Page 1

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

Si tiene dudas o comentarios, contáctenos.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

1-800-4-DEWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

(JAN11) Part No. N081335 DWP849, DWP849X Copyright © 2011 D

The following are trademarks for one or more DEWALT power tools: the yellow and black

color scheme, the “D” shaped air intake grill, the array of pyramids on the handgrip, the kit box

configuration, and the array of lozenge-shaped humps on the surface of the tool.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word.

Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not

avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL

US TOLL FREE AT: 1-800-4-D

WARNING: To reduce the risk of injury, read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is earthed

or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce dustrelated hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

EWALT (1-800-433-9258).

FOR FUTURE REFERENCE

DWP849, DWP849X

Polishers

Polisseuses

Pulidoras

EWALT

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result

in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Safety Instructions for All Operations

a) This power tool is intended to function as a polisher. Read all safety warnings,

instructions, illustrations and specifications provided with this power tool. Failure to

follow all instructions listed below may result in electric shock, fire and/or serious injury.

b) Operations such as grinding, sanding, wire brushing or cutting-off are not

recommended to be performed with this power tool. Operations for which the power

tool was not designed may create a hazard and cause personal injury.

c) Do not use accessories which are not specifically designed and recommended by

the tool manufacturer. Just because the accessory can be attached to your power tool, it

does not assure safe operation.

d) The rated speed of the accessory must be at least equal to the maximum speed

marked on the power tool. Accessories running faster than their rated speed can break

and fly apart.

e) The outside diameter and the thickness of your accessory must be within the

capacity rating of your power tool. Incorrectly sized accessories cannot be adequately

guarded or controlled.

f) The arbor size of wheels, flanges, backing pads or any other accessory must

properly fit the spindle of the power tool. Accessories with arbor holes that do not match

the mounting hardware of the power tool will run out of balance, vibrate excessively and may

cause loss of control.

g) Do not use a damaged accessory. Before each use inspect the accessory such as

abrasive wheels for chips and cracks, backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If power tool or accessory is dropped, inspect

for damage or install an undamaged accessory. After inspecting and installing an

accessory, position yourself and bystanders away from the plane of the rotating

accessory and run the power tool at maximum no-load speed for one minute.

Damaged accessories will normally break apart during this test time.

h) Wear personal protective equipment. Depending on application, use face shield,

safety goggles or safety glasses. As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron capable of stopping small abrasive or

workpiece fragments. The eye protection must be capable of stopping flying debris

generated by various operations. The dust mask or respirator must be capable of filtrating

particles generated by your operation. Prolonged exposure to high intensity noise may cause

hearing loss.

i) Keep bystanders a safe distance away from work area. Anyone entering the work

area must wear personal protective equipment. Fragments of workpiece or of a broken

accessory may fly away and cause injury beyond immediate area of operation.

j) Hold power tool by insulated gripping surfaces only, when performing an operation

where the cutting accessory may contact hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and

shock the operator.

k) Position the cord clear of the spinning accessory. If you lose control, the cord may be

cut or snagged and your hand or arm may be pulled into the spinning accessory.

l) Never lay the power tool down until the accessory has come to a complete stop. The

spinning accessory may grab the surface and pull the power tool out of your control.

m) Do not run the power tool while carrying it at your side. Accidental contact with the

spinning accessory could snag your clothing, pulling the accessory into your body.

n) Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the

housing and excessive accumulation of powdered metal may cause electrical hazards.

o) Do not operate the power tool near flammable materials. Sparks could ignite these

materials.

p) Do not use accessories that require liquid coolants. Using water or other liquid coolants

may result in electrocution or shock.

Further Safety Instructions for All Operations

KICKBACK AND RELATED WARNINGS

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any

other accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in

turn causes the uncontrolled power tool to be forced in the direction opposite of the accessory’s

rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump toward or away from the operator, depending on

direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under

these conditions.

Kickback is the result of tool misuse and/or incorrect operating procedures or conditions and can

be avoided by taking proper precautions as given below:

a) Maintain a firm grip on the power tool and position your body and arm to allow you

to resist kickback forces. Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start up. The operator can control

torque reaction or kickback forces, if proper precautions are taken.

b) Never place your hand near the rotating accessory. Accessory may kickback over your

hand.

c) Do not position your body in the area where power tool will move if kickback occurs.

Kickback will propel the tool in direction opposite to the wheel’s movement at the point of

snagging.

d) Use special care when working corners, sharp edges, etc. Avoid bouncing and

snagging the accessory. Corners, sharp edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades

create frequent kickback and loss of control.

Safety Warnings Specific for Polishing Operations

a) Do not allow any loose portion of the polishing bonnet or its attachment strings

to spin freely. Tuck away or trim any loose attachment strings. Loose and spinning

attachment strings can entangle your fingers or snag on the workpiece.

Additional Specific Safety Instructions for Polishers

• Always use eye protection. All users and bystanders must wear eye protection that conforms

to ANSI Z87.1.

• Clean out your tool often, especially after heavy use. Dust and grit containing metal

particles often accumulate on interior surfaces and could create an electric shock hazard.

• Do not operate this tool for long periods of time. Vibration caused by the operating action

of this tool may cause permanent injury to fingers, hands and arms. Use gloves to provide extra

cushion, take frequent rest periods and limit daily time of use.

• Air vents often cover moving parts and should be avoided. Loose clothes, jewelry or long

hair can be caught in moving parts.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is

16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using more than one extension to make up

the total length, be sure each individual extension contains at least the minimum wire size. The

following table shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also

use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Always wear proper personal hearing protection that conforms to ANSI

S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Not More

Than

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

Page 2

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out microscopic

particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Use extra care when working into a corner because a sudden, sharp movement

of the polisher may be experienced when the wheel or other accessory contacts a secondary

surface or a surface edge.

• The label on your tool may include the following symbols. The symbols and their definitions are

as follows:

