Page 1

m

Model 10C

Single Sensor Control Module

Operator’s Installation and Instruction Manual

Covers all Model 10C Control Modules

The Woodlands, Texas 77387

Ph.281.367.4100 / Fax 281.298.2868

January 29, 2009 • Document #3256 • Revision 0.B

DETCON, Inc.

3200 Research Forest Dr.,

www.detcon.co

Page 2

Model 10C

Blank Page

Shipping Address: 3200 A-1 Research Forest Dr., The Woodlands Texas 77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Phone: 888.367.4286, 281.367.4100 • Fax: 281.292.2860 •

10C Control Module Instruction Manual ii

www.detcon.com • sales@detcon.com

Page 3

Model 10C

Table of Contents

1.0 Description................................................................................................................................................ 1

1.1 Display Function .................................................................................................................................. 2

1.2 Alarm Functions................................................................................................................................... 2

1.2.1 Latching or Non-latching Relays.................................................................................................. 2

1.2.2 Energized or De-energized Relay Coils ....................................................................................... 2

1.2.3 Ascending or Descending............................................................................................................. 3

1.2.4 Silenceable or Non-silenceable (Alarm Acknowledge) ................................................................ 3

1.2.5 Alarm Reset .................................................................................................................................. 3

1.3 Fault Circuit Functions......................................................................................................................... 4

1.4 RS-485 Modbus™................................................................................................................................ 5

1.5 Controller Models................................................................................................................................. 5

2.0 Operator Interface................................................................................................................................... 7

2.1 Normal Operation................................................................................................................................. 7

2.2 Program Mode...................................................................................................................................... 8

3.0 Normal Operation.................................................................................................................................. 10

3.1 Display Gas Concentration and Alarm Condition.............................................................................. 10

3.2 Displaying Gas Type and Units.......................................................................................................... 11

3.3 Program Status ................................................................................................................................... 11

4.0 Program Mode ....................................................................................................................................... 12

4.1 Set Gas Type ...................................................................................................................................... 12

4.2 Range Set............................................................................................................................................ 14

4.3 Set Units ............................................................................................................................................. 15

4.4 Alarm 1, 2, and Fault Set.................................................................................................................... 15

4.4.1 Set-Point ..................................................................................................................................... 15

4.4.2 Direction: Ascending / Descending............................................................................................ 16

4.4.3 Latching / Non-latching.............................................................................................................. 16

4.4.4 Energized / Non-energized ......................................................................................................... 16

4.4.5 Acknowledge: Silenceable / Non-silenceable............................................................................. 16

4.5 Modbus™ Set..................................................................................................................................... 17

4.6 Sensor-Cal Mode................................................................................................................................ 17

4.7 Test ..................................................................................................................................................... 18

5.0 Special Configuration (Technician Access) ......................................................................................... 19

5.1 Trim Input........................................................................................................................................... 19

5.2 Trim Output........................................................................................................................................ 20

5.3 Default Settings .................................................................................................................................. 21

6.0 Calibration.............................................................................................................................................. 22

7.0 Specifications.......................................................................................................................................... 23

8.0 Warranty and Service Policy................................................................................................................ 24

Table of Figures

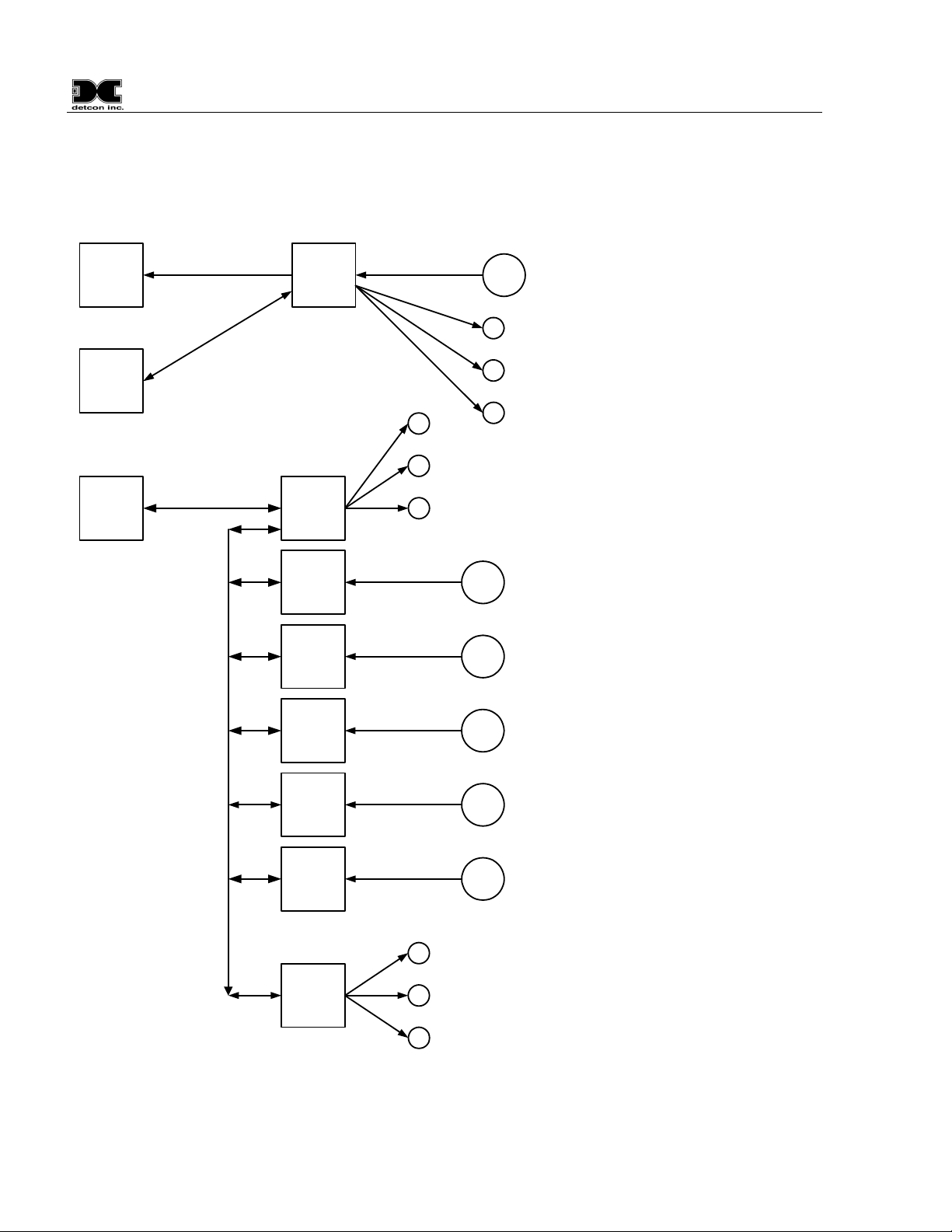

Figure 1 System Application Diagrams............................................................................................................ iv

Figure 2 Front Panel of 10C Controller............................................................................................................ 1

Figure 3 Board Assembly Picture of 10C Controller ......................................................................................9

10C Control Module Instruction Manual iii

Page 4

Model 10C

Master

Controller

Modbus

HOST

Modbus

HOST

4-20mA Current Output

M

O

C

S

U

B

D

O

M

5

8

4

S

R

10C

Controller

M

Facilities

Module

10C

Controller

4-20mA Current Input

4-20mA Current Input

Sensor

Fault

Alarm1

Alarm2

ZONE 1 OUTPUTS

Sensor

OUTPUT DEVI CES

10C

Controller

4-20mA Current Input

Sensor

10C

Controller

10C

Controller

10C

Controller

Relay

Outputs

4-20mA Current Input

4-20mA Current Input

4-20mA Current Input

Sensor

Sensor

Sensor

ZONE 2 OUTPUTS

Figure 1 System Application Diagrams

10C Control Module Instruction Manual iv

Page 5

Model 10C

1.0 Description

The Detcon Model 10C single sensor control module (10C Controller) is designed to supervise and display gas

concentration and the status of a remote gas sensor assembly. Mod 10C Controllers may be configured for a

variety of toxic and combustible gases. The 10C Controller is designed to operate on a nominal input voltage

range of 12 VDC to 24VDC and is compatible with a complete line of Detcon enclosures. The available

enclosures include designs for stand-alone, rack, or panel mount indoor non-hazardous areas (NEMA 1 and

12), weatherproof indoor/outdoor locations in non-hazardous areas (NEMA 4 and 4X), and for indoor/outdoor

location in areas classified as Class 1, Division 1, Groups B, C, and D hazardous (NEMA 7).

