Page 1

@

€-

Q.

Q.

€-

0

oc = =

O

o_eq _t'tt'tt-t "O '-

-z

;.!

_X _

:::: O0

m

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

(MAY10) Part No. N052789 D25712, D25762, D25891

Copyright © 2010 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black

color scheme; the "D" shaped air intake grill; the array of pyramids on the handgrip; the kit box

configuration; and the array of lozenge-shaped humps on the surface of the tool. •

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

_ WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

_ CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

NOTICE: indicates a practice not related to personal injury which, if not avoided, may

result in property damage.

\ J

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258).

_ WARNING: To reduce the risk of injury, read the instruction manual.

General Power Tool Safety Warnings

_ ARNING! Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tooL

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dusL Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a power tooL Distractions can

cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tooL Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) ff operating a power tool in a damp location is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool

Carrying power tools with your finger on the switch or energising power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce dust-

related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tooL Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misallgnment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool's operation, ff

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result

in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Safety Instructions for Rotary Hammers

Wear ear protectors. Exposure to noise can cause hearing loss.

Use auxiliary handle(s), ff supplied with the tooL Loss of control can cause personal

injury.

Hold power tools by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Cutting accessory

contacting a "live" wire may make exposed metal parts of the power tool "live" and could

give the operator an electric shock.

Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control

Wear safety goggles or other eye protection. Hammering operations cause chips to

fly. Flying particles can cause permanent eye damage. Wear a dust mask or respirator for

applications that generate dust. Ear protection may be required for most applications.

Keep a firm grip on the tool at all times. Do not attempt to operate this tool without

holding it with both hands. It is recommended that the side handle be used at all times.

Operating this tool with one hand will result in loss of control Breaking through or encountering

hard materials such as re-bar may be hazardous as well. Tighten the side handle securely

before use.

Do not operate this tool for long periods of time. Vibration caused by hammer action may

be harmful to your hands and arms. Use gloves to provide extra cushion and limit exposure

by taking frequent rest periods.

Do not recondition bits yourself. Chisel reconditioning should be done by an authorized

specialist. Improperly reconditioned chisels could cause injury.

Wear gloves when operating tool or changing bits. Accessible metal parts on the tool and

bits may get extremely hot during operation. Small bits of broken material may damage bare

hands.

Never lay the tool down until the bit has come to a complete stop. Moving bits could

cause injury.

• Do not strike jammed bits with a hammer to dislodge them. Fragments of metal or

material chips could dislodge and cause injury.

• Slightly worn chisels can be resharpened by grinding.

NOTE: Do not overheat the bit (discoloration) while grinding a new edge. Badly worn chisels

require reforging. Do not reharden and temper the chisel

Keep the power cord away from the rotating bit. Do not wrap the cord around any part

of your body. An electric cord wrapped around a spinning bit may cause personal injury and

loss of control

• Air vents often cover moving parts and should be avoided. Loose clothes, jewellery or

long hair can be caught in moving parts.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. When using more than one extension to

make up the total length, be sure each individual extension contains at least the minimum

wire size. The following table shows the correct size to use depending on cord length and

nameplate ampere rating, ff in doubt, use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0

6

10

12

_ WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also

use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out microscopic

particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Always use eye protection. All users and bystanders must wear eye protection

that conforms to ANSI Z87.1.

_ WARNING: Always wear proper personal hearing protection that conforms to ANSI

$12.6 ($3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V........................ volts

Hz...................... hertz

min .................... minutes

--- ................. direct current

@ ...................... Class I Construction

[] ...................... Class II Construction

.../min ............... per minute

Not More

Than

6

10

12

16

(grounded)

(double insulated)

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

18

18

16

14

A....................... amperes

W...................... watts

'_ .................... alternating current

no ..................... no load speed

_, ..................... safety alert symbol

BPM ................. beats per minute

RPM ................. revolutions per minute

AWG

16

16

16

12

.................... alternating or direct current

..................... earthing terminal

16 14

14 12

14 12

Not Recommended

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be sure your power supply agrees

with the nameplate markings. Voltage decrease of more than 10% will cause loss of power and

overheating. All DEWALT tools are factory tested.

