Page 1

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in China (98-1) Form No. 569590-01

DW830,DW840,DW841 Copyright © 1998

DW830,etc./569590-01 8/3/00 2:46 PM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW830,DW840,DW841

5"(127mm)Heavy Duty Angle Grinder

Rectifieuse coudée de service intensif de 127 mm (5 po)

Esmeriladora angular para trabajo pesado de 127 mm (5")

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Questions? See us in the World Wide Web at www.dewalt.com

DW830,etc./569590-01 8/3/00 2:46 PM Page 3

Page 3

English

General Safety Instructions

WARNING! Read and understand all instructions. Failure to

follow all instructions listed below, may result in electric shock, fire

and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify the plug

in any way. Do not use any adaptor plugs. Check with a qualified

electician if you are in doubt as to whether the outlet is properly

grounded. If the tools should electrically malfunction or break down,

grounding provides a low resistance path to carry electricity away

from the user. Applicable only to Class I (grounded) tools.

• Double insulated tools are equipped with a polarized plug (one

blade is wider than the other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in any way. Double

insulation eliminates the need for the three wire grounded power

cord and grounded power supply system.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is grounded. Applicable only to Class II

(double insulated ) tools.

• Don’t expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull

the plug from an outlet. Keep cord away from heat, oil, sharp edges

or moving parts. Replace damaged cords immediately. Damaged

cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor

extension cord marked “W-A” or “W.” These cords are rated for

outdoor use and reduce the risk of electric shock.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

ThanThan

0-618161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Not Recommended

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or under

the influence of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in serious

personal injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain long

hair. Keep your hair, clothing , and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught in moving parts.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

DW830,etc./569590-01 8/3/00 2:46 PM Page 4

Page 4

1

English

• Avoid accidental starting. Be sure switch is off before plugging

in. Carrying tools with your finger on the switch or plugging in tools

that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool

on. A wrench or a key that is left attached to a rotating part of the

tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enables better control of the tool in

unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be used

for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to loss of control.

• Do not force tool. Use the correct tool for your application. The

correct tool will do the job better and safer at the rate for which it is

designed.

• Do not use tool if switch does not turn it on or off. Any tool that

cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such

preventative safety measures reduce the risk of starting the tool

accidentally.

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less likely to

bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tools

operation. If damaged, have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer

for your model. Accessories that may be suitable for one tool, may

become hazardous when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual. Use

of unauthorized parts or failure to follow Maintenance Instructions

may create a risk of electric shock or injury.

Additional Specific Safety Instructions for

Grinders

• Always use proper guard with grinding wheel. A guard protects

operator from broken wheel fragments.

• Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other accessories

running over rated speed can fly apart and cause injury.

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring

or its own cord. Cortact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

• Before using, inspect recommended accessory for cracks or

flaws. If such a crack or flaw is evident, discard the accessory. The

accessory should also be inspected whenever you think the tool

may have been dropped.

• When starting the tool (with a new or replacement wheel

installed) hold the tool in a well protected area and let it run for

one minute. If the wheel has an undetected crack or flaw, it should

burst in less than one minute. Never start the tool with a person in

line with the wheel. This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough

treatment. If this occurs, stop the tool and inspect the wheel.

• Always use Side handle. The side handle should always be used

DW830,etc./569590-01 8/3/00 2:46 PM Page 1

Page 5

2

to maintain control of the tool at all times.

• Clean out your tool periodically. Dust and grit containing metal

particles often accumulate on interior surfaces and could create an

electric shock hazard.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out

microscopic particles.

• The label on your tool may include the following symbols.

V..........................volts

A..........................amperes

Hz........................hertz

W ........................watts

min ......................minutes

........................alternating current

....................direct current

n

o ........................no load speed

........................

Class II Construction

…/min ..................revolutions or reciprocation per minute

........................earthing terminal

........................safety alert symbol

English

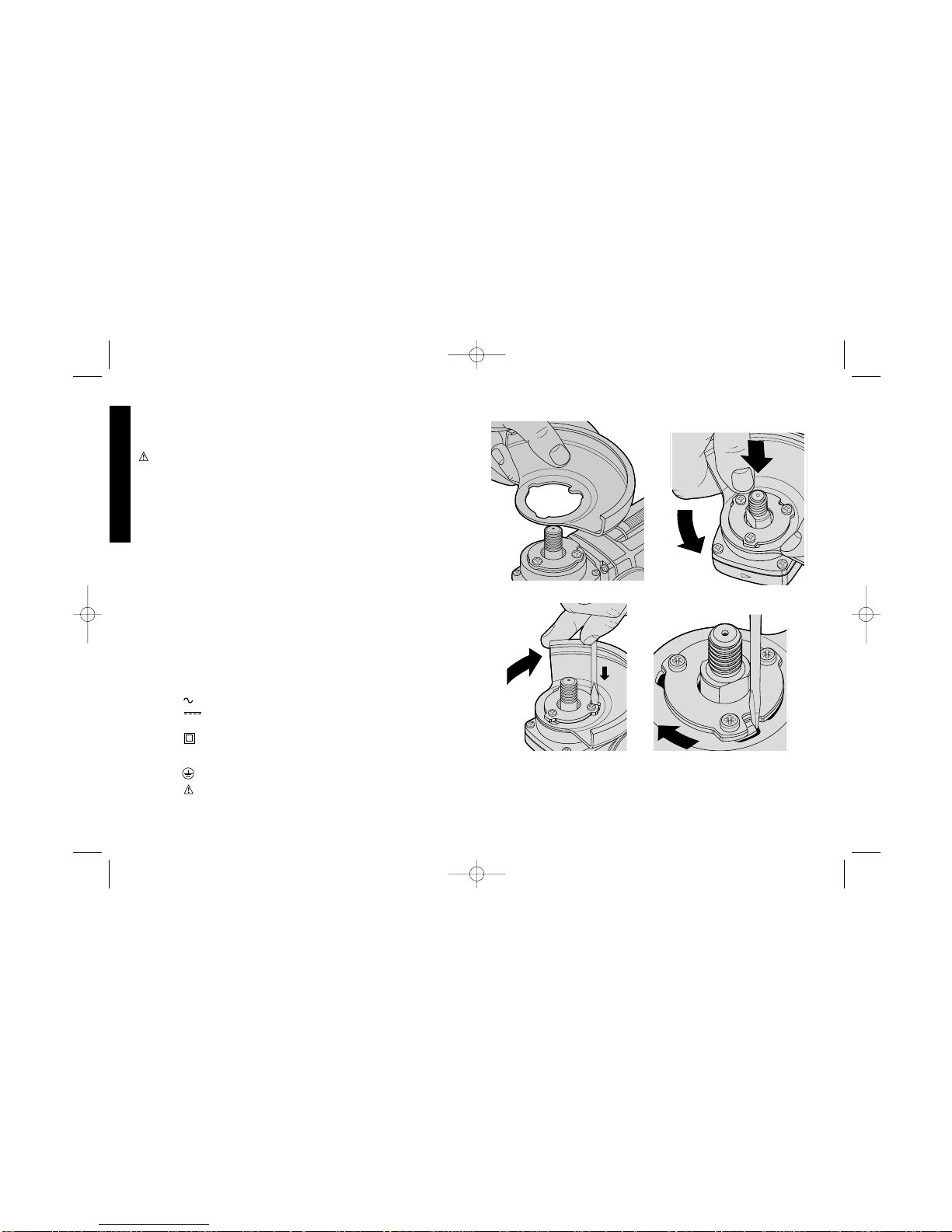

FIG. 1

FIG. 1A

FIG. 2

FIG. 3

DW830,etc./569590-01 8/3/00 2:46 PM Page 2

Page 6

Fitting and Removing the Guard DW830

(Fig. 1 & 1A)

A guard is not required when using the tool for sanding with the

backing pad. To fit the guard for other applications:

1. Align the lug on the guard with the slot in the bracket fixed to the

base of the gear case (Fig. 1).

2. Press the guard down toward the gear case, and then rotate the

guard in the direction of the arrow (Fig. 1A).