10C controllers accept 4-20mA current-loop analog input, and feature a four-character display, RS-485

Modbus™ serial communications, 4-20mA analog signal output, and three alarm relays (Alarm 1, Alarm 2,

and Fault). Alarm status is displayed via light emitting diodes (LEDs) located on the front panel. Multiple

10C Controllers, each configured individually and installed in a 10-Series Detcon Enclosure, provide the

monitoring of a variety of gases from several field sensors in one system.

The , exemplifies how 10C Controllers can be utilized and connected

Figure 1 System Application Diagrams

in an overall Model 10C System.

The overall 10C system design includes Facilities Modules and Relay Modules to be applied with a collection

of 10C Controllers. These additional modules are optional and are the same form-factor as the 10C Controller.

The Facilities Module communicates with 10C Controllers to gather data to associate the controllers in

assigned zones, to optionally log data, to report multiple controllers as one Modbus™ ID, and to logically

process and output conditions to the Relay Modules. The scope of this document is restricted to the 10C

controller and does not include any further description of the Facilities and Relay modules.

Pushbuttons located on the Front Panel provide access to retrieve and set information within the controller and

to provide the “Alarm Reset” and “Alarm Silence” functions. The pushbuttons allow the user to navigate

through an interactive menu to access programming of the 10C Controller’s configuration.

RESET ALARM. The “UP”

pushbutton doubles as the Reset

Alarm function.

SILENCE ALARM. The

“DOWN” pushbutton doubles

as the Silence Alarm function.

Figure 2 Front Panel (faceplate) of 10C Controller

10C Control Module Instruction Manual Rev. 0.B Page 1 of 25

Four character display shows

numeric values and text. Scrolls text

for improved interactive function.

Alarm 1 and Alarm 2 LED

indicators.

Fault Alarm LED indicator.

Four pushbuttons provided for

interactive user interface to configure

and view values and settings in

Controller. Keys are: ESCAPE,

ENTER,

×UP and ØDOWN.

Page 6

Model 10C

1.1 Display Function

The main purpose of the 10C Controller’s 4-character display is to show the gas concentration reading at all

times. The reading is given in numeric form and with the desired units, as converted from the current input

signal of the attached gas sensor. Upon operation of the pushbuttons, the display also allows viewing gas type

and units very simply, and with further manipulation allows viewing of any configurable setting.

1.2 Alarm Functions

The alarm configuration, programmed into the controller, determines how the 10C Controller responds to the

4-20mA current-loop analog input. In response to the analog input relative to alarm configuration, the

Controller outputs to its relays and panel LEDs. Alarm configurations for the alarm output relays and LEDs

can be programmed as latching or non-latching, ascending or descending, energized or de-energized, and

silenceable or non-silenceable operation. Any combination of these settings can be programmed to provide

setups for almost any contingency. Some planning may be needed to determine the best configuration for the

application.

1.2.1 Latching or Non-latching Relays

All alarms, Alarm 1, Alarm 2, and Fault, can be programmed as Latching or Non-latching. If an alarm is

programmed to Latch, its corresponding relay and LED Indicator, once activated, will stay activated until

reset, even if the analog input “clears”.

NOTE: The term “Clear” refers to when the alarm condition of the sensor signal returns to

normal, which means that the input current changes to the non-alarm side of the Set-Point

threshold.

If an alarm is programmed as Non-latching, the alarm will not remain activated if the analog input clears.

There is a reset pushbutton on the 10C front panel and there is also a signal input to the 10C controller via the

backplane where an external switch can be connected. When the “Reset” pushbutton on the front panel or the

external switch is momentarily activated, the 10C accepts the signal as an alarm reset function. If resettable

alarms are latched, and in response to the front panel reset switch, the 10C front panel display will scroll the

text: “Reset Alarms?” In response to this query, the “ENT” pushbutton should be pressed to acknowledge the

reset. In response to an front panel reset button acknowledgement , the front panel display scrolls the text:

“Reset DONE”.

The external reset does not have an acknowledge feature and when the 10C Controller senses that the external

reset signal is momentarily activated, the 10C scrolls a text message on its front panel display: “Ext Alm Rst”.

1.2.2 Energized or De-energized Relay Coils

All alarm relays (Alarm 1, Alarm 2, and Fault) can be programmed as normally Energized or normally Deenergized. The standard setting for alarms is De-energized, however, a relay can be programmed as Energized

to provide application specific features. For De-energized relays, the coil will energize in an alarm state. For

Energized relays, the coil is normally Energized and will de-energize in an alarm state. It should be noted that

with a normally Energized relay the N.O. (Normally Open) contact and the COM (Common) contact are

CLOSED, and the N.C. (Normally Closed) contact and the COM contact are OPEN, while in the non-alarm

state.

10C Control Module Instruction Manual Rev.0.B Page 2 of 25

Page 7

Model 10C

A typical application of an Energized relay could be the use of the Fault Relay in a Fail-Safe Fault Circuit. The

loss of functionality of the Controller would cause the coil to De-Energize, thus creating a Fault output to the

receiving equipment, for instance: if power is lost to the 10C Controller, or if the 10C module is unplugged

from the live chassis.

1.2.3 Ascending or Descending

Alarm 1, and Alarm 2 can be programmed for whether the alarm condition is triggered by an increasing

concentration (Ascending) or a decreasing concentration (Descending) through a set-point. The descending

feature, although mainly used for oxygen deficiency, can be useful for setting the trigger of alarms when there

is lack of gas concentration. When set for ascending, the associated alarms will trigger when the gas

concentration goes above the preset set-point. When set for descending, the associated alarms will trigger

when the gas concentration falls below the preset set-point.

1.2.4 Silenceable or Non-silenceable (Alarm Acknowledge)

The terminology “to acknowledge alarms” is synonymous with the terminology “to silence an alarm”. All

Alarms (Alarm 1, Alarm 2, and Fault) can be programmed as Silenceable or Non-silenceable. When an alarm

is programmed as Silenceable, the setting allows the alarm(s) to be silenced even during an alarm state. To

silence an alarm the 10C controller’s alarm must be programmed as Silenceable. When an alarm occurs, the

Silenceable alarm can be silenced by pressing the “SLNC” pushbutton, followed by acknowledging the

“Silence Alarms?” scrolling display by pressing the “ENT” pushbutton. An instance where this feature might

be used is a Strobe device connected to Alarm 1 and a Horn device connected to Alarm 2. In the event of an

alarm, where both the Strobe and Horn were activated, the Horn could be silenced while the Strobe would

remain activated. The silenced state is reset when and if the alarm condition clears and then exceeds alarm setpoint again. The Horn would be reactivated upon the return of the alarm condition.

