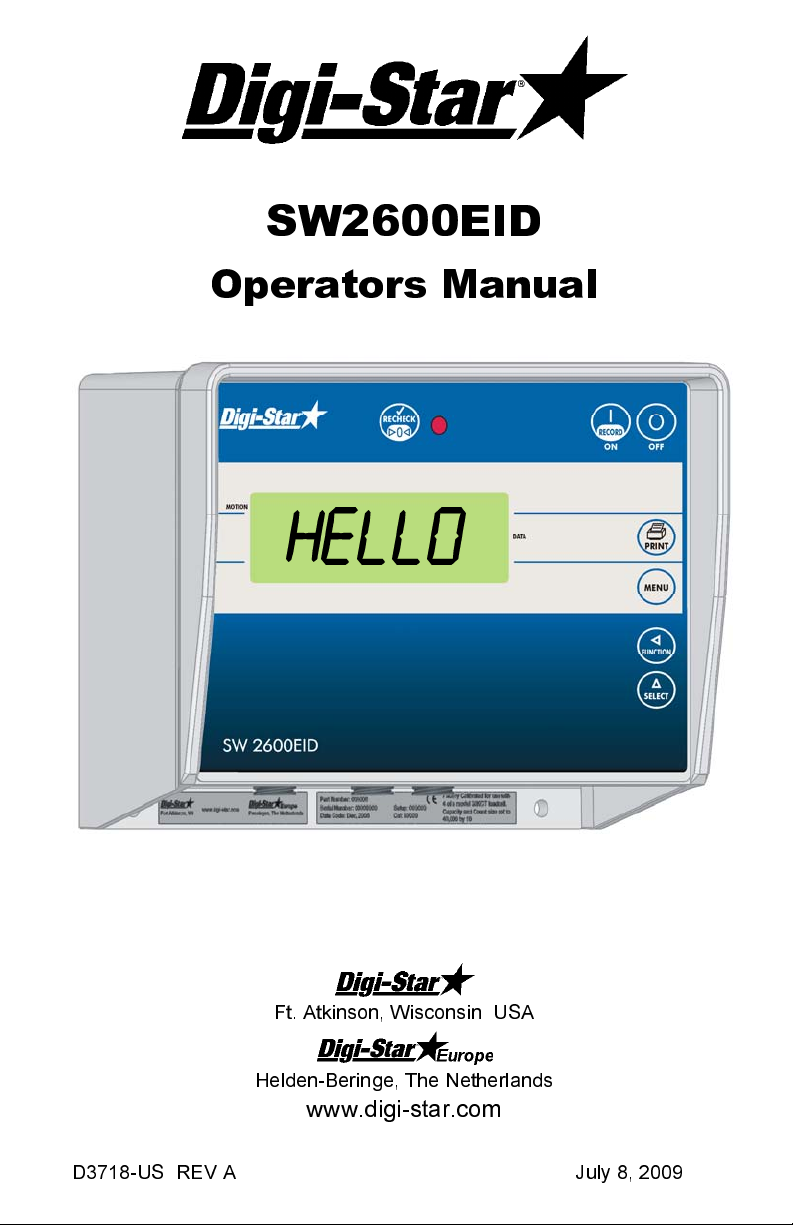

SW2600EID

Operators Manual

HELLO

Ft. Atkinson, Wisconsin USA

Helden-Beringe, The Netherlands

www.digi-star.com

D3718-US REV A July 8, 2009

Page 2

SW2600EID

TABLE OF CONTENTS

Charging Battery Or Welding ............................................... 4

Indicator overview ................................................................. 5

Operation ............................................................................... 8

Turn On indicator .................................................................................. 8

Zero Balance indicator ......................................................................... 8

Reading Eartags and Weighing Animals ............................. 8

Recheck Lock On Weigh .................................................................... 11

Low Battery Indication ........................................................................ 11

Self Test ............................................................................................. 11

Optional Settings ................................................................. 12

Change Setup and Calibration ........................................................... 12

Changing Options Using Long Form Setup ....................................... 13

Setting Options ................................................................................... 14

StockWeigh Link™ PC Software ........................................ 21

Getting Started ................................................................................... 21

Read Software License Agreement.................................................... 21

Minimum System Requirements ........................................................ 21

Installing the StockWeigh Link™ PC Software .................................. 21

Opening Stockweigh Link Program .................................................... 23

Stockweigh Link Set-up ...................................................................... 24

Files/Utilities ....................................................................................... 26

Files/Help ............................................................................................ 27

Transferring Data from Indicator to PC .............................................. 27

EID Reader – Optional ......................................................... 29

Re-Configuring Allflex Stick Reader ................................................... 30

Weigh Methods .................................................................... 31

General Weigh Method #1 ................................................................. 31

Slow Weigh Method #2 ...................................................................... 31

Fast Weigh Method #3 ....................................................................... 31

Lock-on Weigh Method #4 ................................................................. 31

Short Form Calibration ....................................................... 32

Setup Number .................................................................................... 32

Calibration Number............................................................................. 32

Calibrating Scale for Maximum Accuracy .......................................... 33

EID Data Formats ................................................................ 34

LSTORE Data Formats ...................................................................... 34

2 D3718

Page 3

Operators Manual

A

Scoreboard Methods .......................................................... 38

Weighing Errors .................................................................. 39

OVRCAP ............................................................................................. 39

+RANGE ............................................................................................. 39

-RANGE .............................................................................................. 39

Software License Agreement ............................................. 40

TroubleShooting Guide ...................................................... 42

Installation ........................................................................... 43

Indicator Mounting .............................................................................. 43

Cable Connection ............................................................................... 44

Optional Equipment ............................................................ 46

ll rights reserved. Reproduction of any part of this manual in any form whatsoever without Digi-

Star’s express written permission is forbidden. The contents of this manual are subject to

change without notice. All efforts have been made to assure the accuracy of the contents of this

manual. However, should any errors be detected, Digi-Star would greatly appreciate being

informed of them. The above notwithstanding, Digi-Star can assume no responsibility for errors

in this manual or their consequence.

© Copyright! 2008 Digi-Star, Fort Atkinson (U.S.A.).

D3718 3

Page 4

SW2600EID

TM

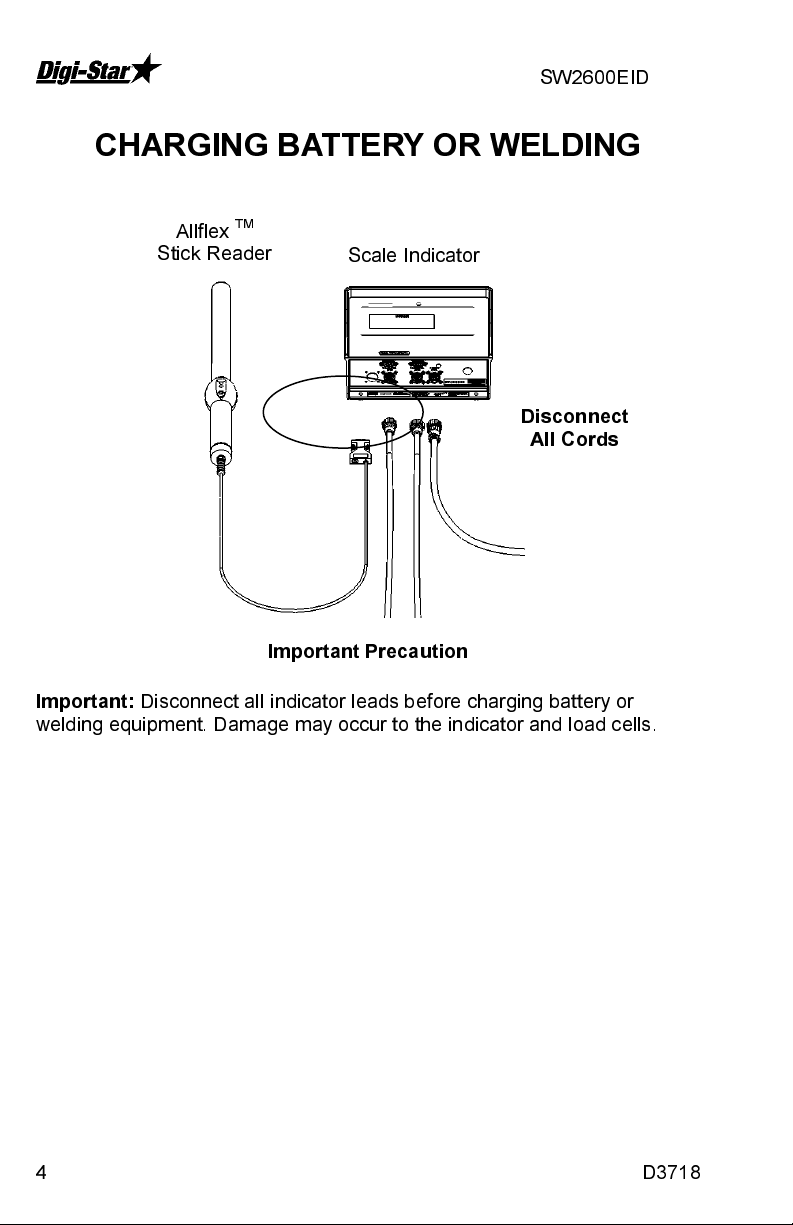

CHARGING BATTERY OR WELDING

Important:

welding equipment. Damage may occur to the indicator and load cells.

Allflex

Stick Reader

Disconnect all indicator leads before charging battery or

Scale Indicator

Disconnect

All Cords

Important Precaution

4 D3718

Page 5

Operators Manual

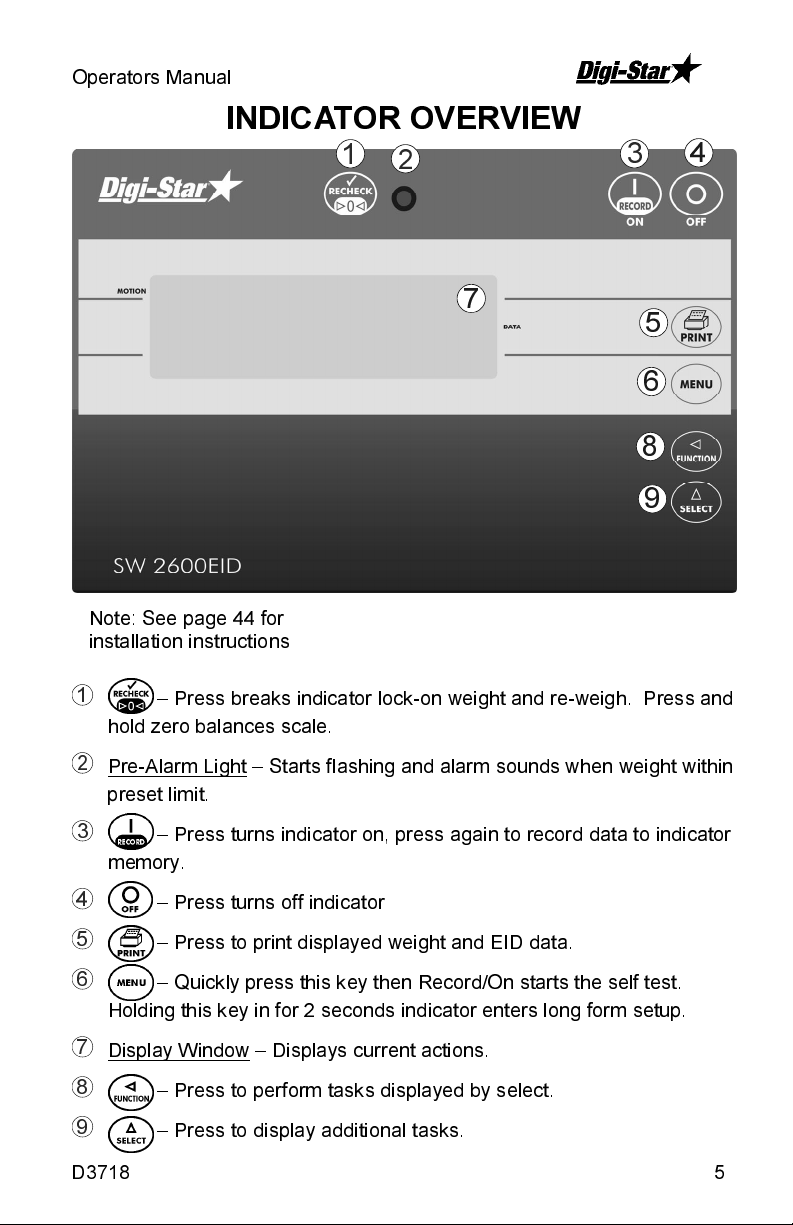

INDICATOR OVERVIEW

1

2

3

7

Note: See page 44 for

installation instructions

1

– Press breaks indicator lock-on weight and re-weigh. Press and

hold zero balances scale.

4

5

6

8

9

2

Pre-Alarm Light – Starts flashing and alarm sounds when weight within

preset limit.

