Page 1

1

DW870,220/383823 5/3/02 1:29 PM Page 1

Page 2

DEWALT Industrial Tool Company, P.O. Box 158, 626 Hanover Pike, Hampstead, MD 21074 Printed in Korea (SEP97-1) Form No. 383823

DW870/DW870-220 Copyright © 1997

DW870,220/383823 5/3/02 1:29 PM Page 2

Page 3

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW870/DW870-220

14" (355 mm) Heavy Duty Chop Saw

Scie fendeuse de service intensif de 355 mm (14 po)

Cortadora de metales de 355 mm (14")

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

DW870,220/383823 5/3/02 1:29 PM Page 3

Page 4

4

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY DEWALT TOOL, CALL US TOLL FREE AT

1-800-4-DEWALT (1-800-433-9258).

IMPORTANT SAFETY INSTRUCTIONS

FOR ALL TOOLS

IMPORTANT: Please make certain that the person who is to

use this equipment carefully reads and understands these

instructions before starting operations.

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock,

and personal injury, including the following:

READ ALL INSTRUCTIONS

Important Safety Instructions

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches

invite injuries.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use

power tools in damp or wet locations, or expose them to rain.

Keep work area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept safe

distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

• DON’T FORCE TOOL. It will do the job better and safer at the

rate for which it was designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for

which it was not designed.

• USE PROPER EXTENSION CORD. Make sure your extension

cord is in good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The following table

shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage.

The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0- 6 18 16 16 14

6 - 10 18 16 14 12

10- 12 16 16 14 12

12- 16 14 12 Not Recommended

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves,

neckties, rings, bracelets, or other jewelry which may get caught

in moving parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair.

• ALWAYS USE SAFETY GLASSES. Also use face or dust mask

if cutting operation is dusty. Everyday eyeglasses only have

impact resistant lenses, they are not safety glasses.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

best and safest performance. Follow instructions for lubricating

and changing accessories.

• DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and the like.

DW870,220/383823 5/3/02 1:29 PM Page 4

Page 5

1

English

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make

sure switch is in off position before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction

manual for recommended accessories. The use of improper

accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool

is tipped or if the cutting tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function–check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don’t leave tool until it comes to a complete stop.

• REPLACEMENT PARTS. When servicing, use only identical

replacement parts.

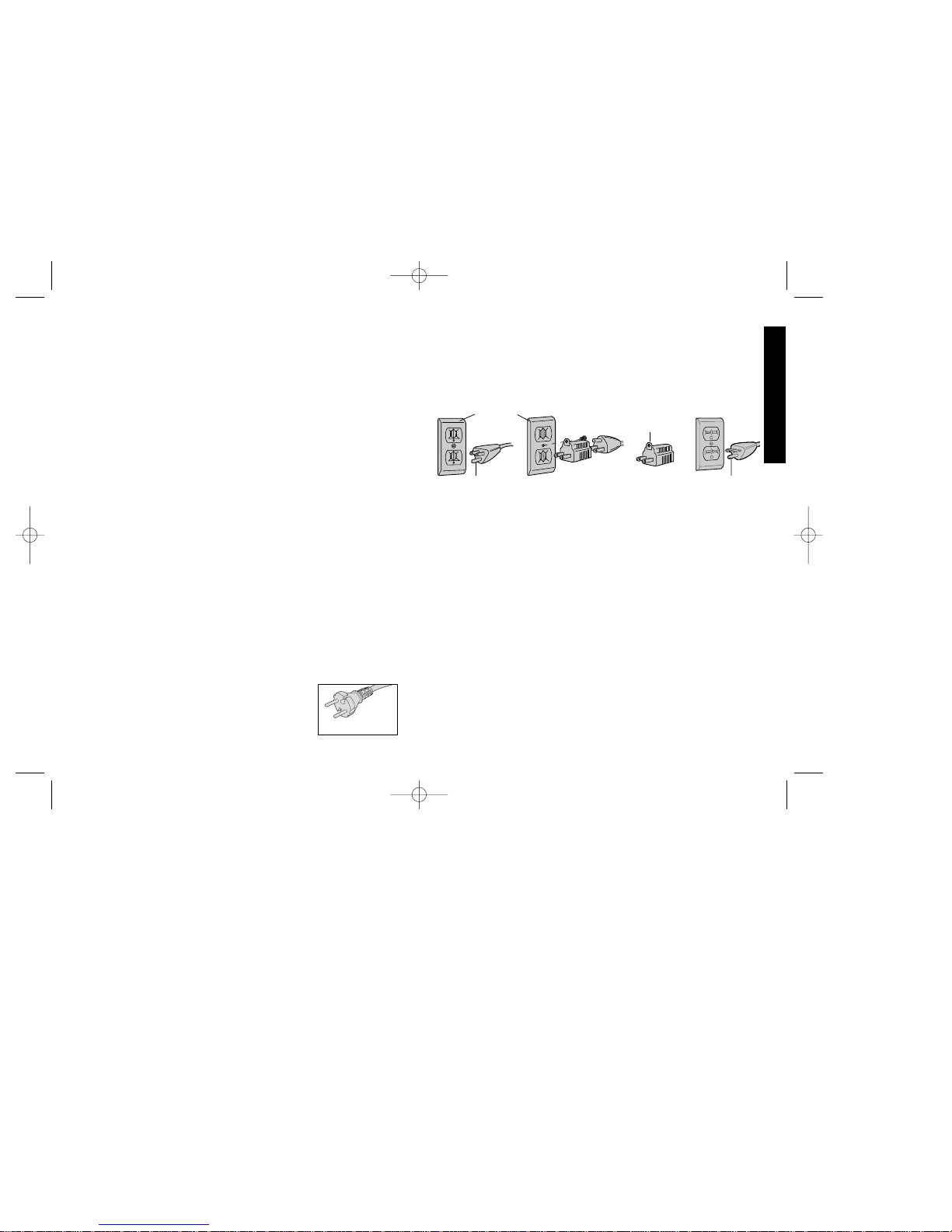

Grounding Instructions (DW870-220)

This tool should be grounded while in use to protect the operator

from electric shock. The tool is equipped with a

3-conductor cord and 3-prong grounding type plug to fit the proper

grounding type receptacle. The green (or green and yellow)

conductor in the cord is the grounding wire. Never connect the

green (or green and yellow) wire to a live terminal. If your unit is

intended for use on less than 150 V, it has a plug that looks like

that shown in sketch A. If it is for use on 150 to 250 V, it has a plug

that looks like that shown in sketch D. An adapter, sketches B and

C, is available for connecting sketch A type plugs

to 2-prong receptacles. The green-colored rigid

ear, lug, or the like, extending from the adapter

must be connected to a permanent ground, such

as a properly grounded outlet box. No adapter is

available for a plug as shown in sketch D. ADAPTER SHOWN IN

FIGURES B and C IS NOT FOR USE IN CANADA. Use only 3wire extension cords that have 3-prong grounding-type plugs and 3pole receptacles that accept the tool’s plug. Replace or repair

damaged cords.

Additional Safety Rules for Chop Saws

• Always wear safety goggles or other eye protection when using this

tool.

• Before using, inspect each cutting wheel for cracks or flaws. If a

crack or flaw is evident—discard the wheel! The wheel should also

be inspected whenever you think the tool may have been dropped.

• When starting the tool (with a new or replacement wheel installed)

place the tool in a well protected area. If the wheel has an

undetected crack or flaw, it should burst in less than one minute.

Never start the tool with a person in line with the wheel. This

includes the operator.

• In operation, avoid bouncing the wheel or giving it rough treatment.

If this occurs, stop the tool and inspect the wheel.

• Clean your chop saw periodically following the procedure in this

manual.

• Do not remove wheel guard.

• Always use the vise or special fixturing to clamp work.

• Use only wheels rated at 4100 rpm or higher.

• Allow cut off parts to cool before handling.

• Do not attempt to cut wood or plastic with this tool.

AB CD

GROUNDING PIN

GROUNDED

OUTLET

BOX

GROUNDING

MEANS

GROUNDING PIN

ADAPTER

220 VOLT PLUG

DW870,220/383823 5/3/02 1:29 PM Page 1

Page 6

2

English

• NEVER CUT MAGNESIUM WITH THIS TOOL.

• Use chop saw in a well-ventilated area.

• Turn chop saw off before removing any pieces from the base.

• DO NOT CUT ELECTRICALLY LIVE MATERIAL.

• NEVER USE A CIRCULAR SAW BLADE IN THIS CHOP SAW.

DO NOT USE TOOTHED BLADES.

• DO NOT OPERATE THIS TOOL NEAR FLAMMABLE LIQUIDS,

GASES OR DUST. Sparks from cutting or motor may ignite dust

and fumes.

SAVE THESE INSTRUCTIONS

Power Supply

Be sure your power supply agrees with the nameplate marking.

120 volts, “60 Hz” means alternating current (normal 120 volt, 60

Hz house current).

A voltage decrease of more than 10% will cause a loss of power and

overheating.

Switch

To start the tool, depress the trigger switch shown in Figure 1. To

turn the tool off, release the switch.

Features and Benefits

• AC/DC permits use with a DC power source such as a welder.

• Switch handle is human engineered for maximum convenience

when the saw is used on a bench, or on the floor.

