DIRECT-VENT FIREPLACE

OWNER’S OPERATION AND INSTALLATION MANUAL

CD32M 32" DV Fireplace with Fan

CD32M-1 32" DV Fireplace

CD32M-2 32" DV Fireplace with Fan & Door Switch

CD36M-A 36" DV Fireplace with Fan

CD36M-A1 36" DV Fireplace

CD36M-A2 36" DV Fireplace with Fan & Door Switch

CD42M-A 42" DV Fireplace with Fan

CD42M-A2 42" DV Fireplace with Fan & Door Switch

WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a quali-

fied installer, service agency or the gas supplier.

Save this manual for future reference.

For more information, visit www.desatech.com

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual for correct installation

and operational procedures. For assistance or additional information consult a qualified installer, service

agency or the gas supplier.

WARNING: This direct-vent gas fireplace is intended for

use with natural or propane/LP gas only. Do not attempt

to burn any solid fuels in this appliance.

This fireplace is manufactured for Stylecrest Inc. under

the Vexar brand name by DESA.

This fireplace may be installed as an OEM installation

in a manufactured (mobile) home and must be installed

in accordance with the manufacturers instructions and

the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 in the United States or the

Mobile Home Standard, CAN/CSA Z240 MH Series, in

Canada. This fireplace is only for use with the type(s)

of gas indicated on the rating plate. A conversion kit is

supplied with the fireplace.

SAVE THIS BOOK

This book is valuable. In addition to instructing you on how to install and

maintain your appliance, it also contains information that will enable you to

obtain replacement parts or optional accessory items when needed. Keep

it with your other important papers.

TABLE OF CONTENTS

Introduction .......................................................... 3

Selecting Location ............................................... 3

Pre-Installation Preparation .................................. 4

Installation ........................................................... 7

Burner Flame Adjustment ..................................

Operating Fireplace ........................................... 14

Converting Fireplace From

Natural Gas To Propane/LP Gas .................. 15

2

www.desatech.com

Troubleshooting .................................................

Illustrated Parts Breakdown and Parts List ....... 18

Specifications .................................................... 22

Wiring Diagram .................................................. 22

13

Accessory and Replacement Parts ................... 23

111916-01F

17

INTRODUCTION

WARNING: This product contains and/or generates chemicals

known to the State of California

to cause cancer or birth defects

or other reproductive harm.

Models CD32M series, CD36M-A series and

CD42M-A seri es are heat circula ti ng grav

ity direct-vent fireplaces with sealed combustion

chamber. These fireplaces use millivolt gas control

valve and millivolt ignition system.

These fireplaces are convertible with the standard

setup as natural gas. Conversion may be performed

by the O.E.M. mobile home builder or by a quali

fied service person on-site. If you are uncertain as

to what gas your unit is equipped for, please check

the rating plate located inside of the appliance

opening or consult your mobile home supplier or

your local distributor of DESA/Vexar products.

NOTICE: Check local building

codes for area requirements before installing this appliance.

BEFORE YOU BEGIN

Before beginning the installation of your appliance, read these instructions through completely.

This DESA/Vexar fireplace and its components are

safe when installed according to this installation

manual and operated as recommended. Unless

you use DESA/Vexar components designed and

tested for this fireplace system,

A SAFETY HAZARD!

The DESA/Vexar warranty will be voided by, and

DESA/Vexar disclaims any responsibility for the

following actions:

A) Modification to the fireplace, components,

doors, blower, fans or vent system.

B) Use of any component part not manufactured or

approved by DESA/Vexar in combination with

a DESA/Vexar fireplace system.

Proper installation is the most important step in

ensuring safe and continuous operation of the

fireplace. Consult the local building codes as to the

particular requirements concerned with the instal

lation of all factory built fireplaces. This fireplace,

when installed, must be electrically grounded in

accordance with local codes or in the absence of

local codes, with the National Electrical Code,

ANSI/NFPA 70 or the Canadian Electrical Code,

CSA C22.1.

YOU MAY CAUSE

The installation must conform with local codes or,

in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1 or the Canadian Installa

tion Code, CAN/CGA B149. This appliance com-

plies with ANSI Z21.88-1998 and CSA 2.33-M98

as a VENTED GAS FIREPLACE HEATER.

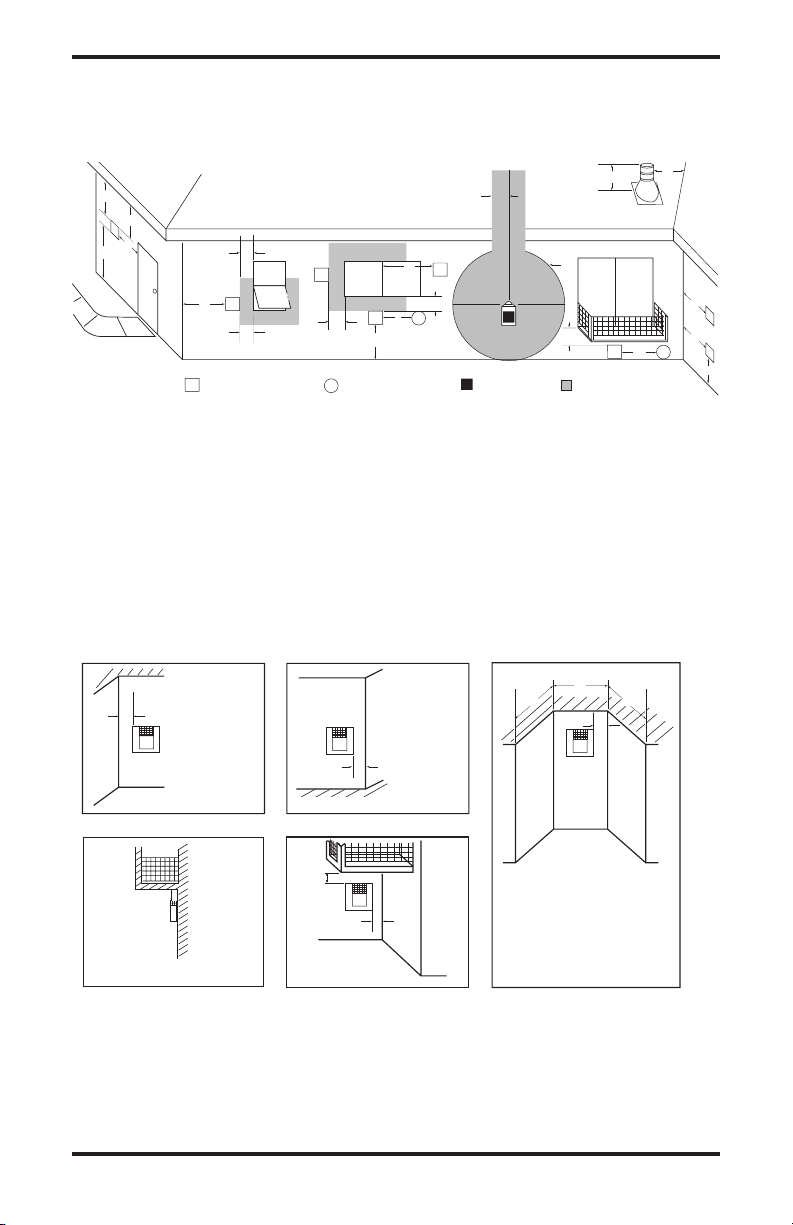

SELECTING LOCATION

To determine the safest and most efficient location for your fireplace, consider the following

guidelines:

1. The location must allow for proper clearances

(see Figure 1).

2. Consider a location where the fireplace would

not be affected by drafts, air conditioning

ducts, windows or doors.

-

3. A location that avoids the cutting of joists or roof

rafters makes ventilation installation easier.

In selecting a location, the following precautions

must be observed:

• Do not connect this appliance to a chimney

system used for solid fuel burning fireplace.

• Due to high temperatures, do not locate this

appliance in high traffic areas or near furniture

and draperies.

• Never obstruct the openings of the appliance

or flow of ventilation air. Keep the control

compartments accessible.

FULL

PROJECTION

Flush installation is recommended where living

space is limited.

Projected installation may be ideal for a new

addition to an existing finished wall.

Corner installation makes use of a space that may

not normally be used and provides a wider and

more efficient range for radiant heat transfer.

