Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in U.S.A. (JUN98-CD-1) Form No. 384621-01

DW866 Copyright © 1998

384621-01/DW866 1/8/02 2:27 PM Page 2

Page 2

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW866

12” (105mm) Cut-off Machine

Machine à tronçonner de 105 mm (12 po)

Máquina cortadora de 105 mm (12”)Máquina cortadora de 105 mm (12”)

384621-01/DW866 1/8/02 2:27 PM Page 3

Page 3

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify the

plug in any way. Do not use any adapter plugs. Check with a

qualified electrician if you are in doubt as to whether the outlet

is properly grounded. If the tools should electrically malfunction or

break down, grounding provides a low resistance path to carry

electricity away from the user.

• Double insulated tools are equipped with a polarized plug (one

blade is wider than the other.) This plug will fit in a polarized

outlet only one way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug

in any way. Double insulation eliminates the need for the three

wire grounded power cord and grounded power supply system.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or

pull the plug from an outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor

extension cord marked “W-A” or “W .” These cords are rated for

outdoor use and reduce the risk of electric shock. When using an

extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and overheating. The

following table shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the heavier the cord.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Rules

WARNING! Read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WARNING: Improper connection of the equipment grounding

conductor can result in the risk of electric shock. Check with a

qualified electrician or service person if you are in doubt as to

whether the outlet is properly grounded. Do not modify the plug

provided with the appliance. If it will not fit the outlet, a proper outlet

must be installed by a qualified electrician.

We recommend that you never disassemble the tool or try to do any

rewiring in the electrical system. Any repairs should be performed

only by authorized service centers. Should you be determined to

make a repair yourself, remember that the green colored wire is the

grounding wire. Never connect this green wire to a live terminal. If

you replace the plug on the power cord, be sure to connect the green

wire only to the grounding (longest) prong on a three-prong plug.

Never remove the grounding prong.

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control.

384621-01/DW866 1/8/02 2:27 PM Page 4

Page 4

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Not Recommended

Grounding

This tool should be grounded while in use to protect the operator from

electric shock. The tool is equipped with an approved threeconductor cord and three-prong grounding type plug to fit the proper

grounding type receptacle. The green (or green and yellow)

conductor in the cord is the grounding wire. Never connect the green

(or green and yellow wire to a live terminal.

If your unit is intended for use on less than 150 volts, it has a plug

similar to that shown in Figure A. An adapter, Figures B and C, is

available for connecting Figure A plugs to two-prong receptacles.

The green-colored rigid ear, lug, etc., must be connected to a

permanent ground such as a properly grounded outlet box.

Whenever the adapter is used, it must be held in place by a metal

screw.

ADAPTER SHOWN IN FIGURES B and C IS NOT FOR USE IN

CANADA.

1

English

AB CD

GROUNDING PIN

GROUNDED

OUTLET

BOX

GROUNDING

MEANS

GROUNDING PIN

ADAPTER

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in serious

personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothing, jewelry, or long hair can be caught

in moving parts.

• Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool

on. A wrench or key that is left attached to a rotating part of the tool

may result in personal injury.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be used

for appropriate conditions.

• The label on your tool may include the following symbols.

V ................................volts

A ................................amperes

Hz ................................hertz

W....................................watts

min..................................minutes

....................................alternating current

................................direct current

n

o....................................no load speed

....................................Class II Construction

384621-01/DW866 1/8/02 2:27 PM Page 1

Page 5

• When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

Additional Safety Instructions for

Cut-Off Machine

CAUTION: When cutting into walls, floors or wherever live

electrical wires may be encountered, DO NOT TOUCH ANY METAL

PARTS OF THE TOOL! Hold the tool only by insulated grasping

surfaces to prevent electric shock if you cut into a live wire.

• ALWA YS WEAR EYE PROTECTION WHEN USING THIS T OOL.

• Use of accessories not specified in this manual is not

2

…/min ..............revolutions or reciprocation per minute

....................earthing terminals

....................safety alert symbol

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to loss of control.

• Do not force tool. Use the correct tool for your application. The

correct tool will do the job better and safer at the rate for which it is

designed.

• Do not use tool if switch does not turn it on or off. Any tool that

cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such

preventative safety measures reduce the risk of starting the tool

accidentally.

• Store idle tools out of reach of children and other untrained

persons. T ools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less likely to

bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tools

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be suitable

for one tool, may become hazardous when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

English

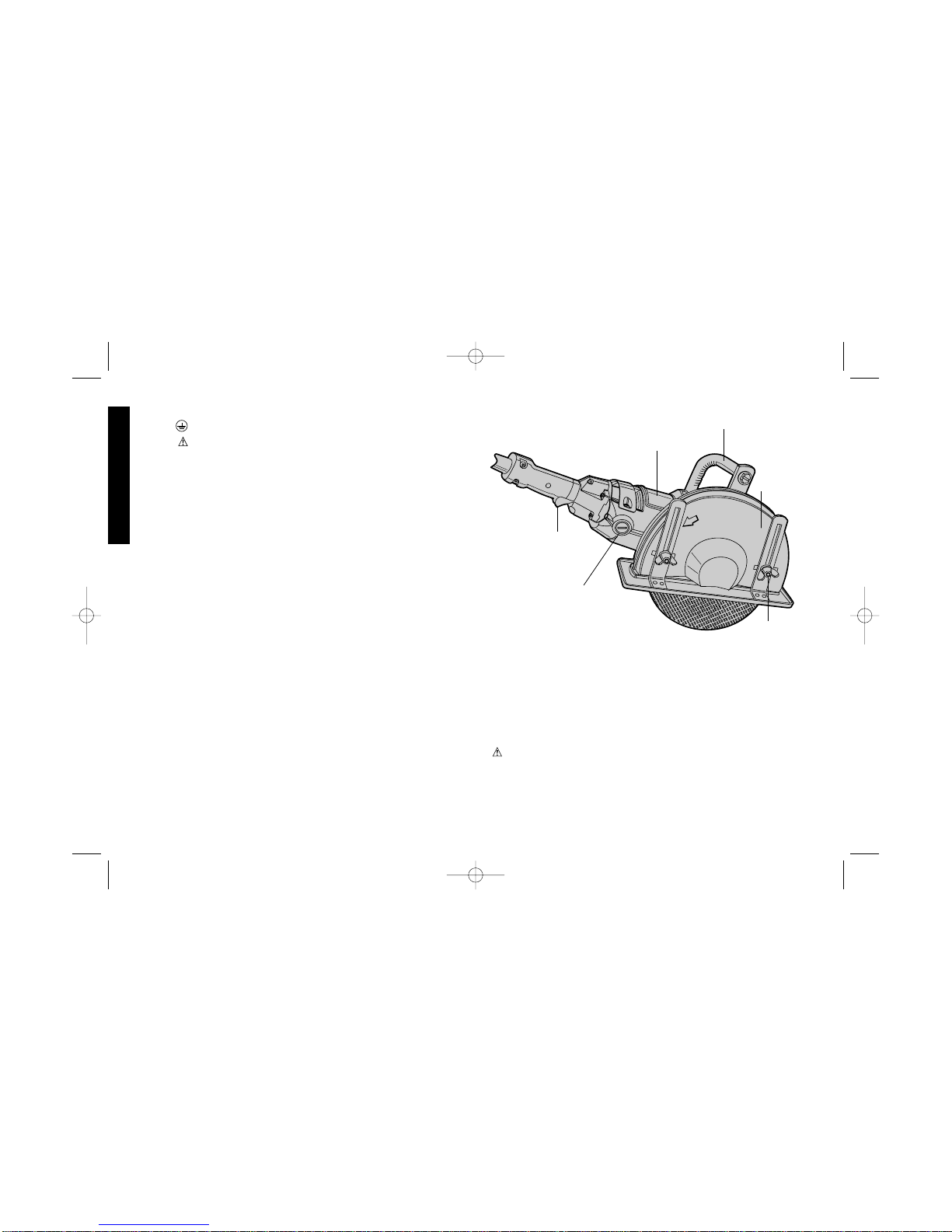

TRIGGER

SWITCH

BRUSH

CAP

FIELD

CASE

BAIL

HANDLE

GUARD

DEPTH

ADJUSTMENT

WING NUT

384621-01/DW866 1/8/02 2:27 PM Page 2

Page 6

recommended and may be hazardous. Use of power boostersthat

would cause the tool to be driven at speeds greater than its rated

speed constitutes misuse.

• Before attaching any wheel, check its manufacturer’s specifications and be sure that its safe operating speed is higher than

the no-load speed of the tool as shown on the nameplate.