Page 2

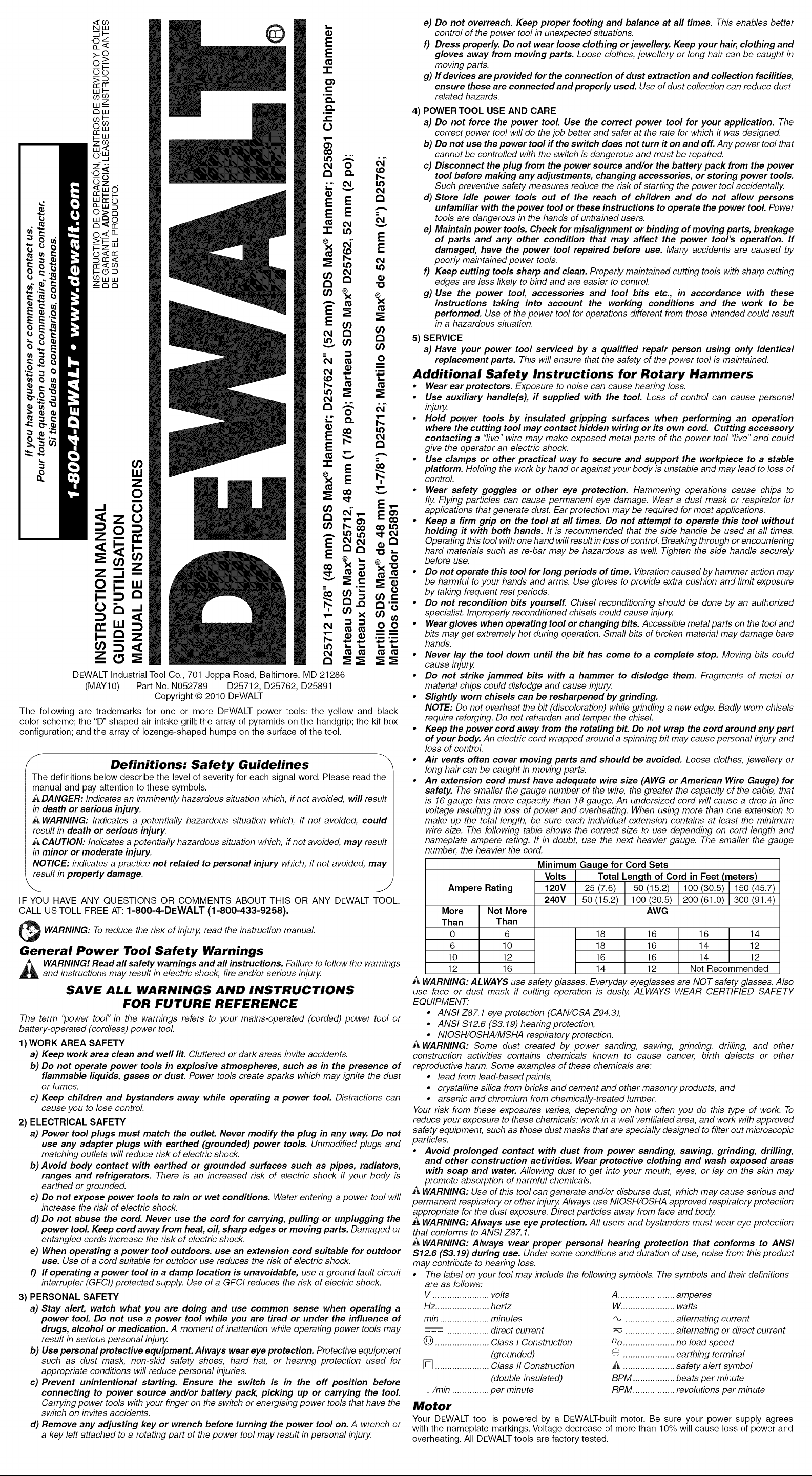

FIG. 1

HAMMERDRILLING MODE

MODE DE MARTEAU PERFORATEUR

MODO TALADRO PERCUTOR

CHISEL BIT ADJUSTMENT MODE

MODE DE REGLAGE DU TRt_PAN ORDINAIRE

MODO DE AJUSTE DE LA BROCA DE ClNCEL

CHIPPING MODE

MODE DE BURINAGE

MODO CINCEL

CHISEL BIT ADJUSTMENT MODE

MODE DE REGLAGE DU TRt_PAN ORDINAIRE

MODO DE AJUSTE DE LA BROCA DE CINCEL

E

F I

J

H

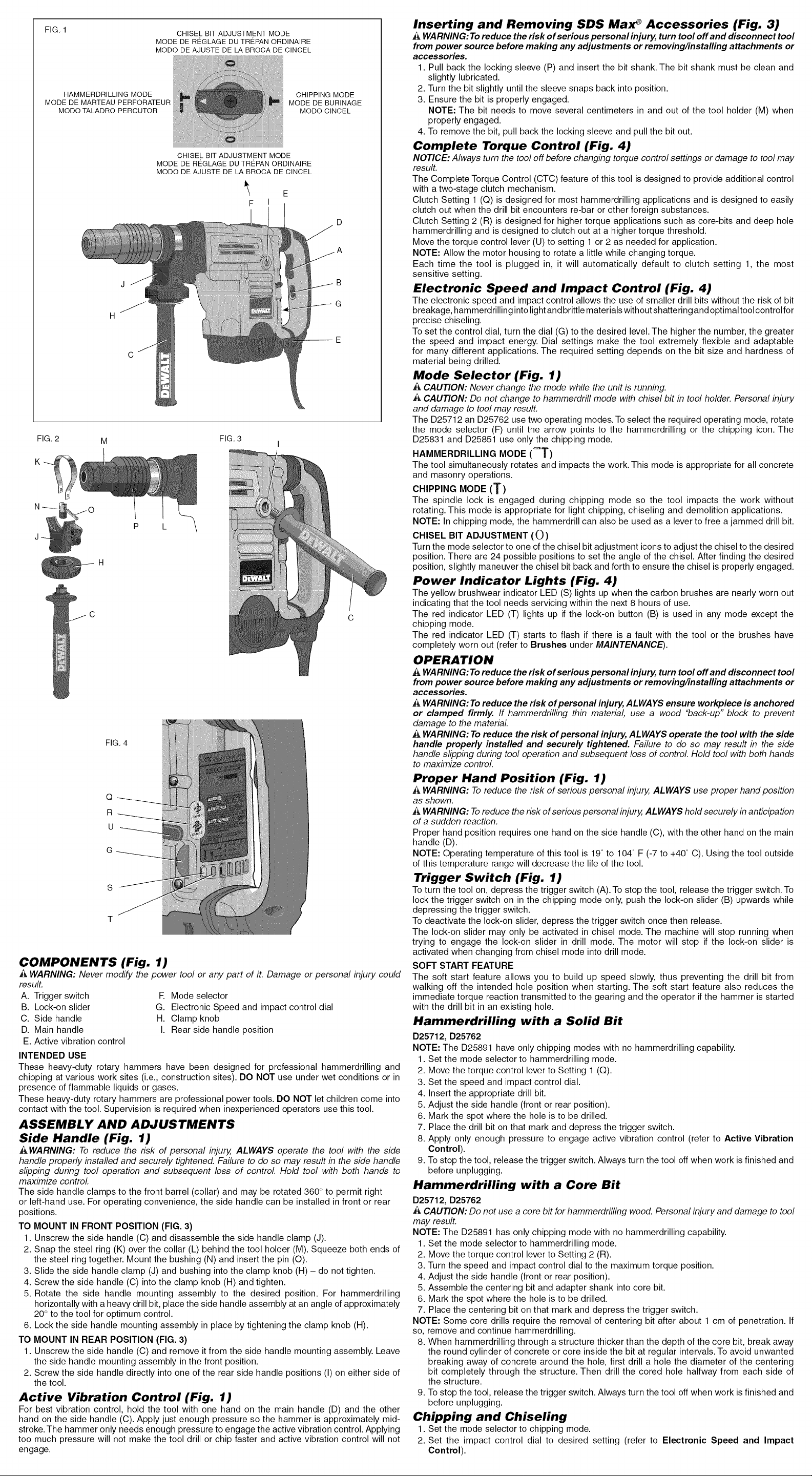

FIG. 2

K

M

P L

C

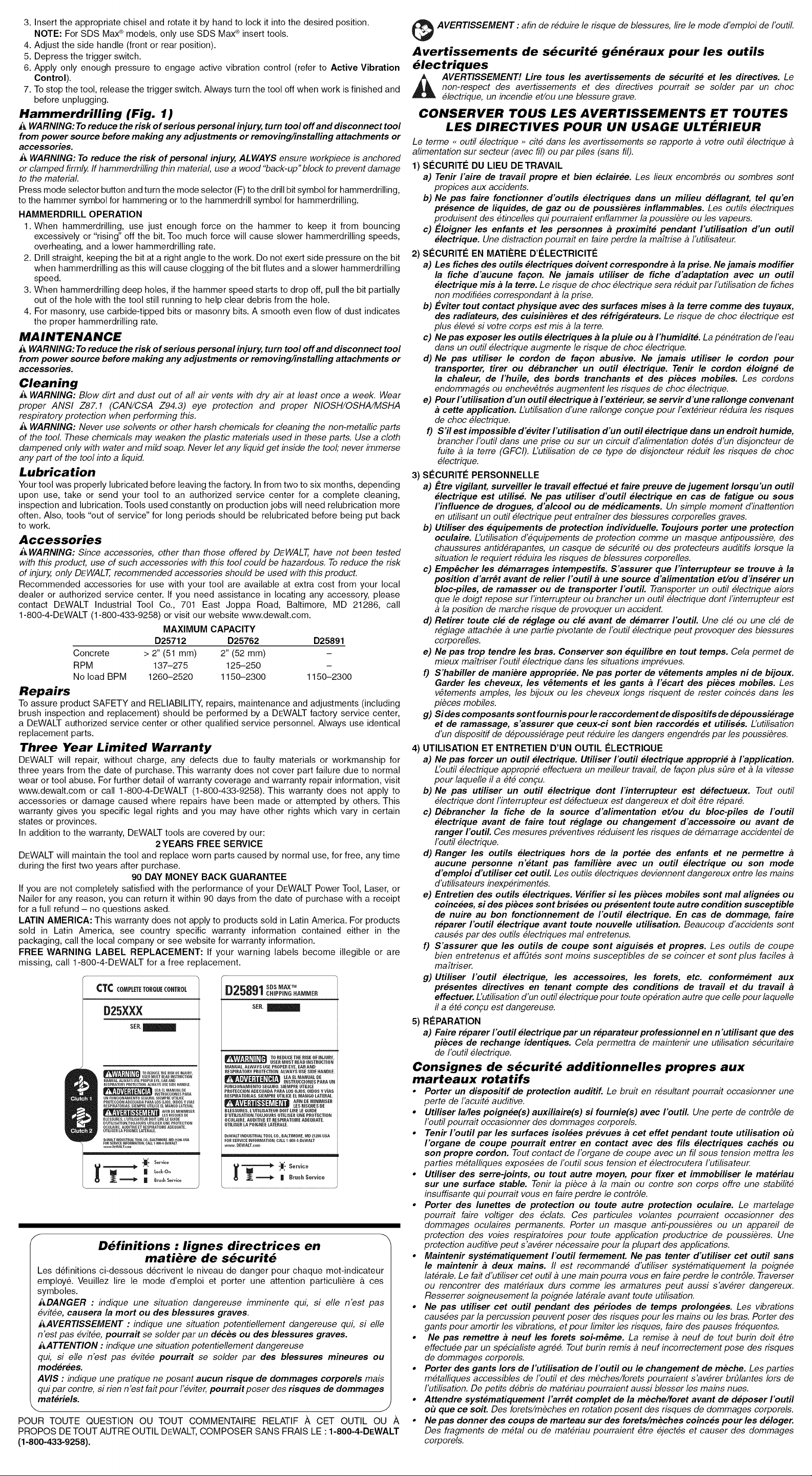

FIG. 4

Q

R

U

T

FIG. 3

COMPONENTS (Fig. 1)

_},WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result.

A. Trigger switch F. Mode selector

B. Lock-on slider G. Electronic Speed and impact control dial

C. Side handle H. Clamp knob

D. Main handle I. Rear side handle position

E. Active vibration control

INTENDED USE

These heaw-duty rotary hammers have been designed for professional hammerdrilling and

chipping at various work sites (i.e., construction sites). DO NOT use under wet conditions or in

presence of flammable liquids or gases.

These heaw-duty rotary hammers are professional power tools. DO NOT let children come into

contact with the tool. Supervision is required when inexperienced operators use this tool.

ASSEMBLY AND ADJUSTMENTS

Side Handle (Fig. 1)

_WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side

handle properly installed and securely tightened. Failure to do so may result in the side handle

slipping during tool operation and subsequent loss of control Hold tool with both hands to

maximize control

The side handle clamps to the front barrel (collar) and may be rotated 360° to permit right

or left-hand use. For operating convenience, the side handle can be installed in front or rear

positions.

TO MOUNT IN FRONT POSITION (FIG. 3)

1. Unscrew the side handle (C) and disassemble the side handle clamp (J).

2. Snap the steel ring (K) over the collar (L) behind the tool holder (M). Squeeze both ends of

the steel ring together. Mount the bushing (N) and insert the pin (O).

3. Slide the side handle clamp (J) and bushing into the clamp knob (H) - do not tighten.

4. Screw the side handle (C) into the clamp knob (H) and tighten.

5. Rotate the side handle mounting assembly to the desired position. For hammerdrilling

horizontally with a heavy drill bit, place the side handle assembly at an angle of approximately

20° to the tool for optimum control.

6. Lock the side handle mounting assembly in place by tightening the clamp knob (H).

TO MOUNT IN REAR POSITION (FIG. 3)

1. Unscrew the side handle (C) and remove it from the side handle mounting assembly. Leave

the side handle mounting assembly in the front position.

2. Screw the side handle directly into one of the rear side handle positions (I) on either side of

the tool.

Active Vibration Control (Fig. 1)

For best vibration control, hold the tool with one hand on the main handle (D) and the other

hand on the side handle (C). Apply just enough pressure so the hammer is approximately mid-

stroke. The hammer only needs enough pressure to engage the active vibration control. Applying

too much pressure will not make the tool drill or chip faster and active vibration control will not

engage.

B

G

C

Inserting and Removing SDS Max _ Accessories (Fig. 3)

WARNING: Toreduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments or

accessories.

1. Pull back the locking sleeve (P) and insert the bit shank. The bit shank must be clean and

slightly lubricated.

