Page 1

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Si tiene dudas o comentarios, contáctenos.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

1-800-4-DEWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

(APR10) Part No. N070577 D26676, D26677 Copyright © 2010 DEWALT

The following are trademarks for one or more D

scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

The definitions below describe the level of severity for each signal word. Please read

the manual and pay attention to these symbols.

result in death or serious injury.

result in death or serious injury.

result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided,

may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-D

WARNING: To reduce the risk of injury, read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and instructions Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

c) Keep children and bystanders away while operating a power tool. Distractions can

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

f) If operating a power tool in a damp location is unavoidable, use a ground fault

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

b) Use personal protective equipment. Always wear eye protection. Protective equipment

c) Prevent unintentional starting. Ensure the switch is in the off position before

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

EWALT power tools: the yellow and black color

Defi nitions: Safety Guidelines

DANGER: Indicates an imminently hazardous situation which, if not avoided, will

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

EWALT (1-800-433-9258).

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

cause you to lose control.

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

increase the risk of electric shock.

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric

shock.

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury.

such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have

the switch on invites accidents.

a key left attached to a rotating part of the power tool may result in personal injury.

D26676, D26677

3-1/4" (82 mm) Hand Planer

Raboteuse portative de 82 mm (3-1/4 po)

Cepilladora manual de 82 mm (3-1/4 pulg.)

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce

dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Safety Instructions for Planers

• Wait for the cutter to stop before setting the tool down. An exposed cutter may engage

the surface leading to possible loss of control and serious injury

• Use clamps or another practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body leaves it unstable and may lead to

loss of control.

• Be sure the voltage agrees with specific data on the nameplate.

• Make certain that the switch is in the off position before connecting plug to a power source.

• Be sure to switch OFF immediately if tool is jammed in work.

• Be sure tool is set for correct depth before turning switch to ON.

• Be sure to maintain tool with care. Follow instructions for lubricating and changing

accessories.

• Stay alert – never operate the unit when tired or under the influence of drugs, alcohol, or

medication.

• Be sure to store tool in a clean dry place after disconnecting from power source.

• Do not use in dangerous environments. Do not use near flammable substances, in damp or

wet locations, or expose to rain.

• Be sure that the blades are mounted as described in the instruction manual and check that

all screws are firmly tightened before connecting unit to power source.

• Keep air vents unobstructed for proper motor cooling.

• DO NOT lay tool down on shoe when the blades are exposed. This can chip the blades.

• Keep side discharge chute unobstructed at all times.

• Never reach under the tool for any reason unless it is turned off and UNPLUGGED. BLADES

ARE EXPOSED AND EX TREMELY SHARP.

• Use this tool for working with wood and wood products only.

• Never operate without securely holding the front handle.

• Always operate planer with two hands.

• Planer blades are extremely sharp. Handle with great care.

• Clean out your tool often, especially after heavy use.

• Air vents often cover moving parts and should be avoided. Loose clothes, jewellery or

long hair can be caught in moving parts.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. When using more than one extension to

make up the total length, be sure each individual extension contains at least the minimum

wire size. The following table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also

use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Always wear proper personal hearing protection that conforms to ANSI

S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V ......................volts A ......................amperes

Hz ....................hertz W .....................watts

min ..................minutes

...............direct current ...................alternating or direct current

....................Class I Construction

........................(grounded) ....................earthing terminal

....................Class II Construction ....................safety alert symbol

........................(double insulated) BPM ................beats per minute

…/min .............per minute RPM ................revolutions per minute

IPM..................impacts per minute

Not More

Than

120V

240V

25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

................... alternating current

n

o ....................no load speed

SAVE THESE INSTRUCTIONS

Page 2

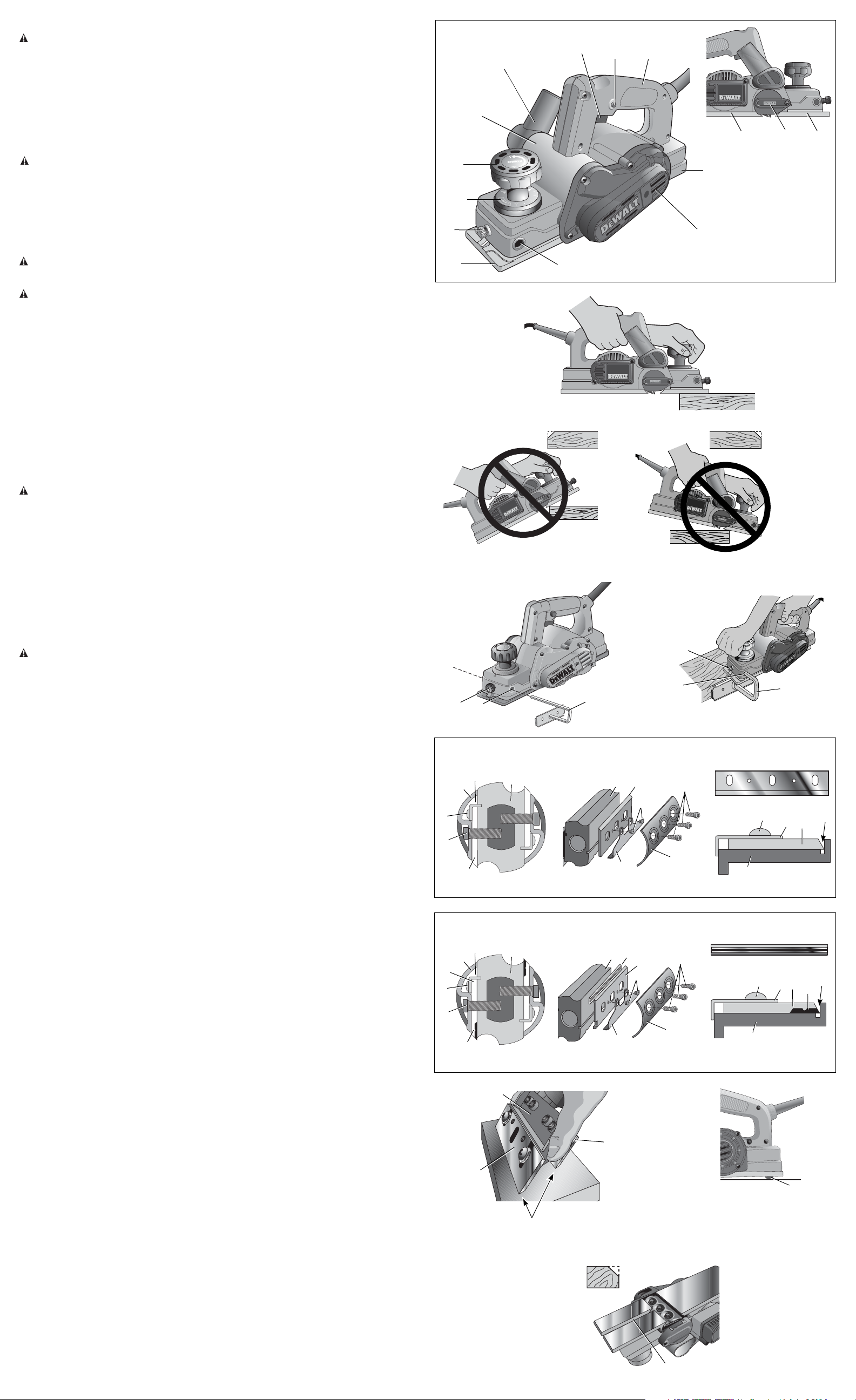

COMPONENTS (Fig. 1)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result.

A. On/Off switch H. Rabbet fence tightening knob

B. Lock-on button I. Planing depth graduation

C. Main handle J. Planing depth adjustment knob/front handle

D. Rear shoe K. Chip discharge chute

E. Drive belt cover L. Dust adapter

F. Hole for rabbet fence M. Rabbetting cover

G. Front shoe

OPERATION

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories.

Motor

Be sure your power supply agrees with the nameplate marking. Voltage decrease of more than

10% will cause loss of power and overheating. D

EWALT tools are factory tested; if this tool does

not operate, check power supply.

Switch (Fig. 1)

CAUTION: Check that the tool is not locked ON before connecting it to a power supply. If the

trigger switch is locked ON when the tool is connected to the power supply, it will start

immediately. Damage to your tool or personal injury may result.

CAUTION: Allow the tool to reach full speed before touching tool to the work surface. Lift the

tool from the work surface before turning the tool off.

To start the planer depress the on/off switch (A).

