Page 1

,,_ 0')

NI.LI

"_F-

@

,o z

o

>

oo

w z

nw

091--

E,,,

z 0'3

LU'_

o" W

<_,,,d

u.-i-- F-

uL-w_

o>cl

wg©

u)

O

13

u)

F..Z _

O,_rr

7_ww

_123121

(D

Q.

u)

0

Z"3--

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

(AUG09) Part No. N042236 D26950, D26960 Copyright © 2009 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black

color scheme; the "D" shaped air intake grill; the array of pyramids on the handgrip; the kit box

configuration; and the array of lozenge-shaped humps on the surface of the tool.

Definitions: Safety Guidelines \

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

A WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

_ CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may

xresult in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

_ _ DANGER: To reduce the risk of injury, read the instruction manual. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury,

IMPORTANT SAFETY INSTRUCTIONS

READ THESE INSTRUCTIONS

Safety Instructions for Heat Guns

• To reduce the risk of explosion, DO NOT use in paint spray booths or within 10' (3.0 m) of

paint spraying operations.

• This appliance has a polarized plug (one blade is wider than the other). To reduce the risk of

electric shock, this plug is intended to fit in a polarized outlet only one way, If the plug does

not fit fully in the outlet, reverse the plug. If # still does not fit, contact a qualified electrician.

Do not modify the plug in any way,

• DO NOT use this tool to remove paint containing lead. The peelings, residue and vapors

of paint may contain lead which is poisonous

• Hidden areas such as behind walls, ceilings, floors, soffit boards and other panels may

contain flammable materials that could be ignited by the heat gun when working in these

locations. The ignition of these materials may not be readily apparent and could result in

property damage and injury to persons. When working in these locations, keep the heat gun

moving in a back-and-forth motion. Lingering or pausing in one spot could ignite the panel or

the material behind it.

NOTE: These heat guns are capable of producing temperatures in excess of 1000 °F

• DO NOT use this tool as a hair dryer.

• DO NOT use this tool to heat food.

• DO NOT lay the heat gun on flammable surfaces when operating the gun or immediately after

shutting it off. Allow the tool to cool before storing. Always set the gun on a flat level surface

so that the nozzle tip is pointed upward.

• DO NOT use in the presence of explosive materials.

• Keep moveable items secured and steady while scraping.

• NEVER obstruct the air intake or nozzle outlet. This may cause excessive heat build up

resulting in damage to the tool

• Be sure to direct the hot air blast in a safe direction; away from other people or flammable

objects.

• DO NOT remove the heat barrel cover during use.

• KEEP FINGERS AWAY FROM METAL NOZZLE; it becomes very hot during use and

remains hot for 30 minutes after use. Wear gloves to protect hands.

• ALWAYS keep nozzle away from cord.

• DO NOT touch the nozzle to any surface while running or shortly after running.

• DO NOT place anything inside the nozzle as it could cause an electric shock. Do not look

down the nozzle while the unit is turned on due to the high temperatures being produced.

• Splinters and small particles of stripped paint can be ignited and blown through holes and

cracks in the surface being stripped.

• DO NOT apply heat to the same area for a long period of time.

• DO NOT burn the paint. Use the scraper provided and keep the nozzle at least 1"(25 mm)

away from the painted surface. When working in a vertical direction, work downwards to

prevent paint from falling into the tool and burning.

• DO NOT allow paint to adhere to the nozzle or scraper. It could ignite.

• ALWAYS use good quality scrapers and stripping knives.

• DO NOT use the heat gun in combination with chemical strippers.

• DO NOT use accessory nozzles as scrapers.

• DO NOT direct heatgun airflow directly on glass. The glass may crack and could result in

property damage or personal injury,

• Maintain labels and nameplates. These carry important information.

• Place the heat gun on a stable, level surface when not hand held. Place the cord in a position

that won't cause the heat gun to tip over.

• Be constantly aware that this tool can ignite flammable materials, soften or melt others.

Regardless of the task you are performing, shield or keep the heat gun away from these

materials.

• You may occasionally notice some slight smoking of the tool after it is turned off. This is

the result of heating the residual oil that was deposited on the heating element during the

manufacturing process.

• Use eye protection and other safety equipment.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the tool

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

• When operating a tool outdoors, use an extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the risk of electric shock.

Do not expose tools to rain or wet conditions. Water entering a tool will increase the risk

of electric shock.

Do not overreach. Keep proper footing and balance at all times. This enables better

control of the tool in unexpected situations.

Store idle tools out of the reach of children and do not allow persons unfamiliar with

the tool or these instructions to operate the tool Tools are dangerous in the hands of

untrained users.

Have your tool serviced by a qualified repair person using only identical replacement

parts. This will ensure that the safety of the tool is maintained.

Air vents often cover moving parts and should be avoided. Loose clothes, jewelry or long

hair can be caught in moving parts.

An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. When using more than one extension to

make up the total length, be sure each individual extension contains at least the minimum

wire size. The following table shows the correct size to use depending on cord length and

nameplate ampere rating, ff in doubt, use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0

6

10

12

_ WARNING: Always use eye protection. All users and bystanders must wear eye protection

that conforms to ANSI Z87.1.

WARNING: Always wear proper personal hearing protection that conforms to ANSI

$12.6 ($3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

A WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out microscopic

particles.

_ WARNING: ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses.

Also use face or dust mask if cutting operation is dusty, All users and bystanders MUST ALWAYS

wear certified safety equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V.....................volts

Hz ...................hertz

min ..................minutes

--- ................direct current

@ ....................Class I Construction

[] .....................Class II Construction

sfpm .............. surface feet

PERSONS REMOVING PAINT SHOULD ALWAYS FOLLOW THESE GUIDELINES:

WARNING: Extreme care should be taken when stripping paint. The peelings, residue and

vapors of paint may contain lead, which is poisonous. Any pre-1977 paint may contain lead and

paint applied to homes prior to 1950 is likely to contain lead. Once deposited on surfaces, hand

to mouth contact can result in the ingestion of lead. Exposure to even low levels of lead can

cause irreversible brain and nervous system damage; young and unborn children are particularly

vulnerable.

Before beginning any paint removal process you should determine whether the paint you are

removing contains lead. This can be done by your local health department or by a professional

who uses a paint analyzer to check the lead content of the paint to be removed. LEAD-BASED

PAINT SHOULD ONLY BE REMOVED BY A PROFESSIONAL AND SHOULD NOT BE

REMOVED USING A HEAT GUN. Persons removing paint should follow these guidelines:

1.Move the workpiece outdoors, ff this is not possible, keep the work area well ventilated. Open

the windows and put an exhaust fan in one of them. Be sure the fan is moving the air from

inside to outside.

2. Remove or cover any carpets, rugs, furniture, clothing, cooking utensils and air ducts.

3. Place drop cloths in the work area to catch any paint chips or peelings. Wear protective

clothing such as extra work shirts, overalls and hats.

4. Work in one room at a time. Furnishings should be removed or placed in the center of the

room and covered. Work areas should be sealed off from the rest of the dwelling by sealing

doorways with drop cloths.

5. Children, pregnant or potentially pregnant women and nursing mothers should not be

present in the work area until the work is done and all clean up is complete.

6. Wear a dust respirator mask or a dual filter (dust and fume) respirator mask which has

been approved by the Occupational Safety and Health Administration (OSHA), the National

Institute of Safety and Health (NIOSH), or the United States Bureau of Mines. These masks

and replaceable filters are readily available at major hardware stores. Be sure the mask

fits. Beards and facial hair may keep masks from sealing properly, Change filters often.

DISPOSABLE PAPER MASKS ARE NOT ADEQUATE.

Not More

Than

6

10

12

16

(grounded)

(double insulated)

per minute (sfpm)

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

18

18

16

14

AWG

16

16

16

12

A.................. amperes

W................. watts

"_ ...............alternating current

no ................no load speed

................. earthing terminal

................safety alert symbol

BPM ............ beats per minute

.../min .........revolutions or

16 14

14 12

14 12

Not Recommended

reciprocation

per minute

Page 2

7.Usecautionwhenoperatingtheheatgun.Keeptheheatgunmovingasexcessiveheatwill

generatefumeswhichcanbeinhaledbytheoperator.

8.Keepfoodanddrinkoutof the work area. Wash hands, arms and face and rinse mouth

before eating or drinking. Do not smoke or chew gum or tobacco in the work area.

9. Clean up all removed paint and dust by wet mopping the floors. Use a wet cloth to clean

all walls, sills and any other surface where paint or dust is clinging. DO NOT SWEEP, DRY

DUST OR VACUUM. Use a high phosphate detergent or trisodium phosphate (TSP) to wash

and mop areas.

10. At the end of each work session put the paint chips and debris in a double plastic bag, close

it with tape or twist ties and dispose of properly.

11. Remove protective clothing and work shoes in the work area to avoid carrying dust into the

rest of the dwelling. Wash work clothes separately. Wipe shoes off with a wet rag that is then

washed with the work clothes. Wash hair and body thoroughly with soap and water.

IMPORTANT NOTICE

In order for this tool to be an effective paint stripper, it must produce extremely high temperatures.

As a consequence, the stripper is capable of igniting paper, wood, paint and varnish residue and

similar materials.

As you become more familiar with the tool and develop the proper technique, the danger of

accidental ignition will be greatly reduced. In establishing the proper technique, the best thing to

do is PRACTICE! Work on simple stripping projects, preferably outdoors, until you get a "feel" for

how to use your stripper safely and effectively.

AS YOU PRACTICE, OBSERVE THE FOLLOWING PROCEDURES FOR SAFETY

• Always be sure the tool is turned off and disconnected from power supply when unattended.

• Clean the scraper blade often during use. Built up residue on the blade is highly flammable.

• Experiment to find the optimum distance from the tool's nozzle to the surface being stripped.

This distance [1"-2" (25.4 mm-50.8 mm)] will vary depending on the material being

removed.

• Keep the heat gun moving ahead of the scraper blade at all times.

• As you work, clean up loose pieces of paint as they accumulate around the work area.

• When working indoors, keep away from curtains, papers, upholstery and similar flammable

materials.

• Above all, remember that this is a serious tool that is capable of producing excellent results

when used properly. Practice on simple projects until you feel comfortable with your stripper.