• Lightweight, sure-grip carrying handle, and fold-down design

combine to make it easy to carry the machine from job to job.

• Rugged steel base with rubber padded feet provide durability

and vibration-free operation for stable cutting.

S

T

O

P

P

E

R

P

I

N

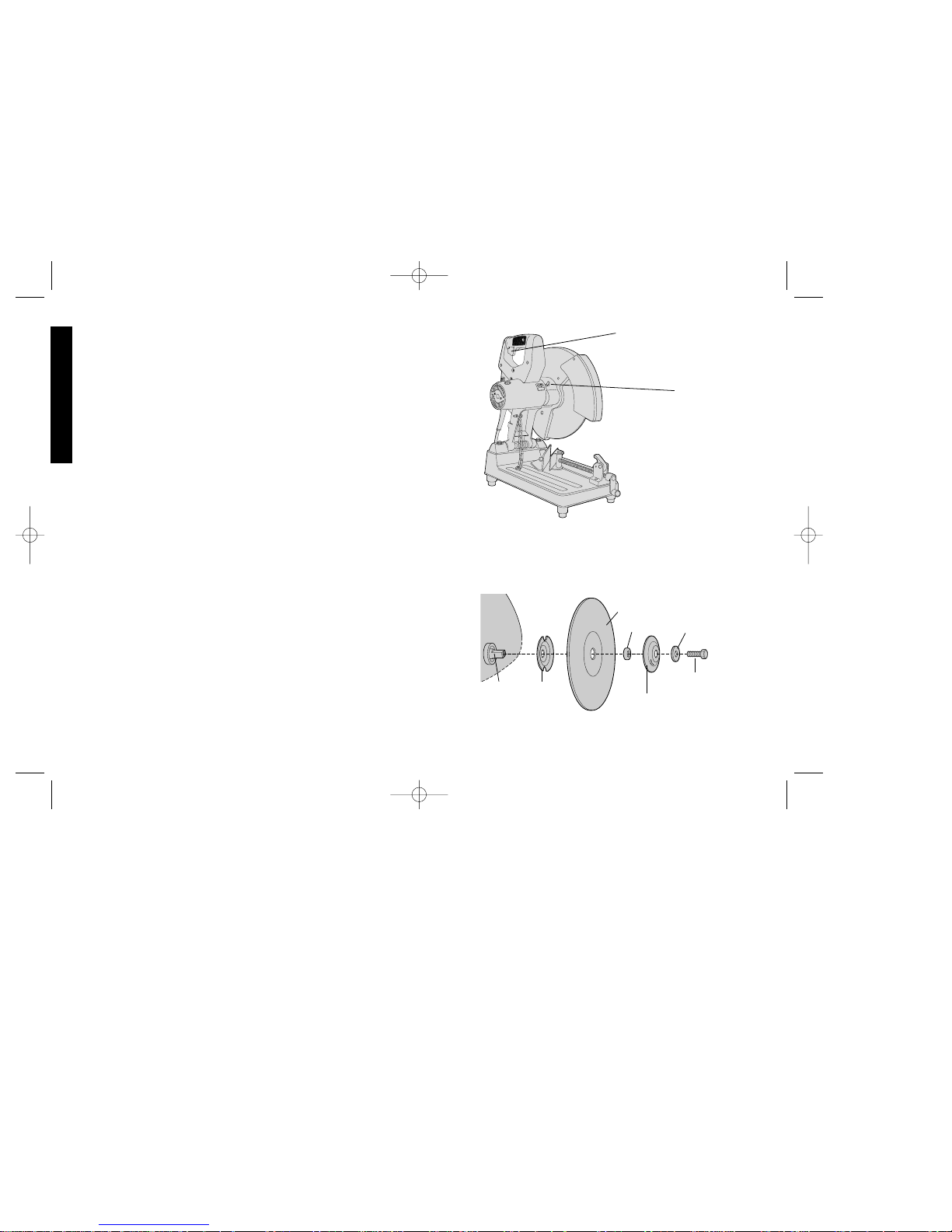

FIG. 1

TRIGGER SWITCH

BLADE LOCK

LEVER

FIG. 2

GEAR

SHAFT

FLANGE,

INSIDE

ABRASIVE WHEEL

ADAPTER

FLANGE, OUTSIDE

WASHER

HEX HEAD BOLT

DW870,220/383823 5/3/02 1:29 PM Page 2

Page 7

3

English

• Pivoting fence for convenience and accuracy in making miter

cuts. Right position graduations for 0°, 15°, 30° and 45°. Left

position graduations for 0°, 15° and 30°.

• Blade spindle lock simplifies and speeds blade changing.

• Blade/Fence wrench is conveniently stored in holder at rear of

base.

• Tough steel wheel guard protects operator from the wheel.

Spark guard in base minimizes escaping sparks and protects

surroundings.

• Heavy duty brush system extends brush life.

• High efficiency cooling fan and improved housing design assure

high airflow for cooler operation and long life.

• 8’ power supply cord with separate cord protector is convenient

and simplifies servicing.

• 100% ball and roller bearing construction for longer tool life.

Removal and Installation of Wheels

1. Be sure tool is disconnected from power supply.

2. Push in blade lock lever (Fig. 1) and rotate wheel by hand until

blade lock lever engages slot in inside flange to lock wheel.

Loosen the hex head bolt in the center of the abrasive wheel

with the wrench provided at rear of base. Bolt has right hand

thread.

3. Remove the bolt, washer, outside flange, adapter, and old

wheel (Fig. 2).

4. Install the new abrasive wheel by reversing the above steps.

Make sure adapter is on gear shaft and centered in wheel.

5. Do not overtighten bolt.

WARNING: Check the work surface that the chop saw rests on

when replacing with a new abrasive wheel. It is possible that the

wheel may contact the work surface (through the base) when the

arm is fully lowered.

DO NOT MAKE ANY ADJUSTMENTS WHILE WHEEL IS IN

MOTION. DO NOT MAKE ANY ADJUSTMENTS WHILE CHOP

SAW IS PLUGGED INTO POWER SUPPLY.

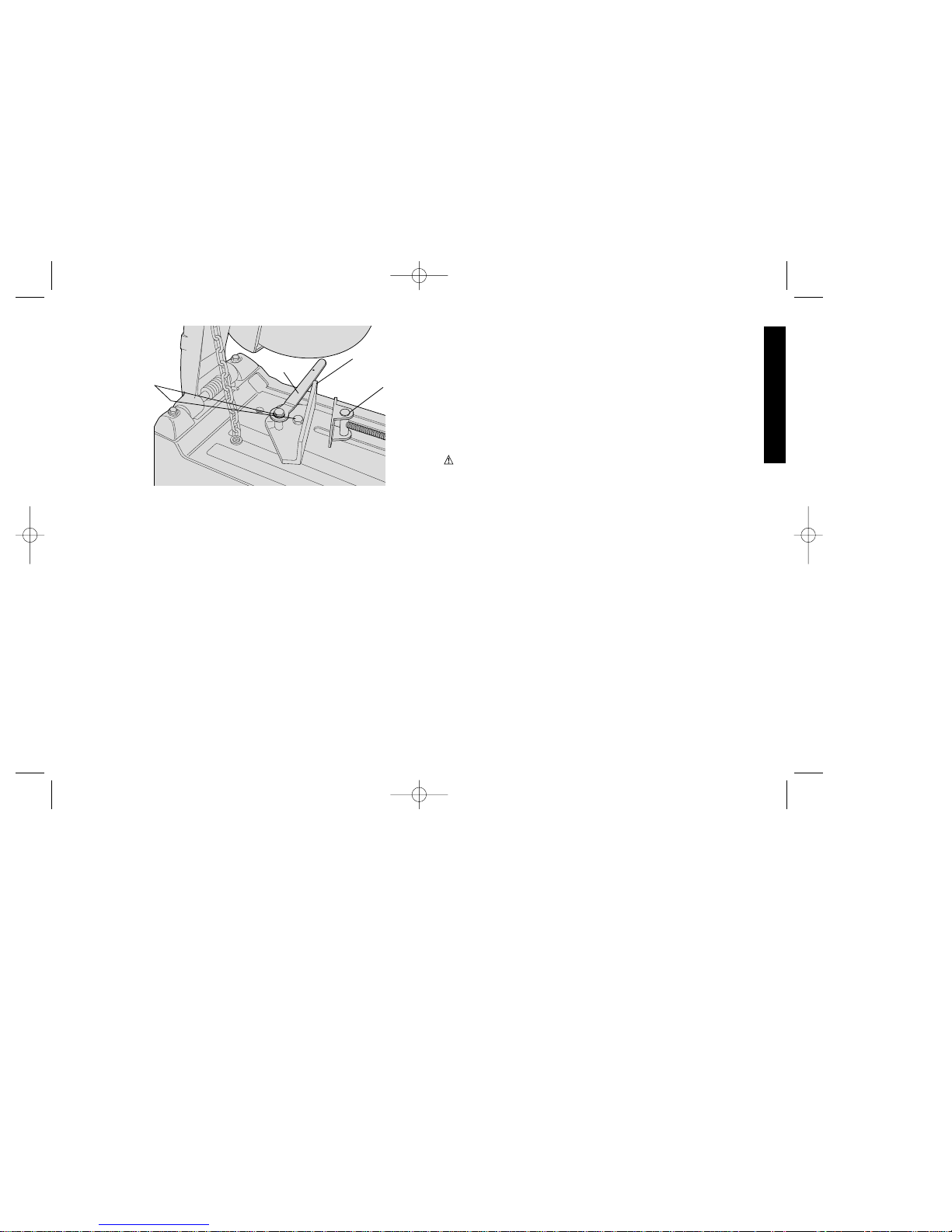

Quick Release Vise

Your saw features a quick release vise for greater convenience. To

release the vise, turn the crank handle a turn or two

counterclockwise to release the pressure on the vise jaw. With the

crank loose, lift the release lever on top of the moveable jaw, as

shown in Figure 3. Hold the lever up as you pull back on the crank

and open the jaws. When clamping an object, you need only to

push in the crank handle to the desired position. The moveable jaw

will slide freely until contact is made with the workpiece. Turn the

crank clockwise to clamp the workpiece in place.

