Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DeWALT

Instruction Manual

Guide D’utilisation

Manual de instrucciones

final page size: 8.5 x 5.5 in

DWFP2350

Pin Nailer

Cloueuse à tiges

Pistola de Clavos de Pasador

Page 2

ENGLISH

English (original instructions) 1

Français (traduction de la notice d’instructions originale) 9

Español (traducido de las instrucciones originales) 18

Page 3

ENGLISH

1

Definitions: Safety Alert Symbols and Words

This instruction manual uses the following safety alert symbols and words to alert you to hazardous situations and your risk

of personal injury or property damage.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or seriousinjury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or seriousinjury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderateinjury.

(Used without word) Indicates a safety related message.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in propertydamage.

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

seriousinjury.

WARNING: To reduce the risk of injury, read the

instructionmanual.

If you have any questions or comments about this or

any

DeWALT

tool, call us toll free at:

1-800-4-

DeWALT

(1-800-433-9258).

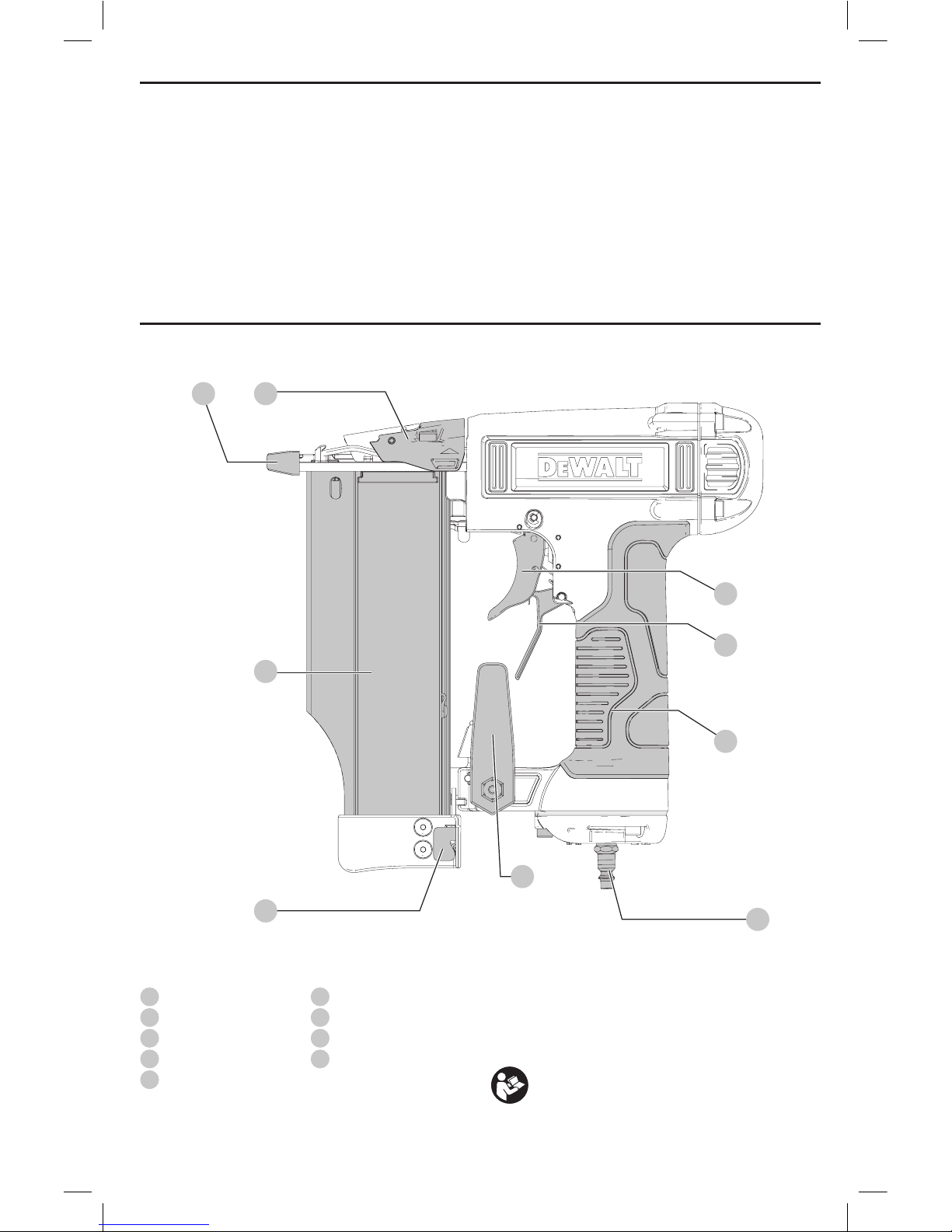

1

Handle

2

Primary trigger

3

Secondary trigger

4

1/4" male fitting

5

Magazine release lever

6

Magazine

7

Belt hook

8

Nose cover

9

No-mar tip

Fig. A

1

2

3

6

5

8

7

9

4

Page 4

ENGLISH

2

DeWALT

tools are precision-built tools, designed for precise,

high volume nailing. These tools will deliver efficient,

dependable service when used correctly and with care.

As with any fine power tool, for best performance the

manufacturer’s instructions must be followed. Please study

this manual before operating the tool and understand

the safety warnings and cautions. The instructions on

installation, operation and maintenance should be read

carefully, and the manual kept for reference.

NOTE: Additional safety measures may be required because

of your particular application of the tool. Contact your

DeWALT

representative or distributor with any questions

concerning the tool and its use.

DeWALT

, 701 E. Joppa Road, Towson, Maryland 21286,

U.S. & Canada Only, É.-U. et Canada seulement

DeWALT

tools have been engineered to provide excellent

customer satisfaction and are designed to achieve

maximum performance when used with precision

DeWALT

fasteners engineered to the same exactingstandards.

DeWALT

cannot assume responsibility for product

performance if our tools are used with fasteners or

accessories not meeting the specific requirements

established for genuine

DeWALT

nails, staples

andaccessories.

Safety Information

WARNING: ALWAYS use safety glasses. Everyday

eyeglasses are NOT safety glasses. Also use face or

dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETYEQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratoryprotection.

WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to the State

of California to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicalsare:

• lead from lead‑based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from

chemically‑treatedlumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are

specially designed to filter out microscopicparticles.

• Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and

wash exposed areas with soap and water. Allowing

dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmfulchemicals.

WARNING: Always wear proper personal hearing

protection that conforms to ANSI S12.6 (S3.19)

during use. Under some conditions and duration

of use, noise from this product may contribute to

hearingloss.

WARNING: (Air and Supply)

• Do not use oxygen, combustible gases, or bottled

gases as a power source for this tool as tool may

explode, possibly causinginjury.

• Do not use supply sources which can potentially

exceed 200p.s.i.g. (14kg/cm2) as tool may burst,

possibly causinginjury.

• The connector on the tool must not hold pressure

when air supply is disconnected. If a wrong fitting

is used, the tool can remain charged with air

after disconnecting and thus will be able to drive

a fastener even after the air line is disconnected

possibly causinginjury.

• Do not pull the primary or secondary trigger while

connected to the air supply as the tool may cycle,

possibly causinginjury.

• Always disconnect air supply: 1.) Before making

adjustments; 2.) When servicing the tool; 3.) When

clearing a jam; 4.) When tool is not in use; 5.) When

moving to a different work area, as accidental

actuation may occur, possibly causinginjury.

WARNING: When loading tool:

• Never place a hand or any part of body in pin

discharge area oftool.

• Never point tool atanyone.

• Do not pull the primary or secondary trigger

as accidental actuation may occur, possibly

causinginjury.

WARNING: When operating the tool:

• Always handle the tool with care:

- Never engage inhorseplay.

- Never pull the trigger unless nose is directed

toward thework.

- Keep others a safe distance from the tool while

tool is in operation as accidental actuation

may occur, possibly causinginjury.

• The operator must not hold the secondary trigger

pulled except during fastening operation as

serious injury could result if the tool accidentally

contacts someone or something, causing the tool

tocycle.

• Keep hands and body away from the discharge

area of the tool. The tool may bounce from the

recoil of driving a pin and an unwanted second

pin may be driven possibly causinginjury.

• Check operation of the secondary trigger

mechanism frequently. Do not use the tool if

the secondary trigger is not working correctly

as accidental driving of a pin may result. Do

not interfere with the proper operation of the

secondary triggermechanism.

• Do not drive pins on top of other pins or with the

tool at an overly steep angle as this may cause

deflection of fasteners which could causeinjury.

Page 5

ENGLISH

3

• Do not drive pins close to the edge of the work

piece as the wood may split, allowing the pin to

be deflected possibly causinginjury.

• This nailer produces SPARKS during operation.

NEVER use the nailer near flammable substances,

gases or vapors including lacquer, paint, benzine,

thinner, gasoline, adhesives, mastics, glues

or any other material that is ‑‑ or the vapors,

fumes or byproducts of which are ‑‑ flammable,

combustible or explosive. Using the nailer in any

such environment could cause an EXPLOSION

resulting in personal injury or death to user

andbystanders.

WARNING: When maintaining the tool:

• When working on air tools note the warnings in

this manual and use extra care when evaluating

problemtools.

Additional Safety Warnings

• Use the

DeWALT

pneumatic tool only for the purpose for

which it wasdesigned.

• Never use this tool in a manner that could cause a pin to

be directed toward the user or others in the workarea.

• Do not use the tool as ahammer.

• Always carry the tool by the handle with hand off both

triggers. Never carry the tool by the airhose.

• Do not alter or modify this tool from the original design or

function without approval from

DeWALT

.

• Always be aware that misuse and improper handling of

this tool can cause injury to yourself andothers.

• Never clamp or tape the trigger or secondary trigger in an

actuated position

• Never leave a tool unattended with the air hoseattached.

• Do not operate this tool if it does not contain a legible

WARNINGLABEL.

• Do not continue to use a tool that leaks air or does

not function properly. Notify your nearest

DeWALT

representative if your tool continues to experience

functionalproblems.

TO PREVENT ACCIDENTAL INJURIES:

• Never place a hand or any other part of the body in nail

discharge area of tool while the air supply isconnected.

• Never point the tool at anyoneelse.

• Never engage inhorseplay.

• Never actuate the tool unless nose is directed at thework.

• Always handle the tool withcare.

• Do not actuate the tool whileloading.

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

COMPONENTS (FIG. A)

WARNING: Never modify the power tool or any part

of it. Damage or personal injury couldresult.

Refer to Figure A at the beginning of this manual for a

complete list ofcomponents.

Intended Use

Your pin nailer is designed for professional

fasteningapplications.

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

Your pin nailer is a professional powertool.

DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use

thistool.

TOOL SPECIFICATIONS

Model DWFP2350

Length 9.2" (234 mm)

Height 8.75" (222 mm)

Width 2.33" (60 mm)

Weight 2.50 lbs (1.1 kg)

Tool Air Fitting

This tool uses a 1/4" N.P.T. male fitting. The inside diameter

should be .200" (5mm) or larger. The fitting must be

capable of discharging tool air pressure when disconnected

from the airsupply.