Only then will you have mastered the proper technique.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

FIG.1

D26950

D26960

F

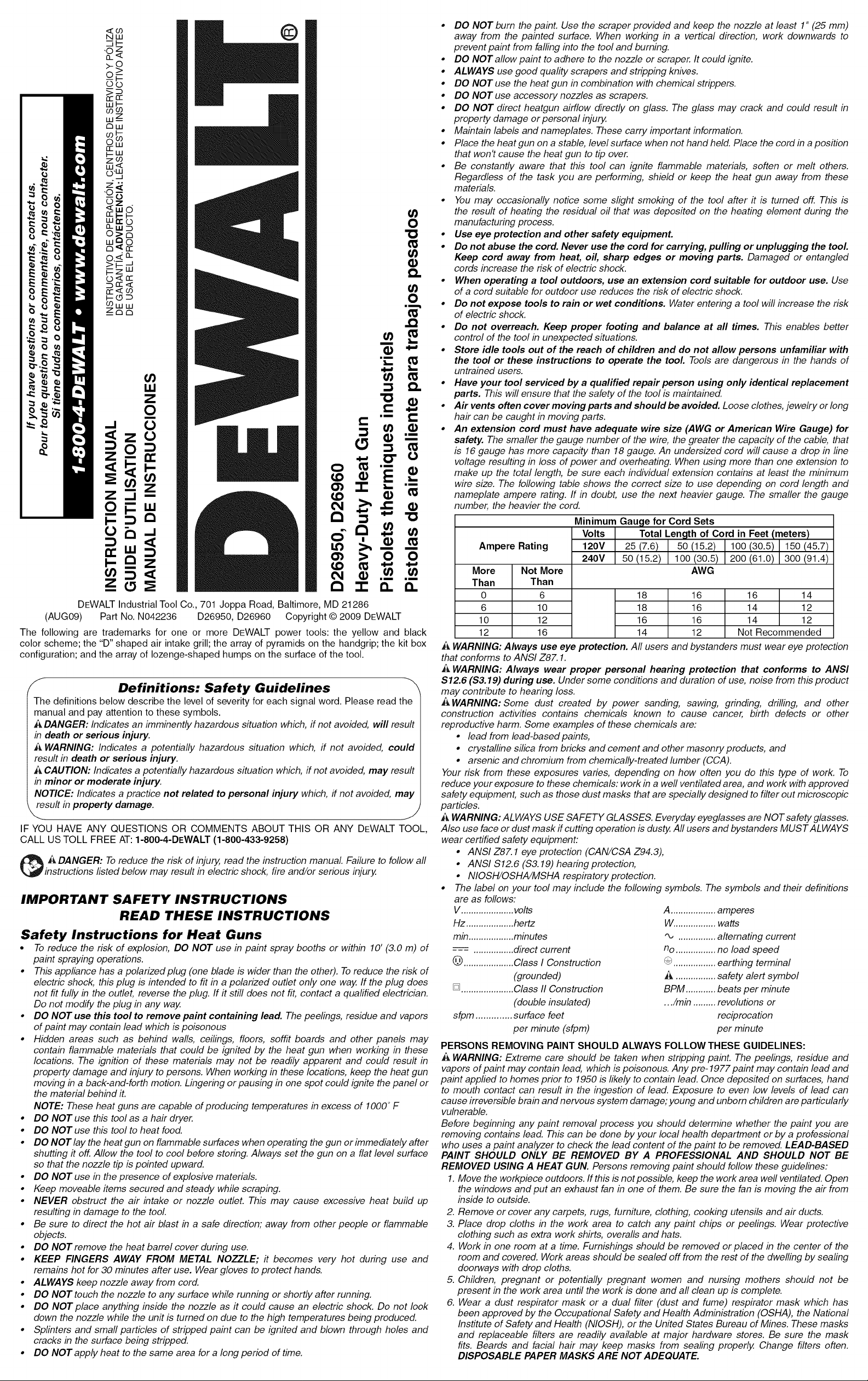

Description (Fig. 1)

WARNING: Never modify the tool or any part of it. Damage or personal injury could result.

A. On/off switch

B. Air vents

C. Kick-off stand

D. Air temperature adjustment knob (D26950)

LCD air temperature indicator and adjuster (D26960)

E. Nozzle

R Tool hanging ring

G. Heat barrel cover

INTENDED USE

Your DEWALT heat gun has been designed for stripping paint, soldering pipes, shrinking PVC,

welding and bending plastics as well as general drying and thawing purposes.

A WARNING: DO NOT use under wet conditions or in presence of flammable liquids or gases.

The heat gun is a professional power tool. DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use this tool.

ASSEMBLY AND ADJUSTMENTS

_ WARNING: To reduce the risk of injury, turn off tool, disconnect from power source and

allow to cool before installing and removing accessories, before making any adjustments or

removing/installing attachments or accessories.

Air Temperature (Fig. 1)

D26950

The air temperature can be adjusted to suit a wide range of applications. Turn the air temperature

adjustment knob (D) clockwise or counterclockwise for higher or lower heat.

D26960

Press and release the LCD air temperature indicator and adjuster (D) to set the desired

temperature in 50°F (10°C) increments. To continously increase or decrease the temperature

press and hold the LCD air temperature indicator and adjuster (D). Release the indicator when

desired temperature or minimum/maximum temperature is reached.

The display shows the actual rising/falling temperature until the desired temperature is

reached.

SET AND FORGET TEMPERATURE CONTROL SYSTEM

D26960

The desired temperature is stored in the memory of the tool. Each time the heat gun is turned

on, the heat gun heats to the last temperature setting, with respect to air flow. If unsure about

the setting, always start with a low temperature setting and gradually increase the temperature

until the desired setting is reached.

Applications

The table below suggests settings for different applications.

Setting Applications

Low • Drying paint and varnish

• Removing stickers

• Waxing and dewaxing

• Drying wet timber prior to filling

• Shrinking PVC wrapping and

insulation tubes

• Thawing frozen pipes

High • Welding plastics

• Bending plastic pipes and sheets

• Loosening rusted or tightly

fastened nuts and bolts

• Removing paint and lacquer

• Soldering plumbing joints

• Removing linoleum or vinyl floor tiles

To Attach the Correct Accessory

This tool is supplied with a set of accessories for different applications.

Icon Description Purpose

Cone nozzle Welding, soldering,

Fish tail removing vinyl or linoleum,

2" (50 mm) Drying, removing paint,

surface nozzle thawing (heat spread over wide area)

1. Make sure the on/off switch (A) is in position O and the tool is disconnected from the power

source. Ensure the nozzle has cooled down.

2. Place the desired accessory onto the nozzle.

shrink sleeving (heat over

concentrated small area)

OPERATION

WARNING: Make sure the nozzle ALWAYS points away from you and any bystanders.

A WARNING: DO NOT drop anything into the nozzle.

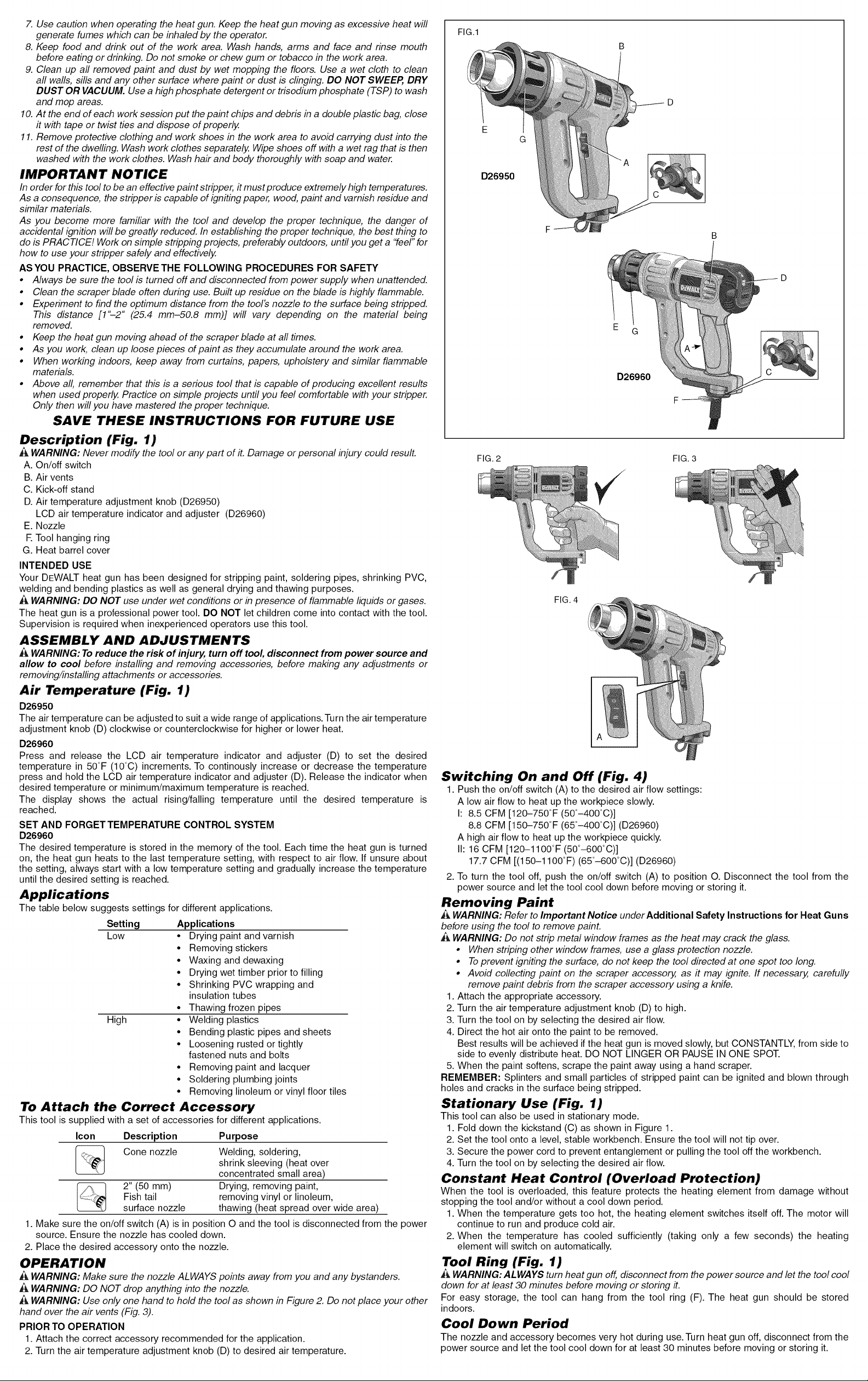

_ WARNING: Use only one hand to hold the tool as shown in Figure 2. Do not place your other

hand over the air vents (Fig. 3).

