Page 1

22

®

DW848

DW852

Page 2

23

Copyright DEWALT

English 1

Español 6

Português12

Page 3

24

B

A

Page 4

25

C

D

Page 5

1 en - 1

ENGLISH

ANGLE GRINDER DW848/DW852

Congratulations!

You have chosen a DEWALT Power Tool. Years of

experience, thorough product development and

innovation make DEWALT one of the most reliable

partners for professional Power Tool users.

Table of contents

Technical data en - 1

Declaration of conformity en - 2

Safety instructions en - 2

Package contents en - 3

Description en - 3

Electrical safety en - 4

Using an extension cable en - 4

Assembly and adjustment en - 4

Instructions for use en - 4

Maintenance en - 5

Guarantee en - 5

Technical data

DW848 DW852

Voltage V 230 230

(Latin America only) V 120 120

Power input W 2,000 1,800

No load speed min-18,000 6,300

Wheel diameter mm 180 230

Spindle M14 M14

Weight kg 4.6 4.6

Fuses:

120 V tools 15 Amperes

230 V tools 10 Amperes

The following symbols are used throughout this

manual:

Denotes risk of personal injury, loss of life

or damage to the tool in case of nonobservance of the instructions in this

manual.

Denotes risk of electric shock.

Fire hazard.

Page 6

2en - 2

ENGLISH

Declaration of conformity

DW848/DW852

DEWALT declares that these Power Tools have been

designed in compliance with: 89/392/EEC,

89/336/EEC, 73/23/EEC, EN 50144, EN 55104,

EN 55014, EN 61000-3-2 & EN 61000-3-3.

Level of sound pressure according to 86/188/EEC &

89/392/EEC, measured according to EN 50144:

DW848 DW852

LpA(sound pressure) dB(A)* 94.2 94.2

LWA(acoustic power) dB(A) 86.2 86.2

* at the operator’s ear

Take appropriate measures for the

protection of hearing if the sound

pressure of 85 dB(A) is exceeded.

Weighted root mean square acceleration value

according to EN 50144:

DW848 DW852

handle/side handle handle/side handle

2.94/1.64 m/s

2

2.94/1.64 m/s

2

Director Engineering and Product Development

Horst Großmann

DEWALT, Idstein, Germany

Safety instructions

When using Power Tools, always observe the

safety regulations applicable in your country to

reduce the risk of fire, electric shock and

personal injury. Read the following safety

instructions before attempting to operate this

product.

Keep these instructions in a safe place!

General

1 Keep work area clean

Cluttered areas and benches can cause accidents.

2 Consider work area environment

Do not expose Power Tools to humidity. Keep

work area well lit. Do not use Power Tools in the

presence of inflammable liquids or gases.

3 Guard against electric shock

Prevent body contact with earthed surfaces (e.g.

pipes, radiators, cookers and refrigerators).

For use under extreme conditions (e.g. high

humidity, when metal swarf is being produced,

etc.) electric safety can be improved by inserting

an isolating transformer or a (FI) earth-leakage

circuit-breaker.

4 Keep children away

Do not let children come into contact with the

tool or extension cord. Supervision is required for

those under 16 years of age.

5 Extension cords for outdoor use

When the tool is used outdoors, always use

extension cords intended for outdoor use and

marked accordingly.

6 Store idle tools

When not in use, Power Tools must be stored in

a dry place and locked up securely, out of reach

of children.

7 Dress properly

Do not wear loose clothing or jewellery. They can

be caught in moving parts. Preferably wear

rubber gloves and non-slip footwear when

working outdoors. Wear protective hair covering

to keep long hair out of the way.

8 Wear safety goggles

Also use a face or dust mask in case the

operations produce dust or flying particles.

9 Beware of maximum sound pressure

Take appropriate measures for the protection of

hearing if the sound pressure of 85 dB(A) is

exceeded.

10 Secure workpiece

Use clamps or a vice to hold the workpiece. It is

safer and it frees both hands to operate the tool.

11 Do not overreach

Keep proper footing and balance at all times.

12 Avoid unintentional starting

Do not carry the plugged-in tool with a finger on

the switch. Be sure that the switch is released

when plugging in.

Page 7

3 en - 3

ENGLISH

13 Stay alert

Watch what you are doing. Use common sense.

Do not operate the tool when you are tired.

14 Disconnect tool

Shut off power and wait for the tool to come to a

complete standstill before leaving it unattended.

Unplug the tool when not in use, before servicing

or changing accessories.

15 Remove adjusting keys and wrenches

Always check that adjusting keys and wrenches

are removed from the tool before operating the

tool.

16 Use appropriate tool

The intended use is laid down in this instruction

manual. Do not force small tools or attachments

to do the job of a heavy-duty tool. The tool will

do the job better and safer at the rate for which it

was intended.

Warning! The use of any accessory or

attachment or performance of any operation with

this tool, other than those recommended in this

instruction manual may present a risk of personal

injury.

17 Do not abuse cord

Never carry the tool by its cord or pull it to

disconnect from the socket. Keep the cord away

from heat, oil and sharp edges.

18 Maintain tools with care

Keep the tools in good condition and clean for

better and safer performance. Follow the

instructions for maintenance and changing

accessories. Inspect the tool cords at regular

intervals and, if damaged, have them repaired by

an authorized DEWALT repair agent. Inspect the

extension cords periodically and replace them if

damaged. Keep all controls dry, clean and free

from oil and grease.

19 Check for damaged parts

Before using the tool, carefully check it for

damage to ensure that it will operate properly

and perform its intended function. Check for

misalignment and seizure of moving parts,

breakage of parts and any other conditions that

may affect its operation. Have damaged guards

or other defective parts repaired or replaced as

instructed.

Do not use the tool if the switch is defective.

Have the switch replaced by an authorized

DEWALT repair agent.

20 Have your tool repaired by an authorized

DEWALT repair agent

This Power Tool is in accordance with the

relevant safety regulations. To avoid danger,

electric appliances must only be repaired by

qualified technicians.

Additional safety rules for Angle Grinders

• Your Angle Grinder has been designed for

grinding and cutting masonry and steel.

Do not cut or grind light metal with a

magnesium content exceeding 80%

since this type of metal is flammable.

• Do not use any accessories other than fibre

reinforced grinding wheels and cutting disks.

• Use the grinding wheels and cutting disks

recommended by the manufacturer only.

• The no-load speed of the grinding wheel or

cutting disk must not exceed the value printed on

the nameplate (instruction sheet).

• Do not cut workpieces requiring a maximum

depth of cut exceeding that of the cutting disk.

Package contents

The package contains:

1 Angle Grinder

1 Guard

1 Side handle

1 Two-pin spanner

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and understand

this manual prior to operation.

