Page 1

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR DEWALT PURCHASE,

CALL 1-800-4-DEWALT

IN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE

YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL.

YOUR FEEDBACK IS VITAL TO THE SUCCESS OF DEWALT'S QUALITY

IMPROVEMENT PROGRAM.

Questions? Visit us at www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW715

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA DE

GARANT[A. ADVERTENCIA: LEASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

12" (305 mm) Compound Miter Saw

Scie & onglets mixtes, 305 mm (12 po)

Sierra ingletadora de 305 mm (12")

Page 2

f Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

i_,DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

_ WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

A CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

NOTICE: Indicatesa practice not related to personal injury which, if not avoided, may

result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALTTOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258}

IMPORTANT SAFETY INSTRUCTIONS

A WARNING: Read allinstructions before operating product. Failure to follow

all.instructions listed below may result in electric shock, fire and/or serious

injury

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate layers of electrical

insulation or one single layer of reinforced insulation between you and the tool's electrical

system. Tools built with this insulation system are not intended to be grounded. As a result,

your tool is equipped with atwo prong plug which permits you to use extension cords without

concern for maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety precautions when

operating this tool. The secondary insulation system is for protection against injury resulting

from a possible failure of the primary insulation within the tool.

_CAUTION: WHEN SERVICING USE ONLYIDENTICAL REPLACEMENT PARTS. Repair or

replace damaged cords.

Polarized Plugs

Polarized plugs (one blade is wider than the other) are used on equipment to reduce the risk

of electric shock. When provided, this plug will fit in the polarized outlet only one way. If the

plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install the proper outlet. Do not change the plug in any way.

Safety Instructions For All Tools

AWARNING: To reduce the risk of eye injury, ALWAYS use eye protection when

operating the miter saw.

• KEEP GUARD IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from spindle before turning tool on. Tools,scrap

pieces, and other debris can be thrown at high speed, causing injury.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

• DO NOT USE THE MACHINE IN A DANGEROUS ENVIRONMENT. The use of power

tools in damp or wet locations or in rain can cause shock or electrocution. Keep your work

area well-lit to avoid tripping or placing arms, hands, and fingers in danger.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area.

Your shop is a potentially dangerous environment.

• MAKE WORKSHOP CHILDPROOF with padlocks, master switches or by removing

starter keys. The unauthorized start-up of a machine by a child or visitor may result in injury.

• DON'T FORCE TOOL. It will do thejob better and be safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not

designed. Using the incorrect tool or attachment may result in personal injury.

• WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets or other

jewelry to get caught in moving parts. Non-slip footwear is recommended. Wear protective

hair covering to contain long hair. Air vents may cover moving parts and should also be

avoided.

• ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses. Also

use face or dust mask ifcutting operation is dusty.ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT."

• ANSI Z87.1 eye protection (CAN/CSA Z94.3)

• ANSI $12.6 ($3.19) hearing protection

• NIOSH/OSHA/MSHA respiratory protection

• SECURE THE WORKPIECE. Use clamps or a vise to hold the workpiece on the table

and against the fence or when your hand will be dangerously close to the blade [within

6" (152 mm)]. It is safer than using your hand and it frees both hands to operate tool

• DON'T OVERREACH. Keep proper footing and balance at all times. Loss of balance may

cause personal injury.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories. Poorly

maintained tools and machines can further damage the tool or machine and/or cause

injury.

• TURN THE MACHINE "OFF" AND DISCONNECT THE MACHINE FROM THE

POWER SOURCE before installing or removing accessories, before adjusting or changing

set-ups, when making repairs or changing locations. An accidental start-up can cause

injury. Do not touch the plug's metal prongs when unplugging or plugging in the cord.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure that the switch is in

the "OFF" position before plugging in the power cord.

• USE PROPER EXTENSION CORD. Make sure your extension cord isin good condition.

If your product is equipped with a cordset, use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole receptacles that accept the tool's plug. When

using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The following table shows the correct size to use depending on

cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating 120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

More

Than

0

6

10

12

Not More

Than

6

10

12

16

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

18

18

16

14

AWG

16

16

16

12

16 14

14 12

14 12

Not Recommended

Page 3

• CHECK FOR DAMAGED PARTS. Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate properly and

perform its intended function--check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any other conditions that may affect its operation.

A guard or otherpart that is damaged should be properly repaired or replaced. Do not use

tool if switch does not turn it on and off.

• USE RECOMMENDED ACCESSORIES. Use only accessories that are recommended

by the manufacturer for your model Accessories that may be suitable for one tool may be

hazardous when used on another tool Consult the instruction manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting

tool is unintentionally contacted.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave

tool until it comes to a complete stop. Serious injury can result.

• DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN

GASEOUS OR EXPLOSIVE ATMOSPHERES. Motors in these tools may spark and

ignite fumes.

• STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE COMMON SENSE. DO

NOT USE THE MACHINE WHEN YOU ARE TIRED OR UNDER THE INFLUENCE

OF DRUGS or ALCOHOL. A moment of inattention while operating power tools may

result in injury.

Additional Safety Rules For Miter Saws

_,WARNING: Do not allow familiarity (gained from frequent use of your saw) to replace safety

rules.Always remember that a careless fraction of a second is sufficient to inflict severe injury.

• DO NOT OPERATE THIS MACHINE until it is completely assembled and installed

according to the instructions. A machine incorrectly assembled can cause serious injury.

• OBTAIN ADVICE from your supervisor, instructor, or another qualified person ifyou are

not thoroughly familiar with the operation of this machine. Knowledge is safety.

• STABILITY. Make sure the miter saw is placed on a secure supporting surface and does

not slip or move during use.

• FOLLOW ALL WIRING CODES and recommended electrical connections to prevent

shock or electrocution. Protect electric supply line with at least a 15 ampere time-delay

fuse or a circuit breaker."

• MAKE CERTAIN the blade rotates in the correct direction. The teeth on the blade should

point in the direction of rotation as marked on the saw.

• TIGHTEN ALL CLAMP HANDLES, knobs and levers prior to operation. Loose clamps

can cause parts or the workpiece to be thrown at high speeds.

• BE SURE all blade and blade clamps are clean, recessed sides of blade clamps are

against blade and arbor screw is tightened securely. Loose or improper blade clamping

may result in damage to the saw and possible personal injury.

• ALWAYS USE A SHARP BLADE. Check the blade to see if it runs true and is free from

vibration. A dull or a vibrating blade can cause damage to the machine and/or serious

injury.

• DO NOT OPERATE ON ANYTHING OTHER THAN THE DESIGNATED VOLTAGE for

the saw. Overheating, damage to the tool and personal injury may occur.

• DO NOT WEDGE ANYTHING AGAINST THE FAN to hold the motor shaft. Damage to

tool and possible personal injury may occur.

• DO NOT FORCE CUTTING ACTION. Stalling or partial stalling of motor can cause

damage. Tothe machine or blade and/or serious injury.

• ALLOW THE MOTOR TO COME TO FULL SPEED priorto starting cut. Starting the cut

too soon may cause damage to the machine or blade and/or serious injury.

• NEVER CUT FERROUS METALS (Those with any iron or steel content) or masonry.

Either of these can cause the carbide tips to flyoff the blade at high speeds causing serious

injury.

• DO NOTUSEABRASIVE WHEELS. The excessive heat and abrasive particles generated

by them may damage the saw and cause personal injury.

• NEVER HAVE ANY PART OF YOUR BODY IN LINE WITH THE PATH OF THE SAW

BLADE. Personal injury will occur.

• NEVER APPLY BLADE LUBRICANT TO A RUNNING BLADE. Applying lubricant could

cause your hand to move into the blade resulting in serious injury.

• DO NOT place either hand in the blade area when the saw is connected to the power

source. Inadvertent blade activation may result in serious injury.

• DO NOT PERFORM FREE-HAND OPERATIONS (workpiece not supported by table

and fence). Hold the work firmly against the fence and table. Free-hand operations on a

miter saw could cause the workpiece to be thrown at high speeds, causing serious injury.

• NEVER REACH AROUND OR BEHIND THE SAW BLADE. A blade can cause serious

injury.

• DO NOT REACH UNDERNEATH THE SAW unless it is unplugged and turned off.

Contact with saw blade may cause personal injury.

• SECURE THE MACHINE TO A STABLE SUPPORTING SURFACE. Vibration can

possibly cause the machine to slide, walk or tip over, causing serious injury.

• USE ONLY CROSSCUT SAW BLADES recommended for miter saws. For best results,

do not use carbide tipped blades with hook angles in excess of 7 degrees. Do not use

blades with deep gullets. These can deflect and contact the guard, and can cause damage

to the machine and/or serious injury.

• USE ONLY BLADES OF THE CORRECT SIZE AND TYPE specified for this tool to

prevent damage to the machine and/or serious injury.

• INSPECT BLADE FOR CRACKS or other damage prior to operation. A cracked or

damaged blade can come apart and pieces can be thrown at high speeds, causing serious

injury. Replace cracked or damaged blades immediately.

• CLEAN THE BLADE AND BLADE CLAMPS prior to operation. Cleaning the blade

and blade clamps allows you to check for any damage to the blade or blade clamps. A

cracked or damaged blade or blade clamp can come apart and pieces can be thrown at

high speeds, causing serious injury.

• DO NOT use lubricants or cleaners (particularly spray or aerosol) in the vicinity of the

plastic guard. The polycarbonate material used in the guard is subject to attack by certain

chemicals.

• ALWAYS USE THE KERF PLATE AND REPLACE THIS PLATE WHEN DAMAGED.

Small chip accumulation under the saw may interfere with the saw blade or may cause

instability of workpiece when cutting.

• USE ONLY BLADE CLAMPS specified for this tool to prevent damage to the machine

and/or serious injury.

• CLEAN THE MOTOR AIR SLOTS of chips and sawdust. Clogged motor air slots can

cause themachine to overheat, damaging the machine and possibly causing a short which

could cause serious injury.

• KEEP ARMS, HANDS, AND FINGERS AWAY FROM THE BLADE to prevent severe

cuts. Clamp all workpieces that would cause your hand to be within 6" (152 mm) of the

saw blade.

• NEVER LOCK THE SWITCH IN THE "ON" position. Severe personal injury may result.

• TURN OFF THE MACHINE and allow the blade to come to a complete stop before

raising the arm and prior to cleaning the blade area, removing debris in the path of the

blade, before servicing or adjusting tool A moving blade can cause serious injury.

Page 4

• PROPERLY SUPPORT LONG OR WIDE WORKPIECES Loss of control of the

workpiece can cause injury.

• NEVER CROSS ARMS IN FRONT OF BLADE while using tool Always make a dry run

(unpowered) before making a finish cut so that you can check the path of the blade or

severe personal injury may result.

• ADDITIONAL INFORMATION regarding the safe and proper operation of power tools

(i.e. a safety video) is available from the Power Tool Institute, 1300 Sumner Avenue,

Cleveland, OH 44115-2851 (www.powertoolinstitute.com). Information is also available

from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201. Please

refer to the American National Standards Institute ANSI 01.1 Safety Requirements for

Woodworking Machines and the U.S. Department of Labor OSHA 1910.213 Regulations.

WARNING: Do not connect unit to electrical power source until complete instructions are

read and understood.

_WARNING: Always wear proper personal hearing protection that conforms to

ANSI $12.6 ($3.19) during use. Under some conditions and duration of use, noise from

this product may contribute to hearing loss.

ON TABLE: (2 PLACES)

J_WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION

MANUAL BEFORE OPERATING MITER SAW. KEEP HANDS OUT

OF PATH OF SAW BLADE. DO NOT OPERATE SAW WITHOUT

GUARDS IN PLACE. CHECK LOWER GUARD FOR PROPER

CLOSING BEFORE EACH USE. ALWAYS TIGHTEN ADJUSTMENT

KNOBS BEFORE USE. DO NOT PERFORM ANY OPERATION

FREEHAND. NEVER REACH IN BACK OF SAW BLADE. NEVER

CROSS ARMS IN FRONT OF BLADE. TURN OFF TOOL AND

WAIT FOR SAW BLADE TO STOPBEFORE MOVING WORKPIECE,

CHANGING SETTINGS OR MOVING HANDS. DISCONNECT

POWER BEFORE CHANGING BLADE OR SERVICING. TO

REDUCE THE RISK OF INJURY, RETURN CARRIAGE TO THE

FULL REAR POSITION AFTER EACH CROSSCUT OPERATION.

THINK! YOU CAN PREVENT ACCIDENTS.

ON BASE: (2 PLACES)

_WARNING: NEVER MAKE ANY CUT UNLESS THE MATERIAL IS SECURED ON THE

TABLEAND AGAINST THE FENCE.

i_,WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling, and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay

on the skin may promote absorption of harmful chemicals.

A WARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body.

For your convenience and safety, the following warning labels are on your miter saw.

ON MOTOR HOUSING:

_ WARNING: FOR YOUR OWN SAFETY;, READ INSTRUCTION MANUAL BEFORE

OPERATING SAW.

WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS.

ALWAYS WEAR EYE PROTECTION.

DO NOT EXPOSE TO RAIN OR USE IN DAMP LOCATIONS.

ON MOVING FENCES: ALWAYSAOJUSTFENCEP_OPERLY_EEOREOBE.

ALWAYS ADJUST FENCE PROPERLY

BEFORE USE. CLAMP SMALL

PIECES BEFORE CUTTING. SEE

MANUAL.

CLAMPSMALL PIECESBEFORECUTIING. SEE MANUAL.

AJUSTE LA GUiA DEBIDAMENTE ANTES DE U_LIZAR LA

HERRAMIENTA. ASEGURE LABPIEZAS PEQUENAS ANTES DE

CORTARLAS.CONSULTEELMANUAL

TOUJOURSREGLERLE GUIDEAYANT L'UTILJSATJON,FIXERLES

PETITS ORJETS AVANT DE LESSCIER.CONSULTERLE GUIDE

D'UTILiSMION,

ON GUARD: DANGER-KEEP AWAY

FROM BLADE.

ON UPPER GUARD."

Electrical Connection

Be sure your power supply agrees with the nameplate marking, f 20 volts, AC means that your

saw will operate on alternating current. The switch issuseptible to failure if direct current is

used. A voltage decrease of f 0 percent or more will cause a lossof power and overheating.

All DEWALT tools are factory tested. If this tool does not operate, check the power supply.

Accessories

i_WARNING: Since accessories, other than those offered by DEWALT,have not been tested

with thi._product, use of such accessori_.s with thi._tool could be hnznrd_u._. T_ m.duce the

risk of injury, only DEWALT,recommended accessories should be used with this product.

