Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, cont&ctenos.

iNSTRUCTiON MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA

DE GARANTiA. ADVERTENClA: L¢:ASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

DWMT70773L

1/2" Impact Wrench Heavy Duty

Cle a chocs de 12,7 mm (1/2 po) service intensif

Llave de impacto de 12,7 mm (1/2") para servicio pesado

®

Page 2

DWMTTO773L

1/2" iMPACT WRENCH HEAVY DUTY

FIG.1

A. 1/2" Square Drive

B. Trigger

C. Forward/Reverse Switch

D. Ergonomic Handle

E. 1/4" Air Inlet

SPECIFiCATiONS

MODEL

i SQUARE DRIVE

CLUTCH TYPE

MAXIMUM TORQUE (REVERSE)

FREE SPEED (@90PSI)

BLOWS PER MINUTE

NET WEIGHT

EXHAUST TYPE

AVERAGE AiR CONSUMPTION

FREE SPEED

AVERAGE AiR CONSUMPTION AT

LOAD

AIR INTLET SIZE

RECOMMENDED HOSE SIZE

MAX. AIR PRESSURE

R Shock Resistant Housing

Bumpers

G. Composite Body

H. Twin Hammer Mechanism

I. Exhaust

J. Adjustable Power Dial

DWMT70773L

1/2"

Twin Hammer

650 Ft.Lbs (880 Nm)

7500 RPM

1100 BPM

4.63 LBS (2.1Kg.)

Handle

41.5SCFM (19.6 L/s)

5.9 CFM (2.8 L!s)

27.2SCFM (12.8 L/s)

3.9 CFM (1.8 L/s)

1/4" NPT(F)

3/8" (10MM)

9O PSI

C

Page 3

Definitions: Safety Guidelines

The definitions below describe the levelof severity

for each signal word. Please read the manual and pay

attention to these symbols.

_ DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

_, WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury.

CAUTION: Used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT

THIS OR ANY DEWALT TOOL, CALL US TOLL FREE AT:

I=800=4=DEWALT (1=800=433=9258)

IMPORTANT SAFETY INSTRUCTIONS

_k WARNING: Some dust created by.power sanding, sawing,

grinding, drilling, and other construcli6n activities contains chemicals

known to the State of California to cause cancer, birth defects or

other reproductive harm. Some example of these chemicals are:

* Lead from lead-based paints

* Crystalline silica from bricks and cement

and other masonry products

* Arsenic and chromium from chemically-treated lumber

Yourrisk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a weft ventilated area, and work with approved safety

equipment, always wear OSNA/MSNA/NIOSH approved,

properly fitting face mask or respirator when using such tools.

When using air tools, basic safety precautions should always be

followed to reduce the risk of personal injury.

,& WARNING: This product contains chemicals, known to the

State of Cafifornia to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling.

SAVE THESE INSTRUCTIONS

A WARNING:

Improper operation or maintenance of this product

could result in serious injury and property damage.

Read and understand aft warnings and operating

instructions before using this equipment. When using

air tools, basicsafety precautions should always be

followed to reduce the risk of personal injury.

A WARNING:

(_ Read and understand this instruction manual and tool labels

before installing, operating or servicing this tool. Keep these

instructions in a safe accessible place.

_ Operators and others in work wear ANSI Z87. CAN/

CSA Z94.3 approved safety glasses with side shields.

Operators and others in work area must wear ear protection.

,_ Oil daily for optimal performance.

area must I

Page 4

A WARNING:

* Avoidprolonged use: repetitive motion or exposure to vibration

may be harmful to your hands or arms. Use gloves toprovide

extra cushion, take frequent rest periods, and limit daily

time of use.

* DO NOT Use oxygen or reactive gases; explosion may occur.

* DO NOT Exceed air pressure of 90 PSL

, Read all manuals included with this product carefully.

Be thoroughly familiar with the controls and the proper use

of the equipment.

, Only persons well acquainted with these rules of safe operation

should be allowed to use the air tool

* DO NOT exceed any pressure rating of any component

in the system.

* Disconnect the air tool from air supply before changing tools or

attachments and during non-operation.

, Always wear safety glasses and ear protection during operation.

Always wear approved safety glasses with shields. Always wear

approved hearing protection.

* DO NOT wear loose fitting clothing or apparel which contains

loose straps or ties, etc. Which could become entangled in

moving parts of the tool and results in serious personal injury.

, DO NOT wear jewel_ watches, identifications, bracelets,

necklace, etc. When operating any tool, they may become

caught in moving parts and result in serious injury.

* DO NOT depress trigger when connecting the air supply hose.

* Always use attachments designed for use with air

powered impact tools.

* DO NOT use damaged or worn attachments.

_, WARNING:

DO NOT use hand tool sockets. Use impact quafity sockets only.

A WARNING:

• Never trigger the tool when not applied to a work object

Attachments must be securely attached.

Loose attachments can cause serious injury.

• Protect air lines from damage or puncture.

• Never point an air tool at oneseff or any other person.

Serious injury could occur.

• Check air hoses for weak or worn condition before each use.

Make sure all connections are secure.

• Keep all nuts, bolts and screws tight and ensure equipment is in

safe working condition.

• DO NOTput hands near or under moving parts.

Page 5

_ WARNING: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN

• Abrasive tools such as

sanders and grinders,

rotating tools such as drills,

and impact tools such as

wrenches, hammers,

and reciprocating saws

are capable of generating

sparks which could

result inignition of

flammable materials.

• Exceeding the maximum

pressure rating of tools

accessories could cause

an explosion resulting

in serious injury.

HOWTO PREVENT IT

• Never operate tools near

flammable substances such

as gasoline, naptha,

cleaning solvents, etc.

• Work in a clean, well

ventilated area free of

combustible materials.

Never use oxygen,

carbon dioxide or other

bottled gases as a power

source for air tools.

Use compressed air regulated

to a maximum pressure at or

below the rated pressure

of any attachments.

WARNING: RiSK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Abrasive tools, such as

grinders, sanders, and

cut-off tools generate dust

and abrasive materials which

can be harmful to human

lungs and respiratory system.

Some materials such as

adhesives and tar contain

chemicals whose vapors

could cause serious injury

with prolonged exposure.

CAUTION: RISK FROM NOISE

WHAT CAN HAPPEN HOWTO PREVENT IT

Long term exposure to noise

produced from the operation

of air tools can lead to

permanent hearing loss.

• Always wear MSHA/NIOSH

approved, properly fitting face

mask or respirator when

using such tools.

• Always work in a clean, dry,

well ventilated area.

• Always wear ANSI (S3.19)

hearing protection.

Page 6

AWARNING: RISK OF INJURY

WHAT CAN HAPPEN

• Tools left unattended, or with

the air hose attached can be

activated by unauthorized

persons leading to their injury

or injury to others.

• Air tools can propel loose

objects or other materials

throughout the work area.

• Air tools can become

activated by accident during

maintenance or tool changes.

• A wrench or a key that is left

attached to a rotating part of

the tool increases the risk of

personal injury.

HOWTO PREVENT IT

• Remove air hose when tool

is not in use and store tool

in a secure location away

from reach of children and/or

untrained users.

Use only parts, fasteners, and

accessories recommended by

the manufacturer.

Keep work area clean and free

of clutter. Keep children and

others away from work area

during operation of the tool.

Keep work area well lit.

Remove air hose to lubricate,

add, or replace sockets.

Never carry the tool

bythe hose.

• Avoid unintentional startin.q.

Don't carry, hooked-up too[ with

finger on trigger.

• Repair service should be done

only by an authorized service

representative.

Remove adjusting keys and

wrench before turning

the tool on.

WHAT CAN HAPPEN

• Using inflator nozzles for

duster applications can cause

serious injury.

• Air tools can cause the work

piece to move upon contact

leading to injury.

• Loss of control of the tool can

lead to injury to self or others

Poor quality, improper, or

damaged tools such as

grinding wheels, chisels,

sockets, drill, etc., can fly

apart during operation,

propelling particles

throughout the work area

causing serious injury.

HOWTO PREVENT IT

• DO NOT use inflator nozzles

for duster applications.

• Use clamps or other devices

to prevent movement.

Never operate tool while

under the influence of

drugs or alcohol.

o

Don't overreach. Keep proper

footing and balance at all times.

o

Keep handles dry, clean, and

free from oil and grease.

o

Stay alert. Watch what you are

doing. Use common sense.

Do not operate tool when

you are tired.

Always use tool attachments

rated for the speed of

the power tool.

Never use tools which have

been dropped, impacted or

damaged by use.

t

Use only impact grade sockets

on an impact wrench.

o

Do not apply excessive force

to the tool - let the tool

perform the work.

Page 7

$_WARNING: RiSK OF INJURY (CONTINUED)

WHAT CAN HAPPEN HOWTO PREVENT iT

• Improperly maintained tool

and accessories can

cause serious injury.

• There is a risk of bursting if

the tool isdamaged.

Fasteners could ricochet or

be propelled causing serious

injury or property damage.

Maintain the tool with care.

• Check for misalignment or

binding of moving parts,

breakage of parts, and any

other condition that affects the

tool's operation. If damaged,

have the tool serviced

before using.

• Never point discharge of tool

atself or others.

• Do not pull trigger unless

tool contact safety device is

against work surface.

• Never attempt to drive

fasteners into hard surfaces

such as steel, concrete, or tile.

• Take care to avoid driving

afastener on top of

another fastener.

• Position tool carefully so that

fasteners will be delivered to

the proper location.

ik WARNING: RISK OF ELETRIC SHOCK

WHAT CAN HAPPEN HOWTO PREVENT IT

• This tool is not provided with

an insulated gripping surface.

Contact with a "live" wire will

also make exposed metal

parts of the tool "live"

and can result in

electrocution or death.

• Avoid body contact with

grounded surfaces such as

pipes, radiators, ranges, and

refrigerators. There is an

increased risk of electric shock

if your body is grounded.

• Thoroughly investigate the

workpiece for possible hidden

wring before performing work.

Page 8

WARNING: RiSK FROM FLYING OBJECTS

WHAT CAN HAPPEN HOWTO PREVENT IT

• Air powered equipment and

power tools are capable of

propelling materials such as

metal chips, saw dust, and

other debris at high speed,

which could result in

serious eye injury.

• Compressed air can be

hazardous. The air stream

can cause injury to soft tissue

areas such as eyes, ears, etc.

Particles or objects

propelled by the stream

can cause injury.

• Toolattachments can be

come loose or break and fly

apart propelling particles at

the operator and others

in the work area.

• Always wear ANSI Z87.1

CAN/CSA Z94.3 approved

safety glasses with side

shields.

• Never leave operating tool

unattended. Disconnect air

hose when tool is not in use.

For additional protection use

an approved face shield in

addition to safety glasses.

Make sure that any

attachments are

securely assembled.

A WARNING: RISK OF CUT OR BURNS

WHAT CAN HAPPEN HOWTO PREVENT IT

Tools which cut, shear,

drill, punch, chisel, etc.,

are capable of causing

serious injury.

WARNING:RISK OF

WHATCAN HAPPEN

Tools which contain moving

elements, or drive other

moving tools such as grinding

wheels, sockets, sanding

discs,etc., can become

entangled in hair,clothing,

jewelry and other loose

objects, resulting

in severe injury.

