CANADIAN PORTABLE FORCED AIR HEATERS

OWNER’S MANUAL

MODELS: BC40, RC40, BC55T, RC55T, BC70T, RC70T, BC115CT,

RC115CT, BC165CT AND RC165CT

IMPORTANT: Read and understand this manual before

assembling, starting, or servicing heater.

Improper use of heater can cause serious injury. Keep

this manual for future reference.

TABLE OF CONTENTS

Safety Information ............................................... 2

Unpacking ........................................................... 2

Product Identification ...........................................

Assembly ............................................................. 4

Theory of Operation ............................................ 5

Fuels .................................................................... 5

Ventilation ........................................................... 6

Operation ............................................................ 6

Storing, Transporting, or Shipping .......................

Save this manual for future reference.

For more information, visit www.desatech.com

Preventative Maintenance Schedule ................... 7

Troubleshooting ...................................................

Service Procedures ............................................. 9

3

Wiring Diagrams ............................................... 15

Illustrated Parts Breakdown and Parts List ....... 16

Specifications ....................................................

Accessories ....................................................... 25

Warranty and Repair Service ............................ 28

7

8

24

SAFETY INFORMATION

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, op

erate, or service this heater.

Improper use of this heater can

cause serious injury or death

from burns, fire, explosion,

electrical shock, and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Early signs of carbon monoxide poisoning resemble the flu, with headaches, dizziness, and/or

nausea. If you have these signs, the heater may not

be working properly. Get fresh air at once! Have

heater serviced. Some people (such as pregnant

women, persons with heart or lung disease, persons

with anemia, those under the influence of alcohol,

and those at high altitudes) are more affected by

carbon monoxide than others.

1. Use only kerosene, #1/#2 diesel/fuel oil, JET A

or JP-8 fuels to avoid risk of fire or explosion.

Never use gasoline, naphtha, paint thinners,

alcohol, or other highly flammable fuels.

2. Use only with the electrical voltage and fre

quency specified on model plate.

3. Heater must be grounded. Use only a properly

grounded three-wire extension cord. Plug into

grounded outlet only.

4. Use only in areas free of flammable vapors or

high dust content.

5. Minimum clearance from any combustible

materials: 8 feet (244 cm) from hot air outlet;

6 feet (183 cm) from top; and 2 feet (61 cm)

from sides and inlet.

6. Locate heater on a stable and level surface

while hot or operating or a fire may occur.

7. Use only in well ventilated areas. Provide venti

lation of at least three square feet (2,800 square

cm) for each 100,000 Btu/Hr of rating.

8. Keep children and animals away from heater

at all times.

9. Never start heater when combustion chamber

is hot or if fuel has accumulated in combus

tion chamber.

10. When used with a thermostat, heater may start

at anytime.

-

11. When heater is moved or stored, it must be in

a level position or fuel spillage may occur.

12. Use heater only in accordance with local

ordinances and codes.

13. Never use gasoline, crankcase drainings,

naphtha, paint thinners, alcohol, or other

highly flammable fuels.

14. Never use heater where gasoline, paint thin

ner, or other highly flammable vapors are

present.

15. Never use heater in living or sleeping areas.

16. Never leave a heater plugged in without adult

supervision if children or animals are likely to

be present.

17. Never move, handle, refuel, or service a hot,

operating, or plugged-in heater.

18. Never block air inlet at motor end (rear) of

heater.

19. Never attach duct work to front of heater.

20. Never attach heater to external fuel tank.

UNPACKING

1. Remove all protective packaging that has been

applied to heater for shipment

2. Remove heater from carton.

3. Check heater for any shipping damage. If dam

age is found, promptly inform dealer where

heater was purchased.

-

-

-

-

-

2

www.desatech.com

111168-01A

Hot Air

Outlet

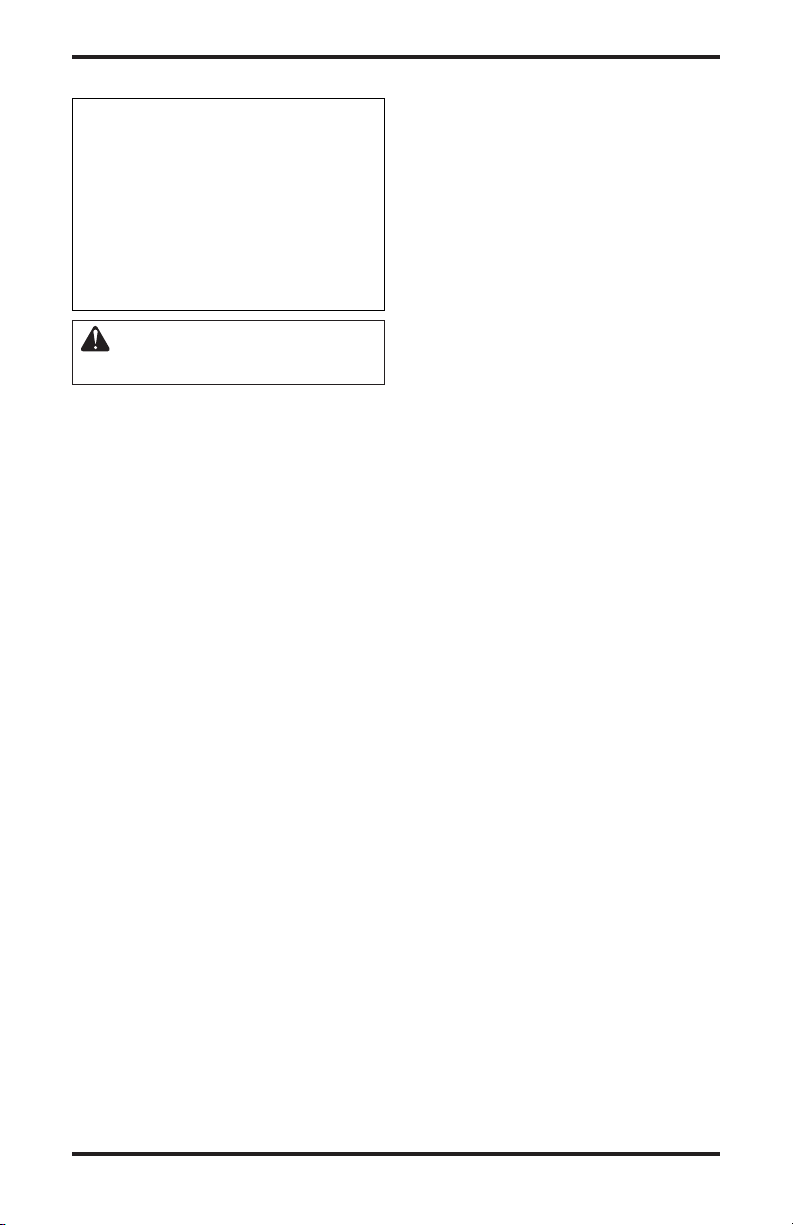

PRODUCT IDENTIFICATION

Nose Cone Guard

Upper Shell

Handle

Lower

Shell

Fuel Tank

Side Cover

Ignition Control Assembly

(assembly on inside of side cover)

Hot Air

Outlet

Lower

Shell

Fuel Tank

Side Cover

Ignition Control Assembly

(assembly on inside of side cover)

Figure 2 - 55T/70T Models

Hot Air

Outlet

Lower Shell

Figure 1 - 40 Model

Nose Cone Guard

Upper Shell

Upper Shell

Fan Guard

Power Cord

Handle

Fan Guard

Air Filter

End Cover

Fuel Cap

Fan Guard

Thermostat

Knob

Air Filter End

Cover

Fuel Cap

Power Cord

Thermostat Knob

Fuel Cap

Side Cover

Ignition Control Assembly

(assembly on inside of side cover)

Figure 3 - 115T/165T Models

www.desatech.com

Power Cord

Fuel Tank

3111168-01A

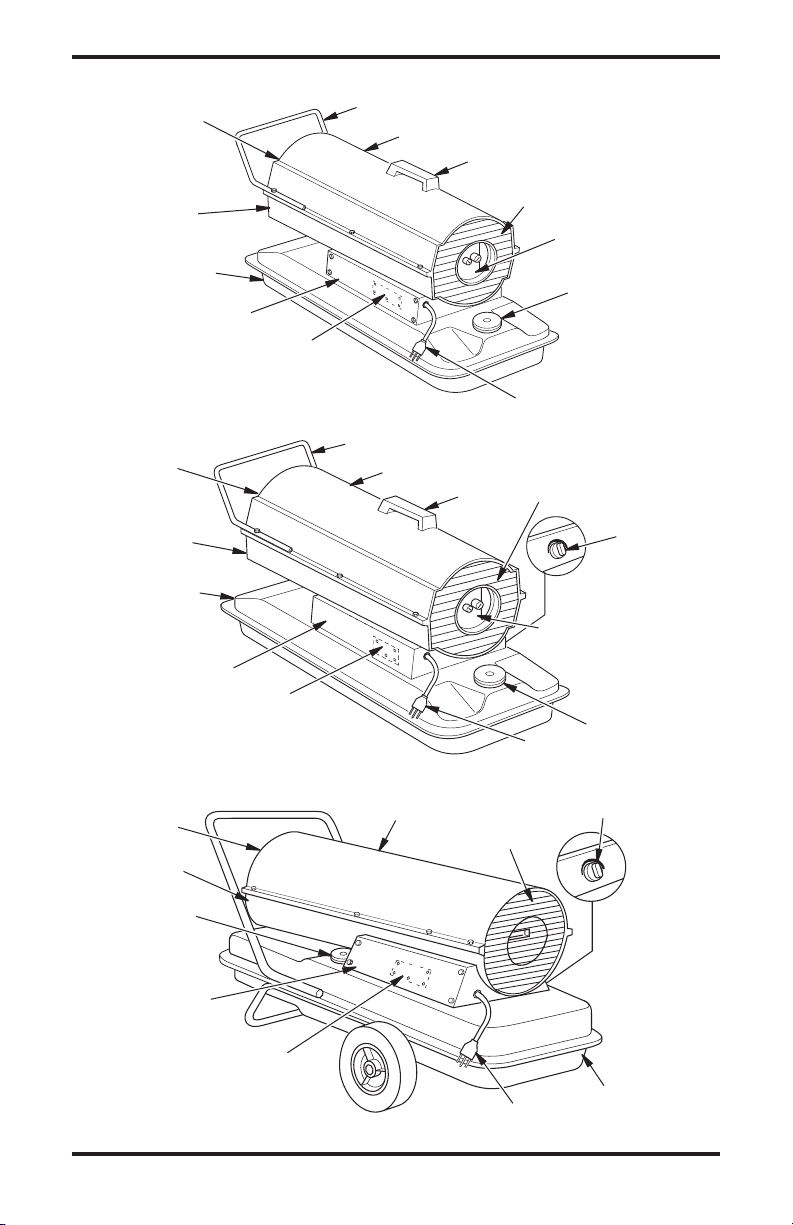

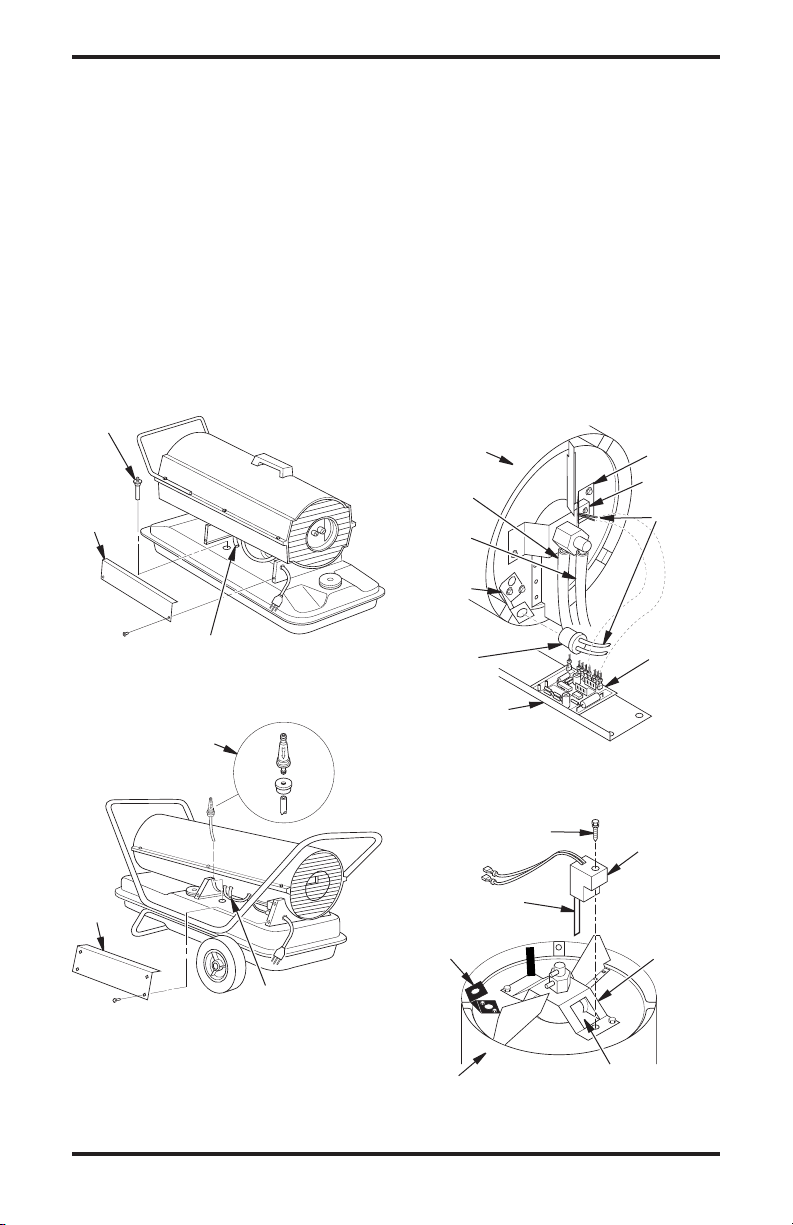

ASSEMBLY

(FOR 40, 55T, AND 70T MODELS ONLY)

These models are furnished with a nose cone

guard. Nose cone guard and mounting screws are

found in the shipping carton.