The “Remote Reset” signal that resets latched alarms also functions as a signal to silence active Silenceable

Alarms.

NOTE: There is a minimum alarm time before acknowledge. When a silenceable alarm

triggers, a minimum-time timer starts. Whenever a silenceable alarm is attempted to be

silenced, the alarm will not silence unless/until the minimum-time timer has timed out. This

guarantees that the alarm has a minimum activity time.

1.2.5 Alarm Reset

An alarm “RESET” pushbutton key-switch is located on the front panel of the 10C Controller. This switch is

used to reset alarms that have been programmed as latching. Once alarm conditions clear, alarms that have

been set as latching can be reset by use of this switch. If cleared latched alarms are pending, pressing the

“RESET” pushbutton will cause the display to scroll the text: “Reset Alarms?” Pressing the “ENT”

pushbutton will reset the alarms which is apparent with the displayed text: “Reset DONE”. The “Remote

Reset” signal, activated from an optional external switch, can be momentarily operated to reset the latched

relays.

The “Remote Reset” signal needs to be operated only once and without an acknowledge sequence, to reset all

pending latched alarms. The text “Ext Alm Rst” scrolls across the 10C Controller front panel display when the

“Remote Reset” signal is sensed.

10C Control Module Instruction Manual Rev. 0.B Page 3 of 25

Page 8

Model 10C

1.3 Fault Circuit Functions

How the 10C Controller responds to a fault condition is determined by the configuration programmed into the

controller. Faults can be programmed as latching or non-latching, energized or de-energized, and silenceable

or non-silenceable operation. Any combination of these settings, and the set-point threshold at which a fault

will trigger, can be programmed to provide setups for almost any contingency. Some system level planning

should be exercised to determine the best configuration for the application.

10C Controllers can be set up in a Fail-Safe Fault supervisory circuit. A Fail-Safe Fault can be created by

setting the Fault Relay as Energized, and connecting the fault circuits of several 10C Controllers in electrical

series. If a fault occurs anywhere in the series circuit, the de-energized fault relay will ‘break’ the circuit,

causing a system fault. The logical “OR” of all faults in the series circuit is simply constructed with such a

method. Mainly, with this set-up, loss of power to any unit will break the circuit because of the normallyenergized coils, thus creating a “Fault Condition” due to the loss of power.

The 10C Controller is designed to detect a sensor as being “In Calibration Mode” when the 4-20mA input is

nominally 2mA. The Display will show “CAL” to signify this sensor Calibration Mode. When the 10C

Controller 4-20mA falls below 2mA, the display will change to “SENS” to signify that there is a sensor related

problem. The Fault Set-Point can be set to any point below 4mA (in steps of .05mA) so that the input of the

sensor can trigger a fault at any point below 4mA.

For 3-wire sensors, the Set-Point can be adjusted to 1.8mA so that when the sensor is in Calibration, a Fault is

not generated. If the input current falls below 1.8mA, a fault will be generated. Since most sensors reduce

their output current for internally detected faults, this set-point is a good setting.

For 2-wire sensors, the sensor uses the loop current for power and so the set-point ordinarily must be set

higher. The fault Set-Point for 2-wire sensors is suggested to be 3.5mA.

10C Control Module Instruction Manual Rev.0.B Page 4 of 25

Page 9

Model 10C

1.4 RS-485 Modbus™

The 10C Controllers feature Modbus™ compatible communications protocol and are addressable via the

programming menu for multi-point communications. Communication is two wire, half-duplex, with the

Model 10C controller set up as a slave device. A master controller can address a maximum of 255 different

10C Controllers. The actual limit of how many 10C Controllers can be connected to one RS485 Multi-drop

line depends upon desired maximum response time, noisy conditions, cable quality, and length. If a multipoint system is utilized, each 10C Controller must be set with a unique Modbus™ address. Address settings

are given in hexadecimal, such as: 01, 02, 03, 04, 05, 06, 07, 08, 09, 0A, 0B, 0C, 0D, 0E, 0F, 10, 11, etc. (See

Section 4.5 to set the Modbus™ address.)

The following register list describes the parameters available from 10C controller:

Register # High Byte Low Byte

40000 Range

40001 Reading

40002 Alarm 1 Set Point

40003 Alarm 2 Set Point

40004 Not Used

40005 Status Bits

40005 Status Bits High Byte:

Bit 15 – Reserved

Bit 14 – Reserved

Bit 13 – Reserved

Bit 12 – Test mode status

Bit 11 – Reserved

Bit 10 – Reserved

Bit 9 – Reserved

Bit 8 – Reserved

40005 Status Bits Low Byte:

Bit 7 – Alarm 2 / 0 – Ascending, 1 – Descending

Bit 6 – Alarm 2 / 0 – Non-latching, 1 – Latching

Bit 5 – Alarm 2 alarm status / 0 – no alarm, 1 – alarm

Bit 4 – Alarm 1 / 0 – Ascending, 1 – Descending

Bit 3 – Alarm 1 / 0 – Non-latching, 1 – Latching

Bit 2 – Alarm 1 alarm status / 0 – no alarm, 1 – alarm

Bit 1 – Fault / 0 – Non-latching, 1 – Latching

Bit 0 – Fault status / 0 – no fault, 1 - fault

1.5 Controller Models

Table 1 provides a list of the available 10C Controller Models, the target gas, the standard Range and Units for

that gas, and the gas formula. Most 10C Controllers can be programmed for a Range other than the standard

Range if needed. (For more information on setting Range, see Section 4.2 Range Set.)

The label on the Model 10 faceplate follows a standard color scheme for identifying the gas type: Yellow =

Solid State H2S, Orange = Combustible Gas, Green = Oxygen and Blue = Electrochemical Toxic (various).

The gas identifier label on the face plate also shows the gas formula and Units: ppm, ppb, or %.