To Adjust Vise Stop

CUTTING ANGLE

Use the wrench to loosen the two hex bolts (Fig. 3). (Do not

remove the bolts). The fence can be rotated in either direction.

Securely tighten both the bolts before use.

30

15

FIG. 3

WRENCH

FENCE

FENCE

BOLTS

VISE

DW870,220/383823 5/3/02 1:29 PM Page 3

Page 8

4

English

FIG. 4

30

15

1

5

0

4

5

30

FIG. 5

30

15

15

0

45

30

INDEX LINE

FIG. 6

FIG. 7

0.3"

7.62 mm

BRUSH

WEAR LINE

OPENING ADJUSTMENT

Remove both fence bolts. Move fence forward or backward to

desired location. Install both bolts. Tighten both bolts.

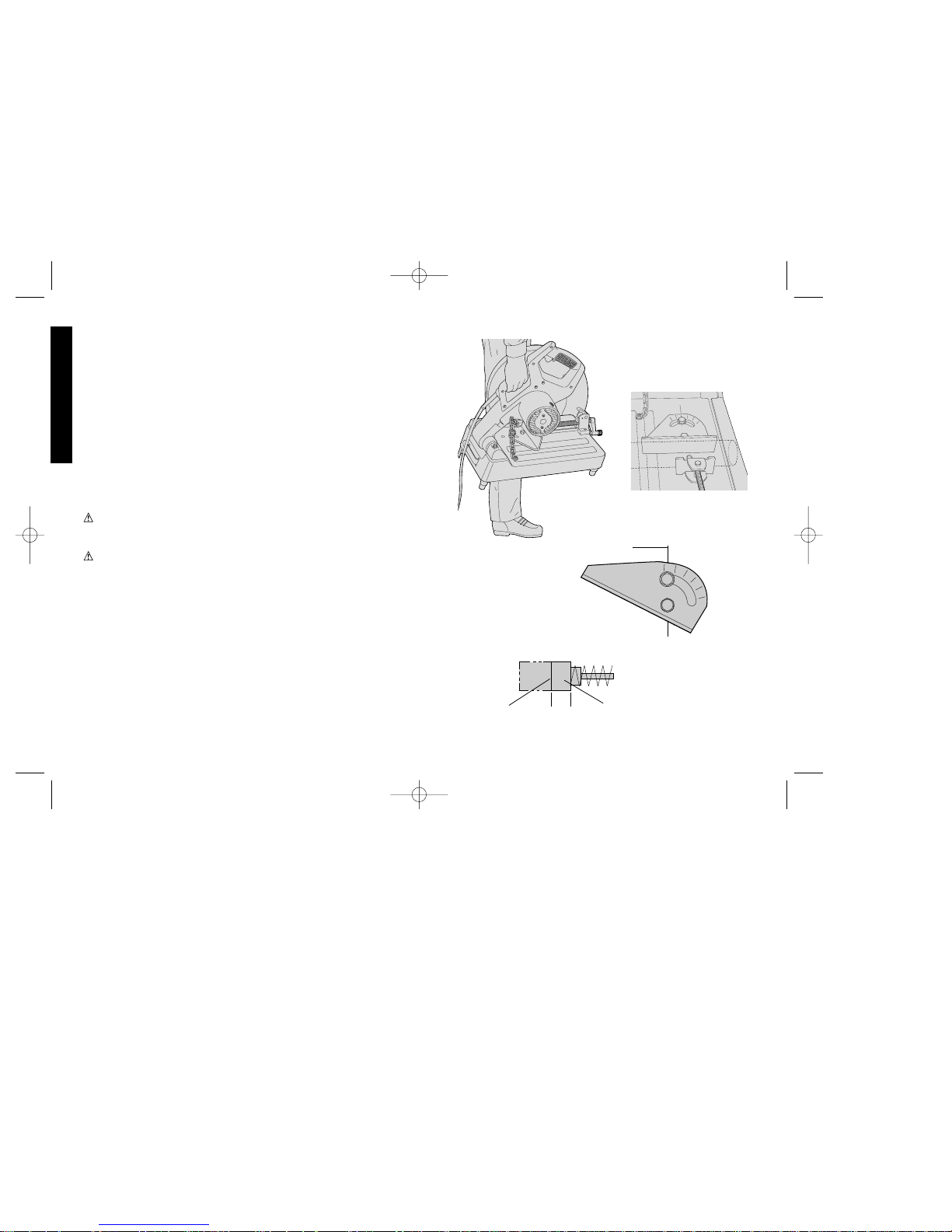

To Carry

Fold down unit to position where you can attach chain to pin on tool

arm (Fig. 4).

Cutting Capacity

The wide vise opening and high pivot point provide cutting capacity

for many large pieces. Use this chart to determine total maximum

size of cuts that can be made with a new wheel. Recommended

applications are: metal studs, electrical conduit up to 4" diameter,

bar stock and reinforcing bar up to 3/4" diameter.

NOTE: As cutting width increases, cutting height decreases.

CAUTION: CERTAIN LARGE , CIRCULAR OR IRREGULARLY SHAPED OBJECTS MAY REQUIRE ADDITIONAL

HOLDING MEANS.

CAUTION: DO NOT CUT MAGNESIUM WITH THIS TOOL.

Maximum Cutting Depth

To obtain maximum cutting depth, move the fence to the rear

position (Fig. 5).

NOTE: A new wheel, when pushed all the way down, will extend

below the base and cut into the work surface.

Degree Setting

Align the index line stamped in the base with the appropriate

degree for the desired angle of cut (Fig. 6). For very accurate cuts,

use a protractor.

DW870,220/383823 5/3/02 1:29 PM Page 4

Page 9

5

English

Maintenance of Tool

Lubrication

Closed-type, grease-sealed ball bearings are used throughout.

These bearings have sufficient lubrication packed in them at the

factory to last the life of the bearing.

Gears should be relubricated every 60 to 90 days, depending upon

use. This lubrication should only be attempted by experienced

power tool repairmen like the mechanics at D

EWALT certified

service centers. (See “Tools, Electric in yellow pages.) The gear

case should be wiped clean and 3/4 oz. (20 grams) of grease

placed in the gear case.

Cleaning

Blowing dust and grit out of the main housing by means of an air

hose is recommended and may be done as often as dirt is seen

collecting in and around the air vents.

Motor Brushes (Fig. 7)

Be sure tool is unplugged before inspecting brushes. Brushes

should be regularly inspected for wear. To inspect brushes,

unscrew the plastic brush caps (located in the sides of the motor

housing) and the spring and brush assemblies may be removed

from the tool. Keep brushes clean and sliding freely in their

guides. When the brushes wear to the point that the wear line

shown in Fig. 7 is even with the end of the brush holder, the

brush/spring assemblies (both) should be replaced.

Mounting Methods

To improve stability during use, the saw should be firmly mounted

as described below. To enhance the tool’s portability, it can be

bolted to a piece of 1/2" or thicker plywood which can be clamped

to a suitable horizontal work surface.

16-3/8"

(416 mm)

8-1/2"

(216 mm)

FIG. 8

S

T

O

P

P

E

R

P

I

N

FIG. 9

20"

2"-3"

NAIL

4"

NOTE: CAPACITY SHOWN ON THE FOLLOWING CHART

ASSUMES NO WHEEL WEAR.

FENCE AT FORWARD

POSITION

FENCE AT REAR

POSITION

6”

5”

4”

3”

2”

1”

0” 1” 2” 3” 4” 5” 6” 7” 8” 9”

4.75”

3.93”

6.25” 7.75”

HEIGHT

WIDTH

DW870,220/383823 5/3/02 1:29 PM Page 5

Page 10

6

English

manual. The use of any other accessory or attachment may be

hazardous. Use only D

EWALT 14", 4100 RPM saw blades.

ALWAYS WEAR SAFETY GLASSES. SECURE WORK IN VISE.

DISCONNECT TOOL FROM POWER SUPPLY BEFORE

CHANGING WHEEL.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year

from date of purchase. We will repair, without charge, any defects

due to faulty materials or workmanship. Arrangements have been

made with the Industrial Tool Division of Black & Decker (U.S.)