2. Turn the bit slightly until the sleeve snaps back into position.

3. Ensure the bit is properly engaged.

NOTE: The bit needs to move several centimeters in and out of the tool holder (M) when

properly engaged.

4. To remove the bit, pull back the locking sleeve and pull the bit out.

Complete Torque Control (Fig. 4)

NOTICE: Always turn the tool off before changing torque control settings or damage to tool may

result.

The Complete Torque Control (CTC) feature of this tool is designed to provide additional control

with a two-stage clutch mechanism.

Clutch Setting 1 (Q) is designed for most hammerdrilling applications and is designed to easily

clutch out when the drill bit encounters re-bar or other foreign substances.

Clutch Setting 2 (R) is designed for higher torque applications such as core-bits and deep hole

hammerdrilling and is designed to clutch out at a higher torque threshold.

Move the torque control lever (U) to setting 1 or 2 as needed for application.

NOTE: Allow the motor housing to rotate a little while changing torque.

Each time the tool is plugged in, it will automatically default to clutch setting 1, the most

sensitive setting.

Electronic Speed and Impact Control (Fig. 4)

The electronic speed and impact control allows the use of smaller drill bits without the risk of bit

breakage, hammerdrilling into light and brittle materials withoutshattering andoptimaltoolcontrolfor

precise chiseling.

To set the control dial, turn the dial (G) to the desired level. The higher the number, the greater

the speed and impact energy. Dial settings make the tool extremely flexible and adaptable

for many different applications. The required setting depends on the bit size and hardness of

material being drilled.

Mode Selector (Fig. 1)

A CAUTION: Never change the mode while the unit is running.

A CAUTION: Do not change to hammerdrill mode with chisel bit in tool holder. Personal injury

and damage to tool may result.

The D25712 an D25762 use two operating modes. Toselect the required operating mode, rotate

the mode selector (F) until the arrow points to the hammerdrilling or the chipping icon. The

D25831 and D25851 use only the chipping mode.

HAMMERDRILLING MODE (-T)

The tool simultaneously rotates and impacts the work. This mode is appropriate for all concrete

and masonry operations.

CHIPPING MODE (T)

The spindle lock is engaged during chipping mode so the tool impacts the work without

rotating. This mode is appropriate for light chipping, chiseling and demolition applications.

NOTE: In chipping mode, the hammerdrill can also be used as a lever to free a jammed drill bit.

CHISEL BIT ADJUSTMENT (O)

Turn the mode selector to one ofthe chisel bit adjustment icons to adjust the chisel to the desired

position. There are 24 possible positions to set the angle of the chisel. After finding the desired

position, slightly maneuver the chisel bit back and forth to ensure the chisel is properly engaged.

Power Indicator Lights (Fig. 4)

The yellow brushwear indicator LED (S) lights up when the carbon brushes are nearly worn out

indicating that the tool needs servicing within the next 8 hours of use.

The red indicator LED (T) lights up if the lock-on button (B) is used in any mode except the

chipping mode.

The red indicator LED (T) starts to flash if there is a fault with the tool or the brushes have

completely worn out (refer to Brushes under MAINTENANCE).

OPERATION

A WARNING: Toreduce the risk of serious personalinjury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments or

accessories.

_ WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored

or clamped firmly, ff hammerdrilling thin material, use a wood "back-up" block to prevent

damage to the material

_ WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side

handle properly installed and securely tightened. Failure to do so may result in the side

handle slipping during tool operation and subsequent loss of control Hold tool with both hands

to maximize control

Proper Hand Position (Fig. 1)

A WARNING: To reduce the risk of serious personal injury, ALWAYS use proper hand position

as shown.

_ WARNING: To reduce the risk of serious personal injury, AL WAYS hold securely in anticipation

of a sudden reaction.

Proper hand position requires one hand on the side handle (C), with the other hand on the main

handle (D).

NOTE: Operating temperature of this tool is 19°to 104 ° F (-7 to +40° C). Using the tool outside

of this temperature range will decrease the life of the tool.

Trigger Switch (Fig. 1)

To turn the tool on, depress the trigger switch (A). To stop the tool, release the trigger switch. To

lock the trigger switch on in the chipping mode only, push the lock-on slider (B) upwards while

depressing the trigger switch.

To deactivate the lock-on slider, depress the trigger switch once then release.

The lock-on slider may only be activated in chisel mode. The machine will stop running when

trying to engage the lock-on slider in drill mode. The motor will stop if the lock-on slider is

activated when changing from chisel mode into drill mode.

SOFT START FEATURE

The soft start feature allows you to build up speed slowly, thus preventing the drill bit from

walking off the intended hole position when starting. The soft start feature also reduces the

immediate torque reaction transmitted to the gearing and the operator if the hammer is started

with the drill bit in an existing hole.

Hammerdrilling with a Solid Bit

D25712, D25762

NOTE: The D25891 have only chipping modes with no hammerdrilling capability.

1. Set the mode selector to hammerdrilling mode.

2. Move the torque control lever to Setting 1 (Q).

3. Set the speed and impact control dial.

4. Insert the appropriate drill bit.

5. Adjust the side handle (front or rear position).

6. Mark the spot where the hole is to be drilled.

7. Place the drill bit on that mark and depress the trigger switch.

8. Apply only enough pressure to engage active vibration control (refer to Active Vibration

Control).

9. To stop the tool, release the trigger switch. Always turn the tool off when work is finished and

before unplugging.

Hammerdrilling with a Core Bit

D25712, D25762

A CAUTION: Do not use a core bit for hammerdrilling wood. Personal injury and damage to tool

may result.

NOTE: The D25891 has only chipping mode with no hammerdrilling capability.

1. Set the mode selector to hammerdrilling mode.

2. Move the torque control lever to Setting 2 (R).

3. Turn the speed and impact control dial to the maximum torque position.

4. Adjust the side handle (front or rear position).

5. Assemble the centering bit and adapter shank into core bit.

6. Mark the spot where the hole is to be drilled.

7. Place the centering bit on that mark and depress the trigger switch.

NOTE: Some core drills require the removal of centering bit after about 1 cm of penetration. If

so, remove and continue hammerdrilling.

8. When hammerdrilling through a structure thicker than the depth of the core bit, break away

the round cylinder of concrete or core inside the bit at regular intervals. To avoid unwanted

breaking away of concrete around the hole, first drill a hole the diameter of the centering

bit completely through the structure. Then drill the cored hole halfway from each side of

the structure.

9. To stop the tool, release the trigger switch. Always turn the tool off when work is finished and

before unplugging.

Chipping and Chiseling

1. Set the mode selector to chipping mode.

2. Set the impact control dial to desired setting (refer to Electronic Speed and Impact

Control).

Page 3

3.Inserttheappropriatechiselandrotateitbyhandtolockitintothedesiredposition.

NOTE:ForSDSMax®models,onlyuseSDSMax®inserttools.

4.Adjustthesidehandle(frontorrearposition).

5.Depressthetriggerswitch.

6.Applyonlyenoughpressuretoengageactivevibrationcontrol(refertoActiveVibration

Control).

7.Tostopthetool,releasethetriggerswitch.Alwaysturnthetooloffwhenworkisfinishedand

beforeunplugging.

Hammerdrilling (Fig. 1)

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments or

accessories.

_, WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored

or clamped firmly. If hammerdrilling thin material, use a wood "back-up"block toprevent damage

to the material.

Press mode selector button and turn the mode selector (F) to the drill bit symbol for hammerdrilling,

to the hammer symbol for hammering or to the hammerdrill symbol for hammerdrilling.

HAMMERDRILL OPERATION

1. When hammerdrilling, use just enough force on the hammer to keep it from bouncing

excessively or "rising" off the bit. Too much force will cause slower hammerdrilling speeds,

overheating, and a lower hammerdrilling rate.

2. Drill straight, keeping the bit at a right angle to the work. Do not exert side pressure on the bit

when hammerdrilling as this will cause clogging of the bit flutes and a slower hammerdrilling

speed.

3. When hammerdrilling deep holes, if the hammer speed starts to drop off, pull the bit partially

out of the hole with the tool still running to help clear debris from the hole.

4. For masonry, use carbide-tipped bits or masonry bits. A smooth even flow of dust indicates

the proper hammerdrilling rate.

MAINTENANCE

_ WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments or

accessories.

Cleaning

_ WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear

proper ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA

respiratory protection when performing this.

A WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Lubrication

Your tool was properly lubricated before leaving the factory. In from two to six months, depending

upon use, take or send your tool to an authorized service center for a complete cleaning,

inspection and lubrication. Tools used constantly on production jobs will need relubrication more

often. Also, tools "out of service" for long periods should be relubricated before being put back

to work.

Accessories

A WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only DEWALT, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory, please

contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call

1-800-4-DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

MAXIMUM CAPACITY

D25712 D25762 D25891

Concrete > 2" (51 mm) 2" (52 mm) -

RPM 137-275 125-250 -

No load BPM 1260-2520 1150-2300 1150-2300

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including

brush inspection and replacement) should be performed by a DEWALT factory service center,

a DEWALT authorized service center or other qualified service personnel. Always use identical

replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. Forfurther detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first two years after purchase.

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DEWALT for a free replacement.

c'rc COMPLETETORQUE(0NTROL

D25XXX

_USER MUSTREADINSTRUCTION

MANUAL¸ALWAYSUSEPROPEREYErEARAND

RESPIRATORYPROTECTION¸ALWAYSUSESIDEHANDLE

_ INSTRUCCIONESPARA

UNFUNCONAMENTOSE6UROSEMPREUT CE

PROTECCIONAOEDUAOAPARALOSOJOS,OJDOS¥ ViAS

RESPIRATORIAS.SlEMPREUTILIDEELMANGOLATERAL.