3. In this position, the guard locking pin located in the slot prevents the

guard from coming loose, but allows rotation through 105°.

To remove the guard:

1. Place the tool upside down on a flat surface.

2. Hold the tool, and using your thumb, rotate the guard in the

direction of the arrow (Fig. 2). At the same time, using a screwdriver

or other pointed instrument, press the locking pin in the slot so the

lug on the guard comes into view (Fig. 3).

3. The locking pin does not hold the guard, and the guard can be

pushed free.

Fitting and Removing the Guard DW840

and DW841 (Fig 4)

1. Place the angle grinder on a table, spindle up.

2. Press the guard down.

4. Position the guard between your body and the work piece.

5. T ighten the cinch collar firmly around the neck of the spindle..

IMPORTANT: Unplug the tool before mounting or removing the guard.

Use the tool without the guard only when sanding with the rubber

backing pad.

Switch (Fig. 5)

To start the tool, squeeze the trigger switch (A) shown in Figure 5. To

turn the tool off, release the switch.The tool can be locked on for

continuous use by holding the trigger switch depressed while you

3

English

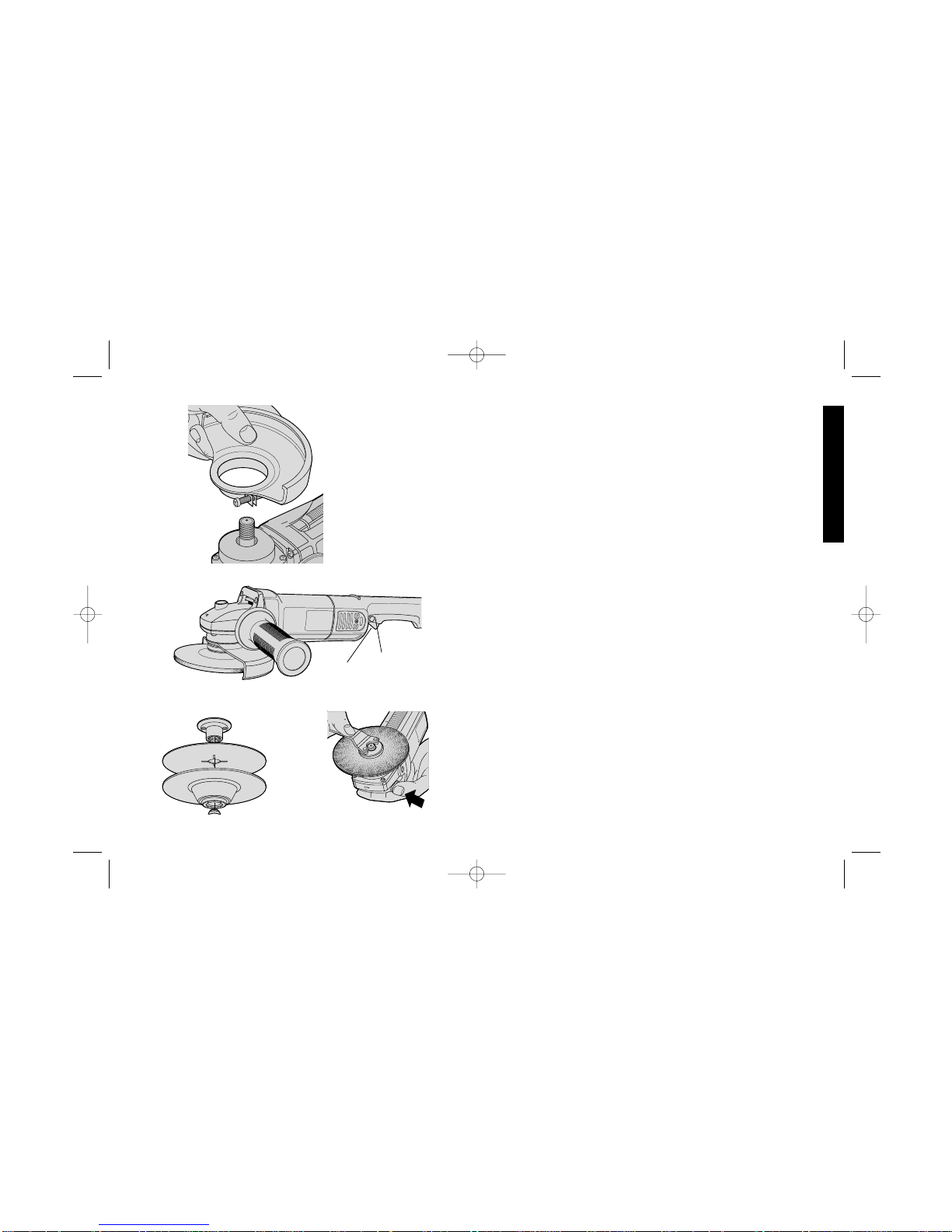

FIG. 4

FIG. 5

B

A

FIG. 6

FIG. 7

DW830,etc./569590-01 8/3/00 2:47 PM Page 3

Page 7

4

English

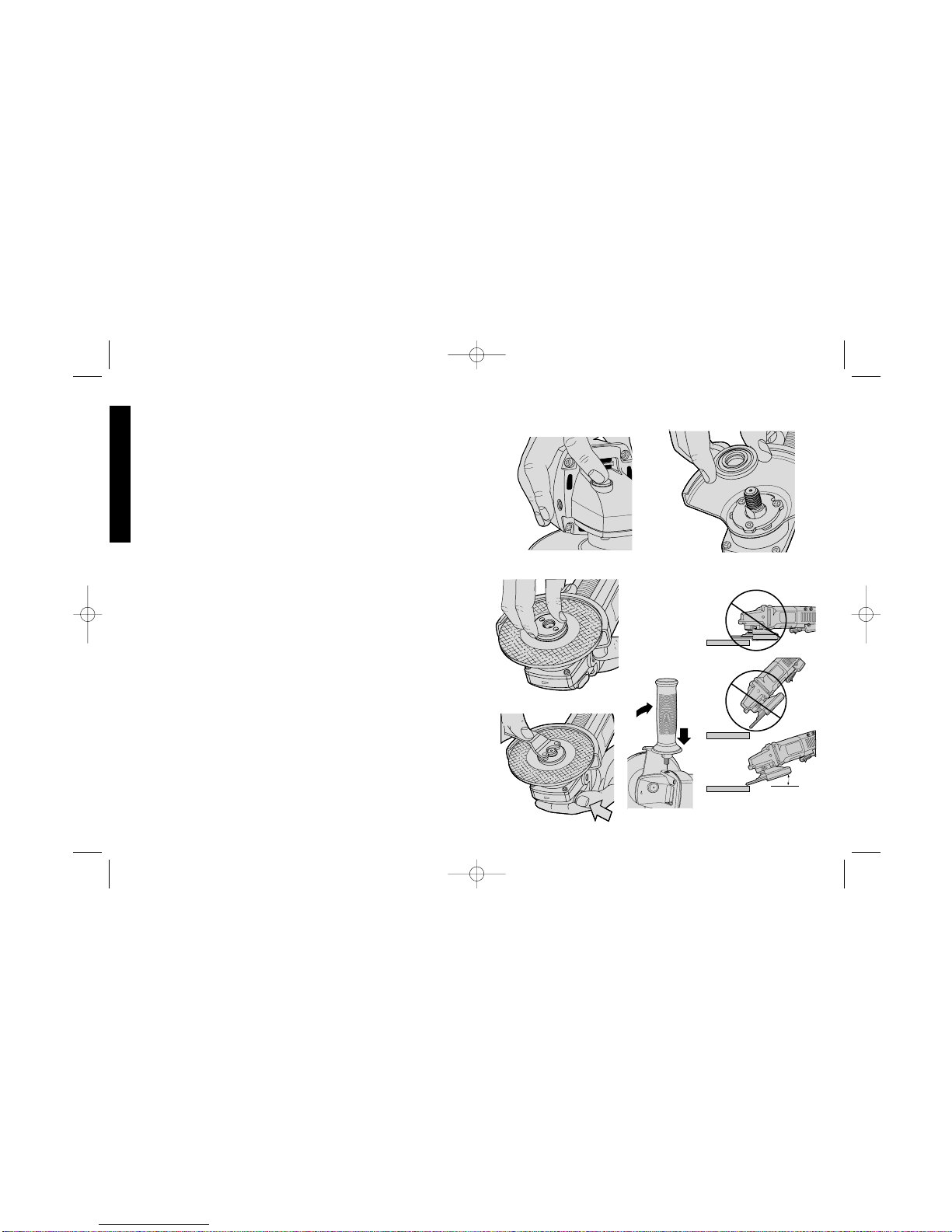

FIG. 8

FIG. 10

FIG. 11

FIG. 9

depress the switch locking button next to the trigger (B). Hold the

locking button in as you gently release the trigger. Release the locking

button and the tool will continue to run. T o turn the tool off from a locked

on condition, squeeze and release the trigger once.

