DeWalt DWM120 User Manual

orquestionshaveyouIf comments, contact us. toutouquestiontoutePourcommentaire, nous contacter. comentarios,odudastieneSi contáctenos. |

•WALTD-4-800-1Ewww.dewalt.com |

MANUALINSTRUCTION |

D'UTILISATIONGUIDE |

INSTRUCCIONESDEMANUAL |

DWM120 BandSpeedVariableCutDeepDuty-HeavySaw servicedevariablevitesseàrubanàScieintensif pour coupes profondes velocidaddepesado,trabajoparabandadeSierra variable para cortes profundos |

|

|

|

|

INSTRUCTIVOOPERACIÓN,CENTROSSERVICIOPÓLIZADEDEY ADVERTENCIA:INSTRUCTIVOGARANTÍA.ANTESLÉASEESTEDE |

PRODUCTO.USARDEEL |

|

|

|

|

|

|

|

|

|

|

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286 |

|||||

|

(AUG08) |

Part No. 662802-00 |

DWM120 Copyright © 2008 DEWALT |

|||

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258).

WARNING: To reduce the risk of injury, read the instruction manual.

WARNING: To reduce the risk of injury, read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and instructions Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1)WORK AREA SAFETY

a)Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b)Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c)Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2)ELECTRICAL SAFETY

a)Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

b)Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c)Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d)Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e)When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f)If operating a power tool in a damp location is unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

3)PERSONAL SAFETY

a)Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

b)Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c)Prevent unintentional starting. Ensure the switch is in the off position before connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

d)Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

e)Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f)Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g)If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

4)POWER TOOL USE AND CARE

a)Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

b)Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c)Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

d)Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e)Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f)Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g)Use the power tool, accessories and tool bits etc., in accordance with these instructions taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

5)SERVICE

a)Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Safety Rules – Portable Band Saws

•Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring. Contact with a “live” wire will make exposed metal parts of the tool “live” and shock the operator.

•Keep hands away from cutting area and blade. Keep one hand on the main handle and the other hand on the front handle to prevent loss of control which could result in personal injury.

•Always make sure the portable band saw is clean before using.

•Always cease operation at once if you notice any abnormality whatsoever.

•Always be sure all components are mounted properly and securely before using tool.

•Always handle the band saw blade with care when mounting or removing it.

•Always keep your hands out of the line of the band saw blade.

•Always wait until the motor has reached full speed before starting a cut.

•Always keep handles dry, clean, and free of oil and grease. Hold the tool firmly when in use.

•Always be alert at all times, especially during repetitive, monotonous operations. Always be sure of position of your hands relative to the blade.

•Never remove work stop.

•Stay clear of end pieces that may fall after cutting off. They may be hot, sharp and/or heavy. Serious personal injury may result.

•An extension cord must have adequate wire size (AWG or American Wire Gauge) for safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. When using more than one extension to make up the total length, be sure each individual extension contains at least the minimum wire size. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

|

|

Volts |

Total Length of Cord in Feet (meters) |

|||

Ampere Rating |

120V |

25 (7.6) |

50 (15.2) |

100 (30.5) |

150 (45.7) |

|

|

|

240V |

50 (15.2) |

100 (30.5) |

200 (61.0) |

300 (91.4) |

More |

Not More |

|

|

AWG |

|

|

Than |

Than |

|

|

|

|

|

0 |

6 |

|

18 |

16 |

16 |

14 |

6 |

10 |

|

18 |

16 |

14 |

12 |

10 |

12 |

|

16 |

16 |

14 |

12 |

12 |

16 |

|

14 |

12 |

Not Recommended |

|

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

•ANSI Z87.1 eye protection (CAN/CSA Z94.3),

•ANSI S12.6 (S3.19) hearing protection,

•NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

•Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Always wear proper personal hearing protection that conforms to ANSI S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

WARNING: Always wear proper personal hearing protection that conforms to ANSI S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

•The label on your tool may include the following symbols. The symbols and their definitions are as follows:

