Page 1

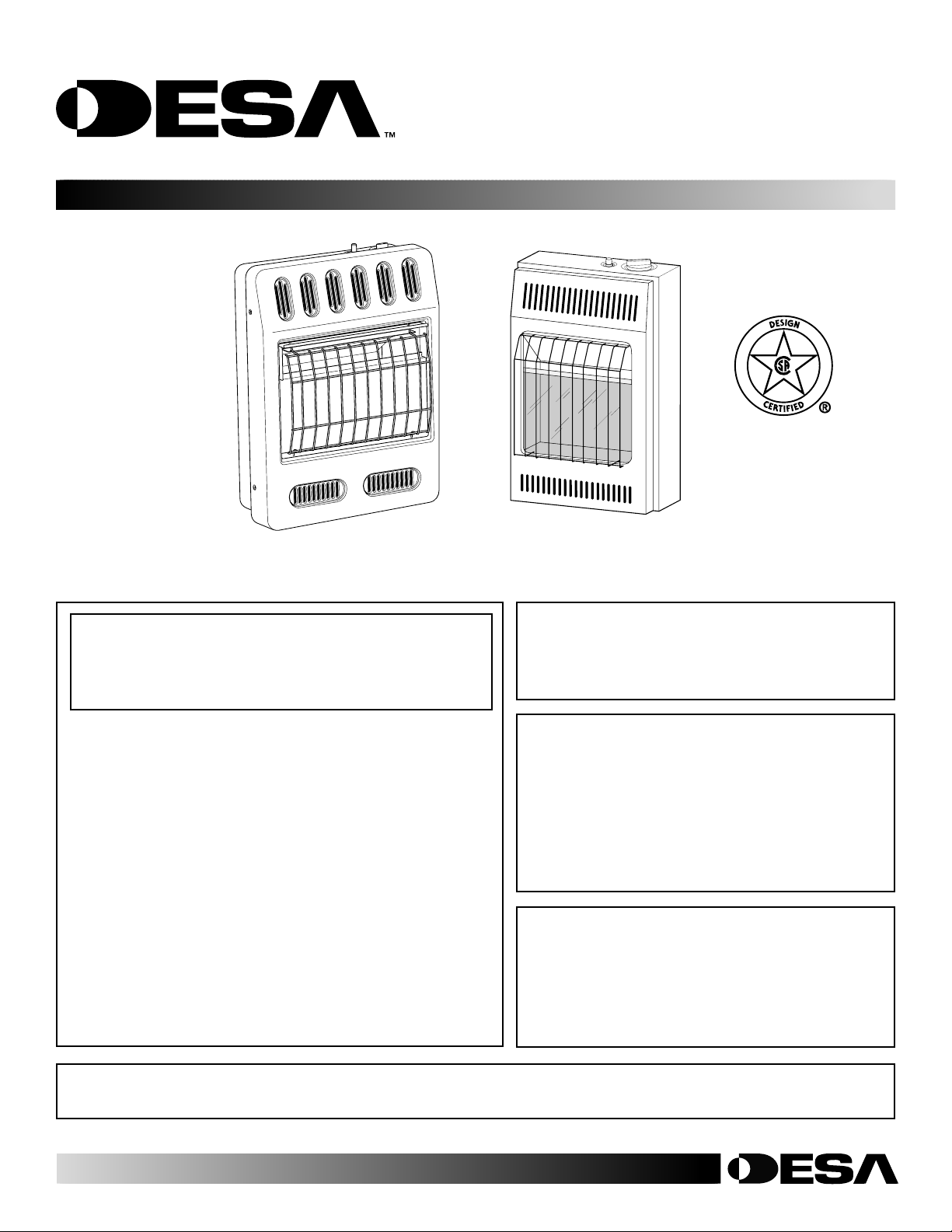

VENT-FREE BLUE FLAME

GAS HEATER

SAFETY INFORMATION AND

INSTALLATION MANUAL

For more information, visit www.desatech.com

For more information, visit www.desatech.com

CR94-001 UNVENTED

ROOM HEATER

GCN20T, GCP20T

WARNING: If the information in this manual is

not followed exactly, a fire or explosion may

result causing property damage, personal injury, or loss of life.

— Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fire department.

— Installation and service must be performed

by a qualified installer, service agency, or

the gas supplier.

GCN6, GCP6

GCN10T, GCP10T

Unvented room heaters are for installation in SINGLE FAMILY TYPE RESIDENCES ONLY, and the installation is

limited to ONE (1) unit per residence.

WARNING: Improper installation, adjustment, alteration, service, or maintenance

can cause injury or property damage.

Refer to this manual for correct installation and operational procedures. For assistance or additional information consult a qualified installer, service agency,

or the gas supplier.

WARNING: This is an unvented gas-fired

heater. It uses air (oxygen) from the room

in which it is installed. Provisions for adequate combustion and ventilation air must

be provided. Refer to

and Ventilation

on page 4 of this manual.

Air For Combustion

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not

convertible for use with other gases.

*Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer

Save this manual for future reference.

Save this manual for future reference.

Page 2

TABLE OF CONTENTS

SAFETY INFORMATION

2

TABLE OF CONTENTS

SAFETY INFORMATION ............................................................ 2

UNPACKING............................................................................... 3

PRODUCT IDENTIFICATION ..................................................... 3

PRODUCT FEATURES .............................................................. 3

LOCAL CODES........................................................................... 4

AIR FOR COMBUSTION AND VENTILATION ........................... 4

INSTALLATION ........................................................................... 6

OPERATING HEATER.............................................................. 14

INSPECTING BURNER ............................................................ 15

CLEANING AND MAINTENANCE ............................................ 16

TROUBLESHOOTING .............................................................. 17

SAFETY INFORMATION

WARNINGS

IMPORTANT: Read this owner’s manual carefully and

completely before trying to assemble, operate, or service this heater. Improper use of this heater can cause

serious injury or death from burns, fire, explosion,

electrical shock, and carbon monoxide poisoning.

DANGER: Carbon monoxide poisoning may lead

to death!

Carbon Monoxide Poisoning: Early signs of carbon monoxide

poisoning resemble the flu, with headaches, dizziness, or nausea. If

you have these signs, the heater may not be working properly. Get

fresh air at once! Have heater serviced. Some people are more

affected by carbon monoxide than others. These include pregnant

women, persons with heart or lung disease or anemia, those under

the influence of alcohol, and those at high altitudes.

Natural and Propane/LP Gas: Natural and propane/LP gases are

fuel gases. Fuel gases are odorless. An odor-making agent is added

to fuel gases. The odor helps you detect a fuel gas leak. However,

the odor added to fuel gas can fade. Fuel gas may be present even

though no odor exists.

Make certain you read and understand all warnings. Keep this

manual for reference. It is your guide to safe and proper operation

of this heater.

ILLUSTRATED PARTS BREAKDOWN AND PARTS LIST ....... 20

SPECIFICATIONS..................................................................... 26

SERVICE CENTER/P ARTS CENTRAL .................................... 26

OWNER’S REGISTRA TION FORM .......................................... 27

REPLACEMENT PARTS .......................................................... 29

SERVICE HINTS....................................................................... 29

TECHNICAL SERVICE ............................................................. 29

SERVICE PUBLICATIONS ....................................................... 29

ACCESSORIES ........................................................................ 29

WARRANTY INFORMATION...................................... Back Cover

WARNING: Do not use a blower insert, heat

exchanger insert or other accessory not approved for

use with this heater.

Children and adults should be alerted to the hazard of

high surface temperature and should stay away to

avoid burns or clothing ignition.

Surface of heater becomes very hot when running

heater. Heater will remain hot for a time after shutdown. Allow surface to cool before touching.

Any safety screen or guard removed for servicing the

appliance must be replaced prior to operation the heater.

Due to high temperatures, the appliance should be

located out of traffic and away from furniture and

draperies.

Do not place clothing or other flammable material on or

near the appliance. Never place any objects on the heater.

Carefully supervise young children when they are in

the same room with heater.

WARNING: Any change to this heater or its

controls can be dangerous.

WARNING: Do not use any accessory not ap-

proved for use with this heater.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Make sure grill guard is in place before running

heater.

Keep the appliance area clear and free from combustible materials, gasoline, and other flammable vapors

and liquids.

112157-01A

Page 3

SAFETY INFORMATION

Continued

SAFETY INFORMATION

UNPACKING

PRODUCT IDENTIFICATION

PRODUCT FEATURES

3

3

Installation and repair should be done by a qualified

service person. The appliance should be inspected

and serviced before use and at least annually by a

professional service person. More frequent cleaning

may be required due to excessive lint from carpeting,

etc. It is imperative that control compartments, burners and circulating air passageways of the appliance

be kept clean.

1. This appliance is only for use with the type of gas indicated on

the rating plate. This appliance is not convertible for use with

other gases.

2. Do not place propane/LP supply tank(s) inside any structure.

Locate propane/LP supply tank(s) outdoors.

3. Do not install in a bedroom or a bathroom.

4. If you smell gas

• Shut off gas supply

• Do not try to light any appliance

• Do not touch any electrical switch; do not use any phone in

your building

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions

• If you cannot reach your gas supplier, call the fire department

5. This heater needs fresh, outside air ventilation to run properly.

This heater has an Oxygen Depletion Sensing (ODS) safety

shutoff system. The ODS shuts down the heater if not enough

fresh air is available. See Air for Combustion and Ventilation,

pages 4 through 6.

6. Keep all air openings in the front and bottom of heater clear and

free of debris. This will insure enough air for proper combustion.

7. If heater and pilot shuts off unexpectedly, do not relight the

pilot until you provide fresh, outside air. If heater keeps shutting off, have it serviced.

8. Do not run heater

• where flammable liquids or vapors are used or stored

• under dusty conditions

9. Before using furniture polish, wax, carpet cleaner, or similar

products, turn heater off. If heated, the vapors from these products may create a white powder residue within burner box or

on adjacent walls or furniture.

10. Do not use heater if any part has been under water. Immediately call a qualified service technician to inspect the room

heater and to replace any part of the control system and any

gas control which has been under water.

11. Turn off heater and let cool before servicing. Only a qualified

service person should service and repair heater.

12. Operating heater above elevations of 4,500 feet (1 370 m) could

cause pilot outage due to lower levels of oxygen in the air.

13. T o prevent performance problems, do not use propane/LP fuel

tank of less than 100 lbs. (45 kg) capacity.

14. Provide adequate clearances around air openings.

15. Before using the heater, provide adequate ventilation. An area

of 10 square inches (65 cm2) of opening of a window or roof

vent is needed for adequate combustion and ventilation air.

UNPACKING

1. Remove heater from carton.

2. Remove all protective packaging applied to heater for shipment.

3. Check heater for any shipping damage. If heater is damaged,

promptly inform dealer where you bought heater.

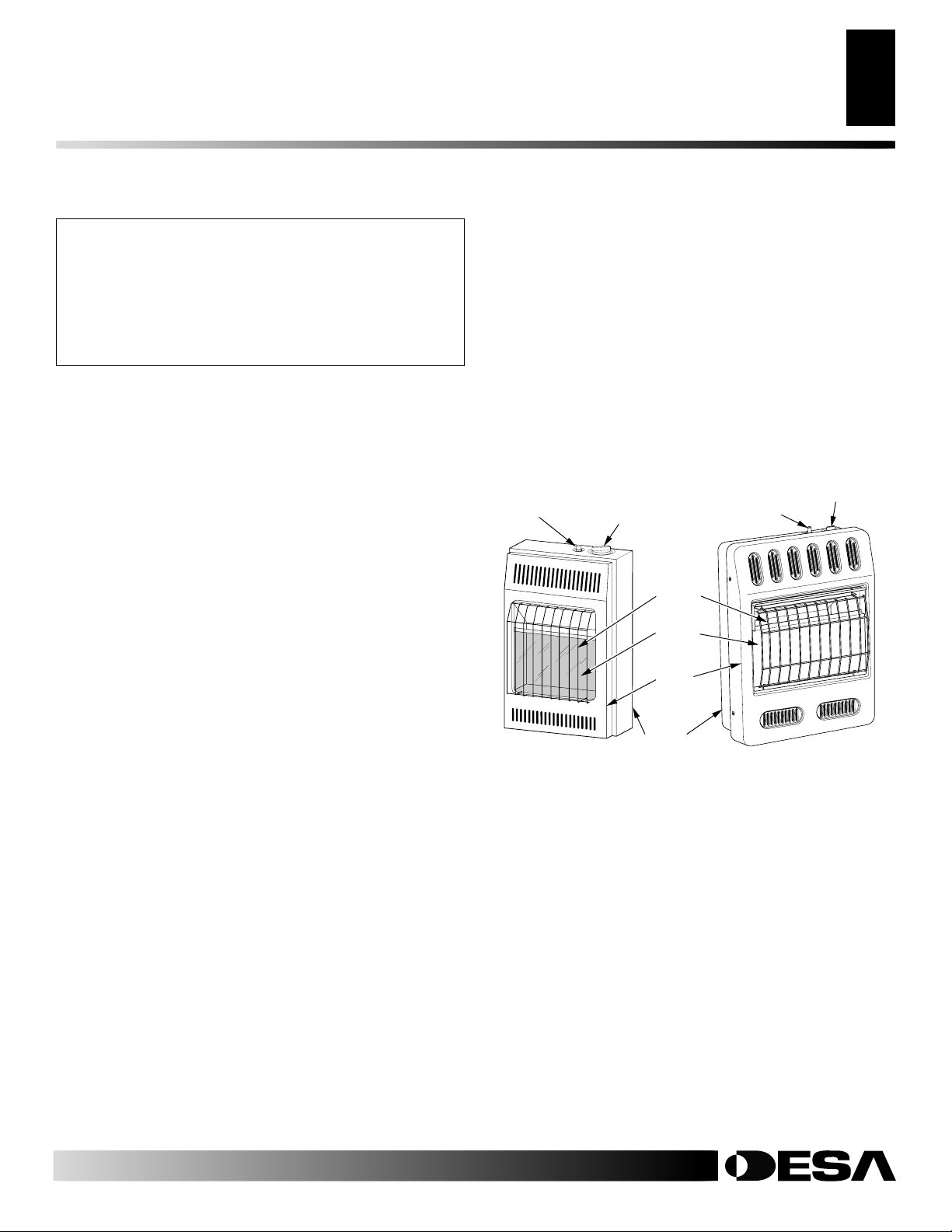

PRODUCT IDENTIFICATION

Piezo Ignitor

Button

6,000/10,000 Btu/Hr

Figure 1 - Vent-Free Gas Heater

Control Knob

Grill

Guard

Glass

Panel

Front

Panel

Heater

Cabinet

Piezo Ignitor

Button

Control Knob

20,000 Btu/Hr

PRODUCT FEATURES

SAFETY DEVICE

This heater has a pilot with an Oxygen Depletion Sensing (ODS)

safety shutoff system. The ODS/pilot is a required feature for ventfree room heaters. The ODS/pilot shuts off the heater if there is not

enough fresh air.