To turn the planer off, release the on/off switch.

LOCK-ON BUTTON

The tool can be locked on for continuous use. To lock the tool on, depress the trigger switch (A)

and push in the lock-on button (B). Hold the lock-on button in as you gently release the trigger

switch. The tool will continue to run.

To turn the tool off from a locked-on position, squeeze and release the trigger once.

Adjusting the Planing Depth (Fig. 1)

To adjust the depth of cut, turn the planing depth adjustment knob (J). Each click is equal to

0.1 mm of depth up to the maximum depth of cut of approximately 1/16" (1.6 mm).

It is recom mended that test cuts be made in scrap wood after each re-adjustment to make sure

that the desired amount of wood is being removed by the planer. Several shallow passes (rather

than one deep one) will produce a smoother finish.

Planing (Fig. 1–4)

CAUTION: Allow the tool to reach full speed before touching tool to the work surface. Lift the

tool from the work surface before turning the tool off.

Hold the planer in the correct position with one hand on the front handle (J) and the other hand

on the main handle (C) as shown in Figure 2. Place the front shoe (G) on the surface to be

planed, making certain that the cutting blades are not touching the surface. Push down firmly on

the front handle of the planer so that the front shoe is ABSOLUTELY FLAT on the work surface.

Squeeze the trigger switch and allow the motor to reach full speed before touching the planer

blades to the work surface.

Move the tool slowly into the work and maintain downward pressure to keep the planer flat. Be

particularly careful to keep the tool flat at the beginning and the end of the work surface.

Planing Tip: For a smoother appearance, fasten a piece of scrap wood to the end of the piece

you are planing. Don’t stop planing until the cutting blades of the planer are past your workpiece

and into the scrap material.

Rabbet Fence (Fig. 5, 6)

WARNING: Allow the tool to reach full speed before touching tool to the work surface. Lift the

tool from the work surface before turning the tool off.

The rabbet fence (N) is used for optimum tool control on narrow workpieces and can be installed

on either side of your planer. The planer makes rabbet cuts up to 23/64" (9 mm).

TO INSTALL RABBET FENCE

1. Loosen the rabbet fence tightening knob (H).

2. Slide the crossbar on the rabbet fence (N) into the hole (F) on the side of the planer as shown

in Figure 5.

3. Set the width of cut by adjusting the edge guide across the width of the shoe.

4. Securely tighten rabbet fence tightening knob.

NOTE: The rabbet fence should be below the planer when installed correctly as shown in

Figure 6

TO MAKE A RABBET CUT

1. Turn the rabbet fence tightening knob (H) to adjust the desired width of cut.

2. Make several cuts until the desired depth is reached.

NOTE: It will be necessary to make quite a few cuts for most rabbet applications.

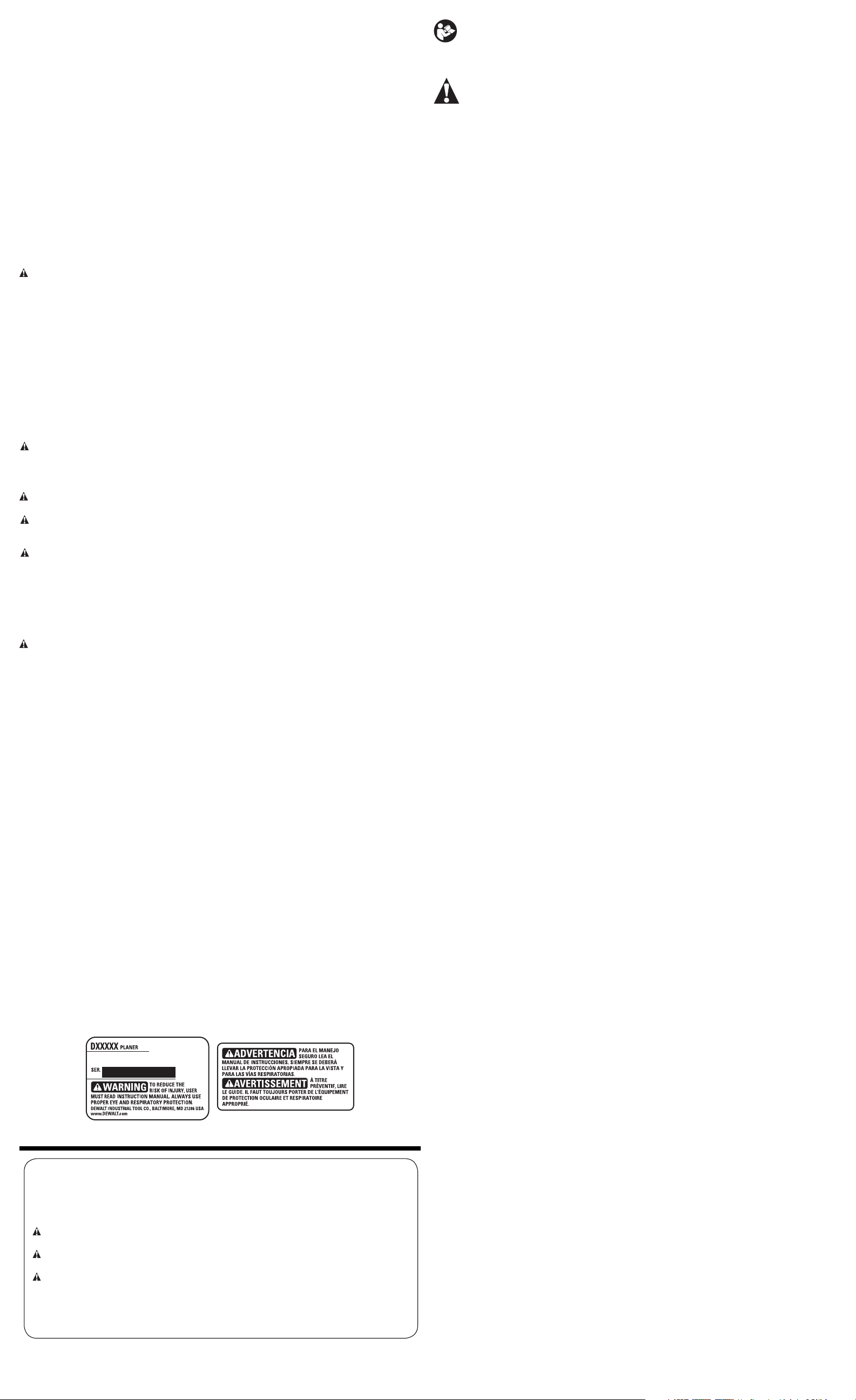

To Change Blades (Fig. 7, 8)

The planer is capable of using high-speed steel and carbide blades. Be sure to check the planer

to verify which blade it is fitted with.

HIGH-SPEED STEEL BLADES (FIG. 7)

D26676

1. To Remove Blade from Planer (Fig. 7B)

a. Loosen and remove the three hex head screws (O) with the 9 mm hex wrench provided.

Remove the drum cover (P) from the drum (Q).

b. Cautiously remove the guide bar/high-speed steel blade assembly (V, U, T).

2. To Adjust Blade Using Gauge Plate (provided with tool) (Fig. 7C)

a. Place the guide bar/high-speed steel blade assembly on the gauge plate (R) with the

cutting edge of the high-speed steel blade flush against the gauge plate inside wall (S).

The heel of the guide bar (T) will overlap the end of the gauge plate (R).

b. Loosen the two cross-shaped screws (U) with the wrench provided.

c. Simultaneously push the high-speed steel blade (V) and the guide bar (T) into the gauge

plate inside wall (S), making sure that the blade is held firmly against the gauge plate

inside wall (S) and securely tighten cross-shaped screws (U).

3. To Reinstall Blade (Fig. 7A, 7B)

a. Cautiously remove the adjusted guide bar/high-speed steel blade assembly from the

gauge plate (R) and place the heel of the guide bar (T) into the groove in the drum (Q).

b. Set the drum cover (P) over the adjusted guide bar/high-speed steel blade assembly and

securely tighten the three hex screws (O) to the drum.

4. Repeat procedure for the other blade.

NOTE: If your planer is not fitted with high-steel blades, the sharpening holder (Y) required to

sharpen high-speed blades is available at additional cost from your local D

service center.

REVERSIBLE CARBIDE BLADES (FIG. 8)

D26677

1. To Remove Blade from Planer (Fig. 8B)

a. Loosen and remove the three hex head screws (O) with the 9 mm hex wrench provided.

