Page 1

®

ELECTRIC CHAIN SAW

OWNER’S MANUAL

ELEKTRISCHE KETTINGZAAG

GEBRUIKERSHANDLEIDING

TRONÇONNEUSE ÉLECTRIQUE

INSTRUCTIONS D’UTILISATION

ELEKTROKETTENSÄGE

BEDIENUNGSANLEITUNG

MODEL/MODELL/MODÈLE

100271-01

®

230V~ 50Hz 1450W

TYPE/TYP

EL-4

Page 2

102891

Page 3

ELECTRIC CHAIN SAW

OWNER’S MANUAL

®

®

MODEL

TYPE

IMPORTANT: Read and understand this manual before assembling or

operating this chain saw. Improper use of saw can cause severe injury.

Keep this manual for future reference.

100271-01

EL-4

230V~ 50Hz 1450W

Page 4

®

ELECTRIC CHAIN SAW

INFORMATION

Read Instruction Manual

Do Not Expose to Rain or Use in Wet Conditions

Remove Plug Immediately if Cable is Damaged or Cut

Hold Chain Saw with Both Hands

SYMBOLS

Beware of Kickback

Hearing and Eye Protection Must Be Worn

Safety Information Warnings Appears Throughout This Manual

Pay close attention to them. Below are definitions for the safety information listed

throughout this manual.

WARNING indicates a hazard which can cause severe personal injury, death, or

substantial property damage if you ignore warning.

CAUTION indicates a hazard which will or can cause minor personal injury or

property damage if you ignore warning.

2

102891

Page 5

OWNER’S MANUAL

SAFETY

WARNINGS

Read and understand all S

Warnings

Improper use of this chain saw can

cause severe injury or death from

fire, electrical shock, body contact

with moving chain, or falling wood.

on pages 3 through 5.

BEFORE OPERATING CHAIN

SAW

1. Read and understand this owner’s

manual before operating chain saw.

2. Use chain saw for cutting wood only. Do

not use for cutting any non-wood items.

3. Only well-instructed adults should operate chain saw. Never allow children

to operate chain saw. First-time user

should obtain informed, practical instruction in addition to reading this

manual. Practice cutting logs on a saw

horse or cradle.

4. Use only electrical voltage noted on

model plate of chain saw.

5. Use only extension cords marked for

outdoor use. See page 8 for extension

cord requirements.

6. Do not operate chain saw

• while under the influence of alcohol,

medication, or drugs

• in rain or in damp or wet areas

• where highly flammable liquids or

gases are present

• if saw is damaged, adjusted wrong,

or not fully assembled

• if trigger does not turn saw on and off.

Chain must stop moving when you release trigger. Have faulty switch replaced by authorized service person.

• while tired or in a hurry

• while in tree or on a ladder unless

trained to do so

7. Wear snug-fitting clothes when operating chain saw. Do not wear loose

clothing or jewelry. They can get caught

in moving saw chain.

8. Wear the following safety gear when

operating chain saw:

• heavy-duty gloves (wear rubber

gloves if working oudtoors)

• steel-toed safety footwear with non-

skid soles

afety

• eye protection such as safety glasses,

goggles, or face screen

• safety hard hat

• ear mufflers or ear plugs

• hair covering to contain long hair

• face or dust mask (if working in dusty

areas)

9. Before cutting, always provide the following:

• clear work area

• secure footing

• planned retreat path from falling tree

10. Inspect tree before cutting down. Make

sure there are no dead limbs or branches

that may fall on you.

11. The typical A-weighted noise levels at

full load while cutting wood when

tested in accordance to ISO 7182 are:

Sound Pressure Level 95 DB(A)

Sound Power Level 100 DB(A)

12. The typical hand-arm vibration at full load

while cutting wood when tested in accordance to ISO/DIS 7205 is 23.8 M/S2.

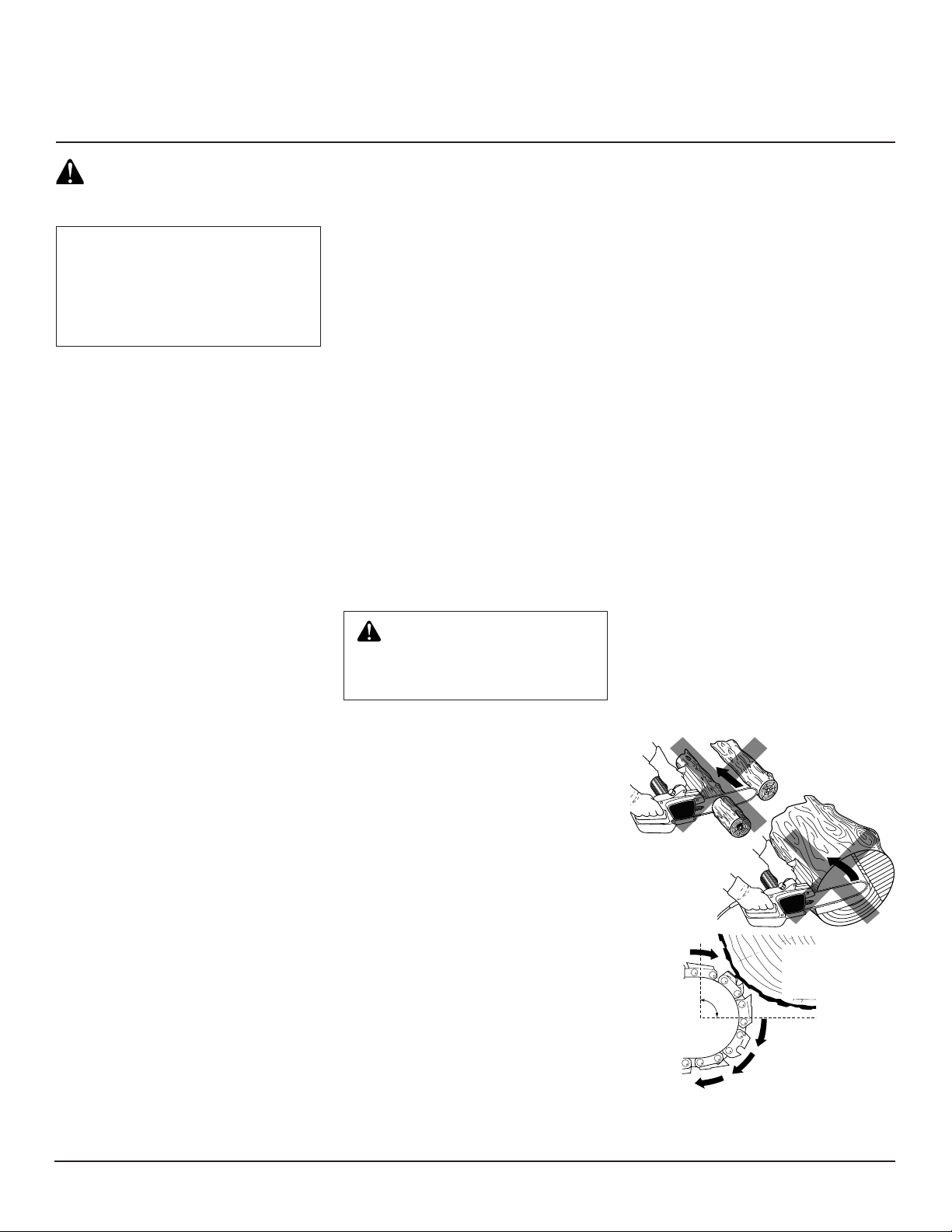

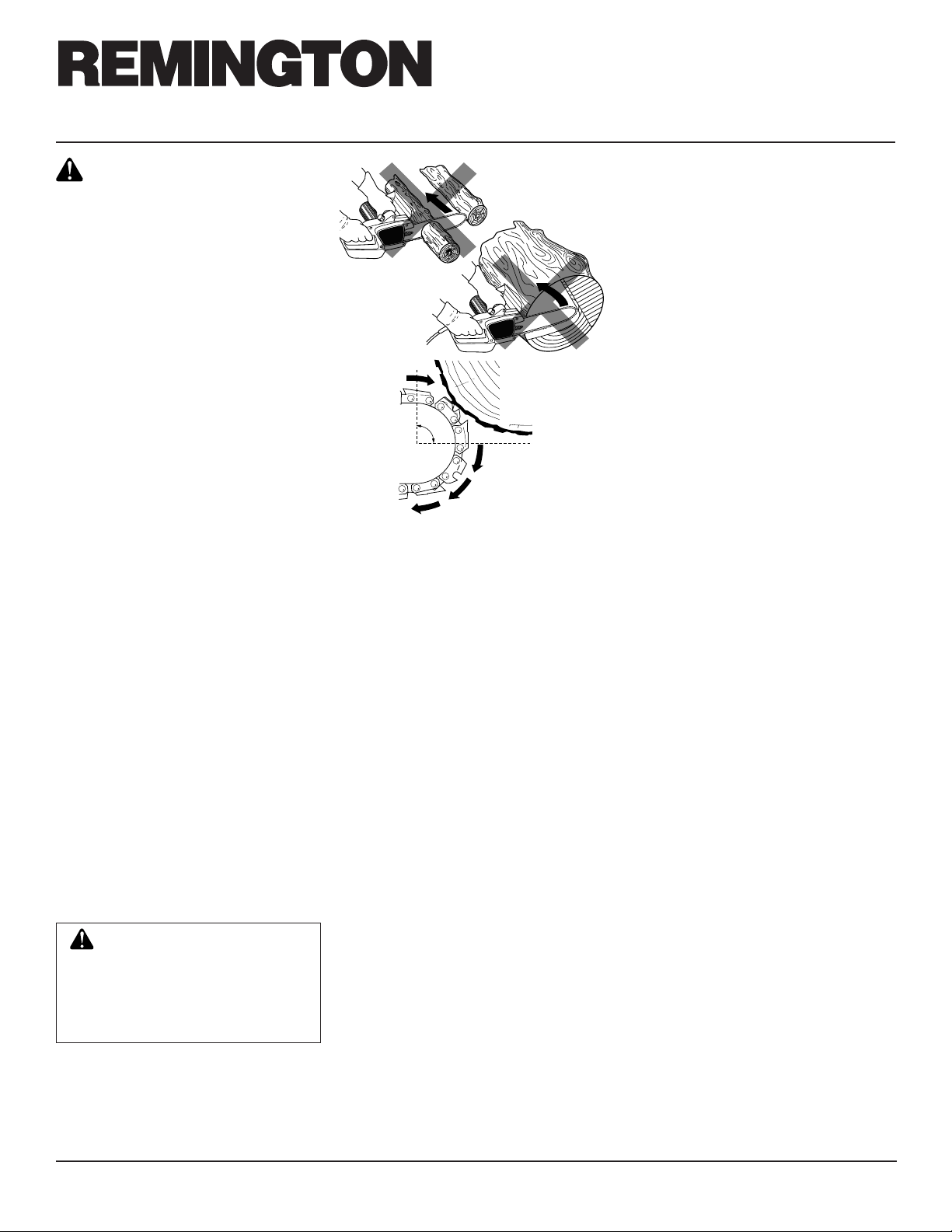

KICKBACK

WARNING: Avoid Kickback.

Kickback can cause you to lose

control of chain saw. Kickback

can cause severe injury or death.

Kickback Safety Devices On

This Saw

This saw has a low-kickback chain and reduced-kickback guide bar. Both items reduce

the chance of kickback. Kickback can still

occur with this saw. Do not let tip of guide bar

touch anything when chain is moving.

This saw has a chain brake. When kickback

occurs, the front hand guard is moved forward by the back of operator’s left hand.

This stops the saw chain quickly, reducing

the chance of serious injury.

Never hold the chain saw by the front hand

guard.

Cause Of Kickback

Kickback may occur when nose or tip of

guide bar touches an object while chain is

moving. If chain cutter catches on object, a

sudden reverse action will result. The guide

bar will kick up and back towards operator.

Kickback may also occur when wood

pinches chain at guide bar nose. A sudden

reverse action will also result.

The following steps will reduce the risk of

kickback:

• Use both hands to grip saw while saw is

running. Use firm grip. Thumbs and

fingers must wrap around saw handles.

•Keep all safety items in place on saw.

Make sure they work properly.

• Do not overreach or cut above shoulder

height.

•Keep solid footing and balance.

• Stand slightly to left side of saw. This

keeps your body from being in direct line

with chain.

• Do not let guide bar nose touch anything

when chain is moving (see Figure 1).

•Never try cutting through two logs at

same time. Only cut one log at a time.

• Do not bury guide bar nose or try plunge

cut (boring into wood using guide bar nose).

•Watch for shifting of wood or other forces

that may pinch chain.

• Use extreme caution when re-entering a

previous cut.

• Use low-kickback chain and guide bar

supplied with this chain saw. Only replace these parts with chains and guide

bars listed in this manual.

•Never use dull or loose chain. Keep chain

sharp and tensioned correctly.