Tools Needed

• 5/16" Nut Driver or Wrench

1. Place nose cone guard on top of upper shell

flange. Make sure nose cone guard is on hot

air outlet end of heater.

2. Insert screws through nose cone guard and

upper shell flange.

3. Tighten screws firmly.

Nose Cone

Guard

Screw

Hot Air

Outlet

Upper Shell

Flange

(FOR 115T AND 165T MODELS ONLY)

These models are furnished with wheels and a front

handle. Some models are furnished with a rear

handle also. Wheels, handle(s), and the mounting

hardware is found in the shipping carton.

Tools Needed

• Medium Phillips Screwdriver

• 3/8" Open or Adjustable Wrench

• Hammer

1. Slide axle through wheel support frame. Install

wheels on axle.

IMPORTANT: Place extended hub of wheel

toward wheel support frame.

2. Place cap nuts on axle ends. Gently tap with

hammer to secure.

3. Place heater on wheel support frame assem

bly. Make sure air inlet end of heater is over

wheels.

4. Place front handle on top of fuel tank flange.

Insert screws through handle(s), fuel tank

flange and wheel support frame. Attach nut

finger tight after each screw is inserted.

5. Tighten all nuts firmly.

Front

Handle

Hot Air

Outlet

Rear Handle

(If Equipped)

Screw

-

Figure 4 - Nose Cone Guard Assembly,

40/55T/70T Models Only

4

www.desatech.com

Fuel Tank

Flange

Wheel

Support

Frame

Wheel

Nut

Cap Nut

Figure 5 - Wheel and Handle Assembly,

115T/165T Models Only

Axle

Air Inlet

Extended Hub

111168-01A

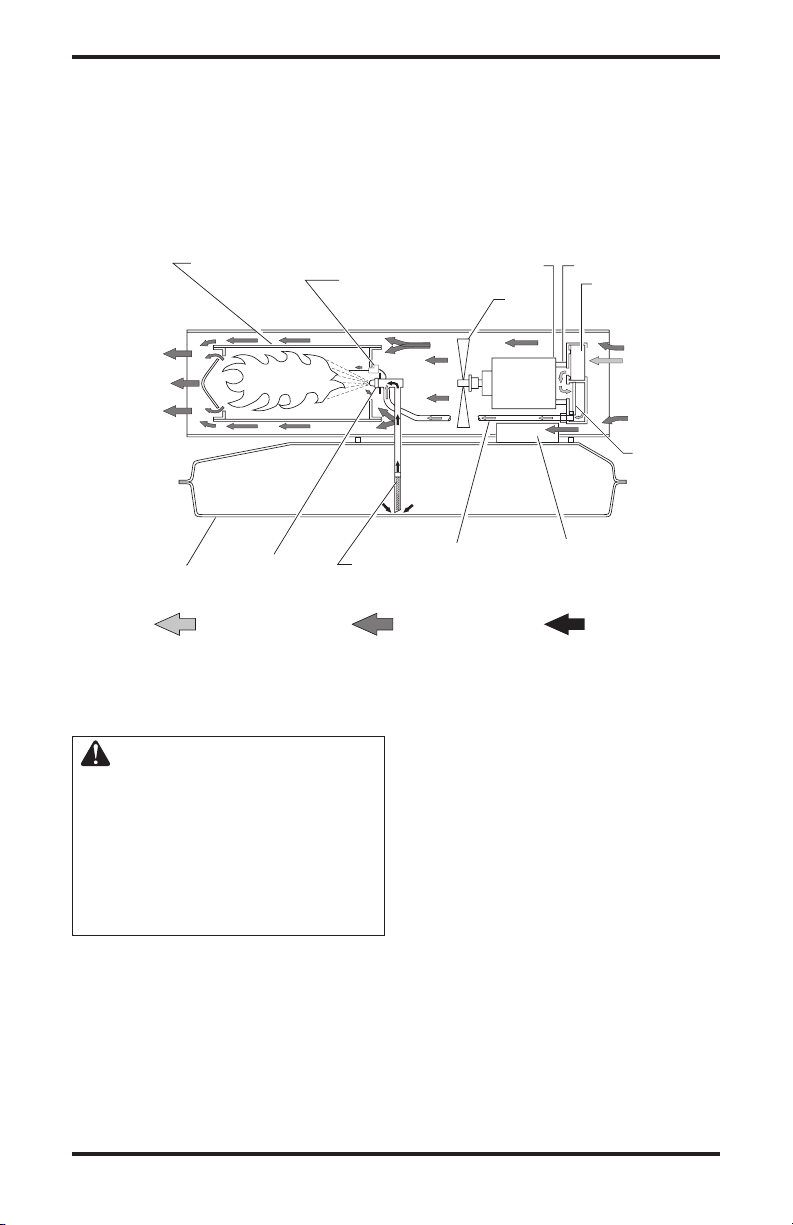

THEORY OF OPERATION

The Fuel System: The air pump forces air through

the air line. The air is then pushed through the

nozzle. This air causes fuel to be lifted from the

tank. A fine mist of fuel is sprayed into the combustion chamber.

The Air System: The motor turns the fan. The

fan pushes air into and around the combustion

chamber. This air is heated and provides a stream

of clean, hot air.

The ignition control assembly provides power to

the ignitor. This ignites the fuel/air mixture in the

combustion chamber.

The Flame-Out Control System: This system causes

the heater to shut down if the flame goes out.

Clean

Heated

Air Out

Fuel Tank

Combustion Chamber

Nozzle

Air For Fuel

System

Figure 6 - Cross Section Operational View

Ignitor

Fuel

Filter

FUELS

WARNING: Use only kerosene, #1/#2 diesel/fuel oil, JET

A or JP-8 fuels to avoid risk

of fire or explosion. Never

use gasoline, oil drained from

crankcases, naphtha, paint

thinners, alcohol or other highly

flammable fuels.

Use only kerosene, #1/#2 diesel/fuel oil, JET A

or JP-8 fuels. Heavier fuels such as No. 2 fuel

oil or No. 2 diesel fuel may also be used but will

result in:

• noticeable odor

• additional fuel filter maintenance

• the need for nontoxic, anti-icer additives in very

cold weather

Motor

Fan

Air Line

To Burner

Air For Combustion

And Heating

Do not use fuels heavier than No. 2 grade or

heavy oils such as oil drained from crankcases.

These heavy oils will not ignite properly and will

contaminate the heater.

IMPORTANT: Use a KEROSENE ONLY (blue)

or DIESEL ONLY (yellow) storage container. Be

sure storage container is clean. Foreign matter

such as rust, dirt, or water will cause the ignition

control assembly to shut down heater. Foreign

matter may also require heater's fuel system to be

frequently cleaned.

Air Pump

Air Intake

Filter

Cool

Air In

Air

Output

Filter

Ignition Control

Assembly

Fuel

www.desatech.com

5111168-01A

VENTILATION

WARNING: Provide a fresh air

opening of at least three square

feet (2,800 square cm) for each

100,000 Btu/Hr rating. Provide

extra fresh air if more heaters

are being used. The minimum

ventilation requirements must

be followed to avoid risks associated with carbon monoxide

poisoning. Make certain these

requirements are met prior to

operating heater.

Example: A 165 model heater requires one of

the following:

• a two-car garage door (16 ft. [4.88 m] wide

opening) raised four inches (10.16 cm)

• a single-car garage door (9 ft. [2.74 m] wide

opening) raised seven inches (17.78 cm)

• two, thirty-inch (76.20 cm) windows raised

twelve inches (30.48 cm)

OPERATION

IMPORTANT: Review and understand the warnings in the Safety

Information section, page 2.

They are needed to safely oper

ate this heater. Follow all local

ordinances and codes when

using this heater.

-

Extension Cord Size Requirement

6 to 10 feet (1.8 to 3 meters) long, use 18 AWG

(0.75 mm2) rated cord

11 to 100 feet (3.3 to 30.5 meters) long, use

16 AWG (1.0 mm2) rated cord

101 to 200 feet (30.8 to 61 meters) long, use

14 AWG (1.5 mm2) rated cord

6.

Plug extension cord into standard 120 volt/60

hertz, 3-prong grounded outlet. Note: Ignitor will

preheat for five seconds, then heater will start.

7. For thermostat models 55T, 70T, 115T, and

165T, adjust thermostat knob to the desired

setting. Not e: A cold heater may affect

the thermostat setting. This thermostat is a

general-heating control. It is not intended for

precise temperature control. Adjust thermostat

until heater cycles at the desired setting.

TO STOP HEATER

Unplug extension cord from outlet.

TO RESTART HEATER

1. Unplug extension cord from outlet and wait

10 seconds. (Wait two minutes if heater has

been running.)

2. Repeat steps under To Start Heater

.

TO START HEATER

1. Follow all ventilation and safety information.

2. Fill fuel tank with kerosene, #1/#2 diesel/fuel

oil, JET A or JP-8 fuels.

3. Attach fuel cap.

4. For thermostat models 55T, 70T, 115T, and

165T, turn thermostat knob clockwise to the

high position.

5. Plug heaterʼs power cord into approved,

grounded, three-wire extension cord. Extension

cord must be at least six feet (1.8 meters) long.

6

www.desatech.com

111168-01A

STORING, TRANSPORTING,

OR SHIPPING

Note: If shipping, transport companies require

fuel tanks to be empty.

1. Drain fuel tank.

Note: Some models have drain plug on un-

derside of fuel tank. If so, remove drain plug

to drain all fuel. If heater does not have drain

plug, drain fuel through fuel cap opening. Be

sure all fuel is removed.

2. Replace drain plug if provided.

3. If any debris is noted in old fuel, add 1 or 2

quarts of clean kerosene to tank, stir, and drain

again. This will prevent excess debris from

clogging filters during future use.

4. Replace fuel cap or drain plug. Properly dis

pose of old and dirty fuel. Check with local

automotive service stations that recycle oil.

5. If storing, store heater in dry place. Make sure

storage place is free of dust and corrosive

fumes.

IMPORTANT: Do not store kerosene over summer

months for use during next heating season. Using

old fuel could damage heater.

PREVENTATIVE MAINTENANCE SCHEDULE

WARNING: To avoid risk of burn and electrical shock, never at-

tempt to service heater while it is plugged in, operating, or hot.

Item How Often How To

Fuel tank Flush every 150-200 hours See Storing, Transporting, or

of operation or as needed Shipping

Air output and lint filters Replace every 500 hours of See Air Output, Air Intake,

operation or once a year and Lint Filters, page 10

Air intake filter Wash and dry with soap and See Air Output, Air Intake,

water every 500 hours of and Lint Filters, page 10

operation or replace as needed

Fuel filter Clean twice a heating season See Fuel Filter, page 11

or replace as needed

-

Ignitor None required

Fan blades Clean every season or See Fan, page 9

as needed

Motor Not required/permanently

lubricated

www.desatech.com

7111168-01A

TROUBLESHOOTING

WARNING: Never service heater while it is plugged in, operating,

or hot. Severe burns and electrical shock can occur.

FAULT CONDITION

Motor does not start five seconds

after heater is plugged in

Motor starts and runs but heater

does not ignite

POSSIBLE CAUSE

1. No power to heater

2. Thermostat setting is too low

WARNING: High voltage!

3. Bad electrical connection be

tween motor and ignition con

trol assembly or ignition control

assembly and power cord

4. Binding pump rotor

5. Defective ignition control as

sembly

6. Defective motor

1. No fuel in tank

2. Pump pressure incorrect

3. Dirty fuel filter

4. Obstruction in nozzle

5. Water in fuel tank

WARNING: High voltage!

6. Bad electrical connection

between ignitor and ignition

control assembly

7. Defective ignitor

8. Defective ignition control as

sembly

REMEDY

1. Check circuit breaker in electrical panel

2. Turn thermostat knob to a

higher setting

-

3. Check all electrical connec-

-

tions. See Wiring Diagrams

page 15

4. If fan does not turn freely, see

Pump Rotor, page 14

-

5. Replace ignition control as

sembly

6. Replace motor

1. Fill tank with kerosene

2. See Pump Pressure Adjust

ment, page 10

3. See Fuel Filter, page 11

4. See Nozzle Assembly, page 12

5. Drain and flush fuel tank with

clean kerosene. See Storing,

Trans porti ng, or Shipping

page 7

6.

Check electrical connections.

See Wiring Diagrams , page 15

7. Replace ignitor, see page 11

-

8. Replace ignition control as

sembly

,

-

-

,

-

Heater ignites but ignition control

assembly shuts heater off after a

short period of time

8

1. Pump pressure incorrect

2. Dirty air intake, air output,

and/or lint filter

3. Dirty fuel filter

4. Obstruction in nozzle

5. Photocell assembly not properly

installed (not seeing the flame)

6. Dirty photocell lens

WARNING: High voltage!

7. Bad electrical connection be

tween photocell and ignition

control assembly

8. Defective photocell

9. Defective ignition control as

sembly

www.desatech.com

1. See Pump Pressure Adjust

ment, page 10

2. See Air Output, Air Intake, and

Lint Filters, page 10

3. See Fuel Filter, page 11

4. See Nozzle Assembly, page 12

5. Make sure photocell boot is

properly seated in bracket

6. Clean photocell lens

-

7. Check electrical connections.

See Wiring Diagrams, page 15

8. Replace photocell

-

9. Replace ignition control as

sembly

111168-01A

-

-

SERVICE PROCEDURES

WARNING: To avoid risk of

burn and electrical shock, never

attempt to service heater while it

is plugged in, operating, or hot.