Remove the drum cover (P) from the drum (Q).

b. Remove the blade carrier/guide bar assembly (T, U, X, W). Carefully remove the carbide

blade (W).

2. To Adjust Blade Using Gauge Plate (provided with tool) (Fig. 8C)

a. Cautiously place the carbide blade on the gauge plate (R) with the grooved side of the

carbide blade facing up. Either edge of the reversible carbide blade can be set flush

against the gauge plate inside wall (S).

b. Place the blade carrier/guide bar assembly on the blade so that the rib on the blade

carrier (X) fits into the groove on the carbide blade (W). The heel of the blade carrier (X)

will overlap the end of the gauge plate (R).

c. Loosen the two cross-shaped screws (U) with the wrench provided.

d. Simultaneously push the blade carrier (X) and the guide bar (T) into the gauge plate inside

wall (S), making sure that the carbide blade (W) is held firmly against the gauge plate

inside wall (S) and securely tighten the two cross-shaped screws (U).

3. To Reinstall Blade (Fig. 8A, 8B)

a. Remove the adjusted blade carrier/guide bar assembly from the gauge plate (R) and

place the heel of the guide bar (T) into the groove on the drum (Q).

EWALT authorized

FIG. 1

J

H

G

FIG. 3

FIG. 5

H

FIG. 7

U

O

FIG. 8

X

U

O

FIG. 9

A

L

K

I

F

FIG. 2

INCORRECT

INCORRECT

INCORRECTO

F

LAME EN ACIER À COUPE RAPIDE / HOJA DE ACERO DE ALTA VELOCIDAD

T

P

V

T

P

W

V

Q

FIG. 7A FIG. 7B FIG. 7C

CARBIDE BLADE / LAME AU CARBURE / HOJA DE CARBURO

Q

FIG. 8A

Y

BLADE EDGE

BORD DE LAME

BORDE DE LA HOJA

FIG. 11

B

N

HIGH-SPEED STEEL BLADE /

Q

FIG. 8B FIG. 8C

V

C

D

D

E

CORRECT

CORRECT

CORRECTO

FIG. 4

FIG. 6

H

F

Q

V

U

T

W

X

U

T

O

P

O

P

FIG. 10

A1

INCORRECTO

U

R

U

R

M

INCORRECT

INCORRECT

N

T

V

W

T

X

Z

G

S

S

Page 3

b. Place the drum cover (P) over the blade carrier/guide bar assembly. Loosely screw the

three hex screws (O) into the drum (Q) so that there is a small gap between the drum

and the blade carrier (X).

c. Slide the carbide blade between the drum (Q) and the blade carrier (X) so that the rib on

the blade carrier sets into the groove in the blade.

d. Center the carbide blade (W) under the blade carrier (X) making sure the blade is clear

of the tool housing on both sides.

e. Securely tighten the three hex screws (O) to the drum.

4. Repeat procedure for the other blade.

NOTE: If your planer is not fitted with carbide blades, the blade carrier (X) required for carbide

blades is available at additional cost from your local D

EWALT authorized service center.

Sharpening High-Speed Steel Blades (Fig. 9)

NOTE: Carbide blades cannot be sharpened.

1. Fasten the blades to the sharpening holder (Y). Make sure both blade edges (V) are facing

the same direction.

2. Place the blade edges so they rest flat on the grinding stone (not included).

3. Firmly grip the sharpening holder and move it back and forward to sharpen the blades (V).

Kickstand (Fig. 10)

Your planer is equipped with a kickstand (Z) that automatically lowers when the tool is lifted from

the work surface allowing the planer to set on the work surface without the blade touching it.

When planing, the kickstand raises as the tool is pushed forward through the material.

CAUTION: Do not lock the trigger switch on and engage the kickstand. The vibration of the

running motor will cause the planer to move, possibly falling from the workpiece.

Edge Chamfering (Fig. 11)

Your planer has a precision machined chamfering groove (A1) in the front shoe for planing along

a corner of the wood. The width of the groove is 4.5 to 8 mm. It’s a good idea to try a piece of

scrap wood before doing finish work.

Dust Adapter (Fig. 1)

A dual adapter (L) is available for the hand planer. The adapter can be attached to both 1"

(inside diameter) and 35 mm (outside diameter) vacuum hose connectors for dust collection.

Insert the adapter (L) onto chip discharge chute (K) and attach the appropriate vacuum hose

connector to the adapter.

If the adapter is not included with your planer please contact your local D

service center to obtain one at additional cost.

EWALT authorized

MAINTENANCE

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments

or accessories.

Cleaning

WARNING: Clean the chip discharge chute (K) regularly. ALWAYS WEAR SAFETY

GLASSES.

WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear

proper ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA

respiratory protection when performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Lubrication

Your power tool requires no additional lubrication.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only D

Recommended accessories for use with your tool are available at extra cost from your local dealer

or authorized service center. If you need assistance in locating any accessory, please contact

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT

(1-800-433-9258) or visit our website www.dewalt.com.

EWALT, recommended accessories should be used with this product.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including

brush inspection and replacement) should be performed by a D

a DEWALT authorized service center or other qualified service personnel. Always use identical

replacement parts.

EWALT factory service center,

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-D

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, D

D

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

If you are not completely satisfied with the performance of your D

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-D

EWALT (1-800-433-9258) for a free replacement.

EWALT (1-800-433-9258). This warranty does not apply to

EWALT tools are covered by our:

1 YEAR FREE SERVICE

90 DAY MONEY BACK GUARANTEE

EWALT Power Tool, Laser, or

Défi nitions : lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur

employé. Veuillez lire le mode d’emploi et porter une attention particulière à ces

symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas

évitée, causera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, pourrait se solder par un décès ou des blessures graves.

ATTENTION : indique une situation potentiellement dangereuse qui, si elle n’est

pas évitée pourrait se solder par des blessures mineures ou modérées.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n’est fait pour l’éviter, pourrait poser des risques de dommages

matériels.

POUR TOUTE QUESTION OU TOUT COMMENTAIRE RELATIF À CET OUTIL OU À

PROPOS DE TOUT AUTRE OUTIL D

(1-800-433-9258).

EWALT, COMPOSER SANS FRAIS LE : 1-800-4-DEWALT

AVERTISSEMENT : afin de réduire le risque de blessures, lire le mode d’emploi de

l’outil.

Avertissements de sécurité généraux pour les outils

électriques

AVERTISSEMENT! Lire tous les avertissements de sécurité et les directives. Le

non-respect des avertissements et des directives pourrait se solder par un choc

électrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS ET TOUTES

LES DIRECTIVES POUR UN USAGE ULTÉRIEUR

Le terme « outil électrique » cité dans les avertissements se rapporte à votre outil électrique à

alimentation sur secteur (avec fil) ou par piles (sans fil).

1) SÉCURITÉ DU LIEU DE TRAVAIL

a) Tenir l’aire de travail propre et bien éclairée. Les lieux encombrés ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu déflagrant, tel qu’en

présence de liquides, de gaz ou de poussières inflammables. Les outils électriques

produisent des étincelles qui pourraient enflammer la poussière ou les vapeurs.

c) Éloigner les enfants et les personnes à proximité pendant l’utilisation d’un outil

électrique. Une distraction pourrait en faire perdre la maîtrise à l’utilisateur.

2) SÉCURITÉ EN MATIÈRE D’ÉLECTRICITÉ

a) Les fiches des outils électriques doivent correspondre à la prise. Ne jamais

modifier la fiche d’aucune façon. Ne jamais utiliser de fiche d’adaptation avec un

outil électrique mis à la terre. Le risque de choc électrique sera réduit par l’utilisation de

fiches non modifiées correspondant à la prise.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des tuyaux,

des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc électrique est

plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à l’humidité. La pénétration de l’eau

dans un outil électrique augmente le risque de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou débrancher un outil électrique. Tenir le cordon éloigné de

la chaleur, de l’huile, des bords tranchants et des pièces mobiles. Les cordons

endommagés ou enchevêtrés augmentent les risques de choc électrique.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge

convenant à cette application. L’utilisation d’une rallonge conçue pour l’extérieur réduira

les risques de choc électrique.

f) S’il est impossible d’éviter l’utilisation d’un outil électrique dans un endroit humide,

brancher l’outil dans une prise ou sur un circuit d’alimentation dotés d’un disjoncteur de

fuite à la terre (GFCI). L’utilisation de ce type de disjoncteur réduit les risques de choc

électrique.

