Page 1

C-189

P.N. 146231

REVISION I

8/2007

LEB SERIES OVENS

INSTRUCTION MANUAL

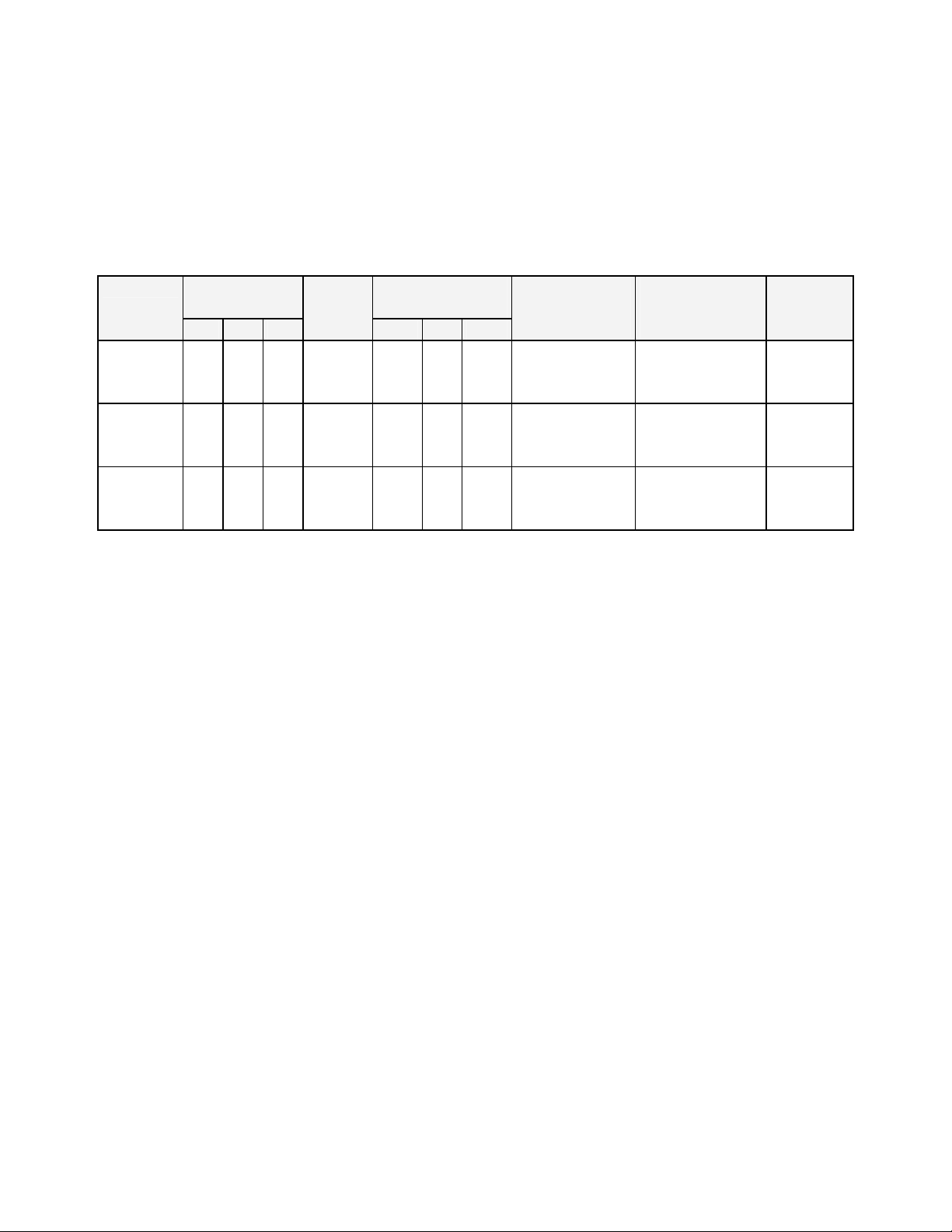

MODEL VOLTS HEATER WATTS AMPS HZ PHASE

LEB1-23*

LEB1-23 240 1,200 5.2 50/60

LEB1-69*

LEB1-69 240 2,400 10.2 50/60

LEB2-18 240 3,600 15.2 50/60

* A 240V conversion kit is available.

Prepared by:

Despatch Industries

8860 207th St. West

Lakeville, MN 55044

Customer Service 800-473-7373

120 1,200 10.4 50/60

120 2,400 20.4 50/60

1

1

1

1

1

Page 2

NOTICE

CAUTION

Users of this equipment must comply with operating procedures and training of

operation personnel as required by the Occupational Safety and Health Act (OSHA) of

1970, Section 6 and relevant safety standards, as well as other safety rules and

regulations of state and local governments. Refer to the relevant safety standards in

OSHA and National Fire Protection Association (NFPA), section 86 of 1990.

Setup and maintenance of the equipment should be performed by qualified personnel

who are experienced in handling all facets of this type of system. Improper setup and

operation of this equipment could cause an explosion that may result in equipment

damage, personal injury or possible death.

Dear Customer,

Thank you for choosing Despatch Industries. We appreciate the opportunity to work

with you and to meet your heat processing needs. We believe that you have selected

the finest equipment available in the heat processing industry.

At Despatch, our service does not end after the purchase and delivery of our

equipment. For this reason we have created the Service Products Division within

Despatch. The Service Products Division features our Response Center for customer

service. The Response Center will direct and track your service call to ensure

satisfaction.

Whenever you need service or replacement parts, contact the Response Center at 1800-473-7373: FAX 612-781-5353.

Thank you for choosing Despatch.

Sincerely,

Despatch

Page 3

Page 4

Despatch Industries

Advantage Service Assurance Program (ASAP)

CONTACT: DESPATCH SERVICE AGREEMENTS SPECIALIST at 800-473-7373 or 952-469-8230

or e-mail: service@despatch.com

Despatch continues to deliver exceptional products backed by a strong sense of responsibility and drive for long term

customer satisfaction. Your partnership with Despatch can offer even higher value through your subscription to one of

Despatch’s Advantage Service Assurance Program(ASAP).

Warranty

Despatch’s exclusive, comprehensive service programs start with the 1 year parts only warranty which is described on

the other side of this document. This warranty can be expanded immediately to meet your most stringent service needs.

Despatch Service Products Group will be able to answer your service questions and provide a quotation for the

immediate expansion of your product warranty. Call 800-473-7373 or 952-469-8230; or e-mail service@despatch.com.

Immediate Service Response

The key to an effective service program is response. Wherever your location, Despatch is only a phone call away. Our

U.S. and Canadian customers can reach Despatch at 1-800-473-7373. Worldwide customers can call 1-952-469-8230

or FAX 1-952-469-8193. Our Customer Service Technicians have over 150 years combined experience and access to

detailed design and manufacturing documentation specific to your Despatch unit(s). This exacting level of service is a

benefit only Despatch can provide and means that you can expect speedy, accurate and the most cost effective

response.

Field Service Network

A worldwide network of factory trained Service Professionals is available to support your Despatch equipment. From

routine repair to certified instrument calibration, the Despatch service network is positioned to respond to your needs. As

a manufacturer of custom equipment, our service programs are customized to meet your specific needs regarding:

Sustained Service Support

At Despatch, long term customer satisfaction means more than just responding quickly and effectively to our customers’

service needs. It means offering comprehensive customer support well beyond the scope and duration of our initial

warranty. Despatch offers two basic service packages which are customized to each individual customer’s need. These

service packages are titled Full Service and Preventive Maintenance Plus+ service agreement products. Each is unique

in the industry and offer the following benefits:

1. Service scope

2. Response time

3. Preventive maintenance frequency and content

4. Payment method

1. Priority response for minimum production interruption

2. Preventive maintenance for longer product life

3. Discounts on parts and services

4. Various payment plans to ease budgeting and recording expenses

5. Reduce purchase ordering costs

i

Page 5

PREFACE

This manual is your guide to the Despatch oven. It is

organized to give you the information you need quickly

and easily.

An efficient way to learn about the oven would be to

read the manual while working with the corresponding

oven control system. This will give you practical

hands-on experience with information in the manual

and the oven.

Before operating the equipment, be sure you

understand all of the technical information contained

in this manual. Information skipped, not understood

or misunderstood could create the possibility of operating the equipment in an unsafe

manner. This can cause damage to the oven or personnel or reduce the efficiency of

the equipment.

Read the entire

INTRODUCTION and

THEORY OF OPERATION

before installing the oven.

WARNING: Failure to heed

warnings in this instruction

manual and on the oven could

result in personal injury, property

damage or death.

ii

Page 6

Revision B: drawings updated

Revision C: drawings updated

Revision D: updates to Specifications section; addition of stand assembly and stacking

kit assembly instructions

Revision E: Corrections, additional drawings added, addition of options and features in

APPENDIX

Revision F: Update Drawings, Product Warranty, and hi-limit information

Revision G: Update Drawing

Revision H: Parts lists corrections in DRAWING AND SPARE PARTS LISTS section.