10C Control Module Instruction Manual Rev. 0.B Page 5 of 25

Page 10

Model 10C

Table 1 10C Controller Models

Model # Target Gas Standard Range Formula

AsH3-10 Arsine 0-1 PPM AsH3

Br2-10 Bromine 0-5 PPM Br2

B2H6-10 Diborane 0-5 PPM B2H6

CG–10 Combustible Gases 0-100 % LEL various

CH20-10 Formaldehyde 0-100 PPM CH20

CH30H-10 Methanol 0-100 PPM CH30H

CH3SH-10 Methyl Mercaptan 0-100 PPM CH3SH

CLO2-10 Chlorine Dioxide 0-1 PPM CLO2

CL2-10 Chlorine 0-10 PPM CL2

CO-10 Carbon Monoxide 0-100 PPM CO

COCL2-10 Phosgene 0-1 PPM COCL2

CO2-10 Carbon Dioxide 0-1 % CO2

CS-10 Carbonyl Sulfide 0-100 PPM CS

CS2-10 Carbon Disulfide 0-100 PPM CS2

C2H2-10 Acetylene 0-100 PPM C2H2

C2H3CL-10 Vinyl Chloride 0-100 PPM C2H3CL

C2H30-10 Acetyldehyde 0-100 PPM C2H30

C2H4-10 Ethylene 0-100 PPM C2H4

C2H4O-10 Ethylene Oxide 0-100 PPM C2H4O

C2H5OH-10 Ethanol 0-100 PPM C2H5OH

C2H6S-10 Dimethyl Sulfide 0-100 PPM C2H6S

C3H3N-10 Acrylonitrile 0-100 PPM C3H3N

C3H5OCL-10 Epichlorohydrin 0-10 PPM C3H5OCL

C4H4S-10 Thiophane 0-100 PPM C4H4S

C4H6-10 Butadiene 0-100 PPM C4H6

C4H8S-10 Tetrahydrothiophene 0-100 PPM C4H8S

C4H6O2-10 Vinyl Acetate 0-100 PPM C4H6O2

F2-10 Fluorine 0-1 PPM F2

GeH4-10 Germane 0-2 PPM GeH4

HBr-10 Hydrogen Bromide 0-30 PPM HBr

HCL-10 Hydrogen Chloride 0-30 PPM HCL

HCN-10 Hydrogen Cyanide 0-30 PPM HCN

HF-10 Hydrogen Fluoride 0-10 PPM HF

H2S-100 Hydrogen Sulfide 0-100PPM H2S

H2-10 Hydrogen 0-100 PPM H2

H2-10 LEL Hydrogen 0-100 % H2

NH3-10 Ammonia 0-100 PPM NH3

NO-10 Nitric Oxide 0-100 PPM NO

NO2-10 Nitrogen Dioxide 0-5 PPM NO2

N2H4-10 Hydrazine 0-1 PPM N2H4

O2-10 Oxygen 0-25 % O2

O3-10 Ozone 0-1 PPM O3

PH3-10 Phosphine 0-5 PPM PH3

SiH4-10 Silane 0-50 PPM SiH4

SO2-10 Sulfur Dioxide 0-20 PPM SO2

10C Control Module Instruction Manual Rev.0.B Page 6 of 25

Page 11

Model 10C

2.0 Operator Interface

The 10C Controller is configured by use of the front panel display and pushbuttons. The 10C Controller User

Interface Menu System allows the user to set various parameters associated with the sensor: Gas type, Range,

Units, Alarm settings, and Modbus ID.) Navigation through the menu system is accomplished by use of the

10C Controller’s Front Panel Pushbuttons: the Enter key “ENT”, the Escape key “ESC”, the Up key “×” (or

“RESET”), and the Down key “Ø” (or “SLNC”). The menu system includes the main Programming menu and

submenus as indicated in this section.

2.1 Normal Operation

Normal Operation of the display is to constantly display the Concentration Reading. Upon power-up

initialization of the 10C Controller, the text “WARM UP” is displayed instead of concentration for about sixty

seconds. While in the Normal Operation mode, the Pushbuttons on the left have the meaning “Alarm Reset”

and “Alarm Silence” and are used to Reset and to Acknowledge alarms.

In Normal Operation the Gas Type and Units can be prompted for momentary display by pressing the “ESC”

pushbutton. The Program Configuration Status can be viewed by pressing the “ENT” pushbutton:

View Program Status:

(Lamp Test)

Gas Type

Range

Units

Alarm 1 Set-Point

Alarm 1 Direction

Alarm 1 Latching

Alarm 1 Energized

Alarm 1 Silenceable

Alarm 2 Set-Point

Alarm 2 Direction

Alarm 2 Latching

Alarm 2 Energized

Alarm 2 Silenceable

Fault Set-Point

Fault Direction

Fault Latching

Fault Energized

Fault Silenceable

Modbus™ Address

Firmware Version

Firmware Checksum

Firmware last programmed address (Top of code address in memory)

10C Control Module Instruction Manual Rev. 0.B Page 7 of 25

Page 12

Model 10C

2.2 Program Mode

While in Normal Operation with Concentration displaying, pressing the “ENT” pushbutton and holding it for

about three seconds allows the Program Mode to be accessed. While in the Program Mode, the left

pushbuttons have the meaning “×”and “Ø”which allow moving back and forth or up and down through the

menu and for changing values up and down. If an alarm triggers while in the Program Mode, the 10C

Controller will automatically exit the Program Mode and return to Normal Operation whereupon the up and

down pushbuttons become the alarm reset/silence pushbuttons. The Program Mode allows setting the many

variables in the 10C Controller:

Set Gas Type

Set Range

Set Units

Set Alarm 1:

Set-Point

Direction

Latching

Energized

Silenceable

Set Alarm 2:

Set-Point

Direction

Latching

Energized

Silenceable

Set Fault:

Set-Point Threshold in milliAmps and always descending

Latching

Energized

Silenceable

Set Modbus™ Address

Set Sensor-Cal Mode

Test

Trim Input (Technician Access only)

Trim Output (Technician Access only)

Restore Default Settings (Technician Access only)

10C Control Module Instruction Manual Rev.0.B Page 8 of 25

Page 13

Model 10C

SW1: Access/Normal Switch

JP1: “LPBAK” jumper

(normally open- only

shunt for testing).

Figure 3 Board Assembly Picture of 10C Controller

10C Control Module Instruction Manual Rev. 0.B Page 9 of 25

Page 14

Model 10C

3.0 Normal Operation

3.1 Display Gas Concentration and Alarm Condition

In normal operation, the 10C Controller display continuously shows the sensor’s gas concentration reading

(normally “00”). Pressing the “ENT” pushbutton and holding it down for about three seconds will take the

user into the Program Mode Menu. The “RESET” pushbutton will reset the alarm(s) if the 10C Controller has

been configured properly, and all conditions for Alarm Reset have been satisfied. The “SLNC” Button will

silence the alarm(s) if the 10C Controller has been configured properly, and the alarm silence conditions have

been satisfied.

Table 2, Input Current Below 4mA

Input Current (mA) Display

0-1.8 SENS

1.8-2.4 CAL

2.40-2.56 -9

2.56-2.72 -8

2.72-2.88 -7

2.88-3.04 -6

3.04-3.20 -5

3.20-3.36 -4

3.36-4.00 00

If the current-loop input reads below the Fault Set-Point, the sensor is in Fault. The 10C Controller will

activate the Fault Alarm relay and the Fault LED will activate to indicate the Fault condition.

Current Below 4mA

input measures nominally 2.0mA, the Sensor is in Calibration Mode and the 10C Controller will display the

text ‘CAL’ and the Fault LED will be activated. Very low input current should cause the display to say

‘SENS’ to indicate Sensor Fault. In either case, the Fault Relay will be set, according to the configuration, to

convey a fault status. Note that if the Fault Relay is configured as normally energized, the relay coil will deenergize to convey a fault status. If the Fault Relay is configured as normally de-energized, the relay coil will

energized to convey a fault status.

When an alarm is triggered the corresponding alarm LED will illuminate to indicate the alarm (Alarm 1 and/or

Alarm 2). The corresponding relays will also be set to convey the appropriate status. If the associated alarm

relay is configured as normally energized, the relay coil will de-energize to convey an alarm status. If the

alarm relay is configured as normally de-energized, the relay coil will energize to convey an alarm status.

In normal operation, the 4-20mA current output corresponds directly with the Sensor 4-20mA input. The RS485 Modbus™ serial communications provides the current gas reading and complete fault status when polled

by the Master Controller.

If Program Mode is accessible because of the “ACCESS/NORM” Switch (see location of SW1 in

Board Assembly Picture of 10C Controller

“ENT” key to enter the Program Mode and internal configuration values can be changed. If the

“ACCESS/NORM” Switch (SW1) is in the “NORM” position then only the review of Program Status (see

section 3.2) is accessible.

, reveals what the display should say for input current less than 4mA. If the current-loop

) in the “ACCESS” position, then the user can hold down the

Table 2, Input

Figure 3

10C Control Module Instruction Manual Rev.0.B Page 10 of 25

Page 15

Model 10C

3.2 Displaying Gas Type and Units

While in Normal mode, and while the Gas Concentration is being displayed, the “ESC” button can be pressed

to momentarily display the Gas Type and the Units; for instance: H

S and ppm.