Direction

Do Not Let

Guide Bar Nose

Touch Here

90°

Quadrant

Figure 1 - Kickback Hazard Example. Do

Not Let Nose of Guide Bar Touch Object

While Chain is Moving

Continued

102891

3

Page 6

®

ELECTRIC CHAIN SAW

SAFETY

WARNINGS

Continued

Saw Maintenance and Kickback

Safety

Follow maintenance instructions in this

manual. Proper cleaning of saw and chain

and guide bar maintenance can reduce

chances of kickback. Inspect and maintain

saw after each use. This will increase the

Note:

service life of your saw.

proper sharpening, risk of kickback can

increase with each sharpening.

PUSHBACK AND PULL-IN

WARNING: Avoid pushback

and pull-in. These hazards can

cause you to lose control of chain

saw. Pushback or pull-in can

cause severe injury.

Cause Of Pushback and Pull-In

Pushback may occur while cutting with top

of guide bar. Pushback will force saw back

towards you. Pull-in may occur while cutting with bottom of guide bar. Pull-in will

force saw in towards wood you are cutting.

These hazards can occur if chain is pinched,

caught, or contacts a non-wood object.

The following steps will reduce the risk of

pushback or pull-in:

• Use both hands to grip saw while saw is

running. Use firm grip. Thumbs and

fingers must wrap around saw handles.

• Do not overreach or cut above shoulder

height.

• Keep solid footing and balance.

• Stand slightly to left side of saw. This

keeps your body from being in direct line

with chain.

•Have saw running at full speed before

starting a cut.

• When cutting, make sure spike of saw is

against wood (pull-in only). See Prod-

uct Identification, page 6, to locate spike.

Even with

•Never try cutting through two logs at

same time. Only cut one log at a time.

•Watch for shifting of log or other forces

that may pinch chain.

• Use extreme caution when re-entering a

previous cut.

• Do not twist saw when removing guide

bar from undercut.

• Use wedges made of plastic, wood, or

light alloy (never steel or iron) to hold

cut open.

CHAIN SAW OPERATION

1. Stay alert. Use common sense while

operating chain saw.

2. Keep work area clean. Cluttered areas

invite injuries.

3. Be aware of extension cord while op-

erating chain saw. Be careful not to trip

over cord.

4. Keep children, animals, and bystand-

ers away from chain saw and extension

cord. Only chain saw user should be in

work area.

5. Do not cut down a tree unless you are

trained or have expert help.

6. If two or more persons perform buck-

ing and felling operations at the same

time, provide plenty of distance between

operations. Provide distance of at least

twice the height of tree being felled.

7. Secure wood you are cutting by using

clamps or chocks.

8. Grip chain saw firmly with both hands.

Never operate chain saw with one hand.

Never use hand guard as handle.

9. Keep finger off trigger until ready to

make cut.

10. Before starting chain saw, make sure

chain is not touching anything.

11. Avoid body contact with grounded ob-

jects such as pipes, wire fences, and

metal posts.

12. Keep all parts of body away from chain

when saw is running.

13. Do not force chain saw while cutting.

Apply light pressure.

14. Cut small brush and saplings with extreme care. Slender material may catch

in chain and be whipped toward you.

This could also pull you off balance.

15. When cutting limb or tree trunk that is

under tension, use extreme caution. Be

alert for wood springing back. When

wood tension is released, limb could

spring back and strike operator causing severe injury or death.

16. Do not activate the chain brake to stop

saw. Always release trigger to stop saw.

17. Carry chain saw from one place to another

• with chain saw unplugged

• by holding front handle (never use

front hand guard as handle)

• with finger off trigger

• with guide bar and chain to rear

• with scabbard in place

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains

chemicals known (to the state of

California) to cause cancer, birth

defects, or other reproductive

harm. Some examples of these

chemicals are:

• lead from lead-based paints

• crystalline silica from bricks

and cement and other masonry

products

• arsenic and chromium from

chemically-treated lumber

Your risk from these exposures

varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out microscopic particles.

4

102891

Page 7

OWNER’S MANUAL

SAFETY

WARNINGS

Continued

MAINTENANCE AND

STORAGE OF CHAIN SAW

1. Unplug chain saw from power source

• when not in use

• before moving from one place to another

• before servicing

• before changing accessories or attachments

2. Inspect chain saw before and after each

use. Check saw closely if guard or other

part has been damaged. Check for any

damage that may affect operator safety

or operation of saw. Check for alignment or binding of moving parts. Check

that switch turns motor on and off.

Check chain brake. Check for broken

or damaged parts. Do not use chain saw

if damage affects safety or operation.

Have damage repaired by authorized

service person.

3. Maintain chain saw with care.

• Never expose saw to rain.

• Keep chain sharp, clean, and lubri-

cated.

• Follow steps outlined in this manual

to sharpen chain.

•Keep handles dry, clean, and free of oil.

• Keep all screws and nuts tight.

• Inspect power cord often. If dam-

aged, have repaired by authorized

service person.

• Never carry chain saw by power cord.

• Never yank power cord to unplug it.

• Keep power cord from heat, oil, and

sharp edges.

• Inspect extension cords often and

replace if damaged.

4. When servicing, use only identical replacement parts.

5. Always store chain saw

• in a high or locked place, out of

children’s reach

• in a dry place

• in a carrying case or with scabbard

over guide bar

Keep this manual for reference. It is your

guide to safe and proper operation of this

chain saw.

CHAIN SAW NAMES

AND TERMS

Bucking Process of cutting a felled tree or

log into lengths.

Felling Process of cutting down a tree.

Felling Cut Final cut when felling a tree.

Make this cut on opposite side of tree from

notching cut.

Front Hand Guard Shield between front

handle and guide bar. Protects left hand

while using saw. When kickback occurs, the

front hand guard is moved forward by the

back of operator’s left hand. This stops the

saw chain quickly, reducing the chance of

serious injury.

Front Handle Located at front of saw body.

Guide Bar Metal bar that extends from

saw body. The guide bar supports and guides

chain.

Guide Bar Nose Tip or end of guide bar.

Kickback Quick backward and upward

motion of guide bar. Kickback may occur

when tip of guide bar touches an object

while chain is moving. The guide bar will

kick up and back towards operator.

Limbing Process of cutting limb(s) from a

felled tree.

Low-Kickback Chain Chain that reduces

chance of kickback as required by ANSI

B175.1.

Normal Cutting Position Stance used

while making bucking and felling cuts.

Notching Cut Notch cut in tree that directs

fall of tree.

Oiler Control System for oiling guide bar

and chain.

Power Head Chain saw without chain and

guide bar. Also known as saw body.

Pushback (Kickback, Pinch) Rapid

pushback of chain saw. Pushback may occur if chain along top of guide bar is pinched,

caught, or contacts a foreign object.

Rear Handle Handle located at rear of saw

body.

Reduced Kickback Guide Bar Guide

bar that reduces chance of kickback.

Replacement Chain Chain that complies

with ANSI B175.1 when used with a specific

saw. It may not meet ANSI requirements

when used with other saws.

Saw Chain (Chain) Loop of chain having

cutting teeth for cutting wood. The motor

drives chain. The guide bar supports chain.

Spiked Bumper (Spike) Pointed teeth at

front of saw body beside guide bar. Keep

spiked bumper in contact with wood when

felling or bucking. It helps maintain position of saw while cutting.

Sprocket Toothed wheel that drives chain.

Switch Device that completes or interrupts

electrical circuit to motor of saw.

Switch Linkage This device connects

switch to trigger. It moves switch when you

squeeze trigger.

Switch Lockout Device that reduces accidental starting of saw.

Trigger Device that turns saw on and off.

Squeezing trigger turns saw on. Releasing

trigger turns saw off.

Trimming (Pruning) Process of cutting

limb(s) from a living tree.

Undercut An upward cut from underside

of log or limb. This is done while in normal

cutting position and cutting with top of

guide bar.

102891

5

Page 8

®

ELECTRIC CHAIN SAW

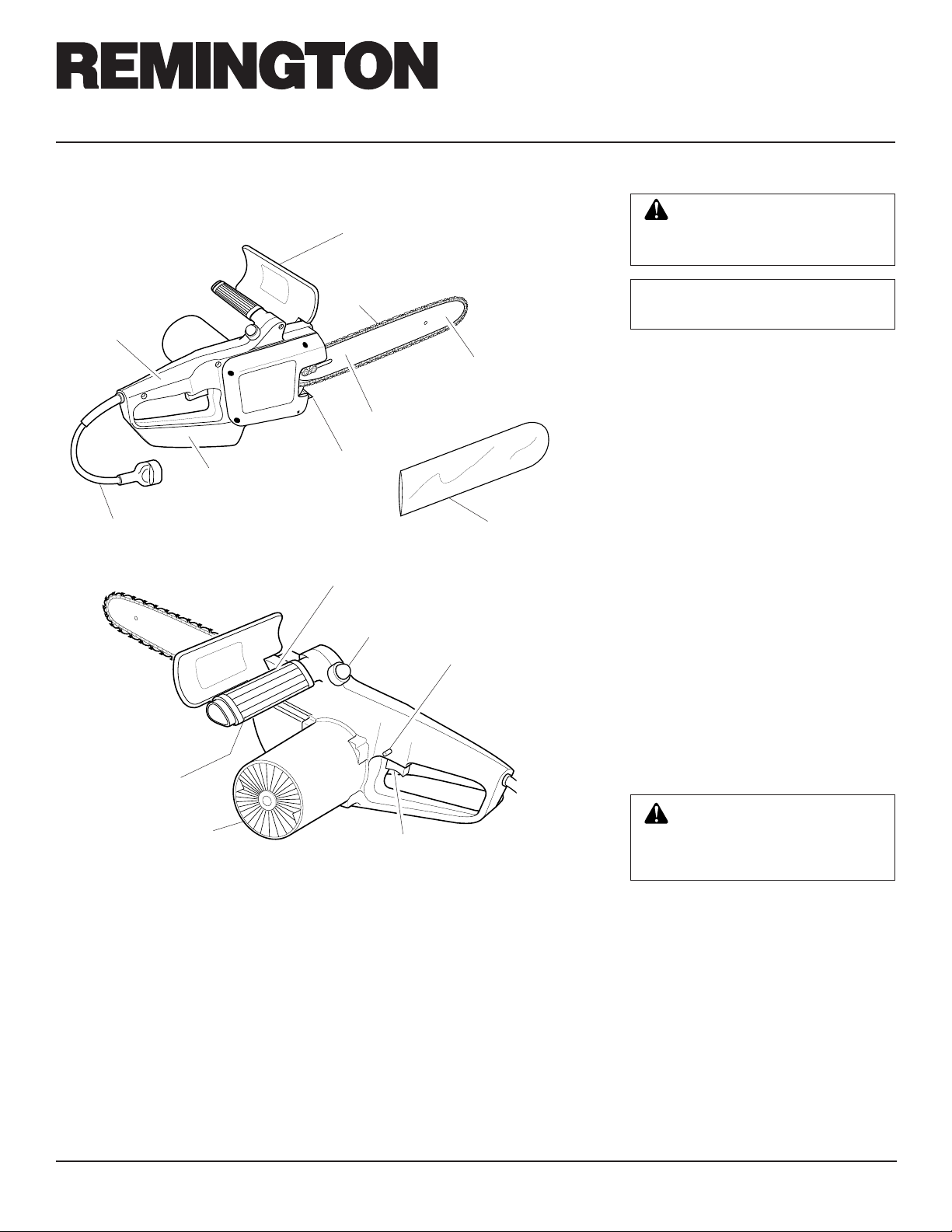

PRODUCT

IDENTIFICATION

Rear

Handle

Rear Hand

Guard

Power Cord

Oil Level Sight Hole (located on saw

body, hidden by front handle)

Front

Handle

Front Hand

Guard

Saw

Chain

Guide Bar

Spike

Oil Cap With

Squeeze Bulb

Guide Bar

Nose

Scabbard

Switch

Lockout

ASSEMBLY

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

IMPORTANT: Do not clamp chain

saw in vise during assembly.

1. Lay chain out flat.

2. Remove guide bar nuts from guide bar

bolts (see Figure 3, page 7).

3. Turn adjusting screw counterclockwise

(see Figure 4, page 7). Continue to turn

adjusting screw until adjusting block is

to rear of adjusting plate.

4. Install guide bar onto saw body. Place

rear of guide bar between adjusting

plate and sprocket support.

IMPORTANT:

justing block into oval adjusting hole

on guide bar.

5. Attach guide bar nuts to guide bar bolts.

IMPORTANT:

finger tight only. Make sure adjusting block

is in oval adjusting hole on guide bar.

6. Place chain around drive sprocket, then

along top groove of guide bar and

around guide bar nose.

sure cutting edges of chain are facing

the right direction. Position chain so

cutting edges on top of guide bar face

guide bar nose (see Figure 3, page 7).