Corrected Despatch address

Revision I: Update Product Warranty

iii

Page 7

TABLE OF CONTENTS

PREFACE........................................................................................................................ i

INTRODUCTION.............................................................................................................1

Special Features..........................................................................................................1

SPECIFICATIONS ..........................................................................................................2

Dimensions..................................................................................................................2

Power....................................................................................................................... 3

Temperature.............................................................................................................4

Capacities ................................................................................................................4

THEORY OF OPERATION .............................................................................................5

CONTROL Instrument.................................................................................................6

HI-LIMIT Instrument.....................................................................................................7

Product HI-LIMIT Instrument.................................................................................... 8

Oven HI-LIMIT Instrument........................................................................................8

Oven Theory................................................................................................................ 9

INSTRUCTIONS ...........................................................................................................10

Unpacking and Inspection ......................................................................................... 10

Setup.........................................................................................................................11

Operating...................................................................................................................12

Loading the Oven...................................................................................................12

Pre-Startup Checklist.............................................................................................13

Startup ................................................................................................................... 14

Control Instructions.................................................................................................... 16

Changing Setpoint.................................................................................................. 16

Parameter Programming Mode..............................................................................17

Set-Up Parameters ................................................................................................19

Changing Display From °C To °F ..................... .........................................................20

Oven Zone Calibration ...........................................................................................21

HI-LIMIT INSTRUCTIONS......................................................................................... 22

Changing Setpoint.....................................................................................................22

Parameter Setup Mode.............................................................................................. 23

Setup Parameters..................................................................................................24

Changing Display From °C To °F ..............................................................................26

Maintenance..............................................................................................................27

Checklist ................................................................................................................ 27

Tests......................................................................................................................28

Replacement..........................................................................................................28

Control Instrument.................................................................................................. 29

Replacement of Hi-limit Instrument ........................................................................30

Heater Unit.............................................................................................................31

Troubleshooting.........................................................................................................32

DRAWINGS ..................................................................................................................35

LEB 1-23-1 (120 VAC) Parts..................................................................................36

LEB 1-23-1 (120 VAC) Drawing.............................................................................37

LEB 1-23-1 (240 VAC) Parts..................................................................................38

LEB 1-23-1 (240 VAC) Drawing.............................................................................39

iv

Page 8

LEB 1-69-1 (120 VAC) Parts..................................................................................40

LEB 1-69-1 (120 VAC) Drawing.............................................................................41

LEB 1-69-1 (240 VAC) Parts..................................................................................42

LEB 1-69-1 (240 VAC) Drawing.............................................................................43

LEB2-18-1 Parts..................................................................................................... 44

LEB 2-18-1 Drawing ..................................................................................................45

Despatch Customer Service......................................................................................46

Procedures and Customer Responsibilities ...........................................................46

Attachment A - Sustained Service Support............................................................47

APPENDIX: OPTIONAL FEATURES............................................................................ 48

Protocol Plus Control Option .....................................................................................48

Timer Option..............................................................................................................48

Timer Operation.....................................................................................................49

Timer Configuration................................................................................................ 49

Stand Assembly Instructions .....................................................................................50

Stacking Kit Assembly Instructions............................................................................51

Timer Option with Audible and Visual Alarm..............................................................52

High Limit Alarm Option............................................................................................. 52

Recorder Option ........................................................................................................52

v

Page 9

INTRODUCTION

The INTRODUCTION section provides an overview of the Despatch LEB Series Ovens.

The LEB Series Ovens have the most effective heat distribution and the fastest

processing time of any lab ovens their size. Air is discharged from the floor plate of the

oven and distributed through the chamber.

Special Features

• The sturdy construction and high grade insulation of the Despatch LEB Series

ovens contribute to excellent high temperature performance. Other special

features include:

• Proportional digital CONTROL instrument to control temperature fluctuations.

• Manual reset HI-LIMIT instrument to protect the chamber workload as well as the

oven itself.

• Unique Despatch design with a system of perforated stainless steel walls for the

ultimate in temperature performance.

• Welded double wall construction and fiberglass insulation to reduce heat loss.

Silicone rubber gaskets further minimize heat leakage.

• Rapid response heater with a five year warranty.

• Scratch-resistant baked enamel exterior and stainless steel interior for easy

cleaning.

• Space-saving, stackable design.

1

Page 10

SPECIFICATIONS

Dimensions

Model

Chamber Size

inches (cm)

W D H

LEB1-23

LEB1-69 30

LEB2-18

18

(46)

(76)

37

(94)

18

(46)

18

(46)

24

(61)

12

(30)

22

(56)

35

(89)

Capacity

feet3

(liters)

2.3

(65)

6.9

(195)

18

(510)

Overall Size

inches (cm)

W D H

24

23

(61)

(58)

34

23

(86)

(58)

43

29

(102)

(74)

26

(66)

36

(91)

51

(130)

Shelves

Provided on

Shelf Centers

2 on 2" 5 1

2 on 2" 10 2

2 on 2" 16 2

Maximum

Number of Shelf

Positions

Chamber

Doors

2

Page 11

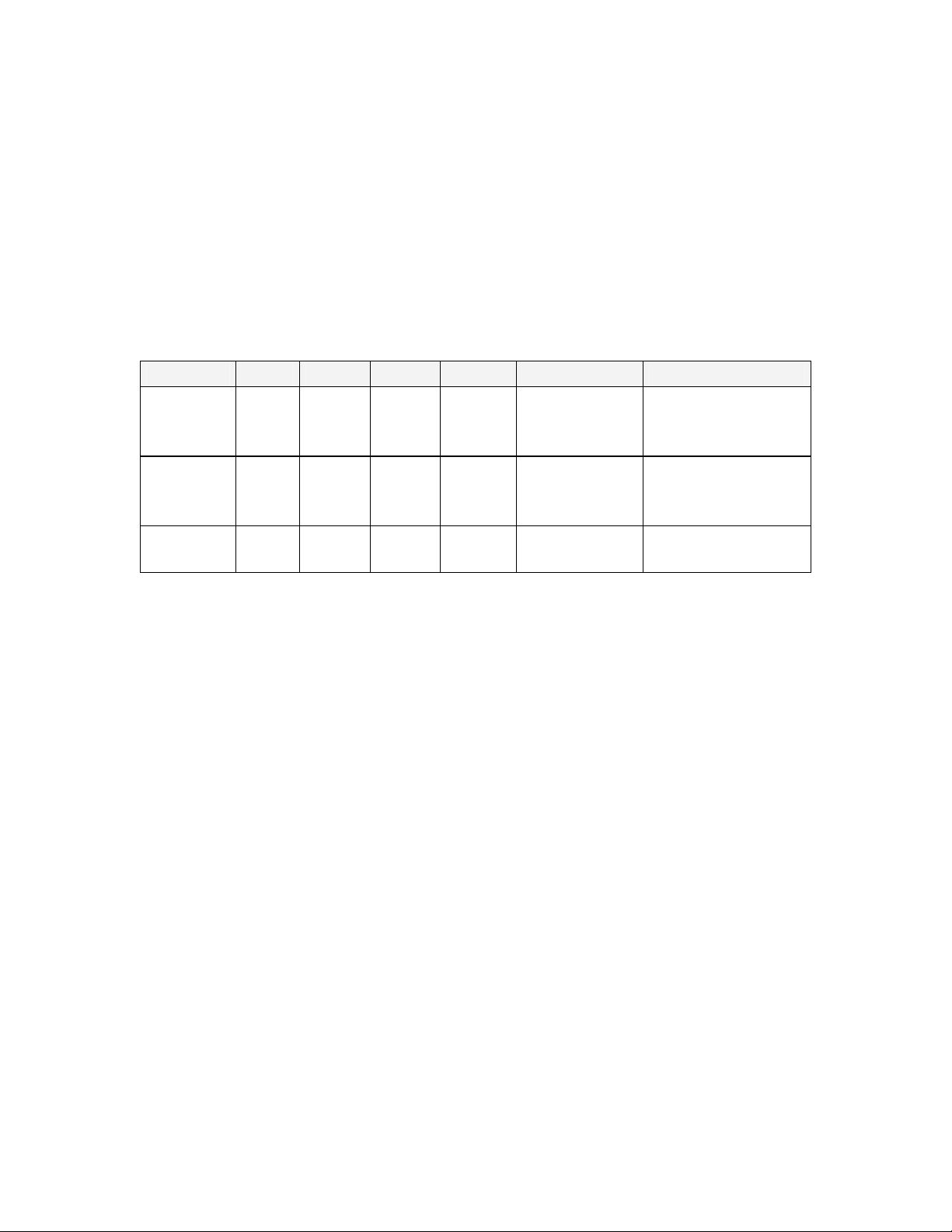

Power

Line voltages may vary in some geographical locations. If your line voltage is much

lower than the oven voltage rating, warm up time will be longer and motors may

overload or run hot. If your line voltage is higher than nameplate rating, the motor may

run hot and draw excessive amps.

If the line voltage varies more than 10% from the oven voltage rating, some electrical

components such as relays, temperature controls, etc. may operate erratically.

Model Volts Amps Hertz Phase Heater (KW) Cord and Plug

LEB1-23 120

240*

LEB1-69 120

240*

LEB2-18 240 15.2 50/60 1 3.6 None, Hardwired

10.4

5.2

20.4

10.2

50/60 1 1.2 Included, 15 Amp

50/60 1 2.4 None, Hardwired

The LEB1-69 and LEB2-18 must be hardwired to the electric supply using 10AWG or

larger wires suitable for at least 75°C (167° F).

Ovens designed for 240 volts (see name plate on oven) will operate satisfactorily on a

minimum of 208 volts, but with a 25% reduction in heater power. If your power

characteristics are lower, contact Despatch Industries.

* Order 240V conversion kit for 240V, on LEB1-23 and LEB1-69.

3

Page 12

Temperature

LEB Model

1-23 1-69 2-18

Time to Temperature 25°C - 100°C

(approximate minutes 25°C - 150°C

with no load) 25°C - 204°C

Recovery Time 100°C

Door Open 1 Min. (approximate 150°C

minutes with no load) 204°C

Operating Range w/20°C Ambient 30°C - 204°C

12

20

35

2

4

6

10

18

30

2.4

4

7

12

20

36

2.2

4

7

Capacities

Model Standard Shelf

Capacity

LEB1-23 50 lbs. (23 kg.) n/a 200 lbs. (91 kg.) 400 lbs. (182 kg.)

