Page 1

Operators Manual

Fort Atkinson, Wisconsin USA

Panningen, The Netherlands

www.digi-star.com

D3664-US Rev G June 2007

Page 2

RF DataLink

D3664-F

Page 3

Operators Manual

RF DataLink Setup 1

Sequence of Operations .............................................. 1

Registering the Software.............................................. 1

Radio Installation and Setup ........................................ 1

Radio Antennas ........................................................... 2

Fresnel Zone................................................................ 3

Radio Interference ....................................................... 3

Standard Range Setup ................................................ 3

Extended Range Setup................................................ 4

USB Black Box Installation .......................................... 5

Passwords ................................................................... 5

Setting the File Paths................................................... 5

Entering Mixer Data ......................................................... 7

Adding Mixers .............................................................. 7

Determining the System Defaults. ............................... 8

Process Selection ........................................................ 9

Pen Data Type............................................................. 9

Make As Fed Data File ................................................ 9

Zone Control ................................................................ 10

Send Mill Demand ....................................................... 10

Pen Delivery List Source.............................................. 11

Batch Number Included ............................................... 11

Timing .......................................................................... 11

Setting the Timing........................................................ 11

Weight Tolerances....................................................... 12

Pen Delivery Weight Tolerances.................................. 12

Operator Acknowledge ................................................ 12

Ration Weight Delivery Tolerances.............................. 13

Operator Acknowledge ................................................ 13

Split Load Minimum Balance ....................................... 13

Operator Interface........................................................ 14

Modify Recipe .............................................................. 15

Modify Pen Enabled..................................................... 15

Manual Load Making ................................................... 15

Wait for Acknowledge .................................................. 15

Bunk Reader .................................................................... 16

Select Bunk Reader Type ............................................ 16

Pen Feeding..................................................................... 17

Pen Delivery Mode ...................................................... 17

Optimize Load to Mixer/Optimize-Split Pens................ 17

Find Pens to Fit............................................................ 18

Mixer Loading .............................................................. 19

Print Mixer Load Sheet ................................................ 19

Weigh Units ................................................................. 19

D3664

Page 4

RF DataLink

Determining the Load Size for the Mixer...................... 19

Feedings To Mixer ....................................................... 20

Transfer Type .............................................................. 20

Full Load Delay............................................................ 20

Variable Mix Control..................................................... 21

Radio Settings ............................................................. 21

Datalink Reserve Channel ........................................... 22

Base Radio Type ......................................................... 22

Installation Test............................................................ 22

Operating the RF DataLink 22

Quantity of Radios to be Used ..................................... 22

Importing the Feeding Data ......................................... 23

Starting the Process .................................................... 23

How the Process Works............................................... 23

Modifying Ration Data.................................................. 25

Changing Ingredients................................................... 25

Deleting Ingredients..................................................... 26

Adding Ingredients....................................................... 27

Modifying Pen Data ..................................................... 27

Changing Pen Rations................................................. 28

Deleting Pens .............................................................. 28

Adding Pens ................................................................ 29

Changing the Pen Order .............................................. 29

Putting an In-Process Pen back in the Feeding ........... 30

Deleting Records ......................................................... 30

Viewing the Error Log .................................................. 31

Test Communications .................................................. 32

Indicator Status............................................................ 32

Reliability Meter ........................................................... 33

Repair Parts – Std. Antenna ........................................ 34

Repair Parts – Extend Range Antenna........................ 35

Page 5

Operators Manual

RF DataLink Setup

Sequence of Operations

After installing your software, please follow this section to setup the RF DataLink for use. It

is important that you follow along with this sequence.

Registering the Software

Once the software has been installed, it must be registered. Contact Digi-Star to obtain

your registration code. The code is case sensitive; all letters must be entered in upper

case.

Radio Installation and Setup

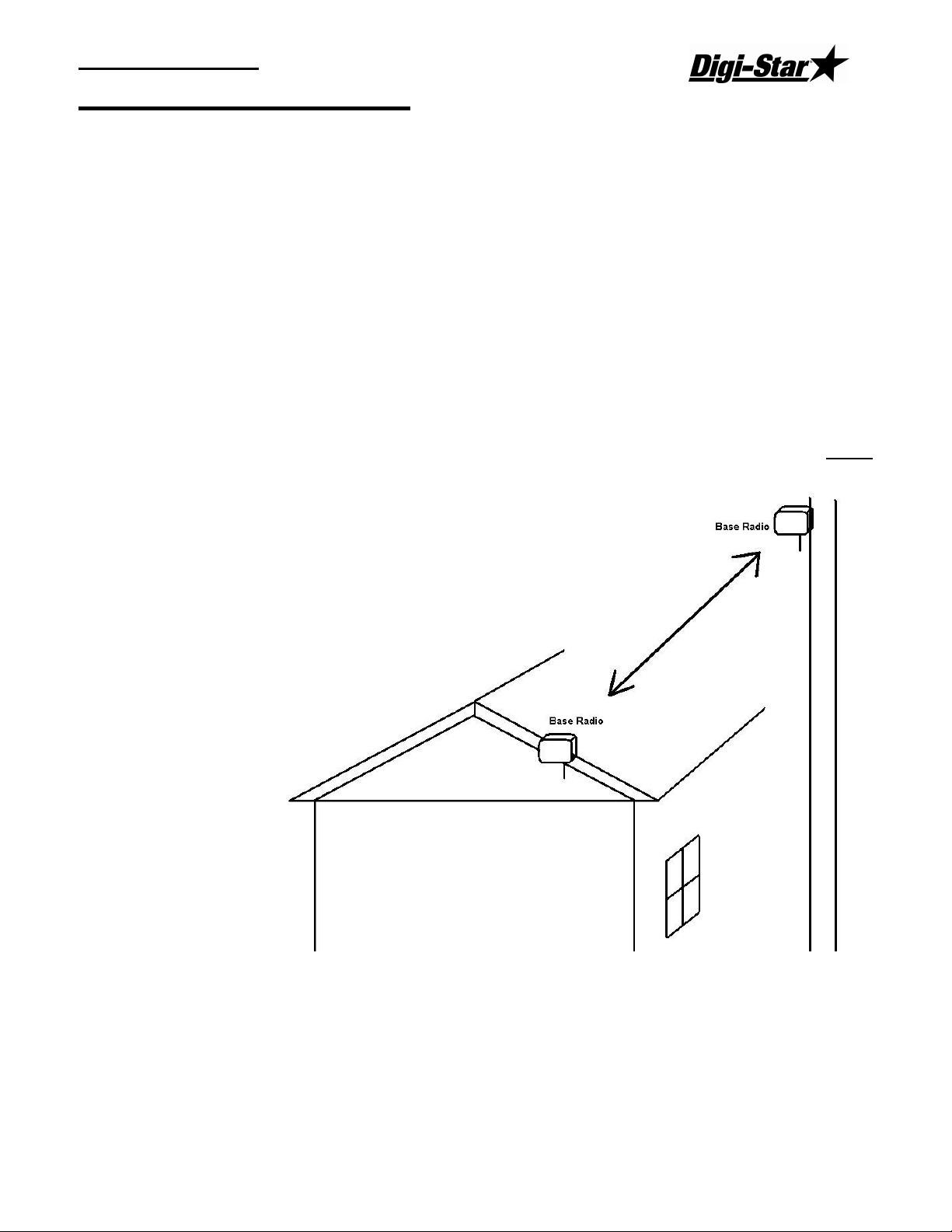

When installing the base radio; make sure the “ram mount” is fully extended away from the

mounting surface.

For greater radio communication and range mount the radio in the highest position that it is

visible from the ground or were the mixers are being loaded. Mount the radio in either

position like the illustration. On the corner of the office or on a utility pole.

D3664

1

Page 6

RF DataLink

Radio Antennas

The location of the antennas is critical. Check the installation of the antennas and the

antenna location.

Indicator and Truck Mounted Antenna: Truck Mounted Antenna, mount the antenna

outside, on the top of the cab, in the center of the roof. Do not modify the cable between

Truck Mounted Antenna and the indicator.

Yes No Are any building near the Base Station Antenna metal?

Yes No Are any metal structures located between the Base Station Antenna and

the mixers?

Yes No When standing at the Base Station Antenna, can you see the mixer?

Yes No Have any of the antenna cables been modified?

