Page 1

INSPIRED INNOVATION

u DF In-line Diffusion System

Diffusion for highly uniform emitters

e Despatch In-line Diusion Furnace incorporates advanced infrared

thermal technology that provides the tight temperature uniformity

needed for increased cell eciencies. Air is passively preheated as it

enters the chamber and lamps on top and bottom along with edge

heaters eectively transfer heat to the wafers. Automated drop-down

access to the chamber reduces maintenance time and the insulation

in the rst zones of the furnace is easily removed if it becomes

contaminated. e furnace provides advanced prole capability

and a fully comprehensive soware system.

In-line processing oers reduced wafer handling and greater throughput

than batch processing. With less handling you will have less breakage

and increased yield. e Despatch Diusion Furnace combined with

USI’s Deposition tool consistently produces highly uniform emitters

using aqueous-based doping. is repeatability enables

higher sheet resistances, excellent yields and optimum

cell eciency.

FEATURES AT A GLANCE

u

High volume production

u

Exceptional thermal uniformity

± 1°C in the dwell region

u

Closed loop temperature controls

u

Advanced graphical user interface

u

Safe, simple chamber accessibility

u

High production up-time

u

Ease of maintenance

High ohm emmiter capability

Industry best emitter uniformity

Best-in-class uptime and yield

Minneapolis • shanghai • Berlin • singapore • hsinchu • ToKYo

Page 2

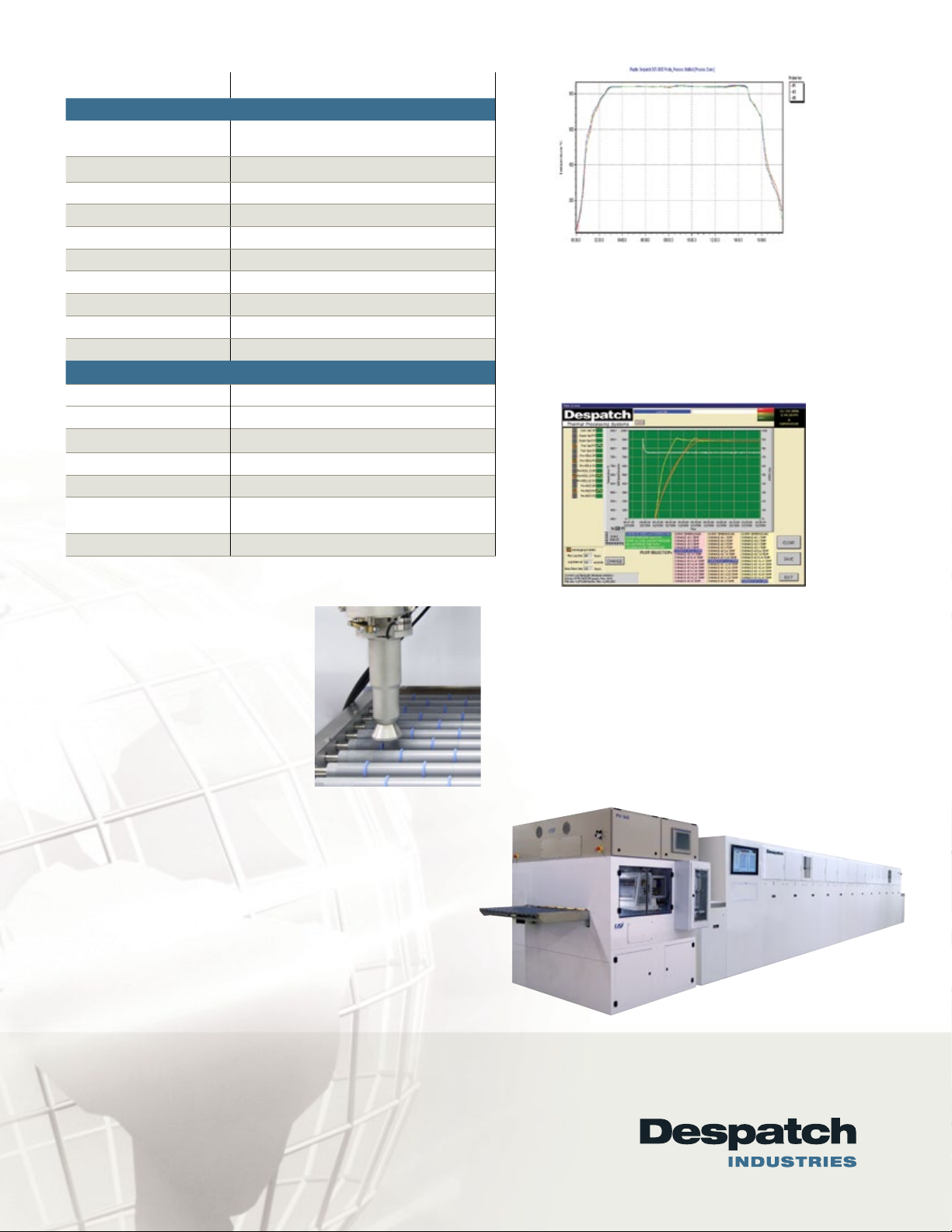

DF 3630 PRODUCTION SCALE

PRODUCT CONFIGURATION

System size

(length x width x height)

Standard entrance table

Heated length 10,516 mm (414 inch)

Cooling length 1,829 mm (72 inch)

Standard exit table 914 mm (36 inch)

Conveyor type Lightweight balance spiral weave, Nichrome V material

Conveyor height above floor 97.8 cm +/-3.6 cm (38.4 in +/-1.5 in)

Product clearance 6.4 mm (0.25 inch)