PRIOR TO OPERATION

1. Attach the correct accessory recommended for the application.

2. Turn the air temperature adjustment knob (D) to desired air temperature.

FIG. 2 FIG. 3

FIG. 4

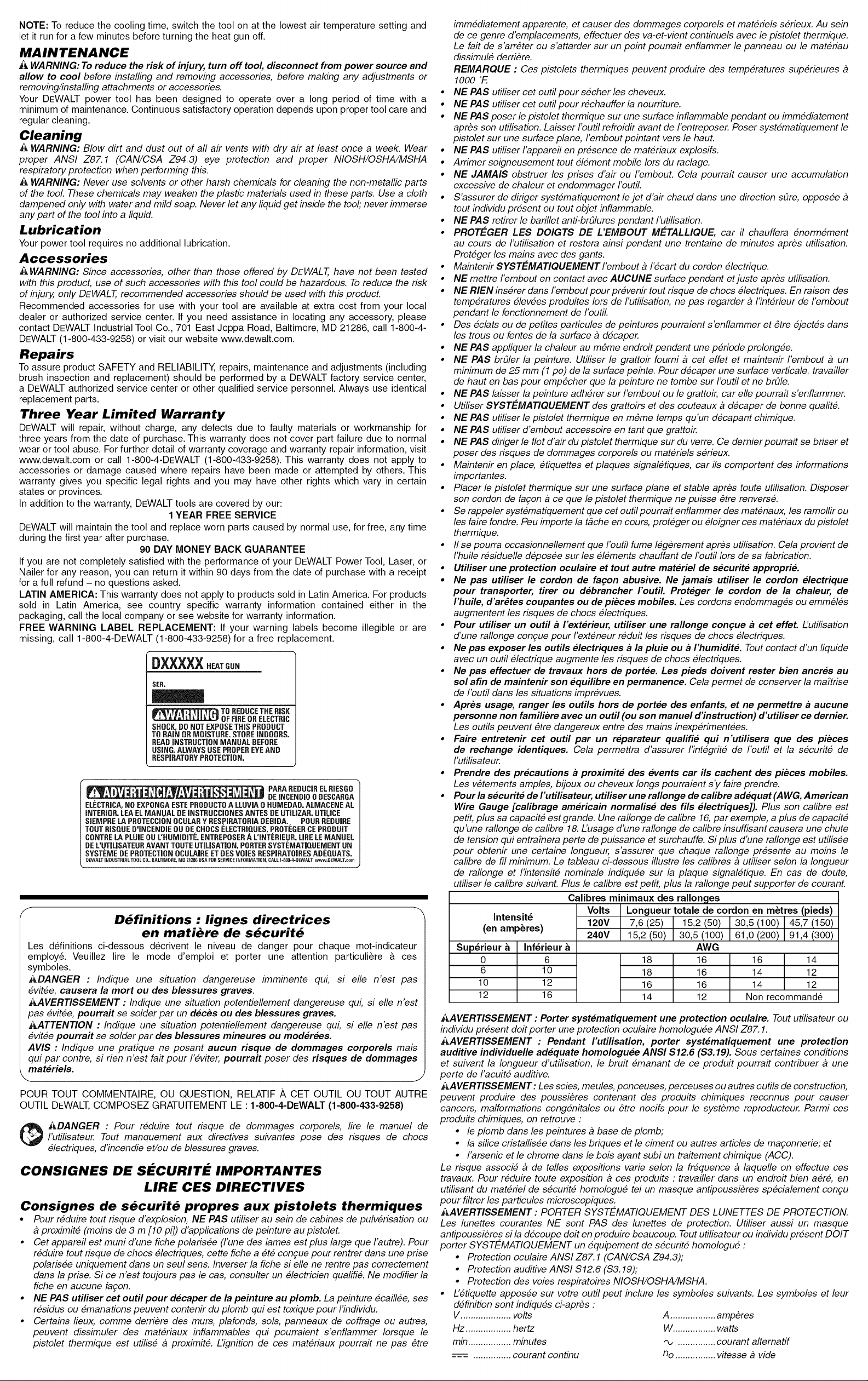

Switching On and Off (Fig. 4)

1. Push the on/off switch (A) to the desired air flow settings:

A low air flow to heat up the workpiece slowly.

I: 8.5 CFM [120-750°F (50°-400°C)]

8.8 CFM [150-750°F (65°-400°C)] (D26960)

A high air flow to heat up the workpiece quickly.

Ih 16 CFM [120-1100°F (50°-600°C)]

17.7 CFM [(150-1100°F)(65°-600°C)] (D26960)

2. To turn the tool off, push the on/off switch (A) to position O. Disconnect the tool from the

power source and let the tool cool down before moving or storing it.

Removing Paint

WARNING: Refer to Important Notice under Additional Safety Instructions for Heat Guns

before using the tool to remove paint.

_ WARNING: Do not strip metal window frames as the heat may crack the glass.

• When striping other window frames, use a glass protection nozzle.

• To prevent igniting the surface, do not keep the tool directed at one spot too long.

• Avoid collecting paint on the scraper accessory, as it may ignite. If necessary, carefully

remove paint debris from the scraper accessory using a knife.

1. Attach the appropriate accessory.

2. Turn the air temperature adjustment knob (D) to high.

3. Turn the tool on by selecting the desired air flow.

4. Direct the hot air onto the paint to be removed.

Best results will be achieved if the heat gun is moved slowly, but CONSTANTLY, from side to

side to evenly distribute heat. DO NOT LINGER OR PAUSE IN ONE SPOT.

5. When the paint softens, scrape the paint away using a hand scraper.

REMEMBER: Splinters and small particles of stripped paint can be ignited and blown through

holes and cracks in the surface being stripped.

Stationary Use (Fig. 1)

This tool can also be used in stationary mode.

1. Fold down the kickstand (C) as shown in Figure 1.

2. Set the tool onto a level, stable workbench. Ensure the tool will not tip over.

3. Secure the power cord to prevent entanglement or pulling the tool off the workbench.

4. Turn the tool on by selecting the desired air flow.

Constant Heat Control (Overload Protection)

When the tool is overloaded, this feature protects the heating element from damage without

stopping the tool and/or without a cool down period.

1. When the temperature gets too hot, the heating element switches itself off. The motor will

continue to run and produce cold air.

2. When the temperature has cooled sufficiently (taking only a few seconds) the heating

element will switch on automatically.

Tool Ring (Fig. 1)

_, WARNING: ALWAYS turn heat gun off, disconnect from the power source and let the tool cool

down for at least 30 minutes before moving or storing it.

For easy storage, the tool can hang from the tool ring (F). The heat gun should be stored

indoors.

Cool Down Period

The nozzle and accessory becomes very hot during use.Turn heat gun off, disconnect from the

power source and let the tool cool down for at least 30 minutes before moving or storing it.

Page 3

NOTE:Toreducethecoolingtime,switchthetoolonatthelowestairtemperaturesettingand

letitrunforafewminutesbeforeturningtheheatgunoff.

MAINTENANCE

WARNING: To reduce the risk of injury, turn off tool, disconnect from power source and

allow to cool before installing and removing accessories, before making any adjustments or

removing/installing attachments or accessories.

Your DEWALT power tool has been designed to operate over a long period of time with a

minimum of maintenance. Continuous satisfactory operation depends upon proper tool care and

regular cleaning.

Cleaning

_ WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear •

proper ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA •

respiratory protection when performing this. •

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth •

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid. •

Lubrication

Your power tool requires no additional lubrication.

Accessories

A WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk •

of injury, only DEWALT, recommended accessories should be used with this product. •

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory, please

contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-

DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including

brush inspection and replacement) should be performed by a DEWALT factory service center,

a DEWALT authorized service center or other qualified service personnel. Always use identical

replacement parts. •

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for •

three years from the date of purchase. This warranty does not cover part failure due to normal •

wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces. •

In addition to the warranty, DEWALT tools are covered by our:

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt •

for a full refund - no questions asked. °

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.

1YEAR FREE SERVICE •

90 DAY MONEY BACK GUARANTEE •

DXXXXX.EATGU.

SER.

. , , ,, , TOREDUCETHERiSK

SHOCK,DONOTEXPOSETHISPRODUCT

TORAiNORMOISTURE.STOREiNDOORS.

READINSTRUCTIONMANUALBEFORE

USING.ALWAYSUSEPROPEREYEAND

RESPIRATORYPROTECTION.

_. _,| , ,_ _ ,, PARA REDUCIRELRJESGD

ELI_CTRiCA,NO EXPDNGAESTEPRODUCTOA LLUVIAO HUMEDAD. ALMACENE AL

iNTERiOR, LEA EL MANUAL DE JNSTRUCCJONESANTES DE UTJLJZAR,UTJL.JCE

SiEMPRE LA PROTECCiDN OCULARY RESPBRATORiADEBIDA. POUR REBUIRE

TOUT RISQUE D'JNCENDJEOU BE CHDCS I_LECTBiQUES,PRDTI_GERCE PRDBUIT

CDNTRELA PLUJEOU L'HUMIDiTE. ENTREPOSER A L'iNTERJEUR.LJRELEMANUEL

DEL'UTJLJSATEURAVANT TOUTEUTJLJSATION,PORTERSYSTEMATJQUEM.ENT UN

SYSTEME DE PROTECTIONOCULAIRE ET DES VOJESRESPJRATOJRESABEQUATS.

BEWALT iNDUSTRiAL TOOL CO., BALTIMORE, MB 21286 USA FOR SERVICE INFORMATION, CALL 1-OO0-4-BEWALT www.DEWALT.com

F

Ddfinitions : lignes directrices

en matidre de sdcuritd

Les dGfinitions ci-dessous dGcrivent le niveau de danger pour chaque mot-indicateur

employ& Veuillez lire le mode d'emploi et porter une attention particuli_re & ces

symboles.

ADANGER : Indique une sfluation dangereuse imminente qui, si elle n'est pas

evitee, causera la mort ou des blessures graves.

_,AVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle n'est

pas evitGe, pourrait se solder par un deces ou des blessures graves.

i_,ATTENTION : Indique une situation potentiellement dangereuse qui, si elle n'est pas

evitee pourrait se solder par des blessures mineures ou moderees.

