Page 1

Model 240

Gas Detection/Alarm System

Operator’s Installation and Instruction Manual

The Woodlands, Texas 77387

Ph.281.367.4100 / Fax 281.298.2868

November 1, 2010 • Document #2923 • Revision 1.8

DETCON, Inc.

3200 Research Forest Dr.,

www.detcon.com

Page 2

240 Operators Manual

This page left intentionally blank

Shipping Address: 3200 A-1 Research Forest Dr., The Woodlands Texas 77381

Phone: 888.367.4286, 281.367.4100 • Fax: 281.292.286 0 •

Model 240 Operator Manual Rev. 1.8 ii

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

www.detcon.com • sales@detcon.com

Page 3

240 Operators Manual

Table of Contents

1. Description.................................................................................................................................1

2. System Operation......................................................................................................................2

3. Specifications.............................................................................................................................3

4. Installation.................................................................................................................................4

4.1 Mounting and Cable Penetrations...................................................................................................................4

4.2 Power and I/O Connections............................................................................................................................ 4

4.2.1 AC Power.................................................................................................................................4

4.2.2 DC Power ................................................................................................................................5

4.2.3 Analog 4-20 mA Sensor Inputs ................................................................................................5

4.2.4 Serial Input Gas Sensors..........................................................................................................7

4.2.5 Serial Polling of the Model 140 Controller.............................................................................8

4.2.6 Relay Outputs...........................................................................................................................8

5. Start-up......................................................................................................................................9

5.1 Power Switch Selections ................................................................................................................................9

5.2 Applying Power..............................................................................................................................................9

6. System Configuration.............................................................................................................10

6.1 Analog/Serial input selection ....................................................................................................................... 10

6.2 Password Protection..................................................................................................................................... 10

6.3 Navigating the Menus................................................................................................................................... 10

6.3.1 PROG Key:............................................................................................................................10

6.3.2 “Up Arrow” Key: ..................................................................................................................11

6.3.3 “Down Arrow” Key:..............................................................................................................11

6.3.4 ENTER and Reset/Ack Key:...................................................................................................11

6.4 Main Display Functions ...............................................................................................................................12

6.5 User-Interface Menu Functions.................................................................................................................... 12

6.5.1 Menu Flow Chart...................................................................................................................13

6.5.2 Calibration Mode...................................................................................................................14

6.5.3 Set # of Channels ...................................................................................................................14

6.5.4 Set Channel Range.................................................................................................................14

6.5.5 Set Channel Type...................................................................................................................14

6.5.6 Set Channel Alarms ...............................................................................................................15

6.5.7 Set Relay Functions ...............................................................................................................15

6.5.8 Set Date and Time..................................................................................................................15

6.5.9 Set Modbus Address: .............................................................................................................16

6.5.10 View TWA and Peak Readings...............................................................................................16

6.5.11 View Event Records...............................................................................................................16

6.5.12 Download History..................................................................................................................16

6.6 Alarm Test Mode..........................................................................................................................................17

6.7 Display Contrast........................................................................................................................................... 17

7. System Features......................................................................................................................18

7.1 Modbus Communications.............................................................................................................................18

7.2 Download Procedure.................................................................................................................................... 20

8. Options.....................................................................................................................................26

8.1 Option for Battery Back-up Operation......................................................................................................... 26

8.2 Option for 4-20mA Output(s).......................................................................................................................26

8.3 Optional Interface PCB for Remote Display................................................................................................ 26

8.4 Optional Remote Alarm Reset/Acknowledge Switch .................................................................................. 27

8.5 Optional Type Z Enclosure Purge Assembly...............................................................................................27

Model 240 Operator Manual Rev. 1.8 iii

Page 4

240 Operators Manual

9. Troubleshooting Guide...........................................................................................................28

10. Spare Parts...........................................................................................................................28

11. Warranty..............................................................................................................................28

Appendix A.....................................................................................................................................29

Revision Log..............................................................................................................................................................29

Table of Figures

Figure 1 System Operational Diagram.............................................................................................................................2