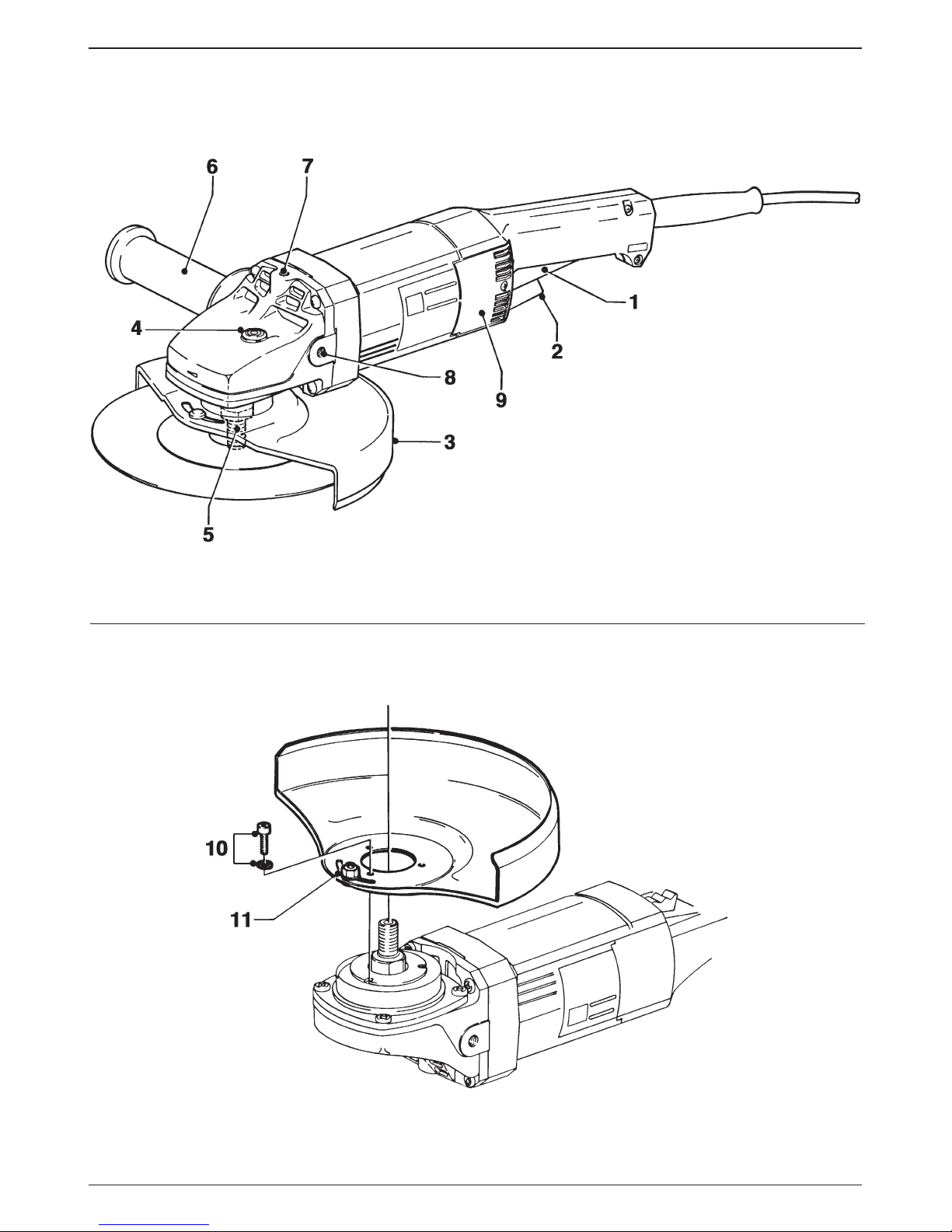

Description (fig. A)

Your DEWALT Angle Grinder has been designed for

professional grinding and cutting applications.

1 ON/OFF-switch

2 Locking switch

3 Guard

4 Spindle lock

5 Spindle

6 Side handle

Page 8

4en - 4

ENGLISH

7 Top hole

8 Side holes

9 Carbon brush covers

Electrical safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

Your DEWALT tool is double insulated in

accordance with EN 50144; therefore no

earth wire is required.

Using an extension cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see technical data). An undersized cable will

cause a drop in line voltage resulting in loss of

power and overheating.

When using a cable reel, always unwind the cable

completely.

Also refer to the table below.

Minimum gage for cable sets

Voltage Total cable length in feet

120 0-25 26-50 51-100 101-150

240 0-50 51-100 101-200 201-300

Ampere rating

More than Not more than AWG

0-6 18 16 16 14

6-10 18 16 14 12

10-12 16 16 14 12

12-16 14 12 not recommended

Assembly and adjustment

Prior to assembly and adjustment always

unplug the tool.

Mounting and removing the guard (fig. B)

• Place the Angle Grinder on a table, spindle up.

• Mount the guard to the tool using the three

screws (10) with star washers.

• Rotate the guard to the required position and

tighten the lock nut (11).

• To remove the guard, loosen the three screws (10).