PIEZO IGNITION SYSTEM

This heater has a piezo ignitor. This system requires no matches,

batteries, or other sources to light heater.

THERMOSTATIC HEAT CONTROL

Thermostat models have a thermostat sensing bulb and a control

valve. This results in the greatest heater comfort. This can also result

in lower gas bills.

112157-01A

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 4

LOCAL CODES

AIR FOR COMBUSTION AND VENTILATION

4

Providing Adequate Ventilation

LOCAL CODES

Install and use heater with care. Follow all local codes. In the absence of

local codes, use the latest edition of CAN/CGA B149.1 Natural Gas

Installation Code or CAN/CGA B149.2 Propane Installation Code*.

*Available from www.csa.ca or 1-800-463-6727 (call your local

gas company for your local codes).

AIR FOR COMBUSTION AND

VENTILATION

WARNING: This heater shall not be installed in a

confined space or unusually tight construction unless provisions are provided for adequate combustion and ventilation air. Read the following instructions to insure proper fresh air for this and other fuelburning appliances in your home.

Today’s homes are built more energy efficient than ever. New materials, increased insulation, and new construction methods help reduce

heat loss in homes. Home owners weather strip and caulk around

windows and doors to keep the cold air out and the warm air in. During

heating months, home owners want their homes as airtight as possible.

While it is good to make your home energy efficient, your home

needs to breathe. Fresh air must enter your home. All fuel-burning

appliances need fresh air for proper combustion and ventilation.

Exhaust fans, fireplaces, clothes dryers, and fuel burning appliances

draw air from the house to operate. You must provide adequate fresh

air for these appliances. This will insure proper venting of vented

fuel-burning appliances.

PROVIDING ADEQUATE VENTILATION

The following are excerpts from CAN/CGA B149.1 Natural Gas

Installation Code or CAN/CGA B149.2 Propane Installation Code.

All spaces in homes fall into one of the three following ventilation

classifications:

1. Unusually Tight Construction

2. Unconfined Space

3. Confined Space

The information on pages 4 through 6 will help you classify your

space and provide adequate ventilation.

Unusually Tight Construction

The air that leaks around doors and windows may provide enough

fresh air for combustion and ventilation. However, in buildings of

unusually tight construction, you must provide additional fresh air.

Unusually tight construction is defined as construction

where:

a. walls and ceilings exposed to the outside atmosphere

have a continuous water vapor retarder with a rating of

one perm (6 x 10

ings gasketed or sealed

b. weather stripping has been added on openable windows

and doors

c. caulking or sealants are applied to areas such as joints

around window and door frames, between sole plates

and floors, between wall-ceiling joints, between wall panels, at penetrations for plumbing, electrical, and gas

lines, and at other openings.

If your home meets all of the three criteria above, you must

provide additional fresh air. See

doors

, page 6

If your home does not meet all of the three criteria above,

proceed to

page 5.

Determining Fresh-Air Flow For Heater Location,

and

.

-11

kg per pa-sec-m2) or less with open-

and

Ventilation Air From Out-

Confined and Unconfined Space

The Canadian Gas Association Certification Requirement, CGA

CR94-001 REV. 2 states that when combustion air supply is for the

unvented room heater only, it shall be sized at the rate of one (1)

square inch per 5000 BTU/HR (1.5 KW) from outdoors or the

manufacturer’s specification (whichever is greater). However, combustion air is acceptable when available from the principal heat

source and sized to the current CAN/CGA-B149.1 or .2 requirements. Where unvented equipment is installed in an area separated

from a combustion air supply by a door, then permanent openings,

grills or louvers shall be provided. One shall be within 18 inches (46

cm) from the ceiling and one 18 inches (46 cm) from the floor, sized

to one (1) square inch per 1000 BTU/HR (0.29 KW) to allow free

movement of air with the source of combustion air supply.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

Page 5

AIR FOR COMBUSTION AND

VENTILATION

Continued

AIR FOR COMBUSTION AND VENTILATION

Determining Fresh-Air Flow For Heater Location

5

5

DETERMINING FRESH-AIR FLOW FOR

HEATER LOCATION

Determining if You Have a Confined or

Unconfined Space

Use this work sheet to determine if you have a confined or unconfined space.

Space: Includes the room in which you will install heater plus any adjoining

rooms with doorless passageways or ventilation grills between the rooms.

1. Determine the volume of the space (length x width x height).

Length x Width x Height =___________ cu. ft. (m

space)

Example:

8 ft. (2.44 m) (ceiling height) = 2560 cu. ft. (72.6m3) (volume of space)

If additional ventilation to adjoining room is supplied with grills or open-

ings, add the volume of these rooms to the total volume of the space.

2. Multiply the space volume by 20 to determine the maximum Btu/Hr

(kW) the space can support.

__________ (volume of space) x 20 = [Maximum Btu/Hr (kW) the

Example:

[maximum Btu/Hr (kW) the space can support]

3. Add the Btu/Hr of all fuel burning appliances in the space.

* Do not include direct-vent gas appliances. Direct-vent draws combustion air from the outdoors and vents to the outdoors.

4. Compare the maximum Btu/Hr the space can support with the actual

amount of Btu/Hr used.

__________________

__________________ Btu/Hr (kW) (actual amount of Btu/Hr used)

Example:

Space size 20 ft. (6.1 m) (length) x 16 ft. (4.88 m) (width) x

space can support]

2560 cu. ft. (72.6m3) (volume of space) x 20 = 51,200

Vent-free heater _____________ Btu/Hr (kW)

Gas water heater* _____________ Btu/Hr (kW)

Gas furnace _____________ Btu/Hr (kW)

Vented gas heater _____________ Btu/Hr (kW)

Gas fireplace logs _____________ Btu/Hr (kW)

Other gas appliances* + _____________ Btu/Hr (kW)

Total = _____________ Btu/Hr (kW)

Example:

Gas water heater _____________ Btu/Hr (kW)

Vent-free heater + _____________ Btu/Hr (kW)

Total = _____________ Btu/Hr (kW)

51,200 Btu/Hr (15kW) (maximum the space can support)

60,000 Btu/Hr (17.6kW) [actual amount of Btu/Hr (kW)

used]

40,000 (11.7)

20,000 (5.9)

60,000 (17.6)

Btu/Hr (kW) (maximum the space can support)

3

) (volume of

The space in the above example is a confined space because the actual Btu/Hr

(kW) used is more than the maximum Btu/Hr (kW) the space can support.

You must provide additional fresh air. Your options are as follows:

A. Rework worksheet, adding the space of an adjoining room. If the

extra space provides an unconfined space, remove door to adjoining

room or add ventilation grills between rooms. See V entilation Air Fr om

Inside Building, page 6.

B. Vent room directly to the outdoors. See Ventilation Air From Out-

doors, page 6.

C. Install a lower Btu/Hr (kW) heater, if lower Btu/Hr (kW) size makes

room unconfined.

If the actual Btu/Hr used is less than the maximum Btu/Hr (kW) the space

can support, the space is an unconfined space. You will need no additional

fresh air ventilation.

WARNING: If the area in which the heater may be

operated is smaller than that defined as an unconfined

space or if the building is of unusually tight construction, provide adequate combustion and ventilation air

by one of the methods described in

Natural Gas Installation Code

Propane Installation Code

or applicable local code.

CAN/CGA B149.1

or

CAN/CGA B149.2

112157-01A

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 6

AIR FOR COMBUSTION AND VENTILATION

6

Ventilation Air

INSTALLATION

Check Gas Type

AIR FOR COMBUSTION AND

VENTILATION

Continued

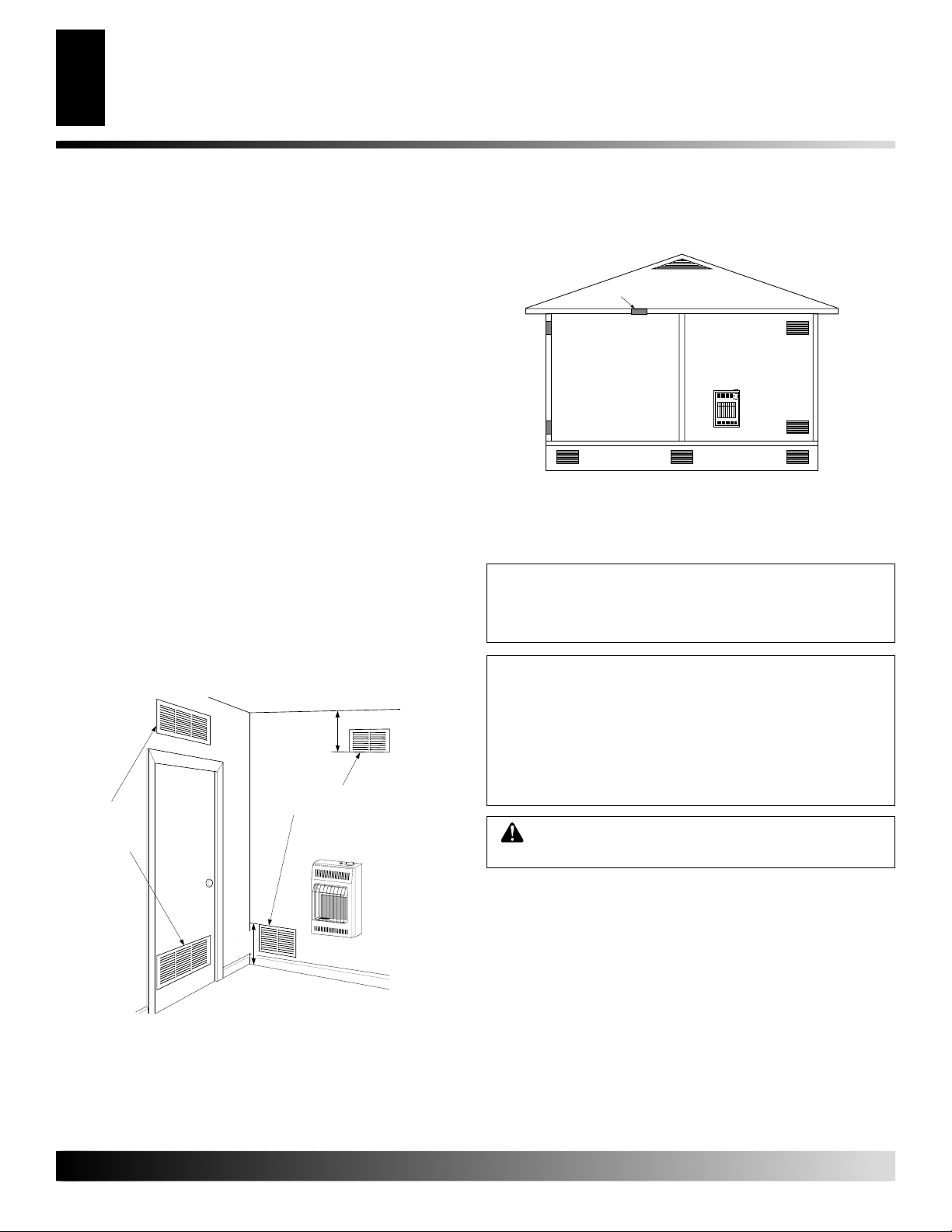

VENTILATION AIR

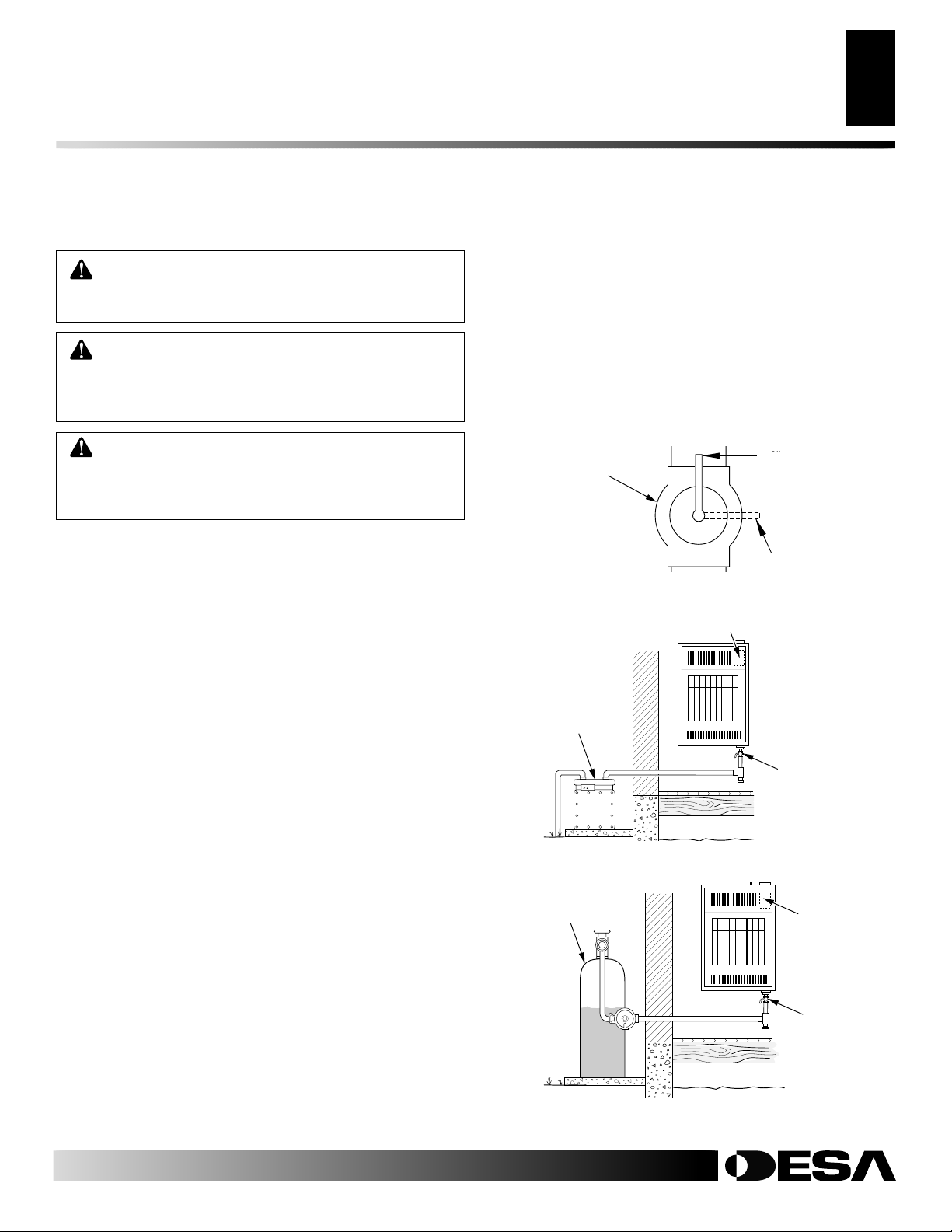

Ventilation Air From Inside Building

This fresh air would come from an adjoining unconfined space.