V ......................volts A ................amperes

Hz ....................hertz W ............... watts

min ..................minutes

.............alternating current

...............direct current .............alternating or direct current

....................Class I Construction

n

o ..............no-load speed

........................(grounded) ...............earthing terminal

....................Class II Construction ..............safety alert symbol

........................(double insulated) BPM ...........beats per minute

…/min .............per minute RPM ...........revolutions per minute

SAVE THESE INSTRUCTIONS

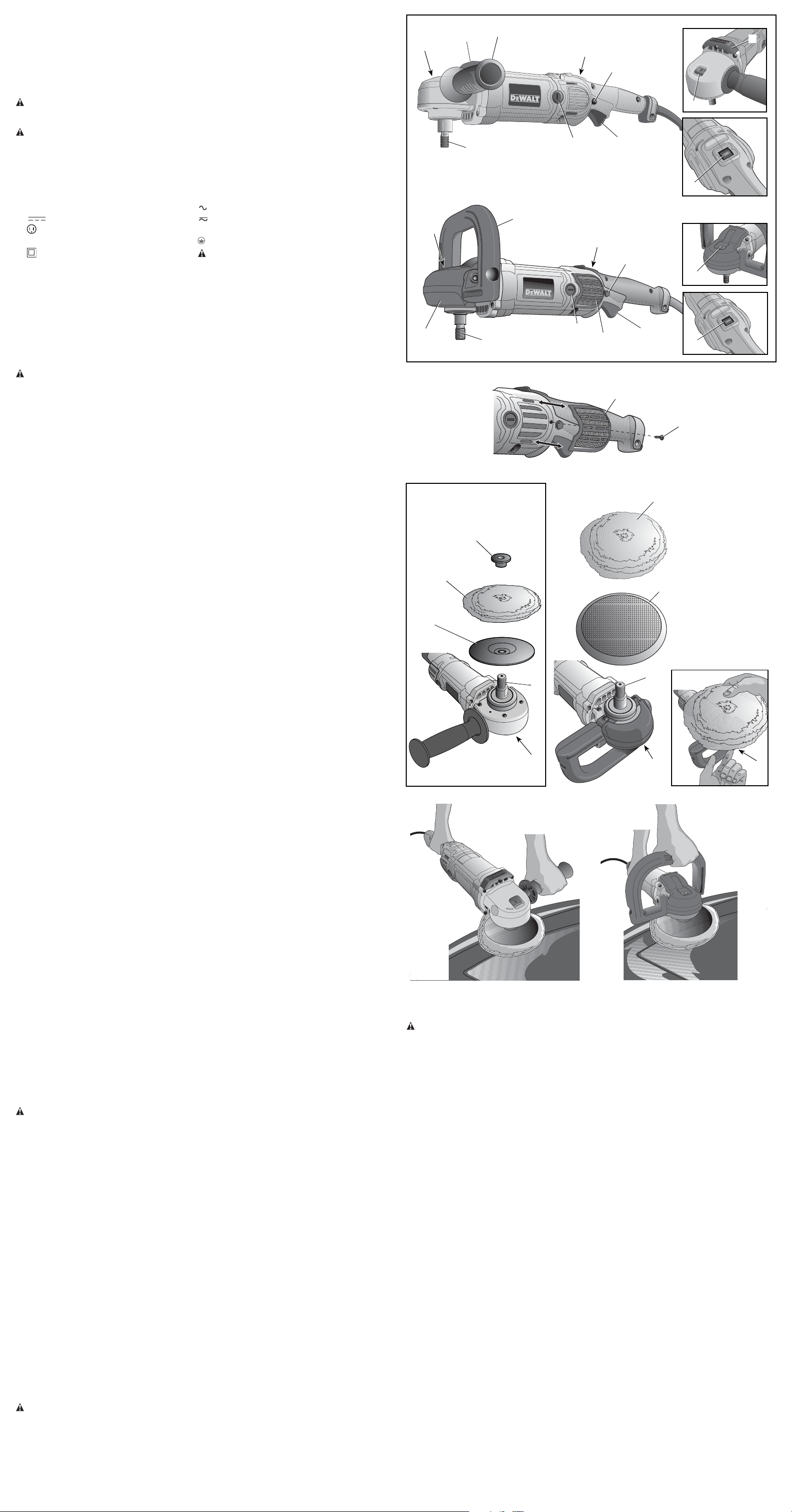

FIG. 1

E

E

B

F

DWP849

I

H

DWP849X

A

G

E

D

C

A

A

G

E

B

Motor

Be sure your power supply agrees with the nameplate marking. Voltage decrease of more than

10% will cause loss of power and overheating.

DEWALT

tools are factory tested; if this tool does not

operate, check power supply.

COMPONENTS (Fig. 1)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result.

A. Speed control wheel G. Trigger locking button

B. Cushion tool rest (DWP849 only) H. Bale handle

C. Variable speed trigger switch I. Spindle

D. Brush inspection cap J. Soft rubber gear case cover

E. Spindle lock button K. Wool ingestion shield

F. Auxiliary handle

INTENDED USE

The DWP849 and DWP849X heavy-duty polishers are designed for polishing painted or unfinished

metal, fiberglass, and composite surfaces in professional applications. Common examples of use

include but are not limited to: auto/marine/RV/motorcycle detailing and finish correction, boat

construction and repair, and metal or concrete finishing.

Do not use in the presence of flammable liquids or gases. Do not let children come into contact

with the tool. Supervision is required when inexperienced operators use this tool.

Auxiliary Handle (Fig. 1)

An auxiliary handle (F) is furnished with your tool and can be installed on either side of the gear

case. This handle should be used at all times to maintain complete control of the tool.

A bale handle (H) is also provided with the DWP849X and can be used in place of the auxiliary

handle.

Variable Speed Trigger Switch (Fig. 1)

These tools are equipped with a variable speed trigger switch that permits speed control from 0

to 3500 RPM. To turn the tool on, squeeze the trigger switch (C) shown in Figure 1 until the tool

starts to run. The farther you depress the trigger, the faster it will operate. Releasing the trigger

turns the tool off.

Use lower speeds for applying liquid waxes and polishes and higher speeds for removing dried

liquid. Use the highest speed (fully depress trigger) for buffing the car to a final lustre.

The tool can be locked on for continuous use by squeezing the trigger switch fully and depressing

the lock button (G) shown in Figure 1. Hold the lock button in as you gently release the trigger

switch. The tool will continue to run. To turn the tool off from a locked-on position, squeeze and

release the trigger switch once. Do not unplug the tool with the switch in the locked-on condition.

Make sure the tool is not locked on when plugging in.

The variable speed trigger switch (C) has a no-volt release function. In the event of a power outage

or other unexpected shut down, the trigger switch needs to be cycled (depress the trigger switch,

release, then depress again) to restart the tool. Do not unplug the tool with the trigger switch in the

locked-on condition. Make sure the tool is not locked on when plugging in. If the tool is plugged

back in with the trigger switch in the locked-on position, the tool will not run until the trigger switch

(C) is cycled as described above.

NOTE: The trigger switch can only be locked on with the tool running at the maximum RPM

designated by the speed control wheel (A).

Speed Control Wheel (Fig. 1)

The maximum speed of your tool can be changed by rotating the speed control wheel (A) to the

desired setting. The wheel incorporates detents to prevent inadvertent wheel movement and

to facilitate speed selection. For added versatility, the trigger switch may be locked in its full on

position and tool speed changed by means of the speed control wheel (A) alone.

The electronic speed control not only lets you select the speed to suit the job, but also helps to

maintain that speed as you load the tool by pressing down. It’s this feature, coupled with the

variable speed trigger switch, that make this tool such a value.

The speed control wheel (A) can be set for any speed between 600 and 3500 RPM and the

variable speed switch will then control tool speed from zero to the wheel setting. For example: A

control wheel setting of 2200 RPM will allow the variable speed switch to operate the tool between

zero and 2200 RPM, depending on how far the trigger switch is depressed. A wheel setting of 600

RPM would allow the switch to operate the tool from zero to 600 RPM.

The electronic speed control feature comes into play whenever the trigger switch is fully depressed

and the tool is running at the selected speed determined by the setting of the control wheel. As

you load the tool by pushing it down on the work surface, (with the trigger fully depressed) the

electronic circuit inside the tool will compensate for the loading and maintain the selected speed.

If the speed selected by the control wheel is 2200 RPM, as in the example above, the tool will

maintain 2200 RPM, as it is loaded.

It is important to remember two things about electronic speed control:

1. The electronic speed control operates only when the trigger switch (C) is fully depressed.

2. The effect of electronic speed control is much easier to observe at lower speed settings

(2600 RPM and below), than at high speeds. As the tool approaches 3000 RPM, the effect is

considerably less dramatic.

Keep in mind that, with a conventional polisher running at a typical no-load speed of 2400 RPM,

the tool slows down to about 2000 RPM under a polishing load. Your DWP849 or DWP849X will

continue to run at 2400 RPM (or any speed you select with the control wheel) as a load is applied.

Since it doesn’t slow down, the speed may be greater than you’re used to, so some extra caution

should be observed until you get the “feel” of your polisher. If you feel the speed is too great, you

can, of course, slow the tool down with either the trigger switch or the control wheel.

Spindle Lock Button (Fig. 1)

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing

attachments or accessories. Before reconnecting the tool, depress and release the

trigger switch to ensure that the tool is off.

In order to prevent the spindle of the tool from rotating while installing or removing accessories, a

spindle lock button (E) has been provided in the gear head of the machine. To lock the spindle,

depress and hold the lock button. NEVER DEPRESS THE SPINDLE LOCK BUTTON WITH THE

TOOL RUNNING OR COASTING.

Wool Ingestion Shields (Fig. 1, 2)

The wool ingestion shields (K) are designed to reduce the amount of wool, dust, and debris that

gets ingested by the motor during normal use. The goal of the ingestion shields is to improve

durability as compared to a unit without the ingestion shields.

Each ingestion shield can be easily removed for cleaning by removing the mounting screw (L),

followed by sliding the shield back towards the trigger end of the tool and then lifting it off.

The wool ingestion shields can be cleaned with soap and water and a soft bristle brush in the event

they get clogged with polish and debris. Clean the shields as soon as you start to see buildup on

the outside.

Your tool may come with a set of wool ingestion shields. The wool ingestion shields are available

at extra cost from your local dealer or authorized service center.

Soft Rubber Gear Case Cover (Fig. 1)

The soft rubber gear case cover (J) is designed to eliminate metal gear case scuffs on painted or

polished surfaces.

The soft rubber gear case cover can be removed if required. To take off the cover, remove the

three mounting screws and lift the cover over the gear case.

Your tool may come with a soft rubber gear case cover. The soft rubber gear case cover is

available at extra cost from your local dealer or authorized service center.