Radio Range:

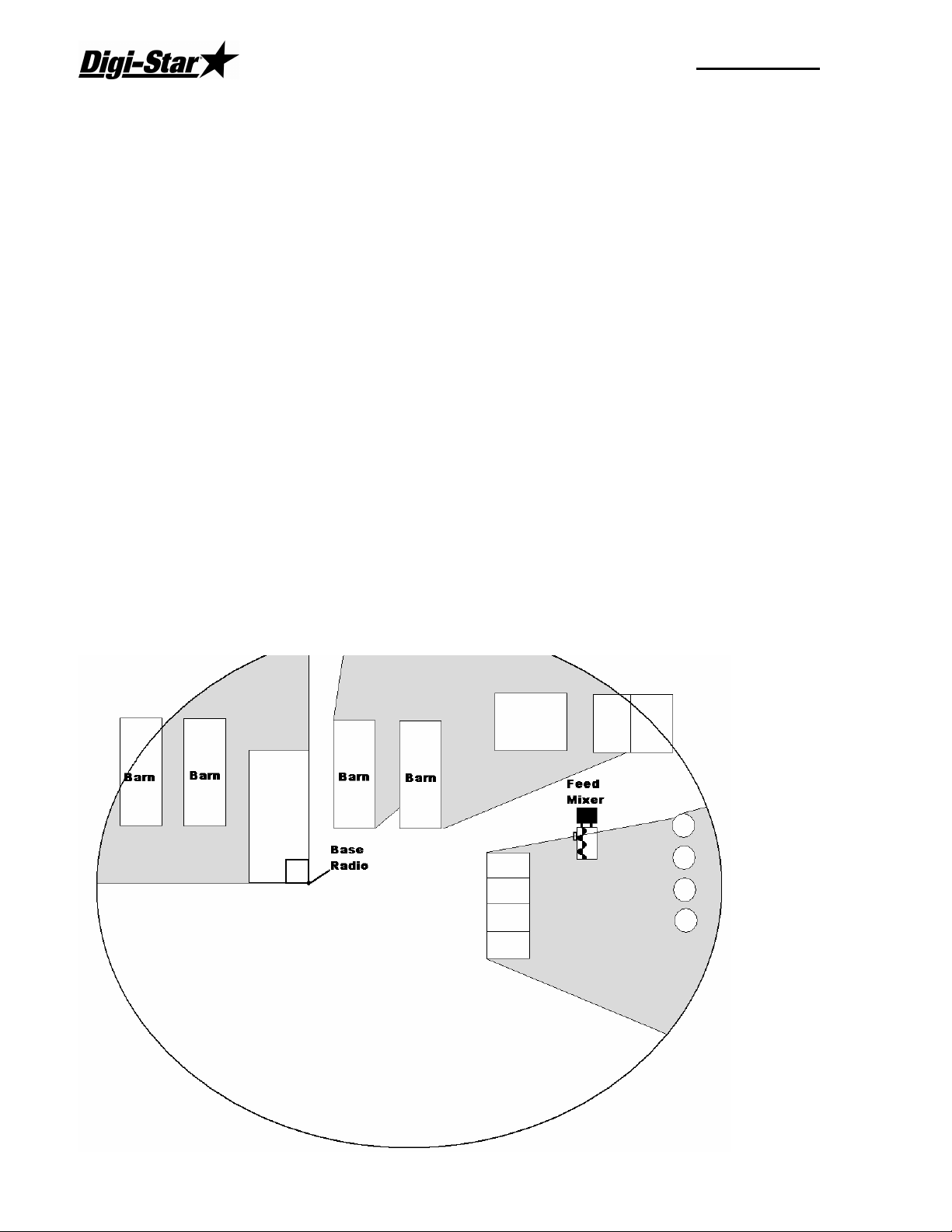

The picture below shows how radio range would be affected by obstructions like metal

barns or earth. The gray areas show poor radio signal. If the radio is mounted higher, this

may improve radio range.

2

Page 7

Operators Manual

Fresnel Zone

The Fresnel Zone can be thought of as a football-shaped tunnel between two sites that

provides a path for RF signals.

In order to achieve the greatest range, the football-shaped path in which radio waves travel

must be free of obstructions. Buildings, trees or any other obstacles in the path will

decrease the communication range. If the antennas are mounted just barely off the ground,

over half of the Fresnel Zone ends up being obstructed by the earth resulting in significant

reduction in range. To avoid this problem, the antennas should be mounted high enough off

the ground so that the earth does not interfere with the central diameter of the Fresnel Zone.

Minimal height of base radio:

Range Distance Height

1000 ft (305 m) 15 ft (4.6 m)

1 Mile (1.61 km) 25 ft (7.6 m)

1.5 Miles (2.42 km) or more 45 ft (13.7 m)

If you do not have enough cable from the computer to the radio there are different cable

lengths that Digi-Star offers, or you would like a higher powered antenna, contact Digi-Star.

Standard length is 50 ft / 15.25 m (RS-232). Extended length is 150 ft / 45.75 m (RS-422)

or custom lengths are available (150+)

Radio Interference

There are many types of wireless networks or (WIFI) and some can interfere with the

DataLink radio. If DataLink is still showing radio interference, check the WIFI network

number. Changing this number can correct for radio interference. For further information

about WIFI, check the website of the brand of your radio. 802.11 2.4GHZ use channels 1 –

6 and 13 & 14.

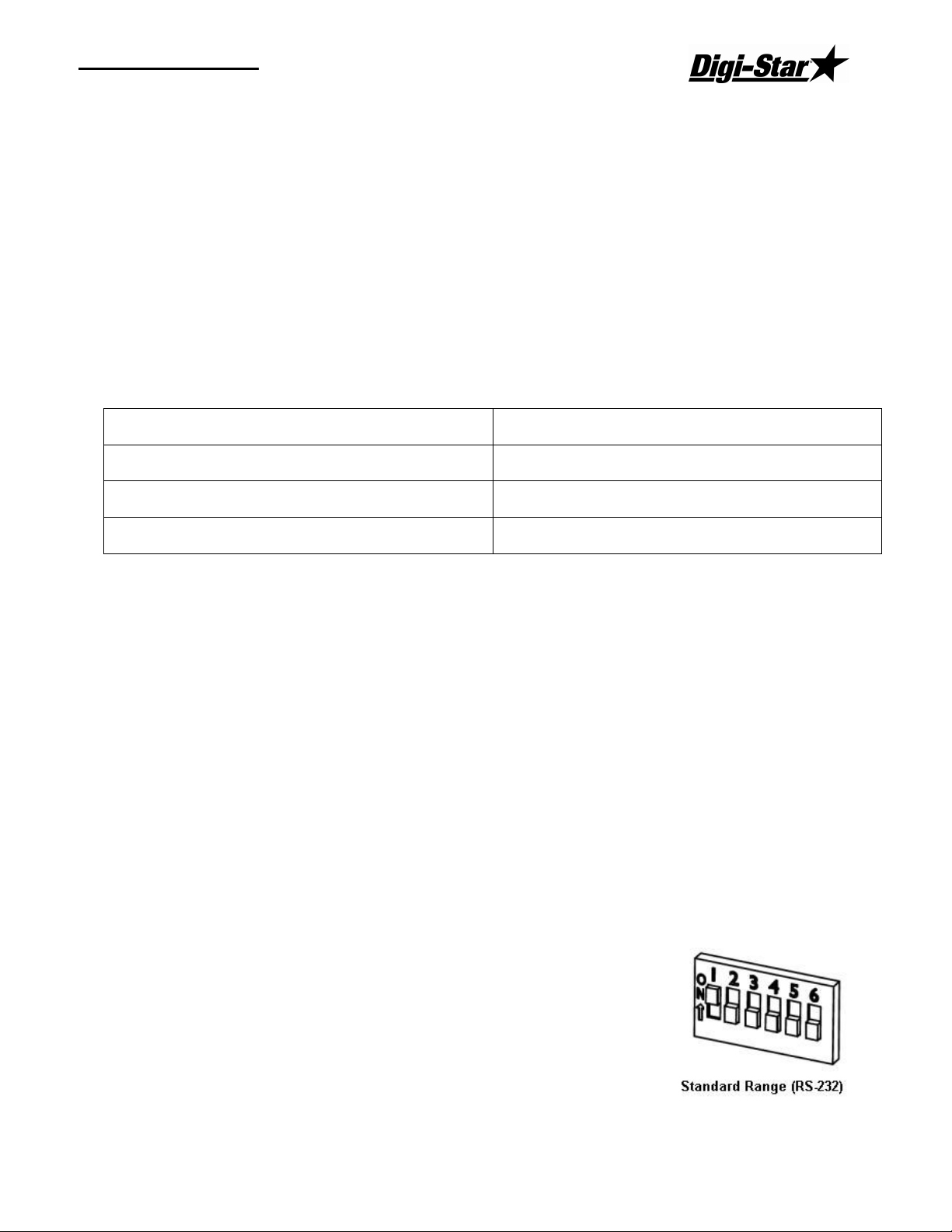

Standard Range Setup

When using the standard range kit, connect the DB9 serial connector to either a serial port on