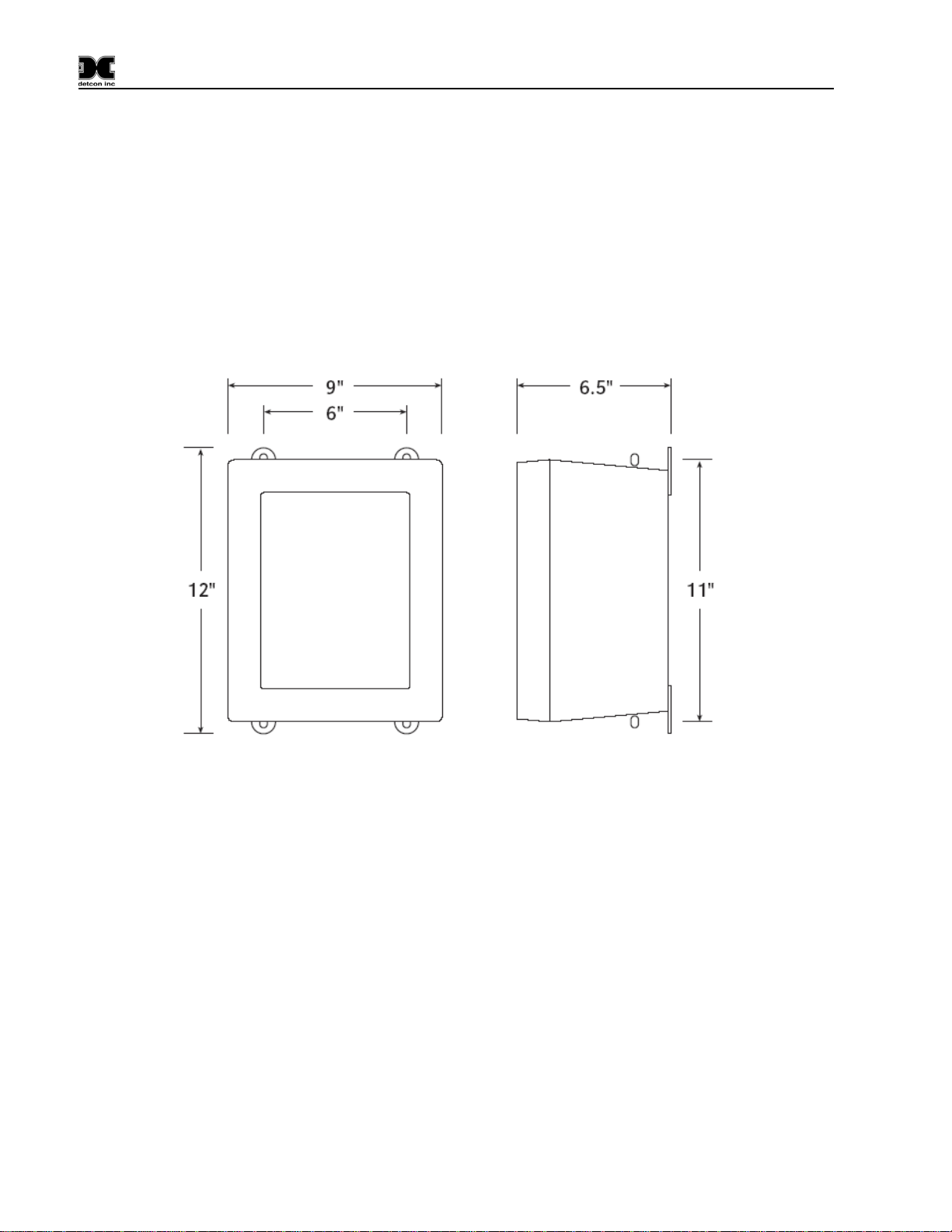

Figure 2 Dimensional View of Enclosure........................................................................................................................4

Figure 3 Power Input Schematic......................................................................................................................................5

Figure 4 Mother Board Layout.........................................................................................................................................6

Figure 5 Control Board Layout........................................................................................................................................7

Figure 6 Power Switch Configuratio n..............................................................................................................................9

Figure 7 Switch SW1.....................................................................................................................................................10

Figure 8 Front Panel User Interface...............................................................................................................................11

Figure 9 Menu Flow Chart.............................................................................................................................................13

Figure 10 Serial connection and jumper locations.........................................................................................................21

Figure 11 Invoking Hyper Terminal..............................................................................................................................21

Figure 12 Connection Description .................................................................................................................................22

Figure 13 Connect to Configuration...............................................................................................................................22

Figure 14 Communications port properties....................................................................................................................23

Figure 15 Setting up capture ..........................................................................................................................................23

Figure 16 Naming Capture File......................................................................................................................................24

Figure 17 Downloading information..............................................................................................................................24

Figure 18 Saving file......................................................................................................................................................25

Figure 19 Optional Plug-in Module fo r 4- 2 0mA Output and Remote Display..............................................................26

Shipping Address: 3200 A-1 Research Forest Dr., The Woodlands Texas 77381

Phone: 888.367.4286, 281.367.4100 • Fax: 281.292.286 0 •

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Model 240 Operator Manual Rev. 1.8 iv

www.detcon.com • sales@detcon.com

Page 5

240 Operators Manual

1. Description

Housed in a NEMA 4X weatherproof enclosure, the Detcon Model

240-N4X Gas Detection Alarm System has the capability to handle

two 4-20mA sensor input or two RS-485 serial sensor inputs. The

remotely mounted gas sensors (purchased separately) can include

any Detcon 4-20mA or RS-485 serial input device such as

combustible gas, toxic gas, or oxygen deficiency sensors.

The system displays real time channel information on a backlit

LCD. Configuration inputs are completely field-programmable and

include channel number, gas type, and gas concentration. It also

shows the current Alarm/Fault status via front panel LED

indicators. Standard features include recorded history of Time

Weighted Average (TWA), Peak readings, and

Alarm/Fault/Maintenance Events. Additional features include onetouch Alarm Reset and Alarm Silence (Acknowledge) functions.

The Model 240-N4X has a built-in power supply, giving the user a multitude of power options. It can be

powered by either 115/230VAC or 11.5 to 30VDC, and has an optional one-hour battery backup in the

event of temporary power loss.

Each control channel has three field programmable alarm relays and one fault relay. The relays have two

discrete form “C” contacts and are rated for 5 Amps at 30VDC and 250VAC. The low, high, and high-high

alarms have individually field adjustable set points for each gas channel and include the provision to

configure the alarm relays in a normally energized (failsafe) or normally de-energized mode of operation.

The low, high, high-high and fault alarm relays may also be configured for latching/non-latching and

silenceable/non-silenceable operation.

Model 240 Operator Manual Rev. 1.8 Page 1 of 29

Page 6

)

240 Operators Manual

2. System Operation

The Model 240-N4X can be configured for either two 4-20mA sensor inputs or two RS-485 serial sensor

inputs via a dipswitch selection. The system displays current status information on its LCD display. The

information displayed during normal operation includes the gas channel #, current reading and gas type.

Alarm values or fault condition can be field-programmed via the User Interface to cause an assigned relay

output to fire, thus triggering an external alarm device. As gas alarm or fault conditions clear, the assigned

relay outputs return to their normal states. Relays can be set-up as Energized/De-Energized, Latching/Nonlatching and Silenceable/Non-Silenceable. Using the front panel function key, the relay outputs can be

silenced or Reset.

The Model 240-N4X gas detection alarm system has onboard data logging to record all alarm, fault and

maintenance events. It also continuously logs the TWA and Peak readings, which can be downloaded for

external storage and review. The RS-485 serial output can continuously transmit sensor and alarm data to a

PC, PLC, DCS or SCADA where it can be further monitored and logged.