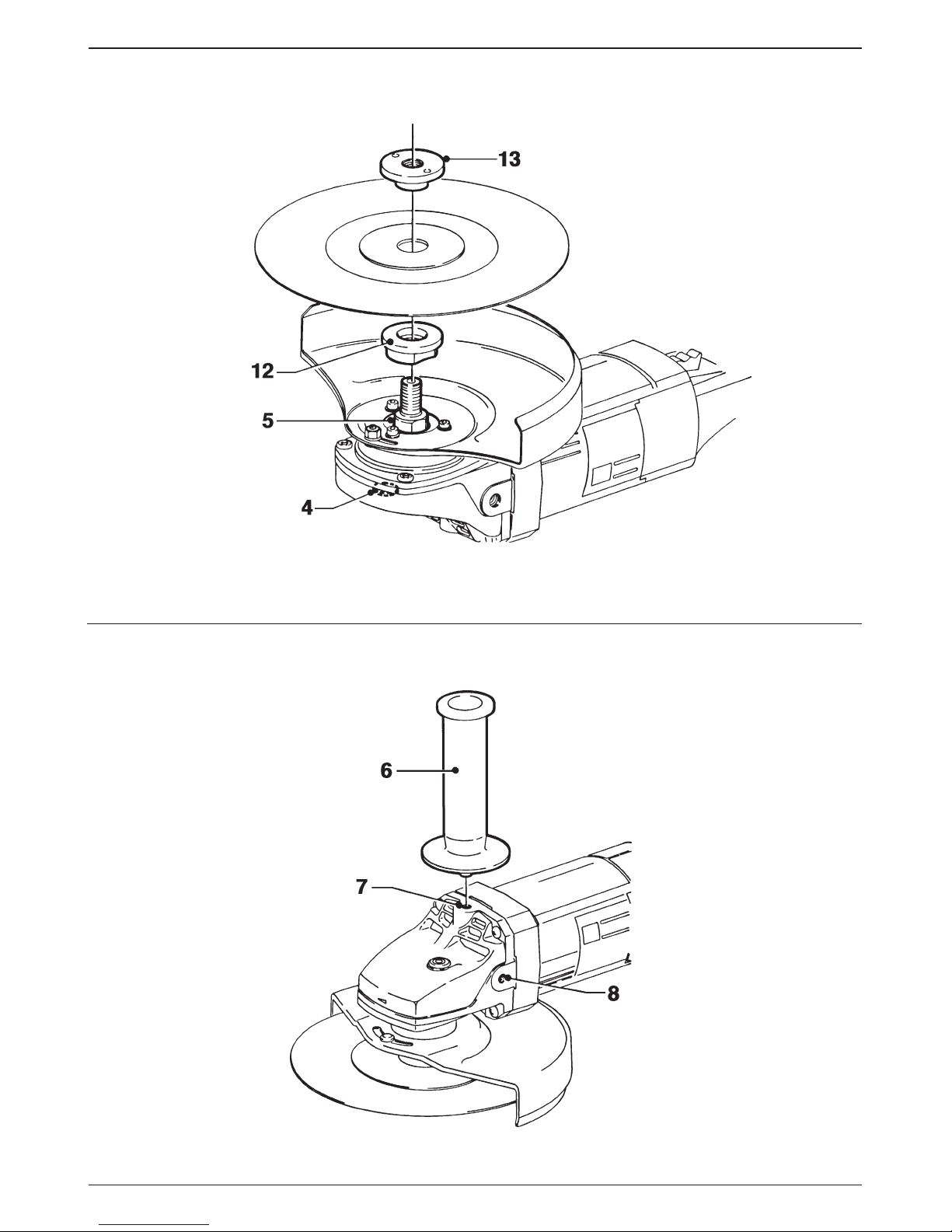

Fitting and removing a grinding wheel or cutting

disk (fig. C)

• Place the tool on a table, guard up.

• Fit the spacer (12) correctly onto the spindle (5).

• Place the grinding wheel or cutting disk on the

spacer.

• Screw the threaded flange (13) onto the spindle (5).

• Press the spindle lock (4) and rotate the grinding

wheel or cutting disk until it locks in position.

• Tighten the threaded flange (13) with the two-pin

spanner supplied.

• Release the spindle lock.

• To remove the grinding wheel or cutting disk,

loosen the threaded flange (13) with the two-pin

spanner.

Fitting a wire cup brush

• Screw the wire cup brush directly onto the

spindle without the use of the spacer and

threaded flange.

Mounting the side handle (fig. D)

• For grinding, screw the side handle (6) tightly into

one of the holes (8) on either side of the gear case.

• For cutting, screw the side handle (6) tightly into

the top hole (7).

Instructions for use

• Always observe the safety instructions

and applicable regulations.

• Ensure all materials to be ground or cut

are secured in place.

• Apply only a gentle pressure to the tool.

Do not exert side pressure on the

grinding wheel or cutting disk.

• Avoid overloading. Should the tool

become hot, let it run a few minutes

under no load condition.

Prior to operation:

• Install the appropriate guard and disk or wheel.

Do not use excessively worn disks or wheels.

• Be sure the spacer and threaded flange are

mounted correctly.

• Make sure the disk or wheel rotates in the

direction of the arrows on the accessory and the

tool.

Page 9

5 en - 5

ENGLISH

Switching ON and OFF (fig. A)

The ON/OFF-switch of your Angle Grinder is

equipped with a locking switch for continuous

operation.

• To run the tool, press the ON/OFF-switch.

The tool now runs in continuous operation.

• To stop the tool, press the locking switch briefly,

and release the ON/OFF-switch.

Do not switch the tool ON or OFF when

under load.

Consult your dealer for further information on the

appropriate accessories.

Maintenance

Your DEWALT Power Tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

Carbon brushes

The carbon brushes are well accessible and can be

replaced easily. The brushes must be checked every

50 hours of operation.

Lubrication

Your Power Tool requires no additional lubrication.

Cleaning

Keep the ventilation slots clear and regularly clean

the housing with a soft cloth.

Unwanted tools and the environment

Take your tool to an authorized DEWALT repair

agent where it will be disposed of in an

environmentally safe way.

GUARANTEE

• 30 DAY NO RISK SATISFACTION GUARANTEE •

If you are not completely satisfied with the

performance of your DEWALT tool, simply return

it within 30 days, complete as purchased, to a

participating Dealer, or an authorized DEWALT

repair agent, for a full refund or exchange. Proof

of purchase must be produced.

• ONE YEAR FREE SERVICE CONTRACT •

If you need maintenance or service for your

DEWALT tool, in the 12 months following

purchase, it will be undertaken free of charge at

an authorized DEWALT repair agent. Proof of

purchase must be produced. Includes labour and

spare parts for Power Tools. Excludes

accessories.

• ONE YEAR FULL WARRANTY •

If your DEWALT product becomes defective due

to faulty materials or workmanship within 12

months from the date of purchase, we guarantee

to replace all defective parts free of charge or, at

our discretion, replace the unit free of charge

provided that:

• The product has not been misused.

• Repairs have not been attempted by

unauthorized persons.

• Proof of purchase date is produced.

This guarantee is offered as an extra benefit

and is additional to consumers statutory rights.

For the location of your nearest authorized

DEWALT repair agent, please use the appropriate

telephone number on the back of this manual.

Page 10

6es - 6

ESPAÑOL

AMOLADORA ANGULAR DW848/DW852

¡Enhorabuena!

Usted ha optado por una herramienta eléctrica

DEWALT. Muchos años de experiencia y una gran

asiduidad en el desarrollo y la innovación de sus

productos han convertido DEWALT en un socio muy

fiable para el usuario profesional.

Contenido

Características técnicas es - 1

Declaración de conformidad es - 2

Instrucciones de seguridad es - 2

Verificación del contenido del embalaje es - 3

Descripción es - 4

Seguridad eléctrica es - 4

Utilización de un cable de prolongación es - 4

Montaje y ajustes es - 4

Instrucciones para el uso es - 5

Mantenimiento es - 5

Garantía es - 6

Características técnicas

DW848 DW852

Voltaje V 230 230

(solo Latinoamérica) V 120 120

Potencia absorbida W 2.000 1.800

Velocidad en vacío min-18.000 6.300

Diámetro del disco mm 180 230

Eje portamuelas M14 M14

Peso kg 4,6 4,6

Fusibles

Herramientas 120 V: 15 A

Herramientas 230 V: 10 A

En el presente manual figuran los pictogramas

siguientes:

Indica peligro de lesiones, de accidentes

mortales o de averías en la herramienta

en caso de no respeto de las

instrucciones en este manual.