BLESSURES,LrUTILISATEURDOlTLIRELEGUIDE

D'UTILISATION.TOUJ OURSUTILISERUNEPROTECTION

OCULAIRErAUDITIVEETRESPIRATOIREADERUATE.

UTILISERLAPOI6NEEL_ERALE.

Ddfinitions : lignes directrices en

Les dCfinitions ci-dessous dCcrivent le niveau de danger pour chaque mot-indicateur

employ& Veuillez lire le mode d'emploi et porter une attention particuli_re & ces

symboles.

i_DANGER : indique une situation dangereuse imminente qui, si elle n'est pas

evitCe, causera la mort ou des blessures graves.

i_,AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle

n'est pas evitCe, pourra# se solder par un d#ces ou des blessures graves.

i_,ATTENTION : indique une situation potentiellement dangereuse

qui, si elle n'est pas evitCe pourra# se solder par des blessures mineures ou

mod#r#es.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n'est fair pour/'eviter, pourrait poser des risques de dommages

materiels.

POUR TOUTE QUESTION OU TOUT COMMENTAIRE RELATIF ,&, CET OUTIL OU A

PROPOS DE TOUT AUTRE OUTIL DEWALT, COMPOSER SANS FRAIS LE •1-800-4-DEWALT

(1-800-433-9258).

2 YEARS FREE SERVICE

90 DAY MONEY BACK GUARANTEE

SER._

TOREDUCETHERISK0FINJURYr

LEAELMANUALDE

LESRISQUESDE

D25891sos. ×,o

MANUAL.ALWAYS USEPROPEREYE,EARAND

RESPIRATORYPROTECTION.ALWAYS USESIDEHANDLE.

FUNUIUNAMIENTOSEGURO.SIEMPRE UTILK.E

PROTECCIONADEUUADAPAUA LOSUJUS,OIDUSY VJAS

RESPIRATORIAS.SIEMPUE UTILICEELMANGO LATERAL.

_ AFINDEMINIMISER

BLESSURES,L'UTILISATEUUDOlT LIRELEGUIDE

U'UTILISATION.TOUJUURSUTILISERUNE PROTECTION

OCULAIRE,AUUITWEETRESPIRATNIREADEQUATE.

UTILISERLAPUIGNEEkATERALE.

OEWAET INDUSTRIAL TOOL CO., BALTIMORE, MD 212fj6 USA

FOR SERVICE INFORMATION, CALL 1-800-4-OEWAET

www. DEWAET.com

CHIPPING HAMMER

SER.

matidre de sdcuritd

TOREDUCETHERiSK OFINJURY,

USER MUSTREAD INSTRUCTION

LEA ELMANUAL DE

INSTRUCCIUNESPARAUN

LESRISQUES DE

| Brush Service

J

_ AVERTISSEMENT :afin de reduire le risque de blessures, Iire le mode d'emploi de Ibutil.

Avertissements de sdcuritd gdndraux pour les outils

dlectriques

non-respect des avertissements et des directives pourrait se solder par un choc

A AVERTISSEMENT! Lire tousles avertissements de securite et les directives. Le

electrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS ET TOUTES

LES DIRECTIVES POUR UN USAGE ULTERIEUR

Le terme , outil electrique _,cite clans les avertissements se rapporte a votre outil electrique

alimentation sur secteur Cavedill) ou par piles (sans ill).

1) S#OURIT# DU LIEU DE TRAVAIL

a) Tenir I'aire de travail propre et bien eclairee. Les lieux encombres ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner d'outils electriques clans un milieu deflagrant, tel qu'en

presence de liquides, de gaz ou de poussieres inflammables. Les outils electriques

produisent des etincelles qui pourraient enflammer la poussiere ou les vapeurs.

c) _:loigner les enfants et les personnes a proximite pendant I'utilisation d'un outil

electrique. Une distraction pourrait en faire perdre la maftrise a I'utillsateur.

2) SI_CURITI_ EN MATIERE D'I_LECTRICITI_

a) Les fiches des outils electriques doivent correspondre a la prise. Ne jamais modifier

la fiche d'aucune fa_on. Ne jamais utiliser de fiche d'adaptation avec un outil

electrique mis a la terre. Le risque de choc electrique sera reduit par I'utilisation de fiches

non modifi#es correspondant a la prise.

b) _:viter tout contact physique avec des surfaces mises a la terre comme des tuyaux,

des radiateurs, des cuisinieres et des refrigerateurs. Le risque de choc electrique est

plus eleve si votre corps est mis a la terre.

c) Ne pas exposer les outils electriques a la pluie ou a I'humidite. La penetration de I'eau

dans un outil electrique augmente le risque de choc electrique.

d) Ne pas utiliser le cordon de fa_on abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou debrancher un outil electrique. Tenir le cordon eloigne de

la chaleur, de I'huile, des bords tranchants et des pieces mobiles. Les cordons

endommages ou enchevCtres augmentent les risques de choc electrique.

e) Pour I'utilisation d'un outil electrique a I'exterieur, se servir d'une railonge convenant

cette application. L'utilisation d'une rallonge con_ue pour I'exterieur reduira les risques

de choc electrique.

f) S'il est impossible d'eviter I'utilisation d'un outil electrique clans un endroit humide,

brancher I'outil dans une prise ou sur un circuit d'alimentation dotes d'un disjoncteur de

fuite a la terre (GFCI). L'utilisation de ce type de disjoncteur reduit les risques de choc

electrique.

3) S#CURIT# PERSONNELLE

a) F=trevigilant, surveiller le travail effectue et faire preuve de jugement Iorsqu'un outil

electrique est utilise. Ne pas utiliser d'outil electrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de medicaments. Un simple moment d'inattention

en utilisant un outil electrique peut entrafner des blessures corporelles graves.

b) Utiliser des equipements de protection individueile. Toujours porter une protection

oculaire. L'utilisation d'equipements de protection comme un masque antipoussiere, des

chaussures antiderapantes, un casque de securite ou des protecteurs auditifs Iorsque la

situation le requiert reduira les risques de blessures corporelles.

c) EmpCcher les demarrages intempestifs. S'assurer que I'interrupteur se trouve a la

position d'arrCt avant de relier I'outil a une source d'alimentation et/ou d'inserer un

bloc-piles, de ramasser ou de transporter I'outil. Transporter unouti/ e/ectrique a/ors

que le doigt repose sur I'interrupteur ou brancher un outil electrique dont I'interrupteur est

la position de marche risque de provoquer un accident.

d) Retirer route Die de reglage ou Die avant de demarrer I'outil. Une cle ou une cle de

reglage attachee a une partie pivotante de Ibutil electrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son equilibre en tout temps. Cela permet de

mieux maftriser Ibutil electrique dans les situations imprevues.

f) S'habiller de maniere appropriee. Ne pas porter de vCtements amples ni de bijoux.

Carder les cheveux, les vCtements et les gants a I'ecart des pieces mobiles. Les

vCtements amples, les bijoux ou les cheveux longs risquent de rester coinces dans les

pieces mobiles.

g) Sides composants sont fournis pour le raccordement de dispositifs de depoussierage

et de ramassage, s'assurer que ceux-ci sont bien raccordes et utilises. L'utillsation

d'un dispositif de depoussierage peut reduire les dangers engendres par les poussieres.

4) UTILISATION ET ENTRETIEN D'UN OUTIL I_LECTRIQUE

a) Ne pas forcer un outil electrique. Utiliser I'outil electrique approprie a I'application.

L'outil electrique approprie effectuera un meilleur travail, de fa_on plus s_re eta la vitesse

pour laquelle il a ere con_u.

b) Ne pas utiliser un outil electrique dont I'interrupteur est defectueux. Tout outil

electrique dont I'interrupteur est defectueux est dangereux et doit 6tre repare.

c) Debrancher la fiche de la source d'alimentation et/ou du bloc-piles de I'outil

electrique avant de faire tout reglage ou changement d'accessoire ou avant de

ranger I'outil. Ces mesures preventives reduisent les risques de demarrage accidentel de

I'outil electrique.

d) Ranger les outils electriques hors de la portee des enfants et ne permettre

aucune personne n'etant pas familiere avec un outil electrique ou son mode

d'emploi d'utiliser cet outil. Les outils electriques deviennent dangereux entre les mains

d'utilisateurs inexperimentes.

e) Entretien des outils electriques. Wrifier si les pieces mobiles sont mal alignees ou

coincees, si des pieces sont brisees ou presentent route autre condition susceptible

de nuire au bon fonctionnement de I'outil electrique. En cas de dommage, faire

reparer I'outil electrique avant route nouveile utilisation. Beaucoup d'accidents sont

causes par des outils electriques mal entretenus.

f) S'assurer que les outils de coupe sont aiguises et propres. Les outils de coupe

bien entretenus et aff_tes sont moins susceptibles de se coincer et sont plus faciles

maftriser.

g) Utiliser I'outil electrique, les accessoires, les forets, etc. conformement aux

presentes directives en tenant compte des conditions de travail et du travail

effectuer. L'utillsation d'un outil electrique pour route operation autre que celle pour laquelle

il a ere con_u est dangereuse.

5) RE_PARATION

a) Faire reparer I'outil electrique par un reparateur professionnel en n'utilisant que des

pieces de rechange identiques. Cela permettra de maintenir une utillsation securitaire

de I'outil electrique.