When ventilating to an adjoining unconfined space, you must

provide two permanent openings: one within 18" (45 cm) of the

ceiling and one within 18" (45 cm) of the floor on the wall

connecting the two spaces (see options 1 and 2, Figure 2). You can

also remove door into adjoining room (see option 3, Figure 2).

Follow CAN/CGA B149.1 Natural Gas Installation Code or CAN/

CGA B149.2 Propane Installation Code for required size of ventilation grills or ducts.

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation grills or ducts. You must

provide two permanent openings: one within 18" (45 cm) of the

ceiling and one within 18" (45 cm) of the floor. Connect these items

directly to the outdoors or spaces open to the outdoors. These spaces

include attics and crawl spaces. Follow CAN/CGA B149.1 Natural

Gas Installation Code or CAN/CGA B149.2 Propane Installation

Code for required size of ventilation grills or ducts.

IMPORTANT:

attic if attic has a thermostat-controlled power vent. Heated air

entering the attic will activate the power vent.

Ventilation

Grills

into Adjoining

Room,

Option 1

Do not provide openings for inlet or outlet air into

18"

12"

(45 cm)

Ventilation Grills

Into Adjoining Room,

Or

Remove

Door into

Adjoining

Room,

Option 3

Option 2

Ventilated

Attic

Crawl Space

Ventilated

To Attic

To

Crawl

Space

Outlet

Air

Inlet

Air

Outlet

Air

Inlet Air

Figure 3 - Ventilation Air from Outdoors

INSTALLATION

Installation must conform with local codes or, in the

absence of local codes, with the current standard

CAN/CGA B149.1 Natural Gas Installation Code

CAN/CGA B149.2 Propane Installation Code

NOTICE: This heater is intended for use as supplemental heat. Use this heater along with your primary

heating system. Do not install this heater as your

primary heat source. If you have a central heating

system, you may run system’s circulating blower

while using heater. This will help circulate the heat

throughout the house. In the event of a power outage,

you can use this heater as your primary heat source.

WARNING: A qualified service person must in-

stall heater. Follow all local codes.

CHECK GAS TYPE

or

18"

12"

(45 cm)

Figure 2 - Ventilation Air from Inside Building

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Use only the correct type of gas (natural or propane/LP). If your gas

supply is not the correct gas type, do not install heater. Call dealer

where you bought heater for proper type heater.

112157-01A

Page 7

)

INSTALLATION

Continued

INSTALLATION

Installation Items

Locating Heater

7

7

INSTALLATION ITEMS

Before installing heater, make sure you have the items listed below.

• for propane/LP gas, external regulator (supplied by installer)

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• equipment shutoff valve *

• ground joint union

• sediment trap

• tee joint

• pipe wrench

• for natural gas, test gauge connection*

* A CSA design-certified equipment shutoff valve with 1/8" NPT

tap is an acceptable alternative to test gauge connection. Purchase

the optional CSA design-certified equipment shutoff valve from

your dealer. See Accessories, page 29.

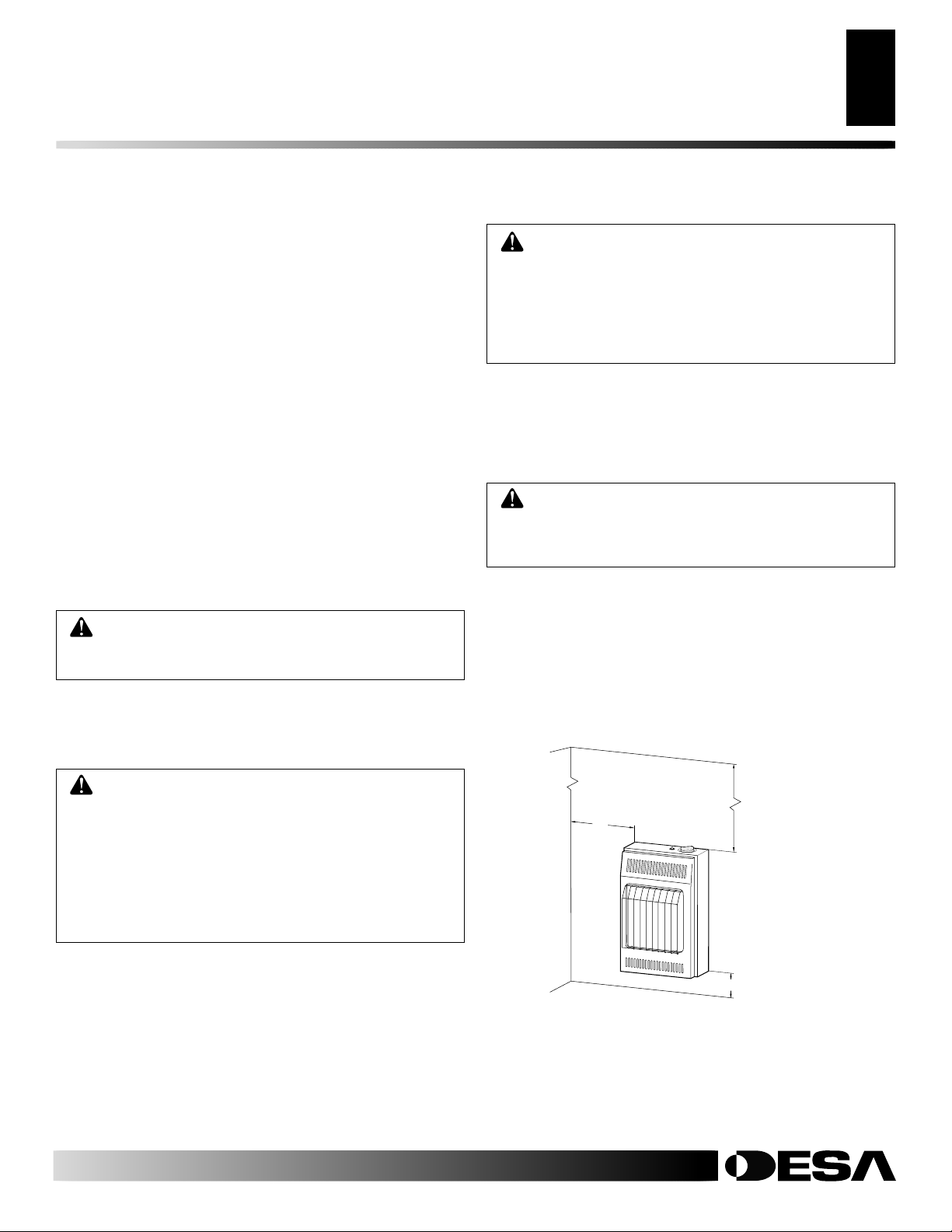

LOCATING HEATER

This heater is designed to be mounted on a wall.

WARNING: Maintain the minimum clearances

shown in Figure 4. If you can, provide greater clearances from floor, ceiling, and joining wall.

Models GCN20T and GCP20T only: You can locate heater on

floor, away from a wall. An optional floor mounting stand is needed.

Purchase the floor mounting stand from your dealer. See Accesso-

ries, page 29.

CAUTION: This heater creates warm air currents.

These currents move heat to wall surfaces next to

heater. Installing heater next to vinyl or cloth wall

coverings or operating heater where impurities (such

as but not limited to, tobacco smoke, aromatic candles,

cleaning fluids, oil or kerosene lamps, etc.) in the air

exist, may discolor walls or cause odors.

IMPORTANT:

Vent-free heaters add moisture to the air. Although

this is beneficial, installing heater in rooms without enough ventilation air may cause mildew to form from too much moisture. See

Air for Combustion and Ventilation, pages 4 through 6. If high

humidity is experienced, a dehumidifier may be used to help lower

the water vapor content in the air.

CAUTION: If you install the heater in a home garage

• heater pilot and burner must be at least 18 inches

(46 cm) above floor

• locate heater where moving vehicle will not hit it

For convenience and efficiency, install heater

• where there is easy access for operation, inspection, and service

• in coldest part of room

For 20,000 Btu/hr (5.9 kW) models, an optional fan kit is available

from your dealer. See Accessories, page 29. If planning to use fan,

locate heater near a grounded electrical outlet. Outlet must be

grounded in accordance with local codes, with the current Canadian

Electrical Code Part 1 CSA C22.1.

CEILING

WARNING: Never install the heater

• in a bedroom or bathroom

• in a recreational vehicle

• where curtains, furniture, clothing, or other flam-

mable objects are less than 36 inches (92 cm) from

the front, top, or sides of the heater

• as a fireplace insert

• in high traffic areas

• in windy or drafty areas

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

6"

(15.3 cm)

Minimum

From

Sides Of

Heater

Left

Side

Figure 4 - Mounting Clearances As Viewed From Front of Heater

36" (91.5 cm

Minimum

6,000 Btu/Hr

(1.8 kW)

Model Shown

Right

Side

Minimum To Top Surface

Of Carpeting, Tile Or Other

Combustible Material

3" (7.7 cm)

Page 8

INSTALLATION

8

Thermostat Sensing Bulb (Thermostat Models Only)

Installing Heater To Wall 6,000 and 10,000 Btu/Hr Models (1.8 and 2.9 kW)

INSTALLATION

Continued

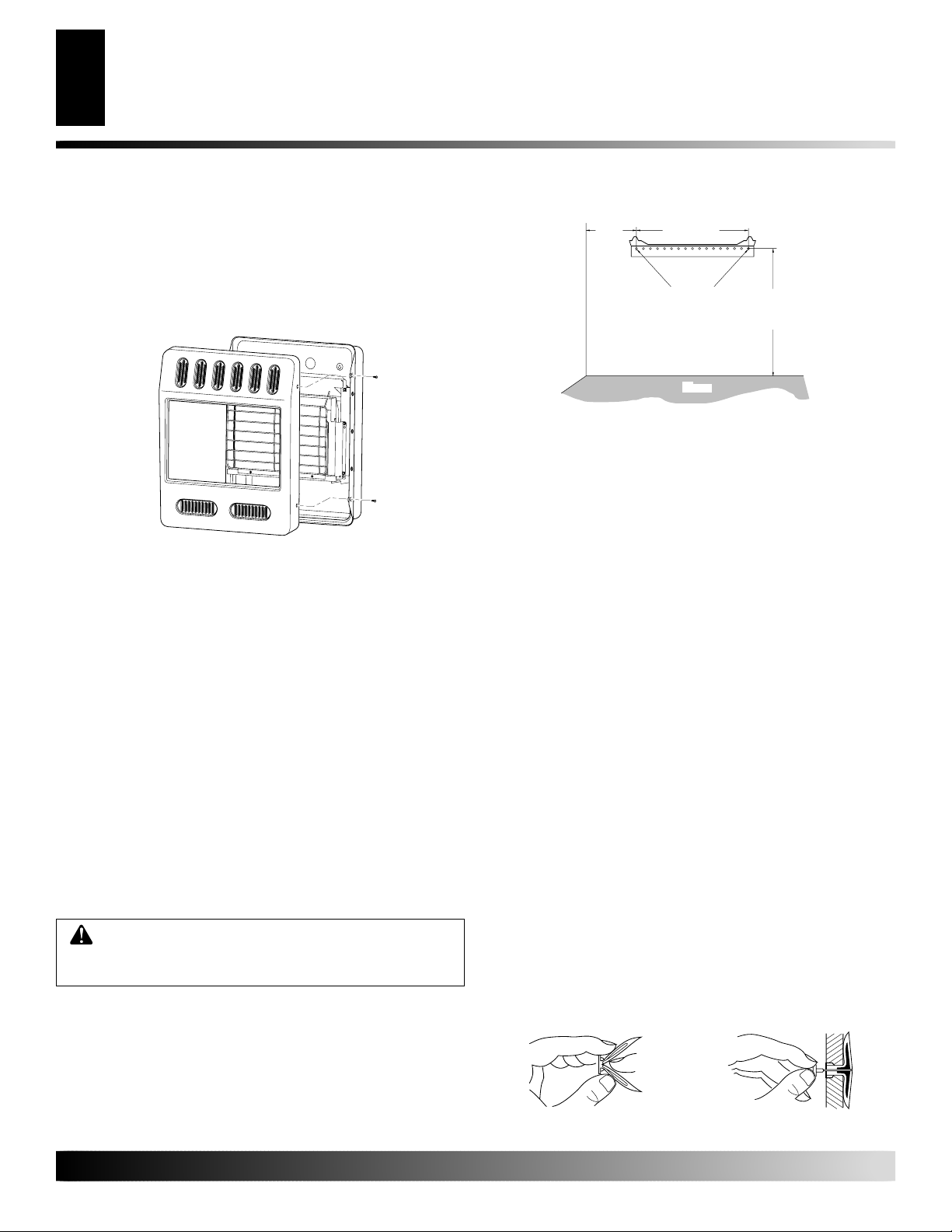

THERMOSTAT SENSING BULB

(Thermostat Models Only)

The thermostat sensing bulb has been placed inside the heater for

protection during shipping.

Locating Thermostat Sensing Bulb (for thermostat

applications)

1. Remove front panel of heater [for 10,000 Btu/Hr (2.9 KW) heater,

see Figure 11 page 9 or for 20,000 Btu/Hr (5.9 KW) heater see

Figure 14, page 10].

2. Locate thermostat sensing bulb just under burner assembly.

IMPORTANT:

Attach thermostat sensing bulb to back of heater for

proper operation.

Attaching Thermostat Sensing Bulb

1. Remove thermostat sensing bulb from holders inside heater.

Route through slot opening in bottom of heater.

2. Place clamp on thermostat sensing bulb as shown in Figure 5.

Clamp is provided in hardware package.

3. Snap clamp into upper mounting hole as shown in Figure 5.

Mounting hole is located on lower left edge on back of heater.

Make sure the thermostat sensing bulb is pointing up.