• Before using, inspect each grinding wheel for cracks or flaws. If

such a crack or flaw is evident- discard the wheel. The wheel

should also be inspected whenever you think the tool may have

been dropped. Do not set unit down on wheel.

• When starting the tool (with a new or replacement wheel installed)

hold the tool in a well protected area. Never start the tool with a

person in line with the wheel. This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough treatment.

If this occurs, stop the tool and inspect the wheel.

• Clean your tool out periodically.

• Protect personnel and combustible material in work area from

sparks generated by this tool.

SAVE THESE INSTRUCTIONS

Motor

Be sure your power supply agrees with the nameplate marking.

Voltage decrease of more than 10% will cause loss of power and

overheating. All D

EWalt tools are factory tested; if this tool does not

operate, check the power supply.

Controls (Figures 1 and 2)

CAUTION: Grasp tool firmly with both hands before attempting to

start.To start, grasp switch handle firmly and squeeze to depress

trigger. To stop tool, release trigger.

GUARD ADJUSTMENT: Disconnect tool from power supply and be

sure switch is in off position before adjusting guard. Guard may be

adjusted approximately 80˚ by loosening the guard adjustment knob.

3

English

Grasp the guard firmly and rotate to desired angle. Lock in position

by tightening the guard adjustment knob.

NOTE: The two guard mounting screws on each end of the clamp

should not be over-tightened, in order to allow the guard to rotate.

SPINDLE LOCK PIN is used to lock the spindle when changing

accessories. To engage the lock pin, disconnect the tool from the

power supply and be sure switch is in off position. Depress the lock

pin and turn the wheel and spindle until the lock pin engages the

spindle. Use wrench, supplied with the unit, to unscrew the spindle

nut and remove or mount accessories. Spindle and nut have right

hand threads.

NOTE: Slot in wrench handle may be used for additional leverage

when tightening or loosening wing nuts. Wrench is a standard part

furnished with the unit. Shoe can be adjusted to give a 4” maximum

depth of cut.

Operation

1. The tool is supplied with a cord and a 3-prong plug. Compare

voltage marked on nameplate of tool with that of your power supply

before plugging in tool. The voltages must be the same.

2. Before turning on tool, grasp both handles firmly and pick up tool.

Make sure nothing is near or in line with the wheel. Line up wheel

with material to be cut.

3. Turn on unit and feed wheel into work slowly, but with firm

pressure, while keeping the shoe firmly and squarely against the

work. Don not force the tool. For maximum efficiency and wheel

life, keep the wheel speed high.

Depth of Cut

The depth of cut can be adjusted by loosening the two wing nuts on

the outside of the guard. NOTE: The slot in handle of included

wrench may be used for additional leverage when loosening or

tightening the wing nuts.

384621-01/DW866 1/8/02 2:27 PM Page 3

Page 7

4

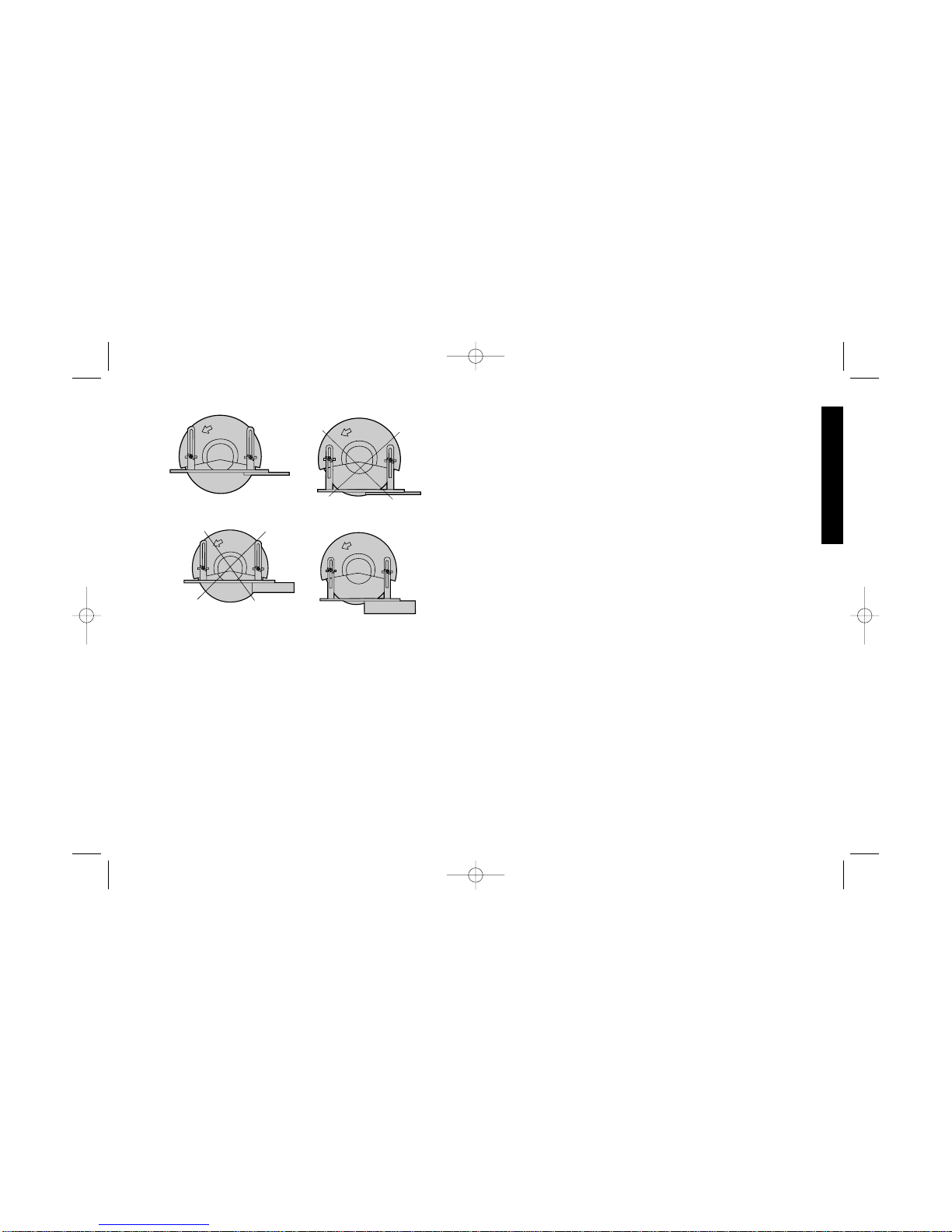

TO CUT METALS AND THIN MATERIALS

For minimum operator effort and greatest efficiency when cutting

metals and other thin materials, adjust shoe for maximum depth of

cut (Figure 3).

TO CUT STONE OR MASONRY MATERIALS

For maximum effectiveness, set the wheel exposure to about 1/2”

(13mm)beyond the shoe. For many applications, the material will

readily break along the 1/2” (13mm) deep scored line. If a deeper

cut is needed, increase the depth of cut in approximately 1/2” (13mm)

increments. See Figure 4.

Installing Abrasive Wheels (Figure 5)

1. TURN OFF TOOL AND DISCONNECT FROM POWER SUPPL Y.

2. Lay unit on a firm surface with bottom of shoe facing up.

3. Loosen shoe adjustment wing nuts, bring shoe up to minimum

cutting depth and tighten wing nuts. This step allows more

freedom in removing spindle nut and washers.

4. Using 1 1/8” (28mm) open end wrench (supplied with unit) remove

spindle nut, outer clamp washer and used wheel if one is installed.

Hold spindle from turning with spindle lock pin. Spindle threads

are right hand.

5. Select proper wheel, use only those approved accessories

specified in this manual. Never use wheels rated lower than

nameplate speed of unit.

6. Make sure inner clamp washer is in place and ears are engaged

with spindle flats. Slip wheel through bottom of shoe and slip

wheel over spindle. Be sure wheel goes over pilot diameter. of

inner clamp washer. Slip on outer clamp washer. Start threading

on spindle nut which will self align outer clamp washer. Engage

spindle lock pin and tighten nut with wrench. Do not over tighten

spindle nut.

7. Turn wheel by hand to make sure the wheel is properly centered,

that the wheel does not hit the shoe or guard and nut and that nut

and flanges are tight.