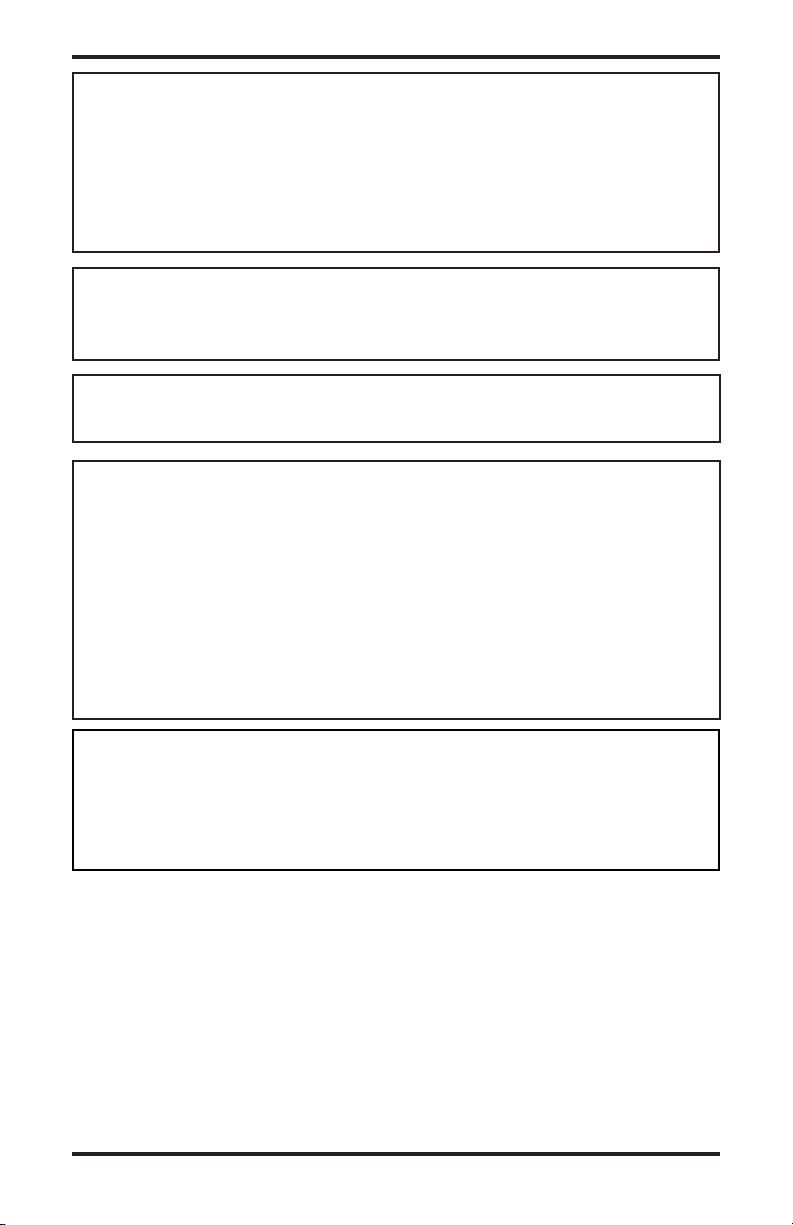

Figure 1 - Common Fireplace Locations

CORNER

INSTALLATION

FLUSH

INSTALLATION

-

111916-01F 3

www.desatech.com

SELECTING LOCATION

C

B

A

D

E

F

G

To

p of Louver Opening

3

2

1

4

5

6

7

Wa

ll

Continued

• Do not locate appliance close to where gasoline

or other flammable liquids may be stored. The

appliance must be kept clear and free from

combustible materials.

• Do not use this appliance if any part has been

under water. Immediately contact a local service

technician to examine the appliance and to re

place any part(s) of the control ignition system

and other related components that have been

submerged under water.

Mantel

Depth

(1) 14" (A) 16"

(2) 12" (B) 14"

(3) 10" (C) 12"

(4) 8" (D) 10"

-

(5) 6" (E) 8"

(6) 4" (F) 6"

(7) 2" (G) 4"

Mantel From Top

of Opening

PRE-INSTALLATION

PREPARATION

CAUTION: Do not block

required air spaces with insulation or any other material. Do not

obstruct the effective opening

of the appliance with any type

of facing material.

CLEARANCES TO COMBUSTIBLES

Minimum clearances to combustibles for the

fireplace are:

• Back and Sides of Fireplace . . . . . . . . . . . .

• Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

• Perpendicular Wall . . . . . . . . . . . . . . . . . . .

• Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

• Top of Standoffs . . . . . . . . . . . . . . . . . . . . .

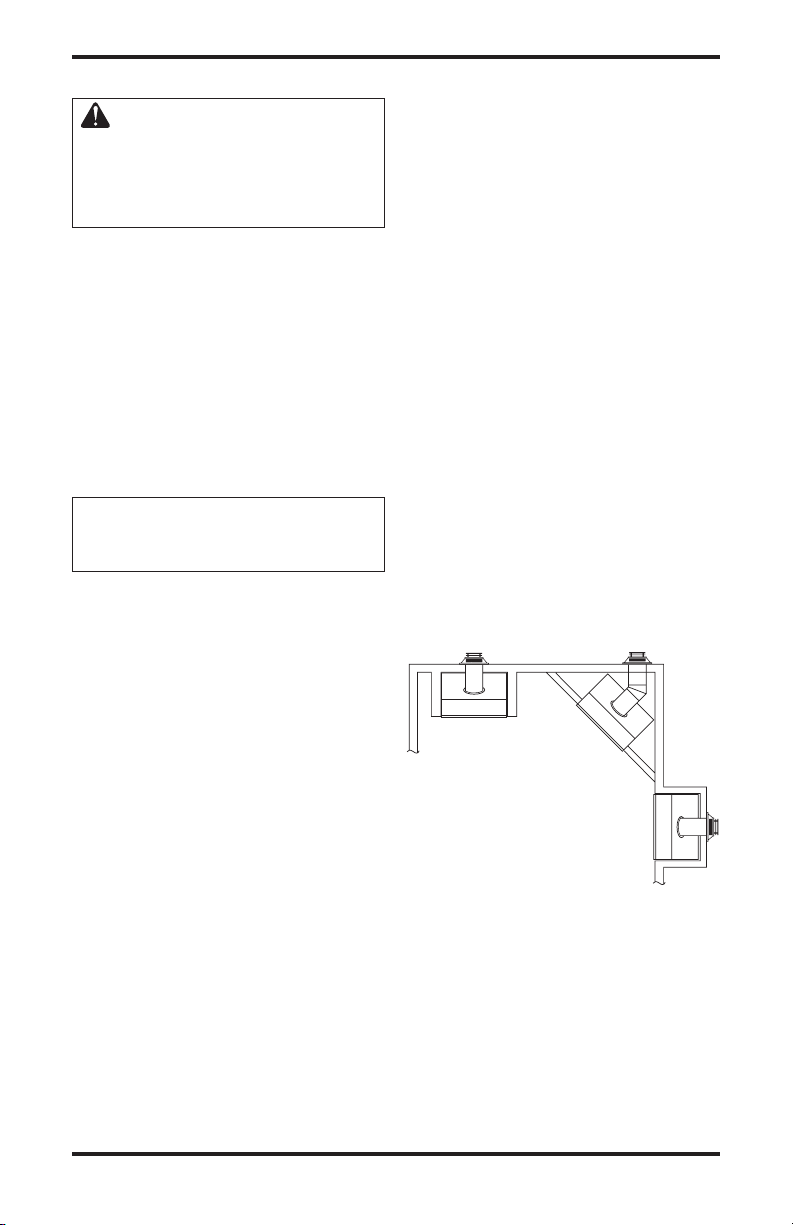

MANTEL CLEARANCES

Woodwork, such as wood trims, mantles and other

combustible materials should be placed within the

required clearance specified in Figure 2.

0"

0"

6"

36"

0"