the PC or use the USB to Serial adapter included and connect the

12VDC power supply to the cable. The base radio is shipped from

Digi-Star setup for standard range. The switch settings on the

radio are set to the picture to the right: Verify this if you are not

able to communicate with the base radio

D3664

3

Page 8

RF DataLink

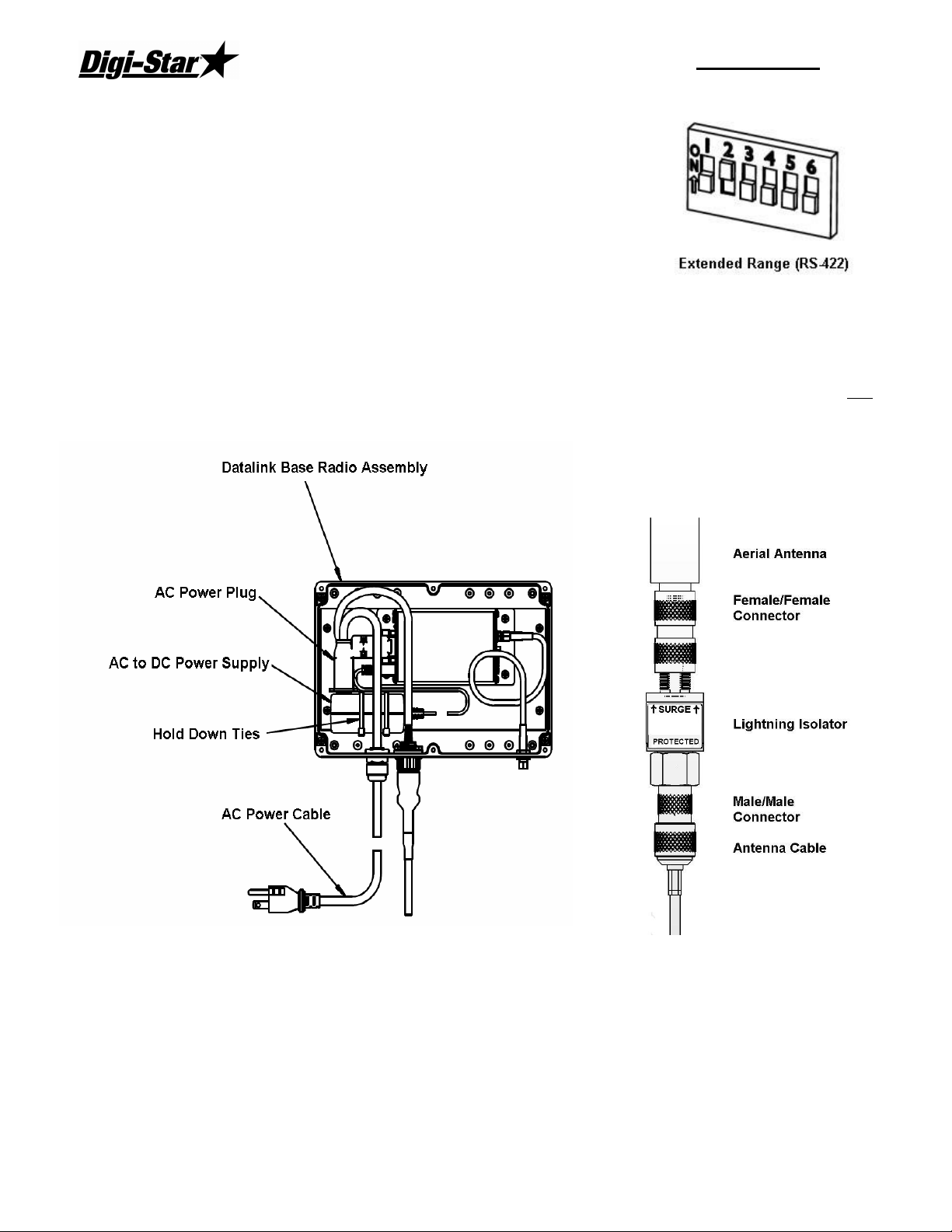

Extended Range Setup

If you are using the extended range radio kit (RS-422) you must

go to System, then Defaults, and select [Radio Settings]. Under

Base Radio Type, select [Extended Range Base Radio (RS-422).

RF Datalink will then pause while looking at the radio for the new

settings.

Next open the housing of the base radio. There is a bank of dip

switches on the right side,

Set switches as the picture on the right:

Install the AC/DC power transformer into the base radio box and run AC power into the unit

as shown. When attaching the female plug to the power cord, remove green ground wire

and attach either of the remaining two wires to either terminal. AC/DC adaptor is not

polarized.

Antenna Assembly

4

Page 9

Operators Manual

USB Black Box Installation

Plug in the Black box into a USB port. Windows will detect

the Black box and at this point Insert the driver CD.

Follow the Windows prompts.

Open the end cover of the Black Box and install the wires

as follows:

Passwords

Many of the settings under the System, Defaults menu are critical to the overall operation of

the RF DataLink program. To protect these settings, you have the ability to set a password

that will prevent unauthorized access to these settings. Once a password has been set on

any default screen, it is set for all default screens.

As with all passwords, please be sure to record your password in a safe place and guard it

from other users. Should you lose or forget your password, you will have to call Digi-Star

to have it reset.

