GAS LOG VENTED

DECORATIVE AP PLI ANCE

OWNER’S OPERATION AND

INSTALLATION MAN U AL

For more information, visit www.desatech.com

VTD-24N-PDG, VTD-24P-PDG,

VTD-18N-PDG, VTD-18P-PDG

ANSI Z21.60-2003

CSA 2.26-2003

APPROVED

WARNING: If the information in this man u al

is not followed exactly, a fi re or explosion

may result caus ing prop er ty damage, per son al in ju ry, or loss of life.

— Do not store or use gasoline or other

fl ammable vapors and liq uids in the vicinity

of this or any other ap pli ance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your build ing.

• Immediately call your gas sup pli er from

a neigh bor’s phone. Follow the gas sup pli er’s in struc tions.

• If you cannot reach y our gas sup plier , call

the fi re de part ment.

— Installation and service must be per formed

by a qualifi ed installer, ser vice agen cy, or

the gas supplier.

VTD-24N-BTB, VTD-24P-BTB,

VTD-18N-BTB, VTD-18P-BTB

WARNING: Improper in stal la tion, ad just ment, al tera tion, service, or main te nance can cause injury or prop er ty

dam age. Re fer to this man u al for

cor rect in stal la tion and op er a tion al

pro ce dures. For as sis tance or ad di tional in for ma tion con sult a qualifi ed

in stall er, ser vice agen cy, or the gas

sup plier.

WARNING: This appliance is for in stal la tion only in a solid-fuel burn ing ma son ry or UL127 fac to ry-built

fi re place, con struct ed of non com bus ti ble ma te ri al, and con nect ed

to a working fl ue. (See page 7 for

min i mum fl ue open ing.)

WARNING: This is a gas-fi red ap pli ance. It uses air (ox y gen) from the room in which it is installed.

Pro vi sions for ad e quate com bus tion and ven ti la tion air must be provided. Refer to the National

Fuel Gas Codes, ANSI Z233.1/NFPA 54, Section 5.3, Air for Combustion and Ventilation.

This appliance may be installed in an aftermarket,* manufactured (mobile) home, where not

pro hib it ed by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This ap pli ance

is not convertible for use with other gases.

Warning: This product must be installed by a Licensed Plumber or Gas Fitter when installed

within The Commonwealth of Massachusetts.

* Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer

Save this manual for future reference.

TABLE OF CONTENTS

2

SAFETY INFORMATION

TABLE OF CONTENTS

SAFETY INFORMATION..............................................................2

LOCAL CODES............................................................................3

PRODUCT IDENTIFICATION.......................................................3

UNPACKING.................................................................................4

PRODUCT FEATURE ..................................................................4

INSTALLATION ............................................................................7

OPERATING AP PLI ANCE..........................................................11

INSPECTING BURNERS ..........................................................13

SAFETY INFORMATION

WARNING ICON G 001

WARNINGS

WARNING: Keep fl ue open when operating unit.

IMPORTANT: Read this owner’s man u al carefully and

completely be fore trying to assemble, op er ate, or ser vice this log set. Im prop er use of this log set can cause

se ri ous injury or death from burns, fi re, ex plo sion, electrical shock, and carbon mon ox ide poi son ing.

DANGER: Carbon mon ox ide poisoning may lead

to death!

WARNING: This product contains and/or generates

chemicals known to the State of California to cause

cancer or birth defects, or other reproductive harm.

Carbon Monoxide Poisoning: Early signs of carbon mon ox ide

poisoning re sem ble the fl u, with head aches, dizziness, or nau sea.

If you have these signs, the log set may not be working properly.

Get fresh air at once! Have log set serviced. Some people are more

affected by carbon monoxide than others. These include preg nant

wom en, peo ple with heart or lung disease or ane mia, those under

the in fl u ence of alcohol, and those at high altitudes.

Natural & LP Gas : Natural & LP gas are odorless. An odor-mak-

ing agent is added to the gas. The odor helps you detect a gas leak.

However, the odor added to the gas can fade. Gas may be present

even though no odor exists.

Make certain you read and understand all warnings. Keep this

manual for reference. It is your guide to safe and proper operation

of this log set.

W ARNING: Any change to this log set or its controls can be dan ger ous.

1. This appliance, as supplied, is only for use with the type of gas

indicated on the rating plate.

2. If you smell gas

• shut off gas supply

CLEANING AND MAINTENANCE .............................................13

TROUBLESHOOTING................................................................14

REPLACEMENT PARTS ............................................................18

ILLUSTRATED PARTS BREAKDOWN AND PARTS LIST.........20

ACCESSORIES..........................................................................22

OWNER'S REGISTRATION FORM............................................23

WARRANTY INFORMATION ...................................... Back Cover

• do not try to light any appliance

• do not touch any elec tri cal switch; do not use any phone in

your build ing

• immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions

• if you cannot reach your gas sup plier, call the fi re de part ment

3. Never install the log set

• in a recreational vehicle

• where curtains, furniture, clothing, or other fl ammable ob jects are less than 42 inches from the front, top, or sides of

the log set

• in high traffi c areas

• in windy or drafty areas

4. Before installing in a solid fuel burn ing fi replace, the chim ney

fl ue and fi re box must be cleaned of soot, creosote, ash es and

loose paint by a qualifi ed chimney cleaner . Creosote will ig nite

if highly heated. Inspect chimney fl ue for damage. If dam aged,

repair fl ue before operating appliance.

5. Y ou must operate this log set with fi replace doors or screens in

place and fully closed. Unless provided by other means, screens

shall have openings for in tro duc tion of combustion air.

6. This log set is designed to be smoke less. If logs ever appear to

smoke, turn off appliance and call a qual i fi ed ser vice per son.

Note: During ini tial op er a tion, slight smok ing could oc cur due

to log curing and the burning of man u fac tur ing res i dues. You

may wish to add more ventilation by opening a win dow.

7. T o reduce the creation of soot, follow the in struc tions in Clean-

ing and Main te nance, page 13.

8. Do not allow f ans to blow directly into the fi replace. Avoid any

drafts that al ter burner fl ame patterns. Ceiling fans can create

drafts that alter burner fl ame patterns. Altered burner patterns

can increase sooting.

9. Do not use a blower insert, heat ex chang er insert or other ac ces so ry not approved for use with this log set.

10. The installation and provisions for combustion and ventilation air

must conform with the National Fuel Gas Codes, ANSI Z233.1/

NFPA 54, Section 5.3, Air for Combustion and Ven ti la tion.

11. Do not run log set

• where fl ammable liquids or vapors are used or stored

• under dusty conditions

For more information, visit www.desatech.com

111826-02F

SAFETY INFORMATION

Continued

12. Do not burn solid fuel in the fi replace after installing the log

set. Do not use this log set to cook food or burn pa per or oth er

ob jects.

13. Log set becomes very hot when in use. Keep chil dren and adults

away from hot sur face to avoid burns or clothing ig ni tion. Log

set will re main hot for a time after shutdown. Al low surface to

cool be fore touch ing.

14. Carefully supervise young children when they are in the room

with log set.

15. Do not use this appliance if any part has been under water.

Immediately call a qualifi ed service technician to inspect the

appliance and to replace any part of the control system and any

gas control which has been under water.

17. Turn log set of f and let cool before ser vic ing, installing, or re pair ing. Only a qualifi ed service person should install, ser vice,

or repair log set.

18. Keep the appliance area clear and free from combustible ma te ri als, gasoline and other fl ammable vapors and liquids.

19. Provide adequate clearances around air openings.

W ARNING: Do not place log scraps or la v a roc ks

on burner.

SAFETY INFORMATION

LOCAL CODES

PRODUCT IDENTIFICATION

3

3

LOCAL CODES

Install and use appliance with care. Follow all local codes. In the

absence of local codes, use the latest edition of The National Fuel

Gas Code ANSI Z223.1/NFPA 54*.

*Available from:

American National Standards In sti tute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