Inc. to provide warranty repairs for D

EWALT tools. Please return

the complete unit, transportation prepaid, to any Black & Decker

(U.S.) Inc. Industrial service center or authorized service station

listed under “Tools, Electric” in the yellow pages. This warranty

does not apply to accessories or damage caused where repairs

have been made or attempted by others. This warranty gives you

specific legal rights and you may have other rights which vary

from state to state.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT heavy duty industrial tool, simply return it to the

participating seller within 30 days for a full refund. Please return the

complete unit, transportation prepaid. Proof of purchase may be

required.

Procedure For Permanent Mounting

1. Drill four holes, 5/16" diameter minimum, through the work

surface (Fig. 8).

2. Remove screws from feet.

3. Insert 1/4-20 screws through underside of work surface, through

feet, into holes in tool base. The proper screw length is equal to

the thickness of the work surface plus 1 inch

(25 mm).

Cradle Mounting (Fig. 9)

1. Cut two boards 20" long x 2" - 3" high x 4" wide.

2. Place chop saw at desired work location.

3. Place boards tightly along side, and nail to work surface

(Fig. 9).

Important!

To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment (including brush inspection and

replacement) should be performed by authorized service centers or

other qualified service organizations, always using identical

replacement parts.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. A

complete listing of service centers is located at the end of this

manual If you need assistance in locating any accessory for your

tool, please contact your local dealer or authorized service center.

CAUTION: The use of any other accessory not recommended

for use with this tool could be hazardous.

CAUTION: Recommended saw blades for your saw are in this

DW870,220/383823 5/3/02 1:29 PM Page 6

Page 11

7

Français

Importantes mesures de sécurité pour

tous les outils

IMPORTANT : S’assurer que l’utilisateur lit attentivement et

comprend bien les mesures de sécurité avant de se servir l’outil.

AVERTISSEMENT : Afin de réduire les risques d'incendie, de

secousses électriques ou de blessures lorsqu'on utilise des outils

électriques, il faut toujours respecter les mesures de sécurité

suivantes.

LIRE TOUTES LES DIRECTIVES.

Importantes mesures de sécurité

• MAINTENIR LES PROTECTEURS EN PLACE et en bon état.

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l'habitude de

vérifier si les clés de réglage ont été retirées avant de faire

démarrer l'outil.

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s'en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l'écart de l'aire de travail.

• S'ASSURER QUE L'ATELIER EST À L'ÉPREUVE DES

ENFANTS. Utiliser des cadenas, un interrupteur principal et

retirer les clés servant au démarrage.

• NE JAMAIS FORCER L'OUTIL. Afin d'obtenir un rendement sûr

et efficace, utiliser l'outil à son rendement nominal.

• UTILISER L'OUTIL APPROPRIÉ. Ne jamais exiger d'un petit

outil ou d'un accessoire le rendement d'un outil de fabrication plus

robuste.

• CORDONS DE RALLONGE. S'assurer que le cordon de rallonge

est en bon état. Lorsqu'on se sert d'un cordon de rallonge,

s'assurer qu'il est de calibre approprié pour la tension nécessaire

au fonctionnement de l'outil. L'utilisation d'un cordon de calibre

inférieur occasionne une baisse de tension entraînant une perte

de puissance et la surchauffe. Le tableau suivant indique le

calibre approprié selon la longueur du cordon et les mentions de

la plaque signalétique de l'outil. En cas de doute, utiliser un

cordon de calibre supérieur. Le chiffre indiquant le calibre est

inversement proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

TensionLongueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0- 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples, des gants, des cravates, des bagues, des

bracelets et d'autres bijoux qui peuvent être happés par les pièces

en mouvement. Porter des chaussures à semelle antidérapante

pour travailler à l'extérieur. Protéger la chevelure si elle est

longue.

• TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. Porter

également un masque respiratoire si le travail de coupe produit de

la poussière. Les lentilles des verres correcteurs ordinaires

résistent seulement aux chocs; il ne s'agit pas de lunettes de

sécurité.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et

DW870,220/383823 5/3/02 1:29 PM Page 7

Page 12

8

Français

affûtés pour qu'ils donnent un rendement supérieur et sûr.

Suivre les directives concernant la lubrification et le remplacement

des accessoires.

• DÉBRANCHER LES OUTILS NON UTILISÉS. Respecter cette

mesure lorsqu'on ne se sert pas de l'outil, ou qu'on doit le réparer

ou en changer un accessoire (comme une lame, un foret ou un

couteau).

• ÉVITER LES DÉMARRAGES ACCIDENTELS. S'assurer que

l'interrupteur est à la position hors circuit lorsqu'on branche l'outil.

• UTILISER DES ACCESSOIRES RECOMMANDÉS. Consulter le

guide d'utilisation pour connaître la liste des accessoires

recommandés. L'utilisation de tout autre accessoire présente des

risques de blessures.

• NE JAMAIS SE TENIR DEBOUT SUR L'OUTIL. Cela présente

des risques de blessures si l'outil bascule ou si on entre en

contact avec le tranchant par inadvertance.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer

à utiliser l’outil, il faut vérifier si le protecteur ou toute autre pièce

endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l’alignement et les attaches des pièces mobiles, le degré

d’usure des pièces et leur montage, ainsi que tout autre facteur

susceptible de nuire au bon fonctionnement de l’outil. Faire

réparer ou remplacer tout protecteur ou toute autre pièce

endommagée .

• NE JAMAIS LAISSER L'OUTIL SANS SURVEILLANCE,

METTRE L'OUTIL HORS TENSION. Attendre l'immobilisation

complète de l'outil avant de s'en éloigner.

• PIÈCES DE RECHANGE. Lors de l'entretien, utiliser seulement

des pièces de rechange identiques.

Mise à la terre (DW870-220)

L'outil doit être mis à la terre lorsqu'on s'en sert

afin de protéger l'utilisateur contre les secousses

électriques. D'ailleurs, l'outil est muni d'un cordon

trifilaire et d'une fiche à trois broches convenant

aux prises mises à la terre. Le conducteur vert (ou vert et jaune) du

cordon constitue la mise à la terre. Ne jamais relier le conducteur

vert (ou vert et jaune) à une borne sous tension. Lorsque l'outil est

conçu pour être alimenté à une tension maximale de 150 volts, sa

fiche ressemble à celle illustrée à la figure A. Lorsque l'outil est

conçu pour être alimenté à une tension maximale de 150 à 250

volts, sa fiche ressemble à celle illustrée à la figure D. Il existe

des adaptateurs (figures B et C) pour brancher le type de fiche

illustré à la figure A dans des prises à deux trous. L'oreille ou la

cosse rigide et verte doit être reliée à une mise à la terre

permanente, comme une prise bien mise à la terre. Il n'y a pas

d'adaptateur pour les fiches semblables à celle illustrée à la figure

D. AU CANADA, ON NE PEUT PAS SE SERVIR DE

L'ADAPTATEUR ILLUSTRÉ AUX FIGURES B ET C. Utiliser

seulement des cordons de rallonge trifilaires ayant une fiche à 3

broches mise à la terre ainsi qu'une prise à 3 trous acceptant la

fiche de l'outil. Remplacer ou réparer les cordons de rallonge

endommagés.

Mesures de sécurité relatives aux scies

fendeuses

• Toujours porter des lunettes de sécurité ou tout autre dispositif de

protection pour les yeux en utilisant l'outil.

• Avant d'utiliser l'outil, vérifier si la meule comporte des fissures ou

des défectuosités. Le cas échéant, jeter la meule. Il faut

AB CD

BROCHE DE PRISE

MISE À LA TERRE

BROCHE DE PRISE

MISE À LA TERRE

PRISE MISE

À LA TERRE

DISPOSITIF DE

MISE À LA TERRE

ADAPTATEUR

BROCHE

220 V

DW870,220/383823 5/3/02 1:29 PM Page 8

Page 13

9

Français

également vérifier la meule lorsque l'outil est tombé.

• Lorsqu'on met l'outil en marche (avec une meule neuve ou de

rechange), il faut le tenir dans un endroit à l'écart et le laisser

fonctionner pendant une minute. Si la meule comporte une

fissure ou une défectuosité non décelée, elle éclate en moins

d'une minute. Ne jamais mettre l'outil en marche lorsqu'une

personne (y compris l'utilisateur) se trouve devant la scie.

• Éviter de faire faire un rebond à la meule ou de la manipuler

rudement. Le cas échéant, mettre l’outil hors circuit et inspecter

la meule.

• Nettoyer l’outil régulièrement conformément aux directives

d’entretien du présent guide.

• Ne jamais enlever le protecteur.

• Utiliser la bride de serrage pour fixer la pièce à découper.

• Utiliser seulement des meules d'une vitesse nominale d'au

moins 4 100 trs/min.

• Laisser refroidir les pièces découpées avant de les manipuler.

• Ne pas tenter de couper du bois ni du plastique avec l'outil.

• NE JAMAIS DÉCOUPER DU MAGNÉSIUM AVEC L'OUTIL.

• Utiliser la scie fendeuse seulement dans une pièce bien aérée.

• Mettre la scie fendeuse hors circuit avant de retirer les pièces qui

s'y trouvent.

• NE PAS COUPER UN MATÉRIAU SOUS TENSION.

• NE JAMAIS UTILISER UNE LAME DE SCIE CIRCULAIRE

AVEC LA SCIE FENDEUSE. NE PAS SE SERVIR DE LAMES À

DENTS.