Figure 2 - Mantel Clearances

4

www.desatech.com

111916-01F

PRE-INSTALLATION

A

B

E

F

G

H

D

C

Nailing Tabs

B

A

C

PREPARATION

Continued

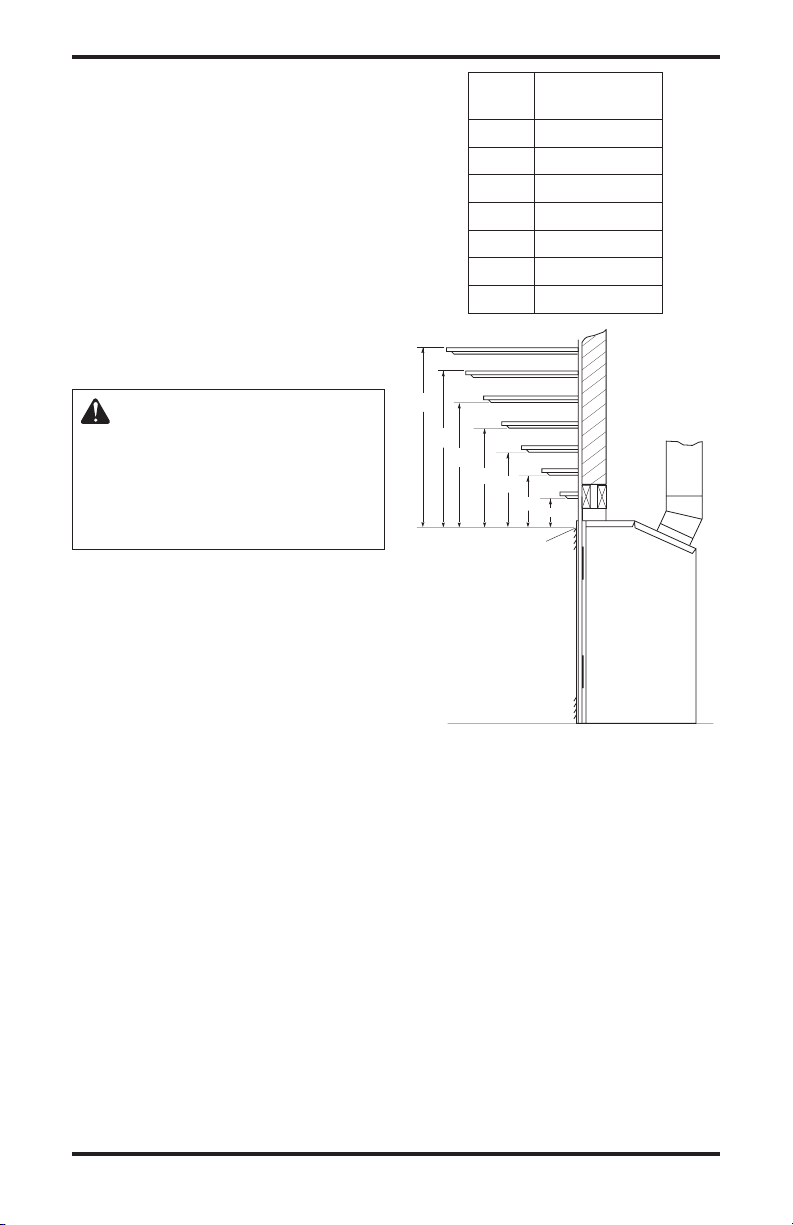

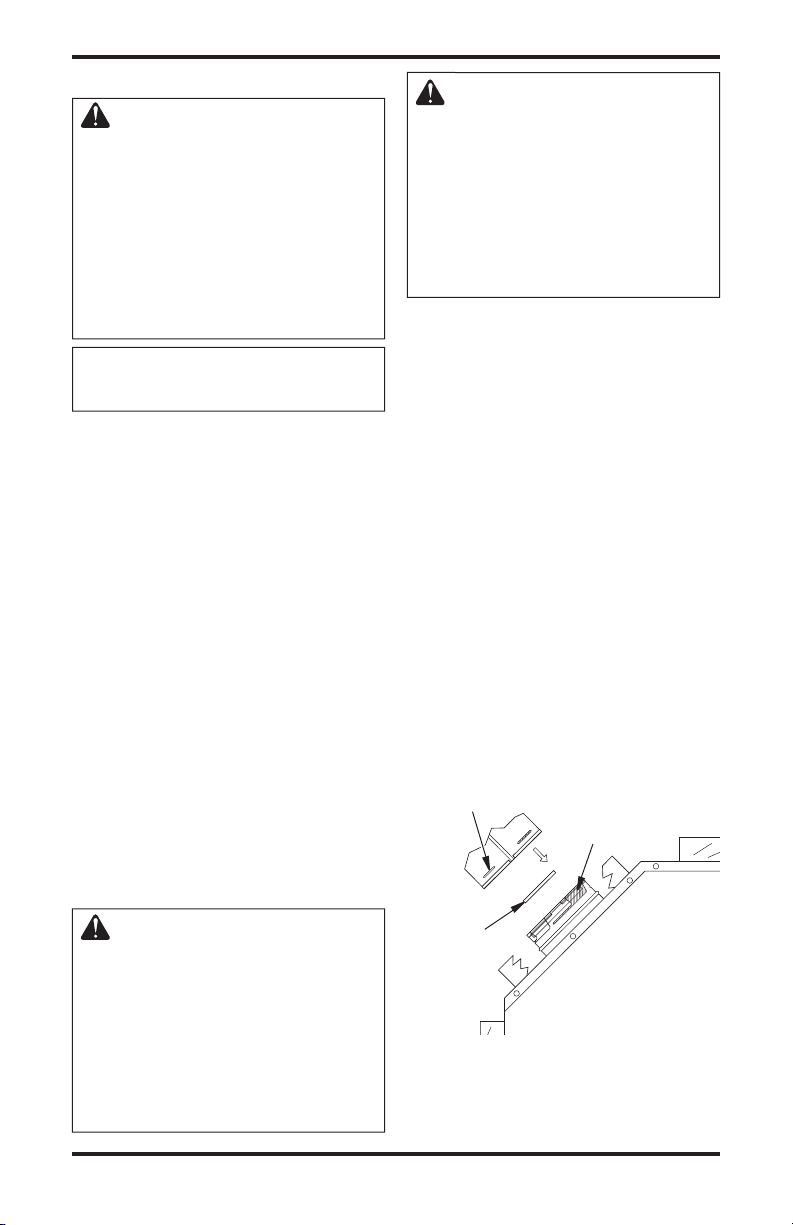

VENT TERMINATION CLEARANCES

The final position of your fireplace depends on

the location of the vent termination in relation to

the clearances that must be observed as shown in

Figure 5 on page 6.

The vent system serves as the “chimney” as well

as the combustion air supply (air intake). The

horizontal run must have a rise of 1/4" (.6 cm) for

every 12" (30.48 cm) of horizontal run towards the

termination. The maximum horizontal run depends

on the vertical rise from the fireplace adapter collar

to the vent termination (see table below).

VERTICAL HORIZONTAL

0 to 1 ft (30.48 cm)

1 ft (30.48 cm) to 4 ft (121.92 cm)

2 ft (60.96 cm) to 8 ft (243.84 cm)

3 ft (91.44 cm) to 12 ft (365.76 cm)

4 ft (121.92 cm) to 16 ft (487.68 cm)

5 ft (152.40 cm) to 15 ft (457.20 cm)

6 ft (182.88 cm) to 14 ft (426.72 cm)

7 ft (213.36 cm) to 13 ft (396.24 cm)

8 ft (243.84 cm) to 12 ft (365.76 cm)

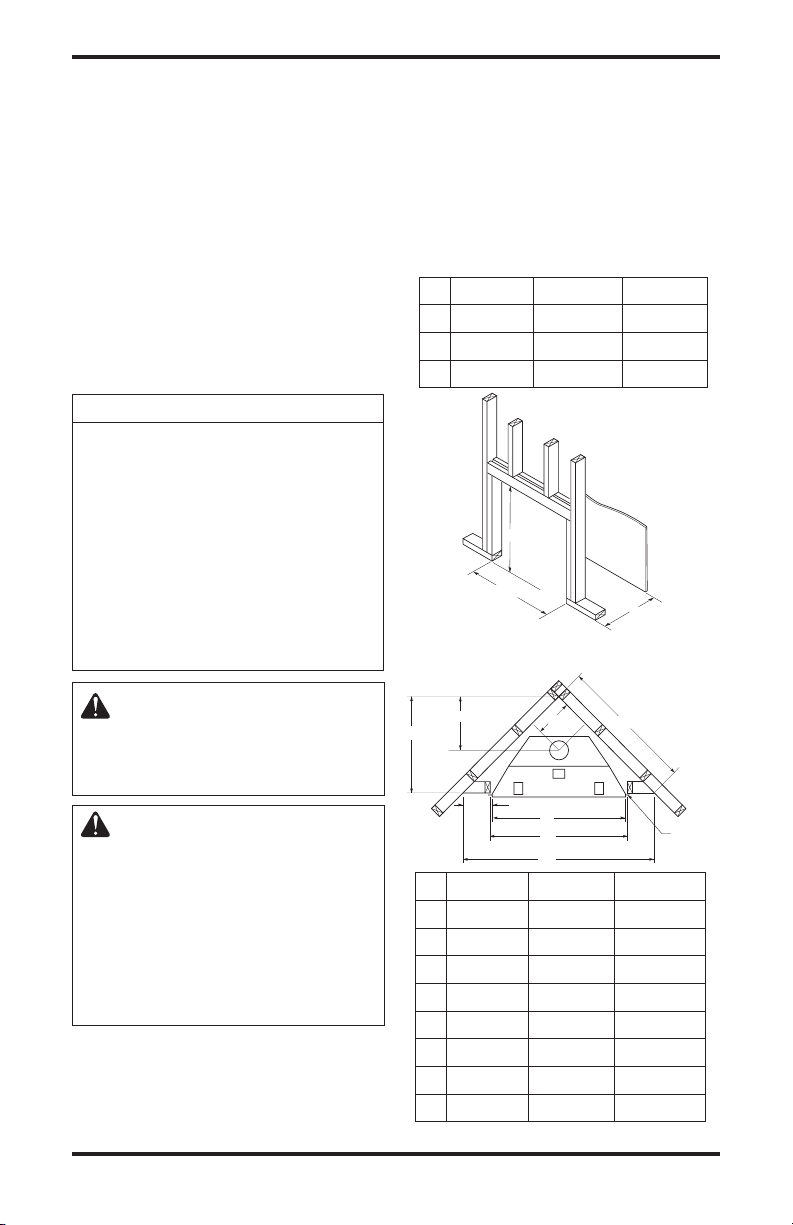

FRAMING

Once the final location has been determined, observing height clearances for vent termination, you

may construct framing using dimensions shown in

Figures 3 and 4, depending on your installation.