Make sure to insert ad-

Tighten guide bar nuts

Note:

Make

Motor

Housing

Figure 2 - Electric Chain Saw

UNPACKING

1. Remove all items from carton.

2. Check all items for any shipping damage. If you find any damage or if any

parts are missing, promptly inform

dealer where you bought chain saw.

Trigger

CAUTION: Do not place chain

on saw backwards. If chain is

backwards, saw will vibrate badly

and will not cut.

7. Adjust saw chain tension. Follow steps

under Saw Chain Tension Adjustment,

page 8.

8. If saw has 2-piece side cover, attach

sprocket cover.

6

102891

Page 9

OWNER’S MANUAL

ASSEMBLY

Continued

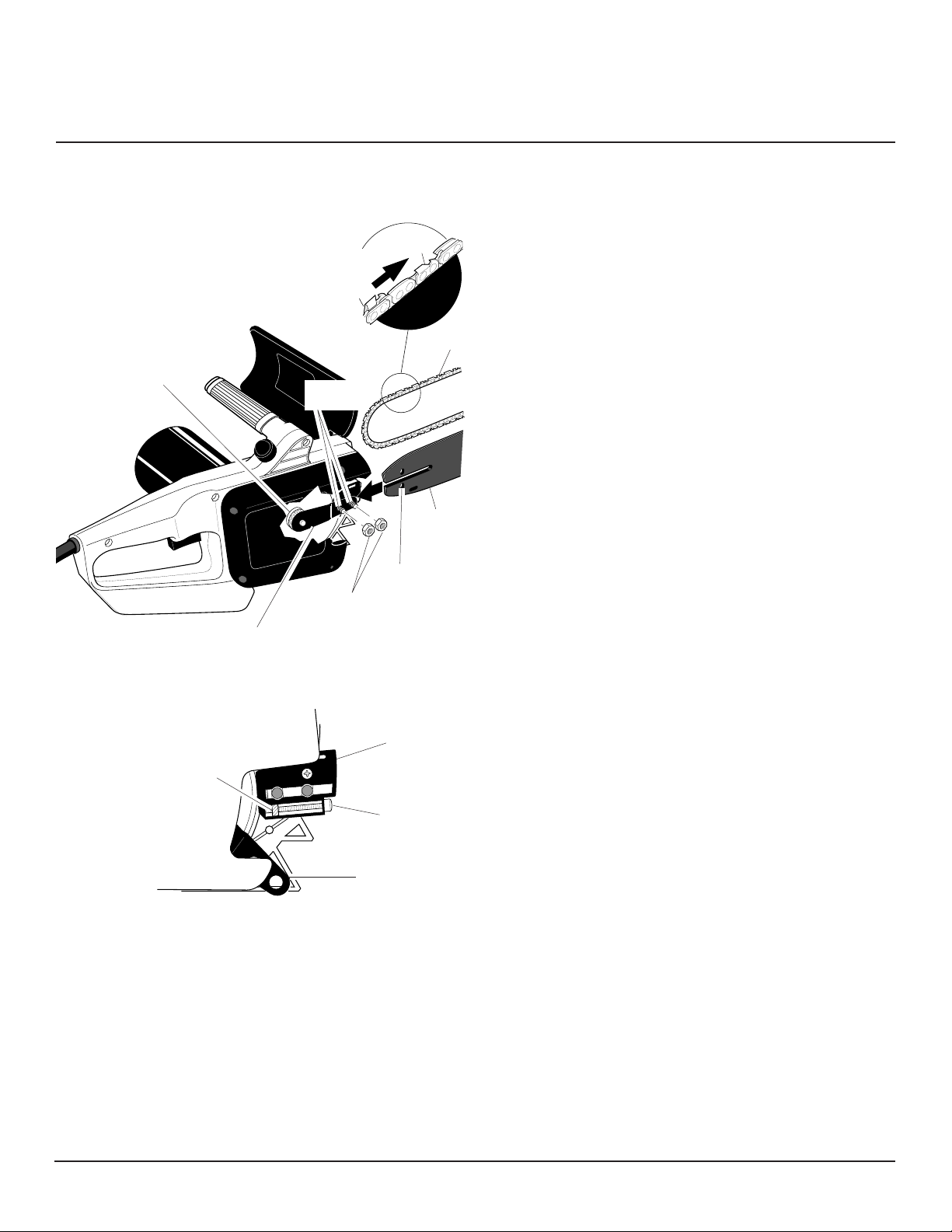

Drive

Sprocket

Sprocket

Support

Towards

Guide

Bar Nose

Guide Bar

Bolts

Guide Bar

Nuts

Cutting

Edge

Saw

Chain

Guide

Bar

Adjusting Hole

FILLING OIL TANK

1. Remove oil cap.

2. Fill oil tank with SAE #30 motor oil.

Note:

For temperatures below -1°C,

use SAE #10 oil. For temperatures

above 24°C, use SAE #40 oil.

3. Replace oil cap at once. Tighten oil cap

firmly for good seal. This will avoid oil

seepage from tank.

4. Wipe off excess oil.

Note:

It is normal for oil to seep when saw

is not in use. Empty oil tank after each use to

prevent seepage.

Figure 3 - Assembling Guide Bar, Chain, and Hand Guard

Adjusting

Plate

Adjusting

Block

Adjusting

Screw

Sprocket

Support

Figure 4 - Part Locations for Assembling Guide Bar

102891

7

Page 10

®

ELECTRIC CHAIN SAW

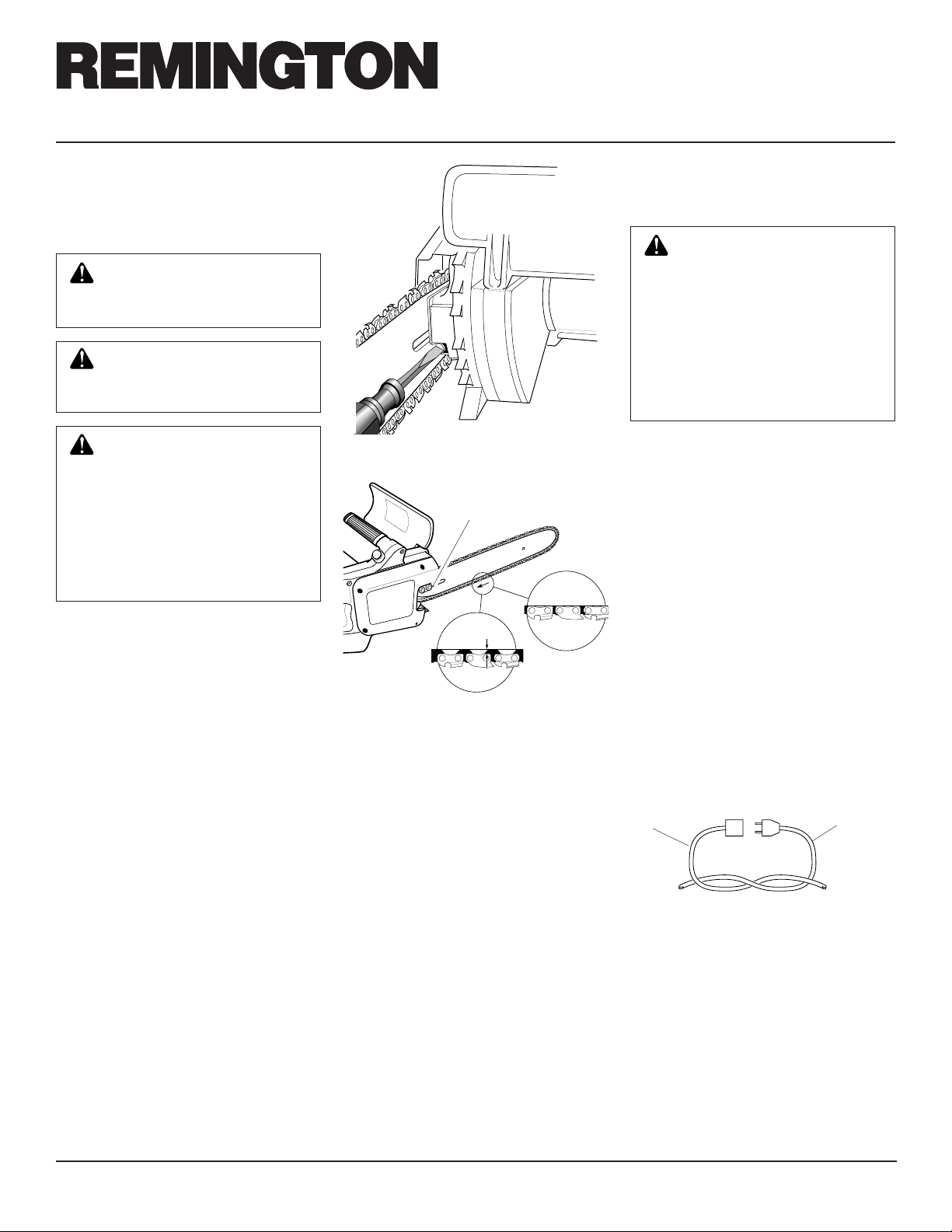

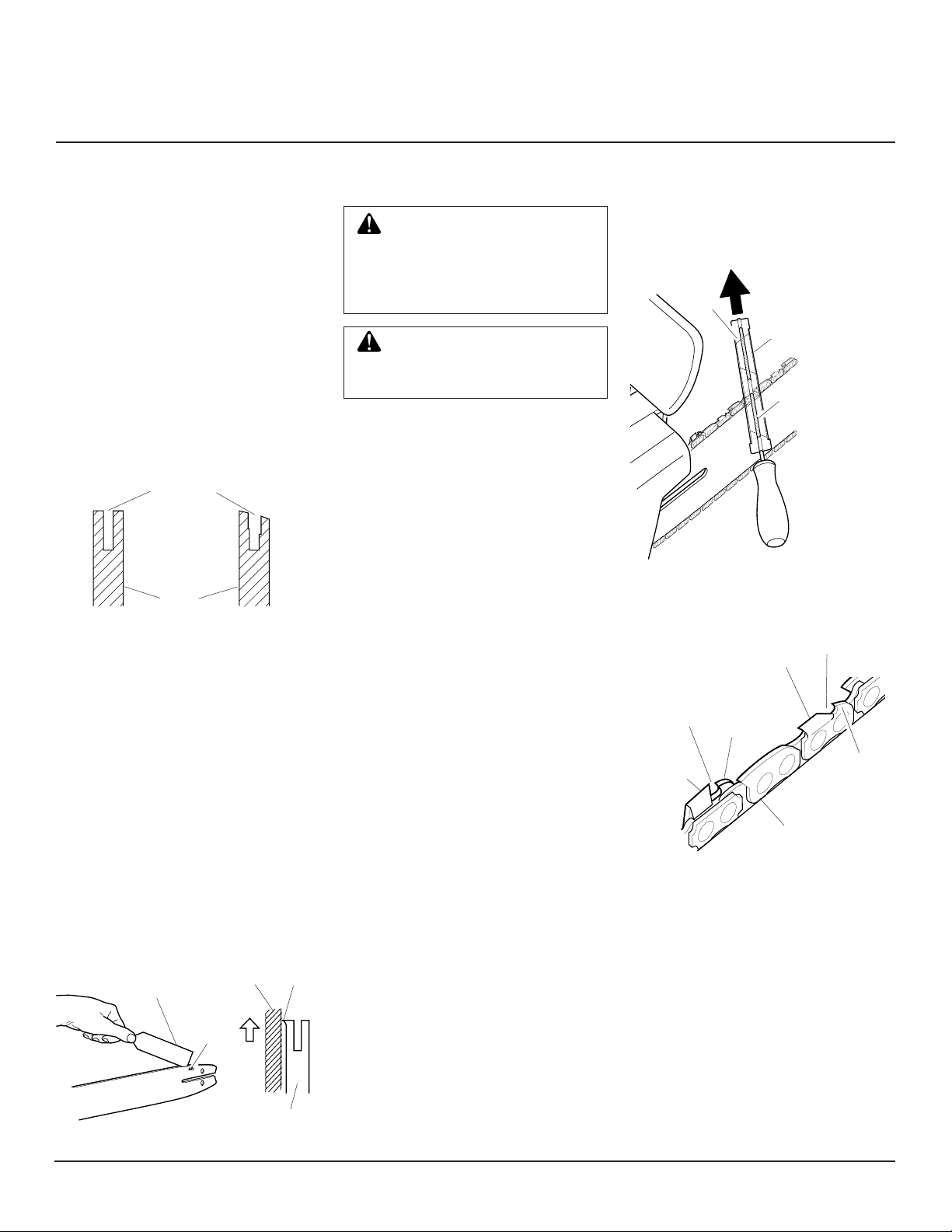

SAW CHAIN

TENSION

ADJUSTMENT

WARNING: Unplug chain saw

from power source before adjusting saw chain tension.