V...................... |

volts |

A ................ |

amperes |

||||||

Hz.................... |

hertz |

W ............... |

watts |

||||||

min .................. |

minutes |

|

|

|

............. |

alternating current |

|||

|

|

|

|

direct current |

|

|

|

|

alternating or direct current |

|

|

|

............... |

no ............. |

|||||

|

|

|

|

Class I Construction |

no load speed |

||||

|

|

|

|

||||||

|

|

.................... |

|

||||||

|

|

|

|

(grounded) |

|

|

|

|

earthing terminal |

|

|

|

|

|

|

|

|

||

........................ |

|

|

|

|

|

............... |

|

||

|

|

.................... |

|

Class II Construction |

|

|

|

.............. |

safety alert symbol |

........................ |

|

|

|

(double insulated) |

BPM........... |

beats per minute |

|||

…/min ............. |

per minute |

RPM .......... |

revolutions per minute |

||||||

SFPM.............. |

surface feet per minute |

|

|

|

|

|

|||

SAVE THESE INSTRUCTIONS FOR FUTURE USE

COMPONENTS (FIG. 1, 2)

A. Multi-position bail handle |

I. |

Speed wheel |

B. Sight light |

J. |

Rubber bumpers |

C. Trigger switch |

K. |

Hang hook |

D. Main handle |

L. |

Pulley |

E. Work stop |

M. |

Blade guard |

F. Guide rollers |

N. |

Rubber tires |

G. Blade tracking adjustment |

O. |

Blade |

H. Blade tension lever |

P. |

Sight light switch |

ASSEMBLY

Blades

This portable band saw is setup for use with .020" (0.5 mm) thick, 1/2" (12.5 mm) wide and 44-7/8" (1140 mm) long blades. DO NOT use .025 (.64 mm) thick blades.

CAUTION: The use of any other blade or accessory might be hazardous. DO NOT use any other type of accessory with your band saw. Blades used on stationary band saws are of different thickness. Do not attempt to use them on your portable unit.

CAUTION: The use of any other blade or accessory might be hazardous. DO NOT use any other type of accessory with your band saw. Blades used on stationary band saws are of different thickness. Do not attempt to use them on your portable unit.

Blade Selection

In general, first consider the size and shape of the work, and the type of material to be cut. Remember, for the most efficient cutting, the coarsest tooth blade possible should be used in a given application, because the coarser the tooth, the faster the cut. In selecting the appropriate number of teeth per inch of the band saw blade, at least two teeth should contact the work surface when the blade is rested against the workpiece. As a rule of thumb, soft materials usually require coarse tooth blades, while hard materials require fine tooth blades. Where a smoother finish is important, select one of the finer tooth blades.

Select the appropriate band saw blade according to the material type, dimensions, and number of teeth. See Blade Description chart.

FIG. 1 |

|

45º |

|

STRAIGHT UP |

|

FIG. 2 |

|

|

|

|

|

|

K |

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

TOUT DROIT |

|

|

|

|

|

|

|

|

HACIA ARRIBA |

|

D |

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

I |

C |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

M |

|

|

|

|

|

|

|

|

|

|

H |

G |

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

L |

LOOSEN |

|

|

|

|

|

|

|

|

|

BLADE DIRECTION |

|

|

|

|

|

|

|

DESSERRER |

|

|

|

|

|

|

|

|

|

DIRECTION DE LA LAME |

|

|

|

FIG. 3 |

BLADE DIRECTION |

|

|

AFLOJE |

|

|

|

|

|

|||

|

DIRECCIÓN DE LA HOJA |

|

|

|

|

DIRECTION DE LA LAME |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

DIRECCIÓN DE LA HOJA |

|

|

|

O |

|

|

J |

POSITION OF TEETH ON LEFT SIDE OF MACHINE |

|

|

|

|

|

|

|

|

POSITION DES DENTS SUR LE CÔTÉ |

|

|

|

F1 |

|

|

F2 |

|

|

|

|

|

|

|

|

|

GAUCHE DE LA MACHINE |

|

||

|

P |

|

|

|

|

POSICIÓN DE LOS DIENTES EN EL LADO |

|

|

|

|

|

|

E |

|

|

IZQUIERDO DE LA MAQUINA |

|

|

|

|

|

|

|

|

|

|

FIG 4 |

|

|

|

|

FIG. 5 |

FIG. 6 |

|

|

E

E

A

J

The following table is intended as a general guide only. Determine the type of material and dimension of the workpiece and select the most appropriate band saw blade.

CAUTION: Never use the band saw to cut resin materials which are subject to melting. Melting of resin material caused by high heat generated during cutting may cause the band saw blade to become bound to the material, possibly resulting in overload and burn-out of the motor.