AVIS : Indique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n'est fait pour I'eviter, pourrait poser des risques de dommages

materiels.

POUR TOUT COMMENTAIRE, OU QUESTION, RELATIF ,_ CET OUTIL OU TOUT AUTRE

OUTIL DEWALT, COMPOSEZ GRATUITEMENT LE •1-800-4-DEWALT (1-800-433-9258)

I'utilisateur. Tout manquement aux directives suivantes pose des risques de chocs

_ ,&DANGER : Pour reduire tout risque de dommages corporels, lire le manuel de

electriques, d'incendie et/ou de blessures graves.

CONSlGNES DE SECURITE IMPORTANTES

LIRE CES DIRECTIVES

Consignes de sdcuritd propres aux pistolets thermiques

• Pour reduire tout risque d'explosion, NE PAS utiliser au sein de cabines de pulverisation ou

proximite (moins de 3 m [10 pi]) d'applications de peinture au pistolet.

• Cet appareil est muni d'une fiche polarisee (l'une des lames est plus large que I'autre). Pour

reduire tout risque de chocs electriques, cette fiche a et6 congue pour rentrer dans une prise

polarisee uniquement dans un seul sens. Inverser la fiche si elle ne rentre pas correctement

dans la prise. Si ce n'est toujours pas le cas, consulter un electricien qualifie. Ne modifier la

fiche en aucune fa_on.

• NE PAS utiliser cet outil pour decaper de la peinture au plomb. La peinture ecaillGe, ses

residus ou emanations peuvent contenir du plomb qui est toxique pour I'individu.

• Certains lieux, comme derriere des murs, plafonds, sols, panneaux de coffrage ou autres,

peuvent dissimuler des materiaux inflammables qui pourraient s'enflammer Iorsque le

pistolet thermique est utilise a proximite. L'ignition de ces materiaux pourrait ne pas 6tre

OFFiRE ORELECTRIC

DE INCENDIOODESCARGA

J

immediatement apparente, et causer des dommages corporels et materiels serieux. Au sein

de ce genre d'emplacements, effectuer des va-et-vient continuels avec le pistolet thermique.

Le fait de s'arrGter ou s'attarder sur un point pourrait enflammer le panneau ou le materiau

dissimule derriere.

REMARQUE : Ces pistolets thermiques peuvent produire des temperatures superieures

1000 OF.

NE PAS utiliser cet outil pour s#cher les cheveux.

NE PAS utiliser cet outil pour r#chauffer la nourriture.

NE PAS poser le pistolet thermique sur une surface inflammable pendant ou imm#diatement

apres son utilisation. Laisser Ibutil refroidir avant de I'entreposer. Poser syst#matiquement le

pistolet sur une surface plane, I'embout pointant vers le haut.

NE PAS utiliser I'appareil en pr#sence de mat#riaux explosifs.

Arrimer soigneusement tout #l#ment mobile lots du raclage.

NE JAMAIS obstruer les prises d'air ou I'embout. Cela pourrait causer une accumulation

excessive de chaleur et endommager Ibutil.

S'assurer de diriger syst#matiquement le jet d'air chaud dans une direction s_re, oppos#e

tout individu pr#sent ou tout objet inflammable.

NE PAS retirer le barillet anti-br_lures pendant I'utilisation.

PROTEGER LES DOIGTS DE L'EMBOUT METALLIQUE, car il chauffera #norm#ment

au cours de I'utilisation et restera ainsi pendant une trentaine de minutes apres utilisation.

Proteger les mains avec des gants.

Maintenir SYSTEMATIQUEMENT I'embout a I'ecart du cordon electrique.

NE mettre I'embout en contact avec AUCUNE surface pendant etjuste apres utilisation.

NE RIEN inserer dans I'embout pour prevenir tout risque de chocs electriques. En raison des

temperatures elevees produites Iors de I'utilisation, ne pas regarder a I'interieur de I'embout

pendant le fonctionnement de I'outil.

Des eclats ou de petites particules de peintures pourraient s'enflammer et 6tre ejectes dans

les trous ou fentes de la surface a decaper.

NE PAS appliquer la chaleur au mGme endroit pendant une periode prolongee.

NE PAS brDler la peinture. Utiliser le grattoir fourni a cet effet et maintenir I'embout a un

minimum de 25 mm (1 pc) de la surface peinte. Pour decaper une surface verticale, travailler

de haut en has pour empGcher que la peinture ne tombe sur I'outil et ne br_le.

NE PAS laisser la peinture adherer sur I'embout ou le grattoir, car elle pourrait s'enflammer.

Utiliser SYSTEMATIQUEMENT des grattoirs et des couteaux a decaper de bonne qualite.

NE PAS utiliser le pistolet thermique en mGme temps qu'un decapant chimique.

NE PAS utiliser d'embout accessoire en tant que grattoir.

NE PAS diriger le flot d'air du pistolet thermique sur du verre. Ce dernier pourrait se briser et

poser des risques de dommages corporels ou materiels serieux.

Maintenir en place, etiquettes et plaques signaletiques, car ils comportent des informations

importantes.

Placer le pistolet thermique sur une surface plane et stable apres toute utilisation. Disposer

son cordon de fa_on ace que le pistolet thermique ne puisse 6tre renverse.

Se rappeler systematiquement que cet outil pourrait enflammer des materiaux, les ramollir ou

les faire fondre. Peu importe la t&che en cours, proteger ou eloigner ces materiaux du pistolet

thermique.

fl se pourra occasionnellement que I'outil fume legerement apres utilisation. Cela provient de

I'huile residuelle deposee sur les elements chauffant de I'outil Iors de sa fabrication.

Utiliser une protection oculaire et tout autre materiel de securite approprie.

Ne pas utiliser le cordon de fa_on abusive. Ne jamais utiliser le cordon electrique

pour transporter, tirer ou debrancher I'outil. Proteger le cordon de la chaleur, de

I'huile, d'arGtes coupantes ou de pieces mobiles. Les cordons endommages ou emmGles

augmentent les risques de chocs electriques.

Pour utiliser un outil a I'exterieur, utiliser une rallonge con_ue a cet effet. L'utilisation

d'une rallonge con_ue pour I'exterieur reduit les risques de chocs electriques.

Ne pas exposer les outils electriques a la pluie ou a I'humidite. Tout contact d'un liquide

avec un outil electrique augmente les risques de chocs electriques.

Ne pas effectuer de travaux hors de portee. Les pieds doivent rester bien ancres au

sol afin de maintenir son equilibre en permanence. Cela permet de conserver la maftrise

de I'outil dans les situations imprevues.

Apres usage, ranger les outils hors de portee des enfants, et ne permettre a aucune

personne non familiere avec un outil (ou son manuel d'instruction) d'utiliser ce dernier.

Les outils peuvent 6tre dangereux entre des mains inexperimentees.

Faire entretenir cet outil par un reparateur qualifie qui n'utilisera que des pieces

de rechange identiques. Cela permettra d'assurer I'integrite de I'outil et la securite de

I'utilisateur.

Prendre des precautions a proximite des events car ils cachent des pieces mobiles.

Les vGtements amples, bijoux ou cheveux longs pourraient s'y faire prendre.

Pour la securite de I'utilisateur, utiliser une rallonge de calibre adequat (AWG, American

Wire Gauge [calibrage americain normalise des ills electriques]). Plus son calibre est

petit, plus sa capacite est grande. Une rallonge de calibre 16, par exemple, a plus de capacite

qu'une rallonge de calibre 18.L'usage d'une rallonge de calibre insuffisant causera une chute

de tension qui entrafnera perte de puissance et surchauffe. Si plus d'une rallonge est utilisee

pour obtenir une certaine Iongueur, s'assurer que chaque rallonge presente au moins le

calibre de fil minimum. Le tableau ci-dessous illustre les calibres a utiliser selon la Iongueur

de rallonge et I'intensite nominale indiquee sur la plaque signaletique. En cas de doute,

utiliser le calibre suivant. Plus le calibre est petit, plus la rallonge peut supporter de courant.

Calibres minimaux des rallonges

Intensit6

(en ampbres)

SupGrieur h

o

6

lO

12

_AVERTISSEMENT : Porter systematiquement une protection oculaire. Tout utilisateur ou

individu present dolt porter une protection oculaire homologuee ANSI Z87.1.

_&AVERTISSEMENT : Pendant I'utilisation, porter systematiquement une protection

auditive individuelle adequate homologuee ANSI S12.6 ($3.19). Sous certaines conditions

et suivant la Iongueur d'utilisation, le bruit emanant de ce produit pourrait contribuer a une

perte de I'acuite auditive.

i_,AVERTISSEMENT : Les scies, meules, ponceuses, perceuses ou autres outils de construction,

peuvent produire des poussieres contenant des produits chimiques reconnus pour causer

cancers, malformations congenitales ou 6tre nocifs pour le systeme reproducteur. Parmi ces

produits chimiques, on retrouve :

• le plomb dans les peintures a base de plomb;

• la silice cristallisee clans les briques et le ciment ou autres articles de ma_onnerie; et

• I'arsenic et le chrome dans le bois ayant subi un traitement chimique (ACC).

Le risque associe a de telles expositions varie selon la frequence a laquelle on effectue ces

travaux. Pour reduire toute exposition a ces produits : travailler dans un endroit bien aere, en

utilisant du materiel de securite homologue tel un masque antipoussieres specialement con_u

pour filtrer les particules microscopiques.

_&AVERTISSEMENT : PORTER SYSTEMATIQUEMENT DES LUNETTES DE PROTECTION.

Les lunettes courantes NE sont PAS des lunettes de protection. Utiliser aussi un masque

antipoussieres si la decoupe dolt en produire beaucoup. Tout utilisateur ou individu present DOlT

porter SYSTEMATIQUEMENT un equipement de securite homologue :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3);

• Protection auditive ANSI $12.6 ($3.19);

• Protection des voles respiratoires NIOSH/OSHA/MSHA.