3

– Press turns indicator on, press again to record data to indicator

memory.

4

– Press turns off indicator

5

– Press to print displayed weight and EID data.

6

– Quickly press this key then Record/On starts the self test.

Holding this key in for 2 seconds indicator enters long form setup.

7

Display Window – Displays current actions.

8

– Press to perform tasks displayed by select.

9

– Press to display additional tasks.

D3718 5

Page 6

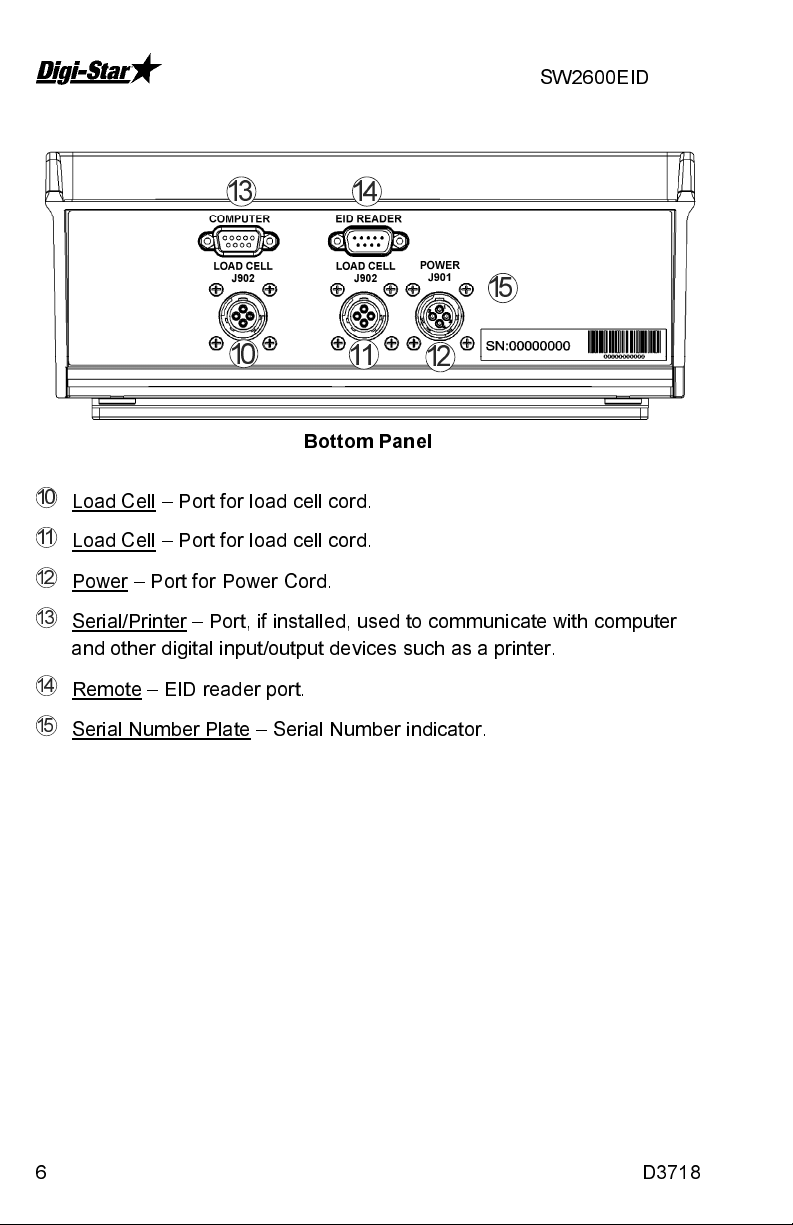

SW2600EID

13 14

15

10

10

Load Cell – Port for load cell cord.

11

Load Cell – Port for load cell cord.

12

Power – Port for Power Cord.

13

Serial/Printer – Port, if installed, used to communicate with computer

and other digital input/output devices such as a printer.

14

Remote – EID reader port.

15

Serial Number Plate – Serial Number indicator.

11

Bottom Panel

12

6 D3718

Page 7

Operators Manual

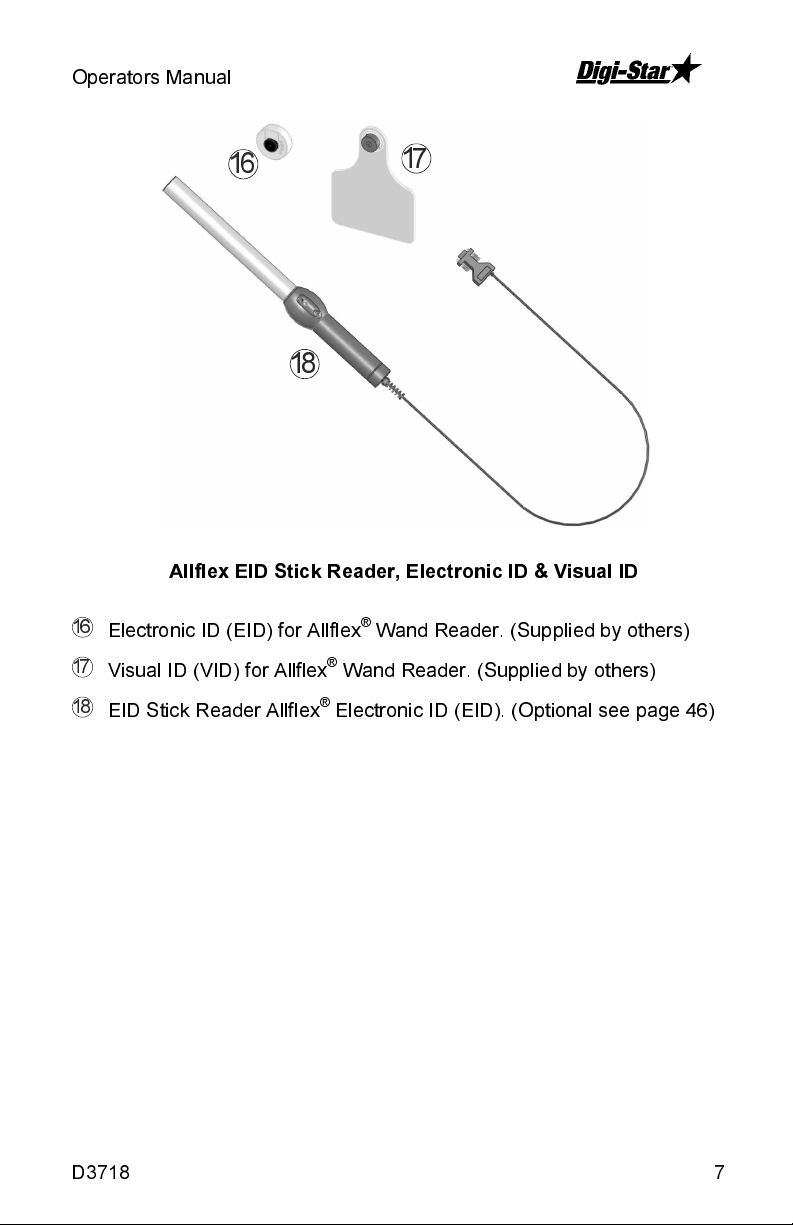

16

17

18

Allflex EID Stick Reader, Electronic ID & Visual ID

16

Electronic ID (EID) for Allflex® Wand Reader. (Supplied by others)

17

Visual ID (VID) for Allflex® Wand Reader. (Supplied by others)

18

EID Stick Reader Allflex® Electronic ID (EID). (Optional see page 46)

D3718 7

Page 8

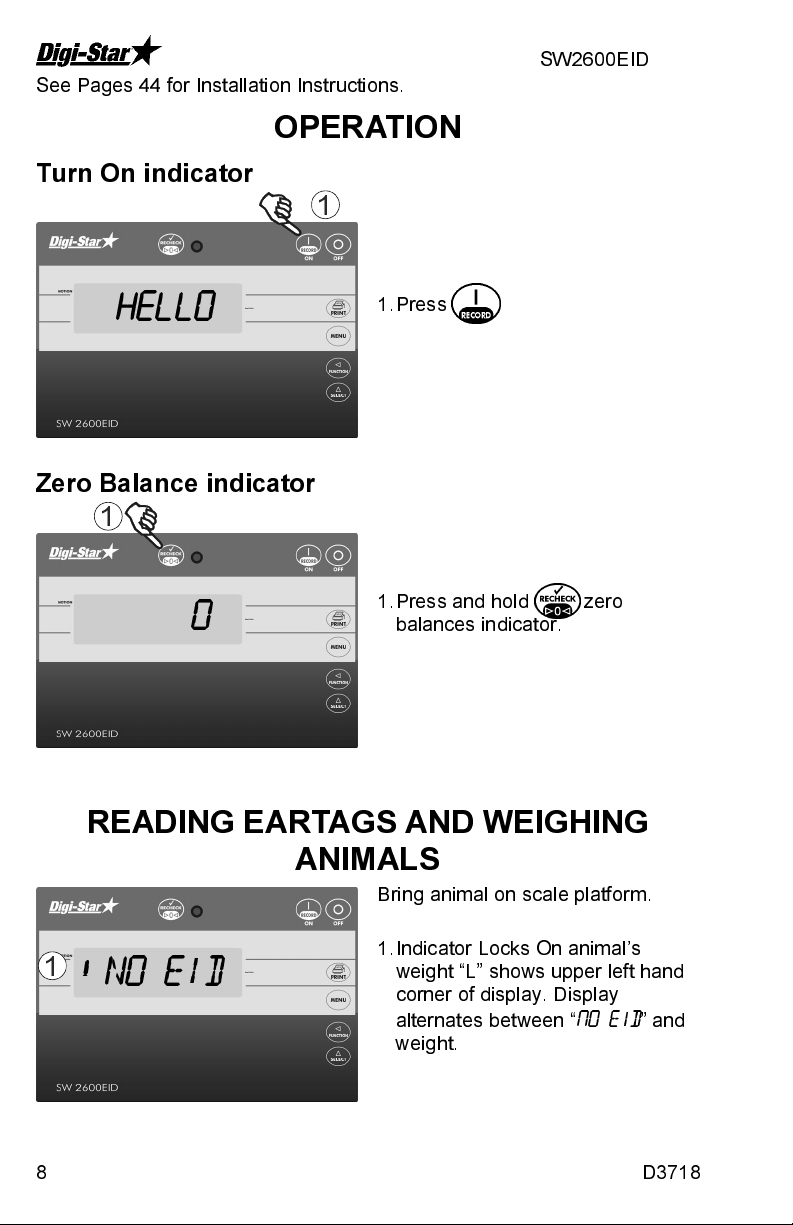

SW2600EID

See Pages 44 for Installation Instructions.

OPERATION

Turn On indicator

1

HELLO

Zero Balance indicator

1

0

READING EARTA GS AND WEIGHING

1

8 D3718

No eid

ANIMALS

1. Press

1. Press and hold zero

balances indicator.

Bring animal on scale platform.

1. Indicator Locks On animal’s

weight “L” shows upper left hand

corner of display. Display

alternates between “

weight.

no eid

” and

Page 9

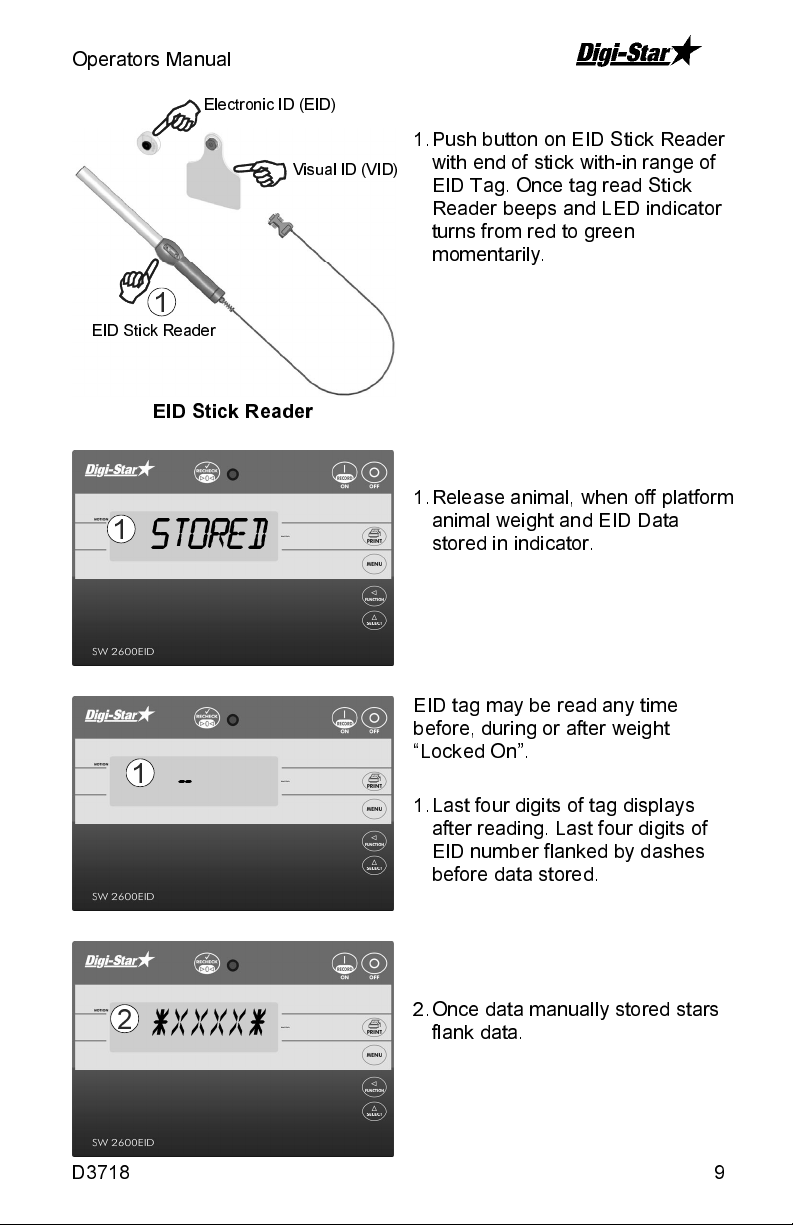

Operators Manual

1

EID Stick Reader

EID Stick Reader

1

Stored

1

2

*XXXX*

Electronic ID (EID)

Visual ID (VID)

-

1. Push button on EID Stick Reader

with end of stick with-in range of

EID Tag. Once tag read Stick

Reader beeps and LED indicator

turns from red to green

momentarily.