OPERATION

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing

attachments or accessories. Before reconnecting the tool, depress and release the

trigger switch to ensure that the tool is off.

Polishing pads with a diameter of 6", 7" or 9" (15.2, 17.8 or 22.9 cm) may be used with the

DWP849 and DWP849X.

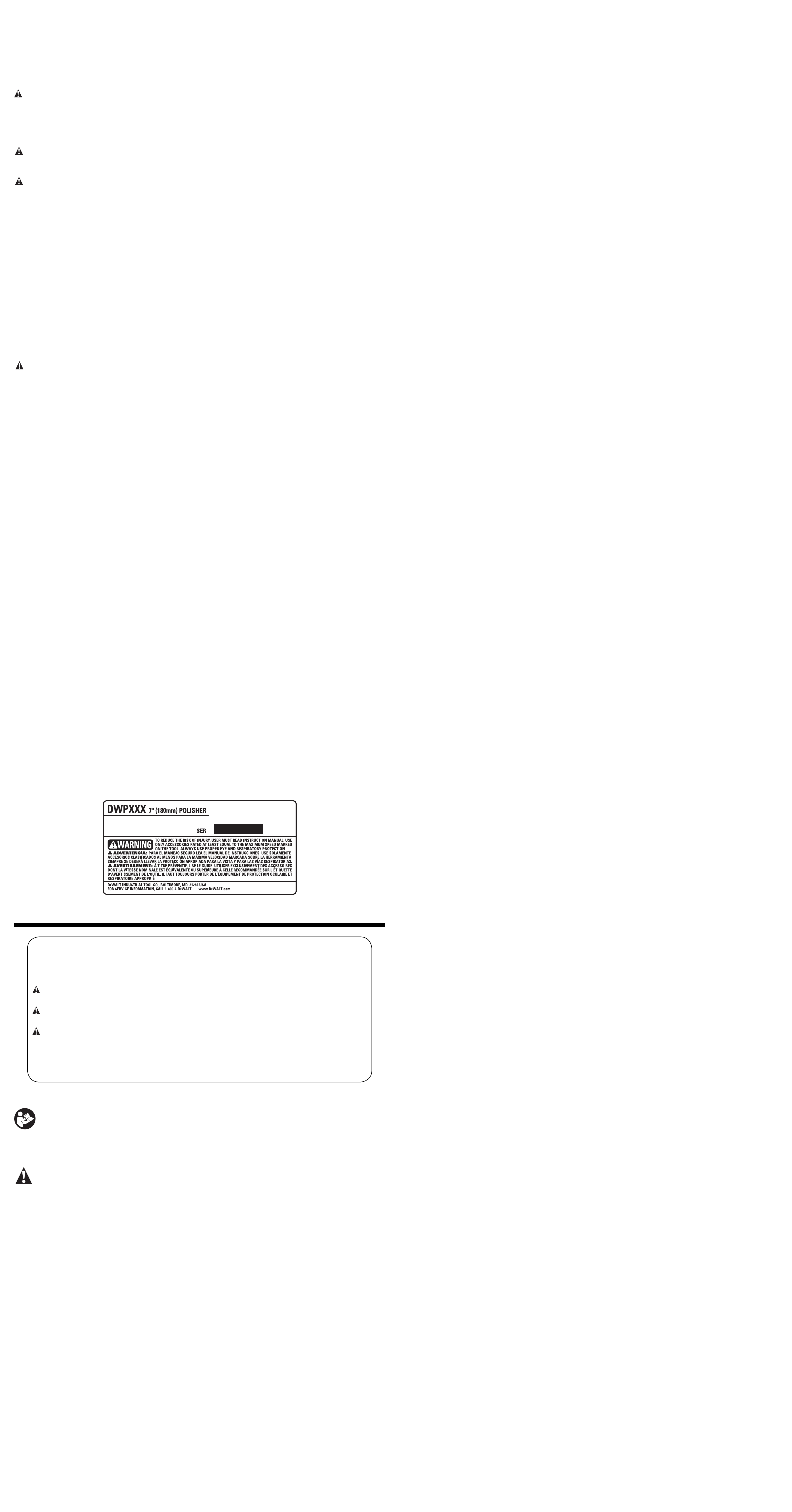

J

FIG. 3A

DWP849

FIG. 4

D

I

FIG. 2

FIG. 3B

K

DWP849X

M

N

O

I

E

C

K

P

Q

I

E

A

L

E

Attaching and Removing Polishing Pads (Fig. 3)

WARNING: To reduce the risk of serious personal injury, do not allow any loose portion of the

polishing bonnet or its attachment strings to spin freely. Tuck away or trim any loose attachment

strings. Loose and spinning attachment strings can entangle your fingers or snag on the workpiece.

NOTE: Both the DWP849 and the DWP849X may use either type of polishing pad assembly

described below.

TO ATTACH POLISHING PAD WITH RUBBER BACKING PAD (FIG. 3A)

1. To attach polishing pad (N), push the hub of the clamp washer (M) through the hole in the

center of the polishing pad as far as it will go.

2. Engage the hexagonal hole in the backing pad (O). Holding the three pieces firmly together,

place the assembly on the tool spindle (I).

3. Hold the spindle lock button (E) while turning the pads clockwise to thread them completely on

the spindle.

TO ATTACH POLISHING PAD WITH HOOK AND LOOP BACKING PAD (FIG. 3B)

1. Attach hook and loop foam or wool pad (P) to hook and loop backing pad (Q), being careful to

center the backing pad with the foam or wool pad.

2. Screw backing pad (Q) onto spindle (I), while depressing spindle lock button (E).

TO REMOVE PADS

Turn them by hand in the opposite direction from normal rotation to allow lock button to engage

spindle, then unscrew pads in normal direction for right-hand thread.

Polishing (Fig. 4)

These instructions and suggestions are intended to familiarize new operators in overall general

operation of power polishing. You will develop your own techniques which will make the job easier

and faster as you learn power polishing.

• You should use utmost care when power polishing around or over sharp objects and contours

of the car body. It is very important to use the correct pressure while polishing various sections

of an automobile body. For example, light pressure should be applied when polishing over

sharp edges of body panels, or over edges of the rain gutter along the top.

• Since everyone does not use the same type of power polish, we recommend you clean and

polish a test section on a flat area of the car first. From this test section, you can judge the

strength or cleaning action of your power polish.

• Remember, all power polish is not the same. Different brands will react differently on various

painted surfaces. Also, you are now using a power polisher with power polish. This is entirely

different from any hand application which you may have done before. Wash the car before

power polishing it. Washing will remove loose dirt, scum, road salt, etc. which could act as an

abrasive and damage paint. Loose dirt, etc. will also clog the polishing pad and you will have to

clean it more often.

• Without turning the tool on, grasp the handles of the tool and pick it up (Fig. 4). Keep the

tool away from your body and depress the trigger switch. Make sure you have a firm grip on

the handles and operate the tool freely without forced effort or unnecessary pressure. The

side handle can be easily changed to either side of the tool for left-handed or right-handed

operation.

NOTE: The high speed rubbing action of the polishing bonnet upon the surface of an automobile

can build a static charge on the metal portions of this tool. This can result in a sensation of a very

short mild electric shock when the metal area of the tool is touched, and will be more noticeable

Page 3

on days when the humidity is low. This is a harmless phenomenon but you are invited to bring the

tool to a D

is present.

EWALT service center where it can be checked to assure that no electrical malfunction

MAINTENANCE

Your DEWALT power tool has been designed to operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation depends upon proper tool care and regular

cleaning.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing

attachments or accessories. Before reconnecting the tool, depress and release the

trigger switch to ensure that the tool is off.

Cleaning

WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear proper

ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA respiratory

protection when performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Lubrication

DEWALT tools are properly lubricated at the factory and are ready for use. Tools should be

relubricated regularly every sixty days to six months, depending on usage. (Tools used constantly

on production or heavy-duty jobs and tools exposed to heat may require more frequent lubrication.)

This lubrication should only be attempted by trained power tool repairpersons such as those at

EWALT service centers or other authorized service locations.