BLADE DESCRIPTION

Type of band saw blade |

|

|

Bi-Metal |

|

|

||

Number of teeth |

24 |

18 |

14 |

10 |

|

14/18 |

10/14 |

Workpiece thickness |

|

|

|

|

|

|

|

1/8" (3.2 mm) and under |

• |

• |

|

|

|

|

|

1/8" - 1/4" (3.2 mm - 6.4 mm) |

|

|

• |

|

|

• |

|

1/4" - 13/32" (6.4 mm - 10.3 mm) |

|

|

|

• |

|

|

• |

13/32" (10.3 mm) and over |

|

|

|

• |

|

|

|

Blade Speed

Your DWM120 portable band saw is equipped with variable speed for greater versatility. Turn the speed wheel (I) to select the desired speed (Fig. 1). Speed 1 is the slowest speed; Speed 5 is the fastest. Use speed settings 1–5 when connected to an AC power supply.

When cutting copper, brass, bronze, aluminum, cast iron, angle iron, and mild steel, use a higher speed.

When cutting plastic pipe, tougher steels, chrome steel, tungsten steel, stainless steel, and other problem materials, use low speed.

NOTE: When cutting plastic pipe, higher speeds may melt plastic.

Blade Tracking

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

Your band saw is equipped with an adjustable blade tracking mechanism which assures proper blade tracking at all times. The back edge of a properly aligned blade will run lightly against one or both of the back up rollers in the blade guides. (The pressure between the edge of the blade and the roller will be very slight and will not damage either the blade or the roller.)

TO ADJUST THE BLADE TRACKING

1.Use a 1/2" (13 mm) wrench to loosen the adjustment locking nut (G), shown in Figure 1 by turning it one or two turns counterclockwise.

2.Use a screwdriver to turn the tracking screw 1/4 turn. Turning the screw clockwise will move the blade up toward the blade guide rollers. Turning the screw counterclockwise will move the blade down away from the rollers.

3.Adjust so that the back edge of the blade lightly touches the rollers then securely tighten the locking nut. (It will be necessary to plug the saw in and run it to observe the tracking.)

4.Observe blade tracking between runs and repeat Steps 1–4 as necessary to achieve proper blade tracking.

Removing and Installing Blades

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

CAUTION: Cut Hazard. Blade tension lever is under spring pressure. Maintain control of lever when releasing blade tension.

CAUTION: Cut Hazard. Blade tension lever is under spring pressure. Maintain control of lever when releasing blade tension.