Indica tensión eléctrica.

Peligro de incendio.

Page 11

7 es - 1

ESPAÑOL

Declaración de conformidad

DW848/DW852

DEWALT certifica que estas herramientas eléctricas

han sido construidas de acuerdo a las normas

siguientes: 89/392/CEE, 89/336/CEE, 73/23/CEE,

EN 50144, EN 55104, EN 55014, EN 61000-3-2 &

EN 61000-3-3.

El nivel de la presión acústica de acuerdo con las

normas 86/188/CEE & 89/392/CEE, medida de

acuerdo con EN 50144:

DW848 DW852

LpA(presión acústica) dB(A)* 94,2 94,2

LWA(potencia acústica) dB(A) 86,2 86,2

* al oído del usuario

Tome medidas adecuadas para proteger

sus oídos cuando la presión acústica

exceda el valor de 85 dB(A).

Valor cuadrático medio ponderado en frecuencia de

la aceleración según EN 50144:

DW848 DW852

empuñadura/empuñadura lateral empuñadura/empuñadura lateral

2,94/1,64 m/s

2

2,94/1,64 m/s

2

Director Engineering and Product Development

Horst Großmann

DEWALT, Idstein, Alemania

Instrucciones de seguridad

Al utilizar Herramientas Eléctricas, observe las

reglas de seguridad en vigor en su país, a fin de

reducir el riesgo de descarga eléctrica, de

lesiones y de incendio. Lea las instrucciones de

seguridad siguientes antes de utilizar este

producto.

¡Conserve bien estas instrucciones de

seguridad!

Generalidades

1 Mantenga limpia el área de trabajo

Un área o un banco de trabajo en desorden

aumentan el riesgo de accidentes.

2 Tenga en cuenta el entorno del área de trabajo

No exponga las Herramientas Eléctricas a la

humedad. Procure que el área de trabajo esté

bien iluminada. No utilice Herramientas Eléctricas

en la proximidad de líquidos o gases inflamables.

3 Protéjase contra las descargas eléctricas

Evite el contacto del cuerpo con las superficies

conectadas a tierra (p. ej. tuberías, radiadores,

cocinas eléctricas y refrigeradores).

Para aplicaciones de uso extremas (por ej.

humedad elevada formación de polvo metálico,

etc.), se puede aumentar la seguridad eléctrica a

través de intercalar un transformador de

separación o un interruptor de protección de

corriente de defecto (FI).

4 ¡Mantenga alejados a los niños!

No permita que otras personas toquen la

herramienta o el cable de prolongación. En caso

de uso por menores de 16 años, se requiere

supervisión.

5 Cables de prolongación para el exterior

Al trabajar fuera, utilice siempre cables de

prolongación destinados al uso exterior y

marcados en consecuencia para ello.

6 Guarde las herramientas que no utiliza

Las Herramientas Eléctricas que no se utilizan,

deben estar guardadas en un lugar seco,

cerrado y fuera del alcance de los niños.

7 Vista ropa de trabajo apropiada

No lleve vestidos anchos ni joyas. Estos podrían

ser atrapados por piezas en movimiento. Para

trabajos al exterior, se recomienda llevar guantes

de goma y calzado de suela antideslizante. Si

tiene el pelo largo, téngalo recogido y cubierto.

8 Lleve gafas de protección

Utilice también una mascarilla si el trabajo

ejecutado produce polvo u otras partículas

volantes.

9 Respete el nivel máximo de la presión acústica

Tome medidas adecuadas para la protección de

los oídos cuando la presión acústica exceda el

valor de 85 dB(A).

10 Sujete bien la pieza de trabajo

Utilice abrazaderas o un torno para sujetar la

pieza de trabajo. Es más seguro que sujetarla

Page 12

8

ESPAÑOL

es - 2

con la mano y le permite utilizar ambas manos

para manejar la herramienta.

11 No alargue demasiado su radio de acción

Mantenga un apoyo firme sobre el suelo y

conserve el equilibrio en todo momento.

12 Evite un arranque involuntario

No mantenga el dedo en el interruptor al

transportar la herramienta enchufada. Asegúrese

de que el interruptor esté en posición de parada

al enchufar la herramienta.

13 Esté siempre alerta

Mire lo que está haciendo. Use el sentido

común. No maneje la herramienta cuando está

cansado.

14 Desenchufe la herramienta

Desconecte la herramienta y espere que esté

completamente parada antes de dejarla sin

vigilar. Desenchufe la herramienta cuando no se

utilice y antes de proceder al mantenimiento o

sustituir accesorios.

15 Retire las llaves de maniobra

Antes de poner la herramienta en marcha,

asegúrese de que las llaves y utensilios de reglaje

hayan sido retirados.

16 Utilice la herramienta adecuada

En este manual, se indica para qué uso está

destinada la herramienta. No utilice herramientas

o dispositivos acoplables de potencia demasiado

débil para ejecutar trabajos pesados. La

herramienta funcionará mejor y con mayor

seguridad al ser utilizada de acuerdo con sus

características técnicas.

¡ATENCION! El uso de accesorios o

acoplamientos, o el uso de la herramienta misma

distintos de los recomendados en este manual

de instrucciones, puede dar lugar a lesiones de

personas.

17 Cuide el cable de alimentación

No lleve la herramienta por el cable, ni tire del

cable para desenchufar la herramienta. Proteja el

cable del calor, del aceite y de las aristas vivas.

18 Mantenga las herramientas asiduamente

Mantenga sus herramientas afiladas y limpias

para trabajar mejor y más seguro. Siga las

instrucciones para el mantenimiento y la

sustitución de accesorios. Verifique los cables de

las herramientas con regularidad y, en caso de

avería, llévelos a un Centro de Servicio DEWALT

para que sean reparados. Inspeccione los cables

de prolongación periódicamente y sustitúyalos

cuando presenten defectos. Mantenga todos los

mandos secos, limpios y libres de aceite y grasa.

19 Comprobar que no haya partes averiadas

Antes de utilizar la herramienta, compruebea que

no haya averías, a fin de asegurar que funcionará

correctamente y sin problemas. Compruebe que

no haya desalineamiento o enganchamiento de

piezas en movimiento, ni roturas de piezas, ni

accesorios mal montados, ni cualquier otro

defecto que pudiera perjudicar al buen

funcionamiento de la herramienta. Haga reparar

o sustituir los dispositivos de seguridad u otros

componentes defectuosos según las instrucciones.

No utilice la herramienta cuando el interruptor

esté defectuoso. Haga sustituir el interruptor en

un Centro de Servicio DEWALT.