If the appliance is to be installed directly on carpet

ing, tile (other than ceramic) or any combustible

material other than wood flooring, the appliance

must be installed on a metal or wood panel extending the full width and depth of the appliance.

CD32M CD36M-A CD42M-A

A 32 3/8" 36 1/8" 40 1/8"

B 34 5/8" 41 1/4" 48 1/4"

C 19" 23 1/2" 25 5/8"

Figure 3 - Framing Dimension

-

WARNING: Never allow the

vent to run downward as this

may cause excessive tempera

-

tures which could cause a fire.

WARNING: Horizontal sections of this vent system require

a minimum clearance of 2" from

the top of the pipe and 1" mini

mum to the sides and bottom.

Vertical sections of this system

require a minimum of 1" clearance to combustible materials

on all sides of the pipe.

111916-01F 5

www.desatech.com

CD32M CD36M-A CD42M-A

A 28 1/2" 35 3/4" 41 5/8"

B 13 5/8" 15" 21 5/8"

C 39 3/8" 49 5/8" 58 1/2"

D 9 1/2" 10 3/8" 13 1/2"

E 9 7/8" 13 3/4" 16 3/4"

F 34 1/2" 41 1/8" 48"

G 35 1/2" 42 1/8" 48 1/4"

H 54 3/8" 68 1/4" 81 1/2"

Figure 4 - Corner Installation

Fixed

Closed

Openable

Fixed

Closed

Openable

V

V

V

V

V

V

V

V

X

X

V

X

G

G

J

F

B

B

K

N

H

I

A

N

E

L

D

B

M

A

C

B

V

V

A

G

G

B

TERMINATION CAP

AIR SUPPLY INLET

GAS METER RESTRICTED AREA

(TERMINATION PROHIBITED)

A = clearance above grade, veranda, porch, deck, or balcony

[*12 inches (30.5cm) minimum]

B = clearance to window or door that may be opened

[12 inches (30.5cm) minimum]

C = clearance to permanently closed window [minimum 12 inches

(30.5cm) recommended to prevent condensation on window]

D = vertical clearance to ventilated soffit located above the terminal

within a horizontal distance of 24 inches (61cm) from the

center-line of the terminal [18 inches (45.7cm) minimum]

E = clearance to unventilated soffit [12 inches (30.5cm) minimum]

F = clearance to outside corner (see below)

G = clearance to inside corner (see below)

H = *not to be installed above a meter/regulator assembly within

36 inches (91.4cm) horizontally from the center-line of the regulator

I = clearance to service regulator vent outlet [*72 inches (182.9cm)

minimum]

J = clearance to non-mechanical air supply inlet to building or the

combustion air inlet to any other fireplace [*12 inches (30.5cm)

minimum]

K = clearance to a mechanical air supply inlet [*72 inches (182.9cm)

minimum]

L = † clearance above paved side-walk or a paved driveway located on

public property [*84 inches (213.4cm) minimum]

M = clearance under veranda, porch, deck [*12 inches (30.5cm) minimum ‡]

N = clearance above a roof shall extend a minimum of 24 inches (61cm)

above the highest point when it passes through the roof surface and

any other obstruction within a horizontal distance of 18 inches (45.7cm)

† vent shall not terminate directly above a side-walk or paved driveway which is located between two

single family dwellings and serves both dwellings *

‡ only permitted if veranda, porch, deck or balconey is fully open on a minimum of 2 sides beneath the floor*

* as specified in CAN/SGA B149 (.1 or .2) Installation Codes (1991) for Canada or for U.S.A. installation follow

the current National Fuel Gas Code, ANSI Z223.1

Note: Local codes or regulations may require different clearances

A = 6" (15.2cm)

Inside Corner

V

B

E

V

B = 6" (15.2cm)

C = Maximum depth of 48" (121.9cm) for

recessed location

D = Minimum width for back wall of

recessed location Combustible - 38" (96.5cm)

Noncombustible - 24" (61cm)

E = Clearance from corner in

recessed location Combustible - 6" (15.2cm)

Noncombustible - 2" (5.1cm)

Outside Corner Recessed Location

G

H

G = Combustible 24" (61cm)

Noncombustible 18" (45.7cm)

Balcony with No Side Wall

V

J

Combustible &

Noncombustible

H = 24" (61cm)

J = 20" (50.8cm)

Balcony with Perpendicular Side Wall

C

D

C

Termination Clearances for Buildings with Combustible and Noncombustible Exteriors

PRE-INSTALLATION PREPARATION

Continued

Figure 5 - Minimum Clearances for Vent Terminations

6

www.desatech.com

111916-01F

INSTALLATION

WARNING: Read all instructions completely and thoroughly

before attempting installation.

Failure to do so could result in

serious injury, property damage or loss of life. Operation of

improperly installed and maintained venting system could

result in serious injury, property

damage or loss of life.

NOTICE: Failure to follow these instructions will void the warranty.

VENTING INSTALLATION

PRECAUTIONS

Consult local building codes before beginning the

installation. The installer must make sure to select

the proper vent system for installation. Before

installing vent kit, the installer must read this

fireplace manual and vent kit instructions.

Only a qualified service person should install

venting system. The installer must follow these

safety rules:

• Wear gloves and safety glasses for protection

• Use extreme caution when using ladders or

when on roof tops

• Be aware of electrical wiring locations in walls

and ceilings

The following actions will void the warranty on

your venting system:

• Installation of any damaged venting component

• Unauthorized modification of the venting system

• Installation of any component part not manu

factured or approved by DESA

• Installation other than as instructed by these

instructions

WARNING: This gas fireplace

and vent assembly must be

vented directly to the outside. The

venting system must NEVER be

attached to a chimney serving a

separate solid fuel burning appliance. Each gas appliance must

use a separate vent system. Do

not use common vent systems.

WARNING: Horizontal sections of this vent system require

a minimum clearance of 2" from

the top of the pipe and 1" mini

mum to the sides and bottom.

Vertical sections of this system

require a minimum of 1" clearance to combustible materials

on all sides of the pipe.

VENTING INSTALLATION

1. Install elbow to fireplace collar adapter located

on back of the unit at a 45° angle. Slide elbow

over collar and twist to lock. Check to insure

proper connection (see Figure 6).

2. Continue to install remainder of pipe for

desired installation. Make sure each section

is twist-locked securely.

3. When installation of vent pipe is complete, in

stall vent termination. Depending on the loca

tion of your fireplace, you will vent vertically

or horizontally.

4. Allow 1" of pipe to protrude from internal

wall, dep ending on wall thic kn ess. See

Figure 7, page 8.

5. For horizontal installation, an optional siding

standoff may be installed between the vent cap

and the exterior wall. Secure horizontal vent cap

to standoff. Secure standoff/vent cap assembly

to wall (see Figure 7, page 8). Do not seal termi

nation to vent pipe. The vent termination must

be removable for service pipe inspection.