Fitting a Rubber Backing Pad (Fig. 6)

The rubber backing pad is available as an optional accessory. To fit the

pad:

1. Unplug the tool.

2. Remove the guard from the tool.

3. Insert the backing pad onto the machine spindle (Fig. 6). The inner

driven flange in Fig. 9 is not needed.

4. Position the abrasive disc on the pad.

5. Screw the outer flange with the two grip holes, together with the pad

fitted, onto the machine spindle (Fig. 7).

6. With your finger firmly on the spindle lock (Fig. 8), tighten the outer

flange with the pin spanner supplied.

7. Release the spindle lock. You can now plug the tool in and start

work.

8. To remove the backing pad, follow the instructions in reverse order.

IMPORTANT: When using the tool for sanding, allow only a segment

of the disc to contact the work and refrain from high-pressure

application.

Mounting Grinding Wheels

The grinding wheels are available as optional accessories. To fit a

grinding wheel:

1. Disconnect the plug.

2. Locate the inner driven flange on the drive flats on the machine

spindle (Fig. 9).

3. Place the wheel against the flange.

4. Screw the threaded flange onto the spindle (Fig. 10).

5. Rotate the grinding wheel while pressing the spindle lock (on the

front of the gear case) fully until it has found its locking location and

hold the spindle still.

FIG. 12

10° - 15°

FIG. 13

DW830,etc./569590-01 8/3/00 2:47 PM Page 4

Page 8

5

English

6. Firmly tighten the threaded flange with the two-pin spanner

supplied (Fig. 11). You can now plug the tool in and start work.

FOR GRINDING:

Using a depressed center disc, use the tool at an angle of

approximately 30° to the work for roughing. (See figure 13.)

Fitting Wire Cup Brushes

The wire cup brush screws directly on the spindle of the machine

without the use of flanges.

Side-handle (Fig. 12)

The side handle can be fitted to either side of the gear case.

Precautions To Take When Sanding Paint

1. Sanding of lead based paint is NOT RECOMMENDED due to the

difficulty of controlling the contaminated dust. The greatest danger

of lead poisoning is to children and pregnant women.

2. Since it is difficult to identify whether or not a paint contains lead

without a chemical analysis, we recommend the following

precautions when sanding any paint:

PERSONAL SAFETY

a. No children or pregnant women should enter the work area where

the paint sanding is being done until all clean up is completed.

b. A dust mask or respirator should be worn by all persons entering

the work area. The filter should be replaced daily or whenever the

wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint

dust and fumes should be used. Ordinary painting masks do not

offer this protection. See your local hardware dealer for the proper

N.I.O.S.H. approved mask.

c. NO EATING, DRINKING or SMOKING should be done in the work

area to prevent ingesting contaminated paint particles. Workers

should wash and clean up BEFORE eating, drinking or smoking.

Articles of food, drink, or smoking should not be left in the work

area where dust would settle on them.

ENVIRONMENTAL SAFETY

a. Paint should be removed in such a manner as to minimize the

amount of dust generated.

b. Areas where paint removal is occurring should be sealed with

plastic sheeting of 4 mils thickness.

c. Sanding should be done in a manner to reduce tracking of paint dust

outside the work area.

CLEANING AND DISPOSAL

a.All surfaces in the work area should be vacuumed and thoroughly

cleaned daily for the duration of the sanding project. Vacuum filter

bags should be changed frequently.

b.Plastic drop cloths should be gathered up and disposed of along

with any dust chips or other removal debris. They should be placed

in sealed refuse receptacles and disposed of through regular trash

pick-up procedures.

During clean up, children and pregnant women should be kept away

from the immediate work area.

c.All toys, washable furniture and utensils used by children should be

washed thoroughly before being used again.

Maintenance

Cleaning

Blowing dust and grit out of the motor housing using compressed air

is a necessary regular maintenance procedure. Dust and grit

containing metal particles often accumulate on interior surfaces and

could create an electrical shock hazard if not frequently cleaned out.

ALWAYS WEAR SAFETY GLASSES.

CAUTION: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. Use clean, dry rag only.

Lubrication

DEWALTtools are properly lubricated at the factory and are ready for

use. Tools should be relubricated regularly every sixty days to six

DW830,etc./569590-01 8/3/00 2:47 PM Page 5

Page 9

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

E

WALT, COMPOSER SANS

FRAIS LE NUMÉRO SUIVANT.

1 800 4-DEWALT (1 800 433-9258)

Importantes mesures de sécurité

AVERTISSEMENT! Lire et comprendre toutes les directives. Le

non-respect de toutes les directives suivantes présente des risques de

secousses électriques, d'incendie ou de blessures graves.

CONSERVER CES MESURES

Régles de sécurité générales

AVERTISSEMENT! Vous devez lire et comprendre toutes les

instructions. Le non-respect, même partiel, des instructions ci-après

entraîne un risque de choc électrique, d’incendie et/ou de blessures

graves.

ZONE DE TRAVAIL

• S'assurer que la zone de travail est propre et bien éclairée.

Des établis encombrés et des endroits sombres présentent des

risques d'accidents.

• Ne pas utiliser des outils électriques en présence de vapeurs

explosives (comme celles dégagées par des liquides, des gaz

ou des poussières inflammables). Les étincelles générées par

le moteur des outils électriques peuvent enflammer les poussières

ou les vapeurs.

• Éloigner les curieux, les enfants et les visiteurs de la zone de

travail lorsqu'on utilise un outil électrique. Une distraction peut

entraîner la perte de maîtrise de l'outil.

MESURES DE SÉCURITÉ RELATIVES À L'ÉLECTRICITÉ

• Les outils mis à la terre doivent être branchés dans une prise

bien installée et mise à la terre conformément à tous les codes

et règlements en vigueur. Ne jamais retirer la broche de terre ni

modifier la fiche. Ne pas utiliser d'adaptateur pour fiche. Vérifier

auprès d'un électricien certifié en cas de doute quant à la mise à la

6

English

months, depending on usage. (T ools used constantly on production or

heavy-duty jobs and tools exposed to heat may require more frequent

lubrication.) This lubrication should only be attempted by trained power

tool repairpersons, such as those at D

EWALT service centers or in

other qualified service organizations.

Motor Brushes

When brushes become worn, the tool will automatically stop and

prevent damage to the motor. Brush replacement should be performed

by D

EWALTauthorized service centers.

Accessories

Recommended accessories for use with your tool are available at extra

cost from your local dealer or authorized service center. If you need

assistance in locating any accessory for your tool, contact:

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286

CAUTION: The use of any other accessory not recommended for

use with this tool could be hazardous.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information, call

1-800-4-D

EWALT. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALTheavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

DW830,etc./569590-01 8/3/00 2:47 PM Page 6

Page 10

7

Français

terre de la prise. En cas de défaillance électrique ou de bris de

l'outil, la mise à la terre procure un chemin de faible résistance au

courant qui autrement traverserait l'utilisateur.