3) SÉCURITÉ PERSONNELLE

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un outil

électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Un simple moment d’inattention

en utilisant un outil électrique peut entraîner des blessures corporelles graves.

b) Utiliser des équipements de protection individuelle. Toujours porter une protection

oculaire. L’utilisation d’équipements de protection comme un masque antipoussière, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque la

situation le requiert réduira les risques de blessures corporelles.

c) Empêcher les démarrages intempestifs. S’assurer que l’interrupteur se trouve à la

position d’arrêt avant de relier l’outil à une source d’alimentation et/ou d’insérer un

bloc-piles, de ramasser ou de transporter l’outil. Transporter un outil électrique alors

que le doigt repose sur l’interrupteur ou brancher un outil électrique dont l’interrupteur est

à la position de marche risque de provoquer un accident.

d) Retirer toute clé de réglage ou clé avant de démarrer l’outil. Une clé ou une clé de

réglage attachée à une partie pivotante de l’outil électrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela permet de

mieux maîtriser l’outil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de bijoux.

Garder les cheveux, les vêtements et les gants à l’écart des pièces mobiles. Les

vêtements amples, les bijoux ou les cheveux longs risquent de rester coincés dans les

pièces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de dépoussiérage

et de ramassage, s’assurer que ceux-ci sont bien raccordés et utilisés. L’utilisation

d’un dispositif de dépoussiérage peut réduire les dangers engendrés par les poussières.

4) UTILISATION ET ENTRETIEN D’UN OUTIL ÉLECTRIQUE

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à l’application.

L’outil électrique approprié effectuera un meilleur travail, de façon plus sûre et à la vitesse

pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil

électrique dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche de la source d’alimentation et/ou du bloc-piles de l’outil

électrique avant de faire tout réglage ou changement d’accessoire ou avant de

ranger l’outil. Ces mesures préventives réduisent les risques de démarrage accidentel

de l’outil électrique.

d) Ranger les outils électriques hors de la portée des enfants et ne permettre à

aucune personne n’étant pas familière avec un outil électrique ou son mode

d’emploi d’utiliser cet outil. Les outils électriques deviennent dangereux entre les mains

d’utilisateurs inexpérimentés.

e) Entretien des outils électriques. Vérifier si les pièces mobiles sont mal alignées ou

coincées, si des pièces sont brisées ou présentent toute autre condition susceptible

de nuire au bon fonctionnement de l’outil électrique. En cas de dommage, faire

réparer l’outil électrique avant toute nouvelle utilisation. Beaucoup d’accidents sont

causés par des outils électriques mal entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres. Les outils de coupe

bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à

maîtriser.

g) Utiliser l’outil électrique, les accessoires, les forets, etc. conformément aux

présentes directives en tenant compte des conditions de travail et du travail à

effectuer. L’utilisation d’un outil électrique pour toute opération autre que celle pour

laquelle il a été conçu est dangereuse.

5) RÉPARATION

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant que des

pièces de rechange identiques. Cela permettra de maintenir une utilisation sécuritaire

de l’outil électrique.

Consignes additionnelles de sécurité propres aux

raboteuses

• Attendre l’arrêt complet de l’organe de coupe avant de poser l’outil sur une surface

quelconque. L’organe de coupe à nu pourrait attaquer la surface et causer la perte de

contrôle de l’outil et des dommages corporels graves.

• Utiliser des serre-joints, ou tout autre moyen, pour fixer et immobiliser le matériau

sur une surface stable. Tenir la pièce à la main ou contre son corps offre une stabilité

insuffisante qui pourrait vous en faire perdre le contrôle.

• S’assurer que le voltage utilisé correspond bien à celui indiqué sur la plaque signalétique.

• S’assurer que l’interrupteur de l’outil est en position d’arrêt avant de le brancher sur le

secteur.

• S’assurer de mettre immédiatement l’interrupteur en position d’ARRÊT si l’outil s’enraye.

• S’assurer que l’outil est réglé à la bonne profondeur de coupe avant de le mettre en

MARCHE.

• S’assurer d’effectuer une bonne maintenance de l’outil. Suivre toute instruction relative à la

lubrification et au changement d’accessoire.

• Rester vigilant – ne jamais utiliser l’appareil en cas de fatigue ou sous l’influence de drogue,

alcool ou médicaments.

• S’assurer de bien ranger l’outil dans un endroit propre et sec après l’avoir débranché.

• Ne pas l’utiliser dans un environnement dangereux. Ne pas utiliser l’outil à proximité de

substances inflammables, sur des lieux humides ou détrempés, ou l’exposer à la pluie.

• S’assurer que l’organe de coupe a bien été monté suivant les instructions du manuel, et que

toute vis sur l’appareil est bien serrée avant de le brancher.

• Maintenir tout évent libre de toute obstruction pour assurer le refroidissement correct du

moteur.

Page 4

• NE PAS poser l’outil sur son patin lorsque ses lames sont à nu.. Ces dernières pourraient

.....................

subir des dommages.

• Maintenir systématiquement tout orifice latéral d’éjection libre de toute obstruction.

• Ne jamais passer la main sous l’outil à moins qu’il ne soit à l’arrêt et DÉBRANCHÉ. SES

LAMES SONT À NU ET EXTRÊMEMENT COUPANTES.

• N’utiliser cet outil que pour travailler le bois ou tout produit du bois.

• Maintenir systématiquement l’appareil solidement par sa poignée avant, pendant toute

utilisation.

• Utiliser systématiquement la raboteuse à deux mains.

• L’organe de coupe de la raboteuse est extrêmement acéré. Utiliser la raboteuse avec la plus

grande vigilance.

• Nettoyer l’outil souvent, particulièrement après un usage intensif.

• Prendre des précautions à proximité des évents, car ils cachent des pièces mobiles.

Vêtements amples, bijoux ou cheveux longs risquent de rester coincés dans ces pièces

mobiles.

• Pour la sécurité de l’utilisateur, utiliser une rallonge de calibre adéquat (AWG, American

Wire Gauge [calibrage américain normalisé des fils électriques]). Plus le calibre est petit,

et plus sa capacité est grande. Un calibre 16, par exemple, a plus de capacité qu’un calibre

18. L’usage d’une rallonge de calibre insuffisant causera une chute de tension entraînant

perte de puissance et surchauffe. Si plusieurs rallonges sont nécessaires pour obtenir une

certaine longueur, s’assurer que chaque rallonge présente au moins le calibre de fil minimum.

Le tableau ci-dessous illustre les calibres à utiliser selon la longueur de rallonge et l’intensité

nominale indiquée sur la plaque signalétique. En cas de doute, utiliser le calibre suivant. Plus

le calibre est petit, plus la rallonge peut supporter de courant.

Calibres minimaux des rallonges

Volts Longueur totale de cordon en mètres (pieds)

Intensité (en ampères)

Plus de Pas plus de AWG

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 Non recommandé

AVERTISSEMENT : Porter SYSTÉMATIQUEMENT des lunettes de protection. Les lunettes

courantes NE sont PAS des lunettes de protection. Utiliser aussi un masque antipoussières si

la découpe doit en produire beaucoup. PORTER SYSTÉMATIQUEMENT UN ÉQUIPEMENT

DE SÉCURITÉ HOMOLOGUÉ :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3 ;

• Protection auditive ANSI S12.6 (S3.19) ;

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

AVERTISSEMENT : Les scies, meules, ponceuses, perceuses ou autres outils de

construction peuvent produire des poussières contenant des produits chimiques reconnus

pour causer cancers, malformations congénitales ou être nocifs au système reproducteur.

Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb ;

• la silice cristallisée dans les briques et le ciment ou autres articles de maçonnerie ; et

• l’arsenic et le chrome dans le bois ayant subi un traitement chimique.

Le risque associé à de telles expositions varie selon la fréquence à laquelle on effectue ces

travaux. Pour réduire toute exposition à ces produits : travailler dans un endroit bien aéré, en

utilisant du matériel de sécurité homologué tel un masque antipoussières spécialement conçu

pour filtrer les particules microscopiques.

• Limiter tout contact prolongé avec les poussières provenant du ponçage, sciage,

meulage, perçage ou toute autre activité de construction. Porter des vêtements de

protection et nettoyer à l’eau savonneuse les parties du corps exposées. Le fait de

laisser la poussière pénétrer dans la bouche, les yeux ou la peau peut provoquer l’absorption

de produits chimiques dangereux.