RS-232 Port for

Uploading

Configuration and

Downloading

Historical Data

Gas Detection/Alarm System

ALM 1 ALM 2 ALM 3 FAULT

RS- 485 Output

to Master

Device

MODEL 240-N4X

CH1 99 PPM CL2

CH2 40 PPM CL2

PROG ↑ ↓ ENTER

RS-485

Gas

Sensor

Input

4-20mA

Gas

Sensor

Input

Input Power

115/230VAC

11.5-30VDC

ALM 1 RELAY

ALM 2 RELAY

ALM 3 RELAY

FAULT RELAY

(2 Discrete

Contacts each

Figure 1 System Operational Diagram

Model 240 Operator Manual Rev. 1.8 Page 2 of 29

Page 7

240 Operators Manual

3. Specifications

Capacity

Sensor Inputs

Accuracy

Outputs

Electrical

Power Input

Power Consumption

2 Input Channels

Analog 4-20mA or

RS-485 Modbus RTU

± 1% Full Scale Range

Qty 4 Relays: 2 Form C Contacts per relay

Rated for 5A @ 30VDC, 5A @ 250VAC

RS-485 (Standard)

RS-232 for Uploading/Downloading to PC (Standard)

4-20mA (Optional)

115-230VAC

11.5-30VDC

Normal: 5 Watts @ 24VDC

Maximum: 12 Watts @ 24VDC

(Total system power dependent on number of gas sensors

& type of gas sensor connected)

Display

Electrical Classification

Dimensions

Physical

Operating Temperature Range

Warranty

Model 240 Operator Manual Rev. 1.8 Page 3 of 29

1”x5” Backlit LCD

NEMA 4X

10”W x 12”H x 6”D

-40F to +167F

-40C to +75C

One year

Page 8

240 Operators Manual

4. Installation

4.1 Mounting and Cable Penetrations

Securely mount the Model 240 N4X enclosure per the mounting dimensions provided in

Provide for suitable conduit/cable entries in the bottom of the enclosure. Keep AC power separate from

DC signals in conduit connections and runs.

Mounting Holes 5/16 Dia.

Figure 2.

Figure 2 Dimensional View of Enclosure

4.2 Power and I/O Connections

Power and I/O connections are made on the Motherboard PCB, mounted inside on the back of the

enclosure. Plug-in male connector terminal blocks are provided for input wire terminations. This

connector style provides for quick disconnect convenience during replacement or servicing. (Refer to

Figure 4)

The connections for serial polling of gas sensors and RS-232 PC downloading activities are located at J7 on

the Controller PCB. (Refer to

4.2.1 AC Power

Connect the 115 or 230VAC input wiring to the terminals at J2, labeled “AC IN” in

Model 240 Operator Manual Rev. 1.8 Page 4 of 29

Figure 5)

Figure 3 and Figure 4.

Page 9

240 Operators Manual

4.2.2 DC Power

For optional DC power input, connect 11.5-30VDC to the terminals at J8, labeled “DC IN” in

Figure 3 and

Figure 4. This input can be used for primary power or back-up power in the event of a VAC power failure.

J2

External

VAC

Input

J8

External

VDC

Input

VIN

SW1

VAC ON/OFF

SW4

+

-

VDC ON/OFF

MOTHER BOARD POWER INPUT

F2

SW2

115VAC/220VAC

VSS

BATTERY

ON/OFF

PS1

TO

FROM

DC POWER

SUPPLY

VIN

SW3

VIN

PS2

BATT1

BATT2

SWOV

BATTERY

RESTORE

VSS

Figure 3 Power Input Schematic

4.2.3 Analog 4-20 mA Sensor Inputs

Connect 4-20mA type gas sensors to the motherboard at the terminals labeled “CH 1” and “CH 2” (J15,

J16, respectively) in

Figure 4. These connections are labeled (+, -, mA). For a 3-wire gas sensor connect

to the “+”, “-”, and “mA” terminations. For a 2-wire sensor connect to the “+” and “mA” terminations,

refer to the Operators Manual for the gas sensor that is being connected.

Note: Analog sensor polling requires switch SW1-1 on the Control PCB to be set in the “OFF” position.

(See

Figure 5)

Model 240 Operator Manual Rev. 1.8 Page 5 of 29

Page 10

240 Operators Manual

VOLTAGE

TO PROCESSOR

RIBBON CABLE

VAC

POWER

SWITCH

BATTERY

ON/OFF

VDC

POWER

SWITCH

Battery Restore

Switch

Jumper for RS-485

Shield to Earth Grnd.

SELECT

Figure 4 Mother Board Layout

Model 240 Operator Manual Rev. 1.8 Page 6 of 29

Page 11

240 Operators Manual

Ribbon Cable to LCD

SW1 - Options

4 - Password Protection

3 - Not Used

RS-485 Input for

Gas Sensor

2 - 600/700 Series Sensors or

Mod 10 Controlers

1 - Analog/Serial

Ni-Cad

Battery

Ribbon Cable to

Mother Board

AUXAUX

Figure 5 Control Board Layout

4.2.4 Serial Input Gas Sensors

When connecting serial input gas sensors such as the Detcon 600 Series, terminate the 3 conductors from

the serial cable in the following manner. Terminate A and B on the Control PCB at connector J7 shown in

Figure 5. If applicable, the shield wire can be terminated on the Mother Board at JP1 the RS-485 Jumper

labeled ‘SHLD TO GND’ (refer to

Figure 4).

Note: Serial sensor polling requires switch SW1-1 on the Control PCB to be in the “ON” position. If

polling 600 or 700 Series Sensors, SW1-2 must be in the “OFF” position. If polling Mod 10 Controllers,

SW1-2 must be in the “ON” position (See

Figure 5).

NOTE: If VDC power for the Detcon Series 600 sensor is not available at the sensor location, then it can

be provided via the + and – pins of channels 1 and 2 on the motherboard. The RS-485 wiring should be a 2

conductor, shielded twisted pair (Belden P/N 9841 is recommended).