2

3.3 Program Status

While in Normal mode, and while the Gas Concentration is being displayed, the ability to view the

configuration or “Program Status” is always available to all operators. To see the Program Status, the “ENT”

pushbutton should be momentarily pressed and the display will scroll “PR STATUS”. To view the Program

Status press the “ENT” pushbutton again. First the Lamp Test function will light up all display light elements.

Then the 10C Controller display will show the configured settings of each of the configuration parameters

starting with the Gas Type, Range, and Units:

Program Status:

(Lamp Test)

Gas Type

Range

Units

Alarm 1 Set-Point

Alarm 1 Direction

Alarm 1 Latching

Alarm 1 Energized

Alarm 1 Silenceable

Alarm 2 Set-Point

Alarm 2 Direction

Alarm 2 Latching

Alarm 2 Energized

Alarm 2 Silenceable

Fault Set-Point

Fault Direction

Fault Latching

Fault Energized

Fault Silenceable

Modbus™ Address

Firmware Version

Firmware Checksum

Firmware last programmed address (Top of code address in memory)

Only the set value of each item in the list is displayed. The “PR STATUS” first item is Gas Type (for

instance: “LEL” or “H2S” or “CO2”, etcetera) and then display will show Range next (for instance: “100”)

and continue through the list. The user needs to be familiar with the order in which these items are displayed,

the order of which is mostly the same as the programming mode menu list. When all of the items have been

displayed or through use of the “ESC” pushbutton, the 10C Controller returns the display function of Gas

Concentration (see 3.1).

10C Control Module Instruction Manual Rev. 0.B Page 11 of 25

Page 16

Model 10C

4.0 Program Mode

Program Mode is only accessible with the “ACCESS/NORM” Switch (SW1) in the “ACCESS” position.

With the switch in the “NORM” position, only the Program Status Function is available, and only the reading

of configuration values is possible. The “ACCESS/NORM” switch is located in the lower left-hand corner on

the PCA just behind the faceplate, and can be accessed by removing the PCA from the card rack.

Ensure that the “ACCESS”/”NORM” Switch (see location of SW1 in

10C Controller

a few seconds, the 10C Controller will enter the Program Mode Menu. When entering the Program Mode

Menu, the first item on the Program Mode Menu will scroll across the display: “GAS TYPE”. The user can

maneuver through the menu via the “×” (or “RESET”), and the “Ø” (or “SLNC”) pushbuttons. When the

selected menu item is reached, the “ENT” pushbutton is used to enter the selected item. The Program Mode

Menu consists of nine menu selections or functions:

GAS TYPE

RANGE SET

UNITS SET

ALM 1 SET

ALM 2 SET

FAULT SET

MODBUS SET

SENSOR-CAL MODE SET

TEST

Three additional menu selections are available only with “Technician Access”; see 5.0 : Special Configuration

(Technician Access)

TRIM INPUT

TRIM OUTPUT

RESTORE DEFAULTS

NOTE: Pushbutton inactivity during any part of the above procedure will eventually cause the

displayed function to time out and return to the display to Normal Operation with the exception

of Technician tests.

Program Mode Menu is unavailable.

) is in the “ACCESS” position. Upon pressing the “ENT” pushbutton and holding it down for

4.1 Set Gas Type

Figure 3 Board Assembly Picture of

Set Gas Type is used to set the “Gas Type” variable inside the 10C Controller to be agreeable with the sensor

being attached. This setting must match the sensor being attached to the controller. The list of Gas Type

choices can be found in Table 3 List of Gas Types.

The menu item appears as: “GAS TYPE”.

From the “GAS TYPE” display, the “ENT” pushbutton can be used to select a particular gas type. In response

the “ENT” key, the display will start to scroll the current gas type. The gas type will flash while being

displayed to show that the gas type is selectable. The “×” and “Ø” pushbuttons allow movement through the

list of choices of gas types.

10C Control Module Instruction Manual Rev.0.B Page 12 of 25

Page 17

Model 10C

Table 3 List of Gas Types

Gas Type Target Gas Standard Range Formula

H2S Hydrogen Sulfide 0-100PPM H2S

LEL LEL Combustible Gases 0-100 % LEL various

O2 Oxygen 0-25 % O2

CO Carbon Monoxide 0-100 PPM CO

CO2 Carbon Dioxide 0-1 % CO2

Cl2 Chlorine 0-10 PPM CL2

NH3 Ammonia 0-100 PPM NH3

H2 Hydrogen 0-100 PPM H2

NO Nitric Oxide 0-100 PPM NO

NO2 Nitrogen Dioxide 0-5 PPM NO2

SO2 Sulfur Dioxide 0-20 PPM SO2

VOC Volatile Organic Com 0-1000PPM Various

AsH3 Arsine 0-1 PPM AsH3

B2H6 Diborane 0-5 PPM B2H6

C2H2 Acetylene 0-100 PPM C2H2

C2H3O Acetaldehyde 0-100 PPM C2H30

C2H3Cl Vinyl Chloride 0-100 PPM C2H3CL

C2H4 Ethylene 0-100 PPM C2H4

C2H4O Ethylene Oxide 0-100 PPM C2H4O

C2H5OH Ethanol 0-100 PPM C2H5OH

C2H6S Dimethyl Sulfide 0-100 PPM C2H6S

C3H3N Acrylonitrile 0-100 PPM C3H3N

C3H5OCL Epichlorohydrin 0-10 PPM C3H5OCL

C4H4S Thiophane 0-100 PPM C4H4S

C4H6 Butadiene 0-100 PPM C4H6

C4H6O2 Vinyl Acetate 0-100 PPM C4H6O2

C4H8S Tetrahydrothiophene 0-100 PPM C4H8S

CH2O Formaldehyde 0-100 PPM CH20

CH3OH Methanol 0-100 PPM CH30H

CH3SH Methyl Mercaptan 0-100 PPM CH3SH

COCl2 Phosgene 0-1 PPM COCL2

CS2 Carbon Disulfide 0-100 PPM CS2

F2 Fluorine 0-1 PPM F2

GeH4 Germane 0-2 PPM GeH4

HBr Hydrogen Bromide 0-30 PPM HBr

HCl Hydrogen Chloride 0-30 PPM HCL

HCN Hydrogen Cyanide 0-30 PPM HCN

HF Hydrogen Fluoride 0-10 PPM HF

N2H4 Hydrazine 0-1 PPM N2H4

PH3 Phosphine 0-5 PPM PH3

SiH4 Silane 0-50 PPM SiH4

Br2 Bromine 0-5 PPM Br2

CLO2 Chlorine Dioxide 0-1 PPM CLO2

O3 Ozone 0-1 PPM O3

10C Control Module Instruction Manual Rev. 0.B Page 13 of 25

Page 18

Model 10C

NOTE: While the term “LEL” is used here as a Gas Type, it must be understood that the term

stands for Lower Explosive Limit and implies a Range for a combustible gas without being

specific about which explosive gas. If the gas is Methane (CH4), the LEL is about 5% by

volume of Methane in Air. Therefore, 100% LEL is equivalent to about 5% equivalent methane

in air by volume.

When the chosen Gas Type is found, the “ENT” pushbutton can be used to select it. The flashing will stop and

the selected gas type will remain solidly displayed. The “ENT” pushbutton or the “ESC” pushbutton can be

used to leave the gas type selection function and return to the “GAS TYPE” menu item.

Move to another menu item by using the “×” and “Ø” pushbuttons, or use the “ESC” pushbutton to leave

Program Mode and return to Normal Operation of the display.

NOTE: Pushbutton inactivity during any part of the above procedure will eventually cause the

displayed function to time out and return the display to Normal Operation.

4.2 Range Set

“Range Set” is used to set the full-scale range of gas concentration, with respect to the attached sensor type.