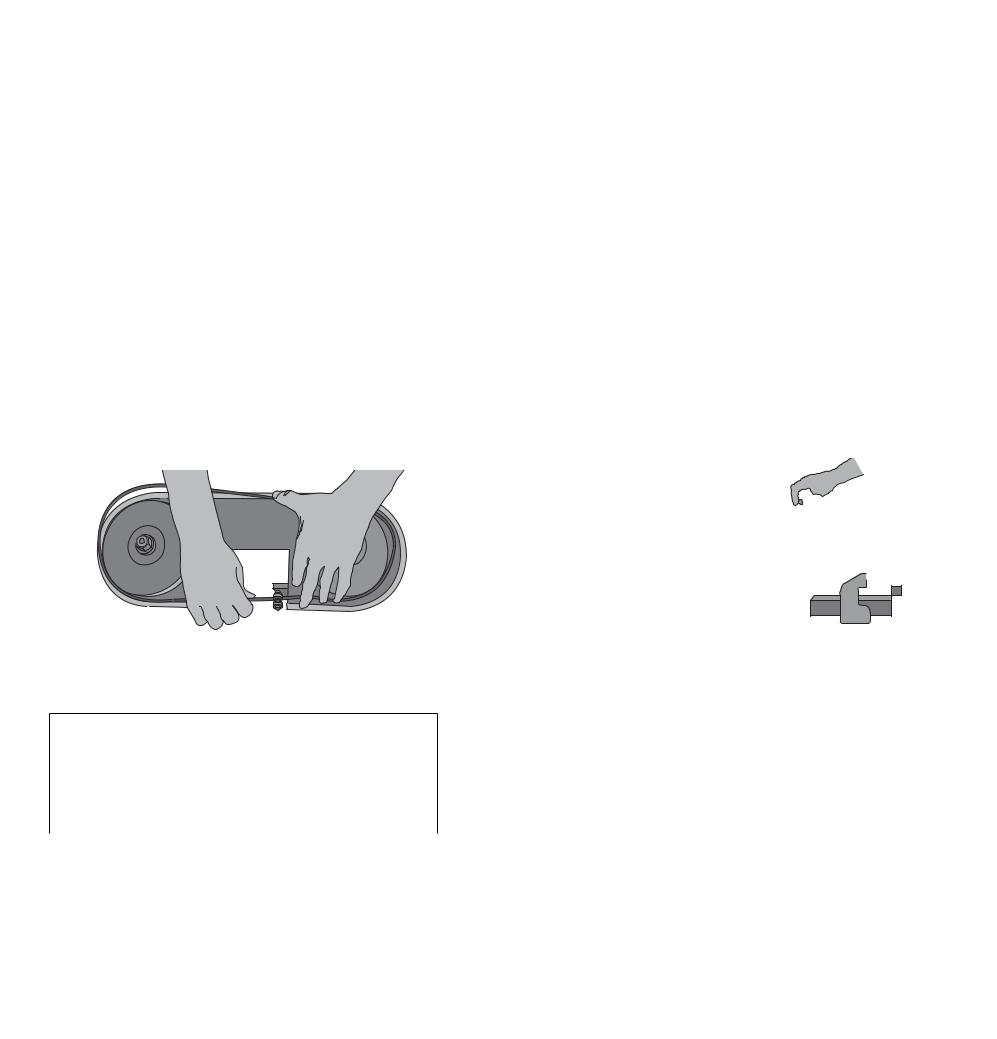

TO REMOVE BLADE (FIG. 1, 2)

1.Rotate the blade tension lever (H) clockwise until it stops to release tension in blade.

2.Turn the saw over and place it on a workbench or table with the cord to the left.

3.Begin removing the blade at the blade guard (M) and continue around the pulleys (L). When removing the blade, tension may be released and the blade may spring free. SAW BLADES ARE SHARP. USE CARE IN HANDLING THEM.

4.Inspect the guide rollers (F1, F2) and remove any large chips which may be lodged in them. Lodged chips can prevent rotation of the guide rollers and cause flat spots on the guide rollers.

5.Rubber tires (N) are mounted on the pulleys (L). The rubber tires should be inspected for looseness or damage when changing the blade. Wipe any chips from the rubber tires on the pulleys. This will extend tire life and keep the blade from slipping. If any looseness or damage occurs, the tool should be brought to an authorized DEWALT service center for repair or replacement as soon as possible. Continued use of the tool with loose or damaged rubber tires will cause unstable travel of the band saw blade.

TO INSTALL BLADE (FIG. 1, 3–5)

1.Position the blade so that the teeth are on the bottom and angled toward the work stop, as shown in Figures 1 and 3.

2.Slip the blade into the guide rollers, as shown in Figure 4.

3.Holding the blade in the guide rollers, place it around both pulleys (L) and through the work stop (E), as shown in Figure 5.

4.Make sure that the blade is fully inserted into the guide rollers and positioned squarely against the rubber tires.

5.Rotate the blade tension lever (H) counterclockwise until it stops and then gently turn the saw over so that the pulleys rest on your work bench or table and. Make sure the teeth face away from the bandsaw (Fig. 1, 3).

6.Turn the speed wheel to low speed (1) and then turn the saw on and off a few times to ensure that the blade is seated properly.

Multi-position Bail Handle (Fig. 1)

A bail handle is provided for carrying the tool and for use as an additional handle. Assemble the bail handle in one of the milti-positions (forward, 45º or straight up) shown in Figure 1. When adjusting the bail handle from one position to the other, loosen the bail handle knob and move the handle to one of the three positions and tighten knob.