LEB1-69* 50 lbs. (23 kg.) 200 lbs. (91 kg.) 400 lbs. (182 kg.) 400 lbs. (182 kg.)

LEB2-18* 50 lbs. (23 kg.) 200 lbs. (91 kg.) 600 lbs. (273 kg.) n/a

NOTE that the shelves supplied with the LEB1-69 and 2-18 are reinforced. The

standard shelf is optional for these ovens.

Reinforced Shelf

Capacity

Max Load

Capacity

Stacked Max

Load Capacity

4

Page 13

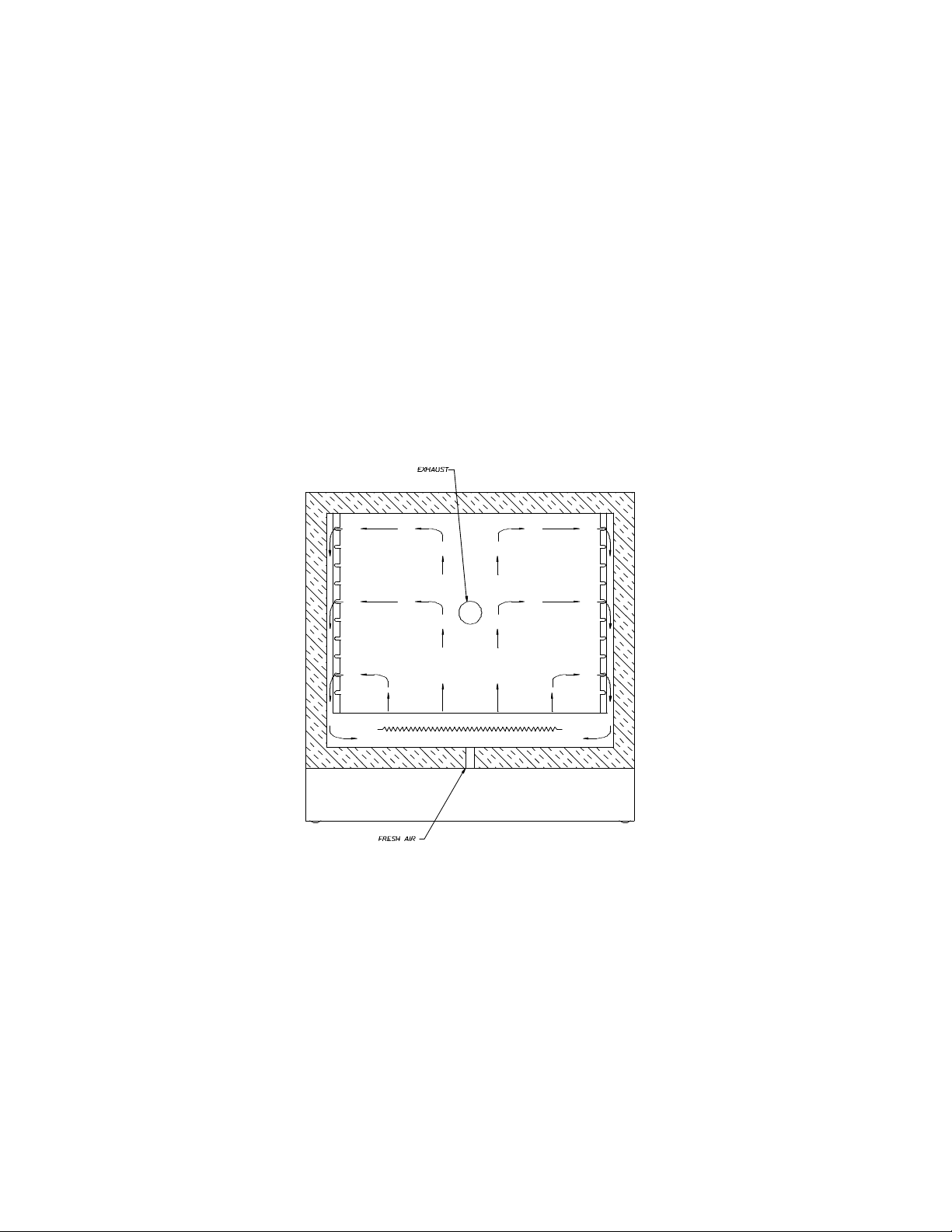

THEORY OF OPERATION

The Despatch LEB Series Ovens have the most economical approach when

productivity and ease of operation are the deciding factors. These ovens are especially

useful for testing, preheating, sterilizing, drying, aging and curing as well as other

production applications. Gravity convected airflow with precision digital control to

deliver fast processing. The overall result is efficient productivity under strenuous

conditions. The LEB Series Ovens are precise and practical.

The unique Despatch design moves gravity convected heat through stainless steel

ducts on each side. The chamber can be densely loaded without interfering with the

process. Air temperature near the sensing element in the chamber is within 1°C of the

process temperature appearing on the digital display. For your convenience the fresh

air intake is fixed. The exhaust rate is regulated by a damper on the back of the unit.

Gravity Convected Airflow in the Despatch LEB Oven

5

Page 14

CONTROL Instrument

The oven is equipped with a microprocessor based digital control instrument. The

Despatch CONTROL instrument has been configured as a proportional controller and

set to its optimum operating values. Initially, the CONTROL will allow the heater to

operate at full power. However; as the actual oven temperature reaches the setpoint,

the Proportional Control will cycle the heater on and off, minimizing process

temperature fluctuations.

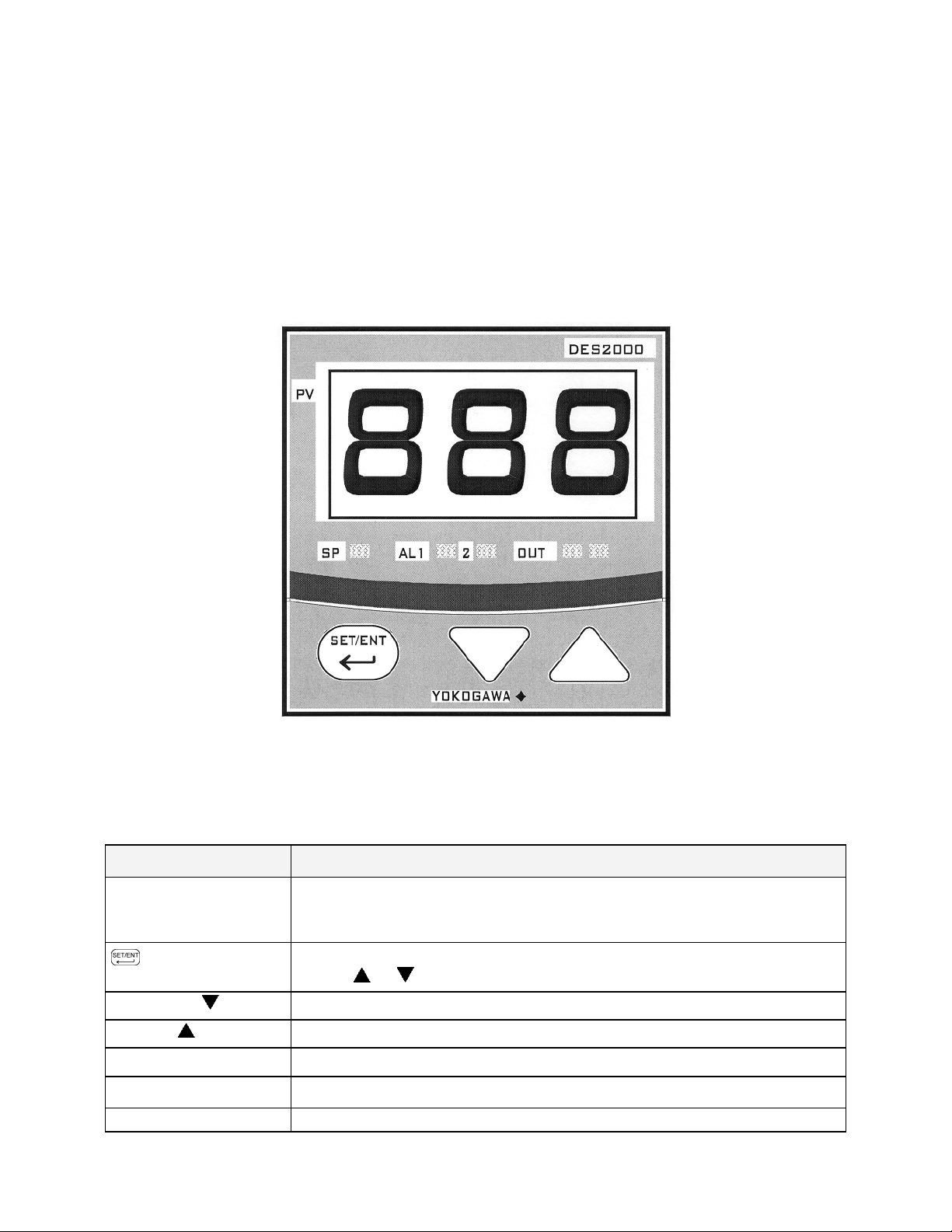

CONTROL Instrument

CONTROL Instrument Features

Features Description

Main (PV) Display Displays the actual oven temperature or displays the setpoint

when the set key is pressed. Displays parameter code and

value.

Key

Down Key Decreases a setpoint or setup parameter.

Up Key Increases a setpoint or setup parameter.

LED SP Indicator Lights when the setpoint value is displayed.

LED OUT Indicator Lights when the control is calling for heat.

LED AL1 –2 Indicator N/A

Switches between PV and SP displays. Enters the data changed

by the or keys. Switches through parameter displays.