D

Motor Brushes

Be sure tool is unplugged before inspecting brushes. Carbon brushes should be regularly inspected

for wear. To inspect brushes, unscrew the plastic brush inspection caps (located in the sides of the

motor housing) so the spring and brush assemblies may be withdrawn from the tool. Keep brushes

clean and sliding freely in their guides. Carbon brushes have varying symbols stamped into them,

and if the brushes are worn down to the line closest to the spring, they must be replaced.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with

this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury,

EWALT recommended accessories should be used with this product.

only D

Recommended accessories for use with your tool are available at extra cost from your local dealer

or authorized service center. If you need assistance in locating any accessory, please contact

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT

D

(1-800-433-9258) or visit our website: www.dewalt.com.

Use only accessories having a maximum operating speed at least as high as the highest “NO LOAD

RPM” marked on the tool’s nameplate. This precaution applies to any accessory on any tool.

• Rubber backing pads: 7" (17.8 cm) Quick Change Super Flexible Rubber Backing Pad

(includes clamp washer)

• 7" (17.8 cm) hook and loop backing pads

• Soft rubber gear case cover

• Wool ingestion shields

• Auxiliary handle

• Bale handle

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including

brush inspection and replacement) should be performed by a D

a D

EWALT authorized service center or other qualified service personnel. Always use identical

replacement parts.

EWALT factory service center,

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.

com or call 1-800-4-D

damage caused where repairs have been made or attempted by others. This warranty gives you

specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

D

during the first year after purchase.

If you are not completely satisfied with the performance of your D

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt for

a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained either in the packaging,

call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing,

call 1-800-4-D

EWALT (1-800-433-9258) for a free replacement.

EWALT (1-800-433-9258). This warranty does not apply to accessories or

EWALT tools are covered by our:

1 YEAR FREE SERVICE

90 DAY MONEY BACK GUARANTEE

EWALT Power Tool, Laser, or

Définitions : lignes directrices

en matière de sécurité

Les définitions ci-dessous décrivent le niveau de gravité pour chaque symbole. Veuillez lire le

mode d’emploi et porter une attention particulière à ces symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas évitée,

causera la mort ou des blessures graves.

AVERTISSEMENT :

pas évitée, pourrait se solder par un décès ou des blessures graves.

ATTENTION : indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée pourrait se solder par des blessures mineures ou modérées.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n’est fait pour l’éviter, pourrait poser des risques de dommages

matériels.

POUR TOUT COMMENTAIRE OU QUESTION RELATIF À CET OUTIL OU TOUT AUTRE OUTIL

D

EWALT, COMPOSEZ GRATUITEMENT LE: 1-800-4-DEWALT (1-800-433-9258).

AVERTISSEMENT : pour réduire tout risque de dommage corporel, lire le manuel de

l’utilisateur.

indique une situation potentiellement dangereuse qui, si elle n’est

Directives de sécurité relatives aux outils électriques

en général

AVERTISSEMENT: lire toutes les directives et consignes de sécurité. Tout

manquement aux directives et consignes pose des risques de décharge électrique,

d’incendie et/ou de blessure grave.

CONSERVER TOUTES CES DIRECTIVES

ET CONSIGNES À TITRE DE RÉFÉRENCE

Le terme «outil électrique» dans ces directives se rapporte à votre outil électrique alimenté sur

secteur (avec fil) ou par piles (sans fil).

1) SÉCURITÉ – AIRE DE TRAVAIL

a) Maintenir l’aire de travail propre et bien éclairée. Les lieux encombrés ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner un outil électrique dans une atmosphère explosive, en

présence par exemple de poussières, gaz ou liquides inflammables. Les outils

électriques peuvent produire des étincelles qui pourraient enflammer toute émanation ou

poussière ambiante.

c) Tenir les enfants, ou toute autre personne, à l’écart pendant l’utilisation d’un outil

électrique. Toute distraction pourrait faire perdre la maîtrise de l’appareil.

2) SÉCURITÉ – ÉLECTRICITÉ

a) La fiche électrique de l’outil doit correspondre à la prise murale. Ne jamais modifier

la fiche en aucune façon. Ne jamais utiliser de fiche d’adaptation avec un outil

électrique mis à la terre. L’utilisation de fiches d’origine et de prises appropriées réduira

les risques de choc électrique.

b) Éviter tout contact corporel avec des éléments mis à la terre comme tuyaux,

radiateurs, cuisinières ou réfrigérateurs. Les risques de choc électrique augmentent

lorsque le corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à l’humidité. Toute pénétration d’un

outil électrique par un liquide augmente les risques de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou débrancher un outil électrique. Protéger le cordon de la chaleur,

de l’huile et de tout bord tranchant ou pièce mobile. Les cordons endommagés ou

emmêlés augmentent les risques de choc électrique.

e) Lors de l’utilisation d’un outil électrique à l’extérieur, n’utiliser que des rallonges

conçues pour l’extérieur. L’utilisation d’une rallonge conçue pour l’extérieur réduit les

risques de choc électrique.

f) S’il est impossible d’éviter l’utilisation d’un outil électrique dans un endroit

humide, brancher l’outil dans une prise ou sur un circuit d’alimentation dotés d’un

disjoncteur de fuite à la terre (GFCI). L’utilisation de ce type de disjoncteur réduit les

risques de choc électrique.

3) SÉCURITÉ PERSONNELLE

a) Rester constamment vigilant et faire preuve de jugement pendant l’utilisation

d’un outil électrique. Ne pas utiliser d’outil électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Tout moment d’inattention

pendant l’utilisation d’un outil électrique pose des risques de blessure grave.

b) Utiliser un équipement de protection individuel. Porter systématiquement des

lunettes de protection. Le fait de porter un équipement de protection tel que masque

antipoussières, chaussures antidérapantes, casque de sécurité ou protecteurs auditifs

lorsque la situation le requiert, réduira les risques de dommages corporels.

c) Prévenir tout démarrage accidentel. S’assurer que l’interrupteur est en position

d’arrêt avant de brancher l’outil et/ou de le connecter à un bloc-piles, et avant de

le saisir ou de le transporter. Transporter un outil le doigt sur l’interrupteur, ou brancher

un outil électrique alors que l’interrupteur est en position de marche, invite les accidents.

d) Retirer toute clé de réglage avant de démarrer l’outil. Une clé laissée sur une pièce

rotative d’un outil électrique pose des risques de blessure.

e) Ne pas effectuer de travaux hors de portée. Les pieds doivent rester bien ancrés au

sol afin de maintenir son équilibre en tout temps. Cela permet de mieux maîtriser l’outil

électrique dans les situations imprévues.

f) Porter des vêtements appropriés. Ne pas porter de vêtements amples ni de bijoux.

Maintenir cheveux, vêtements et gants éloignés des pièces mobiles. Vêtements

amples, bijoux ou cheveux longs risquent de rester coincés dans ces pièces mobiles.

g) Lorsqu’un dispositif de connexion à un système de dépoussiérage ou d’élimination

est fourni, s’assurer qu’il est connecté et utilisé correctement. L’utilisation d’aspirateurs

peut réduire les risques engendrés par les poussières.

4) UTILISATION ET ENTRETIEN DES OUTILS ÉLECTRIQUES

a) Ne pas forcer un outil électrique. Utiliser l’outil approprié au travail en cours. L’outil

approprié effectuera un meilleur travail, de façon plus sûre et à la vitesse pour laquelle il a été

conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout appareil

dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche du secteur et/ou le bloc-piles de l’outil électrique avant de

faire tout réglage ou changement d’accessoire, ou avant de ranger ce dernier. Ces

mesures préventives réduisent les risques de démarrage accidentel de l’appareil.

d) Après usage, ranger les outils électriques hors de la portée des enfants, et ne

permettre à aucune personne n’étant pas familière avec un outil électrique (ou son

manuel d’instruction) d’utiliser ce dernier. Les outils peuvent être dangereux entre les

mains des novices.

e) Entretenir les outils électriques. Vérifier les pièces mobiles pour s’assurer qu’elles

sont bien alignées et tournent librement, qu’elles sont en bon état et ne sont

affectées d’aucune condition susceptible de nuire au bon fonctionnement de l’outil.

En cas de dommage, faire réparer l’outil électrique avant toute nouvelle utilisation.

Bien des accidents sont causés par des outils mal entretenus.

f) Maintenir toute lame aiguisée et propre. Les outils de coupe bien entretenus et affûtés

sont moins susceptibles de se coincer et sont plus faciles à contrôler.

g) Utiliser un outil électrique, ses accessoires, mèches, etc., conformément aux

présentes directives en tenant compte des conditions de travail et du travail à

effectuer. L’utilisation d’un outil électrique pour toute opération autre que celle pour laquelle

il a été conçu est dangereuse.