• Les outils à double isolation comportent une fiche polarisée

(une lame plus large que l'autre). La fiche n'entre que d'une

façon dans une prise polarisée. Lorsque la fiche n'entre pas à fond

dans la prise, essayer de nouveau après avoir inversé les broches

de la fiche. Si la fiche n'entre toujours pas dans la prise,

communiquer avec un électricien certifié afin de faire installer une

prise polarisée. Ne modifier en aucune façon la fiche. La double

isolation élimine le besoin d'un cordon trifilaire mis à la terre et d'un

système d'alimentation mis à la terre.

• Éviter de toucher à des surfaces mises à la terre comme des

tuyaux, des radiateurs, des cuisinières et des réfrigérateurs.

Les risques de secousses électriques sont plus élevés si le corps

de l'utilisateur est mis à la terre.

• Protéger les outils électriques de la pluie ou des conditions

mouillées. Une infiltration d'eau dans l'outil augmente les risques

de secousses électriques.

• Manipuler le cordon avec soin. Ne jamais se servir du cordon

afin de transporter l'outil ni tirer sur le cordon pour débrancher l'outil.

Éloigner le cordon des sources de chaleur, des flaques d'huile, des

arêtes tranchantes et des pièces mobiles. Remplacer

immédiatement les cordons endommagés. Les cordons

endommagés augmentent les risques de secousses électriques.

• Lorsqu'on utilise un outil électrique à l'extérieur, se servir d'un

cordon de rallonge prévu pour l'extérieur, portant la mention

«W-A» ou «W». Ces cordons sont conçus pour servir à l'extérieur

et minimisent les risques de secousses électriques.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Non recommandé

SÉCURITÉ DES PERSONNES

• Demeurer vigilant, prendre soin et faire preuve de jugement

lorsqu'on utilise un outil électrique. Ne pas s'en servir lorsqu'on

est fatigué ou affaibli par des drogues, de l'alcool ou des

médicaments. De graves blessures peuvent résulter d'un moment

d'inattention lors de l'utilisation d'un outil électrique.

• Porter des vêtements appropriés. Éviter de porter des

vêtements amples ou des bijoux. Recouvrir la chevelure si elle est

longue. Éloigner les cheveux, les vêtements et les gants des

pièces en mouvement qui peuvent les happer.

• Éviter les démarrages accidentels. S'assurer que l'interrupteur

est en position hors tension avant de brancher l'outil. Afin d'éviter

les risques de blessures, ne pas transporter l'outil avec le doigt sur

l'interrupteur ni brancher un outil dont l'interrupteur est en position

sous tension.

• Enlever les clés de réglage avant de mettre l'outil sous

tension. Une clé qui est laissée sur une pièce rotative de l'outil

présente des risques de blessures.

• Ne pas dépasser sa portée. Garder son équilibre en tout temps.

On s'assure d'une meilleure maîtrise de l'outil dans des situations

imprévues grâce à une position stable et un bon équilibre.

• Porter de l'équipement de sécurité. Toujours porter des lunettes

de sécurité. Dans certaines conditions, il faut porter des masques

respiratoires, des chaussures antidérapantes, un casque de

sécurité ou des protège-tympans.

DW830,etc./569590-01 8/3/00 2:47 PM Page 7

Page 11

Utilisation et entre tien de l'outil

• Utiliser des pinces de serrage ou de tout autre moyen pratique

afin de fixer et de soutenir la pièce à ouvrer sur une plateforme stable. La pièce est instable lorsqu'elle est retenue par la

main ou le corps de l'utilisateur. Cela présente des risques de perte

de maîtrise de l'outil.

• Ne pas forcer l'outil. Utiliser l'outil approprié à la tâche. L'outil

approprié fonctionne mieux et sûrement lorsqu'on s'en sert à son

rendement nominal.

• Ne pas se servir de l'outil lorsque l'interrupteur est défectueux.

Le cas échéant, l'outil est dangereux et il faut le réparer.

• Débrancher l'outil de la source d'alimentation avant de le

régler, d'en remplacer les accessoires ou de le ranger. On

minimise de la sorte le risque de démarrage accidentel de l'outil.

• Ranger l'outil hors de portée des enfants et de toute autre

personne qui n'en connaît pas le fonctionnement. L'outil est

dangereux entre les mains de ces personnes.

• Prendre soin des outils. S'assurer que les outils de coupe sont

tranchants et propres. Des outils bien entretenus à arêtes

tranchantes ont moins tendance à se coincer et ils se maîtrisent

mieux.

• Vérifier l'alignement et les attaches des pièces mobiles, le

degré d'usure des pièces ainsi que tout autre facteur susceptible de

nuire au bon fonctionnement de l'outil. Faire réparer un outil

endommagé avant de s'en servir. Des outils mal entretenus sont

la cause de nombreux accidents.

• Utiliser seulement les accessoires recommandés par le

fabricant. Des accessoires qui conviennent à un outil peuvent

présenter des risques avec un autre outil.

Entretien

• Confier l'entretien de l'outil seulement à du personnel qualifié. Le

non-respect de la présente directive présente des risques de

blessures.

• Lors de l'entretien de l'outil, utiliser seulement des pièces de

rechange identiques. Respecter les consignes relatives à

l'entretien du présent guide d'utilisation. Il y a risque de secousses

électriques ou de blessures lorsqu'on utilise des pièces non

autorisées ou lorsqu'on ne respecte pas les consignes relatives à

l'entretien.

Mesures de sécurité relatives aux

rectifieuses

• Toujours utiliser le protecteur approprié à la meule. Le

protecteur protège l'utilisateur des fragments de meule cassés.

• Utiliser seulement des accessoires dont le régime nominal

équivaut au moins au régime indiqué sur la plaque

signalétique de l’outil. Une meule ou tout accessoire utilisé à une

vitesse excessive peut se détacher de l'outil et provoquer des

blessures.

• Saisir les surfaces isolées de l’outil lorsqu’on s’en sert là où il

pourrait y avoir des fils sous tension et lorsqu’il pourrait entrer

en contact avec son propre fil. En cas de contact avec un fil sous

tension, les composantes métalliques à découvert de l’outil

deviendraient sous tension et l’utilisateur subirait des secousses

électriques.

• Avant de s’en servir, vérifier si les accessoires recommandés

ne renferment aucune fêlure ni défaut. Le cas échéant, jeter

l’accessoire. Il faut également inspecter l’accessoire lorsque l’outil

est tombé.

• Au moment du démarrage (après avoir installé une nouvelle

meule), saisir l’outil dans un endroit bien protégé et le laisser

fonctionner pendant une minute. Si la meule renferme une fêlure

ou un défaut non décelé, elle éclatera en moins de une minute. Ne

jamais mettre l’outil en marche lorsqu’une personne se trouve dans

la trajectoire de la meule. Cette mesure vaut également pour

l’utilisateur.

8

Français

DW830,etc./569590-01 8/3/00 2:47 PM Page 8

Page 12

9

Français

• Pendant les travaux, éviter de faire sauter la meule ou de la

maltraiter. Le cas échéant, arrêter l’outil et inspecter la meule.

• Toujours utiliser la poignée latérale. Il faut toujours se servir de la

poignée latérale afin de bien maîtriser l'outil en tout temps.

• Nettoyer l’outil régulièrement. De la poussière et des saletés

renfermant des particules métalliques s'accumulent souvent sur les

surfaces internes de l'outil et cette accumulation présente un risque

de secousses électriques.

AVERTISSEMENT : Certains outils, tels que les sableuses

électriques, les scies, les meules, les perceuses ou certains autres

outils de construction, peuvent soulever de la poussière contenant des

produits chimiques susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système

reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de

maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence

avec laquelle on effectue ces travaux. Pour réduire l’exposition à de

tels produits, il faut travailler dans un endroit bien ventilé et utiliser

l’équipement de sécurité approprié tel un masque anti-poussières

spécialement conçu pour filtrer les particules microscopiques.

•L’étiquette de l’outil peut comporter les symboles suivants.

V ................................volts

A ................................ampères

Hz ..............................hertz

W ..............................watts

min ............................minutes

............................courant alternatif

..........................courant continu

n

o ..........................sous vide

..............................construction de classe II

/min............................tours ou courses à la minute

..............................borne de mise à la terre

............................symbole d´avertissement

Installation et retrait du protecteur

(Fig. 1)

On peut enlever le protecteur pour effectuer des travaux de ponçage

à l’aide du disque d’appui. Faire ce qui suit pour installer le

protecteur lors de toute autre utilisation.