1. Release animal, when off platform

animal weight and EID Data

stored in indicator.

EID tag may be read any time

before, during or after weight

“Locked On”.

1. Last four digits of tag displays

after reading. Last four digits of

EID number flanked by dashes

before data stored.

2. Once data manually stored stars

flank data.

D3718 9

Page 10

SW2600EID

NOTES:

Each time pressed one line of data stored. Multiple entries

made of same tag by pressing more than once (results in

multiple beeping). Data stored manually for animal, will not be

stored when animal steps off scale. Automatic mode will resume

for next animal.

Stick Reader can read data from other devices such as car keys.

Such devices can cause confusion.

No print device necessary for operation of indicator when weighing

animals.

10 D3718

Page 11

Operators Manual

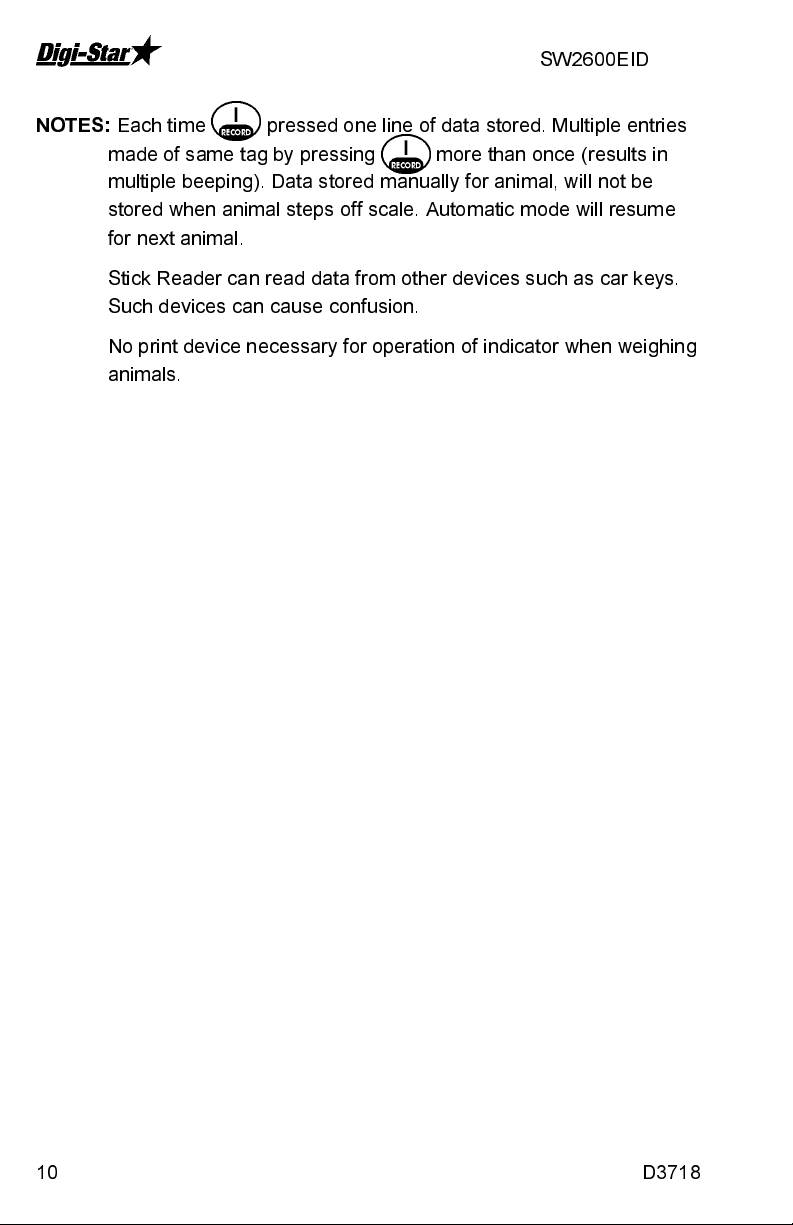

Recheck Lock On Weigh

1

Rechck

Low Battery Indication

1

1

Recharge

1. Animal on platform, press to

recheck or recalculate weight of

animal. Weight stored/ printed

when animal steps off platform or

press .

1. Battery voltage low, “

BATTERY - TURNING OFF

BAT

” shows on display. After 2

minutes indicator shuts off.

RECHARGE

” and “

LO

NOTE:

Self Test

2

test

D3718 11

1

1. Press .

2. Then during normal system

Disconnect indicator from

battery while recharging.

DAMAGE CAN OCCUR to

indicator and stick reader.

operation starts self-test.

Press to stop the self test at

any point.

Page 12

SW2600EID

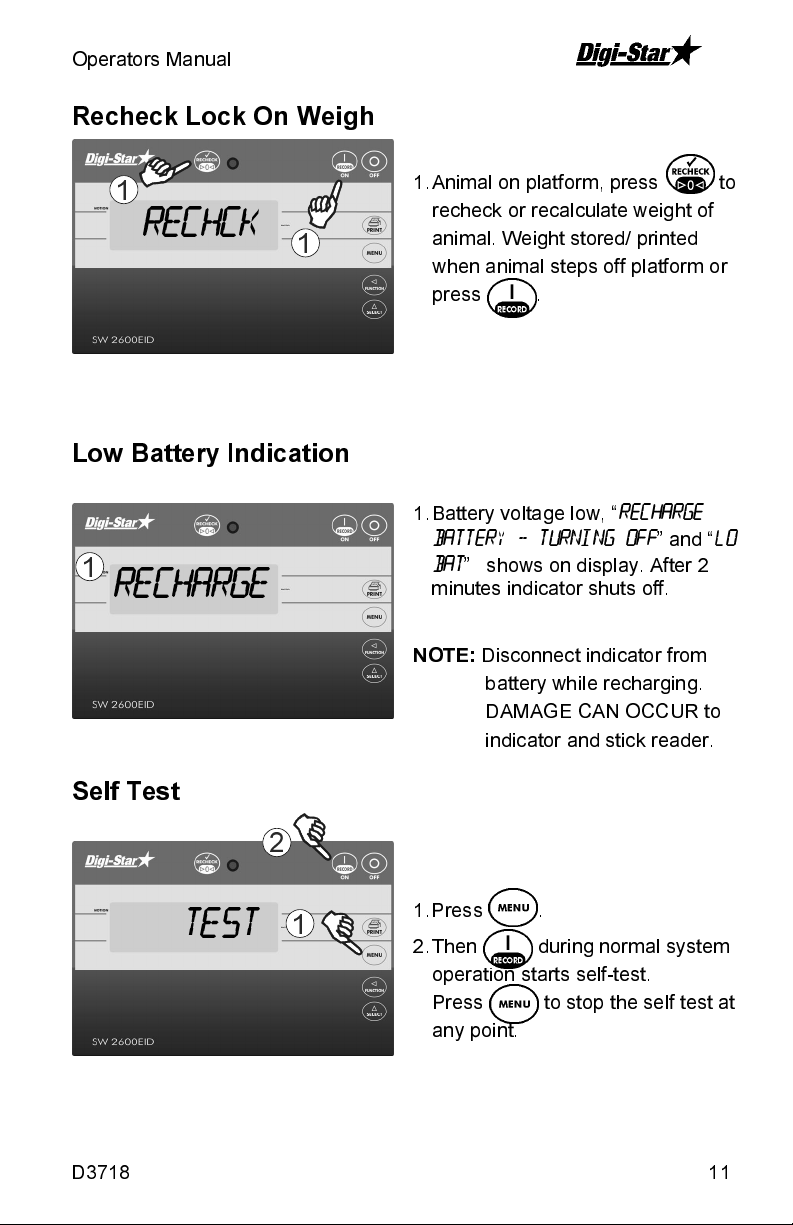

OPTIONAL SETTINGS

Change Setup and Calibration

2

1

10k kg

3

3300LB StockWeigh 3300 with Lock On (pounds)

6600LB StockWeigh 6600 with Lock On (pounds)

10K LB StockWeigh 10000 with Lock On (pounds)

14K LB StockWeigh 14000 with Lock On (pounds)

3300KG StockWeigh 3300 with Lock On (kilograms)

6600KG StockWeigh 6600 with Lock On (kilograms)

10K KG StockWeigh 10000 with Lock On (kilograms)

14K KG StockWeigh 14000 with Lock On (kilograms)

1. Press and hold .

2. Push three seconds.

3. Press advances through

selections.

Custom Press indicator displays SETUP and then 6-digit

number with right digit flashing. To change setup number,

enter new number on keypad and press then CAL

displays followed by a 3 to 5-digit number. To change

calibration number enter new number on keypad then

press .

Verify accuracy of scale and procedure complete!

12 D3718

Page 13

Operators Manual

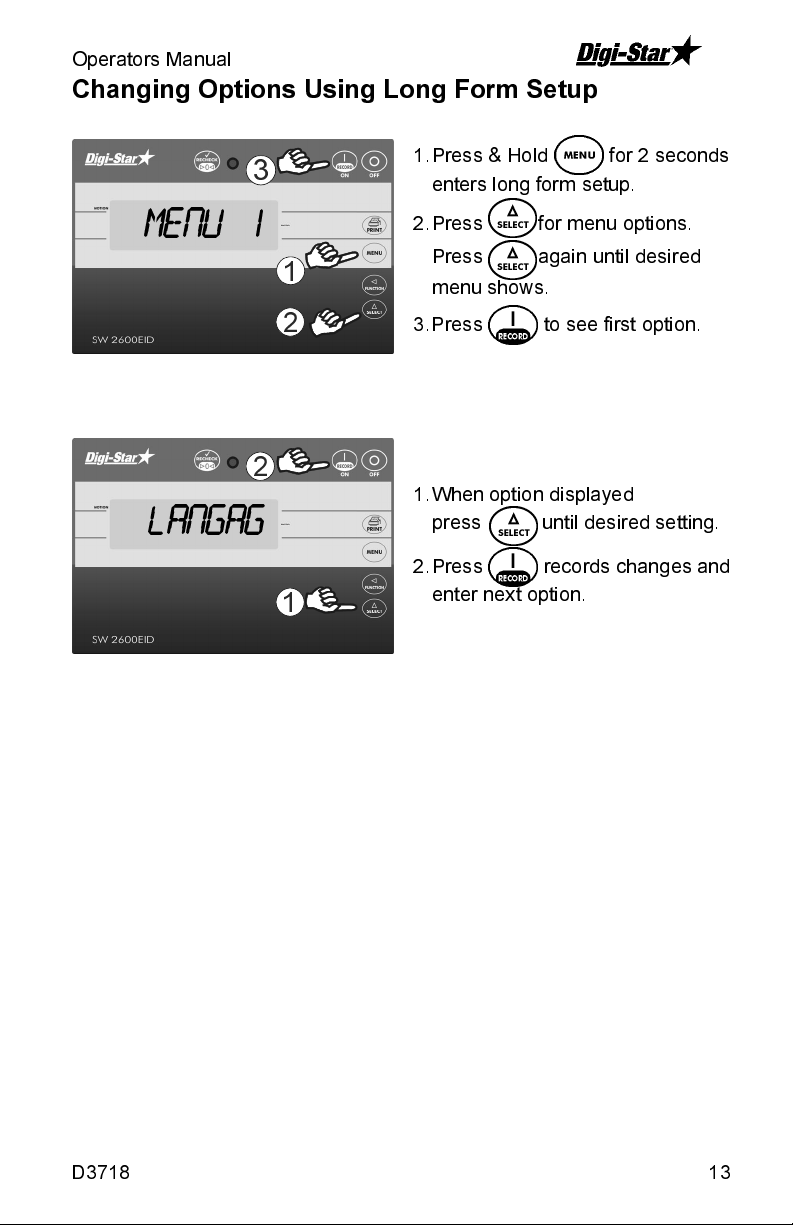

Changing Options Using Long Form Setup

3

1. Press & Hold for 2 seconds

enters long form setup.