Operating Pressure

70 to 100p.s.i.g. (4.8 to 6.9kg/cm²). Select the operating

pressure within this range for best pin performance. DONOT

EXCEED THIS RECOMMENDED OPERATINGPRESSURE.

Air Consumption

The DWFP2350 requires 2.05 cubic feet per minute (58liters

per minute) of free air to operate at the rate of 50pins per

minute, at 80p.s.i.g. (5.6kg/cm²). Take the actual rate at

which the tool will be run to determine the amount of air

required. For instance, if your pin usage averages 30pins per

minute, you need 50% of the tool’s c.f.m. of free air which is

required to operate the tool at 100pins perminute.

PIN SPECIFICATIONS

Model DWFP2350

Pins DeWALT DWPN23xxx

PORTER-CABLE PPN23xxx, PN23PP

BOSTITCH PT-23xx-3M, BTPN23PP

Gauge 23

Pin range 5/8"–2" (15.8–50.8 mm)

Magazine capacity 135 nails plus lock-out quantity

Adjustments and Usage Prep

Air Supply and Connections

WARNING: Do not use oxygen, combustible

gases, or bottled gases as a power source for this

tool as tool may explode, possibly causinginjury.

Page 6

ENGLISH

4

Fittings

Install a male fitting on the tool which is free flowing

and which will release air pressure from the tool when

disconnected from the supplysource.

Hoses

Air hoses should have a minimum of 150 p.s.i.g.

(10.6kg/cm²) working pressure rating or 150 percent of

the maximum pressure that could be produced in the air

system. The supply hose should contain a fitting that will

provide “quick disconnecting” from the male fitting

4

on

thetool.

Supply Source

Use only clean regulated compressed air as a power source

for this tool. NEVER USE OXYGEN, COMBUSTIBLE GASES, OR

BOTTLED GASES, AS A POWER SOURCE FOR THIS TOOL AS

TOOL MAYEXPLODE.

Regulator

A pressure regulator with an operating pressure of

0–125p.s.i.g. (0–8.79 kg/cm²) is required to control the

operat iing pressure for safe operation of this tool. Do not

connect this tool to air pressure which can potentially

exceed 200 p.s.i.g. (14 kg/cm²) as tool may fracture or burst,

possibly causinginjury.

Operating Pressure

Do not exceed recommended maximum operating pressure

as tool wear will be greatly increased. The air supply must

be capable of maintaining the operating pressure at the

tool. Pressure drops in the air supply can reduce the tool’s

driving power. Refer to Tool Specifications for setting the

correct operating pressure for thetool.

Filter

Dirt and water in the air supply are major causes of

wear in pneumatic tools. A filter will help to get the best

performance and minimum wear from the tool. The

filter must have adequate flow capacity for the specific

installation. The filter has to be kept clean to be effective

in providing clean compressed air to the tool. Consult the

manufacturer’s instructions on proper maintenance of your

filter. A dirty and clogged filter will cause a pressure drop

which will reduce the tool’sperformance.

Oil Free Motor

The nailer is designed to be used without the need to add

any air tool oil and still deliver long life. If air tool oil is added

tool it will still functionproperly.

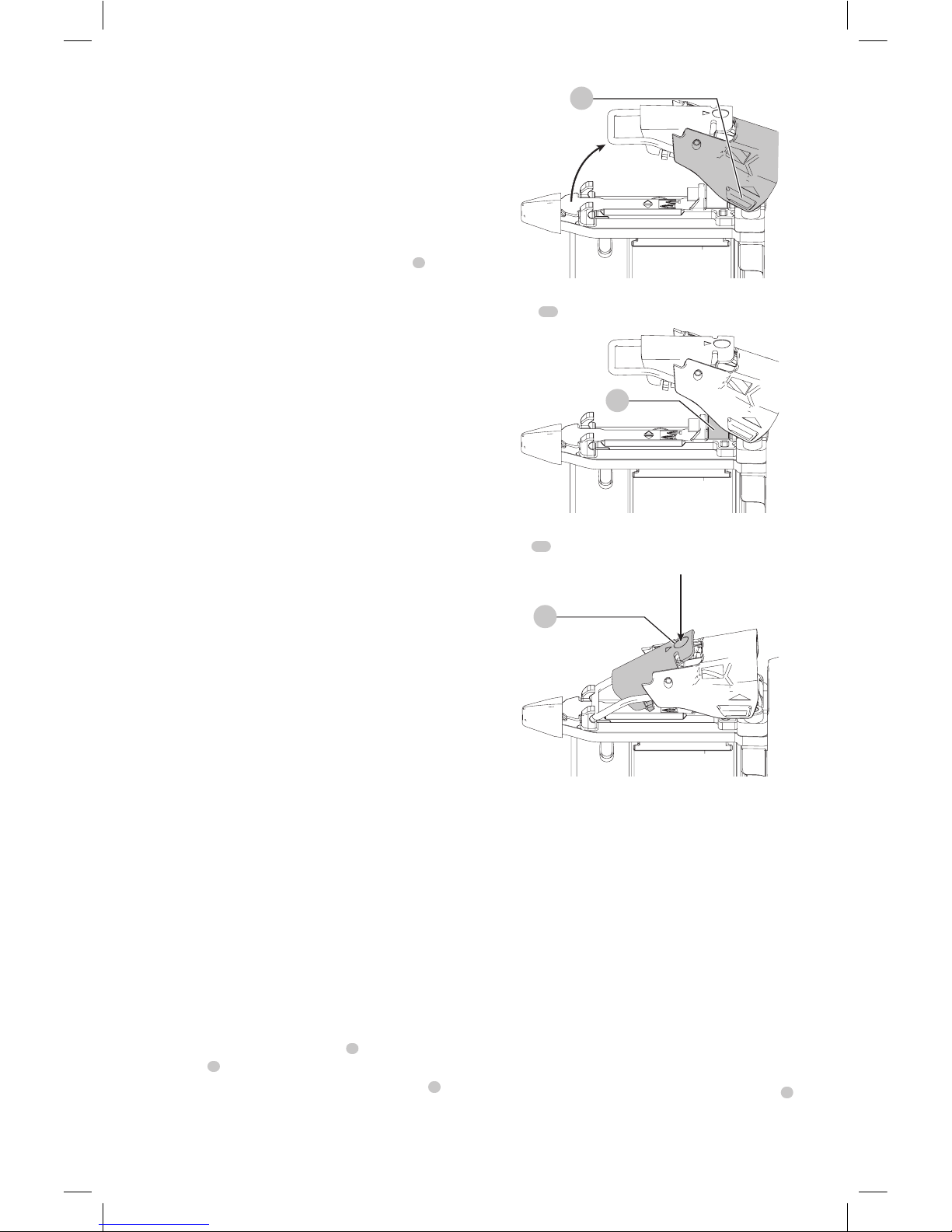

Tool-Free Depth Adjustment (Fig. A, B–D)

You pin nailer features tool-free depth adjustment for

adjusting the driving depth ofpins.

To Adjust the Depth

1. Disconnect the air supply from tool.

2. Depress the magazine release lever

5

and pull the

magazine

6

back to stop pinfeeding.

3. Grab the small tabs on each side of the nose cover

8

and pullup.

Fig. B

8

4. With the nose cover lifted, turn the depth adjustment

wheel

10

to adjust thedepth.

Fig. C

10

5. After adjusting to the desired depth, push the pinch

lever

11

down to lock the mechanism back to

operating position .

Fig. D

11

6. Close the magazine and reconnect the airsupply.

Low Pin Lock Out

The nailer is equipped with a low pin lock out which

prevents the tool from actuating when the magazine is

nearly empty. When approximately 10 to 12 pins remain in

the magazine, the tool ceases to operate. Refer to Loading

the Tool to reload a stick of collatedpins.

OPERATION

Proper Hand Position (Fig. E)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the handle

1

.

Page 7

ENGLISH

5

Fig. E

1

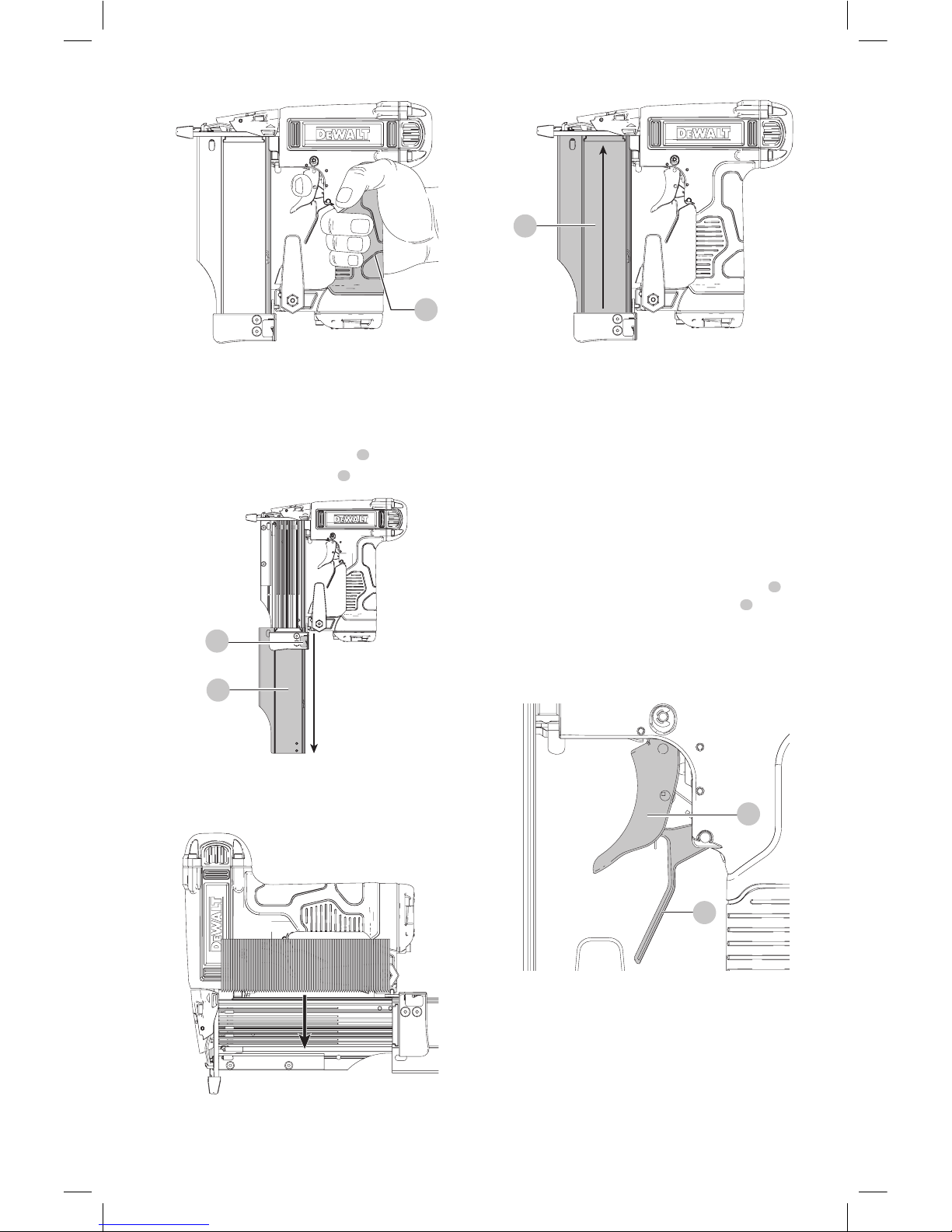

Loading the Tool (Fig. F–H)

NOTICE: Use only pins recommended for use in your

pin nailer which meet the

DeWALT

specifications.