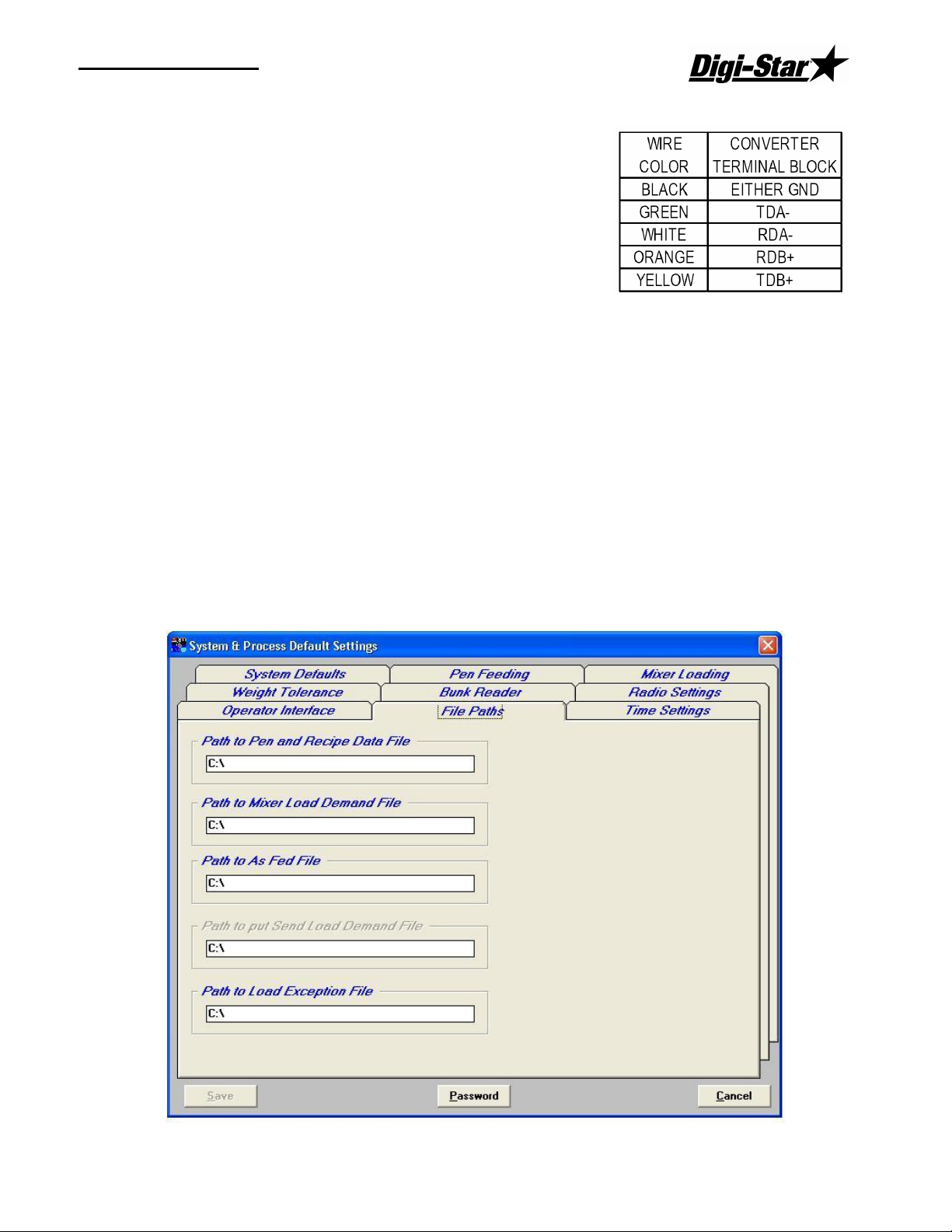

Setting the File Paths

RF DataLink shares files with other software. As such, each program must know where to

send and where to look for these files.

D3664

5

Page 10

RF DataLink

To set the File Paths, from the main menu select [Systems], [Defaults] and [File Paths].

This will display the File Path screen.

1. Path to Pen and Ration Data Files - this is the data that is transferred from the third

party software or TMR Tracker. Ration mixes and pen calls.

2. Path to Mixer Load Demand File - Not used in this application.

3. Path to As Fed File - this is the data that is transferred from the RF DataLink to the third

party software. Completed Ration mixes and pen feedings.

4. Path to put Send Load Demand File - this option will send a file out to a mill demand to

show the total load size of the next load sent to the mixer.

5. Path to Load Exception File - this is the error log for any weight tolerance that you set.

This data does not have to be transferred from the PC running the RF DataLink program.

If you are not using a network, the path settings for 1 and 3 would be set to C:\. If you are

using a network, set the paths to whatever your network drives have been set too.

If you setup a file such as ERROR above, that Folder must exist before you can save the

settings. The RF DataLink will not create the Folder for you.

When complete, click [Save].

6

Page 11

Operators Manual

Entering Mixer Data

Adding Mixers

To access the Mixers screen, select Mixers from the File Menu. This will display the Mixers

screen. In a new installation, the Mixer screen will be blank.

Select the Add button to add a new mixer. Enter the Mixer number 1-12 (this number

should match the Scale Number).

D3664

7

Page 12

RF DataLink

Mixer Number – a two-digit number to identify the Mixer.

Description – a detailed Mixer description. The first letter of this may be displayed on the

Process Screen.

Radio Channel – the radio number will be set on the EZ indicator. To view or change the

number use the direct access number (231). Press (Select) to change the number, and

press (On) to save. Make sure if you are using two or more mixers that you don’t use the

same radio ID.

Mixer Size – Enter the lbs/Kg per cubic foot/Meter or enter the load number. The load

number is used with Bunk reader programs.

Active - to signify that the Mixer is available for feeding, click on [Yes] in the Active box.

Clicking on [No] will make the Mixer un-available for loads or feeding.

Acknowledge – Acknowledge – This option is used to send a message to the scale if the

operator would like to receive another load. If the operator does not press the Tare key

within 10 seconds at the scale, Datalink will continue to other mixers.

To save your entries, click [Save].

If you are using static mixers/dump boxes and delivery wagons, go to the default setting to

change this setting.

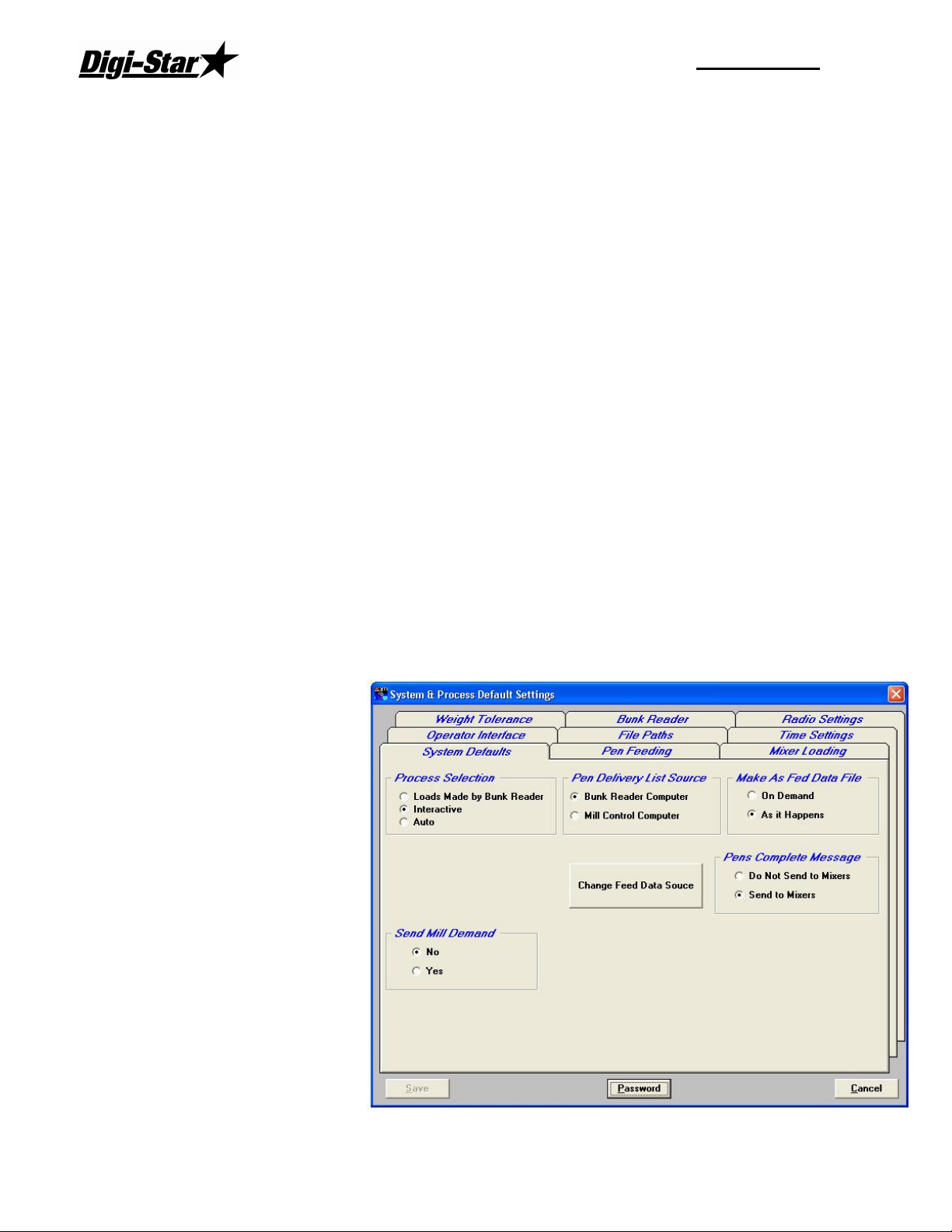

Determining the System Defaults.

The system defaults control how you process your feedings. These settings can help to

further optimize your feeding process. Please take some time to read and understand these

settings and their affect on your feeding process.

To set the System Default Settings, from the main menu select [Systems], [Defaults], and

[System Defaults].

The system defaults screen

contains all the choices

available to change the

manner in which the RF

DataLink processes your

feedings.

8

Page 13

Operators Manual

Process Selection

Interactive – this process selection allows the input of an external load demand to make

loads for your feed mixers. This external demand will typically

be generated from a mill software package. This selection also

allows an operator at the PC running the RF DataLink to

manually enter loads.