Female

Locking Lugs

-

Vertical Flue

Restrictor

(For Vertical

Venting

Application)

Figure 6 - Venting Installation

Male

Locking Lugs

-

-

-

111916-01F 7

www.desatech.com

INSTALLATION

Continued

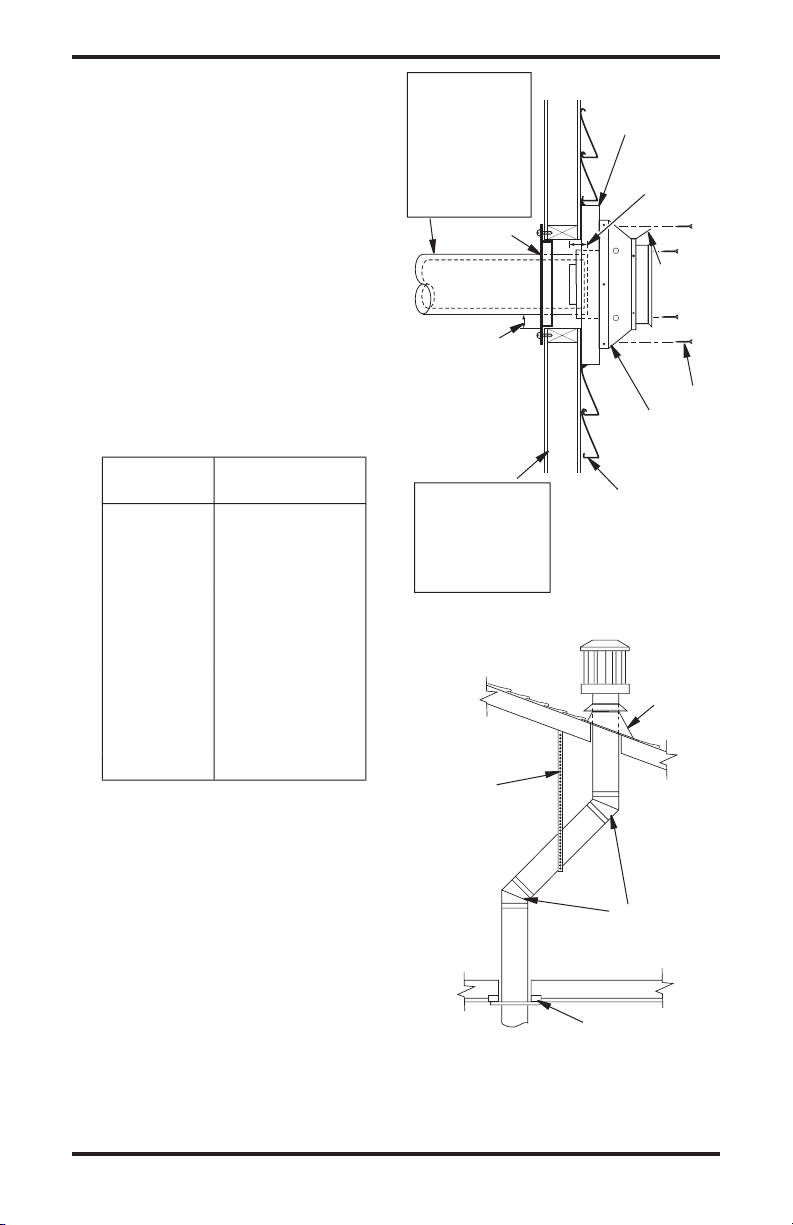

6. For vertical installation, a vertical termination is

available. Also for vertical venting application,

install vertical flue restrictor into inner collar of

fireplace as shown in Figure 6, page 7.

When installing a length of pipe for vertical

termination that is over 3 ft., support the pipe

every 3 ft. using metal wall straps. Vertical to

horizontal pipe must be kept at a 1 ft. to 4 ft. ratio

with a maximum run of no more than 20 ft.

If an offset is necessary in the attic to avoid

obstruction, it is important to support the

vent pipe every 3 ft. to avoid excessive

stress on the elbows and possible separation

(see Figure 8).

Clearances must be maintained between the roof

and the termination. Refer to chart below.

Roof Pitch Minimum Height

Flat - 7/12 1 ft. (30.48 cm)

7/12 - 8/12 1

8/12 - 9/12 2 ft (60.96 cm)

9/12 - 10/12 2

10/12 - 11/12

11/12 - 14/12

14/12 - 16/12 6 ft (182.88 cm)

16/12 - 18/12 7 ft (213.36 cm)

18/12 - 20/12 7

20/12 - 21/12 8 ft (243.84 cm)

Above Roof

1

/

ft. (45.72 cm)

2

1

/

ft (76.20 cm)

2

4 ft (121.92 cm)

5 ft (152.40 cm)

1

/

ft (228.60 cm)

2

Direct-Vent Pipe

CD32M and

CD36M-A

4 1/4" Inner and

7 1/4" Outer

CD42M-A

5" Inner and 8"

Siding Standoff

(Optional)

Minimum Pipe

Overlap 1 1/4"

Outer

Wall Firestop

Deflector

Shield

Maintain 1"

Minimum

Air Space

Around Outer

Pipe when

Penetrating a

Wall

Framed Openings

CD32M and

CD36M-A

Screws

Horizontal

Termination

(Vent Cap)

Exterior Wall

with Vinyl

Siding

10" x 10"

CD42M-A

10

3

4

/

" x 10

3

4

/

"

Figure 7 - Vent Termination (Horizontal)

Roof

Flashing

Wall Strap

45° Elbows

Ceiling Firestop

Figure 8 - Vertical Termination with

Offset and Wall Strap

8

www.desatech.com

111916-01F

INSTALLATION

Continued

ELECTRICAL HOOKUP AND

REMOTE RECEIVER DIAGRAM

An outlet box with two receptacles (see Figure 9) has

been supplied for your convenience and is located

inside on the lower right side of the fireplace.

The remote control receiver is factory wired and

connected to the convertible gas valve as shown

in Figure 10.

Outlet Box

The appliance must be isolated from the gas supply piping system by closing its individual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

The gas control valve is secured underneath the

firebox. Two 1/8" ports are provided on the gas

control valve for pressure test gauge connections

(see Figure 11).

Pilot Gas Line

Do Not Kink

Pilot Adjustment

ON/OFF

Knob

To Pilot

Burner

To Main

Burner

Three-prong Plug

Figure 9 - Duplex Outlet

Convertible

Gas Valve

Figure 10 - Remote Control Receiver

Remote

Control

Receiver

GAS SUPPLY TESTING

NOTICE: This section is intended as a guide for qualified

technicians installing gas to the

appliance.

WARNING: Do not connect

appliance before pressure testing gas piping. Damage to gas

valve may result and an unsafe

condition may be created.

The appliance and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5 kPa).

Inlet

Pressure

Outlet

Pressure

Figure 11 - Gas Control Valve

Flame

Adjustment Knob

GAS LINE HOOK-UP

WARNING: Gas line hookup should be done by your gas

supplier or a qualified service

person.

WARNING: Before you proceed, make sure your gas supply

is OFF.

An equipment shutoff valve has been included in

the fireplace's gas supply system. However, consider installing an extra shutoff valve outside the

applianceʼs enclosure (check local codes), where

it can be accessed more conveniently with a key

through a wall as shown in Figure 12.

Key

Figure 12- Typical Exterior Wall Gas

Shutoff Installation

Shutoff

Valve

Extension

111916-01F 9

www.desatech.com

INSTALLATION

1/8"

(0.3cm)

3/8" - 1/2"

(.95cm-1.3cm)

Continued

In conformance with local codes, route a 1/2"

NPT gas line towards the appliance coming in

from either the left or right side of the fireplace

(see Figure 13).

Install a sediment trap between the incoming gas

line and the gas control box (see Figure 14). The

sediment trap should extend down a minimum of

3" (7.62 cm) beyond the center of the pipe.

When routing gas line through conduit sleeve,

make sure to repack insulation to fill gaps between

gas line and conduit sleeve. Compounds used on

threaded joints of gas piping shall be resistant to

the action of propane or natural gas. Compounds

should be applied lightly to ensure excess sealant

does not enter the gas line.

Complete your gas line installation by connect

ing the incoming gas line to the flexible gas

line. Secure tightly with a wrench but do not

over-tighten.

WARNING: All gas piping

and connections must be tested

for leaks after the installation is

completed.

Never use an open flame to

check for a leak. After ensuring

that the gas valve is open apply commercial leak detection

fluid to all gas joints. Bubbles

forming show a leak. Correct all

leaks at once.

Do not operate any appliance if

a leak is detected.

Incoming 1/2" Gas Line

Permitted By Local Codes

Sediment Trap

(Not Supplied)

3" Min.

(7.6 cm)

Figure 14 - Sediment Trap

PILOT ADJUSTMENT

The pilot or electrode assembly is factory preset

for the proper flame height. Alterations to these

settings may have occurred during shipping and

handling. If this is the case, some minor readjust-

-

ments may be necessary and should be done by a

qualified service technician. The proper settings

for the thermopile height should be at a distance

of 3/8" (.95 cm) to 1/2" (1.27 cm) from the pilot

flame as shown in Figure 15.

Figure 15 - Pilot Assembly

REMOVING GLASS PANEL

Gas Routing

(Right Side Not Shown)

Side of

Fireplace

Front Face

Figure 13 - Gas Line Routing

10

CAUTION: Before you proceed, make sure your gas control

valve is in the OFF position.

1. To remove louvers, pull both spring latches

(located in each end of louver) toward center

of appliance at the same time until disengaged

from locating holes. Repeat for bottom end

spring latches (see Figure 16, page 11).