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

WARNING: Maintain proper

chain tension always. A loose

chain will increase the risk of

kickback. A loose chain may jump

out of guide bar groove. This may

injure operator and damage

chain. A loose chain will cause

chain, guide bar, and sprocket to

wear rapidly.

Note:

For pre-assembled models, the saw

chain tension is properly set at factory. A

new chain will stretch. Check new chain

after first few minutes of operation. Allow

chain to cool down. Follow steps below to

readjust saw chain tension.

1. Before adjusting chain, make sure guide

bar nuts are only finger tight (see Figure

3, page 7). Also make sure adjusting

block is in oval adjusting hole on guide

bar (see Figures 3 and 4, page 7).

2. Turn adjusting screw clockwise until all

slack is out of chain (see Figure 5).

Note:

There should be no gap between

side links of chain and bottom of guide

bar (see Figure 6).

3. Wearing protective gloves, move chain

around guide bar. Chain should move

freely. If chain does not move freely,

loosen chain by turning adjusting screw

counterclockwise.

4. After chain tension is correct, tighten

guide bar nuts firmly. If not, guide bar

will move and loosen chain tension.

This will increase the risk of kickback.

This can also damage saw.

chain will stretch. Check new chain

after first few minutes of operation.

Allow chain to cool down. Readjust

chain tension.

Note:

A new

Figure 5 - Turning Adjusting Screw

Guide Bar

Nuts

Guide Bar

Guide

Bar

Correct

Gap

Incorrect

Tension

Figure 6 - Saw Chain Adjustment

Tension

OPERATING CHAIN

SAW

WARNING: Read and understand this owner’s manual before operating this saw. Make

certain you read and understand

all

Safety Warnings

through 5. Improper use of this

chain saw can cause severe injury or death from fire, electrical

shock, or body contact with moving chain, or falling wood.

EXTENSION CORDS

Use proper extension cord with this chain

saw. Use a HO7RN extension cord no less

than 1.5 mm2 at distances up to 30 meters.

Use a ground fault circuit interrupter as part

of the power supply system.

Use an extension cord heavy enough to

carry the current your saw will draw. An

undersized cord will cause a voltage drop at

the saw, loss of power, and overheating.

Keep cord away from cutting area. Make

sure cord does not catch on branches or logs

during cutting. Inspect cords often. Replace

damaged cords.

The extension cord may come undone from

the power cord during use. To avoid this,

make a knot with the two cords as shown in

Figure 7 below.

Extension

Cord

Figure 7 - Tying Extension Cord and Power

Cord in Knot

, pages 3

Chain Saw

Power Cord

8

102891

Page 11

OWNER’S MANUAL

OPERATING CHAIN

SAW

Continued

OILING CHAIN

Always check oil level before using saw. To

oil chain, press squeeze bulb on oil cap. Do

not attempt to operate the oiler while cutting

with the saw. Oil will feed onto guide bar

and chain. Press squeeze bulb on oil cap at

least once before each cut. Check oil level

often by looking at oil sight level hole. Oil

sight level hole is on left side of saw, between front handle and front hand guard.

Figure 8 - Pressing Squeeze Bulb on Oil

Cap to Oil Chain

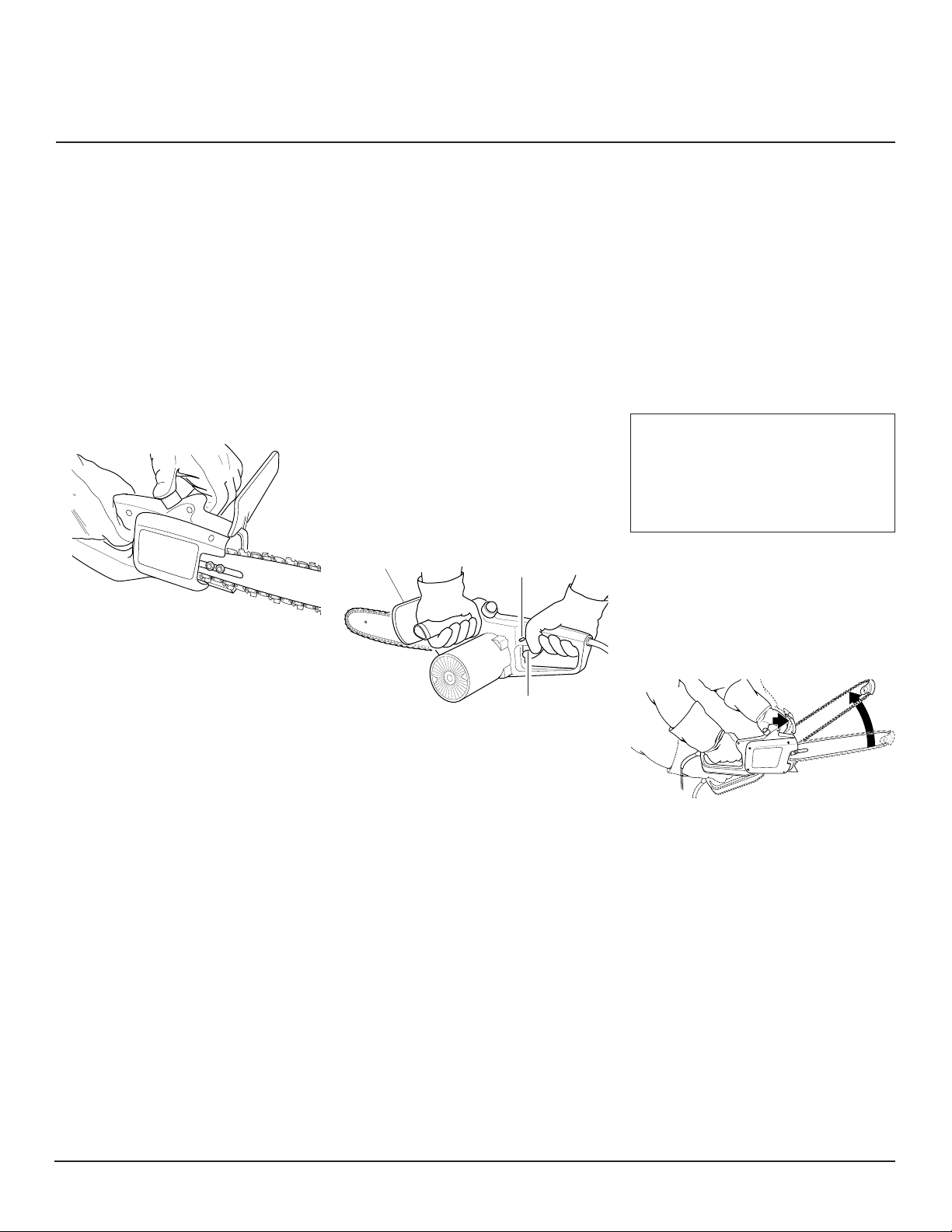

CUTTING WITH THE CHAIN

SAW

1. Connect saw to extension cord. Connect extension cord to power supply.

2. Make sure section of log to be cut is

not laying on ground. This will keep

chain from touching ground as it cuts

through log. Touching ground with

moving chain will dull chain.

3. Use both hands to grip saw. Always use

left hand to grip front handle and right

hand to grip rear handle. Use firm grip.

Thumbs and fingers must wrap around

saw handles (see Figure 9).

4. Make sure your footing is firm. Keep

feet apart. Divide your weight evenly

on both feet. Stand slightly to left side

of saw. This keeps your body from being in direct line with chain.

5. When ready to make a cut, press in

switch lockout with right thumb and

squeeze trigger (see Figure 9). This will

turn saw on. Releasing trigger will turn

saw off. Make sure saw is running at

full speed before starting a cut.

6. When starting a cut, place moving

chain against wood. Hold saw firmly

in place to avoid possible bouncing or

skating (sideways movement) of saw.

7. Guide saw using light pressure. Do not

force saw. The motor will overload and

can burn out.

8. Remove saw from a cut with saw running at full speed. Stop saw by releasing trigger. Do not use the chain brake.

Make sure chain has stopped before

setting saw down.

9. Practice until you can maintain a steady,

even cutting rate.

Front Hand

Guard

Figure 9 - Front Hand Guard, Switch

Lockout, and Trigger Location

Switch

Lockout

Trigger

CHAIN BRAKE

The chain brake quickly stops the saw chain.

Kickback causes the back of operator’s left

hand to contact front hand guard (see Figure

10). When front hand guard moves forward,

the saw chain stops. This reduces the chance

of serious injury during kickback. When the

chain brake activates, release trigger at once.

To reset chain brake, release trigger and

move front hand guard back into position.

You must release trigger first. If not, the saw

will start when you reset the front hand

guard.

CAUTION: Do not use the chain

brake to stop and start your saw.

Quick repeated stops may cause

overheating of the chain brake.

Damage to the chain brake will

occur.

Note:

Test chain brake before each use.

Firmly grip saw with both hands. With saw

running, move front hand guard forward

with back of left hand. Keep both hands on

the handles. Saw chain should stop. If chain

brake does not work, have saw repaired by

authorized service person.

STOP

Figure 10 - The chain brake quickly

stopping the saw chain

102891

Continued

9

Page 12

®

ELECTRIC CHAIN SAW

OPERATING CHAIN

SAW

Continued

TRIMMING A TREE (Pruning)

WARNING: Avoid kickback.

Kickback can result in severe injury or death. See

3 and 4, to avoid risk of kickback.

WARNING: Do not operate

chain saw while

• in a tree

• on a ladder or any other un-

stable surface

• in any awkward position

You may lose control of saw caus-

ing severe injury.

WARNING: Do not cut limbs

higher than your shoulders.

Trimming a tree is the process of cutting

limbs from a living tree. Make sure your

footing is firm. Keep feet apart. Divide your

weight evenly on both feet. Follow directions below to trim a tree.

1. Make first cut 15 centimeters from tree

trunk on underside of limb. Use top of

guide bar to make this cut. Cut 1/3

through diameter of limb (see Figure 11).

2. Move five to ten centimeters farther out

on limb. Make second cut from above

limb. Continue cut until you cut limb off.

3. Make third cut as close to tree trunk as

possible on underside of limb stub. Use

top of guide bar to make this cut. Cut

1/3 through diameter of stub.

4. Make fourth cut directly above third

cut. Cut down to meet third cut. This

will remove limb stub.

Kickback,

pages

2nd Cut - Pruning

4th Cut Final

Stub Cut

3rd Cut - Stub Undercut

(to avoid splintering)

Figure 11 - Cutting A Limb

Cut (to avoid

pinching)

15

cm

5 to 10 cm

1st Cut - Pruning

Undercut (to avoid

splintering)

FELLING A TREE (Cutting

Down a Tree)

WARNING

• Avoid kickback. Kickback can

result in severe injury or death.

See

Kickback,

to avoid risk of kickback.

• Do not fell a tree without ample

skill or expert help.

• Keep children, animals, and

bystanders away from area

when felling a tree.

• If two or more persons perform bucking and felling operations at the same time, provide ample distance between

operations. Provide distance

of at least twice the height of

tree being felled.

WARNING: When felling a

tree, be aware of your

surroundings. Do not endanger

any person, strike utility lines, or

cause property damage. If tree

strikes utility lines, contact utility

company at once.

pages 3 and 4,

CAUTION: Seek professional

help if facing conditions beyond

your ability.

Felling is the process of cutting down a tree.

Make sure your footing is firm. Keep feet

apart. Divide your weight evenly on both

feet. Follow directions below to fell a tree.

Before Felling a Tree

1. Before felling, inspect tree. Make sure

there are no dead limbs or branches that

may fall on you. Study natural lean of

tree, location of larger branches, and

wind direction. This will help you judge

which way tree will fall.

2. Clear work area around tree.

3. Plan and clear a retreat path before felling. Make retreat path opposite to

planned direction of fall of tree and at

45° angle (see Figure 12).

4. Remove dirt, stones, loose bark, nails,

staples, and wire from tree where you

will make felling cuts.

5. Stay on uphill side when felling tree.

Tree could roll or slide downhill after

falling.

Retreat

Path

45°

Retreat

Path

Figure 12 - Retreat Path From Tree

Direction

of Fall

Tree

CAUTION: Seek professional

help if facing conditions beyond

your ability.

10

102891

Page 13

OWNER’S MANUAL

OPERATING CHAIN

SAW

Continued

FELLING PROCEDURE

Felling Notch

A properly placed felling notch will determine direction tree will fall. Place felling

notch on side of tree in direction you want

tree to fall (see Figure 13). Follow directions below to create a felling notch.

1. Make lower notch cut as close to

ground as possible. Hold saw so guide

bar is horizontal. Cut 1/3 the diameter

of tree trunk (see Figure 13).

ways make this horizontal lower notch

cut first. If you make this cut second,

tree can pinch chain or guide bar.

2. Start upper notch cut the same distance

above first cut as first cut is deep.