• L'etiquette apposee sur votre outil peut inclure les symboles suivants. Les symboles et leur

definition sont indiques ci-apres :

V.................... volts A.................. amperes

Hz .................. hertz W................. watts

min................. minutes % ............... courant alternatif

.................. courant continu no ................ vitesse a vide

InfGrieur h

6

10

12

16

Volts Longueur totale de cordon en mbtres (pieds)

120V 7,6 (25) 30,5 (100) 45,7 (150)

240V 15,2 (50) 61,0 (200) 91,4 (300)

18

18

16

14

15,2 (50)

30,5 (100)

AWG

16

16

16

12

16 14

14 12

14 12

Non recommand6

Page 4

@ ................... Classe / Fabrication

(mis a la terre)

[] ................... Fabrication Classe II

(double isolation)

sfpm .............. pieds lineaires

par minute (plpm)

TOUT INDIVIDU D#CAPANT DE LA PEINTURE SE DOlT DE SUIVRE

SYST#MATIQUEMENT LES CONSIGNES SUIVANTES :

i_,AVERTISSEMENT : II est recommande de faire preuve de la plus extr6me prudence lots

du decapage de la peinture. La peinture ecaillee, ses residus ou emanations peuvent contenir

du plomb qui est toxique pour I'individu. Les peintures pre 1977 peuvent contenir du plomb et

la peinture des maisons datant d'avant 1950 contiennent presque surement du plomb. Une

fois le plomb etale sur une surface, tout contact manuel posera des risques d'ingestion. Toute

exposition au plomb, m6me a des taux minimes, pose des risques de dommages irreversibles

au cerveau et au systeme nerveux. Les jeunes enfants et les foetus sont particulierement

vulnerables.

Avant de decaper toute peinture, il est recommande de determiner si elle contient du plomb.

Cela peut 6tre fait par votre departement local de la sante ou par un professionnel qui

utilisera un analyseur de peinture pour verifier le taux de plomb contenu par la peinture

decaper. TOUTE PEINTURE AU PLOMB DOlT Y=TRE RETIREE EXCLUSlVEMENT PAR

UN PROFESSIONNEL, ET JAMAIS .4 L'AIDE D'UN PISTOLET THERMIQUE. Tout individu

decapant de lapeinture se doff de suivre les consignes suivantes :

1. Deplacer la piece a decaper a I'exterieur. Si c'est impossible, maintenir I'aire de travail bien

ventilee. Ouvrir les fen6tres et installer un ventilateur d'aspiration a I'une d'elles. S'assurer

que le ventilateur deplace I'air de I'interieur vers I'exterieur.

2. Retirer ou couvrir moquettes, tapis, meubles, v6tements, ustensiles de cuisine et conduits

de ventilation.

3. Installer des toiles de protection sur les lieux de travail pour recup6rer toute peinture ecaillee

ou debris. Porter des v6tements de protection tels que chemises de travail, salopettes,

chapeaux.

4. Travailler dans une piece a la fois. II est recommande de sortir les meubles ou de les

placer au centre de la piece et de les recouvrir. Les lieux de travail devraient 6tre isoles

hermetiquement du reste de I'habitation en scellant les ouvertures avec des toiles de

protection.

5. E-Ioigner les enfants, les femmes enceintes ou potentiellement enceintes, les meres

allaitant, des lieux de travail tant que le travail et le nettoyage ne sont pas termines.

6. Porter un appareil de protection des voies respiratoires normal ou a double filtre (poussieres

et emanations) homologue par I'Administration de la securite et de la sante au travail

(OSHA), I'lnstitut national pour la securite et la sante (NIOSH), ou le Bureau des Mines

americain. Ces appareils respiratoires et leurs filtres de remplacement sont disponibles

aupres de la plupart des grands magasins de bricolage. S'assurer que le masque sied

correctement. La barbe et les poils peuvent interferer avec I'efficacite des masques.

Changer regulibrement les filtres. LES MASQUES JETABLES EN PAPIER NE SONT PAS

ADEQUATS.

7. Utiliser le pistolet thermique avec precautions. Deplacer le pistolet thermique constamment

car une chaleur excessive produira des emanations qui pourront 6tre inhalees par

I'utilisateur.

8. Maintenir toute nourriture ou boisson hors de I'aire de travail. Se laver soigneusement les

mains, bras et le visage, et se rincer la bouche avant de manger ou boire. Ne pas fumer, ou

m_cher du chewing-gum ou du tabac, au sein de I'aire de travail.

9. Nettoyer toute peinture decap6e et poussiere des sols a I'aide d'une lavette humide. Utiliser

un chiffon humide pour nettoyer murs, rebords de fen6tre, et toutes autres surfaces ob

la peinture ou la poussiere s'est accrochee. NE PAS BALAYER, EPOUSSETER .4 SEC

OU PASSER L'ASPIRATEUR. Utiliser un detergent a taux concentre de phosphate ou

triphosphate de sodium (Na3P04) pour nettoyer et laver les lieux de travail.

10. En fin de travail, mettre peinture ecaillee et debris dans un sac de plastique double, fermer

soigneusement a I'aide d'un ruban adhesif ou un lien torsade et jeter conformement aux

normes en vigueur.

11. Retirer tout v6tement de protection et chaussures de travail sur les lieux de travail pour

eviter de transporter la poussiere dans le reste de I'habitation. Nettoyer les v6tements de

travail separement. Nettoyer les chaussures avec un chiffon humide que I'on lavera avec les

v6tements de travail. Laver soigneusement le corps et les cheveux a I'eau et au savon.

................. borne de terre

_&................symbole d'avertissement

BPM ............ battements par minute

.../min ..........tours ou retour

par minute

AVIS IMPORTANT

Pour que cet outil fonctionne efficacement en tant que decapant peinture, il doit produire des

temperatures extr6mement elevees. Par consequent, cet outil est capable d'enflammer papier,

bois, peinture, vernis et autres materiaux similaires.

En vous familiarisant avec Ibutil et son utilisation adequate, vous reduirez grandement les

dangers d'ignition accidentelle. Pour apprendre a maftriser la bonne technique, rien ne vaut

la PRATIQUE ! Travaillez tout d'abord sur des projets de decapage simples, a I'exterieur de

preference, jusqu'a acquerir I'experience voulue pour utiliser Ibutil efficacement et en toute

securite.

EN COURS DE PRATIQUE, SUlVRE LES PROCI_DURES DE SI-CURITI- SUlVANTES :

• S'assurer que I'outil est systematiquement arr6te et deconnecte du secteur Iorsqu'il est

laisse sans surveillance.

• Nettoyer regulierement la lame du grattoir au cours de I'utilisation. Toute accumulation de

residus sur la lame sera extr6mement inflammable.

• Effectuer divers essais pour determiner la distance optimale entre I'embout de Ibutil et

la surface a decaper. Cette distance (25,4 mm a 50,8 mm [1 po a 2 po]) variera selon le

materiau a decaper.

• Maintenir constamment le pistolet thermique en mouvement devant la lame du grattoir.

• Au cours de I'operation, nettoyer tout debris ou peinture ecaillee qui se sera accumule au

sein de I'aire de travail.

• En interieur, rester a distance de tout rideau, papier, tissu d'ameublement ou autre materiau

similaire inflammable.

• Rester surtout conscient que cet outil peut 6tre dangereux mais qu'il peut produire un

excellent resultat Iorsqu'il est utilise correctement. S'exercer sur des projets simples jusqu'a

acquerir une certaine familiarite avec Ibutil. C'est ainsi que I'on apprendra a ma_triser la

bonne technique.

CONSERVER CES CONSIGNES

POUR UTILISATION ULTERIEURE

Description (Fig. 1)

_AVERTISSEMENT : Ne jamais modifier I'outil ni aucun de ses composants, IIy a risques de

dommages corporels ou materiels.

A. Interrupteur marche/arr_t

B. Orifices d'a6ration

C. B6quille

D. R6gulateur de temp6rature d'air (D26950)

Voyant LCD de temp6rature d'air et bouton de r6glage (D26960)

E. Embout

E Anneau d'accrochage

G. Barillet anti-brfilures

USAGE PRI_VU

Votre pistolet thermique DEWALT a 6t6 congu pour d6caper les peintures, souder les tuyaux,

contracter le PVC, souder et modeler les plastiques ainsi que pour des applications g6n6rales

de s6chage et de fonte.

i_AVERTISSEMENT : NE PAS utiliser I'outil en milieu ambiant humide ou en presence de

liquides ou de gaz inflammables.

Ce pistolet thermique est un outil 61ectrique de professionnels. NE PAS le laisser & la port6e

des enfants. Une supervision est n6cessaire aupr_s de tout utilisateur non exp6riment&

ASSEMBLAGE ET REGLAGES

_AVERTISSEMENT : Pour reduire tout risque de dommages corporels, arr6ter et

debrancher I'outil et le laisser refroidir avant tout reg/age ou avant de retirer ou installer toute

piece ou tout accessoire

Temperature de I'air (Fig. 1)

D26950

La temp6rature de I'air peut _tre ajust6e pour I'adapter & une grande vari6t6 d'applications.

Tournez le r6gulateur de temp6rature d'air (D) vers la droite ou vers la gauche pour 61ever ou

r6duire la temp6rature.

D26960

Appuyez rapidement sur le voyant LCD de temp6rature d'air et bouton de r6glage (D) pour

r6gler la temp6rature d6sir6e par incr6ments de 10 °C (50 °F). Pour augmenter ou r6duire la

temp6rature en continu, maintenez appuy6 le voyant LCD de temp6rature d'air et bouton de

r6glage (D). Rel&chez le voyant Iorsque la temp6rature d6sir6e ou le minimum/maximum est

atteint.

1'6cran affichera la temp6rature r6elle, augmentant ou diminuant, jusqu'& ce que la temp6rature

d6sir6e soit atteinte.

R#GLAGE SANS SOUCl DU SYST#ME DE CONTROLE DE LA TEMP#RATURE

D26960

La temp6rature d6sir6e est enregistr6e par la m6moire de I'outil. Chaque fois que le pistolet

thermique est mis en marche, il ajustera le d6bit d'air sur le r6glage de la derni_re temp6rature

utilis6e. Si vous n'6tes pas st]r de ce param_tre, choisissez syst6matiquement une temp6rature

basse et augmentez-la graduellement jusqu'au param_tre d6sir&

Utilisations

Le tableau ci-dessous propose les r6glages appropri6s & diff6rentes applications.

Param_tre Utilisatio ns

Bas • S6cher la peinture et le vernis

€:lev6 • Souder les plastiques

• D6coller les autocollants

• Cirer ou 61iminer la cire

• S6cher le bois avant le masticage

• Contracter le PVC, envelopper et isoler les tubes

• D6geler les tuyaux gel6s

• Modeler tuyaux et panneaux plastiques

• Desserrer 6crous ou boulons rouill6s ou bloqu6s

• D6caper peinture et laque

• Souder les raccords de plomberie

• Retirer le linoleum ou les carreaux en vinyle

Installation des accessoires ad_quats

I'outil est fourni avec un ensemble d'accessoires destin6s & diff6rentes applications.