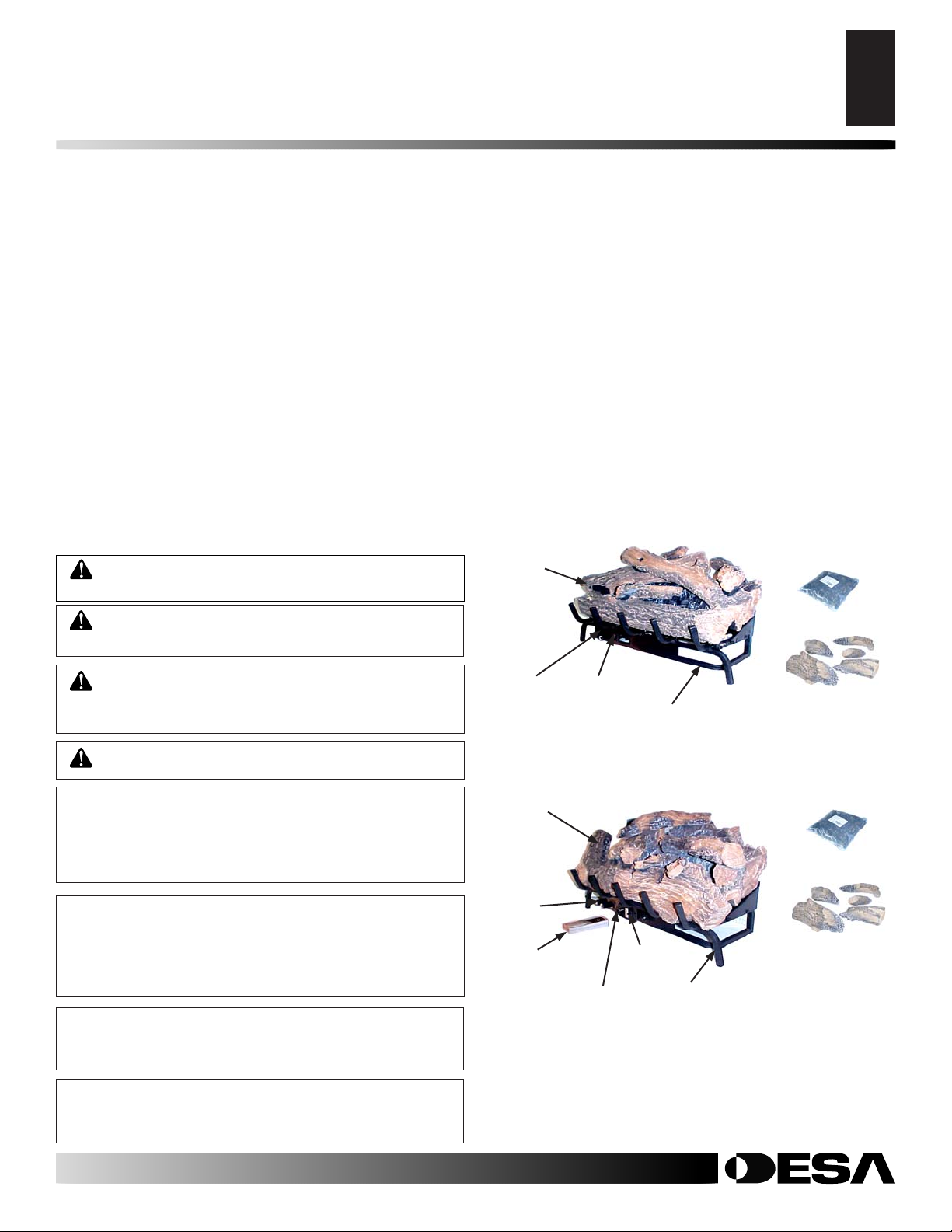

PRODUCT IDENTIFICATION

Log Set

WARNING: Any change to this log set or its controls

can be dangerous.

WARNING: Do not use a blow er insert, heat ex chang er insert, or other accessory not ap proved for

use with this appliance.

WARNING: Keep fl ue open when operating unit.

Appliance base assembly be comes very hot when

run ning appliance. Keep chil dren and adults away

from hot surface to avoid burns or clothing ignition.

Appliance will remain hot for a time after shut down.

Allow surface to cool be fore touching.

Carefully supervise young chil dren when they are in

the room with appliance. When using the hand-held

remote accessory (Remote-Ready Models Only), keep

se lec tor switch in the OFF position to prevent chil dren

from turn ing on burners with remote.

Y ou must operate this appliance with a fi re place screen

in place. Make sure fi re place screen is closed before

run ning appliance.

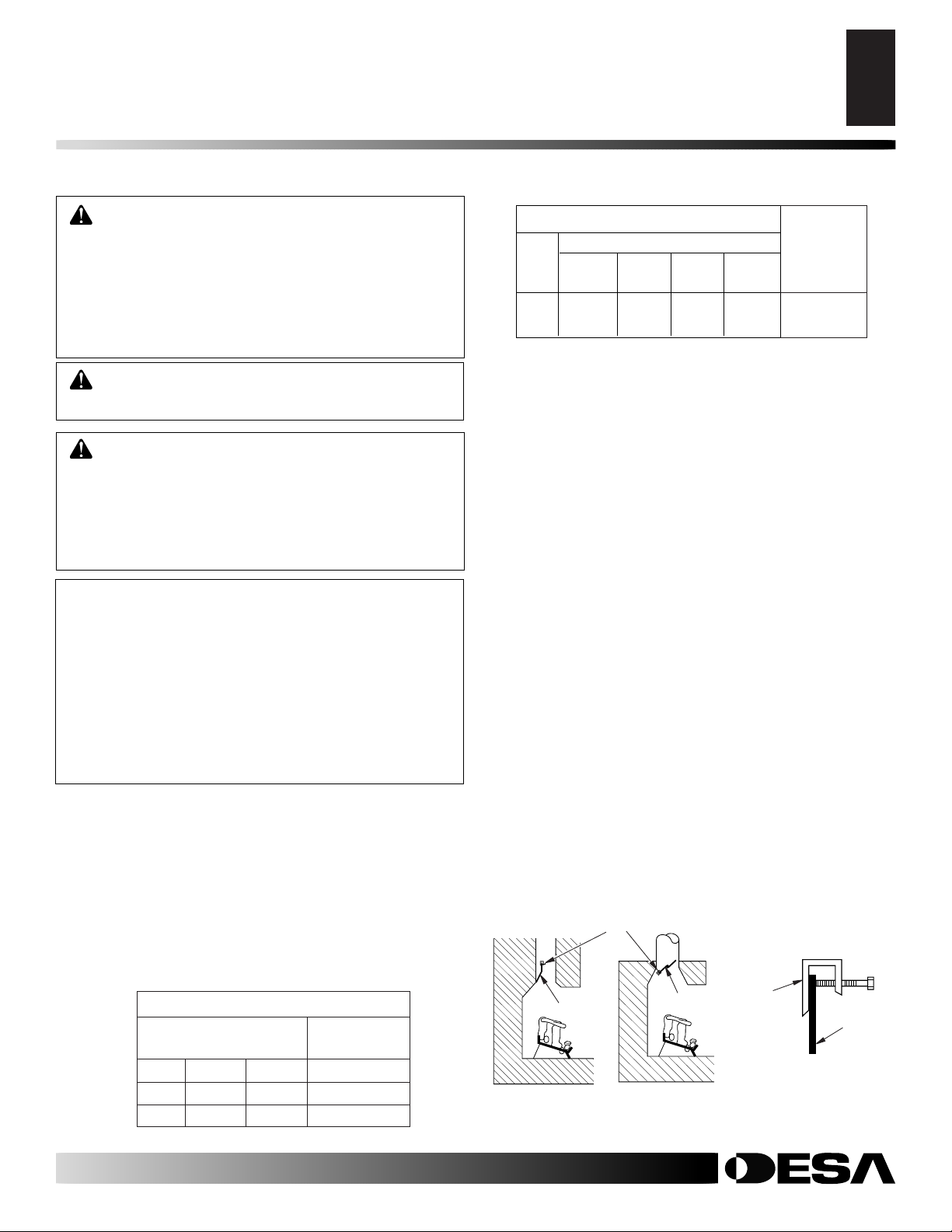

Piezo

Ignitor

Log Set

Piezo

Ignitor

Remote

Control

Control Knobs

Control Knobs

REMOTE CONTROLLED MODELS

Chassis Assembly

REMOTE READY MODELS

Remote

Reciever

Chassis Assembly

Lava Rock

Log Scraps

Lava Rock

Log Scraps

Keep the appliance area clear and free from com bus ti ble materials, gasoline, and other fl ammable

vapors and liquids.

For more information, visit www.desatech.com

111826-02F

Figure 1 - Product Identifi cation

OPTIONAL REMOTE CONTROL ACCESSORIES

4

UNPACKING

PRODUCT FEATURES

AIR FOR COMBUSTION AND VENTILATION

Providing Adequate V entilation

OPTIONAL REMOTE CONTROL

ACCESSORIES

There are two optional remote controls that can be purchased separately for Remote-Ready Models:

• wall switch • hand-held ON/OFF remote

See Accessories, page 22.

The wall thermostat or hand-held ther mo stat may not be used with

vented dec o ra tive appliances.

UNPACKING

CA UTION: Do not remove the data plates from the

grate assembly. The data plates con tain im por tant

warranty and safety in for ma tion.

1. Remove log set as sem bly from carton. Note: Do not pick up

assembly by logs. This could dam age the unit. Alw ays handle

assembly by grate.

2. Remove control cover fl oor media components & remote

control if supplied.

3. Remove all protective packaging ap plied to log set for shipment.

4. Check all items for any shipping dam age. If damaged, prompt ly

inform deal er where you bought appliance.

PRODUCT FEATURES

REMOTE READY & REMOTE CONTROLLED

This unitized gas log set is tested and approved to ANSI Z21.60a

and CSA 2.26a-2000 as a vented decorati ve appliance. This log set

has a piezo ignitor . This system requires no matches, batteries or

other source to light log set.

SAFETY DEVICE

This unit has a pilot with an Oxygen Depletion Sensing (ODS)

safety shutoff sys tem. The ODS/pilot shuts off the appliance if there

is not enough fresh air.

PIEZO IGNITION SYSTEM

This unit has a piezo ignitor. This system requires no matches, batteries, or other sourc es to light appliance.

AIR FOR COMBUSTION AND

VENTILATION

W ARNING: This appliance shall not be installed in

a confi ned space or unusually tight con struc tion un less pro vi sions are pro vid ed for ad e quate com bus tion

and ven ti la tion air. Read the fol low ing in struc tions to

in sure prop er fresh air for this and other fuel-burning

ap pli anc es in your home.

Today’s homes are built more energy ef fi cient than ever. New ma te ri als,

increased in su la tion, and new construction methods help reduce heat

loss in homes. Home own ers weather strip and caulk around windows

and doors to keep the cold air out and the warm air in. During heating

months, home owners want their homes as airtight as pos si ble.

While it is good to make your home energy effi cient, your home

needs to breathe. Fresh air must enter your home. All fuel-b urning

appliances need fresh air for proper com bus tion and ven ti la tion.