2. Remove screen rod by removing rod loop

from glass door center bracket. Slide screen

rod either to the left or right of fireplace until

one end is free to completely remove screen

from fireplace.

www.desatech.com

111916-01F

INSTALLATION

Open

Close

1

2

3

4

Continued

3. Undo latches located on top and bottom of

firebox (see Figure 17). Carefully swing door

to the left. The glass door is securely mounted

to the firebox with 5 screws.

Glass

Locating

Holes

Spring

Latch

Bottom Louver

Figure 16 - Removing Louvers

CD32M

Log #1

Placement

Figure 18 - Installing Log #1

(CD36M-A Series Shown)

Figure 19 - Installing Log #2

(CD36M-A Series Shown)

Figure 17 - Spring Latches

INSTALLING LOG SET

Each log is marked with a number in the following

diagram. These numbers will help in identify

ing the logs when installed. It is very important

to install these logs exactly as instructed. Do

not modify logs. Only use logs supplied with

fireplace.

Models CD32M and CD36M-A Series

1. Place log #1 (back log) on top of grate as

shown in Figure 18 for the CD36M-A Series.

Log #1 will go in front of the metal partition

on grate (see Figure 18). Make sure notches

in bottom of log fit over grate.

2. Place log #2 (large front log) over pins on grate

(see Figure 19).

3. Place log #3 (c-shaped crossover log) onto rear

4. Place log #4 (small round log) on pin on right

111916-01F 11

and front logs as shown in Figure 20. Make

sure it is seated properly on the smooth surface

on front log and on the pin on back log.

side of front log (see Figure 21).

-

Figure 20 - Installing Log #3

(CD36M-A Series Shown)

Figure 21 - Installing Log #4

(CD36M-A Series Shown)

www.desatech.com

INSTALLATION

5

6

1

1

2

3

5

6

7

4

Continued

5. Place log #5 (small front log) onto the front

left part of grate making sure notches fit over

prongs of grate (see Figure 22).

6. Place log #6 onto two pins on left side of back

and front logs (see Figure 22).

5. Place log #5 (top log) onto right pin of front log

(#2) and smooth surface of rear log (#3). Make

sure it is seated properly (see Figure 27).

6. Place log #6 (left log) on left pin of front log

(#2) and smooth surface of rear log (#3). Make

sure it is seated properly (see Figure 28).

7. Place log #7 (right log) on right pin of top

log (#5). Make sure it is seated properly (see

Figure 28).

Figure 22 - Installing Logs #5 and #6

(CD36M-A Series Shown)

Model CD42M-A Series

1. Place log #1 (small base log) onto pin on left

side of grate extension (see Figure 23).

2. Rest left side of log #2 (front log) on top of

log #1 and right side onto pin located on right

side of grate extension (see Figure 24).

3. Place log #3 (rear log) onto pins on rear of

grate (see Figure 25).

4. Place log #4 (crossover log) onto pins from

both logs #2 and #3 (see Figure 26).

Figure 23 - Installing Log #1, Model

CD42M-A

Figure 25 - Installing Log #3, Model

CD42M-A

Figure 26 - Installing Log #4, Model

CD42M-A

Figure 27 - Installing Log #5, Model

CD42M-A

Figure 24 - Installing Log #2, Model

12

CD42M-A

Figure 28 - Installing Logs #6 and #7,

www.desatech.com

Model CD42M-A

111916-01F

INSTALLATION

Continued

Lava Rock and Ember Material

1. For all models, place lava rock along sides and

front of firebox bottom in areas that are visible. It

is not necessary to use all lava rock provided.

NOTICE: Do not put lava rock

on or under burner. Placing

lava rock on burner could cause

performance problems.

2. Pull ember material apart into pieces no larger

than a dime. Place loosely and directly onto

exposed section of front burner and along space

between burner and grate prongs. These will create glowing ember appearance as flame touches

ember material. Do not block air slots by using

too much ember material in one area. It is not

necessary to use all ember material provided.

3. When lava rock and ember material are in

place, close and latch glass door and secure

louvers in place.

3. Align holes on right face extension with holes

on right side of front face assembly and secure

with screws previously removed (see Figure

29). Do the same for left side.

4. Secure top face extension with left and right

face extensions with two sheet metal screws

(see Figure 29).

Top Face

Extension

WARNING: The glass door

must be securely in place before

operating fireplace. Do not operate fireplace if glass is missing

or broken.

DECORATIVE FACING

Any noncombustible material may be used as facing (glass, tile, brick, etc.) as long as the proper

clearances are observed (see Clearances to Com-

bustibles, page 4). Louvered openings must not

be obstructed and upper and lower panels must

remain accessible for service. Use only heat-resistant, noncombustible mortar or adhesive when

securing decorative facing materials.

FACE EXTENSION FOR MODEL

CD32M ONLY

Model CD32M comes equipped with a front face

extension. The front face extension would add

3 1/2" to the width and 3/4" to the height of the

fireplace face.

To install face extension:

1. Remove existing screws from front face as

sembly as shown in Figure 29.

2. Align holes on top face extension with holes on

top side of front face assembly and secure with

screws previously removed (see Figure 29).

Side Face

Extensions

Figure 29 - Front Face Extension, Model

CD32M Only

BURNER FLAME

ADJUSTMENT

The burner flame adjustment (shutter opening) has

been factory preset (for natural gas) to the proper

air-to-gas ratio. This ratio results in an even, clean

burning flame across the burner (see Figure 30).

CORRECT

INCORRECT

CLOSE

SHUTTER

-

INCORRECT

OPEN

SHUTTER

Long, Blue Flame with Yellow Tips

Short, Sharp, Blowing Flame

Long, Uneven, Yellow Flame

Figure 30 - Burner Flame Patterns

111916-01F 13

www.desatech.com

BURNER FLAME

ADJUSTMENT

Continued

If adjustment is necessary, you can restore the

proper flame setting by loosening the air shutter

screw and rotating the air shutter until proper

setting is achieved (see Figure 31). The correct

shutter openings are as follows:

Tube Burner Pan Burner

Model Natural Propane/

CD32M 0.188" Max. — —

CD36M-A 0.188" Max — —

CD42M-A 0.188" 0.313" 0.188" 0.500"

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer

to this manual for assistance.

Consult a qualified installer for

additional information.

Adjustment

Screw

Firebox

Bottom

Adjustment Screw

Air Shutter

Opening

Firebox

Bottom

Burner

Gas Line

Figure 31 - Air Shutter Adjustments

Natural Propane/

LP

Burner Pan

Manifold

Air Shutter

Opening

LP

Burner

Gas Line

Burner

Tube

Manifold

OPERATING FIREPLACE

OPERATION GUIDELINES

• When used for the first time, the fireplace may

emit a slight odor for about 16 to 24 hours. This

is normal and is due to the “curing” of the logs

and the “burn-in” of internal paint and lubricant

used in the manufacturing process.

• Keep compartments, logs, burners and area sur

rounding logs clean by vacuuming and brushing

at least twice a year or as necessary.

• Turn off gas and remote switch before servicing

appliance. Any safety screen or guard removed

for servicing the fireplace must be replaced

prior to operation.

• Have a qualified agency periodically inspect

vent system at the start of each heating season

for any obstruction which will hinder its normal

operation. Never obstruct the flow of combus

tion and ventilation air. Keep the front of the

fireplace clear of all obstacles and materials.

FOR YOUR SAFETY

READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly,

a fire or explosion may result

causing property damage, per

sonal injury or loss of life.

A. This appliance has a pilot which must be

lighted by hand. When lighting the pilot,

follow these instructions exactly.

B. BEFORE LIGHTING smell all around the

appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than

air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neig h bor ʼs phon e. Fo llo w the gas

supplierʼs instructions.

• If you cannot reach your gas supplier, call

the fire department.

C. Use only your hand to push in control knob.

Never use tools. If the knob will not push

in or slide by hand, donʼt try to repair it,

call a qualified service technician. Force

or attempted repair may result in a fire or

explosion.

-

-

-

14

www.desatech.com

111916-01F

OPERATING FIREPLACE

Continued

D. Do not use this appliance if any part has been

under water. Immediately call a qualified

service technician to inspect the appliance and

to replace any part of the control system and

any gas control which has been under water.

Thermocouple

Piezo

Ignitor

Pilot Burner

Thermopile

LIGHTING

INSTRUCTIONS

1. STOP! Read the safety information above

before proceeding.

2. Set the “HI-LO” knob to the lowest setting.

3. Turn off all electrical power to the appliance.

4. Open control access panel.

5. Push in gas control knob slightly and turn

clockwise to “OFF”.

6. Wait five (5) minutes to clear out any gas.

Then smell for gas, including near the floor.

If you smell gas, STOP! Follow “B” in the

safety information above. If you donʼt smell

gas, go to the next step.