English

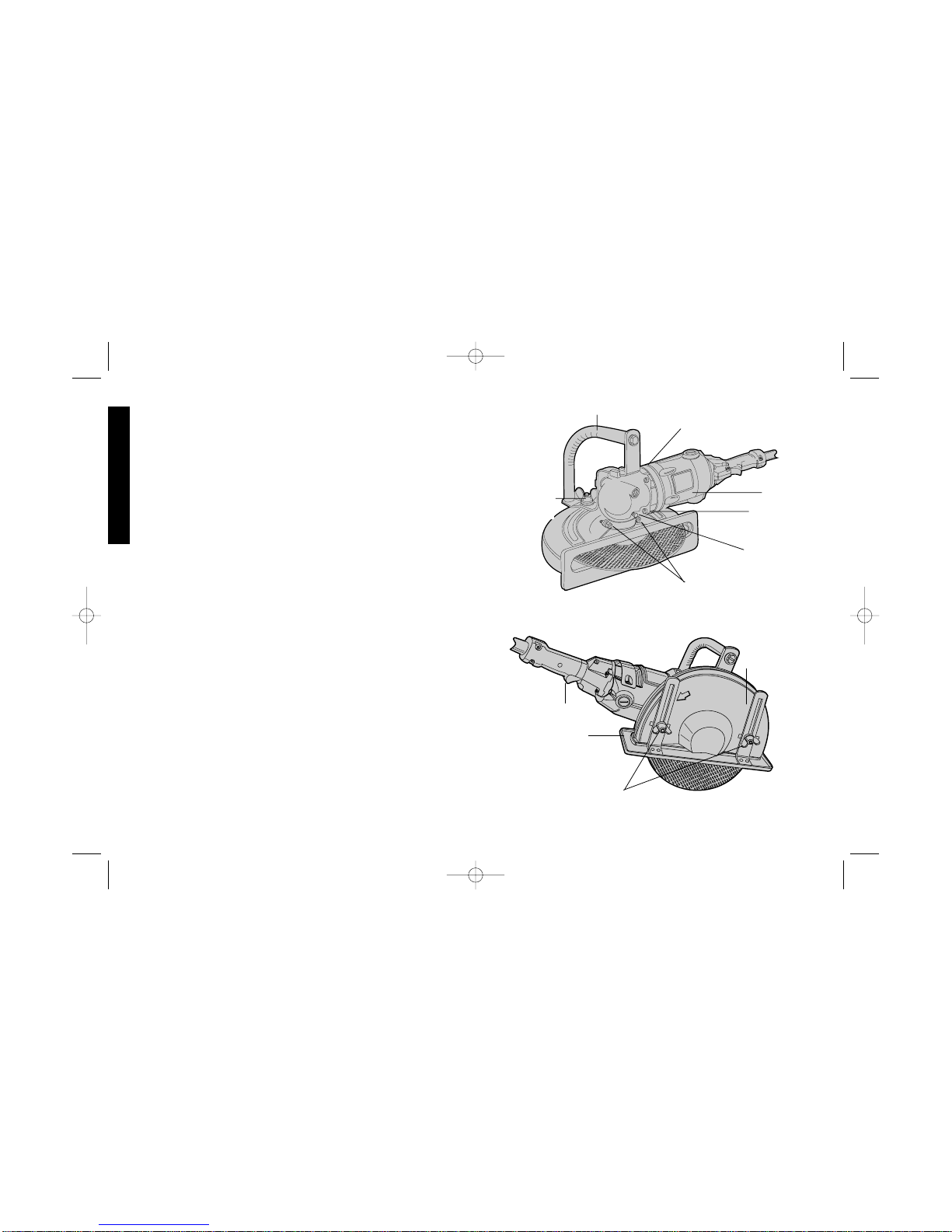

Figure 1

Figure 2

BAIL HANDLE

WEAR RING (GEAR CASE

COVER UNDERNEATH)

FIELD

SPINDLE

LOCK PIN

GUARD MOUNTING

SCREWS

GUARD

ADJUSTMEN

T KNOB

GEAR CASE

MOUNTING

SCREWS (4)

TRIGGER

SHOE

GUARD

DEPTH ADJUSTMENT

WING NUTS

384621-01/DW866 1/8/02 2:27 PM Page 4

Page 8

5

English

Figure 3

Figure 4

YES

NO

NO

YES

METALS OR THIN

MATERIAL

MASONRY

MATERIAL

Applications

1/8” (3mm) max. gauge sheet metal

concrete, cinder blocks and bricks

reinforcing rod- generally under 3/4” (19mm) diameter

1/8”(3mm) diameter concrete wire mesh

corrugated floor and ceiling form (concrete forms)

electrical conduit 1/8” (3mm) wall thickness

1/8” (3mm) max. thick structural forms such as channel, angles,

plate, etc.

NOTE: The cutting of materials heavier than those listed above are

not recommended due to the possibility of electrical overloading.

Conversion From Right Handed to Left

Handed

Operation

NOTE: This machine is assembled at the factory with the spindle on

right side of the unit for right handed operation.

1. TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

2. Place unit on a firm, flat work surface.

3. Remove brush caps and brushes.

4. Remove bail handle by removing guard adjusting knob and hex

bolt.

5. Remove the 4 gear case mounting screws.

6. Remove gear case.

7. Remove wear ring.

8. Pry the gear case cover, with armature attached, from field case.

The armature and gear case cover are one subassembly.

9. IMPORTANT:Notice a flat tab projecting from the gear case cover

and a corresponding recess in the gear case opposite the spindle.

Line up these two features and reassemble the gear case and

cover.

10. Replace the wear ring on the field case.

11.Rotate the field case and switch handle assembly 180˚. Then,

when viewing from the cord end, with the trigger switch down, the

spindle should be on the left side of the unit.

12. Replace the 4 gear case mounting screws.

13. Rotate the guard until the shoe faces in the same direction as the

switch guard. Be sure the guard is on the spindle bearing hub as

far as it will go and tighten guard mounting screws.

14. Replace the bail handle with the bolt and the guard adjusting knob.

15. Replace brushes and brush caps.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or authorized service center.

384621-01/DW866 1/8/02 2:27 PM Page 5

Page 9

6

CAUTION: The use of any non-recommended accessory may be

hazardous.

Accessory Maximum Safe Speed

Masonry Wheel* 6300 RPM

(Silicon Carbide) 12” Dia. x 1/8” Thick x 1” Hole

Metal Cutting Wheel* 6300 RPM

(Aluminum Oxide) 12” Dia. x 1/8” Thick x 1” Hole

*Internally Reinforced

Cleaning

Blowing dust and grit out of the main housing by means of an air

hose is recommended and may be done as often as dirt is seen

collecting in and around the air vents. The motor should be running

while air is being blown into the vents.

Lubrication

Except for the needle roller bearings used at the upper end of the

spindle, closed-type, grease-sealed ball bearings are used

throughout. These bearings have sufficient lubrication packed in

them at the factory to last the life of the bearing. The needle bearings

mentioned above receive their lubrication from the grease in the gear

case.

Gears should be relubricated every 60 to 90 days, depending upon

use. This lubrication should only be attempted by experienced power

tool repair technicians like the mechanics at B&D service centers.

Brushes

Inspect carbon brushes often. Replace when brushes are worn down

to the identifying groove or when spring exerts insufficient pressure

to hold brush against commutator. Keep brushes clean and sliding

free in brass inserts.

English

Figure 5

SPINDLE NUT

ABRASIVE

WHEEL

OUTER

CLAMP

WASHER

INNER CLAMP

WASHER

WRENCH

SPINDLE

LOCK PIN

384621-01/DW866 1/8/02 2:27 PM Page 6

Page 10

7

English

TO REMOVE BRUSHES:

1. TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

2. Remove brush cap.

3. Pull brush assembly out of brass insert.

Motor Brushes

DEWALT uses an advanced brush system which automatically stops

the drill when the brushes wear out. This prevents serious damage to

the motor.

Maintenance

Use only mild soap and damp cloth to clean the tool. Never let any

liquid get inside the tool; never immerse any part of the tool into a

liquid.

Self-lubricating bearings are used in the tool and periodic

relubrication is not required. In the unlikely event that service is ever

needed, take your tool to an authorized service location.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or local service center.

ACCESSORY MUST BE RATED FOR USE AT SPEED EQUAL TO

OR HIGHER THAN NAMEPLATE R.P.M. OF T OOL WITH WHICH IT

IS BEING USED.

If you need assistance in locating any accessory, please contact

D

EWALT Industrial Tool Company, 626 Hanover Pike, P.O. Box 158,

Hampstead, MD 21074 or call 1-800-4-D

EWALT (1-800-732-4441).