Refer to PinSpecifications.

1. Depress the magazine release lever

5

.

2. Pull sliding portion of magazine

6

back.

Fig. F

5

6

3. Load the stick of pins with the arrow pattern pointing

down as shown. If pins have black dots instead of

arrows, the dots should be positionedup.

Fig. G

4. Close magazine until it latches. The tool is now ready

foruse.

Fig. H

6

Trigger Operation with a Secondary

Trigger (Fig. I)

WARNING: Never inadvertently pull or grasp the

secondary trigger when moving about, changing

work location, when holstering or hanging tool, or

when preparing work surface for fasteningoperation.

WARNING: The operator must not hold the secondary

trigger pulled except during fastening operation as

serious injury could result if the trigger accidentally

contacts someone or something, causing the tool

tocycle.

The tool will actuate each time the primary trigger

2

under

the valve is pulled until the secondary trigger

3

under the

hand grip is released. This trigger operated tool is operated

by first pulling or grasping the secondary trigger under the

hand grip, followed by pulling the primary trigger under the

valve as shown.

Fig. I

2

3

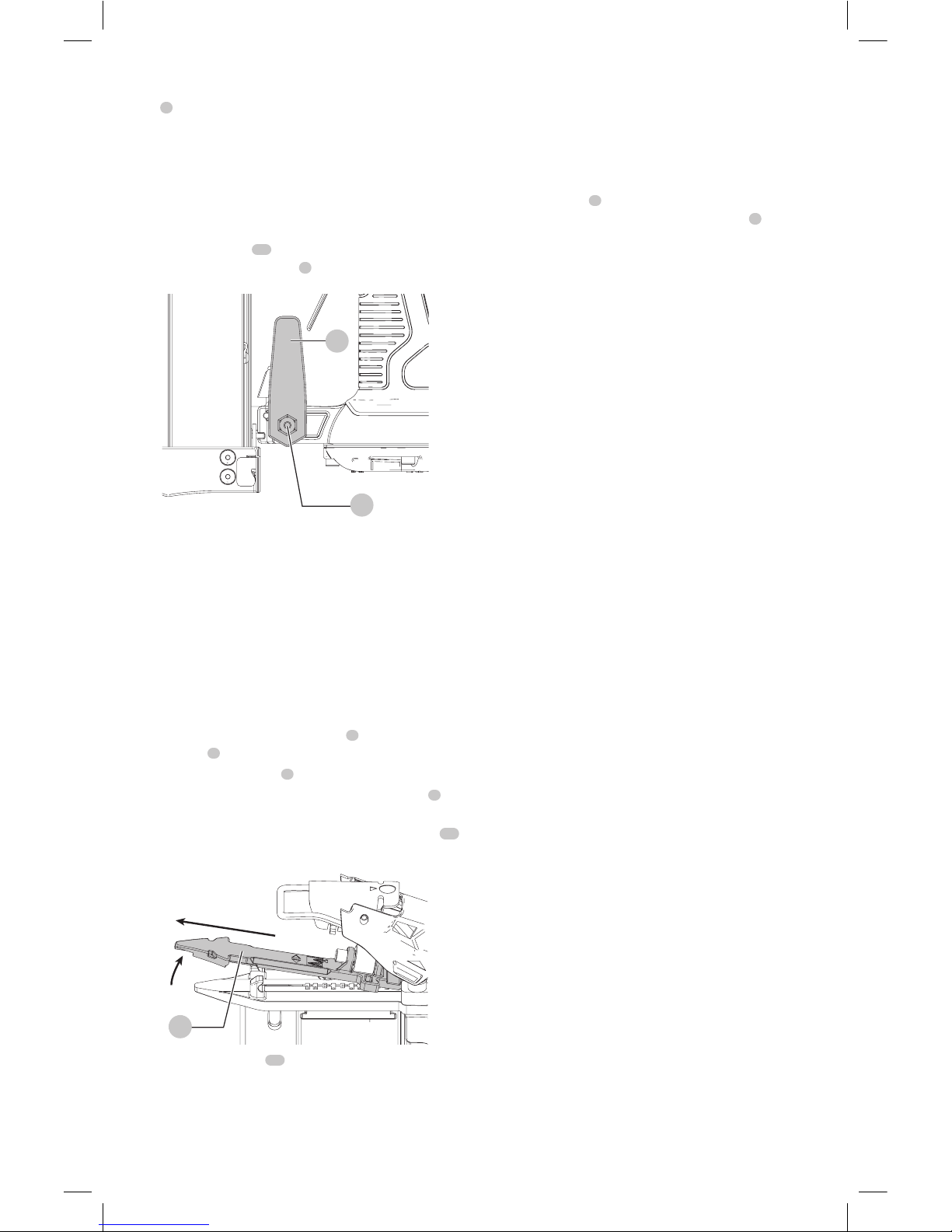

Belt Hook (Fig. J)

WARNING: Remove pins from magazine before

making any adjustments or servicing this tool. Failure

to do so may result in serious injury.

WARNING: Disconnect the air supply from tool before

making any adjustments, changing accessories,

servicing, or moving the tool. Such preventative

safety measures reduce the risk of actuating the

toolaccidentally.

Page 8

ENGLISH

6

Your

DeWALT

pin nailer includes an integrated belt

hook

7

and can be attached to either side of the tool to

accommodate left- or right-handed users.

If the belt hook is not desired at all, it can be removed from

thetool.

Removing and Reattaching the Belt Hook

1. Disconnect the air supply from tool.

2. To switch the tool from right- to left-hand usage simply

remove the screw

12

from the opposite side of the tool

and reattach the belt hook

7

on the other side.

Fig. J

7

12

MAINTENANCE

Tool-Free Jam Release (Fig. A, B, D, K)

WARNING: Always disconnect air supply before

clearing a jammedpin.

Your pin nailer features a tool-free jam release for clearing

jammedpins.

To Clear a Jammed Pin

1. Disconnect the air supply from thetool.

2. Depress the magazine release lever

5

and pull the

magazine

6

back to stop pinfeeding.

3. Remove the no-mar tip

9

.

4. Grab the small tabs on each side of the nose cover

8

and pull up as shown in FigureB.

5. With the nose cover lifted, slide the inner nose cover

13

forward and lift up to clear the jammedpin.

Fig. K

13

6. Push the pinch lever

11

down to lock the mechanism

back to operating position after the jam is cleared as

shown in FigureD.

7. Attach the no-martip.

8. Close the magazine and reconnect the airsupply.

Tool Operation Check (Fig. A)

WARNING: Remove all fasteners from tool before

performing tool operationcheck.

Trigger Operation with a Secondary

Trigger

The primary trigger

2

is located uder the trigger valve. It

can actuate the tool only if the secondary trigger

3

has

already been pulled.

The secondary trigger is located under the handle. The

secondary trigger prevents the primary trigger from

actuating the tool if the secondary trigger has not been

pulledfirst.

Place the nose of the tool against a work piece for all of the

following operationchecks.

1. With hand on rear end of the handle, further back away

from the secondary trigger, and not squeezing the

secondary trigger, use finger to pull the primarytrigger.

THE TOOL MUST NOTCYCLE.

2. With hand on handle, and squeezing the secondary

trigger, use finger to pull the primarytrigger.

THE TOOL MUSTCYCLE.

CAUTION: While the secondary trigger remains

squeezed, the tool will cycle each time the

primary trigger ispulled.

Accessories

WARNING: Since accessories, other than those

offered by

DeWALT

have not been tested with this

product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only

DeWALT

recommended accessories should be used with

thisproduct.

Recommended accessories for use with your tool are

available at extra cost from your local dealer or authorized

service center. If you need assistance in locating any

accessory, please contact

DeWALT

, call 1-800-4-

DeWALT

(1-800-433-9258).

Cleaning

WARNING: Blow dirt and dust out of all air vents with

clean, dry air at least once a week. To minimize the risk

of eye injury, always wear ANSI Z87.1 approved eye

protection when performingthis.

WARNING: Never use solvents or other harsh

chemicals for cleaning the non‑metallic parts of

the tool. These chemicals may weaken the plastic

materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid

get inside the tool; never immerse any part of the tool

into aliquid.

Repairs

WARNING: To assure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

should be performed by a

DeWALT

factory service

center or a

DeWALT

authorized service center. Always

use identical replacementparts.

Page 9

ENGLISH

7

Register Online

Thank you for your purchase. Register your product nowfor:

• WARRANTY SERVICE: Registering your product will

help you obtain more efficient warranty service in case

there is a problem with yourproduct.

• CONFIRMATION OF OWNERSHIP: In case of

an insurance loss, such as fire, flood or theft, your

registration of ownership will serve as your proof

ofpurchase.

• FOR YOUR SAFETY: Registering your product will

allow us to contact you in the unlikely event a safety

notification is required under the Federal Consumer

SafetyAct.

Register online at www.dewalt.com/support/

product-registration.

Three Year Limited Warranty

DeWALT

will repair, without charge, any defects due to

faulty materials or workmanship for three years from

the date of purchase. This warranty does not cover part

failure due to normal wear or tool abuse. For further detail

of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-

DeWALT

(1-800433-9258). This warranty does not apply to accessories

or damage caused where repairs have been made

or attempted by others. THIS LIMITED WARRANTY IS

GIVEN IN LIEU OF ALL OTHERS, INCLUDING THE IMPLIED

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, AND EXCLUDES ALL INCIDENTAL

OR CONSEQUENTIAL DAMAGES. Some states do not allow

limitations on how long an implied warranty lasts or the

exclusion or limitation of incidental or consequential

damages, so these limitations may not apply to you. This

warranty gives you specific legal rights and you may have

other rights which vary in certain states orprovinces.

In addition to the warranty,

DeWALT

tools are covered

byour:

1 YEAR FREE SERVICE

DeWALT

will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first year

afterpurchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of

your

DeWALT

Power Tool, Laser, or Nailer for any reason, you

can return it within 90 days from the date of purchase with

a receipt for a full refund – no questionsasked.

LATIN AMERICA: This warranty does not apply to products

sold in Latin America. For products sold in Latin America,

see country specific warranty information contained in

the packaging, call the local company or see website for

warrantyinformation.

FREE WARNING LABEL REPLACEMENT: If your warning

labels become illegible or are missing, call 1-800-4-

DeWALT

(1-800-433-9258) for a freereplacement.