• Keep the working part

of the tool away from

hands and body.

ENTANGLEMENT

HOWTO PREVENT IT

• Never wear loose fitting

clothes, or apparel which

contains loose straps or ties,

etc., which could become

entangled in moving parts

of the tool.

• Remove any jewelry, watches,

identifications, bracelets,

necklaces, etc., which might

become caught by the tool.

• Keep hands away from moving

parts. Tie up or cover long hair.

• Always wear proper fitting

clothing and other safety

equipment when

using this tool.

Page 9

_'_WARNING: AIR SUPPLY AND CONNECTIONS

* Do not use oxygen, combustible gases, or bottled gases

as a power source for this tool as the tool may explode,

possibly causing injury.

* Do not use supply sources which can potentially exceed

200 PSI (13.8 bar) as tool may burst, possibly causing injury.

* The connector on the tool must not hold pressure

when air supply is disconnected. If a wrong fitting is used,

the tool can remain charged with air after disconnecting

and thus will be able to after the air line is disconnected

possibly causing injury.

* Always disconnect air supply:

1) Before making adjustments;

2) When servicing the tool;

3) When tool is not in use;

4) When moving to a different work area, as accidental

actuation may occur, possibly causing injury.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Page 10

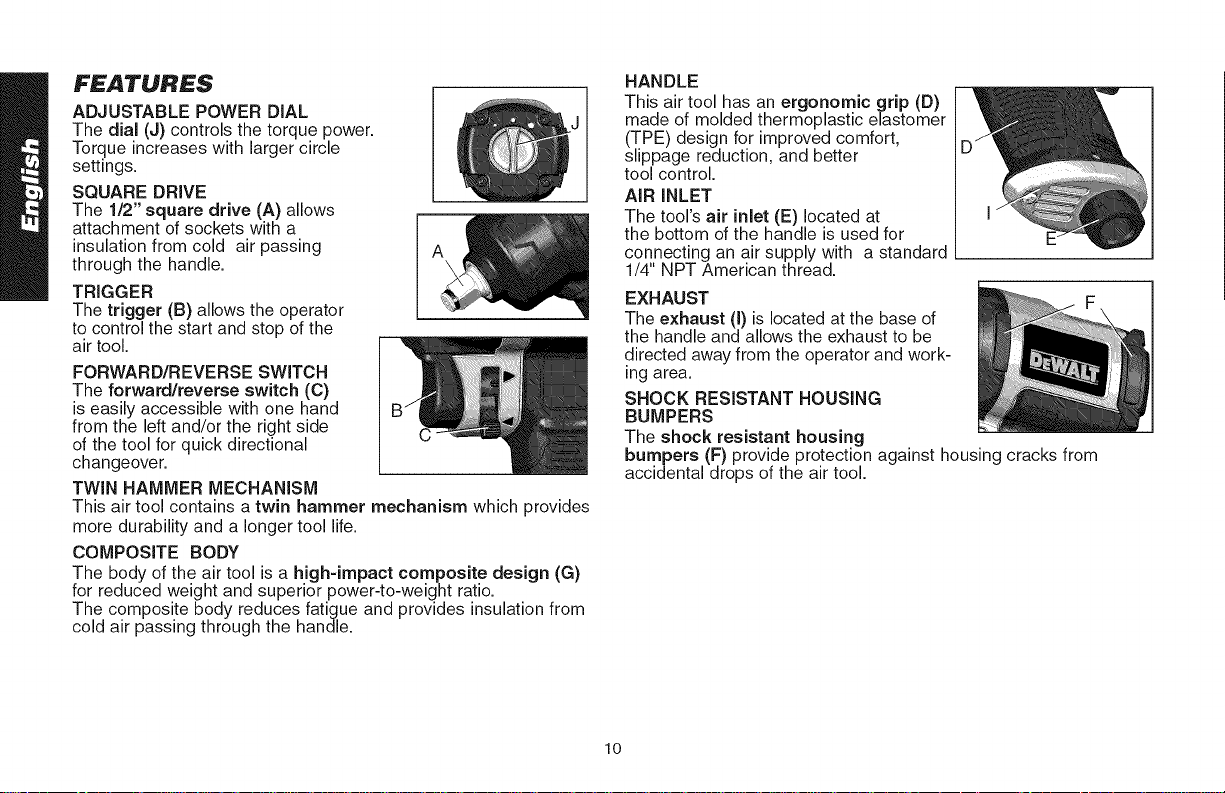

FEATURES

ADJUSTABLE POWER DiAL

The dial (J) controls the torque power.

Torque increases with larger circle

settings.

SQUARE DRIVE

The 1/2" square drive (A) allows

attachment of sockets with a

insulation from cold air passing

through the handle.

TRIGGER

The trigger (B) allows the operator

to control the start and stop of the

air tool.

FORWARD/REVERSE SWITCH

The forward/reverse switch (C)

is easily accessible with one hand

from the left and/or the right side

of the tool for quick directional

changeover.

TWIN HAMMER MECHANISM

This air tool contains a twin hammer mechanism which provides

more durability and a longer tool life.

COMPOSITE BODY

The body of the air tool is a high-impact composite design (G)

for reduced weight and superior power-to-weight ratio.

The composite body reduces fatigue and provides insulation from

cold air passing through the handle.

HANDLE

This air tool has an ergonomic grip (D)

made of molded thermoplastic elastomer

(TPE) design for improved comfort,

slippage reduction, and better

tool control.

AiR INLET

The tool's air inlet (E) located at

the bottom of the handle is used for

connecting an air supply with a standard

1/4" NPT American thread.

EXHAUST

The exhaust (I) is located at the base of

the handle and allows the exhaust to be

directed away from the operator and work-

ing area.

SHOCK RESISTANT HOUSING

BUMPERS

The shock resistant housing

bumpers (F) provide protection against housing cracks from

accidental drops of the air tool.

lO

Page 11

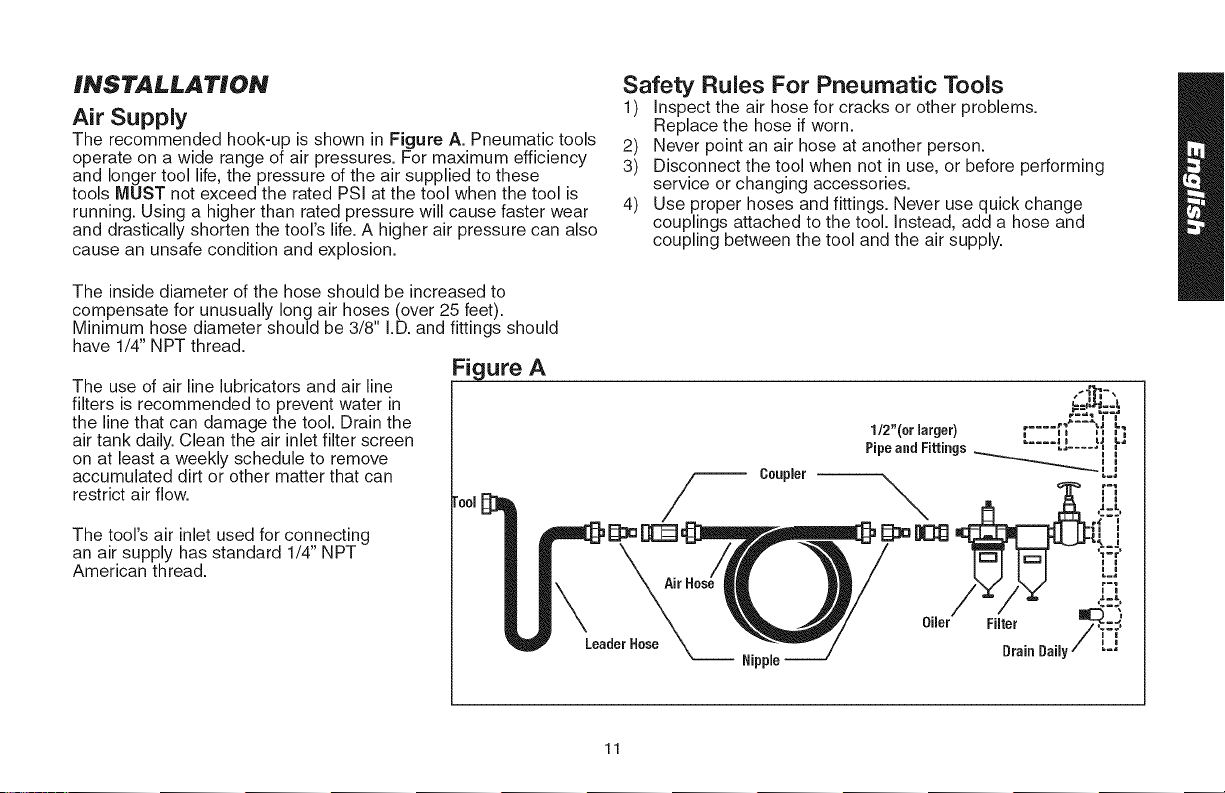

INSTA[.LA TION

Air Supply

The recommended hook-up isshown inFigure A. Pneumatic tools

operate on a wide range of air pressures. For maximum efficiency

and longer tool life, the pressure of the air supplied to these

tools MUST not exceed the rated PSi at the tool when the tool is

running. Using a higher than rated pressure will cause faster wear

and drastically shorten the tool's life. A higher air pressure can also

cause an unsafe condition and explosion.

The inside diameter of the hose should be increased to

compensate for unusually long air hoses (over 25 feet).

Minimum hose diameter should be 3/8" I.D. and fittings should

have 1/4" NPT thread.

The use of air line lubricators and air line

filters is recommended to prevent water in

the line that can damage the tool. Drain the

air tank daily. Clean the air inlet filter screen

on at least a weekly schedule to remove

accumulated dirt or other matter that can

restrict air flow.

The tool's air inlet used for connecting

an air supply has standard 1/4" NPT

American thread.

Figure A

reel _ .J:.L,

Safety Rules For Pneumatic Tools

1) Inspect the air hose for cracks or other problems.

Replace the hose if worn.

2) Never point an air hose at another person.

3) Disconnect the tool when not in use, or before performing

service or changing accessories.

4) Use proper hoses and fittings. Never use quick change

couplings attached to the tool. Instead, add a hose and

coupling between the tool and the air supply.

_ _==_,

-= b=_

-- Coupler....