Adjustments

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

FIG. 7 RECOMMENDED CUTTING POSITIONS / POSITIONS DE COUPE

RECOMMANDÉES / POSICIONES DE CORTE RECOMENDADAS

YES / OUI / SÍ |

NO / NON / NO |

YES / OUI / SÍ |

NO / NON / NO |

YES / OUI / SÍ |

NO / NON / NO |

YES / OUI / SÍ |

NO / NON / NO |

YES / OUI / SÍ |

NO / NON / NO |

YES / OUI / SÍ |

NO / NON / NO |

Item |

Model |

DWM120 |

Motor |

Type |

Protected type, series commutator motor |

|

Power source |

single-phase, AC 60Hz |

|

Voltage |

120 volts |

|

Full-load current |

10 amp |

Band Saw |

Dimensions |

1/2" x 44-7/8" x .020" |

Blade |

|

(12.5 mm x 1140 mm x .5 mm) |

|

Peripheral speed |

100 - 350 ft/min (30 - 106 m/min) |

Max. Cutting |

Pipe outer dimensions |

4-3/4" (120.7 mm) |

Dimensions |

Stock |

5" x 4-3/4" (127 mm x 120.7 mm) |

Net Weight |

|

15 lbs. (6.8 kg) |

Cord |

|

3 conductor type captive cable 8.0 ft. (2.4 m) |

Article |

Modèle |

DWM120 |

Moteur |

Type |

Type protégé, série moteur à collecteur |

|

Source de courant |

monophasé, CA 60Hz |

|

Tension |

120 volts |

|

Courant de pleine |

10 amp |

|

charge |

|

Lame de |

Dimensions |

12,5 mm x 1140 mm x 0,5 mm |

scie à ruban |

|

(1/2 po x 44-7/8 po x 0,020 po) |

|

Vitesse périphérique |

30 - 106 m/min (100 - 350 pi/min) |

Longueurs |

Dimensions externes |

120.7 mm (4-3/4 po) |

max. de |

de tuyau |

|

coupe |

Bois spéciaux |

127 mm x 120.7 mm (5 po x 4-3/4 po) |

Poids net |

|

6,8 kg (15 lb) |

Cordon |

|

Cordon à 3 broches et 3 conducteurs |

|

|

de 2,4 m (8 pi) |

Artículo |

Modelo |

DWM120 |

Motor |

Tipo |

Tipo protegido, serie de motor commutador |

|

Alimentación Eléctrica |

Corriente alterna de 60Hz, monofásica |

|

Voltaje |

120 voltios |

|

Corriente a carga |

10 amperios |

|

completa |

|

Hoja de la |

Dimensiones |

12.5 mm x 1140 mm x .5 mm |

Sierra de |

|

(1/2 pulg. x 44-7/8 pulg. x .020 pulg.) |

Banda |

Velocidad periférica |

30 - 106 m/min (100 - 350 pie/min) |

Máx. |

Dimensiones externas |

120.7 mm (4-3/4 pulg.) |

Dimensiones de tubería |

|

|

de Corte |

Reserva |

127 mm x 120.7 mm (5 pulg. x 4-3/4 pulg.) |

Peso Neto |

|

6,8 kg (15 lbs) |

Cable |

|

3 Cables tipo cautivos conductores |

|

|

de 2,4 m (8,0 pie) |

WORK STOP ADJUSTMENT

To support large workpieces, the work stop should be lowered following these steps:

1.Loosen the two screws (R), shown in Figure 1, with the hex wrench provided.

2.Move the work stop (E) to the desired position (Fig 5).

3.Securely tighten screws (R).

OPERATION

Motor

Be sure your power supply agrees with the voltage marked on the nameplate. 120 Volts AC 60 Hz means alternating current only. Voltage decrease of more than 10% will cause loss of power and overheating. All DEWALT tools are factory-tested. If this tool does not operate, check the power supply line for blown fuses and the plug and receptacle for proper contact. There are certain applications for which this tool was designed.

This band saw is designed to cut various types of material up to 4-3/4" (120.7 mm) diameter or 5" (127 mm) x 4-3/4" (120.7 mm) rectangular shape at 90º.

WARNING: Thoroughly remove any oil or grease from the workpiece before securing in a vise or other clamping device. If the workpiece is not secure, it may come loose during the cutting and/or cause breakage, which may result in serious personal injury.

WARNING: Thoroughly remove any oil or grease from the workpiece before securing in a vise or other clamping device. If the workpiece is not secure, it may come loose during the cutting and/or cause breakage, which may result in serious personal injury.

WARNING: Never connect the power tool unless the available AC power is of the same voltage as that specified on the nameplate of the tool. Never connect this power tool to a DC power source.

WARNING: Never connect the power tool unless the available AC power is of the same voltage as that specified on the nameplate of the tool. Never connect this power tool to a DC power source.