Icene Description

Embout conique

50 mm (2 po)

Embout queue de poisson

1. Assurez-vous que I'interrupteur marche/arr_t (A) est bien sur la position ,_O _ et que I'outil

est d6connect6 du secteur. Assurez-vous que I'embout a refroidi.

2. Placez I'accessoire d6sir6 sur I'embout.

But

Souder, braser, contracter les gaines

(chauffe sur de petites surfaces

concentr6es)

S6cher et d6caper la peinture,

Retirer le vinyle ou le linol6um,

d6geler (chauffe sur de larges

surfaces)

FONCTIONNEMENT

i_AVERTISSEMENT : S'assurer SYSTEMATIQUEMENT que I'embout pointe a I'oppose de

I'utilisateur et de tout individu present.

i&AVERTISSEMENT : NE RIEN inserer dans I'embout.

AAVERTISSEMENT : Maintenir I'outil d'une seule main comme illustre en figure 2. Ne pas

placer I'autre main sur les orifices d'aeration (fig. 3).

AVANT TOUT UTILISATION

1. Installez I'accessoire ad6quat, recommand6 pour I'application.

2. Ajustez le r6gulateur de temp6rature d'air (D) sur la temp6rature d'air d6sir6e.

Mise en marche et arr_t de I'appareil (Fig. 4)

1. Poussez I'interrupteur marche/arr_t (A) sur le param_tre de d6bit d'air d6sir6 :

Un d6bit d'air r6duit pour chauffer lentement une piece & d6caper.

I : 8,5 piS/min [50 & 400 °C (120 &750 °F)]

8,8 piS/min [65 & 400 °C (150 &750 °F)] (D26960)

Un d6bit d'air 61ev6pour chauffer rapidement une piece & d6caper.

I1:16 piS/min[50 & 600 °C (120 & 1100 °F)]

17,7 piUmin [65 °C & 600 °C (150 & 1100 °F)] (D26960)

2. Pour arr_ter I'outil, d6placez I'interrupteur (A) sur la position ,_O _. D6connectez I'outil du

secteur et laissez-le refroidir avant de le d6placer ou I'entreposer.

D_capage de la peinture

i_AVERTISSEMENT : Se reporter au paragraphe Avis important sous la section Consignes

De S6curit6 Propres Aux Pistolets Thermiques avant d'utiliser I'outil pour decaper la

peinture.

AAVERTISSEMENT :Ne pas decaper les cadres metalliques de fen6tre car la chaleur pourrait

briser le verre.

• Pour decaper les cadres des autres fen6tres, utiliser un embout de protection du verre.

• Pour prevenir I'ignition de toute surface, ne pas diriger I'outil sur le m6me point trop

Iongtemps.

• Eviter toute accumulation de peinture sur le grattoir, car elle pourrait s'enflammer. Si

necessaire, retirer prudemment la peinture ecaillee du grattoir a I'aide d'un couteau.

1. Rattachez I'accessoire ad6quat.

2. Ajustez le r6gulateur de temp6rature d'air (D) sur 61ev&

3. D6marrez routil en choisissant le d6bit d'air d6sir&

4. Dirigez rair chaud sur la peinture & d6caper.

Pour des r6sultats optimums, d6placez le pistolet thermique lentement mais CONSTAMM ENT,

lat6ralement pour distribuer lachaleur uniform6ment. NE PAS S'ATTARDER OU S'ARRC:TER

SUR UN POINT.

5. Lorsque la peinture ramollit, 61iminez-la & I'aide du grattoir.

SE RAPPELER QUE : des 6clats ou de petites particules de peinture pourraient s'enflammer et

_tre 6ject6s dans les trous ou fentes de la surface & d6caper.

Utilisation fixe (Fig. 1)

Cet outil peut aussi _tre utilis6 en mode fixe.

1. Rabattez la b6quille (C) comme illustr6 en figure 1.

2. Installez I'outil sur un 6tabli stable et de niveau. Assurez-vous que I'outil ne tombera pas.

3. Arrimez le cordon 61ectrique pour 6viter qu'il ne s'emm_le ou fasse tomber I'outil de 1'6tabli.

4. D6marrez routil en choisissant le d6bit d'air d6sir&

Contr_le continu de la chaleur (protection contre les

surcharges)

Lorsque I'outil surcharge, cette fonctionnalit6 protege 1'616mentchauffant contre tout dommage

sans pour autant arr_ter I'outil, et/ou sans p6riode de refroidissement.

1. Lorsque la temp6rature est trop 61ev6e, 1'616mentchauffant s'arr_te automatiquement. Le

moteur continuera de fonctionner et de produire de I'air froid.

2. Lorsque la temp6rature aura suffisamment baiss6 (en quelques secondes), 1'616ment

chauffant se remettra automatiquement en marche.

Anneau d'accrochage (Fig. 1)

i_AVERTISSEMENT :Arr6ter SYSTEMATIQUEMENT le pistolet thermique, le deconnecter du

secteur et le laisser refroidir 30 minutes minimum avant de le deplacer ou de I'entreposer.

Pour faciliter le stockage, I'outil peut _tre accroch6 par son anneau (F). Le pistolet thermique

doit _tre rang6 &I'int6rieur.

Temps de refroidissement

I'embout et les accessoires chauffent 6norm6ment pendant I'utilisation. Arr_tez le pistolet

thermique, d6connectez-le du secteur et laissez-le refroidir 30 minutes minimum avant de le

d6placer ou I'entreposer.

Page 5

REMARQUE:Pourr6duireletempsderefroidissement,mettreI'outilsurunetemp6ratured'air

basseetlelaisserfonctionnerquelquesminutesavantd'arr6terlepistolet.

MAINTENANCE

_AVERTISSEMENT : Pour reduire tout risque de dommages corporels, arr6ter et

debrancher I'outil et le laisser refroidir avant tout reg/age ou avant de retirer ou installer toute

piece ou tout accessoire.

Cet outil DEWALT a 6t6 con_u pour fonctionner Iongtemps avec un minimum de maintenance. Le

fonctionnement continu et satisfaisant de I'outil d6pend d'un entretien ad6quat et d'un nettoyage

r6gulier.

Entretien

_AVERTISSEMENT : Expulser tout debris ou poussiere des events a/'aide d'un jet d'air sec

au moins une fois par semaine. Porter une protection oculaire ANSI Z87.1 (CAN/CSA Z94.3)

et respiratoire NIOSH/OSHA/MSHA adequates pour effectuer cette operation.

i_AVERTISSEMENT : Ne jamais utiliser de solvants ou tout autre produit chimique decapant

pour nettoyer les parties non metalliques de I'outil. Ces produits chimiques pourraient attaquer

les materiaux plastiques utilises. Utilisez un chiffon humidifie avec de I'eau et un savon doux.

S'assurer qu'aucun liquide ne penbtre dans I'outil ; ne jamais immerger aucune partie de I'outil

dans un liquide.

Lubrification

Cet outil 61ectrique ne requiert aucune lubrification additionnelle.

Accessoires

J\AVERTISSEMENT : Comme les accessoires autres que ceux offerts par DEWALT n'ont pas

et6 testes avec ce produit, leur utilisation avec cet appareil pourrait comporter un danger. Pour

reduire tout risque de dommages corporels, seuls des accessoires DEWALT recommandes

doivent 6tre utilises avec cet appareil.

Les accessoires recommand6s pour cet outil sont vendus s6par6ment chez les distributeurs

Iocaux ou dans les centres de r6paration agr66s. Si vous avez besoin d'aide pour Iocaliser ces

accessoires, veuillez contacter DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

MD 21286 ou appeler 1-800-4-DEWALT (1-800-433-9258) ou vous rendre sur notre site www.

dewalt.com.

Rdparations

Pour assurer votre S¢:CURIT¢: et la FIABILIT¢: du produit, toute r6paration, maintenance et tout

r6glage (y compris I'inspection et le remplacement des balais) doivent 6tre effectu6s dans un

centre de r6paration en usine DEWALT, un centre de r6paration DEWALT agr66 ou par tout autre

personnel de r6paration qualifi6. Utilisez syst6matiquement des pi_ces de rechange d'origine.

Garantie limit_ de trois ans

DEWALT r6parera, sans frais, tout produit d6fectueux caus6 par un d6faut de mat6riel ou de

fabrication pour une p6riode de trois ans & compter de la date d'achat. La pr6sente garantie

ne couvre pas les pi_ces dont la d6fectuosit6 a 6t6 caus6e par une usure normale ou rusage

abusif de routil. Pour obtenir de plus amples renseignements sur les pi_ces ou les r6parations

couvertes par la pr6sente garantie, visiter le site www.dewalt.com ou composer le 1-800-4-

DEWALT (1-800-433-9258). Cette garantie ne s'applique pas aux accessoires et ne vise pas les

dommages caus6s par des r6parations effectu6es par un tiers. Cette garantie conf_re des droits

16gaux particuliers & racheteur, mais celui-ci pourrait aussi b6n6ficier d'autres droits variant d'un

6tat ou d'une province & I'autre.

En plus de la pr6sente garantie, les outils DEWALT sont couverts par notre :

CONTRAT D'ENTRETIEN GRATUlT D'UN AN

DEWALT entretiendra I'outil et remplacera les pi_ces us6es au cours d'une utilisation normale et

ce, gratuitement, pendant une p6riode d'un an & compter de la date d'achat (& rexception des

articles de la cloueuse susceptibles de s'user rapidement, comme les joints toriques et les lames

de I'enfonceur), et la

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si I'acheteur n'est pas enti_rement satisfait, pour quelque raison que ce suit, du rendement de

I'outil 61ectrique, du laser ou de la cloueuse DEWALT, celui-ci peut le retourner, accompagn6

d'un re£u, dans les 90 jours & compter de la date d'achat pour obtenir un remboursement

int6gral, sans aucun probl_me.

AM#RIQUE LATINE : Cette garantie ne s'applique aux produits vendus en Am6rique latine.

Pour ceux-ci, veuillez consulter les informations relatives & la garantie sp6cifique pr6sente dans

I'emballage, appeler I'entreprise locale ou consulter le site Web pour les informations relatives

&cette garantie.