6

Page 15

HI-LIMIT Instrument

The oven is equipped with a HI-LIMIT instrument. The purpose of the HI-LIMIT

instrument is to provide a protective measure for the product and/or the oven itself. If

the setting on the HI-LIMIT is exceeded, the heating process will discontinue, thus

protecting the product and/or the oven.

Set the HI-LIMIT instrument to a temperature 10°C - 14°C higher than the CONTROL

instrument setpoint or a temperature that should not be exceeded in the process. If the

setting on the HI-LIMIT instrument is exceeded the heater will shut down. The HI-LIMIT

instrument must be manually reset by pushing the RESET button on the HI-LIMIT

instrument.

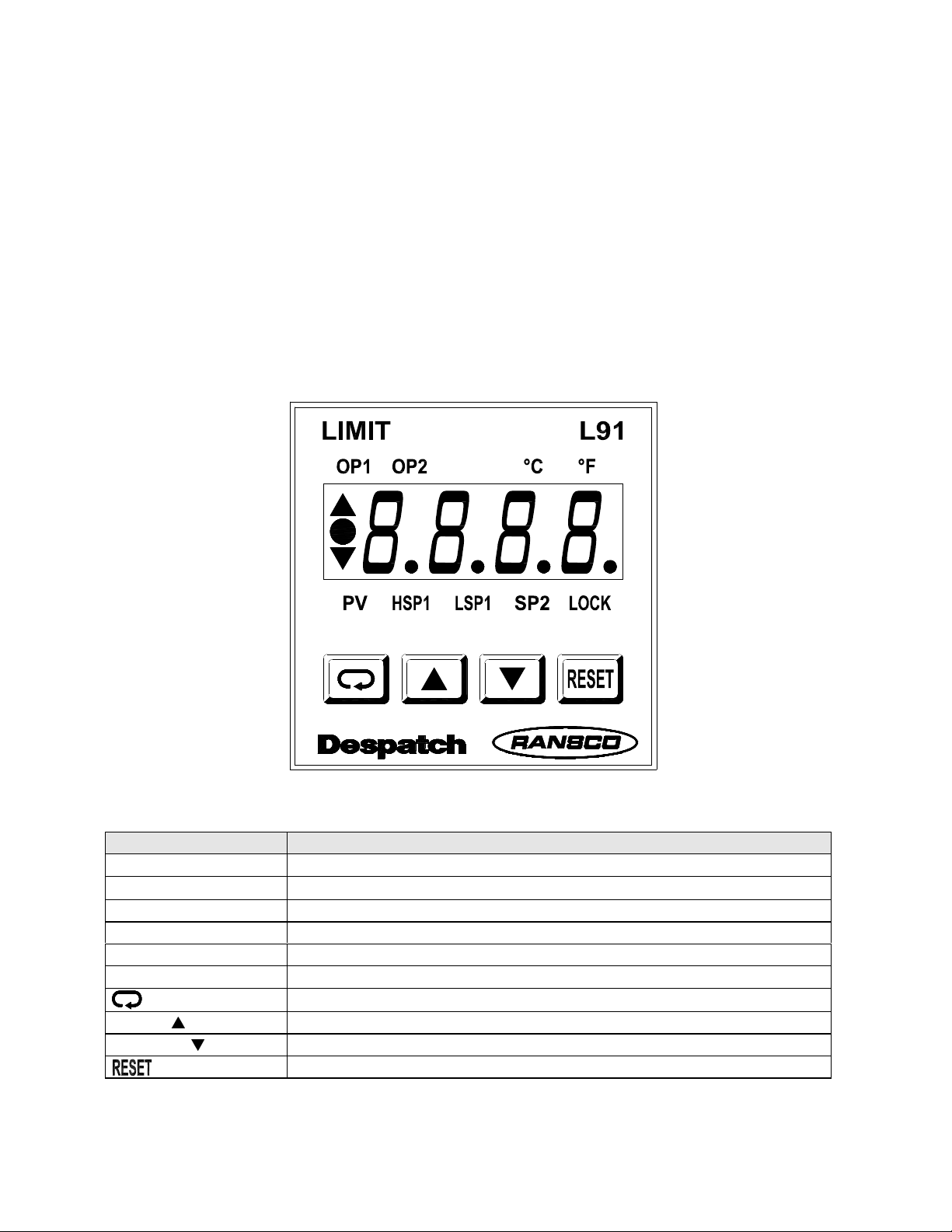

HI-LIMIT Instrument

Features Description

OP1 Output 1 status value. (OP2 normally not used for LBB Ovens).

°C/°F

PV Process value.

HSP1 High limit setpoint 1. (LSP1 normally not used for LBB Ovens).

SP2 Setpoint 2 for output 2 (normally not used for LBB Ovens).

LOCK Lock status indicator.

Up Key Increases a setpoint or mode parameter.

Down Key Decreases a setpoint or mode parameter.

Degree indicator.

Scroll Key, used for advancing available displays.

Reset the high limit, return to normal display.

7

Page 16

Product HI-LIMIT Instrument

If the product being processed has a critical high temperature limit, the HI-LIMIT

instrument should be used as a product HI-LIMIT instrument. The HI-LIMIT instrument

should be set to a temperature somewhat below the temperature at which the product

could be damaged.

Oven HI-LIMIT Instrument

If the product does not have a critical high temperature limit, the HI-LIMIT can be used

as an oven HI-LIMIT instrument. An oven HI-LIMIT instrument protects oven

equipment. The HI-LIMIT should be set at 204°C

8

Page 17

Oven Theory

The oven has an efficient gravity convected airflow to 204°C (400°F). A gravity

convected oven relies on gravity to move air through the chamber. The process of

moving air by relying on gravity is a slow responding process. Thus, the overall

chamber temperature takes a finite amount of time (roughly a few minutes) to soak

in at the desired operating temperature. The time that it takes the unit to soak in at

setpoint is related to such parameters as chamber area, load mass, and exhaust

rate. The unique Despatch design and CONTROL action compensates for this

fact.

The oven uses an indicating microprocessor based digital control that displays the

actual chamber temperature at the sensing point. Despatch strategically locates

the CONTROL's temperature sensor to optimize the control action for the entire

chamber for various load conditions. The CONTROL display will fluctuate a few

degrees around the setpoint, but the overall chamber temperature will remain very

stable. The underlying reason for this is that the display is showing temperature

fluctuations at the temperature sensor location, not the overall chamber

temperature. The strategic location of the sensor compensates for delays in

gravity convection and enhances the performance and temperature control of the

oven. The oven has been engineered to have an overall result of quality

productivity while still maintaining an economical approach and ease of use.

9

Page 18

INSTRUCTIONS

The INSTRUCTIONS section provides directions on unpacking, installation,

operation and maintenance of the Despatch LEB Series Ovens.

Unpacking and Inspection

Remove all packing materials and thoroughly inspect the oven for damage of any

kind that could have occurred during shipment.

• See whether the carton and plastic cover sheet inside carton are still in

good condition.

• Look at all outside surfaces and corners of the oven for scratches and

dents.

• Check the oven controls and indicators for normal movement, bent shafts,

cracks, chips or missing parts such as knobs and lenses.

• Check the door and latch for smooth operation.

If there is damage, and it could have happened during shipment follow these

instructions.

1. Contact the shipper immediately and file a written damage claim.

2. Contact Despatch Industries to report your findings and to order

replacement parts for those that were damaged or missing.

3. Please send a copy of your filed damage claims to Despatch.

Next, check to make sure you have received all the required materials. Your

shipment should include:

• One (1) Despatch oven,

• One (1) Instruction manual,

• One (1) Warranty card,

• Two (2) Shelves

• One (1) Damper assembly

If any of these items are missing from the packaged contents, contact Despatch

Industries to have the appropriate materials forwarded to you.

10

Page 19

Setup

1. Place oven on a bench top or an optional stand.

The oven must have a minimum of two (2) inches clearance in the rear to

provide proper ventilation. The oven may be placed next to another cabinet,

or next to another oven, with three (3) inch clearance (the doors will still

open).

Make sure oven is level and plumb; this will

assure proper heat distribution and

operation of all mechanical components.

2. Identify correct power source indicated on

the specification plate.

3. Plug or hardwire oven directly to the electric supply.

WARNING: All grounding

and safety equipment

must be in compliance

with applicable codes,

ordinances and accepted

safe practices.

11

Page 20

atmo

s

phere.

of 204°C (400°F).

Operating

Users and operators of this oven must comply with

operating procedures and training of operating

personnel as required by the Occupational Safety and

Health Act (OSHA) of 1970, Section 5 and relevant

safety standards, and other safety rules and

regulations of state and local governments. Refer to

the relevant OSHA and National Fire Protection

Association (NFPA) safety standards.

Loading the Oven

Despatch Industries cannot be responsible for either the

process or process temperature used, or for the quality of

the product being processed. It is the responsibility of the

purchaser and operator to see that the product

undergoing processing in a Despatch oven is adequately

protected from damage.

Carefully following the instructions in this manual will help the purchaser and

operator in fulfilling that responsibility.

When loading the oven avoid spills of anything onto the heater elements or onto

the floor of the oven. Do not place the load on the oven floor plate. This may

cause the load to heat unevenly and the weight may cause shorting out of the

heater elements. Use the shelves provided.

The two shelves are designed to be pulled out about half way without tipping. The

support capacity of the shelves is listed in the Capacities Table in the

Specifications section in this manual. Do not overload the shelves.

Distribute the workload evenly so that airflow is not restricted. Do not overfill your

oven. The workload should not take up more than two-thirds of any dimension of

the inside cavity.