WARNING: Laceration Hazard. If the power cord is connected to the power source with the trigger switch turned ON the power tool will start suddenly and could cause a serious accident.

WARNING: Laceration Hazard. If the power cord is connected to the power source with the trigger switch turned ON the power tool will start suddenly and could cause a serious accident.

Trigger Switch

To start the tool, squeeze the trigger switch (C). To turn the tool off, release the switch.

Cutting

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

Refer to Figure 7 for recommended cutting positions for various materials.

NOTE: Select and use a band saw blade that is most appropriate for the material being cut. See BLADE DESCRIPTION.

This portable band saw may be hung using the hang hook (K). Hang tool on a pipe vice or other suitable, stable structure. (Fig. 2)

1. Mount the material to be cut solidly in a vise or other clamping device.

WARNING: Never attempt to use this tool by resting it upside down on a work surface and bringing the material to the tool. Always securely clamp the workpiece and bring the tool to the workpiece, securely holding the tool with two hands as shown in Figure 6.

WARNING: Never attempt to use this tool by resting it upside down on a work surface and bringing the material to the tool. Always securely clamp the workpiece and bring the tool to the workpiece, securely holding the tool with two hands as shown in Figure 6.

2.If additional light is needed, a sight light (B) can be activated using the sight light switch

(P)as shown in Figure 1. If replacement is required, return to an authorized service center or other qualified service personnel, always using identical replacement parts.

WARNING: To reduce the risk of electric shock, DO NOT use the tool if LED lens is broken.

WARNING: To reduce the risk of electric shock, DO NOT use the tool if LED lens is broken.

3.Bring the work stop (E) into contact with the workpiece. Turn the saw ON.

4.When saw reaches desired rotation speed, slowly and gently tilt the main body of the tool to bring the band saw blade into contact with the workpiece. Do not apply additional pressure in excess of the weight of the main body of the tool. Carefully avoid bringing the band saw blade suddenly and heavily into contact with the upper surface of the workpiece. This will cause serious damage to the band saw blade. To obtain maximum service life of the band saw blade, ensure there is no sudden impact at the beginning of the cutting operation.

5.As shown in Figure 6, straight cutting can be accomplished by keeping the band saw blade aligned with the side surface of the motor housing. Any twisting or cocking of the blade will cause the cut to go offline and decrease the life of the blade.

CAUTION: During cutting, if the band saw becomes locked or jammed in the workpiece material, release the switch immediately to avoid damage to the band saw blade and motor.

6.The tool’s own weight provides the most efficient downward cutting pressure. Added operator pressure slows the blade and reduces blade life.

7.End pieces, which would be heavy enough to cause injury when they drop, after cut-off, should be supported. Safety shoes are strongly recommended. End pieces may be hot.

8.Hold the saw firmly in both hands so that the saw does not fall against clamped or supported material when the cut is completed. DO NOT MAKE ANY SPEED CHANGES

UNLESS TOOL HAS BEEN TURNED OFF.

Tips for Better Cutting

The following recommendations should be used as a guide. Results may vary with the operator and the particular material being cut.

•Never twist the band saw blade during cutting operation.

•Never use liquid coolants with portable band saws. Use of liquid coolants will cause buildup on tires and reduce performance.

•If excessive vibration occurs during the cut, turn the bandsaw off and adjust the speed slightly. Ensure that the material being cut is is securely clamped down. If vibration continues, change the band saw blade.

MAINTENANCE

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect toolfrompowersourcebeforemakinganyadjustmentsorremoving/installingattachments or accessories. An accidental start-up can cause injury.

Lubrication

Self-lubricating bearings are used in the tool and periodic relubrication is not required. In the unlikely event that service is ever needed, take your tool to an authorized service location.

Cleaning

WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear proper ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA respiratory protection when performing this.

WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear proper ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA respiratory protection when performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals may weaken the materials used in these parts. Use a cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals may weaken the materials used in these parts. Use a cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including brush inspection and replacement) should be performed by a DEWALT factory service center, a DEWALT authorized service center or other qualified service personnel. Always use identical replacement parts.

ACCESSORIES

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury, only DEWALT, recommended accessories should be used with this product.

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury, only DEWALT, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local dealer or authorized service center. If you need assistance in locating any accessory, please contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase.This warranty does not cover part failure due to normal wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to accessories or damage caused where repairs have been made or attempted by others. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see country specific warranty information contained either in the packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-DEWALT for a free replacement.

