Page 1

ELECTRIC CHAIN SAW

OWNER’S MANUAL

®

®

MODELS

LNT-2: 076728K, 099178H, 100089-06, 100089-08, & 107709-01

EL-7: 075762J, 098031J, 099039J, 100089-04, 100089-05,

100089-07, & 107714-02

Pole Saw: 104316-04 (8"), 106890-01(10")

Pole Saw Assembly: 104317 (8"), 106821 (10")

IMPORTANT: Read and understand this manual before assembling or

operating this chain saw. Improper use of saw can cause severe

injury. Keep this manual for future reference.

®

Page 2

®

ELECTRIC CHAIN SAW

SAFETY

WARNINGS

Make certain you read and understand all

pages 2 and 3. Improper use of

this chain saw can cause severe

injury or death from fire, electrical shock, body contact with

moving chain, or falling wood.

BEFORE OPERATING SAW

1. Read and understand this owner’s

manual before operating chain saw.

2. Watch what you are doing. Use common sense. Do not operate saw when

you are tired.

3. Use chain saw for cutting wood only.

Do not use chain saw for purpose not

intended. Do not use for cutting plastic, masonry, etc.

4. Only well-instructed adults should operate chain saw. Never allow children

to operate chain saw.

5. Use only electrical voltage noted on

model plate of chain saw.

6. Use only extension cords marked for

outdoor use. See page 8 for extension

cord requirements.

7. Do not operate chain saw

• while under the influence of alcohol,

medication, or drugs

• in rain or in damp or wet areas

• where highly flammable liquids or

gases are present

• if saw is damaged, adjusted wrong,

or not fully and securely assembled

• if trigger does not turn saw on and off.

Chain must stop moving when you

release trigger. Have faulty switch

replaced by authorized service center.

• while in a hurry

• while in tree or on a ladder unless

trained to do so

8. Wear snug-fitting clothes when operating chain saw. Do not wear loose

clothing or jewelry. They can get caught

in moving saw chain.

9. Wear the following safety gear when

operating chain saw.

• heavy-duty gloves (wear rubber

gloves when working outdoors)

Safety Warnings

on

• steel-toed safety footwear with nonskid soles

• eye protection such as safety glasses,

goggles, or face screen

• safety hard hat

• ear mufflers or ear plugs

• hair covering to contain long hair

• face or dust mask (if working in dusty

areas)

10. Before cutting, always provide the following:

• clear work area

• secure footing

• planned retreat path from falling tree

11. Inspect tree before cutting down. Make

sure there are no dead limbs or branches

that may fall on you.

12. To reduce the risk of electric shock, this

saw has a polarized plug (one blade is

wider than the other). This plug will fit

in a polarized outlet only one way. If

the plug does not fit fully in the outlet

of your extension cord, reverse the

plug. If it still does not fit, a polarized

extension cord will be necessary. Do

not change the plug in any way.

WHILE OPERATING SAW

1. Stay alert. Use common sense while

operating chain saw.

2. Keep work area clean. Cluttered areas

invite injuries.

3. Be aware of extension cord while operating chain saw. Be careful not to trip

over cord. Keep cord away from chain

and operator at all times.

4. Keep children, animals, and bystanders away from chain saw and extension

cord. Only chain saw user should be in

work area.

5. Do not cut down a tree unless you are

trained or have expert help.

6. If two or more persons perform bucking and felling operations at the same

time, provide plenty of distance between operations. Provide distance of

at least twice the height of tree being

felled.

7. Secure wood you are cutting by using

clamps or chocks.

8. Grip chain saw firmly with both hands.

Never operate chain saw with one hand.

Never use hand guard as handle.

9. Keep finger off trigger until ready to

make cut.

10. Before starting chain saw, make sure

chain is not touching anything.

11. To guard against electrical shock, avoid

body contact with grounded objects

such as pipes, fences, and metal posts.

12. Keep all parts of body away from chain

when saw is running.

13. Do not force chain saw while cutting.

Apply light pressure. It will do the job

better and safer at the rate for which it

was intended.