Model 240 Operator Manual Rev. 1.8 Page 7 of 29

Page 12

240 Operators Manual

4.2.5 Serial Polling of the Model 140 Controller

When polling this device serially, connect the incoming RS-485 wiring to the terminals labeled “RS-485

IN” (J10) on the Motherboard. For connection to the next polled device in the serial loop, connect the RS485 wiring to J25 labeled “RS-485 OUT”. These terminals are labeled “A”, “B”, and “S” (Shield) for

standard RS-485 Modbus™ communication as shown in

Figure 4. A jumper on the Motherboard PCB

(JP1) provides the option to leave the shield open or tied to earth ground. Choose the appropriate selection

for the application.

NOTE: The RS-485 wiring should be a 2 conductor, shielded twisted pair (Belden P/N 9841 is

recommended).

4.2.6 Relay Outputs

The standard Model 240 Controller provides four relays. Each relay has 2 Form C contacts. They can be

used to fire annunciating devices or as signal inputs to other control devices. Connect to the relay contact

terminals of the Motherboard PCB. There are two sets of terminals labeled FAULT, ALARM 1, ALARM

2, and ALARM 3 (

Figure 4 – J17-J24). The relays are double pole double throw (DPDT), which allow

more flexibility in the creation of alarm system set-ups. Connections are labeled C (common), NO

(normally open) and NC (normally closed).

NOTE: The current ratings of the relay contacts should not be exceeded. (5A @ 30VDC, 5A @ 250VAC)

Model 240 Operator Manual Rev. 1.8 Page 8 of 29

Page 13

240 Operators Manual

5. Start-up

NOTE: Before applying power, check and make sure that all the wiring connections and external devices

are installed correctly.

NOTE: Applying power with devices hooked up incorrectly may cause damage to the equipment.

5.1 Power Switch Selections

Refer to

setting. If the unit will be powered by AC voltage only, then the VAC power switch (SW1) should be

turned to the ON position, and insure the VDC power switch (SW4) is in the OFF position. If DC is used

to power the unit, the VDC power switch should be turned to ON and the VAC power switch should be

OFF. If the unit is to be powered by AC and DC sources simultaneously, then both power switches should

be in the ON position. The switches are located on the Motherboard, shown in

Figure 6. For AC power, locate the V-SELECT switch (SW2) and select the appropriate voltage

Figure 4.

VOLTAGE

VAC

POWER

SWITCH

SELECT

BATTERY

ON/OFF

VDC

POWER

SWITCH

Figure 6 Power Switch Configuration

NOTE: An optional battery back up can be installed in all basic units. A switch to connect or disconnect

the battery back up is located on the Motherboard. If the Battery Back-up option is installed this switch

will normally be “ON”. See Section

8.1 for details on the Battery Back-up Option.

5.2 Applying Power

Connect power per Section 4.2.

With the AC or DC power source connected, turn the applicable power switches to the ON positions.

Verify that the Main Display LCD comes up displaying gas readings on the display. Assuming there is no

target gas in the area of the gas sensor, the sensor should read 0 (zero) after a short warm-up period of 1-2

minutes.

NOTE: All alarm relays will be disengaged for the first 1-minute after power-up to provide for an

adequate sensor warm-up time.

Model 240 Operator Manual Rev. 1.8 Page 9 of 29

Page 14

240 Operators Manual

6. System Configuration

6.1 Analog/Serial input selection

On the Controller PCB, switch SW1 position 1 is used to select between Analog and Serial sensor inputs

for the 240 Controller. Switch SW1-1 must be placed in the “ON” position for the unit to accept Serial RS485 Modbus™ sensors, and SW1-1 must be placed in the “OFF” position if the sensors are 4-20mA type

sensors (

“OFF” for use with 600 or 700 Series Sensors. SW1-2 has no effect when SW1-1 is set for Analog (“OFF”

Position).

NOTE: Incorrect placement switch SW1-1 when using Serial Sensors will cause the unit to display

“FAULT” on all channels, and the “FAULT” LED will be lit. Incorrect placement of switch SW1-1 when

using Analog Sensors will cause the unit to display “NO-COMM” on all channels, and the “FAULT” LED

will be lit. When using Serial Sensors or Mod 10 Controller inputs ensure that SW1-2 is in the correct

position for the type of sensor or controller being polled or the unit will display incorrect readings.

Figure 7). For Serial Inputs SW1-2 should be “ON” for use with Mod 10 Control Boards, and

Part of Control Board

RS-485 Input for

Gas Sensors

1 2 3 4

ON

OFF

Figure 7 Switch SW1

Switch SW1

Pos 1 - Analog or Serial Mode

Pos 2 - 600/700 Series Sensors or

Mod 10 Controllers

Pos 4 - Password Protected

6.2 Password Protection

Password protection is accomplished via a switch selection on the backside of the Controller PCB (Figure 7

SW1). With SW1-4 in the ON position, Password Protection is turned off and there is complete access to

the Menus. With Switch SW1 position 4 in the OFF position, the Controller will be in Password Protected

mode. In this mode, there is no access to the Menus. The only functionality provided for is the Main

Display and the use of the Reset and Acknowledge functions.

6.3 Navigating the Menus

The menu text is displayed on the backlit LCD and is interfaced via the four function keys located below it.

These keys are labeled from left to right: PROG, UP, DOWN, ENTER. The ENTER key is a multiple-use

key that also controls the Reset and Acknowledge relay functions. With reference to the Menu Flow Chart

(See

Figure 9) and the correct function key sequencing, it is easy to learn how to navigate the menus, make

changes, and access the logged data.

6.3.1 PROG Key:

From the Main Display, the PROG key enters into the Main Menu. Once inside the Main Menu, the PROG

key acts as an “Escape” key that moves backwards in the Menu flow chart.

Model 240 Operator Manual Rev. 1.8 Page 10 of 29

Page 15

240 Operators Manual

NOTE: While in Menu Mode there are no updates to gas readings and hence no alarms will take place.

6.3.2 “Up Arrow” Key:

This key moves the user up the Main Menu flow chart. It is also used to change highlighted entries within

menu selections in the upward direction.

6.3.3 “Down Arrow” Key:

This key moves the user down the Main Menu flow chart. It is also used to change highlighted entries

within menu selections in the downward direction.