Consignes de s_curit_ additionnelles propres aux

marteaux rotatifs

• Porter un dispositif de protection auditif. Le bruit en resultant pourrait occasionner une

perte de I'acuite auditive.

• Utiliser la/les poignee(s) auxiliaire(s) si fournie(s) avec I'outil. Une perte de contrCle de

I'outil pourrait occasionner des dommages corporels.

• Tenir I'outil par les surfaces isolees prevues a cet effet pendant route utilisation ob

I'organe de coupe pourrait entrer en contact avec des ills electriques caches ou

son propre cordon. Tout contact de I'organe de coupe avec un fil sous tension mettra les

parties metalliques exposees de I'outil sous tension et electrocutera I'utillsateur.

• Utiliser des serre-joints, ou tout autre moyen, pour fixer et immobiliser le materiau

sur une surface stable. Tenir la piece a la main ou contre son corps offre une stabilite

insuffisante qui pourrait vous en faire perdre le contr&le.

• Porter des lunettes de protection ou route autre protection oculaire. Le martelage

pourrait faire voltiger des eclats. Ces particules volantes pourraient occasionner des

dommages oculaires permanents. Porter un masque anti-poussieres ou un appareil de

protection des voies respiratoires pour route application productrice de poussieres. Une

protection auditive peut s'averer necessaire pour la plupart des applications.

• Maintenir systematiquement I'outil fermement. Ne pas tenter d'utiliser cet outil sans

le maintenir a deux mains. II est recommande d'utiliser systematiquement la poignee

laterale. Le fair d'utillser cet outil a une main pourra vous en faire perdre le contr&le. Traverser

ou rencontrer des materiaux durs comme les armatures peut aussi s'averer dangereux.

Resserrer soigneusement la poignee laterale avant route utilisation.

• Ne pas utiliser cet outil pendant des periodes de temps prolongees. Les vibrations

causees par la percussion peuvent poser des risques pour les mains ou les bras. Porter des

gants pour amortir les vibrations, et pour limiter les risques, faire des pauses frequentes.

• Ne pas remettre a neuf les forets soi-mCme. La remise a neuf de tout burin doit 6tre

effectuee par un speciallste agree. Tout burin remis a neuf incorrectement pose des risques

de dommages corporels.

• Porter des gants lore de I'utilisation de I'outil ou le changement de meche. Les parties

metalliques accessibles de I'outil et des meches/forets pourraient s'averer brDlantes lots de

I'utillsation. De petits debris de materiau pourraient aussi blesser les mains hues.

• Attendre systematiquement I'arrCt complet de la meche/foret avant de deposer I'outil

ob que ce soit. Des forets/meches en rotation posent des risques de dommages corporels.

• Ne pas donner des coups de marteau sur des forets/meches coinces pour les deloger.

Des fragments de metal ou de materiau pourraient 6tre ejectes et causer des dommages

corporels.

Page 4

• Les burins legerement uses peuvent 6tre reaffutes.

REMARQUE : ne pas surchauffer une meche (jusqu'a sa decoloration) pendant le

reaffutage. Les burins tres emousses doivent 6tre remarteles. Ne pas retremper un burin ou

en faire un revenu.

• Maintenir le cordon d'alimentation a I'ecart d'une meche en rotation. Ne pas enrouler

le cordon autour d'une partie quelconque de votre corps. Un cordon electrique enroule

autour d'une meche en rotation pose des risques de dommages corporels et de perdre le

contr61e de I'outiL

• Prendre des precautions a proximite des events, car ils cachent des pieces mobiles.

V6tements amples, bijoux ou cheveux longs risquent de rester coinces dans ces pieces

mobiles.

• Pour la securite de I'utilisateur, utiliser une rallonge de calibre adequat (AWG,

American Wire Gauge [calibrage americain normalise des ills electriques]). Plus

le calibre est petit, et plus sa capacite est grande. Un calibre 16, par exemple, a plus de

capacite qu'un calibre 18. L'usage d'une rallonge de calibre insuffisant causera une chute de

tension entrafnant perte de puissance et surchauffe. Si plusieurs rallonges sont necessaires

pour obtenir une certaine Iongueur, s'assurer que chaque rallonge presente au moins le

calibre de fil minimum. Le tableau ci-dessous illustre les calibres a utiliser selon la Iongueur

de rallonge et I'intensite nominale indiquee sur la plaque signaletique. En cas de doute,

utiliser le calibre suivant. Plus le calibre est petit, plus la rallonge peut supporter de courant.

Calibres minimaux des rallonges

Volts

Intensit6 (en amperes)

Plus de

0

6

10

12

AAVERTISSEMENT : Porter SYSTEMATIQUEMENT des lunettes de protection. Les lunettes

courantes NE sont PAS des lunettes de protection. Utiliser aussi un masque antipoussieres si

la decoupe doit en produire beaucoup. PORTER SYSTEMATIQUEMENT UN EQUIPEMENT

DE SECURITE HOMOLOGUE :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3 ;

• Protection auditive ANSI $12.6 ($3.19) ;

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

A_AVERTISSEMENT : Les scies, meules, ponceuses, perceuses ou autres outils de

construction peuvent produire des poussieres contenant des produits chimiques reconnus pour

causer cancers, malformations congenitales ou 6tre nocifs au systeme reproducteur. Parmi ces

produits chimiques, on retrouve :

• le plomb dans les peintures a base de plomb ;

• la silice cristallisee dans les briques et le ciment ou autres articles de ma_onnerie ; et

• I'arsenic et le chrome dans le bois ayant subi un traitement chimique.

Le risque associe a de telles expositions varie selon la frequence a laquelle on effectue ces

travaux. Pour reduire toute exposition aces produits : travailler dans un endroit bien aere, en

utilisant du materiel de securite homologue tel un masque antipoussieres specialement con_u

pour filtrer les particules microscopiques.

• Limiter tout contact prolonge avec les poussieres provenant du pon_age, sciage,

meulage, per_age ou toute autre activite de construction. Porter des v6tements de

protection et nettoyer a I'eau savonneuse les parties du corps exposees. Le fait de

laisser la poussiere penetrer dans la bouche, les yeux ou la peau peut provoquer I'absorption

de produits chimiques dangereux.

AAVERTISSEMENT : Cet outil peut produire et/ou repandre de la poussiere susceptible de

causer des dommages serieux et permanents au systeme respiratoire. Toujours utiliser un

appareil respiratoire antipoussieres homologue par le NIOSH ou I'OSHA. Diriger les particules

dans le sens oppose au visage et au corps.

_AVERTISSEMENT : Porter systematiquement une protection oculaire. Tout utilisateur ou

individu present doit porter une protection oculaire homologuee ANSI Z87.1.

AAVERTISSEMENT : Pendant I'utilisation, porter systematiquement une protection

auditive individuelle adequate homologuee ANSI S12.6 ($3.19). Sous certaines conditions

et suivant la Iongueur d'utilisation, le bruit emanant de ce produit pourrait contribuer a une perte

de I'acuite auditive.

• L'etiquette apposee sur votre outil peut inclure les symboles suivants. Les symboles et leur

definition sont definis ci-apres :

V................... volts

Hz................. hertz

min ............... minutes

- -- ............ courant continu

@ ................. Classe / Fabrication

[] ................. Classe II Fabrication

.../min .......... par minute

Pas plus de

6

10

12

16

(mis a la terre)

(double isolation)

120V 7,6 (25) 30,5 (100) 45,7 (150)

240V 15,2 (50) 61,0 (200) 91,4 (300)

Longueur totale de cordon en m_tres (pieds)

15,2 (50)

30,5 (100)

AWG

18

18

16

14

A.................... amperes

W................... watts

no .................. vitesse a vide

_, .................. symbole d'avertissement

BPM .............. battements par minute

R/MIN ............ tours par minute

16

16

16

12

................. courant alternatif

................. courant alternatif ou continu

.................. borne de terre

16 14

14 12

14 12

Non recommand6

Moteur

Votre outil DEWALT est 6quip6 d'un moteur d'origine DEWALT. S'assurer que le courant utilis6

correspond bien & celui indiqu6 sur la plaque signal6tique. Une baisse de tension de plus de

10% causera perte de puissance et surchauffe. Tousles outils DEWALT sont test6s en usine.

DESCRIPTION (Fig. 1)

_AVERTISSEMENT : Ne jamais modifier I'outil electrique ni aucun de ses composants. IIy a

risques de dommages corporels ou materiels.

A. G&chette E S61ecteur de mode

B. Glissi_re de verrouillage G. R6gulateur 61ectronique de vitesse et d'impact

C. Poign6e lat6rale H. Bouton de fixation

D. Poign6e principale I. Position arri_re de la poign6e lat6rale

E. Syst_me d'amortissement des vibrations

USAGE PRI_VU

Ces marteaux rotatifs industriels ont 6t6 congus pour le martelage-perforage et le burinage

professionnels sur des chantiers divers (ex. :chantiers de construction). NE PAS les utiliser en

milieu ambiant humide ou en pr6sence de liquides ou de gaz inflammables.

Ces marteaux rotatifs industriels sont des outils de professionnels. NE PAS les laisser & la

port6e des enfants. Une supervision est n6cessaire aupr_s de tout utilisateur non exp6riment6.