20 Haga reparar su herramienta en un Centro de

Servicio DEWALT

Esta Herramienta Eléctrica cumple con las reglas

de seguridad en vigor. Para evitar situaciones

peligrosas, la reparación de Herramientas

Eléctricas debe ser efectuada únicamente por un

técnico competente.

Normas de seguridad adicionales para

amoladoras angulares

• La amoladora angular se ha diseñado para el

amolado y corte de mampostería y acero.

No corte ni amole metales de poca

densidad con un contenido en magnesio

superior al 80%, ya que este tipo de

metales son inflamables.

• No utilice accesorios distintos de las muelas y

discos de corte reforzados con fibra.

• Utilice exclusivamente muelas y discos de corte

recomendados por el fabricante.

• La velocidad en vacío de la muela o del disco de

corte no debe superar el valor impreso en la

placa de características (hoja de instrucciones).

• No corte piezas que requieran una profundidad

máxima de corte superior a la del disco de corte.

Verificación del contenido del embalaje

El paquete contiene:

1 Amoladora Angular

1 Protector

Page 13

9

es - 3

ESPAÑOL

1 Empuñadura lateral

1 Llave de dos clavijas

1 Manual de instrucciones

1 Dibujo despiezado

• Compruebe si la herramienta, piezas o

accesorios han sufrido algún daño durante el

transporte.

• Tómese el tiempo necesario para leer y

comprender este manual antes de utilizar la

herramienta.

Descripción (fig. A)

Esta amoladora angular de DEWALT ha sido

diseñada para realizar amolados o cortes

profesionales:

1 Conmutador ON/OFF

2 Botón de bloqueo

3 Protector

4 Bloqueo del eje portamuelas

5 Eje portamuelas

6 Empuñadura lateral

7 Orificio superior

8 Orificios laterales

9 Cubiertas de escobillas de carbono

Seguridad eléctrica

El motor eléctrico ha sido diseñado para un solo

voltaje. Compruebe siempre que el voltaje de la red

corresponde al valor indicado en la placa de

características.

Su herramienta DEWALT tiene doble

aislamiento, conforme a la norma

EN 50144; por consiguiente, no se

requiere conexión a tierra.

Utilización de un cable de prolongación

En caso de que sea necesario utilizar un cable de

prolongación, deberá ser un cable de prolongación

aprobado, adecuado para la potencia de esta

herramienta (véanse las características técnicas). Un

cable de prolongación de menor calibre al necesario

ocasionará una caída en el voltaje de la línea,

produciendo pérdida de potencia y

sobrecalentamiento.

Si utiliza un carrete de cable, desenrolle siempre el

cable completamente.

Véase la tabla.

Calibre mínimo para cables de prolongación

Voltaje

Longitud total del cable de prolongación en

metros

120 0-7,6 7,7-15,2 15,3-30,4 30,5-45,7

240 0-15,2 15,3-30,4 30,5-60,9 70-91,4

Amperaje

Más de No más de AWG

0-6 18 16 16 14

6-10 18 16 14 12

10-12 16 16 14 12

12-16 14 12 no se recomienda

Montaje y ajustes

Desenchufe la herramienta antes de

proceder con el montaje y los ajustes.

Montar y desmontar el protector (fig. B)

• Coloque la Amoladora angular en una mesa, con

el eje portamuelas arriba.

• Monte el protector en la herramienta con los tres

tornillos (10) y las arandelas dentadas.

• Gire el protector hasta obtener la posición

deseada y apriete la tuerca (11).

• Para desmontar el protector, saque los tres

tornillos (10).

Insertar y desmontar una muela o un disco de

corte (fig. C)

• Coloque la herramienta en una mesa, con el

protector arriba.

• Posicione el separador (12) correctamente en el

eje portamuelas (5).

• Coloque la muela o el disco de corte en el

separador.

• Atornille la brida roscada (13) en el eje

portamuelas (5).

• Pulse el botón de bloqueo del eje portamuelas

(4) y gire la muela o el disco de corte hasta que

se bloquee en la posición correcta.

• Apriete la brida conducida (13) con la llave de

dos clavijas suministrada.

• Suelte el bloqueo del eje portamuelas.

• Para desmontar la muela o el disco de corte,

afloje la brida enroscada (13) con la llave de dos

clavijas suministrada.

Page 14

10

ESPAÑOL

es - 4

Montar un cepillo de alambre esférico

• Enrosque el cepillo de alambre esférico

directamente sobre el eje portamuelas sin utilizar

ni el separador ni la brida conducida.

Montar la empuñadura lateral (fig. D)

• Para esmerilar, atornille bien la empuñadura

lateral (6) en uno de los orificios (8) de la carcasa,

en cualquier lado.

• Para cortar, atornille bien la empuñadura el

orificio superior (7).

Instrucciones para el uso

• Respete siempre las instrucciones de

seguridad y las normas de aplicación.

• Asegure que todos los objetos a ser

pulidos o cortados están bien sujetados.

• Sólo se debe ejercer una ligera presión

sobre la herramienta. Evite ejercer

presión lateral sobre la muela o el disco

de corte.

• Evite sobrecargar la herramienta. Si la

amoladora se calienta, hágala funcionar

en vacío durante unos minutos.

Antes del uso:

• Montar el protector adecuado y un disco o una

muela. No use discos o muelas excesivamente

desgastados.

• Asegúrese de que el separador y la brida

conducida han sido montados correctamente.

• Asegúrese de que el disco o la muela gira en el

sentido indicado por las flechas en el accesorio y

la herramienta.

Encender y apagar (fig. A)

El conmutador ON/OFF de esta amoladora angular

está provisto de un botón de bloqueo.

• Para encender la herramienta, pulse el

conmutador ON/OFF. La amoladora funcionará

en modo continuo.

• Para apagar, pulse brevemente el botón de

bloqueo, y suelte el conmutador ON/OFF.

No se debe encender o apagar la

herramienta mientras esté cortando o

puliendo.

Consulte a su proveedor si desea información más

detallada sobre los accesorios apropiados.

Mantenimiento

Su herramienta eléctrica DEWALT ha sido diseñada

para funcionar mucho tiempo con un mínimo de

mantenimiento. El funcionamiento satisfactorio

depende del buen cuidado de la herramienta y de

una limpieza frecuente.

Escobillas de carbono

Las escobillas de carbono son de acceso fácil y

pueden ser sustituidas sencillamente. Las escobillas

deben ser verificadas después de cada 50 horas de

operación.

Lubricación

Su herramienta eléctrica no requiere lubricación

adicional.

Limpieza

Evite que se obturen las ranuras de ventilación y

limpie el exterior con regularidad utilizando un paño

suave.

Herramientas desechadas y el medio

ambiente

Lleve la herramienta vieja a un Centro de Servicio

DEWALT, donde será eliminada sin efectos

perjudiciales para el medio ambiente.