14. Cut small brush and saplings with extreme care. Slender material may catch

in chain and be whipped toward you.

This could also pull you off balance.

15. When cutting limb or tree trunk that is

under tension, use extreme caution. Be

alert for wood springing back. When

wood tension is released, limb could

spring back and strike operator causing severe injury or death.

16. Carry chain saw from one place to another

• with saw stopped and unplugged

• by holding front handle (never use

hand guard as handle)

• with finger off trigger

• with guide bar and chain to rear

WARNING: Some dust created

by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals

known (to the state of California) to

cause cancer, birth defects, or

other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints

• crystalline silica from bricks

and cement and other masonry

products

• arsenic and chromium from

chemically-treated lumber

Your risk from these exposures

varies, depending on how often

you do this type of work. To reduce

your exposure to these chemicals:

work in a well ventilated area, and

work with approved safety equipment, such as those dust masks

that are specially designed to filter

out microscopic particles.

For more information, visit www.desatech.com

2

107990

Page 3

OWNER’S MANUAL

SAFETY

WARNINGS

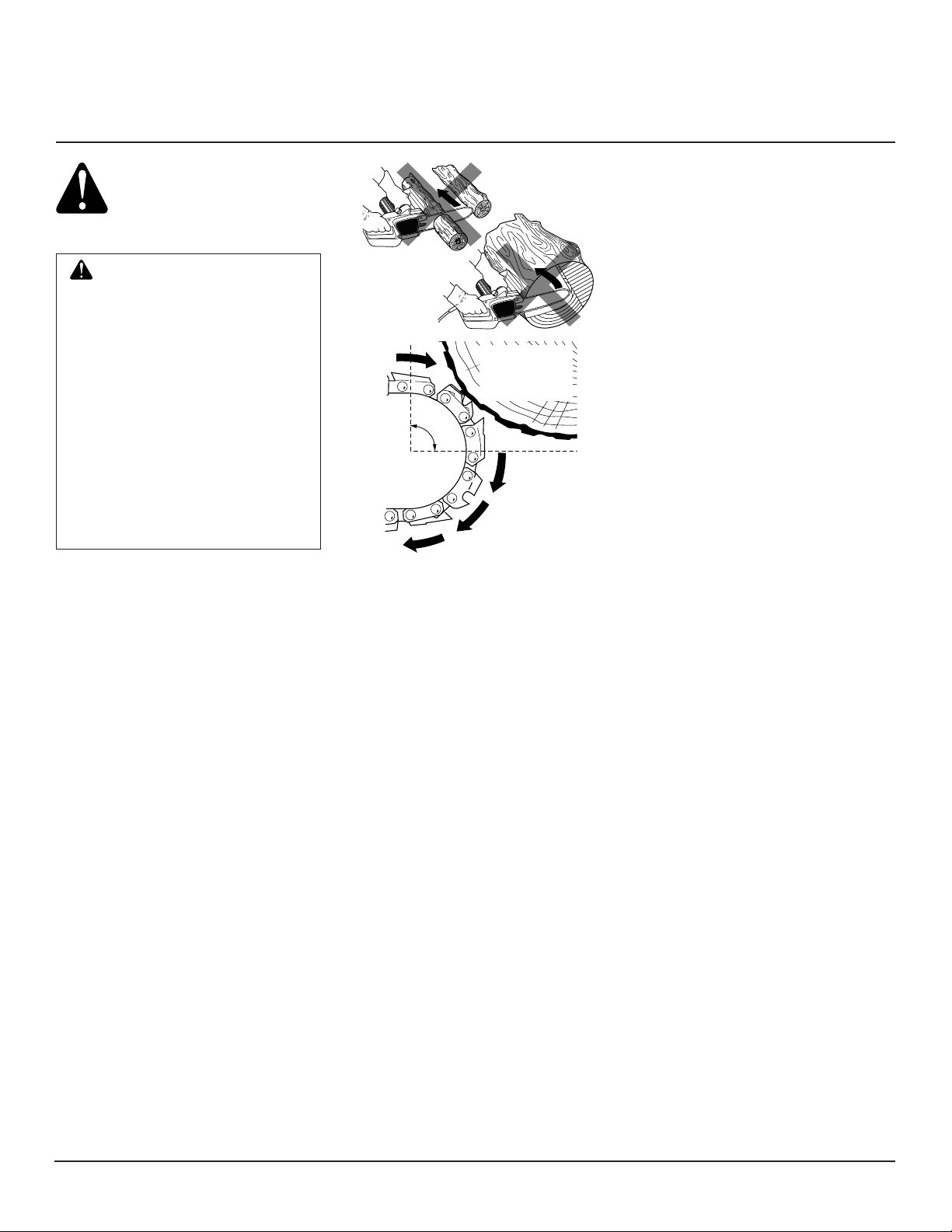

KICKBACK

WARNING: Kickback may occur when the nose or tip of the

guide bar touches an object, or

when the wood closes in and

pinches the saw chain in the cut.

Tip contact in some cases may

cause a lightning fast reverse reaction, kicking the guide bar up

and back towards the operator.

Pinching the saw chain along the

top of the guide bar may push the

guide bar rapidly back towards

the operator. Either of these reactions may cause you to lose

control of the saw which could

result in serious injury to user.

Kickback Safety Devices On

This Saw

This saw has a low-kickback chain and

reduced kickback guide bar. Both items

reduce the chance of kickback. Kickback

can still occur with this saw.

Properly install front hand guard. This item

can reduce injuries from kickback. Follow

assembly instructions on page 6. Do not

remove front hand guard. Do not replace

front hand guard with substitute.

The following steps will reduce the risk of

kickback.

• Use both hands to grip saw while saw is

running. Use firm grip. Thumbs and

fingers must wrap around saw handles.