• NE PAS UTILISER l'outil PRÈS DE LIQUIDES, DE GAZ OU DE

POUSSIÈRES INFLAMMABLES. Les étincelles que produit la

coupe ou le moteur en marche pourraient enflammer ces

produits.

CONSERVER CES MESURES.

Alimentation

Veiller à ce que la tension d'alimentation soit conforme aux

exigences de la plaque signalétique de l'outil. La mention «120

volts, 60 Hz» signifie que l'outil fonctionne seulement sur du courant

alternatif (courant domestique standard de 120 volts, 60 Hz).

Une baisse de tension de plus de 10 p. 100 entraîne une perte de

puissance et la surchauffe.

Interrupteur

Enfoncer la détente illustrée à la figure 1 pour mettre le moteur en

marche et la relâcher pour arrêter le moteur.

Caractéristiques et avantages

• L'alimentation en courant alternatif ou direct permet d'utiliser une

source de courant direct, comme une soudeuse.

• La poignée de l'interrupteur a été conçue afin d'en optimiser le

confort lorsqu'on se sert de la scie sur un établi ou sur le sol.

• La poignée légère et profilée se replie afin de faciliter le transport

de l'outil d'un endroit à un autre.

• Le socle robuste en acier est doté de pieds en caoutchouc afin

d'assurer la durabilité et le fonctionnement en douceur de l'outil.

• Le guide orientable pratique et précis permet de faire des coupes

en onglets à angles de 0°, 15°, 30° et 45° vers la droite, et à

angles de 0°, 15° et 30° vers la gauche.

• Le dispositif de verrouillage de l'arbre de la meule simplifie et

accélère le remplacement de la meule.

• La clé de démontage de la meule et du guide se range

commodément dans une case située à l'arrière du socle.

• Le robuste protecteur en acier de la meule protège l'utilisateur

des risques de coupe. Le pare-étincelles minimise les fuites

d'étincelles et les risques d'incendies.

• Le système de balais de service intensif prolonge la durée des

balais.

DW870,220/383823 5/3/02 1:29 PM Page 9

Page 14

10

Français

• Le ventilateur de rendement supérieur et le concept amélioré du

boîtier assure un fort débit d'air afin d'optimiser la ventilation et la

durée de l'outil.

• Le protège-cordon amovible du cordon d'alimentation de7,3 m

(8 pi) est des plus pratiques et il en simplifie l'entretien.

• L'outil est entièrement monté sur des roulements à billes et à

rouleaux afin d'en prolonger la durée.

Retrait et installation de la meule

1. S'assurer que l'outil est débranché.

2. Enfoncer le levier de verrouillage de la meule (fig. 1) et faire

tourner la meule à la main jusqu'à ce que le levier de verrouillage

de la meule s'enclenche dans la fente de la bride intérieure afin

de verrouiller la meule. Desserrer le boulon à tête hexagonale

qui se trouve au centre de la meule abrasive à l'aide de la clé

fournie à l'arrière du socle de l'outil. Le boulon est fileté à droite.

3. Retirer le boulon, la rondelle, la bride extérieure, l'adaptateur et

l'ancienne meule (fig. 2).

4. Installer la nouvelle meule abrasive en se conformant aux étapes

précédentes dans le sens inverse. S'assurer que l'adaptateur se

trouve sur l'arbre de transmission au centre de la meule.

5. Éviter de trop serrer le boulon.

AVERTISSEMENT : Vérifier la surface sur laquelle repose la

scie fendeuse lorsqu'on en remplace la meule abrasive. Cette

dernière pourrait entrer en contact avec la surface à ouvrer (du

côté du socle) lorsqu'on abaisse le bras de la scie.

N'EFFECTUER AUCUN RÉGLAGE LORSQUE LA MEULE

TOURNE. N'EFFECTUER AUCUN RÉGLAGE LORSQUE LA

SCIE FENDEUSE EST BRANCHÉE.

Bride de serrage à dégagement rapide

La scie comporte une bride de serrage à dégagement rapide pour

plus de commodité. Pour dégager la bride, faire tourner la

S

T

O

P

P

E

R

P

I

N

FIG. 1

INTERRUPTEUR

À DÉTENTE

LEVIER DE

VERROUILLAGE

DE LA LAME

FIG. 2

LEVIER DE

VITESSES

BRIDE

INTERNE

MEULE ABRASIVE

ADAPTATEUR

BRIDE EXTERNE

RONDELLE

BOULON À TÊTE

HEXAGONALE

30

15

FIG. 3

CLÉ

GUIDE

BOULONS

DU GUIDE

BRIDE DE

SERRAGE

FIG. 4

DW870,220/383823 5/3/02 1:29 PM Page 10

Page 15

11

Français

manivelle dans le sens antihoraire de un ou deux tours afin de

dégager la pression de la mâchoire. Desserrer la manivelle et

soulever le levier de dégagement sur le dessus de la mâchoire

mobile (fig. 3). Laisser le levier soulevé en tirant la manivelle vers

l'arrière et ouvrir les mâchoires. Pour fixer un objet, il suffit de

pousser la poignée de la manivelle dans la position voulue. La

mâchoire mobile glisse librement jusqu'à ce qu'elle entre en contact

avec la pièce à ouvrer. Faire tourner la manivelle dans le sens

horaire pour serrer la pièce à ouvrer.

Réglage de la bride de serrage

ANGLE de coupe

Utiliser la clé pour desserrer les deux boulons à tête hexagonale (fig.

3). (Ne pas retirer les boulons.) On peut faire tourner la réglette

dans un sens ou dans l'autre. Bien serrer les deux boulons avant

d'utiliser la scie de nouveau.

Réglage de l'ouverture

Retirer les deux boulons de la réglette. Déplacer la réglette vers

l'avant ou l'arrière selon la position voulue. Réinstaller les deux

boulons et bien les serrer.

Transport

Plier l'outil de façon à pouvoir attacher la chaîne à la tige du bras

(fig. 4).

Capacité de coupe

La grande ouverture de la bride de serrage ainsi que l'articulation

exceptionnelle de la scie permettent de couper de nombreuses

pièces de grandes dimensions. Utiliser le tableau suivant afin de

déterminer la dimension maximale totale de coupe que la nouvelle

meule peut faire. Il est conseillé de l'utiliser pour découper : des

montants métalliques, des conduites électriques d'un diamètre

maximal de 100 mm (4 po), des barres et des barres de

renforcement d'un diamètre maximal de 19 mm (3/4 po).

NOTE : Prière de noter que la largeur augmente pendant la coupe

tandis que la hauteur de coupe diminue.

MISE EN GARDE : IL PEUT ÊTRE NÉCESSAIRE DE FIXER

CERTAINS OBJETS DE DIMENSIONS EXTRAORDINAIRES,

CIRCULAIRES OU DE FORMES IRRÉGULIÈRES.

MISE EN GARDE : NE PAS COUPER DU MAGNÉSIUM AVEC LA

SCIE.

Profondeur de coupe maximale

Afin de maximiser la profondeur de coupe, déplacer la réglette vers

l'arrière (fig. 5).

NOTE : Lorsqu'on abaisse à fond une nouvelle meule, celle-ci

dépasse la base de l'outil et découpe la surface de travail.

Réglage des angles

Aligner la marque imprimée sur le socle sur l'angle de coupe

30

1

5

1

5

0

4

5

30

FIG. 5

30

15

15

0

45

30

MARQUE

SUR LE

SOCLE

FIG. 6

FIG. 7

0.3"

7.62 mm

BALAI

LIGNE

D'USURE

DW870,220/383823 5/3/02 1:29 PM Page 11

Page 16

12

Français

approprié (fig. 6). Utiliser un rapporteur afin d'obtenir des coupes

des plus précises.

NOTE : LES CAPACITÉS INDIQUÉES SUR CE TABLEAU NE

TIENNENT PAS COMPTE DE L'USURE DE LA MEULE.

Entretien de l'outil

Lubrification

L'outil est entièrement monté sur des roulements à rouleaux scellés

et graissés. Ces derniers sont lubrifiés en permanence à l'usine.

Il faut lubrifier les engrenages à des intervalles entre 60 et 90 jours,

selon le degré d'utilisation de l'outil. Il faut confier ces travaux à des

techniciens qualifiés comme ceux des centres de service de produits

DeWalt. Il faut essuyer l'outil et ajouter 20 grammes (3/4 oz) de

graisse dans le boîtier des engrenages.

Nettoyage

Il est conseillé de nettoyer le boîtier principal de l'outil en y soufflant

de l'air comprimé pour en chasser la poussière et les charpies dès

qu'il s'en accumule autour des évents.

Balais du moteur (Fig. 7)

S'assurer que l'outil est débranché avant d'en vérifier les balais. Il

faut examiner ces derniers régulièrement afin d'en observer le degré

d'usure. Pour ce faire, dévisser les bouchons en plastique (qui se

trouvent sur les côtés du carter de l'outil) et retirer les porte-balais de

l'outil. S'assurer que les balais sont propres et qu'ils glissent bien

dans leurs guides. Lorsque les balais sont usés jusqu'à la ligne

illustrée à la figure 7, il faut remplacer les balais et les porte-balais.