AVERTISSEMENT : Cet outil peut produire et/ou répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un

appareil respiratoire antipoussières homologué par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé au visage et au corps.

AVERTISSEMENT : Pendant l’utilisation, porter systématiquement une protection

auditive individuelle adéquate homologuée ANSI S12.6 (S3.19). Sous certaines conditions

et suivant la longueur d’utilisation, le bruit émanant de ce produit pourrait contribuer à une

perte de l’acuité auditive.

• L’étiquette apposée sur votre outil peut inclure les symboles suivants. Les symboles et leur

définition sont définis ci-après :

V ................... volts A .................... ampères

Hz ................. hertz W ................... watts

min ............... minutes

............ courant continu ................. courant alternatif ou continu

................. Classe / Fabrication

..................... (mis à la terre) ..................borne de terre

................. Classe II Fabrication .................. symbole d’avertissement

..................... (double isolation) BPM ..............battements par minute

…/min ..........par minute r/min .............. tours par minute

IPM..............impacts par minute

120V

240V

7,6 (25) 15,2 (50) 30,5 (100) 45,7 (150)

15,2 (50) 30,5 (100) 61,0 (200) 91,4 (300)

................. courant alter natif

n

o .................. vitesse à vide

CONSERVER CES CONSIGNES

DESCRIPTION (FIG. 1)

AVERTISSEMENT : ne jamais modifier l’outil électrique ni aucun de ses composants, car il

y a risques de dommages corporels ou matériels.

A. Interrupteur marche/arrêt H. Bouton de serrage du guide à rainure

B. Bouton de verrouillage en position de marche I. Réglette de profondeur de rabotage

C. Poignée principale J. Bouton de réglage de profondeur de

D. Patin arrière rabotage/poignée avant

E. Couvercle de courroie K. Couloir d’éjection

F. Orifice du guide à rainure L. Buse de dépoussiérage

G. Patin avant M. Couvercle de refeuillement

UTILISATION

AVERTISSEMENT : pour réduire tout risque de dommages corporels graves, arrêter et

débrancher l’outil avant tout réglage ou avant de retirer ou installer toute pièce ou tout

accessoire.

Moteur

S’assurer que le courant utilisé correspond à celui indiqué sur la plaque signalétique. Une baisse

de tension de plus de 10 % causera perte de puissance et surchauffe. Tous les outils D

sont soumis à des essais en usine ; si cet outil ne fonctionne pas, vérifier le secteur.

EWALT.

Interrupteur (Fig. 1)

ATTENTION : s’assurer que l’outil n’est pas verrouillé en position de MARCHE avant de le

brancher. Si c’est le cas, lorsque l’outil sera branché, il se mettra immédiatement en marche.

Cela pose des risques de dommages corporels et matériels.

ATTENTION : laisser l’outil atteindre sa vitesse maximum avant de le mettre en contact avec

la surface à travailler. Retirer l’outil de la pièce à travailler avant de l’arrêter.

Pour mettre la raboteuse en marche, appuyez sur l’interrupteur marche/arrêt (A).

Pour arrêter l’outil, relâchez l’interrupteur marche/arrêt.

BOUTON DE VERROUILLAGE EN POSITION DE MARCHE

L’outil peut être verrouillé en position de marche continue. Pour verrouiller l’outil en position

de marche, appuyez sur l’interrupteur à gâchette (A) puis poussez le bouton de verrouillage

en position de marche (B). Maintenez ce bouton de verrouillage enfoncé tout en relâchant

lentement l’interrupteur. L’outil continuera de tourner.

Pour arrêter l’outil lorsqu’il est verrouillé en position de marche, appuyez une fois sur l’interrupteur

à gâchette puis relâchez.

Réglage de la profondeur de rabotage (Fig. 1)

Pour régler la profondeur de coupe, tournez le bouton de réglage de profondeur de rabotage

(J). Chaque clic correspond à 0,1 mm de profondeur, et ce, jusqu’à une profondeur maximum

de coupe de 1,6 mm (1/16 po).

Il est recommandé de faire un essai sur un morceau de bois après chaque réajustement

pour s’assurer que seule la quantité de bois désirée sera enlevée par la raboteuse. Plusieurs

passages légers (plutôt qu’un seul profond) produiront un fini plus satiné.

Rabotage (Fig. 1 à 4)

ATTENTION : laisser l’outil tourner à plein régime avant de le mettre en contact avec la

surface à travailler. Retirer l’outil de la pièce à travailler avant de l’arrêter.

Maintenez la raboteuse dans la bonne position, une main sur la poignée avant (J) et l’autre sur

la poignée principale (C), comme illustré en figure 2. Placez le patin avant (G) sur la surface à

raboter, en s’assurant que l’organe de coupe ne touche pas la surface. Appuyez fermement sur

la poignée avant de la raboteuse pour que le patin avant soit COMPLÈTEMENT À PLAT sur la

surface à travailler. Appuyez sur la gâchette et laissez l’outil atteindre sa vitesse maximum avant

de laisser les lames entrer en contact avec la surface à travailler.

Faites avancer l’outil lentement sur la surface à travailler en exerçant une certaine pression

pour maintenir la raboteuse horizontale. Faites particulièrement attention à maintenir l’outil à

l’horizontale aux deux extrémités de la surface à travailler.

Conseil de rabotage : pour une apparence satinée, ajoutez un morceau de bois à l’extrémité de

la pièce à raboter. Continuez de raboter tant que les lames de la raboteuse ne sont pas au-delà

de la pièce à travailler, sur le morceau rajouté.

Guide à rainure (Fig. 5, 6)

AVERTISSEMENT : laisser l’outil tourner à plein régime avant de le mettre en contact avec la

surface à travailler. Retirer l’outil de la pièce à travailler avant de l’arrêter.

Le guide à rainure (N) est utilisé pour optimiser le contrôle de l’outil sur des pièces étroites,

et peut être installé sur l’un ou l’autre côté de la raboteuse. La raboteuse peut effectuer des

feuillures jusqu’à 9 mm (23/64 po).

POUR INSTALLER LE GUIDE À RAINURE

1. Desserrez le bouton de serrage du guide à rainure (H).

2. Faites glisser la barre latérale du guide à rainure (N) dans le trou (F) sur le côté de la

raboteuse, comme illustré en figure 5.

3. Ajustez la largeur de coupe en réglant le guide de chant transversalement au patin.

4. Resserrez soigneusement le bouton de serrage du guide à rainure.

REMARQUE : le guide à rainure doit se trouver plus bas que la raboteuse pour être installé

correctement, comme illustré en figure 6.

POUR FAIRE UNE RAINURE

1. Ajustez le bouton de réglage du guide à rainure (H) pour déterminer la largeur de coupe.

2. Repassez plusieurs fois jusqu’à ce que la profondeur voulue soit atteinte.

REMARQUE : un nombre répété de coupes sera nécessaire pour la plupart des découpes de

rainures.

Changement de lames (Fig. 7, 8)

Cette raboteuse peut utiliser des lames en acier à coupe rapide et au carbure. Assurez-vous de

vérifier quel type de lames est installé sur la raboteuse.

LAMES EN ACIER À COUPE RAPIDE (FIG. 7)

D26676

1. Pour retirer la lame de la raboteuse (Fig. 7B)

a. Desserrez puis retirez les trois vis à tête hexagonale (O) à l’aide de la clé hexagonale de

9 mm fournie à cet effet. Retirez le couvercle du logement des lames (P) du logement

(Q).

b. Retirez avec précautions le dispositif barre de guidage/lame en acier à coupe rapide

(V, U, T).

2. Pour régler la lame à l’aide de la plaque étalon (fournie avec l’outil), (Fig. 7C)

a. Disposez le dispositif barre de guidage/lame en acier à coupe rapide sur la plaque

étalon (R) en alignant le bord acéré de la lame en acier à coupe rapide tout contre la

paroi interne (S) de la plaque étalon.. Le talon de la barre de guidage (T) débordera sur

l’extrémité de la plaque étalon (R).

b. Desserrez les deux vis en croix (U) avec la clé pourvue à cet effet.

c. Poussez simultanément la lame en acier à coupe rapide (V) et la barre de guidage (T)

contre la paroi interne (S) de la plaque étalon, en vous assurant que la lame est maintenue

fermement contre la paroi interne (S) de la plaque étalon puis resserrez fermement les vis

en croix (U).