Recommended accessories for use with your tool are available for purchase from your local

dealer or authorized service center. If you need assistance in locating any accessory for your

tool, please contact DEWALTIndustrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

call 1-800-4-DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

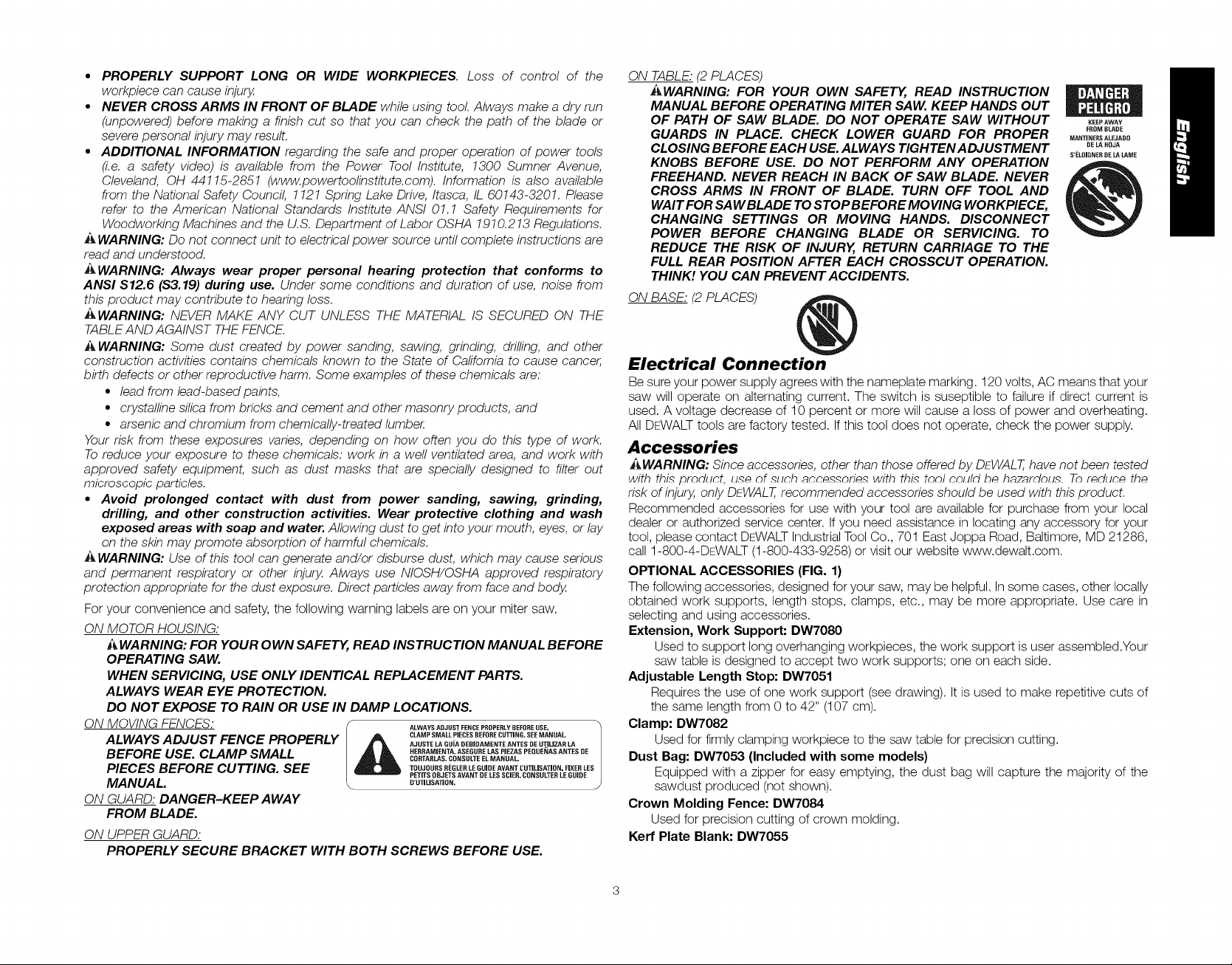

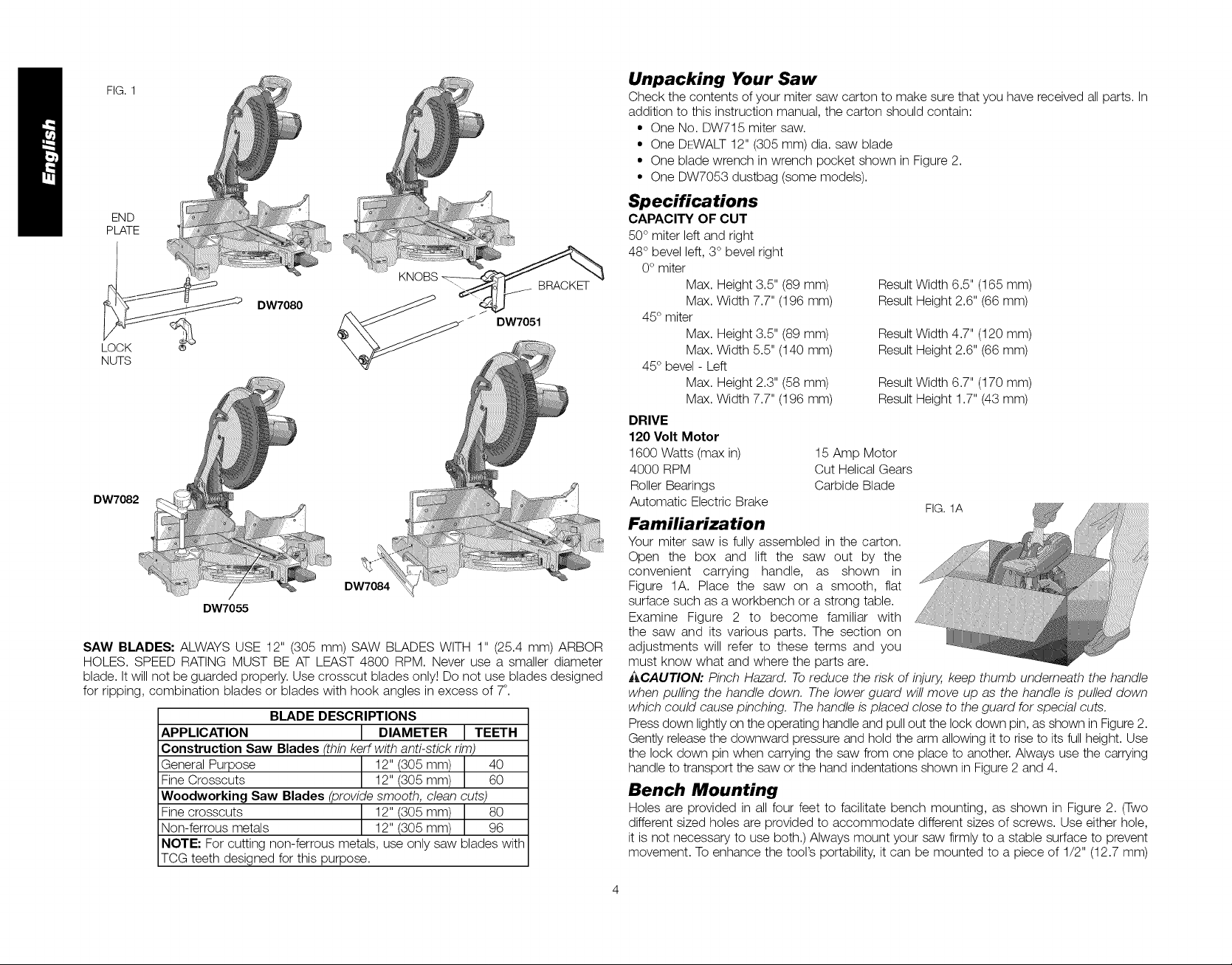

OPTIONAL ACCESSORIES (FIG. 1)

The following accessories, designed for your saw, may be helpful. Insome cases, other locally

obtained work supports, length stops, clamps, etc., may be more appropriate. Use care in

selecting and using accessories.

Extension, Work Support: DW7080

Used to support long overhanging workpieces, the work support is user assembled.Your

saw table isdesigned to accept two work supports; one on each side.

Adjustable Length Stop: DW7051

Requires the use of one work support (see drawing). It is used to make repetitive cuts of

the same length from 0 to 42" (107 cm).

Clamp: DW7082

Used for firmly clamping workpiece to the saw table for precision cutting.

Dust Bag: DW7053 (Included with some models)

Equipped with a zipper for easy emptying, the dust bag will capture the majority of the

sawdust produced (not shown).

Crown Molding Fence: DW7084

Used for precision cutting of crown molding.

Kerf Plate Blank: DW7055

PROPERLY SECURE BRACKET WITH BOTH SCREWS BEFORE USE.

KEEP AWAY

FROM BLADE

MANTENESS ALEJADO

DE LA HO3A

S'ELOIBBED DE LA LAME

Page 5

FIG. 1

END

PLATE

DW7_0

LOCK

NUTS

DW7_2

DW7_4

DW7055

SAW BLADES: ALWAYS USE 12" (305 mm) SAW BLADES WITH 1" (25.4 mm) ARBOR

HOLES. SPEED RATING MUST BE AT LEAST 4800 RPM. Never use a smaller diameter

blade. It will not be guarded properly. Use crosscut blades only! Do not use blades designed

for ripping, combination blades or blades with hook angles in excess of 7°.

BLADE DESCRIPTIONS

APPLICATION [ DIAMETER J TEETH

Construction Saw Blades (thin kerr with anti-stick rim)

General Purpose 12" (305 mm) 40

Fine Crosscuts 12" (305 mm) 60

Woodworking Saw Blades (provide smooth, clean cuts)

Fine crosscuts 12" (305 mm) 80

Non-ferrous metals 12" (305 mm) 96

NOTE: For cutting non-ferrous metals, use only saw blades with

TCG teeth designed for this purpose.

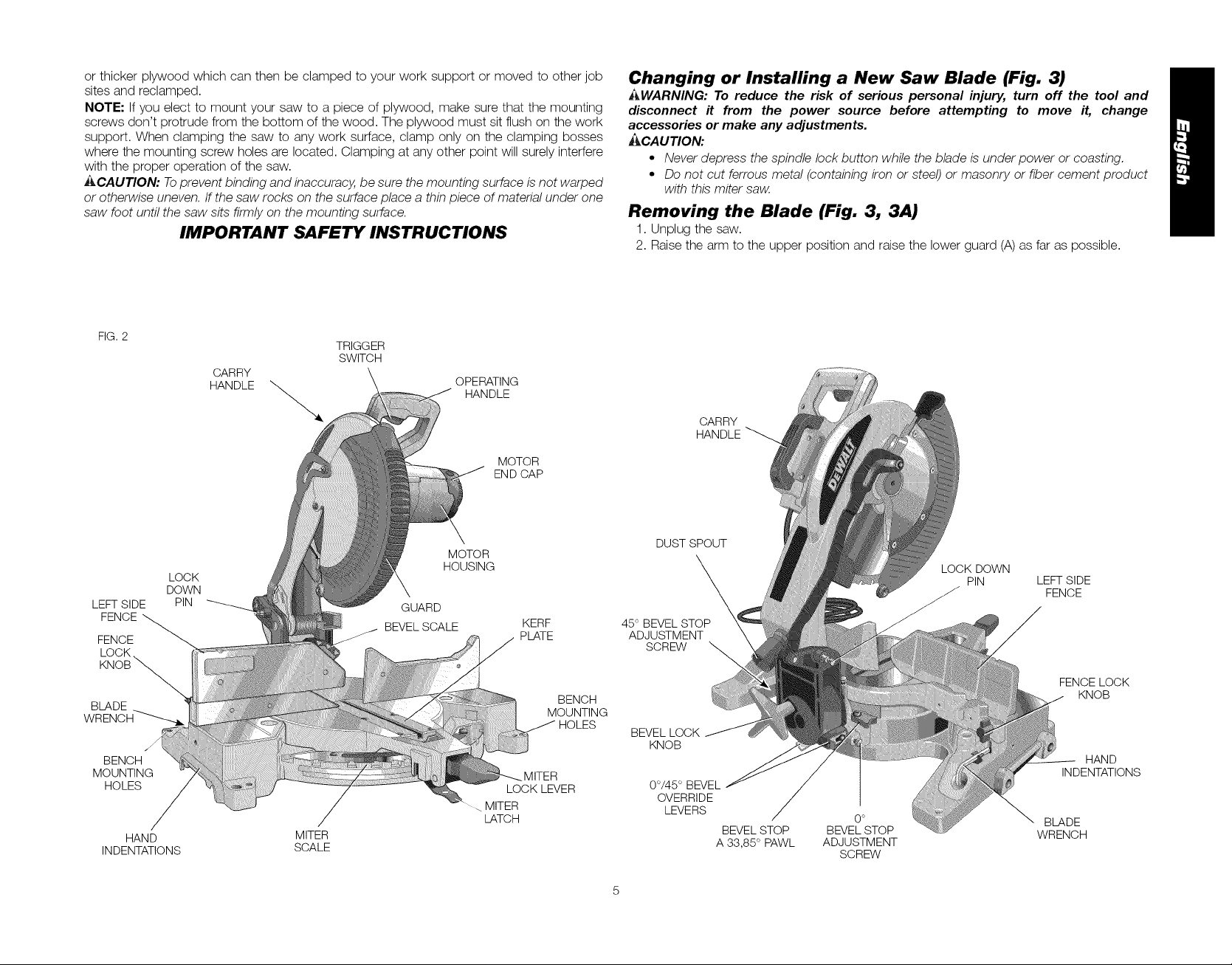

Unpacking Your Saw

Check the contents of your miter saw carton to make sure that you have received allparts. In

addition to this instruction manual, the carton should contain:

• One No. DW715 miter saw.

• One DEWALT 12" (305 mm) dia. saw blade

• One blade wrench in wrench pocket shown in Figure 2.

• One DW7053 dustbag (some models).

Specifications

CAPACITY OF CUT

50° miter left and right

48° bevel left, 3° bevel right

0° miter

Max. Height 3.5" (89 mm)

Max. Width 7.7" (196 mm)

Result Width 6.5" (165 mm)

Result Height 2.6" (66 mm)

45° miter

Max. Height 3.5" (89 mm)

Max. Width 5.5" (140 mm)

Result Width 4.7" (120 mm)

Result Height 2.6" (66 mm)

45° bevel - Left

Max. Height 2.3" (58 mm)

Max. Width 7.7" (196 mm)

Result Width 6.7" (170 mm)

Result Height 1.7" (43 mm)

DRIVE

120 Volt Motor

1600 Watts (max in)

4000 RPM

Roller Bearings

Automatic Electric Brake

15 Amp Motor

Cut Helical Gears

Carbide Blade

FIG. 1A

Familiarization

Your miter saw is fully assembled in the carton.

Open the box and lift the saw out by the

convenient carrying handle, as shown in

Figure 1A. Place the saw on a smooth, flat

surface such as a workbench or a strong table.

Examine Figure 2 to become familiar with

the saw and its various parts. The section on

adjustments will refer to these terms and you

must know what and where the parts are.

=_CAUTION: Pinch Hazard. To reduce the risk of injury, keep thumb underneath the handle

when pulling the handle down. The lower guard will move up as the handle is pulled down

which could cause pinching. The handle is placed close to the guard for special cuts.

Pressdown lightly on the operating handle and pull out the lock down pin, as shown inFigure 2.