Thermostat

Sensing Bulb

Clamp

Figure 5 - Attaching Thermostat Sensing Bulb

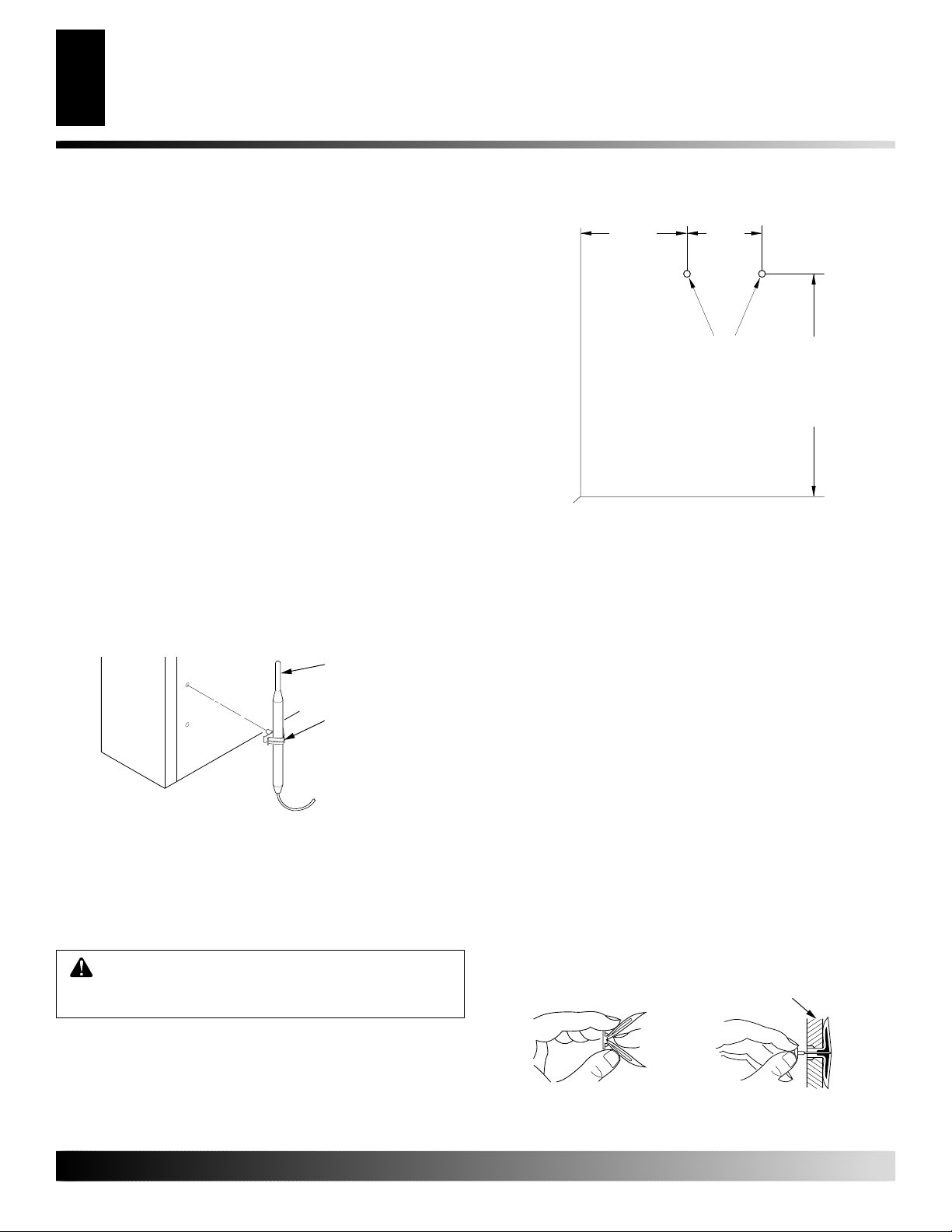

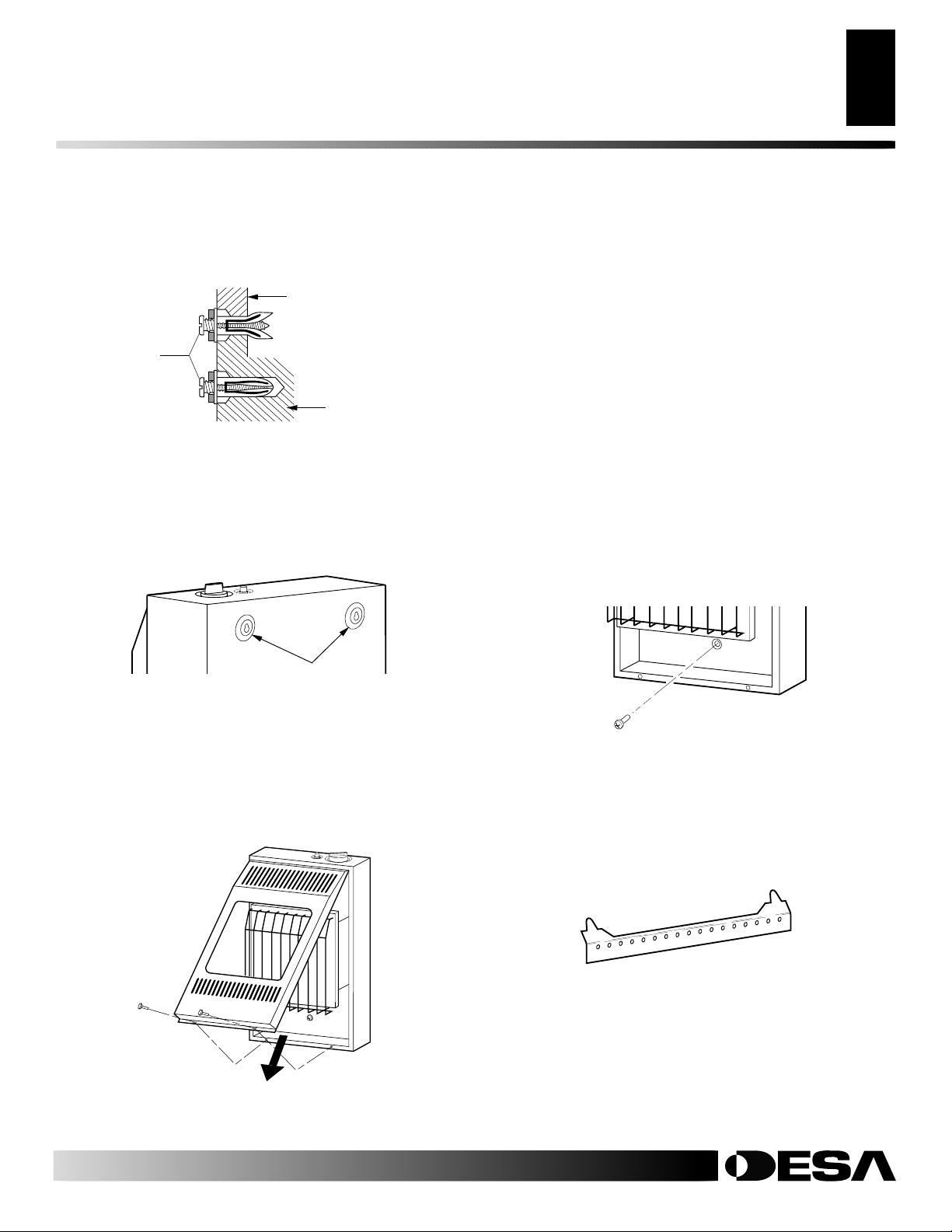

INSTALLING HEATER TO WALL 6,000 AND

10,000 BTU/HR MODELS (1.8 AND 2.9 KW)

Marking Screw Locations

1. Determine where you will locate heater.

WARNING: Maintain minimum clearances shown

in Figure 6. If you can, provide greater clearances

from floor and joining wall.

7

/8"

8

(22.5 cm)

Blue Flame

Minimum To

Maintain 6"

Clearance

From Wall

JOINING WALL

FLOOR

Figure 6 - Mounting Screw Locations

3

/4"

7

(19.7 cm)

Mounting

Screw

Locations

1

/4" (51.4 cm)

20

Minimum To

Maintain 3" (7.6

cm) Clearance

From Floor

Installing Two Mounting Screws

Note:

Wall anchors and mounting screws are in hardware package.

The hardware package is provided with heater.

Attaching to wall stud method

For attaching mounting screw to wall stud

1. Drill hole at marked location using 9/64" drill bit.

2. Insert mounting screw into wall stud.

3. Tighten screw until 1/16" (1.6 mm) space (thickness of penny)

is between screwhead and wall.

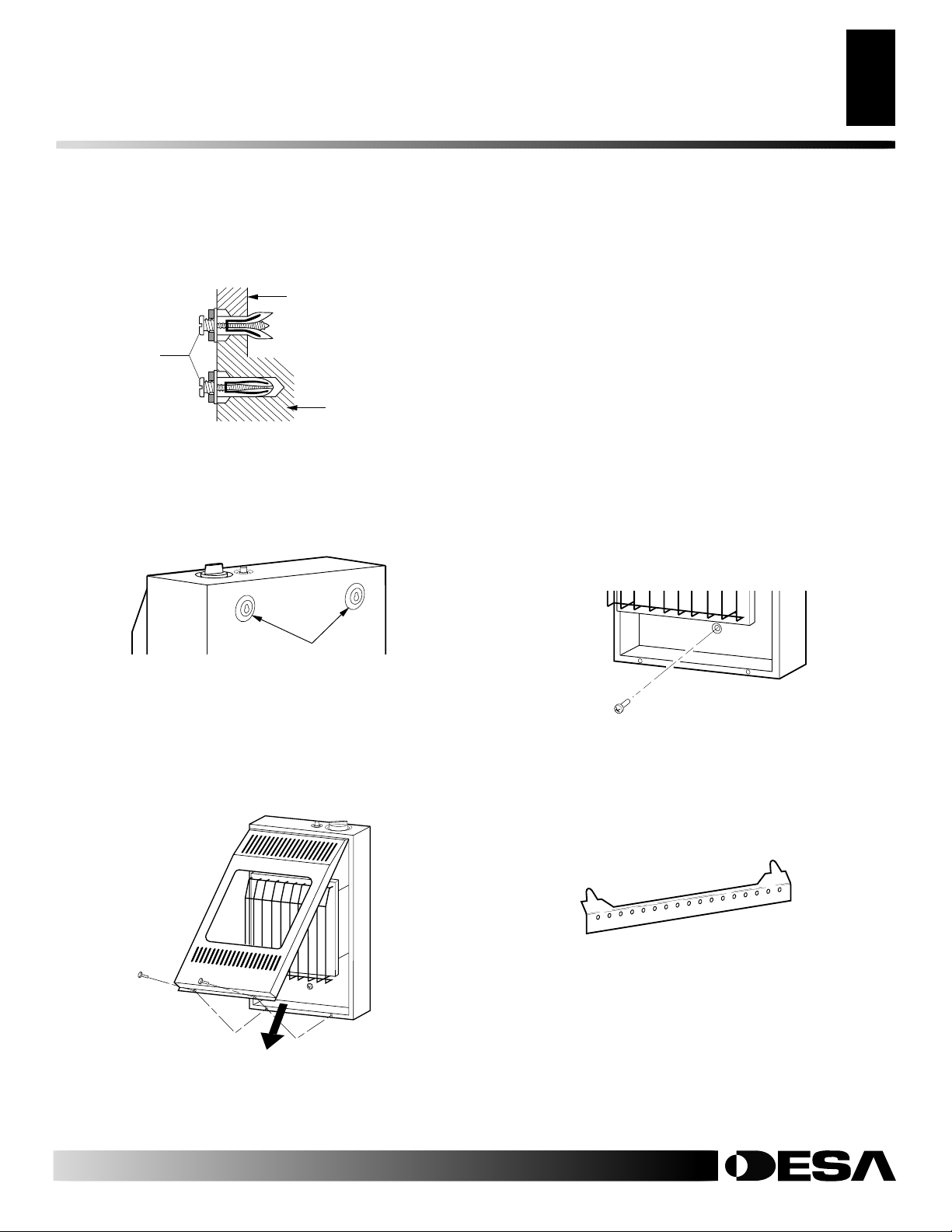

Attaching to wall anchor method

Follow instructions below to attach mounting screws to hollow walls

(wall areas between studs) or solid walls (concrete or masonry).

1. Drill holes at marked locations using 5/16" drill bit. For solid

walls (concrete or masonry), drill at least 1 1/4" (3.2 cm) deep.

2. Fold wall anchor (see Figure 7).

3. Insert wall anchor (wings first) into hole. Tap anchor flush

to wall.

4.

For thin walls [1/2" (1.27 cm ) or less], insert red key into wall

anchor. Push red key to “pop” open anchor wings (see Figure 8).

IMPORTANT:

(1.27 cm) thick] or solid walls, do not pop open wings.

Do not hammer key! For thick walls [over 1 /2"

Thin Walls (1/4" to 1/2" thick)

(1.6 to 1.2 cm)

2. Mark two mounting screw locations on wall (see Figure 6).

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Figure 7 - Folding Anchor

Figure 8 - Popping Open Anchor

Wings For Thin Walls

112157-01A

Page 9

INSTALLATION

Continued

Installing Heater To Wall 6,000 and 10,000 Btu/Hr Models (1.8 and 2.9 kW) (Cont.)

INSTALLATION

Installing Heater To Wall 20,000 Btu/Hr Models (5.9 kW)

9

9

5. Tighten two screws until 1/16" (1.6 mm) space (thickness of

penny) is between screwheads and wall (see Figure 9).

Thin or

Thick Wall

(thick wall

shown)

1/16"

Space

(1.6 mm)

Solid

Wall

Figure 9 - Tightening Anchors

Placing Heater On Mounting Screws

1. Locate two keyhole slots on back panel of heater (see Figure 10).

2. Place large openings of slots over screwheads. Slide heater

down until screws are in small portion of slots.

Keyhole Slots

Installing Bottom Mounting Screw

1. Locate bottom mounting hole. This hole is near bottom on back

panel of heater (see Figure 12).

2. Mark screw location on wall.

3. Remove heater from wall.

4. If installing bottom mounting screw into hollow or solid wall,

install wall anchor. Follow steps 1 through 5 under Attaching T o

Wall Anchor Method, page 10. If installing bottom mounting

screw into wall stud, drill hole at marked location using 9/64"

drill bit.

5. Replace heater on wall.

6. Insert bottom anchor screw through back panel into bottom

anchor or drilled hole (see Figure 12).

7. Tighten screw until heater is firmly secured to wall. Do not

over tighten.

Note:

Do not replace front panel at this time. Replace front

panel after making gas connections and checking for leaks (see

pages 11 and 12).

Figure 10 - Location Of Keyhole Slots On Back Panel Of Heater

Removing Front Panel Of Heater

1. Remove two screws near bottom corners of front panel.

2. Lift straight up on grill guard until it stops. Grill guard will slide

up about 1/4" (6 mm).