1/2"(or larger) ....... _" 'J_ ,_"

PipeandFittings_i i

L.... LJ L_

LJ....

d 1

u\ o k ,jj r,

eaderH DrainDaily -_=I

11

Nipple

Oiler Filter _, =",'

i=i

Page 12

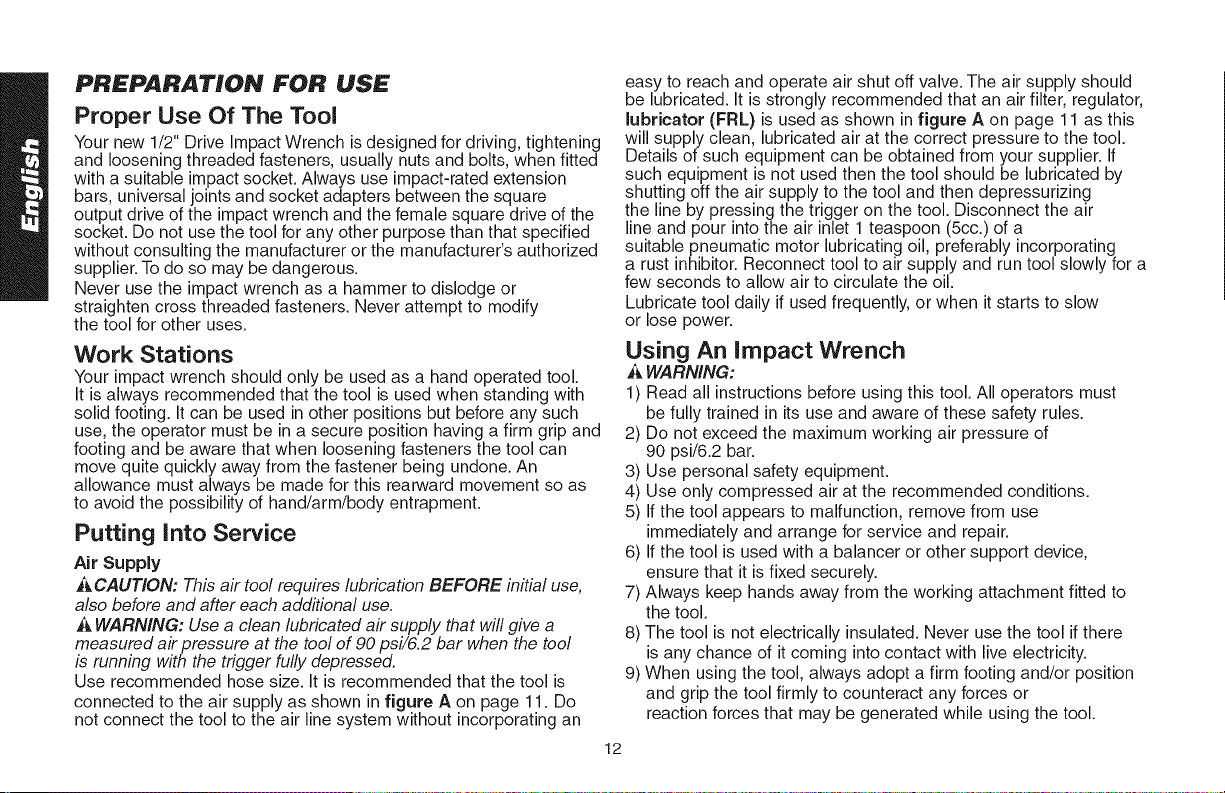

PREPARATION FOR USE

Proper Use Of The Tool

Your new 1/2" Drive Impact Wrench is designed for driving, tightening

and loosening threaded fasteners, usually nuts and bolts, when fitted

with a suitable impact socket. Always use impact-rated extension

bars, universal joints and socket adapters between the square

output drive of the impact wrench and the female square drive of the

socket. Do not use the tool for any other purpose than that specified

without consulting the manufacturer or the manufacturer's authorized

supplier. To do so may be dangerous.

Never use the impact wrench as a hammer to dislodge or

straighten cross threaded fasteners. Never attempt to modify

the tool for other uses.

Work Stations

Your impact wrench should only be used as a hand operated tool.

It is always recommended that the tool is used when standing with

solid footing. It can be used in other positions but before any such

use, the operator must be in a secure position having a firm grip and

footing and be aware that when loosening fasteners the tool can

move quite quickly away from the fastener being undone. An

allowance must always be made for this rearward movement so as

to avoid the possibility of hand!arm/body entrapment.

Putting Into Service

Air Supply

iJ,CAUTION: This air tool requires lubrication BEFORE initial use,

also before and after each additional use.

WARNING: Use a clean lubricated air supply that will give a

measured air pressure at the tool of 90 psi!6.2 bar when the tool

is running with the trigger fully depressed.

Use recommended hose size. It is recommended that the tool is

connected to the air supply as shown in figure A on page 11. Do

not connect the tool to the air line system without incorporating an

easy to reach and operate air shut off valve. The air supply should

be lubricated. It is strongly recommended that an air filter, regulator,

lubricator (FRL) is used as shown infigure A on page 11 as this

will supply clean, lubricated air at the correct pressure to the tool.

Details of such equipment can be obtained from your supplier. If

such equipment is not used then the tool should be lubricated by

shutting off the air supply to the tool and then depressurizing

the line by pressing the trigger on the tool. Disconnect the air

line and pour into the air inlet 1 teaspoon (5cc.) of a

suitable pneumatic motor lubricating oil, preferably incorporating

a rust inhibitor. Reconnect tool to air supply and run tool slowly for a

few seconds to allow air to circulate the oil.

Lubricate tool daily if used frequently, or when it starts to slow

or lose power.

Using An impact Wrench

A WARNING:

1) Read all instructions before using this tool. All operators must

be fully trained in its use and aware of these safety rules.

2 Do not exceed the maximum working air pressure of

90 psi/6.2 bar.

3 Use personal safety equipment.

4 Use only compressed air at the recommended conditions.

5 If the tool appears to malfunction, remove from use

immediately and arrange for service and repair.

6 If the tool is used with a balancer or other support device,

ensure that it is fixed securely.

7 Always keep hands away from the working attachment fitted to

the tool.

8) The tool is not electrically insulated. Never use the tool if there

is any chance of it coming into contact with live electricity.

9) When using the tool, always adopt a firm footing and/or position

and grip the tool firmly to counteract any forces or

reaction forces that may be generated while using the tool.

12

Page 13

Using an impact Wrench Continued

10) Use only genuine Dewalt spare parts or parts which perform

equivalently. Do not make temporary or permanent repairs with

unauthorized parts.

11) Do not lock, tape, wire, etc., the on/off trigger in the run position.

The trigger must always be free to return to the "off" position

when it is released.

12) Always shut off the air supply to the tool and depress the trigger

to release air from the feedhose before fitting, adjusting or

removing the working attachment.

13) Check hoses and fittings regularly for wear. Replace if

necessary. Do not carry the tool by its hose. Ensure the hand is

removed from the on/off trigger when carrying the tool with the

air supply connected.

14) Take care against entanglement of moving tool parts with

clothing, ties, hair, cleaning rags, etc. This will cause the body to

be drawn towards the tool andrcan be very dangerous.

15) Safe working practices and observe all relevant legal

requirements when installing, using or maintaining the tool.

16) Only install the tool when an easily accessible and easily

operable on/off switch is incorporated in the air supply.

17) Take care that the tool exhaust air does not cause problems

or blow onto another person.

18) Never lay a tool down unless the working attachment has

stopped moving.

19) Always ensure that the forward/reverse switch is in the desired

position before starting the tool.

20) Do not use sockets with excessive wear to the input or output

drives. Periodically check the square drive on the impact wrench.

Make surer the socket, extension bar, or other attachment is

securely fitted before operating tool.

21) When loosening fasteners first ensure that there is sufficient

clearance behind the tool to avoid hand entrapment. The tool will

move away from the threaded joint as the nut/bolt is loosened

and rides up the thread, moving the tool with it.

PRE-START CHECKLIST

• Drain water from air compressor tank and condensation from

air lines. (Please refer to air compressor's operation manual.)

, Lubricate the tool. (Please refer to the "Maintenance" section

in the manual.)

, Select the necessary impact sockets. The sockets have to

match with the size of the drive on the air impact wrench.

, Connect air impact wrench to air source with

the hose of recommended size.

,_ WARNING: Risk of unsafe operation. Firmly grasp air hose

with hand when installing or disconnenting to prevent hose whip.

_, WARNING: Risk of bursting. Too much air pressure causes

a hazardous risk of bursting. Check the manufacturer's maximum

pressure rating for air tools and accessories. The regulator output

pressure must never exceed the maximum pressure rating.

OPERATING PROCEDURES

START-UP 1,PC.2j

Turn on the air compressor and allow the air tank to be filled.

• Set the air compressor regulator to 90 PSI. This air

tool operates at a maximum of 90 PSi air pressure.

• Adjust power dial (if it is available) to desired torque.

• Adjust tool either in forward or reverse position. See Features on

page 10 for diagram.

, Depress the trigger to start operating the tool.

SHUT-DOWN (FIG. 1_ PG. 2)

• Release the trigger in order to stop the tool.

• When changing sockets, always disconnect air supply to

avoid injury.

• When job is completed, turn off the air compressor and store

the air tool after lubrication.

13

Page 14

OPERATING INSTRUCTIONS

• Securely fit the socket or attachment to the impact wrench.

• Ensure that the forward/reverse switch is in the correct position

for tightening or loosening the fastener.

• The nut/bolt can then run down the thread using the power

drive of the tool. For loosening a joint the tool can be used

in the reverse sequence.

MAINTENANCE

Lubrication

Air tools require lubrication throughout the lifetime of the tools.

The air motor and bearing uses compressed air to power the tool.

The compressed air contains moisture that will rust the air motor

and other parts in side of the tools, therefore lubrication is required

daily. Failure to lubricate the air tool properly will dramatically

shorten the life of the tool and will void the warranty

CAUTION: This air tool requires lubrication BEFORE initial use,

also before and after each additional use.

To Lubricate The Air Tool Manually:

1. Remove any attachment on the drive of air tools, such as:

sockets, chisels and etc.

2. Disconnect the tool from the air supply source, place

the air inlet face up.

3. Depress the trigger and place about 1 teaspoon

(5cc.) of air tool oil into the air inlet. (Depressing the trigger

will help circulate oil in the motor.)

NOTE:Use SAE #10 weight oil if air tool oil is not available.

4. Connect the tool to an air source, cover the exhaust end

with a towel and run for about 20 to 30 seconds.

•_ WARNING: Keep out of the reach of children, ff taken internally, do

not induce vomiting, call a doctor immediately.

/& WARNING: Any excess oil in the motor is immediately expelled

from the exhaust port. Always direct exhaust port away from people

or objects.

Storage:

The air tool must be lubricated before storing.

Follow the "Lubrication" instruction with exception of step 4.

SERVICE INFORMATION

Please have the following information available for all service calls:

Model Number

Date and Place of Purchase

FULL THREE YEARS WARRANTY

DEWALT heavy duty industrial tools are warranted for 3 years from

date of purchase. We will repair, without charge, any defects due

to faulty materials or workmanship. For warranty repair information,

call 1-800-4=DEWALT. This warranty does not apply to accessories

or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

Latin America: This warranty does not apply to products sold in

Latin America. For products sold in Latin America, see country

specific warranty information contained either in the packaging, call

the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call I=800=4=DEWALT

for a free replacement.