Gently release the downward pressure and hold the arm allowing it to rise to its full height. Use

the lock down pin when carrying the saw from one place to another. Always use the carrying

handle to transport the saw or the hand indentations shown in Figure 2 and 4.

Bench Mounting

Holes are provided in all four feet to facilitate bench mounting, as shown in Figure 2. (Two

different sized holes are provided to accommodate different sizes of screws. Use either hole,

it is not necessary to use both.) Always mount your saw firmly to a stable surface to prevent

movement. To enhance the tool's portability, it can be mounted to a piece of 1/2" (12.7 mm)

Page 6

orthickerplywoodwhichcanthenbeclampedtoyourworksupportormovedtootherjob

sitesandreclamped.

NOTE"Ifyouelecttomountyoursawtoapieceofplywood,makesurethatthemounting

screwsdon'tprotrudefromthebottomofthewood.Theplywoodmustsitflushonthework

support.Whenclampingthesawtoanyworksurface,clamponlyontheclampingbosses

wherethemountingscrewholesarelocated.Clampingatanyotherpointwillsurelyinterfere

withtheproperoperationofthesaw.

_,OAUTION:Toprevent binding and inaccuracy, be sure the mounting surface is not warped

or otherwise uneven. If the saw rocks on the surface place a thin piece ofmaterial under one

saw foot until the saw sits firmly on the mounting surface.

IMPORTANT SAFETY INSTRUCTIONS

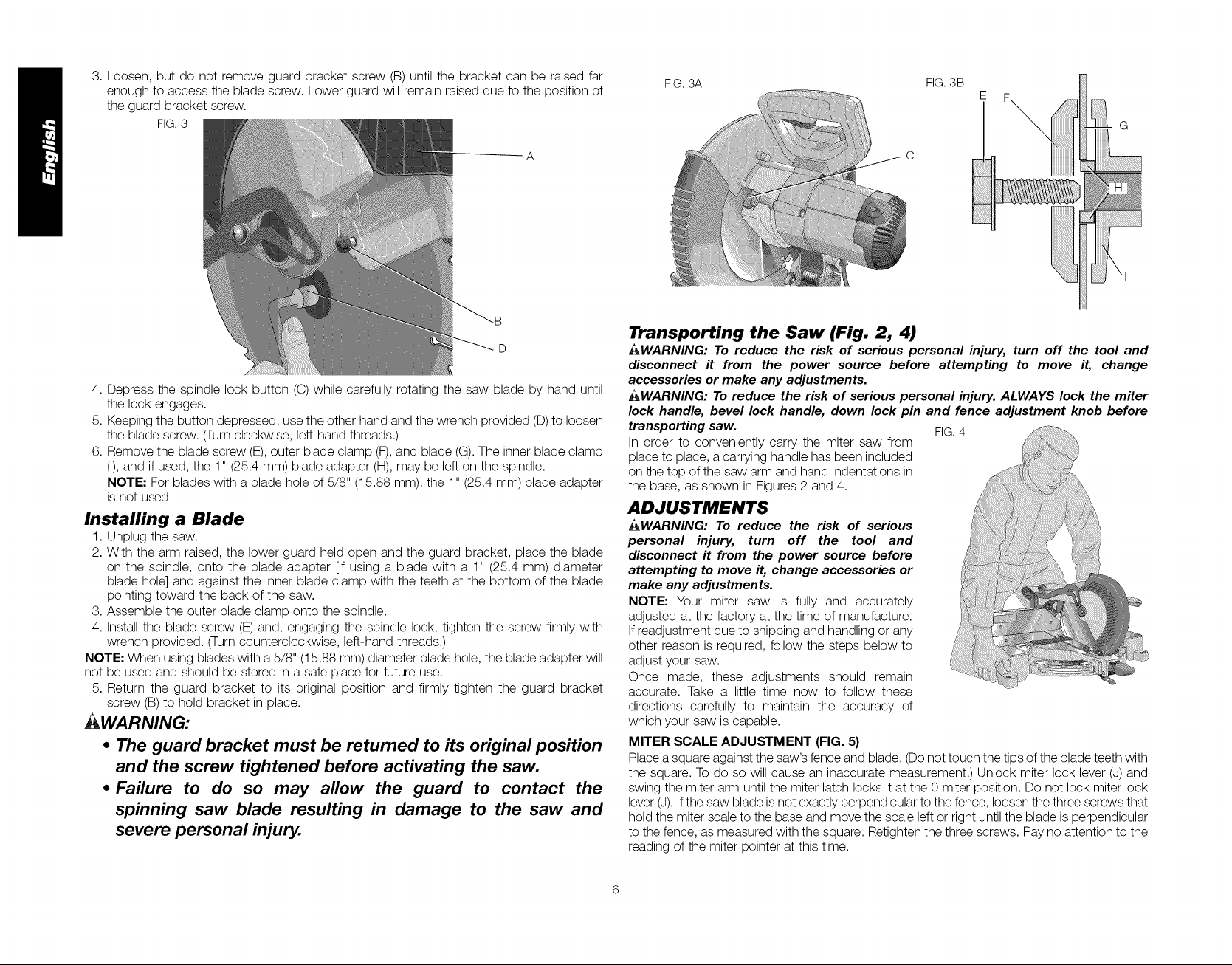

Changing or Installing a New Saw Blade (Fig. 3)

_WARNING: To reduce the risk of serious personal injury, turn off the tool and

disconnect it from the power source before attempting to move it, change

accessories or make any adjustments.

_CAUTION:

• Never depress the spindle lock button while the blade is under power or coasting.

• Do not cut ferrous metal (containing iron or steel) or masonry or fiber cement product

with this miter saw.

Removing the Blade (Fig. 3, 3A)

1. Unplug the saw.

2. Raise the arm to the upper position and raise the lower guard (A) as far as possible.

FIG. 2

LOCK

LEFT SIDE PIN

FENCE _

FENCE

LOCK

KNOB

BLADE

BENCH

MOUNTING

HOLES

INDENTATIONS

DOWN

HAND

CARRY

HANDLE

MITER

SCALE

TRIGGER

SWITCH

jj BEVEL SCALE

GUARD

HANDLE

OPERATING

MOTOR

HOUSING

MOTOR

END CAP

LOCK LEVER

MITER

LATCH

KERF

PLATE

MITER

BENCH

MOUNTING

HOLES

HANDLE

DUST SPOUT

45° BEVEL STOP

ADJUSTMENT

SCREW

BEVEL LOCK

KNOB

0°_5°BEVEL

OVERRIDE

LEVERS

CARRY

BEVEL STOP

A 33,85 ° PAWL

LOCK DOWN

PIN

O° BLADE

BEVELSTOP WRENCH

ADJUSTMENT

SCREW

LEFT SIDE

FENCE

FENCE LOCK

INDENTATIONS

KNOB

HAND

Page 7

3. Loosen, but do not remove guard bracket screw (B) until the bracket can be raised far

enough to access the blade screw. Lower guard will remain raised due to the position of

the guard bracket screw.

FIG.3

FIG.3A FIG.3B

G

A

4. Depress the spindle lock button (C) while carefully rotating the saw blade by hand until

the lock engages.

5. Keeping the button depressed, use the other hand and the wrench provided (D)to loosen

the blade screw. (Turn clockwise, left-hand threads.)

6. Remove the blade screw (E), outer blade clamp (F), and blade (G).The inner blade clamp

(I),and if used, the 1" (25.4 ram) blade adapter (H),may be left on the spindle.

NOTE: For blades with a blade hole of 5/8" (15.88 ram), the 1" (25.4 ram) blade adapter

is not used.

Installing a Blade

1. Unplug the saw.

2. With the arm raised, the lower guard held open and the guard bracket, place the blade

on the spindle, onto the blade adapter [if using a blade with a 1" (25.4 ram) diameter

blade hole] and against the inner blade clamp with the teeth at the bottom of the blade

pointing toward the back of the saw.

3. Assemble the outer blade clamp onto the spindle.

4. Install the blade screw (E)and, engaging the spindle lock, tighten the screw firmly with

wrench provided. (Turn counterclockwise, left-hand threads.)

NOTE" When using blades with a 5/8" (15.88 ram) diameter blade hole, the blade adapter will

not be used and should be stored in a safe place for future use.

5. Return the guard bracket to its original position and firmly tighten the guard bracket

screw (B)to hold bracket in place.

_WARNING:

• The guard bracket must be returned to its original position

and the screw tightened before activating the saw.

• Failure to do so may allow the guard to contact the

spinning saw blade resulting in damage to the saw and

severe personal injury.

C

Transporting the Saw (Fig. 2, 4)

i_WARNING: To reduce the risk of serious personal injury, turn off the tool and

disconnect it from the power source before attempting to move it, change

accessories or make any adjustments.

_WARNING: To reduce the risk of serious personal injury. ALWAYS lock the miter

lock handle, bevel lock handle, down lock pin and fence adjustment knob before

transporting saw. FIG 4

In order to conveniently carry the miter saw from

place to place, a carrying handle has been included

on the top of the saw arm and hand indentations in

the base, as shown in Figures 2 and 4.

ADJUSTMENTS

_WARNING: To reduce the risk of serious

personal injury, turn off the tool and

disconnect it from the power source before

attempting to move it, change accessories or

make any adjustments.

NOTE: Your miter saw is fully and accurately

adjusted at the factory at the time of manufacture.

Ifreadjustment due to shipping and handling or any

other reason is required, follow the steps below to

adjust your saw.

Once made, these adjustments should remain

accurate. Take a little time now to follow these

directions carefully to maintain the accuracy of

which your saw is capable.

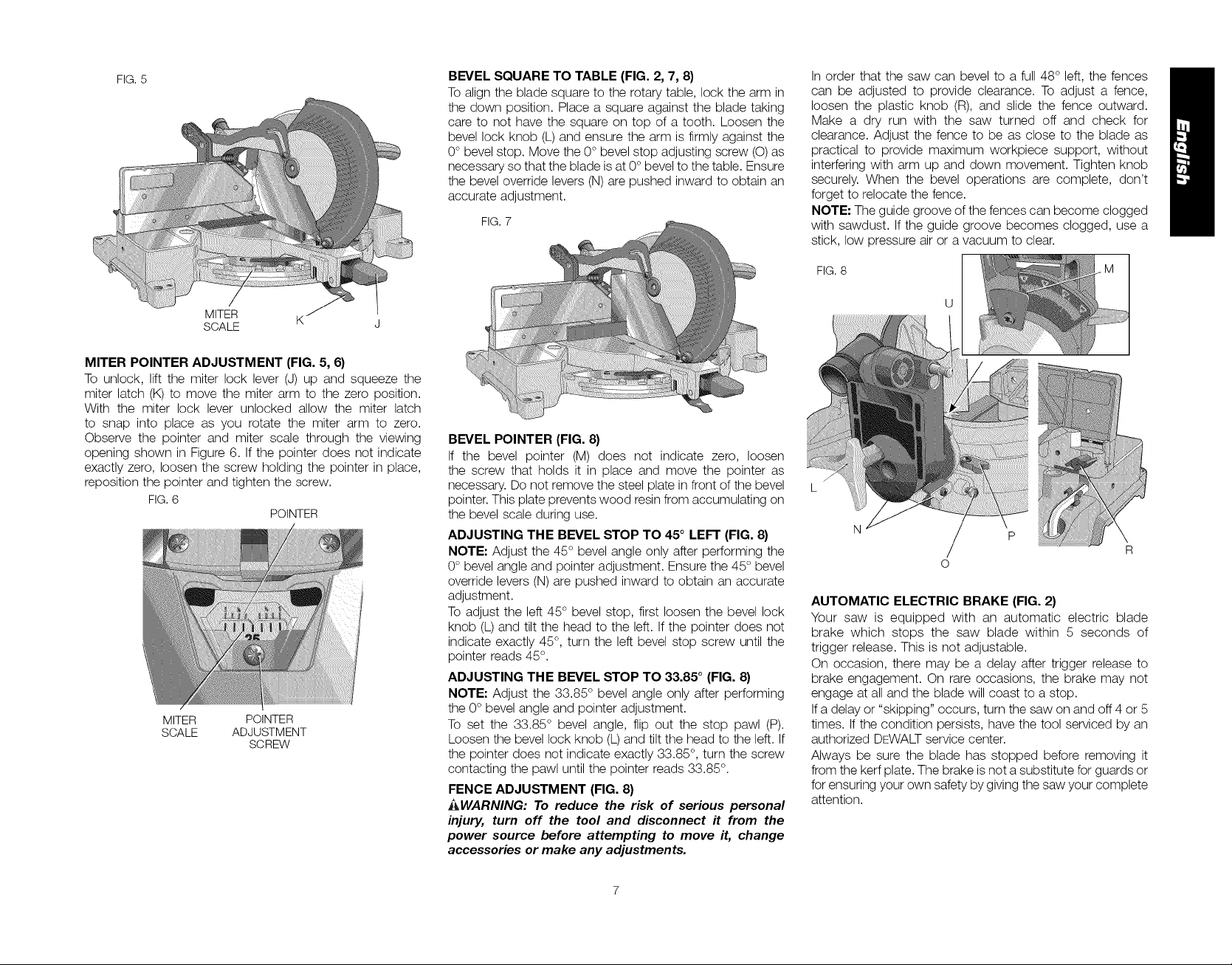

MITER SCALE ADJUSTMENT (FIG. 5)

Place a square against the saw's fence and blade. (Do not touch the tips of the blade teeth with

the square. To do so will cause an inaccurate measurement.) Unlock miter lock lever (J)and

swing the miter arm until the miter latch locks it at the 0 miter position. Do not lock miter lock

lever (J).Ifthe saw blade is not exactly perpendicular to the fence, loosen the three screws that

hold the miter scale to the base and move the scale left or right until the blade is perpendicular

to the fence, as measured with the square. Retighten the three screws. Pay no attention to the

reading of the miter pointer at this time.

Page 8

FIG. 5

BEVEL SQUARE TO TABLE (FIG. 2, 7, 8)

Toalign the blade square to the rotary table, lock the arm in

the down position. Place a square against the blade taking

care to not have the square on top of a tooth. Loosen the

bevel lock knob (L)and ensure the arm is firmly against the

0° bevel stop. Move the 0° bevel stop adjusting screw (O)as

necessary so that the blade is at 0° bevel to the table. Ensure

the bevel override levers (N) are pushed inward to obtain an

accurate adjustment.

FIG. 7

In order that the saw can bevel to a full 48° left, the fences

can be adjusted to provide clearance. To adjust a fence,

loosen the plastic knob (R), and slide the fence outward.

Make a dry run with the saw turned off and check for

clearance. Adjust the fence to be as close to the blade as

practical to provide maximum workpiece support, without

interfering with arm up and down movement. Tighten knob

securely. When the bevel operations are complete, don't

forget to relocate the fence.

NOTE: The guide groove of the fences can become clogged

with sawdust. If the guide groove becomes clogged, use a

stick, low pressure air or a vacuum to clear.

FIG. 8

MITER

SCALE

i

J

MITER POINTER ADJUSTMENT (FIG. 5, 6)

To unlock, lift the miter lock lever (J) up and squeeze the

miter latch (K) to move the miter arm to the zero position.