CAUTION: The use of any non-recommended accessory may be

hazardous.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information, call

1-800-4-D

EWALT. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

DEWALTheavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

384621-01/DW866 1/8/02 2:27 PM Page 7

Page 11

Importantes mesures de sécurité

• S’ASSURER QUE LES PROTECTEURS sont en place et en bon

état.

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s’en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l’écart de l’aire de travail.

• RENDRE L’ATELIER SÛR POUR LES ENFANTS à l’aide de

cadenas, de disjoncteurs, ou en retirant les clés de mise en

tension.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr

et efficace, utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil

ou d’un accessoire le rendement d’un outil de fabrication plus

robuste.

• UTILISER DES CORDONS DE RALLONGE APPROPRIÉS.

S’assurer que le cordon de rallonge est en bon état. Lorsqu’on se

sert d’un cordon de rallonge, s’assurer qu’il est de calibre approprié

pour la tension nécessaire au fonctionnement de l’outil. L’utilisation

d’un cordon de calibre inférieur occasionne une baisse de tension

entraînant une perte de puissance et la surchauffe. Le tableau

suivant indique le calibre approprié selon la longueur du cordon et

les mentions de la plaque signalétique de l’outil. En cas de doute,

utiliser un cordon de calibre supérieur. Le chiffre indiquant le

calibre est inversement proportionnel au calibre du cordon.

• CORDONS DE RALLONGE POUR L’EXTÉRIEUR. Lorsque l’outil

sert à l’extérieur, utiliser seulement des cordons de rallonge prévus

à cet effet et portant la mention appropriée.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Non recommandé

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples, des gants, des cravates, des bagues, des

bracelets ou d’autres bijoux qui peuvent être happés par les pièces

en mouvement. Le port des chaussures à semelle antidérapante

est recommandé. Protéger la chevelure si elle est longue.

• TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. Porter

également un masque respiratoire si le travail de coupe produit de

la poussière. Des lunettes de correction de la vue standard

comportent seulement des verres résistant aux chocs; ce NE sont

PAS des lunettes de sécurité.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et

affûtés pour qu’ils donnent un rendement supérieur et sûr. Suivre

les directives relatives à la remplacement des accessoires.

• DÉBRANCHER L’OUTIL avant de le réparer ou d’en changer un

accessoire (comme une lame, un foret ou un couteau).

• MINIMISER LES RISQUES DE DÉMARRAGES ACCIDENTELS.

S’assurer que l’interrupteur est en position hors tension avant de

brancher l’outil.

• UTILISER LES ACCESSOIRES RECOMMANDÉS. Consulter le

guide d’utilisation afin de connaître les accessoires recommandés.

L’utilisation d’accessoires inappropriés présente des risques de

blessures.

8

Français

384621-01/DW866 1/8/02 2:27 PM Page 8

Page 12

Réparer ou remplacer immédiatement les cordons endommagés ou

usés.

L ‘outil est conçu pour être branché sur un circuit dont les prises

ressemblent à celle illustrée à la figure A. L’outil comporte une fiche

de terre qui ressemble à celle illustrée à la figure A. On peut se servir

d’un adaptateur temporaire (comme celui des figures B et C) pour

brancher la fiche dans une prise à 2 orifices (fig. B) lorsqu’il n’y a

pas de prise mise à la terre. Il faut seulement se servir de

l’adaptateur temporaire jusqu’à ce qu’un électricien certifié puisse

installer une prise mise à la terre appropriée. Il faut alors relier l’oreille

rigide, la cosse ou tout autre objet du genre de couleur verte à une

mise à la terre permanente (comme à la boîte d’une prise bien mise

à la terre).

Mesures de sécurité additionnelles

relatives aux machines à tronçonner

MISE EN GARDE : Lorsqu’on coupe dans les murs, les planchers

ou tout autre endroit o∫ peuvent se trouver des fils sous tension,

NE PAS TOUCHER ÀTOUT COMPOSANT MÉTALLIQUE DE

L’OUTIL. Ne le saisir que par ses surfaces de prise isolées afin de se

protéger des secousses électriques.

• TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ

LORSQU’ON SE SERT DE L’OUTIL.

• L’utilisation d’accessoires non mentionnés dans le présent guide

9

Français

• NE JAMAIS SE TENIR SUR L’OUTIL. Cela présente des risques

de blessures graves si l’outil bascule ou si on touche à la lame par

inadvertance.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à

utiliser l’outil, il faut vérifier si le protecteur ou toute autre pièce

endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l’alignement et les attaches des pièces mobiles, le degré

d’usure des pièces et leur montage, ainsi que tout autre facteur

susceptible de nuire au bon fonctionnement de l’outil. Il faut réparer

ou remplacer tout protecteur ou autre composant endommagé.

• NE JAMAIS LAISSER UN OUTIL EN MARCHE SANS

SURVEILLANCE. LE METTRE HORS TENSION. Ne pas laisser

l’outil avant l’immobilisation complète de la lame.

Mise à la terre

En cas de mauvais fonctionnement ou de bris de l’outil, la mise à la

terre procure un chemin de moindre résistance au courant électrique

afin de minimiser les risques de secousses électriques. Le cordon de

l’outil comporte un conducteur de terre et une fiche de mise à la terre.

La fiche doit être branchée dans une prise de machine bien installée

et mise à la terre conformément aux lois et règlements locaux. Ne

pas modifier la fiche fournie. Lorsque la fiche n’entre pas dans la

prise, demander à un électricien qualifié d’installer une prise

appropriée.

La mauvaise connexion du conducteur de terre de l’outil présente

des risques de secousses électriques. Le conducteur dont l’isolant

est vert ou vert avec des lignes jaunes constitue la mise à la terre. En

cas de réparation ou de remplacement du cordon ou de la fiche, ne

pas relier le conducteur de terre à une borne sous tension.

Consulter un électricien qualifié ou le personnel des centres de

service an cas d’incompréhension des instructions relatives à la mise

à la terre ou en cas de doute quant à la mise à la terre de l’outil.

Utiliser seulement des cordons de rallonge trifilaires dotés de fiche

mise à la terre à trois broches, ainsi que des prises à 3 orifices

acceptant la fiche de l’outil.

AB C

BROCHE DE PRISE

MISE À LA TERRE

PRISE MISE

À LA TERRE

DISPOSITIF DE

MISE À LA TERRE

ADAPTATEUR

384621-01/DW866 1/8/02 2:27 PM Page 9

Page 13

10

Français

INTERRUPTEUR

À DÉTENTE

COUVERCLE DES

BALAIS

BOÎTER

DU CHAMP

POIGNÉECONTOUR

PROTECTEUR

ÉCROU À OREILLES

DU RÉGLAGE DE LA

PROFONDEUR

Commandes (Figures 1 et 2)

MISE EN GARDE : Saisir fermement l’outil des deux mains avant

de le mettre en marche. Pour l’actionner, bien saisir la poignée de

l’interrupteur et l’écraser afin d’enfoncer la détente. Pour arrêter

l’outil, relâcher la détente.

RÉGLAGE DU PROTECTEUR : Débrancher l’outil et s’assurer que

l’interrupteur est à la position hors tension avant de régler le

protecteur. On peut régler le protecteur d’environ 80¡ en desserrant

le bouton de réglage du protecteur. Saisir fermement le protecteur et

le faire tourner à l’angle voulu. Verrouiller en place en serrant le

bouton de réglage du protecteur. NOTE: Il ne faut pas trop serrer les

deux vis de montage du protecteur à chaque extrémité de la bride

afin de permettre au protecteur de tourner.

n’est pas recommandé et peut être dangereuse. L’utilisation de

dispositifs de suralimentation permettant de faire fonctionner l’outil

plus vite que sa vitesse nominale constitue une mauvaise

utilisation.

• Avant d’installer une meule, en vérifier les spécifications du

fabricant et s’assurer la vitesse nominale de la meule est

supérieure à la vitesse sous vide indiquée sur la plaque

signalétique de l’outil.

• Avant d’utiliser une meule, s’assurer qu’elle n’est ni craquée, ni

fêlée. Le cas échéant, jeter la meule. Il faut également inspecter

la meule lorsqu’on pense que l’outil est tombé. Ne pas déposer

l’outil sur la meule.

• Lorsqu’on démarre l’outil (aprés avoir installé une nouvelle meule),

le saisir dans un endroit bien protégé. Ne jamais mettre l’outil en

marche lorsque quelqu’un se tient devant la meule (y compris

l’utilisateur).

• Lors de l’utilisation, éviter de faire sauter la meule ou de la

maltraiter. Le cas échéant, arrêter l’outil et vérifier la meule.