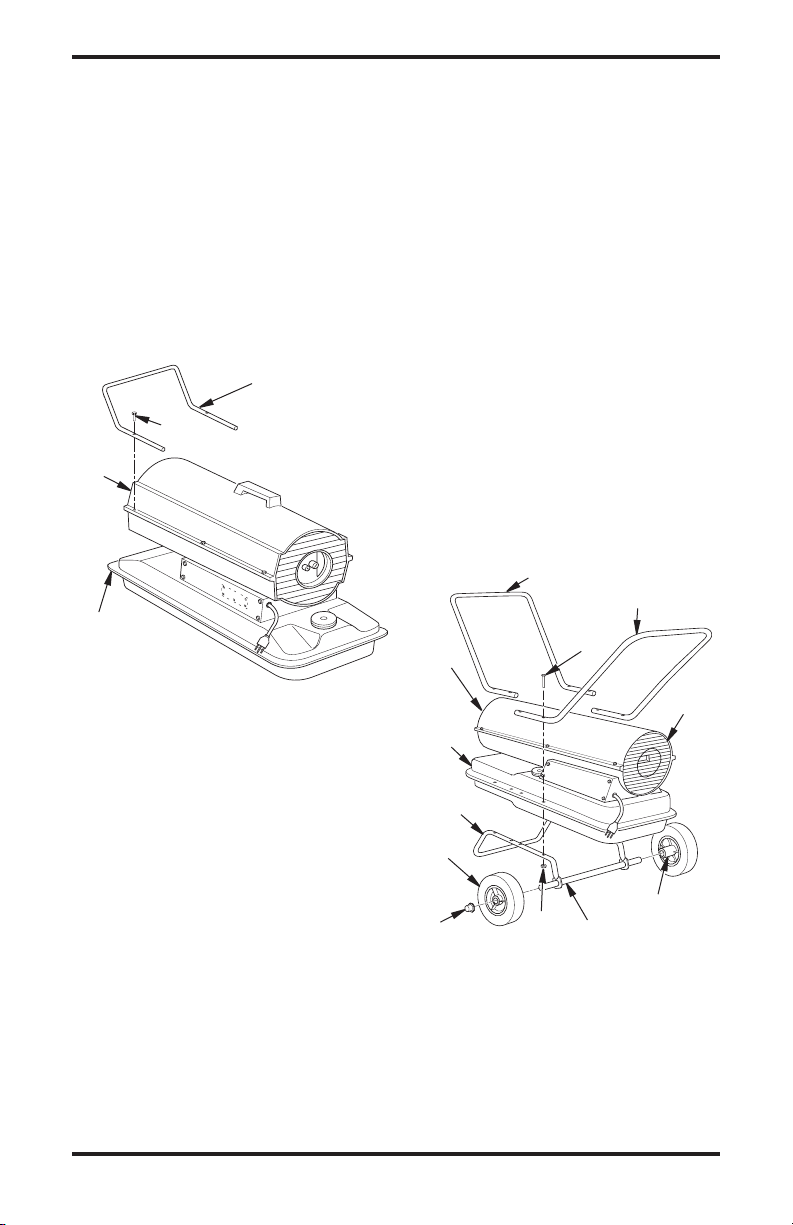

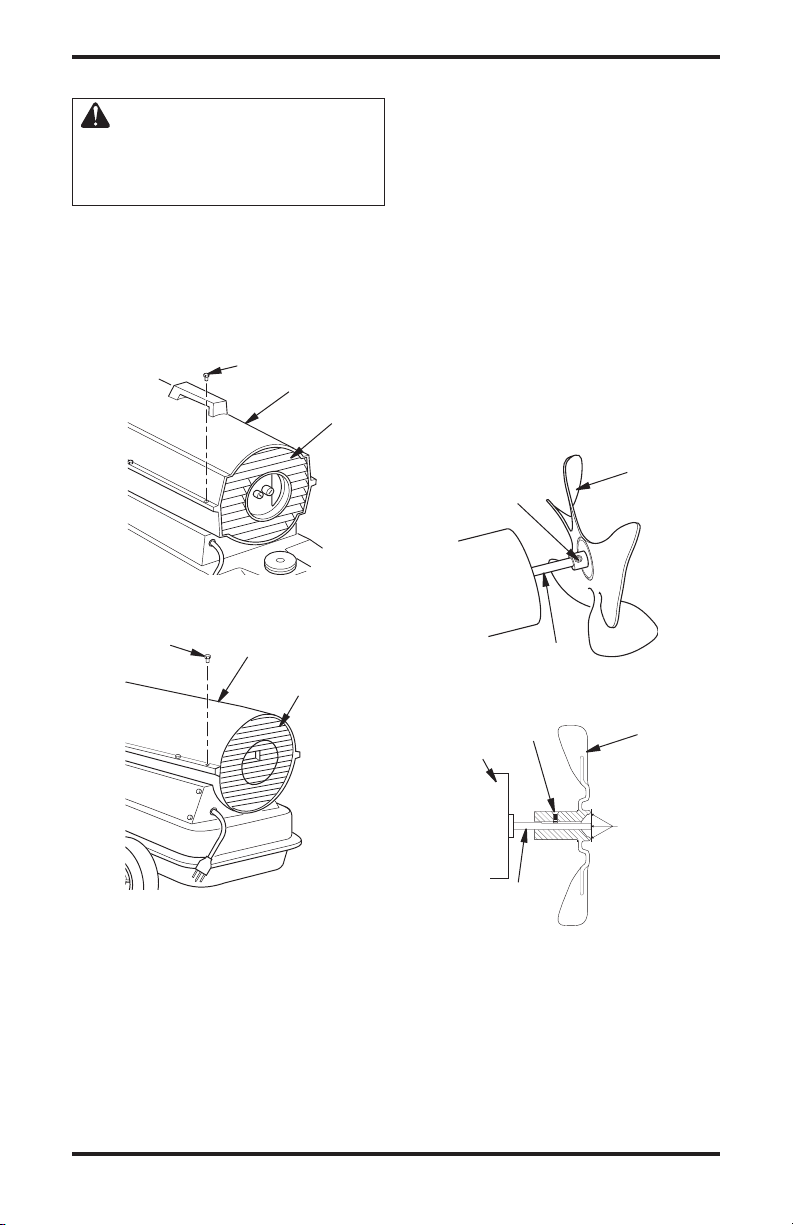

UPPER SHELL REMOVAL

1. Remove screws along each side of heater using

5/16" nut-driver. These screws attach upper

and lower shells together. See Figure 7 or 8.

2. Lift upper shell off.

3. Remove fan guard.

Screw

Upper Shell

Fan Guard

Figure 7 - Upper Shell Removal

(40/55T/70T Models Only)

FAN

IMPORTANT: Remove fan from motor shaft

before removing motor from heater. The weight

of the motor resting on the fan could damage the

fan pitch (see Figure 9).

1. Remove upper shell (see Figure 7 or 8).

2. Use 1/8" allen wrench to loosen setscrew

which holds fan to motor shaft.

3. Slip fan off motor shaft.

4. Clean fan using a soft cloth moistened with

kerosene or solvent.

5. Dry fan thoroughly.

6. Replace fan on motor shaft. Place fan hub flush

with end of motor shaft (see Figure 10).

Place setscrew on flat of shaft. Tighten

7.

setscrew firmly (40-50 inch-pounds/4.5-

5.6 n-m).

8. Replace fan guard and upper shell.

Fan

Setscrew

Screw

Figure 8 - Upper Shell Removal

(115T/165T Models Only)

Upper Shell

Fan Guard

www.desatech.com

Motor Shaft

Figure 9 - Fan, Motor Shaft, and

Setscrew Location

Setscrew

Motor

Motor Shaft

Figure 10 - Fan Cross Section

Fan

Flush

9111168-01A

SERVICE PROCEDURES

Continued

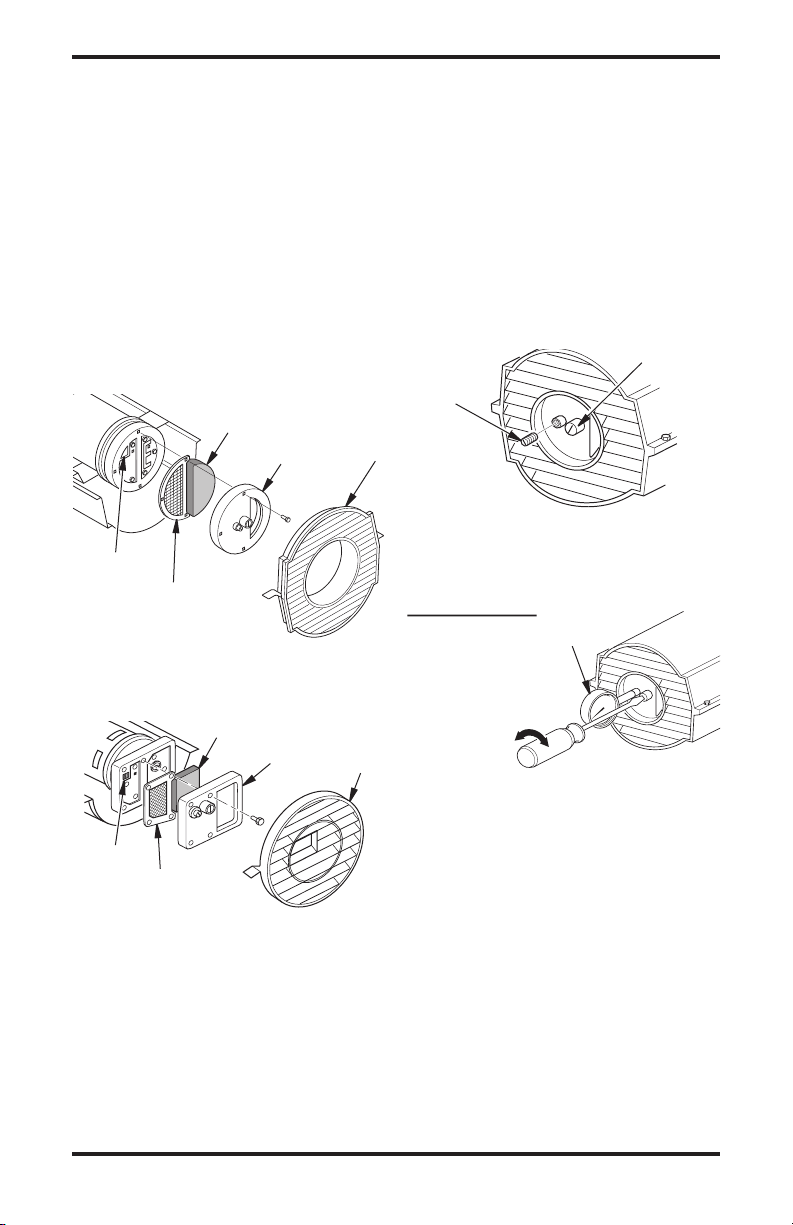

AIR OUTPUT, AIR INTAKE AND LINT

FILTERS

Remove upper shell (see Figure 7 or 8, page 9).

1.

2. Remove filter end cover screws using 5/16"

nut-driver. See Figure 11 or 12.

3. Remove filter end cover.

4. Replace air output and lint filters.

5. Wash or replace air intake filter (see Preventa

tive Maintenance Schedule, page 7).

6. Replace filter end cover.

7. Replace fan guard and upper shell.

IMPORTANT: Do not oil filters.

Air Intake

Filter

Filter End

Cover

Lint Filter

Air Output Filter

Figure 11 - Air Output, Air Intake, and

Lint Filters, 40/55T/70T Models

Air Intake

Filter

Filter End

Cover

Fan

Guard

Fan

Guard

PUMP PRESSURE ADJUSTMENT

1. Remove pressure gauge plug from filter end

cover (see Figure 13).

2. Install accessory pressure gauge (part number

HA1180).

3. Start heater (see

motor to reach full speed.

4. Adjust pressure. Turn relief valve to right to

increase pressure. Turn relief valve to left to

decrease pressure. See specifications correct

pressure for each model (see Figure 14).

-

5. Remove pressure gauge. Replace pressure

gauge plug in filter end cover.

Pressure

Gauge

Plug

Figure 13 - Pressure Gauge Plug

Removal (40/55T/70T Models Shown)

Pump

Model Pressure

40 3.0 PSI

55T 3.4 PSI

70 T 4.7 PSI

115T 5.1 PSI

165T 5.6 PSI

Figure 14 - Adjusting Pump Pressure

(40/55T/70T Models Shown)

Operation, page 6). Allow

Relief Valve

Pressure

Gauge

Lint Filter

Air Output

Filter

Figure 12 - Air Output, Air Intake, and

Lint Filters, 115T/165T Models

10

www.desatech.com

111168-01A

SERVICE PROCEDURES

Continued

FUEL FILTER

1. Remove side cover screws using 5/16" nutdriver.

2. Remove side cover.

3. Pull upper fuel line off fuel filter neck (see

Figure 15 or 16).

4. Carefully pry bushing, fuel filter, and lower

fuel line (115T/165T models only) out of fuel

tank (see Figure 16).

5. Wash fuel filter with clean fuel and replace in

tank.