5) SERVICE

a) Faire entretenir les outils électriques par un réparateur qualifié en utilisant

seulement des pièces de rechange identiques. Cela permettra d’assurer l’intégrité de

l’outil électrique et la sécurité de l’utilisateur.

Consignes de sécurité propres à toute utilisation

a) Cet outil électrique a été conçu pour être utilisé comme polisseuse. Lire toutes

les consignes de sécurité, les directives, les illustrations et les caractéristiques

techniques fournies avec cet outil électrique. Tout manquement aux directives suivantes

pose des risques de chocs électriques, d’incendie et/ou de blessures graves.

b) Les opérations de ponçage, brossage métallique, meulage ou découpe ne sont pas

recommandées avec cet outil électrique. Toute utilisation de cet outil électrique dans

un but autre que celui pour lequel il a été conçu est dangereuse et pose des risques de

dommages corporels.

c) Ne pas utiliser des accessoires qui n’ont pas été spécialement conçus pour cet outil

ou recommandés par son fabricant. Le fait qu’un accessoire peut être connecté à l’outil

ne veut pas automatiquement dire que son utilisation ne posera aucun risque.

d) La vitesse nominale des accessoires utilisés doit être équivalente ou supérieure à

la vitesse maximale apposée sur l’outil. Les accessoires utilisés à une vitesse plus rapide

que leur vitesse nominale peuvent éclater ou se détacher de l’outil.

e) Le diamètre externe et l’épaisseur de l’accessoire utilisé doivent se conformer aux

spécifications de la plaque signalétique de l’outil électrique. Les accessoires aux

spécifications incorrectes ne peuvent être ni maintenus ni contrôlés de façon adéquate.

f) L’alésage des meules, brides, tampons de soutien, ou de tout autre accessoire,

doit correspondre parfaitement à la taille de la broche de l’outil. Les accessoires dont

l’alésage ne correspond pas au dispositif d’installation de l’outil électrique ne tourneront pas

correctement, vibreront de façon excessive et pourront causer la perte de contrôle de l’outil.

g) Ne pas utiliser d’accessoire endommagé. Avant toute utilisation, vérifier que les

accessoires, comme les meules abrasives, ne sont endommagés en aucune façon,

que les tampons de soutien ne sont pas fendus, qu’il n’existe aucune fissure

ou usure excessive, que les fils des brosses métalliques ne sont ni lâches ni

endommagés. En cas de chute, vérifier que l’outil électrique ou l’accessoire n’a pas

été endommagé, et remplacer toute pièce abîmée. Après avoir inspecté et installé

un accessoire, se positionner, soi-même et tout individu présent, hors du plan de

rotation de l’accessoire et laisser tourner l’outil une minute à sa vitesse à vide

maximale. En général, les accessoires endommagés se brisent pendant le temps d’essai.

h) Porter un équipement individuel de protection. Selon l’application, utiliser une

protection faciale et des lunettes ou un masque de protection. Si approprié, porter

un masque anti-poussières, une protection auditive, des gants et un tablier d’atelier

capables de vous protéger contre toute projection abrasive ou tout fragment. La

protection oculaire doit pouvoir arrêter toute projection de débris engendrés par

des opérations diverses. Le masque anti-poussières, ou l’appareil de protection des voies

respiratoires, doit pouvoir filtrer les particules engendrées par l’opération en cours. Toute

exposition prolongée à un haut niveau de décibels peut occasionner une perte de l’acuité

auditive.

i) Maintenir à distance toute personne étrangère au travail en cours. Toute personne

à l’intérieur de l’aire de travail doit porter un équipement individuel de protection.

Des débris provenant de la pièce à travailler ou d’un accessoire brisé pourraient être éjectés

et causer des dommages corporels au-delà de l’aire de travail immédiate.

j) Tenir l’outil électrique par les surfaces isolées prévues à cet effet pendant toute

utilisation où l’organe de coupe pourrait entrer en contact avec des fils électriques

cachés ou son propre cordon. Tout contact de l’organe de coupe avec un fil sous

tension met les parties métalliques exposées de l’outil électrique sous tension et électrocute

l’utilisateur.

k) Positionner le cordon hors du chemin de l’accessoire en rotation. En cas de perte de

contrôle de l’outil, le cordon pourrait être coupé ou arraché, et les mains ou bras pourraient

entrer en contact avec l’accessoire en rotation.

l) Attendre systématiquement l’arrêt complet de l’accessoire avant de poser l’outil

électrique. L’accessoire en rotation pourrait s’accrocher à une surface et vous faire perdre

le contrôle de l’outil électrique.

m) Ne pas laisser l’outil électrique tourner alors que vous le transportez à votre côté.

Tout contact accidentel de l’accessoire en rotation pourrait faire que ce dernier s’accroche

aux vêtements et entre en contact avec le corps.

n) Nettoyer régulièrement les orifices d’aération de l’outil. Le ventilateur du moteur

attirera de la poussière à l’intérieur du boîtier et une accumulation excessive de poussières

métalliques pose des risques d’électrocution.

o) Ne pas utiliser cet outil électrique à proximité de matériaux inflammables, car des

étincelles pourraient les enflammer.

p) Ne pas utiliser d’accessoires nécessitant l’utilisation de réfrigérants fluides.

L’utilisation d’eau ou de réfrigérants fluides pose des risques d’électrocution ou de chocs

électriques.

Consignes de sécurité additionnelles propres à toute

utilisation

REBONDS ET AVERTISSEMENTS AFFÉRENTS

Les rebonds sont la conséquence du grippage ou coinçage d’une meule, d’un tampon de

soutien, d’une brosse en rotation ou de tout autre accessoire. Tout grippage ou coinçage causera

rapidement le blocage de l’accessoire en rotation, ce qui projettera l’outil électrique non contrôlé

dans la direction opposée à l’accessoire en rotation au point du grippage.

Par exemple, si une meule abrasive reste accrochée ou pincée dans une pièce à travailler, le bord

de la meule engagée au point de grippage peut s’enfoncer dans la surface du matériau et faire

sauter ou rebondir la meule. La meule peut alors rebondir en direction ou à l’opposé de l’utilisateur,

selon le sens du mouvement de la meule au point de grippage. Dans ces conditions, il peut aussi

arriver que les meules abrasives se brisent.

Les rebonds proviennent d’une utilisation inadéquate de l’outil et/ou d’une procédure ou de

conditions d’utilisation incorrectes, et peuvent être évités en prenant les précautions appropriées

détaillées ci-après:

a) Maintenir l’outil électrique fermement et positionner les bras et le corps de façon

à pouvoir résister à toute force de rebonds. Utiliser systématiquement la poignée

Page 4

auxiliaire, si fournie, pour optimiser le contrôle de l’outil en cas de rebonds ou de

........................

........................

tout retour de couple au démarrage. En prenant les précautions adéquates, l’utilisateur

pourra contrôler tout retour de couple ou force de rebond.

b) Ne jamais approcher les mains de l’accessoire en rotation. L’accessoire pourrait

rebondir sur celles-ci.

c) Ne pas positionner le corps dans l’espace que pourrait occuper l’outil électrique en

cas de rebonds. Les rebonds projetteront l’outil dans la direction opposée au mouvement

de la meule au point de grippage.

d) Prendre des précautions supplémentaires pour travailler des coins, des bords

acérés, etc. Éviter que l’accessoire rebondisse ou reste accroché. Les coins, bords

acérés ou les sursauts ont tendance à retenir l’accessoire en rotation et causer la perte de

contrôle de l’outil, ou des rebonds.

e) Ne pas rattacher une lame à chaîne coupante, à sculpter ou une lame dentée. Ces

lames posent des risques de rebonds fréquents et de perte de contrôle de l’outil.

Consignes de sécurité spécifiques propres au polissage

a) Ne laisser aucune portion lâche du bonnet de polissage ou ses cordons de fixation

tourner librement. Dissimuler ou couper toute partie excessive des cordons de

fixation. Des cordons lâches, en rotation libre, pourraient se prendre dans les doigts ou

s’accrocher à la pièce à travailler.