• Nettoyer l’outil régulièrement.

• Protéger les objets personnels combustibles de la zone de travail

des étincelles que produit l’outil.

CONSERVER CES MESURES.

Moteur

Veiller à ce que la tension d’alimentation soit conforme aux exigences de la

plaque signalétique de l’outil. Une baisse de tension de plus de 10 p. 100

entra”ne une perte de puissance et la surchauffe. Tous les outils DEWALT

sont essayés avant de quitter l’usine. Lorsque celui-ci refuse de fonctionner,

vérifier la source de courant électrique.

384621-01/DW866 1/8/02 2:27 PM Page 10

Page 14

LA TIGE DE VERROUILLAGE DE L’ARBRE sert lors du

remplacement des accessoires. Pour l’engager, débrancher l’outil et

s’assurer que l’interrupteur est à la position hors tension. Enfoncer

la tige de verrouillage et faire tourner la meule et l’arbre jusqu’à ce

que la tige de verrouillage s’engage dans l’arbre. Se servir de la clé

fournie pour dévisser l’écrou de l’arbre, puis retirer ou installer des

accessoires. L’arbre et l’écrou ont des filets à droite.

NOTE : La fente dans la poignée de la clé peut servir de levier

lorsqu’on serre ou qu’on desserre les écrous ˆ oreilles. La clé est

comprise dans l’emballage. On peut régler le patin afin d’obtenir une

profondeur de coupe maximale de 100 mm (4 po).

Fonctionnement

1. L’outil comprend un cordon et une fiche à3 broches. Comparer la

tension indiquée sur la plaque signalétique de l’outil à celle

d’alimentation avant de brancher l’outil. Les tensions doivent être

identiques.

2. Avant de mettre l’outil en marche, bien saisir les deux poignées et

soulever l’outil. S’assurer qu’il n’y a rien à proximité ni devant la

meule. Aligner la meule sur le matériau à découper.

3. Mettre l’outil en marche et faire avancer lentement la meule dans

le matériau, en y exerçant une pression ferme, tout en maintenant

le patin à plat contre le matériau. Éviter de forcer l’outil. Afin de

maximiser le rendement et la durée de l’outil, utiliser l’outil à sa

vitesse nominale.

Profondeur de coupe

On peut régler la profondeur de coupe en desserrant les deux écrous

à oreilles qui se trouvent sur la face extérieure du protecteur..

NOTE : La fente dans la poignée de la clé fournie peut servir de

levier lorsqu’on serre ou qu’on desserre les écrous à oreilles.

COUPE DE MÉTAUX ET DE MATÉRIAUX MINCES

Afin de minimiser les efforts de l’utilisateur et optimiser l’efficacité de

l’outil lors de la coupe de m≥taux ou de mat≥riaux minces, r≥gler le

11

Français

Figure 1

Figure 2

POIGNÉE-CONTOUR

BAQUE D´USURE (OUVERCLE

DU BOÎTIER DES ENGRENAGES

SOUS LA BAGUE)

BOÎTIER DU

CHAMP

TIGE DE

VERROUILLAGE

DE LARBRE

VIS DE MONTAGE

DU PROTECTEUR

BOUTON DE

RÉGLAGE DU

PROTECTEUR

VIS DE MONTAGE

DU BOÎTIER DES

ENGRENAGES (4)

INTERRUPTEUR

À DÉTENTE

PATIN

PROTECTEUR

ÉCROUS À OREILLES DU

RÉGLAGE DE LA PROFONDEUR

384621-01/DW866 1/8/02 2:27 PM Page 11

Page 15

12

7. Faire tourner la meule ˆ la main afin de s’assurer que la meule

est bien centr≥e, qu’elle ne frappa pas le patin ni le protecteur et

l’≥crou, et que les brides et l’≥crou sont serr≥s.

Utilisations

tôle d’une épaisseur maximale de 3 mm (1/8 po)

béton, blocs de cendre et brique

barre d’armature - habituellement d’un diamètre de moins de 19 mm

(3/4 po)

treillis métallique d’un diamètre de 3 mm (1/8 po)

plancher ondulé et coffrage de plafond (coffrages de béton)

conduit électrique à gaine de 3 mm (1/8 po)

profilés d’une épaisseur maximale de 3 mm (1/8 po) comme des

Français

Figure 3

Figure 4

OUI

NON

NON

OUI

MÉTAUX OU

MATÉRIAU

MINCE

MAÇONNERIE

patin ˆ la profondeur de coupe maximale (fig. 3).

COUPE DE PIERRE OU DE MA≤ONNERIE

Afin de maximiser l’efficacité de l’outil, régler l’ouverture de la meule

à environ 13 mm (1/2 po) au-delà du patin. Dans de nombreux cas,

le matériau se brise aisément le longe du trait gravé de 13 mm

(1/2 po) de profondeur. Lorsque la coupe doit être plus profonde,

augmenter la profondeur de coupe en multiples de 13 mm (1/2 po)

(fig. 4).

Installation de la meule (Figure 5)

1. METTRE L’OUTIL HORS TENSION ET LE DÉBRANCHER.

2. Déposer l’outil sur une surface ferme avec le dessous du patin

vers le haut.

3. Desserrer les écrous à oreilles du réglage du patin, soulever le

patin à la profondeur de coupe minimale et serrer les écrous

à oreilles. On facilite de la sorte le retrait de l’écrou et des

rondelles de l’arbre.

4. Utiliser la clé à fourche de 28 mm (1 1/8 po) fournie pour retirer

l’écrou de l’arbre, la rondelle de fixation externe et la meule usée

(le cas échéant). Empêcher l’arbre de tourner à l’aide de la tige

de verrouillage. Les filets de l’arbre sont à droite.

5. Choisir la meule appropriée, utiliser seulement un des

accessoires spécifés dans le présent guide. Ne jamais utiliser des

meules dont la vitesse nominale est inférieure à celle de l’outil.

6. S’assurer que la rondelle de fixation interne est en place et que

les oreilles sont engagées sur les côtés plats de l’arbre. Faire

glisser la meule sous le patin et sur l’arbre. S’assurer que la

meule passe par-dessus le diamètre du guide de la rondelle de

fixation interne. La faire glisser sur la rondelle de fixation externe.

La fileter sur l’écrou de l’arbre ce qui permet le centrage

automatique de la rondelle de fixation externe. Engager la tige de

verrouillage de l’arbre et serrer l’écrou à l’aide de la clé. Éviter

de trop serrer l’≥crou de l’arbre.

384621-01/DW866 1/8/02 2:27 PM Page 12

Page 16

poutres en U, des cornières et des plaques

NOTE : Il n’est pas conseillé de couper des matériaux plus épais que

ceux mentionnés en raison d’une éventuelle surcharge électrique

de l’outil.

Conversion de l’outil pour les droitiers ou

les gauchers

Fonctionnement

NOTE : En usine, l’arbre est installé du côté droit de l’outil pour les

droitiers.

1. METTRE L’OUTIL HORS TENSION ET LE DÉBRANCHER.

2. Déposer l’outil sur une surface solide et plane.

3. Retirer les couvercles des balais et les balais.

4. Retirer la poignée-contour en enlevant le bouton de réglage du

protecteur et le boulon hexagonal.

5. Retirer les quatre vis de montage du boîtier des engrenages.

6. Retirer le boîtier des engrenages.

7. Retirer la bague d’usure.

8. Soulever le couvercle du boîtier des engrenages du boîtier du

champ avec l’induit fixé. Le couvercle du boîtier des engrenages

et l’induit forment un sous-assemblage.

9. IMPORTANT: Remarquer l’ergot plat du couvercle du boîtier des

engrenages et le creux correspondant du boîtier des engrenages

à l’opposé de l’arbre. Aligner ces deux éléments et remonter le

boîtier des engrenages et le couvercle.

10. Remettre la bague d’usure sur le boîtier du champ.

11.Faire tourner le boîtier du champ et la poignée de l’interrupteur

sur 180¡. Ensuite, lorsqu’on se place à l’extrémité o∫ se trouve le

cordon et avec l’interrupteur à détente vers le bas, l’arbre devrait

se trouver du côté gauche de l’outil.

