Desa VT36EP User Manual

DIRECT-VENT FIREPLACE

OWNER’S OPERATION AND

TM

INSTALLATION MANUAL

For more information, visit www.desatech.com

For more information, visit www.desatech.com

NATURAL GAS “TUDOR” MODEL (V)T32EN, (V)T36EN SERIES

PROP ANE/LP GAS “TUDOR” MODEL (V)T32EP, (V)T36EP SERIES

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire

department.

WARNING: Improper installation, adjustment, alteration, service, or maintenance can cause injury or property

damage. Refer to this manual for correct installation and operational procedures. For assistance or additional information consult a qualified installer,

service agency, or the gas supplier.

— Installation and service must be

performed by a qualified installer,

service agency, or the gas supplier.

— This appliance is only for use with

the type of gas indicated on the rating

plate. This appliance is not convertible

for use with other gases, unless a

certified kit is used.

This appliance may be installed in an aftermarket* manufactured (mobile) home, where not

prohibited by state or local codes.

*Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer.

Save this manual for future reference.

Save this manual for future reference.

TABLE OF CONTENTS

SAFETY INFORMATION

2

TABLE OF CONTENTS

SAFETY INFORMATION ............................................................ 2

LOCAL CODES........................................................................... 3

PRODUCT IDENTIFICATION ..................................................... 3

PRODUCT FEATURES .............................................................. 4

PRE-INSTALLATION PREP ARATION ........................................ 4

LOCATION OF TERMINATION CAP .......................................... 6

VENTING INSTALLATION INSTRUCTIONS .............................. 7

FIREPLACE INSTALLATION .................................................... 16

WIRING DIAGRAM ................................................................... 24

OPERA TING FIREPLACE ........................................................ 25

SAFETY INFORMATION

WARNINGS

IMPORTANT: Read this owner’s manual carefully

and completely before trying to assemble, operate, or

service this fireplace. Improper use of this fireplace

can cause serious injury or death from burns, fire,

explosions, electrical shock, and carbon monoxide

poisoning.

DANGER: Carbon monoxide poisoning may lead

to death!

This fireplace must be installed by a qualified (certified or licensed)

service person. It has a sealed gas combustion chamber that uses a

coaxial pipe (pipe within a pipe and having the same center) venting

system. It brings in fresh air for combustion through the outer pipe and

combustion gases are exhausted through the inner pipe. If the glass

door assembly and venting pipe are not properly seated, connected,

and sealed, carbon monoxide leakage (spillage) can occur.

Carbon Monoxide Poisoning: Early signs of carbon monoxide

poisoning resemble the flu, with headaches, dizziness, or nausea. If

you have these signs, the fireplace may not have been installed

properly. Get fresh air at once! Have fireplace inspected and

serviced by a qualified service person. Some people are more

affected by carbon monoxide than others. These include pregnant

women, people with heart or lung disease or anemia, those under the

influence of alcohol, and those at high altitudes.

Propane/LP gas and natural gas are both odorless. An odor-making

agent is added to each of these gases. The odor helps you detect a gas

leak. However, the odor added to these gases can fade. Gas may be

present even though no odor exists.

INSPECTING BURNERS.......................................................... 26

CLEANING AND MAINTENANCE ............................................ 27

TROUBLESHOOTING .............................................................. 28

REPLACEMENT PARTS .......................................................... 30

SPECIFICATIONS .................................................................... 30

SERVICE HINTS....................................................................... 30

TECHNICAL SERVICE ............................................................. 30

ACCESSORIES ........................................................................ 31

ILLUSTRATED PARTS BREAKDOWN AND PARTS LIST ....... 32

WARRANTY INFORMATION......................................Back Cover

Make certain you read and understand all warnings. Keep this

manual for reference. It is your guide to safe and proper operation

of this fireplace.

WARNING: Any change to this fireplace or its

controls can be dangerous.

1. This appliance is only for use with the type of gas indicated on

the rating plate. This appliance is not convertible for use with

other gases unless a certified kit is used.

2. For propane/LP fireplace, do not place propane/LP supply

tank(s) inside any structure. Locate propane/LP supply tank(s)

outdoors. To prevent performance problems, do not use propane/LP fuel tank of less than 100 lbs. capacity.

3. If you smell gas

• shut off gas supply

• do not try to light any appliance

• do not touch any electrical switch; do not use any phone in

your building

• immediately call your gas supplier from a neighbor’ s phone.

Follow the gas supplier's instructions

• if you cannot reach you gas supplier , call the fire department.

4. Never install the fireplace

• in a recreational vehicle

• in windy or drafty areas where curtains or other combustible

(flammable) objects can make contact with the fireplace front

• in high traffic areas

5. This fireplace reaches high temperatures. Keep children and

adults away from hot surfaces to avoid burns or clothing ignition. Fireplace will remain hot for a time after shutdown. Allow surfaces to cool before touching.

6. Carefully supervise young children when they are in the room

with fireplace.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

108860-01C

SAFETY INFORMATION

LOCAL CODES

PRODUCT IDENTIFICATION

3

3

SAFETY INFORMATION

Continued

7. Do not modify this fireplace under any circumstances. Any

parts removed for servicing must be replaced prior to operating fireplace.

8. Turn fireplace off and let cool before servicing, installing, or

repairing. Only a qualified service person should install, service, or repair this fireplace. Have fireplace inspected annually by a qualified service person.

9. You must keep control compartments, burners, and circulating air passages clean. More frequent cleaning may be needed

due to excessive lint and dust from carpeting, bedding material, etc. Turn of f the gas valve and pilot light before cleaning

fireplace.

10. Have venting system inspected annually by a qualified service

person. If needed, have venting system cleaned or repaired.

See Cleaning and Maintenance, page 27.

11. Keep the area around your fireplace clear of combustible materials, gasoline, and other flammable vapor and liquids. Do

not run fireplace where these are used or stored. Do not place

items such as clothing or decorations on or around fireplace.

12. Do not use this fireplace to cook food or burn paper or other

objects.

13. Do not use any solid fuels (wood, coal, paper , cardboard, etc.)

in this fireplace. Use only the gas type indicated on fireplace

nameplate.

14. This appliance, when installed, must be electrically grounded

in accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70, or the Ca-

nadian Electrical Code, CSA C22.1.

15. Do not use fireplace if any part has been exposed to or under

water. Immediately call a qualified service person to arrange

for replacement of the unit.

16. Do not operate fireplace if any log is broken.

17. Do not use a blower insert, heat exchanger insert, or other accessory not approved for use with this fireplace.

18. Do not operate fireplace with glass door removed, cracked, or

broken.