ASSEMBLAGE ET REGLAGES

Poignde latdrale (Fig. 1)

_AVERTISSEMENT : pour reduire tout risque de dommages corporels, utiliser

SYSTEMATIQUEMENT I'outil avec sa poignee laterale installee correctement et solidement

arrimee. Toutmanquement a cette directive pourrait faire que la poignee laterale glisse pendant

I'utilisation de I'outil et entrafner la perte du contr61e de celui-cL Maintenir I'outil fermement

deux mains pour un contr61e optimal

La poign6e lat6rale se fixe sur le barillet avant (collier) et peut effectuer une rotation de 360 o

pour permettre d'etre utilis6e par un gaucher ou un droitier. Pour faciliter I'utilisation, la poign6e

lat6rale peut _tre install6e sur la position avant ou arri_re.

INSTALLATION EN POSITION AVANT (FIG. 3)

1. D6vissez la poign6e lat6rale (C) et d6montez le dispositif de fixation de la poign6e lat6rale

(J).

2. Enclenchez la bague d'acier (K) sur le collier (L) derriere le porte-outil (M). Appuyez en

m_me temps sur les deux extr6mit6s de la bague d'acier. Installez la bague (N) puis ins6rez

la goupille (O).

3. Repoussez le dispositif de fixation de la poign6e lat6rale (J) et I'anneau sur le bouton de

fixation (H) (ne pas resserrer).

4. Vissez la poign6e lat6rale (C) sur le bouton de fixation (H) puis serrez & fond.

5. Faites tourner le dispositif de la poign6e lat6rale sur la position d6sir6e. Pour le martelage-

perforage horizontal avec un foret 6pais, placez le dispositif de la poign6e lat6rale & un

angle approximatif de 20 ° de routil pour optimiser le contr61e de ce dernier.

6. Verrouillez le dispositif de fixation de la poign6e lat6rale en place en resserrant le bouton de

fixation (H).

INSTALLATION EN POSITION ARRI#RE (FIG. 3)

1. D6vissez la poign6e lat6rale (C) et retirez-la du dispositif de fixation de la poign6e lat6rale.

Laissez le dispositif de la poign6e lat6rale sur la position d6sir6e.

2. Vissez directement la poign6e lat6rale sur I'une de ses positions arri_re (I) d'un c6t6 ou de

I'autre de I'outil.

Systdme d'amortissement des vibrations (Fig. 1)

Pour optimiser le contr61e des vibrations, maintenez I'outil une main sur la poign6e principale

(D) et I'autre sur la poign6e lat6rale (C). Appliquez juste assez de pression sur le marteau

de fagon & ce qu'il tourne & mi-r6gime. Seule une quantit6 limit6e de pression sur le marteau

est n6cessaire pour activer le syst_me d'amortissement. Appliquer une pression excessive

sur I'outil ne le fera ni percer ni buriner plus rapidement et pr6viendra I'activation du syst_me

d'amortissement.

Installation et retrait des accessoires SDS Max _ (Fig. 3)

_AVERTISSEMENT : pour reduire tout risque de dommages corporels graves, arr6ter et

debrancher I'outil avant tout reglage ou avant de retirer ou installer toute piece ou tout

accessoire.

1. Tirez vers I'arri_re le manchon de verrouillage (P) et ins6rez une tige de m_che. La tige de

m_che doit _tre propre et 16g_rement lubrifi6e.

2. Tournez la m_che 16g_rement jusqu'& ce que le manchon s'enclenche en position.

3. Assurez-vous que la m_che est correctement arrim6e.

REMARQUE : la m_che doit pouvoir bouger de quelques centim_tres, vers I'avant ou

I'arri_re, dans le porte-outil (M) pour _tre correctement install6e.

4. Pour retirer la m_che, tirez le manchon de verrouillage vers I'arri_re et sortez la m_che.

Correcteur de couple intdgral (Fig. 4)

AVIS : arr6ter systematiquement I'outil avant de changer les parametres de couples pour eviter

d'endommager I'outiL

La fonctionnalit6 de correcteur de couple int6gral (CCI) de cet outil a 6t6 congue pour permettre

d'optimiser le contr61e gr&ce & un m6canisme d'embrayage & deux phases.

Le r6glage de couple 1 (Q) a 6t6 congu pour la plupart des applications de martelage-perforage

et pour d6brayer facilement Iorsque la m_che rencontrera une armature ou tout autre mat6riel

6tranger.

Le r6glage de couple 2 (R) a 6t6 pr6vu pour des applications n6cessitant un couple 61ev6

comme le pergage &percussion avec tr6pans carottiers ou m_ches demi-rondes et congu pour

d6brayer & un seuil plus 61ev6 de couple.

D6placez le levier du r6gulateur de couple (U) sur les r6glages 1 ou 2 en fonction de I'application.

REMARQUE : laisser le boftier du moteur tourner un peu avant de changer le couple.

Chaque fois que I'outil sera branch6, il retournera automatiquement par d6faut sur le r6glage

d'embrayage 1, le r6glage le plus sensible.

R_gulateur _lectronique de vitesse et d'impact (Fig. 4)

Le r6gulateur 61ectronique de vitesse et d'impact permet I'utilisation de m_ches plus petites

sans risquer de les briser, le pergage & percussion de mat6riaux 16gersou fragiles sans les faire

6clater, et I'optimisation du contr61e de I'outil pour le ciselage de pr6cision.

Pour I'ajuster, tournez le r6gulateur (G) sur le niveau d6sir6. Plus le chiffre est 61ev6, plus

la vitesse et 1'6nergie d'impact seront grandes. Les param_tres du r6gulateur rendent I'outil

extr_mement flexible et adaptable &diff6rentes applications. Le r6glage requis d6pendra de la

taille de la m_che et de la duret6 du mat6riau & percer.

Sdlecteur de mode (Fig. 1)

_ATTENTION :ne jamais changer de mode alors que I'appareil tourne.

i_ATTENTION : ne pas passer au mode martelage-perforage avec un foret dans le porte-outil

pour prevenir tout risque de dommages corporels ou materiels.

Les modules D25712 et D25762 poss_dent deux modes d'op6rations. Pour choisir le mode

d'utilisation requis, tournez le s61ecteur de mode (F) jusqu'& ce que la fl_che pointe sur I'ic6ne

martelage-perforage ou burinage. Les modules D25831 et D25851 ne poss_dent que le mode

burinage.

MODE MARTELAGE-PERFORAGE (-T)

I'outil tourne et percute simultan6ment la piece & travailler. Ce mode est appropri6 pour travailler

le b6ton et la magonnerie.

MODE BURINAGE (T)

Le verrou de la broche est activ6 en mode burinage de fagon & permettre la percussion sans

rotation. Ce mode est appropri6 pour la d6molition, le burinage et le ciselage 16gers.

REMARQUE : en mode burinage, le marteau-perforateur peut aussi _tre utilis6 comme levier

pour d6bloquer une m_che enray6e.

RI_GLAGE DU FORET (O)

Tournez le s61ecteur de mode sur I'une des ic6nes de r6glage de foret pour I'ajuster sur la

position d6sir6e. Le burin peut _tre r6g16sur 24 positions d'angles. Une fois la position d6sir6e

choisie, d6placez 16g_rement d'avant en arri_re le foret pour vous assurer qu'il est correctement

engag6.

Voyants d'alimentation (Fig. 4)

Le voyant DEL jaune (S) d'usure des balais s'allumera Iorsque les balais de charbon seront

presque us6s pour indiquer que la maintenance de I'outil devrait _tre effectu6e dans les 8 heures

d'utilisation.

Le voyant DEL rouge (T) s'allumera Iorsque le bouton de verrouillage en position de marche (B)

sera activ6 dans tousles modes, except6 celui de burinage.

Le voyant DEL rouge (T) clignotera en cas de probl_me avec I'outil ou si les balais sont

compl_tement us6s (se reporter & la section Balais sous MAINTENANCE).

FONCTIONNEMENT

_AVERTISSEMENT : Pour reduire tout risque de dommages corporels graves, arr6ter et

debrancher I'outil avant tout reglage ou avant de retirer ou installer toute piece ou tout

accessoire.

J_AVERTISSEMENT : pour reduire tout risque de dommages corporels, s'assurer

SYSTEMATIQUEMENT que la piece est ancree ou arrimee solidement. Pour le martelage-

perforage de materiaux fins, utiliser un morceau de bois , de renfort _, pour eviter de les

endommager.

_AVERTISSEMENT : Pour reduire tout risque de dommages corporels, utiliser

SYSTEMATIQUEMENT I'outil avec sa poignee laterale installee correctement et solidement

arrimee. Tout manquement a cette directive pourrait faire que la poignee laterale glisse pendant

I'utilisation de I'outil et entrafner la perte du contr61e de celui-cL Maintenir I'outil fermement

deux mains pour un contr61e maximum.

Position correcte des mains (Fig. 1)

_AVERTISSEMENT : Pour reduire tout risque de dommages corporels graves, adopter

SYSTEMATIQUEMENT la position des mains illustree.

AAVERTISSEMENT : Pour reduire tout risque de dommages corporels graves, Maintenir

SYSTEMATIQUEMENT I'outil fermement pour anticiper toute reaction soudaine.

La position correcte des mains requiert une main sur la poign6e lat6rale (C), et I'autre sur la

poign6e principale (D).

REMARQUE : il est recommand6 d'utiliser cet outil & des temp6ratures entre -7 ° et +40 °C (19 °

et 104 °F). I'utilisation de cet outil en dehors de ces temp6ratures en r6duira la dur6e de vie.