With the miter lock lever unlocked allow the miter latch

to snap into place as you rotate the miter arm to zero.

Observe the pointer and miter scale through the viewing

opening shown in Figure 6. If the pointer does not indicate

exactly zero, loosen the screw holding the pointer in place,

reposition the pointer and tighten the screw.

FIG.6

POINTER

MITER POINTER

SCALE ADJUSTMENT

SCREW

BEVEL POINTER (FIG. 8)

If the bevel pointer (M) does not indicate zero, loosen

the screw that holds it in place and move the pointer as

necessary. Do not remove the steel plate in front of the bevel

pointer. This plate prevents wood resin from accumulating on

the bevel scale during use.

ADJUSTING THE BEVEL STOP TO 45° LEFT (FIG. 8}

NOTE: Adjust the 45° bevel angle only after performing the

0° bevel angle and pointer adjustment. Ensure the 45° bevel

override levers (N)are pushed inward to obtain an accurate

adjustment.

To adjust the left 45° bevel stop, first loosen the bevel lock

knob (L) and tilt the head to the left. If the pointer does not

indicate exactly 45°, turn the left bevel stop screw until the

pointer reads 45°.

ADJUSTING THE BEVEL STOP TO 33.85 ° (FIG. 8}

NOTE: Adjust the 33.85 ° bevel angle only after performing

the 0 ° bevel angle and pointer adjustment.

To set the 33.85 ° bevel angle, flip out the stop pawl (P).

Loosen the bevel lock knob (L)and tilt the head to the left. If

the pointer does not indicate exactly 33.85 °, turn the screw

contacting the pawl until the pointer reads 33.85 °.

FENCE ADJUSTMENT (FIG. 8)

_WARNING: To reduce the risk of serious personal

injury, turn off the tool and disconnect it from the

power source before attempting to move it, change

accessories or make any adjustments.

O

AUTOMATIC ELECTRIC BRAKE (FIG. 2)

Your saw is equipped with an automatic electric blade

brake which stops the saw blade within 5 seconds of

trigger release. This is not adjustable.

On occasion, there may be a delay after trigger release to

brake engagement. On rare occasions, the brake may not

engage at all and the blade will coast to a stop.

Ifa delay or "skipping" occurs, turn the saw on and off 4 or 5

times. If the condition persists, have the tool serviced by an

authorized DEWALT service center.

Always be sure the blade has stopped before removing it

from the kerf plate. The brake is not a substitute for guards or

for ensuring your own safety by giving the saw your complete

attention.

Page 9

GUARD ACTUATION AND VISIBILITY

i_CAUTION: Pinch Hazard. To reduce the risk of injury, keep thumb underneath the handle

when pulling the handle down. The lower guard will move up as the handle is pulled down

which could cause pinching.

The blade guard on your saw has been designed to automatically raise when the arm is

brought down and to lower over the blade when the arm is raised.

The guard can be raised by hand when installing or removing saw blades or for inspection of

the saw. NEVER RAISE THE BLADE GUARD MANUALLY UNLESS THE SAW IS TURNED

OFF.

NOTE: Certain special cuts of large material will require that you manually raise the guard.

The front section of the guard is Iouvered for visibility while cutting. Although the louvers

dramatically reduce flying debris, there are openings in the guard and safety glasses should

be worn at all times when viewing through the louvers. Refer to Cutting Large Material

under Special Cuts.

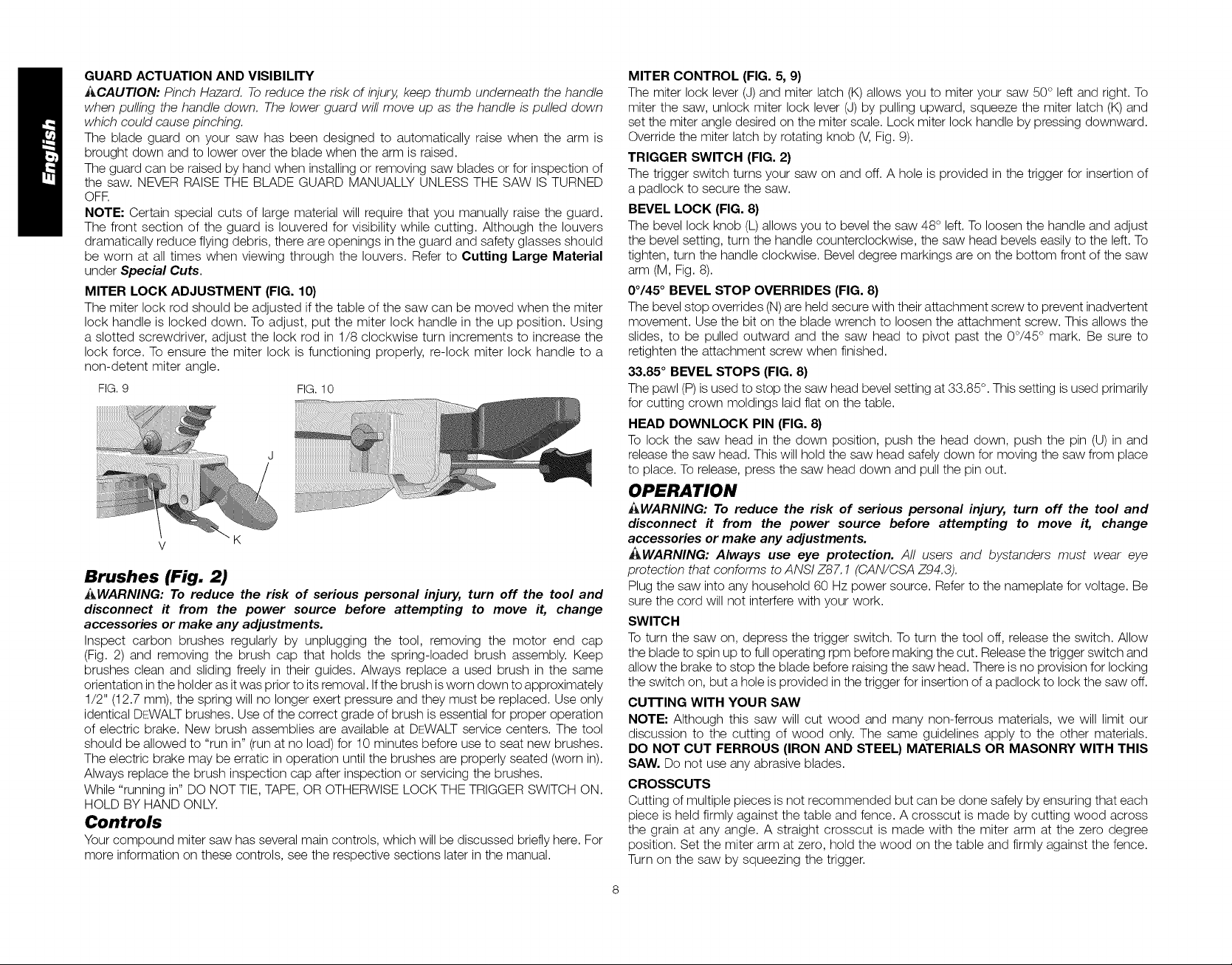

MITER LOCK ADJUSTMENT (FIG. 10)

The miter lock rod should be adjusted if the table of the saw can be moved when the miter

lock handle is locked down. To adjust, put the miter lock handle in the up position. Using

a slotted screwdriver, adjust the lock rod in 1/8 clockwise turn increments to increase the

lock force. To ensure the miter lock is functioning properly, re-lock miter lock handle to a

non-detent miter angle.

FIG.9 FIG.10

V

K

Brushes (Fig. 2)

J_WARNING: To reduce the risk of serious personal injury, turn off the tool and

disconnect ff from the power source before attempting to move it, change

accessories or make any adjustments.

Inspect carbon brushes regularly by unplugging the tool, removing the motor end cap

(Fig. 2) and removing the brush cap that holds the spring-loaded brush assembly. Keep

brushes clean and sliding freely in their guides. Always replace a used brush in the same

orientation inthe holder as it was prior to itsremoval. Ifthe brush isworn down to approximately

1/2" (12.7 mm), the spring will no longer exert pressure and they must be replaced. Use only

identical DEWALTbrushes. Use of the correct grade of brush is essential for proper operation

of electric brake. New brush assemblies are available at DEWALT service centers. The tool

should be allowed to "run in" (runat no load) for 10 minutes before use to seat new brushes.

The electric brake may be erratic in operation until the brushes are properly seated (worn in).

Always replace the brush inspection cap after inspection or servicing the brushes.

While "running in" DO NOT TIE, TAPE, OR OTHERWISE LOCK THE TRIGGER SWITCH ON.

HOLD BY HAND ONLY.

Controls

Your compound miter saw has several main controls, which will be discussed briefly here. For

more information on these controls, see the respective sections later in the manual.

MITER CONTROL (FIG. 5, 9)

The miter lock lever (J) and miter latch (K)allows you to miter your saw 50° left and right. To

miter the saw, unlock miter lock lever (J) by pulling upward, squeeze the miter latch (K) and

set the miter angle desired on the miter scale. Lock miter lock handle by pressing downward.

Override the miter latch by rotating knob (V,Fig. 9).

TRIGGER SWITCH (FIG. 2)

The trigger switch turns your saw on and off. A hole is provided in the trigger for insertion of

a padlock to secure the saw.

BEVEL LOCK (FIG. 8)

The bevel lock knob (L) allows you to bevel the saw 48° left. To loosen the handle and adjust

the bevel setting, turn the handle counterclockwise, the saw head bevels easily to the left. To

tighten, turn the handle clockwise. Bevel degree markings are on the bottom front of the saw

arm (M, Fig. 8).

0°/45 ° BEVEL STOP OVERRIDES (FIG. 8)

The bevel stop overrides (N)are held secure with their attachment screw to prevent inadvertent

movement. Use the bit on the blade wrench to loosen the attachment screw. This allows the

slides, to be pulled outward and the saw head to pivot past the 0°/45 ° mark. Be sure to

retighten the attachment screw when finished.

33.85 ° BEVEL STOPS (FIG. 8)

The pawl (P) is used to stop the saw head bevel setting at 33.85 °. This setting is used primarily

for cutting crown moldings laid flat on the table.

HEAD DOWNLOCK PIN (FIG. 8}

To lock the saw head in the down position, push the head down, push the pin (U) in and

release the saw head. This will hold the saw head safely down for moving the saw from place

to place. To release, press the saw head down and pull the pin out.

OPERATION

_WARNING: To reduce the risk of serious personal injury, turn off the tool and

disconnect it from the power source before attempting to move it, change

accessories or make any adjustments.

_WARNING: Always use eye protection. All users and bystanders must wear eye

protection that conforms to ANSI Z87.1 (CAN/CSA Z94.3).

Plug the saw into any household 60 Hz power source. Refer to the nameplate for voltage. Be

sure the cord will not interfere with your work.

SWITCH

To turn the saw on, depress the trigger switch. To turn the tool off, release the switch. Allow

the blade to spin up to full operating rpm before making the cut. Release the trigger switch and

allow the brake to stop the blade before raising the saw head. There is no provision for locking

the switch on, but a hole is provided in the trigger for insertion of a padlock to lock the saw off.

cu'n'ING WITH YOUR SAW

NOTE: Although this saw will cut wood and many non-ferrous materials, we will limit our

discussion to the cutting of wood only. The same guidelines apply to the other materials.

DO NOT CUT FERROUS (IRON AND STEEL) MATERIALS OR MASONRY WITH THIS

SAW. Do not use any abrasive blades

CROSSCUTS

Cutting of multiple pieces is not recommended but can be done safely by ensuring that each

piece is held firmly against the table and fence. A crosscut is made by cutting wood across

the grain at any angle. A straight crosscut is made with the miter arm at the zero degree

position. Set the miter arm at zero, hold the wood on the table and firmly against the fence.

Turn on the saw by squeezing the trigger.

Page 10

_J,CAUTION: Always use a work clamp to maintain control and reduce the risk of workpiece

damage and personal injury.

When the saw comes up to speed (about 1 second) lower the arm smoothly and slowly to cut

through the wood. Let the blade come to a full stop before raising arm.

Miter crosscuts are made with the miter arm at some angle other than zero. This angle isoften

45° for making corners, but can be set anywhere from zero to 50° left or right. After selecting

the desired miter angle, be sure to lock miter lock lever. Make the cut as described above.

To cut through an existing pencil line on a piece of wood, match the angle as close as

possible. Cut the wood a little too long and measure from the pencil line to the cut edge to

determine which direction to adjust the miter angle and recut. This will take some practice,

but it is a commonly used technique.

BEVEL CUTS (FIG. 8, 19}

A bevel cut is a crosscut made with the saw blade at a bevel to the wood. Inorder to set the

bevel, loosen the bevel clamp knob (L)and move the saw to the left as desired. (It is necessary

to move the fence to allow clearance). Once the desired bevel angle has been set, tighten the

bevel clamp knob firmly.

Bevel angles can be set up to 48° left and can be cut with the miter arm set between zero

and 50° right or left. At some extreme angles, the left side fence might have to be removed.

To remove the left fence, unscrew the fence locking knob (R)several turns and slide the fence

out.

QUALITY OF CUT

The smoothness of any cut depends on a number of variables. Things like material being

cut, blade type, blade sharpness and rate of cut all contribute to the quality of the cut.

When smoothest cuts are desired for molding and other precision work, a sharp (60 tooth

carbide) blade and a slower, even cutting rate will produce the desired results.

Ensure that material does not creep while cutting, clamp it securely in place. Always let the

blade come to a full stop before raising arm.

Ifsmall fibers of wood still split out at the rear of the workpiece, stick a piece of masking tape

on the wood where the cut will be made. Saw through the tape and carefully remove tape

when finished.

For varied cutting applications, refer to the list of recommended saw blades for your saw and

select the one that best fits your needs. Refer to Saw Blades under Accessories.