•Keep all safety items in place on saw.

Make sure they work properly.

• Do not overreach or cut above shoulder

height.

• Keep solid footing and balance at all

times

• Stand slightly to left side of saw. This

keeps your body from being in direct line

with chain.

• Do not let guide bar nose touch anything

when chain is moving (see Figure 1).

Direction

90°

Quadrant

Figure 1 - Kickback Hazard Example: Do

Not Let Nose of Guide Bar Touch Object

While Chain is Moving

•Never try cutting through two logs at

same time. Only cut one log at a time.

• Do not bury guide bar nose or try plunge

cut (boring into wood using guide bar

nose).

•Watch for shifting of wood or other

forces that may pinch chain.

• Use extreme caution when reentering a

previous cut.

• Use low-kickback chain and guide bar

supplied with this chain saw. Only replace these parts with chains and guide

bars listed in this manual.

• Never use dull or loose chain. Keep chain

sharp with proper tension.

• Do not hand sharpen chain on automatic

chain sharpening (Fast Sharp) models.

Do Not Let

Guide Bar

Touch Here

Saw Maintenance and Kickback

Safety

Follow maintenance instructions in this

manual. Proper cleaning of saw and chain

and guide bar maintenance can reduce

chances of kickback. Inspect and maintain

saw after each use. This will increase the

service life of your saw.

proper sharpening, risk of kickback can

increase with each sharpening.

Note:

Even with

MAINTENANCE AND

STORAGE OF CHAIN SAW

1. Unplug chain saw from power source

• when not in use

• before moving from one place to another

• before servicing

• before changing accessories or attachments, such as saw chain and

guard

2. Inspect chain saw before and after each

use. Check saw closely if guard or other

part has been damaged. Check for any

damage that may affect operator safety

or operation of saw. Check for alignment or binding of moving parts. Check

for broken or damaged parts. Do not

use chain saw if damage affects safety

or operation. Have damage repaired by

authorized service center.

3. Maintain chain saw with care.

• Never expose saw to rain.

• Keep chain sharp, clean, and lubri-

cated for better and safer performance.

• Follow steps outlined in this manual

to sharpen chain.

•Keep handles dry, clean, and free of

oil and grease.

• Keep all screws and nuts tight.

• Inspect power cord often. If dam-

aged, have repaired by authorized

service center.