Montage

Afin d'améliorer la stabilité de l'outil pendant son utilisation, il faut

solidement monter la scie de la façon décrite plus bas. Pour

optimiser la mobilité de l'outil, on peut le visser à une pièce de

contreplaqué d'au moins 13 mm (1/2 po) qu'on fixe ensuite à une

surface de travail horizontale appropriée.

16-3/8"

(416 mm)

8-1/2"

(216 mm)

FIG. 8

S

T

O

P

P

E

R

P

I

N

FIG. 9

20"

2"-3"

CLOU

4"

GUIDE À LA POSITION

AVANT

GUIDE À LA POSITION

ARRIÈRE

6”

5”

4”

3”

2”

1”

0” 1” 2” 3” 4” 5” 6” 7” 8” 9”

4.75”

3.93”

6.25” 7.75”

HAUTEUR

LARGEUR

DW870,220/383823 5/3/02 1:29 PM Page 12

Page 17

13

Français

Montage permanent

1. Percer quatre trous d'un diamètre minimal de 8 mm (5/16 po)

dans la surface de travail (fig. 8).

2. Retirer les vis des pieds de la base.

3. Insérer des vis nº 20 de 7 mm (1/4 po) sous la surface de

travail jusque dans les pieds de la base. La longueur appropriée

de la vis correspond à l'épaisseur de la surface de travail plus

25 mm (1 po).

Montage sur chevalet (Fig. 9)

1. Découper deux planches d'une longueur de 508 mm (20 po) sur

une hauteur de 50 à 76 mm (de 2 à 3 po), sur une largeur de

100 mm (4 po).

2. Placer la scie fendeuse à l'emplacement voulu.

3. Placer les deux planches tout contre chaque côté de la scie et les

clouer dans la surface de travail (fig. 9).

Important!

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil,

n’en confier la réparation, l’entretien et les rajustements (y compris

l'inspection et le remplacement des balais) qu’au personnel d'un

centre de service ou d'un atelier d’entretien autorisé n’utilisant que

des pièces de rechange identiques.

Accessoires

Les accessoires recommandés pour l’outil sont vendus séparément

chez les détaillants et au centre de service de la région. La liste

complète des centres de service se trouve à la fin du présent guide.

Pour trouver un accessoire, communiquer avec les détaillants ou le

centre de service de la région.

MISE EN GARDE : L’utilisation de tout accessoire non

recommandé peut être dangereuse.

MISE EN GARDE : Les meules recommandées pour l'outil sont

indiquées dans le présent guide. L’utilisation de tout autre

accessoire peut être dangereuse. Utiliser seulement des meules

DeWalt de 350 mm (14 po) et de 4 100 trs/min.

TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. FIXER LA

PIÈCE À OUVRER DANS LA BRIDE DE SERRAGE.

DÉBRANCHER L'OUTIL AVANT D'EN REMPLACER LA MEULE.

Garantie complète

Les outils industriels de service intensif DeWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

DeWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée ou remplacée sans frais. Selon une

entente convenue entre DeWALT et la Division des outils industriels

de Black & Decker, celle-ci s’engage à effectuer les réparations

couvertes par la présente garantie. Il suffit de retourner l’outil port

payé à l’un des centres de service d’outils industriels Black &

Decker ou à tout autre atelier d’entretien d’outils industriels inscrit à

la rubrique «Outils électriques» des Pages Jaunes. La présente

garantie ne couvre pas les accessoires ni les dommages causés

par des réparations tentées ou effectuées par des tiers. Les

modalités de la présente garantie donnent des droits légaux

spécifiques. L'utilisateur peut également se prévaloir d'autres droits

selon l'état ou la province qu'il habite.

En outre, la garantie suivante couvre les outils DeWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT

REMIS

Si, pour quelque raison que ce soit, l'outil industriel de service

intensif DeWalt ne donne pas entière satisfaction, il suffit de le

retourner chez le marchand participant dans les 30 jours suivant la

date d'achat afin d'obtenir un remboursement complet. Il faut

retourner, port payé, l'outil complet. On peut exiger une preuve

d'achat.

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

IMPORTADOR: BLACK & DECKER S.A. DE C.V.

BOSQUES DE RADIATAS NO. 42

BOSQUES DE LAS LOMAS, 05120 MEXICO, D.F.

TEL 326-7100

DW870,220/383823 5/3/02 1:29 PM Page 13

Page 18

14

Español

INSTRUCCIONES IMPORTANTES DE

SEGURIDAD PARA TODAS LAS

HERRAMIENTAS

IMPORTANTE: Por favor, asegúrese que la persona que emplee

este equipo lea cuidadosamente estas instrucciones y las entienda

antes de iniciar las operaciones.

ADVERTENCIA: Es indispensable sujetarse a las precauciones

básicas de seguridad, con la finalidad de reducir el peligro de

incendio, choque eléctrico y lesiones personales, en todas las

ocasiones en que se utilicen herramientas eléctricas. Entre estas

precauciones se incluyen las siguientes.

LEA TODAS LAS INSTRUCCIONES

Instrucciones de seguridad para todas

las herramientas

• CONSERVE LAS GUARDAS EN SU SITIO y listas para el

trabajo.

• RETIRE LAS LLAVES DE AJUSTE Y OTRAS

HERRAMIENTAS. Hágase el hábito de revisar para verificar que

las llaves se hayan retirado de la herramienta antes de

encenderla.

• CONSERVE LIMPIA EL AREA DE TRABAJO. Los lugares y los

bancos desordenados propician los accidentes.

• NO SE UTILICE EN AMBIENTES PELIGROSOS. No utilice

herramientas eléctricas en lugares húmedos o inundados, ni las

exponga a la lluvia. Conserve el área de trabajo bien iluminada.

• CONSERVE APARTADOS A LOS NIÑOS. Todos los visitantes

deben permanecer a distancia segura del área de trabajo.

• HAGA SU TALLER A PRUEBA DE NIÑOS con candados,

interruptores maestros o quitando las llaves de encendido.

• NO FUERCE LA HERRAMIENTA. Esta hará el trabajo mejor y de

manera más segura bajo las especificaciones para las que se

diseñó.

• UTILICE LA HERRAMIENTA ADECUADA. No fuerce a una

herramienta o sus dispositivos a hacer trabajos para los que no

se han diseñado.

• UTILICE CABLES DE EXTENSION ADECUADOS. Asegúrese

que su cable de extensión esté en buenas condiciones. Cuando

utilice una extensión, asegúrese que tenga el calibre necesario

para soportar la corriente que su herramienta requiere. Un cale

con calibre menor causará una caída en el voltaje de la línea,

ocasionando pérdida de potencia y sobrecalentamiento. El

cuadro siguiente muestra el calibre correcto para usarse de

acuerdo con la longitud y el amperaje descrito en la placa de

identificación. Si tiene dudas, utilice el calibre siguiente. Mientras

más pequeño sea el número del calibre, mayor será su

capacidad.

Calibre mínimo requerido (AWG) para cables de extensión

Volts Longitud total de la extensión

(metros)

120 V 0 - 7.5 7.6 - 15.2 15. 3 - 30.4 30.5 - 45.7

240 V 0 - 15.2 15.3 - 30.4 30.5 - 60.8 60.9 - 121.2

Amperaje en la placa de identificación

Más No más Calibre promedio del alambre

de de

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No se recomienda

• UTILICE LAS ROPAS ADECUADAS. No utilice prendas flojas,

guantes corbatas, anillos brazaletes ni otros artículos de joyería

que pudiesen quedar atrapados por las piezas en movimiento. Se

recomienda el uso de calzado antiderrapante. Cúbrase el cabello

DW870,220/383823 5/3/02 1:29 PM Page 14

Page 19

15

Español

si lo tiene largo.

• SIEMPRE UTILICE ANTEOJOS DE SEGURIDAD. También

utilice una máscara contra polvo si la operación que efectuará lo

produce. Los anteojos de diario solamente tienen lentes

resistentes al impacto, no son anteojos de seguridad.

• NO SE SOBREEXTIENDA. Conserve los pies bien apoyados, lo

mismo que el equilibrio.

• CUIDE SUS HERRAMIENTAS. Consérvelas afiladas y limpias

para un rendimiento más seguro y más eficaz. Siga las

instrucciones para la lubricación y el cambio de accesorios.

• DESCONECTE LAS HERRAMIENTAS antes de darles servicio

y cuando cambie de accesorios, tales como discos, brocas,

cuchillas, y otros similares.

• EVITE EL RIESGO DE ENCENDIDO ACCIDENTAL. Asegúrese

que el interruptor esté en posición de apagado antes de conectar

la herramienta.

• UTILICE LOS ACCESORIOS RECOMENDADOS. Consulte el

manual de instrucciones para conocer los accesorios

recomendados. El empleo de accesorios no apropiados puede

ocasionar riesgos de lesiones a las personas.

• NUNCA SE PARE EN LA HERRAMIENTA. Se puede lesionar

gravemente si la herramienta se vuelca o hace contacto accidental

con la pieza de corte.

• REVISE LAS PARTES DAÑADAS. Antes de seguir utilizando la

herramienta, una guarda u otra pieza que esté dañada debe ser

examinada cuidadosamente para determinar si funcionará

apropiadamente y cumplirá con su función. Revise la alineación de

las piezas móviles, su montaje, la ruptura de las piezas, montajes

y cualesquiera otras condiciones que pudiesen afectar su

operación. Una guarda u otra parte dañada debe ser reparada

correctamente o reemplazada.