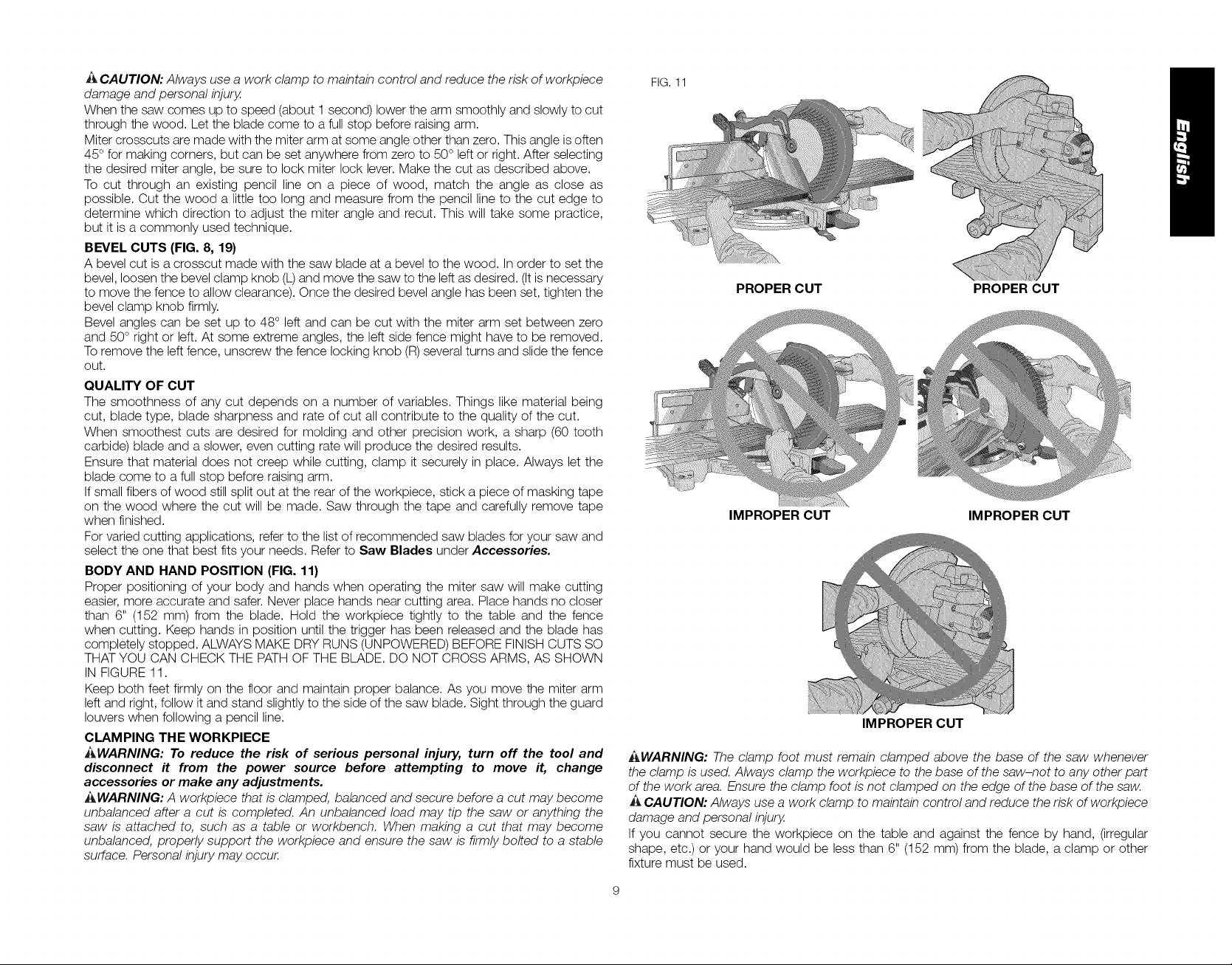

BODY AND HAND POSITION (FIG. 11)

Proper positioning of your body and hands when operating the miter saw will make cutting

easier, more accurate and safer. Never place hands near cutting area. Place hands no closer

than 6" (152 mm) from the blade. Hold the workpiece tightly to the table and the fence

when cutting. Keep hands in position until the trigger has been released and the blade has

completely stopped. ALWAYS MAKE DRY RUNS (UNPOWERED) BEFORE FINISHCUTS SO

THAT YOU CAN CHECK THE PATH OF THE BLADE. DO NOT CROSS ARMS, AS SHOWN

IN FIGURE 11.

Keep both feet firmly on the floor and maintain proper balance. As you move the miter arm

left and right, follow it and stand slightly to the side of the saw blade. Sight through the guard

louvers when following a pencil line.

CLAMPING THE WORKPIECE

_WARNING: To reduce the risk of serious personal injury, turn off the tool and

disconnect it from the power source before attempting to move it, change

accessories or make any adjustments.

_WARNING: A workpiece that is clamped, balanced and secure before a cut may become

unbalanced after a cut is completed. An unbalanced load may tip the saw or anything the

saw is attached to, such as a table or workbench. When making a cut that may become

unbalanced, properly support the workpiece and ensure the saw is firmly bolted to a stable

surface. Personal injury may occur.

FIG. 11

PROPER CUT

IMPROPER CUT

IMPROPER CUT

_WARNING: The clamp foot must remain clamped above the base of the saw whenever

the clamp is used. Always clamp the workpiece to the base of the saw-not to any other part

of the work area. Ensure the clamp foot is not clamped on the edge of the base of the saw.

A CAUTION: Always use a work clamp to maintain control and reduce the risk of workpiece

damage and personal injury.

Ifyou cannot secure the workpiece on the table and against the fence by hand, (irregular

shape, etc.) or your hand would be less than 6" (152 mm) from the blade, a clamp or other

fixture must be used.

PROPER CUT

IMPROPER CUT

Page 11

ForbestresultsusetheDW7082clampmadeforusewithyoursaw.Itisavailablefor

purchaseatyourlocalretailerorDEWALTservicecenter(Fig.1).

Otheraidssuchasspringclamps,barclampsorC-clampsmaybeappropriateforcertain

sizesandshapesofmaterial.Usecareinselectingandplacingtheseclamps.Taketimeto

makeadryrunbeforemakingthecut.Theleftfencewillslidefromsidetosidetoaidin

clamping

TO INSTALL CLAMP (SOLD SEPARATELY (FIG. 1)

1. Insert the clamp into the hole behind the fence. The clamp should be facing toward the

back of the miter saw. The groove on the clamp rod should be fullyinserted into the base.

Ensure this groove is fully inserted into the base of the miter saw. If the groove is visible,

the clamp will not be secure.

2. Rotate the clamp 180° toward the front of the miter saw.

3. Loosen the knob to adjust the clamp up or down, then use the fineadjust knob to firmly

clamp the workpiece.

NOTE: Place the clamp on the opposite side of the base when beveling. ALWAYS MAKE

DRY RUNS (UNPOWERED) BEFORE FINISH CUTS TO CHECK THE PATH OF THE BLADE.

ENSURE THE CLAMP DOES NOT INTERFERE WITH THE ACTION OF THE SAW OR

GUARDS.

WARNING: A workpiece that is clamped, balanced and secure before a cut may become

unbalanced after a cut is completed. An unbalanced load may tip the saw or anything the

saw is attached to, such as a table or workbench. When making a cut that may become

unbalanced, properly support the workpiece and ensure the saw is firmly bolted to a stable

surface.

i_ WARNING: The clamp foot must remain clamped above the base of the saw whenever

the clamp is used. Always clamp the workpiece to the base of the saw-not to any other part

of the work area. Ensure the clamp foot is not clamped on the edge of the base of the saw.

SUPPORT FOR LONG PIECES (FIG. 1)

_WARNING: To reduce the risk of serious personal injury, turn off the tool and

disconnect it from the power source before attempting to move it, change

accessories or make any adjustments.

ALWAYS SUPPORT LONG PIECES.

Never use another person as a substitute for a table extension; as additional support for a

workpiece that is longer or wider than the basic miter saw table or to help feed, support or

pull the workpiece.

For best results, use the DW7080 extension work support to extend the table width of your

saw. These are available from your dealer at extra cost.

Support long workpieces using any convenient means such as sawhorses or similar devices

to keep the ends from dropping.

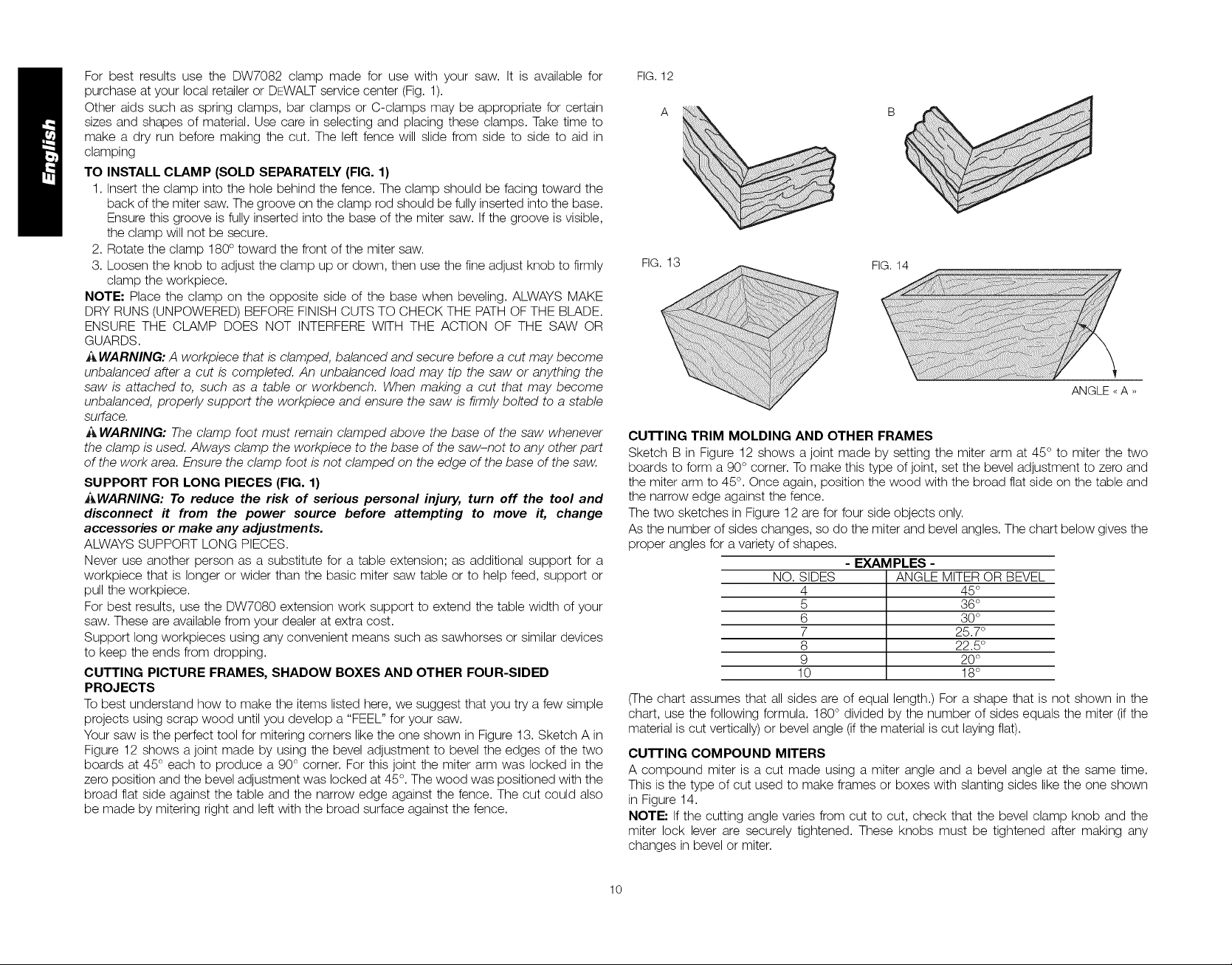

CUTTING PICTURE FRAMES, SHADOW BOXES AND OTHER FOUR-SIDED

PROJECTS

To best understand how to make the items listed here, we suggest that you try a few simple

projects using scrap wood until you develop a "FEEL" for your saw.

Your saw is the perfect tool for mitering corners like the one shown in Figure 13. Sketch A in

Figure 12 shows a joint made by using the bevel adjustment to bevel the edges of the two

boards at 45° each to produce a 90° corner. For this joint the miter arm was locked in the

zero position and the bevel adjustment was locked at 45°. The wood was positioned with the

broad flat side against the table and the narrow edge against the fence. The cut could also

be made by mitering right and left with the broad surface against the fence.

FIG. 12

A

FIG. 13 FIG. 14

ii !!i!iiiiiilililili iii!!!il,i

ANGLE _,A _,

cu'n'ING TRIM MOLDING AND OTHER FRAMES

Sketch B in Figure 12 shows a joint made by setting the miter arm at 45° to miter the two

boards to form a 90° corner. To make this type of joint, set the bevel adjustment to zero and

the miter arm to 45°. Once again, position the wood with the broad flat side on the table and

the narrow edge against the fence.

The two sketches in Figure 12 are for four side objects only.

As the number of sides changes, so do the miter and bevel angles. The chart below gives the

proper angles for a variety of shapes.

- EXAMPLES-

NO. SIDES ANGLE MITER OR BEVEL

4 45°

5 36°

6 30°

7 25.7°

8 22.5°

9 20°

10 18°

(The chart assumes that all sides are of equal length.) For a shape that is not shown in the

chart, use the following formula. 180° divided by the number of sides equals the miter (if the

material is cut vertically) or bevel angle (if the material is cut laying flat).

cu'n'ING COMPOUND MITERS

A compound miter is a cut made using a miter angle and a bevel angle at the same time.

This is the type of cut used to make frames or boxes with slanting sides like the one shown

in Figure 14.

NOTE: Ifthe cutting angle varies from cut to cut, check that the bevel clamp knob and the

miter lock lever are securely tightened. These knobs must be tightened after making any

changes in bevel or miter.