1. Aligner l’oreille du protecteur dans la fente du support fixé au socle

du boîtier des engrenages (fig. 1).

2. Abaisser le protecteur vers le boîtier des engrenages, puis le faire

pivoter dans le sens de la flèche (fig. 2).

3. Dans cette position, la tige de verrouillage du protecteur située dans

la fente empêche le protecteur de se détacher, mais elle en permet

la rotation jusqu’à 105°.

Faire ce qui suit pour retirer le protecteur.

1. Déposer l’outil à l’envers sur une surface plane.

2. Saisir l’outil et, à l'aide du pouce, faire pivoter le protecteur dans le

sens de la flèche (fig. 3). Simultanément, pousser sur la tige de

verrouillage dans le fente à l’aide d’un tournevis ou d’un autre

instrument pointu jusqu’à ce que l’oreille du protecteur soit visible

(fig. 4).

3. La tige de verrouillage ne retient alors plus le protecteur, qu’on

peut retirer en le poussant.

IMPORTANT : Débrancher l’outil avant d’installer ou de retirer le

protecteur. Utiliser l’outil sans protecteur seulement pour les travaux

de ponçage avec le disque d’appui en caoutchouc.

DW830,etc./569590-01 8/3/00 2:47 PM Page 9

Page 13

10

Français

Interrupteur

Pour actionner l'outil, enfoncer l'interrupteur à détente (fig. 5). Pour

l'arrêter, relâcher l'interrupteur. On peut verrouiller l'outil en mode de

fonctionnement continu en enfonçant l'interrupteur à détente tout en

enfonçant le bouton de verrouillage de l'interrupteur qui se trouve près

de la détente (fig. 5). Maintenir le bouton de verrouillage enfoncé et

relâcher doucement l'interrupteur. On peut alors relâcher le bouton

de verrouillage et l'outil continue de fonctionner. Pour arrêter l'outil

alors qu'il est en mode de fonctionnement continu, enfoncer et relâcher

immédiatement la détente.

Installation d'un disque d'appui en caoutchouc (Fig. 6)

Le disque d’appui en caoutchouc est vendu séparément. Faire ce qui

suit pour l’installer.

1. Débrancher l’outil.

2. Retirer le protecteur de l’outil.

3. Insérer le disque d’appui sur l’arbre (fig. 6). La bride interne (fig. 9)

n’est pas nécessaire.

4. Placer le disque abrasif sur le disque d’appui.

5. Une fois le disque installé, visser la bride externe sur l’arbre en se

servant des deux trous de serrage (fig. 7).

6. En appuyant fermement sur le dispositif de verrouillage de l’arbre

avec un doigt (fig. 8), serrer la bride externe à l’aide de la clé à

griffes fournie.

7. Relâcher le dispositif de verrouillage de l’arbre. L’outil est prêt à être

branché et utilisé.

8. Pour retirer le disque d’appui, répéter les étapes précédentes dans

l’ordre inverse.

IMPORTANT : Lors du ponçage avec l’outil, ne laisser qu’une portion

du disque entrer en contact avec la pièce et éviter d’exercer une trop

grande pression.

Installation de la meule

Les meules sont vendues séparément. Faire ce qui suit pour les

installer.

1. Débrancher l’outil.

2. Placer la bride interne sur les surfaces planes de l’arbre (fig. 9).

3. Placer la meule sur la bride.

4. Visser la bride filetée sur l’arbre (fig. 10).

5. Faire pivoter la meule tout en enfonçant complètement le dispositif

de verrouillage de l’arbre (à l’avant du boîtier des engrenages)

jusqu’à ce que la meule s’enclenche et immobilise l’arbre.

6. Serrer la bride filetée fermement avec la clé à deux griffes incluse

(fig. 11). L’outil est prêt à être branché et utilisé.

Meulage

Lorsqu’on travaille avec un disque à moyeu creux, il faut toujours

donner un angle d’environ 30° à l’outil pour dégrossir (fig. 13).

Installation d'une brosse boisseau

métallique

Visser la brosse boisseau métallique directement sur l’arbre sans avoir

recours aux brides.

Poignée latérale (Fig. 12)

La poignée latérale peut être fixée d’un côté ou de l’autre du boîtier des

engrenages.

Mesures à prendre lors du ponçage de

peinture

1. IL N’EST PAS RECOMMANDÉ de poncer de la peinture à base de

plomb puisqu’il est difficile d’en maîtriser la poussière contaminée.

Ce genre de ponçage présente de sérieux risques

d’empoisonnement au plomb pour les femmes enceintes et les

enfants.

2. Puisqu’il est difficile de déterminer si la peinture renferme du plomb

sans en faire une analyse chimique, il est conseillé de se conformer

DW830,etc./569590-01 8/3/00 2:47 PM Page 10

Page 14

11

Français

aux mesures suivantes lors du ponçage de tout type de peinture.

SÉCURITÉ PERSONNELLE

a. Ne laisser aucun enfant ni aucune femme enceinte entrer dans la

pièce où il y a ponçage de peinture jusqu’à ce que la pièce soit

nettoyée.

b. Toute personne entrant dans la pièce de travail devrait porter un

masque ou un respirateur. L’utilisateur devrait en remplacer le

filtre chaque jour ou dès qu’il éprouve de la difficulté à respirer.

NOTE : Il faut seulement utiliser des masques conçus pour le travail

en présence de poussières ou de vapeurs de plomb. Les masques

ordinaires ne sont pas conçus à cet effet. Consulter le quincaillier pour

choisir le masque approprié.

c. IL EST DÉCONSEILLÉ DE MANGER, DE BOIRE ET DE FUMER

dans la pièce de travail afin de ne pas ingérer de particules

contaminées. L’utilisateur doit se laver et se nettoyer AVANT de

manger, de boire ou de fumer. Il ne faut pas laisser dans la pièce

de travail de la nourriture, des boissons ou des cigarettes car de la

poussière pourrait se déposer sur ces articles.

PROTECTION DE L’ENVIRONNEMENT

a. Il faut enlever la peinture de manière à produire un minimum de

poussière.

b. Il faut sceller la zone de travail à l’aide de feuilles de plastique d’une

épaisseur minimale de 4 mils.

c. Il faut poncer de façon à réduire la propagation de la poussière hors

de la pièce de travail.

NETTOYAGE ET DÉCHETS

a. Il faut bien aspirer toutes les surfaces de la pièce de travail et les

nettoyer à fond chaque jour pendant la durée des travaux. Il faut

remplacer fréquemment le filtre de l’aspirateur.

b. Ramasser les feuilles de plastique et les jeter avec la poussière et

les autres débris dans des contenants étanches à placer avec les

ordures ménagères pour l’enlèvement.

Tenir les enfants et les femmes enceintes à l’écart de la zone de

travail pendant les travaux de nettoyage.

c. Il faut nettoyer à fond les jouets, les meubles et les ustensiles des

enfants avant de les utiliser de nouveau.

Entretien

NETTOYAGE

Le retrait de la poussière du carter du moteur à l’aide d’un jet d’air

comprimé fait partie de l’entretien normal de l’outil. De la poussière

contenant des particules métalliques s’accumule fréquemment sur les

surfaces intérieures et cela présente un risque de secousses

électriques si la poussière n’est pas enlevée régulièrement.

TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ.

MISE EN GARDE : Ne jamais utiliser de solvants ni de produits

chimiques puissants pour nettoyer les composants non métalliques

de l’outil. Utiliser seulement un chiffon sec et propre.

Lubrification

Les outils DeWalt sont lubrifiés et prêts à être utilisés à leur sortie de

l’usine. Ils devraient être lubrifiés régulièrement, entre 60 jours et six

mois, selon l’usage qu’on en fait. (Les outils constamment utilisés ou

servant aux travaux de service intensif ainsi que ceux exposés à la

chaleur peuvent nécessiter des lubrifications plus fréquentes.) Confier

la lubrification à des techniciens qualifiés, comme ceux des centres

de service DeWalt et des autres centres de service autorisés.