6.3.4 ENTER and Reset/Ack Key:

This key has a multiple-use purpose. The ENTER function is used to accept selections within all Menu

screens.

The Enter Key is also used to execute the Reset and Acknowledge functions. The Reset function releases

all latched relays if pressed after they have cleared the alarm/fault condition. The Acknowledge function

will disengage any silenceable relays that are in a currently active state. This is typically used to silence

alarm annunciators, once the end-user has assessed the alarm condition.

Figure 8 Front Panel User Interface

NOTE: The controller automatically times out of Menu Mode and returns to the Main Display after 1

minute of inactivity.

Model 240 Operator Manual Rev. 1.8 Page 11 of 29

Page 16

240 Operators Manual

6.4 Main Display Functions

The Main Display is a 1”x 5” backlit LCD that has 2 lines by 24 characters. In normal operation “CH # =

XX ppm GAS” will be displayed. If any channel is in any gas alarm condition, the “CH#” will change to

“ALM”. If any gas channels are in Fault, they will display “CH # = IN FAULT”. If any channels are in

CAL MODE, they will display as “CH # = IN CAL”. If any channels are not communicating with sensors

set up as serial input sensors, then they will display “CH # = NO COMM”.

NOTE: The LCD has a backlight that will automatically turn off after 30 seconds of inactivity. The LCD

backlight will come on automatically as soon as any function key is pressed. This is a feature designed to

save on power.

6.5 User-Interface Menu Functions

The User-Interface is conducted via the Model 240-N4X Front Plate shown above in Figure 8. The Menu

Flow Chart (

activity is conducted via the 1”x5” LCD and the four function keys. Four LED indicators on the front

panel show alarm and fault relay status. The LED’s represent ALM 1 (green), ALM 2 (amber), ALM 3

(red) and FAULT (blue). There are 13 Main Menu entries and their functional descriptions are discussed

below.

Figure 9) is navigated using the function keys described in Figure 8. User-Interface menu

Model 240 Operator Manual Rev. 1.8 Page 12 of 29

Page 17

240 Operators Manual

6.5.1 Menu Flow Chart

NORMAL OPERATION

MAIN DISPLAY

MAIN MENU

CALIBRATION MODE

MAIN MENU

SET # OF CHANNELS

MAIN MENU

SET CHANNEL RANGE

MAIN MENU

SET CHANNEL TYPE

MAIN MENU

SET CHANNEL ALAMRS

MAIN MENU

SET RELAY FUNCTION

CALIBRATION MODE

ON/OFF

SET # OF CHANNELS

####

SET CHANNEL RANGE

CHX = XXXXX

SET CHANNEL TYPE

CHX = ####

SET CHANNEL ALARMS

CHX - ALRM1 = ####

CHX - ALRM2 = ####

CHX - ALRM3 = ####

SET RELAY FUNCTION

FLT - L/NL, E/DE, S/NS

ALM1 - L/NL, E/DE, S/NS

ALM2 - L/NL, E/DE, S/NS

ALM3 - L/NL, E/DE, S/NS

CH1 ... CHX

CH1 ... CHX

KEY

UP ARROW

MAIN MENU

SET DATE & TIME

MAIN MENU

SET MODBUS ADDRESS

MAIN MENU

VIEW TWA / PEAK DATA

MAIN MENU

VIEW ALARM RECORDS

MAIN MENU

DOWNLOAD HISTORY

SET DATE & TIME

MM/DD/YY HH:MM

SET MODBUS ADDRESS

## HEX

05/06/07 1200 - 1300

TWA #### PK ####

05/06/07 10:00:00

REC# MESSAGE

DOWN ARROW

ENTER

PROG

Figure 9 Menu Flow Chart

Model 240 Operator Manual Rev. 1.8 Page 13 of 29

Page 18

240 Operators Manual

6.5.2 Calibration Mode

This menu entry allows CALIBRATION MODE to be toggled “ON” or “OFF”. With CALIBRATION

MODE on, the attached sensor can be calibrated without triggering any alarms. While the controller is in

CALIBRATION MODE, the Main Display will show each channel as “CH # = IN CAL”. The controller

will automatically time out of CAL MODE after 60 minutes. The menu appears as:

CALIBRATION MODE:

ON or OFF

NOTE: Some Detcon sensor models (Series 500/600/700) give a 2.0mA signal input when they are being

calibrated. The Cal Mode feature is not necessary for these sensor types, and the channel bei ng calibrated

will automatically read “IN CAL” while calibration is in process. O2 sensors are usually set as descending

alarms, so use of the CALIBRATION MODE: ON is required for them during sensor calibration to avoid

unwanted alarm activation.

6.5.3 Set # of Channels

This menu entry allows setting the number of active channels being used. The number of active channels

should match the number of sensors being connected to the controller. The menu appears as:

SET # OF CHANNELS:

8

NOTE: the number of activated channels can be less than (but not greater than) the controller’s maximum

input capacity.

6.5.4 Set Channel Range

This menu entry allows the selection of the Channel Range for each gas channel input. This is a scrolling

list from 1.00 up to 10,000 and covers all of the Detcon gas sensor range possibilities. This menu appears

as:

SET CHANNEL RANGE:

CH1 = XX.X

NOTE: If the range is changed, the alarm levels will have to be reset!

6.5.5 Set Channel Type

This menu entry allows the selection of the Channel Type for each gas channel input. The alphanumeric

string should encompass the units of measure followed by the chemical formula. (I.E. “ppm H2S” or “%

LEL”.) Use the up and down arrows to find the appropriate alphanumeric selection and then use the

ENTER button to select it. Enter the character string, as it is expected to be displayed on the Main Display.

NOTE: The character entry for a “space” is required and is available in the alphanumeric choices. All

character positions must have an entry, including “spaces” for unused characters at the end of the string.