• Never carry chain saw by power cord.

• Never yank power cord to unplug it.

• Keep power cord from heat, oil, and

sharp edges.

• Inspect extension cords often and

replace if damaged.

4. When servicing, use only identical replacement parts.

5. When not in use, always store chain saw

• in a high or locked place, out of

children’s reach

• in a dry place

• in a carrying case or with scabbard

over guide bar

Keep this manual for reference. It is your

guide to safe and proper operation of this

chain saw.

107990

3

For more information, visit www.desatech.com

Page 4

®

ELECTRIC CHAIN SAW

CHAIN SAW NAMES

AND TERMS

Bucking Process of cutting a felled tree or

log into lengths.

Felling Process of cutting down a tree.

Felling Cut Final cut when felling a tree.

Make this cut on opposite side of tree from

notching cut.

Front Handle Located at front of saw body.

Front Hand Guard Shield between front

handle and guide bar. Protects left hand

while using saw.

Guide Bar Metal bar that extends from saw

body. The guide bar supports and guides chain.

Guide Bar Nose Tip or end of guide bar.

Kickback Quick backward and upward

motion of guide bar. Kickback may occur

when tip of guide bar touches an object

while chain is moving. The guide bar will

kick up and back towards operator.

Limbing Process of cutting limb(s) from a

felled tree.

Low-Kickback Chain Chain that reduces

chance of kickback as required by ANS

B175.1.

Normal Cutting Position Stance used while

making bucking and felling cuts.

Notching Cut Notch cut in tree that directs

fall of tree.

Oiler Control System for oiling guide bar

and chain.

Power Head Chain saw without chain and

guide bar. Also known as saw body.

Pushback (Kickback, Pinch) Rapid

pushback of chain saw. Pushback may occur if chain along top of guide bar is pinched,

caught, or contacts a foreign object.

Rear Handle Handle located at rear of saw

body.

Reduced Kickback Guide Bar Guide bar

that reduces chance of kickback.

Replacement Chain Chain that complies

with ANS B175.1 when used with a specific

saw. It may not meet ANS requirements

when used with other saws.

Saw Chain (Chain) Loop of chain having

cutting teeth for cutting wood. The motor

drives chain. The guide bar supports chain.

Spiked Bumper (Spike) Pointed teeth at

front of saw body beside guide bar. Keep

spiked bumper in contact with wood when

felling or bucking. It helps maintain position of saw while cutting.

Sprocket Toothed wheel that drives chain.

Switch Device that completes or interrupts

electrical circuit to motor of saw.

Switch Linkage This device connects switch

to trigger. It moves switch when you squeeze

trigger.

Switch Lockout Device that reduces acci-

dental starting of saw.

Trigger Device that turns saw on and off.

Squeezing trigger turns saw on.

Releasing trigger turns saw off.

Trimming (Pruning) Process of cutting

limb(s) from a living tree.

Undercut An upward cut from underside of

log or limb. This is done while in normal

cutting position and cutting with top of

guide bar.