Exhaust fans, fi replaces, clothes dryers, and fuel burning appliances

draw air from the house to operate. Y ou must provide ad e quate fresh

air for these ap pli anc es. This will insure proper venting of vented

fuel-burning appliances.

PROVIDING ADEQUATE VENTILATION

The following are excerpts from National Fuel Gas Code, ANSI

Z223.1/NFPA 54, Sec tion 5.3, Air for Combustion and Ven ti la tion.

All spaces in homes fall into one of the three following ventilation

classifi cations:

1. Unusually Tight Construction

2. Unconfi ned Space

3. Confi ned Space

The information on pages 4 through 6 will help you classify your

space and provide ad e quate ven ti la tion.

Unusually Tight Construction

The air that leaks around doors and win dows may provide enough

fresh air for combustion and ventilation. Howe ver, in buildings of unusually tight construction, you must provide additional fresh air.

Unusually tight construction is de fi ned as construction

where:

a. walls and ceilings exposed to the outside at mo sphere

have a con tin u ous water vapor retarder with a rating

of one perm (6 x 10

open ings gasketed or sealed and

b. weather stripping has been add ed on openable win-

dows and doors and

c. caulking or sealants are applied to areas such as

joints around window and door frames, be tween sole

plates and fl oors, be tween wall-ceiling joints, be tween

wall panels, at pen e tra tions for plumb ing, electrical,

and gas lines, and at other openings.

If your home meets all of the three criteria above, you

must pro vide ad di tion al fresh air . See Ventilation Air

From Outdoors, page 5.

If your home does not meet all of the three criteria above,

proceed to De ter min ing Fresh-Air Flow For Appliance

Lo ca tion, below.

-11

kg per pa-sec-m2) or less with

For more information, visit www.desatech.com

111826-02F

AIR FOR COMBUSTION AND VENTILATION

Providing Adequate V entilation (Cont.)

Determining Fresh-Air Flow for Appliance Location

V entilation Air

5

5

AIR FOR COMBUSTION AND

VENTILATION

Continued

Confi ned and Unconfi ned Space

The National Fuel Gas Code, ANSI Z223.1/NFPA 54 defi nes a

con fi ned space as a space whose volume is less than 50 cubic feet

per 1,000 Btu per hour (4.8 m3 per kw) of the ag gre gate input rating

of all ap pli anc es in stalled in that space and an un con fi ned space as

a space whose vol ume is not less than 50 cubic feet per 1,000 Btu

per hour (4.8 m3 per kw) of the ag gre gate input rating of all appliances in stalled in that space. Rooms com mu ni cat ing di rect ly with

the space in which the ap pli anc es are in stalled*, through openings

not fur nished with doors, are con sid ered a part of the unconfi ned

space.

* Adjoining rooms are communicating only if there are doorless

passageways or ven ti la tion grills between them.

DETERMINING FRESH-AIR FLOW FOR

APPLIANCE LOCATION

Determining if You Have a Confi ned or Unconfi ned

Space

Use this work sheet to determine if you have a confi ned or un con fi ned

space.

Space: Includes the room in which you will install appliance plus any

adjoining rooms with doorless passageways or ventilation grills between

the rooms.

1. Determine the volume of the space (length x width x height).

Length x Width x Height =____________cu. ft. (vol ume of space)

Example: Space size 20 ft. (length) x 16 ft. (width) x 8 ft. (ceil ing

height) = 2560 cu. ft. (vol ume of space)

If additional ventilation to adjoining room is supplied with grills or open-

ings, add the volume of these rooms to the total vol ume of the space.

2. Multiply the space volume by 20 to determine the maximum Btu/Hr

the space can support.

____________(volume of space) x 20 = (Maximum Btu/Hr the space

can sup port)

Example: 2560 cu. ft. (volume of space) x 20 = 51,200 (max i mum

Btu/Hr the space can sup port)

3. Add the Btu/Hr of all fuel burning ap pli anc es in the space.

Vent-free appliance _____________ Btu/Hr

Gas wa ter appliance* _____________ Btu/Hr

Gas fur nace _____________ Btu/Hr

Vented gas appliance _____________ Btu/Hr

Gas fi re place logs _____________ Btu/Hr

Other gas appliances* + _____________ Btu/Hr

Total = _____________ Btu/Hr

* Do not include direct-vent gas ap pli anc es. Direct-vent draws com-

bus tion air from the outdoors and vents to the outdoors.

Example:

Gas water appliance _____________ Btu/Hr

Vent-free appliance + _____________ Btu/Hr

Total = _____________ Btu/Hr

4. Compare the maximum Btu/Hr the space can support with the actual

amount of Btu/Hr used.

____________________Btu/Hr (maximum the space can sup port)

____________________Btu/Hr (actual amount of Btu/Hr used)

Example: 51,200 Btu/Hr (max i mum the space can support)

73,000 Btu/Hr (actual amount of Btu/Hr used)

The space in the above example is a con fi ned space because the actual

Btu/Hr used is more than the maximum Btu/Hr the space can sup port. Y ou

must provide additional fresh air. Your op tions are as follows:

A. Rework worksheet, adding the space of an adjoining room. If the ex tra

space provides an unconfi ned space, remove door to ad join ing room or

add ven ti la tion grills between rooms. See Ven ti la tion Air From Inside

Building, page 6.

B. V ent room directly to the outdoors. See V entilation Air F rom Out doors,

page 6.

C. Install a lower Btu/Hr appliance, if lower Btu/Hr size makes room un con -

fi ned.

If the actual Btu/Hr used is less than the maximum Btu/Hr the space can sup port, the space is an unconfi ned space. You will need no additional fresh air

ven ti la tion.

40,000

33,000

73,000

WARNING: If the area in which the appliance

may be operated is smaller than that defi ned as an

un con fi ned space or if the building is of unusually

tight construction, pro vide ad e quate com bus tion and

ven ti la tion air by one of the methods described in

the National Fuel Gas Code, ANSI Z223.1/NFPA 54

Sec tion 5.3 or applicable local codes.

VENTILATION AIR

Ventilation Air From Inside Building

This fresh air would come from an adjoining unconfi ned space. When

ventilating to an adjoining unconfi ned space, you must pro vide two

permanent open ings: one within 12" of the ceiling and one within

12" of the fl oor on the wall con nect ing the two spaces (see options

1 and 2, Figure 2). You can also remove door into adjoining room

(see op tion 3, Figure 2). Follow the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, Section 5.3, Air for Combustion and Ventilation

for required size of ventilation grills or ducts.

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation grills or ducts. You

must provide two per ma nent open ings: one within 12" of the ceiling and one within 12" of the fl oor. Connect these items directly to

111826-02F

For more information, visit www.desatech.com

I

AIR FOR COMBUSTION AND VENTILATION

6

V entilation Air (Cont.)

AIR FOR COMBUSTION AND

VENTILATION

Continued

the outdoors or spaces open to the outdoors. These spaces include

attics and crawl spaces. Follow the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, Section 5.3, Air for Combustion and Ventilation

for required size of ven ti la tion grills or ducts.

IMPORTANT: Do not provide openings for inlet or outlet air into

attic if attic has a ther mo stat-controlled power vent. Heated air

entering the attic will activate the power vent.

12"

Ventilation

Grills

nto Adjoining

Room,

Option 1

Or

Remove

Door into

Adjoining

Room,

Option

3

Ventilation Grills

Into Adjoining Room,

Option 2

Outlet

Air

Outlet

Air

Inlet

Air

Inlet Air

Figure 3 - Ventilation Air from Outdoors

Ventilated

Attic

To Attic

To

Crawl

Space

Ventilated

Crawl Space

12"

Figure 2 - Ventilation Air from Inside Building

For more information, visit www.desatech.com

111826-02F

INSTALLATION

Flue Opening Specifi cations

Installation and Clearances

Venting Specifi cations for Installation

Installing Damper Clamp

7

7

INSTALLATION

WARNING: Before installing in a solid fuel burn ing fi replace, the chimney fl ue and fi rebox must be

cleaned of soot, creosote, ash es and loose paint by

a qual i fi ed chim ney cleaner. Creosote will ignite if

highly heated. A dirty chimney fl ue may create and

dis trib ute soot within the house. In spect chim ney fl ue

for damage. If damaged, repair fl ue damper before

operating appliance.

W ARNING: Make sure the selector switch is in the

OFF po si tion before installing appliance .

WARNING: Before installing in a solid fuel burn ing fi replace, the chimney fl ue and fi rebox must be

cleaned of soot, creosote, ash es and loose paint by

a qual i fi ed chim ney cleaner. Creosote will ignite if

highly heated. A dirty chimney fl ue may create and

dis trib ute soot within the house. In spect chim ney

fl ue for damage.

NOTICE: Installation, service, and repair of this ap pli ance must be performed by a qualifi ed in stall er,

ser vice agency, com pa ny or gas supplier ex pe ri enced

with this type of gas ap pli ance. Only fac to ry au tho rized

components list ed in these in struc tions may be used

in ac cor dance with the man u fac tur er’s in struc tions

and all codes and requirements of the authority having ju ris dic tion. Any modifi cations to this kit, or use

of unauthorized com po nents or ac ces so ry items will

void the man u fac tur er’s war ran ty, and may result in

a haz ard ous condition.

FLUE OPENING SPECIFICATIONS

Note: This vented appliance must be in stalled only in a solid-fuel

burning fi replace with a working fl ue and constructed of non com bus ti ble material.

The charts in Figure 4 indicate technical in for ma tion regarding the

installation of your gas log set. Please make sure that all of the spec i fi ca tions shown are applicable be fore in stal la tion is at tempt ed.

The fi replace must include a working fl ue and venting system with

the minimum open ings shown in the Figure 5.