If you do not have a mill software package or do not want to

interface the mill and the RF DataLink, you must have an

operator running the RF DataLink in order to use this selection.

Auto – this process selection will automatically make and send loads to your mixer without

operator intervention. You will still have the ability to send manual loads if you elect to turn

that option on. This selection allows the RF DataLink to operate independent of user

intervention or input.

Notes: [Auto] is the typical selection for most installations. Manual is not an available selection.

When you have completed your entries, click [Save].

Pen Data Type

Single Pen – this mode will send a single pen load at a time to

your mixer. One pen, one load. This mode can be used if your

mixer is undersized for your operation and cannot hold enough

feed to process more than one pen at a time.

(This mode is the least efficient.)

Multiple Pens – this mode will send multiple pens to your mixer based on your vehicles

size and how much of a particular ration it can hold. Multiple pens, one load.

(This mode is the most efficient and is the typical setting for most installations.)

When you have completed your entries, click [Save].

Make As Fed Data File

The As Fed Data File is the completed loading and feeding data

that is transferred to third party software. This file can be sent in

two ways;

On Demand – this selection sends the data file on a demand

basis. When a completed load is received by the RF DataLink program, the file is stored

until a demand for the file is received. The file is then written to the file path set for the As

Fed File. The demand is triggered by selecting Make As Fed File from the File main menu.

D3664

9

Page 14

RF DataLink

As it Happens – this selection writes the data file as it is

received. When a completed load is received by the RF

DataLink program, it is immediately written to the file path

set for the As Fed File.

When you have completed your entries, click [Save].

Zone Control

This setting determines whether the ability to set up zones and

assign pens and Mixers to zones is turned on.

The Zone Control allows you to split your pens into separate

Zones and to assign specific feed mixers to those Zones. If you

set this to On, you must include the Zone field in the pen data being sent. Additionally, you

must set the Zone for the Mixers. To access that

setting, from the main menu, select [Files] and

[Mixers]. If you have already setup Mixers in this

file, click on Modify to assign the Zones.

In the example shown, the Mixer 11 has been set

to service Zones 01 and 02.

By setting up Zones, you limit the pens assigned

to a Mixer to only those assigned to its Zone. You

can override this setting by sending a load outside

of the Mixer’s Zone manually. The RF DataLink

will ask you to verify that you want to send a load

outside of the Mixers Zone. If you select [Yes],

the load will be sent.

When you have completed your entries, click

[Save].

Send Mill Demand

This option is only used of the site has a mill batching

software program that will import batch load sizes. This

option will export the load size that was sent to the next ready

mixer.

10

Page 15

Operators Manual

Pen Delivery List Source

This option sets the source of where RF DataLink will look for

the pen delivery information. From either a bunk reader

program or a mill program. This option will have different

formats in how it will read in the pen delivery information. Be

sure to set this correctly.

Batch Number Included

This option will be used if the third party program sends over

a batch number in the W2T_Pen.dat file.

Timing

The Timing Settings allow you to

optimize the efficiency of the radio

communications within the RF

DataLink program.

The RF DataLink continuously

searches for Mixers. To optimize

this process you can take into

consideration the time required for a

Mixer to service the pens.

Example: It takes your operator 10

minutes to load the ration, 5 minutes

to mix and another 5 minutes to

drive to pen 3. That being the case,

you can tell the RF DataLink

program to ignore the Mixer for the

initial 20 minutes that it will take just

to get to the pen.

Setting the Timing

To set the Timing, from the main menu select [Systems], [Defaults], and [Timing].

Enter the pen numbers and the time delay in seconds. In this example, the time delay for

pens 0 to 5 is 5 minutes (60 seconds x 5).

These settings are optional and do not have to be used.

When you have completed your entries, click [Save].

D3664

11

Page 16

RF DataLink

Weight Tolerances

The weight tolerance

settings allow you to

establish an accuracy

level for the loading and

feeding of your rations

and pens. This tolerance

is applied to each

ingredient in a ration and

each pen in a load. The

tolerance is then used to

compare the call weight

and the actual weight. If

the result is more than the

tolerance established, an

error message is

displayed showing the

resulting error and an

error log is created.

Pen Delivery Weight Tolerances

To set the Weight Tolerances, from the main menu select [Systems], [Defaults], and [Weight

Tolerance].

To set the Pen Delivery Tolerances, first set the Pen Delivery Validate to [On].

To set the Tolerance Weight for the pen deliveries, select the feeding number and enter a

tolerance in pounds. You can set different tolerance weights for each feeding.

Example: You can have a relatively large window (tolerance) for the 1st feeding of the day

when the goal is to get feed in front of the animals, where you may have a much tighter

window (tolerance) in the afternoon when the goal is to get as close to the total amount for

the day as possible.

When you have completed your entries, click [Save].

Operator Acknowledge

This setting determines whether the error message showing the feeding error must be

acknowledged by an operator before the RF DataLink program continues. If you select

[Yes], an operator must acknowledge the error before the RF DataLink program will

continue. If you select [No], the error message will time out after 10 seconds and the RF

DataLink program will continue.

Either choice will write the error to an error log if you have turned on the Pen Delivery

Validate.

When you have completed your entries, click [Save].

12

Page 17

Operators Manual

Ration Weight Delivery Tolerances

To set the Ration Weight Tolerances, from the main menu select [Systems], [Defaults], and

[Weight Tolerance].

To set the Ration Weight Tolerance, first

turn the Ingredient Load Validate [On].

To set the tolerance weight, enter the

tolerance weight in pounds. This is a

global setting that will apply to all

ingredients loaded.

Example:

Tolerance = 500 pounds

Call weight = 4000 pounds

Actual loaded weight = 3600 pounds

Result = No error message

Actual loaded weight = 3400 pounds

Result = error message

When you have completed your entries,

click [Save].

Operator Acknowledge

This setting determines whether the error message showing the loading error must be

acknowledged by an operator before the RF DataLink program continues. If you select

[Yes], an operator must acknowledge the error before the RF DataLink program will

continue. If you select [No], the error message will time out after 10 seconds and the RF

DataLink program will continue.

Either choice will write the error to an error log if you have turned on the Ingredient Load

Validate.

When you have completed your entries, click [Save].

Split Load Minimum Balance

To set the Split Load Minimum Balance setting, from the main menu select [Systems],

[Defaults], and [Weight Tolerances].

The Split Load Minimum Balance determines whether the remaining amount of a split load

will be built

D3664

13

Page 18

RF DataLink

Example: You had a 4000-pound call weight to deliver to pen 1 and a split load occurred

that left 200 pounds to be fed to pen 1. You could set the split load minimum balance to

300 pounds. In this case, the remainder of the call for pen 1 would not be fed.

This setting is typically set to 50

pounds.

To set this, enter the amount in pounds

that you want to set as your split load

minimum. This setting is feeding

specific. Repeat as needed for each

feeding. Each feeding can have

different settings.

When you have completed your

entries, click [Save].

Operator Interface

To access the operator interface, from the main menu select [Systems], [Defaults], and

[Operator Interface].

14

Page 19

Operators Manual

Modify Recipe

To set the Modify Rations Enabled Selection, from the main

menu select [Systems], [Defaults], [Processing]. This will display

the Process Settings screen.

This selection determines whether you will allow rations to be

modified in the RF DataLink program. If you select [Yes], you

will be able to edit a ration.

Selecting [No] will not allow ration modification within the RF DataLink program.

Ration data is created and sent from third party software. If you edit a ration within the RF

DataLink program, you will not be able to obtain accurate reporting on that ration unless you

make the identical changes within third party software.

Modify Pen Enabled

To set the Modify Pens Enabled Selection, from the main menu

select [Systems], [Defaults], [Processing]. This will display the

Process Settings screen.

This selection determines whether you will allow pens to be

modified in the RF DataLink program. If you select [Yes], you will

be able to edit a pen.

Selecting [No] will not allow pen modification within the RF DataLink program.

Pen data is created and sent from third party software. If you edit a pen within the RF

DataLink program, you will not be able to obtain accurate reporting on that pen unless you

make the identical changes within third party software.

Manual Load Making

To set the Manual Load Making Selection, from the main menu

select Systems, Defaults, Processing. This will display the

Process Settings screen.