Page 10

ENGLISH

8

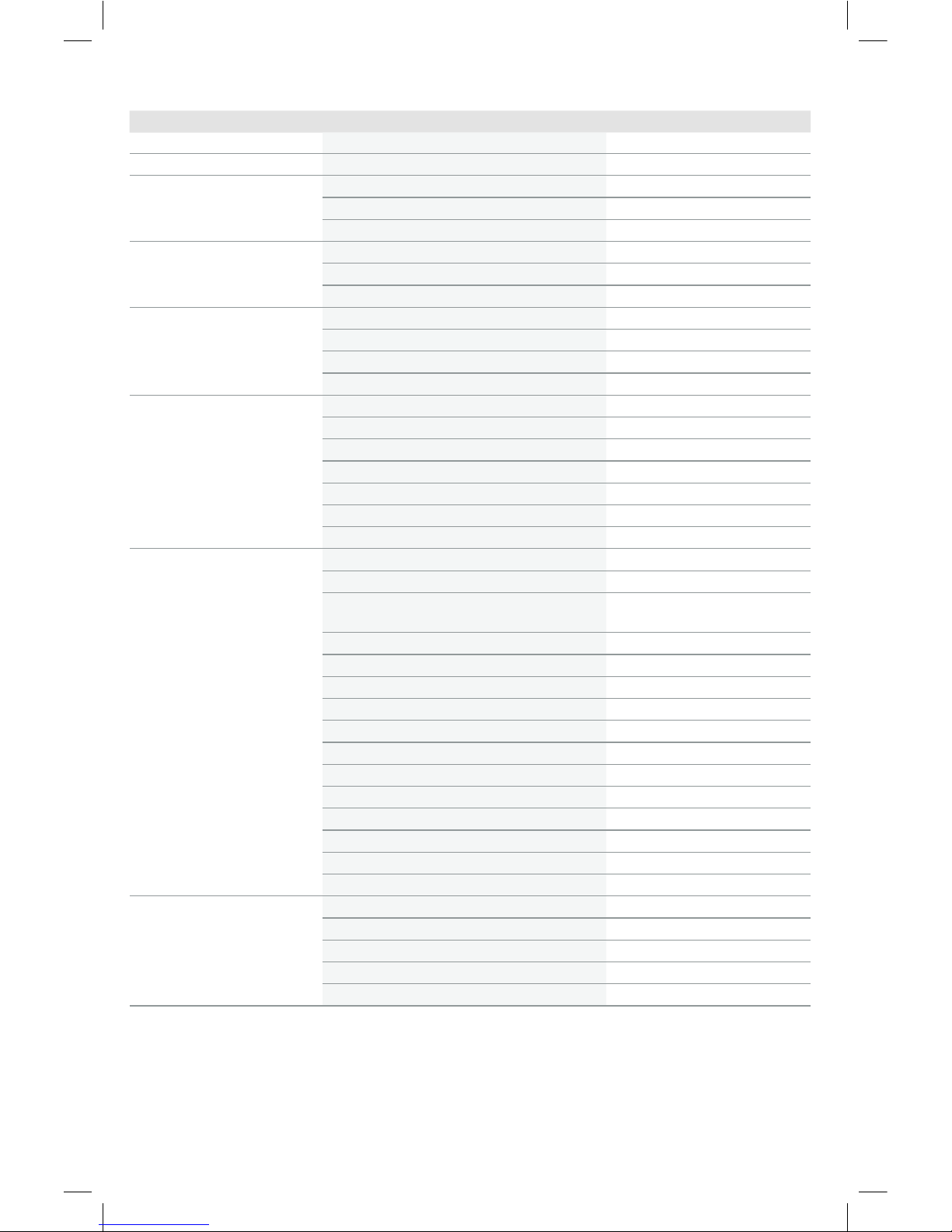

Troubleshooting

Problem Cause Correction

Trigger valve housing leaks air. O-ring cut or cracked. Replace O-ring.

Trigger valve stem leaks air. O-ring/seals cut or cracked. Replace trigger valve assembly.

Frame/nose leaks air. Loose nose screws. Tighten and recheck.

O-ring or Gasket is cut or cracked. Replace O-ring or gasket.

Bumper cracked/worn. Replace bumper.

Frame/cap leaks air. Damaged gasket or seal. Replace gasket or seal.

Cracked/worn head valve bumper. Replace bumper.

Loose cap screws. Tighten and recheck.

Failure to cycle. Air supply restriction. Check air supply equipment.

Worn head valve O-rings. Replace O-rings.

Broken cylinder cap spring. Replace cylinder cap spring.

Head valve stuck in cap. Disassemble/Check/Lubricate.

Lack of power; slow to cycle. Broken cylinder cap spring. Replace cap spring.

O-rings/seals cut or cracked. Replace O-rings/seals.

Exhaust blocked . Check bumper, head valve spring, muffler.

Trigger assembly worn/leaks. Replace trigger assembly.

Dirt/tar build up on driver. Disassemble nose/driver to clean.

Cylinder sleeve not seated correctlyon bottom bumper. Disassemble to correct.

Air pressure too low. Check air supply equipment.

Skipping pins; intermittent feed. Worn bumper. Replace bumper.

Tar/dirt in driver channel. Disassemble and clean nose and driver.

Air restriction/inadequate air flow through quick disconnect

socket and plug.

Replace quick disconnect fittings.

Worn piston O-ring. Replace O-ring, check driver.

Damaged pusher spring. Replace spring.

Low air pressure. Check air supply system to tool.

Loose magazine nose screws. Tighten all screws.

Pins too short for tool. Use only recommended pins.

Bent pins. Discontinue using these pins.

Wrong size pins. Use only recommended pins.

Leaking head cap gasket. Tighten screws/replace gasket.

Trigger valve O-ring cut/worn. Replace O-ring.

Broken/chipped driver. Replace driver (check piston O-ring).

Dirty magazine. Clean.

Worn magazine. Replace magazine.

Pins jam in tool. Driver channel worn. Replace nose/check door.

Wrong size pins. Use only recommended pins.

Bent pins. Discontinue using these pins.

Loose magazine/nose screws. Tighten all screws.

Broken/chipped driver. Replace driver.

Page 11

FRANÇAIS

9

Définitions : symboles et termes d'alarmes sécurité

Ces guides d'utilisation utilisent les symboles et termes d'alarmes sécurité suivants pour vous prévenir de situations

dangereuses et de risques de dommages corporels ou matériels.

DANGER: indique une situation dangereuse imminente qui, si elle n’est pas évitée, entraînera la mort ou des

blessuresgraves.

AVERTISSEMENT: indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner la

mort ou des blessuresgraves.

ATTENTION: indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner des

blessures légères oumodérées.

(Si utilisé sans aucun terme) Indique un message propre à la sécurité.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais qui par contre, si rien n’est fait

pour l’éviter, pourrait poser des risques de dommages matériels.

AVERTISSEMENT! lire tous les avertissements de

sécurité et toutes les directives. Le non‑respect

des avertissements et des directives pourrait se

solder par un choc électrique, un incendie et/ou une

blessuregrave.

AVERTISSEMENT : afin de réduire le risque de

blessures, lire le mode d’emploi del’outil.

Pour toute question ou remarque au sujet de cet outil

ou de tout autre outil

DeWALT

, composez le numéro

sans frais : 1-800-4-

DeWALT

(1-800-433-9258).

1

Poignée

2

Gâchette principale

3

Gâchette secondaire

4

Raccord mâle de 1/4 po

5

Levier de libération du

magasin

6

Chargeur

7

Agrafe pour courroie

8

Capuchon du nez

9

Extrémité antimarques

Fig. A

1

2

3

6

5

8

7

9

4

Page 12

FRANÇAIS

10

Les outils

DeWALT

sont des outils de précision conçus

pour un clouage exact et à haut rendement. Ils offrent

un service efficace et fiable lorsque utilisés correctement

et avec soin. Comme pour tout outil sophistiqué, il est

nécessaire de suivre les instructions du fabricant pour

obtenir de meilleures performances. Veuillez étudier ce

manuel avant la mise en fonction de l’outil, et vous assurer

d’avoir compris les avertissements et consignes de sécurité

inclus. Lisez avec précaution les instructions d’installation,

de fonctionnement et de maintenance; conservez le manuel

pour référenceultérieure.

REMARQUE : Des mesures de sécurité supplémentaires

peuvent être requises en fonction de votre utilisation

particulière de l’outil. Pour toute question concernant l’outil

et son utilisation, contactez votre

DeWALT

représentant

oudistributeur

DeWALT

, 701 E. Joppa Road, Towson, Maryland 21286, U.S.

& Canada Only, É.-U. et Canadaseulement

Les outils

DeWALT

ont été conçus et fabriqués pour offrir

une grande satisfaction de la clientèle et pour atteindre un

rendement maximal, lorsqu’utilisé avec des attaches de

précision

DeWALT

conçues et fabriquées pour répondre à

des normesidentiques.

DeWALT

ne garantit pas les performances de vos

outils s’ils sont utilisés avec des pièces de fixation

ou accessoires ne répondant pas aux exigences

strictes établies pour les clous, agrafes et accessoires

DeWALT

d’origine.

Consignes de sécurité

AVERTISSEMENT: porter SYSTEMATIQUEMENT

des lunettes de protection. Les lunettes courantes

NE sont PAS des lunettes de protection. Utiliser aussi

un masque antipoussières si la découpe doit en

produire beaucoup. PORTER SYSTÉMATIQUEMENT UN

ÉQUIPEMENT DE SÉCURITÉ HOMOLOGUÉ:

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3);

• Protection auditive ANSI S12.6 (S3.19);

• Protection des voies respiratoires NIOSH/OSHA/

MSHA.

AVERTISSEMENT: les scies, meules, ponceuses,

perceuses ou autres outils de construction peuvent

produire des poussières contenant des produits

chimiques reconnus par l’État californien pour causer

cancers, malformations congénitales ou être nocifs au

système reproducteur. Parmi ces produits chimiques,

on retrouve:

• Le plomb dans les peintures à base de plomb;

• La silice cristallisée dans les briques et le ciment,

ou autres produits de maçonnerie; et

• L’arsenic et le chrome dans le bois ayant subi un

traitementchimique.

Le risque associé à de telles expositions varie selon la

fréquence à laquelle on effectue ces travaux. Pour réduire

toute exposition à ces produits: travailler dans un endroit

bien aéré, en utilisant du matériel de sécurité homologué, tel

un masque antipoussières spécialement conçu pour filtrer les

particulesmicroscopiques.

• Limiter toute exposition prolongée avec les

poussières provenant du ponçage, sciage, meulage,

perçage ou toute autre activité de construction.

Porter des vêtements de protection et nettoyer à

l’eau savonneuse les parties du corps exposées. Le

fait de laisser la poussière pénétrer dans la bouche, les

yeux ou la peau peut favoriser l’absorption de produits

chimiquesdangereux.

AVERTISSEMENT: pendant l’utilisation, porter

systématiquement une protection auditive

individuelle adéquate homologuée ANSI S12.6

(S3.19). Sous certaines conditions et suivant la durée

d’utilisation, le bruit émanant de ce produit pourrait

contribuer à une perte de l’acuitéauditive.