Number of Lanes (156 x 156 mm) 5

Conveyor width 914 mm (36 inch)

PROCESS CAPABILITIES

Maximum temperature 1000 °C (1832 °F)

Approx. throughput (156 x 156 mm)

Conveyor speed range

Conveyor speed accuracy ± 0.5%

Conveyor speed control Closed loop feedback

Wafer size 100x100, 125 x125, 156 x 156 mm (4, 5, 6 inch)

Sheet resistance 40 to >120 ohm/sq configurable

15,329 × 1,870 × 1,750 mm (603.5 x 74 x 69 inches)

914 mm (36 inch)

1200-1400 wafers/hr

10–100 cm/min (4-40 ipm)

Option for 210 x 210 mm (8 inch) support

IN-LINE DIFFUSION FURNACE

u

Tight temperature control for maximum

process window

u

Maximum up-time for higher yields

u

Process profiles for high efficiency solar cells

OPTIONS

u

Water-cooled heat exchanger

u

Failed element monitor

u

Master production control interface

u

Profiling systems

u

Ultrasonic belt cleaner/dryer

u

Uninterruptible power supply

u

Extended process profiles

u

Conveyor table extensions

u

CE Compliance

A plasma system is

available for chemicalfree conditioning of the

wafer surface.

The Despatch Diffusion Furnace combined with USI’s Deposition

tool is a reliable system for highly uniform emitters.

GLOBAL OFFICES

Germany: +49 30 629 073 410 / europe@despatch.com

China: +86-21-62365868 / shanghai@despatch.com

Taiwan:

+886-3-6588484 / taiwan@despatch.com

Japan: +81-42-729-5355 / japan@despatch.com

INTEGRATED PROCESS

conTrol sYsTeM

u

Doper/Furnace recipe creation

u

Process window monitoring with

audible and visual alarming

u

Real-time process window display

u

Data logging

u

Process repeatability

USA HEADQUARTERS

Phone: 1-952-469-5424

toll free usa: 1-888-337-7282

fax: 1-952-469-4513

sales@despatch.com

service@despatch.com

www.despatch.com

8860 207th Street West

Minneapolis, MN 55044 USA

© 2011 Despatch Industries. All rights reserved. Despatch is a registered trademark of Despatch Industries in the U.S. and other countries. DF-6-11

Loading...

Loading...