Menu 1

1

2

2

langag

1

2. Press for menu options.

Press again until desired

menu shows.

3. Press to see first option.

1. When option displayed

press until desired setting.

2. Press records changes and

enter next option.

D3718 13

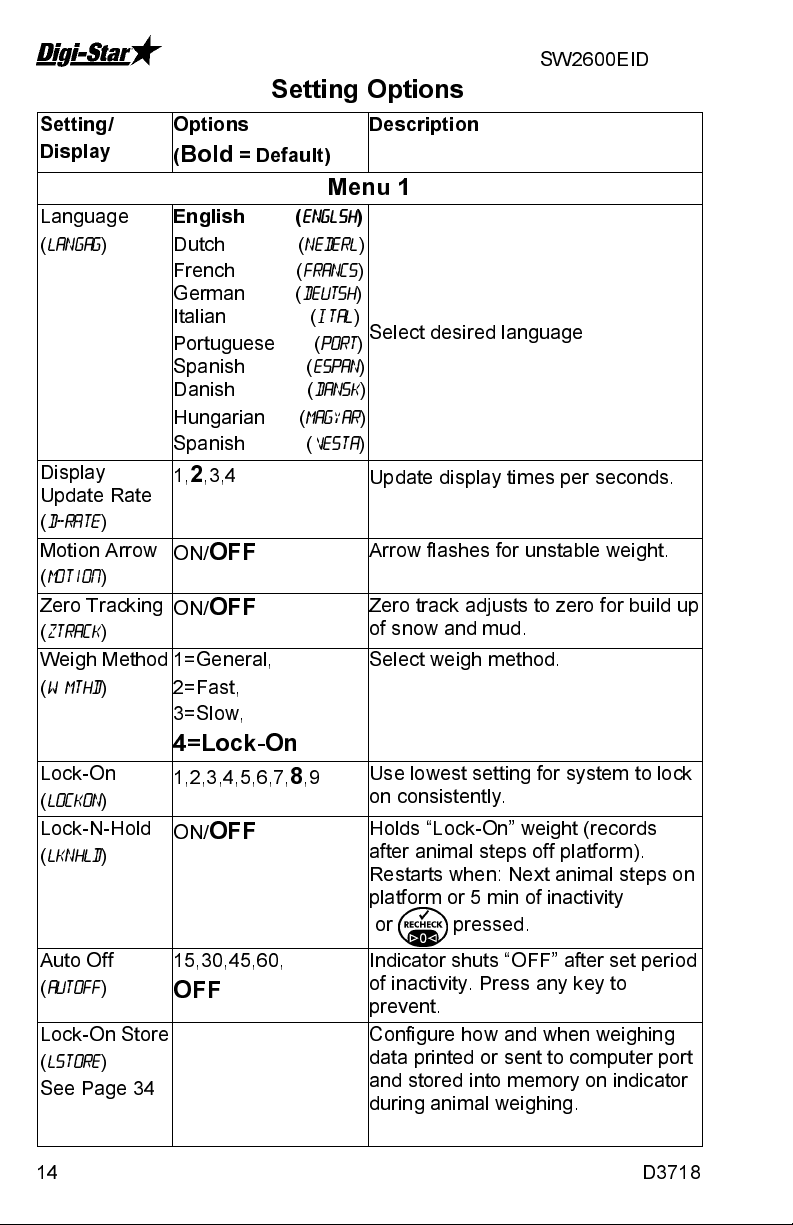

Page 14

Setting/

Display

Language

(

LANGAG)

Display

Update Rate

(

D-Rate

Motion Arrow

(

Motion

Zero Tracking

(

ZTRACK

Weigh Method

(

W MTHD

Lock-On

(

LOCKON

Lock-N-Hold

(

LKNHLD

)

)

)

)

)

)

SW2600EID

Setting Options

Options

(

Bold

= Default)

English (

Dutch (

French (

German (

Italian (

Portuguese (

Spanish (

Danish (

Hungarian (

Spanish (

1,

2

,3,4

ON/

OFF

ON/

OFF

1=General,

2=Fast,

3=Slow,

ENGLSH

NEDERL

FRANCS

DEUTSH

4=Lock-On

1,2,3,4,5,6,7,

ON/

OFF

8

,9

MAGYAR

Description

Menu 1

)

)

)

)

ITAL

)

Select desired language

PORT

)

ESPAN

)

DANSK

)

)

VESTA

)

Update display times per seconds.

Arrow flashes for unstable weight.

Zero track adjusts to zero for build up

of snow and mud.

Select weigh method.

Use lowest setting for system to lock

on consistently.

Holds “Lock-On” weight (records

after animal steps off platform).

Restarts when: Next animal steps on

platform or 5 min of inactivity

or pressed.

Auto Off

(

AUTOFF

)

Lock-On Store

(

LSTORE

)

See Page 34

14 D3718

15,30,45,60,

OFF

Configure how and when weighing

Indicator shuts “OFF” after set period

of inactivity. Press any key to

prevent.

data printed or sent to computer port

and stored into memory on indicator

during animal weighing.

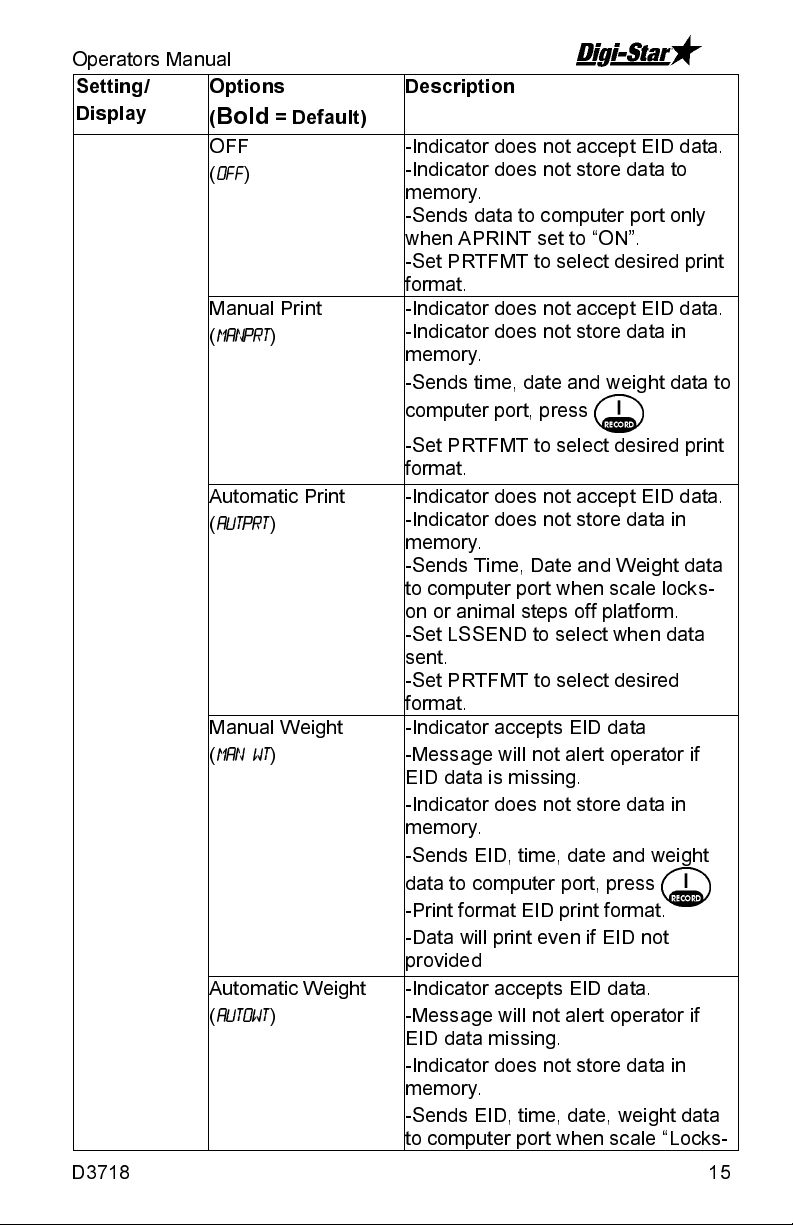

Page 15

Operators Manual

Setting/

Display

Options

(

Bold

= Default)

OFF

(

OFF

)

Manual Print

(

MANPRT

)

Automatic Print

(

AUTPRT

)

Manual Weight

(

MAN WT

)

Automatic Weight

(

AUTOWT

)

Description

-Indicator does not accept EID data.

-Indicator does not store data to

memory.

-Sends data to computer port only

when APRINT set to “ON”.

-Set PRTFMT to select desired print

format.

-Indicator does not accept EID data.

-Indicator does not store data in

memory.

-Sends time, date and weight data to

computer port, press .

-Set PRTFMT to select desired print

format.

-Indicator does not accept EID data.

-Indicator does not store data in

memory.

-Sends Time, Date and Weight data

to computer port when scale locks-

on or animal steps off platform.

-Set LSSEND to select when data

sent.

-Set PRTFMT to select desired

format.

-Indicator accepts EID data

-Message will not alert operator if

EID data is missing.

-Indicator does not store data in

memory.

-Sends EID, time, date and weight

data to computer port, press .

-Print format EID print format.

-Data will print even if EID not

provided

-Indicator accepts EID data.

-Message will not alert operator if

EID data missing.

-Indicator does not store data in

memory.

-Sends EID, time, date, weight data

to computer port when scale “Locks-

D3718 15

Page 16

Setting/

Display

SW2600EID

Options

(

Bold

= Default)

Manual EID

(

MANEID

)

Description

On” or when animal steps off

platform.

-Set LSSEND to select when data

sent to computer port.

-Print format is EID print format.

If LSSEND “ON”, data sent to

computer port when scale “Locks-

On” to weight. EID must be read

before animal weighed in this mode.

If LSSEND “OFF”, and EID not read

time, date, weight data sent when

animal off platform.

-Indicator accepts EID data.

-Message alerts operator if EID data

missing.

-Sends EID, time, date, weight data

to computer port and stores comma-

separated values (CSV) in memory

when . pressed

-Print format EID print format.

-Data stored in EID data format.

-If ESTORE “OFF”, data not stored

into indicator memory.

Automatic EID

(

AUTEID)

16 D3718

-Indicator accepts EID data.

-Message alerts operator if EID data

missing.

-Sends EID, time, date, weight data

to computer port and stores CSV in

memory when scale “Locks-On” or

when animal off platform.

-Set LSSEND to select when data

printed.

If LSSEND “ON” and EID not read,

press prints data.

If LSSEND “OFF” and EID not read,

time, date, weight data prints when

animal off platform.

-Print format EID print format.

-Data stored in EID data format.

Page 17

Operators Manual

Setting/

Display

Lock-On-

Store Send

(

LSSEND

EID Store

(

ESTORE

D3718 17

)

)

Options

(

Bold

= Default)

Manual Check

(

MANCHK

)

Automatic Check

(

AUTCHK

)

ON/

OFF

ON

/OFF

Description

-If ESTORE “OFF”, data not stored

into indicator memory.

-Indicator accepts EID data.

-Message alerts operator EID data

missing. Operator must press

to print and store data with or without

EID.

-Sends EID, time, date, weight data

to computer port and stores comma-

separated values (CSV) in memory

when press .

-Print format EID print format.

-Data stored in EID data format.

-If ESTORE “OFF”, data not stored

into indicator memory.

-Indicator accepts EID data.

-Message alerts operator if EID data

missing. Press prints and

stores data without EID.

-Sends EID, time, date, weight data

to computer and stores (CSV) in

memory when EID data read and

scale locks-on or when animal off

platform.

-Set LSSEND to select when data

printed.

-Print format EID print format.

-Data stored in EID data format.

-If ESTORE “OFF”, data not stored

into indicator memory

Data sent when scale LOCKS-ON

and EID read.

Press rechecks weight and

send/store new data.