Page 15

11

es - 5

ESPAÑOL

GARANTÍA

• 30 DÍAS DE SATISFACCIÓN COMPLETA •

Si no queda totalmente satisfecho con su

herramienta DEWALT, contacte con su Centro de

Servicio DEWALT. Presente su reclamación,

juntamente con la máquina completa, así como

la factura de compra y le será presentada la

mejor solución.

• UN AÑO DE SERVICIO GRATUITO •

Si necesita mantenimiento o servicio técnico para

su herramienta DEWALT en los 12 meses

siguientes a la compra, podrá obtenerlos

gratuitamente en un Centro de Servicio DEWALT.

Para ello es imprescindible presentar la prueba

de compra. Incluye mano de obra y piezas para

las Herramientas Eléctricas. No se incluye los

accesorios.

• UN AÑO DE GARANTÍA •

Si su producto DEWALT presenta algún defecto

debido a fallos de materiales o mano de obra en

los 12 meses siguientes a la fecha de compra, le

garantizamos la sustitución gratuita de todas las

piezas defectuosas siempre y cuando:

• El producto no haya sido utilizado

inadecuadamente.

• No se haya intentado su reparación por parte

de una persona no autorizada.

• Se presente la prueba de compra.

Para la localización del Centro de Servicio

DEWALT más cercano, consulte el dorso de este

manual.

Page 16

12

PORTUGUÊS

pt - 1

REBARBADORA DW848/DW852

Parabéns!

Escolheu uma Ferramenta Eléctrica DEWALT. Muitos

anos de experiência, um desenvolvimento contínuo

de produtos e o espírito de inovação fizeram da

DEWALT um dos parceiros mais fiáveis para os

utilizadores profissionais.

Conteúdo

Dados técnicos pt - 1

Declaração de conformidade pt - 2

Instruções de segurança pt - 2

Verificação do conteúdo da embalagem pt - 3

Descrição pt - 4

Segurança eléctrica pt - 4

Extensões pt - 4

Montagem e afinação pt - 4

Modo de emprego pt - 5

Manutenção pt - 5

Garantia pt - 6

Dados técnicos

DW848 DW852

Voltagem V 230 230

(apenas Latino-America) V 120 120

Potência W 2.000 1.800

Velocidade em vazio rpm 8.000 6.300

Diâmetro da roda mm 180 230

Veio M14 M14

Peso kg 4,6 4,6

Fusíveis

Ferramentas de 120 V 15 Ampéres

Ferramentas de 230 V 10 Ampéres

Os seguintes símbolos são usados neste manual:

Indica risco de ferimentos, perda de vida

ou danos à ferramenta no caso do nãocumprimento das instruções deste

manual.

Indica tensão eléctrica.

Perigo de incêndio.

Page 17

13

pt - 2

PORTUGUÊS

Declaração de conformidade

DW848/DW852

A DEWALT declara que estas ferramentas eléctricas

foram concebidas em conformidade com

89/392/CEE, 89/336/CEE, 73/23/CEE, EN 50144,

EN 55104, EN 55014, EN 61000-3-2 & EN 61000-3-3.

De acordo com as Directivas 86/188/CEE &

89/392/CEE da Comunidade Europeia, o nível de

potência sonora, medido de acordo com a EN 50144, é:

DW848 DW852

LpA(pressão sonora) dB(A)* 94,2 94,2

LWA(potência sonora) dB(A) 86,2 86,2

* junto ao ouvido do operador

Use protectores auditivos quando a

potência sonora ultrapassar 85 dB(A).

Valor médio quadrático ponderado em frequência

de aceleração conforme à EN 50144:

DW848 DW852

punho/punho lateral punho/ punho lateral

2,94/1,64 m/s

2

2,94/1,64 m/s

2

Director Engineering and Product Development

Horst Großmann

DEWALT, Idstein, Alemanha

Instruções de segurança

Quando usar Ferramentas Eléctricas, cumpra

sempre os regulamentos de segurança

aplicáveis no seu país para reduzir o risco de

incêndio, de choque eléctrico e de ferimentos.

Leia as seguintes instruções de segurança antes

de tentar utilizar este produto.

Guarde estas instruções!

Instruções gerais

1 Mantenha a área de trabalho arrumada

As mesas e áreas de trabalho desarrumadas

podem provocar ferimentos.

2 Cuide do ambiente da área de trabalho

Não exponha Ferramentas Eléctricas à

humidade. Ilumine bem as áreas de trabalho.

Não utilize Ferramentas Eléctricas em presença

de líquidos ou gases inflamáveis.

3 Tenha cuidado com os choques eléctricos

Evite o contacto directo com superfícies ligadas

à terra (p.ex. tubos, radiadores, fogões,

frigoríficos).

Nos casos de serviço sob condições extremas

(tais como humidade elevada, execução de

soldadura, etc.) a segurança eléctrica pode ser

aumentada intercalando-se um transformador de

separação ou um disjuntor de corrente de

defeito (FI).

4 Mantenha as crianças afastadas

Não deixe as crianças tocarem na ferramenta

nem no cabo de extensão. As crianças com

menos de 16 anos de idade devem ser vigiadas.

5 Cabos para uso exterior

Quando as ferramentas se utilizarem no exterior,

empregue sempre cabos previstos para uso no

exterior.

6 Guarde as ferramentas que não estiverem a

ser utilizadas

Quando não forem utilizadas as Ferramentas

Eléctricas, estas devem guardadas num sítio

seco, fechado à chave e fora do alcance das

crianças.

7 Vista-se de maneira apropriada

Não use vestuário largo nem jóias porque podem

prender-se numa peça móvel. Quando se

trabalha no exterior, é de aconselhar o uso de

luvas de borracha e de calçado antiderrapante.

Cubra o cabelo se tiver cabelo comprido.

8 Utilize óculos de protecção

Utilize também uma máscara no caso de os

trabalhos produzirem pó.

9 Tenha cuidado com o ruído

Tome medidas de protecção apropriadas se o

nível do ruído exceder 85 dB(A).

10 Segure firmemente as peças de trabalho

Utilize grampos ou um torno para segurar as

peças a trabalhar. É mais seguro e permite

manter as duas mãos livres para trabalhar.

Page 18

14

PORTUGUÊS

pt - 3

11 Verifique a sua posição

Mantenha sempre o equilíbrio.

12 Evite arranques acidentais

Não transporte uma ferramenta ligada à rede com

o dedo colocado no interruptor. Verifique se o

interruptor está desligado ao ligar a ferramenta à

rede.

13 Esteja atento

Dê atenção ao que vai fazendo. Trabalhe com

precaução. Não utilize ferramentas quando estiver

cansado.

14 Desligue a ferramenta

Desligue e espere até a ferramenta parar

completamente antes de a deixar sem vigilância.