WARNING: Do not use

oven in wet, corrosive

or explosive

atmospheres unless

this oven is specifically

designed for a special

WARNING: Never

operate oven at a

temperature in excess

of the maximum

operating temperature

12

Page 21

Pre-Startup Checklist

Know the system. Read this manual carefully. Make use of its instructions

and explanations. The know how of safe, continuous, satisfactory, troublefree operation depends primarily on the degree of your understanding of the

system and of your willingness to keep all parts in proper operating

condition.

Check line voltage. Voltage must correspond to nameplate requirements of

motors and controls. Refer to the section on power connections in the

INTRODUCTION of this manual.

Fresh air, exhaust, and electrical cabinet openings.

Do not be careless about restrictions in and around

the fresh air and exhaust openings. Under no

condition permit them to become so filled with dirt

that they appreciably reduce the air quantity. Refer

to the Set-up instructions in this manual.

Ventilation. There is an exhaust opening in the rear of the unit.

The exhaust vent may have to be closed to reach the maximum

temperature of 204°C, especially if operating on 20 8 volts. They may need

to be opened to operate properly at the lower range of the oven's design.

Helpful hints

• For drying ovens, open vent to prevent buildup of moisture.

• For sample heating, close the vent when no ventilation is required.

NOTE:

The exhaust vent may

have to be adjusted to

achieve maximum

performance at various

operating temperatures.

13

Page 22

Startup

For fastest oven heat-up time, close the exhaust

vent. After the desired temperature is reached,

the vent may be adjusted as needed.

1. Start oven.

a. Turn POWER switch to on. The circulating fan will start.

b. Set exhaust vent to desired opening. The vent may have to be adjusted

to achieve maximum performance at various operating temperatures.

WARNING: Do not use

flammable solvent or flammable

material in this oven. Do not

process closed containers of any

substance or liquid in this oven

because they may explode under

heat.

LBB Control Panel

2. Enter setpoint on the HI-LIMIT instrument.

Set HI-LIMIT instrument to a temperature

10°C to 14°C higher than the setpoint or to a

temperature that should not be exceeded in

the process.

a. If the

and hold the

seconds to enable the and keys

b. Press

c. Use key and key to set hi limit temperature.

d. Press

process variable PV mode.

3. Enter setpoint on the CONTROL instrument.

a. Press key until the SP LED is lit.

b. Use key and key to set operating temperature.

on the HI-LIMIT is lit, press

key, HSP1 will be lit.

or

for four (4)

once to return (also enters the value) to the

NOTE:

If the HI-LIMIT instrument is

exceeded the heater will shut

down. Reset the HI-LIMIT by

pushing

instrument.

on the HI-LIMIT

14

Page 23

c. Press key to enter setpoint.

d. Press key again to display process temperature.

4. Turn HEATER switch to the on position. When process value on the

CONTROL reaches setpoint, the OUT LED will cycle on and off to maintain

the temperature setpoint. The OUT LED will be lit when the control is

calling for heat.

5. Turn the HEATER switch off after heating cycle is complete. Do not turn the

fan off until the oven chamber temperature is below 100°C (212°F).

15

Page 24

of 204°C (400°F).

Control Instructions

The oven has been tested and preset at the factory for

normal operating conditions. In most applications, it will

not be necessary to alter the oven's settings, except for

the Setpoint. This section contains information and

reference material to change Setpoint, display from °C to

°F, and access the Operating and Set-up modes. This

section also covers oven zone calibration for the

CONTROL.

The CONTROL instrument was carefully programmed at the factory using the

Operating and Set-up modes. The parameters that may be accessed include

tuning and display functions, and thermocouple selection.

The Oven Zone Calibration section covers the procedure necessary to recalibrate

the CONTROL. Recalibration may be necessary to align the CONTROL for a

specific operating condition.

WARNING: Failure to

heed warnings in this

manual and on the oven

could result in death,

personal injury or

property damage.

Changing Setpoint

To enter Setpoint on the CONTROL instrument:

1. Press , the SP LED will be lit.

2. Use key or key to set operating temperature.

The right decimal point LED will flash indicating

that the Setpoint is being changed. This will stop

flashing when the new value has been entered.

3. Press to enter Setpoint.

4. Press again to display process temperature.

WARNING: Never

operate oven at a

temperature in excess

of the maximum

operating temperature

16

Page 25

Parameter Programming Mode

The control parameters are set through the

Operating and Set-up modes. In most applications,

it is not necessary to alter the oven settings. The

following instructions describe how to access, view

and, if desired, change the parameters.

Once the Operating and Set-up modes are accessed, the SP LED will start blinking

on and off. The CONTROL will not allow the display to be altered improperly.

The CONTROL will automatically exit the Parameter Programming mode if no keys

are pressed for about 2 minutes.

1. Press for three (3) seconds.

2. Press the until the desired parameter is displayed. See Operating and

Set-up Parameter tables on the following pages.

3. Press the or to display value.

4. Use the or to the desired setting.

5. Press the to enter the value.

6. Press and hold the for three (3)

seconds to return to the display mode.

WARNING: Make sure

you understand what you

are changing before

doing so. Changing the

program parameters will

alter the functions of the

CONTROL.

17

CONTROL Instrument

Page 26

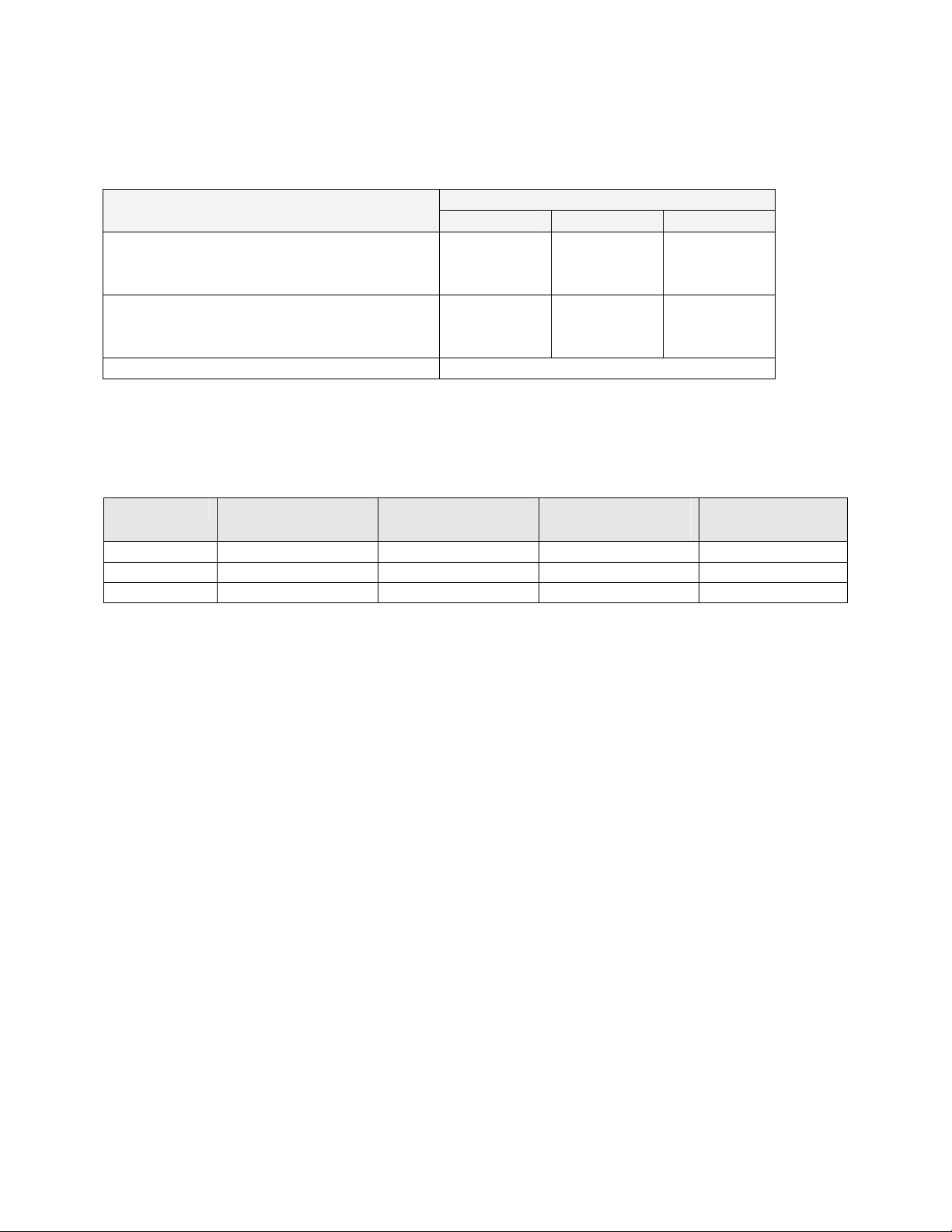

Operating Parameter Outline

Code

CtL

At

P

I

d

nr

HyS

Ct

FL

bS

LoC

*If P is not displayed the Control Mode (CtL) must be first set to PID.

CtL Control Mode - This parameter determines whether controller functions as a

At Auto-tuning – OFF for PID tuning, ON for controller to tune process.

P Proportional Band - Expressed in degrees. This value determines the band

I Integral Time - Expressed in seconds. This parameter corrects for errors in

D Derivative Time - Expressed in seconds. This effect of the derivative time is

nr Manual Reset - Expressed in percent. Controller outputs this value when

HyS Hysteresis - Expressed in degrees. When CtL = OFF, this value

Ct Cycle Time - Expressed in seconds. This is the total time for one ON/OFF

FL Input Filter – Expressed in seconds. This function should be used when the

Name

Control Mode

Auto-tuning

Proportional Band

Integral Time

Derivative Time

Manual Reset (only when I & d are OFF)

Hysteresis (only when CtL is ONF, change CtL to PID) N/A

Cycle Time

Input Filter

PV Bias (Offset)

Key Lock

time proportional or an on/off control.

width on both sides of the setpoint within which the control provides

proportional control.

actual temperature versus the setpoint.

in direct proportion to the time setting.

process variable equals setpoint (Only if I = 0).

determines the change in temperature needed to turn controller output from

full off to full on.

cycle of the controller output during the proportional action.

