Page 1

P.N. 200560

Electric Heater Lead

Welding Instructions

Gas Weld

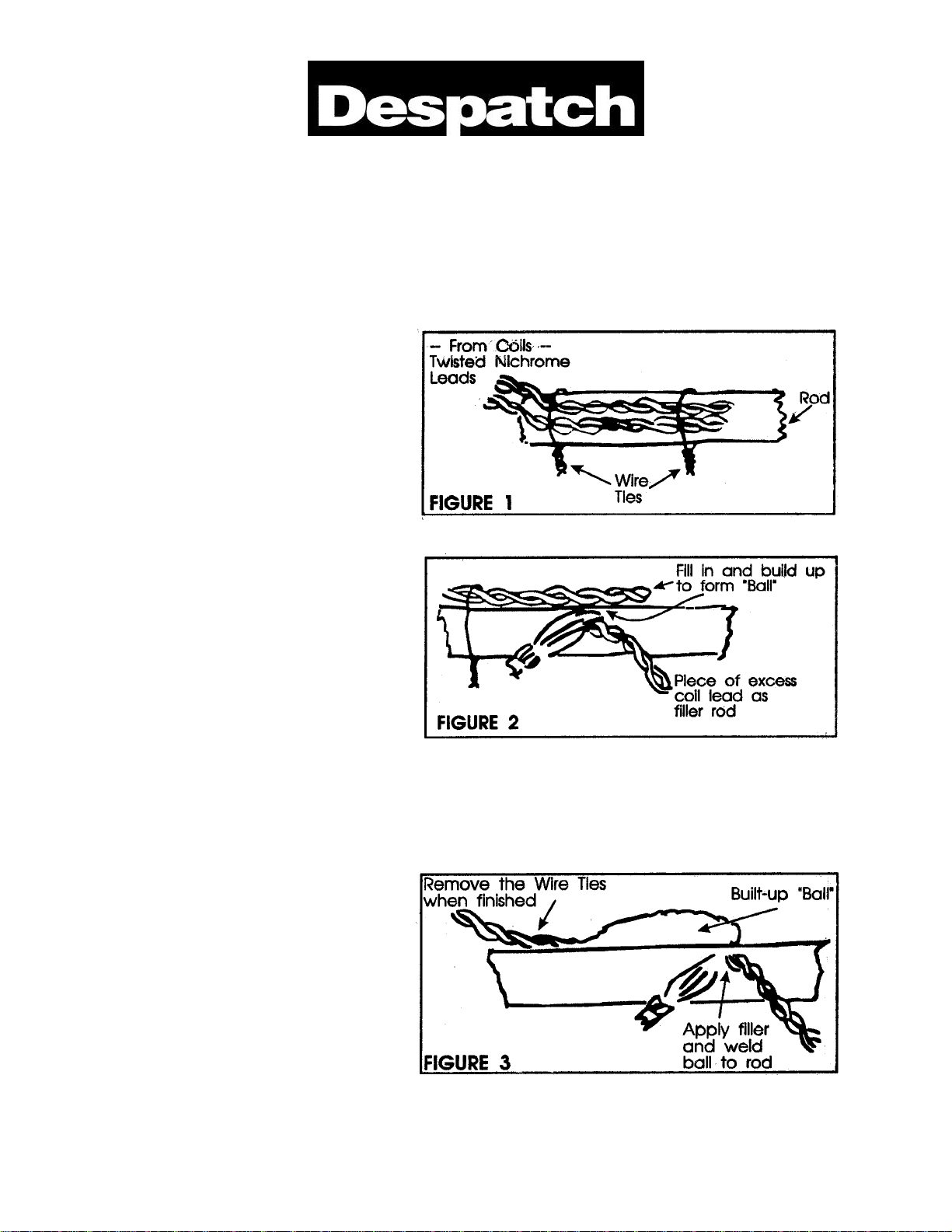

1. Place coil end parallel to

the rod and tie the coil

lead to the rod with

nichrome wire to hold the

lead in place while

welding. (See Figure 1).

2. To weld the coil to the rod,

use an oxyacetylene

flame. For filler rod, use

excess heater coil wire.

Use a soft flame to melt

filler rod and fill in around

coil leads to form a “ball”.

Do not try to weld the coil

leads directly to the rod.

No flux is required. (See

Figure 2).

CAUTION: Too hot a flame or applying too much heat to the coil leads can

burn them off or cause crystallizing. Keep flame moving.

3. When the coil leads have

been built up by the

appolication of filler rod,

increase flame heat.

Apply the flame to the rod

and add filler between the

rod and built-up leads,

gradually fusing them

together. (See Figure 3).