Tire a ficha da tomada quando a ferramenta não

estiver a ser utilizada, antes de proceder à

manutenção ou à substituição de acessórios.

15 Tire as chaves de aperto

Verifique sempre se as chaves de aperto foram

retiradas da ferramenta antes de a utilizar.

16 Empregue as ferramentas apropriadas

Neste manual indicam-se as aplicações da

ferramenta. Não force pequenas ferramentas ou

acessórios para fazer o trabalho duma ferramenta

forte. A ferramenta trabalhará melhor e de uma

maneira mais segura se for utilizada para o efeito

indicado.

AVISO O uso de qualquer acessório ou o uso da

própria ferramenta, além do que é recomendado

neste manual de instruções pode dar origem a

risco de ferimento.

17 Não force o cabo eléctrico

Nunca transporte a ferramenta pelo cabo e não

puxe pelo cabo para tirar a ficha da tomada.

Proteja o cabo contra o calor e evite o contacto

com óleo e objectos cortantes.

18 Cuide das suas ferramentas com atenção

Para uma maior rentabilidade, mantenha as

ferramentas sempre afinadas e limpas. Cumpra as

instruções relativas à manutenção e substituição

dos acessórios. Verifique regularmente os cabos

da ferramenta e, no caso de estes estarem

danificados, mande-os consertar a um Centro de

Assistência Técnica DEWALT. Verifique

periodicamente os cabos de extensão e substituaos se estiverem danificados. Mantenha os

comandos secos, limpos e sem óleo ou gordura.

19 Verifique as peças danificadas

Antes de utilizar a ferramenta, verifique

cuidadosamente se esta apresenta sinais de

danos de modo a assegurar um bom

funcionamento e a obtenção do resultado

desejado.

Verifique o bom alinhamento e fixação das peças

móveis e confirme a ausência de ruptura das

peças. Verifique ainda se a montagem foi bem

feita ou se existe qualquer outra condição que

possa impedir que a ferramenta funcione bem.

Mande consertar ou substituir os dispositivos de

protecção ou outras peças danificadas conforme

as instruções.

Não utilize a ferramenta se o interruptor não

estiver a funcionar. Mande substituir o interruptor

num Centro de Assistência Técnica DEWALT.

20 Mande consertar a sua ferramenta por um

Centro de Assistência Técnica DEWALT.

Esta Ferramenta Eléctrica está conforme às

regulamentações de segurança que lhe dizem

respeito. Para evitar qualquer perigo, a

reparação de ferramentas eléctricas deverá estar

fica exclusivamente a cargo de técnicos

qualificados.

Normas de segurança adicionais parar Discos

de Rebarbar

• O seu Disco de Rebarbar foi concebido para

rebarbar e cortar alvenaria e aço.

Não corte nem rebarbe metais leves

com conteúdo de magnésio superior a

80% pois este tipo de metais é inflamável.

• Não utilize outros acessórios que não sejam os

discos de rebarbar reforçados com fibra e os

discos de corte.

• Utilize apenas os discos de rebarbar e os discos

de corte recomendados pelo fabricante.

• A velocidade sem carga do disco de rebarbar ou

disco de corte não deve exceder o valor

impresso na placa de identificação (folha de

instruções).

• Não corte peças de trabalho que exijam uma

profundidade máxima de corte que exceda a do

disco de corte.

Verificação do conteúdo da embalagem

A embalagem contém:

1 Rebarbadora

Page 19

15

pt - 4

PORTUGUÊS

1 Resguardo

1 Punho lateral

1 Chave de dois pinos

1 Manual de instruções

1 Vista dos componentes destacados

• Verifique se a ferramenta, as peças ou os

acessórios apresentam sinais de danos que

possam ter ocorrido durante o transporte.

• Antes de utilizar a ferramenta, dedique o tempo

necessário à leitura e compreensão deste

manual.

Descrição (fig. A)

A sua Rebarbadora DEWALT foi concebida para

aplicações profissionais de rebarbar e de corte:

1 Interruptor de Ligar/Desligar “ON/OFF”

2 Bloqueio do interruptor

3 Resguardo

4 Botão de travamento do veio

5 Veio

6 Punho lateral

7 Orifício superior

8 Orifícios laterais

9 Coberturas das escovas de carvão

Segurança eléctrica

O motor eléctrico foi concebido para uma única

tensão. Verifique sempre se a tensão da rede

corresponde à voltagem indicada na placa de

identificação.

A sua ferramenta DEWALT tem duplo

isolamento em conformidade com o

estipulado na norma EN 50144, não

sendo, por isso, necessária uma ligação

à terra.

Extensões

Se fôr necessário um fio de extensão, use um cabo

especial, conveniente para a corrente desta

ferramenta (Veja os dados técnicos). Um cabo com

uma amperagem demasiada baixa causará uma

redução na voltagem de linha, resultando em perda

de energia e sobreaquecimento.

No caso de se usar uma bobina, desenrole o cabo

todo.

Use também a tabela em baixo.

Medições mínimas para extensões

Voltagem Comprimento total de cabo (m)

120 0-7,6 7,7-15,2 15,3-30,4 30,5-45,7

240 0-15,2 15,3-30,4 30,5-60,9 70-91,4

Valor nominal de amperes

Mais que Não mais que AWG

0-6 18 16 16 14

6-10 18 16 14 12

10-12 16 16 14 12

12-16 14 12 não se recomende

Montagem e afinação

Antes da montagem de acessórios e da

afinação retire sempre a ficha da

tomada.

Montagem e remoção do resguardo (fig. B)

• Coloque a Rebarbadora sobre uma mesa, com o

veio para cima.

• Monte o resguardo na ferramenta utilizando os

três parafusos (10) com anilhas de estrela.

• Rode o resguardo para a posição requerida e

aperte a porca (11).

• Para remover o resguardo, desaperte os três

parafusos (10).

Instalação e remoção de um disco de corte ou

de rebarbar (fig. C)

• Coloque a ferramenta sobre uma mesa, com o

resguardo para cima.

• Instale o espaçador (12) correctamente no veio (5).

• Coloque o disco no espaçador.

• Aparafuse a flange de rosca (13) no veio (5).

• Pressione o fecho de veio (4) e rode o disco até

prender na posição correcta.

• Aperte a flange exterior (13) com a chave de dois

pinos que vem incluída.

• Solte o botão de bloqueio do veio.

• Para retirar o disco, desaperte a flange exterior

(13) com a chave de dois pinos.

Instalação de uma catrabucha

• Aparafuse a catrabucha de arame directamente

ao veio sem utilizar o espaçador e a flange

exterior.