Indicator stores data in following

LSTORE modes: MANEID, AUTEID,

MANCHK, AUTCHK. “StockWeigh

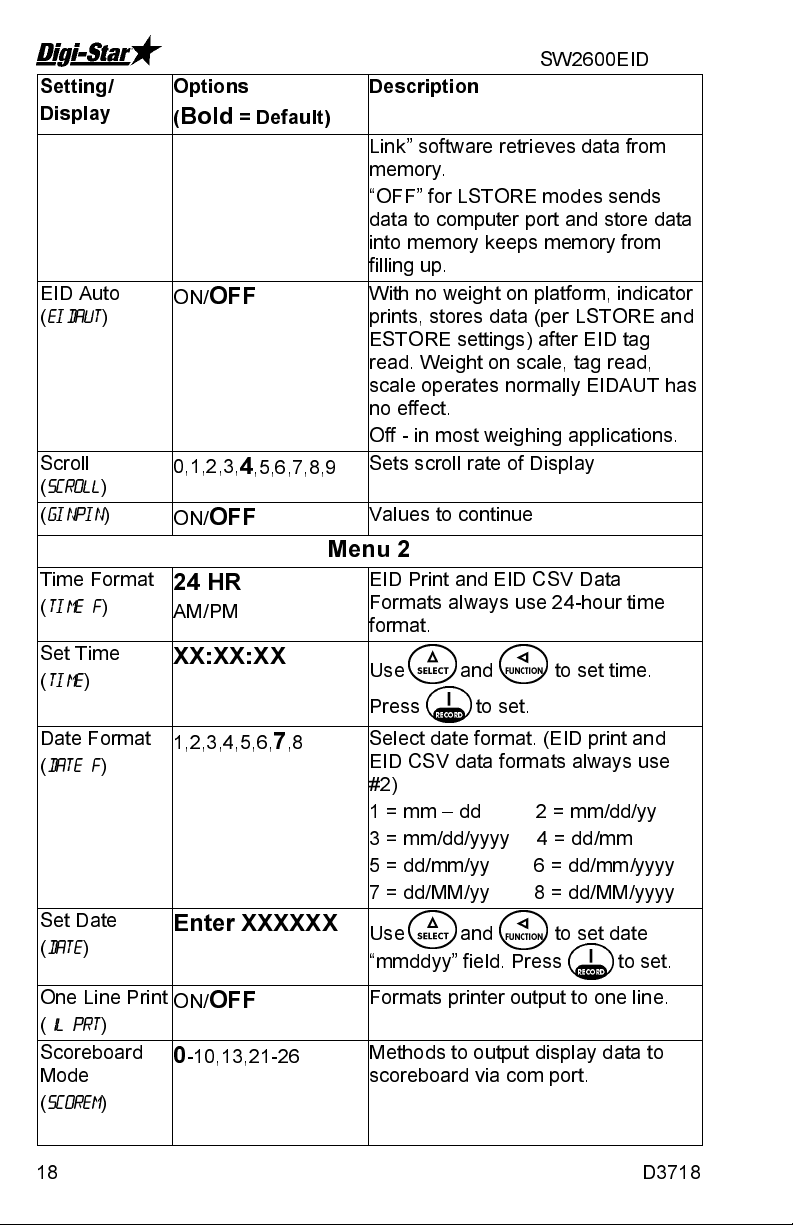

Page 18

Setting/

X

X

Display

EID Auto

(

EIDAUT

Scroll

(

SCROLL

(

GINPIN

Time Format

(

TIME F

Set Time

(

TIME

Date Format

(

DATE F

Set Date

(

DATE

)

)

)

)

)

)

)

SW2600EID

Options

(

Bold

ON/

OFF

0,1,2,3,

ON/

OFF

= Default)

4

,5,6,7,8,9

Description

Link” software retrieves data from

memory.

“OFF” for LSTORE modes sends

data to computer port and store data

into memory keeps memory from

filling up.

With no weight on platform, indicator

prints, stores data (per LSTORE and

ESTORE settings) after EID tag

read. Weight on scale, tag read,

scale operates normally EIDAUT has

no effect.

Off - in most weighing applications.

Sets scroll rate of Display

Values to continue

Menu 2

24 HR

AM/PM

XX:XX:X

1,2,3,4,5,6,

7

,8

Enter XXXXX

EID Print and EID CSV Data

Formats always use 24-hour time

format.

Use and to set time.

Press to set.

Select date format. (EID print and

EID CSV data formats always use

#2)

1 = mm – dd 2 = mm/dd/yy

3 = mm/dd/yyyy 4 = dd/mm

5 = dd/mm/yy 6 = dd/mm/yyyy

7 = dd/MM/yy 8 = dd/MM/yyyy

Use and to set date

“mmddyy” field. Press to set.

One Line Print

(

1L PRT

)

Scoreboard

Mode

(

SCOREM

)

18 D3718

ON/

OFF

0

-10,13,21-26

Formats printer output to one line.

Methods to output display data to

scoreboard via com port.

Page 19

Operators Manual

Setting/

Display

Auto Print

(

APRINT

Print Format

(

PRTFMT

Zero Out

)

)

Options

(

Bold

ON/

OFF

AUTO

= Default)

Description

Pressing keys will automatically print

weight values.

See Page 34 for details.

Press & hold

Com 1 Delay

(

C1 DLY

)

Com 2 Delay

(

C2 DLY

)

Estimated

Weight

(

EST WGHT

Display Count

(

COUNT

Auto-Range

(

ARANGE

Display Unit

(

LB-KG

Capacity

(

CAP

WM1

ADJUST

(

WMA 1-1

WM1

ADJUST 2

(

WMA 1-2

WM1

ADJUST 3

(

WMA 1-3

WM2

ADJUST 1

(

WMA 2-1

)

)

)

)

)

)

)

)

)

OFF

,.10,.25,.50,.75,

1-5

OFF

,.10,.25,.50,.75,

1-5

0

,1,2,3,4,5,6,7,8,9

.01,

.02

,.05,.1,.2,.5,1,

2,5,10,20, 50,100

ON/

OFF

LB

/KG

4000

10

0,1,2,3,

4

,5,6,7,8,9

400

30

Seconds printer delays before

advancing line.

Enter weight on scale

Menu 3

Count set too small, readings

unstable and indicator not accurate

Scale increases display count size

for weights over 300 again at 600

lbs/kgs.

When changing weight unit

calibration adjusted so scale displays

accurately in new display unit

Enter maximum weight measurable

Increase number to smooth

weighing

0=OFF Use values less than WMA 1-

1 for quick weight response.

Enter weight to activate quick weight

response.

Increase number to smooth

weighing

D3718 19

Page 20

SW2600EID

Setting/

Display

WM2

ADJUST 2

(

WMA 2-2

WM2

ADJUST 3

(

WMA 2-3

Buzzer

(

BUZZER

Relay

(

RELAY

SETCHG

SETDEL

SETOUT

SETCTR

Tcalb

Zero

)

)

)

)

Options

(

Bold

= Default)

10

400

1

-4, ON, OFF

SETPNT

50

0

OVER

0,

ON

/UNDER

1

,2,3,4,5,6,7,8,9

/OFF

/OFF

Description

0=OFF Use values less than WMA2-

1 for quick weight response.

Enter weight activate quick weight

response.

Menu 4

Decrease # shortens alarm horn

Set control for 12 VDC alarm

Press enter @ setpnt gives option to

enter value

Weight below SETPNT to change

12VDC alarm

Time before 12 VDC alarm output

changes

12 VDC alarm = +12 VDC when over

or under setpnt

Use keypad to enter values.

Calib

Scale adjust for temperature

changes

Press and hold to zero

balance

Add Wt Enter weight amount on scale

20 D3718

Page 21

Operators Manual

STOCKWEIGH LINK™ PC SOFTWARE

StockWeigh Link™ software can be configured to automatically or manually

import data collected indicator. Tag number, weight, date, time and other

information transmitted from indicator and stored in CSV (Comma

Separated Value) file that works easily with ordinary spreadsheet programs

like Microsoft Excel

Getting Started

This section explains necessary steps to install software and run

StockWeigh Link

Read Software License Agreement

Read Digi-Star ®Software License Agreement on page 40. When seal

broken on CD, and software installed, you agree to terms of license

agreement.

Minimum System Requirements

Make certain your PC includes the following:

Pentium

100 meg free disk space, 32 meg Ram, CD Drive, mouse, printer, serial

port or USB port and USB to Serial Port Adapter.

NOTE:

™

100 or better PC, Microsoft Windows 98, 2000, ME, XP or NT

A USB to Serial Port Adapter should be used if PC does not have a

free serial port. Serial port must be assigned to port number 1 to 8.

Certain programs interfere with operation of serial port /

StockWeigh Link

auto ID software. Shut off these programs when reading / writing to

indicator. Failure to shut off these programs during this sequence

may result in errors and lost data.

®

.

™

Software using default settings.

™.

Programs include Palm Desktop and some

™

Installing the StockWeigh Link™ PC Software

Install software:

1. Close all open programs.

2. Insert CD into drive. If Auto Run enabled on computer, follow installation

instructions. If installation screen does not appear, go to Start and select

Run. From Run menu, browse CD and select “setup.exe”. Install screen

will appear. Follow installation instructions.

3. Disconnect computer from StockWeigh computer port.

4. Double-click on StockWeigh Link icon starts program.

5. Click on StockWeigh Link icon in taskbar.

D3718 21

Page 22

SW2600EID

6. Program directs Plug StockWeigh Scale into working comm port and

press the ‘Start’ button”. Connect one end of data cable to a serial port

(DB-9 connector) on PC. If only USB port available, use “USB to Serial

Port Converter”. Connect other end of data cable to indicator bottom

panel DB-9 connector labeled “COMPUTER”. Click start. Attach power to

indicator, press click Start.

Find Comm Port

7. Program will search and find comm. port. A box pops up with “Working

Stockweigh found” and tell where it was found. Click OK.

NOTE:

When first connecting to computer with Stockweigh Link already

installed or if comm port needs to change, select Files\Comm. port for

StockWeigh, the screen above will appear. Press start.

8. Enter 6-digit StockWeigh Link

™

serial number from CD.

9. “Setup Options” window appears, click “OK” selects default settings. See

page 24 for instructions.

22 D3718

Page 23

Operators Manual

Opening Stockweigh Link Program

1

2

1. To open program double click on Stockweigh Link icon on your desktop.

2. Once started it will show in the taskbar of the PC.

3

3. Click on icon in taskbar to popup Stockweigh Link Screen.

D3718 23

Page 24

SW2600EID

Stockweigh Link Set-up

Files/Setup Options

This command opens a dialog box enabling operator to configure software.

Defaults shown below.

Received Text File Storage

Enter file path to folder where data files to be saved. Default file

path shown above.

Fixed File Name:

Always stores data to same file name in folder defined in “File

Path” field.

NOTE

: Previously existing data file will be overwritten and lost when using

fixed file name. Use Date Specific File Name (see below) to avoid

loss of data.

24 D3718

Page 25

Operators Manual

Ask Each Time for File Name:

PC prompts operator for filename each time data stored to PC.

Date Specific File Name [yymmdd_xx.csv] (default):

A unique file name automatically generated by program. File name

includes date and sequential number.

Remove Checksum character from stored livestock data line:

Put a check in this box prevents data verification number from

printing on spread sheet.

Auto File Retrieval

Auto Detect StockWeigh and Retrieve Livestock Data (default):

PC senses indicator connected, and automatically stores data in

CSV file. StockWeigh Link software must be running 15 seconds

before indicator connected.

NOTE

: Duplicate files created using this command. Be aware that data file

automatically created when indicator connected to PC.

Only Retrieve Livestock Data by Operator Demand:

Operator must enter utilities menu and select the command “Read

StockWeigh” to transfer data from indicator to CSV file in PC.

Clear StockWeigh Memory Mode

Auto Clear After Read:

Memory cleared automatically after read and stored on PC.

Ask to Clear After Read (default)

Program will ask operator “Do you wish to clear the St ockWeigh

memory?” after data read and stored on PC.

Only Clear with Function Control

Operator must enter utilities menu and select command “Clear

StockWeigh” to clear memory in indicator.

NOTE

: If indicator memory not cleared before reading more ear tags, new

EID data will be added to previously read EID data. Memory

capacity is used up by old data and duplicate data transferred to

the PC.