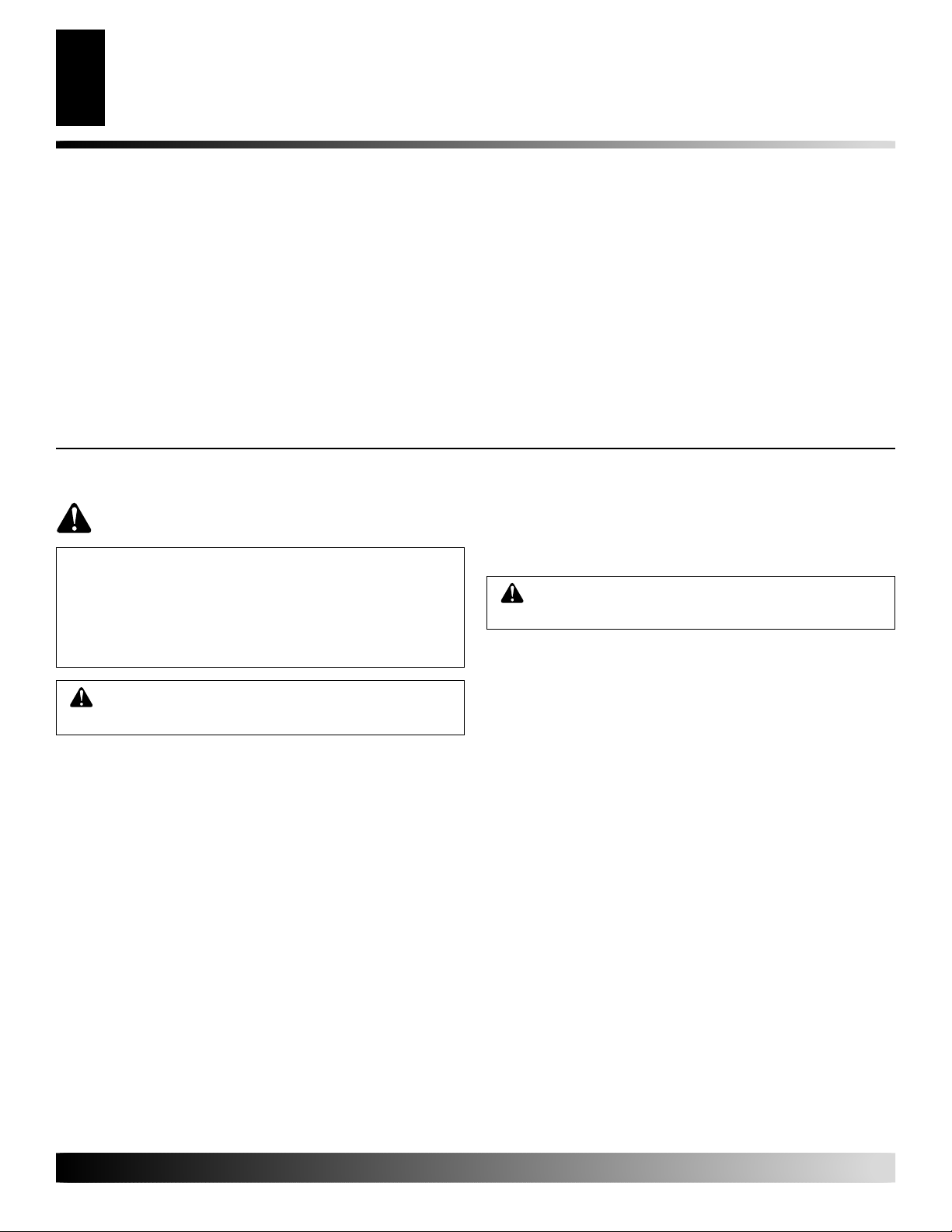

PRODUCT IDENTIFICATION

Upper Louver

Panel

Nailing

Flange

Glass

Door

Assembly

Control

Valve

Lower

Louver

Panel

Figure 1 - Tudor Direct-Vent Fireplace with Electronic Ignition

Glowing

Embers

ON/OFF/REMOTE Switch

(Optional Installation)

Flue Collar

Log

Set

Lava

Rock

Grate

Assembly

Blower Switch

(Optional Installation)

LOCAL CODES

Install and use fireplace with care. Follow all local codes. In the

absence to local codes, use the current National Fuel Gas Code

ANSI Z223.1/NFPA 54* (USA) or the current CSA-B149.1 Installation Code (Canada).

*Available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

For more information, visit www.desatech.com

For more information, visit www.desatech.com

108860-01C

PRODUCT FEATURES

PRE-INSTALLATION PREPARATION

4

Location and Space Requirements

PRODUCT FEATURES

These are a few facts that can help you understand and enjoy your

direct-vent fireplace:

• The venting system may be routed to the outside of your home

in several ways. It may vent through the roof (vertical) or it may

vent to an outside/exterior wall (horizontal). The vent pipe installation is very important to allow for proper operation. You

must follow the venting instructions very carefully for either

vertical or horizontal applications.

• This fireplace may be installed in any room of your house provided

all local codes and these installation instructions are followed.

• This fireplace does not require electricity to operate.

• Only the blower requires electricity if installed and if you plan

to install the blower at a later date, do not forget to wire the

outlet at the bottom of the fireplace when framing.

• The electronic ignition creates spark to ignite the pilot light. It

does not require any matches, batteries or any other sources of

ignition to light the pilot.

• Each time you turn on your fireplace, you may notice some

amount of condensation on the inside of the fireplace glass. This

is normal and will disappear after 10-20 minutes of operation.

• Your direct-vent gas fireplace system (fireplace and venting) is a

balanced and sealed gas operating unit. It requires approximately

10-20 minutes of operating time before the flame pattern stabilizes.

PRE-INSTALLATION

• Your fireplace is designed to be used in zero clearance installations. Wall or framing material can be placed directly against

any exterior surface on the back, sides, or top of your fireplace,

except where standoff spacers are integrally attached. If standoff spacers are attached to your fireplace, these spacers can be

placed directly against wall or framing material. See framing

details on page 5.

• If you plan on installing a television or entertainment center recessed above your fireplace, it is recommended that you maintain a minimum 18" above top of louver opening.

• When locating termination cap, it is important to observe the

minimum clearances shown in Figure 7, page 6.

• If recessing into a wall, you can avoid extra framing by positioning your fireplace against an already existing framing member.

• Do not recess termination cap into a wall or siding.

• You may paint the termination cap with 450ºF (232ºC) heatresistant paint to coordinate with the exterior finish.

• There must not be any obstruction such as bushes, garden sheds,

fences, decks, or utility buildings within 24" from the front of

the termination cap.

• Do not locate termination cap where excessive snow or ice build

up may occur. Be sure to clear vent termination area after snow

falls to prevent accidental blockage of venting system. When

using snow blowers, do not direct snow towards vent termination area.