14

Page 15

raN K OPEN VALVE SLOWLY AND TILT COMPRESSOR TO EMpl_ ACCUMULATED WATER |

IF PUEDE OCAS_ONAR CORROSION O_NTRO I)EL TAN QUE Y PROVOCAH FALLA °EL TANQUE

CONSULTE EL MANUAL PARA CON OCER LOS PROCEO[M_ENTOS DE [NSPECC[ON PARA DRENAR EL TANOUE. ABRA LA |

VALVULA LENTAMENTE E [NCL]NE EL COMPRESOR PARAEUM_NAR EL AGUA ACUMULADA

•_ iNSIDE TAN K RESULTING ]N TANK FAILURE SEE MANUAL FOR INSPECTIO NPHOCEDURES_._I_ l_ ,|| _ L 11_f_! TO I)I_A[N_ _//]

_ CON DENSATION PEUT CAUSER LA COHROSIO N _, L [NTER[[UR DO RESERVOIR AYANT POUR

HALVE TO MAKE SURE THE VALVE MOVES FREELY DRAIN WATER FROM TANK AFTER EACH USE RISK OF F]_E OR EXP_S]OM DO NOT SP_AY A _MMA£LE OR COMBUSTIBLE

I_U_D 0R PAINT NEAR SPA_KS FLAMES PILOT LIGHTS OR IN ACONRN_D A_EA THE SPRAY AREA MUST BE W_LL V_NTI_T_D K_EP COMPRESSOR AT LEAST 20 F_ET AWAY FRO_

£PRAY AREA DO NOT CARRY AND OPEI_ATE THE COMPRESSOR OR ANY OTHEI_ _L_CTfilCAL DEVICE NEAR THE SPRAY AI_EA NEVER SMOKE WHEN SPRAYING USE A MINIMUM OF

ZSEE_r OFHOSETO CONNECTASPRAYGUNTOTHECOMPR_SSOR ffI$!_OFp_SOMALIN,_UBY, WEARANSIZ87SAF£TYGLASSES N_VERSPRAYCOMPRESSEOAI£ORI_4ATER_AL

_TS£LF OR OTHERS DO NOT USE COMPRESSE° Al_ FOR BREATHING REGULAT_ PRESSURE TO ZERO BEFORE REMOVING HOSE _iSK OF ELECTRICAL SHOCK HAZARDOUS VOLTAGE

JNPLUG UNIT _FOR£ REMOVING COVER DO NOT EXPOSE TO RAIN STORE iNDOORS READ OW[_£ _'S _Ai_UAL FORCOMPL[?E SAFETY Op_RKflON AND R_ PAIB INS II{UCTIONS

ELCO MPRESOR TIP_R D ELAN ILLO EN b_VALB UI_ DE S EGURI_D PARA A_EGURARS_ OUE b_ VAL_U b_ SE M UE_E LI£REMENTE DR ENAR EL AGUA DELTAN_UE DESPUES DE CADA USO

RI[S60 _E FUEGO 0 EXPLOSION NO ROCIAR L[OUIDO NI PINTURAS _N_MABL_S 0 COMBUSTIBLES C_RCA D_CHISPAS LL_:_AS LLAMAS 0£ PILOTO 0£N _REAS CERRADAS EL_REA °E

ALGUNO CE_CA D ELA R_ DEL ROClAD 0 NU NCAm M_ EN _L AR _ D_L RO ClAD O U_AR O NA MANG U _RE D EUN MINIM O DE25 PIES PARA CON ECT_R k_ PISTO k_ AL COM P RES0 R _S_O _

D_OS _RSaNA_$ USAR GAFAS OE S_URIDAD ANSI_7 NUNCA APUNT_R ELCH_RRO DEAIR_ COMPRIMID000_ M_T_RIALaU_ S_ EST_ ROClANDO a Sl MISMO NIA 0T_AS P_RSONAS

[IUITARLA CUB IERT_ N0 EXpo N£R A LLUVIA ALMAC_NARENI_TE_IOR_SpARASEGURI_AO_O_pL_OP_A_ __ST_UCCIO_SpaPA_pARAaLE_EL_NUALDELOP_A_O_

L ACCESS o ln_AVANT D_ 0 EMARRER LECO M PRESSEU n T IR_ S UR LANNEAU DE LA SOU PAPE 0 E SO ngfE POU R VOUS ASSU HEn aM ELLF FON CTIONNE U B REM EN_ V IOANGEZ LEAU DU RES_RVOI_

AIR APR_ S CHAQU E UTILISATIO N _ISOU[ D_NCENDE O UD'E,_LOSION N_ PAS VAPO RISERU NLIQUIDE 0 UUN PEINTU R_ INFL&MMA_LE OU COM BUST] BLE PROS° _TIN CELLFS DEFL&M ME SDE

VEILLEUSES N IDANS U NENOR 0IT R ESTREINT OU R_NFERM_ LAIR£ DEVAPO RI£ATIO N D0IT _TRE BEN A EREE GARO EZ LFCO MPRESSE° n AU N_ °ISTANCE DAU M OINS 20 p4EOSDE L& SURFACE A

VAPOR_SER N E_R_ P_ L[COMPR£SSEUR _ NE LUTIUS_ PAS N IAUCUN AL_R£ APPARE]L _L_CTRIQU_ A PROXiMIT_ O_ LAIR£ 0 EVAPORI_T_0N NE FUM_ JAMA_S QUANO VOUS

VAPOR IS_ U TiLIS_ UN FL_]BLE DAIR D UNE LON GUEU RMINIM UM D_25PlEbS POU R R_LIER• PISTO LETVAPORiSATEUR AU COM PR£SS[U£ RISQUE {_ B lFSSaLES CORR3R[U_S PORT_ OE S

LUNEIT_S DE PROTECTION AN SIZe7 NE DIRIGEZJ AMAIS LAIR CO MPRIM[ OU DE SMATE RIAUX _RS S OI OUVERS AU_ UI N_ JAMA]S UT_US_ D ELAIR COM PRIM E_ UR _ RESPIRATION REGL_

LApRSS$10N AZ£qO AVANT DE R_TIR_R LE80YAU RISQUE DE _ROC [ECT_[QU[ VOLTAGE °ANGER_UY. DEBRANC_ _ MACHIN EA_NT D ENL_R 80 m ER N EX_ £_ PAS LECO MPR_SS_UR

DRAIN TANK DAILY OR AFTER EACH USE. CONDENSATIO N BU&D UP MAY CAUSE CORROSION

t l , DRENE EL TANQUE A DIARIO r)DESPUE$ DE CADA USO LA ACU MULACIO N DE CON DENSACION

RESULTAT L ECHEC DE RESERVOIR VO[R LE MANU_L POUR DES PROCEDURES D]NSPECT[ON A LA VALVE OUVERTE

DE RESERV01R _)_ ViDANGE LENTEM ENT FT AU O0M PRESSEUR DINCU NAISON ,_ L'FAU ACCUM ULEE VIDE _

_z'_ '1 pR_SSl0N DE SORTIE OU COM_ESSEUR _ST_EGL_ _ UN NI_U IN_EUR _ pR_SSl0N DUTIUS_TION M_IMU M DU P_STOL_r VAPO RIS_NUR OU DE

RESERVOIR DE VIDANGE UUOTIDIEN OU APRES CBAQUE UTIUSATION L'HABILLAGE DE

INCO_R_(_ _S[ CA_ 6AUS_ HAZ_D$ FOLLOW Tff[S_ IN$_RUCTIONS: _1$_ OF B#_$ liNG MAK_ SURE THE COMPRESSOR OUTLET PRESSURE IS SET

LOWER THAH TH_ M_MUM OPERATING PRESSURE OF THE SPRAY GUN OR TOOL B_FOR_ STARTIHG THE COMPRESSOR PULL THE RING ON THE £AFE_

_L USO _N_B_O pU_ G_N_AR _I_SGOS S[eU_R ESTAS _NST_UCCIO_E$: £1[S60 I]_ ESTA$L_DO ASEG L]RES E _U EL& VALVOL& DE _ALID_ DEL

COMPRESOR EST_ RgSU_DA pOR DB_00EL M_IMO D_ _ PRESI_N DEOP[_ACI_N DE _ p4STOb_ ROClADORA O HERRAMIENT_ ANTES DE ARRANC_R

GLOSSARY

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute;

a unit of measure of air delivery.

PSi: Pounds per square inch; a unit of measure of pressure.

Code Certification: Products that bear one or more of the

following marks: UL, CUL, ETL, CF:TL, have been evaluated by

OSHA certified independent safety laboratories and meet the

applicable Underwriters Laboratories Standards for Safety.

RPM: Revolutions per minute; is a measure of the frequency

of a rotation

BPM: Beats per minute.

NPT: National pipe thread (tapered thread); is a U.S. standard

for tapered threads used on threaded pipes and fittings.

ID: Inner diameter

15

Page 16

DWMT70773L

r

CLE A CHOCS DE 12_7 MM (112 PO

SERVICE INTENSIF

A. Carr6 conducteur 12,7 mm

(1/2 pc)

B. G&chette

C. Interrupteur Avant/arri_re

D. Poign_e ergonomique

E. Entr6e d'air 8,4 mm (1/4 pc)

R Coussinets antichoc pour

boftier

G. Corps en composite

H. M_canisme & double marteau

I. Echappement

J. Cadran de puissance r6glable

CHETECHNIQUE

MODELE

CARRi_ CONDUCTEUR

TYPE D'EMBRAYAGE

COUPLE MAXIMAL {iNVERSiON)

VITESSE .&ViDE {A 620 KPA (90 PSi}

COUPS PAR MINUTE

POIDS NET

TYPE D'i'-=CHAPPEMENT

CONSOMMATION MOYENNE D'AIR

CONSOMMATION MOYENNE D'AIR EN 12,8 Iis (27,2 pieds cubes

CHARGE standard par minute)

DWMT70773L

1/2"

Double percussion

880 Nm (650 pi-lb)

7500 trimin

1100 CPM

2,1 kg (4,63 Ib)

Poignee

19,6 Iis (41,5 pieds cubes

standard par minute)

2,8 Iis (5,9 pieds cubes

standard par minute)

1,8 Iis (3,9 pieds cubes

standard par minute)

1{5

FIG.1

H

A

G

\

B

C

D

DIMENSION DE UENTRi_E D'AIR Filetage conique (F)

8,35 mm (1/4 pc)

DIMENSION RECOMMANDEE DU TUYAU 10 mm (3/8 pc)

PRESSION D'AIR MAXlMALE 90 psi

Page 17

De_fireitions : ligrees directrices ere

rnati_re de s_curit_

Les d_finitions ci-dessous d_crivent le niveau de gravit6 pour

chaque symbole. Veuillez lire le mode d'emploi et porter une

attention particuli_re &ces symboles.

&DANGER: Indique une situation dangereuse imminente qui, si

elle n'est pas evitee, causera la mort ou des blessures graves.

_AVERTISSEMENT : Indique une situation potentiellement

dangereuse quL si elle n'est pas evit_e, pourrait se solder par un

deces ou des blessures graves.

iJLATTENTION : Indique une situation potentiellement dangereuse

quL si elle n'est pas evitee pourrait se solder par des blessures

mineures ou moderees.

ATTENTION : Utilise sans le symbole d'alerte a la s6cufit_,

indique une situation potentiellement dangereuse quL si elle n'est

pas evit_e pourrait se solder par des dommages _ la propriete.

POUR TOUTES QUESTIONS O.U COMMENTAIRES

RELATIFS(VES) A L:OUTIL OU A PROPOS DE TOUT AUTRE

OUTIL DEWALT, COMPOSER SANS FRAIS LE :

1-800-4-DEWALT(1-800-433-9258)

DIRECTIVES Df $fCUBITf

IMPOBTANTES

_A VERTISSEMENT : Nertaines poussieres produites par los

travaux de pon_age, sciage, meulage, portage et autres peuvent

contenir des produits chimiques pouvant selon 1'6tatde Califomie

causer le cancer, des anomalies congenitales ou d'autres problbmes

li6s aux fonctions reproductrices. Voici quelques exemples de ces

produits chimiques :

* le plomb contenu clans les peintures a base de plomb;

* la silice cristalline provenant de la brique, du ciment et d'autres

produits de ma_onnerie;

• I'arsenic et chrome provenant de bois trait6 chimiquement.