PV may fluctuate greatly (i.e. input signal contains noise).

Settings

PID

OFF

4 (8 if

15

0

N/A

1

0

0

1

°°°°

F)*

18

Page 27

bS PV Bias - Expressed in degrees from –199 to 999. This parameter is used

to set the actual oven temperature to the controller display.

LoC Key Lock - This provides levels of access to the controller.

0 = No key lock, full access to controller.

1 = Prevents changing of all parameters except setpoint.

2 = Prevents all parameters from being changed including the setpoint.

-1 = Set to enter the Setup parameter setting display.

The controller is set to LoC=1 at the factory. This prevents inadvertent changing

of control parameters with the exception of setpoint.

If it becomes necessary to alter control parameters, change the LoC=1 to LoC=0.

Follow the parameter programming mode found earlier in this manual.

When LoC = -1, the parameters are displayed in the order shown in the Set-Up

Parameters section, below. Note: If you are unable to change the setup

parameters, go back out and change the LoC = 0. Press the

appears again, change LoC = -1 and press the

key.

key until LoC

Set-Up Parameters

Set-up Parameter Outline

Code

In Input Type

SPH

SPL Setpoint Low

Dr

DSP PV/SP Display

In Input Type – This parameter is set for type of input and whether PV is in °C

SPH The maximum setpoint limit for oven. The user cannot set the setpoint

SPL The minimum setpoint limit of oven. The user cannot change the setpoint

dr Direct/Reverse action. This value is set for 0 (reverse action).

dSP Priority of PV/SP display. This parameter either displays the PV (process

Setpoint High

Direct/Reverse Action 0

or °F.

above the maximum setpoint.

below this lower setpoint limit.

variable) or SP (setpoint). 0 = process variable, and 1 = setpoint.

Name

Settings

5 (35 if °F)

204 (400 if °F)

30 (86 if °F)

0

19

Page 28

CONTROL.

Changing Display From °C To °F

The control can be configured for either °C or °F. Use the following steps to

change control from displaying °C to °F.

1. Press and hold the for three (3) seconds.

2. The display will read CtL. The SP LED will

flash indicating that Operating Parameter

mode has been entered.

3. Press the until LoC appears on the

display. Press the or to enter the

parameter.

4. Press the to set the value to –1. The SP LED will flash rapidly, indicating

that the Set-Up Parameter mode has been entered.

5. Press the to enter the value. The display will read In. Press the or

to enter the parameter. Note: If you are unable to change the setup

parameters, go back out and change the LoC = 0. Press the

LoC appears again, change LoC = -1 and press the

6. Enter a value of 35. The right decimal point LED will flash indicating that

the setpoint is being changed. This will stop flashing when the new value

has been entered.

7. Press the to enter the value.

8. Press the until SPH is displayed. Press

the or to enter the parameter.

9. Enter a value of 400.

10. Press the to enter the value.

11. Repeat steps 12 –14 for SPL; the value is 32.

12. Press and hold the for three (3) seconds to return to the operation

mode. The control now reads °F. Enter the desired setpoint.

13. Refer to Parameter Programming Mode, Operating Parameters section to

change tuning parameters, if necessary.

WARNING: Make sure

you understand what

you are changing

before doing so.

Changing the program

parameters will alter the

functions of the

key until

key.

NOTE: To change from

°F to °C repeat the above

steps. The following are

the values to be entered:

In = 5

SPH = 204

SPL = 0

20

Page 29

CONTROL.

Oven Zone Calibration

The CONTROL instrument has been tested and calibrated at the factory. Under

normal operating conditions, recalibration should not be necessary. However, if

the user would like to recalibrate the CONTROL for a specific operating condition,

then recalibration is easily accomplished.

Set-Up Parameters

(Equipment needed: temperature measuring device with a Compatible

Temperature sensor)

1. Verify that the bS (PV Bias) programmed in the

CONTROL is 0. Refer to Instructions on viewing

the parameter in the PARAMETER

PROGRAMMING mode.

2. Locate the temperature sensor of the temperature

measuring device at the center of the chamber.

3. Operate the oven until it reaches the desired

operating temperature and the CONTROL is regulating. The user may wish

to have a loaded chamber with a standard amount of product to simulate a

specific operating condition. It will take several minutes for the unit to

stabilize at the controlled temperature. Allow at least 30 minutes of

operation at the stabilized temperature before proceeding.

4. Subtract the average controlled temperature (number appearing on the

CONTROL display) from the actual oven temperature (number appearing on

the temperature measuring device display). The CONTROL and the device

must be in the same scale (°C or °F).

Actual Oven Temperature - Controlled Temperature = calculated value

5. Enter the calculated value from Step 4 as the new bS (PV Bias) value in the

instrument.

WARNING: Make sure

you understand what

you are changing

before doing so.

Changing the program

parameters will alter the

functions of the

21

Page 30

HI-LIMIT INSTRUCTIONS

The oven has been tested and the HI-LIMIT preset at

the factory for normal operating conditions. In most

applications, it will not be necessary to alter the oven's

settings, except for the Setpoint. This section contains

information and reference material to change Setpoint,

access the Set-up mode and change display between

°C and °F.

The HI-LIMIT instrument was carefully programmed at the factory using the

Operating and Set-up mode. The parameters that may be accessed include;

display functions, and thermocouple selection.

WARNING: Failure to

heed warnings in this

manual and on the

oven could result in

death, personal injury

or property damage.

Changing Setpoint

Enter setpoint on the HI-LIMIT instrument. Set HILIMIT instrument to a temperature 10°C to 14°C

higher than the setpoint or to a temperature that

should not be exceeded in the process.

1. If the

2. Press

3. Use key and key to set hi limit temperature.

4. Press

5. If the HI-LIMIT instrument is exceeded the heater will shut down. Reset the

hold the

the and keys.

variable PV mode.

HI-LIMIT by pushing on the HI-LIMIT instrument.

on the HI-LIMIT is lit, press and

for four (4) seconds to enable

key, HSP1 will be lit.

or

once to return (also enters the value) to the process

WARNING: Never operate

oven at a temperature in

excess of the maximum

operating temperature of 204°C

(400°F).

22

Page 31

functions of the HI

-

LIMIT.

Parameter Setup Mode

The HI-LIMIT parameters are set through the

Operating and Set-up modes. In most applications, it

is not necessary to alter the oven settings. The

following instructions describe how to access, view

and, if desired, change the parameters.

If the on the HI-LIMIT is lit, press and hold the

enable the and keys. The HI-LIMIT will automatically exit the Setup mode if

no keys are pressed for about two (2) minutes.

1. Press and hold the

been entered.

2. Press the

displayed. See the Setup Parameter Table on the

following page.

3. The display will alternate between the parameter

name and value.

4. Use the or to move to the desired setting.

5. Press the key, this enters the value and

advances to the next parameter.

6. To get out of the setup parameters press the

automatically exit the Setup mode if no keys are pressed for about two (2)

minutes.

key until the desired parameter is

key for four (4) seconds, the setup mode has now

WARNING: Make sure you

understand what you are

changing before doing so.

Changing the setup

parameters will alter the

for four (4) seconds to

HI-LIMIT Instrument

key. The HI-LIMIT will

23

Page 32

Setup Parameters

Note: When changing between °C and °F, the setup parameters Filt, o1.Hy, HSP.L, and HSP.H

settings convert automatically.

Code

inPt Input type. J_tC

Name

Settings

unit Process unit.

rESo Display resolution. No.dP

SHif PV shift value (offset). 0

Filt PV filter. 0

out1 Output 1 function. Hi.

o1.Hy Output 1 hysteresis value. 2.0

HSP.L Lower limit of HSP1.

HSP.H Upper limit of HSP1.

out2 Output 2 function. (N/A) None

Addr Address assignment for digital communication. (N/A) 1

bAud Baud rate of digital communication. (N/A) 4.8

PAri Parity bit of digital communication. (N/A) EVEn

diSP Normal display format. PV

°°°°

C (or

°°°°

F)

0 (32 if

204 (400 if

°°°°

F)

°°°°

F)

inPt Input type – this selects thermocouple type. LBB ovens use type J

thermocouple.

unit Process unit – selects between °C and °F for reading process

temperature.

rESo Display resolution – selects the location of the decimal point on process

related parameters.

SHif PV shift value (offset) – this moves the display temperature to the oven

temperature.

Filt PV filter – if process value is unstable to read, increasing this value will

steady the input signal.

out1 Output 1 function – this the function of the output. This must be set to .Hi

for

HI-LIMIT control.

o1.Hy Output 1 hysteresis value – the amount of degrees that the temperature

must be below the setpoint temperature before the HI-LIMIT can be reset.

HSP.L Lower limit of HSP1 – the minimum temperature that the HI-LIMIT can be

set.

HSP.H Upper limit of HSP1 – the maximum temperature that the HI-LIMIT can be

24

Page 33

set.

out2 Output 2 function.

(N/A)

Addr Address assignment for digital communication. (N/A)

bAud Baud rate of digital communication. (N/A)

PAri Parity bit of digital communication. (N/A)

out2 Output 2 function. (N/A)

diSP Normal display format – used to select the display in normal condition.

PV = Process value.