10

Page 12

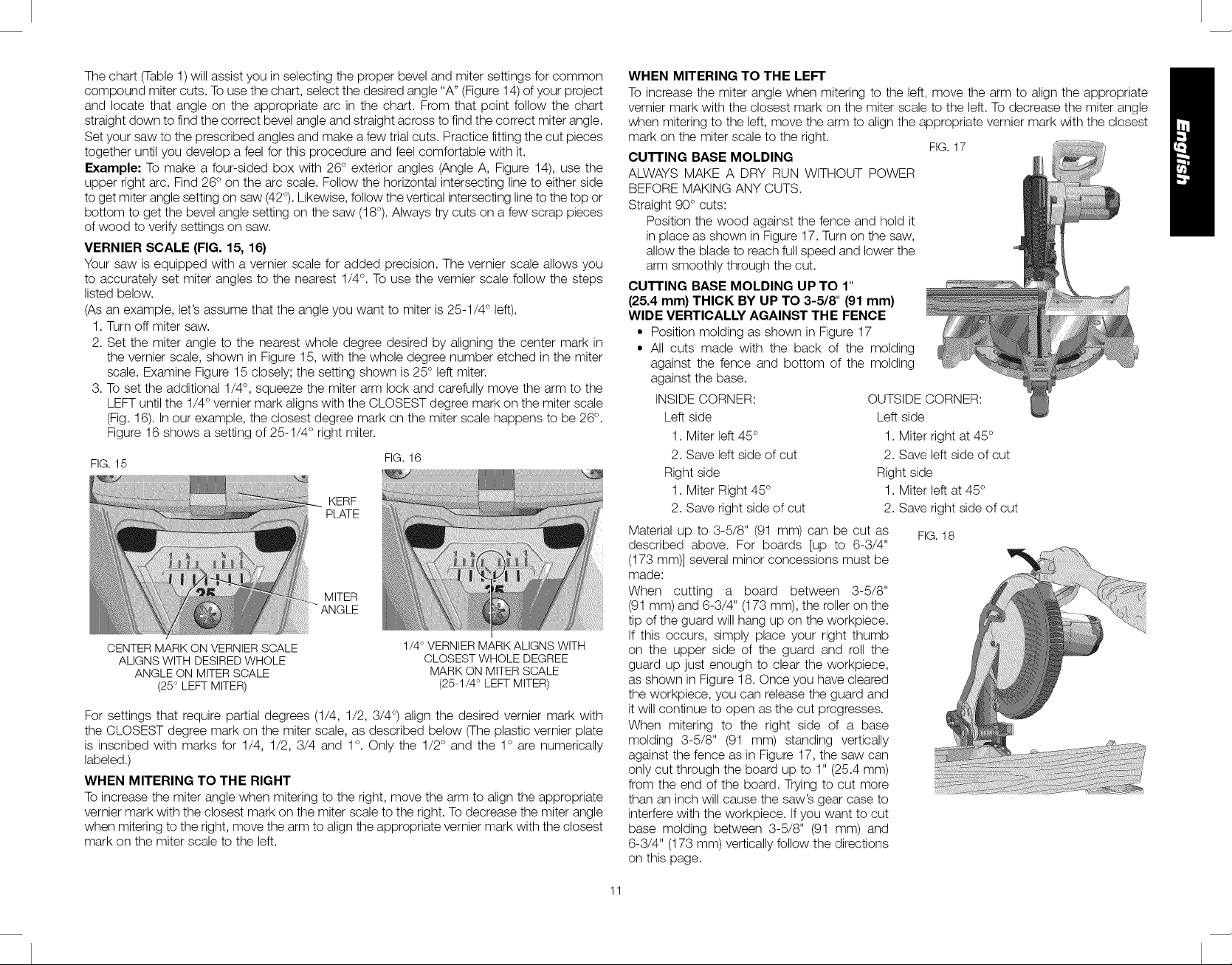

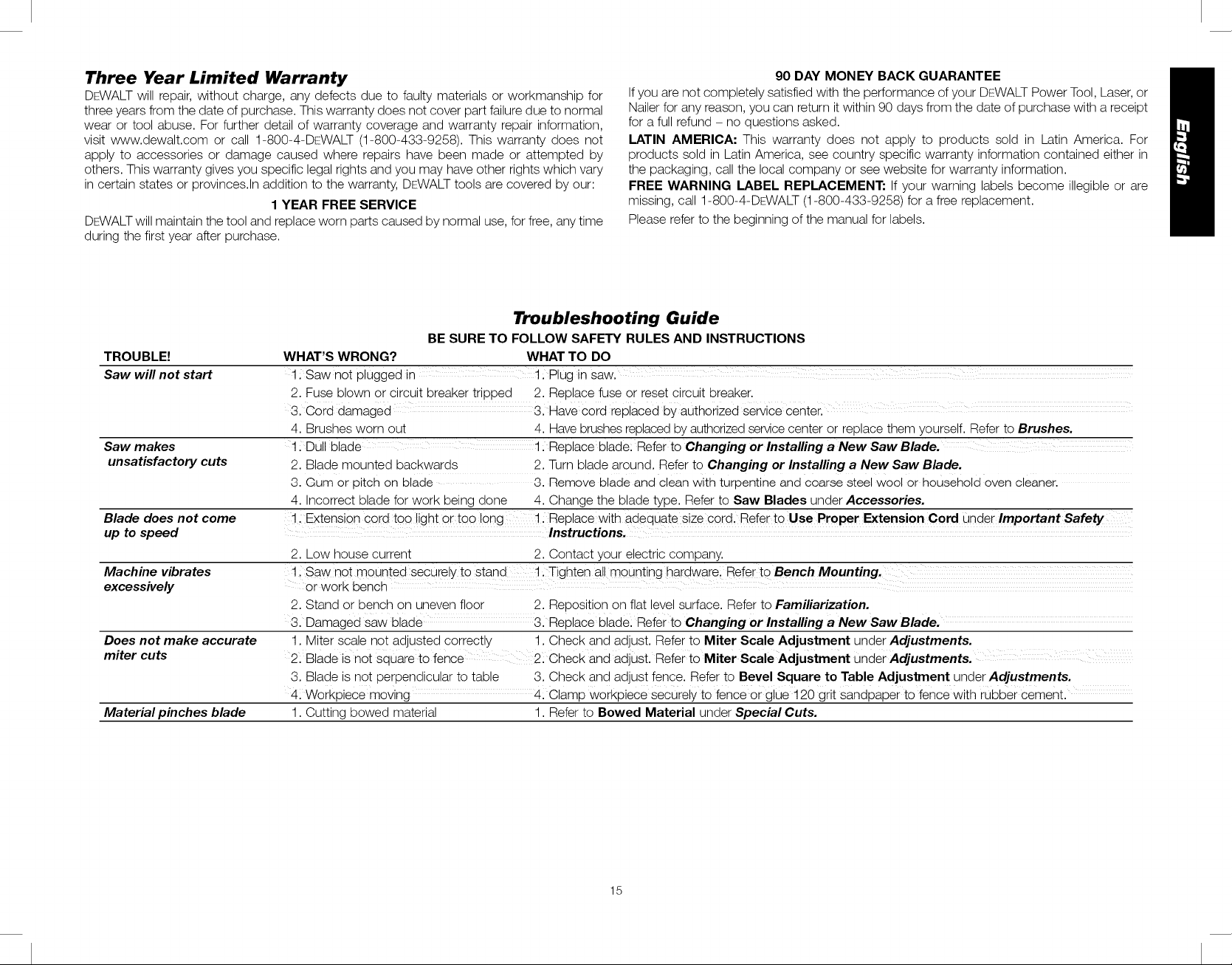

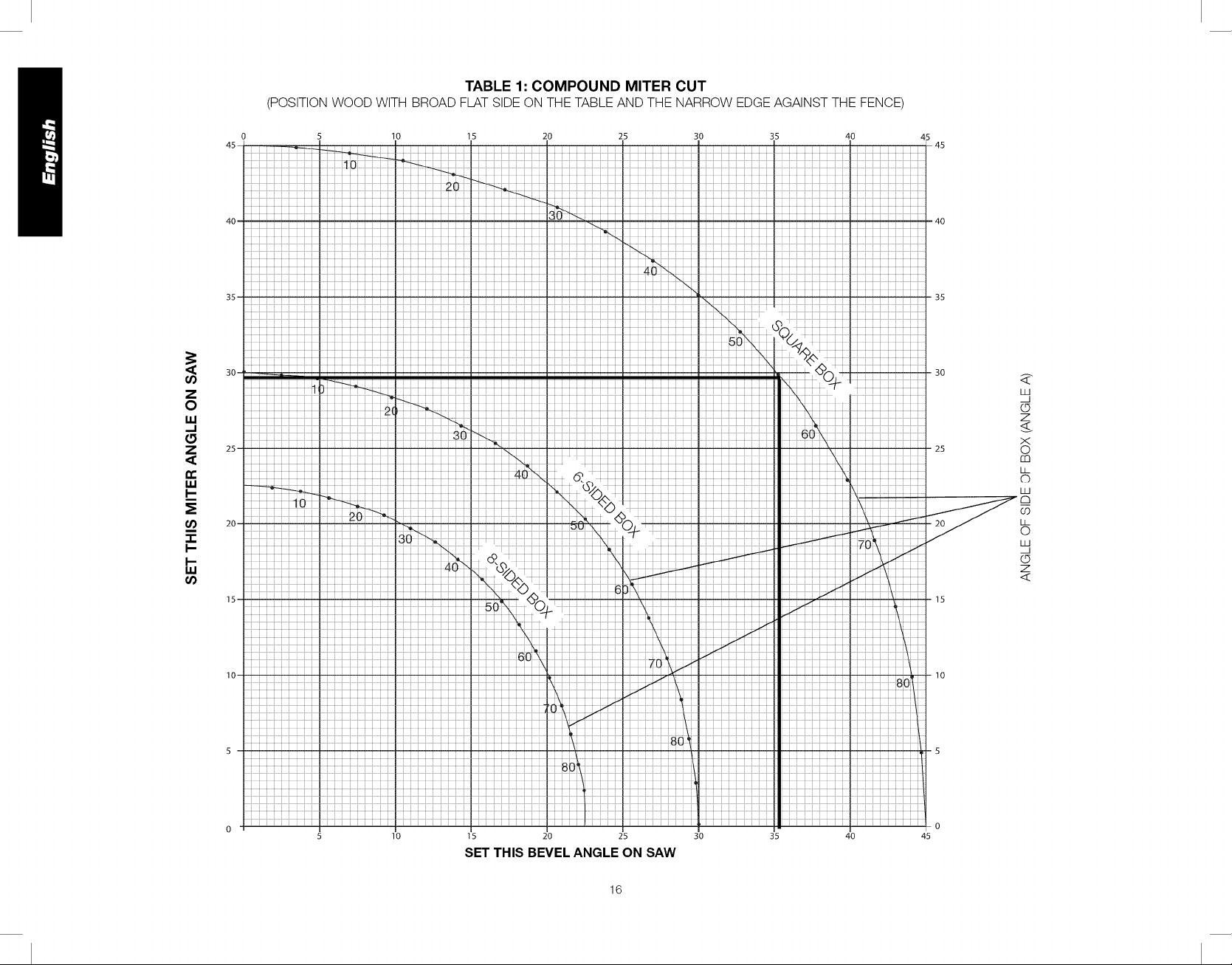

The chart (Table 1) will assist you in selecting the proper bevel and miter settings for common

compound miter cuts. To use the chart, select the desired angle "A" (Figure 14) of your project

and locate that angle on the appropriate arc in the chart. From that point follow the chart

straight down to find the correct bevel angle and straight across to find the correct miter angle.

Set your saw to the prescribed angles and make a few trial cuts. Practice fitting the cut pieces

together until you develop a feel for this procedure and feelcomfortable with it.

Example: To make a four-sided box with 26° exterior angles (Angle A, Figure 14), use the

upper right arc. Find 26 ° on the arc scale. Follow the horizontal intersecting line to either side

to get miter angle setting on saw (42°).Likewise, follow the vertical intersecting lineto the top or

bottom to get the bevel angle setting on the saw (18°). Always try cuts on a few scrap pieces

of wood to verify settings on saw.

VERNIER SCALE (FIG. 15, 16}

Your saw is equipped with a vernier scale for added precision. The vernier scale allows you

to accurately set miter angles to the nearest 1/4°. To use the vernier scale follow the steps

listed below.

(As an example, let's assume that the angle you want to miter is 25-1/4 ° left).

1. Turn off miter saw.

2. Set the miter angle to the nearest whole degree desired by aligning the center mark in

the vernier scale, shown in Figure 15, with the whole degree number etched in the miter

scale. Examine Figure 15 closely; the setting shown is 25° left miter.

3. To set the additional 1/4°, squeeze the miter arm lock and carefully move the arm to the

LEFT until the 1/4 °vernier mark aligns with the CLOSEST degree mark on the miter scale

(Fig. 16). Inour example, the closest degree mark on the miter scale happens to be 26°.

Figure 16 shows a setting of 25-1/4 ° right miter.

FIG. 15

KERF

PLATE

MITER

ANGLE

CENTER MARK ON VERNIER SCALE

ALIGNS WITH DESIRED WHOLE

ANGLE ON MITER SCALE

(25° LEFT MITER)

FIG. 16

1/4° VERNIER MARK ALIGNS WITH

CLOSEST WHOLE DEGREE

MARK ON MITER SCALE

(25-1/4 ° LEFTMITER)

For settings that require partial degrees (1/4, 1/2, 3/4 °) align the desired vernier mark with

the CLOSEST degree mark on the miter scale, as described below (The plastic vernier plate

is inscribed with marks for 1/4, 1/2, 3/4 and 1°. Only the 1/2° and the 1° are numerically

labeled.)

WHEN MITERING TO THE RIGHT

Toincrease the miter angle when mitering to the right, move the arm to align the appropriate

vernier mark with the closest mark on the miter scale to the right. To decrease the miter angle

when mitering to the right, move the arm to align the appropriate vernier mark with the closest

mark on the miter scale to the left.

WHEN MITERING TO THE LEFT

To increase the miter angle when mitering to the left, move the arm to align the appropriate

vernier mark with the closest mark on the miter scale to the left. To decrease the miter angle

when mitering to the left, move the arm to align the appropriate vernier mark with the closest

mark on the miter scale to the right.

cu'rI'ING BASE MOLDING

FIG. 17

ALWAYS MAKE A DRY RUN WITHOUT POWER

BEFORE MAKING ANY CUTS.

Straight 90° cuts:

Position the wood against the fence and hold it

in place as shown in Figure 17. Turn on the saw,

allow the blade to reach full speed and lower the

arm smoothly through the cut.

CU'I-I'ING BASE MOLDING UP TO 1"

(25.4 mm) THICK BY UP TO 3-5/8" (91 mm)

WIDE VERTICALLY AGAINST THE FENCE

• Position molding as shown in Figure 17

• All cuts made with the back of the molding

against the fence and bottom of the molding

against the base.

INSIDE CORNER:

Left side

1. Miter left 45°

2. Save left side of cut

Right side

1. Miter Right 45°

2. Save right side of cut

Material up to 3-5/8" (91 ram) can be cut as

described above. For boards [up to 6-3/4"

OUTSIDE CORNER:

Left side

1. Miter right at 45°

2. Save left side of cut

Right side

1. Miter left at 45°

2. Save right side of cut

FIG.18

(173 ram)] several minor concessions must be

made:

When cutting a board between 3-5/8"

(91 ram) and 6-3/4" (173 ram), the roller on the

tip of the guard will hang up on the workpiece.

If this occurs, simply place your right thumb

on the upper side of the guard and roll the

guard up just enough to clear the workpiece,

as shown in Figure 18. Once you have cleared

the workpiece, you can release the guard and

it will continue to open as the cut progresses.

When mitering to the right side of a base

molding 3-5/8" (91 ram) standing vertically

against the fence as in Figure 17, the saw can

only cut through the board up to 1" (25.4 ram)

from the end of the board. Trying to cut more

than an inch will cause the saw's gear case to

interfere with the workpiece. If you want to cut

base molding between 3-5/8" (91 ram) and

6-3/4" (173 ram) vertically follow the directions

on this page.

11

Page 13

CUTTING BASE MOLDING UP TO 1" (25.4 mm) THICK BY 3-5/8" - 6-3/4" (91 X

173 mm) WIDE 1" (25.4 mm) VERTICALLY AGAINST THE FENCE

• Position molding as shown in Figure 17

• All cuts made with the back of the molding against the fence

INSIDE CORNER:

Left side

1. Position molding with bottom of molding

against the base of the saw

2. Miter left 45°

3. Save left side of cut

Right side

1. Position molding with top of the molding

resting on the base of the saw

2. Miter left 45°

3. Save the right side of cut

OUTSIDE CORNER:

Left side *

1. Position molding with bottom of

molding against the base of the saw

2. Miter right 45 °

3. Save left side of cut

Right side

1. Position molding with bottom of the

molding against the base of the saw

2. Miter left 45°

3. Save the right side of cut

* NOTE: If the cut must be made somewhere other than 1" from the end of the molding:

cut off the molding at 90° approx. 1" (25.4 mm) longer than your final length then make

the miter cut as described above.