This menu appears as:

SET CHANNEL TYPE:

CH1 = (PPM_H2S___)

Model 240 Operator Manual Rev. 1.8 Page 14 of 29

Page 19

240 Operators Manual

6.5.6 Set Channel Alarms

This menu entry allows the selection of the Channel Alarms for each gas channel input. These represent

the alarm level set points. These set points can be entered in 5% increments of the full-scale r ange selected

for that channel. Selection of ascending (right arrow) or descending (left arrow) alarms is also made in this

menu selection. This menu appears as:

SET CHANNEL ALARMS:

CH1 – ALM1 = X.X Æ

Each gas channel has the capability to set up to 3 alarms (ALM1, ALM2, and ALM3).

NOTE: If there is no intention of using a gas alarm relay, a setting of 0.00 (zero) will make it inactive.

NOTE: Any channels that are in alarm will display “ALM” instead of “CH#” on the Main Display.

NOTE: If the channel range is changed, then the alarm set points must be re-entered!

6.5.7 Set Relay Functions

This menu entry is used for relay function set-up. This unit has four relays. Three relays are used for

ALM1, ALM2 and ALM3 and the fourth relay is used for the FAULT condition. All four relays must be

set-up to account for the following 3 settings: latching or non-latching, energized or de-energized, and

silenceable or non-silenceable. This is accomplished by toggling the selection entries. The menu appears

as shown below. The menu guides the user through the required set-up for all the relay parameters shown

in the order below.

FLT - LATCHING/NON-LATCHING

FLT - ENERGIZED/NON-ENERGIZED

FLT - SILENCE/NO-SILENCE

ALM2 - LATCHING/NON-LATCHING

ALM2 - ENERGIZED/NON-ENERGIZED

ALM2 - SILENCE/NO-SILENCE

SET RELAY FUNCTION:

FLT - LATCHING/NON-LATCHING

ALM1 - LATCHING/NON-LATCHING

ALM1 - ENERGIZED/NON-ENERGIZED

→

ALM1 - SILENCE/NO-SILENCE

ALM3 - LATCHING/NON-LATCHING

ALM3 - ENERGIZED/NON-ENERGIZED

→

ALM3 - SILENCE/NO-SILENCE

→

NOTE: It is generally recommended to set the FAULT relay as energized so that it will trip upon loss of

power.

NOTE: The FAULT condition is assigned to the FAULT relay as a standard. It cannot be disengaged i n

the configuration of the controller. The Main Display will show FAULT for any channel that is in FAULT.

6.5.8 Set Date and Time

This menu entry allows for the correct entry of the current date and time. The menu appears as:

SET DATE AND TIME:

01/26/04_14:56:07

Model 240 Operator Manual Rev. 1.8 Page 15 of 29

Page 20

240 Operators Manual

6.5.9 Set Modbus Address:

This menu entry allows for the setting of the serial address of this controller when it is to be polled by

another master device via RS485 Modbus RTU. This should be set in hexadecimal format.

SET MODBUS ADDRESS:

01

6.5.10 View TWA and Peak Readings

This menu entry is used to view the recorded TWA and Peak readings for the different gas channels. This

data can be viewed on the screen or can be downloaded via the RS232 port to a PC for graphical

presentation. Refer to Section

7.2 on instruction for using the downloading software provided with this

controller.

05/05/04 09:00 0001

CH1 TWA XX PK XX

This data is recorded and formatted for display. It will report the date (05/05/04), time (09:00), record #

(0001), CH#, TWA and Peak reading as shown above.

6.5.11 View Event Records

This menu entry is used to view the recorded and saved Alarm, Fault and Maintenance records for the

different gas channels. This data can be viewed on the screen or can be downloaded via the RS-232 port to

a PC for graphical presentation. Refer to Section

7.2 on instruction for using the downloading software

provided with this controller.

05/06/04 09:00

0000 CH1 ALM1 ON

The data is formatted for display. It will report the date, time, record #, CH#, Event type and Event status.

All events will be logged with their start and stop times in the order that they occur.

6.5.12 Download History

The menu item allows downloading the units’ history to a PC. Continuous data for TWA and Peak

readings are stored at 1-hour increments in permanent memory for retrieval. All Event Records are stored

only as they occur. The duration of the recorded storage is 1 month for the TWA readings, Peak readings,

and Event Records. Refer to Section

7.2 for complete procedure.

DOWNLOAD HISTORY

Model 240 Operator Manual Rev. 1.8 Page 16 of 29

Page 21

240 Operators Manual

6.6 Alarm Test Mode

Alarm conditions can be simulated and relay contacts can be verified by use of this special software

feature. To activate the Alarm Test Mode, hold the z (Down) key for 5 seconds while in the Main Display

Mode. After holding the z (Down) key for 5 seconds there will be an audible “Chirp”, then all active gas

channels will display “CH# 00 TESTING”. The readings will increment up at 1% full scale per second.

When full scale is reached the readings will decrement to 0. The unit will continue to cycle until Alarm

Test Mode is exited. As the readings cross their respective alarm set points, the relays will fire according to

their configuration. To exit Alarm Test Mode, hold the z (Down) key for 5 seconds and the unit will

return to Normal Operation.

6.7 Display Contrast

The display contrast can be adjusted by pressing the “up-arrow” key when the unit is in Normal Operation.

Pressing the “up-arrow” key repeatedly will cause the display contrast to change in steps to the minimum

limit; the contrast will then ‘roll’ back to the maximum limit and start the cycle over. When the correct

contrast level is obtained stop pressing the “up-arrow” key and the contrast will remain at that level.

Model 240 Operator Manual Rev. 1.8 Page 17 of 29

Page 22

240 Operators Manual

7. System Features

7.1 Modbus Communications

The model 240 controller features a Modbus compatible communications protocol and is addressable by a

PLC, PC/HMI, DCS, or other Modbus RTU master polling device. Communications is accomplished by

two wire half duplex RS-485, 9600 baud, 8 data bits, 1 stop bit, no parity, through the controllers secondary

port. Wiring should be brought directly to J10 located on the motherboard.

A Modbus™ RTU master device up to 4000 feet away can theoretically poll up to 64 different controllers.