AVERTISSEMENT: (air et Approvisionnement)

• N’utilisez pas d’oxygène, de gaz combustibles, ou

de gaz en bouteille comme source d’alimentation

pour cet outil car l’outil risque d’exploser, pouvant

provoquer des blessurescorporelles.

• N’utilisez pas de sources d’alimentation

pouvant excéder 14kg/cm2 (200 p.s.i.g.) car

l’outil risque d’exploser, pouvant provoquer des

blessurescorporelles.

• Le raccord sur l’outil ne doit pas maintenir

de pression quand l’alimentation en air est

déconnectée. Si un mauvais raccord est utilisé,

l’outil risque de rester chargé en air après avoir

été déconnecté et sera donc capable d’enfoncer

une fixation même après que la conduite d’air

ait été débranchée, pouvant provoquer des

blessurescorporelles.

• Ne pas appuyer sur la gâchette principale ou

secondaire pendant que l’outil est connecté à

l’alimentation de l’air puisqu’il peut s’enclencher,

causant possiblement uneblessure.

• Déconnectez toujours l’alimentation d’air:

1.) Avant d’effectuer des réglages; 2.) Lors de

l’entretien de l’outil; 3.) Lorsque vous dégagez

un bourrage; 4.) Lorsque l’outil n’est pas

utilisé; 5.) Lorsque vous vous déplacez vers une

autre zone de travail, car un actionnement

accidentel peut survenir, pouvant provoquer des

blessurescorporelles.

AVERTISSEMENT: lors du chargement de l’outil:

• Ne jamais placer une main ou toute autre partie

du corps dans la zone de sortie des tiges de l’outil.

• Ne pointez jamais l’outil en direction de quelqu’un.

• Ne pas appuyer sur la gâchette principale ou

secondaire puisqu’un déclenchement accidentel

peut se produire, causant possiblement

uneblessure.

AVERTISSEMENT: lorsque vous utilisez l'outil:

• Manipulez toujours l’outil avec précaution:

- Ne chahutez jamais avec l’outil.

- Ne pressez jamais la gâchette si le bec de

l’outil n’est pas dirigé vers l’ouvrage.

- Maintenez les autres à une distance

sécuritaire de l’outil pendant que l’outil est

en fonctionnement car l’outil risque de se

Page 13

FRANÇAIS

11

mettre en marche accidentellement, pouvant

provoquer des blessurescorporelles.

• L’utilisateur doit ne pas maintenir la gâchette

secondaire appuyée sauf durant la fixation

puisque cela pourrait causer une blessure grave

si l’outil entre accidentellement en contact

avec quelqu’un ou quelque chose, causant

l’enclenchement de l’outil.

• Gardez vos mains et votre corps à l’écart de la

zone de sortie de l’outil. L’outil peut rebondir en

raison du recul de l’enfoncement d’une tige et une

deuxième tige non désirée peut être possiblement

enfoncée causant uneblessure.

• Vérifiez régulièrement l’utilisation du mécanisme

de la gâchette secondaire. Ne pas utiliser l’outil

si la gâchette secondaire ne fonctionne pas bien

puisque cela peut entraîner le déclenchement

accidentel d’une tige. Ne pas nuire au

bon fonctionnement du mécanisme de la

gâchettesecondaire.

• Ne pas enfoncer des tiges au‑dessus d’autres tiges

ou avec l’outil à un angle beaucoup trop prononcé

puisque cela peut causer la déviation des fixations

qui pourrait causer une blessure.

• Ne pas enfoncer de tiges près du bord de la

pièce de travail puisque le bois peut fendre,

laissant la tige être possiblement déviée causant

uneblessure.

• Cette cloueuse produit des ÉTINCELLES pendant

son fonctionnement. N’utilisez JAMAIS la cloueuse

près de produits inflammables, de gaz ou de

vapeurs, y comprises vernis, peintures, le benzène,

le diluant, l’essence, les colles, les mastics, les glus

ou tout autre matériau ‑‑ y compris les vapeurs,

fumées ou sous‑produits ‑‑ inflammables,

combustibles ou explosifs. L’utilisation de

la cloueuse dans un tel environnement

peut provoquer une EXPLOSION ayant pour

conséquence des blessures corporelles ou le

décès de l’utilisateur et des personnes se trouvant

àproximité.

AVERTISSEMENT: entretien de l’outil:

• Lorsque vous travaillez sur des outils

pneumatiques prenez notes des avertissements

contenus dans le présent manuel et évaluez les

problèmes des outils avec le plus grandsoin.

Autres avertissements de sécurité

• N’utilisez l’outil pneumatique

DeWALT

que dans le but

pour lequel il a étéconçu.

• Ne jamais utiliser cet outil d’une manière qui pourrait

faire en sorte que la tige soit redirigée vers l’utilisateur ou

d’autres personnes dans l’aire detravail.

• N’utilisez pas l’outil en tant quemarteau.

• Portez toujours l’outil par la poignée. Ne portez jamais

l’outil par le flexiblepneumatique.

• N’altérez pas et ne modifiez pas cet outil par rapport à

sa conception ou fonction originelle sans l’approbation

de

DeWALT

.

• Rappelez‑vous qu’une mauvaise utilisation ou

manipulation de cet outil peut provoquer des blessures

pour vous‑même et lesautres.

• Avant d’utiliser cet outil, vérifiez que l’actionneur est

en position non‑actionnée. L’outil déconnecté de

l’alimentation d’air, appuyez sur l’actionneur et confirmez

qu’il revient en position non‑actionnée.

• Ne laissez jamais un outil seul avec le flexible

pneumatiqueraccordé.

• N’utilisez pas cet outil s’il ne contient pas une ÉTIQUETTE

D’AVERTISSEMENT lisible.

• Ne continuez pas à utiliser un outil qui fuit ou qui ne

fonctionne pas correctement. Avertissez votre représentant

DeWALT

le plus proche si votre outil continue de présenter

des problèmes defonctionnement.

POUR EMPÊCHER LES BLESSURES ACCIDENTELLES:

• Ne mettez jamais une main ou toute autre partie du

corps dans la zone de sortie des fixations de l’outil quand

l’alimentation en air estconnectée.

• Ne pointez jamais l’outil en direction de quelqu’un.

• Ne chahutez jamais avec l’outil.

• N’actionnez jamais l’outil si le bec n’est pas dirigé

versl’ouvrage.

• Manipulez toujours l’outil avecprécautions.

• N’actionnez pas l’outil pendant lechargement.

CONSERVER CES CONSIGNES POUR

UTILISATION ULTÉRIEURE

DESCRIPTION (FIG. A)

AVERTISSEMENT: ne jamais modifier l’outil

électrique ni aucun de ses composants, car il y a

risques de dommages corporels oumatériels.

Reportez-vous en FigureA au début de ce manuel pour

obtenir la liste complète descomposants.

Usage prévu

Votre cloueuse à tiges est conçue pour des

applicationsprofessionnelles.

NE PAS les utiliser en milieu ambiant humide ou en

présence de liquides ou de gazinflammables.

Votre cloueuse à tiges est un outil

pneumatiqueprofessionnel.

NE PAS le laisser à la portée des enfants. Une supervision

est nécessaire auprès de tout utilisateur nonexpérimenté.

SPÉCIFICATIONS DE L’OUTIL

Modèle DWFP2350

Longueur 234 mm (9,2 po)

Hauteur 222 mm (8,75 po)

Largeur 60 mm (2,33 po)

Poids 1,1 kg (2,50 lbs)

Page 14

FRANÇAIS

12

Raccord pneumatique de l’outil

Cette outil utilise un raccord mâle NPT 1/4 po. Le diamètre

interne doit être de 5mm (0,200 po) ou plus. Le raccord doit

être capable de libérer la pression pneumatique de l’outil

lorsqu’il est déconnecté de l’alimentation d’air.

Pression de service

4,8 à 6,9kg/cm² (70 à 100 p.s.i.g.). Sélectionnez la pression

de fonctionnement dans cette plage pour une meilleure

performance de l’axe. NE DÉPASSEZ PAS CETTE PRESSION

DE SERVICERECOMMANDÉE.

Consommation d’air

Le modèle DWFP2350 nécessite 58litres par minute

(2,05pieds cubes par minute) d’air libre pour fonctionner à

un rythme de 50 tiges par minutes à 5,6kg/cm² (80p.s.i.g).

Prenez le taux actuel auquel l’outil fonctionnera pour

déterminer la quantité d’air requise. Par exemple, si votre

utilisation des tiges s’établit en moyenne à 30 tiges par

minute, vous avez besoin de 50% du pi3/min d’air libre

de l’outil qui est requis pour utiliser l’outil à 100 tiges

parminute.

CARACTÉRISTIQUES DE TIGES

Modèle DWFP2350

Tiges DeWALT DWPN23xxx

PORTER-CABLE PPN23xxx, PN23PP

BOSTITCH PT-23xx-3M, BTPN23PP

Calibre 23

Gamme de tiges 15,8–50,8 mm (5/8 po–2 po)

Capacité du magasin 135 clous plus la quantité verrouillée

Ajustements et préparation de

l’utilisation

Connexions et alimentation de l’air

AVERTISSEMENT: n’utilisez pas d’oxygène,

de gaz combustibles, ou de gaz en bouteille

comme source d’alimentation pour cet outil car

l’outil risque d’exploser, pouvant provoquer des

blessurescorporelles.

Raccords

Installez un raccord mâle sur l’outil non obstrué et qui

évacue la pression d’air de l’outil lorsqu’il est déconnecté de

la source d’alimentation.

Flexibles

Les flexibles pneumatiques doivent avoir une pression de

service nominale minimale de 10,6kg/cm² (150 p.s.i.g.)

ou 150 pour cent de la pression maximale pouvant être

produite par le système. Le tuyau d’alimentation doit

comporter un raccord qui offre une «déconnexion rapide»

du connecteur mâle

4

sur l’outil.

Source d’alimentation

N’utilisez que de l’air comprimé régulé propre comme

source d’alimentation pour cet outil. N’UTILISEZ JAMAIS

D’OXYGÈNE, DE GAZ COMBUSTIBLES, OU DE GAZ EN

BOUTEILLE COMME SOURCE D’ALIMENTATION POUR CET

OUTIL CAR IL RISQUE D’EXPLOSER.

Régulateur

Un régulateur de pression avec une pression de service de

0–8,79kg/cm2 (0–125 p.s.i.g.) est requis pour contrôler la

pression de service pour une utilisation de l’outil en toute

sécurité. Ne connectez jamais cet outil à une pression

pneumatique pouvant dépasser 14kg/cm2 (200 p.s.i.g.) car

l’outil peut se fracturer ou exploser, pouvant provoquer des

blessurescorporelles.

Pression de service

Ne dépassez pas la pression de service maximale

recommandée car cela augmentera considérablement

l’usure de l’outil. L’alimentation d’air doit être capable

de maintenir la pression de service vers l’outil. Des

chutes de pression dans l’alimentation d’air peuvent

réduire la puissance d’expulsion de l’outil. Consultez les

Spécifications de l’outil pour régler la bonne pression de

service pour l’outil.