SPECIFICATIONS (W.C.)

FUEL INLET MANIFOLD

PRESSURE PRESSURE

Min. Max.

NG 7 10.5 3.5

LP 11 14 10

Figure 4 - Technical Information Charts

INSTALLATION AND CLEARANCES

LOG SIZING REQUIREMENTS Min.

Minimum Firebox Size Flue size

Log Front Rear*

Size Height Depth Width Width

18" 17" 14" 24" 20" 8"

24" 17" 14" 28" 22" 8"

*Measured at 14" depth

Figure 5 - Sizes & Clearances

CHECK GAS TYPE

Use the correct gas type (natural or propane/LP) for your unit. If

your gas supply is not correct, do not instal in fi replace. Call dealer

where you bought the appliance for proper type of appliance.

VENTING SPECIFICATIONS FOR

INSTALLATION

The fi replace chimney fl ue and vent must be draft ing properly. To

check the vent for proper drafting: Light a tightly rolled news pa per

on one end and place it at the inside front edge of the fi replace. Observe the smoke and be sure the vent is properly drawing it up the

chimney . If the smoke spills out into the room, extinguish the fl ame

and remove any obstruction until proper venting is achieved.

The chimney fl ue damper must be fi xed open to provide a min i mum

of 43 sq. in. of free air opening during operation of this log set. A multipurpose damper clamp is provided to fi x the damper in position.

The minimum fl ue sizes shown in Figure 5 are based on a 6' chimney

height using round pipe. Your minimum fl ue size will vary based

on input rate and chimney height. Refer to the National Fuel Gas

Code ANSI Z223.1/NFPA 54, Section 6.6, for details.

INSTALLING DAMPER CLAMP

Secure the damper stop clamp provided to the leading edge of the

damper as shown in Figure 6. If for any reason this clamp doesn't

work on your fi replace, an oth er suitable clamp or permanent stop

must be installed, or the damper blade must be cut or removed.

Damper Clamp

Damp er

Masonry Fireplace

Figure 6 - Attaching Damper Clamp

Manufactured

Fireplace

Damper

Damper

Clamp

Damper

111826-02F

For more information, visit www.desatech.com

INSTALLATION

8

Installing Appliance Assembly

Connecting To Gas Supply

INSTALLATION

Continued

INSTALLING APPLIANCE ASSEMBLY

W ARNING: If installing in a sunken fi re place, special care is needed. Y ou must raise the fi re place fl oor

to allow access to appliance control panel. This will

in sure ad e quate air fl ow and guard against soot ing.

Raise fi replace fl oor with noncom bus ti ble ma te ri al.

Make sure material is secure.

CAUTION: Do not pick up appliance as sem bly by

logs. This could damage unit. Only handle assembly

by grates.

IMPORTANT: Make sure the appliance is level. If unit is not lev el,

unit will not work properly.

Installation Items Needed

• control cover kit (provided with appliance)

• approved fl exible gas hose and fi ttings (pro vid ed with appliance)

(if al lowed by lo cal codes)

• sealant (resistant to propane/LP gas, not pro vid ed)

Note: Install optional Hand-Held Remote Control Kit (see Ac ces -

so ries, page 22) before in stall ing gas log appliance (Remote-Ready

Models Only). See installation in struc tions in clud ed with the kit.

1. Apply pipe joint sealant lightly to male threads of gas fi tting

(not provided). Connect ap proved fl exible gas hose to inlet side

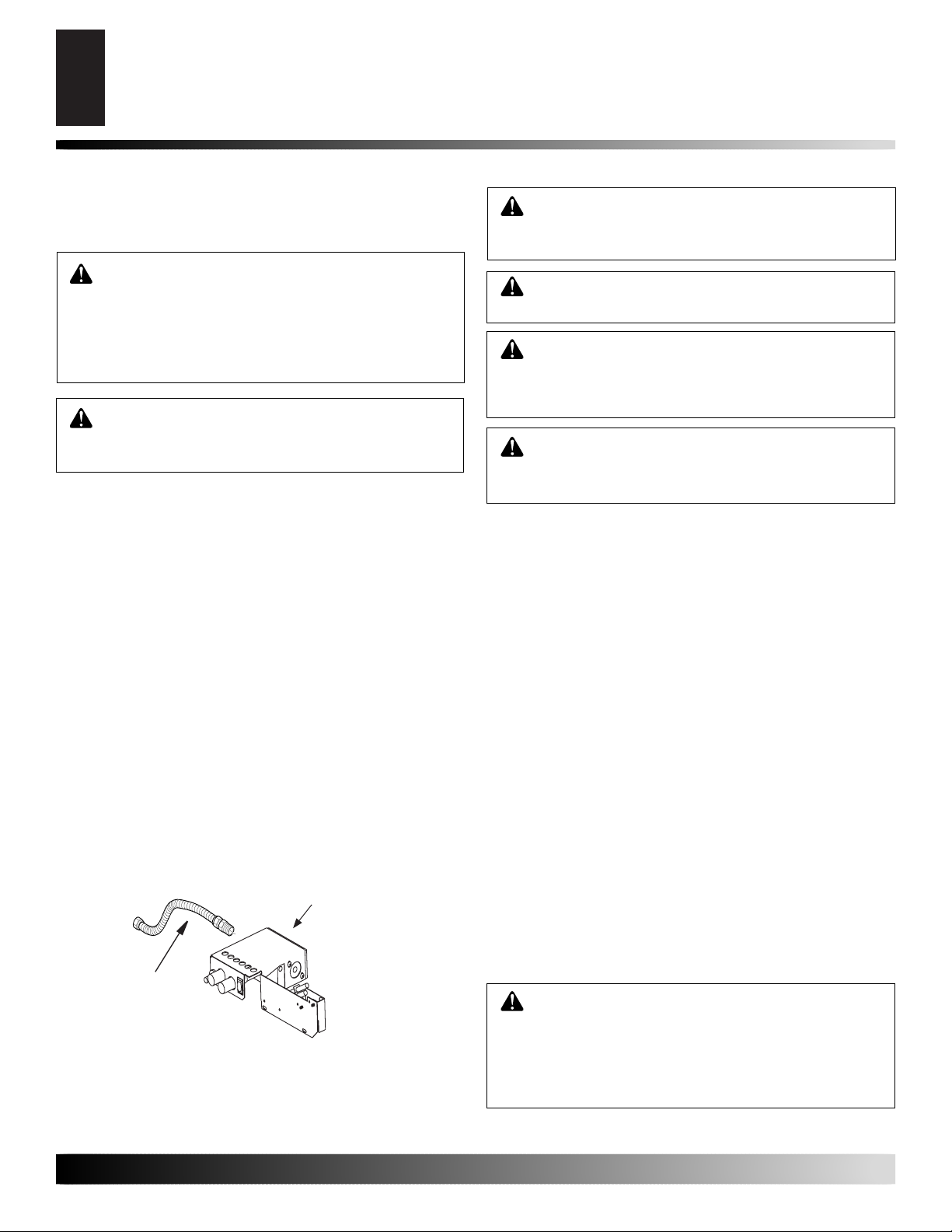

of gas con trol (see Figure 7).

2. Position appliance in fi re place.

3. Connect to gas supply. See Con nect ing To Gas Supply.

Gas Control

Flexible Gas

Hose (if allowed

by local codes)

CONNECTING TO GAS SUPPLY

WARNING: This appliance requires a 3/8" NPT

(National Pipe Thread) inlet connection to the pres sure regulator.

WARNING: A qualifi ed ser vice per son must con nect

appliance to gas sup ply. Follow all local codes.

CAUTION: Never connect propane/LP fi replace

directly to the propane/LP supply. This unit re quires

an external regulator (not supplied). Install the external

regu la tor be tween the unit and propane/LP supply.

W ARNING: Never connect natural gas fi replace to

pri vate (non-utility) gas wells. This gas is com mon ly

known as wellhead gas.

Installation Items Needed

Before installing appliance, make sure you have the items listed

below.

• external regulator (supplied by installer)

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• equipment shutoff valve *

• test gauge connection *

• sediment trap

• tee joint

• pipe wrench

• approved fl exible gas line with gas con nec tor (if allo wed by lo cal

codes) (provided)

* A CSA design-certifi ed equipment shutoff valve with 1/8" NPT

tap is an ac cept able alternative to test gauge con nec tion. Pur chase

the optional CSA design-certifi ed equipment shutoff valve from

your dealer. See Accessories, page 22.

For propane/LP units, the installer must supply an external reg u la tor. The external re g u la tor will reduce incoming gas pressure. You

must reduce in com ing gas pressure to between 11 and 14 inches of

water. If you do not reduce in com ing gas pressure, regulator damage could occur. Install external reg u la tor with the vent point ing

down as shown in Figure 8 page 9. Pointing the vent do wn protects

it from freezing rain or sleet.

CA UTION: Use onl y new, blac k iron or steel pipe.

In ter nal ly-tinned copper tubing may be used in cer tain areas. Check your local codes. Use pipe of 1/2"

di am e ter or greater to allow prop er gas vol ume to

appliance. If pipe is too small, undue loss of volume

will occur.

Figure 7 - Attaching Flexible Gas Hose to Gas Regulator

For more information, visit www.desatech.com

111826-02F

INSTALLATION

Connnecting to Gas Supply (cont.)

Checking Gas Connections

Pressure Testing Gas Supply Piping System

9

9

INSTALLATION

Continued

Installation must include an equipment shutoff valve, union, and

plugged 1/8" NPT tap. Locate NPT tap within reach for test gauge

hook up. NPT tap must be up stream from appliance (see Figure

9).