Example:

timeters deep, start upper notch cut 20

centimeters above it. Cut downward at

45° angle. The upper notch cut should

meet end of lower notch cut (see Figure 13).

3. Remove tree trunk wedge created by

notching cuts.

If lower notch cut is 20 cen-

Note:

Al-

Never use wedge made of steel. This

could cause kickback and damage to

chain.

4. When tree begins to fall, quickly

•remove saw from felling cut

•release trigger to turn saw off

• put saw down

•exit area using retreat path

Direction of Fall

3rd Cut Felling Cut

5 cm

Figure 13 - Felling A Tree

WARNING: Be alert for falling

overhead limbs. Watch your footing while exiting area.

5 cm

Hinge

2nd Cut Upper

Notch

Cut

1st Cut Lower

Notch

Cut

LIMBING A TREE

Limbing is removing branches from a fallen

tree. Make sure your footing is firm. Keep

feet apart. Divide your weight evenly on

both feet. Do not remove larger limbs under

tree that support log off ground. Remove

each limb with one cut (see Figure 14).

Clear cut limbs from work area often. This

will help maintain a safe work area.

Make sure you start your cut where limb

will not pinch saw during cutting. To avoid

pinching, start cut on freely hanging limbs

from above limb. Start cut on limbs under

tension from under limb. If pinch occurs,

turn saw off, lift limb, and remove saw.

Figure 14 - Limbing A Tree

Felling Cut

1. Make felling cut five centimeters higher

than lower notch cut and on opposite

side of tree (see Figure 13). Keep felling cut parallel to lower notch cut.

2. Cut towards notch.

WARNING: Do not cut all the

way through tree. Leave about

five centimeters of tree diameter

uncut directly behind felling

notch (see Figure 13). This uncut

portion acts as a hinge. The hinge

helps keep tree from twisting and

falling in wrong direction.

3. As felling cut nears hinge, tree should

begin to fall.

wedges into felling cut to control direction of fall. If tree settles back and

pinches chain, drive wedges into felling cut to remove saw. Only use wedges

made of wood, plastic, or aluminum.

102891

Note:

If needed, drive

WARNING: Avoid kickback.

Kickback can result in severe injury or death. See

3 and 4, to avoid risk of kickback.

WARNING: When cutting limb

that is under tension, use extreme

caution. Be alert for wood springing back. When wood tension is

released, limb could spring back

and strike operator causing severe injury or death.

CAUTION: Seek professional

help if facing conditions beyond

your ability.

Kickback,

11

pages

Continued

Page 14

®

ELECTRIC CHAIN SAW

OPERATING CHAIN

SAW

Continued

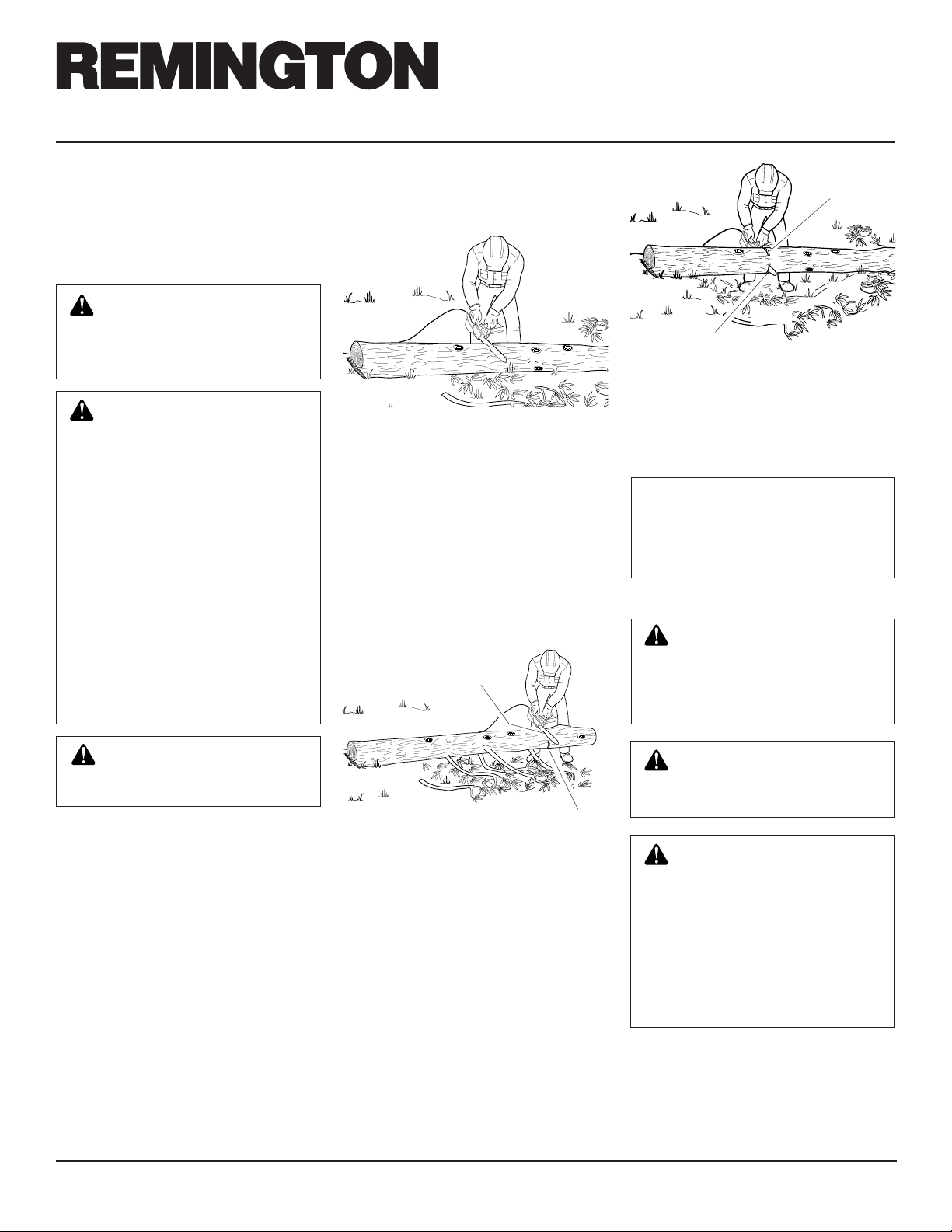

BUCKING A LOG

WARNING: Avoid kickback.

Kickback can result in severe injury or death. See

3 and 4, to avoid risk of kickback.

WARNING

• If on slope, make sure log will

not roll down hill. Secure log

by using wooden stakes. Drive

wooden stakes into ground on

downhill side of log. Stand on

uphill side of log while cutting.

Log may roll after cutting.

• Never try cutting through two

logs at same time. This could

increase the risk of kickback.

• While cutting log, never hold

log with your hand, leg, or foot.

• While cutting log, never allow

another person to hold log.

• Turn off and unplug saw be-

fore moving from one place to

another.

Kickback,

pages

Entire Length Of Log On

Ground

1. Cut log from top (see Figure 15).

Figure 15 - Bucking Log With Entire

Length On Ground

Log Supported On One End

1. Make first cut on underside of log (see

Figure 16). Use top of guide bar to

make this cut. Cut 1/3 through diameter of log. This cut will keep section

from splintering when cut.

2. Make second cut directly above first

cut. Cut down to meet first cut. This

cut will keep log from pinching guide

bar and chain.

2nd Cut

1st Cut

2nd Cut

Figure 17 - Bucking Log When Log Is

Supported On Both Ends

CLEANING AND

MAINTENANCE

NOTICE: Below are instructions

for servicing your chain saw. Any

servicing not mentioned below

should be done by an authorized

service person.

CLEANING SAW BODY

WARNING: Unplug chain saw

from power source before servicing. Severe injury or death could

occur from electrical shock or

body contact with moving chain.

CAUTION: Seek professional

help if facing conditions beyond

your ability.

Bucking a log is cutting a log into sections.

Make sure your footing is firm. Keep feet

apart. Divide your weight evenly on both

feet. Stand slightly to left of saw. This keeps

your body from being in direct line with

chain. When possible, raise log or section

off ground. Do this by using limbs, logs,

chocks, etc.

When cutting through log, maintain control

by reducing cutting pressure near end of cut.

Do not relax your grip on chain saw handles.

Do not let moving chain touch ground.

Ground will dull moving chain. After cutting through log, release trigger to turn saw

off before moving saw.

Follow directions in column 2 to buck a log.

1st Cut

Figure 16 - Bucking Log When Log Is

Supported On One End

Log Supported On Both Ends

1. Make first cut from above log (see Figure 17). Cut 1/3 through diameter of

log. This cut will keep section from

splintering when cut.

2. Make second cut on underside of log,

directly under first cut. Use top of guide

bar to make this cut. Cut up to meet

first cut. This will keep log from pinching guide bar and chain.

12

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

WARNING: When cleaning

saw body,

• do not submerge saw in any

liquids

• do not use products that con-

tain ammonia, chlorine, or

abrasives

• do not use chlorinated clean-

ing solvents, carbon tetrachloride, kerosene, or gasoline

Keep saw body clean. Use a soft cloth dampened with a mild soap and water mixture.

Wipe saw body to clean.

102891

Page 15

OWNER’S MANUAL

FILE HO

LDER

CLEANING AND

MAINTENANCE

Continued

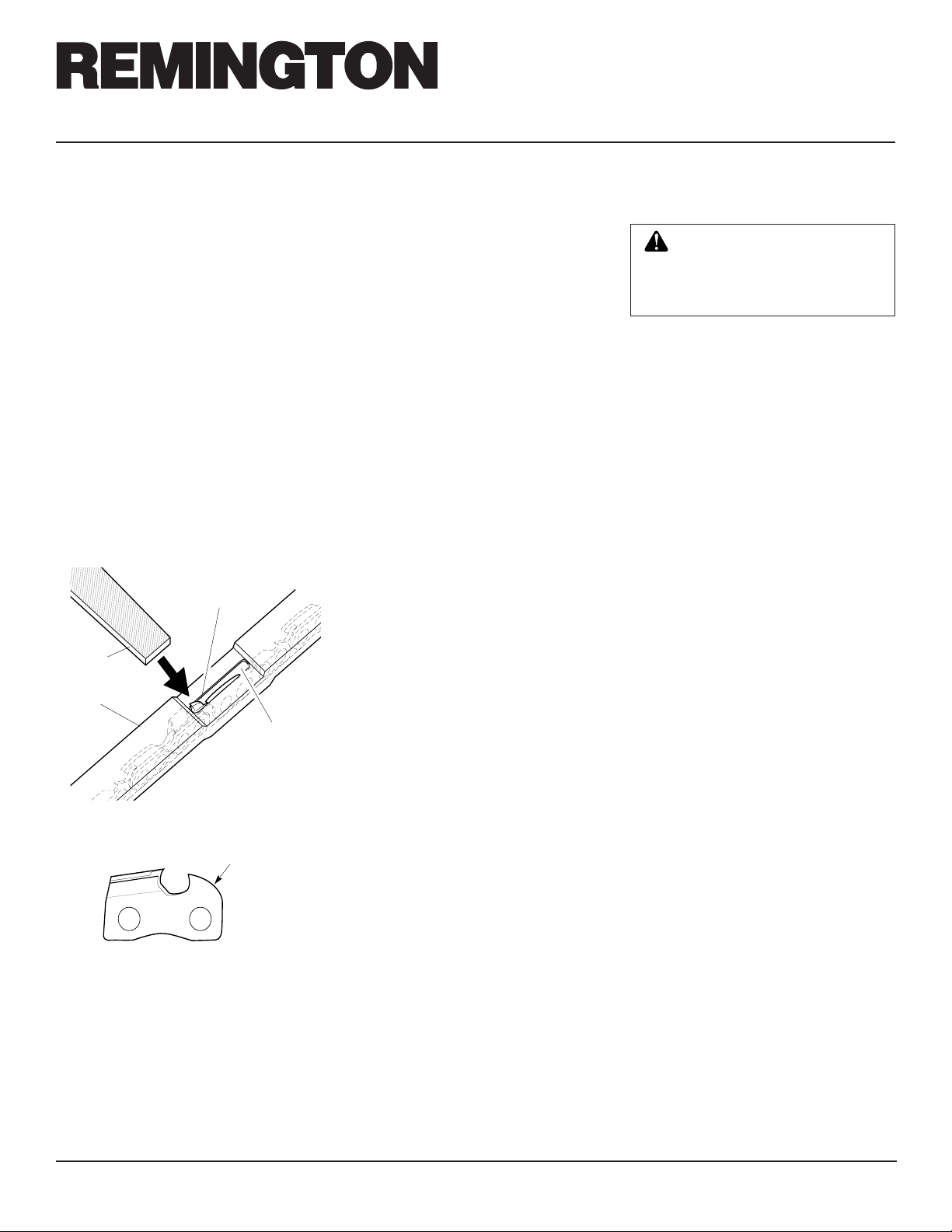

CARE OF GUIDE BAR

Uneven bar wear causes most guide bar

problems. Incorrect sharpening of chain

cutter and depth gauge settings often cause

this. When bar wears unevenly, it widens

guide bar groove (see Figure 18). This causes

chain clatter and rivet popping. Saw will not

cut straight. Replace guide bar if this occurs.