Directives de sécurité spécifiques supplémentaires pour les

polisseuses

• Toujours porter une protection oculaire. Tous les utilisateurs et personnes à proximité

doivent porter une protection oculaire conforme à la norme ANSI Z87.1.

• Nettoyer l’outil régulièrement, particulièrement après une utilisation intensive. La

poussière et les saletés contenant des particules métalliques s’accumulent souvent sur les

surfaces internes de l’outil et pourraient créer un risque de choc électrique.

• Ne pas faire fonctionner cet outil durant de longues périodes. Les vibrations causées par

le fonctionnement de cet outil peuvent provoquer des blessures permanentes aux doigts, aux

mains et aux bras. Utiliser des gants pour amortir davantage les vibrations, prendre de fréquentes

périodes de repos et limiter la durée quotidienne d’utilisation.

• Prendre des précautions à proximité des évents, car ils cachent des pièces mobiles.

Vêtements amples, bijoux ou cheveux longs risquent de rester coincés dans ces pièces

mobiles.

• Pour la sécurité de l’utilisateur, utiliser une rallonge de calibre adéquat (AWG,

American Wire Gauge [calibrage américain normalisé des fils électriques]). Plus le

calibre est petit, et plus sa capacité est grande. Un calibre 16, par exemple, a plus de capacité

qu’un calibre 18. L’usage d’une rallonge de calibre insuffisant causera une chute de tension

entraînant perte de puissance et surchauffe. Si plus d’une rallonge est utilisée pour obtenir une

certaine longueur, s’assurer que chaque rallonge présente au moins le calibre de fil minimum.

Le tableau ci-dessous illustre les calibres à utiliser selon la longueur de rallonge et l’intensité

nominale indiquée sur la plaque signalétique. En cas de doute, utiliser le calibre suivant. Plus le

calibre est petit, plus la rallonge peut supporter de courant.

Calibres minimaux des rallonges

Volts Longueur totale de cordon en mètres (pieds)

Intensité (en ampères)

Supérieur

à

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 Non recommandé

AVERTISSEMENT : TOUJOURS porter des lunettes de sécurité. Les lunettes de vue ne

constituent PAS des lunettes de sécurité. Utiliser également un masque facial ou antipoussière si l’opération de découpe génère de la poussière. TOUJOURS PORTER UN

ÉQUIPEMENT DE PROTECTION HOMOLOGUÉ :

• protection oculaire conforme à la norme ANSI Z87.1 (CAN/CSA Z94.3),

• protection auditive conforme à la norme ANSI S12.6 (S3.19) et

• protection des voies respiratoires conformes aux normes NIOSH/OSHA/MSHA.

AVERTISSEMENT : TOUJOURS porter une protection auditive appropriée

conformément à la norme ANSI S12.6 (S3.19) lors de l’utilisation du produit. Dans certaines

conditions et selon la durée d’utilisation, le bruit émis par ce produit peut contribuer à une perte

auditive.

AVERTISSEMENT : les scies, meules, ponceuses, perceuses ou autres outils de construction

peuvent produire des poussières contenant des produits chimiques reconnus par l’État californien

pour causer cancers, malformations congénitales ou être nocifs au système reproducteur. Parmi

ces produits chimiques, on retrouve:

• Le plomb dans les peintures à base de plomb ;

• La silice cristallisée dans les briques et le ciment, ou autres produits de maçonnerie ; et

• L’arsenic et le chrome dans le bois ayant subi un traitement chimique.

Les risques reliés à l'exposition à ces poussières varient selon la fréquence à laquelle

l'utilisateur travaille avec ce type de matériaux. Pour réduire votre exposition à ces

produits chimiques : travailler dans un endroit bien ventilé et porter un équipement de sécurité

approuvé comme un masque antipoussières conçu spécialement pour filtrer les particules

microscopiques.

• Éviter le contact prolongé avec les poussières produites par les activités de ponçage,

sciage, meulage, perçage et autres activités de construction. Porter des vêtements

de protection et laver les parties du corps exposées avec une solution d'eau et de

savon. Laisser la poussière pénétrer dans la bouche, les yeux ou reposer sur la peau peut

favoriser l'absorption de produits chimiques nocifs.

AVERTISSEMENT : l’utilisation de cet outil peut produire et/ou disperser des poussières pouvant

causer des problèmes respiratoires graves et permanents ou d’autres blessures. Toujours porter

une protection des voies respiratoires approuvée par la NIOSH/OSHA lors d’une exposition à la

poussière. Diriger les particules loin du visage et du corps.

ATTENTION : prendre des précautions supplémentaires dans les coins, car la polisseuse

pourrait avoir un sursaut soudain et brusque si la meule ou tout autre accessoire entrait en contact

avec une surface secondaire ou un bord.

• L’étiquette apposée sur votre outil peut inclure les symboles suivants. Les symboles et leur

définition sont définis ci-après:

V ......................volts A ..................... ampères

Hz ....................hertz W .................... watts

min ..................minutes

...............courant continu ..................courant alternatif ou continu

....................Classe I Fabrication

........................(mis à la terre) ....................borne de terre

....................Classe II Fabrication ...................symbole d’avertissement

........................(double isolation) BPM ...............battements par minute

…/min .............par minute RPM ...............tours par minute

Inférieur

à

120 V 7,6 (25) 15,2 (50) 30,5 (100) 45,7 (150)

240 V 15,2 (50) 30,5 (100) 61,0 (200) 91,4 (300)

AWG

..................courant alternatif

n

o ...................vitesse à vide

CONSERVER CES MESURES

Moteur

S’assurer que le bloc d’alimentation est compatible avec l’inscription de la plaque signalétique. Une

diminution de tension de plus de 10 % provoquera une perte de puissance et une surchauffe. Les

outils

DEWALT

sont testés en usine ; si cet outil ne fonctionne pas, vérifier l’alimentation électrique.

COMPOSANTS (fig. 1)

AVERTISSEMENT : ne jamais modifier l’outil électrique ou l’une de ses parties. Une telle

pratique risque de provoquer des dommages matériels ou des blessures corporelles.

A. Volant de commande de vitesse G. Bouton de verrouillage de la gâchette

B. Coussinet ergonomique (DWP849 seulement) H. Poignée étrier

C. Gâchette à vitesse variable I. Broche

D. Capuchon d’inspection du balai J. Protection en caoutchouc souple du

E. Bouton de verrouillage de la broche carter d’engrenage

F. Poignée auxiliaire K. Écran anti-infiltration en laine

USAGE PRÉVU

Les polisseuses industrielles, DWP849 et DWP849X, ont été conçues pour le polissage des

surfaces peintes, composite ou en métal brut au sein d’applications professionnelles. Les exemples

courants d’utilisation comprennent, mais sans s’y limiter: le détaillage et la correction du fini dans

le secteur automobile/maritime/véhicules de camping/motocycle, la construction et la réparation de

bateaux, et le fini des métaux et du béton.

Ne pas les utiliser en présence de gaz ou de liquides inflammables. Ne pas les laisser à la portée

des enfants. Une supervision est nécessaire auprès de tout utilisateur non expérimenté.

Poignée auxiliaire (fig. 1)

Une poignée auxiliaire (F) est fournie avec l’outil et peut être installée sur l’un ou l’autre côté

du carter d’engrenage. Cette poignée devrait être utilisée systématiquement pour conserver le

contrôle intégral de l’outil.

Une poignée étrier (H) a aussi été fournie avec la DWP849X et peut être utilisée au lieu de la poignée

auxiliaire.

Gâchette à vitesse variable (Fig. 1)

Ces outils sont équipés d’une gâchette à vitesse variable permettant de réguler la vitesse entre 0 et

3500r/min. Pour démarrer l’outil, presser la gâchette (C) illustrée en figure 1 jusqu’au démarrage

de l’outil. Plus on enfonce la gâchette et plus le régime augmente. La relâcher pour arrêter l’outil.

Utiliser les basses vitesses pour appliquer les cires liquides et les produits à polir et les vitesses

élevées, pour enlever le liquide séché. La vitesse maximale (gâchette complètement enfoncée) sert

à procurer le lustre final au véhicule.