7. The pilot is located by the main burner.

8. Turn knob on gas control counterclockwise

9. Push in the control knob all the way and hold

10. Turn gas control knob counterclockwise

11. Set “HI-LO” knob to desired setting.

12. Turn on all electric power to the appliance.

Note: It is recommended that you maintain the

gas control knob in the full OFF position during

lengthy periods of seasonal non-usage.

Position

Indicator

Gas Control

Knob

Figure 32 - Control Knob in Pilot Position

111916-01F 15

to “PILOT”.

in. Immediately light the pilot by pressing the

red ignitor button until a flame appears. Con

tinue to hold the control knob in for about one

(1) minute after the pilot is lit. Release knob

and it will pop back up. Pilot should remain

lit. If it goes out, repeat steps 5 through 9.

• If knob does not pop out when released, stop

and call service technician or gas supplier.

• If the pilot will not stay lit after several tries,

turn gas control knob to “OFF” and call

your service technician or gas supplier.

to “ON”. Knob can be turned to “ON”

only if the control knob is popped out.

HI/LO Knob

www.desatech.com

1. Turn off the wall switch.

2. Turn off all electric power to the appliance

if service is to be performed.

3. Remove control access panel.

4. Push in gas control knob slightly and turn

clockwise

5. Replace control access panel.

CONVERTING FIREPLACE

FROM NATURAL GAS TO

The conversion kit is packaged with the unit.

Ple as e che ck the contents before beginnin g

this conversion.

-

ing, make sure the gas control

valve is in the OFF position and

all electrical power to the appli

ance is turned off.

CONVERTING PILOT

1. Wait five (5) minutes to clear out any gas. Smell

for any gas odor, especially near the floor. If any

gas odor is present, STOP! See For Your Safety

Read Before Lighting on page 14.

2. Locate the latch on the louver assembly.

Remove top and bottom louvers by pulling

the spring latches toward the center of the

fireplace simultaneously until they are disen

gaged from the locating holes.

3. Undo latches located on top and bottom of fire

box and swing door to the fully open position.

4. Carefully remove log set and ember material from

burner and place them aside in a safe place.

5. Replace main burner orifice with burner orifice

included in conversion kit (Model CD42M-A

series contains two burner orifices).

Figure 33 - Pilot

TO TURN OFF GAS

TO APPLIANCE

to “OFF”. Do not force.

PROPANE/LP GAS

WARNING: Before proceed-

-

-

-

HI

LO

O

F

F

P

I

L

O

T

O

N

CONVERTING FIREPLACE

HI

LO

O

F

F

P

I

L

O

T

O

N

FROM NATURAL GAS TO

PROPANE/LP GAS

Continued

6. Locate air shutter at end of burner manifold (end

of tube burner for CD42M series). Loosen screw

and adjust air shutter to proper setting (see Burner

Flame Adjustment, page 13). Retighten screw.

7. Remove pilot hood by pulling up until it

disengages from barrel. Do not remove the

retainer clip (see Figure 34).

8. Remove pilot orifice from inside barrel using

a 5/32" allen wrench to unscrew the orifice.

9. Replace pilot orifice with LP orifice supplied

with this kit. The number 30 is stamped on the

sleeve for identification. Insert small end of

new pilot orifice into barrel and thread until

tight with the allen wrench.

10. Line up notch on pilot hood to the positioning tab

on barrel receiver and snap back into position.

IMPORTANT: Be careful not to bend or kink the

aluminum tubing during conversion. Make sure

the pilot hood and orifice are properly mated and

aligned after finishing this conversion.

Pilot Hood

Pilot Orifice

Barrel Clip

5/32" Allen

Wrench

Pilot Bracket

3. Install the identification label enclosed with

gas valve regulator to the valve body where

it can easily be seen (see Figure 36).

WARNING: The conversion kit

must be installed by a qualified

service technician in accordance

with the manufacturers instructions and all applicable codes

and requirements of the authority

having jurisdiction. If any information is these instructions is not followed correctly, a fire, explosion

or production of carbon monoxide

may result causing property damage, personal injury or loss of life.

The qualified service technician is

responsible for the proper installation of this conversion kit.

Mounting

Screws

Diaphragm/

Spring

Components

Pressure

Regulator

Tower

Figure 34 - Converting Pilot

CONVERTING CONTROL VALVE

Convert the gas control valve by swapping out the

valve regulator portion of the gas valve.

1. Using a TORX T20 or a slotted screwdriver,

remove and dis ca rd the three mou nt in g

screws, pressure regulator tower and dia

phragm/spring components (see Figure 35).

2. Insure that the rubber gasket is properly

positioned on the new pressure regulator

assembly. Install new pressure regulator as

sembly to valve using new mounting screws

supplied with kit. Tighten screws securely

(approximately 25 in/lb). See Figure 36.

16

www.desatech.com

Figure 35- Removing Parts for Gas

Control Valve Conversion

Mounting

Screws

-

-

Identification

Label

Figure 36- Installing New Parts for Gas

Control Valve Conversion

Rubber

Gasket

111916-01F

TROUBLESHOOTING

WARNING: Turn off heater and let cool before servicing. Only a

qualified service person should service and repair heater.

WARNING: Turn off heater and let cool before servicing. Only a

qualified service person should service and repair heater.

OBSERVED PROBLEM

Pilot will not stay lit

Pilot lit but no flame on burner

POSSIBLE CAUSE

1. Defective thermocouple

1. Remote or wires defective

2. Thermopile not generating

sufficient milivoltage

3. Plugged burner orifice

REMEDY

1. Check pilot flame. It must

impinge on thermocouple

2. Clean or adjust pilot for maxi

mum flame impingement on

thermocouple

3. En su re the con ne ct io n be

tween valve and thermocouple

are tight and secure

4. Che ck ther moc ouple with

millivolt meter. Take reading

at thermocouple terminals of

gas valve with remote control

off. It should read 18 millivolts

minimum. Replace faulty ther

mocouple if reading is below

specified minimum

1. Check remote wires for proper

connectio ns . Place jumper

wire across terminals at re

mote control. If burner comes

on, replace remote. If okay,

pl ace ju mpe r wire ac ros s

remote contr ol at valve. If

burner comes on, wires are

faulty or connections are bad

2. Check thermopile with mil

livolt meter. Take reading at

thermopile terminals of gas

valve with remote control off.

It should read 325 millivolts

minimum. Replace thermopile

if reading is below specified

minimum

3. Check burner orifice for stoppage and remove

-

-

-

-

-

Frequent pilot outage

111916-01F 17

1. Pilot flame may be too low

or blowing (high) causing

safety pilot to “drop out”

www.desatech.com

1. Clean and/or adjust pilot flame

for maximum flame impinge

ment on thermocouple

-

6

7

19

18

10

12

23

24

34

2

11

17

8

21-2

21-6

21-4

21-5

21-3

21-1

1

13

9

16

3

14

4

20

15

5

15

42

40

35

36

22

37

39

38

25

41

26

30

27

28

29

33

31

32

ILLUSTRATED PARTS BREAKDOWN

MODELS CD32M AND CD36M-A SERIES

18

www.desatech.com

111916-01F

PARTS LIST

MODELS CD32M AND CD36M-A SERIES

KEY PART NUMBER

NO.

1 ** ** Firebox Assembly 1

2 ** ** Face Weldment 1

3 108892-01 108010-01 Door Assembly 1

4 108903-01 108011-01 Top Panel Assy Louver 1

5 108903-02 108011-02 Bottom Panel Assy Louver 1

6 ** ** Fireplace Top 1

7 ** ** Fireplace Top Insulation 1

8 ** ** Fireplace Surround 1

9 108885-01 108074-01 Burner Assembly 1

10 108890-01 108076-01 Burner Base Gasket 1

11

12 108901-01 110990-01 Right Refractory† 1

13 108901-02 110989-01 Left Refractory† 1

14 11418 11418 Push-On Nut 2

15 108440-01 12105 Screen 2

16 108455-02 13113 Screen Rod 1

17 ** ** Electrical Duct Assy 1

18 ** ** Gas Knock-Out Cover 2

19 ** ** Gas Conduit Assy 1

20 109082-03 109082-01 Heat Shield 1

21 109022-01 109006-01 Log Set 1

21-1 109403-01 110182-01 Front Log (Log 1) 1

21-2 109404-01 109007-01 Rear Log (Log 2) 1

21-3 109407-01 109009-01 Base Log (Log 3) 1

21-4 109406-01 109008-01 Crossover Log (Log 4) 1

21-5 109405-01 107348-01 Left Top Log (Log 5) 1

21-6 109408-01 107347-01 Right Top Log (Log 6) 1

22 11102 11102 Screw #8-32 x 3/8 PPH Zinc 2

23 11105 11105 Screw #10 x 1/2 Zinc 9

24 11179 11179 Screw #10-24 x 1/4 Zinc 4

25 11237 11237 Screw Trilab M4 x 8mm 1

26 14389 14389 HI-LO Sit Valve (Nat Gas) 1

27 14492 14492 Piezo Ignitor 1

28 14500 14500 Brass Fitting 2

29 14253 14253 Flexible Connector 1

30 14511 14511 Ignitor Bracket 1

31 14528 14528 Brass Elbow Fitting 1

32 104506-25 14496 Orifice 1

33 104509-02 14576 Aluminum Tubing Assy 1

34 26808 26808 Valve Bracket 1

35 26827 26827 Switch Bracket 1

36 108886-01 108077-01 Grate Base 1

37 108891-01 104504-03 Burner Tube 1

38 108084-02 108084-02 Pilot Assembly (Nat Gas) 1

39 ** ** Burner Base Assembly 1

40 109699-01 — Right Face Extension 1

41 109699-02 — Left Face Extension 1

42 109700-01 — Top Face Extension 1

** Not a field replaceable part. † Optional - See page 23.

111916-01F 19

CD32M CD36M-A DESCRIPTION QTY.