D3718 25

Page 26

SW2600EID

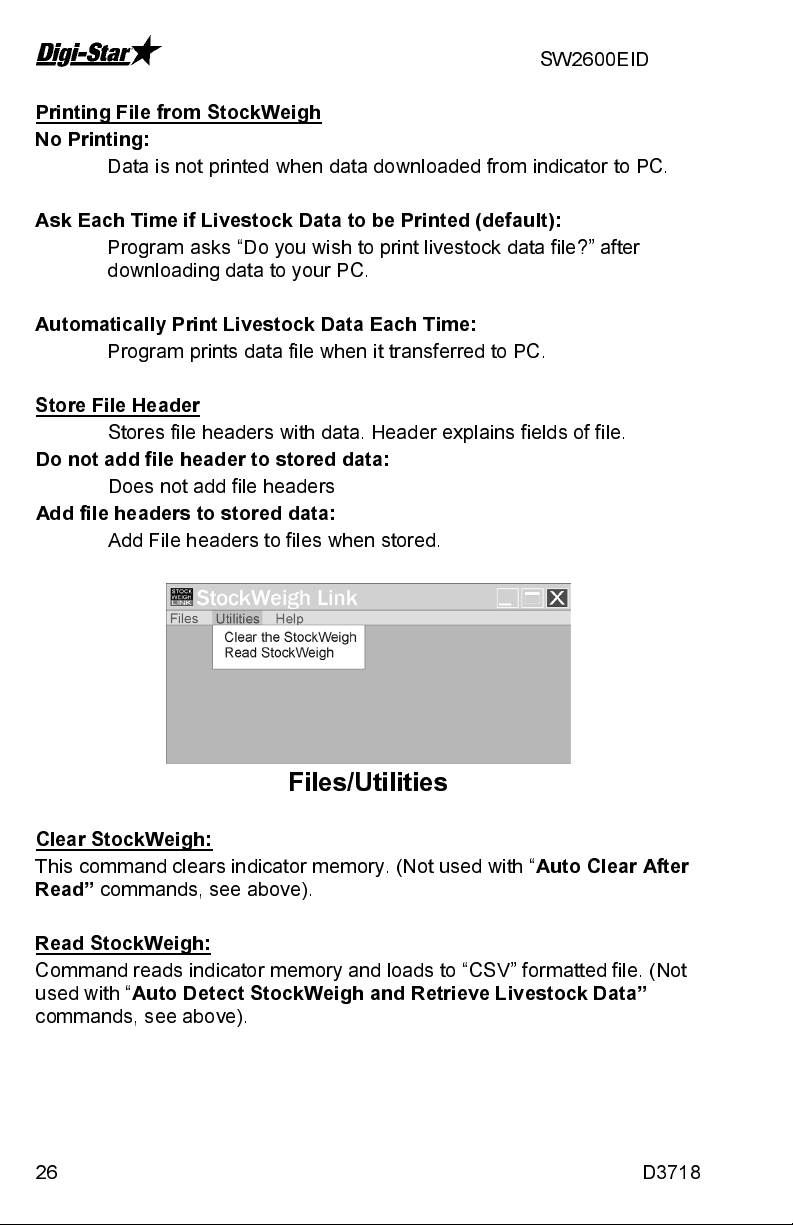

Printing File from StockWeigh

No Printing:

Data is not printed when data downloaded from indicator to PC.

Ask Each Time if Livestock Data to be Printed (default):

Program asks “Do you wish to print livestock data file?” after

downloading data to your PC.

Automatically Print Livestock Data Each Time:

Program prints data file when it transferred to PC.

Store File Header

Stores file headers with data. Header explains fields of file.

Do not add file header to stored data:

Add file headers to stored data:

Add File headers to files when stored.

Does not add file headers

Files/Utilities

Clear StockWeigh:

This command clears indicator memory. (Not used with “

Read”

commands, see above).

Read StockWeigh:

Command reads indicator memory and loads to “CSV” formatted file. (Not

used with “

commands, see above).

26 D3718

Auto Detect StockWeigh and Retrieve Livestock Data”

Auto Clear After

Page 27

Operators Manual

Files/Help

About:

Contains software version number and serial number.

Instructions

Contains text file with detailed instructions. Instructions can be

printed.

Transferring Data from Indicator to PC

NOTE

: Do not run weigh while Stockweigh Link is running. This is not a

“Chute Side” application. Do not connect both stick reader and

computer to indicator while running program.

1. StockWeigh Link

running and ready for next step. Allow software to run 15 seconds before

proceeding.

2. Connect one cable end to serial port (DB-9 connector) on PC. Connect

other cable end to indicator bottom panel connector labeled

“COMPUTER”. Connect power to indicator, press .

™

icon on taskbar indicates that software installed,

NOTE:

3. If configured for “Auto Detect” a window pops up indicating that data

D3718 27

For the Stockweigh Link Software to communicate with indicator it

must be on the weigh or stats screen.

being transferred. When it is complete window will clear.

Page 28

SW2600EID

NOTE:

If Auto Detect is not set to on, select “Utilities/Read Stockweigh”,

window pops up indicating that data being transferred. Follow

screen instructions to print and clear indicator records.

1

Files are now saved in specified file in C.S.V. (Comma Separated Format).

These files can now be opened in an Excel spread sheet and manipulated

as required by user.

28 D3718

Page 29

Operators Manual

EID READER – OPTIONAL

NOTES

The Allfex™ Stick Reader reconfigures output format if the button

The Allflex250™ Stick Reader gets its power from StockWeigh

If problem with Allflex™ RFID Stick Reader or number of

Refer to Allflex

: The StockWeigh connects to Allflex™ ISO Compatible RFID Stick

Readers only. Do not attempt to use with other RFID readers or

peripherals that are not approved by Digi-Star. DAMAGE MAY

OCCUR.

is depressed while powering “ON”. Be careful not to lay stick

reader with button down while applying power.

“EID Reader” port and does not use external power cube. Allflex

320 reader uses batteries in handle

characters it is transmitting, follow procedure below to re-configure

stick reader to TIRIS S2000 output format.

™

RFID Stick Reader manual for details.

D3718 29

Page 30

SW2600EID

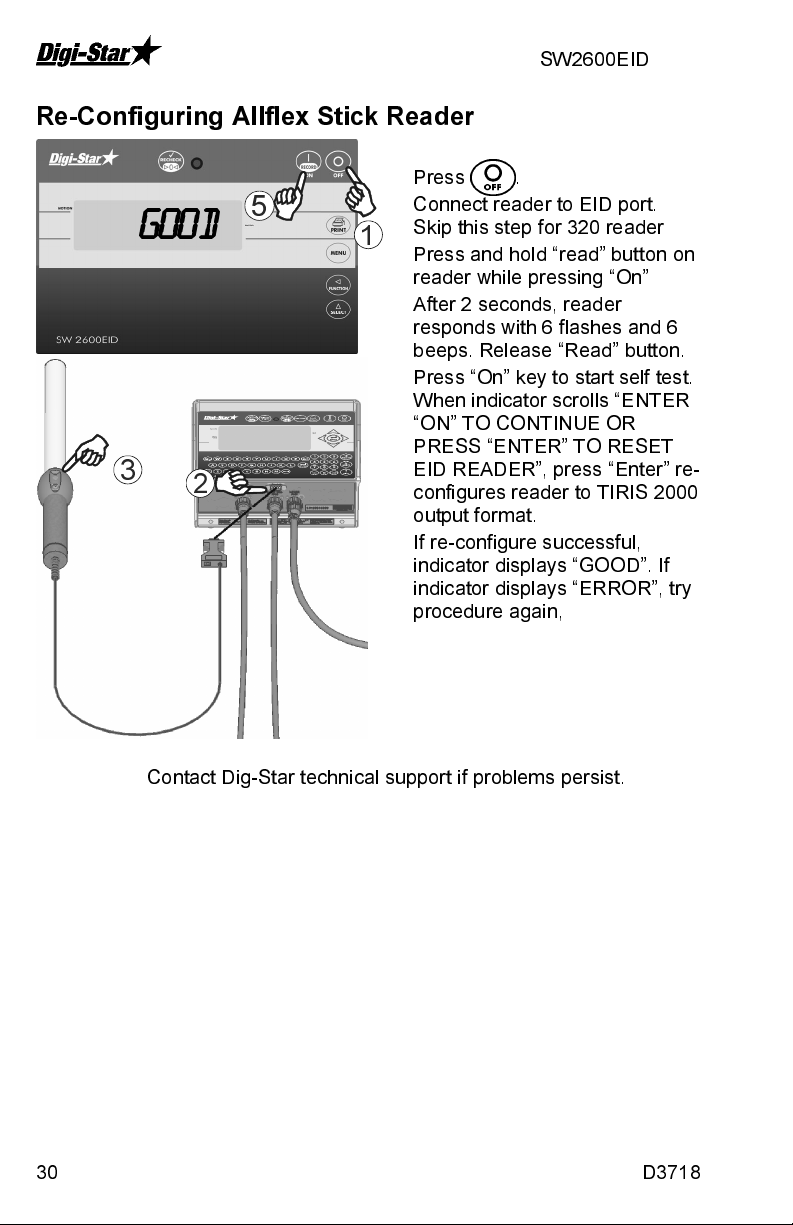

Re-Configuring Allflex Stick Reader

Press .

Connect reader to EID port.

Skip this step for 320 reader

1

Press and hold “read” button on

reader while pressing “On”

After 2 seconds, reader

responds with 6 flashes and 6

beeps. Release “Read” button.

Press “On” key to start self test.

When indicator scrolls “ENTER

“ON” TO CONTINUE OR

PRESS “ENTER” TO RESET

EID READER”, press “Enter” re-

configures reader to TIRIS 2000

output format.

If re-configure successful,

indicator displays “GOOD”. If

indicator displays “ERROR”, try

procedure again,

good

3

5

2

Contact Dig-Star technical support if problems persist.

30 D3718

Page 31

Operators Manual

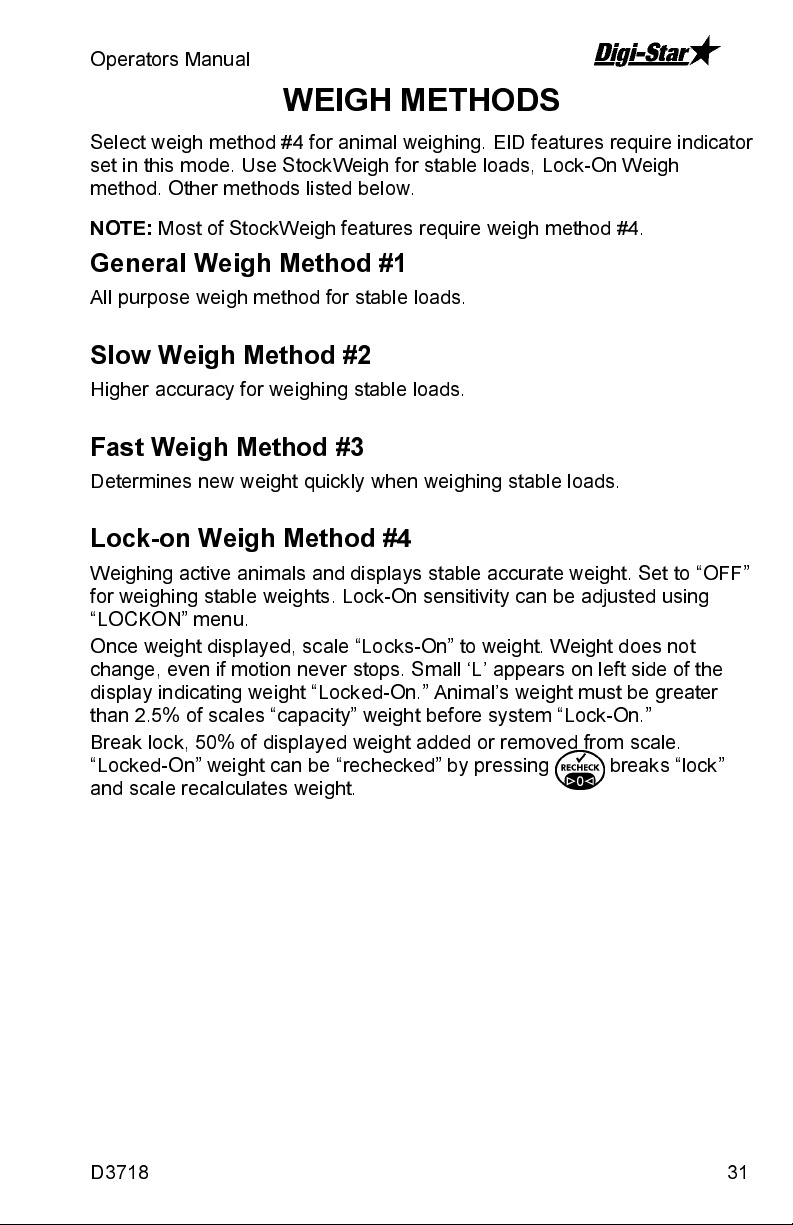

WEIGH METHODS

Select weigh method #4 for animal weighing. EID features require indicator

set in this mode. Use StockWeigh for stable loads, Lock-On Weigh

method. Other methods listed below.

NOTE:

Most of StockWeigh features require weigh method #4.

General Weigh Method #1

All purpose weigh method for stable loads.

Slow Weigh Method #2

Higher accuracy for weighing stable loads.

Fast Weigh Method #3

Determines new weight quickly when weighing stable loads.

Lock-on Weigh Method #4

Weighing active animals and displays stable accurate weight. Set to “OFF”

for weighing stable weights. Lock-On sensitivity can be adjusted using

“LOCKON” menu.

Once weight displayed, scale “Locks-On” to weight. Weight does not

change, even if motion never stops. Small ‘L’ appears on left side of the

display indicating weight “Locked-On.” Animal’s weight must be greater

than 2.5% of scales “capacity” weight before system “Lock-On.”

Break lock, 50% of displayed weight added or removed from scale.

“Locked-On” weight can be “rechecked” by pressing . This breaks “lock”

and scale recalculates weight.

D3718 31

Page 32

SW2600EID

SHORT FORM CALIBRATION

Short Form Setup & Calibration procedure allows changing “SETUP” and

“CAL” numbers of indicator.