Filtre

Les impuretés et l’eau présentes dans l’alimentation

d’air sont des causes majeures de l’usure des outils

pneumatiques. Un filtre aide à obtenir les meilleures

performances et une usure minimale de l’outil. Le filtre doit

avoir une capacité de débit adéquate pour l’installation

spécifique. Le filtre doit être maintenu dans un bon état de

propreté pour fournir efficacement de l’air comprimé propre

à l’outil. Consultez les instructions du fabricant pour le bon

entretien de votre filtre. Un filtre sale et bouché provoque

une chute de pression qui aura pour effet de réduire les

performances de l’outil.

Moteur sans huile

La tige est conçue pour être utilisée sans avoir besoin

d’ajouter d’huile pour outils pneumatiques et offrir

quand même une longue durée de vie. Si de l’huile pour

outils pneumatiques est ajoutée à l’outil, il continuera de

bienfonctionner.

Ajustement de la profondeur sans outil

(Fig. A, B–D)

Votre cloueuse à tiges comprend un ajustement de la

profondeur sans outil pour ajuster la profondeur destiges.

Pour ajuster la profondeur

1. Déconnectez l’alimentation de l’air de l’outil.

2. Appuyez sur le levier de libération du magasin

5

et retirez le magasin

6

pour arrêter l’alimentation

destiges.

3. Saisissez les petites languettes de chaque côté du

capuchon du nez

8

ettirez.

Page 15

FRANÇAIS

13

Fig. B

8

4. Avec le capuchon du nez levé, tournez la roulette

d’ajustement de la profondeur

10

pour ajuster

laprofondeur.

Fig. C

10

5. Après avoir ajusté la profondeur désirée, poussez le

levier de pincement

11

vers le bas pour verrouillez le

mécanisme à la position defonctionnement.

Fig. D

11

6. Fermez le magasin et reconnectez l’alimentation de l’air.

Verrouillage lorsqu’il y a peu de tiges

La cloueuse est munie d’un verrouillage lorsqu’il y a peu

de tiges qui empêche l’outil de s’activer lorsque le magasin

est presque vide. Lorsqu’il reste environ 10 à 12 tiges

dans le magasin, l’outil cesse de fonctionner. Consultez

Chargement de l'outil pour recharger un bâton de

tigesregroupées.

UTILISATION

Position correcte des mains (Fig. E)

AVERTISSEMENT: pour réduire tout risque

de dommages corporels graves, adopter

SYSTÉMATIQUEMENT la position des mains illustrée.

AVERTISSEMENT: pour réduire tout risque

de dommages corporels graves, maintenir

SYSTÉMATIQUEMENT l’outil fermement pour

anticiper toute réactionsoudaine.

La position des mains adéquate nécessite une main sur la

poignée

1

.

Fig. E

1

Chargement de l'outil (Fig. F–H)

AVIS: utilisez seulement des tiges recommandées

pour l’utilisation dans votre cloueuse à tiges qui

correspondent aux caractéristiques

DeWALT

. Consultez

Caractéristiques detiges.

1. Appuyez sur le levier de libération du magasin

5

.

2. Tirez la section coulissante du magasin

6

vers l’arrière.

Fig. F

5

6

3. Chargez la barrette de goupilles la flèche pointant vers

le bas. Si les goupilles présentent des points noirs au lieu

de flèches, ces points doivent être orientés vers lehaut.

Fig. G

Page 16

FRANÇAIS

14

4. Fermez le magasin jusqu’à ce qu’il se verrouille. L’outil est

maintenant prêt à êtreutilisé.

Fig. H

6

Fonctionnement de la gâchette avec la

gâchette secondaire (Fig. I)

AVERTISSEMENT : n’appuyez jamais sur la gâchette

et ne la saisissez jamais par inadvertance alors que

vous bougez, changez de lieu de travail, lorsque vous

rangez l’outil dans son étui ou l’accrochez pour le

suspendre ou lorsque vous préparez une surface de

travail pour une opération de pose d’attaches.

AVERTISSEMENT : l’opérateur ne doit pas maintenir

la gâchette secondaire enfoncée sauf lors des

opérations de pose d’attaches puisque de graves

blessures peuvent être causées si la gâchette entrait

accidentellement en contact avec quelqu’un ou

quelque chose, ce qui pourrait actionner l’outil.

L’outil sera actionné chaque fois que la gâchette

principale

2

sous la soupape est appuyée jusqu’à ce que

la gâchette secondaire

3

sous la poignée de main soit

relâchée. Cet outil à gâchette est actionné en appuyant

sur ou en saisissant d’abord la gâchette secondaire sous

la poignée de main, puis en appuyant sur la gâchette

principale sous la soupape, tel qu’indiqué.

Fig. I

2

3

Agrafe pour courroie (Fig. J)

AVERTISSEMENT: retirez les tiges du magasin avant

de faire tout ajustement ou entretien de cet outil. Ne

pas le faire peut entraîner une blessure grave.

AVERTISSEMENT: déconnectez l’alimentation

de l’air de l’outil avant de faire tout ajustement,

changement d’accessoires, entretien ou déplacement

de l’outil. Ces mesures de sécurité préventives réduisent

le risque d’activation accidentelle de l’outil.

Votre cloueuse à tiges préventive inclut une agrafe pour

courroie

7

et peut être fixée d’un côté ou de l’autre

de l’outil pour accommoder les utilisateurs droitiers

ougauchers.

Si vous ne voulez pas du tout de l’agrafe pour courroie, vous

pouvez la retirer de l’outil.

Retirer et rattacher l’agrafe pour

courroie

1. Déconnectez l’alimentation de l’air de l’outil.

2. Pour changer de l’utilisation de droite ou de droite,

retirez simplement la vis

12

du côté opposé de l’outil et

rattachez l’agrafe pour courroie

7

de l’autre côté.

Fig. J

7

12

MAINTENANCE

Déblocage sans outil (Fig. A, B, D, K)

AVERTISSEMENT: déconnectez toujours

l’alimentation de l’airavant de retirer une

tigebloquée.

Votre cloueuse à tiges comprend un levier de déblocage

sans outil pour retirer les tigesbloquées.

Pour retirer une tige bloquée

1. Déconnectez l’alimentation de l’air de l’outil.

2. Appuyez sur le levier de libération du magasin

5

et retirez le magasin

6

pour arrêter l’alimentation

destiges.

3. Retirez l’extrémité antimarques

9

.

4. Saisissez les petites languettes de chaque côté du

capuchon du nez

8

et tirez comme illustré dans la

FigureB.

5. Avec le capuchon du nez levé, glissez le capuchon

du nez interne

13

vers l’avant et levez pour retirer la

tigebloquée.

Page 17

FRANÇAIS

15

Fig. K

13

6. Poussez le levier de pincement

11

vers le bas pour

verrouiller le mécanisme dans la position d’utilisation

une fois le blocage retiré comme illustré dans la

FigureD.

7. Fixez l’extrémitéantimarques.

8. Fermez le magasin et reconnectez l’alimentation de l’air.

Vérification du système de déclenchement

(Fig. A)

AVERTISSEMENT : retirer toutes les attaches

de fixation de l’outil avant de procéder à une

vérification du fonctionnement de celui-ci.

Fonctionnement de la gâchette avec la

gâchette secondaire

La gâchette principale

2

est située sous la soupape de la

gâchette. Elle ne peut qu’actionner l’outil seulement si la

gâchette secondaire

3

est déjà enfoncée.

La gâchette secondaire est située sous la poignée. La

gâchette secondaire empêche la gâchette principale

d’actionner l’outil si la gâchette secondaire n’a pas été

enfoncée aupréalable.

Placez le nez de pose de l’outil contre la surface de travail

pour toutes les vérifications d’utilisationsuivantes.

1. La main sur l’extrémité arrière de la poignée, loin de

la gâchette secondaire, et n’appuyant pas sur cette

même gâchette, enfoncez la gâchette principale avec

votredoigt.

L’OUTIL NE DOIT PAS EFFECTUER UN CYCLE.

2. La main sur la poignée, et tout en enfonçant la gâchette

secondaire, enfoncez la gâchette principale avec

votredoigt.

L’OUTIL DOIT EFFECTUER UN CYCLE.

ATTENTION : lorsque la gâchette secondaire reste

enfoncée, l’outil effectue un cycle à chaque fois

que la gâchette principale estenfoncée.

Accessoires

AVERTISSEMENT : puisque les accessoires autres

que ceux offerts par

DeWALT

n’ont pas été testés

avec ce produit, leur utilisation pourrait s’avérer

dangereuse. Pour réduire le risque de blessures, utiliser

exclusivement les accessoires

DeWALT

recommandés

avec le présentproduit.

Les accessoires recommandés pour cet outil sont vendus

séparément au centre de service de votre région. Pour

obtenir de l’aide concernant l’achat d’un accessoire,

communiquer avec

DeWALT

; composer le 1-800-4-

DeWALT

(1-800-433-9258).

Nettoyage

AVERTISSEMENT : enlever les saletés et la poussière

hors des évents au moyen d’air comprimé propre et

sec, au moins une fois par semaine. Pour minimiser

le risque de blessure aux yeux, toujours porter une

protection oculaire conforme à la norme ANSI Z87.1

lors dunettoyage.

AVERTISSEMENT : ne jamais utiliser de solvants ni

d’autres produits chimiques puissants pour nettoyer

les pièces non métalliques de l’outil. Ces produits

chimiques peuvent affaiblir les matériaux de plastique

utilisés dans ces pièces. Utiliser un chiffon humecté

uniquement d’eau et de savon doux. Ne jamais laisser

de liquide pénétrer dans l’outil et n’immerger aucune

partie de l’outil dans unliquide.

Réparations

AVERTISSEMENT : pour assurer la SÉCURITÉ et

la FIABILITÉ du produit, les réparations, l’entretien

et les réglages doivent être réalisés par un centre

de réparation en usine

DeWALT

ou un centre de

réparation agréé

DeWALT

. Toujours utiliser des pièces

de rechangeidentiques.

Registre en ligne

Merci pour votre achat. Enregistrez dès maintenant

votreprodui:

• RÉPARATIONS SOUS GARANTIE: cette carte remplie

vous permettra de vous prévaloir du service de

réparations sous garantie de façon plus efficace dans le

cas d’un probléme avec leproduit.

• CONFIRMATION DE PROPRIÉTÉ: en cas de perte

provoquée par un incendie, une inondation ou un vol,

cette preuve de propriété vous servira de preuve auprès

de votre compagnie d’assurances.

• SÉCURITÉ: l’enregistrement de votre produit

nous permettra de communiquer avec vous dans

l’éventualité peu probable de l’envoi d’un avis de

sécurité régi par la loi fédérale américaine de la

protection desconsommateurs.

Registre en ligne à www.dewalt.com/support/

product-registration.

Garantie limitée de trois ans

DeWALT

réparera, sans frais, tout produit défectueux

causé par un défaut de matériel ou de fabrication pour

une période de trois ans à compter de la date d’achat.