Les risques reli6s a I'exf?osition aces poussieres varient selon la

fr6quence a laquelle I'utilisateur travaille avec ce type de mat6riaux.

Pour reduire votre exposition aces produits chimiques : travailler clans

un endroit bien ventil6 et porter un 6quipement de s6curit6 approuve

par I OSHA/MSHA/NIOSH comme un masque anti-poussieres

specialement adapt6 ou un respirateur lots de I'ut/lisation de cos outils.

Lors de I'utilisation d'outils pneumatiques, des precautions de base

en matibre de securit6 doivent _tre suivies afin de reduire le risque de

blessurepersonnelle.

AAVERTISSEMENT : ce produit contient des pro_uits

chimiques, notamment le plomb, reconnus par I Etat de

Californie comme _tant canc_rig_nes et pouvant entrainer

des anomalies cong_nitales et d autres dangers relatifs _ la

reproduction. Se laver los mains apr_s toute manipulation.

CONSEBP'_B CES _NSTFtUCT_ONS

_&AVERTISSEMENT :

pout causer des blessures graves Et des dommages

_ a mauvaise utilisation ou maintenance de ce produit

(_ _AVERTISSEMENT :

faire I'entretien. Gardez ces instructions clans un lieu sot a pottle de

®

©

A

17

s6rieux aux biens, fl faut fire et comprendre tous los

avertissements et la. Notice d'emploi avant d'utiliser

cot equipement. Lorsque vous utflisez des outils

PfoneUmatiques, il faut respecter los mesures de securite

ndamentales pour reduire leRisque de blessures.

I faut fire et comprendre ce guide d'instructions et les

#tiquettes de I'outfl avant d'_bstaller, d'utiliser cot out/'/ou d'en

la main.

Les operateurs et autres personnes clans la zone de travail

doivent porter des lunettes de securit# avec #crans lat#raux

approuvees ANSI Z87. I CAN/CSA Z94.3.

Les utilisateurs et los gens clans la zone de travail doivent

porter une protection auditive.

Graissez tousles jours pour un rendement optimal.

Page 18

,_AVERTISSEMENT :

* Evitez I'utilisation prolong@e :le mouvement r@p@titifou I'exposition

aux vibrations peuvent @trenocifs pour vos mains ou vos bras.

Utiliser des gants pour offrir un maximum de protection, prendre

des pauses fr@quenteset limiter le temps d'utilisation quotidien.

* N'utilisez pas de gaz oxyg@neou reactif,"une explosion

peut survenir.

* Ne pas exc@derune pression d'air de 90 psi.

* II faut life attentivement tousles fivrets inclus avec ce produit.

IIfaut bien se familiariser avec les commandes et I'emploi correct

de 1'6quipement.

, Seules les personnes qui connaissent bien ces r@glesde

s@curit@devraient utiliser Ibutil pneumatique.

* flne faut pas exc@derla pression limite des composantes

du syst@me.

* D@brancherI'outil pneumatique de I'arriv@ed'air avant de changer

les outils ou les accessoires et Iorsqu'il n'est pas utilis@.

* fl faut toujours porter des lunettes de protection et une

protection auditive durant I'emploLfl faut toujours porter des

lunettes de protection avec @cranslat@raux.IIfaut toujours porter

une protection auditive.

* flne fautjamais porter des v@tements amples ou un habillement

comportant des attaches ou bretelles Igches, etc. qui pourraient

@trehapp@espar les pi@cesmobiles de I'outil et causer des

blessures graves.

* flne faut pas porter de bijou, montre, identification, bracelet,

collier, etc. Iorsque vous utilisez Ibutil, car ils pourraient @tre

happ@spar les pi@cesmobiles de I'outil et causer des

blessures graves.

* flne faut pas abaisser la ggchette Iorsque vous raccordez I'outil

au boyau d'air d'arriv@e.

* Toujours utiliser un accessoire con_u pour les outils percuteurs

pneumatique.

* flne fautjamais utiliser des accessoires endommag@s ou us@s.

AAVERTISSEMENT :

IL NE FAUT JAMAIS utiliser les douilles des outils a main.

_&AVERTISSEMENT :

* II ne fautjamais d@clencherIbutil Iorsqu'iln'est pas appliqu@

contre un objet. Les accessoires doivent @trebien ancr@s.

Les accessoires I_ches peuvent causer des blessures graves.

* Prot@gezles conduits d'air des dommages et des perforations.

* II ne fautjamais pointer I'outilpneumatique vers sol ou

autrui. Des blessures graves peuvent survenir.

* V@rifiezles boyaux d'air en cas d'usure ou de d@t@rioration

avant chaque emploL S'assurer que tousles raccords sont

bien branch@s.

* S'assurer que les boulons, @crouset vis sont bien serr@set

que I'@quipementest en bon 6tat.

. Liejamais placer ses mains pr@sd'une pi@cemobile ou en dessous.

18

Page 19

AAVERTISSEMENT : RISQUE D'EXPLOSION OU D'INCENDIE

CE QUI PEUT SE PRODUIRE COMMENT U¢:ViTER

• Les outils abrasifs comme

les sableuses et les meules,

les outils rotatifs comme

les perceuses et les outils &

choc comme les cl6s,

les marteaux et les scies

action r6ciproque peuvent

produire des 6tincelles

qui pourraient allumer des

produits inflammables.

• Ne jamais utiliser les outils

pres des substances

inflammables, comme

I'essence, lenaphte, les

solvants de degraissage, etc.

• Travaillerdans une zone

de travail bienventil6e et

propre, exempte de

materiaux combustibles.

• Ne jamais utiliserde gaz

oxyg_ne, de dioxyde de

carbone ou autres gaz

en bouteille comme source

d'energie pour les outils

pneumatiques.

• D6passer la pression

maximale nominale des

accessoires de I'outilpeut

causer une explosion

• Utiliserde I'air comprime regl6

& une pression maximale pres

ou au-dessous de la pression

nominale des accessoires.

causant des blessures

graves.

_DANGER : RISQUE REPIRATOIRE (ASPHYXIE)

CE QUI PEUT SE PRODUIRE COMMENT L'C:VITER

Les outils abrasifs comme

les sableuses et les meules

et lesoutils a trongonner

produisent de la poussi@e

et de mat6riaux abrasifs qui

Toujours porter un masque

facial bien ajust6 ou un

respirateur homologu6

MSNA/NIOSN Iorsque

vous utilisez ces outils.

peuvent 6tre nocifs pour

les poumons et le

systeme respiratoire.

Certains mat6riaux, comme

les adh6sifs et le goudron,

contiennent des produits

Toujours travailler dans

unezone de travail bien

ventilee etpropre.

chimiques qui peuvent causer

des blessures graves

I'exposition prolong6e.

AATTENTION : RISQUE DE PERTED'OUTE

QUE FAIRE COMMENT PRE_VENIR

Une exposition prolong6e

au bruit produit par le

Toujours porter une protection

auditive ANSI (S3.19).

fonctionnement des

outils pneumatiques peut

causer une perte auditive

permanente.

19

Page 20

%

AAVERTISSEMENT: RISQUE DE PERTED'OUTE

QUE FAIRE COMMENT PREVENIR

• Les outils laiss6s sans

c_urveillanceou dont le boyau

'air est branch6 peuvent 6tre

activ6s par des personnes

non autoris6es qui peuvent se

blesser ou blesser autrui.

• Les outils pneumatiques

peuvent projeter les objets

nonfix6s et autres mat_riaux

dans toutes lesdirections de

la zone de travail.

• Les outils pneumatiques

peuv.ent6tre actionn6s

accidentellement Iors d'un

entretien ou d'un changement

d'outil.

• Le faitde laisser unecl6 de

r6glag.eou une cl6 fixee sur

_enepiece tournante augmente

nsque ae ulessures.

• Retirer le tuyau d'air Iorsque

'outil n'est pas utilis6 et ra:nger

'outil dans un endroit sQrhors

de port6e des enfants et des

utilisateurs n'ayant pas re(_ula

formation requlse.

• Utiliser uniquement les pieces,

les fixations et lesaccessoires

recommand6s par lefabricant.

• Conserver la zone de travail

_erOpreet en bon ordre. Eloigner

s enfants etautrui de la zone

de travail durant I'utilisationde

I'outil.

• Conserver les lieuxbien

illumin6s.

• Retirer le tuyau d'air pour

lubrifier ajouter ou remplacer

des dou es.

• Ne jamais transporter I'outil par

le boyau.

• Evitez lesd6marrages non

intentionnels. Ne transportez pas

I'outilbranch6 avec le doigt sur

la g&chette.

• Les r6parations doivent 6tre

effectu6es seulement par un

repr6sentant de service autoris6.

• Retirer toutes les cl6s de

reglage, et!es cles avant de

mettre i'ou[il en marone.

QUE FAIRE

• Utilis,er.des buses gonflantes

pour i'epouss,e_agepeu_

causer aes Dlessures graves.

• Les outils 6,1eqtriquespeuyent

prov.oquerleaep.!acementa.e

la piece ae _ray,allau contac_

e[ causer aes ulessures.

• La Rerte de c9ntr6,1ede I'out.il

peu[ causer.qes qlessures a

SOl-memee[a au[rul.

• ,D.esoutils de m.auvaisequa-

u[e,in.ap,p,ropnesou ena,om-

,mages_elsque les meules,

les clseaux,/es aOUllleS, les

perceuses, etc., peuvent,

voer en morceaux ors au

fonctionnement,.prgjetant des

p,amcules aans _ou_es,les .,

alrec[ions ae lazone ae [ravall

et causer des

blessures graves.

2O

COMMENT PRE_VENIR

• NE PAS utiliser de buses

gonflantes pour I'epoussetage.

• Utiliser des pinces ouautres

alsposmTSpour empecner le

mouvemenL

• Neiamais utiliser I'outilsous

I'infruenced'alcool ou de

drogues.

• Ine_ut pas t.endreI'outil,tro,p

on. (_araez 'equ Dreen [ou[

temps.

• G.ardezles mains propres,.

seones e_exemp[es ae gralsse

et d'huile.

• Restez alerte. Portez attention _.

c_eque vgus faites. ,,Servez-yous

e,vo_reDon,sens, u neTaKe.pas

U[lllser I'OU[IIIorsque vous e[es

fatigu6.

• Toujours utiliser les accesso,ires

c.9[espour la vl[esse ae I'ou[ll

elec[rlque.

• Ne jamais u.ti!iserdes outils ,q.ue

vous avez ecna.ppes,!mpac[es

ou enaommages par i'usage.

• Ne pas exercer de,force

excessive sur I'OU][ll -- lalsser

I'outileffectuer letravail.

Page 21

AAVERTISSEMENT: RISQUE DE BLESSURE (SUITE)

QUE FAIRE COMMENT PRE_VENIR

• Les outils et les accessoires •

qui ne sont pas entretenus

correctement peuvent causer ,

des blessures graves.