G_chette (Fig. 1)

Pour mettre I'outil en marche, appuyez sur la g&chette (A). Pour arr_ter I'outil, rel&chez la

g&chette. Pour verrouiller la g&chette sur le mode burinage seulement, poussez la glissi_re de

verrouillage (B) vers le haut tout en appuyant sur la g&chette.

Pour d6sactiver la glissi_re de verrouillage, r6appuyez rapidement une fois sur la g&chette.

La glissi_re de verrouillage ne peut _tre activ6e qu'en mode ciselage. I'appareil s'arr_tera

de fonctionner si on tente d'activer la glissi_re de verrouillage en mode pergage. Le moteur

s'arr_tera de tourner si la glissi_re de verrouillage est activ6e pour passer du mode ciselage au

mode pergage.

FONCTION D#MARRAGE EN DOUCEUR

La fonction d6marrage en douceur permet d'accroftre la vitesse progressivement, pour pr6venir

que la m_che quitte la position d6sir6e pour le trou au d6marrage. La fonction d6marrage

en douceur r6duit aussi la transmission imm6diate de retour de couple & I'engrenage et &

I'utilisateur si le marteau venait & d6marrer alors que la m_che est dans un trou existant.

Martelage a percussion avec un trdpan plein

D25712, D25762

REMARQUE : le module D25891 ne poss_de que le mode burinage et pas de martelage-

perforage.

1. R6glez le s61ecteur de mode sur le mode martelage-perforage.

2. Ajustez le levier du r6gulateur de couple sur le r6glage 1 (Q).

3. R6glez le r6gulateur 61ectronique de vitesse et d'impact.

4. Ins6rez la m_che appropri6e.

5. Ajustez la poign6e lat6rale (position arri_re ou avant).

6. Marquez I'endroit ot_le trou doit _tre perc6.

7. Placez la m_che sur le trac6 et appuyez sur la g&chette.

8. Appliquez seulement une quantit6 limit6e de pression sur le marteau pour activer le syst_me

d'amortissement (se reporter & la section Syst_me d'amortissement des vibrations).

9. Pour arr_ter I'outil, rel&chez la g&chette. Mettez syst6matiquement rinterrupteur en position

d'arr_t une fois le travail termin6 et avant de d6brancher I'outil.

Per_:age a percussion avec un trdpan carottier

D25712, D25762

_&ATTENTION : ne pas utiliser un trepan carottier pour le per_age a percussion du bois pour

prevenir tout risque de dommages corporels ou materiels.

REMARQUE : le module D25891 ne poss_de que le mode burinage et pas de martelage-

perforage.

1. R6glez le s61ecteur de mode sur le mode martelage-perforage.

2. Ajuster le levier du r6gulateur de couple sur le r_glage 2 (R).

3. Tournez le r6gulateur 61ectronique de vitesse et d'impact sur la position de couple maximum.

4. Ajustez la poign6e lat6rale (position arri_re ou avant).

5. Installez la m_che de centrage et I'adaptateur de tige sur le tr6pan carottier.

6. Marquez I'endroit oQ le trou doit _tre perc6.

7. Placez la m_che de centrage sur le trac6 et appuyez sur la g&chette.

Page 5

REMARQUE:certainstrGpanscarottiersnGcessitentleretraitdelam_chedecentrageapr_s

1cmdepGnGtration.Sic'estlecas,retirez-lapuiscontinuezlepergage&percussion.

8.Pourlepergage&percussion&traversunestructureplus6paissequelaIongueurdu

trGpancarottier,cassezlecylindredebGton,oucarotte,&I'intGrieurdutrGpan&intervalles

rGguliers.Pour6vitertoutfendillementindGsirabledubGtonautourdutrou,perceztout

d'aborduntroududiam_tredelam_chedecentrageautraversdelastructure.Puis

percezletroumoul6demoiti6dechaquec6t6delastructure.

9.PourarrGterI'outil,rel&chezlag&chette.MettezsystGmatiquementI'interrupteurenposition

d'arrGtunefoisletravailtermingetavantdedGbrancherI'outil.

Burinage et ciselage

1. RGglez lesGlecteur de mode sur le mode burinage.

2. RGglez le rGgulateur 61ectronique d'impact sur le param_tre dGsir6 (se reporter & la section

RGgulateur 61ectronique de vitesse et d'impact).

3. InsGrez le burin appropri6 et faites le tourner manuellement pour le verrouiller sur la position

requise.

REMARQUE : pour les modules SDS Max®, utiliser exclusivement des accessoires

SDS Max®.

4. Ajustez la poign6e lat6rale (position arri_re ou avant).

5. Appuyez sur la g&chette.

6. Appliquez seulement une quantit6 limit6e de pression sur le marteau pour activer le syst_me

d'amortissement (se reporter & la section Systbme d'amortissement des vibrations).

7. Pour arrGter I'outil, rel&chez la g&chette. Mettez systGmatiquement I'interrupteur en position

d'arrGt une fois le travail terming et avant de dGbrancher I'outil.

Per_:age a percussion (Fig. 1)

A AVERTISSEMENT : pour reduire tout risque de dommages corporels graves, arrGter et

debrancher I'outil avant tout reglage ou avant de retirer ou installer toute piece ou tout

accessoire.

J_AVERTISSEMENT : pour reduire tout risque de dommages corporels, s'assurer

SYSTEMATIQUEMENT que la piece est ancree ou arrimee solidement. Pour le martelage-

perforage de materiaux fins, utiliser un morceau de bois , de renfort _ pour eviter de les

endommager.

Appuyez sur le bouton sGlecteur de mode puis tournez le sGlecteur de mode (F) sur le symbole

de m_che pour le pergage & percussion, sur le symbole marteau pour le martelage ou lesymbole

marteau-perforateur pour le martelage & percussion.

MARTELAGE-PERFORAGE

1. Pour le martelage-perforage, appliquez juste assez de force sur le marteau pour I'empGcher

de rebondir excessivement ou sortir du trou. Un exc_s de force ralentira la vitesse du

pergage & percussion, entrainera surchauffe et rGduira le rendement.

2. Maintenez I'outil bien droit avec la m_che & angle droit avec le travail en cours. N'exercez

aucune pression latGrale sur la m_che Iors du pergage & percussion, car cela encrasserait

les goujures de m_che et ralentirait la vitesse du perforage & percussion.

3. Pour le perforage & percussion de trous profonds, si la vitesse du marteau venait & baisser,

retirez partiellement la m_che du trou alors que I'outil est toujours en marche pour aider

I'expulsion des dGbris.

4. Pour la magonnerie, utilisez des m_ches au carbure ou & magonnerie. Un jet fluide et

rGgulier de dGbris sera indicateur d'une vitesse adGquate de pergage & percussion..

MAINTENANCE

_AVERTISSEMENT : Pour reduire tout risque de dommages corporels graves, arrGter et

debrancher I'outil avant tout reglage ou avant de retirer ou installer toute piece ou tout

accessoire.

Entretien

_AVERTISSEMENT : Expulser tout debris ou poussiere des events a I'aide d'un jet d'air sec

au moins une fois par semaine. Porter une protection oculaire ANSI Z87.1 (CAN/CSA Z94.3) et

respiratoire NIOSH/OSHA/MSHA adequates pour effectuer cette operation.

AAVERTISSEMENT : Ne jamais utiliser de solvants ou tout autre produit chimique decapant

pour nettoyer les parties non metalliques de I'outiL Ces produits chimiques pourraient attaquer

les materiaux plastiques utilises. Utilisez un chiffon humidifie avec de I'eau et un savon doux.

S'assurer qu'aucun liquide ne penetre dans I'outil ; ne jamais immerger aucune partie de I'outil

dans un liquide.

Lubrification

Votre outil a 6t6 parfaitement lubrifi6 avant son dGpart d'usine. Entre deux & six mois, selon

la frGquence d'utilisation, amenez ou envoyez votre outil dans un centre de rGparation agr66

DEWALT pour entretien, inspection et lubrification complets. Les outils utilisGs constamment pour

des travaux de production nGcessiteront d'etre lubrifiGs plus souvent. Les outils inutilisGs pendant

des pGriodes prolongGes doivent _tre relubrifiGs avant rGutilisation.

Accessoires

_AVERTISSEMENT : Comme les accessoires autres que ceux fournis par DEWALT n'ont pas

6t6 testGs avec ce produit, leur utilisation avec cet appareil pourrait comporter un danger. Pour

rGduire tout risque de dommages corporels, seuls des accessoires DEWALT recommandGs

doivent _tre utilisGs avec cet appareil.

Les accessoires recommandGs pour cet outil sont vendus sGparGment chez les distributeurs

Iocaux ou dans les centres de rGparation agr66s. Si vous avez besoin d'aide pour Iocaliser ces

accessoires, veuillez contacter DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

MD 21286 ou appeler 1-800-4-DEWALT (1-800-433-9258) ou vous rendre sur notre site www.

dewalt.com.

CAPACITIESMAXIMALESRECOMMANDI_ES

D25712 D25762 D25891

BGton > 2" (51 mm) 2" (52 mm) -

R/MI N 137-275 125-250 -

BPM &vide 1 260-2 520 1 150-2 300 1 150-2 300

Rdparations

Pour assurer la SI2CURITI2 et la FIABILITI2 du produit, les rGparations, I'entretien et les rGglages

(y compris I'inspection et le remplacement de la brosse) doivent _tre rGalisGspar un centre de

rGparation en usine DEWALT, un centre de rGparation autoris6 DEWALT ou par un personnel de

rGparation professionnel. Toujours utiliser des pi_ces de rechange identiques.