Setup Number

The “SETUP” numbers affects some parameters that also appear in Long

Form Calibration. Following is a list of functions controlled by “SETUP”

number:

Weigh Method (W MTHD)

Display Units (LB-KG)

Display Counts (COUNT)

Gain

Scale Capacity

Calibration Number

The “CAL” number adjusted to make scale read proper weight for different

load cells and to make accuracy adjustments on scale system. If a

StockWeigh indicator provided with StockWeigh load cells as a package,

calibration number adjusted at factory for maximum accuracy. Systems

that are assembled from separate components are given “STANDARD

SETUP AND CALIBRATION NUMBERS” and are not factory calibrated.

These systems should be checked and adjusted if necessary using known

weights to insure accuracy. See “Calibrating the Scale for Maximum

Accuracy” below.

List of Standard Setup and Calibration numbers for StockWeigh 3300,

6600, 10000 and 14000 load cells shown below. If not using StockWeigh

load cells, contact Digi-Star Tech Support at 920-563-9700 for setup and

calibration information:

StockWeigh

Scale Type Unit Setup # Calibration #

3300 Lbs 413004 776

6600 Lbs 413007 1560

10000 Lbs 454010 14000

14000 Lbs 443015 13828

3300 Kg 812002 352

6600 Kg 812003 708

10000 Kg 854010 6351

14000 Kg 843007 6272

32 D3718

Page 33

Operators Manual

Calibrating Scale for Maximum Accuracy

First write down current SETUP and CAL numbers of indicator. These

numbers are displayed during self test. To run self test with indicator

already ON, press “On”. Press “On” pauses self test while numbers

displayed. Press “On” again to resume.

SETUP # _______________ CAL # ________________

A large amount of known weight needed to calibrate scale. For best results

have at least as much weight as largest load to weigh.

Determining New Setup and Calibration Numbers.

Zero-Balance scale so display reads zero.

Put KNOWN WEIGHT on scale platform and write down WEIGHT

DISPLAY. Perform the following equation to find ACCURATE CAL #.

KNOWN WEIGHT

WEIGHT DISPLAY

Example:

The KNOWN WEIGHT 1000lbs, but WEIGHT DISPLAY 950lbs. The

EXISTING CAL # is 776.

1000

950

817 is the ACCURATE CAL #. The setup number does not change.

X 776 = 817

X EXISTING CAL # = ACCURATE CAL #

D3718 33

Page 34

SW2600EID

EID DATA FORMATS

Data output thru computer port to be stored in a computer or printed. There

are many different data formats to choose. “LSTORE” mode can configure

data format automatically or allow user to set print format by using

“PRTFMT” menu.

LSTORE Data Formats

Use PRTFMT when in “LSTORE” modes:

OFF

MANPRT Manual Print

AUTPRT Auto Print

Print Formats

Following is a detailed explanation of print formats that are available on

StockWeigh. Some are Comma Separated Values (CSV) that make it

easier to input scale data into PC Spreadsheet and Data Base programs.

NOTE

: The appearance of the printouts may be affected by option settings

of 1L PRT, TIME F and DATE F.

AUTO -

set to “AUTO”, standard EZ Indicator print format will be used. Print

example:

WTONLY -

(GR, M+, etc.). Ends with a

DOWNLD

weight, display unit, $' if unit "locked on", weight tag (GR, M+, etc.) date

and time.

DT+TM

on", weight tag (GR, M+, etc...) and date. Ends with a

example:

ID+TM

on", weight tag (GR, M+, etc...) and time. Ends with a

example:

If “LSTORE” is set to “MANPRT” or “AUTPRT” and “PRTFMT” is

09MR04 10:15

880LB$GR

Includes weight, display unit, $' if unit is "locked on", weight tag

<CR>,<LF>.

Print example:

635LB$GR

- This format compatible with original Downloader. Includes

- This CSV format includes weight, display unit, $' if unit "locked

<CR>,<LF>.

" 610,LB, ,GR,13MR02,11:08"

Print

- This CSV format includes ID, weight, display unit, $' if unit "locked

<CR>,<LF>

" , 0,LB, ,GR,11:08"

. Print

34 D3718

Page 35

Operators Manual

IDWTTM

- This CSV format includes ID, weight, display unit, $' if unit

"locked on", weight tag (GR, M+, etc...), date and time. Ends with a

<CR>,<LF>.

ANIMAL

Print example:

"FARM 1, 16090,LB, ,GR,27JA00,10:37P"

- This CSV format includes information for animal weighing.

Includes $' if unit "locked on”, weight, weight tag (GR, M+, etc...), display

unit, Memory Weight (RM), Average Count (Number of times M+ key was

pressed), Average Weight, Gross weight on scale, ID, date and time. Ends

with a

<CR>,<LF>.

" , 1400,GR,LB, 2180, 4, 545, 1400, ,11:09,13MR02"

Print example:

3200 A See service bulletin # 19 for details.

3200 B See service bulletin # 20 for details.

32 TMR See service bulletin # 19 for details.

BATCH1 Contact Digi-Star technical support for details.

FDINFO Contact Digi-Star technical support for details.

WTRCTM - This CSV format includes basic weighing information.

Includes Gross Weight, display unit, weight tag (GR, M+, etc...), Total

Rotation Count, Date & Time. Ends with a

" 280,LB,GR, 187,03JL03, 3:41P"

<CR>,<LF>.

Print example:

EIDINF - This CSV format includes EID memory status information. Ends

with a

<CR>,<LF>.

The response from the StockWeigh Indicator will be as

follows:

“uuuuuu,UUUUUU,mmmmmm<CR><LF>”

uuuuuu

UUUUUU

mmmmmm

<CR>

= Used Livestock EID lines (6 digits)

= Un-used Livestock EID lines (6 digits)

= Maximum Livestock EID lines (6 digits)

'Carriage Return' [0D] hex or [13] decimal

<LF>

'Line Feed' [0A] hex or [10] decimal

Print example:

" 157, 1379, 1536"

EID

- This CSV format includes EID tag number if available, weight info,

date, and time. Print example:

,860,LB,$,GR,03/09/04,08:58,j

Print example (1L PRT=ON):

, 860,LB,$,GR,03/09/04,08:58,j

NOTE

: Only the StockWeigh indicator supports EID memory storage.

The following “LSTORE” modes automatically configure the print format for

animal weighing with EID data.

MAN WT

AUTOWT

MANEID

- Manual Weight

- Automatic Weight

- Manual EID. See EID Print Format and CSV Data Format

D3718 35

Page 36

SW2600EID

AUTEID

EID MANCHK

AUTCHK

- Automatic

- Manual Check

- Automatic Check

EID Print Format

EID print data transmitted out COMPUTER port on bottom of indicator

while weighing animals.

NOTE

: When using computer port for EID data, make sure SCOREM set

to “0”, TAREAP set to “OFF” and APRINT set to “OFF”.

EID data may vary in number of characters, spaces etc. Refer to

Allflex TM Stick Reader User Manual for more information.

C>XXXXX>X>XXX>XXXXXXXXXXXX,

XXXXXX,LB,$,GR,mm/dd/yy,hh:mm,Z<cr><lf>

Examples of EID Print Format:

A 00000 0 982 000017383201,<cr><lf>

890,LB,$,GR,8/27/03,10:15,_<cr><lf>

A 00000 0 982 000017383201,<cr><lf>

1001,LB, ,GR,8/27/03,10:21,M<cr><lf>

EID Print Data Format always uses date format #2 and 24-hour time format

as shown.

EID CSV Data Format

EID CSV Data collected from ear tag using EID Stick Reader and stored in

memory along with weight, date, time and other information. Eight data

fields each separated by a comma followed by carriage return and line

feed:

Field 1 EID Data

Field 2 Weight Value

Field 3 Unit of Measure (Lb/Kg)

Field 4 “$” Indicates Weight Locked-On

Field 5

Field 6 Date

Field 7 Time

Field 8 Checksum Character

Carriage Return

Line Feed

36 D3718

Page 37

Operators Manual

Four modes that store the EID CSV data into indicator memory.

MANEID

EID AUTEID

EID MANCHK

AUTCHK

- Manual

- Automatic

- Manual Check

- Automatic Check

Data formatted as CSV file transferred to PC. CSV files make it easier to

input scale data into PC Spreadsheet and Data Base programs.

Following an example of two data lines. Note that in last line of data, no

“$”shown because weight not “Locked On.

Examples of EID CSV Data:

A 00000 0 982 000017383201, 890,LB,$,GR,8/27/03,10:15,_<cr><lf>A

00000 0 982 000017383201, 1001,LB, ,GR,8/27/03,10:21,M<cr><lf>

EIDVID Data Format

Indicator response will be as follows:

<RS>EEEEEEEEEEEEEEEEEEEEEEEEEEEEEE,vvvvvvv,rrrrrrr,ppppppp,wwwwwww,kk

,$,gg,mm/dd/yy,hh:mm,ccc,aaaaaaa,nnnnnnnnnnnnnnnnnnnnnnnnnn,C<CR><LF>

<RS>

................................................. =Right Shift’ [1E] hex or [30] decimal

EEEEEEEEEEEEEEEEEEEEEEEEEEEEE

vvvvvvv ......................

rrrrrrr

ppppppp

wwwwwww

kk

$

gg

mm/dd/yy

hh:mm

ccc

aaaaaa

nnnnnnnnnnnnnnnnnnnnnnnnnnn ..

C

<CR>

<LF>

........................................... =Group ID (7 alphanumeric characters)

........................................... =Premise ID (7 alphanumeric characters)

........................................... =Weight (7 numeric characters)

.................................................... =’LB’ for pounds ‘KG’ for kilograms

...................................................... =$ character or a space character. The $

.................................................... =“GR” for gross or ‘NT’ for net

......................................... =Date

............................................... =Time 24 hour format

................................................... =Code (3 alphanumeric characters)

............................................. =Average Daily Weight Gain (6 numeric

...................................................... =Checksum character

................................................. =”Carriage Return’ [0D] hex or [13] decimal

................................................. =’Line Feed’ [0A] hex or [10] decimal

=EID tag (29 alhpanumeric characters)

=VID tag (7 alphanumeric characters)

character indicates the indicator is setup for the

“Lock On” weigh method and has “locked onto”

a weight value.

characters. Example: 123.45, -12.34, 2.45)

=Note (26 alphanumeric characters)

D3718 37

Page 38

SW2600EID

SCOREBOARD METHODS

Ten scoreboard methods available. Methods one thru six sends numeric

display data out RS232 port periodically while other methods send data

stream described below.

1. Transmit numeric display data once/second.

2. Transmit numeric display data two times/second.

3. Transmit numeric display data three times/second.

4. Transmit numeric display data at A-D conversion rate.

5. Transmit numeric display data at display rate.

6. Transmit numeric display data whenever a display weight changes.

7. Transmit status data string every second. Status data string includes

weight, rotation counter data, date and time.

8. Transmit status data every five seconds. Status data string includes

weight, rotation counter data, date and time.

9. Reserved.

10.Transmit EID data string every 2 seconds.

13.Transmit EIDVID data string every 2 seconds.

NOTES

When using SCOREM = 7, 8 and 10, print data will not be

38 D3718

: When using SCOREM = 1, 2, 3, 4, 5, 6 and 9 be sure to set

LSTORE = OFF, TAREAP = OFF and APRINT = OFF to avoid

corrupted data when transmitting scoreboard data and printing

scale data.

corrupted by scoreboard data.

Page 39

Operators Manual

WEIGHING ERRORS

OVRCAP

Capacity Limit:

Display shows message "OVRCAP" if weight on scale system exceeds

capacity limit. Capacity value entered in SETUP to warn of overloading

scale system.

+RANGE

Over Range:

Display show message "+RANGE" if weight on scale system exceeds

maximum weight measurable by scale system. Over range value always

system’s maximum A/D counts multiplied by scaling factor. Actual weight

at which over range occurs depends on calibration, zero, and display count

size.

-RANGE

Under Range:

Display shows message "-RANGE" if weight on scale system less than

minimum weight measurable by scale system. Under range value always

system’s minimum A/D counts multiplied by scaling factor. Actual weight at

which under-range occurs depends on calibration, zero, and display count

size.

NOTE:

D3718 39

EZII Series supports –RANGE that is equal to +RANGE in absolute

value.

Page 40

SW2600EID

SOFTWARE LICENSE AGREEMENT

Digi -Star® LLC

®

IMPORTANT:

The Digi-Star

technical staff will be licensed to you, the licensee, on the condition that

you agree with DIGI-STAR

software being installed by you or by our

®

LLC ("Digi-Star") to the terms and conditions

set forth in this legal agreement. PLE ASE READ THIS AGREEM E NT

CAREFULLY, YOU WILL BE BOUND BY THE TERMS OF THIS

AGREEMENT IF YOU INSTALL, OR IF YOU HAVE DIGI-STAR

®

'S

TECHNICAL STAFF OR AUTHORIZED REPRESENTATIVE INSTALL

SOFTWARE FOR YOU. If you do not agree to the terms contained in this

agreement, please return the disk package to your dealer for a full refund,

or do not have a Digi-Star

®

technician or authorized representative insta ll

this software. Once you have allowed the software to be installed you are

bound by this agreement.