IMPORTANT: Install equipment shutoff valve in an ac ces si ble

lo ca tion. The equip ment shutoff valve is for turning on or shut ting

off the gas to the appliance.

Apply pipe joint sealant lightly to male NPT threads. This will

prevent excess sealant from going into pipe. Excess sealant in pipe

could result in clogged appliance valves.

W ARNING: Use pipe joint seal ant that is resistant

to liquid pe tro leum (LP) gas.

We recommend that you install a sediment trap in sup ply line as

shown in Figure 9, depending on your model. Locate sed i ment

trap where it is with in reach for cleaning. Install in piping system

between fuel supply and appliance. Locate sed i ment trap where

trapped mat ter is not likely to freeze. A sediment trap traps mois ture and con tam i nants. This keeps them from going into appliance

controls. If sediment trap is not in stalled or is installed wrong, appliance may not run properly.

CSA Design-Certifi ed Equipment

Shutoff Valve With 1/8" NPT Tap*

Approved Flexible

Gas Hose (if allowed

by local codes)

3" Minimum

Gas Control

Pipe Cap Tee

Nipple Joint

Sediment T r ap

Figure 9 - Gas Connection

* Purchase the optional CSA design-cer ti fi ed equipment shutoff valve

from your dealer. See Accessories, page 22.

**Minimum inlet pressure for purpose of input adjustment.

PROPANE/LP

- From External

Regulator

(11" W .C.**

to 14" W.C.

Pressure)

NATURAL

- From Gas

Meter

(5" W .C.**

to 10.5" W.C.

Pressure)

CHECKING GAS CONNECTIONS

CA UTION: Av oid damage to gas control. Hold gas

control with wrench when connecting it to gas piping

and/or fi ttings.

Installation must include an equipment shutoff valve, union, and

plugged 1/8" NPT tap. Locate NPT tap within reach for test gauge

hook up. NPT tap must be up stream from appliance (see Figure

9).

IMPORTANT: Install equipment shutoff valve in an ac ces si ble

lo ca tion. The equip ment shutoff valve is for turning on or shut ting

off the gas to the appliance.

Apply pipe joint sealant lightly to male NPT threads. This will

prevent excess sealant from going into pipe. Excess sealant in pipe

could result in clogged appliance valves.

External Regulator

Propane/LP

Supply T ank

Vent Pointing Down

Figure 8 - External Regulator With Vent Pointing Down

WARNING: Test all gas pip ing and connections

for leaks after in stall ing or serv ic ing. Cor rect all leaks

at once.

W ARNING: Ne ver use an open fl ame to check for

a leak. Apply a noncorrosive leak detection fl u id to

all joints. Bub bles form ing show a leak. Correct all

leaks at once.

CAUTION: Make sure ex ter nal regulator has been

installed between propane/LP supply and appliance.

See guidelines under Con nect ing to Gas Sup ply, page

8.

Pressure Testing gas Supply Piping system

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1. Dis con nec t appliance with its appliance main gas v alve (control

valve) and equip ment shutoff valve from gas sup ply pip ing

sys tem. Pres sures in ex cess of 1/2 psig will dam age appliance

reg u la tor.

2. Cap off open end of gas pipe where equip ment shutoff valve

was con nect ed.

3. Pressurize supply pip ing sys tem by ei ther opening pro pane/LP

sup ply tank valve for propane/LP gas or opening main gas valve

lo cat ed on or near gas meter for natural gas, or using com pressed

air.

111826-02F

For more information, visit www.desatech.com

10

ON

INSTALLATION

Pressure Testing Gas Supply Piping System (Cont.)

Pressure Testing Appliance Gas Connections

INSTALLATION

Continued

4. Check all joints of gas supply pip ing system. Apply non cor ro sive

leak detection fl u id to all joints. Bubbles form ing show a leak.

5. Correct all leaks at once.

6. Reconnect appliance and equipment shutoff valve to gas supply .

Check re con nect ed fi ttings for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Fig ure 10).

2. Pressurize supply pip ing sys tem by ei ther opening pro pane/LP

sup ply tank valve for propane/LP gas or opening main gas valve

lo cat ed on or near gas meter for natural gas, or using com pressed

air.

3. Check all joints from gas meter to equip ment shutoff valve for

natural gas or pro pane/LP sup ply to equip ment shutoff valve for

propane/LP (see Figure 11). Ap ply non cor ro sive leak detection

fl u id to all joints. Bub bles form ing show a leak.

4. Correct all leaks at once.

Pressure Testing Appliance Gas Connections

1. Open equipment shutoff valve (see Fig ure 10).

2. Open main gas valve located on or near gas meter for natural

gas or open pro pane/LP supply tank valve.

3. Make sure control knob of appliance is in the OFF position.

4. Check all joints from equipment shutoff valve to gas control

(see Fig ures 11 and 12). Ap ply non cor ro sive leak de tec tion

fl u id to all joints. Bub bles form ing show a leak.

5. Correct all leaks at once.

6. Light appliance (see Operating Appliance, pages 11 through

13). Check all other internal joints for leaks.

7. Turn off appliance.

Equipment

Propane/LP

Supply T ank

Figure 11- Checking Gas Joints (propane/LP only)

Gas Meter

Shutoff Valv e

Equipment

Shutoff Valv e

Control Valv e Location

Control Valv e Location

Equipment

Shutoff

Valve

Figure 10 - Equipment Shutoff Valve

Open

POSITION

Figure 12 - Checking Gas Joints (Natural Gas Only)

Closed

OFF

POSITION

For more information, visit www.desatech.com

111826-02F

OPERATING APPLIANCE (REMOTE-READY MODELS)

Flame Adjustment Knob

For Your Safety Read Before Lighting

Lighting Instructions

11

11

OPERATING APPLIANCE

REMOTE-READY MODELS

FOR YOUR SAFETY READ

BEFORE LIGHTING

WARNING: Keep fl ue open when operating unit.

W ARNING: If y ou do not fol low these instructions

exactly, a fi re or ex plo sion may result caus ing prop er ty

damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pi lot, fol low these instructions ex act ly.

B. BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the fl oor be cause some gas

is heavier than air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

your build ing.

• Immediately call your gas sup pli er from a neighbor’s

phone. Follow the gas sup pli er’s instructions.

• If you cannot reach your gas sup pli er, call the fi re de part ment.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

don’t try to repair it, call a qualifi ed service tech ni cian or

gas supplier . F orce or attempted r epair may result in a fi re

or ex plo sion.

D. Do not use this appliance if any part has been under water .

Immediately call a qualifi ed service technician to inspect

the appliance and to replace any part of the control system

and any gas control which has been un der water.

LIGHTING INSTRUCTIONS

NOTICE: During initial operation of new appliance,

metallic components may emit an odor as paint and

assembly compounds are heated and cure. Be sure

to provide adequate fresh air if odors are detected.

W ARNING: Damper handle will be hot if appliance

has been running.

CAUTION: A mild gas fl ash may occur within 10

seconds of normal shutdown of this appliance. Remain clear of the hearth area for the entire shutdown

process to avoid possible injury.

Selector Switch in

O

N

OFF Position

O

L

H

I

AUTO

OFF

ON

Control Knob

T

O

L

I

P

F

F

O

Ignitor Button

Figure 13 - Control Knob and Ignitor Button Location,

Remote Ready Units.

1. STOP! Read the safety information, starting in column 1,

of this page.

2. Make sure equipment shutoff valve is ful ly open.

3. Set selector switch in the OFF po si tion.

4. Press in and turn control knob clock wise to the

OFF position (see Figure 13).

WARNING: Burners will come on automatically

within one minute when the selector switch is in the

ON position after the pilot is lit.

5. Wait fi ve (5) minutes to clear out any gas. Then smell for

gas, in clud ing near the fl oor . If y ou smell gas, STOP! Fol low

“B” in the safety information, starting in column 1 of this

page. If you don’t smell gas, go to the next step.

6. Press in and turn control knob coun ter clock wise

to the PILOT po si tion. Press in control knob for fi ve (5)

seconds (see Figure 13).

Note: You may be running this appliance for the fi rst time

after hook ing up to gas supply. If so, the con trol knob may

need to be pressed in for 30 sec onds or more. This will allow

air to bleed from the gas system.

7. With control knob pr essed in, press and release ignitor b utton. This will light pilot. The pilot is attached to the front

burner. If needed, keep press ing ig ni tor button until pilot

lights.

Note: If pilot does not stay lit, con tact a qualifi ed service

person or gas sup pli er for repairs. Until repairs are made,

light pilot with match. T o light pilot with match, see Man u al

Light ing Procedure, page 12.

8. Keep contr ol knob pressed in for 30 seconds after lighting

pilot. After 30 seconds, release control knob.

• If control knob does not pop out when released, contact

a qualifi ed ser vice person or gas supplier for re pairs.

Note: If pilot goes out, repeat steps 4 through 8.

111826-02F

For more information, visit www.desatech.com

12

Selector Switch in

OPERATING APPLIANCE (REMOTE-READY MODELS)

Lighting Instructions (Cont.)

Remote Control Operations

OPERATING APPLIANCE

Continued

9. Slightly push in and turn control knob counterclockwise

to the ON position.

10. Wait one minute and switch selector switch to the ON po-

si tion to light burners. Note: AUTO is not func tion al.

11. Set fl ame adjustment knob to any lev el be tween HI and

LO.

CAUTION: Do not try to ad just heating levels by

using the equipment shutoff valve.

W ARNING: Make sure the selector switch is in the

OFF po si tion when you are away fr om home for long

periods of time. Appliance will come on au to mat i cal ly

with selector switch in the ON position.