This selection determines whether you will allow a user at the RF

DataLink to enter a manual load. In the Auto Process, the RF

DataLink will automatically make your loads, if you select [Yes] to allow manual load

making, an operator can override the RF DataLink and force the next load.

If you select No, manual load making is disabled.

Wait for Acknowledge

To set the Wait for Acknowledge Selection, from the main

menu select Systems, Defaults, Processing. This will

display the Process Settings screen.

This setting determines whether the RF DataLink program

will wait for a response from an operator for any programgenerated message.

If you select [Yes], an operator must respond to the message before the program will

resume. If you select [No], the message will automatically time out after 10 seconds and the

program will resume.

D3664

15

Page 20

RF DataLink

Bunk Reader

Select Bunk Reader Type

To set the Bunk Reader type, from the main menu select Systems, Defaults, and then the

Bunk Reader tab.

This option will determine the format in how the data will be received into the RF DataLink

software. You will only use the standard TMR Tracker File Type if you are using TMR

Tracker software to make your batch and pen files.

16

Page 21

Operators Manual

Pen Feeding

Pen Delivery Mode

To set the Pen Delivery Mode, from the main menu select Systems, Defaults, and then the

Pen Feeding tab.

Single Pen – this mode will send a single pen load at a time to the

mixer. One pen, one load. This mode can be used of your mixer is

undersized for your operation and cannot hold enough feed to

process more than one pen at a time. This mode is least efficient.

Multiple Pens – this mode will send multiple pens to your mixer based on your mixers size

and how much of a particular ration it can hold. Multiple pens, one load. This mode is most

efficient and is the typical setting for most installations.

Optimize Load to Mixer/Optimize-Split Pens

To set the Optimize/Split Pens Selection, from the main menu

select Systems, Defaults, and then the Pen Feeding tab.

This setting determines whether the RF DataLink will split pens in

order to fill your mixer to capacity. When you select [Yes], the RF

DataLink program will maximize the load in your feed mixer and

split pens as needed.

Example;

D3664

17

Page 22

RF DataLink

Maximum load size is 8,000 pounds of Ration 1

Pens and call weights: Pen 1 2,000

Pen 2 2,000

Pen 3 2,000

Pen 4 3,000

Pen 5 1,000

If you select [Yes], the load would total 8,000 pounds and would feed pens 1, 2, 3 and 1,000

pounds of the call weight for pen 4. The next load that is built would feed the remaining

2,000 pounds.

This setting is typically set at [Yes].

Find Pens to Fit

To set the Find Pens to Fit Selection, from the main menu select

Systems, Defaults, and then the Pen Feeding tab.

This setting is only available if you have selected [No] at the

Optimize Split Pens selection.

This setting determines how the RF DataLink will optimize your

feeding when you elect Not to maximize the load in your feed

mixer. The system can search the pen list to find smaller pens to get the load as close to

the maximum as possible or can be set to stop at the first pen that will exceed the maximum

load size.

Example;

Maximum load size is 8,000 pounds of Ration 1

Pens and call weights:

Pen 1 2,000

Pen 2 2,000

Pen 3 2,000

Pen 4 3,000

Pen 5 1,000

With the option set to Look for smaller Pens that Fit, the load would total 7,000 pounds

and would feed pens 1, 2, 3 and 5.

With the option set to Stop at first pen that is over, the load would total 6,000 pounds and

would feed pens 1, 2 and 3.

When you have completed your entries, click [Save].

18

Page 23

Operators Manual

Mixer Loading

Print Mixer Load Sheet

To set the Print Load Sheet Selection, from the main menu

select Systems, Defaults, and then the mixer loading tab.

This selection determines whether a Load Sheet will be printed

for each load sent to the EZ Indicator in your mixer. The Load

Sheet contains the ration loading and pen feeding information as

loaded into the EZ Indicator.

This setting is typically set to [No].

Note: You must have a printer connected to the PC running the RF DataLink in order to use

this setting. If you select [Yes] and do not have a printer connected, the RF DataLink

program will not process another load until you either connect the printer or change the

setting to No.

Weigh Units

To set the Weigh Units, from the main menu select Systems,

Defaults, and then the Mixer Loading tab.

This selection sets the weigh units of the RF DataLink to either

pounds or kilograms. Be sure that the EZ indicator is set to the

same weigh units.

Determining the Load Size for the Mixer

To set the Load Size, from the main menu select Systems,

Defaults, and then the Mixer Loading tab.

D3664

19

Page 24

RF DataLink

This setting is used by RF DataLink to determine how much of a particular ration can be

loaded into your feed mixer.

This setting must be set to Mixer Volume.

Feedings To Mixer

To set how the feedings are sent

to the mixer, from the main menu

select Systems, Defaults, and then

the Mixer Loading Tab.

This option allows the PC operator

to either send one load to the

mixer at a time, send the entire

feeding or feedings for the day to

the mixer and allow the PC to only

send the pens for that load, or

send the entire feeding or feedings

for the day to the mixer and have

the scale operator control what pens get the ration. This option is most useful if the ration is

most likely not to change over the coarse of the feeding period. Or the feed mixer is out of

range of the base radio for more than 2 loads.

When you select, [All Loads at one time. PC controls loads] or [All pens and Recipes at one

time to the mixer. Mixer controls the loads]. The “Distribute All Pens to All Mixers” option

will appear. This option is set to [No] if the mixers have zones assigned to them. It will only

send the correct zone to the correct mixer if the option is set to [NO].

Transfer Type

This option determines how the feed data will be sent to

either a stationary mixer/box or a standard mixer system.

When using the stationary mixer/box Datalink will send the

ingredient loading information to the stationary mixer/box

and the pen unloading information to the delivery

mixer/box. When a load is compete at the stationary

mixer/box, Datalink will send a message to the delivery

mixer/box of what stationary mixer/box to pick up the load.

When using a stationary mixer/box and delivery mixer/box

you also have an option to send what pens are in the load

to be displayed at the stationary mixer/box.

Full Load Delay

This option is used with a bunk reader program. If the bunk

reader program sends pens to Datalink when new pens are

20

Page 25

Operators Manual

available, Datalink will wait until there are pens to make a complete

load to send to a mixer.

Variable Mix Control

This option is used when sending a mix time to the mixer/box.

When set to “Yes” Datalink will adjust the mix time based on a

10,000 lbs or kg load. If the mix time is set for 5:00 minutes

and the load is 15,000, the mix time will increase to 7:30

minutes.

Radio Settings

D3664

21

Page 26

RF DataLink

Datalink Reserve Channel

Radio Channel – The radio channel will normally be set to 7. This number can be changed

incase you have neighboring sites causing interference.

Radio Retries – This number is used to by the base radio recheck the EZ indicator to make

sure that the feed data sent is correctly.

Base Radio Type

Standard Range Base Radio (RS-232) – Set this option if the base radio is the standard

range.

Extended Range Base Radio – Set this option if the base radio is the extended range, the

PC will have the “Black Box” signal converter.

Installation Test

This option is useful when testing the range of the radio system. To use this option set

option to YES and save it.

Next set the scale to test mode, to change this enter short cut number (457) and press

(Select). Change the option to (Yes) by pressing (Select) and then press (ON) to save.

Operating the RF DataLink

Now send feedings to DataLink and start the process. DataLink will send feeding data to

the scale. and then press the (Recipe) key to send the data back to the PC. This will repeat

until the number of feeding are gone.

Quantity of Radios to be Used

You may use up to 24 channels. In order to use more than 12 channels you must contact

Digi-Star for an unlock code. (920) 563-1400

22

Page 27

Operators Manual

Importing the Feeding Data

To import the feeding data, select Process from the main menu of the RF DataLink

program. The program will automatically read the feeding data. A screen called Importing

Pen File will be displayed while the feeding data is being read. When the file has been

completed, the Importing Pen File box will be removed from the screen. The second

window will now display the Feeding Number, Ration, Zone, Call Weight, Millmix and

Externally Loaded amounts as shown:

The Call Weight is the total amount of that ration to be fed for that feeding.

Millmix refers to the amount of that ration that is mixed at a mill.

Ex. Loaded is the amount of that ration that will be loaded at the Mixer.

If the RF DataLink program is already running in the Process mode, the program will

automatically read any new feeding data sent from third party software. The RF DataLink

program looks for feeding updates between each conversation with the EZ Indicator.