• Loutil risque de voler

en morceaux s'il est

endommage.

• Les attaches peuvent

rebondir ou 6tre projetees

et causer des blessures

graves et des dommages

importants.

Entretenir les outils de fa£on

minutieuse.

Keep a cutting tool sharp an.d

clean. A properly maintai.ned

tool, with sharp cutting edges

reduces the risk of binding and

iseasier to control.

• V6rifier I'alignement et la

torsion des pi_ces mobiles

la pr6sence de pieces

brisees ou de toute autre

_ondition pouvant nuire #.u

onctionnement de I'outil.

Faire r6parer I'outil s'il est

endommage avant de I'utiliser.

• Ne iam#is pointer 1'6jecteur

de Ioutil vers vous ou vers

quelqu'un d'autre.

• Ne pas appuyer sur lagg.chette

avant que ]e dispositit de

s6curit6 de I'outll ne soit en

contact avec la piece de travail.

• Ne jamais tenter d'enfoncer

des attaches dans des

surfaces dures telles que

I'acier,le beton ou lescarreaux.

• Prendre soin de ne pas

entoncer une attache

pardessus une autre attache.

• Positionner I'outil avec soin afin

de poser les attaches aux bons

endroits.

_,A VERTISSEMENT: RISQUE D'_-LECTROCUTION

QUE FAIRE

Cet outil ne comporte pas

de surface de prise isolee.

Le contact avec un fil <,sous

tension ,>mettra les surfaces

metalliques de I'outil aussi

<,sous tension ,>,ce qui peut

causer une electrocution ou

la mort.

21

COMMENT PRE:VENIR

• €:vitertout contact corporel

avec les surfaces mises &la

terre telles que les tuyaux,

radiateurs, cuisini@es et

r6frigerateurs. Le risque

d'electrocution est plus grand

si votre corps est mis _.la terre.

• Inspecter minutieusement la

piece de travail afin de detecter

tout c&blage dissimule avant

d'ex6cuter le travail.

Page 22

,&AVERTISSEMENT :RISQUE DE BLESSURE

,il LA TETE OU AUX YEUX

QUE FAIRE

• L_6quipementpneumatique

et lesoutils 61ectriques

peuvent propulser des

mat@iaux, comme les

copeaux de m6tal, le bran

de scie et autres d6bris, &

haute vitesse, ce qui pourrait

causer des blessures graves.

• Eair comprim6 peut 6tre

dangereux. Le courant d'air

peut causer des 16sions

COMMENT PRE_VENIR

Toujours porter des lunettes

de s6curit6 avec 6crans

lat@auxapprouv6es ANSI

Z87.1 CAN/CSA Z94.3.

• Ne jamais laisser I'outil sans

surveillance. D6brancher le

boyau d'air Iorsque I'outiln'est

pas utilis&

Pour plus de protection, utiliser

un masque facial approuv6 en

plus des lunettes de protection.

aux tissus mous, comme

les yeux, les oreilles, etc.

Les particules ou objets

propuls6s par lecourant

d'air peuvent causer

des blessures.

• Les accessoires des outils

peuvent devenir I&ches ou

briser et se d6gager en

S'assurer que tous les

accessoires sont fixes

solidement.

propulsant des particules en

direction de I'utilisateur ou

des autres personnes dans

la zone de travail.

,&AVERTISSEMENT : RISQUE DE

COUPURES OU DE BROLURES

QUE FAIRE

Les outils qui coupent,

cisaillent, percent,

poin_onnent, cis_lent, etc.

peuvent causer des

blessures graves.

,&AVERTISSEMENT : ARISQUE D'EMMELEMENT

QUE FAIRE COMMENT PRC:VENIR

• Les outils qui contiennent

des 616mentsmobiles ou

entrafnent d'autres outils

mobiles, comme lesdisques

de meulage lesdouilles

les meules etc.#euvent

s emm_ er avec es cheveux,

les vStements, les bijoux et

les objets I&ches et causer

des b essures graves.

22

COMMENT PRE_VENIR

• €:loigner la piece mobile de

I'outildes mains etdu corps.

Ne jamais porter de v6tements

amples ou d'habillement

comprenant des attaches ou

des bretelles I&ches,etc. qui

pourraient s'emm_ler dans

les pieces mobiles de I'outil.

• Enlever les bijoux montres

dentf cat ons, brace ets,

colliers, etc. pouvant 6tre

happ6s par ['outil.

Garder les mains 61oi.qn6es

des pieces mobiles. A_tacher

ou couvrir les cheveux longs.

Portez toujours des v@ements

bien aiust6s et les appareils de

protection appropri_s Iorsque

vous utilisez ['outil.

Page 23

AAVERTISSEMENT:ARRIVEE D'AIR ET RACCORDS

• N'utilisez jamais de gaz oxyg_ne, de gaz combustible ou

autres gaz en bouteille comme source d'6nergie pour cet

outil, car I'outil peut exploser et possiblement causer des

blessures.

• Ne pas utiliser de sources d'alimentation qui peuvent

d6passer 13,8 bars (200 psi), car les outils peuvent voler en

morceaux et causer des blessures.

• Le raccord ne dolt pas maintenir une pression Iorsque

I'arriv6e d'air est d6branch6e. Si le mauvais raccord est

utilis6, I'outil peut rester charg6 d'air apres I'avoir d6branch6;

I'outil pourra fonctionner apres que le conduit d'air est

d6branch6 et pourra causer des blessures.

• Toujours d6brancher I'arriv6e d'air :

1) avant d'effectuer des ajustements;

2) pour faire I'entretien de I'outil;

3) Iorsque I'outil n'est pas utilis6;

4) pour le d6placer & une autre zone de travail,

car I'outil peut 6tre activ6 par accident et peut

causer des blessures.

CONSERVER CES DIRECTIVES

POUR UN USAGE ULTI'-'RIEUR

23

Page 24

CARA CTERISTIQU ES

CADRAN DE PUISSANCE

RIeGLABLE

Le cadran (J) contr61e la puissance

de couple. Le couple augmente

Iorsqu'un r6glage de cercle

plus grand est utilis6.

CARRIe CONDUCTEUR A

Le cart6 conducteur (A) de

12,7 mm (1/2 po) permet de fixer les _,_

douilles a I'aide de I'air froid passant

dans la poign6e.

GACHETTE

La g_chette (B) permet & I'op@ateur

de contr61er la raise en marche et

I'arr@de I'outil pneumatique.

INTERRUPTEUR AVANT/ARRiieRE

L'interrupteur AvantJarri_re (C) est

facilement accessible d'une main du

c5t6 gauche ou du c6t6 droit de I'outil et permet de changer la

direction rapidement.

MIeCANISME _, DOUBLE MARTEAU

Cet outil pneumatique est muni d'un m6canisme a double

marteau pour plus de durabilit6 et une plus Iongue vie de I'outil.

CORPS ERGONOIVIIQUE

Le corps de I'outil pneumatique est un corps en composite (G)

tr_s r6sistant aux chocs afin d'en r6duire le poids et d'obtenir un

rapport puissance-poids sup@ieur. Le corps en composite r6duit

la fatigue et isole de I'air froid passant dans la poign6e.

\

POIGNIeE

Cet outil pneumatique comporte une poJgn6e ergonomique (D)

faite d'61astom@e thermoplastique (TPE) moul6 con_ue pour plus

de confort, moins de glissement et un

meilleur contr61e de I'outil.

ENTRIeE D'AIR

L'entr6e d'air de FoutiJ (E), situ6e tout

en bas de la poign6e, est utilis6e pour

raccorder I'alimentation en air ayant

un filetage conique NPT de 6,4 mm

(1/4 po).

IeCHAPPEMENT

L'6chappement (I) est situ6 dans la E

base de la poign6e et permet de diriger

1'6chappement loin de I'op@ateur et de

la zone de travail.

COUSSINETS ANTICHOC POUR

BOJTIER

Les coussinets antichoc pour boitier

(F) emp6chent le bo_tierde se fissurer

Iorsque I'outil pneumatique tombe

accidentellement.

24

Page 25

INSTALLATION

Alirnentation d'air

Le branchement recommande est illustre dans la figure A. Les

outils pneumatiques fonctionnent selon une grande plage de

pression d'air. Pour une efficacite maximale et une Iongue vie de

I'outil, la pression de Fairfourni _.ces outils NE DOlT PAS depasser

la pression nominale de I'outil Iorsque I'outil fonctionne. Lutilisation

d'une pression plus 61ev6eque la pression nominale peut provoquer

I'usure plus rapide de I'outil et en ecourter la duree. Une pression

d'air plus 61ev6e peut aussi provoquer des conditions dangereuses

et une explosion. II faut augmenter le diam_tre interieur du boyau

comme compensation Iorsqu'il est tr_s long (plus de 25 pieds).

Le diam_tre interieur minimum

du boyau est 6tre de 3/8 poet

les raccords doivent avoir les

m6mes dimensions int6rieures.

II est recommande d'utiliser des

lubrificateurs et des filtres _.air dans

les conduits d'air pour emp6cher

I'eau de pen6trer dans le conduit et

endommager I'outil. Vider le reservoir

d'air tousles jours. Nettoyer le grillage

du filtre du conduit d'air au moins une

fois par semaine pour supprimer la

salete accumulee ou autre debris qui

peutrestreindre le debit d'air.

Lentree d'air de I'outil utilisee

pour raccorder I'alimentation d'air

comporte un fil standard americain

de 1/4 po NPT.

FIGURE A

Outil

Regles de s6curit6 pour les Outils

pneumatiques

1) Inspecter le boyau d'air pour noter les f61uresou

autres problemes. Remplacer le boyau s'il est us6.

2) Ne jamais pointer le boyau d'air en direction d'une personne.

3) Debrancher I'outil Iorsqu'il n'est pas utilise ou avant

d'en effectuer I'entretien ou de changer les accessoires.

4) Utiliser les boyaux et raccords appropri6s. Ne jamais utiliser de

manchons de conversion rapide fix6s directement sur I'outil.

Ajoutez plut6t un boyau et un raccord entre I'outil et

I'alimentation d'air.

IVlarnelon

25

Page 26

EMPLOI CORRECT DE L'OUTIL

Postes de travail

Votre nouvelle cl6 & choc & prise de Yzpo est fabriqu6e pour

enfoncer, serrer et desserrer les fixations filet6es, habituellement

les 6crous et les boulons Iorsqu'elle utilise une douille appropri6e

pour cl6 & choc. Toujours utiliser les rallonges & r6sistance

d6termin6e, les joints universels et les interm6diaires de douilles

entre la prise de sortie carr6e de la cl6 & choc et la prise carr6e

femelle de la douille. N'utilisez jamais I'outil pour toute autre fin que

celle pr6cis6e sans consulter le fabricant ou le fournisseur autoris6

du fabricant. Cela peut 6tre dangereux.

Ne jamais utiliser la cl6 & chocs comme un marteau pour d61oger

ou redresser des attaches filet6es fauss6es. Ne jamais essayer de

modifier I'outil pour d'autres usages.