This number may not be realistic in harsh environments where noise and/or wiring conditions would make

it impractical to place so many devices on the same pair of wires. If a multi-point system is being utilized,

each controller must be set to a different device address.

Modbus™ Register Detail:

Code 03 - Read Holding Registers is the only code supported by the 240 controller.

Register #

40000 Channel 1 Reading

40001 Channel 2 Reading

40002 Fault Status Bits

High Byte

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 Not Used

Bit 0 Not Used

Low Byte

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 1 = Channel 2 Fault 0 = Channel 2 no Fault

Bit 0 1 = Channel 1 Fault 0 = Channel 1 no Fault

40003 Alarm 1 Status Bits

High Byte

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 Not Used

Bit 0 Not Used

Low Byte

Model 240 Operator Manual Rev. 1.8 Page 18 of 29

Page 23

240 Operators Manual

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 1 = Channel 2 Alarm 1 0 = Channel 2 no Alarm 1

Bit 0 1 = Channel 1 Alarm 1 0 = Channel 1 no Alarm 1

40004 Alarm 2 Status Bits

High Byte

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 Not Used

Bit 0 Not Used

Low Byte

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 1 = Channel 2 Alarm 2 0 = Channel 2 no Alarm 2

Bit 0 1 = Channel 1 Alarm 2 0 = Channel 1 no Alarm 2

40005 Alarm 3 Status Bits

High Byte

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 Not Used

Bit 0 Not Used

Low Byte

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 1 = Channel 2 Alarm 3 0 = Channel 2 no Alarm 3

Bit 0 1 = Channel 1 Alarm 3 0 = Channel 1 no Alarm 3

40006 Cal Status Bits

High Byte

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Model 240 Operator Manual Rev. 1.8 Page 19 of 29

Page 24

240 Operators Manual

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 Not Used

Bit 0 Not Used

Low Byte

Bit 7 Not Used

Bit 6 Not Used

Bit 5 Not Used

Bit 4 Not Used

Bit 3 Not Used

Bit 2 Not Used

Bit 1 1 = Channel 2 Cal 0 = Channel 2 no Cal

Bit 0 1 = Channel 1 Cal 0 = Channel 1 no Cal

7.2 Download Procedure

The Model 240-N4X Gas Detection Alarm System has very capable features in the area of data logging and

event reporting. Continuous data for TWA and Peak readings are stored at 1-hour increments in permanent

memory for retrieval. All Event Records are stored only as they occur. The duration of the recorded

storage is 1 month for the TWA readings, Peak readings, and Event Records.

This data can be downloaded to an external PC. The downloaded data can be exported into a Microsoft

Excel spreadsheet for graphing purposes. The procedure requires a computer with windows Hyper

Terminal, a serial port, and Detcon connections cable part number 980-26117. If the computer does not

have a serial port, a USB to serial adapter will also be required. USB to serial adapters may be purchased

from many retail electronics stores.

NOTE: The download feature will only work with the following X40 controller hardware. This number is

printed in white on the back of the controller PCB. The controller firmware must be a version that supports

this feature. The controller firmware revision can be checked by cycling power to the controller and

observing the LCD display.

Hardware Number Firmware Version

440-005071-001 1.23 or higher.

440-005072-001 1.23 or higher.

440-005073-001 1.18 or higher.

Model 240 Operator Manual Rev. 1.8 Page 20 of 29

Page 25

240 Operators Manual

Figure 10 Serial connection and jumper locations

Make the connection from the Model X40 controller to your PC (COM1) using the supplied cable. The

controller’s 1/8” jack connection is located on the bottom of the PCB.

From the Start menu, select Programs> Accessories> Communications> Hyper Terminal.

Figure 11 Invoking Hyper Terminal

Hyper Terminal will open with the following Connection Description Dialog box. Type “X40 Download”

as the name for the connection and click ‘OK’.

Model 240 Operator Manual Rev. 1.8 Page 21 of 29

Page 26

240 Operators Manual

Figure 12 Connection Description

The “Connect To” Dialog box will appear. For Connect using: choose COM1 and Click OK.

Figure 13 Connect to Configuration

The COM1 Properties Dialog box will appear. Insure the settings are:

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

Click OK.

Model 240 Operator Manual Rev. 1.8 Page 22 of 29

Page 27

240 Operators Manual

Figure 14 Communications port propertie s

From the main menu Select: Transfer> Capture Text.

Figure 15 Setting up capture

Select a Name and location where the downloaded data is to be saved, and click “Start”. The file will be

saved as a text file and the file extension of *.txt should be used.

Model 240 Operator Manual Rev. 1.8 Page 23 of 29

Page 28

240 Operators Manual

Figure 16 Naming Capture File

On the X40 controller, enter the main menu. Scroll down to “MAIN MENU:” “DOWNLOAD

HISTORY”. Press the Enter button. The display should read “STREAMING DATA…..” Once the

controller has finished sending data to the PC, it will return to the main menu. If no buttons are pressed,

the controller will return to normal operation.

If the download was successful the display should look similar to figure 7 on the PC.

Figure 17 Downloading information

Once the data stream from the controller has been verified as stopped, select: Transfer> Capture Text> Stop

from the main menu.

Model 240 Operator Manual Rev. 1.8 Page 24 of 29

Page 29

240 Operators Manual

Figure 18 Saving file

Disconnect the controller from the PC.

The raw data from the controller is now stored in the file and location selected, and available for the user to

use as desired.

Model 240 Operator Manual Rev. 1.8 Page 25 of 29

Page 30

240 Operators Manual

8. Options

8.1 Option for Battery Back-up Operation

This option provides a nominal 1-hour of battery back-up power to the Gas Detection Alarm System. The

battery back-up system consists of two 12VDC / 0.8 Amp-hour batteries in series, along with the requisite

low voltage cut-off circuitry. The batteries may be isolated during exchange or while in long-term storage

by using the battery disconnect switch shown in

disconnect the battery supply if the voltage is drained below 20VDC. This is for battery protection

purposes. There is a battery restore switch on the Motherboard PCB, which must be pressed after the low

voltage cut-off is triggered. This is only necessary if the unit is going to be restored under battery power.