6. Attach upper fuel line to fuel filter neck.

7. Replace side cover.

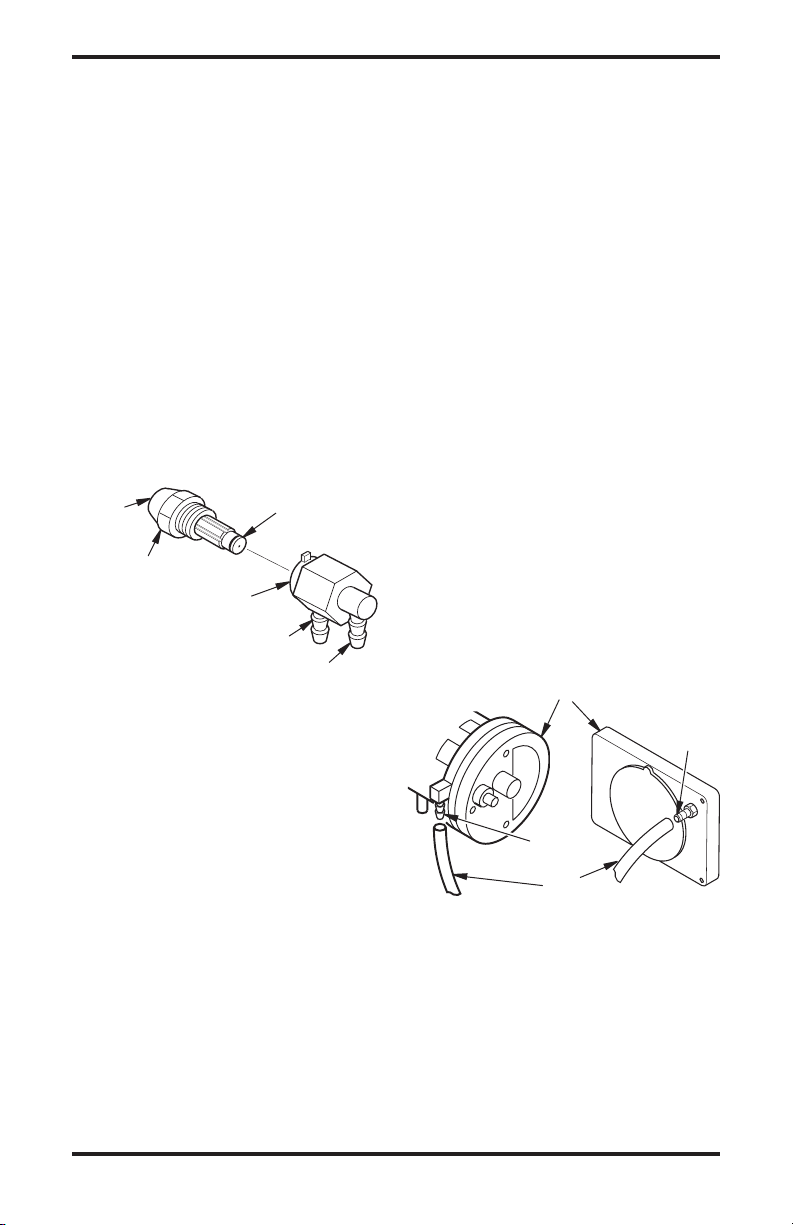

Fuel Filter

Side

Cover

IGNITOR

1. Remove upper shell and fan guard (See Upper

Shell Removal, page 9).

2. Remove fan (see page 9).

3.

Remove 4 side cover screws with a 5/16"

nut driver. Remove side cover (see Figures

15 and 16).

4. Disconnect ignitor wires (yellow) from ignition control assembly (see Figure 17). Pull

the ignitor wires up through the hole in the

lower shell.

5. Disconnect fuel line hose and air line hose.

Remove photocell from photocell bracket (see

Figure 17).

6. Remove combustion chamber. Stand com

bustion chamber on end with nozzle adapter

bracket on top (see Figure 18).

Nozzle

Combustion

Chamber

Air Line

Hose

Fuel Line

Hose

Photocell

Bracket

Adapter

Bracket

Ignitor

Ignitor Wire

(Yellow)

-

Upper Fuel Line

Figure 15 - Fuel Filter Removal,

40/55T/70T Models

Fuel Filter, Bushing,

and Lower Fuel Line

Side

Cover

Upper Fuel Line

Figure 16 - Fuel Filter Removal,

115T/165T Models

111168-01A

Photocell

Assembly

Side Cover

Figure 17 - Disconnecting Ignitor Wires

from Ignition Control Assembly

Ignitor Screw/

Washer Assembly

Ignitor Element

Photocell

Bracket

Combustion Chamber

Figure 18 - Ignitor Replacement

www.desatech.com

Ignition

Control

Assembly

Ignitor

Nozzle

Adapter

Bracket

Nozzle Adapter

Bracket Opening

11

SERVICE PROCEDURES

Continued

7. Remove ignitor screw with a 1/4" nut driver.

Carefully remove ignitor from nozzle adapter

bracket.

CAUTION: Do not bend or

strike ignitor element. Handle

with care.

8. Carefully remove replacement ignitor from

styrofoam packing.

9. Carefully guide ignitor into opening in nozzle

adapter bracket. Do not strike ignitor element.

Attach ignitor to nozzle adapter bracket with

screw using a 1/4" nut driver (see Figure 18, page

11). Torque 8 to 15 in. lbs. Do not over torque.

10. Replace combustion chamber.

11. Route the ignitor wires back down through

the hole in the lower shell. Connect wires to

the ignition control assembly (see Figure 17,

page 11).

12. Replace side cover (see Figures 15 and 16,

page 11).

13. Connect and route fuel line hose and air line

hose to nozzle adapter assembly. See Fuel and

Air Line Replacement and Proper Routing

page 13.

14. Replace photocell in photocell bracket. Route

wires as shown in Figure 19, 20, or 21.

15. Replace fan (see

16. Replace fan guard and upper shell (see

Shell Removal, page 9).

Combustion

Chamber

Burner Strap

Photocell

Bracket

Air Line

Hose

Figure 19 - Removing Air and Fuel Line

Hoses, (40/55T/70T Models Only)

Fan, page 9).

Upper

Nozzle/

Adapter

Assembly

Fuel Line

Hose

Combustion

Chamber

Burner Strap

Photocell

Bracket

Air Line Hose

Figure 20 - Removing Air and Fuel Line

Hoses, (115T Model Only)

Combustion

Chamber

Burner Strap

Photocell

Bracket

Air Line

Hose

Figure 21 - Removing Air and Fuel Line

,

Hoses (165T Model Only)

Nozzle/

Adapter

Assembly

Fuel Line

Hose

Fuel Line

Hose

NOZZLE ASSEMBLY

1. Remove upper shell (see Upper Shell Removal, page 9).

2. Remove fan (see

3. Remove fuel and air line hoses from nozzle

assembly (see Figure 19, 20, or 21).

4. Turn nozzle assembly 1/4 turn to left and pull

toward motor to remove (see Figure 22).

5. Place plastic hex-body into vise and lightly

tighten.

Burner Strap

Fan, page 9).

Nozzle

Assembly

Nozzle/

Adapter

Assembly

Figure 22 - Removing Nozzle Assembly,

12

www.desatech.com

All Models

111168-01A

SERVICE PROCEDURES

Continued

6. Carefully remove nozzle from the nozzle adapter

using 5/8" socket wrench. See Figure 23.

7. Blow compressed air through face of nozzle.

This will free any dirt in nozzle area.

8. Inspect nozzle sleeve for damage.

9. Replace nozzle into nozzle adapter until

nozzle seats. Tighten 1/3 turn more using

5/8" socket wrench (40-45 inch-pounds). See

Figure 23.

10. Attach nozzle assembly to burner strap (see

Figure 22).

11. Attach fuel and airline hoses to nozzle adapter

assembly. See Fuel and Air Line Replacement

and Proper Routing

12. Replace fan (see

13. Replace fan guard and upper shell (see

Shell Removal, page 9).

Nozzle

Face

Nozzle

Nozzle Adapter

Figure 23 - Nozzle and Nozzle Adapter,

.

Fan, page 9).

Upper

Nozzle

Sleeve

Air Line Fitting

Fuel Line Fitting

All Models

FUEL AND AIR LINE REPLACEMENT

AND PROPER ROUTING

1. Remove upper shell (see Upper Shell Removal, page 9).

2. Remove side cover screws using 5/16" nut

driver (see Figure 15 or 16, page 11).

3. Remove side cover.

4. Inspect fuel and air line hoses for cracks and/or

holes. If fuel line hose is damaged, disconnect

from nozzle adapter (see Figure 19, 20, or 21,

page 12) and from fuel filter (see Fuel Filter

page 11). If air line hose is damaged, discon

nect from nozzle adapter (see Figure 19, 20,

or 21, page 12) and from barb fitting on pump

end cover (see Figure 24).

5. Install new air and/or fuel line. Attach one

end of air line hose to barb fitting on pump

end cover (see Figure 24) and the other end to

nozzle adapter (see Figure 19, 20, or 21, page

12). Attach one end of fuel line hose to fuel

filter (see Fuel Filter, page 11) and the other

end to nozzle adapter (see Figure 19, 20, or

21, page 12).

Note: Route hoses as shown in Figure 19, 20,

or 21, page 12, according to model. Hoses are

not to touch photocell bracket.

6. Replace side cover.

7. Replace upper shell and fan guard (see

Shell Removal, page 9).

Pump End Cover

Upper

Barb

Fitting

,

-

40/55T/70T

Models

Figure 24 - Air Hose to Barb Fitting

www.desatech.com

Barb

Fitting

Air Hose

115T/165T

Models

13111168-01A

SERVICE PROCEDURES

Continued

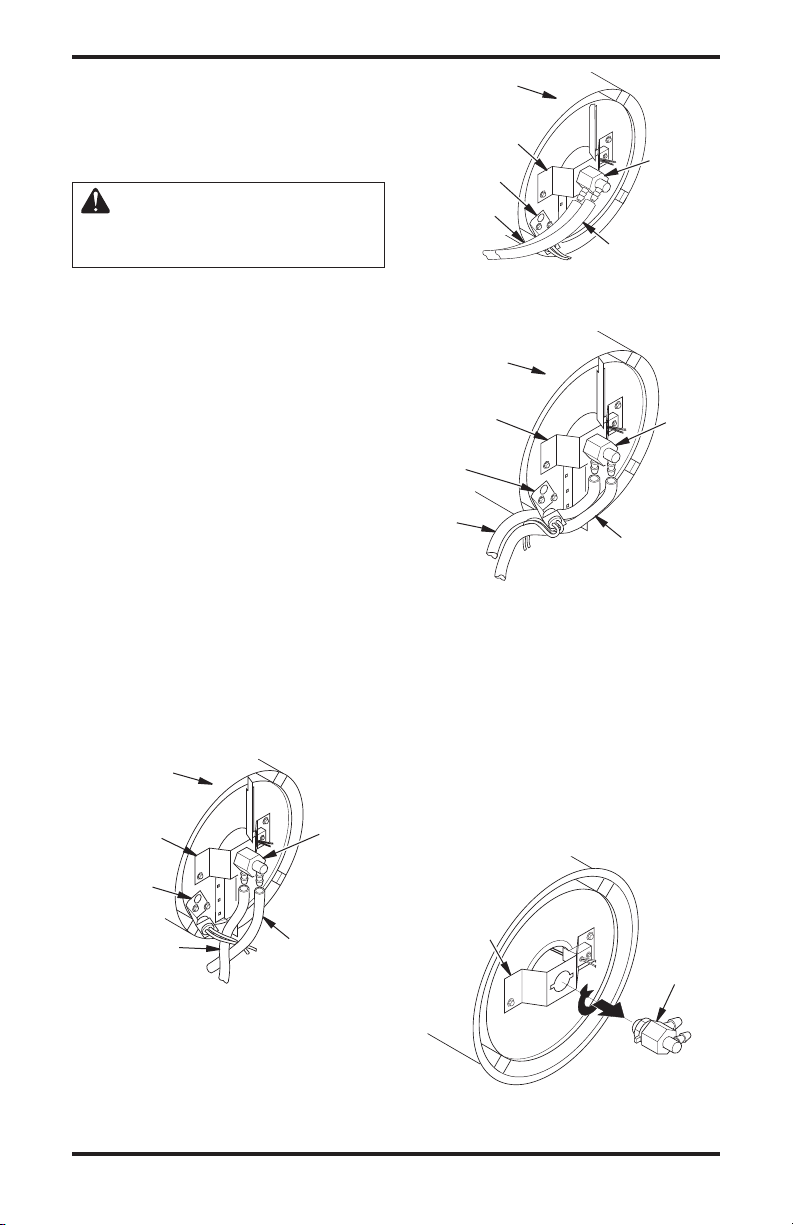

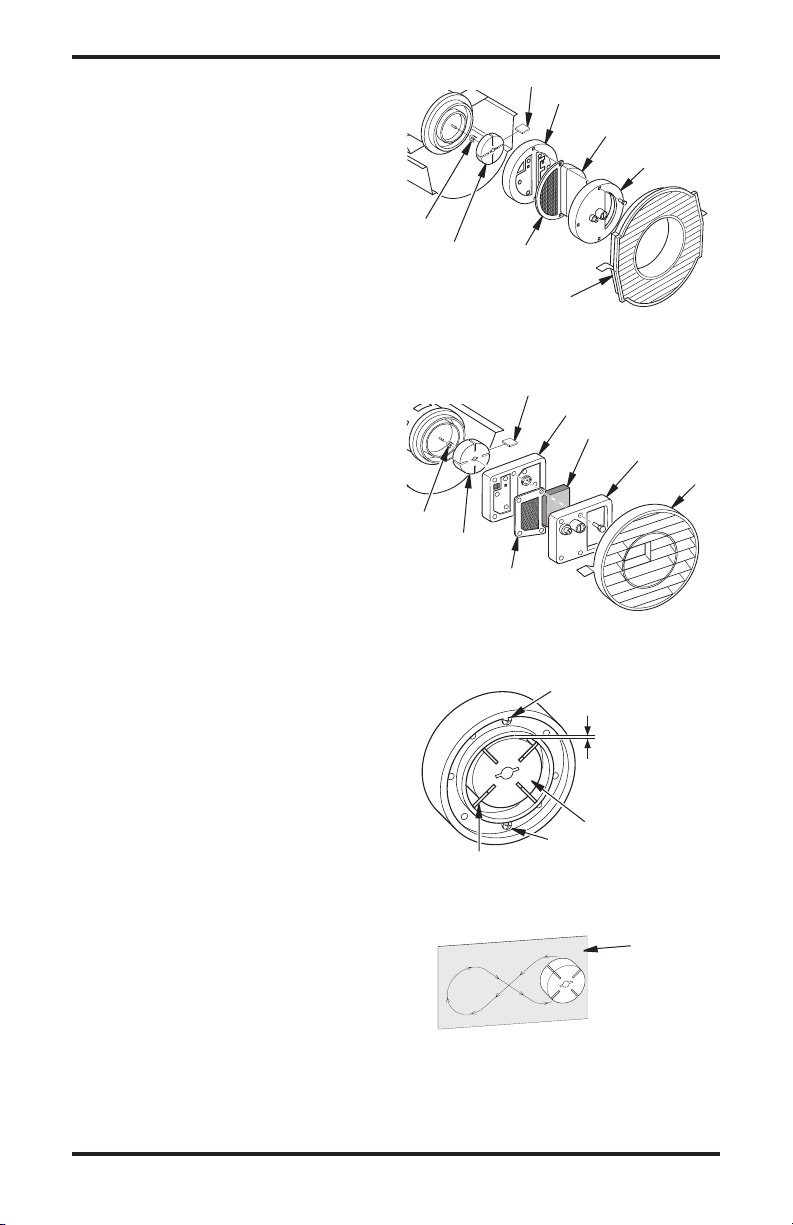

PUMP ROTOR

(Procedure if Rotor is Binding)

1. Remove upper shell (see Upper Shell Re

moval, page 9).