For more information, visit www.desatech.com

4

107990

Page 5

OWNER’S MANUAL

PRODUCT

IDENTIFICATION

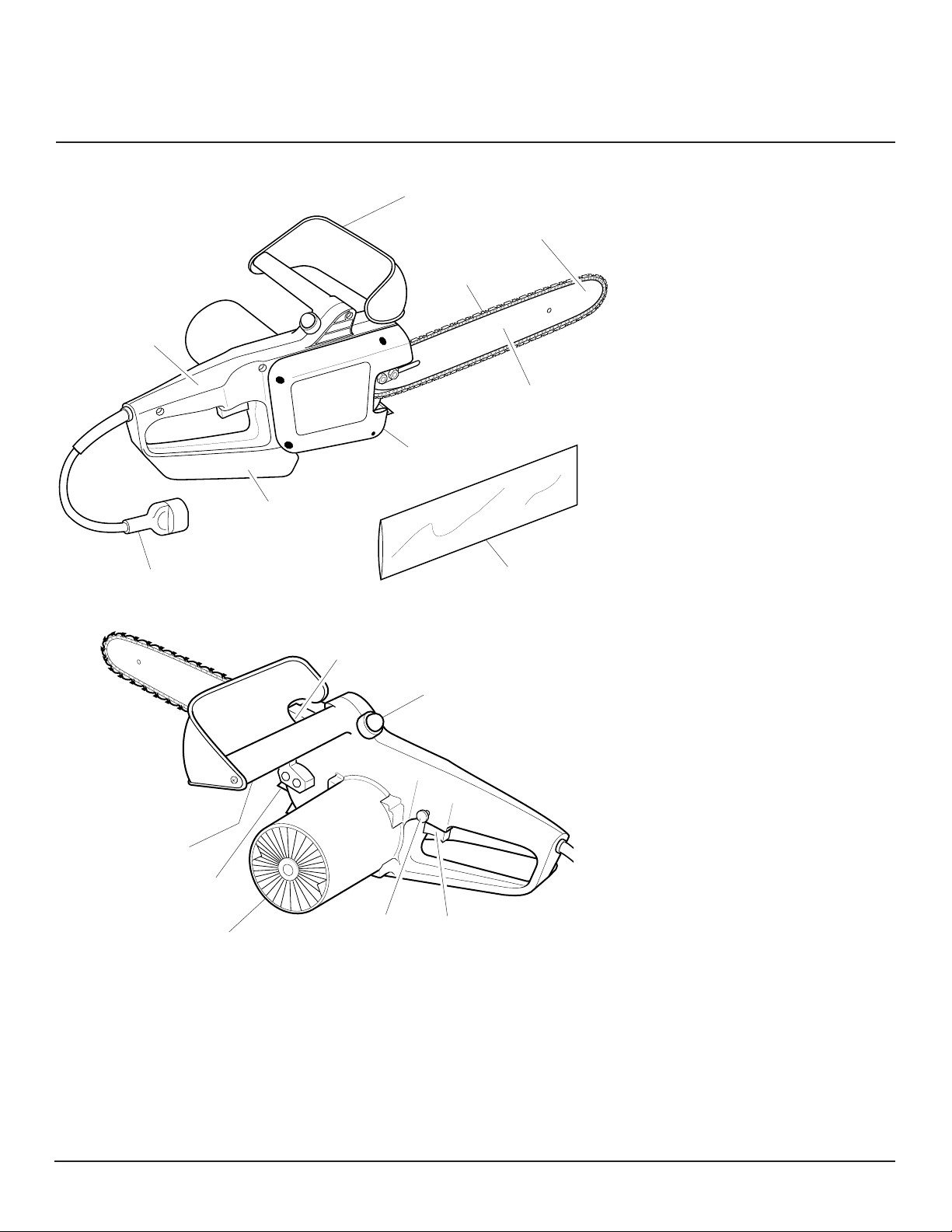

Rear

Handle

Rear Hand

Guard

Power Cord

Front Hand

Guard

Saw

Chain

Sprocket

Cover

Oil Level Sight Hole

(located on saw body,

hidden by front handle)

Guide Bar

Nose

Guide Bar

Scabbard

UNPACKING

1. Remove all items from carton.

2. Check all items for any shipping damage. If you find any damage or if any

parts are missing, promptly inform

dealer where you bought chain saw.