If you agree to these terms and conditions, Digi-Star

®

grants to you a

nonexclusive license to use the accompanying software (the "Software")

and documentation. The Software and the documentation are referred to in

this Agreement as the "Licensed Material".

Ownership: The Licensed Materials are the sole and exclusive property of

Digi-Star

Treaty Provisions. By paying the license fee and b y installing, or by

allowing a Digi-Star

®

and are protected by U.S. Copy Right Law and international

®

technical or authorized representative to install the

software, you do not become the owner of the Licensed Material according

to the terms of this agreement.

License: The license granted to you by Digi-Star

®

in this agreement

authorizes you to use the Software on any single computer, or any

replacement for that computer. The Software may not be used on a

Network Server. A separate disk, licensed under an additional software

agreement, is required for any other computer on which you wish to load

the Software. YOU MAY NOT USE, COPY, OR MODIFY THE LICENSED

MATERIAL IN WHOLE OR PART, EXCEPT AS EXPRESSLY PROVIDED

IN THIS AGREEMENT.

Term: This Agreement is effective from the date on which you open the

sealed disk package and installed the Software or have the Software

installed by Digi-Star

®

. This agreement may be terminated by you at any

time by destroying the Licensed Material, together with all copies,

modifications and merged portions in any form. It will also terminate

automatically if you fail to comply with any term of condition of this

agreement.

Restrictions and Transfer: You may not sublicense, assign, share, rent,

lease, or otherwise transfer your right to use the Licensed Material, nor any

other rights granted to you under this agreement, except stated in this

paragraph. You may permanently transfer the software to any other party if

the other party is purchasing your business operation, the other part y

40 D3718

Page 41

Operators Manual

agrees to the terms and conditions of this agreement, you transfer all

copies of the Licensed Material to that party, or destroy those which are

not transferred and that new party pays a license transfer fee of 25% of the

original license fee. By such transfer, you terminate the license granted to

you in this agreement.

Restrictions against copying or modifying the Licensed Material: The

Licensed Materials are copyrighted by Digi-Star

®

. Except as expressly

permitted in this agreement, you may not copy or otherwise reproduce the

Licensed Materials. In no event does the limited copying or reproduction

permitted under this Agreement include the right to decompile,

disassemble, or electrically transfer the Software in any form, in whole or in

part, or of any modification of the Software, or any updated work containing

the Software, or any part thereof. You also agree not to remove any

existing copyright notice of the License Materials.

Protection and Security: You agree to use your best efforts and take all

reasonable steps to safeguard the License Materials to ensure that no

unauthorized person has access to them and that non authorized copying,

publication, disclosure, or distribution of any of the Licensed Material is

made. You acknowledge that the Licensed Materials contain valuable,

confidential, and trade secrets and that unauthorized use and copying are

harmful to Digi-Star

®

and its software suppliers, and that you have the

confidential obligation on such valuable information and trade secrets.

Limited Warranty: Digi-Star

®

warrants that the media on which the

Software is recorded will be free from defects in workmanship and

materials for a period of 90 (ninety) days from the payment of the license

fee, and if Digi-Star

the media was not subject to misuse, abuse, or use in defective

equipment, Digi-Star

®

determines the media to be defective and provided

®

will replace the media. ALL IMPLIED WARRANTIES

ON THE MEDIA, INCLUDING IMPUTED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO THE DURATION OF THE EXPRESS WARRANTY SET

FORTH ABOVE. IN NO EVENT WILL DIGI-STAR

®

OR ANY OTHER

PARTY WHO HAS BEEN INVOLVED IN THE CREATION,

PRODUCTION, OR DELIVERY AND INSTALLATION OF THE LICENSE

MATERIALS BE LIABLE FOR SPECIAL, DIRECT, INDIRECT, OR

CONSEQUENTIAL DAMAGES, IN NO EVENT SHALL DIGI-STAR

®

'S OR

SUCH OTHER PARTY'S LIABILITY FOR ANY DAMAGE, OR LOSS TO

YOU OR ANY OTHER PARTY EXCEED DIGI-STAR REPLACING THE

MEDIA ON WHICH THE LICENSED MATERIALS HAS SUPPLIED.

General:

If any provision or of portion of a provision of this Agreement is

determined to be invalid under any applicable law, it shall be deemed

omitted and the remaining provision and partial provisions of this

Agreement shall continue in full force and effect.

This Agreement constitutes the entire agreement between the parties with

respect to the subject matter hereof, and all prior agreements, statements

and undertakings are hereby expressly canceled.

D3718 41

Page 42

SW2600EID

NO

T

TROUBLESHOOTING GUIDE

YES

Does the Indicator respond when

you step on the scale?

YES

Does the scale weigh you

close to your weight?

YES

Check for debris around

and under the platform

and load cells. Check for

warped or damaged

mounts on platform.

Disconnect the load cell cable from the Indicator.

Press the Indicator “TARE” key. (The Indicator

display should go to zero). Stand on the load cell.

Does it display a reading about twice your weight?

YES

This Load Cell is OK.

Disconnect the first load cell

and connect the other load

cell to the same connector.

Now stand over the second

load cell. Does it weigh twice

your weight?

YES

Connect the load cell to the

Indicator. Stand on the load

cell. Does it display about twice

NO

The load cell is defective.

Check its cables for cuts or

flattened areas or send it back

for repair. Check indicator

using a known good load cell.

other connector on the

your weight?

YES

Check the platform

for debris and mud

interference. Check

mounts for binding

and obstructions.

NO YES

The Indicator is defective.

Verify this by substituting a

NO

NO

Check for debris around

and under the scale

mounts or platform.

Check the load cell

cables for cuts and

flattened areas.

NO

Disconnect the first load cell and

connect the other load cell to the

same connector. Now stand over

the second load cell. Does it

weigh twice your weight?

Connect both load cells (one at a time)

to the other connector on the Indicator.

Do both load cells weigh you about

good working Indicator.

STAR

Does the indicator come on?

Check for 12 VCD at the AC/DC convertor power cord. If you

do not have a multimeter, use a car battery to power the

scale. If the Indicator still does not come on, send in for repair.

The other load cell is

defective. Check its cable

for cuts or flattened areas or

send it back for repair.

Check the defective load

cell by connecting it to the

Indicator and verifying that it

does not weigh.

YES

NO

The other load

cell is defective.

Check its cables

for cuts or

flattened areas

or send it back

for repair.

twice your weight?

NO

Do both load cells weigh you

about the same but not within

20% of twice your weight?

YES

NO

Disconnect one of the load cells and stand over

the connected load cell. Does the indicator

display a reading about twice your weight?

YES

Disconnect the first load cell and

connect the other load cell to the

same connector on the Indicator.

Does the Indicator display a

reading about half your weight?

NO

YES

The other load cell is defective.

Check its cables for cuts or flattened

areas or send it back for repair.

Perform the paper test. Take two paper clips and

carefully insert one into pin 2 and the other into

pin 3 of either load cell connector jack on the

Indicator. Hold one paper clip in each hand (if

they touch it will not damage the Indicator). Does

the reading on the Indicator jump around?

YES

NO

Both load cells are defective.

The Indicator is probably

OK. Check the cables for

damage and send both load

cells in for repair.

The Indicator is defective. Send it in for

repair. Note: Load cells may also be

defective. Check the load cells by

attaching to a good work in Indicator.

NO

One of the Load Cells is Bad. A

good load cell will weigh you at

about twice your weight with only

one load cell connected.

42 D3718

Page 43

Operators Manual

W

W

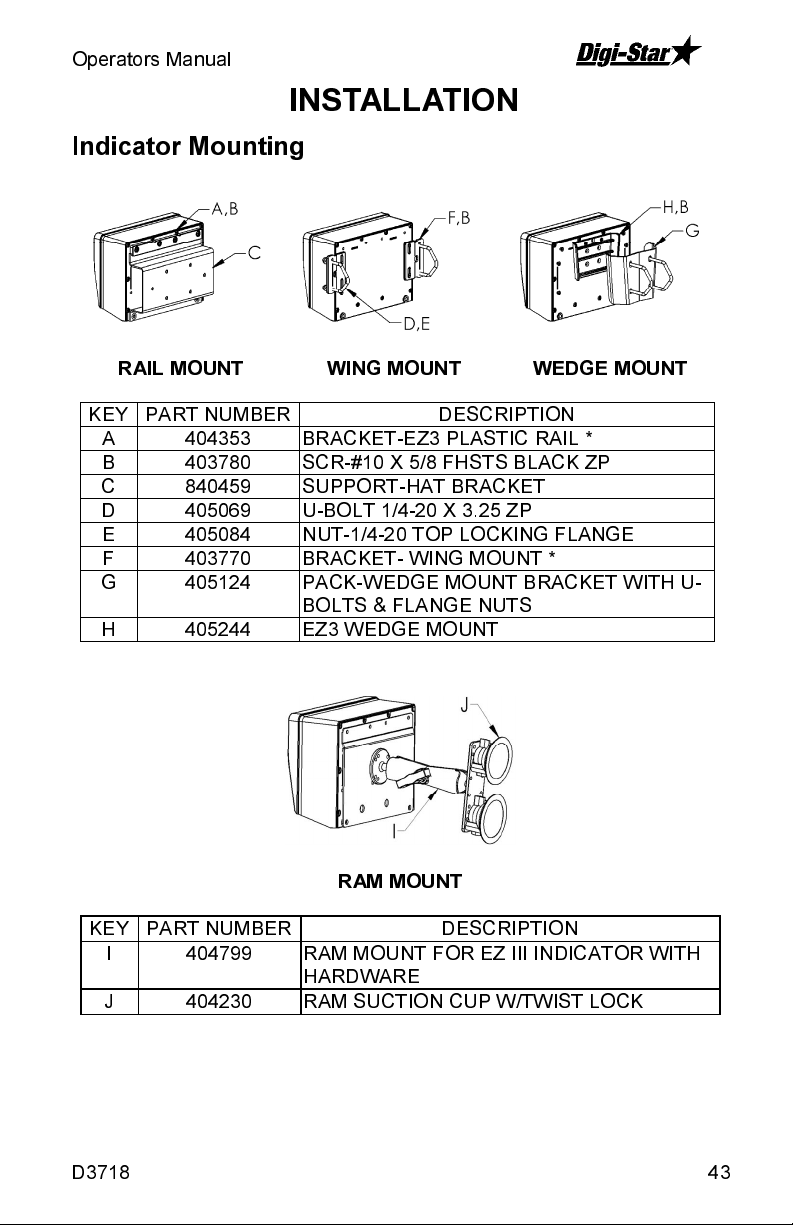

INSTALLATION

Indicator Mounting

RAIL MOUNT

KEY PART NUMBER

A 404353 BRACKET-EZ3 PLASTIC RAIL *

B 403780 SCR-#10 X 5/8 FHSTS BLACK ZP

C 840459 SUPPORT-HAT BRACKET

D 405069 U-BOLT 1/4-20 X 3.25 ZP

E 405084 NUT-1/4-20 TOP LOCKING FLANGE

F 403770 BRACKET- WING MOUNT *

G 405124 PACK-WEDGE MOUNT BRACKET WITH U-

H 405244 EZ3 WEDGE MOUNT

KEY PART NUMBER

I 404799 RAM MOUNT FOR EZ III INDICATOR WITH

J 404230 RAM SUCTION CUP W/TWIST LOCK

ING MOUNT

DESCRIPTION

BOLTS & FLANGE NUTS

RAM MOUNT

DESCRIPTION

HARDWARE

EDGE MOUNT

D3718 43

Page 44

SW2600EID

–

Cable Connection

Allflex TM

Stick Reader

See Illustration

on next page.

Scale Indicator

Power Cord

12VDC Power Supply

Red +Terminal

Black -Terminal

NOTE:

A small 12V deep cycle lead

acid battery will provide hours of

operation.

NOTE:

120VAC power cube to wall

outlet may also be used.

Load Cell Cables

Indicator Connection Diagram

Provided.

44 D3718

Page 45

Operators Manual

Allflex TM

Stick Reader

Computer

Load Cell

Connections

Power Cord

Connection

Bottom Panel Cable Connections

D3718 45

Page 46

SW2600EID

OPTIONAL EQUIPMENT

403635

Use to scan ear tag and send data

to indicator. Powered by indicator

using cord.

404375

only

404448

Bluetooth (wireless) Includes

404375 reader with the transmitter

in handle and receiver that plugs

into RS232 port on indicator

403360

attaches to StockWeigh

3300-24” load cells, 90” long x 24.5”

wide at top and 15.5” wide where

animal walks

403975

403315

series of indicators

Allflex 250 EID Tag Reader

Allfex 320 EID Tag Reader

EID Tag Reader Kit

Animal Platform easily

Converter USB to RS232

1.5” mount assembly for EZ

TM

46 D3718

Loading...

Loading...