2. Remove filter end cover screws using 5/16"

nut-driver (see Figure 25 or 26).

3. Remove filter end cover and air filters.

4. Remove pump plate screws using 5/16" nutdriver.

5. Remove pump plate.

6. Remove rotor, insert, and blades.

7. Check for debris in pump. If debris is found,

blow out with compressed air.

8. Install insert and rotor.

9. Check gap on rotor. Adjust to .003"/.004"

(.076-.101 mm) if needed (see Figure 27).

Note: Rotate Rotor one full turn to insure the gap

is .003"/.004" (.076-.101 mm) at tightest position.

Adjust if needed.

10. Install blades, pump plate, air filters, and filter

end cover.

11. Replace fan guard and upper shell (see

Shell Removal, page 9).

12. Adjust pump pressure (see Pump Pressure

Adjustment, page 10).

Note: If rotor is still binding, proceed as follows.

13. Perform steps 1 thru 6.

14. Place fine grade sandpaper (600 grit) on flat

surface. Sand rotor lightly in “figure 8” motion

four times (see Figure 28).

15. Reinstall insert and rotor.

16. Perform steps 10 thru 12.

Upper

Blade

Pump Plate

Air Intake Filter

-

Insert

Rotor

Air Output

Filter

Fan Guard

Figure 25 - Rotor Location, 40/55T/70T

Insert

Rotor

Air Output

Filter

Figure 26 - Rotor Location, 115T/165T

Models

Blade

Pump Plate

Air Intake Filter

Filter End Cover

Models

Gap Adjusting Screw

.003"/.004"

(.076-.101 mm)

Gap Measured

With Feeler

Gauge

Filter End

Cover

Fan Guard

Rotor

Blade

Figure 27 - Gap Adjusting Screw

Figure 28 - Sanding Rotor

14

www.desatech.com

Gap Adjusting Screw

Locations

Sandpaper

111168-01A

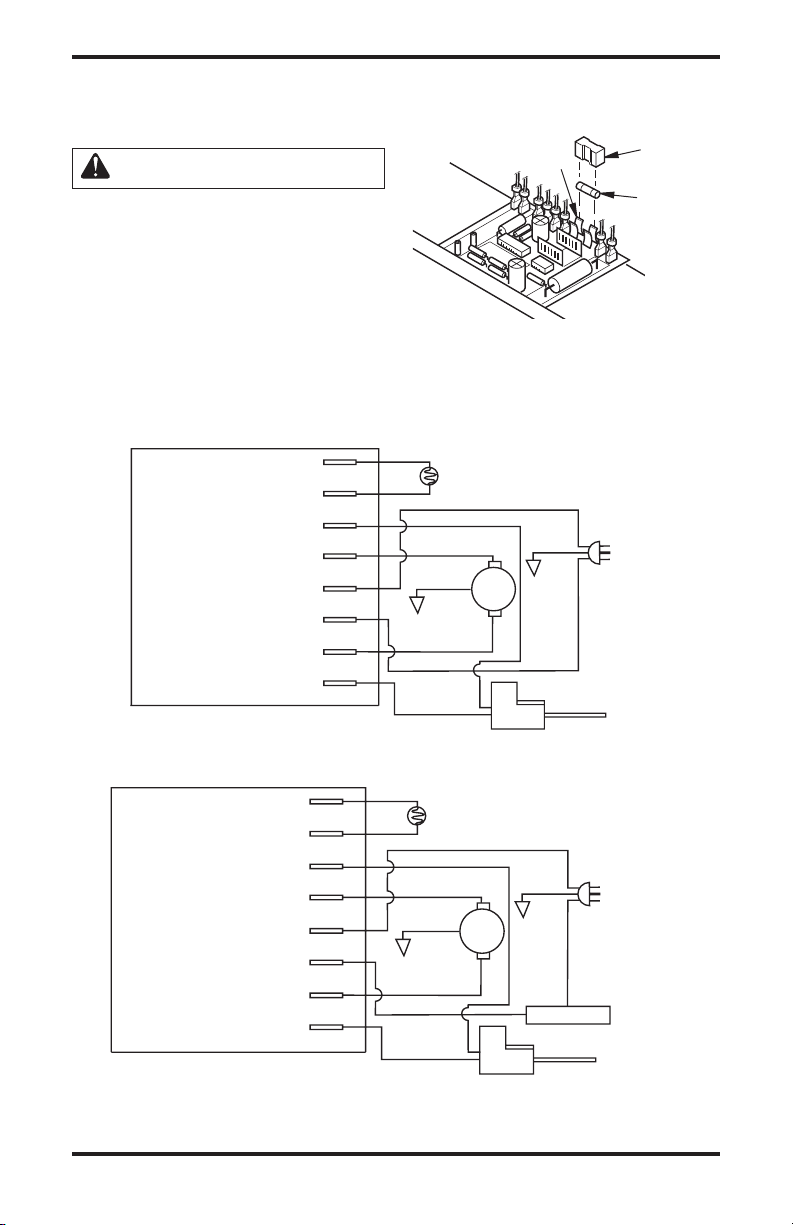

Power Plug

120V/60Hz

Blue

Blue

White

White

Photocell

Ignition Control Assembly

Green

Green

Red

Black

Black

Yellow

Yellow

Motor

Ignitor

Thermostat

Photocell

Photocell

Ignitor

Motor Return

AC Neutral (L2)

120V (L1)

Ignitor

Motor

Power Plug

120V/60Hz

Blue

Blue

White

White

Photocell

Green

Green

Red

Black

Ye

l low

Yel low

Motor

Ignitor

Ignition Control Assembly

Photocell

Photocell

Ignitor

Motor Return

AC Neutral (L2)

120V (L1)

Ignitor

Motor

SERVICE PROCEDURES

Continued

IGNITION CONTROL ASSEMBLY

WARNING: High Voltage!

1. Unplug heater.

2. Remove side cover screws (4) using 5/16"

nut-driver to expose ignition control assembly

(see Figure 15 or 16, page 11).

3. Remove fuse cover (see Figure 29).

4. Remove fuse from fuse clips (see Figure 29).

5. Replace fuse with fuse of the same type and

rating (GMA-10). Do not substitute a fuse

with a higher current rating.

WIRING DIAGRAMS

6. Replace fuse cover (see Figure 29).

Replace side cover (see Figure 15 or 16, page 11).

7.

Fuse

Clips

Fuse

Cover

Fuse

Figure 29 - Replacing Fuse

Figure 31 - Wiring Diagram for 55T/70T/115T/165T Thermostat Models

Figure 30 - Wiring Diagram for 40 Models

www.desatech.com

15111168-01A

1

2

3

4

31

5

6

7

8

9

10

11

12

13

14

15

16

9-2

9-1

9-3

9-4

9-5

17

18

19

20

21

22

23

24

25

26

27

28

29

30

34

35

36

32

33

9-6

37

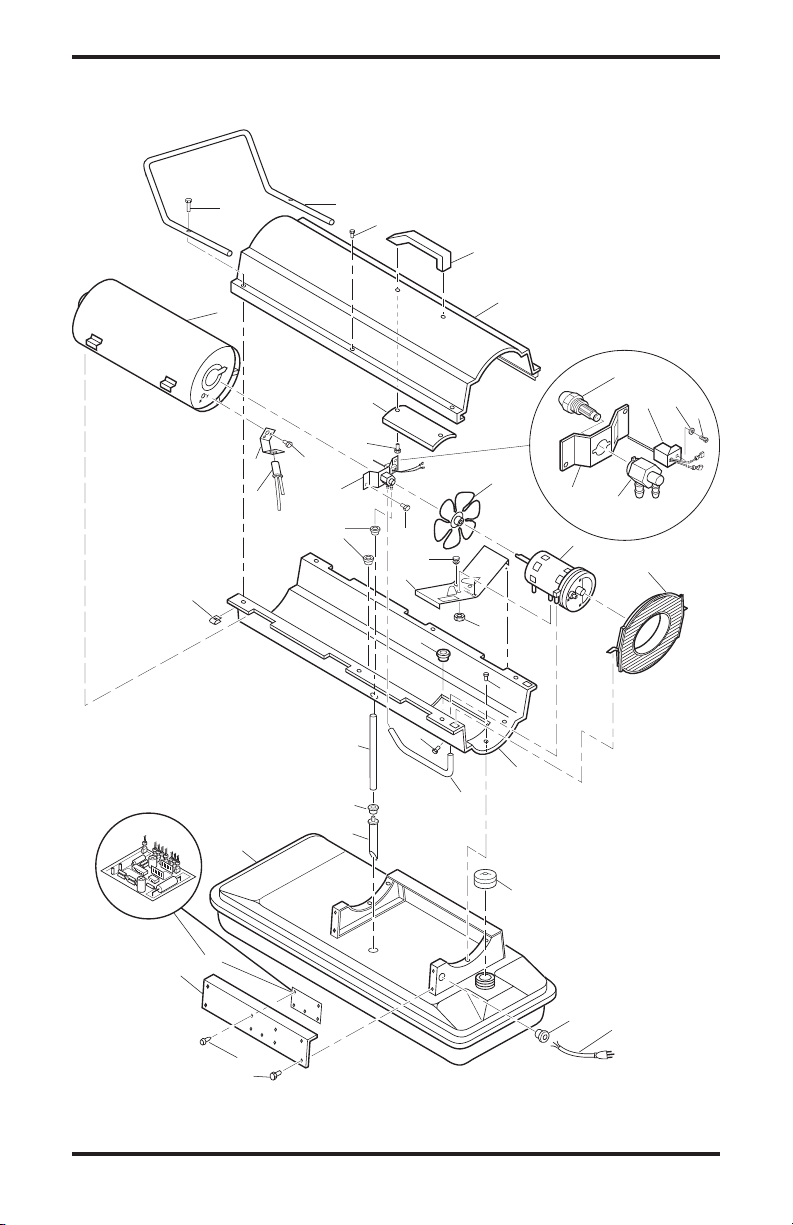

ILLUSTRATED PARTS BREAKDOWN

MODELS BC40 AND RC40

16

www.desatech.com

111168-01A

PARTS LIST

MODELS BC40 AND RC40

This list contains replaceable parts used in your heater. When ordering parts, be sure to provide the correct

model and serial numbers (from the model plate), then the part number and description of the desired part.

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 M51104-01 Handle 1

2 098511-67 Upper Shell (Service Part Will Be Black) 1

3 M11084-29 Screw, #10-16 x 3/4" 2

4 108631-01 Screw, #10-16 x 1" 2

5 098512-58 Combustion Chamber 1

6 M10908-2 Screw, #6-32 x 3/8" 2

7 103154-03 Photocell Bracket 1

8 M16656-24 Photocell Assembly 1

9 ** Burner Head Assembly 1

9-1 HA3006 Nozzle Assembly 1

9-2 HA1000 Ignitor Kit 1

9-3 104056-01 Nozzle Adapter 1

9-4 102336-01 Nozzle Adapter Bracket 1

9-5 M10908-75 Screw, Hex Head, Tapping 1

9-6 103347-01 Belleville Washer 1

10 M11084-26 Screw, #10-16 x 3/8" 2

11 103684-01 Fan 1

12 ** Motor (see page 22) 1

13 M51105-01 Fan Guard 1

14 098219-38 Power Cord 1

15 M11143-1 Strain Relief Bushing 1

16 NTC-4C Hex Lock Nut, 1/4-20 2

17 M11084-26 Screw, #10-16 x 3/8" 4

18 M50631 Rubber Bumper 2

19 097461-09 Side Cover 1

20 101205-01 Motor Bracket 1

21 M30865-02 Bushing 2

22 M11271-8 Clip Nut 6

23 M50104-02 Bushing 1

24 M11084-26 Screw, #10-16 x 3/8" 6

25 097211-02 Screw, #8-18 x 1/2" 1

26 098511-234 Lower Shell (Service Part will be Black) 1

27 M50814-06 Rubber Airline 1

28 079973-01 Fuel Line 1

29 M50876-04 Fuel Filter with bushing 1

30 M10990-3 Rubber Bushing 1

31 079532-01 Guard, Nose Cone 1

32 102349-01 PCB Support 5

33 104068-02 Ignition Control Assembly 1

34 097702-01 Fuel Cap (Includes Gasket) 1

35 108088-01 Fuel Tank 1

36 M51108-01 Shell Heat-Shield 1

37 M15823-27 Screw, #10-16 x 1/2" 4

PARTS AVAILABLE - NOT SHOWN

103814-01 Wire Tie 1

105550-01 Warning/Maintenance Decal 1

105550-02 Warning/Maintenance Decal 1

** Not available as an assembly

www.desatech.com

17111168-01A

ILLUSTRATED PARTS BREAKDOWN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

34

35

36

32

33

37

9-2

9-1

9-3

9-4

9-5

9-6

41

40

39

38

31

MODELS BC55T, RC55T, BC70T, AND RC70T

18

www.desatech.com

111168-01A

PARTS LIST

MODELS BC55T,

RC55T, BC70T,

AND RC70T

This list contains replaceable parts used in your

heater. When ordering

parts, be sure to provide

the correct model and se

rial numbers (from the

model plate), then the part

number and description of

the desired part.