12. Remettre les quatre vis de montage du boîtier des engrenages.

13. Faire tourner le protecteur jusqu’à ce que le patin soit dans le

même sens que le protecteur de l’interrupteur. S’assurer que le

13

Français

Figure 5

ÉCROU DE

L´ARBRE

MEULE

ABRASIVE

RONDELLE DE

FIXATION

EXTERNE

RONDELLE DE

FIXATION

INTERNE

CLÉ

TIGE DE VERROUILLAGE

DE L´ARBRE

384621-01/DW866 1/8/02 2:27 PM Page 13

Page 17

14

Il faut lubrifier les engrenages entre 60 et 90 jours, selon l’utilisation

de l’outil. Confier cette lubrification seulement au personnel

qualifiéd’un centre de service autorisé.

Balais

Vérifier souvent les balais au carbone. Les remplacer lorsqu’ils sont

usés jusqu’à la rainure d’identité ou lorsque le ressort n’exerce plus

la pression suffisante pour maintenir le balai contre le commutateur.

S’assurer que les balais sont propres et qu’ils glissent librement dans

les pièces rapportés de laiton.

Faire ce qui suit pour retirer les balais.

1. METTRE L’OUTIL HORS TENSION ET LE DÉBRANCHER.

2. Retirer le couvercle des balais.

3. Tirer le balai hors de la pièce rapportée de laiton.

IImportant

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’au personnel d’un

centre de service D

EWALT ou d’un atelier d’entretien autorisé

n’utilisant que des pièces de rechange identiques.

Garantie complète

Les outils industriels de service intensif D

EWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

D

EWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée ou remplacée sans frais. Pour obtenir de

plus amples renseignements sur les réparations couvertes par la

garantie, composer le 1 (800) 4-D

EWALT (! (800) 433-9258). La ga

rantie ne couvre pas les accessories ni les réparations tentées ou

effectuées par des tiers. Les modalités de la présente garantie

donnent des droits légaux spécifiques. L’utilisateur peut également

se prévaloir d’autres droits selon l’état ou la province qu’il habite.

Français

protecteur soit à fond sur le moyeu de soutien de l’arbre et serrer

les vis de montage du protecteur.

14. Remettre la poignée-contour en place à l’aide du boulon et du

bouton de réglage du protecteur.

15. Remettre en place les balais et les couvercles des balais.

Accessoires

Les accessoires recommandés sont vendus séparément au centre

de service de la région.

MISE EN GARDE : L’utilisation de tout accessoire non

recommandé peut être dangereuse.

Accessoire Vitesse nominale

Meule pour maéonnerie* 6 300 trs/min

(carbure de silicium) Diam. de 304 mm (12 po), épaiss. de

4 mm (1/8 po) et trou de 25 mm (1 po)

Meule pour métaux* 6 300 trs/min

(oxyde d’aluminium) Diam. de 304 mm (12 po), épaiss. de

4 mm (1/8 po) et trou de 25 mm (1 po)

*Armature interne

Nettoyage

Il est conseilé d’utiliser un boyau d’air pour souffler la poussière et les

saletés hors du bo”tier de l’outil. On peut souffler de l’air dès que les

saletés s’accumulent dans les évents du ventilateur et autour de

ceux-ci. Le moteur devrait fonctionner lorsqu’on souffle de l’air dans

les évents.

Lubrification

À l’exception des roulements à rouleaux et à aiguilles utilisés

àl’extrémité supérieure de l’arbre, l’outil comporte des roulements

scellés et lubrifiés. Ces derniers renferment suffisamment de graisse

pour la durée du roulement. Les roulements à aiguilles sont lubrifiés

par la graisse du bo”tier des engrenages.

384621-01/DW866 1/8/02 2:27 PM Page 14

Page 18

En outre, la garantie suivante couvre les outils DEWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT REMIS

Si, pour quelque raison que ce soit, l’outil industriel de service intensif

D

EWALT ne donne pas entière satisfaction, il suffit de le retourner

chez le marchand participant dans les 30 jours suivant la date

d’achat afin d’obtenir un remboursement complet. Il faut retourner,

port payé, l’outil complet. On peut exiger une preuve d’achat.

15

Français

384621-01/DW866 1/8/02 2:27 PM Page 15

Page 19

16

Español

Instrucciones importantes de seguridad

ADVERTENCIA: Es indispensable sujetarse a las precauciones

básicas de seguridad, con la finalidad de reducir el peligro de

incendio, choque eléctrico y lesiones personales, en todas las

ocasiones en que se utilicen herramientas eléctricas. Entre estas

precauciones se incluyen las siguientes.

LEA TODAS LAS INSTRUCCIONES

Instrucciones de conexión a tierra

En el caso de mal funcionamiento, la tierra proporciona una vía de

menor resistencia a la corriente eléctrica para reducir el riesgo de

choque eléctrico. Esta herramienta está equipada con un cable

eléctrico con un conductor a tierra y pata de aterrizaje. La clavija debe

conectarse a una toma de corriente instalada correctamente y

aterrizada de conformidad con todos los reglamentos locales. No

modifique la clavija, si no se ajusta a la toma de corriente, haga que

un electricista calificado le instale una toma adecuada.

La conexión incorrecta del conductor a tierra del equipo puede

originar riesgos de choque eléctrico. El conductor cuyo aislamiento es

de color verde con o sin franjas amarillas es el conductor a tierra del

equipo. Si se requiere reparación o cambio del cable eléctrico o la

clavija, no conecte el conductor a tierra a una terminal viva.

Consulte con un electricista si no comprende perfectamente las

instrucciones de aterrizaje, o si tiene dudas acerca de la conexión a

tierra de su equipo.

Utilice solamente extensiones de tres cables que tengan clavijas de

tres patas y tomas de corriente de tres polos que acepten la clavija de

la herramienta.

Repare o reemplace inmediatamente los cables dañados o

desgastados.

Esta herramienta está diseñada para utilizarse en circuitos que

tengan una toma de corriente similar a la ilustrada en la figura A. Se

INTERRUPTOR

DE GATILLO

TAPA DE

CARBONES

CAJA DEL CAMPO

MANGO EN ARCO

GUARDA

MARIPOSA DE AJUSTE

GUARDA

Epecificaciones

Tensión de alimentación 120 V CA/CD

Potencia nominal: 500 W

Frecuencia de operación: 50/60 Hz

Consumo de corriente: 15 A

384621-01/DW866 1/8/02 2:27 PM Page 16

Page 20

17

Español

puede utilizar un adaptador temporal, que se parece al mostrado en

las figuras B y C, para conectar esta clavija a una toma de corriente

de dos polos como se observa en la figura B si no dispone de una

toma aterrizada. Solamente debe utilizar el adaptador temporal hasta

que un electricista le instale una toma apropiada.

La oreja, lengüeta, o similar de color verde que se extiende del

adaptador debe conectarse a tierra permanente, como una toma de

corriente aterrizada.

Instrucciones importantes de seguridad

• CONSERVE LAS GUARDAS EN SU SITIO y listas para trabajar.

• CONSERVE LIMPIA EL AREA DE TRABAJO. Las áreas y bancos

con objetos acumulados en desorden propician los accidentes.

• NO SE EMPLEE EN AMBIENTES PELIGROSOS. No utilice

herramientas eléctricas en ligares inundados o mojados, ni las

exponga a la lluvia. Conserve bien iluminada el área de trabajo.

• CONSERVE APARTADOS A LOS NIÑOS. Todos los visitantes

deben permanencer a distancia segura de la zona de trabajo.

• HAGA SU TALLER A PRUEBA DE NIÑOS con candados,

interruptores maestros y retirando las llaves de encendido.

• NO FUERCE LA HERRAMIENTA. Esta cumplirá mejor con su

trabajo y de manera más segura bajo las especificaciones para las

que se diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce una

herramienta o sus dispositivos en una tarea para los que no han

sido diseñados.

• UTILICE UN CABLE DE EXTENSION ADECUADO. Asegúrese

que su extensión esté en buenas condiciones. Cuando utilice una

extensión, asegúrese de emplear una que soporte la corriente que

su herramienta necesita. Una extensión con calibre insuficiente

provocará una caída en el voltaje de la línea, ocasionando pérdida

de potencia y sobrecalentamiento. El cuadro siguiente muestra el

calibre correcto a utilizarse de acuerdo con la longitud y el

amperaje indicado en la placa de identificación. Si tiene dudas,

utilice el calibrte siguiente. Mientras más pequeño sea el número

del calibre, mayor será su capacidad.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

AMPERAJE

Más No más Calibre del cordón AWG

de de

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16- 14 12 No recomendado

• CORDONES DE EXTENSION PARA INTEMPERIE. Cuando

utilice la herramienta a la intemperie, solamente utilice extensiones

diseñadas para ello y así marcadas.