Front Handle

Spike

Motor

Housing

Figure 2 - Electric Chain Saw

Switch

Lockout

Oil Cap With

Squeeze Bulb

Trigger

107990

5

For more information, visit www.desatech.com

Page 6

®

ELECTRIC CHAIN SAW

ASSEMBLY

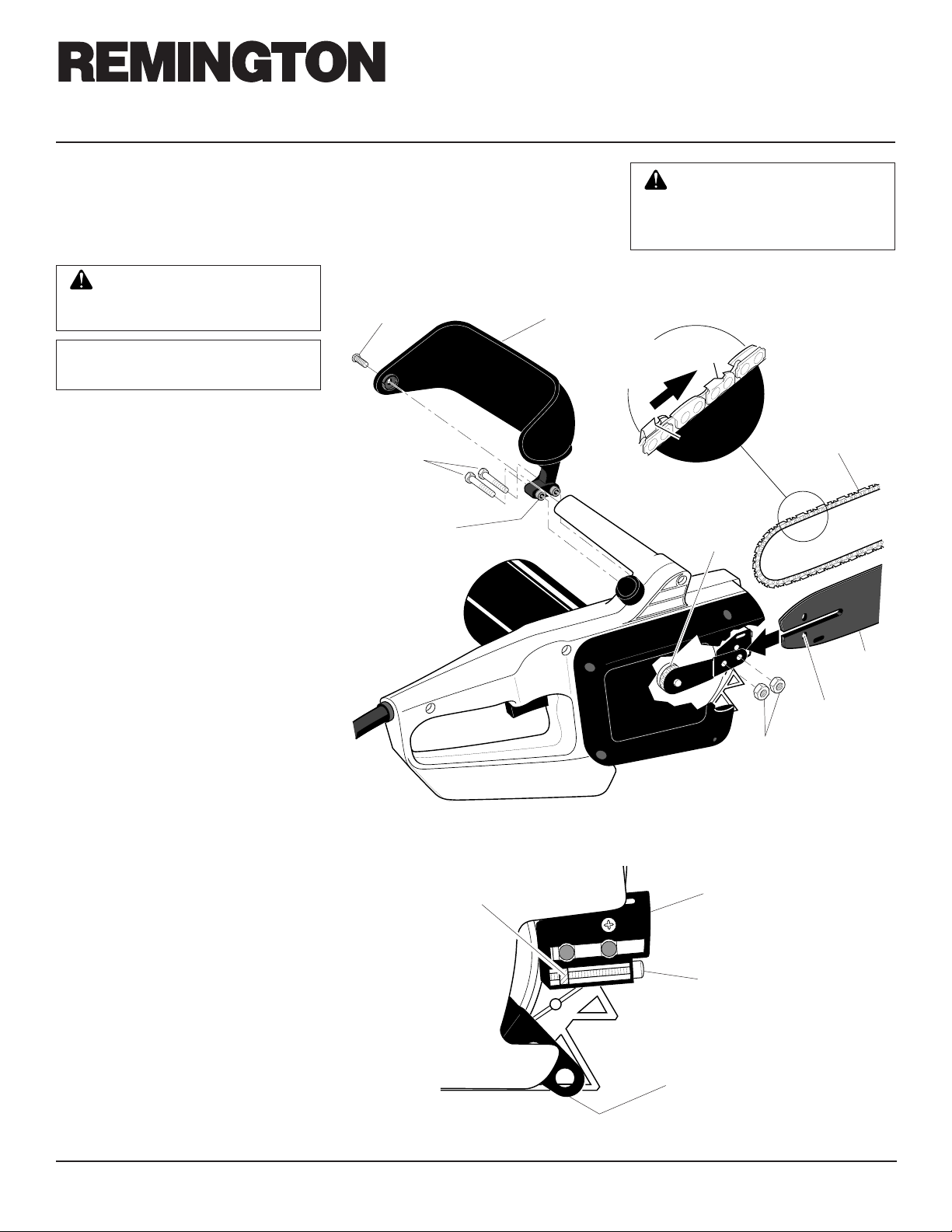

Note:

Some models are pre assembled. As-

sembly is not needed on these models.

See Saw Chain Tension Adjustment, page 7.

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

IMPORTANT: Do not clamp chain

saw in vise during assembly.

The plastic hardware bag should include:

• two guide bar bolts

• two guide bar nuts

• one Phillips-head tapping screw

• automatic chain sharpener (Fast Sharp

models only)

1. Lay chain out flat.

2. Install front hand guard onto saw body.

Do this by pressing two mounting standouts on hand guard into hex-shaped

holes in saw body (see Figure 3).

3 Insert tapping screw through hand

guard and into saw handle. Tighten

screw firmly.