** Not available as an

assembly

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 M51104-01 Handle 1

2 098511-67

Upper Shell (Service Part Will Be Black)

3 M11084-29 Screw, #10-16 x 3/4" 2

4 108631-01 Screw, #10-16 x 1" 2

5 098512-50 Combustion Chamber (55T) 1

098512-51 Combustion Chamber (70T) 1

6 M10908-2 Screw, #6-32 x 3/8" 2

7 103154-03 Photocell Bracket 1

-

8 M16656-24 Photocell Assembly 1

9 ** Burner Head Assembly

9-1 HA3024 Nozzle Assembly (55T) 1

HA3026 Nozzle Assembly (70T) 1

9-2 HA1000 Ignitor Kit 1

9-3 104056-01 Nozzle Adapter 1

9-4 102336-02 Nozzle Adapter Bracket (55T) 1

102336-01 Nozzle Adapter Bracket (70T) 1

9-5 M10908-75 Screw, Hex Head, Tapping 1

9-6 103347-01 Belleville Washer 1

10 M11084-26 Screw, #10-16 x 3/8" 2

11 103684-01 Fan (55T) 1

M29678 Fan (70T) 1

12 ** Motor (see page 22) 1

13 M51105-01 Fan Guard 1

14 098219-38 Power Cord 1

15 M11143-1 Strain Relief Bushing 1

16 NTC-4C Hex Lock Nut, 1/4-20 2

17 M11084-26 Screw, #10-16 x 3/8" 4

18 M50631 Rubber Bumper 2

19 097461-09 Side Cover 1

20 101205-01 Motor Bracket 1

21 M30865-02 Bushing 2

22 M11271-8 Clip Nut 6

23 M50104-02 Bushing 1

24 M11084-26 Screw, #10-16 x 3/8" 6

25 097211-02 Screw, #8-18 x 1/2" 1

26 098511-234

Lower Shell (Service Part will be Black)

27 M50814-06 Rubber Airline 1

28 079973-01 Fuel Line 1

29 M50876-05 Fuel Filter (with bushing) 1

30 M10990-3 Rubber Bushing 1

31 WLE-2 Lock Washer, #8 1

32 102349-01 PCB Support 5

33 104068-02 Ignition Control Assembly 1

34 097702-01 Fuel Cap (Includes Gasket) 1

35 108088-03 Fuel Tank 1

36 M51108-01 Shell Heat-Shield 1

37 104458-01 Thermostat 1

38 M12461-18 Screw, #8-32 x 7/8" 1

39 104460-01 Thermostat Knob 1

40 M15823-27 Screw, #10-16 x 1/2" 4

41 079532-01 Guard, Nose Cone 1

PARTS AVAILABLE - NOT SHOWN

100621-09 Thermostat Decal 1

103814-01 Wire Tie 1

M9900-170 Wire Assembly 1

105550-01 Warning/Maintenance Decal 1

105550-02 Warning/Maintenance Decal 1

www.desatech.com

1

1

19111168-01A

1

2

3

23

19

9

10

16

11

12

15

25

26

27

24

28

29

20

22

21

30

31

17

14

14

33

34

35

36

32

26

18

5

4

6

7

8

7-2

7-1

7-5

7-4

7-3

39

38

37

41

41

47

45

44

46

42

43

40

7-6

13

ILLUSTRATED PARTS BREAKDOWN

MODELS BC115CT, RC115CT, BC165CT AND RC165CT

20

www.desatech.com

111168-01A

PARTS LIST

MODELS BC115CT, RC115CT, BC165CT AND RC165CT

KEY PART NUMBER

NO. 115T 165T DESCRIPTION QTY.

1 098511-292 098511-292 Upper Shell (Service Part Will Be Black) 1

2 M15823-27 M15823-27 Screw, #10-16 x 1/2" 8

3 098512-71 098512-75 Combustion Chamber 1

4 103154-05 M16660-02 Photocell Bracket 1

5 M10908-2 M10908-2 Screw, #6-32 x 3/8" 2

6 M16656-24 M16656-24 Photocell Assembly 1

7 *** *** Burner Head Assembly 1

7-1 HA3027 HA3028 Nozzle Assembly 1

7-2 HA1000 HA1000 Ignitor Kit 1

7-3 M10908-75 M10908-75 Screw, Hex Head, Tapping 1

7-4 102336-01 102336-01 Nozzle Adapter Bracket 1

7-5 104054-01 104054-01 Nozzle Adapter 1

7-6 103347-01 103347-01 Belleville Washer 1

8 M11084-27 M11084-27 Screw, #10-16 x 1/2" 2

9 097293-01 102042-01 Fan 1

10 *** *** Motor (see page 22) 1

11 M50631 M50631 Rubber Bumper 2

12 101206-01 101206-01 Motor Mounting Bracket 1

13 WLE-2 WLE-2 Washer, #8 1

14 104068-02 104068-02 Ignition Control Assembly 1

15 NTC-4C NTC-4C Hex Lock Nut, 1/4-20 2

16 111037-01 111037-01 Fan Guard 1

17 M27417 M27417 Drain Plug (Includes “o” Ring) 1

18 099213-01 099213-01 Button Plug 1

19 M51345-06 M51345-06 Fuel Line 1

20 106896-01** 106896-01** Fuel Filter 1

21 M51151-01 M51151-02 Fuel Line Tube 1

22 M10990-3 M10990-3 Rubber Bushing 1

23 M50814-03 M50814-03 Airline 1

24 098511-293 098511-293 Lower Shell (Service Part will be Black) 1

25 M50104-06 M50104-06 Bushing 1

26 M50104-01 M50104-01 Bushing 2

27 M11084-27 M11084-27 Screw, #10-16 x 1/2" 6

28 M11271-8 M11271-8 Clip Nut 8

29 M10908-14 M10908-14 Screw, #8-32 x 3/8" 1

30 108088-04 108088-05 Fuel Tank 1

31 097702-01 097702-01 Fuel Cap (Includes Gasket) 1

32 102349-01 102349-01 P.C. Board Support 5

33 M11143-1 M11143-1 Strain Relief Bushing 1

34 098219-38 098219-38 Power Cord 1

35 M51077-15 M51077-15 Side Cover 1

36 M11084-27 M11084-27 Screw, #10-16 x 1/2" 4

37 104458-01 104458-01 Thermostat 1

38 M12461-18 M12461-18 Screw, #8-32 x 7/8" 2

39 104460-01 104460-01 Thermostat Knob 1

40 079998-01 099614-01 Front Handle 1

41 M12345-33 M12345-33 Screw #10-24 x 1 3/4" 8

42 107426-01 107426-01 Wheels 2

43 M28526 M28526 Nut Cap 2

44 M12342-3 M12831-3 Wheel Support Frame 1

45 NTC-3C NTC-3C Hex Lock Nut, #10-24 6

46 M51015-01 M16801-2 Axle 1

_____

47

103814-01 103814-01 Wire Tie

HA1180 HA1180 Air Gauge Kit

HA2210 HA2210 Fuel Tank Filter Screen

HA3004 HA3004 Rotor Kit (M22456-1, M22009, M8643)

HA3017 HA3017 Filter Kit (M11637, M12179, M12244-1,106896-01)

HA3020 HA3020 Pump Kit (M27694, M10993-1, M22997,M8940)

100621-08 100621-08 Thermostat Decal 1

** See OPTIONAL ACCESSORIES *** Not available as an assembly.

099614-02 Rear Handle (If Equipped) 1

OPTIONAL ACCESSORIES

www.desatech.com

21111168-01A

ILLUSTRATED PARTS BREAKDOWN

MOTOR AND PUMP ASSEMBLY MODELS BC40, RC40, BC55T, RC55T,

BC70T AND RC70T

1

3

4

2

18

17

16

6

15

14

5

7

8

13

12

9

10

11

MODELS BC115CT, RC115CT, BC165CT AND RC165CT

1

2

3

4

5

17

16

15

13

14

22

www.desatech.com

6

13

12

7

8

9

10

11

111168-01A

This list contains replaceable parts used in your heater. When ordering parts, be sure to provide the correct

PARTS LIST

model and serial numbers (from the model plate), then the part number and description of the desired part.

MODELS BC40, RC40, BC55T, RC55T, BC70T AND RC70T

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 102001-01 Motor (40 & 55T) 1

102001-20 Motor (70T)

2 079975-02 Pump Body (40 & 70T) 1

079975-03 Pump Body (55T)

3 M22009*, ** Insert 1

4 M22456-1* Rotor (40 & 70T) 1

M22456-2** Rotor (55T) 1

5 M29608 Pump End Cover 1

6 M29632*** Lint Filter 1

7 M29633*** Intake Filter 1

8 M29609 Filter End Cover 1

9 M12461-31 Screw, #10-32 x 1" 3

10 M27694 ∞ Adjusting Screw 1

11 M10993-1 ∞ Pressure Relief Spring 1

12 M22997 ∞ Plug 1

13 M8940 ∞ Steel Ball, 1/4" Diameter 1

14 M29612-01*** Output Filter 1

15 M12461-31 Screw, #10-32 x 1" (40 & 70T) 6

M12461-32 Screw, #10-32 x 1 1/8" (55T) 6

16 103676-01 Nylon Elbow, 90° 1

17 M8643* Blade (40 & 70T) 4

M8643-2** Blade (55T) 4

18 FHPF3-5C Screw (40 & 70T) 2

FHPF3-6C Screw (55T) 2

* Included in Rotor Kit (Part No. HA3004)

** Included in Rotor Kit (Part No. HA3005)

*** Included in Filter Kit (Part No. HA3014)

MODELS BC115CT, RC115CT, BC165CT AND RC165CT

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 102001-30 Motor 1

2 079975-02 Pump Body 1

3 FHPF3-5C Screw, #10-32 x 5/8" 2

4 M22009** Rotor Insert 1

5 M22456-1** Pump Rotor 1

6 M50545 Pump End Cover 1

7 M12179** Intake Filter 1

8 M16545 Filter End Cover 1

9 M8940** Steel Ball, 1/4" Diameter 1

10 M10993-1** Relief Spring 1

11 M27694** Adjusting Screw 1

12 M22997** Plug 1

13 M12461-31 Screw, #10-32 x 1" 10

14 M12244-1** Output Filter 1

15 M11637** Lint Filter 1

16 M50820-02 Barb Fitting 1

17 M8643** Blade 4

** Included in Rotor Kit (Part No. HA3004)

∞ Included in Pump Adjustment Kit (Part No.

HA3020)

www.desatech.com

23111168-01A

SPECIFICATIONS

Model Size 40 55T 70T 115T 165T

Output Rating (Btu/Hr) 40,000 55,000 70,000 115,000 165,000

Fuel Use only kerosene, #1/#2 diesel/fuel oil, JET A or JP-8 fuels*

Fuel Tank Capacity

(U.S. Gal./Liters) 3/11.3 5/18.9 5/18.9 9/34 13.5/51

Fuel Consumption

(Gal. Per Hr/Liters Per Hr) .3/1.14 .44/1.67 .52/1.97 .85/3.00 1.2/4.54

Pump Pressure (psi) 3.0 3.4 4.7 5.1 5.6

Electric Requirements 120 V/60 HZ (Same All Models)

Amperage (Normal Run) 2.0 2.0 2.8 3.6 3.6

Motor RPM 1725 1725 3440 3440 3440

Hot Air Output (CFM) 170 180 360 490 575

Shipping Weight 32/14.5 35/15.9 35/15.9 54/24.5 65/29.5

(Approximate lbs./kg)

Heater Weight without Fuel 28/12.2 30/14 30/14 46/21 55/25

(Approximate lbs./kg)

* Use of #2 diesel & fuel oil will result in noticeable odor and could require additional fuel filter maintenance. Use in extreme cold temperatures may require nontoxic anti-icer additives.

24

www.desatech.com

111168-01A

ACCESSORIES

Heater accessories and parts are available at your

local dealer. Should your dealer not stock or is unable to order a particular accessory or part, please

contact DESA Industries for more information.

DESA Industries of Canada, Inc.

2220 Argentia Road, Unit #4

Mississauga, Ontario L5N 2K7

Parts Department

1-905-826-8010

AIR GAUGE KIT - HA1180

For all models. Special tool to check pump

pressure.

THERMOSTAT KIT - HA1210

For 40 model. Keeps your building at the temperature you select day and night. Helps economize

on fuel.

IGNITION CONTROL ASSEMBLY/

PHOTOCELL TESTER - HA1170

Special tool used to test the ignition control assembly and photocell.

HEAVY DUTY WHEELS AND

HANDLE KIT - HA1202

For heavy duty applications. Makes your heater even more portable and convenient. Fits

40/55T/70T models.

www.desatech.com

25111168-01A

WARRANTY AND REPAIR SERVICE

KEEP THIS WARRANTY

Model No.

Serial No.

Date of Purchase

(To be filled in by purchaser)

LIMITED WARRANTY

DESA Industries warrants this product and any parts thereof, to be free from defects in materials and workmanship

for one (1) year from the date of first purchase when operated and maintained in accordance with instructions. This

warranty is extended only to the original retail purchaser, when proof of purchase is provided.

This warranty covers only the cost of parts and labor required to restore the product to proper operating condition.

Transportation and incidental costs associated with warranty repairs are not reimbursable under this warranty.

Warranty service is available only through authorized dealers and service centers.

This warranty does not cover defects resulting from misuse, abuse, negligence, accidents, lack of proper main

tenance, normal wear, alteration, modification, tampering, contaminated fuels, repair using improper parts, or

repair by anyone other than an authorized dealer or service center. Routine maintenance is the responsibility of

the owner.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF ANY OTHER WARRANTY EITHER EXPRESSED

OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

DESA Industries assumes no responsibility for indirect, incidental or consequential damages. Some states do

not allow the exclusion or limitation of incidental or consequential damages or limitations or exclusions may not

apply to you. This Limited Warranty gives you specific legal rights and you may also have other rights which

vary from province to province.

WARRANTY SERVICE

Should your heater require service, return it to your nearest authorized service center. Proof of purchase must be

presented with the heater. The heater will be inspected. A defect may be caused by faulty materials or workmanship.

If so, DESA Industries will repair or replace the heater without charge.

REPAIR SERVICE

Return the heater to your nearest authorized service center. Each Service Center is independently owned and operated.

Repairs not covered by the warranty will be billed at standard prices. We reserve the right to amend these specifications

at any time without notice.

Illustrated parts lists can be obtained free of charge. Send a self-addressed stamped envelope to the address listed

below. List the heater model number and the date located in the lower right corner of this page. A service manual may

be purchased from the address listed below. Send a cheque for $5.00 payable to DESA Industries.