108897-01 110991-01 Rear Refractory† 1

25487 25487 Lava Rock 1

110251-01 110251-01 Micro Switch Assembly

27253 27253 Notice Label 1

109896-01 112033-01 Gas Conversion Kit 1

PARTS AVAILABLE NOT SHOWN

www.desatech.com

1

ILLUSTRATED PARTS BREAKDOWN

37

23

41

42

38

22

39

32

31

33

28

26

25

29

24

34

35

40

36

30

27

28

6

7

19

18

10

12

2

11

17

8

20

1

4

13

16

3

14

15

5

15

9

212

21-3

21-6

21-7

21-5

21-4

21-1

MODEL CD42M-A

20

www.desatech.com

111916-01F

MODEL CD42M-A

PARTS LIST

KEY

NO.

1 ** Firebox Assembly 1

2 ** Face Weldment 1

3 108328-01 Door Assembly 1

4 108331-01 Top Panel Assembly Louver 1

5 108331-03 Bottom Panel Assembly Louver 1

6 ** Fireplace Top 1

7 ** Fireplace Top Insulation 1

8 ** Fireplace Surround 1

9 108329-05 Burner Assembly 1

10 108374-01 Burner Base Gasket 1

11 111300-01

12 111301-01 Right Refractory† 1

13 111302-01 Left Refractory† 1

14 11418 Push-On Nut 2

15 107840-01 Screen 2

16 108455-01 Screen Rod 1

17 110037-01 Electrical Duct Assembly 1

18 ** Gas Knock-Out Cover 2

19 ** Gas Conduit Assembly 1

20 ** Heat Shield 1

21 108778-01 Log Set 1

21-1 109402-01 Small Base Log (Log 1) 1

21-2 109396-01 Front Log (Log 2) 1

21-3 109397-01 Rear Log (Log 3) 1

21-4 109398-01 Crossover Log (Log 4) 1

21-5 109399-01 Top Center Log (Log 5) 1

21-6 109400-01 Top Left Log (Log 6) 1

21-7 109401-01 Top Right Log (Log 7) 1

22 11102 Screw #8-32 x 3/8 PPH Zinc 2

23 11105 Screw #10 x 1/2 Zinc 9

24 11179 Screw #10-24 x 1/4 Zinc 4

25 11237 Screw Trilab M4 x 8mm 1

26 14389 HI-LO Sit Valve (Natural Gas) 1

27 14492 Piezo Ignitor 1

28 14500 Brass Fitting 2

29 14253 Flexible Connector 1

30 14511 Ignitor Bracket 1

31 14528 Brass Elbow Fitting 1

32 104506-25 Orifice 1

33 14544 Aluminum Tubing Assembly 1

34 26808 Valve Bracket 1

35 26827 Switch Bracket 1

36 108346-01 Grate Base 1

37 108376-01 Burner Tube 1

38 108084-02 Pilot Assembly (Natural Gas) 1

39 108755-01 Pilot Bracket 1

40 108373-01 Burner Base Assembly 1

41 108330-01 Burner Pan Assembly 1

42 104506-24 Orifice 1

** Not a field replaceable part.

† Optional - See page 23.

PART

NUMBER

25487 Lava Rock 1

110251-01 Micro Switch Assembly

27253 Notice Label 1

111007-01

DESCRIPTION QTY.

Rear Refractory† 1

PARTS AVAILABLE NOT SHOWN

Gas Conversion Kit 1

1

111916-01F 21

www.desatech.com

SPECIFICATIONS

Thermocouple

Incoming

Main

Gas

Supply

Piezo Ignitor

Control

Valve

Electrical Rating:

120v, 60Hz, 0.7A

Optional Wiring Diagram

For Fan Kit

Pilot

TH

TP

TPTH

Thermopile

Piezo Ignitor

Do Not

Connect

To 120V

(Remote Switch

Field Supplied)

Safety Microswitch for

Models CD32M-2, CD36M-A2

and CD42M-A2 Only

Pilot

Gas Line

Wireway

GND

BLK

WHT

GRN

Incoming

120V AC

(Fuse Box

or

Breaker)

Connectors

(Not Supplied)

Field Wire

N.O.SW

CD32M CD36M-A CD42M-A

Gas Rate (Natural) 12,000/

18,000 Btu/hr

Gas Rate (Propane/LP) 11,000/

17,000 Btu/hr

15,000/

22,000 Btu/hr

14,000/

20,000 Btu/hr

25,000/

35,000 Btu/hr

23,000/

33,000 Btu/hr

Ignition Piezo Piezo Piezo

Natural Gas Manifold Pressure 3.5" w.c. 3.5" w.c. 3.5"w.c.

Propane/LP Manifold Pressure 10" w.c. 10" w.c. 10" w.c.

Minimum Inlet Supply Pressure 4.5" w.c. 4.5" w.c. 4.5" w.c.

WIRING DIAGRAM

22

www.desatech.com

111916-01F

P/N 104506-20

P/N 104506-20

P/N 110994-01 (CD36M-A SERIES)

P/N 108328-01 (CD42M-A)

USED ON BLOWER ONLY

P/N 00710 (OPTIONAL)

REMOTE CONTROL KIT

P/N 108892-01 (CD32M SERIES)

GLASS DOOR ASSEMBLY

ORIFICE #56 (LP)

PAN BURNER

P/N 104506-24

ORIFICE #46(NAT)

ORIFICE #47(NA

T)

ORIFICE #56 (LP)

P/N 104506-25

TUBE BURNER

CD42M-A

CD36M-A

SERIES

ORIFICE #43 (NAT)

ORIFICE #55 (LP)

P/N 14514

P/N 14496

ORIFICE #55 (LP)

P/N 14514

P/N 104506-25

ORIFICE #47(NA

T)

CD32M SERIES

107840-01 (CD42M-A)

108440-01 (CD32M SERIES)

12105 (CD36M-A SERIES)

SCREEN

ROD

108719-01 (CD36M SERIES)

108455-01 (CD42M)

109479-01 (CD32M SERIES)

BK

BLOWER KIT

REGULAR

TRANSMITTER

TRANSMITTER

RECEIVER

RECEIVER

TRANSMITTER

STANDARD REMOTE CONTROL KIT

P/N 14187 (MILLIVOLT ONLY

)

RECEIVER AND TRANSMITTER)

RECEIVER

P/N 00825 (ELECTRONIC ONLY)

(BA

TTERY REQUIRED FOR

TRANSMITTER)

OPTIONAL REMOTE CONTROL KIT

(BATTERIES REQUIRED FOR

PIEZO IGNITOR

P/N 14492

108085-01 #51 NAT

108085-02 #30 LP

PILOT ORIFICE

CD36M-A2, AND CD42M-A2 ONLY

FOR MODELS CD32M-2,

P/N 108331-03 (CD42M-A)

P/N 108903-03 (CD32M SERIES)

BOTTOM LOUVER

P/N 108011-03 (CD36M-A SERIES)

STANDARD

VALVE

PILOT ASSY.

PN 108084-02 (NG)

P/N 110251-01

MICRO SWITCH ASSEMBLY

TPTH

TP

TH

P/N #14389

P/N 108903-01 (CD32M SERIES)

P/N 108331-01 (CD42M-A)

P/N 108011-01 (CD36M-A SERIES)

CD36M-A, CD36M-A2 AND CD42M-A

FOR MODELS CD32M, CD32M-2

STANDARD TOP LOUVER

MILLIVOLT

O

O

F

F

P

I

L

ON

T

O

L

T

I

P

HI-LO

ACCESSORY AND REPLACEMENT PARTS

111916-01F 23

www.desatech.com

111916 01

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

www.desatech.com

NOT A UPC

111916-01

Rev. F

04/05

Loading...

Loading...