This setting must match the attached sensor’s range. Setting the range to something other than the range of

the sensor attached to the controller will cause erroneous readings, and is not advised.

The menu item appears as: “RANGE SET”.

From the “RANGE SET” display the “ENT” pushbutton is used to enter the range set function. The display

will flash the range that is currently set to show that the range is selectable. Use of the “×” and “Ø”

pushbuttons allows movement through the available ranges. When the chosen range value is found, the

“ENT” pushbutton sets the range to the displayed value. The display will stop flashing to signify the range

selection was set. The “ENT” pushbutton or the “ESC” pushbutton can be used to leave the range selection

function and return and return to the “RANGE SET” menu item.

The list of Range selection choices are:

1.00, 2.00, 3.00, 4.00, 5.00, 6.00, 7.00, 8.00. 9.00,

10.0, 11.0, 12.0, 13.0, 14.0, 15.0, 16.0, 17.0, 18.0, 19.0, 20.0, 21.0, 22.0, 23.0, 24.0, 25.0,

30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95,

100, 150, 200, 250, 300, 350, 400, 450, 500, 550, 600, 650, 700, 750, 800, 850, 900, 950,

1000, 1500, 2000, 2500, 3000, 3500, 4000, 4500,

5000, 5500, 6000, 6500, 7000, 7600, 8000, 8500, 9000, 9500, 9999

NOTE: % (percent) can only be found in the Units selection if the range is set to 100 or less.

Likewise, the range cannot be set above 100 if the Units are set to “%”.

The “×” and “Ø” pushbuttons can be used to move to another menu item, or the “ESC” pushbutton can be

used to leave Program Mode.

NOTE: Pushbutton inactivity during any part of the above procedure will eventually cause the

displayed function to time out and return to the display to Normal Operation..

10C Control Module Instruction Manual Rev.0.B Page 14 of 25

Page 19

Model 10C

4.3 Set Units

Set Units provides a means to adjust the units of measure for the Range selected. The Units should match the

units of measure of the associated sensor.

The menu item appears as: “UNITS SET”.

From the “UNITS SET” display use the “ENT” pushbutton to enter the function. The display will flash the

units of measure currently set. Use the “×” and “Ø” pushbuttons to move through the different units of

measure available. When the correct unit is found, use the “ENT” pushbutton to select that unit of measure.

The display will stop flashing and the units selected will be displayed continuously. Press the “ENT”

pushbutton again, or the “ESC” pushbutton, to leave the function and return to the “UNITS SET” menu item.

Choice for Units is given as:

“ppm” parts per million concentration

“ppb” parts per billion concentration

“%” percent concentration

“mA” milliAmps of loop current

NOTE: % (percent) can only be found in the Units selection if the range is set to 100 or less.

Likewise, the range cannot be set above 100 if the Units are set to “%”.

Move to another menu item by using the “×” and “Ø” pushbuttons, or use the “ESC” pushbutton to leave

Program Mode.

NOTE: Pushbutton inactivity during any part of the above procedure will eventually cause the

displayed function to time out and return the display to Normal Operation.

4.4 Alarm 1, 2, and Fault Set

Alarm 1 Set, Alarm 2 Set, and Fault Set are used to set the configuration parameters that will dictate the

behavior of Alarm 1, Alarm 2, and Fault, respectively. Setting the configuration of Alarm 1, and Alarm 2 is

the same, and setting Fault parameters is mostly the same. The exception is that “FAULT SET” does not

provide an option for “direction” because Fault is always triggered on descending input current, the “direction”

step is skipped when setting up the Fault parameters. The first variable in the list for each function is the SetPoint.

NOTE: For Gas Type “LEL”, the 10C Controller restrains Set-Point settings to be no greater

than 60%, and for Alarm 2 to be not less than Alarm 1 Set-Point and for Alarm 2 to be forced to

Latching relay configuration.

The menu item appears as: “ALARM 1 SET” or “ALARM 2 SET”, or “FAULT SET”, depending upon

which function is chosen.

From the “ALARM 1 SET”, “ALARM 2 SET” or “FAULT SET” display, use the “ENT” pushbutton to

enter the function.

4.4.1 Set-Point

The display will show the current Set-Point. Use the “×” and “Ø” pushbuttons to move through choices of

values for the Set-Point. When the chosen value is found, the “ENT” pushbutton is used to select the value.

10C Control Module Instruction Manual Rev. 0.B Page 15 of 25

Page 20

Model 10C

The display will stop flashing and the selected Set-Point values will be solidly displayed. Pressing the “ENT”

pushbutton again will move to the next parameter in the list.

Note that when setting the Set-Point of the Alarms that the reading is directly proportional to the Range.

Therefore, if the range is set to 500ppm the Set-Point display will step by the increment of 5ppm. That is, for

every press of the “×” or the “Ø” pushbutton, the display will increase or decrease by 5ppm.

When setting the Fault Set-Point, that the reading corresponds directly to milliAmps (mA) units. Input current

that descends through the Fault Set-Point triggers a Fault alarm. For instance, if the desired level for Fault

alarm is when the mA input from a sensor drops below 2.5mA, then this parameter should be set for 2.50.

Latching / Non-latching, Energized / Non-Energized, and Silenceable / Non-silenceable can be set to the

customer’s preference.

4.4.2 Direction: Ascending / Descending

For Fault, the direction is always set to Descending and cannot be changed. For Alarm 1 and Alarm 2 the

flashing display will show the set value of the “direction” variable as “UP” for ascending and “DN for

descending. The “×” and “Ø” pushbuttons can be used to select either “UP” or “DN”. The “ENT”

pushbutton can then be used to accept the value. The display will stop flashing to signify that the value was

set. Pressing the “ENT” pushbutton again will move to the next parameter in the list.

4.4.3 Latching / Non-latching

The flashing display will show the set value of the Latching / Non-latching variable as “LT=0” for NonLatching, and “LT=1” for Latching. The “×” and “Ø” pushbuttons can be used to select either “LT=0” for

Non-latching or “LT=1” for Latching. “ENT” pushbutton can be used to set the selected value, signified by

the fact that display stops flashing. Pressing the “ENT” pushbutton again will move to the next parameter in

the list.

4.4.4 Energized / Non-energized

The alarm relay coil can be set to be energized when the alarm is OFF or non-energized when the alarm is

OFF. The flashing display will show the set value of the Energized / Non-energized variable as “EN=0” for

Non-energized, and “EN=1” for Energized. The “×” and “Ø” pushbuttons can be used to select either

“EN=0” for Non-energized or “EN=1” for Energized. The “ENT” pushbutton can be used to accept the

selected value. The display will stop flashing to signify the value has been set. Pressing the “ENT”

pushbutton again will move to the next parameter in the list.

4.4.5 Acknowledge: Silenceable / Non-silenceable

The flashing display will show the set value of the Silenceable / Non-silenceable Alarm variable as “SL=0” for

Non-silenceable, and “SL=1” for Silenceable. The “×” and “Ø” pushbuttons can be used to select either

“SL=0” for Non-silenceable or “SL=1” for Silenceable. The “ENT” pushbutton can be used to accept the

selected value. The display will stop flashing to signify the value has been set. Pressing the “ENT”

pushbutton again will return to the appropriate “ALARM 1 SET”, “ALARM 2 SET”, or “FAULT SET”

scrolling display.

After setting the alarm/Fault configuration parameters, another Program Mode Menu item can be selected by

use of the “×” and “Ø” pushbuttons, or use of the “ESC” pushbutton to leave Program Mode.

NOTE: Pushbutton inactivity during any part of the above procedure will eventually cause the

displayed function to time out and return to the display to Normal Operation..