On peut verrouiller l’outil en mode de fonctionnement continu en enfonçant complètement la

gâchette puis le bouton de verrouillage (G) illustré en figure 1. Maintenir le bouton de verrouillage

enfoncé en relâchant doucement la gâchette. L’outil maintiendra son régime. Pour éteindre l’outil

bloqué en mode continu, presser une fois sur la gâchette et la relâcher. Ne pas débrancher l’outil

lorsque la gâchette est verrouillée en mode de fonctionnement continu. S’assurer que l’outil n’est

pas verrouillé en mode de fonctionnement continu lorsqu’on le branche.

La gâchette à vitesse variable (C) est équipée d’une fonction de disparition de tension. En cas

de panne de courant ou toute autre coupure accidentelle, il faut réinitialiser la gâchette (appuyer

sur la gâchette, relâcher puis réappuyer) pour redémarrer l’outil. Ne débranchez pas l’outil alors

que sa gâchette est en mode de verrouillage. Assurez-vous que l’outil n’est pas verrouillé en état

de marche avant de le brancher. Si l’outil est rebranché alors que sa gâchette est en mode de

verrouillage, l’outil ne fonctionnera pas tant que la gâchette (C) n’aura pas été réinitialisée comme

décrit ci-dessus.

REMARQUE: la gâchette peut seulement être verrouillée lorsque l’outil tourne aux r/min maximum

affichés par le régulateur automatique de vitesse (A).

Volant de commande de vitesse (fig. 1)

On peut modifier la vitesse maximale de l’outil en faisant tourner la commande du régulateur de

vitesse (A) au réglage voulu. La commande comporte des cliquets qui empêchent le déplacement

imprévu de la commande et facilitent le choix de la vitesse. Pour plus de polyvalence, on peut

verrouiller la gâchette à plein régime et modifier le régime de l’outil uniquement avec la commande

du régulateur de vitesse (A).

Le régulateur électronique permet non seulement de choisir la vitesse appropriée à la tâche

mais également de maintenir la vitesse choisie lorsqu’on exerce de la pression sur l’outil. Cette

fonctionnalité, alliée à la commande du régulateur de vitesse, rehausse la valeur de l’outil.

On peut régler la commande du régulateur de vitesse (A) à tout point entre 600 et 3500 tr/min, puis

on se sert de l’interrupteur de vitesse variable qui contrôlera le régime de l’outil de zéro à la vitesse

préétablie avec la commande. Ainsi, lorsque la commande du régulateur de vitesse est réglée à

2200 tr/min, l’interrupteur de vitesse variable fonctionnera entre zéro et 2200 tr/min selon la force

exercée sur la gâchette. Lorsque la commande du régulateur de vitesse est réglée à 600 tr/min,

l’outil fonctionne entre zéro et 600 tr/min avec l’interrupteur.

La fonction électronique de commande de vitesse entre en action lorsque la gâchette est

complètement enfoncée et que l’outil est à plein régime selon le réglage de la commande du

régulateur de vitesse. Lorsqu’on exerce une pression sur l’outil (et que la gâchette est complètement

enfoncée), le circuit électronique de l’outil compensera pour la charge et maintiendra la vitesse

choisie. Ainsi, lorsque la commande du régulateur de vitesse est réglée à 2200 tr/min, comme

dans l’exemple précédent, l’outil fonctionnera toujours à 2200 tr/min, même sous charge.

Voici deux points importants à se rappeler relativement à la commande électronique de vitesse :

1. La commande électronique de vitesse fonctionne seulement lorsque la gâchette est

complètement enfoncée.

2. L’effet de la commande électronique de vitesse se voit mieux lorsque l’outil est réglé à basses

vitesses (moins de 2600 tr/min). Lorsque l’outil fonctionne à près de 3000 tr/min, son effet se

remarque moins.

Rappelez-vous qu’avec une polisseuse conventionnelle tournant à une vitesse à vide typique de

2400r/min, l’outil ralentira jusqu’à environ 2000 r/min pendant le polissage. Alors qu’une charge

sera appliquée, votre DWP849 ou DWP894X continuera de tourner à 2400r/min (ou n’importe

quelle autre vitesse choisie sur le régulateur automatique). Comme elles ne ralentiront pas, la

vitesse pourra être supérieure à celle à laquelle vous pouvez être habitué, aussi prenez des

précautions supplémentaires tant que vous n’aurez pas votre polisseuse bien en main. Si vous

pensez que la vitesse est trop élevée, vous pouvez, bien-entendu, ralentir l’outil avec la gâchette

ou avec le régulateur automatique de vitesse.

Bouton de verrouillage de la broche (fig. 1)

AVERTISSEMENT : pour réduire le risque de blessures corporelles graves, éteindre

l’outil et le débrancher avant d’effectuer tout réglage ou d’enlever ou d’installer des

accessoires. Avant de rebrancher l’outil, enfoncer et relâcher la gâchette pour s’assurer

que l’outil est hors tension.

Afin d’empêcher le mouvement de la broche de l’outil lors de l’installation ou du retrait d’accessoires,

l’outil comporte un bouton de verrouillage de la broche (E), logée près des engrenages de l’outil.

Pour verrouiller la broche, il faut enfoncer le bouton de verrouillage et le maintenir enfoncé. NE

JAMAIS ENFONCER LE BOUTON DE VERROUILLAGE DE LA BROCHE LORSQUE L’OUTIL

FONCTIONNE.

Écrans anti-infiltration en laine (fig.1, 2)

Les écrans anti-infiltration en laine (K) ont été conçus pour réduire la quantité de laine, poussière ou

débris pouvant s’infiltrer dans le moteur au cours d’une utilisation normale. La fonction des écrans

anti-infiltration est d’augmenter la durée de vie de l’appareil comparé à un appareil sans écran.

Chaque écran anti-infiltration peut être facilement retiré pour le nettoyer en retirant la vis de

montage (L), puis en poussant l’écran vers l’extrémité de l’outil pour enfin le retirer.

Dans l’éventualité ou les écrans anti-infiltration en laine seraient encrassés à cause de débris ou

cire, ils peuvent être nettoyés à l’eau savonneuse avec une brosse douce. Nettoyez ces écrans dès

qu’une accumulation est visible à l’extérieur.

Votre outil peut venir équipé d’un jeu d’écrans anti-infiltration en laine. Des écrans anti-infiltration en

laine sont vendus séparément chez votre distributeur local ou dans les centres de service autorisés.

Protection en caoutchouc souple du carter d’engrenage

(fig.1)

La protection en caoutchouc souple du carter d’engrenage (J) a été conçue pour éliminer toute

éraflure que pourrait laisser le carter d’engrenage métallique sur les surfaces peintes ou polies.

La protection en caoutchouc souple du carter d’engrenage peut être retirée le cas échéant. Pour

l’enlever, retirez les trois vis de fixation puis enlevez la protection du carter d’engrenage.

Votre outil peut venir équipé d’une protection en caoutchouc souple du carter d’engrenage. Des

protections en caoutchouc souple du carter d’engrenage sont vendues séparément chez votre

distributeur local ou dans les centres de service autorisés.

FONCTIONNEMENT

AVERTISSEMENT : pour réduire le risque de blessures corporelles graves, éteindre

l’outil et le débrancher avant d’effectuer tout réglage ou d’enlever ou d’installer des

accessoires. Avant de rebrancher l’outil, enfoncer et relâcher la gâchette pour s’assurer

que l’outil est bien hors tension.

Des tampons à polir d’un diamètre de 15,2, 17,8 ou 22,9cm (6, 7, ou 9po) peuvent être utilisés

sur les DWP849 et DWP849X.

Insertion et retrait de tampons de polissage (fig. 3)

AVERTISSEMENT : pour réduire le risque de blessures corporelles graves, ne pas laisser

tourner librement une partie lâche de la coiffe à polir ou ses ficelles. Bien les insérer sous la coiffe

ou couper les extrémités des ficelles qui dépassent. Des ficelles lâches et en rotation peuvent

s’enchevêtrer dans les doigts ou s’accrocher à la pièce.

REMARQUE: la DWP849 et la DWP849X peuvent utiliser l’un ou l’autre dispositif de tampon à

polir décrit ci-après.

POUR RATTACHER UN TAMPON À POLIR AVEC UN TAMPON DE SOUTIEN EN

CAOUTCHOUC (FIG.3A)

1. Pour installer le tampon (N), pousser le moyeu de la rondelle de serrage (M) dans le trou, aussi

loin que possible, au centre du tampon.