Garantie limit_e trois ans

DEWALT rGparera gratuitement tous les probl_mes dus & des dGfauts de matGriau ou de

fabrication pendant trois ans & compter de la date d'achat. Cette garantie ne couvre pas des

dGfaillances de piece dues & une usure normale ou & une mauvaise utilisation de I'outil. Pour

plus de dGtails relatifs & la couverture de la garantie et aux rGparations sous garantie, visiter le

site Web www.dewalt.com ou composer le 1 (800) 4-DEWALT (1 (800) 433-9258). Cette garantie

ne s'applique pas aux accessoires ni aux dommages causGs par des rGparations rGalisGes ou

tentGes par des tiers. Cette garantie vous accorde des droits 16gaux spGcifiques et il est possible

que vous ayez d'autres droits qui varient d'un Etat ou d'une province & I'autre.

En plus de la garantie, les outils DEWALT sont couverts par notre •

SERVICE D'ENTRETIEN GRATUlT DE 2 ANS

DEWALT entretiendra I'outil et remplacera les pi_ces usGes par une utilisation normale et ce,

gratuitement, en tout temps, pendant deux ans & compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n'_tes pas enti_rement satisfait des performances de votre outil 61ectrique, laser ou de

votre cloueuse DEWALT pour quelque raison que ce soit, vous pouvez le retourner accompagn6

d'un regu dans les 90 jours suivant la date d'achat et nous vous rembourserons enti_rement -

sans poser de questions.

AMI_RIQUE LATINE : cette garantie ne s'applique pas aux produits vendus en AmGrique latine.

Pour ceux-ci, veuillez consulter les informations relatives & la garantie spGcifique prGsente dans

I'emballage, appeler I'entreprise locale ou consulter le site Web pour les informations relatives

&cette garantie.

REMPLACEMENT GRATUlT DES I_TIQUETTES D'AVERTISSEMENT : si les 6tiquettes

d'avertissement deviennent illisibles ou sont manquantes, composer le 1 (800) 4-DEWALT pour

en obtenir le remplacement gratuit.

CTC COMPLETETORQUE(UNTRUE

D25XXX

SER._

_USER MUSTREADINSTRUCTION

MANUAL¸ALWAYSUSEPROPEREYErEARAND

RESPIRATORYPROTECTION¸ALWAYSUSESIDEHANDLE

_f_[_ LEAELMANUALDE

UNFUNCONAMENTOSE6UROSEMPREUT CE

PROTECCIONAOEDUAOAPARALOSOJOS,OiDOS¥ viAs

RESPIRATORIAS.SlEMPREUTILICEELMANGOLATERAL.

_AFIN DEMINIMISER

BLESSURES,LrUTILISATEURDOlTLIRELEGUIDE

D'UTILISATION.TOUJ OURSUTILISERUNEPROTECTION

OCULAIRErAUDITIVEETR[SPIRATOIREADEtlUATE.

UTILISERLAPOI6NEEL_ERALE.

TOREDUCETHERISK0FINJURYr

INSTRUCCIONESPARA

LESRISQUESDE

D25891sos

MANUAL.ALWAYS USEPROPEREYE,EARAND

RESPIRATORYPROTECTION.ALWAYS USESIDEHANDLE.

FUNUIUNAMIENTOSEGURO.SIEMPRE UTILK.E

PROTECCIONADEUuADAPAUA LOSUJUS,OIDUSY ViAS

RESPIUATORIAS.SIEMPRE UTILICEELMANGO LATERAL.

_ FINDE MINIMISER

BLESSURES,t'UTILISATEUU DOlTLIRELEGUIDE

U'UTILIS_ION.TOUJUURS UTILISERUNEPROTECTION

OCULAIRE,AUUITWEETRESPIRATNIREADEQUATE.

UTILISERLAPUIGNEEk_TERALE.

OEWAET INDUSTRIAL TOOL CO., BALTIMORE, MD 212_6 USA

FOR SERVICE INFORMATION, CALL 1-8004-OEWALT

www. DEWALT.com

CHIPPING HAMMER

SER.

TOREDUCETHERiSK OFINJURY,

USER MUSTREAU INSTRUCTION

LEA ELMANUAL DE

INSTRUCCIUNESPARAUN

o,v,oo

| Brush Service

LESRISQUES DE

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada palabra de

seSal. Lea el manual y preste atenci6n a estos simbolos.

•&PELIGRO: indica una situacidn de peligro inminente que, si no se evita,

provocara la muerte o lesiones graves.

AADVERTENClA: indica una situacidn de peligro potencial que, si no se

evita, podrfa provocar la muerte o lesiones graves.

AATENClON: indica una situacidn de peligro potencial que, si no se evita,

posiblemente provocarfa lesiones leves o moderadas.

AVlSO: se refiere a una practica no relacionada a lesiones corporales que

de no evitarse puede resultar en dafios a la propiedad.

J

Sl TIENE ALGUNA DUDA O ALGON COMENTARIO SOBRE ESTA U OTRA HERRAMIENTA

DEWALT, LLAMENOS AL NUMERO GRATUITO: 1-800-4-DEWALT (1-800-433-9258)

_ ADVERTENClA: Para reducir el riesgo de lesiones, lea el manual de instrucciones.

Advertencias generales de seguridad para herramientas

eldctricas

incumplimiento de las advertencias e instrucciones puede provocar descargas electricas,

A iADVERTENCIA! Lea todas las advertencias de seguridad e instrucciones El

incendios o lesiones graves.

CONSERVE TODAS LAS ADVERTENCIAS E

INSTRUCCIONES PARA FUTURAS CONSULTAS

El termino "herramienta electrica "incluido en las advertencias hace referencia alas herramientas

electricas operadas con corriente (con cable electrico) o a las herramientas electricas operadas

con baterfas (inalambricas).

1) SEGURIDAD EN EL AREA DE TRABAJO

a) Mantenga el area de trabajo limpia y bien iluminada. Las areas abarrotadas y oscuras

propician accidentes.

b) No opere las herramientas electricas en atmosferas explosivas, comb ambientes

donde haya polvo, gases o liquidos inflamables. Las herramientas electricas originan

chispas que pueden encender el polvo o los vapores.

c) Mantenga alejados a los nifios y a los espectadores de la herramienta electrica en

funcionamiento. Las distracciones pueden provocar la perdida de control

2) SEGURIDAD ELI-CTRICA

a) Los enchufes de la herramienta electrica deben adaptarse al tomacorriente. Nunca

modifique el enchufe de ninguna manera. No utilice ningOn enchufe adaptador con

herramientas electricas con conexion a tierra. Los enchufes no modificados y que se

adaptan a los tomacorrientes reduciran el riesgo de descarga electrica.

b) Evite el contacto corporal con superficies con descargas a tierra comB, por ejemplo,

tuberias, radiadores, cocinas electricas y refrigeradores. Existe mayor riesgo de

descarga electrica si su cuerpo esta puesto a tierra.

c) No exponga las herramientas electricas a la Iluvia o a condiciones de humedad. Si

entra agua a una herramienta electrica, aumentara el riesgo de descarga electrica.

d) No maltrate el cable. Nunca utilice el cable para transportar, tirar o desenchufar

la herramienta electrica. Mantenga el cable alejado del calor, el ace#e, los bordes

filosos y las piezas moviles. Los cables dafiados o enredados aumentan el riesgo de

descarga electrica.

e) AI operar una herramienta electrica en el exterior, utilice un cable prolongador

adecuado para tal uso. Utilice un cable adecuado para uso en exteriores a fin de reducir

el riesgo de descarga electrica.

f) Si el uso de una herramienta electrica en un lugar hOmedo es imposible de evitar,

utilice un suministro protegido con un interruptor de circuito por falla a tierra (GFCI). El uso

de un GFCI reduce el riesgo de descargas electricas.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle Io que esta haciendo y utilice el sentido comOn

cuando emplee una herramienta electrica. No utilice una herramienta electrica si

esta cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de

descuido mientras se opera una herramienta electrica puede provocar lesiones personales

graves.

b) Utilice equipos de proteccion personaL Siempre utilice proteccion para los ojos. En

las condiciones adecuadas, el uso de equipos de proteccidn, comB mascaras para polvo,

calzado de seguridad antideslizante, cascos o proteccidn auditiva, reducira las lesiones

personales.

c) Evite el encendido por accidente. AsegOrese de que el interruptor este en laposicion

de apagado antes de conectarlo a la fuente de energ(a o paquete de bater(as, o antes

de levantar o transportar la herramienta. Transportar herramientas electricas con el

dedo apoyado en el interruptor o enchufar herramientas electricas con el interruptor en la

posicidn de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la Ilave de tuercas antes de encender la herramienta

electrica. Una Ilave de tuercas o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta electrica puede provocar lesiones personales.

e) No se estire. Conserve el equilibrio y parese adecuadamente en todd momento. Esto

permite un mejor control de la herramienta electrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga el cabello,

la ropa y los guantes alejados de las piezas en movimiento. Las ropas holgadas, las

joyas o el cabello largo pueden quedar atrapados en las piezas en movimiento.

g) Si se suministran dispositivos para la conexion de accesorios con fines de

recoleccion y extraccion de polvo, asegOrese de que esten conectados y que se

utilicen correctamente. El uso de dispositivos de recoleccidn de polvo puede reducir los