PREPARATION

LOCATION AND SPACE REQUIREMENTS

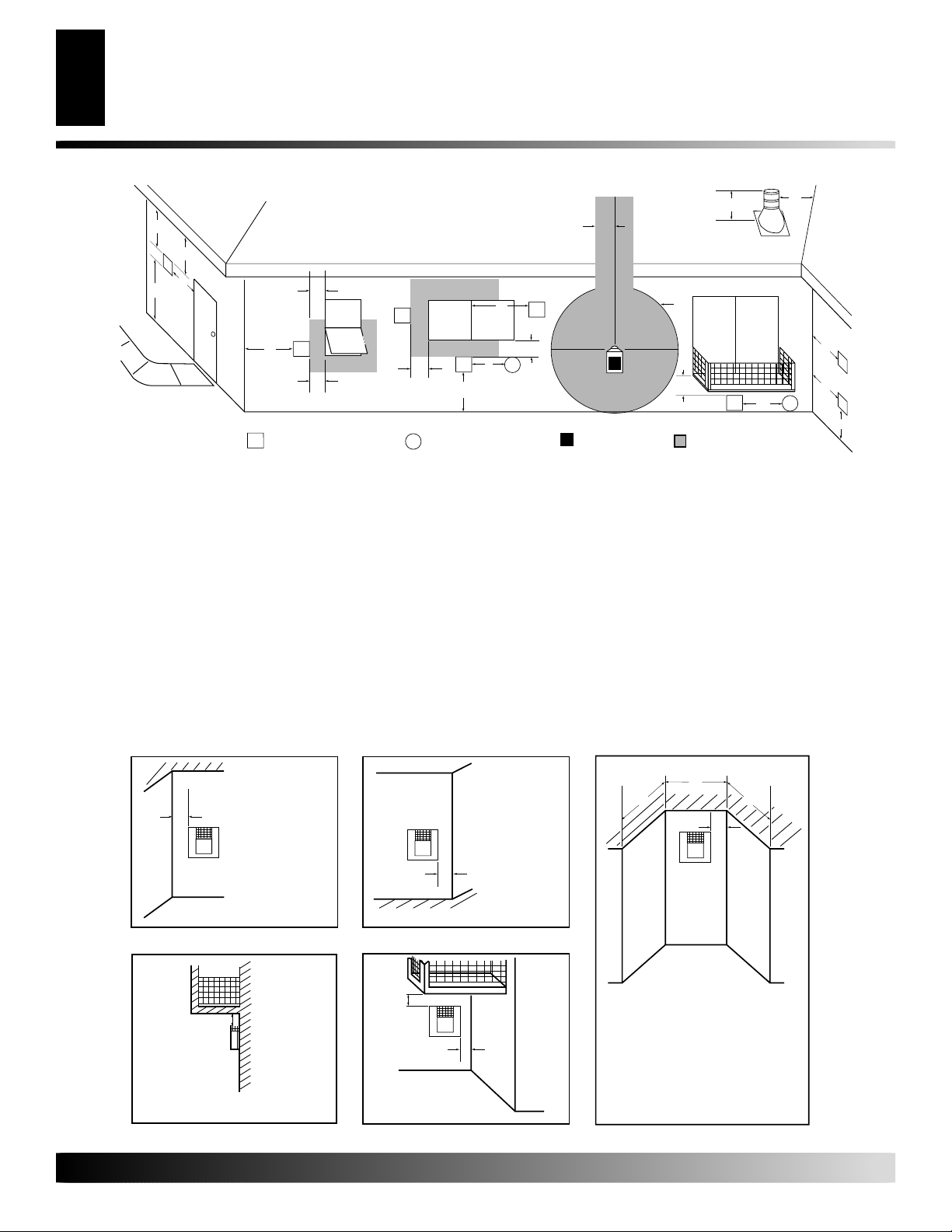

Determine the safest and most efficient location for your DESA

International direct-vent fireplace. Make sure that rafters and wall

studs are not in the way of the venting system. Choose a location

where the heat output is not affected by drafts, air conditioning

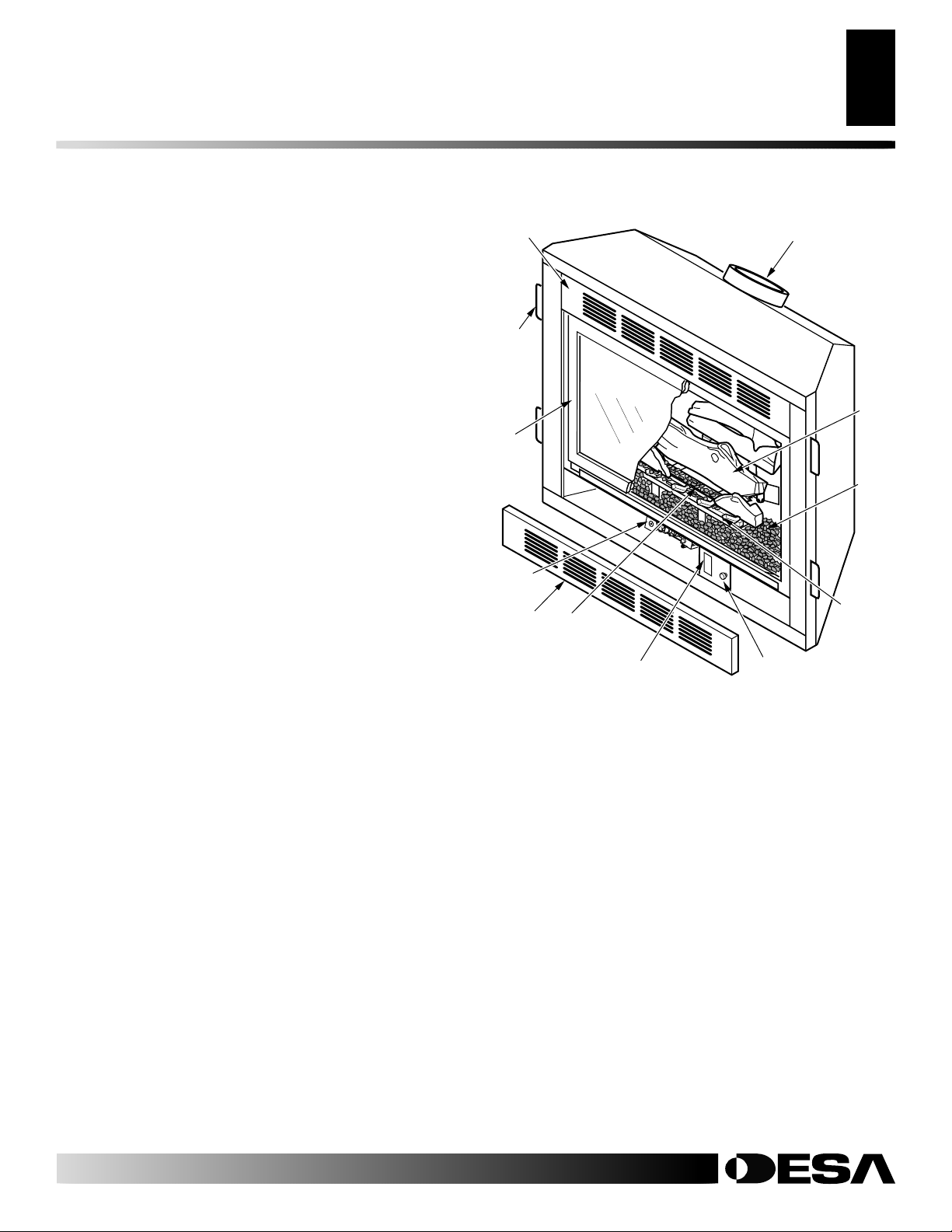

ducts, windows or doors. Figure 2 shows some common locations.

Be aware of all restrictions and precautions before deciding the

exact location for your fireplace and termination cap.

When deciding the location of your fireplace, follow these rules:

• Do not connect this fireplace venting to a chimney flue serving

a separate solid-fuel burning fireplace or appliance.

• Due to high temperatures, do not locate this fireplace in high traffic areas, windy or drafty areas, or near furniture or draperies.

• Proper clearances must be maintained.

• If your fireplace is to be installed directly on carpeting, vinyl

tile, or any combustible material other than wood, it must be

installed on a metal or wood panel extending the full width and

depth of the fireplace. See Figure 3.