Définitions : lignes directrices en matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur employé. Veuillez lire le mode d’emploi et porter une attention particulière à ces symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas évitée, causera la mort ou des blessures graves.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas évitée, causera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait se solder par un décès ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait se solder par un décès ou des blessures graves.

ATTENTION : indique une situation potentiellement dangereuse qui, si elle n’est pas évitée pourrait se solder par des blessures mineures ou modérées.

ATTENTION : indique une situation potentiellement dangereuse qui, si elle n’est pas évitée pourrait se solder par des blessures mineures ou modérées.

ATTENTION : utilisé sans le symbole d’alerte à la sécurité, indique une situation potentiellement dangereuse qui, si elle n’est pas évitée pourrait se solder par des dommages à la propriété.

POUR TOUT COMMENTAIRE OU QUESTION RELATIF À CET OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSEZ GRATUITEMENT LE : 1-800-4-DEWALT (1-800-433-9258).

AVERTISSEMENT : Pour réduire tout risque de dommage corporel, lire le manuel de l’utilisateur.

AVERTISSEMENT : Pour réduire tout risque de dommage corporel, lire le manuel de l’utilisateur.

Directives de sécurité relatives aux outils électriques en général

AVERTISSEMENT ! Lire toutes les directives et consignes de sécurité. Tout manquement aux directives et consignes pose des risques de choc électrique, d’incendie et/ou de blessure grave.

CONSERVER TOUTES CES DIRECTIVES

ET CONSIGNES À TITRE DE RÉFÉRENCE

Le terme « outil électrique » dans ces directives se rapporte à votre outil électrique alimenté sur secteur (avec fil) ou par piles (sans fil).

1)SÉCURITÉ - AIRE DE TRAVAIL

a)Maintenir l’aire de travail propre et bien éclairée. Les lieux encombrés ou sombres sont propices aux accidents.

b)Ne pas faire fonctionner un outil électrique dans une atmosphère explosive, en présence par exemple de poussières, gaz ou liquides inflammables. Les outils électriques peuvent produire des étincelles qui pourraient enflammer toute émanation ou poussière ambiante.

c)Tenir les enfants, ou toute autre personne, à l’écart pendant l’utilisation d’un outil électrique. Toute distraction pourrait faire perdre la maîtrise de l’appareil.

2)SÉCURITÉ – ÉLECTRICITÉ

a)La fiche électrique de l’outil doit correspondre à la prise murale. Ne jamais modifier la fiche en aucune façon. Ne jamais utiliser de fiche d’adaptation avec un outil électrique mis à la terre. L’utilisation de fiches d’origine et de prises appropriées réduira les risques de choc électrique.

b)Éviter tout contact corporel avec des éléments mis à la terre comme tuyaux, radiateurs, cuisinières ou réfrigérateurs. Les risques de choc électrique augmentent lorsque le corps est mis à la terre.

c)Ne pas exposer les outils électriques à la pluie ou à l’humidité. Toute pénétration d’un outil électrique par un liquide augmente les risques de choc électrique.

d)Ne pas utiliser le cordon de façon abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou débrancher un outil électrique. Protéger le cordon de la chaleur, de l’huile et de tout bord tranchant ou pièce mobile. Les cordons endommagés ou emmêlés augmentent les risques de choc électrique.

e)Lors de l’utilisation d’un outil électrique à l’extérieur, n’utiliser que des rallonges conçues pour l’extérieur. L’utilisation d’une rallonge conçue pour l’extérieur réduit les risques de choc électrique.

f)Si l’utilisation d’un outil électrique en milieu humide est inévitable, utiliser une alimentation protégée par un disjoncteur de fuites à la terre (DDFT). L’utilisation d’un DDFT réduit les risques de choc électrique.