10C Control Module Instruction Manual Rev.0.B Page 16 of 25

Page 21

Model 10C

4.5 Modbus™ Set

Set Modbus™ provides a means to set the unique identifying Modbus™ Address. The Address is also known

as the “ID” or “Modbus RTU ID”.

The menu item appears as: “MODBUS SET”.

From the “MODBUS SET” display press the “ENT” pushbutton to enter the function.

To enter “ID Set” function, press the “ENT” pushbutton while the “ID Set” display is scrolling. The display

will flash the current Modbus™ ID Address in Hexadecimal format. Use the “×” and “Ø” pushbuttons to set

the appropriate address and press the “ENT” pushbutton to accept this value. The display will stop flashing

and the ID address will be displayed continuously. Press the “ENT” pushbutton again to leave the menu item.

The display will return to “MODBUS SET”.

The “×” and “Ø” pushbuttons can be used to move to another menu item, or the “ESC” pushbutton can be

used to leave Program Mode.

NOTE: Pushbutton inactivity during any part of the above procedure will eventually cause the

displayed function to time out and return the display to Normal Operation.

4.6 Sensor-Cal Mode

Sensor Cal Mode is used to set the 10C Controller’s output current to 2mA and to inhibit alarm processing

temporarily during a field calibration of the sensor.

The menu item appears as: “SENSOR-CAL MODE”.

From the “SENSOR-CAL MODE” display, the “ENT” pushbutton is used to enter the function. The display will flash and show “Cal-Mode OFF”. The “ENT” pushbutton is used to change the state to “Cal-Mode ON” or the “ESC” pushbutton can be used to escape to the menu.

When the 10C Controller is set to “Cal-Mode ON”, the Current Output will change to and remain at 2mA and

input current will not be processed for alarm triggering. The purpose of this is to allow the sensor’s output

current signal to be ignored while calibrating the sensor.

Until the controller is returned to normal operation by pressing the “ESC” pushbutton or when the 10C

Controller reaches a time limit. To help remind the user that the 10C Controller is in Sensor Calibration Mode,

the Fault LED will flash on/off rapidly and continuously while the display scrolls the text “Cal-Mode ON”.

To escape this function, the “ESC” pushbutton can be pressed and the Sensor-Cal Mode will be turned off and

the 10C Controller will leave the Program Mode and return to Normal Mode.

NOTE: The Sensor-Cal Mode will eventually time-out and return the controller to Normal

Operation if escape of the function is not manually executed. The timeout period is nominally

one hour.

10C Control Module Instruction Manual Rev. 0.B Page 17 of 25

Page 22

Model 10C

4.7 Test

The 10C Controller “TEST” provides a means of checking the external alarm system by artificially setting off Relay Outputs without having to force them on/off through the external sensor input to the Controller. The “TEST” consists of an internal test variable that starts at zero and increases to full-scale range and then decreases back to zero. The internal variable is fed into the internal Controller processing as if it were an external sensor signal. During this test the 10C Output Current stays at nominal zero reading or 4mA. As the internal test variable sweeps through alarm set point values, the appropriate triggering of alarms should occur. This allows the verification of proper operation of the relays, the connection through to the backplane, the wiring, the power source, and the actual Horns, Strobes or other actuated devices. The alarm configuration with regard to set-point thresholds, direction, latching, coil energize setting, and silenceable setting, can all be tested for desired performance. Performance results deviating from expected desired results should be evaluated for cause, whether equipment malfunctions, or incorrect settings or bad configuration.

The “ENT” pushbutton can be used to enter the “TEST” function and “TEST OFF” will display. The “ENT”

pushbutton can be pressed again and the test begins with the displayed text: “TEST ON”. Then the display

will start displaying the internal test variable value, starting at zero and increasing. When the display returns

to zero, the test in complete. The “ESC” pushbutton can be used to return the display to the menu selection or

back to display Normal Operation. The “ESC” pushbutton can be used during the test to exit the test.

NOTE: Alarm Outputs that are latched during the test remain latched after the test is finished

and are not automatically reset.

10C Control Module Instruction Manual Rev.0.B Page 18 of 25

Page 23

Model 10C

5.0 Special Configuration (Technician Access)

Only personnel who are technically trained to configure the equipment should be allowed to access some of

the features built-in to the 10C controller. There are three levels of access:

NORMAL Normal Operation Access (See section 3.0 on “Normal Operation”)

ACCESS Program Mode Access (See section 4.0“Program Mode”)

TECHNICIAN ACCESS Technician Access (This section on Special Configuration)

The “ACCESS/NORM” Switch (see location of SW1 in

) on the 10C Controller controls whether access is limited to just viewing the data and operating the alarm

reset/silence controls, the “Normal” mode, or whether further access is allowed. If it is desired that the 10C

Controller be open to being accessed for changes to configuration data, the “ACCESS” position should be

used, otherwise the switch should be put in the “NORM” position.

Technician access allows further control by personnel of the controller for the purposes of testing some of the

internal workings of the board, for trimming the analog-to-digital conversion and digital-to-analog conversion,

and for restoring the default configuration.

To acquire technician access, only if the switch SW1 is in the ACCESS position, the user can permit

technician access by holding in two front panel switches simultaneously for a continuous duration of at least

ten seconds. By pressing and holding down both the “×” and “Ø” pushbuttons for more than ten seconds, the

technician mode is enabled but not indicated on the display. For a short period of time, the access to

technician functions is available and continue to be available as long as the time is extended by the controller

remaining in the technician access mode. Otherwise, the timer times out and technician mode is not available

until access is gained by the described procedure with holding down the pushbuttons.

5.1 Trim Input

Figure 3 Board Assembly Picture of 10C Controller

Trim Input Mode allows a technician to adjust the analog-to-digital-conversion inside the 10C Controller. A

two-point-trim is accomplished by setting the zero-current input point and the full-scale current input point at

20.0mA. During the input trimming procedure the adjustment at the zero-current input point is called “SET 0

mA” and the adjustment at the 20.0mA current input point is called “SET 20mA”.

NOTE: The Trim Input function is only accessible in Technician Access Mode. The 10C

Controller analog input is trimmed at the factory and under normal circumstances should not

need to be trimmed again.

NOTE: If the Default Settings function (see section 5.3) is executed the input trim values are

restored to un-trimmed values and the 10C Controller’s input will not be as accurate as if it

were trimmed.

In order for the technician to do this procedure, there needs to be available an accurate 20.0mA current source.

The convenient way to accomplish the input trim is to use the Detcon Mod 10/12 Controller Test Fixture.

Another way is to ascertain that the 10C Controller’s output is sufficiently accurate to use as a source of

20.0mA, and temporarily connect a jumper to JP1 “LPBAK” to loop-back the output current to the input

current. An accurate Digital Volt Meter (DVM) can be placed in a current mode and clipped across the JP1

jumper pins to monitor the current. See section 5.2 Trim Output for procedure to trim the output current.

The menu item appears as: “TRIM INPUT”.

10C Control Module Instruction Manual Rev. 0.B Page 19 of 25

Page 24

Model 10C

From the “TRIM INPUT” display the technician can use the “ENT” pushbutton to enter the function. The

display will scroll “SET 0mA”. Apply 0 mA to the 10C Controller’s 4-20mA current input. Removal of the

input current wire to the sensor is the same as applying 0mA. Once 0mA is applied, press the “ENT”

pushbutton to accept the value, the display will scroll “0mA Done”. Press the “ENT” pushbutton again, and

the display will scroll “SET 20mA”. Apply 20.0mA to the current input and press the “ENT” pushbutton.