• NUNCA DEJE LA HERRAMIENTA EN OPERACION

DESATENDIDA. APAGUELA. No deje la herramienta hasta que

se haya detenido completamente.

• PARTES DE REPUESTO. Utilice únicamente piezas de repuesto

idénticas cuando haga servicio.

• ASEGURE LAS PIEZAS DE TRABAJO. Utilice prensas para

sujetar su trabajo cuando le sea práctico. Esto es más seguro que

usar sus manos y le deja ambas libres para operar la herramienta.

Instrucciones de aterrizaje (DW870-220)

Esta herramienta debe conectarse a tierra para

proteger al operador de choques eléctricos. Esta

unidad está equipada con un cordón eléctrico de

tres hilos aprobado y una clavija para aterrizaje de

tres patas para conectarse a la toma de corriente

adecuada. El conductor verde (o verde y amarillo)

es el cable de tierra. Nunca conecte el cable verde (o verde y amarillo)

a una terminal viva. Si su unidad está hecha para funcionar con menos

de 150 volts, tiene una clavija similar a la que se muestra en la figura

A. Si es para usarse con corriente de 150 a 250 volts, tiene una

clavija como la que se muestra en la figura D. Hay adaptadores,

figuras B y C, para conectar clavijas del tipo de la figura A a tomas de

corriente para dos patas. La oreja de color verde deberá conectarse a

tierra permanente, tal como una toma de corriente aterrizada

adecuadamente. No hay adaptadores para clavijas como la de la

figura D. EL ADAPTADOR MOSTRADO EN LAS FIGURAS B Y C NO

ESTA HECHO PARA USARSE EN CANADA. Unicamente utilice

cordones de extensión que tengan clavijas de tres patas y tomas de

corriente de tres ranuras que acepten estas clavijas. Reemplace o

repare los cordones eléctricos dañados.

CLAVIJA PARA

220 V

AB CD

PATA DE CONEXION A TIERRA

TOMA DE

CORRIENTE

ATERRIZADA

MEDIO DE

ATERRIZAJE

PATA DE

CONEXION A TIERRA

ADAPTADOR

DW870,220/383823 5/3/02 1:29 PM Page 15

Page 20

16

Español

Reglas de seguridad adicionales para

cortadoras de metales

• Utilice siempre anteojos de seguridad u otra protección ocular

cuando emplee esta herramienta.

• Antes de usar un disco, revíselo en busca de cuarteaduras o

fallas. Si tales son evidentes, deseche el disco. También deberá

inspeccionar el disco si piensa que la herramienta pudo haber

caído.

• Cuando encienda la herramienta (con un disco nuevo o después

de haberlo cambiado) colóquela en un área bien protegida. Si la

herramienta tiene una falla o cuarteadura no detectada, el disco

estallará en menos de un minuto. Nunca encienda la herramienta

con una persona parada en línea con el disco; esto incluye al

operador.

• Durante la operación, evite que el disco rebote, no lo trate

descuidadamente. Si esto ocurre, apague la herramienta y revise

el disco.

• Limpie la sierra periódicamente siguiendo el procedimiento

descrito en este manual.

• No quite la guarda del disco.

• Utilice siempre la prensa o el dispositivo especial para sujetar la

pieza de trabajo.

• Utilice siempre discos especificados para 4100 o más rpm.

• Permita que las partes cortadas se enfríen antes de manipularlas.

• No intente cortar madera o plástico con esta herramienta.

• NUNCA CORTE MAGNESIO CON ESTA HERRAMIENTA.

• Utilice la cortadora de metales en un área bien ventilada.

• Apague la cortadora antes de retirar cualquier pieza de la base.

• NO CORTE MATERIAL ELECTRICAMENTE VIVO.

• NUNCA UTILICE UN DISCO PARA SIERRA CIRCULAR EN

ESTA HERRAMIENTA. NO UTILICE DISCOS DENTADOS.

• NO UTILICE ESTA HERRAMIENTA CERCA DE LIQUIDOS,

GASES O POLVOS INFLAMABLES. Las chispas emitidas por el

motor pueden originar las ignición de estos polvos o vapores.

CONSERVE ESTAS

INSTRUCCIONES

Alimentación

Asegúrese que su fuente de alimentación concuerde con la

especificada en la placa de identificación de la herramienta. “120

volts, 60 Hz” significa corriente alterna (corriente doméstica normal

de 120 volts a 60 ciclos).

Disminuciones en el voltaje superiores al 10% causarán pérdida de

potencia y sobrecalentamiento.

Interruptor

Para encender la herramienta, oprima el interruptor de gatillo

ilustrado en la figura 1. Para apagar la herramienta, libere el

interruptor.

Características y beneficios

• Al poder utilizar corriente alterna y corriente continua es posible

emplear una fuente de poder portátil, tal como una planta de

soldar.

• El mango del interruptor está diseñado pensando en el factor

humano para máxima comodidad al usar la sierra en una banca,

o en el piso.

• El peso ligero, el mango de acarreo de empuñadura segura, y el

diseño plegable se combinan para facilitar el transporte de la

máquina de un lado a otro.

• Resistente base de acero con patas de goma que permiten

durabilidad y operación libre de vibraciones para cortes estables.

• Guía giratoria para comodidad y precisión en cortes angulares.

Graduaciones a la derecha para 0°, 15ª, 30ª y 45ª. Graduaciones

a la izquierda para 0ª, 15ª, 30ª.

• Seguro en la flecha que simplifica el cambio de discos.

DW870,220/383823 5/3/02 1:29 PM Page 16

Page 21

17

Español

• La llave para el disco y la guía se guarda en la parte posterior de

la base.

• Guarda para el disco en acero que protege al operador. La

guarda contra chispas en la base reduce el número de chispas

que escapan y protege a los alrededores.

• Sistema de carbones para trabajo pesado de larga duración.

• El ventilador de alta eficiencia y el diseño mejorado de la carcaza

aseguran un alto flujo de aire para una operación más fría y

mayor durabilidad.

• Cable de alimentación de 2,4 m con protector por separado que

simplifica el servicio.

• Construcción 100% con baleros de bolas y rodillos para mayor

duración de la herramienta.

Remoción e instalación de discos

1. Asegúrese que la herramienta esté desconectada de la toma de

corriente.

2. Empuje la palanca del disco (Fig. 1) y gire el disco con la mano

hasta que la palanca se enganche con la ranura de la arandela

interior para fijar el disco. Afloje el tornillo con cabeza hexagonal

que se encuentra en el centro del disco abrasivo con la llave que

le proporcionamos. El tornillo tiene cuerda derecha.

3. Quite el tornillo, la roldana, la arandela exterior, el adaptador, y

el disco viejo (Fig. 2).

4. Instale el nuevo disco abrasivo invirtiendo los pasos anteriores.

Asegúrese que el adaptador esté en el eje de engranaje y

centrado en el disco.

5. No apriete excesivamente el tornillo.

ADVERTENCIA: Revise la superficie de trabajo sobre la que

descansa la cortadora cuando cambie de disco abrasivo. Es posible

que el disco haga contacto con la superficie de trabajo (a través de

la base) cuando se baja el brazo totalmente.

S

T

O

P

P

E

R

P

I

N

FIG. 1

INTERRUPTOR DE

GATILLO

PALANCA DE

SEGURO DEL

DISCO

FIG. 2

EJE DE

ENGRANAJE

ARANDELA

INTERIOR

DISCO ABRASIVO

ADAPTADOR

ARANDELA

EXTERIOR

ROLDANA

TORNILLO CON

CABEZA

HEXAGONAL

DW870,220/383823 5/3/02 1:29 PM Page 17

Page 22

18

Español

determinar el tamaño total máximo de los cortes que pueden

hacerse con un disco nuevo. Las aplicaciones recomendadas son:

pernos metálicos, conduit hasta de 10 cm de diámetro y barras de

refuerzo hasta de 19 mm de diámetro.

NOTA: Al aumentar el ancho de corte se disminuye la altura de

corte.

PRECAUCION: ALGUNOS OBJETOS GRANDES CON FORMA

CIRCULA IRREGULAR PUEDEN REQUERIR DE MEDIOS DE

SUJECION ADICIONALES.

PRECAUCION: NO CORTE MAGNESIO CON ESTA

HERRAMIENTA.

Profundidad máxima de corte

Para obtener la profundidad máxima de corte, mueva la guía a la

posición trasera (Fig. 5).

NOTA: Un disco nuevo, cuando se baja completamente, se

extenderá por debajo de la base y cortará la superficie de trabajo.

Ajuste de inclinación

Haga coincidir la línea indicadora grabada en la base con el número

30

15

FIG. 3

LLAVE

GUIA

TORNILLO

S DE LA

GUIA

PRENSA

NO HAGA NINGUN AJUSTE CUANDO EL DISCO ESTE EN

MOVIMIENTO. NO HAGA NINGUN AJUSTE CUANDO LA

CORTADORA ESTE CONECTADA A LA TOMA DE CORRIENTE.