La présente garantie ne couvre pas les pièces dont la

défectuosité a été causée par une usure normale ou

l’usage abusif de l’outil. Pour obtenir de plus amples

renseignements sur les pièces ou les réparations couvertes

par la présente garantie, visiter le site www.dewalt.

com ou composer le 1 800 433-9258 (1 800 4-

DeWALT

).

CETTE GARANTIE LIMITÉE REMPLACE TOUTE AUTRE

GARANTIE, Y COMPRIS TOUTE GARANTIE IMPLICITE DE

QUALITÉ MARCHANDE OU DE CONFORMITÉ À DES FINS

PARTICULIÈRES, ET EXCLUT TOUT DOMMAGE ACCESSOIRE

OU INDIRECT. Certains états n’autorisent aucune limitation

Page 18

FRANÇAIS

16

quant à la durée d’une garantie implicite ni aucune

exclusion ou limitation de garantie contre tout préjudice

accessoire ou indirect, aussi il se peut que ces exclusions

ne vous soient pas applicables. Cette garantie confère des

droits légaux particuliers à l’acheteur, mais celui-ci pourrait

aussi bénéficier d’autres droits variant d’un territoire à

l’autre.

En plus de la présente garantie, les outils

DeWALT

sont

couverts par notre :

CONTRAT D’ENTRETIEN GRATUIT D’UNAN

DeWALT

entretiendra l’outil et remplacera les pièces usées

au cours d’une utilisation normale et ce, gratuitement,

pendant une période d’un an à compter de la date d’achat.

GARANTIE DE REMBOURSEMENT DE90JOURS

Si l’acheteur n’est pas entièrement satisfait, pour quelque

raison que ce soit, du rendement de l’outil électrique, du

laser ou de la cloueuse

DeWALT

, celui-ci peut le retourner,

accompagné d’un reçu, dans les 90 jours à compter de la

date d’achat pour obtenir un remboursement intégral, sans

aucunproblème.

AMÉRIQUE LATINE : cette garantie ne s’applique aux

produits vendus en Amérique latine. Pour ceux-ci, veuillez

consulter les informations relatives à la garantie spécifique

présente dans l’emballage, appeler l’entreprise locale ou

consulter le site Web pour les informations relatives à

cettegarantie.

REMPLACEMENT GRATUIT DES ÉTIQUETTES

D’AVERTISSEMENT : si les étiquettes d’avertissement

deviennent illisibles ou sont manquantes, composer le

1 800 433-9258 (1 800 4-

DeWALT

) pour en obtenir le

remplacementgratuit.

Page 19

FRANÇAIS

17

Dépannage

Problème Cause Correction

Fuite d’air dans le logement de la. Joint torique coupé ou fendu. Remplacez le joint torique vanne de gâchette.

Fuite d’air dans la tige de la. Joint torique/joints coupés ou fendus. Remplacez la vanne de gâchette vanne de gâchette.

Fuite d’air au châssis/bec. Vis du bec desserrées. Serrez et revérifiez.

Joint torique ou d’étanchéité coupé ou fendu. Remplacez le joint torique ou d’étanchéité.

Butoir fendu ou usé. Remplacez le butoir.

Fuite d’air au châssis/tête. Joint ou joint d’étanchéité endommagé. Remplacez le joint ou joint d’étanchéité.

Butoir de la soupape principale fendu ou usé. Remplacez le butoir.

Vis de la tête desserrées. Serrez et revérifiez.

Cycle non amorcé. Alimentation d’air restreinte. Vérifiez l’équipement de l’alimentation d’air.

Joints toriques de la soupape principale usés. Remplacez les joints toriques.

Ressort de la tête du cylindre cassé. Remplacez le ressort de la tête du cylindre.

Soupape principale coincée dans la tête. Démonter, vérifier, lubrifier.

Manque de puissance, l’outil

tourne au ralenti.

Ressort de la tête du cylindre cassé. Remplacez le ressort de la tête.

Joints toriques/joints coupés ou fendus. Remplacez les joints toriques/joints.

Échappement bouché . Vérifiez le butoir, le ressort de la soupape principale,

le silencieux.

Ensemble de gâchette usé/fuit. Remplacez l’ensemble de gâchette.

Crasse/goudron accumulée sur l’entraînement. Démontez le bec/entraînement pour les nettoyer.

Le manchon du cylindre n’est pas correctement

installé sur le butoir inférieur.

Démontez et corrigez.

Pression d’air trop basse. Vérifiez l’équipement de l’alimentation d’air.

Manques de tiges;

alimentation intermittente.

Butoir usé. Remplacez le butoi.

Goudron/crasse dans le canal d’entraînement. Démontez et nettoyez le bec et l’entraînement.

Air restreint/débit d’air inadéquat dans la douille et

la prise à déconnexion rapide.

Remplacez les raccords à déconnexion rapide.

Joint torique du piston usé. Remplacez le joint torique, vérifiez l’entraînement.

Ressort du pousseur endommagé. Remplacez le ressort.

Pression d’air basse. Vérifiez l’alimentation d’air vers l’outil.

Vis du bec du chargeur desserrées. Resserrez toutes les vis.

Les tiges sont trop courtes pour l’outil. Utilisez seulement les tiges recommandées.

Tiges pliées. Cessez d’utiliser ces tiges.

Mauvais formats de tiges. Utilisez seulement les tiges recommandées.

Fuite au joint d’étanchéité de tête. Serrez les vis; remplacez le joint d’étanchéité.

Joint torique de la vanne de la gâchette coupé/usé. Remplacez le joint torique.

Entraînement cassé/abîmé. Remplacez l’entraînement (vérifiez le joint torique du piston).

Chargeur sec. Nettoyez.

Chargeur usé. Remplacez le chargeur.

Blocage de tiges dans l’outil. Canal d’entraînement usé. Remplacez le bec/vérifiez la porte.

Mauvais formats de tiges. Utilisez seulement les tiges recommandées.

Tiges pliées. Cessez d’utiliser ces tiges.

Vis du bec/chargeur desserrées. Resserrez toutes les vis.

Entraînement cassé/abîmé. Remplacez l’entraînement.

Page 20

ESPAÑOL

18

¡ADVERTENCIA! Lea todas las advertencias de

seguridad e instrucciones. El incumplimiento

de las advertencias e instrucciones puede provocar

descargas eléctricas, incendios o lesionesgraves.

ADVERTENCIA: Para reducir el riesgo de lesiones, lea

el manual deinstrucciones.

Si tiene alguna duda o algún comentario sobre ésta

u otra herramienta

DeWALT

, llámenos al número

gratuito: 1-800-4-

DeWALT

(1-800-433-9258).

1

Manija

2

Gatillo principal

3

Gatillo secundario

4

Accesorio macho de 1/4"

5

Palanca de liberación de

cargador

6

Cartucho

7

Gancho de cinturón

8

Cubierta de punta

9

Punta que no causa

daños

Definiciones: Símbolos y Palabras de Alerta de Seguridad

Este manual de instrucciones utiliza los siguientes símbolos y palabras de alerta de seguridad para alertarle de situaciones

peligrosas y del riesgo de lesiones corporales o dañosmateriales.

PELIGRO: Indica una situación de peligro inminente que, si no se evita, provocará la muerte o lesionesgraves.

ADVERTENCIA: Indica una situación de peligro potencial que, si no se evita, podría provocar la muerte o

lesionesgraves.

ATENCIÓN: Indica una situación de peligro potencial que, si no se evita, posiblemente provocaría lesiones leves

omoderadas.

(Utilizado sin palabras) indica un mensaje de seguridadrelacionado.

AVISO: Se refiere a una práctica no relacionada a lesiones corporales que de no evitarse puede resultar en daños a

lapropiedad.

Fig. A

1

2

3

6

5

8

7

9

4

Page 21

ESPAÑOL

19

Las herramientas

DeWALT

son herramientas construidas

a precisión, diseñadas para clavar con exactitud un alto

volumen de clavos. Estas herramientas entregan un

servicio eficiente y fiable cuando se usan correctamente

y con cuidado. Al igual que con toda herramienta

automática de calidad, deben seguirse las instrucciones

del fabricante para obtener el óptimo rendimiento. Estudie

este manual antes de operar la herramienta y tome nota

de las advertencias y precauciones de seguridad. Deben

leerse en detalle las instrucciones sobre la instalación,

operación y mantenimiento, y debe conservarse el manual

parareferencia.

NOTA: Pueden necesitarse medidas adicionales de

seguridad según la aplicación particular de la herramienta.

Diríjase al representante o distribuidor de

DeWALT

si tiene

alguna pregunta referente a la herramienta y su uso.

DeWALT

, 701 E. Joppa Road, Towson, Maryland 21286,

EE.UU.

Las herramientas

DeWALT

han sido diseñadas para satisfacer

completamente al cliente y lograr el máximo desempeño

cuando se utilizan con sujetadores de precisión

DeWALT

construidos según los mismos estándaresexigentes.

DeWALT

no puede asumir responsabilidad alguna por

el desempeño del producto si nuestras herramientas

se utilizan con sujetadores o accesorios que no

cumplan con los requisitos específicos establecidos

para los clavos, grapas y accesorios originales

DeWALT

Información de Seguridad

ADVERTENCIA: Use SIEMPRE lentes de seguridad.

Los anteojos de diario NO SON lentes de seguridad.

Utilice además una cubrebocas o mascarilla antipolvo

si la operación de corte genera demasiado polvo.

SIEMPRE LLEVE EQUIPO DE SEGURIDADCERTIFICADO:

• protección ocular ANSI Z87.1 (CAN/CSA Z94.3),

• protección auditiva ANSI S12.6 (S3.19),

• protección respiratoria NIOSH/OSHA/MSHA.

ADVERTENCIA: Algunas partículas de polvo

generadas al lijar, serrar, esmerilar y taladrar con

herramientas eléctricas, así como al realizar otras

actividades de construcción, contienen químicos que

el Estado de California sabe que pueden producir

cáncer, defectos congénitos u otras afecciones

reproductivas. Ejemplos de estos químicosson:

• plomo de algunas pinturas en base a plomo,

• polvo de sílice proveniente de ladrillos y cemento y

otros productos de albañilería, y

• arsénico y cromo provenientes de madera

tratadaquímicamente.

Su riesgo de exposición a estos químicos varía, dependiendo

de la frecuencia con la cual realiza usted este tipo de trabajo.

Para reducir su exposición a estas sustancias químicas: trabaje

en una zona bien ventilada y llevando equipos de seguridad

aprobados, como mascarillas antipolvo especialmente

diseñadas para filtrar partículasmicroscópicas.

• Evite el contacto prolongado con polvo generado

por el lijado, aserrado, pulido, taladrado y otras

actividades de construcción. Vista ropas protectoras

y lave las áreas de la piel expuestas con agua y

jabón. Si permite que el polvo se introduzca en la boca u

ojos o quede sobre la piel, puede favorecer la absorción de

productos químicospeligrosos.