SP1 = HI-LIMIT setpoint.

SAFE = the word safe in normal condition.

25

Page 34

functions of the HI

-

LIMIT.

Changing Display From °°°°C To °°°°F

The HI-LIMIT can be configured for either °C or °F.

Use the following steps to change HI-LIMIT from

displaying °C to °F (and for changing back to °C).

1. If the

2. Press and hold the

3. Press the

4. Press the or to display value.

5. Use the or to move to the desired setting.

6. Press the key, this enters the value and advances to the next

7. Press the

8. The HI-LIMIT has been changed, enter the desired setpoint.

the

and keys.

been entered.

parameter.

on the HI-LIMIT is lit, press and hold

for four (4) seconds to enable the

key for four (4) seconds, the setup mode has now

key until the unit is displayed.

, this will return the HI-LIMIT to the normal mode.

WARNING: Make sure you

understand what you are

changing before doing so.

Changing the setup

parameters will alter the

26

Page 35

Maintenance

Do not attempt any service on this oven before opening the main power disconnect

switch.

Checklist

Keep equipment clean. Gradual dirt accumulation retards airflow. A dirty

oven can result in unsatisfactory operation such as unbalanced temperature

in the work chamber, reduced heating capacity, reduced production,

overheated components, etc. Keep the walls, floor and ceiling of the oven

work chamber free of dirt and dust. Floating dust or accumulated dirt may

produce unsatisfactory work results. Keep all equipment accessible. Do

not permit other materials to be stored or piled against it.

Protect controls against excessive heat. This is particularly true of

controls, motors or other equipment containing electronic components.

Temperatures greater than 51.5°C (125°F) should be avoided.

Establish maintenance & checkup schedules. Do this promptly and

follow the schedules faithfully. Careful operation and maintenance will be

more than paid for in continuous, safe and economical operation.

Maintain equipment in good repair. Make repairs immediately. Delays

may be costly in added expense for labor and materials and in prolonged

shut down.

Practice safety. Make it a prime policy to know what you are doing before

you do it. Make CAUTION, PATIENCE, and GOOD JUDGMENT the safety

watchwords for the operation of your oven.

Lubrication. Fan motor bearings are permanently lubricated. All door

latches, hinges, door operating mechanisms, bearing or wear surfaces

should be lubricated to ensure easy operation.

27

Page 36

damage.

Tests

Tests should be performed carefully and regularly.

The safety of personnel as well as the condition of

equipment may depend upon the proper operation of

any one of the functions of these controls. Test the

CONTROL instrument every 40 hours. Check that

the CONTROL instrument OUT LED is cycling on and

off. Also, verify that the heater is working.

Test the HI-LIMIT instrument every 40 hours.

With the oven operating at a given

temperature, set the HI-LIMIT down to the

setpoint operating temperature. The HI-LIMIT

instrument has tripped when OP1 is lit. Push

after adjusting the

HI-LIMIT instrument back to a higher setting,

or letting the oven temperature drop a few degrees based on the hysteresis value

of the HI-LIMIT.

WARNING:

Disconnect the main power

switch or power cord before

attempting any repair or

adjustment.

WARNINGS:

Failure to heed

warnings in this manual

and on the oven could

result in death, personal

injury or property

Replacement

Parts

To order or return parts, contact the Service

Products Group at Despatch. The Service

Products Group features our Parts Center for

customer service at 1-800-473-7373, option

#2. When returning parts, the Despatch

representative will provide you with an RMA (Return Material Authorization)

number. The RMA number must be attached to the returned part for identification.

When you are ordering parts, be sure to give the model number, serial number and

the part number. This will expedite the process of obtaining a replacement part.

When you have a service need, just contact a product service technician at 1-800-

473-7373 option #3 or FAX 612-781-5485.

WARNING:

Disconnect the main power switch

or power cord before attempting

any repairs or adjustments.

28

Page 37

Control Instrument

(Tools needed: one-quarter (¼) inch socket set screwdriver with Torx drive)

1. Disconnect power.

2. Remove screws from the face of the control panel and slide it forward.

3. Remove wires from the old control instrument, noting which wires connect to

which terminals.

Connections to the CONTROL Instrument

4. Disconnect the CONTROL mounting bracket.

5. Remove old CONTROL instrument from control panel.

6. Install new CONTROL instrument into the control panel.

7. Secure CONTROL with mounting bracket.

8. Reattach wires to the new CONTROL instrument. Make sure that the wires

are connected correctly.

9. Replace control panel.

29

Page 38

Replacement of Hi-limit Instrument

(Tools needed: one quarter (¼) inch socket set; screwdriver)

1. Disconnect power.

2. Remove screws from the face of the control panel and slide it forward.

3. Disconnect HI-LIMIT PLUG from circuit board.

4. Disconnect the thermocouple wires.

5. Press and hold down the tabs holding the HI-LIMIT instrument to the control

panel and slide it out.

Connections to HI-LIMIT Instrument

6. Install new HI-LIMIT instrument into the control panel.

7. Replace mounting screws.

8. Connect HI-LIMIT plug to the circuit board. Make sure that the wires are

connected correctly.

9. Reattach thermocouple wires.

10. Replace control panel.

30

Page 39

Heater Unit

(Tools needed: 3/8” wrench, screwdriver, one-quarter (¼) inch socket set with

Torx drive)

1. Remove shelves.

2. Remove side ducts (right and left)

a. Remove screws from each duct.

b. Remove duct from oven.

3. Remove heater cover.

a. Remove screws from heater cover.

b. Remove heater cover from oven.

4. Disconnect heater leads from heater element with wrench. Note which

wires go on which terminals.

5. Remove screws holding the heater frame to the oven body.

6. Remove heater and discard.

7. Install new heater frame to oven body.

8. Attach heater leads to appropriate terminals.

9. Replace heater cover.

10. Replace side ducts.

11. Replace shelves.

31

Page 40

Troubleshooting

Equipment which operates for long periods of time may develop problems. Below

are possible problems and suggested solutions. If you have a problem not listed

and do not know what to do, contact Despatch industries at our toll-free Help Line

800-473-7373.

Difficulty Probable Cause Suggested Remedy

Failure to heat

Slow heat up

Frequent heater element

burnout.

Erratic temperature CONTROL instrument

Inaccurate temperature CONTROL instrument

temperature

setpoint

No power Check power source and/or

oven and wall fuses

Burned-out heater(s) Replace element (see

warranty statement)

CONTROL instrument

malfunction

Loose wire connections Disconnect power and check

Improperly loaded workload Reduce load or redistribute

Low line voltage Supply sufficient power and

One or two heating

elements burned out

Vent is wide open Close vent.

Harmful fumes generated by

load

Spillage or splattering of

material on heater elements

Overheating oven Check the CONTROL and

malfunction

malfunction

Door seal deterioration Replace door seal. Excess surface or door

Door closed into top or

bottom latch only

HI-LIMIT instrument set too

low

CONTROL instrument

malfunction

Replace controller if OUT

LED on controller does not

turn on.

connections behind control

panel.

load in chamber.

proper connections. Check

for circuit overload.

Check heater amperage on

the nameplate. Replace

burned out element (see

warranty statement, back

page)

Increase vent opening or

discontinue process.

Disconnect power and clean

oven chamber and

elements.

HI-LIMIT instruments.

Check control parameters

before replacing the

CONTROL instrument

Recalibrate CONTROL

instrument

See specific difficulty below

for this problem.

Set the HI-LIMIT higher. Oven will not control at

Check control parameters

before replacing CONTROL

instrument.

32

Page 41

Difficulty Probable Cause Suggested Remedy

Exhaust air vent Adjust exhaust air vent. Unit

will not control at minimum

operating temperature with

vent(s) closed.

Heater does not shutdown

until temperature reaches

the HI-LIMIT setting

Door closes into top or

bottom latch only.

Door will not stay closed. Inadequate latch tension Ensure that latch strike is

CONTROL instrument

malfunction

SSR Relay malfunction Replace relay if no

Uneven latch tension

adjustment

Verify control parameters.

Replace relay if no output

exists. Replace CONTROL

instrument if 5 VDC output

exists.

CONTROL output exists.

Ensure that latch strike is

contacting center of latch.

Adjust mounting angle as

required. Adjust door for

even top and bottom latch

tension by turning screws on

ends of latch. Clockwise

increases tension on latch.

Counterclockwise decreases

tension.

contacting center of latch.

Adjust mounting angle to

center as required. Increase

latch tension by turning

screws on end of latch

clockwise. Adjust in even

increments on all four

screws to keep door pull

even.

33

Page 42

34

Page 43

DRAWINGS

Drawings and parts lists begin on the next page.