2. Insérer le trou hexagonal du tampon d’appui (O). Tout en retenant fermement les trois pièces

ensemble, les enfiler sur la broche (I) de l’outil.

3. Enfoncer le bouton de verrouillage de la broche (E) en faisant tourner les tampons dans le sens

horaire pour les visser complètement sur les filets de la broche.

POUR RATTACHER UN TAMPON À POLIR AVEC UN TAMPON DE SOUTIEN CROCHET

ET BOUCLE (FIG. 3B)

1. Rattachez un tampon (P) crochet et boucle en mousse ou en laine au tampon de soutien

crochet et boucle (Q), en faisant attention à bien centrer le tampon de soutien sur le tampon

en mousse ou en laine.

2. Vissez le tampon de soutien (Q) sur la broche (I) en appuyant sur le bouton de blocage de

l’arbre (E).

RETRAIT DES TAMPONS

Pour retirer les tampons, les faire tourner à la main dans le sens opposé afin d’enclencher le bouton

de verrouillage de la broche, puis les dévisser en sens antihoraire (filets normaux).

Polissage (fig. 4)

Les directives et suggestions suivantes ont pour but de familiariser les nouveaux utilisateurs

au fonctionnement général de l’outil électrique de polissage. Chacun développera ses propres

techniques afin de faciliter le travail et de l’accomplir plus rapidement en connaissant mieux l’outil.

• Prendre le plus grand soin lorsqu’on polit des objets pointus ou des angles aigus de la

carrosserie. Il est essentiel d’exercer la pression appropriée pour polir les différentes sections

de la carrosserie d’un véhicule. Ainsi, il faut exercer une légère pression sur l’outil lorsqu’on

polit des arêtes tranchantes de la carrosserie ou les rebords des gouttières du capot.

• Puisqu’il existe différents types de produits de polissage, il est conseillé de nettoyer et de polir

un coin plat du véhicule au préalable. À partir de cet essai, on peut alors déterminer la force à

utiliser sur l’outil ou la puissance de nettoyage pour obtenir le lustre voulu.

• Se rappeler que les différents produits ne procurent pas tous les mêmes résultats. Différentes

marques réagiront différemment sur différents types de surfaces peintes. En outre, on utilise

une polisseuse électrique avec le produit à polir correspondant qui donne des résultats

complètement différents si on les compare au polissage manuel antérieur. Laver le véhicule

avant de le polir. On enlève de la sorte toute trace de poussière, de sel et de crasse qui peut

agir comme abrasif et abîmer ainsi la peinture. De plus, ces saletés bloqueront le tampon et il

faudra le nettoyer plus souvent.

• Sans mettre l’outil en marche, attrapez les poignées de l’outil pour prendre l’outil en main

(fig. 4). Éloignez l’outil de votre corps, puis appuyez sur la gâchette. Assurez-vous de tenir

fermement l’outil par ses poignées puis utilisez-le librement sans forcer ou imposer de pression

inutile. La poignée latérale sur l’outil peut facilement être changée de côté pour accommoder

un gaucher ou d’un droitier.

REMARQUE : le frottement à haute vitesse de la coiffe à polir contre la surface du véhicule

peut occasionner une accumulation de statique sur les sections métalliques de l’outil. On peut

alors ressentir un léger choc électrique instantané lorsqu’on touche aux composants métalliques

de l’outil et le choc sera un peu plus important si la teneur en humidité de l’air est basse. Ce

phénomène n’est pas dangereux, mais il est conseillé de confier l’outil à un centre de réparation

D

EWALT pour vérifier s’il ne s’agit pas d’une défaillance électrique.

Page 5

ENTRETIEN

AVERTISSEMENT : pour réduire le risque de blessures corporelles graves, éteindre

l’outil et le débrancher avant d’effectuer tout réglage ou d’enlever ou d’installer des

accessoires. Avant de rebrancher l’outil, enfoncer et relâcher la gâchette pour s’assurer

que l’outil est bien hors tension.

Nettoyage

AVERTISSEMENT : enlever les saletés et la poussière hors des évents au moyen d’air

comprimé sec, au moins une fois par semaine. Porter une protection oculaire conforme à la

norme ANSI Z87.1 (CAN/CSA Z94.3) et une protection des voies respiratoires conforme aux

normes NIOSH/OSHA/MSHA au cours de cette tâche de nettoyage.

AVERTISSEMENT : ne jamais utiliser de solvants ni d’autres produits chimiques puissants pour

nettoyer les pièces non métalliques de l’outil. Ces produits chimiques peuvent affaiblir les matériaux

de plastique utilisés dans ces pièces. Utiliser un chiffon humecté uniquement d’eau et de savon

doux. Ne jamais laisser de liquide pénétrer dans l’outil et n’immerger aucune partie de l’outil dans un

liquide.

Graissage

Les outils DEWALT sont correctement graissés en usine et sont prêts à l’emploi. Les outils doivent

être régulièrement lubrifiés de nouveau après une période variant entre soixante jours et six mois

selon l’utilisation. (Les outils utilisés constamment en production ou pour des travaux intensifs et les

outils exposés à la chaleur peuvent exiger une lubrification plus fréquente.) Seul du personnel formé

pour la réparation d’outillage électrique, tel que le personnel des centres de réparations D

ou d’autres centres qualifiés, devrait effectuer cette lubrification.

EWALT

Balais de moteur

Assurez-vous que l’outil est bien débranché avant d’inspecter les balais. Vérifiez régulièrement

l’état des balais de charbon. Pour cela, dévissez les capuchons plastiques d’inspection des balais

(situés de chaque côté du boîtier du moteur) de façon à pouvoir retirer les dispositifs ressort et balai

de l’outil. Maintenez les balais propres et vérifiez qu’ils glissent librement dans leurs supports. Les

balais de charbon comportent des symboles variés, et si les balais sont usés au niveau de la ligne

la plus proche du ressort, il faut les changer.

Accessoires

AVERTISSEMENT : puisque les accessoires autres que ceux offerts par DEWALT n’ont pas été

testés avec ce produit, l’utilisation de ceux-ci avec l’outil pourrait s’avérer dangereuse. Pour réduire

le risque de blessures, utiliser exclusivement les accessoires D

produit.

Les accessoires recommandés pour utilisation avec l’outil sont disponibles, à un coût supplémentaire,

auprès du distributeur ou du centre de réparation autorisé de votre région. Pour toute demande

d’assistance pour trouver un accessoire, communiquer avec D

Joppa Road, Baltimore, MD 21286, États-Unis, composer le 1-800-4-D

ou visiter le site Web www.dewalt.com.

N’utiliser que des accessoires ayant une vitesse de fonctionnement maximum au moins aussi

élevée que le « RÉGIME À VIDE » inscrit sur la plaque signalétique de l’outil. Cette mesure de

précaution est valide pour tout accessoire sur n’importe quel outil.

• Tampons de soutien en caoutchouc: tampon de soutien en caoutchouc super flexible et

à changement rapide de 17,8cm (7po) (inclus une rondelle de serrage)

• Tampons de soutien crochet et boucle de 17,8cm (7po)

• Protection en caoutchouc souple du carter d’engrenage

• Écrans anti-infiltration en laine

• Poignée auxiliaire

• Poignée étrier

EWALT recommandés avec ce

EWALT Industrial Tool Co., 701 East

EWALT (1-800-433-9258)

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations, l’entretien et les réglages (y

compris l’inspection et le remplacement des balais) doivent être réalisés par un centre de réparation

en usine D

professionnel. Toujours utiliser des pièces de rechange identiques.

EWALT, un centre de réparation autorisé DEWALT ou par un personnel de réparation

Garantie limitée de trois ans

DEWALT réparera, sans frais, tout produit défectueux causé par un défaut de matériel ou de

fabrication pour une période de trois ans à compter de la date d’achat. La présente garantie ne

couvre pas les pièces dont la défectuosité a été causée par une usure normale ou l’usage abusif

de l’outil. Pour obtenir de plus amples renseignements sur les pièces ou les réparations couvertes

par la présente garantie, visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

EWALT). Cette garantie ne s’applique pas aux accessoires et ne vise pas les dommages

4-D

causés par des réparations effectuées par un tiers. Cette garantie confère des droits légaux

particuliers à l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un état ou

d’une province à l’autre.

En plus de la présente garantie, les outils D

CONTRAT D’ENTRETIEN GRATUIT D’UN AN