Flush with a wall

Through exterior wall

enclosed in a chase

Figure 2 - Common Fireplace Locations

RW

D

FW

Fireplace size D x FW x RW

32" 16 5/8" 34 3/8" 22 1/2"

36" 21

Figure 3 - Fireplace Bottom Dimensions

1

/8" 41" 29"

Corner

installation

For more information, visit www.desatech.com

For more information, visit www.desatech.com

108860-01C

PRE-INSTALLATION

PREPARATION

Continued

CLEARANCES

Minimum clearances to combustibles for the fireplace are as follows:

Back, and sides 0"/mm

Perpendicular walls 6" (152mm)

Floor 0"/mm

Ceiling to louver opening 42" (1067mm)

Front 36" (914mm)

Top 0"/mm

Vent (See venting instructions for

specific venting clearances.)

Combustible material with a maximum thickness of 5/8" may be

flush with the top front of fireplace .

NOTICE: This fireplace is intended for use as supplemental heat. Use this fireplace along with your primary heating system. Do not install this fireplace as

your primary heat source. If you have a central heating system, you may run system’s circulating blower

while using fireplace. This will help circulate the heat

throughout the house.

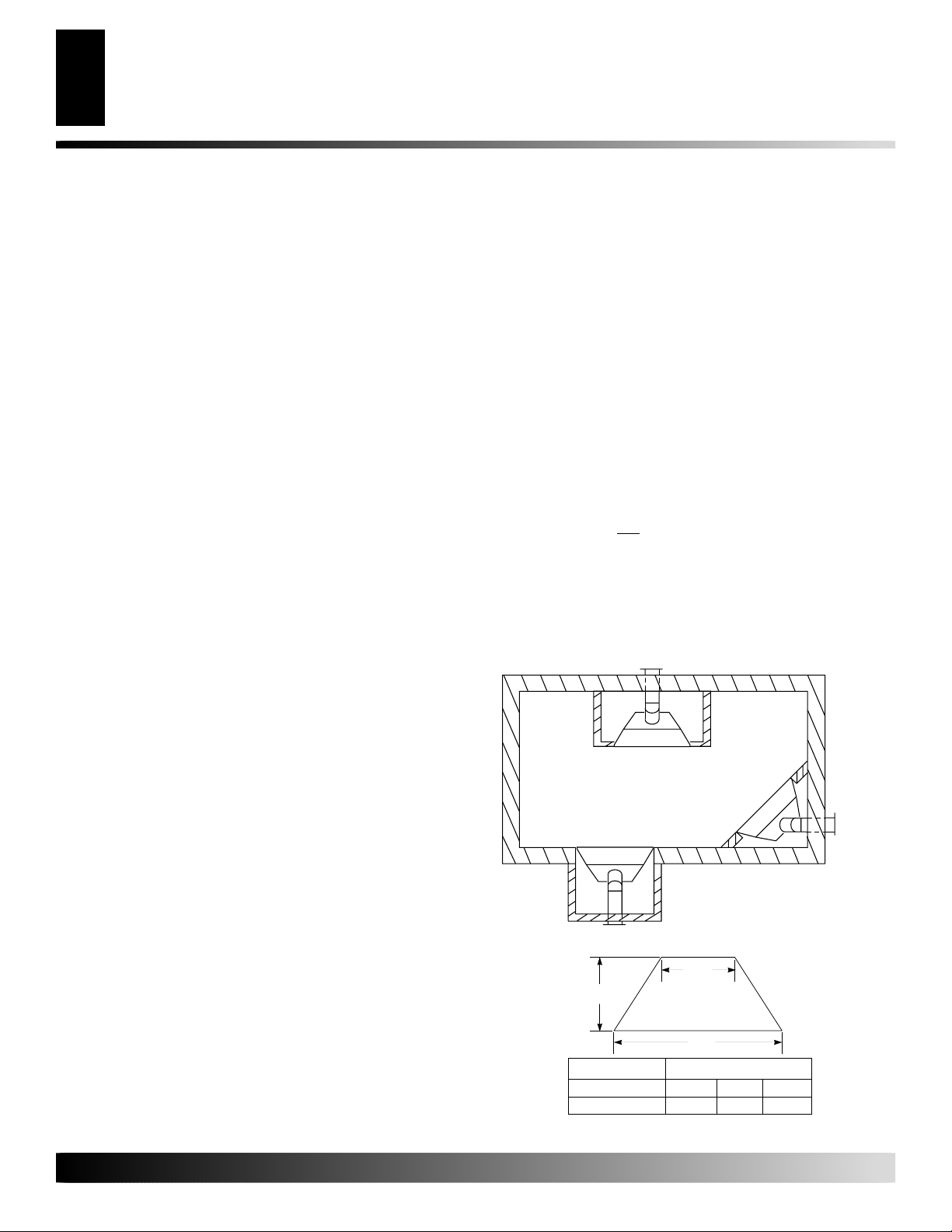

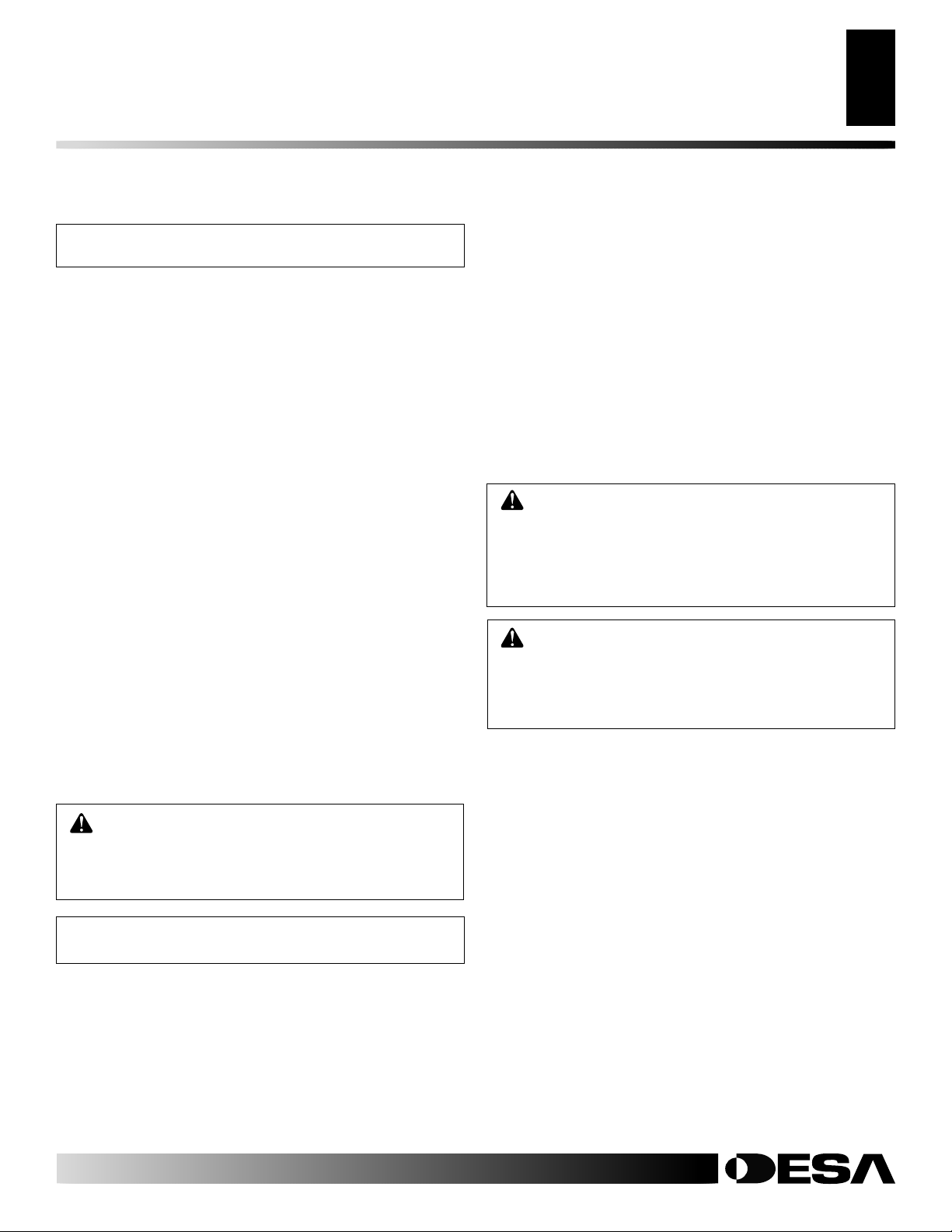

FRAMING AND FINISHING

Figure 4 shows typical framing of this fireplace. Figure 5 shows

framing for corner installation. All minimum clearances must be met.