3. Pour réinstaller la lame (Fig. 7A, 7B)

a. Retirez avec précautions le dispositif ajusté barre de guidage/lame en acier à coupe

rapide de la plaque étalon (R) et placez le talon de la barre de guidage (T) dans la rainure

du logement (Q).

b. Posez le couvercle du logement de lames (P) sur le dispositif ajusté barre de guidage/

lame en acier à coupe rapide et vissez soigneusement les trois vis hexagonales (O) sur

le logement.

4. Répétez la même procédure pour l’autre lame.

REMARQUE : si votre raboteuse n’est pas équipée de lames en acier à coupe rapide, un

porte-meule (Y), requis pour affûter les lames à coupe rapide, est à votre disposition, en option,

auprès des centres de réparation autorisés D

LAMES AU CARBURE RÉVERSIBLES (FIG. 8)

D26677

1. Pour retirer la lame de la raboteuse (Fig. 8B)

a. Desserrez puis retirez les trois vis à tête hexagonale (O) à l’aide de la clé hexagonale de

9 mm fournie à cet effet. Retirez le couvercle du logement des lames (P) du logement

(Q).

b. Retirez le dispositif porte-lame/barre de guidage (T, U, X, W). Retirez avec précautions la

lame au carbure (W).

2. Pour régler la lame à l’aide de la plaque étalon (fournie avec l’outil), (Fig. 8C)

a. Placez avec précautions la lame au carbure sur la plaque étalon (R), son côté avec la

rainure vers le haut.. L’un ou l’autre côté de la lame réversible au carbure peut être aligné

tout contre la paroi interne (S) de la plaque étalon..

b. Placez le dispositif porte-lame/barre de guidage sur la lame de façon à ce que la nervure

du porte-lame (X) s’encastre dans la rainure de la lame au carbure (W). Le talon du porte-

lame (X) débordera de la plaque étalon (R).

c. Desserrez les deux vis en croix (U) avec la clé pourvue à cet effet.

d. Poussez simultanément le porte-lame (X) et la barre de guidage (T) contre la paroi interne

(S) de la plaque étalon, en vous assurant que la lame au carbure (W) est maintenue

fermement contre la paroi interne (S) de la plaque étalon puis resserrez fermement les

deux vis en croix (U).

3. Pour réinstaller la lame (Fig. 8A, 8B)

a. Retirez avec précautions le dispositif ajusté porte-lame/barre de guidage de la plaque

étalon (R) et placez le talon de la barre de guidage (T) dans la rainure du logement (Q).

b. Replacez le couvercle du logement (P) sur le dispositif porte-lame/barre de guidage.

Vissez légèrement les trois vis hexagonales (O) dans le logement de lames (Q) de façon

à laisser un interstice entre le logement et le porte-lame (X).

c. Insérez la lame au carbure entre le logement (Q) et le porte-lame (X) de façon à ce que

la nervure sur le porte-lame s’encastre dans la rainure de la lame.

d. Centrez la lame au carbure (W) sous le porte-lame (X) en vous assurant que la lame ne

touche pas les côtés du boîtier de l’outil.

e. Vissez fermement les trois vis hexagonales (O) sur le logement de lames.

4. Répétez la même procédure pour l’autre lame.

REMARQUE : si votre raboteuse n’est pas équipée de lames au carbure, un porte-lame (X),

requis pour les lames au carbure, est à votre disposition, en option, auprès des centres de

réparation autorisés D

EWALT.

EWALT.

Affûtage des lames en acier à coupe rapide (Fig. 9)

REMARQUE : les lames au carbure ne peuvent pas être affûtées.

1. Rattachez les lames au porte-meule (Y). Assurez-vous que les deux bords de lames (V)

sont dans le même sens.

2. Placez les bords de lame de façon à ce qu’ils reposent contre la meule (non incluse).

3. Attrapez fermement le porte-meule et déplacez-le d’avant en arrière pour affûter les

lames (V)

Béquille (Fig. 10)

La raboteuse est munie d’une béquille (Z) qui se déplie automatiquement lorsque l’outil est

soulevé de la surface de travail, permettant à la raboteuse d’être posée sur la surface de travail

sans que la lame ne touche cette dernière. Lors du rabotage, la béquille se rétracte dès que

l’outil est poussé en avant dans le matériau.

Page 5

ATTENTION : ne pas verrouiller la gâchette lorsque la béquille est activée. Les vibrations du

moteur pourraient faire bouger la raboteuse, et la faire tomber hors de la pièce de travail.

Chanfreinage (Fig. 11)

La raboteuse est équipée d’une rainure (A1) haute précision de chanfreinage sur le patin avant

pour raboter un coin de bois. La largeur de rainure va de 4,5 à 8 mm. Il est recommandé de faire

des essais sur un rebut avant tout travail définitif.

Buse de dépoussiérage (Fig. 1)

La raboteuse portative est équipée d’une buse double (L). La buse peut être rattachée aux deux

raccords de tuyau d’aspirateur de 1 po (diamètre interne) et 35 mm (diamètre externe) pour

aspirer la poussière. Insérez la buse (L) sur le couloir d’éjection (K) et rattachez le raccord de

tuyau d’aspirateur approprié à la buse.

Si la buse n’est pas incluse avec votre raboteuse, veuillez contacter votre centre de réparation

agréé D

EWALT. pour en obtenir une en option.

MAINTENANCE

AVERTISSEMENT : Pour réduire le risque de blessures, éteindre l’appareil et le

débrancher avant d’installer ou de retirer tout accessoire et avant d’effectuer des

réglages ou des réparations. Un démarrage accidentel peut provoquer des blessures.

Entretien

AVERTISSEMENT : nettoyer régulièrement le couloir d’éjection (K). PORTER

SYSTÉMATIQUEMENT DES LUNETTES DE PROTECTION.

AVERTISSEMENT : Expulser tout débris ou poussière des évents à l’aide d’un jet d’air sec

au moins une fois par semaine. Porter une protection oculaire ANSI Z87.1 (CAN/CSA Z94.3)

et respiratoire NIOSH/OSHA/MSHA adéquates pour effectuer cette opération.

AVERTISSEMENT : Ne jamais utiliser de solvants ou tout autre produit chimique décapant

pour nettoyer les parties non métalliques de l’outil. Ces produits chimiques pourraient attaquer

les matériaux plastiques utilisés. Utilisez un chiffon humidifié avec de l’eau et un savon doux.

S’assurer qu’aucun liquide ne pénètre dans l’outil ; ne jamais immerger aucune partie de l’outil

dans un liquide.

Lubrifi cation

Cet outil électrique ne requiert aucune lubrification additionnelle.

Accessoires

AVERTISSEMENT : Comme les accessoires autres que ceux fournis par DEWALT n’ont pas

été testés avec ce produit, leur utilisation avec cet appareil pourrait comporter un danger. Pour

réduire tout risque de dommages corporels, seuls des accessoires D

doivent être utilisés avec cet appareil.

Les accessoires recommandés pour cet outil sont vendus séparément chez les distributeurs

locaux ou dans les centres de réparation agréés. Si vous avez besoin d’aide pour localiser ces

accessoires, veuillez contacter D

MD 21286 ou appeler 1-800-4-D

dewalt.com.

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

EWALT (1-800-433-9258) ou vous rendre sur notre site www.

EWALT recommandés

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations, l’entretien et les réglages

(y compris l’inspection et le remplacement de la brosse) doivent être réalisés par un centre de

réparation en usine D

réparation professionnel. Toujours utiliser des pièces de rechange identiques.

EWALT, un centre de réparation autorisé DEWALT ou par un personnel de

Garantie limitée trois ans

DEWALT réparera gratuitement tous les problèmes dus à des défauts de matériau ou de

fabrication pendant trois ans à compter de la date d’achat. Cette garantie ne couvre pas des

défaillances de pièce dues à une usure normale ou à une mauvaise utilisation de l’outil. Pour

plus de détails relatifs à la couverture de la garantie et aux réparations sous garantie, visiter le

site Web www.dewalt.com ou composer le 1 (800) 4-D

ne s’applique pas aux accessoires ni aux dommages causés par des réparations réalisées ou

tentées par des tiers. Cette garantie vous accorde des droits légaux spécifiques et il est possible

que vous ayez d’autres droits qui varient d’un État ou d’une province à l’autre.

En plus de la garantie, les outils D

SERVICE D’ENTRETIEN GRATUIT DE 1 AN

D

EWALT entretiendra l’outil et remplacera les pièces usées par une utilisation normale et ce,

gratuitement, à tout instant pendant la première année à compter de la date d’achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n’êtes pas entièrement satisfait des performances de votre outil électrique, laser ou de

votre cloueuse D

d’un reçu dans les 90 jours suivant la date d’achat et nous vous rembourserons entièrement –

sans poser de questions.