Inspect guide bar before sharpening chain.

A worn or damaged guide bar is unsafe. A

worn or damaged guide bar will damage

chain. It will also make cutting harder.

Guide Bar

Groove

Guide

Normal

Guide Bar

Figure 18 - Guide Bar Cross Section

Showing Uneven Bar Wear

Normal Guide Bar Maintenance

1. Remove guide bar from chain saw.

2. Remove sawdust from guide bar groove

periodically. Use putty knife or wire.

3. Clean oil slots after each day of use.

4. Remove burrs from sides of guide bar.

Use flat file to make side edges square.

Replace guide bar when

• bar is bent or cracked

• inside groove of bar is badly worn

Note:

When replacing guide bar, see Re-

placement Parts, page 14, for proper bar.

Cleaning Groove

With Putty Knife

Bar

Guide Bar With

Uneven Wear

Flat

File

Oil

Slot

Burr

SHARPENING YOUR SAW

CHAIN

WARNING: Unplug chain saw

from power source before servicing. Severe injury or death could

occur from electrical shock or

body contact with moving chain.

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

Keep chain sharp. Your saw will cut faster

and more safely. A dull chain will cause

undue sprocket, guide bar, chain, and motor

wear. If you must force chain into wood and

cutting creates only sawdust with few large

chips, chain is dull.

Items Needed to Sharpen Chain

Purchase these items from your local dealer,

hardware store, or chain saw supplies outlet.

•4 mm round file

• Depth gauge tool

• File guide

•Vise

• Medium sized flat file

Sharpening Cutters

Use file guide for 30° filing.

1. Adjust chain for proper tension (see Saw

Chain Tension Adjustment, page 8).

2. Clamp guide bar in vise to hold saw

steady.

3. Press four millimeter round file (attached to file guide) into groove between top plate and depth gauge on

chain. File guide should rest on both

top plate and depth gauge (see Figures

20 and 21).

guide bar.

4. Hold file guide level. Make sure 30°

mark on file guide is parallel to center

of guide bar (see Figure 20). This will

insure that you file cutters at 30° angle.

5. File from inside towards outside of cutter until sharp. Only file in this one direction (see Figure 20).

strokes with file should sharpen cutter.

Note:

Do not clamp chain.

Note:

File at midpoint of

Note:

Two or three

6. After each cutter if sharpened, move

chain forward to sharpen next cutter.

File all cutters on one side of chain.

7. Move to other side of chain and repeat

process.

30°

Guide

Mark

Figure 20 - File and File Guide Placement

On Chain

Left

Side of

Chain

Groove

Top Plate

(left side

of chain)

Figure 21 - Chain Part Locations

Top Plate

(right side

of chain)

Depth

Gauge

(left side

of chain)

Filing

Direction

File Guide

4 mm

Round File

Note:

illustration

shows file guide

placement and

filing direction

for sharpening

cutters on left

side of chain.

Right

Side of

Chain

This

Groove

Depth

Gauge

(right side

of chain)

Guide Bar

Figure 19 - Guide Bar Maintenance

102891

Continued

13

Page 16

®

ELECTRIC CHAIN SAW

CLEANING AND

MAINTENANCE

Continued

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced

as cutters are sharpened. After every second

or third sharpening, reset cutter depth gauges.

1. Place depth gauge tool firmly across top

of two cutters. Make sure depth gauge

enters slot in depth gauge tool (see Figure 22).

2. Use medium flat file. File depth gauge

level with depth gauge tool.

3. Remove depth gauge tool. With flat file,

round off front corner of cutter depth

gauge (see Figure 23).

After several hand filings, have authorized

service center or sharpening service machine

sharpen chain. This will insure even filing.

Depth

Gauge

Flat File

Depth

Gauge

Tool

Depth

Gauge

Slot

Figure 22 - Depth Gauge Tool On Chain

Front Corner

Replacing Saw Chain

Replace chain when cutters are too worn to

sharpen or when chain breaks. Only use

replacement chain noted in this manual. Always include new drive sprocket when replacing chain. This will maintain proper driving of chain.

drive sprocket, see Replacement Parts.

Note:

For proper chain and

RECYCLING

In the event it is not practical to repair your

chain saw, be sure to follow local and country codes for recycling plastic and metallic

materials when disposing of the unit.

STORAGE

If storing saw for more than 30 days, follow

steps below.

1. Drain oil tank.

2. Remove and clean guide bar and chain.

Clean guide bar and chain by soaking

in petroleum based solvent or mild soap

and water mixture.

3. Dry guide bar and chain.

4. Place chain in container filled with oil.

This will prevent rust.

5. Wipe a thin coating of oil over surface

of guide bar.

6. Wipe off outside of saw body. Do this

with soft cloth dampened with a mild

soap and water mixture.

7. Store chain saw

• in a high or locked place, out of

children’s reach

• in a dry place

• in a carrying case or with scabbard

over guide bar

REPLACEMENT

PART S

WARNING: Use only replacement parts described in this

manual. Use of other parts could

damage saw or injure operator.

Purchase these parts from your local dealer.

Part Number Description

097570-01 Guide bar, 350 mm

091374-02S Chain, 350 mm

107713-01 Drive sprocket

Figure 23 - Round Off Front Corner Of

Depth Gauge

14

102891

Page 17

OWNER’S MANUAL

TROUBLESHOOTING

OBSERVED FAULT

Saw runs, but does not cut

Saw does not cut unless heavily forced.

Cutting produces only sawdust with few

large chips

Saw runs slow. Saw stalls easily

Motor of saw does not run when you squeeze

trigger

WARNING: Unplug chain saw from power source before servicing.

Severe injury or death could occur from electrical shock or body contact

with moving chain.

POSSIBLE CAUSE

1. Chain assembled backwards on guide

bar

1. Chain is dull

1. Low power supply voltage

1. Switch lockout not pressed in to release

trigger

2. Chain brake activated

3. Extension cord connections loose

4. Open line fuse or circuit breaker

5. Bad motor brushes

REMEDY

1. See Assembly, pages 6 and 7

1. See Sharpening Your Saw Chain, pages

13 and 14

1. Extension cord wire size too small. See

Extension Cords, page 8

1. Press in switch lockout before squeezing trigger

2. Release trigger and move front hand

guard back towards rear of saw

3. Check cord connections

4. Check line fuse or circuit breaker

5. Contact authorized service person

Motor of saw runs, but chain does not move

Chain does not get oil

Chain comes off guide bar

Saw smokes

Saw leaks oil

Chain brake does not stop saw chain

1. Open wiring circuit on saw

2. Gear train failure

1. Clogged oil slot in guide bar

2. Oil is too thick

1. Chain is loose

2. Guide bar and chain not assembled right

1. Saw damaged. Do not use saw

1. Oil cap is not secure

1. Brake failure

1. Contact authorized service person

2. Contact authorized service person

1. Remove guide bar and clean oil slot

2. Use correct weight of oil. See Filling Oil

Tank, page 7

1. Tighten chain. See Saw Chain Tension

Adjustment, page 8

2. See Assembly, pages 6 and 7

1. Contact authorized service person

1. Tighten oil cap.

when not in use

1. Contact authorized service person

Note:

Empty oil tank

102891

15

Page 18

WARRANTY INFORMATION

KEEP THIS WARRANTY

Model ___________________________________

Date Purchased ___________________________

Always specify model and serial numbers when writing the factory.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standard written warranty.

We make no other warranty, expressed or implied.

LIMITED WARRANTY

ELECTRIC CHAIN SAW

This product is warranted to be free from defects in materials and workmanship for six (6) months from the date of first purchase when

operated and maintained in accordance with instructions. This warranty is extended only to the original retail purchaser.

This warranty covers only the cost of parts required to restore this to proper operating condition. Transportation and incidental costs

associated with warranty repairs are not reimbursable under this warranty.

Warranty service is available only through authorized dealers or service centres.

This warranty does not cover commercial, industrial, or rental usage, nor does it apply to parts that are not in original condition because

of normal wear and tear, or parts that fail or become damaged as a result of misuse, accident, lack of proper maintenance, tampering, or

alteration.

The warrantor assumes no responsibility for indirect, incidental or consequential damages.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF ANY OTHER WARRANTY EITHER EXPRESSED OR IMPLIED,

INCLUDING WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Importer:

DESA Europe B.V.

Innsbruckweg 144

3047 AH Rotterdam

Postbus 11158

Manufacturer:

DESA Specialty Products™

2701 Industrial Drive

Bowling Green, KY 42101

U.S.A.

3004 ED Rotterdam

The Netherlands

Page 19

®

ELEKTRISCHE KETTINGZAAG

GEBRUIKERSHANDLEIDING

®

MODELL

TYP

BELANGRIJK: Lees deze handleiding en zorg dat u hem begrijp alvorens

deze kettingzaag in elkaar te zetten en te bedienen. Verkeerd gebruik van

deze zaag kan ernstige verwondingen veroorzaken. Bewaar deze handleiding voor toekomstig gebruik.

100271-01

EL-4

230V~ 50Hz 1450W

Page 20

®

ELEKTRISCHE KETTINGZAAG

Lees de handleiding

Niet in regen of nat weer gebruiken

Stekker onmiddellijk verwijderen indien kabel beschadigd wordt

SYMBOLENBETEKENIS

Houd de kettingzaag met beide handen vast

Pas op voor terugslag

Oog- en gehoorbescherming verplicht

Waarschuwingen en veiligheidsinformatie zijn opgenomen in alle delen van

deze handleiding

Besteed bijzondere aandacht aan de waarschuwingen. Hieronder vindt u de

definities voor de veiligheidsinformatie in deze handleiding.

WAARSCHUWING duidt op een gevaar dat ernstig persoonlijk letsel, de dood

of ernstige materiële schade tot gevolg kan hebben als de waarschuwing

genegeerd wordt.

VOORZICHTIG duidt op een gevaar dat persoonlijk letsel of materiële schade tot

gevolg kan hebben als de waarschuwing genegeerd wordt.

2

102891

Page 21

GEBRUIKERSHANDLEIDING

WAARSCHUWIN-

GEN

Lees alle

gina 3, 4, en 5 en zorg dat u ze

begrijpt. Verkeerd gebruik van deze

kettingzaag kan tot ernstige of fatale gevolgen leiden als gevolg van

brand, een elektrische schok, het

aanraken van de draaiende ketting

of vallende takken.

Waarschuwingen

ALVORENS DE

KETTINGZAAG TE

GEBRUIKEN

1. Lees deze handleiding en zorg dat u

hem begrijpt alvorens de kettingzaag

te gebruiken.

2. Zaag uitsluitend hout met de kettingzaag. Gebruik de zaag niet voor het

zagen van ander materiaal.

3. De kettingzaag mag alleen gebruikt

worden door volwassenen die met de

bediening en de werking ervan op de

hoogte zijn. Personen die voor het eerst

de kettingzaag gebruiken, dienen praktische instructie in het gebruik ervan te

ontvangen naast het lezen van deze

handleiding. Oefen door stammen te

zagen die op een zaagbok liggen.

4. Gebruik uitsluitend elektrische voeding

zoals aangegeven op het modelplaatje

van de zaag.

5. Gebruik uitsluitend verlengsnoeren

geschikt voor gebruik buitenshuis. Zie

pagina 9 voor verlengsnoerspecificaties.

6. Gebruik de kettingzaag niet

• terwijl u onder de invloed bent van

alcohol, medicijnen of drugs

• in de regen of in een natte of voch-

tige werkomgeving

• in de buurt van brandbare vloeistof-

fen of gassen

• als hij beschadigd is, niet goed is bij-

gesteld of niet volledig in elkaar gezet is

• als hij niet met de trekker aan en uit

kan worden gezet. De ketting moet

tot stilstand komen als de trekker

wordt losgelaten. Laat een defekte

schakelaar vervangen door bevoegd

onderhoudspersoneel.

op pa-

• als u moe of gehaast bent

• terwijl u in een boom zit of op een

ladder staat tenzij u desbetreffende

training gevolgd hebt.

7. Draag tijdens het werken met de

kettingzaag goed passende kleding.

Draag geen losse kleding en sieraden

daar deze door de draaiende ketting

kunnen worden meegenomen.

8. Draag tijdens het werken met de

kettingzaag de onderstaande beschermende uitrusting:

• heavy-duty handschoenen (draag

rubberen handschoenen voor het

werken buitenshuis)

• veiligheidsschoenen met stalen neus

en anti-slip zolen

• oogbescherming zoals een

veiligheidsbril of een gelaatsmasker

• een veiligheidshelm

• gehoorbeschermers of oordopjes

• een haarnetje voor lang haar

• een stofmasker (in een stoffige werk-

omgeving).