• VISTA LAS PRENDAS ADECUADAS. No utilice prendas de

vestir flojas, guantes, corbatas, anillos, brazaletes ni otras piezas

de joyería que pudiesen quedar atrapadas en las partes móviles.

Se recomienda el empleo de calzado antiderrapante. Cúbrase el

cabello si lo tiene largo.

• SIEMPRE UTILICE GAFAS DE SEGURIDAD. También utilice una

máscara contra polvo si la operación a efectuar lo produce. Los

anteojos de uso diario solamente tienen lentes resistentes al

impacto, NO SON anteojos de seguridad.

• NO SE SOBREEXTIENDA. Conserve siempre bien apoyados los

pies, lo mismo que el equilibrio.

AB C

PATA DE

CONEXION A

TIERRA

TOMA DE

CORRIENTE

ATERRIZADA

MEDIO DE

ATERRIZAJE

ADAPTADOR

384621-01/DW866 1/8/02 2:27 PM Page 17

Page 21

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas

afiladas y limpias para que funcionen mejor y de manera más

segura. Siga las instrucciones de cambio de accesorios.

• DESCONECTE LA HERRAMIENTAS antes de efectuarles

servicio y cuando les cambie acesorios, como cuchillas, brocas y

similares.

• REDUZCA EL RIESGO DE ENCENDIDO ACCIDENTAL.

Asegúrese que el interruptor esté en posición de apagado antes

de conectar la herramienta.

• UTILICE LOS ACCESORIOS RECOMENDADOS. Busque en el

manual de instrucciones los accesorios recomendados. El uso de

accesorios inadecuados puede causar riesgos de lesiones.

• NUNCA SE PARE EN LA HERRAMIENTA. Puede provocarse

lesiones graves si la herramienta se vuelca o si hace contacto

accidental con la herramienta de corte.

• REVISE LAS PARTES DAÑADAS. Antes de seguir utilizando la

herramienta, debe revisar cuidadosamente una guarda o cualquier

otra pieza que esté dañada para determinar si cumplirá

adecuadamente con su función; revise la alineación de las piezas

móviles, sus montajes, ruptura de partes y cualesquiera otras

condiciones que pudiesen afectar su operación. Repare o

reemplace las piezas dañadas.

• NUNCA DEJE LA HERRAMIENTA EN FUNCIONAMIENTO Y

DESATENDIDA. APAGUELA. No deje la herramienta hasta que

se haya detenido por completo.

Instrucciones adicionales de seguridad

para la máquina cortadora

PRECAUCION: Cuando emplee esta herramienta para el corte

sobre paredes, pisos u otras zonas en las que puedan encontrarse

cables eléctricos “vivos”, ¡NO TOQUE NINGUNA PARTE

METÁLICA DE LA MISMA! Sostenga la herramienta sólo por las

superficies de sujeción aislantes para evitar el choque eléctrico si la

segueta entrara en contacto con un cable “vivo”.

18

Español

Figura 1

Figura 2

MANGO EN ARCO

ANILLO DE DESGASTE (TAPA DE

CAJA DE ENGRANES DEBAJO)

CAJA DEL

CAMPO

PERNO DE

SEGURO DE LA

FLECHA

TORNILLOS DE MONTAJE DE

LA GUARDA

PERILLA DE

AJUSTE DE

LA GUARDA

TORNILLOS DE

MONTAJE DE LA CAJA

DE ENGRANES (4)

GATILLO

ZAPATA

GUARDA

MARIPOSAS DE AJUSTE DE

PROFUNDIDAD

384621-01/DW866 1/8/02 2:27 PM Page 18

Page 22

• SIEMPRE UTILICE ANTEOJOS DE SEGURIDAD CUANDO

EMPLEE ESTA HERRAMIENTA.

• No se recomienda el empleo de accesorios no especificados en

este manual. El uso de amplificadores de potencia que permitan

que la herramienta funcione a mayor velocidad que la especificada

constituye mal uso.

• Antes de instalar cualquier disco, verifique las especificaciones del

fabricante y cerciórese que la velocidad de operación segura es

mayor que la velocidad sin carga especificada en la placa de

identificación de la herramienta.

• Antes de usar la unidad, revise los discos de corte en busca de

cuarteaduras. Si hay cuarteaduras, deseche el disco. También

debe revisarse el disco si usted piensa que se ha golpeado. Nunca

deje la unidad apoyada sobre el disco.

19

Español

Figura 3

Figura 4

SI

NO

NO

SI

METALES O

MATERIAL

DELGADO

MATERIAL DE

MAMPOSTERIA

• Cuando encienda la herramienta (con un disco nuevo, o después

de haberlo cambiado), colóquela en un área protegida. Si el disco

se cuartea, puede estallar en menos de un minuto. Nunca

encienda la unidad si hay personas en línea con la herramienta,

incluyendo al operador.

• Durante la operación, evite que el disco rebote. Si esto ocurre,

detenga la unidad y revise el disco.

• Limpie su cortadora periódicamente.

• Proteja a personal y material combustible que se encuentren en

el área de trabajo de las chispas generadas por esta herramienta.

CONSERVE ESTAS

INSTRUCCIONES

Motor

Asegúrese que su alimentación de corriente concuerde con la

marcada en la placa de identificación de la herramienta.

Disminuciones en el voltaje mayores a 10% causarán pérdida de

potencia y sobrecalentamiento. Todas las herramientas DeWALT se

prueban en la fábrica; si esta herramienta no funciona, revise la

alimentación de corriente.

Controles (figuras 1 y 2)

PRECAUCION: Sujete la herramienta firmemente con ambas

manos antes de intentar encenderla. Para encenderla, sujete el

mango del interruptor con firmeza y oprima el gatillo.

AJUSTE DE LA GUARDA: Desconecte la herramienta de la toma

de corriente y asegúrese que el interruptor esté en posición de

apagado antes de ajustar la guarda. La guarda se puede ajustar

aproximadamente 80° aflojando la perilla de ajuste. Tome la guarda

con firmeza y gírela hasta el ángulo que desee. Asegúrela en

posición apretando la perilla de ajuste. NOTA: No deben

sobreapretarse los dos tornillos de montaje de la guarda que se

384621-01/DW866 1/8/02 2:27 PM Page 19

Page 23

20

Español

PARA CORTAR METALES Y MATERIALES DELGADOS

Para que el operador haga esfuerzo mínimo y obtenga la mayor

eficiencia al cortar metales y otros materiales delgados, ajuste la

zapata para la máxima profundidad de corte (figura 3).

PARA CORTAR PIEDRA Y MATERIALES DE ALBAÑILERIA

Para obtener la máxima efectividad, ajuste la exposición del disco a

aproximadamente 13 mm (1/2”) por debajo de la zapata. En muchas

aplicaciones, el material se romperá con la línea de corte a 13 mm

(1/2”), si llegase a requerir mayor profundidad, auméntela en

incrementos de aproximadamente 13 mm (1/2”). Observe la figura 4.

Instalación de los discos abrasivos

(figura 5)

1. APAGUE Y DESCONECTE LA HERRAMIENTA DE LA TOMA

DE CORRIENTE.

2. Deje la unidad sobre una superficie firme con la parte inferior de

la zapata apuntando hacia arriba.

3. Afloje las mariposas de ajuste de la zapata, lleve la zapata hasta

la profundidad mínima de corte y apriete las mariposas. Este paso

le permite mayor libertad para quitar la tuerca de la flecha y las

roldanas.

4. Afloje la tuerca de la flecha con la llave de 28 mm (1 1/8”)

(suministrada con la unidad), quite la roldana y el disco usado, si

es que hay uno instalado. Evite que la flecha gire por medio del

seguro. La cuerda de la flecha es derecha.

5. Seleccione el disco apropiado; utilice únicamente los accesorios

especificados en este manual. Nunca utilice discos para

velocidades inferiores a la señalada en la placa de identificación

de la unidad.

6. Asegúrese que la roldana de sujeción interior esté en su sitio y

que las orejas estén enganchadas con los planos de la flecha.

Deslice el disco a través de la parte inferior de la zapata y sobre

la flecha. Asegúrese que el disco quede sobre el diámetro piloto

Figura 5

TUERCA DE

LA FLECHA

DISCO

ABRASIVO

ROLDANA DE

SUJECION

EXTERIOR

ROLDANA DE

SUJECION

INTERIOR

LLAVE

PERNO DE

SEGURO DE LA

FLECHA

384621-01/DW866 1/8/02 2:27 PM Page 20

Page 24

encuentran en cada extremo del soporte, para permitir que la guarda

gire.