Postes de travail

Votre cl6 & chocs ne doit 6tre utilis6e que comme outil & main. II

est toujours recommand6 que I'utilisateur se tienne debout pour

utiliser I'outil. L:outil peut 6tre utilis6 si I'utilisateur est dans une

autre position, mais avant d'en faire I'utilisation, ce dernier doit

s'assurer qu'il se trouve darts une position s6curitaire et qu'il peut

avoir une prise ferme sur I'outil; prendre note que Iorsque I'outil

est utilis6 pour d6visser des attaches, I'outil peut alors s'61oigner

rapidement de I'attache &d6visser. II faut pr6voir un espace &

I'arri@e pour le mouvement de recul de I'outil afin d'6viter le

coincement de la main, du bras ou du corps.

iVliseen service

ALIMENTATION D'AIR

/_MISE EN GARDE : Cet outilpneumatique doit _tre lubrifi6 AVANT sa

premiere utilisation, ainsi qu'avant et apres chaque utilisation ult6rieure.

&AVERTISSEMENT : Utilisez une alimentation d'air propre et

graissde qui foumit une pression d'air mesuree a Ibutil de 90

psi/6.2 bar Iorsque Ibutil fonctionne avec la ggchette

pleinement abaissee.

Utiliser le boyau de diam_tre recommand6. II est recommand6 de

raccorder I'outil sur I'alimentation en air comme illustr6 & la figure A

de la page 11..Ne p..asraccorder I'outil sur le circuit d'air sans y

int6grer un robinet d'arr6t4facile d'acc_s et facile & faire fonctionner.

Ealimentation en air doit etre lubrifi6e. IIest tortement recommand6

d'utiliser un filtre a air un r6gulateur et un lubrificateur (FRL) .

comme illustr6 a la figure A de la page 11, car cela permettra de

fournir & I'outil de I'air propre et lubrifie a la pression appropri6e. Les

d6tails de cet 6quipement s'obtiennent aupr_s de .v.otrefournisseur.

Si cet 6quiperqent n'est pas utilis6 il faut graisser ['outil en fermant

I'alimentation d'air et d6pressuriser le conduit en abaissant la

q&chette de routil. S6parer la conduite d'air et verser 1 cuiller6e

th6 (5 cc) d'une huile de lubrification pour moteurs pneumatiques

appro0riee, en y ajoutant de pr6f6rence un antirouille. Rebranchez

I'outil a ralimentation d'air et taites tourner I'outil lentement pendant

quelques secondes pour permettre & I'air de circuler I'huile.

Graissez I'outil tousles jours si vous I'utilisez fr6quemment ou

Iorsqu'il commence a ralentir ou a perdre de la puissance.

Utilisation d'une cle a chocs

&AVERTISSEMENT :

1) LiFetoutes les instructions avant d'utiliser cet outil. Tousles

utilisateurs doivent recevoir une formation complete sur son

utilisation et connaftre les r_gles de s6curit6.

2) Ne pas exc6der la pression maximum d'utilisation d'air de

90 psi/6.2 bar.

3) U.tihser 1'6quipement de protection personnelle.

4)

Utiliser seulement I'air comprim6 dans les conditions

recommanaees.

5) Si I'outil semble real fonctionner cesser de I'utiliser et prendre les

disposi.t.ions pour son entretien et sa r6paration. . .

6) Si ['outil s'utilise avec un compensateur ou tout autre dispositit de

support, s'assurer qu'il est bien assujetti.

7) Toujours garder les mains 61oign6es de I'accessoire de travail

fix6 & routil.

8) I'outil n'est pas isol6 61ectriquement. Ne jamais #tiliser I'outil s'il

existe un risque .q.u'il entre en contact avec une ligne sous tension.

9) Lorsque vous utihsez I'outil, vous devez vous assurer d'avoir un

bon 6quilibre et de tenir I'outil fer.mement Rgur cqntre[ les forces

ou r6actions qui peuvent se produire en utilisant I'outil.

26

Page 27

Utilisation d'une cle a chocs (suite)

10) Utiliser uniquement des pieces de rechange d'ongine Dewalt ou

des pieces de qualit6 6quivalente. Nepas effectuer de r@arations

temporaires ou permanentes & I'aide de pieces inad6quates.

11) Ne pas verrouil]er utiliser du ruban ou du fil m@allique etc.

pour immobiliser la g&chette r_versible dans la position de

marche. La g&chette doit toujours 8tre en mesure de retourner

& la position _ arrSt _ Iorsqu'elle est lib@6e.

12) Touiours fermer I'alimentatlon d'air en direction de I'outil et

abalss .e.rla g&chette pour lib@er I'air du boyau d'alimentation

avant d'installer, d'ajuster ou de retirer I'accessoire de travail.

13) V@ifiez r6guli@ement les boyaux et les raccords pour en noter

rusure. Remplacer au besoin. Ne pas transporter I'outil par le

boyau. S'assurer.de retirer la main de la q&chette r6versible

pour transporter I'outil branch_ & I'alimenfation d'air.

14) ..Assurez-vous d'_viter I'emmSlement des pi_ces mobiles de

I'outil par les vStements les attaches les cheveux les chiff#ns

etc, car cela aurait pour ettet de pousser le corps vers routil et

peut 8tre tr_s dangereu_.

15) II est attendu que les utilisateurs adopteront des habitudes de

prudence au travail et respecteront toutes les prescriptions

I_gales pertinentes pour installer, utiliser et entretenir I'outil.

16) Installer seulement I'outil Iorsqu'un interrupteur facilemen'_

accessible et utilisable est incorpor6 dans I'alimentation d'air.

17) S'assurer que I'_chappement d'air de I'outil ne cause pas de

probl_me ou n'est pas dirig_ sur une personne.

18) Ne jamais poser I'outil sur-le sol si I'accessoire de travail est

encore en marche.

19) Toujours s'assurer que I'interrupteur r_versil_le est dans la

position recherch6e avant de d_marrer I'outil.

20) Ne pas utiliser les douilles tr_s us6es sur les prises .

q'entrafnement ou de sortie. V@ifiez p@iodiquement le carr6

d'entrafnement sur la cl_ & choc. S'assurer que la douille, la

[allol?ge ou autre accessoire est bien assujetti avant d'utiliser

I'outil.

21) Pour desserrer les fixations, s'assurer qu'il y a suffisamment

d'espace derri@e I'outil pour 6viter de se coincer les mains.

L:oug s'61oigne du joint filet_ Iorsque I'_c[ou ou le boulon

est desserre et remonte le ill, d6pla(2ant I'outil dans son

mouvement.

MST DE VERIFICATION DE PRE-

OEMARRAGE

• Vidanger I'eau du reservoir d'air comprim6 et la condensation des

conduits d'air. (Veuillez consulter la notice d'emploi du compresseur

d'air.)

• Lubrifier Ibutil

• S61ectionner les douilles et les accessoires a chocs n6cessaires.

La dimension des douilles doit correspondre a la dimension de la

cle a chocs pneumatique.

• Brancher la ct6 a choc pneumatique a la source d'air en utilisant le

boyau de la taille recommandee.

&AVERTISSEMENT :Risque d'utilisation dangereuse. Saisir

fermement le tuyau en main lots du raccordement ou de la

deconnexion pour emp#cher un a-coup du tuyau.

_,AVERTISSEMENT : RISQUE DE RUPTURE. Une trop forte

pression d'air represente un risque de rupture. V#rifiez la pression

maximum sugge'ree par le fabricant pour les outils pneumatiques

et les accessoires. La pression de sortie du r#gulateur ne doit

jamais depasser la pression maximale nominale.

PROC_'_UR_S D_ FONCT"_ONN_M_NT

DEMARRAGE (FIG. 1, PG2)

• Mettre le compresseur & air en marche et permettre au r_servoir &

air de se remplir.

• R_gler le r_gulateur du compresseur sur 6,2 bars (90 PSI). Cet outil

fonctionne & une pression dair maximale de 6,2 bars (90 PSI).

• R_gler le cadran de puissance (le cas _ch_ant) au couple d_sir&

• R_gler I'outil & la position Avant ou Arri@e. Voir la section

Caract_ristiques a la page 10 pour consulter le schema.

• Maintenir la g&chette enfonc_e pour mettre I'outil en marche.

ARR_'T (FIG. 1, PG2)

• Rel&cher la g&chette afin d'arrSter routil.

• Avant de changer les douilles, toujours s@arer ralimentation en air

afin d'_viter les blessures.

27

Page 28

,,Une fois le travail termin6, arr@er le compresseur & air et ranger

routil pneumatique apr_s ravoir lubrifi&

NOTICE DJEMP£OI

,,Fixer la douille ou I'accessoire solidement sur la cl_ & chocs.

• S'assurer que I'interrupteur Avant/arri@e est & la position

appropri6e pour visser ou d_visser rattache.

L:6crou ou le boulon peut ensuite @re viss6 sur le filetage & I'aide

de I'entrafnement de I'outil. L:outilpeut @re utilis_ sur la position

Inverser pour d6visser un joint.

ENTRET"IEN

Graissage

Les outils pneumatiques doivent @re graiss_s pendant toute la

vie des outils. Le moteur pneumatique et les coussinets utilisent

I'air comprim_ pour actionner I'outil et comme rhumidit6 de I'air

comprim6 entrafne la formation de rouille sur le moteur et les

pi_ces int@ieures de routil, il faut graisser I'outil tousles jours. Tout

manquement 9,graisser les outils correctement r6duira fortement la

vie de routil et annulera la garantie.

_4TTENTION : fl faut graisser I'outil AVANT I'emploi initial,

avant et apr#s chaque usage additionneL

Pour graisser I'outil pneumatique _ la main :

1. D_brancher I'outil de la source d'alimentation d'air, placer les

entr_es d'air vers le haut.

2. Retirer I'accessoire de la prise de I'outil pneumatique, comme

les douilles, les ciseaux, etc.

3. Maintenir la g&chette enfonc_e et mettre environ 1 cuiller6e &

th6 (5 cc.) d'huile pour outil pneumatique dans I'entr_e d'air.

(Maintenir la g&chette enfonc_e permettra de faire circuler I'huile

dans le moteur.)

Remarque : Utiliser I'huiie SAE n°lO si I'huile a outil

pneumatique n'est pas disponible.

4. Raccorder I'outil sur une source d'air, couvrir I'extr_mit_ de

I'_chappement d'une serviette et faire fonctionner de 20 & 30

secondes.

AAVERTISSEMENT : Gardez hors de la portde des enfants. En

cas d'ingestion, ne pas provoquer de vomissement, appelez un

medecin immediatement.

AAVERTISSEMENT : L'exc4dent d'huile clans le moteur est

immediatement expulse par Ibrifice d'dchappement. Toujours

dloigner Ibrifice d'dchappement des gens ou objets.

Graissage

II faut graisser I'outil pneumatique avant de le ranger. Se reporter

aux instructions sur le <<Graissage ,>en omettant I'@ape 4.

INFOFtMA't'ION SUR LES REPARATIONS

Veuillez recueillir les informationssuivantes pour tousles appels au

Service a laclientele :

Num@o du module

Date et lieu de I'achat

G.nRANTIE COMP£#=TE D'UN (3) AN

Les outils industriels de service intensif de DEWALT sont garantis

pour une p@iode de un (3) an &partir de la date d'achat. DEWALT

r.@arera 9ratuitement toutes defectuosit6s provoqu6es pa[ un defaut

de mat@lel ou de fabrication. Pour des renseignements relatits aux

r@arations sous garantie composer le 1-800-4-DEWALT. Cette

garantie ne s'applique pas aux accessoires niaux dommages causes

par des r6parati6ns realis6es ou tentees par des tiers. Cette garantie

vous a:ccorde d.esdroits legaux specifiques e.til est possible que vous

ayez d'autres droits qui vanent d'un Etat ou d'une province &/'autre.