3. Pull bottom of front panel forward, then down.

Figure 11 - Removing Front Panel Of Heater

Figure 12 - Installing Bottom Mounting Screw

INSTALLING HEATER TO WALL

20,000 BTU/HR MODELS (5.9 KW)

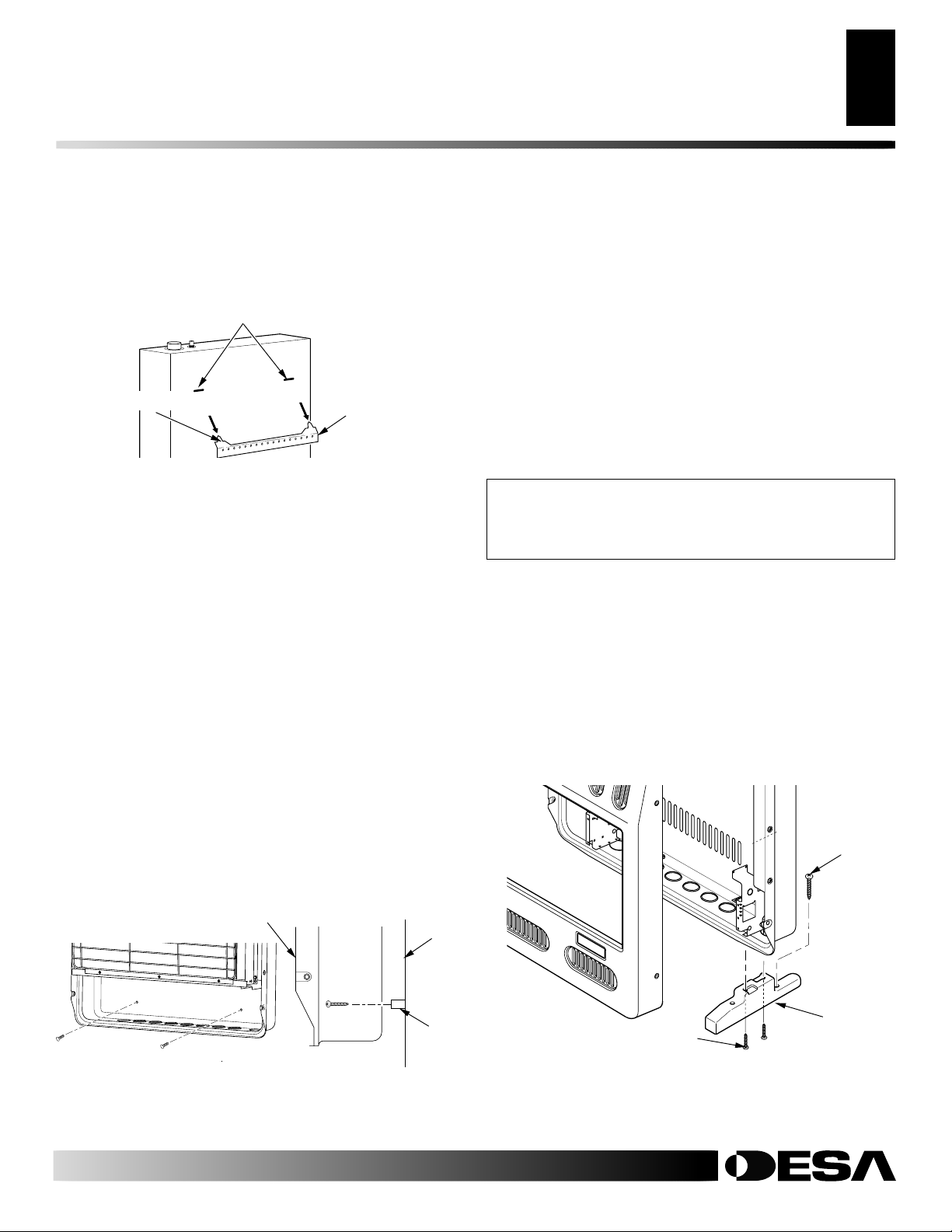

Mounting Bracket

Locate mounting bracket in heater carton. Remove mounting bracket

from heater carton.

Figure 13 - Mounting Bracket

112157-01A

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 10

INSTALLATION

10

Installing Heater To Wall 20,000 Btu/Hr Models (5.9 kW) (Cont.)

INSTALLATION

Continued

Removing Front Panel Of Heater (20,000 Btu/Hr

Models Only) (5.9 kW)

1. Remove the four painted screws, two on each side of front panel.

2. Pull bottom of front panel forward, then out.

3. Remove any remaining packaging materials.

8"

(20.3 cm)

Min.

Only Insert Mounting

Screws Through Last

Hole On Each End

Adjoining Wall

Figure 15 - Mounting Bracket Clearances

14"

(35.6 cm)

18 3/4"

(47.7 cm)

Min.

Floor

Attaching Mounting Bracket To Wall

Note:

Wall anchors, mounting screws, and spacers are in hardware

package. The hardware package is provided with heater.

Figure 14 - Removing Front Panel Of Heater

Methods For Attaching Mounting Bracket To Wall

Only use last hole on each end of mounting bracket to attach bracket

to wall. These two holes are 14 inches (35.5 cm) apart from their

centers. Attach mounting bracket to wall in one of two ways:

1. Attaching to wall stud

2. Attaching to wall anchor

Attaching to Wall Stud: This method provides the strongest hold.

Insert mounting screws through mounting bracket and into wall studs.

Attaching to Wall Anchor: This method allows you to attach

mounting bracket to hollow walls (wall areas between studs) or to

solid walls (concrete or masonry).

Decide which method better suits your needs. Either method will

provide a secure hold for the mounting bracket.

Marking Screw Locations

1. Tape mounting bracket to wall where heater will be located.

Make sure mounting bracket is level.

WARNING: Maintain minimum clearances shown

in Figure 15. If you can, provide greater clearances

from floor and joining wall.

2. Mark screw locations on wall (see Figure 15).

Note:

Only mark last hole on each end of mounting bracket.

Insert mounting screws through these holes only.

3. Remove tape and mounting bracket from wall.

Attaching To Wall Stud Method

For attaching mounting bracket to wall studs

1. Drill holes at marked locations using 9/64" drill bit.

2. Place mounting bracket onto wall. Line up last hole on each

end of bracket with holes drilled in wall.

3. Insert mounting screws through bracket and into wall studs.

4. Tighten screws until mounting bracket is firmly fastened to

wall studs.

Attaching To Wall Anchor Method

For attaching mounting bracket to hollow walls (wall areas between studs) or solid walls (concrete or masonry)

1. Drill holes at marked locations using 5/16" drill bit. For solid

walls (concrete or masonry), drill at least 1" (2.5 cm) deep.

2. Fold wall anchor as shown in Figure 16.

3. Insert wall anchor (wings first) into hole. Tap anchor flush

to wall.

4. For thin walls [1/2" (1.27 cm) or less ], insert red key into wall

anchor. Push red key to “pop” open anchor wings.

IMPORTANT:

Do not hammer key!

For thick walls [over 1/2" (1.27 cm) thick] or solid walls, do

not pop open wings.

5. Place mounting bracket onto wall. Line up last hole on each

end of bracket with wall anchors.

6. Insert mounting screws through bracket and into wall anchors.

7. Tighten screws until mounting bracket is firmly fastened to wall.

Figure 16 - Folding Anchor

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Figure 17- Popping Open

Anchor Wings For Thin Walls

112157-01A

Page 11

INSTALLATION

Continued

Installing Heater To Wall 20,000 Btu/Hr Models (5.9 kW) (Cont.)

INSTALLATION

Mounting Heater To Floor With Optional Floor Kit [20,000 Btu/Hr (5.9 kW) Only]

11

11

Placing Heater On Mounting Bracket

1. Locate two horizontal slots on back panel of heater.

2. Place heater onto mounting bracket. Slide horizontal slots onto

stand-out tabs on mounting bracket.

Horizontal Slots

Stand-Out Tab

Figure 18 - Mounting Heater Onto Mounting Bracket

Mounting Bracket

(attached to wall)

Installing Bottom Mounting Screws

1. Locate two bottom mounting holes. These holes are near bottom on back panel of heater (see Figure 19).

2. Mark screw locations on wall.

3. Remove heater from mounting bracket.

4. If installing bottom mounting screws into hollow or solid wall,

install wall anchors. Follow steps 1 through 4 under Attaching T o

W all Anc hor Method, page 10.

If installing bottom mounting screw into wall stud, drill holes

at marked locations using 9/64" drill bit.

5. Replace heater onto mounting bracket.

6. Place spacers between bottom mounting holes and wall anchor

or drilled hole.

7. Hold spacer in place with one hand. With other hand, insert

mounting screw through bottom mounting hole and spacer.

Place tip of screw in opening of wall anchor or drilled hole.

8. Tighten both screws until heater is firmly secured to wall. Do

not over tighten.

Note:

Do not replace front panel at this time. Replace front

panel after making gas connections and checking for leaks (see

pages 11 and 12).

Heater

Wall

MOUNTING HEATER TO FLOOR WITH OPTIONAL

FLOOR KIT [20,000 BTU/HR (5.9 KW) ONLY]

Mounting Base Feet to Heater

1. Lay heater cabinet on its back on a table with the heater bottom overhanging the table edge.

2. Align holes in base foot with mounting holes on bottom of

cabinet (see Figure 20).

3. Secure base foot to heater using sheet metal screws.

4. Repeat for other side.

Mounting Base Feet to Floor (Where required by

local code)

If heater is being installed directly on carpeting, tile or

other combustible material (other than wood flooring),

the heater shall be installed on a metal or wood panel

extending the full width and depth of the appliance.

1. Remove front cover (see Removing Front Panel of Heater,

page 10).

2. Position heater with base feet in desired location. Mark holes

for drilling. Remove heater with base.

3. If mounting base to a wood floor, drill 1/8 inch diameter hole,

3/4 inch (2 cm) deep. (Do not use anchors in wood floors).

If mounting base to a concrete floor, drill with 1/4 inch diameter concrete drill bit, 13/8 inches (3.5 cm) into floor. Insert

anchors completely into holes.

4. Reposition heater with base feet over holes. Secure base to floor

with wood screws. See Figure 20.

Wood

Screw

Front View

Figure 19 - Installing Bottom Mounting Screws

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

Side View

Spacer

Base Foot

Sheet Metal Screw

Figure 20 - Installing Base Feet (Heater may vary from illustration)

Page 12

INSTALLATION

12

Connecting To Gas Supply

INSTALLATION

Continued

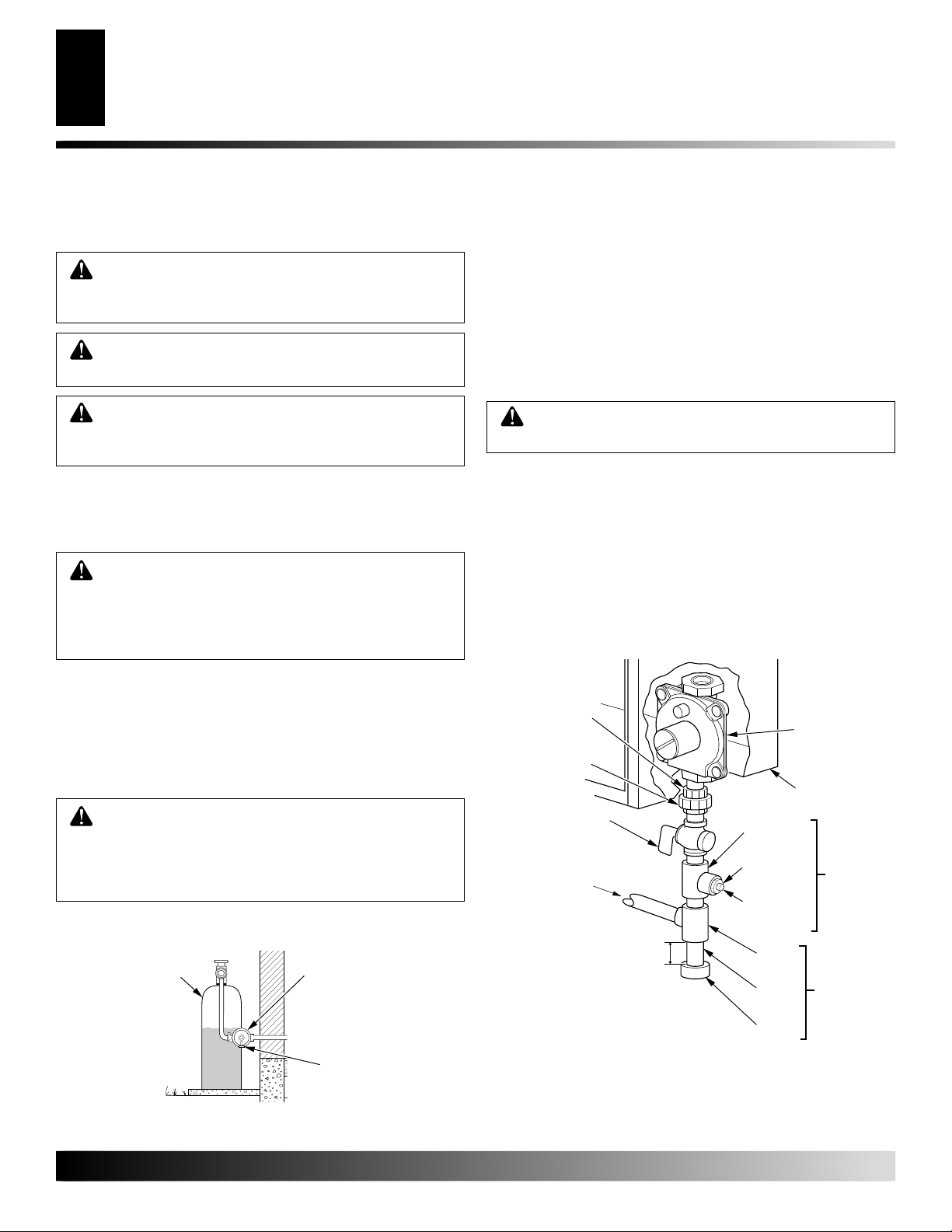

CONNECTING TO GAS SUPPLY

WARNING: This appliance requires a 3/8" NPT

(National Pipe Thread) inlet connection to the pressure regulator.

WARNING: A qualified service person must connect heater to gas supply. Follow all local codes.

WARNING: For natural gas, never connect heater to

private (non-utility) gas wells. This gas is commonly

known as wellhead gas.

IMPORTANT

connecting heater to gas line. Gas line pressure must be no greater than

10.5 inches (26.6 cm) of water. If gas line pressure is higher, heater

regulator damage could occur.