It is not necessary if restored under VAC power.

Figure 4. The low voltage cut-off circuit is designed to

8.2 Option for 4-20mA Output(s)

An optional PCB that plugs into the controller board is available for 4-20mA outputs. This PCB has four

channels of 4-20mA output. Only the first two channels are used with the 240 Control Unit. See

for the correct installation and wire terminations for this feature.

Figure 19

Figure 19 Optional Plug-in Module for 4-20mA Output and Remote Display

8.3 Optional Interface PCB for Remote Display

The same PCB that provides the 4-20mA output option is also used as the required interface for the Remote

Display option (

to the Remote Display. The actual Remote Display hardware is ordered separately as a Model 240-RD

Read-Only-Remote display.

Figure 19). The RS-485 terminal block labeled ‘A B S - TO REMOTE’ is used to connect

Model 240 Operator Manual Rev. 1.8 Page 26 of 29

Page 31

240 Operators Manual

8.4 Optional Remote Alarm Reset/Acknowledge Switch

Model X40 controllers are designed for an optional Remote Alarm Reset/Acknowledge Switch. This

enables the user to reset or acknowledge alarms without having to open the NEMA 4X enclosure. The

Reset Switch is a momentary type switch and will typically be mounted on the bottom or side of the NEMA

4X enclosure. Toggle the momentary switch to execute the reset/acknowledge function.

The Remote Alarm Reset/Acknowledge Switch is wired to the terminal block labeled SW3 on the backside

of the Main Controller PCB. Refer to

Figure 5.

8.5 Optional Type Z Enclosure Purge Assembly

Model X40 controllers are available with an optional, externally mounted, Model 1001A Z-Purge system.

This purge assembly achieves a Class 1, Division 2, Group CD area classification. The Type Z-Purge

assembly is installed on the X40 Controller at the Detcon factory.

The Z-Purge option is factory wired to automatically removed AC power from the controller if there is a

loss of pressure. The Z-Purge is not wired to removed DC Power or battery backup power from the unit. It

is the responsibility of the user to manually shut off all power sources if pressure is lost or the X40

Controller enclosure is opened.

The Type Z purge option includes a factory installed bypass switch that can be used to continue operation

of the Model X40 Controller even when the NEMA 4X enclosure is opened and the purge system pressure

is lost. The bypass switch can be toggled between Bypass and Normal, where in the Bypass mode the

purge protection and Class 1 Div 2 area classification is lost.

NOTE1: The Z-Purge option is factory wired to automatically removed AC power from the controller if

there is a loss of pressure. The Z-Purge is not wired to remove DC Power or battery backup power from

the unit. It is the responsibility of the user to manually shut off all power sources if pressure is lost or the

X40 Controller enclosure is opened.

NOTE2: Use of the purge bypass switch invalidates the Class 1 Div 2 area classification and should not be

done without proper authorization. When purge pressure is lost, Class 1 Div 2 area classification is lost

regardless.

The instruction manual for the Model 1001A Type Z purge system is supplied separately. Refer to this

manual for details on purge supply requirements.

Model 240 Operator Manual Rev. 1.8 Page 27 of 29

Page 32

240 Operators Manual

9. Troubleshooting Guide

Problem Potential Fix

Unit will not Power Up

Relays are not firing

Program Locks up or showing

erroneous information

Alarms on constantly

Alarm Firing causes unit to ‘LockUp’

Analog Sensors reading “FAULT”

Serial Sensors reading “NO-COMM”

Serial Sensors display incorrect readings

Contact the Detcon Service Department for further troubleshooting assistance at 281-367-4100.

→ Check for correct AC or DC voltage selection.

→ Check for correct VAC and VDC powering configuration.

→ Check that the alarm relays are configured properly

→ Re-initialize unit. By pressing the Program Key for 3-5

seconds during power-up recycle (Screen will display

“Restoring Defaults)

→ Re-enter all Channel and alarm information.

→ Insure that no channels are set to ascending or descending

incorrectly.

→ Check that Alarm Annunciators current draw does not

exceed the on-board Power Supply limitations. Replace with

external Power Supply if necessary.

→ SW1-4 must be set to “OFF” position.

→ SW1-4 must be set to “ON” position.

→ SW1-2 Must be set to the correct position for the sensor or

Mod 10 Controller (“ON” for Mod 10 Controllers, “OFF” for

600/700 Series Sensors)

10. Spare Parts

500-005075-001 Motherboard PCB

500-005071-LCD Controller Board PCB W/ LCD Display

360-500001-000 Replaceable Power Supply with cables

500-005079-000 4-20mA output/RS-485 output PCB (Optional)

340-120800-000 12 VDC Batteries (Optional)

360-BR2330 Date/Time Clock NICAD Battery

11. Warranty

Detcon, Inc., as the manufacturer, warrants under intended normal use each new Model 240-N4X controller

to be free from defects in material and workmanship for a period of one year from the date of shipment to

the original purchaser. Should the controller fail to perform in accordance with published specifications

within the warranty period, return to Detcon, Inc., for necessary repairs or replacement. All warranties and

service policies are FOB the Detcon facility located in The Woodlands, Texas.

Shipping Address: 3200 A-1 Research Forest Dr., The Woodlands Texas 77381

Phone: 888.367.4286, 281.367.4100 • Fax: 281.292.286 0 •

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

www.detcon.com • sales@detcon.com

Model 240 Operator Manual Rev. 1.8 Page 28 of 29

Page 33

240 Operators Manual

Appendix A

Revision Log

Revision Date Changes made Approval

1.7 01/12/2009 Correction to Password Protection switch direction

Section 6.2

1.8 11/1/2010 Correction to Note regarding use of Calibration Mode

when sensors in calibration, Section 6.5.2

BM

LU

Model 240 Operator Manual Rev. 1.8 Page 29 of 29

Loading...

Loading...