For available accessories for this fireplace, see Accessories on page

31. If you are using a separate combustible mantel piece, refer to

Figure 6 for proper installation height. You can install noncombustible mantels at any height above the fireplace.

tible mantels may discolor!

A 32

B 34 5/8" 41 1/4"

C 19" 23

A

B

Figure 4 - Framing Clearances for Installation Against an

Exterior Wall

C

Note:

Noncombus-

32" Models 36" Models

3

/8" 36 1/8"

1

/2"

PRE-INSTALLATION PREPARATION

Framing and Finishing

B

A

E

D

F

G

H

Clearances

C

Nailing T abs

32" Models 36" Models

A 28 1/2" 35 3/4"

B 13

C 39

D9 1/2" 10 3/8"

E9

F 34

G 34 5/8" 41 1/4"

H 54

5

/8" 15"

3

/8" 49 5/8"

7

/8" 13 3/4"

3

/8" 41"

1

/8" 68 1/2"

Figure 5 - Framing Clearances for Corner Installation

1

2

A

B

C

D

E

Top of Louver Opening

Ref. Mantel Depth Ref. Mantel from Top

1 14" (356mm) A 16" (406mm)

2 12" (305mm) B 14" (356mm)

3 10" (254mm) C 12" (305mm)

4 8" (203mm) D 10" (254mm)

5 6" (152mm) E 8" (203mm)

6 4" (101mm) F 6" (152mm)

7 2" (51mm) G 4" (101mm)

of Louver Opening

3

4

5

6

7

F

G

Wall

Figure 6 - Clearances for Combustible Mantels

5

5

108860-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

LOCATION OF TERMINATION CAP

6

LOCATION OF TERMINATION CAP

D

E

V

B

L

V

A = clearance above grade, veranda, porch, deck, or balcony

[*12 inches (305mm) minimum]

B = clearance to window or door that may be opened

[12 inches (305mm) minimum]

C = clearance to permanently closed window [minimum 12 inches

(305mm) recommended to prevent condensation on window]

D = vertical clearance to ventilated soffit located above the terminal

within a horizontal distance of 24 inches (610mm) from the

center-line of the terminal [18 inches (457mm) minimum]

E = clearance to unventilated soffit [12 inches (305mm) minimum]

F = clearance to outside corner (see below)

G = clearance to inside corner (see below)

H = *not to be installed above a meter/regulator assembly within

36 inches (914mm) horizontally from the center-line of the regulator

† vent shall not terminate directly above a side-walk or paved driveway which is located between two

single family dwellings and serves both dwellings*

‡ only permitted if veranda, porch, deck or balconey is fully open on a minimum of 2 sides beneath the floor*

* as specified in CAN/CSA B149 (.1 or .2) Installation Codes (1991) for Canada and U.S.A.

Note

: Local codes or regulations may require different clearances

C

Fixed

Closed

V

Openable

B

F

TERMINATION CAP

V

Openable

B

AIR SUPPLY INLET

X

B

Fixed

Closed

J

V

A

I = clearance to service regulator vent outlet [*72 inches (1829mm)

J = clearance to non-mechanical air supply inlet to building or the

K = clearance to a mechanical air supply inlet [*72 inches (1829mm)

L = † clearance above paved side-walk or a paved driveway located on

M = clearance under veranda, porch, deck [*12 inches (305mm) minimum ‡]

N = clearance above a roof shall extend a minimum of 24 inches (610mm)

N

H

V

B

X

G

minimum]

combustion air inlet to any other fireplace [*12 inches (305mm)

minimum]

minimum]

public property [*84 inches (2133mm) minimum]

above the highest point when it passes through the roof surface and

any other obstruction within a horizontal distance of 18 inches (457mm)

G

GAS METER RESTRICTED AREA

I

M

V

(TERMINATION PROHIBITED)

N

G

G

X

K

V

V

A

Termination Clearances for Buildings with Combustible and Noncombustible Exteriors

Inside Corner

A

Balcony with No Side Wall

G = 12" (305mm) minimum clearance

A = 6" (152mm)

V

G

V

Outside Corner Recessed Location

Balcony with Perpendicular Side Wall

Combustible &

Noncombustible

H = 24" (610mm)

J = 20" (508mm)

Figure 7 - Minimum Clearances for Termination Cap

For more information, visit www.desatech.com

For more information, visit www.desatech.com

D

C

V

B = 6" (152mm)

B

H

V

J

C = Maximum depth of 48" (1219mm) for

recessed location

D = Minimum width for back wall of

recessed location Combustible - 38" (965mm)

Noncombustible - 24" (610mm)

E = Clearance from corner in

recessed locationCombustible - 6" (152mm)

Noncombustible - 2" (51mm)

V

C

E

108860-01C

VENTING INSTALLATION

INSTRUCTIONS

VENTING INSTALLATION INSTRUCTIONS

Installation Precautions

Installation Planning

7

7

NOTICE: Read these instructions completely before attempting installation.

These models are tested and approved for use with DESA International (direct-vent) pipe components and terminations.

The venting system must terminate on the outside of the structure and

can not be attached to a chimney or flue system serving a separate

solid fuel or gas burning appliance. A direct-vent appliance must have

its own venting system. DO NOT common vent this appliance.

These models are approved to be vented either horizontally through

an outside wall or vertically through a roof or chase enclosure using

the following guidelines:

• When venting system terminates horizontally on an outside wall,

you must install a standoff if the termination cap is to be installed directly on a combustible finish such as vinyl, wood,

stucco, etc.

• Never run the vent downward as this may cause excessive temperatures which could cause a fire.

• V ent pipe air space clearances to combustibles are 1" on all sides

except on the horizontal sections, which requires 2" clearance

from the top of the pipe. Where the termination cap penetrates a

combustible wall, 1" air space clearance is required.

• Snorkel terminations are required when minimum clearance to grade

cannot be met (see Figure 16 on page 11).

• Have fireplace and selected vent components on hand to help

determine the exact measurements when elbowing or offsetting.

Always use wall firestops when penetrating walls and firestops

when penetrating ceilings or attic spaces.

• Install horizontal venting with a 1/4" rise for every 12" of run

toward the termination.

WARNING: Read all instructions completely and

thoroughly before attempting installation. Failure to

do so could result in serious injury, property damage

or loss of life.

NOTICE: Failure to follow these instructions will void

the warranty.