ADVERTENCIA: Siempre lleve la debida

protección auditiva personal en conformidad

con ANSI S12.6 (S3.19) durante el uso de esta

herramienta. Bajo algunas condiciones y duraciones

de uso, el ruido producido por este producto puede

contribuir a la pérdidaauditiva.

ADVERTENCIA: Suministro y conexiones de aire

• No use oxígeno, gases combustibles o gases

embotellados como fuente de energía para

esta herramienta, ya que ella puede explotar y

posiblemente causarlesiones.

• No use fuentes de suministro que posiblemente

puedan superar los 14 kg/cm2 (200 p.s.i.g.) ya que

la herramienta puede explotar, y posiblemente

causarlesiones.

• El conector de la herramienta no debe retener

presión cuando se desconecta el suministro

de gas. Si se usa un accesorio incorrecto, la

herramienta puede permanecer cargada con aire

después de la desconexión y así, podrá colocar un

remache incluso después de desconectar la línea

de aire, lo que producirá potencialeslesiones.

• No apriete el gatillo principal o secundario

mientras está conectado al suministro de aire,

ya que la herramienta puede realizar un ciclo y

causarlesiones.

• Siempre desconecte el suministro de aire: 1.)

Antes de realizar ajustes. 2.) Al realizar tareas

de servicio en la herramienta. 3.) Al liberar una

obstrucción. 4.) Cuando la herramienta no está

en uso. 5.) Al pasar a un área de trabajo diferente,

puede producirse el accionamiento accidental, y

posiblemente causar unalesión.

ADVERTENCIA: Al cargar la herramienta:

• Nunca coloque una mano o parte del cuerpo en el

área de descarga de pasador de laherramienta.

• Nunca apunte la herramienta a ningunapersona.

• No apriete el gatillo primario o secundario ya que

puede producirse una activación accidental, que

podría causar lesiones.

ADVERTENCIA: Al operar la herramienta:

• Siempre maneje la herramienta con cuidado:

- Nunca participe en juegos conella.

- Nunca presione el gatillo a menos que la nariz

apunte hacia eltrabajo.

- Mantenga a las demás personas a una

distancia segura de la herramienta mientras

está en funcionamiento, ya que puede

accionarse por accidente, y posiblemente

causarlesiones.

• El operador no debe sostener el gatillo secundario

apretado, excepto durante la operación de

fijación, ya que podría resultar en lesiones serias

si la herramienta hace contacto accidentalmente

Page 22

ESPAÑOL

20

con alguien o algo, haciendo que la herramienta

realice unciclo.

• Mantenga las manos y el cuerpo alejados del área

de descarga de la herramienta. La herramienta

puede rebotar por el retroceso de la inserción de

un pasador y un segundo pasador no deseado

puede insertarse, posiblemente causandolesiones.

• Verifique el funcionamiento del mecanismo de

disparo secundario con frecuencia. No use la

herramienta si el gatillo secundario no funciona

correctamente, ya que puede ocasionar la

inserción accidental de un pasador. No interfiera

con el funcionamiento correcto del mecanismo de

disparosecundario.

• No coloque los pasadores encima de otros

pasadores o con la herramienta en un ángulo

demasiado pronunciado ya que esto puede

provocar la desviación de los sujetadores, lo que

podría ocasionar lesiones.

• No coloque los pasadores cerca del borde de

la pieza de trabajo ya que la madera se puede

dividir, lo que permite que el pasador se desvíe y

posiblemente causelesiones.

• Esta clavadora produce CHISPAS durante el uso.

NUNCA use la clavadora cerca de sustancias

inflamables, gases o vapores como laca, pintura,

bencina, diluyente, gasolina, adhesivos, masilla,

pegamentos o cualquier otro material que sea,

o que sus vapores, humos o productos derivados

sean, inflamables, combustibles o explosivos.

Usar la clavadora en tal ambiente podría causar

una EXPLOSIÓN que resulte en lesiones físicas o la

muerte del usuario y personascercanas.

ADVERTENCIA: Mantenimiento de

laherramienta:

• Al trabajar con herramientas neumáticas, tenga

en cuenta las advertencias en este manual y tenga

precaución adicional al evaluar herramientas

conproblemas

Consigne de Sécurité Supplémentaire

• Use la herramienta neumática

DeWALT

solo para el

propósito que fuediseñada.

• Nunca use esta herramienta de una manera que pueda

causar que un pasador se dirija hacia el usuario u otras

personas en el área detrabajo.

• No use la herramienta comomartillo.

• Siempre transporte la herramienta por la manija. Nunca

transporte la herramienta por la manguera deaire.

• No altere ni modifique la herramienta del diseño o función

originales sin la aprobación previa de

DeWALT

.

• Siempre recuerde que el uso o la manipulación incorrectos

de esta herramienta pueden causarle lesiones a usted y a

otraspersonas.

• Antes de usar la herramienta, verifique que el accionador

se encuentre en posición no accionada. Con la

herramienta desconectada del suministro de aire, presione

el accionador y corrobore que vuelva a la posición de

noaccionamiento.

• Nunca deje la herramienta sin atención con la manguera

de aireconectada.

• No utilice esta herramienta si no contiene una ETIQUETA

DE ADVERTENCIAlegible.

• No continúe usando una herramienta con una fuga

de aire o que no funciona correctamente. Informe a su

representante de

DeWALT

más cercano si la herramienta

continúa experimentando problemasfuncionales.

PARA PREVENIR LESIONES ACCIDENTALES:

• Nunca coloque la mano ni otra parte del cuerpo en el área

de descarga de clavos de la herramienta mientras el aire

de suministro estáconectado.

• Nunca apunte la herramienta a otrapersona.

• Nunca participe en juegos conella.

• Nunca accione la herramienta a menos que la nariz esté

apuntando altrabajo.

• Siempre maneje la herramienta concuidado.

• No accione la herramienta mientras secarga.

GUARDE ESTAS INSTRUCCIONES PARA

VOLVER A CONSULTAR EN EL FUTURO

COMPONENTES (FIG. A)

ADVERTENCIA: Nunca modifique la herramienta

eléctrica, ni tampoco ninguna de sus piezas. Podría

producir lesiones corporales odaños.

Consulte la Figura A al principio de este manual para

obtener una lista completa de loscomponentes.

Uso Debido

Su pistola de clavos de pasador está diseñada para

aplicaciones de sujeciónprofesionales.

NO utilice la herramienta en condiciones de humedad o en

presencia de líquidos o gasesinflamables.

Su pistola de clavos de pasador es una herramienta

eléctricaprofesional.

NO permita que los niños toquen la herramienta. Si el

operador no tiene experiencia operando esta herramienta,

su uso deberá sersupervisado.

ESPECIFICACIONES DE LA

HERRAMIENTA

Modelo DWFP2350

Longitud 234 mm (9,2")

Altura 222 mm (8,75")

Ancho 60 mm (2,33")

Peso 1,1 kg (2,50 lbs)

Accesorio Neumático de la Herramienta

Esta herramienta usa un accesorio macho de 1/4" N.P.T.

El diámetro interno debe ser de 5mm(0,200") o más.

El accesorio debe poder descargar presión de aire de la

herramienta cuandose desconecta del suministro deaire.

Page 23

ESPAÑOL

21

Presión de Funcionamiento

4,8 a 6,9kg/cm² (70 a 100 p.s.i.g.). Seleccione la presión

de operación dentro de este rango para obtener el mejor

desempeño del sujetador. NO SUPERE ESTA PRESIÓN DE

FUNCIONAMIENTORECOMENDADA.

Consumo de Aire

La DWFP2350 requiere 58litros por minuto (2,05 pies

cúbicos por minuto) de aire libre para operar a una

velocidad de 50pasadores por minuto, a 5,6kg/cm²

(80p.s.i.g.). Tome la velocidad real a la que se operará la

herramienta para determinar la cantidad de aire requerida.

Por ejemplo, si el uso de su pasador promedia 30pasadores

por minuto, necesita 50% c.f.m. de aire libre de la

herramienta que se requiere para operar la herramienta a

100 pasadores porminuto.

ESPECIFICACIONES DE PASADOR

Modelo DWFP2350

Pasadores DeWALT DWPN23xxx

PORTER-CABLE PPN23xxx, PN23PP

BOSTITCH PT-23xx-3M, BTPN23PP

Calibre 23

Rango de pasador 15,8–50,8 mm (5/8"–2")

Capacidad de cargador 135 clavos más cantidad de bloqueo

Ajustes y Preparación de uso

Suministro de aire y conexiones

ADVERTENCIA: No use oxígeno, gases

combustibles o gases embotellados como fuente

de energía para esta herramienta, ya que ella

puede explotar y posiblemente causarlesiones.

Accesorios

Instale una conexión macho en la herramienta que tenga

flujo libre y que libere presión de aire de la herramienta

cuando se desconecte de la fuente desuministro.

Mangueras

Las mangueras de aire deben tener un mínimo de

10,6kg/cm2 (150p.s.i.g.) de clasificación de presión de

trabajo o 150 por ciento de la presión máxima que podría

producirse en el sistema neumático. La manguera de

suministro debe contener un accesorio que proporcione

"desconexión rápida" de la conexión macho

4

en

laherramienta.

Fuente de Suministro

Use solo aire comprimido regulado limpio como fuente de

alimentación de esta herramienta. NUNCA USE OXÍGENO,

GASES COMBUSTIBLES O GAS EMBOTELLADO COMO

FUENTE DE ALIMENTACIÓN PARA ESTA HERRAMIENTA, YA

QUE PUEDEEXPLOTAR.

Regulador

Se requiere un regulador de presión con una presión de

funcionamiento de 0–8,79 kg/cm2 (0–125 p.s.i.g.) para

controlar la presión de funcionamiento para la utilización

segura de esta herramienta. No conecte esta herramienta

a presión de aire que potencialmente podría exceder

los 14 kg/cm2 (200p.s.i.g.), ya que la herramienta puede

fracturarse o explotar, y posiblemente causarlesiones.

Presión de Funcionamiento

No exceda la presión máxima recomendada de

funcionamiento, ya que se aumentará significativamente el

desgaste de la herramienta. El suministro de aire debe poder

mantener la presión de funcionamiento en la herramienta.

Las caídas de presión en el suministro de aire pueden

reducir la potencia de accionamiento de la herramienta.

Consulte las Especificaciones de la Herramienta para

ajustar la presión correcta de funcionamiento para

laherramienta.

Filtro

El polvo y el agua en el suministro de aire son causas

importantes de desgaste en las herramientas neumáticas.

Un filtro ayudará a obtener el mejor rendimiento y

mínimo desgaste de la herramienta. El filtro debe tener

una capacidad adecuada de flujo para la instalación

específica. El filtro debe mantenerse limpio para ser

efectivo al proporcionar aire comprimido limpio a la

herramienta. Consulte las instrucciones del fabricante sobre

el mantenimiento apropiado de su filtro. Un filtro sucio

y obstruido causará una caída de presión que reducirá el

rendimiento de laherramienta.

Motor Libre de Aceite

La pistola de clavos está diseñada para ser utilizada sin la

necesidad de agregar aceite de herramienta neumática