Starting the Process

Once the feeding data has been read into the RF DataLink program, you can start the

actual feeding process by clicking on the Start button on the Process screen. The feeding

process will not begin until you click on the Start button.

How the Process Works

The feeding process in the RF

DataLink program begins with

a check of all available Mixers.

The program initiates radio

communication with each

Mixer. It determines the status

of the Mixer by reading the

memory of the EZ Indicator. If

the memory contains any

loading or feeding data, then

the RF DataLink program will

not attempt to send a load to

that Mixer. If the memory is

empty, the RF DataLink will

send a load to that Mixer.

D3664

23

Page 28

RF DataLink

After all the Mixers have

been checked, the RF

DataLink program will

begin making loads. It

will begin servicing the

pens in the order sent

from the third party

software.

As the data is being

transferred to the EZ

Indicator at the Mixer, the

upper window in the

Process screen will show

the status of the

communication. The

third window will also

display the load

information for this

specific load.

This information includes the Mixer Number and Description, the Batch Number, Ration,

Total Call Weight, Mill Weight and Externally Loaded amount. The L refers to Loaded and

the F refers to Feeding Number. Each

of these fields are updated when the

communication is complete.

Once the communication is complete,

the bottom window will display the Pen

Numbers and the Call Weights for each

pen in this specific load. The L and F fields will be updated in the third window as well. An

X signifies that the load is complete.

The RF Datalink will now move to the next Mixer and make/send another load. Once all the

Mixers have been loaded, it will then begin to search for each of the loaded Mixers. When it

contacts a loaded Mixer that has completed its load, it will download that data from the EZ

Indicator and send another load.

This process will repeat until all the pens have been fed and no loading or feeding data

remains.

24

Page 29

Operators Manual

Modifying Ration Data

To access the Ration data, from the Process screen, click on Rations or select Rations from

the File menu. This will display the Ration Library screen.

Listed here will be all the loaded rations in the RF DataLink program. Listed are the

following:

Ration – this is the ration code as

assigned by third party software

program.

Lbs/cu.ft. – this is the pounds per cubic

foot rating of this ration. This value is

set in the third party software program

and is used to determine how large a

load can be placed into your feed mixer.

Ingredient – this lists the individual

ingredients that make up the ration.

Percentage – is the load percentage of

each ingredient.

Type – refers to whether the ingredient

is mill loaded or Mixer loaded.

Modifying rations in the RF DataLink

program should only be done on a shortterm fix basis. Rations should always be

created within third party software. The

ability to change rations is available in the RF DataLink program, as a means of quickly

addressing problems not accounted for prior to the ration being built in third party software.

These problems can be running out of a particular ingredient, having to skip an ingredient

for a feeding, etc.

Any changes made to a ration in the RF DataLink program will be overwritten by third party

software when the next feeding data is sent. This will occur only if the ration has the same

name as the ration you edited.

Note: If you access the ration data from the process screen, the process will be halted until

you are done making your changes.

Changing Ingredients

To access the Ration data, from the Process screen, click on Rations or select Rations from

the File menu. This will display the Ration Library screen.

To change an Ingredient in a ration, highlight the ingredient you want to change by clicking

on it with the mouse. This will make the Modify button selectable. Click on the Modify

button. This will display the Ration Data screen.

D3664

25

Page 30

RF DataLink

Click on the ingredient you want to

change.

This will highlight the ingredient and

make the Modify Item button

selectable.

Click on the Modify Item button.

This will display the Ration Ingredient

Data screen.

At this screen you can change the

Ingredient Name, load percentage

and how the ingredient will be loaded.

To change the ration name or

percentage, highlight the current

entry and type in the new name or

percentage.

To change how the ingredient will be

loaded, click on By Mixer to load at

the Mixer (by loader), or click on By

Mill to load by automated process.

Click on [OK] to save your changes. When the Ration

Data main screen is displayed, click [Save Ration] to

save your changes.

Note: Iif you change the percentage of an ingredient

and the overall percentage of the ration is less

than or greater than 100%, an error message will

appear asking you to verify that you want to save

the ration. Choose [Yes] to save the ration, [No]

to exit without saving.

Deleting Ingredients

To access the Ration data, from the Process screen, click on Rations or select Rations from

the File menu. This will display the Ration Library screen.

To delete an Ingredient in a ration, highlight the ingredient you want to delete by clicking on

it with the mouse. This will make the Modify button selectable. Click on [Modify]. This will

display the Ration Data screen.

Click on the ingredient you want to delete.

This will highlight the ingredient and make the Delete Item button selectable.

Click on the [Delete] Item button.

The RF DataLink program will ask you to verify that you want to delete the ingredient.

Choose [Yes] to delete the ingredient, [No] to exit without deleting.

Click [Save Ration] to save your changes.

26

Page 31

Operators Manual

If your change results in making the overall percentage of the ration

less than or greater than 100%, an error message will appear asking you to verify that you

want to save the ration. Choose [Yes] to save the ration, [No] to exit without saving.

Adding Ingredients

To access the Ration data, from the Process screen, click on Rations or select Rations from

the File menu. This will display the Ration Library screen.

To add an Ingredient to a ration, highlight the Ration you want to add an ingredient to by

clicking on it with the mouse. This will make the Modify button selectable. Click on the

Modify button. This will display the Ration Data screen.

Click on the Add Item button. This will display the Ration Ingredient Data screen with No

data entered.

Enter the Ingredient Name, Load Percentage of the

new ingredient and whether the ingredient will be

loaded at the Mixer or at the mill.

Click on [OK] to save your changes. When the Ration

Data main screen is displayed, click [Save Ration] to

save your changes.

Note: If your change results in making the overall

percentage of the ration less than or greater than

100%, an error message will appear asking you

to verify that you want to save the ration.

Modifying Pen Data

To access the Pen data, from the

Process screen, click on Pen List

or select Pen List from the File

menu. This will display the Pens

to Deliver screen.

Listed here will be all the loaded

pens in the RF DataLink

program. The pens will be in the

order sent from the third party

software. Pens can be marked in

three ways:

D3664

27

Page 32

RF DataLink

In-Process – the pen will have an “&” in front of the call weight. This signifies that the pen

is in the process of being fed. It has been loaded into the EZ Indicator.

Split Load – the pen will have an “*” in front of the call weight. This signifies that the pen

has been split into two loads to optimize the Mixer load.

Manual Load – the pen will have an “!” in front of the call weight. This signifies that the pen

was manually added at the EZ Indicator.

Pen – this field displays the pen number.

Feeding – displays the feeding number of this pen.

Ration – shows the ration code or ration to be fed to the pen.

Call Weight – is the amount of ration to be fed to the pen.

Zone – displays the zone assigned to the pen.

Notes: Changes to pens should only be done as a quick fix solution to a problem. Pen feeding

data should always be created in the third party software.

If you access the pen data from the process screen, the process will be halted until you

are done making your changes.

Changing Pen Rations

To access the Pen data, from the Process

screen, click on [Pen List] or select Pen List

from the File menu. This will display the Pens

to Deliver screen.

To change a ration fed to pen, click on the pen

you want to change.

This will highlight the pen and make the Modify

button selectable.

Click on [Modify].

This will display the Pen Delivery – View/Modify screen.

To change the ration, highlight the current entry and enter the new ration. The new ration

must be in the current ration list.

Click [Save] to save your changes.

Deleting Pens

To access the Pen data, from the Process screen, click on [Pen List] or select [Pen List]

from the File menu. This will display the Pens to Deliver screen.

To delete a pen, click on the pen you want to delete.

Click [Delete].

The RF DataLink program will ask you to verify that you want to delete the pen. Choose

[Yes] to delete the pen, [No] to exit without deleting.

Note: Once a pen has been deleted, it cannot be recovered. It would have to be re-created if

deleted by mistake.

28

Page 33

Operators Manual

Adding Pens

To access the Pen data, from the

Process screen, click [Pen List] or select

[Pen List] from the File menu. This will

display the Pens to Deliver screen.

To add a pen, click on the Add button.

This will display the Pen Delivery – Add

screen.

Enter the Pen Number, Feeding Number,

Ration and Call Weight and Zone for the

new pen.