INSTALLATION PRECAUTIONS

• Wear gloves and safety glasses for protection

• Use extreme caution when using ladders or when on roof tops

• Be aware of electrical wiring locations in walls and ceilings

The following actions will void the warranty on your venting

system:

• Installation of any damaged venting component

• Unauthorized modification of the venting system (Do not cut

or alter vent components)

• Installation of any component part not manufactured or approved by DESA International

• Installation other than as instructed by these instructions

WARNING: This gas fireplace and vent assembly

must be vented directly to the outside. The venting

system must NEVER be attached to a chimney serving a separate solid fuel burning appliance. Each

direct-vent gas appliance must use a separate vent

system. Do not use common vent systems.

WARNING: Vent pipe air space clearances to combustibles are 1" on all sides except on the horizontal

sections, which require 2" clearances from the top of

the pipe. Where the termination cap penetrates a combustible wall, 1" air space clearance is required.

INSTALLATION PLANNING

There are two basic types of direct-vent installation:

• Horizontal Termination

• Vertical Ter mination

Horizontal Termination Installation

IMPORTANT:

portion of wall firestop. Horizontal installations using round termination require exterior portion of wall firestop available only in vent

kit HTK (see Figure 14, page 10).

1. Set the fireplace in its desired location and determine the route

your horizontal venting will take. Do not secure the fireplace

until all venting has been installed. Some installations require

sliding the fireplace in and out of position to make final venting connections. Figures 14 through 18 on pages 10 through

12 show different configurations for venting with horizontal

termination that will help you decide which application best

suits your installation. Check to see if wall studs or roof rafters

are in the path of your desired venting route. If they are, you

may want to adjust the location of the fireplace.

Horizontal square terminations require only inner

108860-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

VENTING INSTALLATION INSTRUCTIONS

8

Installation Planning

VENTING INSTALLATION

INSTRUCTIONS

Continued

2. Direct vent pipe sections and components are designed with

special twist-lock connections.

Twist-Loc k Procedure: The female ends of the pipes have lock-

ing lugs (indentations). These lugs will slide straight into matching slots on the male ends of adjacent pipes. Push pipe sections

together and twist one section clockwise approximately one-quarter turn until the sections are fully locked (see Figure 8).

Note:

Horizontal runs of vent must be supported every three

feet. Use wall straps for this purpose.

3. Use a 45° elbow to connect venting system to fireplace flue collar. The elbow is designed to be twist-locked onto the flue collar

as described in step 2.

configuration of the elbow by cutting, twisting, bending, etc.

4. Assemble the desired combination of pipe and elbows to the

fireplace. If there are long portions of venting run, pre-assembled pipe sections may be installed as subassemblies for

convenience.

5. Carefully determine the location where the vent pipe assembly

will penetrate the outside wall. The center of the hole should line

up with the center-line of the horizontal vent pipe. Mark the wall

for a 10" x 10" square hole. Cut and frame the square hole in the

exterior wall where the vent will be terminated. If the wall being

penetrated is constructed of noncombustible material, such as

masonry block or concrete, a 7 3/4" hole with zero clearance is

acceptable (see Figure 9).

IMPORTANT:

Do not attempt to alter the

Female Locking Lugs

Figure 8 - Vent Pipe Connections

Vent Opening

Combustible W all

10"

(254mm)

10"

(254mm)

Vent Opening

Noncombustible W all

10" Inside Framing

(Framing

Detail)

Male Slots

(254mm)

WARNING: Do not recess vent termination into

any wall. This will cause a fire hazard.

6. Noncombustible Exterior Wall: Position the horizontal vent

cap in the center of the 7 3/4" round hole and attach to the exterior wall with four wood screws provided. Before attaching

the vent cap to exterior wall, run a bead of non-hardening mastic

(pliable sealant) around the outside edges to make a seal between it and the outside wall.

Note:

The four wood screws

provided should be replaced with appropriate fasteners for

stucco, brick, concrete, or other types of sidings.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

7 3/4"

(197mm)

Center

of Hole

Figure 9 - Vent Opening Requirements

108860-01C

VENTING INSTALLATION

INSTRUCTIONS

Continued

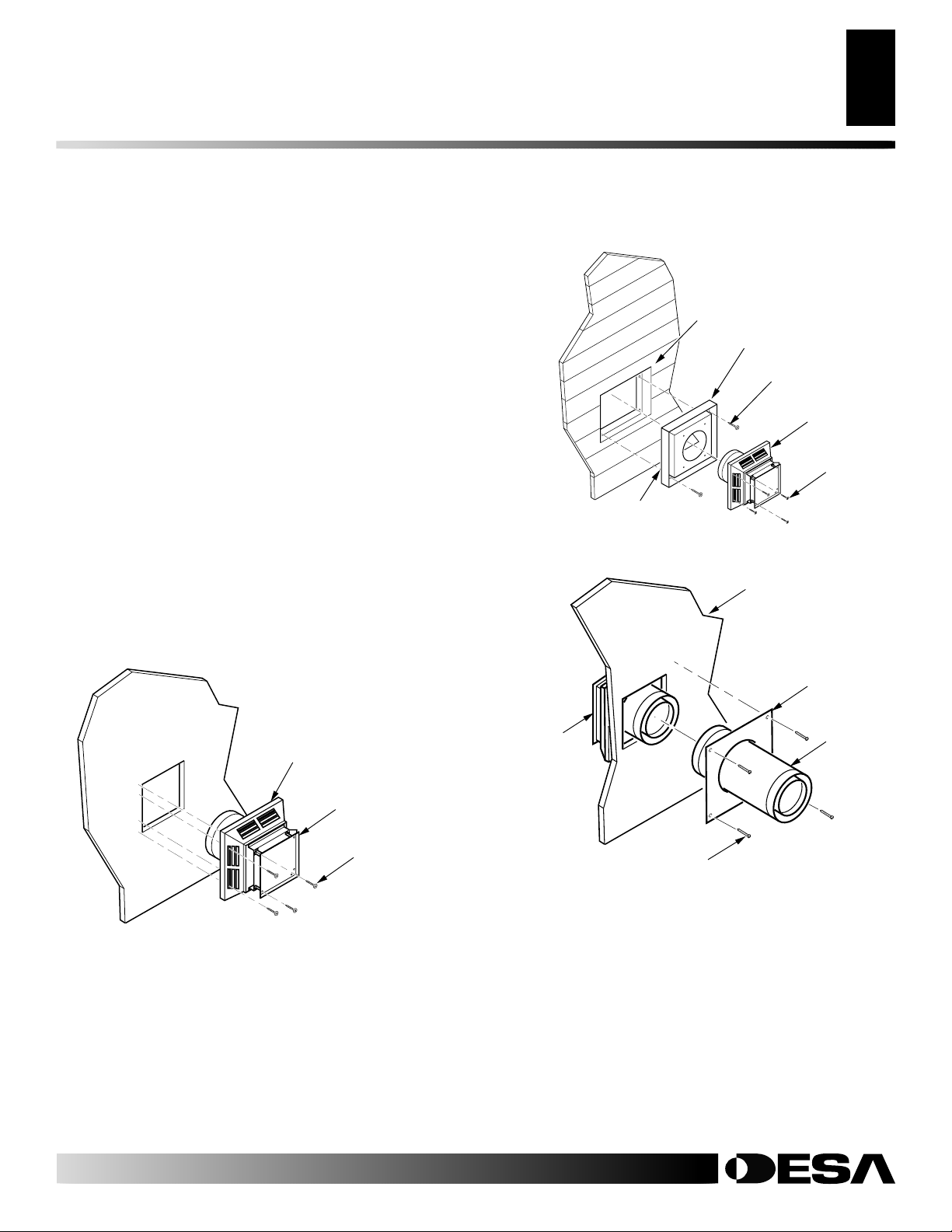

Combustible Exterior W all: For vinyl siding, stucco, or wood

exteriors, a siding standoff must be installed between the vent

cap and exterior wall. The siding standoff prevents excessive

heat from damaging siding materials. Siding material must be

cut to accommodate standoff. Bolt the vent cap to the standoff. Apply non-hardening mastic around outside edge of standoff. Position the standoff/cap assembly in the center of the 10"

square hole and attach to exterior wall with wood screws provided (see Figure 11). The siding standof f must sit flush against

the exterior fascia material.