4. Turn adjusting screw counterclockwise

(see Figure 4). Continue to turn adjusting screw until adjusting block is to rear

of adjusting plate.

5. Install guide bar onto saw body. Place

rear of guide bar between adjusting

plate and sprocket support.

IMPORTANT:

justing block into oval adjusting hole

on guide bar.

6. Line up holes on sprocket support with

center slot on guide bar and holes in

saw body.

7. Insert guide bar bolts through front

hand guard, saw body, center slot of

guide bar, and sprocket support. Attach

guide bar nuts to guide bar bolts.

IMPORTANT:

finger tight only. Make sure adjusting block is in oval adjusting hole on

guide bar.

Make sure to insert ad-

Tighten guide bar nuts

8. Place chain around drive sprocket, then

along top groove of guide bar and

around guide bar nose.

Note:

Make

sure cutting edges of chain are facing

the right direction. Position chain so

CAUTION: Do not place chain

on saw backwards. If chain is

backwards, saw will vibrate badly

and will not cut.

cutting edges on top of guide bar face

guide bar nose (see Figure 3).

9. Adjust saw chain tension. Follow steps

under Saw Chain Tension Adjustment,

Tapping

Screw

Guide Bar

Bolts

Mounting

Stand-Outs

Figure 3 - Assembling Guide Bar, Chain, and Hand Guard

Adjusting

Block

Front Hand

Guard

Towards

Guide

Bar Nose

page 7.