Ignitor

Electrode

Pilot

Burner

Ignitor

Electrode

Pilot

Burner

MANUAL LIGHTING PROCEDURE

1. Fol low steps 1 through 6 under Light ing In struc tions.

2. Depress control knob and light pilot with match.

3. Keep contr ol knob pressed in for 30 seconds after lighting

pilot. After 30 seconds, release control knob. Now follow

steps 9 through 11, Lighting In struc tions, column 1.

REMOTE CONTROL OPERATION

Remote Control Operation

GHRC Series Operation:

1. After lighting, let pilot fl ame burn for about one minute.

T urn control knob to ON position. Adjust fl ame ad just ment

knob anywhere between HI and LO. Slide the se lec tor

switch to the RE MOTE po si tion. Note: The burn ers may

light if hand-held re mote ON button was on when se lec tor

switch was last turned off. You can now turn the burn ers

on and off with the hand-held re mote con trol unit.

IMPORTANT: Do not leave the se lec tor switch in the RE-

MOTE or ON position when the pilot is not lit. This will

drain the battery.

2. Press the ON/OFF button to turn the burners on and off.

When turning burners off, the pilot will remain lit.

Figure 14 - Pilot (Propane/LP)

Pilot (Natural)

TO TURN OFF GAS TO APPLIANCE

Shutting Off Appliance

1. Turn control knob clockwise to the OFF po si tion.

2a. Set selector switch in the OFF po si tion.

2b. If Using Optional Hand-Held Re mote: Set selector switch

in the OFF po si tion to pre vent drain ing battery.

Shutting Off Burner Only (pilot stays lit)

You may shut off the burners and keep the pilot lit by doing

one of the fol low ing:

1. Turn control knob clockwise

si tion.

2. Use remote control manual OFF button.

3. Set selector switch in the OFF po si tion.

to the PILOT po-

IMPORTANT: Be sure to press the ON/OFF buttons on the

hand-held remote control unit for up to 3 sec onds to assure

proper operation.

Note: All additional re mote control accessories must be pur-

chased sep a rate ly (see Ac ces so ries, page 22). Fol low instructions

included with the re mote control.

Control Knob

F

F

O

Ignitor Button

Remote Control

Figure 15- Setting the Selector switch, Contr ol Knob, and Flame

Adjustment Knob for Remote Operation

OFF Position

T

O

L

I

O

P

N

O

L

H

I

Flame Adjustment Knob

AUTO

OFF

ON

Selector T oggle Switch

REMOTE OFF ON

For more information, visit www.desatech.com

111826-02F

OPERATING APPLIANCE (REMOTE-READY MODELS)

Lighting Instructions (Cont.

Remote Controlled Operation (Cont.)

Cleaning And Maintenance)

13

13

OPERATING APPLIANCE

Continued

INSPECTING BURNER

Check pilot fl ame pattern and burner fl ame patterns often.

PILOT FLAME PATTERN

Figure 16 shows a correct pilot fl ame pat tern. Figure 17 shows an

incorrect pilot fl ame pattern. The incorrect pilot fl ame is not touch ing

the thermo couple. This will cause the thermo couple to cool. When

the thermo couple cools, the appliance will shut down.

If pilot fl ame pattern is incorrect, as shown in Figure 17

• turn appliance off (see To Turn Off Gas to Appliance, page 12

• see Troubleshooting, pages 14 through 16

Note: The pilot fl ame on natural gas units will have a slight curv e,

but fl ame should be blue and have no yellow or orange color.

Pilot Burner

Pilot Burner

BURNER FLAME PATTERN

Figure 18 shows correct burner fl ame pattern.

NOTICE: Do not mistake orange fl ames with yellow

tipping. Dirt or other fi ne particles are burned b y appliance, causing brief patches of orange fl ame.

If burner fl ame pattern is incorrect, as shown in Figure 19

• turn appliance off (see To Turn Off Gas to Appliance, page 12

• see Troubleshooting, pages 14 through 16

Figure 18 - Correct Burner Flame Pattern

Thermocouple

Figure 16 - Correct Pilot Flame Pattern (Your pilot may vary

from pilots shown)

Pilot Burner

Pilot Burner

Thermocouple

Figure 17 - Incorrect Pilot Flame Pattern (Your pilot may vary

from pilots shown)

Thermocouple

Thermocouple

Yellow Tipping At Top

of Blue Flame

Figure 19 - Incorrect Burner Flame Pattern

CLEANING AND MAINTENANCE

• Keep the area around the log set clean and clear of debris.

• Periodically inspect the air mixer and burner tube for foreign

matter blocking the air inlet and fl ame holes.

• Once every year a qualifi ed agency or certifi ed chimney sweep

should ex am ine and clean the venting system of the fi re place.

111826-02F

For more information, visit www.desatech.com

14

TROUBLESHOOTING

TROUBLESHOOTING

Note: For additional help, visit DESA

In ter na tion al’s technical service web

site at www.desatech.com.

Note: All troubleshooting items are listed

in order of operation.

OBSERVED PROBLEM

When ignitor button is pressed, there is no

spark at ODS/pilot

When ignitor button is pressed, there is spark

at ODS/pilot but no ig ni tion

WARNING: Turn off and un-

plug appliance and let cool before

servicing. Only a qualifi ed ser vice

person should service and repair

heater.

POSSIBLE CAUSE

1. Ignitor electrode not con nect ed to ig ni tor

ca ble

2. Ignitor cable pinched or wet

3. Piezo ignitor nut is loose

4. Broken ignitor cable

5. Bad piezo ignitor

6. Ig ni tor electrode po si tioned wrong or

broken

1. Gas supply turned off or equipment

shutoff valve closed

2. Control knob not in PI LOT po si tion

3. Control knob not pressed in while in

PI LOT po si tion

4. Air in gas lines when in stalled

5. Depleted gas supply (propane/LP

only)

6. ODS/pilot is clogged

7. Gas regulator setting is not correct

CAUTION: Never use a wire,

needle, or similar object to clean

ODS/pilot. This can damage ODS/

pilot unit.

REMEDY

1. Reconnect ignitor cable

2. Free ignitor cable if pinched by any

metal or tubing. Keep ignitor ca ble dry

3. Tighten nut holding pi ezo ignitor to base

panel of log set. Nut is located behind

base panel.

4. Replace ignitor cable

5. Replace piezo ignitor

6. Replace pilot assembly for remote-ready

units; Replace ignitor electrode for vari able manually controlled units

1. Turn on gas supply or open equipment

shutoff valve

2. Turn control knob to PI LOT position

3. Press in control knob while in PI LOT

po si tion

4. Continue holding down control knob.

Repeat ig nit ing op er a tion until air is

re moved

5. Contact local propane/LP gas com pany

6. Clean ODS/pilot (see Cleaning and

Main te nance, page 13) or re place

ODS/pilot as sem bly

7. Replace gas regulator

ODS/pilot lights but fl ame goes out when

control knob is released

For more information, visit www.desatech.com

1. Control knob not fully pressed in

2. Control knob not pressed in long

enough

3. Safety interlock system has been

trig gered

4. Equipment shutoff valve not fully open

5. Pilot fl ame not touch ing ther mo cou ple,

which al lows ther mo cou ple to cool,

caus ing pilot fl ame to go out. This prob lem could be caused by one or both of

the fol low ing:

A) Low gas pressure

B) Dirty or partially clogged ODS/

pilot

6. Ther mo cou ple con nec tion loose at con trol valve

1. Press in control knob fully

2. After ODS/pilot lights, keep control

knob pressed in 30 sec onds

3. Wait one minute for safety in ter lock sys tem to reset. Repeat ignition operation

4. Fully open equipment shutoff valve

5. A) Contact local natural or pro pane/LP

gas company

B) Clean ODS/pilot (see Cleaning and

Main te nance, page 13) or replace ODS/

pilot assembly

6. Hand tighten until snug, then tighten

1/4 turn more

7. Replace pilot assembly

8. Replace control valve

111826-02F

TROUBLESHOOTING

Continued

TROUBLESHOOTING

15

15

OBSERVED PROBLEM

One or both burner does not light after

ODS/pilot is lit

Delayed ignition of burner

Burner backfi ring dur ing com bus tion

POSSIBLE CAUSE

1. Inlet gas pressure is too low

2. Burner orifi ce(s) clogged

3. Mislocated crossover tube

4. Burner orifi ce(s) di ame ter is too small

5. Remote selector in OFF position (Re mote-Ready Models Only)

6. Wire disconnected from gas control

(Re mote-Ready Models Only)

1. Manifold pressure is too low

2. Burner orifi ce(s) clogged

3. Mislocated crossover tube

1. Burner orifi ce is clogged or damaged

2. Damaged burner

3. Gas regulator defective

REMEDY

1. Contact local natural or pro pane/LP gas

company

2. Clean burner(s) (see Cleaning and

Main te nance, page 13) or re place burner

orifi ce(s)

3. Contact qualifi ed service person

4. Replace burner orifi ce(s)

5. Put remote selector in ON position

6. See Wiring Diagram, page 18

1. Contact local natural or pro pane/LP gas

company

2. Clean burner(s) (see Cleaning and

Main te nance, page 13) or replace burner

orifi ce(s)