35

Page 44

LEB 1-23-1 (120 VAC) Parts

Part # Qty. Description

144755 1 Thermocouple

140097 2 Switch For Power And Heater

142861 1 Cord For Muffin Fan

057345 1 Relay Heater SSR

165051 1 Hi-Limit Despatch L91

144749 1 Control - Des2000

007818 1 Heater 1.2kw 120/240v

145858 1 Door Seal

148048 1 Door Pull

008199 2 Latch Ay

146010 1 LBB Exhaust Damper Assembly

145828 2 Standard Shelf

006049 1 Control Compartment Muffin Fan

150131 1 Circuit Board 120v

119457 1 Fuse Atdr-01.25A Control

125562 1 Fuse Atdr-12.00A Heater

36

Page 45

LEB 1-23-1 (120 VAC) Drawing

37

Page 46

LEB 1-23-1 (240 VAC) Parts

Part # Qty. Description

144755 1 Thermocouple

140097 2 Switch For Power And Heater

142861 1 Cord For Muffin Fan

057345 1 Relay Heater SSR

165051 1 Hi-Limit - Despatch L91

144749 1 Control - Des2000

007819 1 Heater 1.2kw 120/240v

145858 1 Door Seal

148048 1 Door Pull

008199 2 Latch Ay

146010 1 LBB Exhaust Damper Assembly

145828 2 Standard Shelf

006049 1 Control Compartment Muffin Fan

150132 1 Circuit Board 240v

119456 1 Fuse Atdr-01.00A Control

125692 1 Fuse Atdr-6.00A Heater

38

Page 47

LEB 1-23-1 (240 VAC) Drawing

39

Page 48

LEB 1-69-1 (120 VAC) Parts

Part # Qty. Description

144755 1 Thermocouple

140097 2 Switch For Power And Heater

142861 1 Cord For Muffin Fan

057345 1 Relay Heater SSR

165051 1 Hi-Limit - Despatch L91

144749 1 Control - Des2000

007819 1 Heater 2.4kw 120/240v

145725 1 Door Seal

008057 2 Center Door Seal

148048 1 Door Pull

008199 2 Latch Ay

146010 1 LBB Exhaust Damper Assembly

146024 2 Standard Shelf

094717 2 Reinforced Shelf

006049 1 Control Compartment Muffin Fan

150131 1 Circuit Board 120v

119457 1 Fuse Atdr-01.25A Control

134923 1 Fuse Atdr-25.00a Heater

40

Page 49

LEB 1-69-1 (120 VAC) Drawing

41

Page 50

LEB 1-69-1 (240 VAC) Parts

Part # Qty. Description

144755 1 Thermocouple

140097 2 Switch For Power And Heater

142861 1 Cord For Muffin Fan

057345 1 Relay Heater SSR

165051 1 Hi-Limit - Despatch L91

144749 1 Control - Des2000

007819 1 Heater 2.4kw 120/240v

145725 1 Door Seal

008057 2 Center Door Seal

148048 1 Door Pull

008199 2 Latch Ay

146010 1 LBB Exhaust Damper Assembly

146024 2 Standard Shelf

094717 2 Reinforced Shelf

015229 1 Control Compartment Muffin Fan

150132 1 Circuit Board 240v

119456 2 Fuse Atdr-01.25A Motor

125562 2 Fuse Atdr-12.00A Heater

42

Page 51

LEB 1-69-1 (240 VAC) Drawing

43

Page 52

LEB2-18-1 Parts

Part # Qty. Description

144755 1 Thermocouple

140097 2 Switch For Power And Heater

142861 1 Cord For Muffin Fan

057345 1 Relay Heater SSR

165051 1 Hi-Limit - Despatch L91

144749 1 Control - Des2000

007818 3 Heater 1.2kw 120/240v

145814 1 Door Seal

008057 3 Center Door Seal

148048 1 Door Pull

008199 2 Latch Ay

146010 1 LBB Exhaust Damper Assembly

016471 2 Standard Shelf

105498 2 Reinforced Shelf

015229 1 Control Compartment Muffin Fan

150132 1 Circuit Board 240v

119456 2 Fuse Atdr-01.00a Motor

124475 2 Fuse Atdr-20.00a Heater

44

Page 53

LEB 2-18-1 Drawing

45

Page 54

Despatch Customer Service

Procedures and Customer Responsibilities

To provide the most effective service to our customers under this warranty, all requests

for repairs are to be initiated by the Customer by telephone to the Despatch Service

Help Line, 800-473-7373. The Standard Period of Maintenance (SPM) is defined as 8

a.m. to 5 p.m. local time, excluding weekends and Despatch Holidays. Calls placed

within the SPM will be handled as follows.

Help Line calls connect the customer with the Despatch Service Group. The technician

will record all pertinent information, including SERIAL and MODEL NUMBER of the

unit(s), the urgency and nature of the problem, and the name and phone number of the

caller or other contact. The technician will advise the customer on suggested steps

and/or tests to either resolve the problem or help to confirm the diagnosis of the

problem.

Customer Agrees to cooperate in performing such tests and attempting to resolve the

problem as quickly as possible. Customer also agrees to replace minor parts such as

fuses, latches, etc. as instructed by Despatch Service Technicians. This approach has

Despatch and the Customer cooperating to effect the most expedient and cost effective

repair and minimize down time. If in Despatch's sole judgment, the equipment cannot

be repaired in this manner, an on-site visit by a Despatch authorized service

representative may be scheduled to repair the equipment. Customer agrees that, when

requested and authorized, such charges will be paid by the Customer within 30 days

from receipt of invoice.

46

Page 55

Attachment A - Sustained Service Support

At Despatch, long term customer satisfaction means more than responding quickly and

effectively to our customers' service requirements. It means offering comprehensive

customer support well beyond the scope of our initial contractual commitment.

Despatch's Service Products Group offers a Full Service Agreement package or a

Preventive Maintenance Plus agreement (PM+). These service products are unique in

the industry and offer the following benefits to our customer:

• Priority response for minimum production interruption.

• Preventive maintenance for longer product life.

• Discount on parts and services where applicable.

• Single payment for reduced billing expense.

• Elimination of need for a separate purchase order for each service requested.

These extra service options are aimed at extending our new equipment productivity, we

will also extend the Despatch one year manufactured parts warranty for another 12

months. This bonus warranty is automatically yours when you purchase a service

agreement from Despatch within the first 12 months after shipment of the equipment.

47

Page 56

APPENDIX: OPTIONAL FEATURES

Protocol Plus Control Option

If the oven is equipped with the Despatch Protocol Plus Controller, consult the Protocol

Plus manual (included).

Timer Option

The timer, which is set-up in hours, is used as a countdown timer. When the timer is on,

the delayed contact remains closed allowing power to the heater. During the first 20%

of the timing cycle, the first LED blinks. During the next 20% of the timing cycle, the first

LED stays on and the second LED blinks. The LED indicators continue in the same

manner until all LED’s are lit. When the LED’s are all lit, the timing cycle is complete,

the delayed contact opens and shuts off the heater. The heater will remain off until

either the TIMER switch is turned OFF, or resetting the timer.

Timer Displays and Switches

48

Page 57

Timer Operation

1. Turn the dials on the timer to the desired time.

2. Turn the Timer switch to ON. The timer is now counting down to zero.

3. Turn the HEATER switch to ON, if it is not already on.

4. When the timer counts down to zero the heater will shut off.

5. To reset the timer, turn the timer switch OFF then to ON.

6. To manually control the time, leave the timer switch OFF.

Timer Configuration

The timer is configured for XX.X hours from our facility. The timer can be easily set up

for different timing ranges. The following are instructions to configure the timer to suit

your needs.

1. Remove power from oven.

2. Remove top cover.

3. Remove socket from rear of timer.

4. Remove timer panel mounting bracket and remove timer from panel.

5. Using a small screwdriver, insert it the adjusting slots for the timer. The slots are

located behind the flange near the front of the timer. See Figure 1 for locations

of switches and displays.

a. Slide the switch to the desired range position.

b. Verify range by looking in face of timer in the range window.

c. Slide the switch to the desired decimal point position.

d. Verify decimal position by looking at the decimal position in face of timer.

6. Remount timer back into panel.

7. Reattach timer socket to timer.

8. Replace top cover.

49

Page 58

9. Apply power to oven, and follow instructions in the timer operation section.

Stand Assembly Instructions

1. Install four rubber grommets into holes in the stand. On LEB1-69 stands, the

rear grommets mount into the forward set of rear holes. On LEB2-12 stands the

rear grommets mount into the set of holes closest to the rear of the stand.

2. Place the oven on top of the stand. The four embossed areas in the bottom of

the oven should center in the grommets.

3. Using the self-drilling screw and large flat washer provided, install through each

embossed area as shown below.

Stand Assembly Components

50

Page 59

Side View of Oven

(1 per bracket)

Front Vie

w of Oven

(4 required)

Stacking Kit Assembly Instructions

1. Locate the four stacking kit brackets found in the kit.

2. Place each of the brackets on top of each of the four corners of one of the lower

ovens in the stack being assembled. Slide the angle of each bracket into the

slots in the embossed area on top of the oven. See the illustration below for

placement.

3. Use the four 10-16 x .50 screws included in the kit to attach the brackets to the

oven top.

4. Place the upper oven onto the lower one. The embossed “feet” on the upper

oven should fit into the brackets attached in the last three steps.

Stacking kit bracket

10-16 x .50 screw

Stacking Kit Assembly Components

51

Page 60

Timer Option with Audible and Visual

Alarm

This option sounds the alarm and a light comes on when the timer times out.

Turning the heater switch off will clear the alarm condition. Do not turn the heater

switch on before resetting the timer.

Turning the timer switch off will also clear the alarm condition but the heater will remain

on.

Wiring for this option is shown in the DRAWINGS section of this manual.

High Limit Alarm Option

This option sounds the alarm and a light comes on when a high limit condition occurs.

To silence the alarm horn, press the alarm silence switch; the light will remain on.

It is necessary to clear the high limit condition to clear the alarm. See the

TROUBLESHOOTING section of this manual for solutions for high limit conditions.

It will be necessary to reset the high limit instrument whenever it has tripped. The high

limit instrument may be reset by first allowing the oven chamber to cool slightly (or by

setting the high limit instrument up several degrees), then pushing the black reset

button.

The wiring for this option is shown on the electrical schematic in the DRAWINGS

section of this manual.

Recorder Option

The circular chart recorder is used to record the user’s process. This is done by an

independent thermocouple. The charts used are 24 hour or 7 day. See the recorder

manufacturer’s manual supplied with this manual.

The wiring for this option is shown on the electrical schematic in the drawing section of

this manual.

52

Loading...

Loading...