9. Doe altijd het volgende alvorens met

zagen te beginnen:

• maak de werkomgeving vrij

• zorg dat u stevig staat

• zorg dat u weet in welke richting u

van de vallende boom wegloopt.

10. Controleer de boom alvorens hem om

te zagen. Zorg dat er geen dode takken

zijn die tijdens het zagen op u kunnen

vallen.

11. De karakteristieke gewogen (A-filter)

geluidsniveaus bij volle belasting tijdens het zagen van hout bij tests uitgevoerd conform ISO 7182 zijn:

Geluidsdrukniveau 95 DB(A)

Geluidssterkteniveau 100 DB(A)

12. De karakteristieke trilling van hand/

arm bij volle belasting tijdens het zagen van hout bij tests uitgevoerd conform ISO/DIS 7505 is 23,8 M/S2.

TERUGSLAG

WAARSCHUWING: Vermijd

terugslag. Terugslag kan u de

controle over de kettingzaag doen

verliezen. Terugslag kan ernstig

of fataal letsel tot gevolg hebben.

Veiligheidsvoorzieningen tegen

terugslag

Deze zaag is voorzien van een ketting en een

kettinggeleider die speciaal voor gereduceerd terugslaggevaar ontworpen zijn. Beide

voorzieningen beperken de kans op terugslag. Terugslagen kunnen zich nochtans

evengoed voordoen. Laat het uiteinde van

de kettinggeleider niet met voorwerpen in

aanraking komen wanneer de ketting draait.

Deze zaag is voorzien van een kettingrem.

Wanneer een terugslag zich voordoet, wordt

de voorste handbeschermer naar voren bewogen door de rug van de linkerhand van de

gebruiker. Op deze manier wordt de ketting

snel tot stilstand gebracht wat de kans op

ernstig letsel beperkt.

Houd de kettingzaag nooit bij de voorste

handbeschermer vast.

Oorzaken van terugslag

Terugslag kan zich voordoen wanneer het uiteinde van de kettinggeleider een voorwerp

raakt terwijl de ketting in beweging is. Als een

snijtand achter het voorwerp blijft hangen, resulteert dit in een krachtige achterwaartse beweging die het uiteinde van de zaag naar boven

en/of in de richting van de gebruiker werpt.

Terugslag kan zich eveneens voordoen wanneer de ketting aan het uiteinde van de

kettinggeleider in het hout wordt vastgeknepen. Het resultaat is een plotselinge

achterwaartse beweging die de zaag recht

achteruit slaat.

De volgende stappen kunnen behulpzaam

zijn bij het beperken van het terugslaggevaar:

• Houd de kettingzaag stevig met beide

handen vast waarbij de duimen tegenover

de vingers rond de handgreep liggen.

• Zorg dat alle veiligheidsvoorzieningen

zijn aangebracht en dat ze naar behoren

werken.

• Reik niet te ver naar voren en zaag niet

boven schouderhoogte.

• Zorg dat u stevig staat en uw balans niet

verliest.

• Zorg dat u zich enigszins links van de

kettingzaag bevindt. Op deze manier bent

u niet in het verlengde van de ketting van

de zaag.

wordt vervolgd

102891

3

Page 22

®

ELEKTRISCHE KETTINGZAAG

WAARSCHUWIN-

GEN

Vervolg

• Laat het uiteinde van de kettinggeleider

niet met voorwerpen in aanraking komen

wanneer de ketting draait (zie Figuur 1).

• Probeer nooit om twee stammen tegelijk

door te zagen. Zaag slechts één stam tegelijk.

• Begraaf het uiteinde niet in het hout.

Steek het uiteinde van de kettinggeleider

niet met draaiende ketting in een boom.

• Let voortdurend op het verschuiven van de

stam of andere omstandigheden die kunnen

leiden tot het vastknijpen van de ketting.

•Wees uiterst voorzichtig als u de kettingzaag weer inbrengt in een bestaande snede.

• Gebruik de originele ketting en de

kettinggeleider die speciaal voor gereduceerd terugslaggevaar ontworpen zijn.

Ve rvang uitsluitend met onderdelen die

in deze handleiding vermeld zijn.

• Gebruik nooit een zaag met een botte of

losse ketting. Gebruik altijd een ketting

die voldoende scherp is en goed is aangespannen.

Kettingzaagonderhoud en

terugslagveiligheid

Volg de onderhoudsinstructies in deze handleiding. Het schoonmaken van de zaag en

het onderhouden van de ketting en de kettinggeleider kunnen het risiko van terugslag

beperken. Inspecteer de zaag na ieder gebruik en voer het nodige onderhoud uit.

op:

Zelfs met het regelmatig slijpen van de

snijtanden kan het risiko van terugslag na

verloop van tijd groter worden.

DUWEN EN TREKKEN

WAARSCHUWING: Vermijd het

duwen en trekken van de kettingzaag. Duwen en trekken kunnen u

de controle over de kettingzaag

doen verliezen en kunnen ernstig

letsel tot gevolg hebben.

Let

Richting

Kwadrant

90˚

Figuur 1 - Voorbeeld van terugslaggevaar.

Laat het uiteinde van de kettinggeleider

niet met een voorwerp in aanraking komen

wanneer de ketting draait

Laat het

uiteinde van de

kettinggeleider

hier niet raken

Oorzaken van duwen en trekken

Duwen kan voorkomen tijdens het zagen

met de bovenkant van de kettinggeleider.

Duwen wil zeggen dat de zaag terugduwt in

de richting van de gebruiker. Trekken kan

voorkomen tijdens het zagen met de onderkant van de kettinggeleider. Trekken houdt

in dat de zaag zich in het hout trekt van de

gebruiker af. Deze gevaren kunnen zich

voordoen als de ketting door het hout vastgeknepen wordt, vast komt te zitten of een

voorwerp raakt dat niet van hout is.

De volgende stappen kunnen behulpzaam

zijn bij het beperken van het risiko van

duwen en trekken:

• Houd de kettingzaag stevig met beide

handen vast waarbij de duimen tegenover

de vingers rond de handgrepen liggen.

• Reik niet te ver naar voren en zaag niet

boven schouderhoogte.

• Zorg dat u stevig staat en uw evenwicht

niet verliest.

• Zorg dat u zich enigszins links van de

kettingzaag bevindt. Op deze manier bent

u niet in het verlengde van de ketting van

de zaag.

• Laat de zaag op volle snelheid draaien

alvorens met zagen te beginnen.

• Zorg tijdens het zagen dat het getande

stootblok tegen het hout ligt (alleen voor

trekken). Zie Identificatie van onderde-

len op pagina 7 om het getande stootblok

te vinden.

• Probeer nooit om twee stammen tegelijk door te zagen. Zaag slechts één stam

tegelijk.

• Let voortdurend op het verschuiven van

de stam of andere omstandigheden die

kunnen leiden tot het vastknijpen van de

ketting.

•Wees uiterst voorzichtig als u de

kettingzaag weer inbrengt in een

bestaande snede.

• Verbuig de zaag niet als u hem terugtrekt

uit de onderkant van een tak.

• Gebruik wiggen van plastic, hout of een

legering om een snede open te houden

(nooit wiggen van staal of ijzer).

MET DE KETTINGZAAG

WERKEN

1. Houd uw aandacht op het werk. Ge-

bruik gezond verstand tijdens het werken met kettingzagen.

2. Houd de werkomgeving schoon. Een

rommelige werkomgeving leidt tot ongelukken.

3. Wees u tijdens het zagen bewust van

het verlengsnoer. Zorg dat u niet over

het snoer struikelt.

4. Houd kinderen, omstanders en dieren

weg van de kettingzaag en het verlengsnoer. Alleen de gebruiker van de

kettingzaag mag zich in de werkomgeving bevinden.

5. Zaag geen bomen om tenzij u daarin

getraind bent of over hulp van een deskundige beschikt.

6. Indien twee of meerdere personen te-

gelijkertijd bezig zijn met het zagen van

stammen en bomen, moet geruime onderlinge afstand bewaard worden. Bewaar een onderlinge afstand die minstens gelijk is aan tweemaal de hoogte

van de boom die omgezaagd wordt.

7. Zet het te zagen hout vast met klem-

men of ondersteun het met blokken.

8. Houd de kettingzaag stevig met twee

handen vast. Bedien de zaag nooit met

één hand. Gebruik de handbeschermer

nooit als handgreep.

4

102891

Page 23

GEBRUIKERSHANDLEIDING

WAARSCHUWIN-

GEN

Vervolg

9. Houd de vingers altijd uit de buurt van

de trekker tot u klaar bent om te zagen.

10. Zorg voor het starten van de kettingzaag dat de ketting met niets in aanraking is.

11. Ve rmijd lichaamscontact met voorwerpen die zich in de grond bevinden, zoals bijv. pijpleidingen, hekken en metalen palen.

12. Houd alle lichaamsdelen uit de buurt

van de draaiende kettingzaag.

13. Forceer de kettingzaag niet. Zaag uitsluitend met lichte kracht.

14. Wees uiterst voorzichtig bij het zagen

van kleine takken. Dunne takken kunnen in de ketting verstrikt raken en in

de richting van de gebruiker slaan. U

zou tevens uit evenwicht kunnen worden getrokken.

15. Wees uiterst voorzichtig bij het zagen

van takken die onder spanning staan.

Pas op voor takken die terugspringen.

Wanneer de spanning wordt opgeheven, kan de tak terugspringen en de

gebruiker van de kettingzaag raken met

ernstig of fataal letsel als gevolg.

16. De kettingrem mag niet gebruikt worden voor het stilzetten van de ketting.

Breng de ketting tot stilstand door de

trekker los te laten.

17. Ga als volgt te werk bij het dragen van

de kettingzaag:

•Verwijder de stekker uit de voedings-

bron.

• Draag de zaag aan de voorste hand-

greep (gebruik de voorste handbeschermer nooit als handvat).

• Houd de vingers uit de buurt van de

trekker.

• Draag de zaag met de kettinggeleider

en de ketting naar achteren gericht.

• Breng de beschermkap aan.

WAARSCHUWING: Sommige

stofdeeltjes, voortkomend van

mechanisch schuren, zagen, slijpen, boren en andere bouwactiviteiten, bevatten chemische

bestanddelen waarvan bekend is

(in de Staat van Californië) dat ze

kankerverwekkend zijn of

geboorteafwijkingen of andere

voortplantingsproblemen kunnen veroorzaken. Sommige voorbeelden van dergelijke chemische stoffen zijn:

• lood afkomstig van lood-

houdende verven

• kristallijn siliciumdioxide af-

komstig van bakstenen, cement en andere

metselwerkproducten

• arsenicum en chroom afkom-

stig van chemisch behandeld

timmerhout

Het risico door blootstelling aan

deze producten is veranderlijk,

en hangt af van hoe vaak u dit

soort werk verricht. Om u minder

bloot te stellen aan deze chemische stoffen dient u in een goed

verluchte zone te werken en gebruik te maken van goedgekeurde

veiligheidsvoorzieningen, zoals

stofmaskers die speciaal ontworpen zijn om microscopisch kleine

deeltjes uit te filteren.

DE KETTINGZAAG

ONDERHOUDEN EN

OPBERGEN

1. Verwijder de stekker van de kettingzaag

uit het stopcontact

•wanneer deze niet in gebruik is

• alvorens de zaag te dragen

• alvorens onderhoud uit te voeren

• alvorens accessoires of onderdelen

aan te brengen of te verwijderen.

2. Controleer de zaag voor en na ieder

gebruik. Controleer de zaag nauwkeurig als de handbeschermer of een ander onderdeel beschadigd is. Controleer op schade die gevaar voor de gebruiker kan opleveren of de werking

van de zaag beïnvloedt. Controleer de

uitlijning van draaiende onderdelen en

let op voor eventueel aanlopen van bewegende delen. Controleer de werking

van de trekker. Controleer de kettingrem. Controleer op defekte of beschadigde onderdelen. Gebruik de kettingzaag niet als schade de werking en veiligheid beïnvloeden. Laat schade aan

de kettingzaag repareren door een bevoegd onderhoudsmonteur.

3. Voer regelmatig onderhoudswerkzaamheden aan de kettingzaag uit.

• Laat de kettingzaag nooit door de

regen nat worden.

• Houd de ketting scherp, schoon en

goed geolied.

•Volg de instructies in deze handlei-

ding voor het slijpen van de ketting.

• Houd de handgrepen droog, schoon

en vrij van olie.

• Houd alle schroeven en moeren vast

aangedraaid.

• Controleer regelmatig het netsnoer.

Laat eventueel repareren door een bevoegde onderhoudsmonteur.

•Draag de kettingzaag nooit aan het

snoer.