CAUTION: For propane/LP gas, never connect

heater directly to the propane/LP supply. This heater

requires an external regulator (not supplied). Install

the external regulator between the heater and propane/LP supply.

For propane/LP gas, the installer must supply an external regulator. The

external regulator will reduce incoming gas pressure. You must reduce

incoming gas pressure to between 11 and 14 inches (28 and 35.5 cm)

of water. If you do not reduce incoming gas pressure, heater regulator

damage could occur. Install external regulator with the vent pointing

down as shown in Figure 21. Pointing the vent down protects it from

freezing rain or sleet.

CAUTION: Use only new, black iron or steel pipe.

Internally-tinned copper tubing may be used in certain areas. Check your local codes. Use pipe of large

enough diameter to allow proper gas volume to heater.

If pipe is too small, undue loss of volume will occur.

Typical inlet pipe diameter for 20,000 btu/hr (5.9 kW) models - 3/8"

or greater.

: For natural gas, check gas line pressure before

Propane/LP

Supply Tank

External Regulator

Installation must include equipment shutoff valve, union, and plugged

1/8" NPT tap. Locate NPT tap within reach for test gauge hook up.

NPT tap must be upstream from heater (see Figure 22).

IMPORTANT:

Install an equipment shutoff valve in an accessible

location. The equipment shutoff valve is for turning on or shutting

off the gas to the appliance.

Apply pipe joint sealant lightly to male NPT threads. This will

prevent excess sealant from going into pipe. Excess sealant in pipe

could result in clogged heater valves.

WARNING: Use pipe joint sealant that is resistant

to liquid petroleum (LP) gas.

We recommend that you install sediment trap in supply line as

shown in Figure 22. Locate sediment trap where it is within reach for

cleaning. Install in piping system between fuel supply and heater.

Locate sediment trap where trapped matter is not likely to freeze. A

sediment trap traps moisture and contaminants. This keeps them

from going into heater controls. If sediment trap is not installed or

is installed wrong, heater may not run properly.

IMPORTANT:

Hold pressure regulator with wrench when connecting it to gas piping and/or fittings. Do not over tighten pipe

connection to regulator. The regulator body could be damaged.

3/8" NPT

Pipe Nipple

Ground

Joint Union

Equipment

Shutoff Valve*

Natural Gas

From Gas Meter

[

6/10,000 Btu/Hr (1.8/2.9 kW)

4" (10 cm) W.C. to

10.5" (26.7 cm) W.C.

Pressure]

20,000 Btu/Hr (5.9 kW)

5" (12.7 cm) W.C. to 10.5"

(26.7 cm) W.C. Pressure]

Propane/LP

From External Regulator

(11" (27.9 cm) W.C. to

14" (35.6 cm) W.C. Pressure)

3"

7.7 cm)

Minimum

Tee Joint

Reducer

Bushing to

1/8" NPT

1/8" NPT

Plug Tap

Tee

Joint

Pipe

Nipple

Cap

Pressure

Regulator

Heater

Cabinet

Test

Gauge

Connection*

Sediment

Trap

Vent Pointing Down

Figure 21 - External Regulator With Vent Pointing Down

(Propane/LP Systems Only)

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Figure 22 - Gas Connection

* A CSA design-certified equipment shutoff valve with 1/8" NPT

tap is an acceptable alternative to test gauge connection. Purchase

the optional CSA design-certified equipment shutoff valve from

your dealer. See Accessories, page 29.

112157-01A

Page 13

ON

POSITIO

OF

POSI

INSTALLATION

Continued

Checking Gas Connections

INSTALLATION

13

13

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping and connections

for leaks after installing or servicing. Correct all leaks

at once.

WARNING: Never use an open flame to check for

a leak. Apply a noncorrosive leak detection fluid to all

joints. Bubbles forming show a leak. Correct all leaks

at once.

CAUTION: For propane/LP gas, make sure external regulator has been installed between propane/LP

supply and heater. See guidelines under

to Gas Supply

, page 12.

Pressure Testing Gas Supply Piping System

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1. Disconnect appliance with its appliance main gas valve (control valve) and equipment shutoff valve from gas supply piping system. Pressures in excess of 1/2 psig (3.5 kPa) will damage heater regulator.

2. Cap off open end of gas pipe where equipment shutoff valve

was connected.

3. Pressurize supply piping system by either opening propane/LP

supply tank valve for propane/LP gas or opening main gas valve

located on or near gas meter for natural gas, or using compressed air.

4. Check all joints of gas supply piping system. Apply a noncorrosive

leak detection fluid to all joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6. Reconnect heater and equipment shutoff valve to gas supply.

Check reconnected fittings for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Figure 23).

2. Pressurize supply piping system by either opening propane/

LP supply tank valve for propane/LP gas or opening main gas

valve located on or near gas meter for natural gas, or using

compressed air.

3. Check all joints from gas meter for natural gas (see Figure 24)

or propane/LP supply tank for propane/LP gas, to equipment

shutoff valve (see Figure 25). Apply a noncorrosive leak detection fluid to all joints. Bubbles forming show a leak.

4. Correct all leaks at once.

Connecting

2. Open main gas valve located on or near gas meter for natural

gas or open propane/LP supply tank valve.

3. Make sure control knob of heater is in the OFF position.

4. Check all joints from equipment shutoff valve to control valve

(see Fig ures 24 and 25 ). Apply a noncorrosive leak detection

fluid to all joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6. Light heater (see Operating Heater pages 14 and 15). Check

the rest of the internal joints for leaks.

7. Turn off heater (see To Turn Off Gas to Appliance, page 15).

8. Replace front panel.

Equipment

Shutoff Valve

Figure 23 - Equipment Shutoff Valve

Control Valve Location

Gas

Meter

Figure 24 - Checking Gas Joints for Natural Gas [6, 000 Btu/Hr

Model (1.8 kW) Shown]

Propane/LP

Supply Tank

Open

Closed

Equipment

Shutoff Valve

Control

Valve Location

Equipment

Shutoff Valve

Pressure Testing Heater Gas Connections

1. Open equipment shutoff valve (see Figure 23).

112157-01A

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Figure 25 - Checking Gas Joints for Propane/LP Gas [6,000

Btu/Hr Model (1.8 kW) Shown]

Page 14

OPERATING HEATER

14

For Your Safety Read Before Lighting

Lighting Instructions

OPERATING HEATER

FOR YOUR SAFETY READ

BEFORE LIGHTING

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by

hand, don’t try to repair it, call a qualified service technician or gas supplier. Force or attempted r epair may result

in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

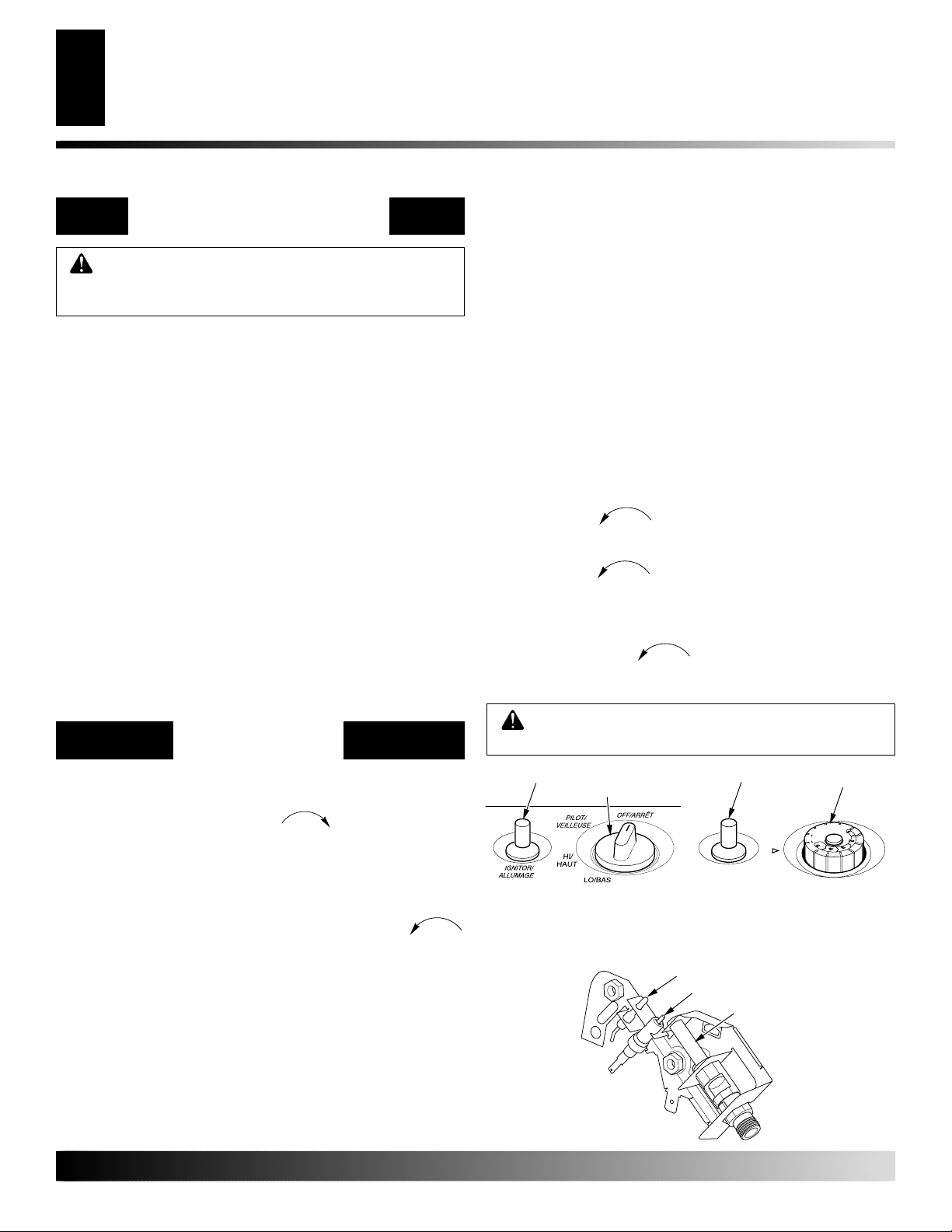

LIGHTING

INSTRUCTIONS

1. STOP! Read the safety information above.

2. Make sure equipment shutoff valve is fully open.

3. Turn control knob clockwise

(see Figure 26 or 27).

4. Wait five (5) minutes to clear out any gas. Then smell for

gas, including near the floor. If you smell gas, STOP! Follow “B” in the safety information, abov e. If you don’t smell

gas, go to the next step.

5. Press in control knob and turn counterclockwise

to the PILOT position. Keep control knob pressed in for

five (5) seconds (see Figure 26 or 27).

Note:

You may be running this heater for the first time

after hooking up to gas supply . If so, the control knob may

need to be pressed in for 30 seconds or more. This will allow air to bleed from the gas system.

• If control knob does not pop up when released, contact a

qualified service person or gas supplier for repairs.

to the OFF position

Clockwise

C-clockwise

6. With control knob pressed in, push down and release ignitor button. This will light pilot. The pilot is attached to the

front of burner. The pilot can be seen through the glass panel.

If needed, keep pressing ignitor button until pilot lights.

Note:

If pilot does not stay lit, refer to Troubleshooting,

pages 18 through 20. Also contact a qualified service person or gas supplier for repairs. Until r epairs are made, light

pilot with a match. To light pilot with amatch, see Manual

Lighting Procedure, page 15.

7. Keep control knob pressed in for 30 seconds after lighting

pilot. After 30 seconds, release control knob.

• If control knob does not pop up when released, contact a

qualified service person or gas supplier for repairs.

Note:

If pilot goes out, repeat steps 3 through 7. Thermostat model heaters have a safety interlock system. W ait one

(1) minute before lighting pilot again.

8. Manual Controlled Models Only T urn control knob coun-

terclockwise

C-clockwise

to the HI position. The main burner

should light. Set control knob to HI or LO. To turn control

knob from HI to LO, press in the control knob and turn counterclockwise

Note:

Both HI and LO are locked positions. Y ou must pr ess

C-clockwise

.

in control knob before turning it from these positions.

9. Thermostat Controlled Models Only T urn control knob

counterclockwise

C-clockwise

to desired heating level. The

main burner should light. Set control knob to any heat le vel

between 1 and 5.

CAUTION: Do not try to adjust heating levels by

using the equipment shutoff valve.

Ignitor Button

Control Knob

Figure 26 - Control Knob In

The OFF Position (Manual

Controlled Models)

Ignitor Button

Control Knob

T

O

L

I

P

F

F

O

Figure 27 - Control Knob In

The OFF Position (Thermostat

Controlled Models)

Thermocouple

Ignitor Electrode

Pilot Burner

Figure 28 - Pilot

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

Page 15

To Turn Off Gas To Appliance

OPERATING HEATER

Thermostat Control Operation (Thermostat Models Only)

Manual Lighting Procedure

INSPECTING BURNER

Pilot Flame Pattern

Burner Flame Pattern

15

15

OPERATING HEATER

Continued

TO TURN OFF GAS

TO APPLIANCE

Shutting Off Heater

1. Press in and turn control knob clockwise

position.

2. Turn off all electric power to the appliance if service is to

be performed.

Shutting Off Burner Only (pilot stays lit)

Turn control knob clockwise

to the PILOT position.

Clockwise

THERMOSTAT CONTROL

OPERATION (THERMOSTAT

MODELS ONLY)

The thermostatic control used on these models differs from

standard thermostats. Standard thermostats simply turn on and

off the burner. The thermostat used on this heater senses the

room temperature. The thermostat adjusts the amount of gas

flow to the burner. This increases or decreases the burner flame

height. At times the room may exceed the set temperature. If so,

the burner will shut off. The burner will cycle back on when room

temperature drops below the set temperature. The control knob

can be set to any heat level between 1 and 5.

Note:

The thermostat sensing bulb measures the temperature of

air near the heater cabinet. This may not always agree with room

temperature (depending on housing construction, installation

location, room size, open air temperatures, etc.). Frequent use of

your heater will let you determine your own comfort levels.

MANUAL LIGHTING

PROCEDURE

1. Remove front panel [for 6,000 (1.8 kW) and 10,000 (2.9 kW)

Btu/Hr heater see Figure 11, page 9, for 20,000 Btu/Hr (5.9

kW) heater, see Figure 14 page 10].

2. Follow steps 1 through 5 under Lighting Instructions,

page 14.

3. With control knob pressed in, strik e match. Hold match to

pilot until pilot lights.

4. Keep control knob pressed in for 30 seconds after pilot is

lit. After 30 seconds, release control knob. Follow step 8

under Lighting Instructions, page 14.

5. Replace front panel.

Clockwise

to the OFF

INSPECTING BURNER

Check pilot flame pattern and burner flame pattern often.