REMPLACEMENT GRATUlT DES #TIQUETTES D'AVERTISSEMENT : Si les 6tiquettes

d'avertissement deviennent illisibles ou sont perdues, composer le 1-800-4-DEWALT (1-800-

433-9258) pour les remplacer sans frais.

gЧЧЧЧЧ .EA Cu.

SER,

t , , , _ , TO REDUCETHERJSK

SHOCK,DONOTEXPOSETHiSPRODUCT

TORAiNORMOISTURE.STOREiNDOORS.

READiNSTRUCTiONMANUALBEFORE

USING.ALWAYSUSEPROPEREYEAND

RESPIRATORYPROTECTION,

ELECTRiCA,NO EXPONGA ESTE PRODUCTOALLUVJAO HUMEDAD. ALMACENE AL

iNTERiOR. LEA EL MANUAL DE INSTRUCCIONES ANTES DE UTIUZAB. UT|LICE

SIEMPRE LA PROTECCION OCULARY BESPJBATOR|A DEBiDA. POUR REDUJRE

TOUT RISQUE D'INCENDIE OU DE.CHOCS ELECTRI.QUES,PROTr:GERCE PRODUIT

CONTRE LA PLUJEOUL'HUMJDJTE.ENTREPOSERA LINTERJEUR. LJRELE MANUEL

BE L'UTiLiSATEURAVANT TOOTEUTJLiSATION. PORTERSYSTEMATiQUEMENT ON

SYSTEME DE PROTECTION OCULAiREET DES VOLESRESPiRATOiBESADEQUATS.

DEWALT iNDUSTRiAL TOOL CO., BALTIMORE, MD 21286 USA FOB SERVICE iNFORMATiON, CALL 1 -OO04-DEWALT Www.REWALT.c0m

/ Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada palabra de sepal. Lea el

manual y preste atenci6n a estos simbolos.

APELIGRO: Indica una situacidn de peligro inminente que, si no se evita, provocara la

muerte o lesiones graves.

AADVERTENClA: Indica una situacidn de peligro potencial que, si no se evita, podria

provocar la muerte o lesiones graves.

i_ATENClON : Indica una situacidn de peligro potencial que, si no se evita, puede provocar

lesiones leves o moderadas.

AVISO : Se refiere a una practica no relacionada a lesiones corporales que de no evi-

tarse puede resu/tar en da#os a la propiedad.

SI USTED TIENE ALGUNA PREGUNTA O COMENTARIO ACERCA DE ESTA

O CUALQUIER OTRA HERRAMIENTA DEWALT, LLAMENOS SIN COSTO AL:

1-800-4-DEWALT (1-800-433-9258)

_ PELIGRO: Para reducir el riesgo de lesiones, lea el manual de instrucciones. No ajustarsea/as instrucciones siguientes puede ser causa de choque electrico, incendio y/o lesiones

graves.

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

LEA ESTAS INSTRUCCIONES

Instrucciones de seguridad para el uso de pistolas de

aire caliente

• Para reducir el riesgo de explosidn, NO use en una cabina de rocfo de pintura o dentro de

3,0 metros (10 pies) de una operaci6n de rocfo de pintura.

OFFiRE ORELECTRIC

PARAREDUCiRELRIESGO

DEINCENDIO O DESCARGA

J

• Este producto esta equipado con una clavija polarizada (una pata es mas ancha que la

otra). Para reducir el riesgo de choque electrico, esta clavija s61oencaja de una forma en los

enchufes polarizados. Si la clavija no se acopla al enchufe, inviertala. Si a#n as[ no entra,

comunfquese con un electricista calificado. No modifique ni cambie nunca la clavija.

• NO use esta herramienta para quitar pinturas de plomo. Los pedazos, residuos y gases

de pintura pueden contener plomo, que es venenoso.

• Las areas ocultas, como detras de paredes o cielorrasos, debajo de pisos, tablas de plaf6n u

otros paneles, pueden contener materiales inflamables que podrfan encenderse al usar una

pistola de aire caliente cuando trabaje en estos lugares. Estos materiales podrfan encenderse

en forma imperceptible al comienzo, Io que podrfa resultar en dai_os de propiedad y lesiones

a personas. Cuando trabaje en este tipo de lugar, mantenga la pistola de aire caliente en

movimiento, hacia adelante y hacia atras. El detenerse o pausar en un lugar podrfa prender

el panel o los materiales que se encuentran detras del mismo.

NOTA: Estas pistolas de aire caliente son capaces de emitir temperaturas superiores a los

1000 °Fahrenhe#

• NO use esta herramienta como secadora de pelo.

• NO use esta herramienta para calentar comida.

• NO deje la pistola de aire caliente sobre superficies inflamables mientras este en operaci6n

o inmediatamente despues de apagarla. Deje que la herramienta se enfrfe bien antes de

guardarla. Siempre ponga la pistola de aire caliente sobre una superficie plana y nivelada de

modo que la punta quede hacia arriba.

• NO Io use en frente de materiales explosivos.

• Afirme y fije cualquier artfculo movible mientras raspe.

• NUNCA obstruya la entrada de aireo la salida de aire de la pistola para evitar la acumulaci6n

excesiva de calor, Io cual puede dai_ar la herramienta.

• Aseg#rese de dirigir la salida de aire caliente en una direcci6n segura; alejela de otras

personas o de objetos inflamables.

• NO quite la tapa del barril de aire caliente durante el uso.

• MANTENGA LOS DEDOS ALEJADOS DE LA PUNTA DE METAL; se calienta mucho y

sigue caliente 30 minutos despues de cada uso. Use guantes para protegerse /as manos.

• SIEMPRE mantenga la punta alejada de/cable.

• NO toque la punta contra ninguna superficie mientras este en operaci6n o al poco tiempo de

haber dejado de operarla.

• NO introduzca nada por la punta, porque podrfa causar un choque electrico. No mire dentro

de la punta cuando la unidad esta prendida por la producci6n de altas temperaturas.

• Las astillas y partfculas peque#as de pintura pueden encenderse y luego introducirse con el

aire de la pistola dentro de orificios y ranuras en la superficie a remover.

• NO aplique el aire caliente sobre la misma superficie durante un perfodo largo.

• NO queme la pintura. Use la espatula incluida y guarde la punta por Io menDs a 25 mm (1

pulg.) de una superficie pintada. Si trabaja en el sentido vertical, trabaje hacia abajo para que

no caiga la pintura dentro de la herramienta y la parte quemada.

• NO permita la adherencia de pintura a la punta o espatula. Puede encenderse.

• SIEMPRE use espatulas y cuchillos de buena calidad cuando remueva pintura.

• NO use la pistola de aire caliente con removedores de pintura qufmicos.

• NO use/as puntas de accesorio como espatulas.

• NO apunte el fluiD de aire de la pistola de aire caliente directamente sobre vidrio. Puede rajar

el vidrio y podrfa resultar en dai_os de propiedad y lesiones corporales.

• Mantenga las etiquetas y las placas nominales, porque incluyen informacidn importante.

• Coloque la pistola de aire caliente sobre una superficie estable y pareja si no la tiene a la

mano. Coloque el cable en un lugar que no va a volcar la pistola de aire caliente.

• Este siempre atento a que esta herramienta puede encender materiales inflamables y

ablandar o derretir otros. No importa que tarea este desempei_ando, siempre proteja y

mantenga alejados de la pistola aquellos materiales.

• Es posible que en ocasidn note algo de humo salir de la herramienta una vez apagada. Este

es el resultado del calentamiento de residuos de aceite depositados en el elemento de calor

durante el proceso de fabricacidn.

• Use proteccion ocular y otro equipo de seguridad.

• No abuse el cable. Nunca use el cable para cargar, jalar o desenchufar la herramienta.

Mantenga el cable alejado de las fuentes de calor, el aceite, las orillas afiladas o las

piezas en movimiento. Los cables da_ados o enredados aumentan el peligro de choque

electrico.

• Si emplea una herramienta electrica en el exterior, use un cable de extension adecuado

para el uso afuera. El uso de un cable de extensi6n para el exterior reduce el peligro de

choque electrico.

• No exponga la herramienta a condiciones de humedad o Iluvia. El agua que entra dentro

de una herramienta aumenta el riesgo de choque electrico.

• No ponga en peligro su estabilidad. Mantengase siempre bien apoyado y equilibrado.

Esto permite controlar mejor la herramienta si se produce alg#n imprevisto.

• Cuando no las utilice, guarde las herramientas fuera del alcance de los nilus y no

permita la operacion en manos de usuarios que no conocen la herramienta o las

instrucciones. Las herramientas son peligrosas en manos de usuarios no capacitados.

• Su herramienta debe de ser reparada por personal de reparacion cafificado usando

solo repuestos originales. Esto asegura la seguridad de la herramienta.

• Las rejillas de ventilacion suelen cubrir piezas en movimiento, por Io que se debe

evitar el contacto con elias. Las piezas en movimiento pueden atrapar prendas de vestir

sueltas, joyas o cabellos largos.

• Los hilos del alargador deben ser de un calibre apropiado (AWG o American Wire

Gauge) para su seguridad. Mientras menor sea el calibre de/hilo, mayor la capacidad

de/cable. Es decir, un hilo calibre 16 tiene mayor capacidad que uno de 18. Un cable de

un calibre insuficiente causara una cafda en la tensi6n de la Ifnea dando por resultado

una perdida de energfa y sobrecalentamiento. Cuando se utilice mas de un alargador para

completar el largo total, aseg#rese que los hilos de cada alargador tengan el calibre mfnimo.

La tabla siguiente muestra el tama#o correcto a utilizar, dependiendo de la Iongitud de/cable

y de/amperaje nominal de la placa de identificaci6n. Si tiene dudas sobre cua/calibre usar,

use un calibre mayor. Cuanto mas peque#o sea el n#mero de/calibre, mas resistente sera el

cable.

Calibre minimo para cables

de alimentacion

Voltios LarDo total del cable en metros (pies)

Mas

Amperaje

de

o

6

lO

12

No mas de

6

10

12

16

120V 7.6 (25) 30.5 (100) 45.7 (150)

240V 15.2 (50) 61.0 (200) 91.4 (300)

18

18

16

14

15.2 (50)

30.5 (100)

AWG

16

16

16

12

16 14

14 12

14 12

No recomendado

_&ADVERTENCIA: Siempre use protecci6n ocular. TodD usuario o persona circunstante

debera utilizar protecci6n ocular en conformidad con ANSI Z87.1.