AIVIERIQUE LATINE : cette qarantie ne s'applique pas aux.produits

vendus en Am@ique lat!ne. Pour ceux-ci, veuillez consulter les

intormations relatives & la garantie sp6citique pr6sente dans

remballage, appeler I'entreprise locale ou consulter le site Web pour

les informations relatives a cette garantie.

REIVIPLACEMENT GRATUIT DES ETIQUETTES

28

Page 29

D'AVERTBSEMENT : si les 6tiquettes d'avertissement deviennent

illisibles ou sont manquantes, composer le 1-800-4-DEWALT pour en

obtenir le remplacement gratuit.

• DRAIN TANK DALLY OR AFTER EACH USE. CONDENSATIO N BUILD-UP MAY CAUSE CORROSIO N

_ _, v.'l iJ,i .I .| i .I _'lvl r .'! PUEDE OCASIONAR DORROSIO N DENTRO DEL T_,N QU E Y PROVOCAR FALLA DEL TANQUE |

CO NSULTE EL MANUAL PARA CONOCER LOS PROCEDIMIENTOS DE I NSPECDIO N PARA DRENAR EL TAN QUE, ABRA LA /

VALVU LA LENTAM ENTE E INDLIN£ EL COMPRESOR PARAEU MINAR EL AGUA ADUMULADA

. . ..• ---'--'-"-"-'"-' --_ INSL_DAENTA_KLREoSULTRIN_slNTAoN_FMAp&lxUREccSEE_ A_ L_OA._IoN.......................... ''lJ_l

T _ ' , , RESERVOIR DE VIDANCE QUOTIDIEN OU APRE$ £HAOUE UTILISATION, L HA[_&LAGE DE

• , , INCORRECT USE CAN CAUSE HAZARDS. FOLLOW THESE INSTRUCTIONS: RISK OF BURSTINC. MAKE SURE THE COMPRESSOR OUTLET PRESSURE 1S SET

VALVE TO MAKE SURE THE VALVE MOVES FREELY DRAIN WATER FROM TANK AFTER EACH USE RISK OF RCE OC EXPLOSION. DO NOT SPRAY AFLAMMA£LE OR COM£USTIBLE

UQUID OR PAINT NEAR SPARKS FLAMES PILOT LIGHTS OR IN A CONFINES AREA TH E SPRAY AREA MUST {}E WELL VENTILATED KEEP COMPRESSOR AT LEAST 2O FEET AWAY FROM

SPRAY AREA DO NOT CARRY ANO OPERATE TH E COMPRESSOR OR ANY OTHER ELECTRICAL DEVICE NEAR THE SPRAY AREA NEVER SMOKE WNEN SPRAYING USE AMINIMUM OC

25 FEET OR HOSE TO CONNECT A SPRAY gUN TO THE CON PRESSOR RISK OF PERSONAL INJUC_ WEAR ANSI ZB7 SAFETY GLASSES NEVER SPRAY COMPRESSED AIR OR MATERIAL

AT SELF OR OTHERS DO NOT USE COMPRESSED AI]t FOR BREATHING REGULATE PRESSURE TO ZERO BEFORE REMOVING H OSE RISE OF ELECTRICAL SHOCK. HAZARDOUS VOLTADE

UNPLUG UNI_ BEFORE REMOVING COVER 50 NOT EXPOSE TO RAIN STORE INDOORS READ OWNER'S MANUAL FOR COMPLETE SAFE_ OPERATION, AND REPAIR INSTRUCtiONS.

EL COMCRESOR, TIF,_R DEL ANILLO _N LA VALBULA DE SE_URIDAD PARA ASE_ORARSE OUE tA VALVNLA SE MUEVE LIBREMENTE DREN_R ELAGUA DE TANaUE DESPUES DE CADA USO

CESGO BE ru[6_ 0 [J(PIOSICN NO ROCIAR L[OUIDO NI PINTURAS INFL_MABLES O COMBUSTIBLES RERCA DE CHISPAS LLAMAS LLAMAS DE PILOTO O EN AREAS CERRADAS EL AR£,_ DE

TRABAJO DEBE ESTAR BIEN VENTILADA MANTENER EL COMPRESOR ALFJADO POR LOMEMOS 33 PIES DELAREA DE PJNTURA NO LL_3/AR NI OPERAR EL COMPRESOR NI DISPOSmVO EL_CTRICO

ALGUNO CERCA DELAREA DEL RORIADO NUNCA FUME EN EL AREA DEL RORIADO USAR UNA MANGUERE DE UN M[NIMO DE 25 PIES PARA CONEC_AR LAPiSTOLA AL COMPRESOR €I£SGO NE

LlAnOS pECSONALES USAR GAFA£ DE SEGURIDAD ANSI Z87 NUNCA APUNTAR E CHORRO DE AIRE COMPR_MIDO 0 DE MATERIAL QUE SE EST_ ROCIANDO A S[ MISMO NI A OTRAS PERSONAS

NE RESPIRAR ELAIRE COMPRIMIDO REDUCIR LA PRESION A CERO ANTES DEDESMONTAR LA MANOUERA €lESGa O_ £HO0#_ £_¢[RlOa ALTO VOLTAJE DESCONEC_AR LA UNIDAD ANTES DE

QUJTAR LA CUBIERTA NO _XPONER ALLUVIA ALMACENAR EN INTERIORES pN_A £EGUCIBAB COUPLE;A, OpeRA CI(}N _ INS ICUCClON_S PACA REpAI_AR, LE_R _L_ANUAL D_L Op_CADOC

_ '' -- PRESS_ON DE SORTIE DU COMPRESSEUR EST REOL_E AUN NIVEAU INFERIEUR ALA PRESS_ON OUTILISATION MAX]MUM OU PISTOLET VAPDRISATEU R OU DE

L ACCESS 0IRE AVANT DE D EMARRER LECON PRES SEUR, TIREZ SU RL ANN_AU DE L_ £0U PAPE DE S OR£-rE POUR VOUS AS SU RERQ UELLE CONC TIONNE LIP REM ENT VIDAN G EZL EAUD U RESERYOIR

A AIR A PRES CHAD U_ UT]USAT40N €iSOIIE D'INCEN BIF O UD'EXpLOS_O N N EPAS VAPO RISER UN UQUID E OU U NP EINTUREIN FL&M MABLE O UCON BU STIDLE PROS DET]NCELLES DE FLAMM ES DE

VEILLEU $ES N IDAN SU N ENDR 0 ITRESTREINT OU REN FERN EL A]RE DE VAPO RISATION D OIT _'IRE BIEN AEREE SARD E7 LE COa P RESSEU R AU NE DISTANCE DAD M 0IN S 2OP IEDS DELA SURFACE A

VAPOR]SER NE P ORTEZ pAS L_CO a PRESSEU RE r NE L U_ILISE7 RASN IAU RUN A UTRE APPAREIL E LECTRJQU EA PROXIMITE DE L AIRE DE VAPORISAT40N N EFU M EZJ AMAIS Q UAND VOU S

VAPOR]S£ 7 U_ILISEZ UN FLEXIBLE DAIR DUNE LONGUEUR MINIMUM DE 25 PIEDS POUR RELIER L[ PISTOLETVAPORISATEUR AU COMPRESSEUR RISOU[ DE BLESSURES COCPOC[L_S PORT& 7 DES

L UNETTES DE PROTECTION AN S IZ87 N ED IRIS EZ J AMAIS LAIR CON PRIM E OU DES M ATERIAUX VERS S OIOU _RS AUTRUI NE J AMAIS UTIU S ER DE LAiR CON PRIM [ POUR LA RESPIRATION REGLE

b_ PRESS]ON A ZERO A_tANT DER_rIRER LE {_OYAU C ISOI IF DE ONORE L£_ICIOUE VOLTAGE DANG EREUX DE8 RANCH EZ LAMAC NINE A_ANT D ENLEVER 80 m ER N EXpO SEZ RAS L EC OMPRESSEUR

_A J_ PLUIE CEMJS_Z L_ A L INTECJEUR U S£Z LE _,'_NU_L D£ L'U[IUSAI_IJC POBC D_SINS;'_UC90NS CO_pL_TES CONC£CNAt{I bt SEC BCH[, L'UT_USA1_ON ET E S CE_A_O N S

DRENE EL TANQUE A DIARIO O DESPUES DE CADA USO. LA ADUMULACI(_N DE CO N DENSACION

CON DENSATION PEUT OAUS£R LA CORROSION A L INTERIENR DU RESERVOIR AYANT POUR

LOWER THAN THE MAXIMUM OPERATING PRESSURE OR THE SPRAY GUN OR TOOL BEFORE STARTING THE CON PRESSOR PULL THE RIN£ ON THE SAFETY

ELV£O INB_BIDO pUED_ _EN[CA_ €IES_OS SEeUIC E_A,S INS[CUCCIONES:CI_S60 D[ ESTALUDO ASEGORESE fiNE LA VALWLA DE SALIDA DEL

COMPRESORESTERE_OLADAPORDEaA_ODEtM_XlMODEU_PRESlONDEOPERAClONDELAPISTOt_ROClADO_OHERRAMIEN_.ANTESDEARRANCAR

UNE UflLISA_ONINCOCCEC_ P£UT E_RE DA_eEC_S£ SU_WZ LES INSTRUCTIONS CH)E£SaUS:CIS_E B'EC_ATEMENt ASSUREZ VOUS QUE LA

GLOSSA_RE

CFM • pied cube par minute.

SCFM : pied cube par minute (standard), une unit6 de mesure du

soufflage.

PSi : livres par pouce carrR, une unit6 de mesure de pression.

Code de certifications : les produits qui affichent un ou

plusieurs des 6tampes suivantes : UL, CUL, ETL, CETL

ont 6t6 6valuCs pas un laboratoire de sCcurit6 indCpendant

sanctionn6 par I'OSHA et qui rCpond aux normes en vigueur des

Underwriters Laboratories en ce qui a trait & la sCcuritC.

TR/MIN : Tours par minute; est une unit6 de mesure indiquant la

frRquence d'un tour

B/MIN : Battements par minute.

NPT : _,National pipe thread _ (filetage conique); est une norme

amCricaine pour les filets coniques utilisCs dans les tuyaux et les

raccords filetCs.

ID : Diam_tre intRrieur

29

Page 30

DWMT70773L

LLAVE DE IMPACTO DE 12,7 MM (112 '_)

PARA SERVICIO PESADO

A. Encastre cuadrado de

12,7 mm (1/2")

B. Gatillo

C. Interruptor de avance/

retroceso

D. Empu_adura ergon6mica

E. Entrada de aire de 1/4"

R Protectores de goma en la

carcasa resistentes a impactos

G. Cuerpo compuesto

H. Mecanismo de martillo doble

I. Escape

J. Cuadrante de potencia

ajustable

FIG.1

G

\\

\

A

d \

\