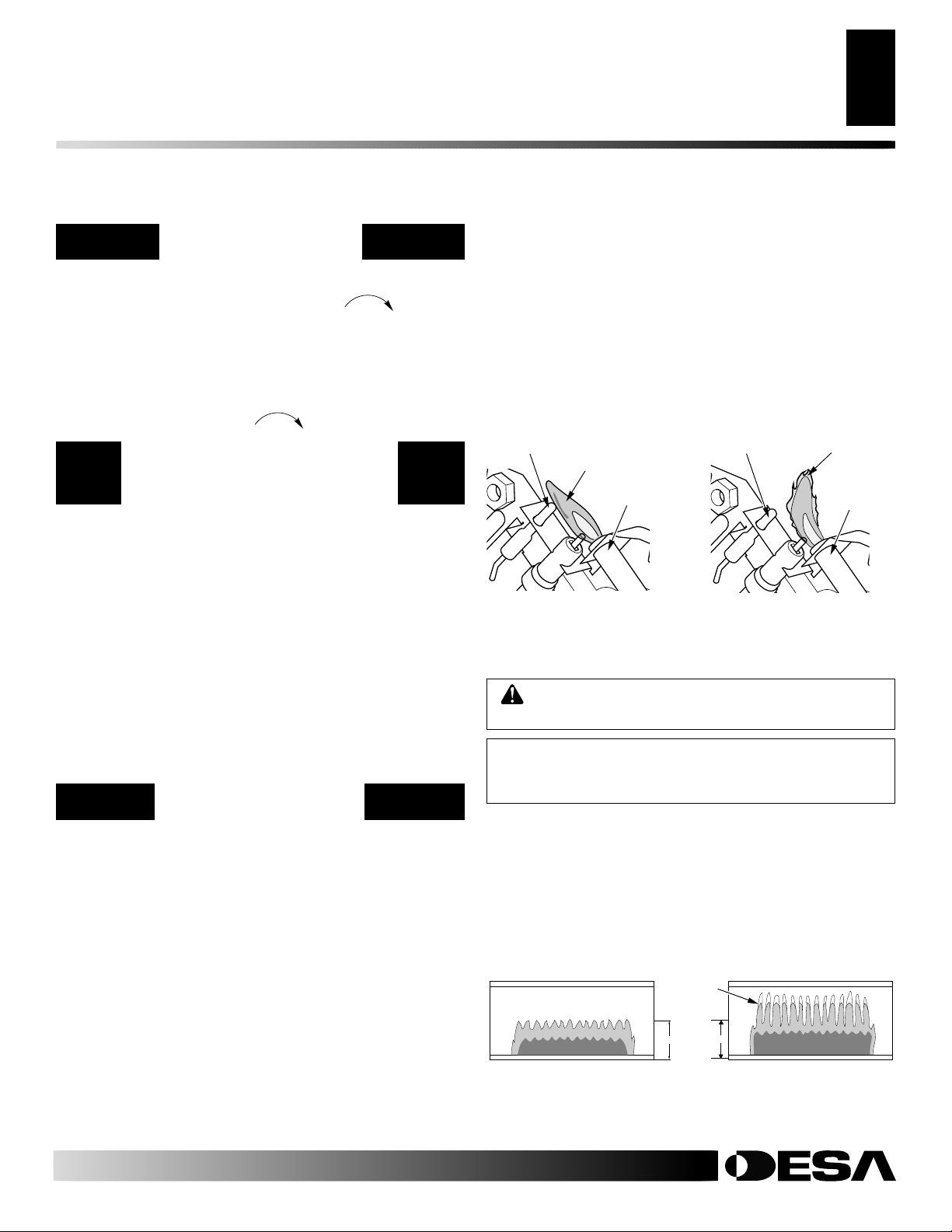

PILOT FLAME PATTERN

Figure 29 shows a correct pilot flame pattern. Figure 30 shows an

incorrect pilot flame pattern. The incorrect pilot flame is not

touching the thermocouple. This will cause the thermocouple to

cool. When the thermocouple cools, the heater will shut down.

If pilot flame pattern is incorrect, as shown in Figure 30

• turn heater off (see To Turn Off Gas to Appliance, column 1)

• see Troubleshooting, pages 18 through 20

Note:

The pilot flame on natural gas units will have a slight curve,

but flame should be blue and have no yellow or orange color.

Thermocouple

Blue Flame

Pilot Burner

Figure 29 - Correct Pilot

Flame Pattern

BURNER FLAME PATTERN

WARNING: If yellow tipping occurs, your heater

could produce increased levels of carbon monoxide.

NOTICE: Do not mistake orange flames with yellow

tipping. Dust or other fine particles enter the heater

and burn causing brief patches of orange flame.

Figure 31 shows a correct burner flame pattern. Figure 32 shows an

incorrect burner flame pattern. The incorrect burner flame pattern

shows yellow tipping of the flame. It also shows the flame higher

than 1/2 the glass panel height.

If burner flame pattern is incorrect, as shown in Figure 32

• turn heater off (see To Turn Off Gas to Appliance, column 1)

• see Troubleshooting, pages 18 through 20

Thermocouple

Figure 30 - Incorrect Pilot Flame

Pattern

Yellow

Tipping

1/2 GLASS HEIGHT

Yellow Flame

Pilot

Burner

112157-01A

(Models GCN6 and GCP6 will be

lower due to lower input rating)

Figure 31 - Correct Burner

Flame Pattern

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Figure 32 - Incorrect Burner

Flame Pattern

Page 16

CLEANING AND MAINTENANCE

16

ODS/Pilot and Burner Orifice

Burner Pilot Air Inlet Hole

Cabinet

CLEANING AND

MAINTENANCE

WARNING: Turn off heater and let cool before

cleaning.

CAUTION: You must keep control areas, burner,

and circulating air passageways of heater clean. Inspect these areas of heater before each use. Have

heater inspected yearly by a qualified service person.

Heater may need more frequent cleaning due to excessive lint from carpeting, bedding material, pet hair, etc.

WARNING: Failure to keep the primary air

opening(s) of the burner(s) clean may result in sooting and property damage.

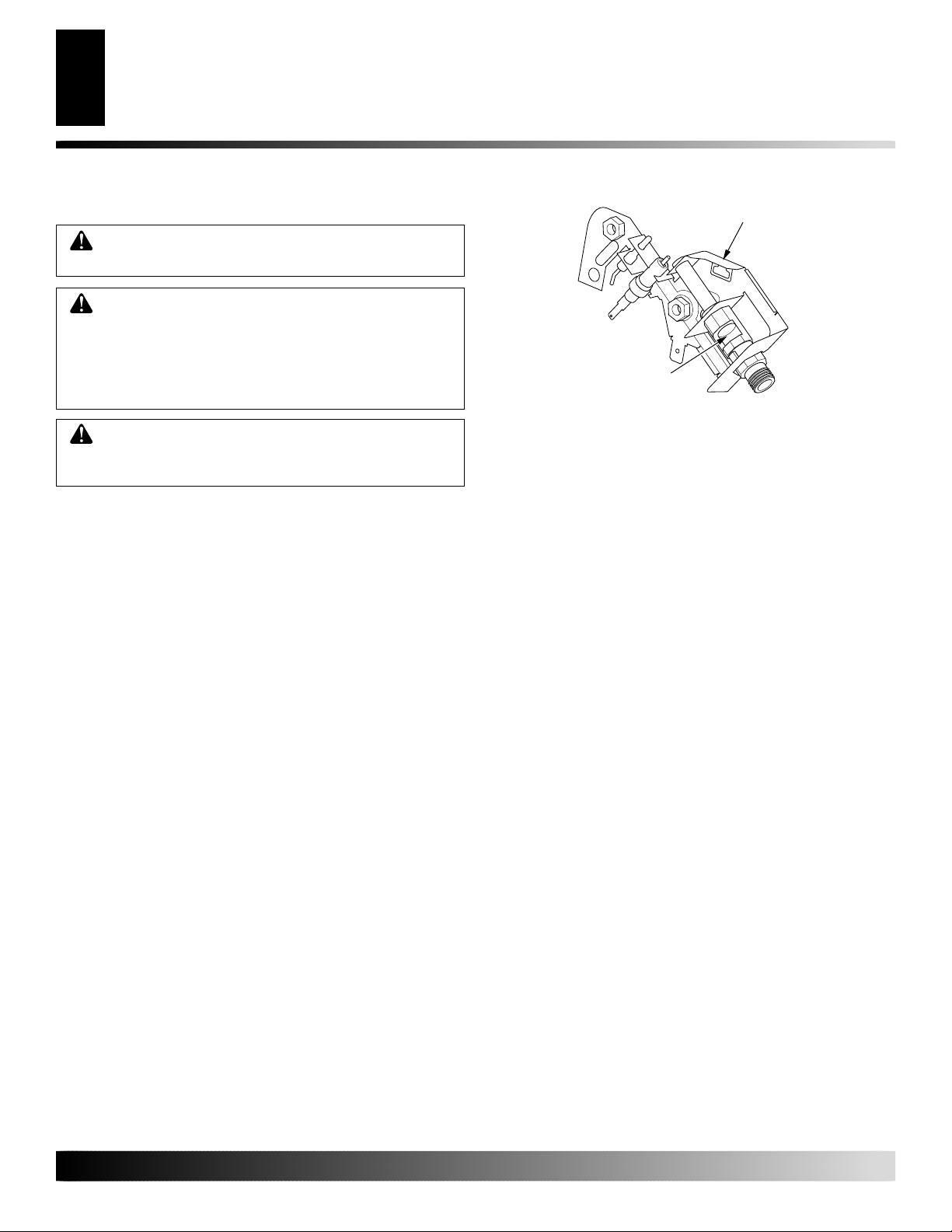

ODS/PILOT AND BURNER ORIFICE

• Use a vacuum cleaner, pressurized air, or small, soft bristled

brush to clean.

BURNER PILOT AIR INLET HOLE

The primary air inlet holes allow the proper amount of air to mix with

the gas. This provides a clean burning flame. Keep these holes clear

of dust, dirt, lint, and pet hair. Clean these air inlet holes prior to each

heating season. Blocked air holes will create soot. We recommend

that you clean the unit every three months during operation and have

fireplace inspected yearly by a qualified service person.

We also recommend that you keep the burner tube and pilot

assembly clean and free of dust and dirt. To clean these parts we

recommend using compressed air no greater than 30 PSI (207 kPa).

Your local computer store, hardware store, or home center may

carry compressed air in a can. You can use a vacuum cleaner in the

blow position. If using compressed air in a can, please follow the

directions on the can. If you don't follow directions on the can, you

could damage the pilot assembly.

1. Shut off the unit, including the pilot. Allow the unit to cool for

at least thirty minutes.

2. Inspect burner, pilot for dust and dirt.

3. Blow air through the ports/slots and holes in the burner.

4. Never insert objects into the pilot tube.

Clean the pilot assembly also. A yellow tip on the pilot flame

indicates dust and dirt in the pilot assembly. There is a small pilot

air inlet hole about two inches from where the pilot flame comes out

of the pilot assembly (see Figure 33). With the unit off, lightly blow

air through the air inlet hole. You may blow through a drinking straw

if compressed air is not available.

Pilot Assembly

Pilot Air Inlet

Figure 33 - Pilot Inlet Air Hole

CABINET

Air Passageways

• Use a vacuum cleaner or pressurized air to clean.

Exterior

• Use a soft cloth dampened with a mild soap and water mixture.

Wipe the cabinet to remove dust.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

Page 17

TROUBLESHOOTING

Note:

For additional help, visit DESA’s

technical service web site at

www.desatech.com.

Note:

All troubleshooting items are listed in

order of operation.

WARNING: Turn off heater

and let cool before servicing. Only

a qualified service person should

service and repair heater.

TROUBLESHOOTING

CAUTION: Never use a wire,

needle, or similar object to clean

ODS/pilot. This can damage ODS/

pilot unit.

17

17

OBSERVED PROBLEM

When ignitor button is pressed, there is no

spark at ODS/pilot

When ignitor button is pressed, there is

spark at ODS/pilot but no ignition

ODS/pilot lights but flame goes out when

control knob is released

POSSIBLE CAUSE

1. Ignitor electrode positioned wrong

2. Ignitor electrode broken

3. Ignitor electrode not connected to ignitor cable

4. Ignitor cable pinched or wet

5. Broken ignitor cable

6. Bad piezo ignitor

1. Gas supply turned off or equipment

shutoff valve closed

2. Control knob not in PILOT position

3. Control knob not pressed in while in

PILOT position

4. Air in gas lines when installed

5. Depleted gas supply (propane/LP only)

6. ODS/pilot is clogged

7. Gas regulator setting is not correct

1. Control knob not fully pressed in

2. Control knob not pressed in long enough

3. Safety interlock system has been

triggered

4. Equipment shutoff valve not fully open

5. Thermocouple connection loose at control valve

6. Pilot flame not touching thermocouple,

which allows thermocouple to cool,

causing pilot flame to go out. This problem could be caused by one or both of

the following:

A) Low gas pressure

B) Dirty or partially clogged ODS/pilot

7. Thermocouple damaged

8. Control valve damaged

REMEDY

1. Replace pilot assembly

2. Replace pilot assembly

3. Reconnect ignitor cable

4. Free ignitor cable if pinched by any

metal or tubing. Keep ignitor cable dry

5. Replace ignitor cable

6. Replace piezo ignitor

1. Turn on gas supply or open equipment

shutoff valve

2. Turn control knob to PILOT position

3. Press in control knob while in PILOT

position

4. Continue holding down control knob.

Repeat igniting operation until air is removed

5. Contact local propane/LP gas company

6. Clean ODS/pilot (see Cleaning and

Maintenance, page 16) or replace ODS/

pilot assembly

7. Replace gas regulator

1. Press in control knob fully

2. After ODS/pilot lights, keep control

knob pressed in 30 seconds

3. Wait one minute for safety interlock system to reset. Repeat ignition operation

4. Fully open equipment shutoff valve

5. Hand tighten until snug, then tighten 1/4

turn more

6. A) Contact local natural or propane/LP

gas company

B) Clean ODS/pilot (see Cleaning and

Maintenance, page 16) or replace ODS/

pilot assembly

7. Replace pilot assembly

8. Replace control valve

112157-01A

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 18

TROUBLESHOOTING

18

TROUBLESHOOTING

Continued

OBSERVED PROBLEM

Burner does not light after ODS/pilot is lit

Delayed ignition of burner

Burner backfiring during combustion

Yellow flame during burner combustion

POSSIBLE CAUSE

1. Burner orifice is clogged

2. Inlet gas pressure is too low

1. Manifold pressure is too low

2. Burner orifice is clogged

1. Burner orifice is clogged or damaged

2. Burner damaged

3. Gas regulator defective

1. Not enough air

2. Gas regulator defective

3. Clogged or dirty burner

REMEDY

1. Clean burner orifice (see Cleaning and

Maintenance, page 16) or replace burner

orifice

2. Contact local natural or propane/LP gas

company

1. Contact local natural or propane/LP gas

company

2. Clean burner orifice (see Cleaning and

Maintenance, page 16) or replace burner

orifice

1. Clean burner orifice (see Cleaning and

Maintenance, page 16) or replace burner

orifice

2. Replace burner

3. Replace gas regulator

1. Check burner for dirt and debris. If

found, clean burner (see Cleaning and

Maintenance, page 16)

2. Replace gas regulator

3. Clean burner (see Cleaning and Main-

tenance, page 16)

Slight smoke or odor during initial operation

Heater produces a whistling noise when

burner is lit

Heater produces a clicking/ticking noise

just after burner is lit or shut off

1. Residues from manufacturing processes

1. Turning control knob to HI position

when burner is cold

2. Air in gas line

3. Air passageways on heater blocked

4. Dirty or partially clogged burner orifice

1. Metal expanding while heating or contracting while cooling

1. Problem will stop after a few hours of

operation

1. Turn control knob to LO position and

let warm up for a minute

2. Operate burner until air is removed from

line. Have gas checked by local natural

or propane/LP gas company

3. Observe minimum installation clearances (see Figure 4, page 7)

4. Clean burner (see Cleaning and Mainte-

nance, page 16) or replace burner orifice

1. This is common with most heaters. If

noise is excessive, contact qualified service person

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

Page 19

TROUBLESHOOTING

Continued

WARNING: If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

TROUBLESHOOTING

19

19

IMPORTANT:

supplies, paint, paint remover, cigarette smoke, cements and glues, new carpet or textiles,

etc., create fumes. These fumes may mix with combustion air and create odors.