When writing for information regarding your heater, be sure to include the model number and serial number as shown

on the model plate.

-

Printed in USA

2220 Argentia Road, Unit #4

Mississauga, Ontario L5N 2K7

(905) 826-8010

Fax (905) 826-8236

APPAREILS DE CHAUFFAGE PORTATIFS

CANADIENS À AIR FORCÉ

GUIDE DU PROPRIÉTAIRE

MODÈLES: BC40, RC40, BC55T, RC55T, BC70T, RC70T, BC115CT,

RC115CT, BC165CT ET RC165CT

IMPORTANT : Assurez-vous d’avoir lu et compris ce guide

avant de commencer à monter, utiliser ou réparer cet appareil. Une mauvaise utilisation de cet appareil pourrait

causer des blessures graves. Gardez ce guide pour vous

y reporter plus tard.

TABLE DES MATIÈRE

Informations Sur La Sécurité ............................... 2

Deballage ............................................................ 2

Nomenclature des pieces principales .................. 3

Montage .............................................................. 4

Principes de fonctionnement ............................... 5

Combustibles ....................................................... 5

Ventilation ........................................................... 6

Fonctionnement .................................................. 6

Entreposage, transport ou expédition ................. 7

Conservez le présent manuel pour consultation future.

Pour en savoir davantage, visitez le www.desatech.com

Calendrier d’entretien .......................................... 7

Diagnostic des pannes ........................................ 8

Entretien marche a suivre ................................... 9

Schemas electriques ....................................... 15

Vue détaillée et liste des pièces ........................

Fiche technique ................................................. 24

Accessoires ....................................................... 25

Ntie et service apres-vente ....... Couverture arrière

16

INFORMATIONS SUR LA

SÉCURITÉ

IMPORTANT : Veuillez lire ce

guide attentivement et complètement avant d’essayer de

monter, de faire fonctionner

ou de réparer cet appareil. Son

utilisation incorrecte pourrait

causer des blessures graves

ou la mort à la suite de brûlures, d’incendie, d’explosion, de

chocs électriques et d’intoxication par l’oxyde de carbone.

DANGER : L’intoxication

par l’oxyde de carbone risque

d’entraîner la mort !

Les signes précurseurs de lʼintoxication par lʼoxyde

de carbone ressemblent à ceux de la grippe : maux

de tête, vertiges et/ou nausée. Si vous ressentez ces

symptômes, il se peut que lʼappareil de chauffage

ne fonctionne pas correctement. Allez immédiate

ment respirer de lʼair frais! Faites réparer lʼappa

reil de chauffage. Certaines personnes (comme les

femmes enceintes, celles souffrant de maladies du

coeur ou des poumons, celles ayant de lʼanémie,

celles étant sous lʼinfluence de lʼalcool, celles se

trouvant à haute altitude) sont plus affectées que

dʼautres par lʼoxyde de carbone.

Assurez-vous dʼavoir lu et compris tous les avertis

sements. Gardez ce guide pour vous y reporter plus

tard. Il est essentiel pour lʼutilisation sécuritaire et

correcte de cet appareil de chauffage.

1. Utiliser uniquement du kérosène, du mazout/

carburant diesel NO 1 ou NO 2, des Carbu

réacteurs A ou JP-8.

2. Branchez-le sur une prise de tension et de

fréquence qui correspond à celles

indiquées sur la plaque signalétique.

3. Lʼappareil de chauffage doit être mis à la terre.

Ne vous servez que dʼune rallonge à trois fils.

Ne le branchez que dans une prise de courant

reliée à la terre.

4. Nʼutilisez pas lʼappareil dans des endroits

qui contiennent des vapeurs inflammables,

ou poussiéreux.

5.

La distance minimale de lʼappareil de tout matériau

combustible est de 244 cm (8 pieds) pour la sortie

dʼair chaud; de 183 cm (6 pieds) pour le dessus et

de 61 cm (2 pieds) pour les côtés et lʼentrée.

6. Pour éviter les risques dʼincendie lorsque

lʼappareil fonctionne ou est chaud, il doit être

sur une surface ferme et plate.

7. Ne le faites fonctionner que dans des endroits

bien aérés. Assurez un espace ouvert dʼau

moins 0,3 m2 (3 pieds carrés) pour chaque

100 000 Btu de rendement.

8. Ne laissez jamais les enfants ou les animaux

domestiques sʼapprocher de lʼappareil de

chauffage.

9. Nʼallumez jamais lʼappareil si la chambre de

combustion est chaude ou si du combustible

sʼy est accumulé.

10. Avec un thermostat, lʼappareil peut sʼallumer

sans préavis.

11. Pour éviter les renversements de combustible

lorsque lʼappareil est déplacé ou entreposé, il

doit se trouver de niveau.

12. Utilisez lʼappareil uniquement en suivant les

règlements et les codes locaux.

13. Ne vous servez jamais dʼessence, dʼhuile de vi

dange, de naphte, de térébenthine, dʼalcool, ou

de tout autre combustible très inflammable.

14. Nʼallumez jamais lʼappareil dans un endroit

contenant des vapeurs dʼessence, du diluant à

-

peinture, ou tout autre produit inflammable.

-

15. Nʼutilisez jamais lʼappareil à des fins domes

tiques ou dans une chambre à coucher.

16. Ne laissez jamais lʼappareil branché sans la

présence dʼun adulte lorsquʼil y a possibilité que

des enfants ou des animaux sʼen approchent.

17. Nʼeffectuez aucune intervention dʼentretien,

ne remplissez jamais le réservoir et ne dépla

cez pas lʼappareil sʼil est chaud, en marche,

ou branché.

18. Ne bloquez jamais lʼentrée dʼair arrière (côté

moteur).

19. Ne montez jamais de gaine à lʼavant de lʼap

pareil.

20. Ne branchez jamais lʼappareil à un réservoir

auxiliaire.

DEBALLAGE

1. Retirez tous les emballages de protection

utilisés pour le transport.

2. Retirez lʼappareil de la boîte.

3. Vérifiez lʼétat de lʼappareil. Sʼil est endom

magé, avertissez immédiatement le conces

sionnaire qui vous lʼa vendu.

-

-

-

-

-

-

2

www.desatech.com

111168-01A

NOMENCLATURE DES PIECES PRINCIPALES

Sortie d’air

chaud

Boîtier

Réservoir

de combustible

Plaque amovible

Commande d’allumage

(se trouve derrière la plaque

amovible)

Sortie d’air

chaud

Boîtier

Réservoir

de combustible

Barre de protection

Couvercle

Figure 1 - Modèle 40

Barre de protection

Couvercle

Poignée

Poignée

Grille de protection

du ventilateur

Cache-filtre

Cordon électrique

Grille de protection

du ventilateur

Cache-filtre

Bouchon du réservoir

de combustible

Bouton de

thermostat

Plaque amovible

Commande d’allumage

(se trouve derrière la plaque

amovible)

Sortie d’air

chaud

Boîtier

Bouchon du

réservoir de

combustible

Plaque amovibl

Commande d’allumage

(se trouve derrière la plaque

amovible)

Figure 2 - Modèles 55T/70T

Couvercle

Figure 3 - Modèles 115T/165T

www.desatech.com

Grille de

protection

du ventilateur

Cordon électrique

Bouchon du

réservoir de

combustible

Cordon électrique

Bouton de thermostat

Réservoir

de combustible

3111168-01A

MONTAGE

(POUR LE MODÈLES 40, 55T ET 70T

SEULEMENT)

Ces modèles sont livré avec une barre de protection. Cette barre se trouve, avec ses vis de montage,

dans la boîte dʼemballage.

Outillage nécessaire

• Clé plate ou tourne-écrous de 5/16 po

1. Placez les bras de la barre de protection sur le

rebord du couvercle. Assurezvous que la barre

se trouve du côté de la sortie dʼair chaud de

lʼappareil.

2. Faites passer les vis dans les trous de fixation

de la barre et vissez-les sur le rebord du cou

vercle.

3. Serrez les vis fermement.

Barre de

protection

Vis

Sortie

d’air

chaud

Robord

Nervure du

couvercle

Figure 4 - Montage de la barre de

protection, modèles 40, 55T et 70T

seulement

(POUR LES MODÈLES 100 ET 150

SEULEMENT)

Ces modèles sont livrés avec des roues et un

guidon pour la partie avant. Certains modèles

sont également livrés avec un guidon arrière. Les

roues et le(s) guidon(s) se trouvent dans la boîte

dʼemballage.

Outillage nécessaire

• Tournevis cruciforme de taille moyenne

• Clé plate ou clé à molette de 3/8 po

• Marteau

1. Faites passer lʼaxe au travers des alésages du

berceau. Installez les roues sur lʼaxe.

IMPORTANT: Installez les roues avec les

-

moyeux tournés vers le berceau.

2. Engagez un capuchon sur chaque bout de

lʼaxe. Tapez légèrement pour bien les mettre

en place.

3. Placez lʼappareil sur le berceau en vous assu

rant que lʼentrée dʼair se trouve au-dessus des

roues.

4. Placez le guidon avant sur le rebord du réser

voir. Faites passer les vis au travers des trous

du guidon, du rebord du réservoir et du berceau.

Serrez un écrou à la main sur chaque vis.

5. Serrez fermement tous les écrous à la clé.

Guidon avant

Sortie

d’air

chaud

Rebord du

réservoir

Guidon arrière

(si équipé)

Vis

-

-

Entrée

d’air

Berceau

Roue

Capuchon

Figure 5 - Montage des roues et

des guidons, modèles 115T et 165T

4

www.desatech.com

Ecrou

seulement

Moyeu

Axe

111168-01A

PRINCIPES DE

FONCTIONNEMENT

Circuit d’alimentation en combustible :

force lʼair dans la conduite dʼair. Lʼair est alors poussé

à travers la buse. Cela provoque la montée du combustible du réservoir. Un fin brouillard de combustible est

vaporisé dans la chambre de combustion.

Chambre de

combustion

La pompe à air

Allumeur

Circuit d’air :

Celui-ci pousse lʼair dans la chambre de combustion

et autour dʼelle. Lʼair est chauffé et produit un courant

dʼair propre chaud.

Dispositif d’allumage :

met lʼallumeur sous tension. Cela allume le mélange

combustible-air dans la chambre de combustion.

Système détecteur d’extinction de flamme :

lʼarrêt de lʼappareil de chauffage si la flamme sʼéteint.

Le moteur fait tourner le ventilateur.

La commande dʼallumage

Moteur

Ventilateur

Filtre d’entrée d’air

Entrée d’air

froid

Provoque

Sortie

d’air

chaud

Réservoir de

combustible

Buse

Air de

combustion

Figure 6 - Coupe, principe de fonctionnement

Filtre à

combustible

COMBUSTIBLES

AVERTISSEMENT :Pour éviter

les risques d’incendie ou d’explosion, utilisez seulement du

kérosène ou du mazout/carburant

diesel no 1 et no 2. Ne vous servez jamais d’essence, d’huile de

vidange, de naphte, de diluant à

peinture, d’alcool ou de tout autre

combustible très inflammable.

Utilisez seulement du kérosène ou du mazout/carburant diesel no 1 et no 2, des carburéacteurs A ou

JP-8. Les huiles plus lourdes comme le mazout no 2

ou le carburant diesel no 2 peuvent également être

utilisées, mais elles occasionneront :

• des odeurs perceptibles

• lʼentretien supplémentaire du filtre de carburant

• le besoin dʼajouter des additifs antigivrants non

toxiques à des températures très froides

www.desatech.com

Filtre de

sortie d’air

Conduite d’air

au brûleur

Air de combustion

et de chauffage

Nʼutilisez pas dʼhuiles plus lourdes que le grade

no 2 ou des huiles lourdes qui proviennent de la

vidange des moteurs. Ces huiles lourdes ne sʼen

flammeront pas bien et contamineront lʼappareil.

IMPORTANT : Utilisez un récipient de stockage

pour KÉROSÈNE SEULEMENT (bleu) ou pour

DIESEL SEULEMENT (jaune). Assurez-vous que

le récipient de stockage est propre. Toute matérière

étrangère, telle que la rouille, la saleté ou lʼeau,

provoquera lʼarrêt de lʼappareil de chauffage par la

commande dʼallumage. Ces matières risquent égale

ment dʼengendrer un nettoyage fréquent du système

dʼalimentation à combustible de lʼappareil.

Commande

d’allumage

Combustible

-

-

5111168-01A

VENTILATION

AVERTISSEMENT : Prévoyez

une ouverture d’au moins 2800

cm2 (3 pi2) pour l’air frais extérieur pour chaque 29,3 kW (100

000 BTU/h) de capacité. Dans

les cas où plus d’un appareil

est utilisé, prévoir une entrée

d’air supérieure pour éviter les

risques d’asphyxie par oxyde

de carbone. Respectez les rè

gles minimales de ventilation.

Assurez-vous que ces règles

sont bien suivies avant de faire

fonctionner l’appareil.

Exemple: Un modèle 165 doit opérer dans les

conditions suivantes:

• Une porte de garage pour deux voitures (ouverture

de 4,88 m [16 pi] de large) relevée de 10,16 cm

(4 po)

• Une porte de garage pour une seule voiture

(ouverture de 2,74 m [9 pi] de large) relevée

de 17,78 cm (7 po)

• Deux fenêtres de 76,20 cm (30 po) relevée de

30,48 cm (12 po)

FONCTIONNEMENT

IMPORTANT : Révisez et assurez-vous de comprendre les

avertissements qui se trouvent

dans les notes sur la sécurité.

Lorsque vous vous servez de cet

appareil de chauffage. Respectez tous les règlements locaux

et les normes régissant l’emploi

de cet appareil.

4. Pour les modèles 55T, 70T, 115T et 165T à

thermostat, tournez le bouton du thermostat

vers la droite en position maximum.

5. Branchez le cordon électrique à une rallonge à

trois fils avec mise à la terre. La rallonge doit

avoir une longueur dʼau moins 1,8 m (6 pi).