EL PERNO DE SEGURO DE LA FLECHA se utiliza para fijar la

flecha para cambiar accesorios. Para accionar el seguro, desconecte

la herramienta de la toma de corriente y asegúrese que el interruptor

esté en posición de apagado. Oprima el perno del seguro y gire el

disco y la flecha hasta que el perno se enganche. Utilice la llave

suministrada con la unidad para destornillar la tuerca y desmontar o

instalar accesorios. La flecha y la tuerca tienen cuerda derecha.

NOTA: La ranura del mango de la llave se puede utilizar para hacer

palanca adicional al apretar o aflojar las mariposas. La llave es una

parte de serie que acompaña a la unidad. Se puede ajustar la zapata

para ofrecer una profundidad máxima de corte de 101 mm (4”).

Operación

1. La herramienta viene con cable y clavija de 3 patas. Compare el

voltaje señalado en la placa de identificación con el de su

alimentación de corriente antes de conectar la unidad. Los voltajes

deben ser los mismos.

2. Antes de encender la unidad, sujete ambos mangos con firmeza

y levante la herramienta. Asegúrese que no haya objetos en línea

con ella o cercanos. Haga coincidir el disco con la línea que desee

cortar.

3. Encienda la unidad y avance el disco en la pieza de trabajo con

lentitud, pero con presión firme, al mismo tiempo que conserva la

zapata firme y a escuadra contra la pieza. No fuerce la

herramienta. Para máxima eficiencia y duración del disco,

conserve alta la velocidad de trabajo.

Profundidad de corte

Se puede ajustar la profundidad de corte aflojando las dos mariposas

de la parte exterior de la guarda. NOTA: La ranura del mango de la

llave se puede utilizar para hacer palanca adicional al apretar o

aflojar las mariposas.

21

Español

de la roldana de sujeción interior. Deslícelo en la roldana de

sujeción exterior. Comience a enroscar la tuerca de la flecha que

alineará automáticamente al roldana de sujeción exterior. Accione

el perno de seguro de la flecha y apriete la tuerca con la llave.

No sobreapriete la tuerca de la flecha.

7. Gire el disco a mano para verificar que esté bien centrado, que no

golpee con la zapata o la guarda y que la tuerca y las arandelas

están apretadas.

Aplicaciones

Lámina metálica con espesor máximo de 3 mm (1/8”)

Concreto, tabicón y ladrillo

Varilla reforzada, generalmente por debajo de 19 mm (3/4”) de

diámetro

Mezcla de alambre y concreto de 3 mm (1/8”) de diámetro máximo

Pisos y techos corrugados (preformados de concreto)

Preformados estructurales de 3 mm (1/8”) máximo como canales,

ángulos, placa, etc.

NOTA: No se recomienda el corte de materiales con espesores

mayores a los señalados debido a la posibilidad de sobrecarga

eléctrica.

Conversión de uso derecho a izquierdo

Operación

NOTA:Esta máquina está ensamblada en la fábrica con la flecha del

lado derecho de la unidad para operación derecha.

1. APAGUE LA HERRAMIENTA Y DESCONECTELA DE LA

ALIMENTACION DE CORRIENTE.

2. Coloque la unidad sobre una superficie firme y plana.

3. Retire las tapas de los carbones y los carbones.

4. Retire el mango en arco quitando la perilla de ajuste de la guarda

384621-01/DW866 1/8/02 2:27 PM Page 21

Page 25

y el tornillo hexagonal.

5. Retire los 4 tornillos de montaje de la caja de engranes

6. Retire la caja de engranes.

7. Retire el anillo de desgaste

8. Levante la cubierta de la caja de engranes, con la armadura

desmontada de la caja del campo. La armadura y la caja de

engranes son un subensamble.

9. IMPORTANTE:Observe una pequeña protuberancia que sale de

la cubierta de la caja de engranes y una muesca correspondiente

en la caja de engranes opuesta a la flecha. Haga coincidir estas

dos partes y rearme la caja de engranes y la cubierta.

10.Coloque de nuevo el anillo de desgaste en la caja del campo.

11.Gire el montaje de la caja del campo y el mango del interruptor

180°. A continuación, viendo del extremo del cable, con el

interruptor de gatillo abajo, la flecha debe quedar del lado

izquierdo de la unidad.

12.Coloque de nuevo los 4 tornillos de montaje de la caja de

engranes.

13.Gire la guarda hasta que la zapata quede en la misma dirección

que la guarda del interruptor. Asegúrese que la guarda entre en el

cubo del balero de la flecha tanto como sea posible y apriete los

tornillos de montaje de la guarda.

14.Coloque de nuevo el mango en arco con el tornillo y la perilla de

ajuste.

15.Coloque de nuevo los carbones y las tapas.

Accesorios

Los accesorios recomendados para emplearse con su herramienta

están a su disposición con costo extra con su distribuidor o centro de

servicio local.

PRECAUCION: El empleo de cualquier accesorio no reco-

mendado puede ser peligroso.

Accesorio Velocidad máxima segura

Disco para mampostería* 6300 rpm

(carburo de silicio)

304 mm diá. x 3 mm

esp. x 25 mm orificio

Disco para corte de metal* 6300 rpm

(óxido de aluminio)

304 mm diá. x 3 mm

esp. x 25 mm orificio

*Refuerzo interno

Lubricación

Con excepción de los baleros de aguja que se emplean en el

extremo superior de la flecha, todos los demás son baleros de bolas

de tipo cerrado, sellados. Estos baleros tienen suficiente lubricación

interna para que dure mientras el balero funcione. Los baleros de

agujas mencionados arriba reciben su lubricación de la grasa de la

caja de engranes.

Los baleros deben relubricarse cada 60 a 90 días, dependiendo del

uso. Esta lubricación deberá ser realizada únicamente por técnicos

de servicio expertos como los mecánicos en los centros de servicio

B&D.

Carbones

Revise los carbones frecuentemente. Reemplácelos cuando se

hayan desgastado hasta el nivel del canal de identificación, o cuando

a los muelles les falte presión para sujetarlos contra el conmutador.

Conserve los carbones limpios y deslizándose en sus guías.

PARA SACAR LOS CARBONES:

1. APAGUE Y DESCONECTE LA HERRAMIENTA DE LA TOMA

DE CORRIENTE.

22

Español

384621-01/DW866 1/8/02 2:27 PM Page 22

Page 26

23

Español

2. Quite la tapa de carbones.

3. Retire el montaje del carbón hacia fuera del inserto de latón.

Mantenimiento

1. Todos los rodamientos son baleros de bolas sellados. Están

lubricados de por vida y no necesitan otro mantenimiento. No

utilice WD-40 ni cualquier otro lubricante.

2. Limpie periódicamente todo serrín y astillas de alrededor del área

de la sierra. A pesar de que hay aberturas para que el polvo pase,

algo se acumulará.

3. Los carbones están diseñados para varios años de uso. Si alguna

vez necesitan reemplazarse, siga las instrucciones de la página

46 o llévela a un centro de servicio para reparación. Los centros

de servicio están anotados al final de este manual.

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros de servicio para herramientas industriales de D

EWALT.

u otras organizaciones calificadas. Estas organizaciones prestan

servicio a las herramientas D

EWALTy emplean siempre refacciones

legítimas D

EWALT.

PARA REPARACION Y SERVICIO DE SUS HERRAMIENT AS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av. Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

384621-01/DW866 1/8/02 2:27 PM Page 23

Page 27

24

Español

Garantía Completa

Las herramientas industriales DEWalt están garantizadas durante un año a

partir de la fecha de compra. Repararemos, sin cargos, cualquier falla debida

a material o mano de obra defectuosos. Por favor regrese la unidad completa,

con el transporte pagado, a cualquier Centro de Servicio para Herramientas

Industriales de DEWalt o a las estaciones de servicio autorizado enlistadas

bajo "Herramientas Eléctricas" en la Sección Amarilla. Esta garantía no se

aplica a los accesorios ni a daños causados por reparaciones efectuadas

por terceras personas. Esta garantía le otorga derechos legales específicos,

y usted puede tener otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas DEWALT están amparadas por

nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño de

su herramienta industrial D

EWalt, sencillamente devuélvala a los vendedores

participantes durante los primeros 30 días después de la fecha de compra

para que le efectúen un reembolso completo. Por favor regrese la unidad

completa, con el transporte pagado. Se puede requerir prueba de compra.

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 326-7100

SECCI N

AMARILLA

Si funciona…

y funciona muy bien.

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

384621-01/DW866 1/8/02 2:27 PM Page 24

Loading...

Loading...