Operating heater where impurities in air exist may create odors. Cleaning

OBSERVED PROBLEM

White powder residue forming within burner

box or on adjacent walls or furniture

Heater produces unwanted odors

Heater shuts off in use (ODS operates)

Gas odor even when control knob is in OFF

position

POSSIBLE CAUSE

1. When heated, vapors from furniture polish, wax, carpet cleaners, etc. may turn

into white powder residue

1. Heater burning vapors from paint, hair

spray, glues, etc. (See

statement above)

2. Low fuel supply (propane/LP only)

3. Gas leak. See W arning statement at

top of page

1. Not enough fresh air is available

2. Low line pressure

3. ODS/pilot is partially clogged

1. Gas leak. See W arning statement at

top of page

2. Control valve defective

IMPORTANT

REMEDY

1. Turn heater off when using furniture

polish, wax, carpet cleaners, or similar

products

1. Ventilate room. Stop using odor -causing

products while heater is running

2. Refill supply tank (propane/LP only)

3. Locate and correct all leaks (see Check-

ing Gas Connections, page 13)

1. Open window and/or door for ventilation

2. Contact local natural or propane/LP gas

company

3. Clean ODS/pilot (see Cleaning and

Maintenance, page 16)

1. Locate and correct all leaks (see Check-

ing Gas Connections, page 13)

2. Replace control valve

Gas odor during combustion

Moisture/condensation noticed on windows

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

1. Foreign matter between control valve

and burner

2. Gas leak. See W arning statement at

top of page

1. Not enough combustion/ventilation air

1. Take apart gas tubing and remove foreign matter

2. Locate and correct all leaks (see Check-

ing Gas Connections, page 13)

1. Refer to Fresh Air for Combustion and

Ventilation requirements (page 4)

Page 20

20

ILLUSTRATED PARTS BREAKDOWN

Models GCP6 and GCN6

ILLUSTRATED PARTS

BREAKDOWN

MANUAL CONTROL MODELS

GCP6 AND GCN6

21

22

23

24

27

20

13

14

12

10

4

11

7

6

3

2

5

9

1

8

26

15

18

25

19

17

10

16

1

PILOT

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

Page 21

PARTS LIST

This list contains replaceable parts used in your heater. When

ordering parts, follow the instructions listed under Replacement

Parts on page 29 of this manual.

KEY PART NUMBER

NO. GCP6 GCN6 DESCRIPTION QTY.

1 M11084-38 M11084-38 Screw, #10 x 3/8" 6

2 099467-07 099467-07 Front Panel 1

3 099318-04 099318-04 Grill Guard 1

4 101108-01 101108-01 Grill Guard Clip 2

5 102017-02 102017-02 Bottom Glass Retainer 1

6 098260-11 098260-11 Glass Panel 1

7 099319-02 099319-02 Top Glass Retainer 1

8 M11084-27 M11084-27 Screw, #8 x 3/8" 4

9 099317-02 099317-02 Deflector Unit 1

10 098271-09 098271-09 Ignitor Cable 1

11 098249-01 098249-01 Nut, M5 2

12 110803-02 110803-01 ODS/Pilot Assembly 1

12-1 110186-01 110186-01 Thermocouple Kit 1

13 104263-02 104263-01 Burner 1

14 099387-17 099387-17 Pilot Tubing 1

15 104259-04 104259-03 Injector, 1 piece 1

16 NJF-8C NJF-8C Hex Nut 1

17 099415-18 099415-17 Pressure Regulator 1

18 099462-01 099462-01 Burner Tubing 1

19 099391-02 099391-02 Regulator Tubing 1

20 099413-02 099413-01 Control Valve 1

21 ** **

22 097159-04 097159-04 Piezo Ignitor 1

23 099393-02 099393-02 Control Knob 1

24 098508-01 098508-01 Valve Retainer Nut 1

25 098303-02 098303-02 Screw, #6 x 5/16" 2

26 099818-01 099818-01 Internal Tooth Washer 1

Cabinet Assembly

Models GCP6 and GCN6

PARTS LIST

21

21

112157-01A

PARTS AVAILABLE - NOT SHOWN

100642-02 100642-02 Assembly, Hardware 1

** Not a field replaceable part.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 22

22

ILLUSTRATED PARTS BREAKDOWN

Models GCP10T and GCN10T

ILLUSTRATED PARTS

BREAKDOWN

THERMOSTAT CONTROLLED MODELS

GCP10T

GCN10T

4

7

6

3

5

9

10

21

20

14

13

12

11

1

8

14

15

19

22

10

16

23

18

17

2

1

PILOT

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

Page 23

PARTS LIST

This list contains replaceable parts used in your heater. When

ordering parts, follow the instructions listed under Replacement

Parts on page 29 of this manual.

KEY PART NUMBER

NO. GCP10T GCN10T DESCRIPTION QTY.

1 M11084-38 M11084-38 Screw, #10 x 3/8" 6

2 099467-07 099467-07 Front Panel Assembly 1

3 099318-04 099318-04 Grill Guard 1

4 101108-01 101108-01 Grill Guard Clip 2

5 102017-02 102017-02 Bottom Glass Retainer 1

6 098260-11 098260-11 Glass Panel 1

7 099319-02 099319-02 Top Glass Retainer 1

8 M11084-27 M11084-27 Screw, #8 x 3/8" 4

9 099317-02 099317-02 Deflector Unit 1

10 098271-09 098271-09 Ignitor Cable 1

11 098249-01 098249-01 Nut, M5 2

12 110803-02 110803-01 ODS/Pilot Assembly 1

12-1 110186-01 110186-01 Thermocouple Kit 1

13 104263-01 104263-01 Burner 1

14 099387-11 099387-11 Pilot Tubing 1

15 104259-06 104259-05 Injector, 1 Piece 1

16 NJF 8C NJF 8C Hex Nut 1

17 099415-18 099415-17 Pressure Regulator 1

18 104261-01 104261-01 Burner Tubing 1

19 104264-01 104264-01 Regulator Tubing 1

20 098522-18 098522-11 Thermostat Gas Valve 1

21 ** ** Cabinet Assembly 1

22 097159-04 097159-04 Piezo Ignitor 1

23 098303-02 098303-02 Screw, #6 x 5/16" 2

PARTS AVAILABLE - NOT SHOWN

100642-02 100642-02 Assembly, Hardware 1

Models GCP10T and GCN10T

PARTS LIST

23

23

112157-01A

** Not a field replaceable part.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 24

ILLUSTRATED PARTS BREAKDOWN

24

Models GCN20T and GCP20T

ILLUSTRATED PARTS

BREAKDOWN

THERMOSTAT CONTROLLED

MODELS

GCN20T AND GCP20T

8

18

15

1

10

17

19

7

20

4

12

13

11

10

9

14

16

6

3

5

2

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

Page 25

PARTS LIST

This list contains replaceable parts used in your heater. When

ordering parts, follow the instructions listed under Replacement

Parts on page 29 of this manual.

KEY PART NUMBER

NO. GCN20T GCP20T DESCRIPTION QTY.

1 097159-04 097159-04 Piezo Ignitor 1

2 107673-01 107673-01 Front Panel 1

3 103476-01 103476-01 Grill Guard 1

4 098522-10 098522-11 Thermostat Gas Valve 1

5 104189-01 104189-01 Bottom Glass Retainer 1

6 098260-09 098260-09 Glass 1

7 ** ** Cabinet 1

8 107894-10 107894-10 Deflector Assembly 1

9 098271-09 098271-09 Ignitor Cable 1

10 098249-01 098249-01 Nut, M5 2

11 110803-01 110803-02 ODS/Pilot Assembly 1

110186-01 110186-01 Thermocouple Kit 1

12 103446-01 103446-01 Burner 1

13 099387-03 099387-03 3/16" Pilot Tubing 1

14 103845-06 103845-05 Injector 1

15 099066-02 099066-02 Mounting Bracket 1

16 099415-17 099415-18 Gas Regulator 1

17 NJF 8C NJF 8C Hex Nut 1

18 103255-02 103255-02 3/8" Outlet Tubing 1

19 103256-02 103256-02 3/8" Inlet Tubing 1

20 109303-04 109303-04 Baffle 1

PARTS AVAILABLE — NOT SHOWN

Models GCN20T and GCP20T

PARTS LIST

25

25

112157-01A

100642-03 100642-03 Hardware Assembly 1

** Not a field replaceable part.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 26

SPECIFICATIONS

26

PARTS CENTRALS

SPECIFICATIONS

GCP6 GCP10T GCP20T

Btu/Hr (kW) (Variable) min/max 4,400/6,000 (1.3/1.8 kW) 5,000/10,000 (1.5/2.9 kW) 10,000/20,000 (2.9/5.9 kW)

Type Gas Propane/LP Only Propane/LP Only Propane/LP Only

Ignition Piezo Piezo Piezo

Pressure Regulator Setting 8" W.C. (203 mm) 8" W.C. (203 mm) 8" W.C. (203 mm)

Inlet Gas Pressure (inches of water)

Maximum 14" (356 mm) 14" (356 mm) 14" (356 mm)

Minimum 11" (279 mm) 11" (279 mm) 11" (279 mm)

Dimensions, Inches (H x W x D)

Heater 20 1/2 x 13 1/2 x 5 inches 21 1/2 x 13 1/2 x 7 24 1/4 x 18 1/4 x 7 inches

52 x 34,3 x 12,7 cm 54,6 x 34,3 x 17,8 cm 61,6 x 46,4 x 17,8 cm

Carton 24 3/8 x 16 7/16 x 7 1/4 inches 24 3/8 x 16 7/16 x 7 1/4 26 1/4 x 20 5/8 x 9 7/8 inches

62 x 41,8 x 18,4 cm 62 x 41,8 x 18,4 cm 66,7 x 52,4 x 25,1 cm

Weight (pounds)

Heater 13.5 lbs (6.1 kg) 14 lbs (6.4 kg) 20 lbs (9 kg)

Shipping 19 lbs (8.7 kg) 19 lbs (8.7 kg) 25 lbs (11.4 kg)

GCN6 GCN10T GCN20T

Btu/Hr (Variable) 4,400/6,000 5,000/10,000 10,000/20,000

Type Gas Natural Only Natural Only Natural Only

Ignition Piezo Piezo Piezo

Pressure Regulator Setting 3" W.C. 3" W.C. 3" W.C.

Inlet Gas Pressure (inches of water)

Maximum 10.5" 10.5" 10.5"

Minimum 4" 4" 5"

Dimensions, Inches (H x W x D)

Heater 20 1/2 x 13 1/2 x 5 inches 20 1/2 x 13 1/2 x 7 inches 24 1/4 x 18 1/4 x 7 inches

52 x 34,3 x 12,7 cm 54,6 x 34,3 x 17,8 cm 61,6 x 46,4 x 17,8 cm

Carton 24 3/8 x 16 7/16 x 7 1/4 inches 24 3/8 x 16 7/16 x 7 1/4 inches 26 1/4 x 20 5/8 x 9 7/8 inches

62 x 41,8 x 18,4 cm 62 x 41,8 x 18,4 cm 66,7 x 52,4 x 25,1 cm

Weight (pounds)

Heater 13.5 lbs (6.1 kg) 14 lbs (6.4 kg) 20 lbs (9 kg)

Shipping 19 lbs (8.7 kg) 19 lbs (8.7 kg) 25 lbs (11.4 kg)

SERVICE CENTER/PARTS CENTRAL

For service and parts inquiries please contact:

DESA Canada

Attn: Brian Hall

2220 Argentia Rd. Unit 4

Mississaugua Ontario L5N2K7

Phone: 905-826-8010

Email: bjthedj@on.aibn.com

For more information, visit www.desatech.com

For more information, visit www.desatech.com

112157-01A

Page 27

OWNER'S REGISTRATION FORM

In order to provide better customer service for this and future purchases, we recommend that you register your product with us.

You can register online at www.desatech.com. If access to our website is not available to you, please complete this Owner’s

Registration Form and mail to the address on the back of this owner’s manual. Please provide the following product information:

Brand:

Model:

Date Purchased:

Serial Number:

First Name: Last Name:

Address:

City: State: Zip: Country:

Home Phone: ( ) -

E-Mail:

Please answer the following questions to register your product with DESA:

1. Where will the product be used?

❍ Living/Family Room ❍ Office/Warehouse ❍ Utility Shed/Outbuilding ❍ Garage ❍ Bedroom ❍ Bathroom ❍ Other

2. If you bought this product yourself, did you plan to purchase this type of product before going into the store? ❍ Yes ❍ No

3. Who selected the product? ❍ Male ❍ Female ❍ Both

4. What is the population of your area? ❍ Under 10,000 ❍ 10,000 to 25,000 ❍ 25,000 to 50,000 ❍ 50,000 to 100,000

❍ 100,000 to 250,000 ❍ Over 250,000