Conditions requises pour les rallonges

électriques

Pour les longueurs de 1,8 à 3 m (6 à 10 pi),

rallonge de calibre 18 (0,75 mm)

De 3,3 à 30,5 m (de 11 à 100 pi), rallonge de

calibre 16 (1 mm)

De 30,8 à 61 m (101 à 200 pi), rallonge de

calibre 14 (1,5 mm)

6. Branchez la rallonge à une prise standard

de 120 volts/60 hertz avec prise de terre.

Remarque : Lʼallumeur préchauffe pendant

cinq secondes, puis lʼappareil de chauffage

démarre.

7. Pour les modèles 55T, 70T, 115T et 165T à

thermostat, mettez le bouton du thermostat

au réglage désiré.

Remarque : Il est possible quʼun appareil

de chauffage froid affecte le réglage du

thermostat. Ce thermostat est une commande

de chauffage globale. Il nʼest pas prévu pour

un contrôle précis de la température. Réglez

le thermostat jusquʼà ce que lʼappareil de

chauffage fonctionne au réglage désiré.

ARRET

Débranchez la rallonge électrique.

REMISE EN SERVICE

1. Débranchez le cordon prolongateur de la

prise et attendez 10 secondes. (Attendez deux

minutes si lʼappareil vient de fonctionner.)

2. Répétez les opérations indiquées sous le titre

Mise en marche

.

MISE EN MARCHE

1. Suivez toutes les recommandations de ventilation et de sécurité.

2. Pour remplir le réservoir - Utiliser uniquement

du kérosène, du mazout/carburant diesel NO

1 ou NO 2, des Carburéacteurs A ou JP-8.

3. Revissez le bouchon du réservoir.

6

www.desatech.com

111168-01A

ENTREPOSAGE, TRANSPORT

OU EXPÉDITION

Remarque: les sociétés de transport exigent que

les réservoirs de combustible soient vides pour

lʼexpédition.

1. Vidanger le réservoir de combustible.

Remarque: certains modèles sont équipés dʼun

bouchon de vidange au-dessous du réservoir. Le

cas échéant, le retirer pour vidanger le réservoir.

Si lʼappareil de chauffage nʼen est pas équipé,

vidanger le réservoir par lʼorifice de remplissage.

Veiller à vider complètement le réservoir.

2.

Le cas échéant, replacer le bouchon de vidange.

3. Si le vieux carburant contient des impuretés,

ajouter 1 ou 2 litres de kérosène propre,

remuer et vidanger à nouveau afin dʼéviter

que lʼaccumulation dʼimpuretés nʼobstrue les

filtres lors dʼun futur usage.

4. Remettre le bouchon de vidange ou de

remplissage. Mettre le vieux carburant sale

au rebut selon une méthode appropriée. Se

renseigner auprès dʼune station-service locale

qui recycle lʼhuile.

5. Entreposer lʼappareil de chauffage dans un

endroit sec, à lʼabri de la poussière et des

vapeurs corrosives.

IMPORTANT : ne pas entreposer le kérosène pour

la durée de lʼété en vue de lʼutiliser la saison sui

vante. Lʼusage de combustible défraîchi pourrait

endommager lʼappareil de chauffage.

CALENDRIER D’ENTRETIEN

AVERTISSEMENT : Pour éviter les risques de brûlure et de chocs

électriques, n’effectuez aucune opération d’entretien sur l’appareil

de chauffage lorsqu’il est branché, fonctionne, ou est chaud.

-

Elément

Réservoir

Filtre de sortie dʼair et

filtre à poussière

Filtre dʼentrée dʼair

Filtre à combustible

Allumeur

Ventilateur

Moteur

Périodicité

Rincez toutes les 150-200 heures de

fonctionnement ou suivant les besoins

Remplacez toutes les 500 heures de

fonctionnement ou une fois par an

Lavez à lʼeau savonneuse et séchez

toutes les 500 heures de fonctionne

ment ou remplacez au besoin

Nettoyez deux fois par saison de chauf

fage ou remplacez au besoin

Aucun entretien requis

Nettoyez chaque saison ou au besoin

Pas dʼentretien/lubrification permanente

www.desatech.com

Opération

Voir chapitre EntrepoSage, Transport

ou Expédition

Voir Filtres de sortie dʼair, dʼentrée

dʼair et à poussière

Voir Filtres de sortie dʼair, dʼentrée

dʼair et à poussière

-

Voir Filtre à combustible, page 11

-

Bougie, page 9

Voir

, page 10

, page 10

7111168-01A

DIAGNOSTIC DES PANNES

AVERTISSEMENT : Pour éviter les risques de brûlure et de chocs

électriques, n’effectuez aucune opération d’entretien sur l’appareil

de chauffage lorsqu’il est branché, fonctionne, ou est chaud.

ANOMALIE

Le moteur ne démarre pas

dans les cinq secondes après le

branchement de lʼappareil de

chauffage

Le moteur démarre et tourne,

mais lʼappareil ne sʼallume pas

CAUSE POSSIBLE

1. Lʼappareil nʼest pas sous tension

2. Le réglage du thermostat est trop

bas

AVERTISSEMENT : Haute tension!

3.

Mauvaise connexion électrique entre

le moteur et la commande dʼallumage

ou entre la commande dʼallumage et le

cordon dʼalimentation

4. Grippage du rotor de la pompe

5. Commande dʼallumage défectueuse

6. Moteur défectueux

1. Pas de combustible dans le réservoir

2. Pression incorrecte de la pompe

3. Filtre à combustible sale

4. Obstruction dans la buse

5. Eau dans le réservoir de combustible

AVERTISSEMENT : Haute tension!

6.

Mauvaise connexion électrique entre

lʼallumeur et la commande dʼallumage

7. Allumeur défectueux

8. Commande dʼallumage défectueuse

REMEDE

1. Vérifiez le coupe-circuit du panneau

électrique

2. Tournez le bouton du thermostat à

une position plus haute.

3. Vérifiez tous les branchements électriques. Voir Schémas électriques,

page 15

4.

Si le ventilateur ne tourne pas aisément,

voir Rotor de la pompe, page 14

5.

Remplacez la commande dʼallumage

6. Remplacez le moteur

1. Remplissez le réservoir avec du

kérosène

2. Voir Réglage de la pression de la

pompe , page 10

3. Voir Filtre à combustible, page 11

4. Voir Buse, page 12

5. Vidangez et rincez le réservoir

de combustible avec du kérosène

propre. Voir Entreposage, transport

ou expédition, page 7

6. Vérifiez les connexions électriques.

Voir Schémas électriques, page 15

7. Remplacez lʼallumeur, page 11

8. Remplacez la commande dʼallumage

Lʼappareil sʼallume mais la

commande dʼallumage lʼarrête

après peu de temps

8

1. Pression incorrecte de la pompe

2. Filtres dʼentrée dʼair, de sortie dʼair

et/ ou à poussière sales

3. Filtre à combustible sale

4. Obstruction dans la buse

5. Cellule photoélectrique mal installée (ne détecte pas la flamme)

6. Lentille de cellule photoélectrique

sale

AVERTISSEMENT : Haute tension!

7. Mauvaise connexion électrique

entre la cellule photoélectrique et

la commande dʼallumage

8. Cellule photoélectrique défectueuse

9. Commande dʼallumage défectueuse

www.desatech.com

1. Voir Réglage de la pression de la

pompe, page 10

2. Voir Filtres de sortie dʼair, dʼentrée

dʼair et à poussière, page 10

3. Voir Filtre à combustible, page 11

4. Voir Buse, page 12

5. Assurez-vous que lʼenveloppe de

la cellule photoélectrique est bien

logée dans le support.

6. Nettoyez la lentille de la cellule

photoélectrique

7. Vérifiez les connexions électriques.

Voir Schémas électriques, page 15

8.

Remplacez la cellule photoélectrique

9.

Remplacez la commande dʼallumage

111168-01A

ENTRETIEN MARCHE A

SUIVRE

AVERTISSEMENT : Pour éviter les risques de brûlure et de

chocs électriques, n’effectuez

aucune opération d’entretien sur

l’appareil lorsqu’il est branché,

fonctionne, ou est chaud.

DÉMONTAGE DU COUVERCLE

1. En se servant dʼun tourne-écrou de 5/16 po,

retirez les vis qui se trouvent de chaque côté

du couvercle. Ces vis retiennent le couvercle

sur le boîtier (voir Figure 7 ou 8).

2. Levez le couvercle.

3. Retirez la grille de protection du ventilateur.

Vis

Couvercle

Grille de

protection

VENTILATEUR

IMPORTANT: Retirez le ventilateur de lʼarbre du

moteur avant de retirer ce dernier de lʼappareil. Le

poids du moteur sur le ventilateur pourrait fausser

les pales (voir Figure 9).

1. Déposez le couvercle (voir Figure 7 ou 8).

2. Utilisez une clé six pans de 1/8 po pour

desserrer les vis de blocage qui retiennent le

ventilateur sur lʼaxe du moteur.

3. Retirez le ventilateur de lʼaxe du moteur.

4. Nettoyez le ventilateur avec un chiffon propre

préalablement mouillé avec du kérosène ou un

diluant.

5. Faites sécher le ventilateur complètement.

6. Remontez le ventilateur sur lʼaxe du moteur.

Placez le moyeu du ventilateur à lʼaffleure

ment de lʼarbre (voir Figure 10).

7. Positionnez les vis de blocage sur le méplat

de lʼarbre. Serrez-les fermement (de 4,5 à 5,6

N.m/40 à 50 po-lb).

8. Remontez la grille de protection du ventilateur

et le couvercle.

-

Figure 7 - Dépose du couvercle

(Modèles 40, 55T, et 70T)

Vis

Figure 8 - Dépose du couvercle

(Modèles 115T et 165T)

Couvercle

Grille de

protection

Vis de

blocage

Arbre du moteur

Figure 9 - Position du ventilateur, de

l’arbre du moteur et des vis de blocage

Vis de blocage

Moteur

Arbre du moteur

Figure 10 - Coupe du ventilateur

Ventilateur

Ventilateur

A l’affleurement

www.desatech.com

9111168-01A

ENTRETIEN MARCHE A

SUIVRE Suite

FILTRES DE SORTIE D’AIR,

D’ENTRÉE D’AIR ET À POUSSIÈRE

1.

Déposez le couvercle (voir Figure 7 ou 8, page 9).

2. En utilisant un tourne-écrou de 5/16 po démontez les vis de fixation du cache-filtre (voir

Figure 11 ou 12).

3. Retirez le cache-filtre.

4. Remplacez les filtres de sortie dʼair et à pous

sière.

5. Lavez ou remplacez le filtre dʼentrée dʼair

(voir Calendrier dʼentretien, page 7).

6. Remontez le cache-filtre.

7. Remontez la grille de protection du ventilateur

et le couvercle.

IMPORTANT: Ne pas huiler les filtres.

Filtre d’entrée

d’air

Filtre à

poussière

Figure 11 - Filtres de sortie et d’entrée

Filtre de

sortie d’air

d’air et filtre à poussière, modèles

40/55T/70T

Filtre d’entrée

d’air

Cachefiltre

Cache-filtre

Grille de

protection

Grille de

protection

RÉGLAGE DE LA PRESSION DE LA

POMPE

1. Retirez le bouchon fileté qui se trouve sur le

cache-filtre (voir Figure 13).

2. Monter le manomètre (référence HA1180).

3. Allumez lʼappareil (voir Fonctionnement

page 6). Attendez que le moteur atteigne sa

vitesse maximale.

4. Réglez la pression. Pour augmenter la pres

sion, tournez le clapet de décharge vers la

-

droite. Pour la diminuer tournez-le vers la

gauche. Consultez les données qui se trouvent

à droite pour la pression requise par chaque

modèle (voir Figure 14).

5. Retirez le manomètre et remontez le bouchon

sur le cache-filtre.

Bouchon

fileté pour

manomètre

Figure 13 - Dépose du bouchon fileté

(Modèles 40/55T/70T seulement)

Pression

Modèle de la pompe

40 20,7 kPa (3 psi)

55T 23,4 kPa (3,4 psi)

70T 32,4 kPa (4,7 psi)

115T 35,2 kPa (5,1 psi)

165T 38,6 kPa (5,6 psi)

Manomètre

Clapet de

décharge

,

-

Filtre à

poussière

Figure 12 - Filtres de sortie et d’entrée

10

Filtre de

sortie d’airr

d’air et filtre à poussière, modèles

115T/165T

www.desatech.com

Figure 14 - Réglage de la pression de la

pompe (Modèles 40/55T/70T seulement)

111168-01A

ENTRETIEN MARCHE A

SUIVRE Suite

FILTRE À COMBUSTIBLE

1. Avec un tourne-écrou de 5/16 poretirez les vis

de fixation de la plaque amovible.

2. Déposez la plaque amovible.

3. Détachez la conduite de combustible supé

rieure de lʼembase du filtre (voir Figure 15

ou 16).

4. Soulevez soigneusement la bague, le filtre et la

conduite inférieure de combustible (modèles

115T/165T seulement) du réservoir (voir

Figure 16).

5. Lavez le filtre avec du combustible propre et

replacez lʼensemble dans le réservoir.

6. Remettez la conduite de combustible supé

rieure sur lʼembase du filtre.

7. Reposez la plaque amovible.

Filtre à

combustible

Plaque

amovible

Conduite de combustible

supérieure

Figure 15 - Dépose du filtre à

combustible, modèles 40/55T/70T

Filtre à combustible,

bague et conduite

de combustible

inférieure

ALLUMEUR

1. Retirez le couvercle et la grille de protection

du ventilateur (voir Démontage du couvercle

page 9).

2. Enlevez le ventilateur, page 9.

3. Enlevez les 4 vis de la plaque amovible avec

une clé à douille de 5/16 po. Retirez la plaque

-

amovible (voir Figures 15 et 16).

4.

Débranchez les fils de lʼallumeur (jaunes) de la

commande dʼallumage (voir Figure 17). Tirez les fils

de lʼallumeur vers le haut par le trou du boîtier.

5. Débranchez les conduites flexibles de combustible et dʼair. Enlevez la cellule photoé

lectrique de son support (voir Figure 17).