Balais du moteur

Lorsque les balais sont usés, l’outil s’arrête automatiquement afin de

ne pas endommager le moteur. Confier le remplacement des balais du

moteur au personnel des centres de service autorisés DeWalt.

Accessoires

On peut se procurer en sus les accessoires recommandés pour l’outil

chez les détaillants ou aux centres de service autorisés. Pour trouver

un accessoire pour l’outil, communiquer à l’adresse suivante.

DW830,etc./569590-01 8/3/00 2:47 PM Page 11

Page 15

12

Français

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286 É.-U.

MISE EN GARDE : L’utilisation de tout autre accessoire non

recommandé pour l’outil peut être dangereuse.

Garantie complète

Les outils industriels de service intensif DEWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

D

EWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée ou remplacée sans frais. Pour obtenir de

plus amples renseignements sur les réparations couvertes par la

garantie, composer le 1 (800) 4-D

EWALT (! (800) 433-9258). La ga

rantie ne couvre pas les accessories ni les réparations tentées ou

effectuées par des tiers. Les modalités de la présente garantie

donnent des droits légaux spécifiques. L’utilisateur peut également

se prévaloir d’autres droits selon l’état ou la province qu’il habite.

En outre, la garantie suivante couvre les outils D

EWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT REMIS

Si, pour quelque raison que ce soit, l’outil industriel de service intensif

D

EWALT ne donne pas entière satisfaction, il suffit de le retourner

chez le marchand participant dans les 30 jours suivant la date

d’achat afin d’obtenir un remboursement complet. Il faut retourner,

port payé, l’outil complet. On peut exiger une preuve d’achat.

Imported by / Importé par

D

EWalt Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

Instrucciones importantes de seguridad

ADVERTENCIA: Lea y comprenda todas las instrucciones. No

seguir todas las instrucciones enlistadas a continuación puede

resultar en choque eléctrico, incendio y (o) lesiones personales de

gravedad.

CONSERVE ESTAS

INSTRUCCIONES

AREA DE TRABAJO

• Conser ve su área de trabajo limpia y bien iluminada. Los

bancos con objetos acumulados en desorden y las zonas oscuras

propician los accidentes.

• No opere herramientas eléctricas en atmósferas explosivas,

como en presencia de líquidos gases o polvos inflamables. Las

herramientas eléctricas producen chispas que pueden originar la

ignición de estos polvos o vapores.

• Conserve a observadores, niños y visitantes alejados mientras

opera una herramienta eléctrica. Las distracciones pueden

ocasionar que pierda el control.

SEGURIDAD ELECTRICA

• Las herramientas con tierra deben conectarse a una toma de

corriente instalada y aterrizada correctamente de conformidad con todos los códigos y regulaciones locales. Nunca

elimine la pata de conexión a tierra ni modifique la clavija en

ninguna manera. No utilice clavijas adaptadoras. Consulte con un

electricista calificado si tiene dudas acerca de la conexión correcta

a tierra de su toma de corriente. En el caso que su herramienta

tenga una falla eléctrica, el aterrizaje proporciona una vía de baja

resistencia para llevar la electricidad lejos del operador.

• Las herramientas con doble aislamiento están equipadas con una

clavija polarizada (con una pata más ancha que la otra). Esta clavija

se acoplará únicamente a una toma de corriente polarizada en

una manera. Si la clavija no se acopla al contacto, inviértala. Si

DW830,etc./569590-01 8/3/00 2:47 PM Page 12

Page 16

13

Français

aún así no se ajusta, comuníquese con un electricista calificado

para que le instalen una toma de corriente polarizada apropiada.

El doble aislamiento elimina la necesidad de cables con tres

hilos y sistemas de alimentación con conexión a tierra.

• Evite el contacto corporal con superficies aterrizadas tales

como tuberías, radiadores, hornos y refrigeradores. Hay un

gran riesgo de choque eléctrico si su cuerpo hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a

condiciones de mucha humedad. El agua que se introduce a las

herramientas aumenta el riesgo de descargas eléctricas.

• No maltrate el cable. Nunca tome el cable para transportar una

herramienta ni para desconectarla de la toma de corriente.

Consérvelo alejado de calor, aceite, bordes afilados o piezas

móviles. Cambie inmediatamente los cables dañados. Los cables

dañados aumentan el riesgo de choque eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie,

utilice una extensión marcada “W-A” o “W”. Estas extensiones

está clasificadas para usarse a la intemperie y para reducir el riesgo

de choques eléctricos.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

AMPERAJE

Más No más Calibre del cordón AWG

de de

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16- 14 12 No recomendado

SEGURIDAD PERSONAL

• Esté alerta, concéntrese en lo que está haciendo. recurra al

sentido común cuando opere una herramienta eléctrica. No

opere ninguna herramienta si se encuentra fatigado o bajo la

influencia de drogas, alcohol o medicamentos. Un momento de

desatención mientras se operan herramientas eléctricas puede

ocasionar lesiones graves.

• Vístase de manera adecuada. No tenga puestas ropas o artículos

de joyería flojos. Cubra su cabello si lo tiene largo. Conserve su

cabello, sus ropas y guantes alejados de las piezas móviles. Las

piezas de vestir flojas, las joyas y el cabello largo pueden quedar

atrapados por las piezas móviles.

• Evite el encendido accidental. Asegúrese que el interruptor esté

en posición de apagado antes de conectar. Sostener una

herramienta con el dedo en el interruptor, o conectarla sin fijarse si

el interruptor está en posición de encendido propicia los accidentes.

• Retire las llaves de ajuste antes de encender la herramienta.

Una llave que se deja en una pieza giratoria puede ocasionar

lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien apoyados,

al igual que el equilibrio. La posición correcta de los pies y el

equilibrio permiten controlar mejor la herramienta en situaciones

inesperadas.

• Utilice equipo de seguridad. Siempre utilice protección en los

ojos. Se deben utilizar mascarillas contra polvo, zapatos

antiderrapantes, casco o protectores para los oídos para tener las

condiciones de trabajo adecuadas.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice prensas u otros medios prácticos para asegurar y

apoyar la pieza de trabajo en una plataforma estable. Sujetar

las piezas con la mano o contra su cuerpo es inestable y puede

originar la pérdida de control.

• No fuerce la herramienta. Utilice la herramienta adecuada para

su aplicación. La herramienta correcta hará el trabajo mejor y de

manera más segura bajo las especificaciones para las que se

diseñó.

• No utilice la herramienta si el interruptor no enciende y apaga.

Cualquier herramienta que no pueda controlarse por medio del

interruptor es peligrosa y éste debe reemplazarse.

DW830,etc./569590-01 8/3/00 2:47 PM Page 13

Page 17

14

Español

• Desconecte la clavija de la toma de corriente antes de hacer

cualquier ajuste, cambio de accesorios o de guardar la

herramienta. Tales medidas de seguridad reducen el riesgo de

encender la herramienta por accidente.

• Guarde las herramientas que no emplee fuera del alcance de

niños y otras personas sin entrenamiento. Las herramientas son

peligrosas en manos de personas sin entrenamiento.

• Cuide sus herramientas. Conserve las herramientas de corte

afiladas y limpias. Las herramientas con mantenimiento adecuado

y con bordes cortantes afilados, son menos propensas a atorarse

y provocar la pérdida de control.

• Revise en busca de mala alineación o piezas móviles atoradas,

ruptura de piezas y cualesquiera otras condiciones que

pudiesen afectar la operación de la herramienta. Si su

herramienta está dañada, haga que le efectúen servicio antes de

utilizarla. Muchos accidentes son ocasionados por herramientas

con mantenimiento pobre.

• Utilice únicamente los accesorios recomendados por el

fabricante para su modelo. Los accesorios que sirven para una

herramienta, pueden volverse peligrosos cuando se emplean con

otra.