Page 20

16

PORTUGUÊS

pt - 5

Instalação do punho lateral (fig. D)

• Para operações de rectificação, aparafuse bem o

punho lateral (6) num dos orifícios (8) nos dois

lados da caixa de engrenagens.

• Para cortar, aparafuse bem o punho lateral (6) no

orifício superior (7).

Modo de emprego

• Cumpra sempre as instruções de

segurança e os regulamentos aplicáveis.

• Certifique-se que todos os materiais a

serem rectificados ou cortados estão

devidamente presos.

• Aplique apenas uma ligeira pressão na

ferramenta. Não exerça pressão lateral

na roda de esmeril ou no disco de corte.

• Evite sobrecargas. Se a ferramenta

aquecer, deixe-a trabalhar em vazio

durante alguns minutos.

Antes de pôr em funcionamento:

• Instale o devido resguardo e disco. Não utilize

discos com um nível de desgaste excessivo.

• Certifique-se que o espaçador e a flange exterior

estão devidamente instalados.

• Certifique-se que o disco roda na direcção das

setas indicadas no acessório ou na ferramenta.

Ligar e Desligar (fig.A)

O interruptor ON/OFF da sua rebarbadora está

equipado com un dispositivo de bloqueio para

serviço contínuo.

• Para pôr a rebarbadora em movimento carregue

o interruptor ON/OFF. A rebarbadora fica agora

em serviço contínuo.

• Para desligá-la apoie ligeiramente no interruptor

para bloqueio e desligue o interruptor ON/OFF.

Não ligue ou desligue a ferramenta

quando estiver com carga.

Para mais informações sobre os acessórios

apropriados, consulte o seu Revendedor autorizado.

Manutenção

A sua Ferramenta Eléctrica DEWALT foi concebida

para funcionar durante muito tempo com um

mínimo de manutenção. O funcionamento

satisfatório contínuo depende de bons cuidados e

limpeza regular da ferramenta.

Escovas de carvão

As escovas de carvão são bastante acessíveis e

podem ser substituídas fácilmente. Deixe verificar as

escovas após cada 50 horas de funcionamento.

Lubrificação

A sua Ferramenta Eléctrica não precisa de

lubrificação suplementar.

Limpeza

Conserve livres as aberturas de ventilação e limpe

regularmente o corpo da máquina utilizando um

pano macio.

Ferramentas indesejadas e o ambiente

Leve a sua ferramenta velha a um Centro de

Assistência Técnica DEWALT onde ela será

eliminada de um modo seguro para o ambiente.

Page 21

17

pt - 6

PORTUGUÊS

GARANTIA

• 30 DIAS DE SATISFAÇÃO COMPLETA •

Se não estiver completamente satisfeito com a

sua ferramenta DEWALT, contacte um Centro de

Assistência Técnica DEWALT. Apresente a sua

reclamação, juntamente com a máquina

completa, bem como a factura de compra e serlhe á apresentada a melhor solução.

• UM ANO DE MANUTENÇÃO GRATUITA •

Se necessitar de manutenção para a sua

ferramenta DEWALT, durante os 12 meses após

a compra, entregue-a, sem encargos, num

Centro de Assistência Técnica DEWALT. Deve

apresentar uma prova da compra.

• UM ANO DE GARANTIA •

Se o seu produto DEWALT se avariar por defeito

de montagem ou de material, durante os 12

meses a partir da data da compra, garantimos a

substituição de todas as peças defeituosas sem

encargos desde que:

• O produto não tenha sido mal usado.

• Eventuais reparações não tenham sido

efectuadas por pessoas estranhas aos Centro

de Assistência Técnica DEWALT.

• Se apresente prova da data de compra.

Para a localização do Centro de Assistência

Técnica DEWALT mais próximo, queira consultar

a parte de trás do presente manual.

Page 22

18

Page 23

19

Page 24

21

Belgique et Luxembourg DEWALT Tel: 02 719 07 12

België en Luxemburg Weihoek 1, Nossegem Fax: 02 721 40 45

1930 Zaventem-Zuid Service fax: 02 719 08 10

Danmark D

EWALT Tlf: 70 20 15 10

Hejrevang 26 B Fax: 48 14 13 99

3450 Allerød

Deutschland D

EWALT Tel: 06 12 62 16

Richard-Klinger-Straße, Postfach 1202 Fax: 061 26 21 24 40

65510 Idstein

EÏÏ¿˜ D

EWALT TËÏ: 019 24 28 70

§ÂˆÊ ™˘ÁÁÚÔ‡ 154 Fax: 019 24 28 69

176 71 K·ÏÏÈı¤· Service: 019 24 28 76-7

∞ı‹Ó·

España D

EWALT Tel: 977 29 71 00

Ctra de Acceso Fax: 977 29 71 38

a Roda de Barà, km 0,7 Fax: 977 29 71 19

43883 Roda de Barà, Tarragona

France D

EWALT Tel: 72 20 39 20

Le Paisy Tlx: 30 62 24F

BP 21 Fax: 72 20 39 00

69571 Dardilly Cedex

Helvetia D

EWALT/Rofo AG Tel: 037 43 40 60

Schweiz Warpel Fax: 037 43 40 61

3186 Düdingen

Ireland D

EWALT Tel: 012 78 18 00

Calpe House Rock Hill Fax: 012 78 18 11

Black Rock

Co. Dublin

Italia D

EWALT Tel: 03 92 38 72 04

Viale Elvezia 2 Fax: 03 92 38 75 93

20052 Monza (Mi)

Nederland D

EWALT Tel: 07 65 08

22

01

Florijnstraat 10 Fax: 07 65 03

81

84

4879 AH Etten-Leur

Norge D

EWALT Tel: 22 99 90 00

Strømsveien 344 Fax: 22 99 90 01

1081 Oslo

Österreich D

EWALT Tel: 022 26 61 16

Werkzeugevertriebs GmbH Tlx: 13228 Black A

Erlaaerstraße 165 Fax: 022 26 61 16 14

Postfach 320,1231 Wien

Portugal D

EWALT Tel: 468 7513/7613

Rua Egas Moniz 173 Tlx: 16607 Bladec P

Apartado 19, S. João do Estoril Fax: 466 38 41

2768 Estoril, Codex

Suomi D

EWALT Puh: +35 89 825

45

40

Rälssitie 7 C Fax: +35 89 825 45 444

01510 Vantaa

Frälsevägen 7 C Tel: +35 89 825

45

40

01510 Vanda Fax: +35 89 825 45 444

Sverige D

EWALT Tel: 031 68 61 00

Box 603 Fax: 031 68 60 08

421 26 Västra Frölunda

Besöksadr. Ekonomivägen 11

United Kingdom D

EWALT Tel: 017 53 57 42 77

210 Bath Road Fax: 017 53 52 13 12

Slough

Berks SL1 3YD

12-96

Loading...

Loading...