7. Slide the wall firestop over the vent pipe before connecting

horizontal run to vent cap (see Figure 12).

8. Carefully move fireplace, with vent assembly attached, toward

wall and insert vent pipe into horizontal termination. The pipe

overlap should be a minimum of 1

9. Slide wall firestop against interior wall surface and attach with

screws provided. See Figure 13, page 10 for horizontal termination details.

10. Place fireplace into position and shim with noncombustible material if needed. Nail or screw side flanges to framing to secure

unit in place.

IMPORTANT:

securing. If fireplace is not level it will not work properly .

1

/4".

Make sure fireplace is level before

VENTING INSTALLATION INSTRUCTIONS

Installation Planning (Cont.)

Cut Siding Away

to Fit Standoff

Standoff

Wood Screw

Apply Mastic

to All Four Sides

Figure 11 - Installing Siding Standoff

Interior Wall

Surface

Vent Cap

Screws

9

9

Apply Mastic to

All Four Sides

Figure 10 - Installing Horizontal Vent Cap

Vent Cap

Wood Screw

Wall

Firestop

Vent Cap

(Horizontal

Termination)

Screw

Figure 12 - Connecting Vent Cap with Horizontal Vent Pipe

Horizontal

Vent Pipe

108860-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

VENTING INSTALLATION INSTRUCTIONS

10

Installation Planning (Cont.)

VENTING INSTALLATION

INSTRUCTIONS

Continued

Direct Vent

Pipe

Minimum Pipe

Overlap 1

Wall

Firestop

1

/4"

Siding Standoff

Screws

GROUND FLOOR INSTALLATION

Recommended Applications:

• Installation using cabinet surrounds

• Through the wall using round or square termination (up to 12"

horizontal pipe)

• NOT FOR CORNER INSTALLATION

Adjustable

Pipe 12" Max.

Horizontal High

Wind Square

Termination

45° Elbow

Maintain 1"

Minimum Air

Space Around

Outer Pipe When

Penetrating a Wall

10" x 10"

Framed

Opening

Figure 13 - Typical Horizontal Termination Cap Mounting with

Additional Siding Standoff Installed

High Wind

Termination

Apply Mastic to

Outside Edge of

Standoff

Exterior Wall

with Vinyl Siding

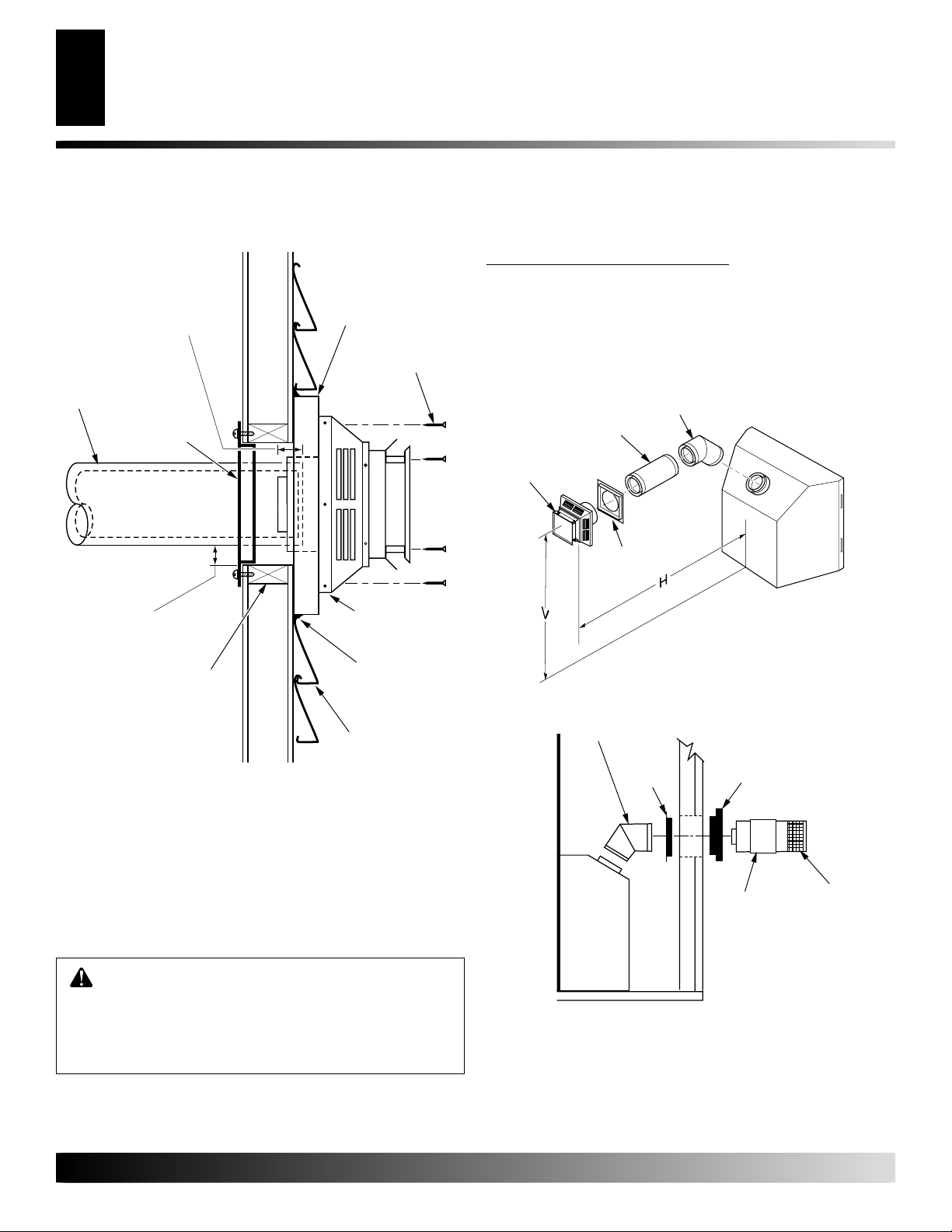

Horizontal Termination Configurations

Figures 14 through 18 show different configurations and alternatives

for venting with horizontal termination. Each figure includes a chart

with critical minimum and maximum dimensions which MUST be

met.

IMPORTANT:

have a 1/4" rise for every 12" of run toward the termination.

WARNING: Never run vent downward as this may

cause excessive temperatures which could cause a

fire. Operation of improperly installed and maintained venting system could result in serious injury,

property damage or loss of life.

Remember that a horizontal run of venting must

Wall Firestop

Square Termination

Vertical (V) Horizontal (H)

T32 Series 29" min. 17" max.

T36 Series 32" min. 17" max.