SERVICIO

• El ser vicio a las herramientas deberá ser efectuado únicamente por personal calificado. El servicio o mantenimiento

realizado por personal no calificado puede resultar en un riesgo de

lesión.

• Cuando haga servicio a una herramienta, utilice únicamente

refacciones idénticas. Siga las instrucciones de la sección de

mantenimiento de este manual. El empleo de partes no

autorizadas, o no seguir las instrucciones de mantenimiento puede

crear riesgos de choque eléctrico o lesiones.

Doble aislamiento

Las herramientas doblemente aisladas se han elaborado de manera

integral con dos “capas” separadas, o una de DOBLE espesor, de

aislamiento eléctrico entre usted y el sistema eléctrico que contienen.

Las herramientas elaboradas con este sistema de aislamiento no

requieren conectarse a tierra. Como resultado, su unidad está

equipada con una clavija de dos patas que le permite emplear

cordones de extensión sin preocuparse por tener una conexión a

tierra.

NOTA: el doble aislamiento no substituye a las precauciones normales

de seguridad cuando se opera esta herramienta. La finalidad de este

sistema de aislamiento es ofrecer a usted protección añadida contra la

lesión resultante de fallas en el aislamiento eléctrico interno de la

unidad.

PRECAUCION: UTILICE SOLAMENTE REFACCIONES

IDENTICAS cuando se haga servicio a cualquier herramienta. Repare

o reemplace los cordones eléctricos dañados.

Clavija polarizada

Se emplean clavijas polarizadas (con una pata más ancha que la otra)

para reducir los riesgos de choque eléctrico. Cuando el cordón

eléctrico cuente con este tipo de clavija, ajustará en un contacto

polarizado solamente de una manera. Si la clavija no ajusta

completamente en su contacto, inviértala. Si aún así no ajusta, llame

a un electricista calificado para que le instale un contacto polarizado

apropiado. No modifique o haga cambios en la clavija por ningún

motivo.

•

Instrucciones adicionales de seguridad

para esmeriladoras

• Utilice siempre la guarda adecuada para su piedra de esmeril.

La guarda protege al operador de los fragmentos de la piedra que

se desprenden.

• Los accesorios deben estar clasificados para al menos la

velocidad recomendada en la etiqueta de advertencia de la

herramienta. Los discos y otros accesorios que funcionen por

arriba de su velocidad de operación nominal pueden estallar, con el

consiguiente riesgo de lesiones.

• Sujete la herramienta por las superficies aislantes cuando

DW830,etc./569590-01 8/3/00 2:47 PM Page 14

Page 18

15

Español

realice operaciones en las que la herramienta de corte pueda

tocar cableados ocultos o su propio cable. Hacer contacto con

un cable “vivo” hará que las partes metálicas de la herramienta

que quedan expuestas se vuelvan “vivas” dando una descarga al

operador.

• Antes de emplear un accesorio recomendado, revíselo en

busca de fallas o cuarteaduras. Si tal falla es evidente, deseche

el accesorio. Debe revisar el accesorio siempre que usted piense

que la herramienta se ha caído.

• Cuando encienda la herramienta (con un disco nuevo o uno de

repuesto instalado) sujete la herramienta en una zona bien

protegida y déjela funcionar durante un minuto. Si la piedra tiene

una cuarteadura que no se haya detectado, deberá estallar en

menos de un minuto. Nunca encienda la herramienta cuando haya

una persona alineada con el disco; esto incluye al propio operador.

• Evite que la rueda opere a saltos o se maltrate mientras está

en funcionamiento. Si sucediera así, apague y desconecte la

herramienta y revise la piedra.

• UTILICE SIEMPRE EL MANGO LATERAL.Debe utilizar el mango

lateral para conservar el control de la herramienta siempre.

• Limpie su herramienta periódicamente. El polvo de esmeril

contiene a menudo partículas metálicas que se acumulan en el

interior y pueden originar un riesgo de choque eléctrico.

PRECAUCION: Algunos tipos de madera contienen conservadores

como el arsenato cúprico de cromo (CCA) que pueden ser tóxicos.

Cuando lije estos materiales, debe tener precaución para evitar la

inhalación y minimizar el contacto de estas sustancias con la piel.

• La etiqueta de su herramienta puede incluir los siguientes

símbolos.

V .............. volts

A .............. amperes

Hz.............. hertz

W .............. watts

.../min ........ minutos

.............. corriente alterna

.......... corriente directa

n

o.............. velocidad sin carga

.............. construcción Clase II

/min .......... revoluciones o reciprocaciones por minuto

.............. erminales de conexión a tierre

..............símbolo de alerta de seguridad

Carbones del motor

DEWALT utiliza un avanzado sistema de carbones que detiene

automáticamente el motor del taladro cuando se desgastan estas

piezas. Esto impide que el motor se dañe seriamente.

CONSERVE EST AS INSTRUCCIONES

Instalación y remoción de la guarda

(fig. 1)

No se requiere usar una guarda cuando emplee la herramienta para

lijar con la base de respaldo. Para colocar la guarda para otras

aplicaciones:

1. Haga coincidir la protuberancia de la guarda con la ranura en el

soporte fijado a la base de la caja de engranes (fig. 1).

2. Oprima la guarda contra la caja de engranes, y a continuación gírela

en dirección de la flecha (fig. 2).

3. En esta posición, el perno de seguridad de la guarda que se localiza

en la ranura evita que la guarda se afloje, pero permite girarla hasta

105°.

Para quitar la guarda:

1. Coloque la herramienta de cabeza sobre una superficie plana.

2. Sujete la herramienta, gire la guarda con la ayuda de su pulgar en

dirección de la flecha (fig. 3). Al mismo tiempo, con un destornillador

u otro instrumento puntiagudo, oprima el perno de seguridad que se

encuentra en la ranura para que la protuberancia de la guarda

quede a la vista (fig. 4).

DW830,etc./569590-01 8/3/00 2:47 PM Page 15

Page 19

16

Español

3. El perno de seguridad no sujeta la guarda, y puede empujarse

libremente.

IMPORTANTE: Desconecte la herramienta antes de montar o

desmontar la guarda. Use la herramienta sin la guarda solamente

cuando lije con el respaldo de goma instalado.

Interruptor

Para encender la herramienta, oprima el interruptor de gatillo que se

muestra en la figura 5. Para apagar la herramienta, libere el gatillo. La

herramienta puede asegurarse en modo de encendido permanente

para operación continua sujetando el interruptor al mismo tiempo que

oprime el botón del seguro del interruptor que se encuentra junto al

gatillo. Sujete el botón del seguro y libere suavemente el interruptor de

gatillo. Suelte el botón del seguro y la herramienta continuará en

funcionamiento. Para apagar la herramienta desde la posición de

encendido permanente, oprima y libere el gatillo una vez.

Encendido de la herramienta (fig. 5)

Para encender la esmeriladora, deslice hacia atrás y oprima el

interruptor de ENCENDIDO y APAGADO. Para sujetar la unidad de

manera más cómoda a dos manos, presione el interruptor de

ENCENDIDO y APAGADO y oprima la palanca del interruptor. Sujete

la palanca del interruptor mientras suelta el interruptor de ENCENDIDO

y APAGADO. La herramienta continuará en funcionamiento mientras

cualquier parte de la palanca del interruptor de conserve oprimida.

Operación continua

Para operar la herramienta en modo de encendido permanente, sujete

el interruptor de encendido y apagado y oprima y DESLICE HACIA

ADELANTE el botón de seguro del interruptor. Libere el botón del

seguro y el interruptor y la herramienta continuará en funcionamiento.

Para apagara la herramienta desde el modo de operación continua,

oprima y suelte el interruptor de encendido y apagado una vez.

Instalación del disco de respaldo de

goma (fig. 6)

Los discos de esmeril son accesorios opcionales. Para instalar un

disco de esmeril.

1 .Desconecte la clavija.

2. Coloque la arandela interior sobre los planos del cuadro de mando

en la flecha de la máquina (figura 9).