CUTTING BASE MOLDING UP TO 1.8" (45 mm) THICK BY UP TO 7-11/16"

(195.6 mm) WIDE LAYING FLAT AND USING THE BEVEL FEATURE

• All cuts made with the saw set at 45° bevel and 0 miter.

• All cuts made with back of molding laying flat on the saw as shown in Figure 19.

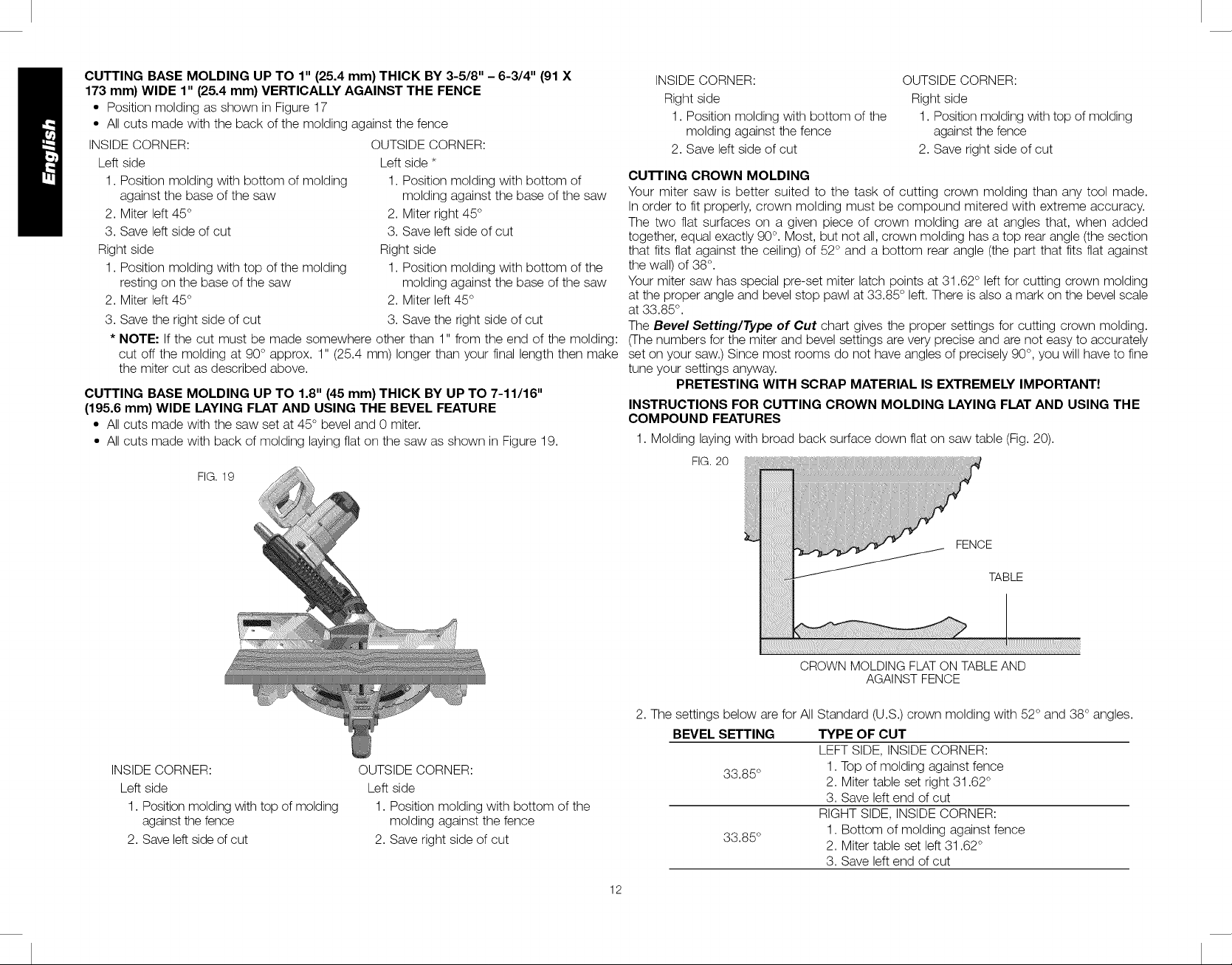

FIG. 19

INSIDE CORNER:

Right side

1. Position molding with bottom of the

molding against the fence

2. Save left side of cut

OUTSIDE CORNER:

Right side

1. Position molding with top of molding

against the fence

2. Save right side of cut

CU'I-I'ING CROWN MOLDING

Your miter saw is better suited to the task of cutting crown molding than any tool made.

Inorder to fit properly, crown molding must be compound mitered with extreme accuracy.

The two flat surfaces on a given piece of crown molding are at angles that, when added

together, equal exactly 90°. Most, but not all, crown molding has a top rear angle (the section

that fits flat against the ceiling) of 52° and a bottom rear angle (the part that fits flat against

the wall) of 38 °.

Your miter saw has special pre-set miter latch points at 31.62 ° left for cutting crown molding

at the proper angle and bevel stop pawl at 33.85 ° left.There is also a mark on the bevel scale

at 33.85 °.

The Bevel Setting/Type of Cut chart gives the proper settings for cutting crown molding.

(The numbers for the miter and bevel settings are very precise and are not easy to accurately

set on your saw.) Since most rooms do not have angles of precisely 90°,you will have to fine

tune your settings anyway.

PRETESTING WITH SCRAP MATERIAL IS EXTREMELY IMPORTANT!

INSTRUCTIONS FOR cu'rI'ING CROWN MOLDING LAYING FLAT AND USING THE

COMPOUND FEATURES

1. Molding laying with broad back surface down flat on saw table (Fig. 20).

FIG. 20

INSIDE CORNER:

Left side

1. Position molding with top of molding

against the fence

2. Save leftside of cut

OUTSIDE CORNER:

Left side

1. Position molding with bottom of the

molding against the fence

2. Save right side of cut

FENCE

TABLE

CROWN MOLDING FLATON TABLEAND

AGAINST FENCE

2. The settings below are for All Standard (U.S.) crown molding with 52° and 38° angles.

BEVEL SETTING TYPE OF CUT

LEFT SIDE, INSIDE CORNER:

33.85 ° 1. Top of molding against fence

2. Miter table set right 31.62 °

3. Save left end of cut

RIGHT SIDE, INSIDE CORNER:

33.85 °

1. Bottom of molding against fence

2. Miter table set left 31.62 °

3. Save left end of cut

12

Page 14

BEVEL SETTING

TYPE OF CUT

LEFT SIDE, OUTSIDE CORNER:

33.85 °

1. Bottom of molding against fence

2. Miter table set left 31.62°

3. Save right end of cut

RIGHT SIDE, OUTSIDE CORNER:

33.85 °

1. Top of molding against fence

2. Miter table set right 31.62 °

3. Save right end of cut

When setting bevel and miter angles for all compound miters, remember that:

The angles presented for crown moldings are very precise and difficult to set exactly.

Since they can easily shift slightly and very few rooms have exactly square corners, all

settings should be tested on scrap molding.

PRETESTING WITH SCRAP MATERIAL IS EXTREMELY IMPORTANT!

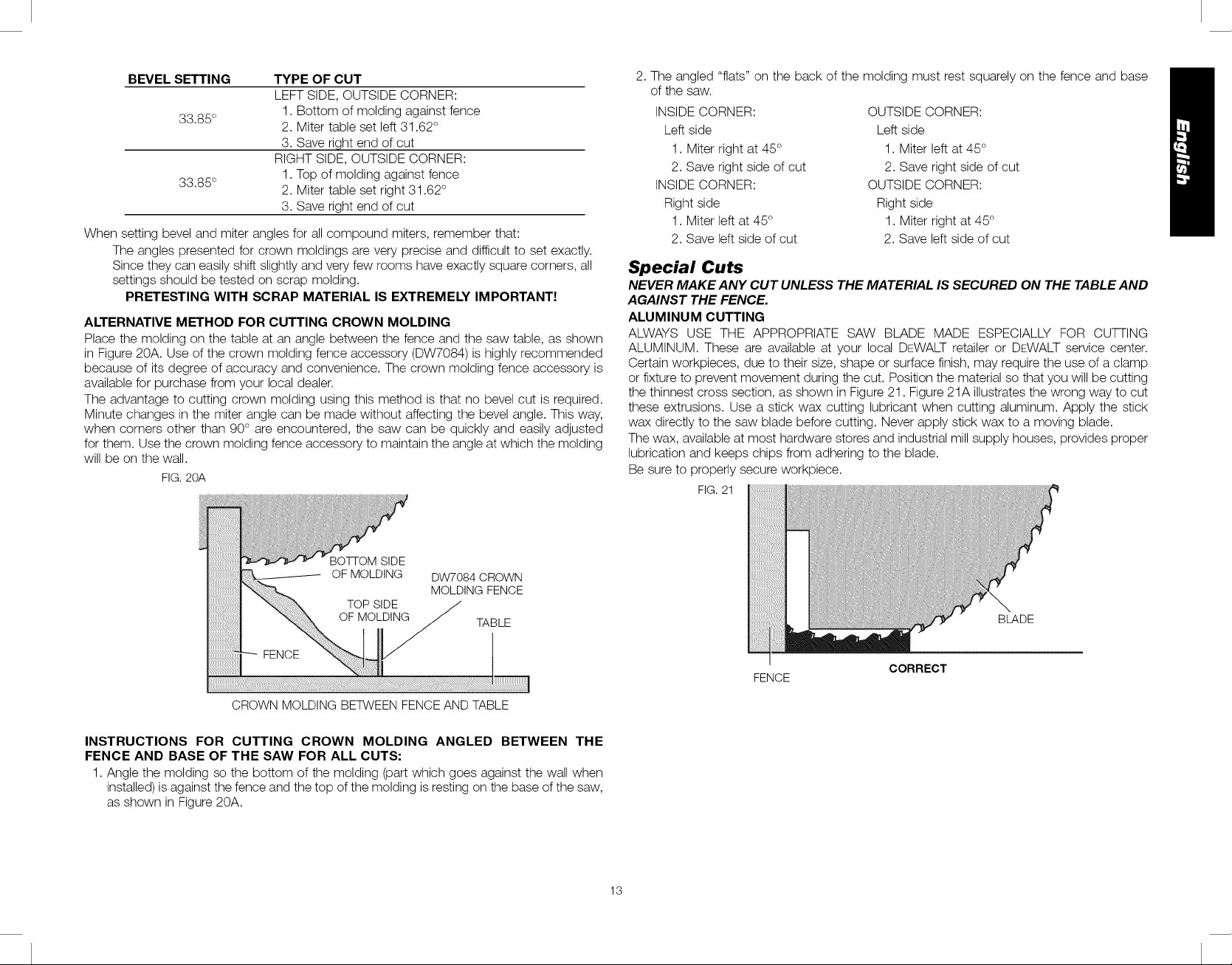

ALTERNATIVE METHOD FOR CUTTING CROWN MOLDING

Place the molding on the table at an angle between the fence and the saw table, as shown

in Figure 20A. Use of the crown molding fence accessory (DW7084) is highly recommended

because of its degree of accuracy and convenience. The crown molding fence accessory is

available for purchase from your local dealer.

The advantage to cutting crown molding using this method is that no bevel cut is required.

Minute changes in the miter angle can be made without affecting the bevel angle. This way,

when corners other than 90° are encountered, the saw can be quickly and easily adjusted

for them. Use the crown molding fence accessory to maintain the angle at which the molding

will be on the wall.

FIG. 20A

2. The angled "flats" on the back of the molding must rest squarely on the fence and base

of the saw.

INSIDE CORNER:

Left side

1. Miter right at 45°

2. Save right side of cut

INSIDE CORNER:

Right side

1. Miter left at 45°

2. Save left side of cut

OUTSIDE CORNER:

Left side

1. Miter left at 45°

2. Save right side of cut

OUTSIDE CORNER:

Right side

1. Miter right at 45°

2. Save left side of cut

Special Cuts

NEVER MAKE ANY CUT UNLESS THE MATERIAL IS SECURED ON THE TABLE AND

AGAINST THE FENCE.

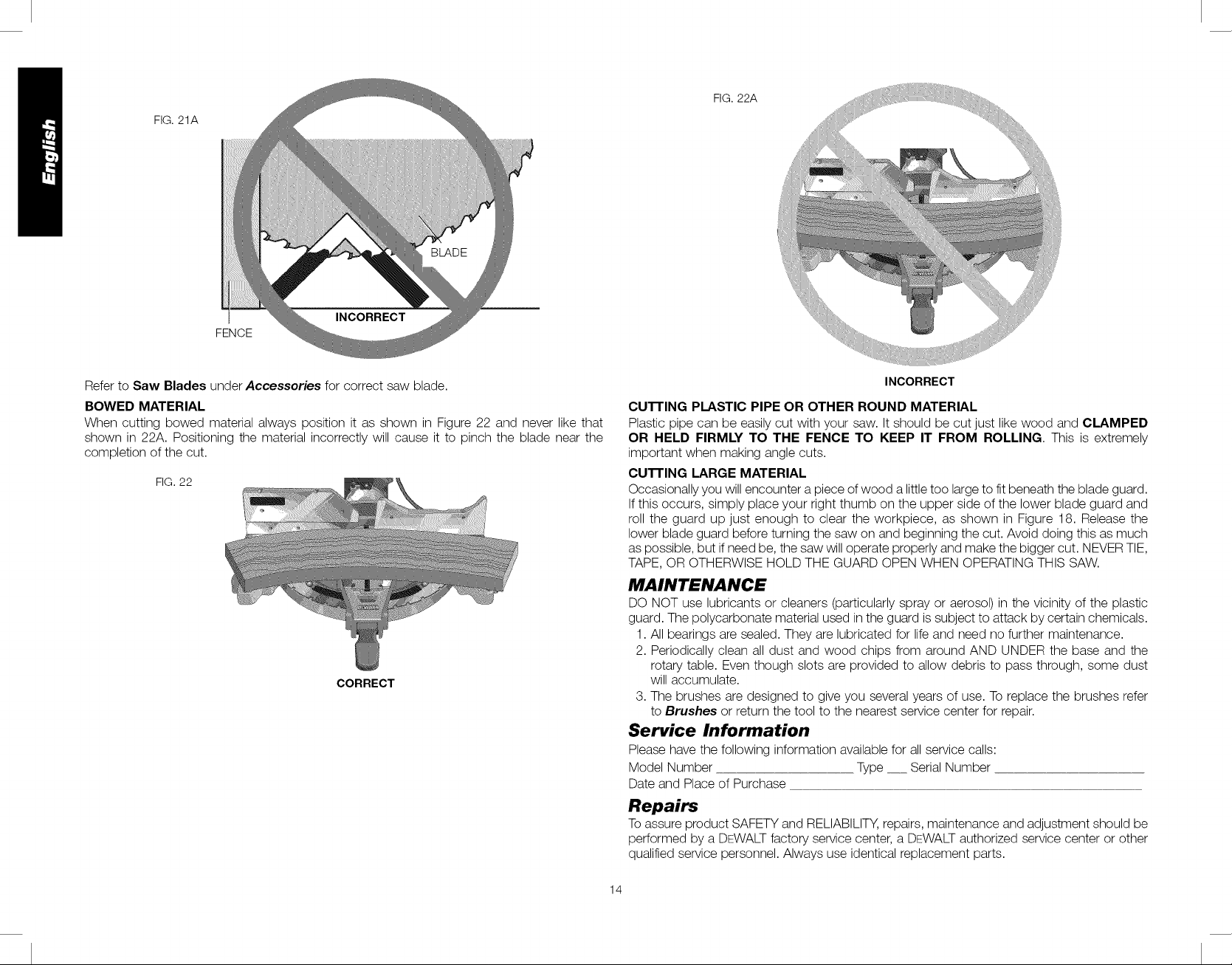

ALUMINUM CUTTING

ALWAYS USE THE APPROPRIATE SAW BLADE MADE ESPECIALLY FOR CUTTING

ALUMINUM. These are available at your local DEWALT retailer or DEWALT service center.