•Trek nooit met een ruk aan het snoer

om de stekker uit het stopcontact te

verwijderen.

• Houd het snoer uit de buurt van hitte,

olie en scherpe randen.

• Controleer regelmatig de verleng-

snoeren en vervang indien beschadigd.

4. Gebruik tijdens het uitvoeren van

onderhoudswerk-zaamheden uitsluitend originele vervangingsonderdelen.

5. Bewaar de kettingzaag altijd:

• op een hoge of afgesloten plaats, bui-

ten bereik van kinderen

• op een droge plaats

• in een draagtas of met de bescherm-

kap over de kettinggeleider.

Bewaar deze handleiding voor toekomstig

gebruik. Deze handleiding is uw gids voor

het veilig en correct gebruik van deze

kettingzaa.

102891

5

Page 24

®

ELEKTRISCHE KETTINGZAAG

BENAMINGEN EN

TERMEN

Aandrijfwiel - Het getande onderdeel dat

de ketting aandrijft.

Achterste handgreep - De handgreep

die zich het verste naar achteren bevindt.

Duwen (terug-, knijpen) - Krachtige achterwaartse beweging van de kettingzaag.

Duwen kan voorkomen wanneer de ketting

langs de bovenkant van de kettinggeleider

vastgeknepen of vastgehouden wordt of een

voorwerp in het hout raakt.

Getand stootblok - Het getande gedeelte

dat vooraan in de zaag naast de kettinggeleider

ligt. Het stootblok moet tijdens het zagen in

contact zijn met het hout. Het dient om tijdens

het zagen een vaste positie aan te houden.

Handbeschermer (voorste handgreep) - Een beschermplaat tussen de voor-

ste handgreep en de kettinggeleider die de

hand beschermt tijdens het zagen. Als zich

een terugslag voordoet, wordt de voorste

handbeschermer naar voren bewogen door

de rug van de linkerhand van de gebruiker.

Op deze manier wordt de ketting snel tot

stilstand gebracht wat de kans op ernstig

letsel beperkt.

Ketting - Een door de motor aangedreven

ketting met snijtanden die over de kettinggeleider loopt en waarmee hout gezaagd

wordt.

Ketting voor gereduceerde terugslag

- Een ketting die de kans op terugslag ver-

mindert zoals vereist door ANSI B175.1.

Kettinggeleider - Een metalen onderdeel

dat uit de zaag naar voren steekt en de

ketting steunt en geleidt.

Kettinggeleider voor gereduceerde

terugslag - Een kettinggeleider waarvan

is aangetoond dat hij het terugslaggevaar

aanmerkelijk verkleint.

Korten - Het zagen van een boomstam in

kleinere stukken.

Motorgedeelte - De kettingzaag zonder

kettinggeleider en ketting.

Normale zaagpositie - Positie die wordt

aangenomen voor het aanbrengen van gebruikelijke zaagsneden.

Onderste snede - Een opwaartse snede

aan de onderkant van een tak of een stam. De

snede wordt met de bovenkant van de

kettinggeleider aangebracht terwijl men in

de normale zaagpositie staat.

Schakelaar - Het onderdeel dat, wanneer

ingedrukt, het elektrische circuit sluit dat de

motor van de zaag in werking stelt.

Schakelaaroverbrenging - Het mechanisme waarmee de beweging van de trekker

wordt overgebracht naar de schakelaar.

Schakelaarblokkering - Een mechanisme waarmee onopzettelijke werking van

de zaag wordt voorkomen.

Smering - Het systeem om olie aan te

brengen op de ketting en de kettinggeleider.

Snoeien - Het verwijderen van takken van

een levende boom.

Takken verwijderen - Een gevelde boom

van takken ontdoen.

Terugslag (kickback) - De opwaartse of

achterwaartse beweging van de kettingzaag

die zich voordoet wanneer het uiteinde van

de kettinggeleider met een voorwerp in aanraking wordt gebracht terwijl de zaag draait.

De kettinggeleider beweegt zich opwaarts en

achterwaarts in de richting van de gebruiker.

Trekker - Het deel van de schakelaar dat

met de vinger in aanraking komt voor het

aan en uit zetten van de kettingzaag. De

trekker indrukken stelt de zaag in werking;

de ketting valt automatisch stil wanneer de

trekker wordt losgelaten.

Uiteinde (van de kettinggeleider) -

Het uiterste deel van de kettinggeleider waar

de ketting van richting verandert.

Valkerf - De gezaagde inkeping die bepaalt

in welke richting de boom zal vallen.

Vellen - Het omzagen van een boom.

Velsnede - De laatste snede tijdens het

vellen van een boom die tegenover de valkerf in de boom wordt aangebracht.

Vervangingsketting - Ketting die voldoet aan ANSI B175.1 bij gebruik met een

specifieke zaag. Het is mogelijk dat niet aan

ANSI-eisen wordt voldaan bij gebruik met

een ander model zaag.

Voorste handgreep - De handgreep die

zich het verste naar voren bevindt.

UITPAKKEN

1. Verwijder alle artikelen uit de verpakking.

2. Controleer alle artikelen op eventuele

transportschade. Als u beschadigde artikelen aantreft of als er onderdelen

vermist worden, dient u onmiddellijk

contact op te nemen met de dealer waar

de kettingzaag gekocht is.

6

102891

Page 25

GEBRUIKERSHANDLEIDING

IDENTIFICATIE VAN

ONDERDELEN

Achterste

handgreep

Getand

Achterste

handbeschermer

Netsnoer

Oliepeilkijkgat (in de behuizing;

verborgen door de voorste handgreep)

Voorste

handgreep

stootblok

Voorste

handbeschermer

Ketting

Kettinggeleider

Oliedop met

Smeerknopje

Uiteinde van de

kettinggeleider

Scabbard

Schakelaarblokkering

BELANGRIJK:

Zorg dat u het stelblokje in het ovale bijstelgat in de

kettinggeleider aanbrengt.

5. Draai de moeren terug aan op de bouten die door de kettinggeleider steken.

BELANGRIJK:

Draai de moeren

slechts met de hand aan. Zorg dat het

stelblokje in het ovale bijstelgat in de

kettinggeleider aangebracht is.

6. Leg de ketting rond het aandrijfwiel en

vervolgens langs de groef in de bovenkant van de kettinggeleider en rond het

uiteinde van de zaag.

Let op:

Zorg dat

de snijranden van de ketting in de gewenste richting wijzen. Breng de ketting zodanig aan dat de snijtanden langs

de bovenkant van de kettinggeleider

naar het uiteinde van de zaag gericht

zijn (zie Figuur 3, pagina 8).

VOORZICHTIG: De ketting

mag niet achterstevoren aangebracht worden. Als de ketting achterstevoren wordt aangebracht,

treedt overmatig trillen op en zal

de kettingzaag niet zagen.

7. Stel de spanning van de ketting bij. Volg

de instructies in De spanning van de

ketting bijstellen op pagina 8 en 9.

8. Als de kettingzaag een zijkap heeft die

uit twee stukken bestaat, moet vervolgens de aandrijfwielkap worden aangebracht.

Motorbehuizing

Figuur 2 - Elektrische kettingzaag

MONTAGE

WAARSCHUWING: De snijtanden van de ketting zijn scherp. Draag

handschoenen voor het omgaan

en hanteren van de ketting.

BELANGRIJK: De ketting mag tijdens het in elkaar zetten van de

kettingzaag niet in een bankschroef worden vastgezet.

102891

Trekker

1. Leg de ketting plat neer.

2. Verwijder de moeren van de bouten die

door de kettinggeleider steken (zie Figuur 3, pagina 8).

3. Draai de stelschroef naar links (zie Figuur 4, pagina 8) tot het stelblokje zich

achter de stelplaat bevindt.

4. Breng de kettinggeleider aan op de behuizing van de kettingzaag. Plaats de

achterkant van de kettingzaag tussen de

stelplaat en de aandrijfwielsteun.

wordt vervolgd

7

Page 26

®

ELEKTRISCHE KETTINGZAAG

MONTAGE

Vervolg

Aandrijfwiel

Aandrijfwielsteun

In de richting van

het uiteinde van de

kettinggeleider

E. Bouten van de

kettinggeleider

Moeren van de

kettinggeleider

Bijstelgat

Snijrand

Kettinggeleider

Ketting

OLIE BIJVULLEN

1. Draai de olievuldop los.

2. Vu l de olietank met motorolie (SAE-30).

Let op:

Gebruik bij buitentemperaturen

onder -1˚C SAE-10 olie en bij temperaturen boven 24˚C SAE-40 olie.

3. Breng de vuldop onmiddellijk na het

bijvullen weer op de tank aan en draai

hem stevig vast om het sijpelen van olie

uit de tank te voorkomen.

4. Veeg eventueel gemorste olie rond de

vuldop weg.

Let op:

Het is normaal dat olie uitsijpelt als

de zaag niet wordt gebruikt. Laat daarom na

elk gebruik het oliereservoir leeglopen.

DE SPANNING VAN

DE KETTING BIJSTELLEN

WAARSCHUWING: Verwijder

de stekker van de kettingzaag uit

het stopcontact alvorens de spanning van de ketting bij te stellen.

Figuur 3 - De kettinggeleider, ketting en de handbeschermer monteren

Stelplaat

Stelblokje

Stelschroef

Aandrijfwielsteun

Figuur 4 - Plaatsing van onderdelen bij het monteren van de kettinggeleider

WAARSCHUWING: De snijranden van de ketting zijn scherp.

Draag handschoenen voor het

hanteren van de ketting.

WAARSCHUWING: Zorg dat

de ketting altijd correct gespannen is. Een losse ketting leidt gemakkelijker tot terugslag of kan

uit de groef van de kettinggeleider

lopen wat tot persoonlijk letsel

van de gebruiker kan leiden of de

ketting kan beschadigen. Een

losse ketting leidt tevens tot snellere slijtage van de ketting, de

kettinggeleider en het aandrijfwiel.

Let op:

reeds in elkaar gezet zijn, is de ketting door

de fabrikant gespannen. Nieuwe kettingen

rekken in het begin uit. Controleer een

nieuwe ketting na de eerste paar minuten

van gebruik. Laat de ketting afkoelen. Volg

de onderstaande stappen voor het aanspannen van de ketting.

Bij kettingzagen die bij verkoop

8

102891

Page 27

GEBRUIKERSHANDLEIDING

DE SPANNING VAN

DE KETTING BIJSTELLEN

Vervolg

1. Zorg vóór het aanspannen van de ketting dat de moeren waarmee de kettinggeleider vastzit, slechts met de hand

zijn aangedraaid (zie Figuur 3, pagina

8). Zorg tevens dat het stelblokje in het

ovale bijstelgat van de kettinggeleider

zit (zie Figuur 3 en 4, pagina 8).

2. Draai de stelschroef naar rechts (met

de klok mee) tot de ketting gespannen

is (zie Figuur 5).

Let op:

sen de schakels van de ketting en de

onderkant van de kettinggeleider (zie

Figuur 6).

3. Beweeg de ketting met de hand heen

en weer (zorg dat u handschoenen

draagt). De ketting moet zonder problemen heen en weer bewogen kunnen

worden. Als de ketting niet vrij heen

en weer kan bewegen, dient u de stelschroef iets los te draaien (linksom).

4. Draai als de spanning eenmaal correct

is, de moeren van de kettinggeleider

vast aan. Als u dit niet doet, zal de

kettinggeleider verschuiven waardoor

de ketting los komt te zitten. Dit verhoogt het risiko van terugslag en kan

de zaag beschadigen.

kettingen rekken in het begin uit. Controleer een nieuwe ketting na de eerste

paar minuten van gebruik. Laat de ketting afkoelen. Span de ketting aan.

Er mag geen speling zijn tus-

Let op:

Nieuwe

Moeren van de

kettinggeleider

Kettinggeleider

Kettinggeleider

Speling

Losse

ketting

Figuur 6 - De ketting aanspannen

Correcte

spanning

DE KETTINGZAAG

BEDIENEN

WAARSCHUWING: Lees deze

gebruikershandleiding alvorens

de kettingzaag te gebruiken en

zorg dat u hem begrijpt. Lees alle

Waarschuwingen

en 5, en zorg dat u ze begrijpt.

Verkeerd gebruik van deze

kettingzaag kan tot ernstige of

fatale gevolgen leiden als gevolg

van brand, een elektrische schok,

het aanraken van de draaiende

ketting of vallende takken.

VERLENGSNOEREN

De kettingzaag mag uitsluitend met een

deugdelijk verlengsnoer gebruikt worden.

Gebruik een HO7RN verlengsnoer van minimaal 1,5 mm2 voor afstanden onder 30 m.

Het verdient aanbeveling om een geaard

verlengsnoer te gebruiken.

Gebruik een verlengsnoer dat voldoende

vermogen heeft voor de stroom die de zaag