The display will scroll “20mA Done” if the controller accepts the input. If the controller does not accept the

input, the display will scroll “20mA Failed”. The cause of the failure is that the 10C Controller did not see a

reasonable input current level for 20mA. If this happens the “TRIM INPUT” function did not make an

adjustment to the gain factor for input current. The “ESC” pushbutton must be pushed to leave the function,

and the controller will return to “TRIM INPUT”.

Move to another menu item by using the “×” and “Ø” pushbuttons, or use the “ESC” pushbutton to leave the

“TRIM INPUT” function.

NOTE: This mode does not automatically time-out and must be exited or power-cycled to

return to normal operation.

5.2 Trim Output

Trim Output Mode allows a technician to adjust the 4mA point and the 20mA point of the 10C Controller’s

current output.

NOTE: The Trim Output function is only accessible in Technician Access Mode. The 10C

Controller analog output is trimmed at the factory and under normal circumstances should not

need to be trimmed again.

NOTE: If the Default Settings function (see section 5.3) is executed the output trim values are

restored to un-trimmed values and the 10C Controller’s output will not be as accurate as if it

were trimmed.

The menu item appears as: “TRIM OUTPUT”.

From the “TRIM OUTPUT” display, the technician can use the “ENT” pushbutton to enter the function. The

display will scroll “DAC Trim Out”. Pressing the “ENT” pushbutton will cause the display to change to

“FORCE 4mA”. The mA output of the controller will change to 4mA. The “×” and “Ø” pushbuttons can be

used to make the output current go up or down in small incremental steps. By monitoring the output current,

the technician can adjust the current to exactly 4.00mA. When the output is trimmed to 4.00mA, the

technician can accept the internal trimmed value by pressing “ENT”. When “ENT” pushbutton is pressed, the

zero is trimmed and the display will change to “FORCE 20mA”. The mA output of the controller will change

to 20mA. The “×” and “Ø” pushbuttons can be used to make the output current go up or down in small

incremental steps. When the output is trimmed to 20.0mA, the technician can accept the internal trimmed

value by pressing “ENT”, and if he has pressed “×” or “Ø” at least once, the internal trimmed value will be

accepted. In response to the “ENT” pushbutton, the 10C Controller will return to the display “FORCE 4mA”

allowing multiple passes through this procedure to attain the best trimming. Usually two passes is sufficient.

The “ESC” pushbutton may be pressed at any time to leave the function, and the controller will return to “TRIM OUTPUT”.

Move to another menu item by using the “×” and “Ø” pushbuttons, or use the “ESC” pushbutton to leave the

“TRIM OUTPUT” function.

10C Control Module Instruction Manual Rev.0.B Page 20 of 25

Page 25

Model 10C

NOTE: This mode does not automatically time-out and must be exited or power-cycled to

return to normal operation.

5.3 Default Settings

NOTE: The Default Settings function is only accessible in Technician Access Mode.

Each and any setting within the 10C Controller should be manually changeable to valid values. This feature

sets all configuration values to default state at once, including the trim coefficients. This feature should only

be used as a last resort if it is suspected that 10C Controller function is not correctly functioning due to a bad

configuration.

To utilize this function the “ENT” pushbutton is pressed, in response to which the Display should say “Restore

Defaults?” Another “ENT” pushbutton entry should cause the 10C Controller to load default constants into

the configuration variables and acknowledge with the Displayed text: “Defaults Restored”.

This is a list of configuration values and the default condition restored with this function:

Analog Input Offset (zero) = 0

Analog Input Gain = 1.000

Alarm 1 = Ascending, not latched, not energized, not silenceable

Alarm 2 = Ascending, not latched, not energized, not silenceable

Fault = Descending, not latched, energized, not silenceable

Alarm 1 set point = 10% of range

Alarm 2 set point = 20% of range

Fault set point = 1.80 mA

Gas Type = H2S

Range = 100

Units = ppm

Modbus ID = 01

Analog Output Offset (zero) = 0

Analog Output Gain = 1.000

Baud Rate = 9600

Parity = none

10C Control Module Instruction Manual Rev. 0.B Page 21 of 25

Page 26

Model 10C

6.0 Calibration

The 10C Controller’s conversion, of input current to a displayed value, can be trimmed up or down. Likewise,

the 10C Controller’s output current can be trimmed so that the Master Controller can register what is on the

10C Controller’s display. Each of the 4-20mA analog current input and the 4-20mA analog current output of

the 10C Controller may be trimmed independently. Both are calibrated at the factory and should require no

further adjustments. The independent trim is useful if the Master Controller cannot be itself trimmed and

instead small errors can be adjusted in the 10C Controller’s output current.

NOTE: Calibration of the sensor to standard gas is performed on the sensor itself, not the 10C

Controller. There is no “calibration” of the Controller, only “trim”.

Trim procedures are given in Trim Input, section 5.1, and Trim Output, section 5.2.

NOTE: The 10C Controller analog input and output is trimmed at the factory and under

normal circumstances should not need to be trimmed again.

10C Control Module Instruction Manual Rev.0.B Page 22 of 25

Page 27

Model 10C

7.0 Specifications

Input Power

9 VDC to 28VDC (For use in nominal 12VDC or 24VDC typical systems)

300mA Maximum (Including Sensor)

3W Maximum (Including Sensor)

Operating Temperature

–40°C to +70°C

Humidity: 10 to 95% Non-condensing

Range

Configurable: From 1 to 25 in increments of 1

From 25 to 100 in increments of 5

From 100 to 1000 in increments of 50

From 1000 to 9999 in increments of 500

Accuracy/Repeatability

Sensor input current conversion to 10C Displayed reading: ±1%F.S. after trim procedure

Output current converted from 10C Displayed reading: ±1%F.S. after trim procedure

Inputs/Outputs

Communications: Serial RS-485 Modbus™

Input: Analog 4-20mA DC, current sinking through 100 ohms.

Output: Analog 4-20mA DC, current sourcing.

Open-Collector outputs follow relay coils.

Relays

Relay Contact terminations: Common, Normally Open, and Normally Closed (x 3 Relays)

Relay Contact Manufacturer’s Specification:

Resistive load: 5A, 250VAC; 5A, 30 VDC

Inductive load: 2A, 250VAC; 2A, 30 VDC

Max. Operating current: 5A

Alarm/Fault Alarm Timing and Triggering

Alarms are inhibited during the power-up initialization period indicated by the display “Warm Up”.

Alarm signal delay: nominally 2 seconds

Alarm set-point hysteresis: nominally 1 unit

Alarm minimum activity before acknowledge silences it: 10 seconds.

Warranty

One year

Five year fixed fee service policy

10C Control Module Instruction Manual Rev. 0.B Page 23 of 25

Page 28

Model 10C

8.0 Warranty and Service Policy

Detcon, Inc., as manufacturer, warrants each new Model 10 series digital electronic control module to be free

from defects in material and workmanship under intended normal use for a period of one year from date of

shipment to the original purchaser. Detcon, Inc., additionally provides for a fixed fee repair/replace service

policy which covers Model 10 series digital control modules for a period of five years. The fixed fee service

policy shall affect any necessary factory repair for the period following the one-year warranty period and shall

end five years after expiration of the warranty. The fixed policy rate is $75.00 per control module, per

transaction, during the period of the policy. The policy is FOB Detcon, Inc., The Woodlands, Texas.

10C Control Module Instruction Manual Rev.0.B Page 24 of 25

Page 29

Model 10C

8.1 Revision Log

Revision Date Changes made

0.0 01/13/2009 None Initial release

10C Control Module Instruction Manual Rev. 0.B Page 25 of 25

Loading...

Loading...