Certain workpieces, due to their size, shape or surface finish, may require the use of a clamp

or fixture to prevent movement during the cut. Position the material so that you will be cutting

the thinnest cross section, as shown in Figure 21. Figure 21A illustrates the wrong way to cut

these extrusions. Use a stick wax cutting lubricant when cutting aluminum. Apply the stick

wax directly to the saw blade before cutting. Never apply stick wax to a moving blade.

The wax, available at most hardware stores and industrial mill supply houses, provides proper

lubrication and keeps chips from adhering to the blade.

Be sure to properly secure workpiece.

FIG.21

3Oqq-OM SIDE

OF MOLDING

CROWN MOLDING BETWEEN FENCE AND TABLE

DW7084 CROWN

MOLDING FENCE

TABLE

INSTRUCTIONS FOR CUTTING CROWN MOLDING ANGLED BETWEEN THE

FENCE AND BASE OF THE SAW FOR ALL CUTS:

1. Angle the molding so the bottom of the molding (part which goes against the wall when

installed) is against the fence and the top of the molding is resting on the base of the saw,

as shown in Figure 20A.

FENCE

13

CORRECT

Page 15

FIG.21A

FIG.22A

FENCE

Refer to Saw Blades under Accesseries for correct saw blade.

BOWED MATERIAL

When cutting bowed material always position it as shown in Figure 22 and never like that

shown in 22A. Positioning the material incorrectly will cause it to pinch the blade near the

completion of the cut.

FIG. 22

CORRECT

INCORRECT

CU'R'ING PLASTIC PIPE OR OTHER ROUND MATERIAL

Plastic pipe can be easily cut with your saw. It should be cut just like wood and CLAMPED

OR HELD FIRMLY TO THE FENCE TO KEEP IT FROM ROLLING. This is extremely

important when making angle cuts.

CU'I-FING LARGE MATERIAL

Occasionally you will encounter a piece of wood a little too large to fit beneath the blade guard.

Ifthis occurs, simply place your right thumb on the upper side of the lower blade guard and

roll the guard up just enough to clear the workpiece, as shown in Figure 18. Release the

lower blade guard before turning the saw on and beginning the cut. Avoid doing this as much

as possible, but if need be, the saw will operate properly and make the bigger cut. NEVER TIE,

TAPE, OR OTHERWISE HOLD THE GUARD OPEN WHEN OPERATING THIS SAW.

MAINTENANCE

DO NOT use lubricants or cleaners (particularly spray or aerosol) in the vicinity of the plastic

guard. The polycarbonate material used in the guard is subject to attack by certain chemicals.

1. All bearings are sealed. They are lubricated for lifeand need no further maintenance.

2. Periodically clean all dust and wood chips from around AND UNDER the base and the

rotary table. Even though slots are provided to allow debris to pass through, some dust

will accumulate.

3. The brushes are designed to give you several years of use. To replace the brushes refer

to Brushes or return the tool to the nearest service center for repair.

Service Information

Please have the following informationavailable for all service calls:

Model Number Type __ Serial Number

Date and Place of Purchase

Repairs

Toassure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should be

performed by a DEWALTfactory service center, a DEWALT authorized service center or other

qualified service personnel. Always use identical replacement parts.

14

Page 16

Three Year Limited Warranty

D_WALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not

apply to accessories or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have other rights which vary

in certain states or provinces.In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALTwill maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

Ifyou are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained either in

the packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.

Please refer to the beginning of the manual for labels.

90 DAY MONEY BACK GUARANTEE

Troubleshooting Guide

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

TROUBLE!

Saw will not start

Saw makes

unsatisfactory cuts

Blade does not come

up to speed

Machine vibrates I : Saw not mounted securely to stand i. Tghten all mounting hardware: Refer to Bench Mounting.

excessively or work bench

Does not make accurate 1. Miter scale not adjusted correctly 1. Check and adjust. Refer to Miter Scale Adjustment under Adjustments.

miter cuts 2: Blade iS not Square to fence Check and adiust. Refer to Miter Scale Adjustment under Adjustments.

Materialpinches blade 1. Cutting bowed material 1. Refer to Bowed Material under Special Cuts.

WHAT'S WRONG? WHAT TO DO

1: Saw not plugged in 1: Plug in saw.

2. Fuse blown or circuit breaker tripped 2. Replace fuse or reset circuit breaker.

3. c0rd damaged 3. Have cord replaced by authorized service center.

4. Brushes worn out 4. Havebrushes replaced by authorizedservice center or replace them yourself. Refer to Brushes.

1: Dull blade l: Replace blade! Refer to Changing or lnstalling a New Saw Blade.

2. Blade mounted backwards 2. Turn blade around. Refer to Changing or Installing a New Saw Blade.

3. Gum or pitch on blade 3. Remove blade and clean with turpentine and coarse Steel Wool or household oven cleaner.

4. Incorrect blade for work being done 4. Change the blade type. Refer to Saw Blades under Accessories.

! :Extension cord too light ortoo long 1 : Replace with adequate size cord, Refer to Use Proper Extension Cord Underlmportant Safety

Instructions.

2. Low house current 2. Contact your electric company.

2. Stand or bench on uneven floor 2. Reposition on flat level surface. Refer to Familiarization.

3. Damaged Saw blade 3. Replace blade: Refer to Changing or Installing a New Saw Blade.

3. Blade is not perpendicular to table 3. Check and adjust fence. Refer to Bevel Square to Table Adjustment under Adjustments.

4: workpiece moving 4: Clamp workpiece Securely to fence or glue t20 grit sandpaper to fence with rubber cement.

15

Page 17

TABLE 1: COMPOUND MITER CUT

(POSITIONWOODWITHBROADFLATSIDEON THETABLEANDTHENARROWEDGEAGAINSTTHEFENCE)

t.t)

Z

O

I,LI

,,--I

O

Z

n-

I,U

I-

t.t)

-r

I-

I--

ILl

t.t)

45

40=

EZZ]Z]ZiZEEZEZ ZZEiZ]ZiZZEiZ]ZLZZ]ZiZZEiZ]Z]Zi ZZZEiZ]Z]ZiZEiZEEiZ]Z]ZiZEiZ]Z]ZZZZEEZEZZEi_ _]ZiZ]Z]Z]ZiZZZ ZZZEiZ]Z]ZiZEiZ EEiZ]Z]ZiZEiZ]Z]

35-

30-.

....T,,,

10 15 20 25 30 35 40

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

iiI!!!!!!!!!__________________!!!!!!!!!__________________!!!!!!!!!!__________________!!!!!!!!!___________________!!!!!i!_iiiiiiiii_iiiiiiiii_iiiiiiiii_iiiiiiiiii__iiiiiiii_iiiiiiiii_iiiiiiiii_iiiiiiiiii_iiiiiiiii__!!!!!!!!!_!!!!!!!!!_!!!!!!!!!_!!!!!!!!!!IIIIIIIIIIIIIIIIII!!!!!!!!_iiiiiiiii_iiiiiiiii_iiiiiiiiii_iiiiiiiii_iiiiii

25"

20-

15-

45

- 4O

- 35

- 3O

- 25

45

LU

(5

Z

<_

X

O

O3

u_

©

LU

O_

U_

O

LU

(5

Z

<

10-

10 15 20 25 30 35 40

0

45

SET THIS BEVEL ANGLE ON SAW

16

Page 18

D_finitions : Lignes directrices en

mati_re de s_curit_

Les definitions ci-dessous decrivent le niveau de gravite pour chaque symbole. Veuillez lire

le mode d'emploi et porter une attention particuli@ea.ces symboles.

_DANGER : Indique une situation dangereuse imminente qui, si el/e n'est pas evitee,

causera la mort ou des blessures graves.

_VERTISSEMENT : Indique une situation potentiellement dangereuse qui, si ellen'est

pas evitee, pourrait se solder par un d_c_s ou des blessures graves.

_ATTENTION : Indique une situation potentiel/ement dangereuse qui, si el/e n'est pas

eviteepourrait se solder par des blessures mineures ou mod_r_es.

AVIS :/ndique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n'est far pour/'eviter, pourra_t poser des risques de dommages

materiels.

.4.

POUR TOUTE QUESTION OU TOUT COMMENTAIRE SUR CET

TOUT AUTRE OUTIL DEWALT, COMPOSER LE NUMC:RO SANS

1-800-4-DEWALT (1-800-433-9258).

OUTIL OU SUR

FRAIS SUIVANT :

CONSIGNES DE SECURITE IMPORTANTES

_ AVERTISSEMENT : Life toutes /es directives avant d'uti/iser /e produit.

Negliger de suivre toutes les directives suivantes peut entra_ner des risques

de chocs electriques, d'incendie et/ou de blessures graves.

LIRE TOUTES CES DIRECTIVES

Double isolation

Afin de proteger I'utilisateur contre les decharges electriques, les outils _.double isolation sont

completement recouverts de deux couches distinctes d'isolant electrique ou d'une simple

epaisseur renforcee de matiere isolante. Les outils comportant ce systeme d'isolation ne sont

pas congus pour 6tre mis a.la terre. L'outil est donc dote d'une prise a.deux broches qui

permet d'utiliser des rallonges sans avoir a.se soucier de maintenir une connexion a.la terre.

REMARQUE : le fait que cet outil soit muni d'une double isolation ne signifie pas que

I'utilisateur peut cesser de respecter les consignes de securit6 qui s'imposent. L'isolation

secondaire offre une protection contre tout dommage corporel pouvant resulter d'une

defaillance electrique possible du systeme primaire d'isolation interne.

iJ_4TTENTION : EN CAS DE REPARATION, UTILISER UNIQUEMENT DES PIECES DE

RECHANGE IDENTIQUES. Reparer ou remplacer les cordons d'alimentation endommages.

Fiches polaris_es

Certains appareils comportent des fiches polarisees (c'est-a.-dire qu'une lame est plus large

que I'autre) afin de reduire lerisque de choc electrique. Lorsqu'elle est presente, cette fiche ne

se branche que d'une seule fagon dans une prise de courant polarisee. Si la fiche ne s'insere

pas totalement dans la prise de courant, I'inverser. Si elle ne s'insere toujours pas dans la

prise, demander a.un electricien competent d'installer une fiche polarisee. Ne pas remplacer

la fiche.

Consignes de s_curit_ pour tous les outils

_AVERTISSEMENT : TOUJOURS utiliser une protection oculaire lots de I'utilisation

de la scie a onglets pour r_duire le risque de blessures aux yeux.

• MAINTENIR LE PROTEGE-LAME EN PLACE et en etat de fonctionnement.

• RETIRER LES CLE'S A MOLETTE ET LES CLE'S DE RE'GLAGE. S'habituer a verifier

si les cles a molette et les cles de reglage sont retirees de la broche avant de mettre I'outil

sous tension. Des outils, des dechets de decoupe et d'autres debris peuvent _tre projetes

grande vitesse, provoquant des blessures.

• GARDER LA ZONE DE TRAVAIL PROPRE. Les zones et etablis encombres sont

souvent des causes d'accidents.

• NE PAS UTILISER L'APPAREIL DANS UN ENVIRONNEMENT DANGEREUX.

L'utilisation d'outils dectriques clans des endroits humides ou mouil/es ou sous la pluie

peut provoquer un choc dectrique ou une dectrocution. Tenir la zone de travail bien

eclairee pour eviter de trebucher ou de mettre bras, mains et doigts en danger.

• TENIR LES ENFANTS A L'£-CART. Tous les visiteurs doivent se trouver a une distance

sore de la zone de travail. Un atelier represente un environnement potentiellement

dangereux.

• S'ASSURER QUE L'ATELIER NE PRESENTE PAS DE DANGER POUR LES

ENFANTS : utiliser des cadenas, des interrupteurs principaux ou retirer les cles de

demarrage. Le demarrage non autorise d'un appareil par un enfant ou un visiteur pourrait

se solder par des blessures.

• NE PAS FORCER L'OUTIL. Le travail sera mieux accompli et sera moins dangereux au

rythme prevu pour I'appareil.

• UTILISER L'OUTIL APPROPRI£-. Ne pas forcer un outil ou un accessoire pour effectuer

un travail auquel il n'a pas ete conqu. L'utilisation d'un outil ou d'un accessoire inapproprie

pourrait se solder par des blessures corporelles.

• PORTER LES VE-TEMENTS APPROPRI£-S. Ne pas porter ni v_tement ample, ni gant,

ni cravate, ni bague, ni bracelet, ni autre bijou, car ces demiers pourraient s'enchev_trer

dans des pieces mobiles. Des souliers antiderapants sont recommandes. Se couvrir les

cheveux s'ils sont longs. Se tenir doigne des events, car ces demiers pourraient camoufler

des pieces mobiles.

• TOUJOURS PORTER DES LUNETTES DE SE'CURITE'. Les lunettes ordina_res

ne constituent PAS des lunettes de securite. Utiliser egalement un masque facial ou

antipoussiere si I'operation de decoupe genere de la poussiere. TOUJOURS PORTER

UN E'QUIPEMENT DE SE'CURITE" HOMOLOGUE" :

• protection oculaire conforme a la norme ANSI Z87.1 (CAN/CSA Z94.3);

• protection auditive conforme a la norme ANSI S12.6 (S3.19);

• protection des voies respiratoires conforme aux normes NIOSH/OSHA/MSHA.

• FIXER LA PIE-CE. Utiliser des brides de fixation ou un etau pour maintenir la piece sur la

table et contre le guide. Faire de m_me Iorsque le travaila effectuer exigera que lamain de

I'operateur se trouve tres proche de la lame (amoins de 152 mm [6 po]). Une tellepratique

est plus securitaire, car I'operateur peut utiliser ses deux mains pour faire fonctionner

I'outil.

• NE PAS TROP TENDRE LES BRAS. Conserver son equilibre en tout temps. Une perte

d'equilibre risque d'entra_ner une blessure corporelle.

• PRENDRE SOIN DES OUTILS. S'assurer que les outils sont aiguises et propres afin

d'optimiser securite et performance. Suivre les consignes de graissage et de changement

d'accessoires. Les machines et outils mal entretenus peuvent s'endommager davantage