AADVERTENClA: Siempre use proteccion auditiva personal en conformidad con ANSI

$12.6 (S3.19) durante el uso de este aparato. Bajo algunas condiciones y duraciones de uso,

el ruido producido por este producto puede contribuir a la perdida auditiva.

i_ADVERTENClA: Parte de/polvo generado al lijar, serrar, esmerilar o taladrar, as[ como

al realizar otras actividades de/ sector de la construcci6n, contienen productos qufmicos

que pueden producir cancer, defectos congenitos u otras afecciones reproductivas. Algunos

ejemplos de estos qufmicos son:

• plomo procedente de pinturas basadas en plomo,

• 6xido de silicio cristalino procedente de ladrillos, cemento y otros productos de

mamposterfa, y

• arsenico o cromo procedente de madera tratada qufmicamente (CCA).

Su riesgo de exposici6n a estos qufmicos varfa, dependiendo de la frecuencia con la cual realiza

usted este tipo de trabajo. Para reducir su exposici6n a estos qufmicos, trabaje en un lugar

con buena ventilaci6n y trabaje con equipo de seguridad aprobado, como mascaras antipolvo

especialmente dise#adas para filtrar partfculas microsc6picas.

AADVERTENClA: USE SIEMPRE LENTES DE SEGURIDAD. Los anteojos de uso diario

NO son anteojos de seguridad. Utilice ademas una mascara para la cara o guardapolvo si

la operaci6n de corte genera demasiado polvo. Todos los usuarios y personas circunstantes

DEBEN Ilevar protecci6n ocular en conformidad con:

• Protecci6n ocular ANSI Z87.1 (CAN/CSA Z94.3),

Page 6

• Proteccidn auditiva ANSI S12.6 (S3.19),

• Protecci6n respiratoria NIOSH/OSHA/MSHA.

La etiqueta de su herramienta puede incluir los siguientes sfmbolos. A continuacidn se

indican los sfmbolos y sus definiciones:

V.................... voltios

Hz .................. hercios

min ................. minutos

corriente directa

@ ................... Construccidn de clase I

(tierra)

[] .................... Construccidn de clase II

(doble aislamiento)

sfpm .............. pies de superficie

por minuto (sfpm)

LAS PERSONAS QUE REMUEVEN PINTURA DEBEN SIEMPRE DE RESPETAR ESTAS

PAUTAS:

i_,ADVERTENCIA: Es importante tener mucho cuidado al remover pintura. Los pedazos,

residuos y gases de pintura pueden contener plomo, que es venenoso. Cualquier pintura

aplicada antes de 1977 puede contener plomo, y es probable que la pintura aplicada a casas

construidas antes de 1950 contenga plomo. Una vez depositada sobre una superficie, el

contacto de las manos con ella puede resultar en una ingestidn de plomo si se Ileva las manos

a la boca. La exposicidn a incluso niveles bajos de plomo puede causar dafios irreversibles al

cerebro y al sistema nervioso; los nifios y bebes no natos son particularmente vulnerables.

Antes de comenzar el proceso de remover pintura, deberfa determinar si la pintura a remover

contiene plomo o no. Esto puede hacerlo su oficina local de la salud o un profesional que use un

analizador de pintura para verificar el contenido de plomo de la pintura a remover. LA PlNTURA

EN BASE A PLOMO SOLO DEBE SER REMOVIDA POR UN PROFESIONAL Y NO DEBER[A

SER REMOVIDA CON UNA HERRAMIENTA QUE EMITA AIRE CALIENTE. La persona que

quita la pintura debe de respetar estas pautas:

1. Coloque la pieza de trabajo afuera. Si esto no es posible, el area de trabajo debe de estar

bien ventilado. Abra las ventanas y coloque un ventilador de extraccidn dentro de una de

elias. Aseg#rese que el ventilador desplaza el aire de adentro a afuera.

2. Quite o cubra alfombras, tapetes, muebles, ropa, utensilios de cocina y conductos de aire.

3. Coloque las laminas de proteccidn en el area de trabajo para contener astillas opedazos de

pintura. Vista ropa protectora como camisas de trabajo adicionales, overoles y cascos.

4. Trabaje en un cuarto a la vez. Debe de quitar o colocar el mobiliario en medic del cuarto y

cubrirlo. El area de trabajo debe de ser aislado del resto de la vivienda sellando las puertas

con laminas de proteccidn.

5. Nifios, mujeres embarazadas oprobablemente embarazadas y madres lactantes no deberfan

de estar presentes en el area de trabajo hasta que el trabajo haya sido completado.

6. Utilice una mascara de respiracidn antipolvo o una mascara de respiracidn de doble filtro

(polvo y humo) que ha sido aprobado pot Occupational Safety and Health Administration

(OSHA), National Institute of Safety and Health (NIOSH) o United States Bureau of Mines.

Puede obtener estas mascaras y estos filtros reemplazables en las grandes ferreterfas.

Aseg#rese que la mascara le queda bien. Las barbas y el vello de la cara pueden

impedir un sello correcto de la mascara. Cambie los filtros a menudo. LAS MASCARAS

DESECHABLES DE PAPEL NO SON ADECUADAS.

7. Tenga cautela cuando opere la pistola de aire caliente. La pistola de aire caliente debe de

permanecer en movimiento porque el exceso de calor genera humos que el operador podrfa

inhalar.

8. Mantenga la comida y las bebidas fuera del area de trabajo. Debe de lavarse las manos, los

brazos y la cara y enjuagar la boca antes de comer o de beber. No fume o mastique chicle

o tabaco en el area de trabajo.

9. Limpie el suelo de pintura y polvo acumulados con un trapeador mojado. Use un trapo

mojado para limpiar las paredes, umbrales y las superficies que acumularon pintura o

polvo. NO LIMPIE CON UNA ESCOBA, UN TRAPO SECO 0 UNA ASPIRADORA. Use un

detergente con un alto nivel de fosfato o fosfato tribasico de sodio (TSP) para lavar y trapear

las areas.

10. Cuando finalice cada sesidn de trabajo, coloque los pedazos de pintura y los restos dentro

de una bolsa de plastico doble, cierre la bolsa con cinta adhesiva o un lazo de enrollo y

deshagase de la bolsa correctamente.

11. Quftese la ropa protectora y los zapatos de trabajo dentro del area de trabajo para no

esparcir el polvo dentro de la vivienda. Lave la ropa de trabajo pot separado. Limpie los

zapatos con un trapo mojado que puede lavar con la ropa de trabajo. Lavese el cabello y el

cuerpo con jabdn y agua.

A.................. amperios

W................. vatios

* ............... corriente altema

no ................no velocidad sin carga

G ................. terminal de conexidn a tierra

...............sfmbolo de advertencia de

seguridad

BPM ............ golpes pot minuto

.../min ..........revoluciones o

inversiones

por minuto

AVISO IMPORTANTE

Para que esta herramienta sirva de removedor de pintura eficaz, debe de producir temperaturas

extremadamente elevadas. Por Io tanto, el removedor es capaz de prender papel, madera,

residuos de pintura y de barniz y materiales similares.

Cuando se familiarice mas con la herramienta y desarrolle la tecnica apropiada, reducira

enormemente el peligro de causar un incendio accidentalmente, iAI establecer la tecnica

apropiada, el mejor metodo es la PR,4CTICA! Trabaje en proyectos simples para remover la

pintura, preferiblemente afuera, hasta que "sepa" cdmo usar el removedor de manera segura y

eficaz.

CUANDO PRACTIQUE, RESPETE LAS PAUTAS SIGUIENTES PARA SU SEGURIDAD

• Aseg#rese siempre que la herramienta esta apagada y desenchufada sin supervisidn.

• Limpie la cuchilla de la espatula a menudo durante el uso. La acumulacidn de residuo sobre

la cuchilla es sumamente inflamable.

• Experimente para encontrar la distancia ideal entre la punta de la herramienta y la superficie

de trabajo. Esta distancia [25.4 mm-50.8 mm (1-2 pulg.)] puede cambiar dependiendo del

material que desea remover.

• La pistola de aire caliente siempre debe de permanecer delante de la cuchilla del

removedor.

• A medida que complete el trabajo, limpie los pedazos de pintura suelta acumulados alrededor

del area de trabajo.

• Cuando trabaje adentro, mantengase alejado de cortinas, papeles, tapizado y materiales

inflamables parecidos.

• Sobre todo, no se olvide que este aparato es serio y capaz de producir resultados excelentes

si Io usa correctamente. Practique con proyectos simples hasta que se sienta a gusto con su

removedor. Sdlo entonces habra dominado la tecnica apropiada.

GUARDE ESTAS INSTRUCCIONES

PARA SU FUTURA UTILIZACION

Descripcidn (Fig. 1)

AADVERTENCIA: Nunca cambie la herramienta o piezas de la herramienta. Podrfa producir

lesiones corporales o dafios.

A. Interruptor de encendido y apagado

B. Orificios de ventilaci6n

C. Pie de apoyo

D. Bot6n de ajuste de la temperatura del aire (D26950)

Ajustador e indicador de latemperatura del aire con pantalla de cristal liquido (D26960)

E. Punta

E Anillo para colgar la herramienta

G. Tapa del barril de aire caliente

USO DEBIDO

Su pistola de aire caliente DEWALT ha sido diseSada para remover pintura, soldar tuberia,

encoger PVC, soldar y torcer plasticos y secar y descongelar en general.

i_ADVERTENCIA: NO utilice la herramienta en condiciones h_medas o en la presencia de

Ifquidos o gases inflamables.

Estas pistolas de aire caliente son herramientas el_ctricas profesionales. NO permita que un

niSo juegue con ellos. 'Si el operador no tiene experiencia operando esta herramienta, su uso

debera ser supervisado.

MONTAJE Y AJUSTES

i_ADVERTENCIA: Para reducir el riesgo de lesiones, apague y desenchufe la herramienta

y permita que se enfrie antes de realizar ajustes o de quitar o poner accesorios.

Temperatura del aire (Fig. 1)

D26950

Puede ajustar la temperatura del aire para que corresponda a una gran variedad de usos. Gire

el bot6n de ajuste de la temperatura del aire (D) hacia la derecha o la izquierda para aumentar

o disminuir el nivel de calor.

D26960

Presione y suelte el ajustador e indicador de la temperatura del aire con la pantalla de cristal