45° Elbow

Wall

Firestop

Figure 14 - Horizontal Termination Configuration for Square and

Round Terminations

Exterior Portion of Wall

Firestop (Round

Termination Only)

Slide Ring

Over Elbow to

Complete

Connection

Round Termination

(Kit HTK Shown)

Round

Termination

Cap

For more information, visit www.desatech.com

For more information, visit www.desatech.com

108860-01C

VENTING INSTALLATION

INSTRUCTIONS

Continued

CORNER AND ALTERNATE INSTALLATION

Recommended Applications:

• Corner ground floor installation

• Ground floor installation where pipe vents horizontally through wall

(over 12" horizontal pipe)

• Basement installation where one foot clearance from ground to

termination is possible

Wall

Firestop

Not to Exceed

(H) Limits

90° Elbow

As Required for (V)

See Chart for Pipe

Section Required

VENTING INSTALLATION INSTRUCTIONS

Vertical (V) Required

32" 36" Vertical Pipe Horizontal (H) (32"/36")

1

/2" min. 431/4" min. None 30" max.

*40

1

/2" min. 541/4" min. 1 ft. 48" max.

51

1

63

/2" min. 661/4" min. 2 ft. 60" max.

1

/2" min. 781/4" min. 3 ft. 84" max.

75

1

/2" min. 901/4" min. 4 ft. 20' max.

87

*Note:

Ground Floor Corner Venting

Installation Planning (Cont.)

Not to Exceed

(H) Limits

90° Elbow

Termination

Cap

11

11

Termination

Cap

Figure 15 - Horizontal Termination Configuration for Corner Installation Using One 90° Elbow

45°

Elbow

Wall

Firestop

45° Elbow

SNORKEL TERMINATION INSTALLATION

Recommended Applications:

• Installations requiring a vertical rise on building exterior

• Any installation using snorkel termination to achieve one foot above ground

Snorkel terminations are available for installations requiring a vertical rise on the exterior of the building. If

installing snorkel termination below grade, you must provide proper drainage to prevent water from entering snorkel

termination (see Figure 16). Do not back fill around snorkel termination.

Snorkel

Termination

12"

Minimum

Snorkel

Termination

12"

Minimum

Adequate

Drainage

90° Elbow

45°

Elbow

Wall

Firestop

12" Minimum

Snorkel

Termination

12"

Minimum

Figure 16 - Snorkel Termination Configurations for Below Ground Installation

For more information, visit www.desatech.com

For more information, visit www.desatech.com

108860-01C

VENTING INSTALLATION INSTRUCTIONS

12

Installation Planning (Cont.)

VENTING INSTALLATION

INSTRUCTIONS

Continued

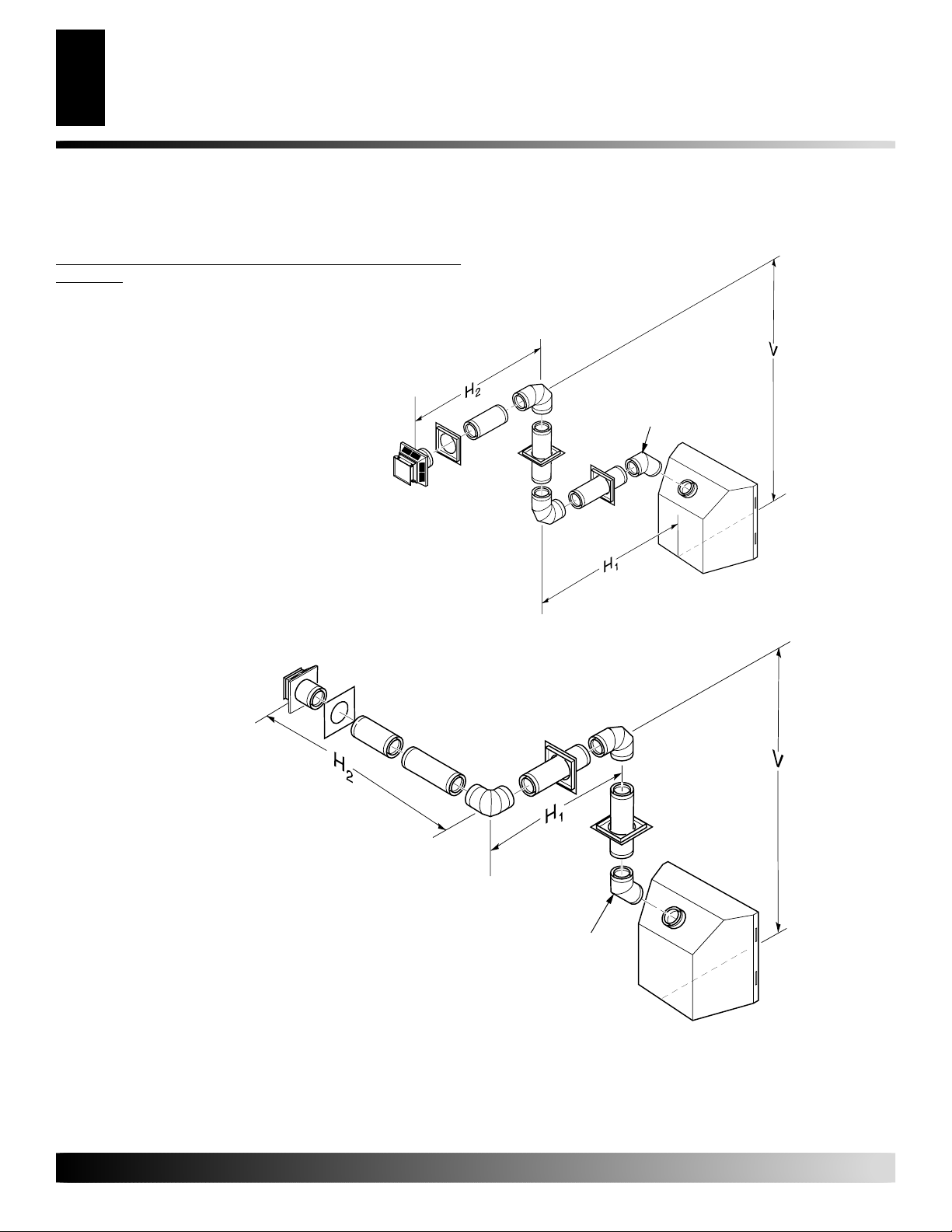

HORIZONTAL SYSTEM INSTALLATION USING TWO 90°

ELBOWS

The following configurations show the minimum vertical rise

requirements for a horizontal system using two 90° elbows.

Venting with Two 90° Elbows

Vertical (V) Horizontal (H1) Horizontal (H1) +

Horizontal (H2)

5' min. 2' max. 6' max.

6' min. 4' max. 12' max.

7' min. 6' max. 18' max.

8' min. 8' max. 20' max.

20' max. 8' max. 20' max.

45° Elbow

Figure 17 - Horizontal Termination Configuration for Venting Using Two 90° Elbows

Venting with Two 90° Elbows

Vertical (V) Horizontal (H1) +

Horizontal (H2)

5' min. 6' max.

6' min. 12' max.

7' min. 18' max.

8' min. 20' max.

20' max. 20' max.

45° Elbow

Figure 18 - Horizontal Termination Configuration for Venting Using Two 90° Elbows with Termination at 90° with Fireplace

For more information, visit www.desatech.com

For more information, visit www.desatech.com

108860-01C

Loading...

Loading...