3. Coloque el disco contra la arandela.

4. Enrosque la arandela con cuerda en la flecha (fig. 10).

5. Gire el disco mientras oprime completamente el seguro de la flecha

(al frente de la caja de engranes) hasta que llegue a posición

segura y conserve fija la flecha.

6. Apriete con firmeza la arandela con cuerda con la llave de pernos

que se suministra (fig. 11). Ahora puede conectar la herramienta y

comenzar a trabajar.

Instalación de discos de esmeril

y de corte

Los discos de esmeril y de corte son accesorios opcionales. Para

instalar un disco de esmeril o de corte:

1. Desconecte la clavija.

2. Coloque la arandela interior sobre los planos del cuadro de mando

en la flecha de la máquina (fig. 9).

3. Coloque la piedra o el disco contra la arandela.

4. Enrosque la arandela con cuerda en la flecha (fig. 10).

5. Gire el disco o la piedra mientras oprime el seguro de la flecha (al

frente de la caja de engranes) completamente hasta que llegue a

posición segura y conserve fija la flecha.

6. Apriete con firmeza la arandela con cuerda con la llave de pernos

que se suministra (fig. 11). Ahora puede conectar la herramienta y

comenzar a trabajar.

DW830,etc./569590-01 8/3/00 2:47 PM Page 16

Page 20

17

Español

PARA ESMERILAR:

Cuando utilice piedras con centro realzado, sujete la herramienta de

manera que haya un ángulo aproximado a 30° en relación con la

superficie que vaya a desbastar (figura 13).

PARA CORTAR:

Con disco plano de corte, siempre aproxímese a la pieza e trabajo en

el ángulo en el que desee hacer el corte. Conserve este ángulo

durante todo el corte y no aplique presión lateral al disco.

Instalación de cepillos cónicos de

alambre

Los cepillos cónicos de alambre se enroscan directamente en la flecha

de la máquina sin usar las arandelas.

Mango lateral (fig. 12)

El mango lateral puede colocarse a cualquier lado de la caja de

engranes.

Precauciones cuando lije pintura

1. NO SE RECOMIENDA el lijado de pintura con base de plomo, por

la dificultad para controlar el polvo contaminado. Los niños y las

mujeres embarazadas son las personas con mayor peligro de sufrir

envenenamiento por plomo.

2. Ya que es difícil identificar si una pintura contiene plomo sin un

análisis químico, recomendamos seguir las precauciones que

siguen cuando se lije cualquier tipo de pintura.

SEGURIDAD PERSONAL

a. No deben tener acceso al área de trabajo niños ni mujeres

embarazadas hasta que ésta se encuentre perfectamente limpia.

b. Todas las personas que ingresen en el área de trabajo deberán

utilizar máscara contra polvo o un respirador. El filtro deberá

reemplazarse diariamente o en el momento en que el usuario

perciba dificultad para respirar a través del dispositivo.

NOTA: Sólo deben emplearse máscaras contra polvo adecuadas

para vapores y polvos originados en pintura que contiene plomo.

Las máscaras ordinarias para pintar no ofrecen ésta protección.

Consulte a su distribuidor local de ferretería para que le recomiende

el equipo adecuado.

c. NO se deberá COMER, BEBER NI FUMAR en el área de trabajo,

para evitar la ingestión de partículas de pintura contaminadas. El

operador deberá lavarse y limpiarse ANTES de comer, beber o

fumar. No se deben dejar artículos de estas clases en un área de

trabajo en la que se puede asentar polvo.

SEGURIDAD AMBIENTAL

a. La pintura debe removerse de manera que se minimice la cantidad

generada de polvo.

b. Se deben sellar los accesos a las áreas en donde se está

removiendo pintura con hojas de plástico cuyo espesor mínimo sea

de 0.1 mm.

c. El lijado se debe realizar de manera que se reduzca la salida de

polvo de pintura fuera del área de trabajo.

LIMPIEZA Y DESECHO

a. Todas las superficies en el área de trabajo deben aspirarse y

limpiarse diariamente mientras dure el lijado. Se deben cambiar

con frecuencia los filtros de bolsa de la aspiradora.

b. Las telas plásticas de recolección se deben recoger y desechar con

todos los restos de polvo y de pintura. Se colocarán en recipientes

desechables sellados, y se desecharán por medio del servicio de

recolección regular de basura. Debe procurarse que, durante la

limpieza, no haya niños ni mujeres embarazadas en las

proximidades del área de trabajo.

c. Todos los juguetes, mobiliario y utensilios usados por niños deben

lavarse a conciencia antes de que se vuelvan a utilizar.

Limpieza

Un procedimiento indispensable de mantenimiento de su unidad es la

eliminación, con regularidad, del polvo y las rebabas que se acumulan

DW830,etc./569590-01 8/3/00 2:47 PM Page 17

Page 21

18

Español

en la coraza de la herramienta mediante sopleteado con aire

comprimido. A menudo se acumulan en la superficie interior de ésta

polvo y partículas metálicas que crean el peligro de choque eléctrico,

por lo que es necesaria su eliminación con frecuencia. SIEMPRE

UTILICE GAFAS DE SEGURIDAD.

PRECAUCION: Nunca utilice solventes o productos químicos

agresivos para limpiar las partes no metálicas de la herramienta.

Utilice exclusivamente trapo limpio y seco.

Mantenimiento

Lubricación

La herramientas DeWalt vienen lubricadas de origen y están listas

para emplearse. Deben relubricarse con regularidad cada 60 días a

seis meses, según la frecuencia con que se utilicen. (Pueden requerir

lubricación más frecuente las unidades que se emplean

constantemente en trabajos pesados, lo mismo que las expuestas al

calor). Debe efectuar esta lubricación personal especializado, como

el de los Centros de Servicio Black & Decker o de otras organizaciones

de servicio autorizadas.

Carbones del motor

DEWALT utiliza un avanzado sistema de escobillas que detiene

automáticamente el motor de la esmeriladora cuando se desgastan

estas piezas. Esto impide que el motor se dañe seriamente. El cambio

de carbones debe ser realizado únicamente por los centros de servicio

autorizado D

EWALT.

Accesorios

Dispone usted de los accesorios recomendados para su herramienta

con cargo adicional con su distribuidor local o en los centros de

servicio autorizado. Si necesita usted ayuda para encontrar algún

accesorio, haga por favor contacto con:

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros de servicio para herramientas industriales de D

EWALT.

u otras organizaciones calificadas. Estas organizaciones prestan

servicio a las herramientas D

EWALT y emplean siempre refacciones

legítimas D

EWALT.

PRECAUCION: El uso de cualquier accesorio no recomendado

para emplearse con esta herramienta puede ser peligroso.

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av. Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

DW830,etc./569590-01 8/3/00 2:47 PM Page 18

Page 22

19

Español

Epecificaciones (DW830 (DW840,DW841)

Tensión de alimentación 120 V CA 120 V CA

Potencia nominal: 225 W 225 W

Frecuencia de operación: 60 Hz 60 Hz

Consumo de corriente: 6,5 A 6,5 A

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

Garantía Completa

Las herramientas industriales DEWALT están garantizadas durante un año a

partir de la fecha de compra. Repararemos, sin cargos, cualquier falla debida

a material o mano de obra defectuosos. Por favor regrese la unidad completa,

con el transporte pagado, a cualquier Centro de Servicio para Herramientas

Industriales de DEWALT o a las estaciones de servicio autorizado enlistadas

bajo "Herramientas Eléctricas" en la Sección Amarilla. Esta garantía no se

aplica a los accesorios ni a daños causados por reparaciones efectuadas

por terceras personas. Esta garantía le otorga derechos legales específicos,

y usted puede tener otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas DE

WALT están amparadas por

nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño de

su herramienta industrial D

EWALT, sencillamente devuélvala a los

vendedores participantes durante los primeros 30 días después de la fecha

de compra para que le efectúen un reembolso completo. Por favor regrese

la unidad completa, con el transporte pagado. Se puede requerir prueba de

compra.

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 326-7100

SECCI N

AMARILLA

Si funciona…

y funciona muy bien.

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

DW830,etc./569590-01 8/3/00 2:47 PM Page 19

Loading...

Loading...