Notes: All added pens are added to the end of the feeding list. If you add a pen for feeding 1

and there are still pens in feeding 1 to be processed, the new pen will be fed last unless

moved in the feeding order.

If an added pen is assigned a feeding number 1 and no feeding number 1s are in

process, the added pen will have priority and will be fed on the next load processed by

the RF DataLink program.

Changing the Pen Order

To access the Pen data, from the Process screen, click [Pen List] or select [Pen List] from the

File menu. This will display the Pens to Delivery screen.

Pens are given priority based

on the Feeding Number and

the Pen Order sent from the

third party software. A

Feeding 1 always has priority

over any other feeding. If no

feeding number 1s are in

process, then the next priority

would be feeding 2. The

priority then goes to the pen

order.

D3664

29

Page 34

RF DataLink

Example: If the pen list contained:

Pen 100 Feeding 1

Pen 200 Feeding 1

Pen 300 Feeding 2

Pen 400 Feeding 2

Pen 500 Feeding 3

Pens 100 and 200 would be fed first, in that order. If you changed the feeding order to:

Pen 500 Feeding 3

Pen 100 Feeding 1

Pen 200 Feeding 1

Pen 300 Feeding 2

Pen 400 Feeding 2

Pens 100 and 200 would still be fed first. This is because those pens are assigned a

feeding 1 and therefore have priority over Pen 500, which is a feeding 3.

To change the pen feeding order, highlight the pen you want to move by clicking on it with

the mouse, this will make the Up and Down arrow buttons selectable.

To move this pen in the feeding order, click the Up arrow to move it up in the order or the

Down arrow to move it down in the order.

If you have a pen scheduled for a feeding number 2 that you want to feed immediately,

change the Feeding Number to 1 and use the Up arrow button to move the pen to the

beginning of the list.

When you have completed making your pen moves, click on Save to save the new feeding

order.

Putting an In-Process Pen back in the Feeding

To access the Pen data, from the Process screen, click on Pen List or select Pen List from

the File menu. This will display the Pens to Delivery screen.

Pens that are InProcess are marked with an “&” in front of the call weight. To place these

pens back into the feeding order, click on the pen you want to change.

This will highlight the pen and make the Modify button selectable.

Click on the Modify button.

This will display the Pen Delivery –

View/Modify screen.

Highlight the “&” in front of the call weight

and press the backspace key. This will

delete the “&”.

Click on Save to place the pen back in the

feeding list.

Deleting Records

30

Page 35

Operators Manual

The RF DataLink program retains a copy of

all data sent to and from the program. This

includes the data sent from third party

software and all communications with the EZ

Indicator. This data is kept for backup and

troubleshooting purposes. These records

need to be periodically deleted.

To delete these records, select Delete Daily

Records from the File menu.

This will display the file choices available for

deletion.

All – will delete the entire currently loaded

pen and ration files. This should not be

done unless you are going to re-send the entire feeding from third party software.

Batches – will delete the current ration data file.

Completed – this will delete the completed/fed data. Deleting this data will prevent the third

party software from recording the feeding.

In Process – will delete only the pens and batches in process.

Pens – will delete the pen list.

As Fed Data – this is a backup file of the completed data sent to the third party software

program. It is recommended that this file be kept for 30 days and then deleted.

Delete History Records – will delete all the communication files between the RF DataLink

and the EZ Indicator. This should be deleted every 30 days.

To delete any of these records, click on the file with the mouse. The RF DataLink will ask

you to verify that you want to delete the record. Click [Yes] to delete the record.

Notes: Once a file has been deleted, it cannot be recovered.

Failing to delete the History Records over a period of time will result in slowing down the

operation of the RF DataLink program.

Viewing the Error Log

If you are using the Weight Tolerance settings, each load that results in an error will create

an error log. This file is called T2w_excp. This file is a simple text file and can be opened

by any text-editing program.

The file displays data in this order:

D3664

31

Page 36

RF DataLink

• User ID

• Batch Number

• Ration

• Ingredient or Feeding Number

• Ingredient Code or Pen Number

• Call Weight

• Actual Loaded or Delivered Weight

• Resulting Error

• Tolerance

• Time

• Date

Using the above example, ALPHAY had a call weight of 4620 pounds, actual loaded weight

of 4410 pounds resulting in an error of 210 pounds.

The error log should be deleted periodically.

Test Communications

To access this screen select Utility, and then Test

Communications.

The option will allow you to test communications with the

EZ indicator.

In this screen you can select the EZ indicator to

communicate with and view that status of the indicator.

Indicator Status

The status of the indicator is what information is in the scales internal memory.

Example: If you send one load of 6 ingredients and 2 pens the status will show:

U0008D0000 This shows that there are 8 records in the scale memory of undone

information. As the operator completes each ingredient and pen the undone records will

then move to the done side. In order for the scale to send back complete data to RF

Datalink there cannot be any undone records in the memory. The status must show:

Example: U0000D0008 at this time the scale will then start to send back the completed

data.

If a load was sent to the EZ indicator that needs to be removed you have the ability to clear

the batches in that indicator by clicking on the “Clear Mixer” button. If the status is:

D9999U9999 this means that the scale is not in range or the scale is scrolling a message.

The scale must be in weighing mode: Net or Gross for the scale to be cleared. Select the

Get Feeding Status to refresh the status screen. Then select Clear Mixer.

You will have the same control in this screen as you would have at the indicator. You can

click on the keys and also send a text message to the indicator. The indicator will continue

to display the message until a key is press.

32

Page 37

Operators Manual

Reliability Meter

This meter will show how well the scale and the base radio is communicating. The Good

Data and Missed Data show how many times the base radio has received an “OK” message

from the scale. Excellent reliability would be over 95%. If you are dropping below into Good

refer to the front section about maximizing radio range.

D3664

33

Page 38

RF DataLink

Repair Parts – Std. Antenna

(P/N 403965 KIT-DATA LINK STANDARD BASE)

KEY QTY. PART NO DESCRIPTION

1 1 404007 HOUSING-DATALINK BASE RADIO

2 1 403987 BRKT-DATALINK BASE RAM MOUNT

3 1 403314 MOUNT-RAM-111 1.5" BALL 7.3"LG

4 1 403986 PLATE-RADIO MOUNTING

5 1 403967 RADIO ASSY-2.4GHZ BASE,RS232

6 1 403988 CABLE-COAX 12" RPSMA M TO F

7 1 403989 CABLE-DATALINK RS232/RS422

8 1 403990 CABLE, DATALINK RS 232 W/POWER

9 1 141885 RELIEF - STRAIN HEYCO

10 1 146724 ROD-PLASTIC 1/4"

11 1 403972 ANTENNA-DATALINK BASE

12 1 403991 DECAL-DATALINK BASE

13 4 403495 SCR- #10-24 X .5 CRG ZP GR2

14 8 145339 SCR-#6-32 x 1/4 PHMS

15 4 403774 SCR-#6x5/16 PHSTS 48-2 ZP

16 4 141967 SCR-#4-40 x 3/8 PHMS PHL

17 4 403501 NUT-#10-24 KEPS ZP

18 4 834109 NUT-#6-32 KEPS

19 4 141966 NUT-#4-40 KEP SS

20 (not shown) 404044 POWER SUPPLY-UNIVERSAL 12V, .42AMP

21 (not shown) 403975 COVERTER-USB TO RS232

22 (not shown) 404045 PLUGS-AC R-SERIES KIT

34

Page 39

Operators Manual

Repair Parts – Extend Range Antenna

(P/N 403966 KIT-EXTENDED RANGE ANTENNA)

KEY QTY PART NO DESCRIPTION

1 1 404010 ANTENNA-2.4GHZ, 6 DB

2 1 404012 SURGE PROTECTOR

3 1 404013 CABLE-COAX N-MALE TO RPSMA 36"

4 1 404014 POWER PLUG-2 TERMINAL, SCREW

5 1 404015 POWER CORD-18 AWG, 3 COND 6 FT

6 1 404016 CABLE-DATALINK RS422 150 FT

7 1 404017 CONVERTER-USB TO RS422

8 2 PS2144 - CABLE TIE-.14x11.625" BLACK

9 1 404011 ADAPTOR-COAX N-MALE TO N-MALE

10 1 404018 ADAPTER-COAX N-FEMALE-N-FEMALE

D3664

35

Loading...

Loading...