3. Contact qualifi ed service person

1. Clean burner (see Cleaning and Main-

te nance, page 13) or replace burner

ori fi ce

2. Replace damaged burner

3. Replace gas regulator

Orange flame in burner during burner

com bus tion

Slight smoke or odor during initial op er a tion

Appliance produces a whis tling noise when

burners are lit

White powder residue forming within burn er

box or on adjacent walls or furniture

Moisture/con den sa tion no ticed on win dows

1. Not enough air

2. Gas regulator defective

1. Residues from manu fac tur ing pro cess es

and logs curing

1. Turning control knob to HI po si tion

when burners are cold

2. Air in gas line

3. Air passageways on appliance blocked

4. Dirty or partially clogged burner

orifi ce(s)

1. When heated, vapors from furniture pol ish, wax, carpet cleaners, etc. turn into

white powder residue

1. Not enough com bus tion/ven ti la tion air

1. Check burner(s) for dirt and debris. If

found, clean burner(s) (see Cleaning and

Main te nance, page 13)

2. Replace gas regulator

1. Problem will stop after a few hours of

operation

1. Turn control knob to LO position and let

warm up for a minute

2. Operate burners until air is re moved

from line. Have gas line checked by lo cal nat u ral or propane/LP gas com pany

3. Observe minimum in stal la tion clear anc es (see pages 7 through 8)

4. Clean burners (see Cleaning and Main-

te nance, page 13) or replace burner

orifi ce(s)

1. Turn appliance off when using furniture

polish, wax, carpet cleaners, or similar

products

1. Refer to Air for Com bus tion and Ven ti -

la tion re quire ments (page 4)

111826-02F

For more information, visit www.desatech.com

16

TROUBLESHOOTING

TROUBLESHOOTING

Continued

WARNING: If you smell gas

• Shut off gas supply.

• Do not try to light any ap pli ance.

• Do not touch any elec tri cal switch; do not use any phone in your

build ing.

• Immediately call your gas sup plier from a neighbor’s phone. Follow

the gas sup pli er’s in struc tions.

• If you cannot reach your gas sup plier, call the fi re de part ment.

IMPORTANT: Operating appliance where impurities in air exist may create odors. Cleaning

supplies, paint, paint remover , cigarette smoke, cements and glues, new carpet or textiles,

etc., create fumes. These fumes may mix with combustion air and create odors. These

odors will disappear over time.

OBSERVED PROBLEM

Remote does not function (Remote-Ready

Models Only)

Appliance produces a click ing/tick ing noise

just after burners are lit or shut off

Appliance produces un wanted odors

Appliance shuts off in use (ODS operates)

Gas odor even when control knob is in OFF

position

POSSIBLE CAUSE

1. Battery is not installed. Battery power is

low

1. Metal expanding while heating or con tract ing while cooling

1. Appliance burning vapors from paint,

hair spray, glues, cleaners, chem i cals,

new carpet, etc. (See IM POR TANT

state ment above)

2. Low fuel supply (propane/LP only)

3. Gas leak. See W arn ing statement at

top of page

1. Not enough fresh air is available

2. Low line pressure

3. ODS/pilot is partially clogged

1. Gas leak. See W arn ing statement at

top of page

2. Control valve or gas control defective

REMEDY

1. Replace 9-volt batteries in receiver and

remote control

1. This is common with most appliances. If

noise is excessive, contact quali fi ed ser vice

per son

1. Open window to ventilate room. Stop us ing

odor causing prod ucts while appliance is

running

2. Refi ll supply tank (propane/LP only)

3. Locate and correct all leaks (see Check ing

Gas Con nec tions, page 9)

1. Open window and/or door for ven ti la tion

2. Contact local natural or pro pane/LP gas

company

3. Clean ODS/pilot (see Cleaning and Main-

te nance, page 13)

1. Locate and correct all leaks (see Check ing

Gas Con nec tions, page 9)

2. Replace control valve or gas control

Gas odor during combustion

1. Foreign matter be tween con trol valve and

burner

2. Gas leak. See W arn ing statement at

top of page

1. T ak e apart gas tubing and remo ve for eign

mat ter

2. Locate and correct all leaks (see Check ing

Gas Con nec tions, page 9)

For more information, visit www.desatech.com

111826-02F

SPECIFICATIONS

VTD-18N-PDG/VTD-18N-BTB VTD-24N-PDG/VTD-24N-BTB

Btu (Variable) 37,000/54,000 41,000/58,000

Type Gas Natural Gas Only Natural Gas Only

Ignition Piezo Piezo

Manifold Pressure 3.5" W.C. 3.5" W.C.

Inlet Gas Pressure (in. of water)

Maximum 10.5" W.C. 10.5" W.C.

Minimum* 5.0" W.C. 5.0" W.C.

Shipping Weight 32 lbs. 34 lbs.

* For purpose of input adjustment

SPECIFICATIONS

17

17

VTD-18P-PDG/VTD-18P-BTB VTD-24P-PDG/VTD-24P-BTB

Btu (Variable) 30,000/46,000 41,000/58,000

Type Gas Propane/LP Only Propane/LP Only

Ignition Piezo Piezo

Manifold Pressure 10" W.C. 10" W.C.

Inlet Gas Pressure (in. of water)

Maximum 14" W.C. 14" W.C.

Minimum* 11" W.C. 11" W.C.

Shipping Weight 32 lbs. 34 lbs.

* For purpose of input adjustment

111826-02F

For more information, visit www.desatech.com

18

WIRING DIAGRAM (REMOTE-READY MODELS ONLY)

SERVICE HINTS

TECHNICAL SERVICE

REPLACEMENT PARTS

WIRING DIAGRAM

(Remote-Ready Models Only)

REPLACEMENT PARTS

Note: Use only original replacement parts. This will protect your

warranty cov er age for parts replaced under warranty.

AUTO

OFF

ON

Thermopile

SERVICE HINTS

When Gas Pressure Is Too Low

• pilot will not stay lit

• burners will have delayed ig ni tion

• propane/LP gas supply may be low

You may feel your gas pressure is too low. If so, contact your local

propane/LP or natural gas supplier.

TECHNICAL SERVICE

You may have further questions about in stal la tion, operation, or

troubleshooting. If so, contact DESA International’s Tech ni cal

Service Department at 1-866-672-6040. When calling please have

your model and serial numbers of your appliance ready.

Y ou can also visit DESA International’ s tech ni cal services web site

at www.desatech.com.

PARTS UNDER WARRANTY

Contact authorized dealers of this product. If they can’t supply

original re place ment part(s), call DESA In ter na tion al’s Tech ni cal

Service Department at 1-866-672-6040.

When calling DESA International, have ready

• your name

• your address

• model and serial numbers of your appliance

• how appliance was malfunctioning

• type of gas used (propane/LP or nat u ral gas)

• purchase date

Usually, we will ask you to return the part to the factory.

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product. If they can’t supply original

re place ment part(s), call DESA International at 1-866-672-6040 for

re fer ral in for ma tion.

When calling DESA International, have ready

• model number of your appliance

• the replacement part number

For more information, visit www.desatech.com

111826-02F

THIS PAGE INTENTIONALLY LEFT BLANK

19

19

111826-02F

For more information, visit www.desatech.com

20

ILLUSTRATED PARTS BREAKDOWN

VTD-24N-PDG, VTD-24P-PDG, VTD-24N-BTB, VTD-24P-BTB

VTD-18N-PDG, VTD-18P-PDG, VTD-18N-BTB, VTD-18P-BTB

ILLUSTRATED PARTS

BREAKDOWN

REMOTE-READY MODELS AND

REMOTE CONTROLLED MODELS

VTD-24N-PDG VTD-24N-BTB

VTD-24P-PDG VTD-24P-BTB

VTD-18N-PDG VTD-18N-BTB

VTD-18P-PDG VTD-18P-BTB

ITEM #5 (AIR SHUTTER) INSTALLATION

NOTES:

FOR NG---FULLY CLOSED

FOR LP----FULLY OPEN

3

Log sets and

mounting

plates are

ordered as an

assembly

GTA Replacement Part Numbers

Model Number GTA Part number

VTD-24N-PDG

VTD-24N-BTB

VTD-24P-PDG

VTD-24P-BTB

VTD-18N-PDG

VTD-18N-BTB

REMOTE MODELS ONLY

VTD-18P-PDG

VTD-18P-BTB

For more information, visit www.desatech.com

111794 01

111794 05

111794 03

111794 04

111826-02F

VTD-24N-PDG, VTD-24P-PDG, VTD-24N-BTB, VTD-24P-BTB,

VTD-18N-PDG, VTD-18P-PDG, VTD-18N-BTB, VTD-18P-BTB

PARTS LIST

This list contains replaceable parts used in your appliance. When

ordering parts, follow the instructions listed under Replacement

Parts on page 18 of this manual.