AMÉRIQUE LATINE : cette garantie ne s’applique pas aux produits vendus en Amérique latine.

Pour ceux-ci, veuillez consulter les informations relatives à la garantie spécifique présente dans

l’emballage, appeler l’entreprise locale ou consulter le site Web pour les informations relatives

à cette garantie.

REMPLACEMENT GRATUIT DES ÉTIQUETTES D’AVERTISSEMENT : si les étiquettes

d’avertissement deviennent illisibles ou sont manquantes, composer le 1 (800) 4-D

(1-800-433-9258) pour en obtenir le remplacement gratuit.

EWALT pour quelque raison que ce soit, vous pouvez le retourner accompagné

EWALT sont couverts par notre :

EWALT (1-800-433-9258). Cette garantie

EWALT

Defi niciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada palabra de señal.

Lea el manual y preste atención a estos símbolos.

PELIGRO: indica una situación de peligro inminente que, si no se evita, provocará

la muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita, podría

provocar la muerte o lesiones graves.

ATENCIÓN: indica una situación de peligro potencial que, si no se evita,

posiblemente provocaría lesiones leves o moderadas.

AVISO: se refiere a una práctica no relacionada a lesiones corporales que de no

evitarse puede resultar en daños a la propiedad.

SI TIENE ALGUNA DUDA O ALGÚN COMENTARIO SOBRE ÉSTA U OTRA HERRAMIENTA

D

EWALT, LLÁMENOS AL NÚMERO GRATUITO: 1-800-4-DEWALT (1-800-433-9258)

ADVERTENCIA: Para reducir el riesgo de lesiones, lea el manual de instrucciones.

Advertencias generales de seguridad para herramientas

eléctricas

¡ADVERTENCIA! Lea todas las advertencias de seguridad e instrucciones El

incumplimiento de las advertencias e instrucciones puede provocar descargas eléctricas,

incendios o lesiones graves.

CONSERVE TODAS LAS ADVERTENCIAS E

INSTRUCCIONES PARA FUTURAS CONSULTAS

El término “herramienta eléctrica” incluido en las advertencias hace referencia a las herramientas

eléctricas operadas con corriente (con cable eléctrico) o a las herramientas eléctricas operadas

con baterías (inalámbricas).

1) SEGURIDAD EN EL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas y oscuras

propician accidentes.

b) No opere las herramientas eléctricas en atmósferas explosivas, como ambientes

donde haya polvo, gases o líquidos inflamables. Las herramientas eléctricas originan

chispas que pueden encender el polvo o los vapores.

c) Mantenga alejados a los niños y a los espectadores de la herramienta eléctrica en

funcionamiento. Las distracciones pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente. Nunca

modifique el enchufe de ninguna manera. No utilice ningún enchufe adaptador con

herramientas eléctricas con conexión a tierra. Los enchufes no modificados y que se

adaptan a los tomacorrientes reducirán el riesgo de descarga eléctrica.

b) Evite el contacto corporal con superficies con descargas a tierra como, por

ejemplo, tuberías, radiadores, cocinas eléctricas y refrigeradores. Existe mayor

riesgo de descarga eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad. Si

entra agua a una herramienta eléctrica, aumentará el riesgo de descarga eléctrica.

d) No maltrate el cable. Nunca utilice el cable para transportar, tirar o desenchufar

la herramienta eléctrica. Mantenga el cable alejado del calor, el aceite, los bordes

filosos y las piezas móviles. Los cables dañados o enredados aumentan el riesgo de

descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable prolongador

adecuado para tal uso. Utilice un cable adecuado para uso en exteriores a fin de reducir

el riesgo de descarga eléctrica.

f) Si el uso de una herramienta eléctrica en un lugar húmedo es imposible de evitar,

utilice un suministro protegido con un interruptor de circuito por falla a tierra (GFCI). El uso

de un GFCI reduce el riesgo de descargas eléctricas.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común

cuando emplee una herramienta eléctrica. No utilice una herramienta eléctrica si

está cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de

descuido mientras se opera una herramienta eléctrica puede provocar lesiones personales

graves.

b) Utilice equipos de protección personal. Siempre utilice protección para los ojos. En

las condiciones adecuadas, el uso de equipos de protección, como máscaras para polvo,

calzado de seguridad antideslizante, cascos o protección auditiva, reducirá las lesiones

personales.

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté en la

posición de apagado antes de conectarlo a la fuente de energía o paquete de

baterías, o antes de levantar o transportar la herramienta. Transportar herramientas

eléctricas con el dedo apoyado en el interruptor o enchufar herramientas eléctricas con el

interruptor en la posición de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de encender la herramienta

eléctrica. Una llave de tuercas o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta eléctrica puede provocar lesiones personales.

e) No se estire. Conserve el equilibrio y párese adecuadamente en todo momento.

Esto permite un mejor control de la herramienta eléctrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga el cabello,

la ropa y los guantes alejados de las piezas en movimiento. Las ropas holgadas, las

joyas o el cabello largo pueden quedar atrapados en las piezas en movimiento.

g) Si se suministran dispositivos para la conexión de accesorios con fines de

recolección y extracción de polvo, asegúrese de que estén conectados y que se

utilicen correctamente. El uso de dispositivos de recolección de polvo puede reducir los

peligros relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica correcta para

el trabajo que realizará. Si se la utiliza a la velocidad para la que fue diseñada, la

herramienta eléctrica correcta permite trabajar mejor y de manera más segura.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con el

interruptor. Toda herramienta eléctrica que no pueda ser controlada mediante el

interruptor es peligrosa y debe repararse.

c) Desconecte el enchufe de la fuente de energía o el paquete de baterías de la

herramienta eléctrica antes de realizar ajustes, cambiar accesorios o almacenar

la herramienta eléctrica. Estas medidas de seguridad preventivas reducen el riesgo de

encender la herramienta eléctrica en forma accidental.

d) Guarde la herramienta eléctrica que no esté en uso fuera del alcance de los niños y

no permita que otras personas no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas eléctricas son peligrosas si son operadas por

usuarios no capacitados.

e) Realice el mantenimiento de las herramientas eléctricas. Revise que no haya piezas

en movimiento mal alineadas o trabadas, piezas rotas o cualquier otra situación

que pueda afectar el funcionamiento de la herramienta eléctrica. Si encuentra

daños, haga reparar la herramienta eléctrica antes de utilizarla. Se producen muchos

accidentes a causa de las herramientas eléctricas que carecen de un mantenimiento

adecuado.

f) Mantenga las herramientas de corte afiladas y limpias. Las herramientas de corte

con mantenimiento adecuado y con los bordes de corte afilados son menos propensas a

trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la herramienta, etc.

de acuerdo con estas instrucciones y teniendo en cuenta las condiciones de trabajo

y el trabajo que debe realizarse. El uso de la herramienta eléctrica para operaciones

diferentes de aquéllas para las que fue diseñada podría originar una situación peligrosa.

5) MANTENIMIENTO

a) Solicite a una persona calificada en reparaciones que realice el mantenimiento

de su herramienta eléctrica y que sólo utilice piezas de repuesto idénticas. Esto

garantizará la seguridad de la herramienta eléctrica.

Instrucciones de seguridad adicionales para cepilladoras

• Espere a que la cuchilla se detenga antes de descargar la herramienta. Una cuchilla

expuesta puede engranar en la superficie causando una posible pérdida de control y lesiones

graves

• Use abrazaderas u otra manera práctica de fijar y sujetar la pieza de trabajo a una

plataforma estable. El sujetar la pieza con la mano o contra su cuerpo la vuelve inestable y

puede dar como resultado el que pierda el control.

• Cerciórese de que el voltaje esté de acuerdo con los datos específicos en la placa de

características.

• Cerciórese de que el interruptor esté en posición off (apagado) antes de conectar la clavija

a una fuente de electricidad.

• Asegúrese de APAGAR inmediatamente si la herramienta se atasca durante el trabajo.

• Cerciórese de que la herramienta esté ajustada para la profundidad correcta antes de

ENCENDERLA.

• Asegúrese de prestar el adecuado mantenimiento a la herramienta. Siga las instrucciones

para lubricar y cambiar piezas.