3)SÉCURITÉ PERSONNELLE

a)Rester constamment vigilant et faire preuve de jugement pendant l’utilisation d’un outil électrique. Ne pas utiliser d’outil électrique en cas de fatigue ou sous l’influence de drogues, d’alcool ou de médicaments. Tout moment d’inattention pendant l’utilisation d’un outil électrique pose des risques de blessure grave.

b)Utiliser un équipement de protection individuel. Porter systématiquement des lunettes de protection. Le fait de porter un équipement de protection tel que masque antipoussières, chaussures antidérapantes, casque de sécurité ou protecteurs auditifs lorsque la situation le requiert, réduira les risques de dommages corporels.

c)Prévenir tout démarrage accidentel. S’assurer que l’interrupteur est en position d’arrêt avant de brancher l’outil et/ou de le connecter à un bloc-piles, et avant de le saisir ou de le transporter. Transporter un outil le doigt sur l’interrupteur, ou brancher un outil électrique alors que l’interrupteur est en position de marche, invite les accidents.

d)Retirer toute clé de réglage avant de démarrer l’outil. Une clé laissée sur une pièce rotative d’un outil électrique pose des risques de blessure.

e)Ne pas effectuer de travaux hors de portée. Les pieds doivent rester bien ancrés au sol afin de maintenir son équilibre en tout temps. Cela permet de mieux maîtriser l’outil électrique dans les situations imprévues.

f)Porter des vêtements appropriés. Ne pas porter de vêtements amples ni de bijoux. Maintenir cheveux, vêtements et gants éloignés des pièces mobiles.

Vêtements amples, bijoux ou cheveux longs risquent de rester coincés dans ces pièces mobiles.

g)Lorsqu’un dispositif de connexion à un système de dépoussiérage ou d’élimination est fourni, s’assurer qu’il est connecté et utilisé correctement.

L’utilisation d’aspirateurs peut réduire les risques engendrés par les poussières.

4)UTILISATION ET ENTRETIEN DES OUTILS ÉLECTRIQUES

a)Ne pas forcer un outil électrique. Utiliser l’outil approprié au travail en cours.

L’outil approprié effectuera un meilleur travail, de façon plus sûre et à la vitesse pour laquelle il a été conçu.

b)Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout appareil dont l’interrupteur est défectueux est dangereux et doit être réparé.

c)Débrancher la fiche du secteur et/ou le bloc-piles de l’outil électrique avant de faire tout réglage ou changement d’accessoire, ou avant de ranger ce dernier.

Ces mesures préventives réduisent les risques de démarrage accidentel de l’appareil.

d)Après usage, ranger les outils électriques hors de la portée des enfants, et ne permettre à aucune personne n’étant pas familière avec un outil électrique (ou son manuel d’instruction) d’utiliser ce dernier. Les outils peuvent être dangereux entre les mains des novices.

e)Entretenir les outils électriques. Vérifier les pièces mobiles pour s’assurer qu’elles sont bien alignées et tournent librement, qu’elles sont en bon état et ne sont affectées d’aucune condition susceptible de nuire au bon fonctionnement de l’outil. En cas de dommage, faire réparer l’outil électrique avant toute nouvelle utilisation. Bien des accidents sont causés par des outils mal entretenus.

f)Maintenir toute lame aiguisée et propre. Les outils de coupe bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à contrôler.

g)Utiliser un outil électrique, ses accessoires, mèches, etc., conformément aux présentes directives en tenant compte des conditions de travail et du travail à effectuer. L’utilisation d’un outil électrique pour toute opération autre que celle pour laquelle il a été conçu est dangereuse.

5)SERVICE

a)Faire entretenir les outils électriques par un réparateur qualifié en utilisant seulement des pièces de rechange identiques. Cela permettra d’assurer l’intégrité de l’outil électrique et la sécurité de l’utilisateur.

Règles de sécurité additionnelles - Scies à ruban portables

•Tenir l’outil par les surfaces isolées prévues à cet effet pendant toute utilisation où l’outil coupant pourrait entrer en contact avec des fils électriques cachés. Tout contact avec un fil sous tension met les parties métalliques exposées de l’outil sous tension et électrocute l’utilisateur.

•Éloigner les mains des zones et organes de coupe Tenir la poignée principale d’une main et la poignée avant de l’autre pour éviter toute perte de contrôle de l’outil et réduire ainsi tout risque de dommages corporels.

•S’assurer systématiquement que la scie à ruban portable est propre avant toute utilisation.

•Arrêter systématiquement toute opération si une anormalité quelconque est décelée.

•S’assurer systématiquement que tous les composants sont installés correctement et solidement avant toute utilisation de l’outil.

•Prendre systématiquement des précautions lors de l’installation et du retrait de la lame de la scie à ruban.

Loading...

Loading...