PART NUMBER FOR

VTD-18N-PDG VTD-18P-PDG VTD-18N-BTB VTD-18P-BTB VTD-24N-PDG VTD-24P-PDG VTD-24N-BTB VTD-24P-BTB

PARTS LIST

21

21

DESCRIPTION QTY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

111808-01

see table

page 20

112789-01

111800-01

111372-02

112370-01

112371-03

111807-01

111796-01

097159-04

103784-01

103784-02

099998-01

------

------

111817-02

111828-01

112376-01

111796-02

111816-01

111808-01

see table

page 20

112789-01

111800-01

111372-02

112370-01

112371-04

111807-02

111796-01

097159-04

103784-01

103784-02

099998-01

------

------

111817-02

111828-01

103778-01

111796-02

111816-01

111808-01

see table

page 20

112790-01

111800-01

111372-02

112370-01

112371-03

111807-01

111796-01

097159-04

103784-01

103784-02

099998-01

112806-01

112806-02

111817-02

111828-01

112376-01

111796-02

111816-01

111808-01

see table

page 20

112790-01

111800-01

111372-02

112370-01

112371-04

111807-02

111796-01

097159-04

103784-01

103784-02

099998-01

112806-01

112806-02

111817-02

111828-01

103778-01

111796-02

111816-01

11793-01

see table

page 20

112359-01

111800-01

111372-01

112370-01

112371-01

111807-01

111796-01

097159-04

103784-01

103784-02

099998-01

------

------

111817-02

111828-01

112376-01

111796-02

111816-01

111793-01

see table

page 20

112359-01

111800-01

111372-01

112370-01

112371-02

111807-02

111796-01

097159-04

103784-01

103784-02

099998-01

------

------

111817-02

111828-01

103778-01

111796-02

111816-01

111793-01

see table

page 20

112360-01

111800-01

111372-01

112370-01

112371-01

111807-01

111796-01

097159-04

103784-01

103784-02

099998-01

112806-01

112806-02

111817-02

111828-01

112376-01

111796-02

111816-01

111793-01

see table

page 20

112360-01

111800-01

111372-01

112370-01

112371-02

111807-02

111796-01

097159-04

103784-01

103784-02

099998-01

112806-01

112806-02

111817-02

111828-01

103778-01

111796-02

111816-01

GRATE ASSEMBLY

GTA (Gas Train Assembly)

LOG ASSEMBLY

SCREW

VENTURI/SHUTTER ASSY.

GASKET

ORIFICE

VALV E

BRACKET-VALVE

PIEZO IGNITOR

CONTROL KNOB EXT.

CONTROL KNOB EXT.

SWITCH

REMOTE CONTROL ASSY.

BRACKET-RECIEVER

FLEXTUBE 3/16

COMPRESSION NUT/

SLEEVE

PILOT

SHIELD-PILOT

SCREW

1

1

1

10-PDG/

14-BTB

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

111826-02F

100563-01

103877-01

100639-01

GA6060

111288-02

------

112363-01

112364-01

100563-01

103877-01

100639-01

GA6060

111288-02

------

112363-01

112364-01

PARTS AVAILABLE NOT SHOWN

100563-01

103877-01

100639-01

GA6060

111288-02

111836-01

112363-01

112364-01

100563-01

103877-01

100639-01

GA6060

111288-02

111836-01

112363-01

112364-01

00563-01

103877-01

100639-01

GA6060

111288-02

------

112363-01

112364-01

100563-01

103877-01

100639-01

GA6060

111288-02

------

112363-01

112364-01

100563-01

103877-01

100639-01

GA6060

111288-02

111836-01

112363-01

112364-01

For more information, visit www.desatech.com

100563-01

103877-01

100639-01

GA6060

111288-02

111836-01

112363-01

112364-01

WARNING PLATE

LIGHTING INSTRUCTION

CAUTION DECAL

LAVA ROCK

GAS LINE FLEX 18

BATTERY

LOG SCRAP KIT#1

LOG SCRAP KIT#2

1

1

1

1

1

2

1

1

22

ACCESSORIES

ACCESSORIES

Purchase these appliance accessories from your local dealer. If they

can not supply these accessories, call DESA International at 1-866672-6040 for referral information. Y ou can also write to the ad dress

listed on the back page of this manual.

EQUIPMENT SHUTOFF VALVE - GA5010

For all models. Equipment shutoff valve with 1/8" NPT tap. Fits

1/2" NPT pipe.

CLEANING KIT - GCK

(Not Shown)

For all models. Y our vented gas appliance requires reg u lar cleaning

and main te nance to prevent performance problems. This kit gives

you the tools and instructions to make it easy to clean all critical

areas of your appliance.

INFORMATION VIDEO - 108917-01

For all models. A care and maintenance video is a vailable by calling 1-866-672-6040.

FIREPLACE HOOD

Black - GA6050

Brass - GA6052

Antique Brass - GA6053

For all models. Helps defl ect heat away from mantel or wall above

fi replace. Fits openings 28" to 48" wide.

RECEIVER AND HAND-HELD REMOTE

CONTROL KIT - GHRC

For all Remote-Ready Mod els. Al lows the gas log appliance to be

turned on and off by using a hand-held remote control.

For all models.

DAMPER CLAMP - GA6080

(Not Shown)

For Remote-Ready and V ariable Manually-Controlled Models.

Per ma nent ly opens chim ney fl ue damper for vent ed operation.

LAVA ROCK - GA6060

(Not Shown)

For all models. Order when additional rock is desired. (1.8 lb.

bag)

For more information, visit www.desatech.com

111826-02F

y

OWNER'S REGISTRATION FORM

In order to provide better customer service for this and future purchases, we recommend that you register your product with us.

• ACCESSORIES

You can register online at www.desatech.com. If access to our website is not available to you, please complete this Owner’s

Registration Form and mail to the address on the back of this owner’s manual. Please provide the following product information:

Brand:

Model:

Date Purchased:

Serial Number:

(Comfort Glow, Vanguard, etc.)

(EFP33PR, VTGH33NR, etc.)

Note:

Keep receipt for warranty verification.

7 or 9 digit number located on product or identification tag.

First Name: Last Name:

Address:

City: State: Zip: Country:

Home Phone: ( ) -

E-Mail:

Please answer the following questions to register your product with DESA:

1. Where will the product be used?

❍ Living/Family Room ❍ Office/Warehouse ❍ Utility Shed/Outbuilding ❍ Garage ❍ Bedroom ❍ Bathroom ❍ Other

2. If you bought this product yourself, did you plan to purchase this type of product before going into the store? ❍ Yes ❍ No

3. Who selected the product? ❍ Male ❍ Female ❍ Both

4. What is the population of your area? ❍ Under 10,000 ❍ 10,000 to 25,000 ❍ 25,000 to 50,000 ❍ 50,000 to 100,000

❍ 100,000 to 250,000 ❍ Over 250,000

5. What is your primary source of heat? ❍ Propane (LP Gas) ❍ Fuel Oil ❍ Wood ❍ Natural Gas ❍ Electric ❍ Other

6. How was the product installed? ❍ Professional Installer ❍ Self ❍ Other

7. Cost of product excluding sales tax? $___________________

8. Cost to install product? $____________________

9. Type of store where product was purchased? ❍ Hardware ❍ Propane Dealer ❍ Natural Gas/Utility Co. ❍ Home Center/Builder’s Suppl

❍ Fireplace or Hearth Shop ❍ Farm Store ❍ Other

10. What motivated you to buy this product? ❍ Sudden Cold Weather ❍ Replace Older Model ❍ D.I.Y. Home Project

❍ Emergency Back-Up Heat ❍ Heater was on Sale ❍ Energy Savings/High Efficiency ❍ Construction Project ❍ Other

11. How did you learn about this product brand? ❍ Advertising ❍ Relative or Friend ❍ Store Display ❍ Other ________________________

12. Level of Education of Purchaser: ❍ Some High School ❍ Completed High School ❍ Completed College ❍ Completed Graduate School

13. Age of Purchaser: ❍ Under 20 ❍ 20 - 29 ❍ 30 - 39 ❍ 40 - 49 ❍ 50 - 59 ❍ 60 or Over

14. Buyer’s total annual household income: ❍ Under $15,000 ❍ $15,000 to $19,999 ❍ $20,000 to $34,999 ❍ $35,000 to $49,999

❍ $50,000 to $74,999 ❍ $75,000 to $99,999 ❍ $100,000 and Over

15. Store where product was purchased:

Name: ______________________________________

City: _______________________ State: __________

16. In choosing this product, how important were the following:

Availability

Price

Brand Name

Overall Quality

Heat Output

Made in USA

Warranty

Local Service

Value for Price

Prior Brand Experience

Controls Location

Thermostat, Remote, or Manual Operation

Ease of Operation

Special Features

Salesperson’s Recommendation

Friend/Relative’s Recommendation

Portability

Quiet Operation

111826-02F

For more information, visit www.desatech.com

Not Important Somewhat Important Very Important

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

23

23

24

2701 S. Harbor Blvd.

Santa Ana, CA. 92704

www.desatech.com

Post age

Required

TM

For more information, visit www.desatech.com

111826-02F

NOTES

25

25

NOTES

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

For more information, visit www.desatech.com

111826-02F

26

WARRANTY INFORMATION

KEEP THIS WARRANTY

Model

Serial No.

Date Purchased

Always specify model and serial numbers when communicating with the factory.

W e reserve the right to amend these specifi cations at any time without notice. The only w arranty applicable is our standard written warranty. We

make no other warranty, expressed or implied.

LIMITED WARRANTY

VENT-FREE GAS LOG APPLIANCES

DESA International warrants this product to be free from defects in materials and components for four (4) years and fi ve (5) years on stainless

steel burners from the date of fi rst purchase, provided that the product has been properly installed, operated and maintained in ac cor dance with all

applicable instructions. To make a claim under this war ranty the Bill of Sale or cancelled check must be presented.

This warranty is extended only to the original retail purchaser. This warranty covers the cost of part(s) required to restore this appliance to proper

op er at ing condition and an allowance for labor when provided by a DESA Authorized Service Center. Warranty part(s) MUST be obtained through

authorized deal ers of this product and/or DESA International who will provide original fac tory replacement parts. Failure to use orig i nal factory

replacement parts voids this warranty. The appliance MUST be installed by a qualifi ed installer in accordance with all local codes and instructions

fur nished with the unit.

This warranty does not apply to parts that are not in original condition be cause of normal wear and tear, or parts that fail or become damaged as a

result of misuse, accidents, lack of proper maintenance or defects caused by improper in stal la tion. Travel, diagnostic cost, labor , transportation and

any and all such other costs related to repairing a defective appliance will be the responsibility of the owner.