• Manténgase alerta: nunca haga funcionar la unidad cuando esté cansado o bajo la influencia

de drogas, alcohol o medicamentos.

• Asegúrese de almacenar la herramienta en un lugar seco y limpio después de desconectarla

de la fuente de energía.

• No utilice la herramienta en ambientes peligrosos. No utilice la herramienta cerca de

sustancias inflamables, en ambientes húmedos o mojados, ni la exponga a la lluvia.

• Cuide que las hojas estén instaladas de la forma descrita en el manual de instrucciones y

compruebe que todos los tornillos estén firmemente apretados antes de conectar la unidad

a una fuente de electricidad.

• Mantenga las rejillas de ventilación sin obstrucciones a fin de permitir la adecuada

refrigeración del motor.

• NO descanse la herramienta sobre la zapata cuando las hojas se encuentren expuestas.

Esto puede desportillar las hojas.

• Mantenga la tolva de descarga lateral libre de obstáculos en todo momento.

• Nunca ponga la mano debajo de la herramienta por ningún motivo a no ser que esté apagada

y DESENCHUFADA. LAS HOJAS ESTÁN EXPUESTAS Y SON EXTREMADAMENTE

AFILADAS.

• Utilice esta herramienta para trabajar sólo con madera y con productos de madera.

• Nunca opere sin sostener firmemente la agarradera frontal.

• Siempre opere la cepilladora con las dos manos.

• Las hojas de la cepilladora son extremadamente afiladas. Maneje con mucho cuidado.

• Limpie su herramienta periódicamente, especialmente después de realizar trabajos

pesados.

Page 6

• Los orificios de ventilación suelen cubrir piezas en movimiento, por lo que también se

deben evitar. La ropa suelta, las joyas y el pelo largo pueden quedar atrapados en las piezas

móviles.

• Los hilos del alargador deben ser de un calibre apropiado (AWG o American Wire

Gauge) para su seguridad. Mientras menor sea el calibre del hilo, mayor la capacidad

del cable. Es decir, un hilo calibre 16 tiene mayor capacidad que uno de 18. Un cable de

un calibre insuficiente causará una caída en la tensión de la línea dando por resultado

una pérdida de energía y sobrecalentamiento. Cuando se utilice más de un alargador para

completar el largo total, asegúrese que los hilos de cada alargador tengan el calibre mínimo.

La tabla siguiente muestra el tamaño correcto a utilizar, dependiendo de la longitud del cable

y del amperaje nominal de la placa de identificación. Si tiene dudas sobre cuál calibre usar,

use un calibre mayor. Cuanto más pequeño sea el número del calibre, más resistente será el

cable.

Calibre mínimo para juegos de cables

Capacidad nominal

en amperios

Desde Hasta AWG

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 No recomendado

ADVERTENCIA: Use SIEMPRE lentes de seguridad. Los anteojos de diario NO SON lentes

de seguridad. Utilice además una máscara para la cara o guardapolvo si la operación de corte

genera demasiado polvo. SIEMPRE LLEVE EQUIPO DE SEGURIDAD CERTIFICADO:

• Protección ocular ANSI Z87.1 (CAN/CSA Z94.3),

• Protección auditiva ANSI S12.6 (S3.19),

• Protección respiratoria NIOSH/OSHA/MSHA.

ADVERTENCIA: Parte del polvo generado al lijar, serrar, esmerilar o taladrar, así como

al realizar otras actividades del sector de la construcción, contienen productos químicos

que pueden producir cáncer, defectos congénitos u otras afecciones reproductivas. Algunos

ejemplos de estos químicos son:

• plomo procedente de pinturas basadas en plomo,

• óxido de silicio cristalino procedente de ladrillos, cemento y otros productos de

mampostería, y

• arsénico o cromo procedente de madera tratada químicamente.

Su riesgo de exposición a estos químicos varía, dependiendo de la frecuencia con la cual

realiza usted este tipo de trabajo. Para reducir su exposición a estos químicos, trabaje en un

lugar con buena ventilación y trabaje con equipo de seguridad aprobado, como máscaras

antipolvo especialmente diseñadas para filtrar partículas microscópicas.

• Evite el contacto prolongado con polvo generado por el lijado, serruchado, pulido y

taladrado mecánico y otras actividades de construcción. Vista ropas protectoras y lave

las áreas de la piel expuestas con agua y jabón. Si permite que el polvo se introduzca en

la boca u ojos o quede sobre la piel, puede favorecer la absorción de productos químicos

peligrosos.

ADVERTENCIA: La utilización de esta herramienta puede generar polvo o dispersarlo, lo que

podría causar daños graves y permanentes al sistema respiratorio, así como otras lesiones.

Siempre use protección respiratoria aprobada por NIOSH (Instituto Nacional de Seguridad y

Salud en el Trabajo) u OSHA (Administración de Seguridad y Salud en el Trabajo) apropiada

para la exposición al polvo. Dirija las partículas en dirección contraria a la cara y el cuerpo.

ADVERTENCIA: Siempre lleve la debida protección auditiva personal en conformidad

con ANSI S12.6 (S3.19) durante el uso de esta herramienta. Bajo algunas condiciones

y duraciones de uso, el ruido producido por este producto puede contribuir a la pérdida

auditiva.

• La etiqueta de su herramienta puede incluir los siguientes símbolos. A continuación se

indican los símbolos y sus definiciones:

V ................. voltios A ..............amperios

Hz ............... hercios W .............vatios

min ............. minutos

.......... corriente directa ...........corriente alterna o directa

............... Construcción de clase I

................... (tierra) .............terminal de conexión a tierra

............... Construcción de clase II ............símbolo de advertencia de seguridad

................... (doble aislamiento) BPM.........golpes por minuto

…/min ........ por minuto RPM ........revoluciones por minuto

IPM..............impactos por minuto

Voltios Largo total del cable en metros (en pies)

120V

240V

7,6 (25) 15,2 (50) 30,5 (100) 45,7 (150)

15,2 (50) 30,5 (100) 61,0 (200) 91,4 (300)

...........corriente alterna

n

o ............velocidad sin carga

CONSERVE ESTAS INSTRUCCIONES

COMPONENTES (FIG. 1)

ADVERTENCIA: Nunca modifique la herramienta eléctrica, ni tampoco ninguna de sus

piezas. Podría producir lesiones corporales.

A. Conmutador de encendido y apagado H. Perilla de apriete del cerco de rebajo

B. Botón de bloqueo en encendido I. Graduación de la altura del cepillado

C. Agarradera principal J Perilla de ajuste de la altura del

D. Zapata trasera cepillado/agarradera frontal

E. Cubierta de la banda del impulsor K. Tolva de descarga de astillas

F. Orificio para cerco de rebajo L. Adaptador para polvo

G. Zapata frontal M. Cubierta para rebajado

FUNCIONAMIENTO

ADVERTENCIA: Para reducir el riesgo de lesiones corporales graves, apague la

herramienta y desconéctela de la fuente de alimentación antes de realizar ajustes o de

quitar o poner accesorios.

Motor

Compruebe que el suministro eléctrico concuerde con el indicado en la placa de características.

Caídas de voltaje de más de 10% causarán una pérdida de potencia y sobrecalentamiento. Las

herramientas D

fuente de alimentación.

EWALTvienen probadas de fábrica; si esta herramienta no funciona, verifique la

Interruptor (Fig. 1)

ATENCIÓN: Verifique que la herramienta no esté bloqueada en OPERACIÓN CONTINUA

antes de enchufarla a la toma de corriente. Si el interruptor de gatillo está bloqueado en

OPERACIÓN CONTINUA, la herramienta arrancará apenas sea enchufada. Esto podría dañar

la herramienta o resultar en lesiones corporales.

ATENCIÓN: Deje que la herramienta alcance su velocidad total antes de tocar con ella la

superficie de la pieza de trabajo. Levante la herramienta de la superficie de trabajo antes de

apagarla.

Para encender la cepilladora, presione el interruptor de encendido/apagado (A).

Para apagar la cepilladora, suelte el interruptor de encendido y apagado.

BOTÓN DE BLOQUEO EN ON

La herramienta puede ser bloqueada para operar continuamente. Para bloquear la herramienta

en operación continua, presione el interruptor de gatillo (A) y oprima el botón de bloqueo

(B). Mantenga apretado el botón de bloqueo al tiempo que suelta el interruptor tipo gatillo

suavemente. La herramienta continuará en funcionamiento.

Para apagar la herramienta desde la posición de funcionamiento continuo, pulse y suelte el