V-28

Rev. 3-02

1

Page 2

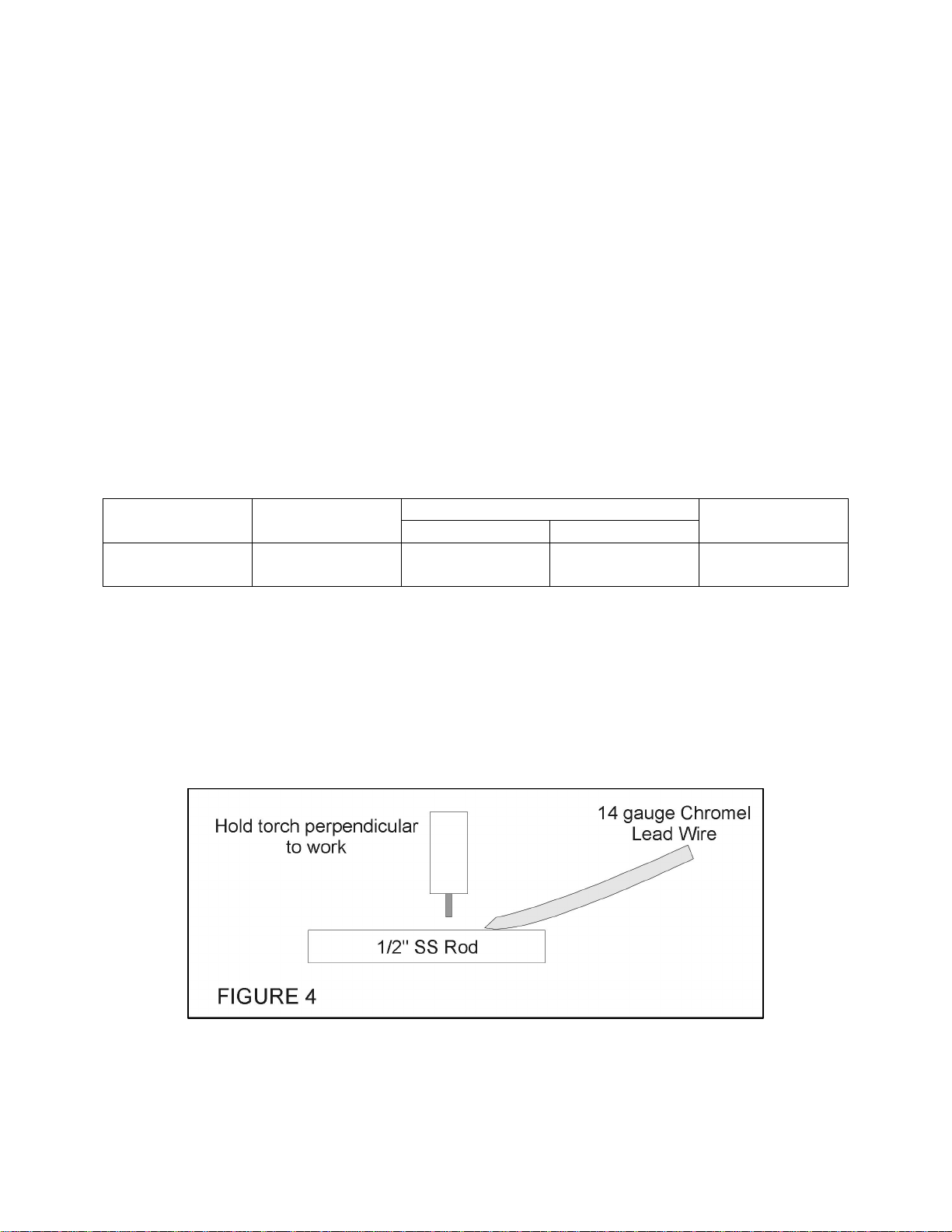

TIG Weld

Joint

Type of Welded Joint: J-Groove

Backing Material: No

Base Metal

Sheet steel to SS Rod (support

steel)

Filler Metal

Specification: If required, chromel

lead wire

Classification: Same as heater lead

Technique

Amperes Volts

1 with 3/8” nozzle

.062 diameter

1. Start puddle.

2. Before melting wire use a slight weave.

3. Once you start melting wire, lead the puddle with torch.

60-78

60 nom.

Gas

Shielding Gas: Argon

Percent Mixture: 100% Argon

Flow Rate: 10-14 CFH

Coating

Type: None

Preheat

Preheat Temperature Min: None

Welding Current Pass No. Tungsten Size

Travel Speed

17-19 N/A

2

Loading...

Loading...