Prensa de liberación rápida

Su cortadora cuenta con un sistema de liberación rápida para mayor

comodidad. Para liberar la prensa, gire la manivela una o dos

vueltas en sentido opuesto a las manecillas del reloj para reducir la

presión en la mordaza. Una vez floja la manivela, levante la palanca

de liberación que se encuentra en la parte superior de la mordaza

móvil, como se muestra en la figura 3. Sujete arriba la palanca

mientas tira de la manivela y abre las mordazas. Cuando prense un

objeto, usted solo necesita empujar el mango de la manivela hasta

la posición deseada. Una mordaza móvil se deslizará libremente

hasta hacer contacto con la pieza de trabajo. Gire la manivela en el

sentido de las manecillas del reloj para sujetar la pieza en posición.

Ajuste de los topes de prensa

ANGULO DE CORTE

Utilice la llave para aflojar los dos tornillos con cabeza hexagonal

(Fig. 3). (No saque los tornillos.) La guía puede girarse en cualquier

dirección. Apriete con firmeza ambos tornillos antes de emplear la

cortadora.

AJUSTE DE LA ABERTURA

Saque ambos tornillos de la guía. Mueva la guía hacia adelante o

hacia atrás hasta la posición que desee. Instale ambos tornillos y

apriételos.

Acarreo

Pliegue la unidad hasta la posición en que pueda enganchar la

cadena al perno del brazo de la herramienta (Fig. 4).

Capacidad de corte

La gran abertura de prensa y el alto punto de giro proporcionan

capacidad para cortar piezas grandes. Utilice la tabla para

DW870,220/383823 5/3/02 1:29 PM Page 18

Page 23

19

Español

apropiado para el ángulo de corte que desee (Fig. 6). Para cortes

muy precisos, utilice un protractor.

NOTA : LA CAPACIDAD ILUSTRADA EN LA TABLA SIGUIENTE

ASUME QUE NO HAY DESGASTE EN EL DISCO.

Mantenimiento de la herramienta

Lubricación

Se han empleado en toda su herramienta rodamientos engrasados

sellados, de tipo cerrado. Estos rodamientos cuentan con la

lubricación necesaria en su interior para toda su vida útil.

Los engranes deben lubricarse cada 60 a 90 días de acuerdo con el

uso. Esta lubricación solamente deberá realizarla personal experto

como los mecánicos de los centros de servicio autorizados

DeWALT. (Busque “ herramientas eléctricas” en la sección

amarilla.) La caja de engranes debe limpiarse y después deben

agregarse 20 gr. (3/4 de oz.) de grasa.

Limpieza

Se recomienda sopletear la carcaza principal con aire comprimido

con la frecuencia que la mugre se acumule dentro y alrededor de las

tomas de aire.

Carbones del motor (Fig. 7)

Asegúrese que la herramienta esté desconectada antes de revisar

los carbones. Estos deben revisarse con regularidad en busca de

desgaste. Para inspeccionar los carbones, destornille las tapas de

plástico (Se encuentran a los lados de la carcaza del motor) y saque

los montajes de resortes y carbones de la herramienta. Conserve

los carbones limpios y deslizándose libremente en sus guías.

Cuando los carbones se desgasten hasta el punto en que la línea

de desgaste ilustrada en la figura 7 este al ras del extremo del

porta carbones, deberán reemplazarse ambos carbones.

Métodos de montaje

Para aumentar la estabilidad durante el uso, la sierra debe

FIG. 4

30

1

5

1

5

0

4

5

30

FIG. 5

30

15

15

0

45

30

LINEA INDICADORA

FIG. 6

FIG. 7

0.3"

7.62 mm

CARBON

LINEA DE

DESGASTE

DW870,220/383823 5/3/02 1:29 PM Page 19

Page 24

20

Español

montarse con firmeza como se describe a continuación. Para

aumentar la portabilidad de la herramienta, puede atornillarse a una

pieza de madera contraplacada de 13 mm de espesor (o mayor),

misma que puede prensarse a una superficie de trabajo horizontal.

Procedimiento para montaje permanente

1. Perfore cuatro orificios con diámetro mínimo 8 mm (5/16”) a

través de la superficie de trabajo (Fig. 8).

2. Quite los tornillos de las patas.

3. Inserte tornillos 1/4-20 desde el lado inferior de la superficie de

trabajo, a través de las patas dentro de los orificios de la base de

la herramienta. La longitud apropiada para los tornillos es igual

al espesor de la superficie de trabajo mas 25 mm.

Montaje de cuna (Fig. 9)

1. Corte dos tablas de 50 cm. de largo por 5 a 7,5 cm de altura por

10 cm de ancho.

2. Coloque la cortadora de metales en el lugar que desee.

3. Coloque las tablas juntas a lo largo de los laterales y clávelas a

la superficie de trabajo (Fig. 9).

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto,

las reparaciones, el mantenimiento y los ajustes (incluyendo

inspección y cambio de carbones) deberán realizarse en los centros

de servicio autorizado u otras organizaciones de servicio calificado

que empleen siempre refacciones originales.

Accesorios

Los accesorios recomendados para emplearse con su herramienta

están a su disposición con costo adicional con su distribuidor o

centro de servicio autorizado. Se incluye una lista completa de los

centros de servicio al final de este manual. Si necesita ayuda para

encontrar cualquier accesorio para su herramienta, por favor

16-3/8"

(416 mm)

8-1/2"

(216 mm)

FIG. 8

S

T

O

P

P

E

R

P

I

N

FIG. 9

20"

2"-3"

CLAVO

4"

GUIA EN LA POSICION

DELANTERA

GUIA EN LA POSICION

TRASERA

6”

5”

4”

3”

2”

1”

0” 1” 2” 3” 4” 5” 6” 7” 8” 9”

4.75”

3.93”

6.25” 7.75”

ALTURA

ANCHO

NOTA : LA CAPACIDAD ILUSTRADA EN LA TABLA SIGUIENTE

ASUME QUE NO HAY DESGASTE EN EL DISCO.

DW870,220/383823 5/3/02 1:29 PM Page 20

Page 25

21

Español

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1770 (91 3) 826 69 78.

LEON

Polara #32 (91 471) 314 56

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 553-9979

MERIDA

Calle 63 #459 (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #2057 (91 22) 46 90 20

QUERETARO

Av. Madero 139 Pte. (91 42) 14 60 60

SAN LOUIS POTOSI

Pedro Moreno #408 Fracc. la Victoria (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 18

VILLAHERMOSA

Zaragoza #105 (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

comuníquese con el distribuidor o centro de servicio autorizado de

su localidad.

PRECAUCION: El uso de cualquier accesorio no recomendado

para emplearse con su herramienta puede ser peligroso.

PRECAUCION: Los discos recomendados para emplearse con

su herramienta se indican en este manual. El empleo de cualquier

otro accesorio o dispositivo puede ser peligrosos. utilice únicamente

discos DeWALT de 355 mm (14”) para 4100 rpm.

UTILICE SIEMPRE GAFAS DE SEGURIDAD. ASEGURE LA

PIEZA DE TRABAJO EN LA PRENSA.

DESCONECTE LA HERRAMIENTA DE LA TOMA DE CORRIENTE

ANTES DE CAMBIAR EL DISCO.

Accesorios

Dispone usted de los accesorios para su herramienta con cargo

adicional con su distribuidor local autorizado o centro de servicio

autorizado.

PRECAUCION: Es peligroso emplear cualquier accesorio no

recomendado para emplearse con esta herramienta.

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

(inclusive inspección y cambio de carbones) en los centros

autorizados de servicio u otras organizaciones autorizadas que

empleen siempre refacciones legítimas.

DW870,220/383823 5/3/02 1:29 PM Page 21

Page 26

22

Español

Garantía Completa

Las herramientas industriales DEWALT están garantizadas durante

un año a partir de la fecha de compra. Repararemos, sin cargos,

cualquier falla debida a material o mano de obra defectuosos. Hemos

hecho arreglos con la División de Herramientas Industriales de Black

& Decker para que hagan las reparaciones en garantía a las

herramientas D

EWALT. Por favor regrese la unidad completa, con el

transporte pagado, a cualquier Centro de Servicio para Herramientas

Industriales de Black & Decker o a las estaciones de servicio

autorizado enlistadas bajo “Herramientas Eléctricas” en la Sección

Amarilla. Esta garantía no se aplica a los accesorios ni a daños

causados por reparaciones efectuadas por terceras personas. Esta

garantía le otorga derechos legales específicos, y usted puede tener

otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas D

EWALT están amparadas

por nuestra:

GARANTIA DE SATISFACCION SIN RIESGO POR 30 DIAS

Si usted no se encuentra completamente satisfecho con el

desempeño de su herramienta industrial DEWALT, sencillamente

devuélvala a los vendedores participantes durante los primeros 30

días después de la fecha de compra para que le efectúen un

reembolso completo. Por favor regrese la unidad completa, con el

transporte pagado. Se puede requerir prueba de compra.

IMPORTADO: BLACK & DECKER S.A. DE C.V.

AVE CENTRAL 186 COL. NVA. IND.

VALLEJO C.P. 07700 MÉXICO, D.F.

TEL 747-95-00

SECCI N

AMARILLA

Si funciona…

y funciona muy bien.

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

DW870,220/383823 5/3/02 1:29 PM Page 22

Loading...

Loading...