Cutting

Edge

Cutting

Edge

Drive

Sprocket

Adjusting

Plate

Adjusting

Screw

Sprocket

Support

Saw

Chain

Guide

Bar

Adjusting

Hole

Guide Bar

Nuts

Figure 4 - Part Locations For Assembling Guide Bar

For more information, visit www.desatech.com

6

107990

Page 7

OWNER’S MANUAL

SAW CHAIN

TENSION

ADJUSTMENT

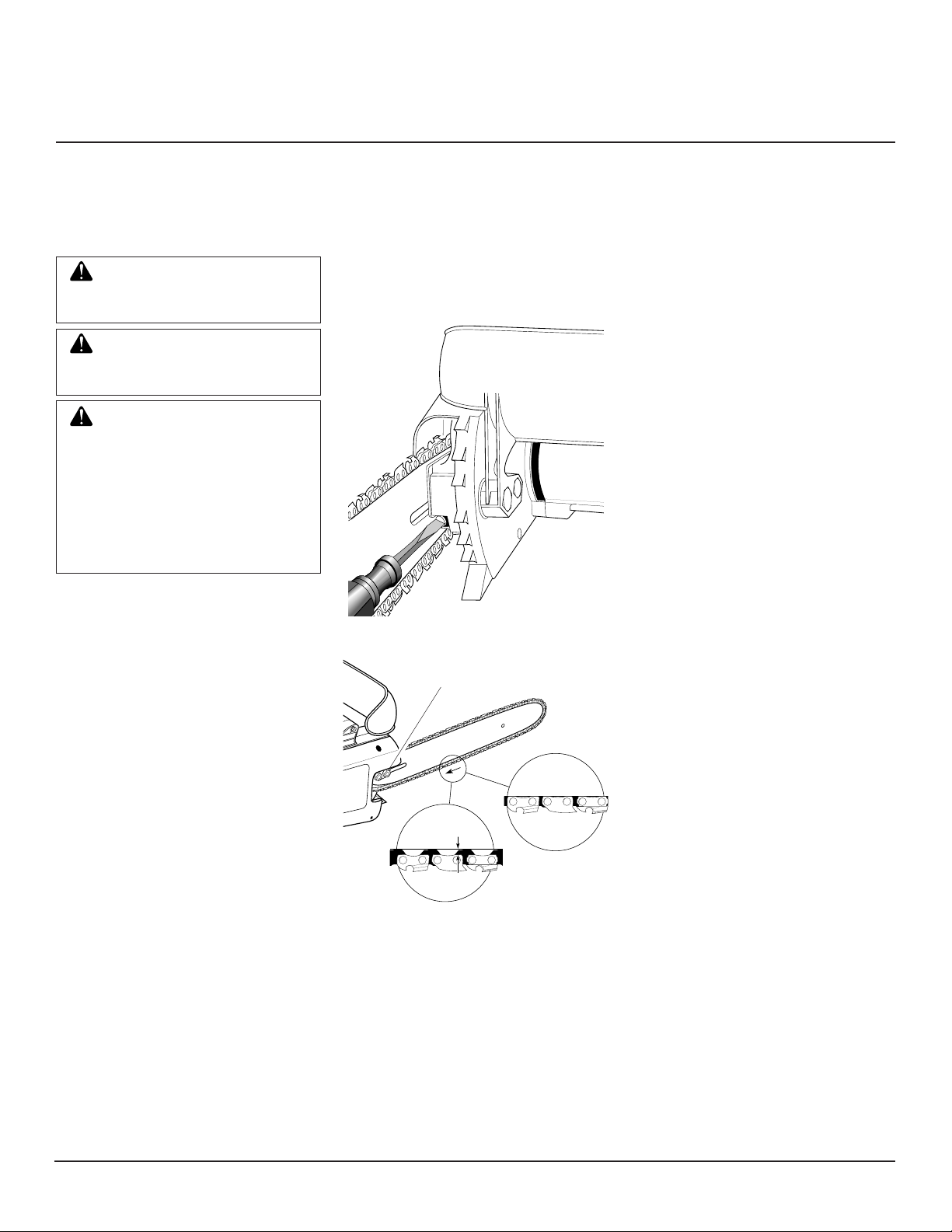

WARNING: Unplug chain saw

from power source before adjusting saw chain tension.

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

WARNING: Maintain proper

chain tension always. A loose

chain will increase the risk of

kickback. A loose chain may jump

out of guide bar groove. This may

injure operator and damage

chain. A loose chain will cause

chain, guide bar, and sprocket to

wear rapidly.

Note:

For pre-assembled models, the saw

chain tension is properly set at factory. A

new chain will stretch. Check new chain

after first few minutes of operation. Allow

chain to cool down. Follow steps below to

readjust saw chain tension.

1. Before adjusting chain, make sure

guide bar nuts are only finger tight (see

Figure 3, page 6). Also make sure adjusting block is in oval adjusting hole on

guide bar (see Figures 3 and 4, page 6).

2. Turn adjusting screw clockwise until

all slack is out of chain (see Figure 5).

Note:

There should be no gap between

side links of chain and bottom of guide

bar (see Figure 6).

3. Wearing protective gloves, move chain

around guide bar. Chain should move

freely. If chain does not move freely,

loosen chain by turning adjusting screw

counterclockwise.

4. After chain tension is correct, tighten

guide bar nuts firmly. If not, guide bar

will move and loosen chain tension.

This will increase the risk of kickback.

This can also damage saw.

chain will stretch. Check new chain

after first few minutes of operation.

Allow chain to cool down. Readjust

chain tension.

Figure 5 - Turning Adjusting Screw

Guide Bar Nuts

Guide Bar

Gap

Incorrect

Tension

Figure 6 - Saw Chain Adjustment

Note:

A new

Guide Bar

Correct

Tension

FILLING OIL TANK

1. Remove oil cap.

2. Fill oil tank with SAE #30 motor oil.

Note:

For temperatures below 30°F, use

SAE #10 oil. For temperatures above

75°F, use SAE #40 oil.

3. Replace oil cap at once. Tighten oil cap

firmly for good seal. This will avoid oil

seepage from tank.

4. Wipe off excess oil.

Note:

It is normal for oil to seep when saw

is not in use. Empty oil tank after each use to

prevent seepage.

107990

7

For more information, visit www.desatech.com

Page 8

®

ELECTRIC CHAIN SAW

OPERATING CHAIN

SAW

WARNING: Read and understand this owner’s manual before operating this saw. Make

certain you read and understand

all

Safety Warnings

3. Improper use of this chain saw

can cause severe injury or death

from fire, electrical shock, or body

contact with moving chain, or

falling wood.

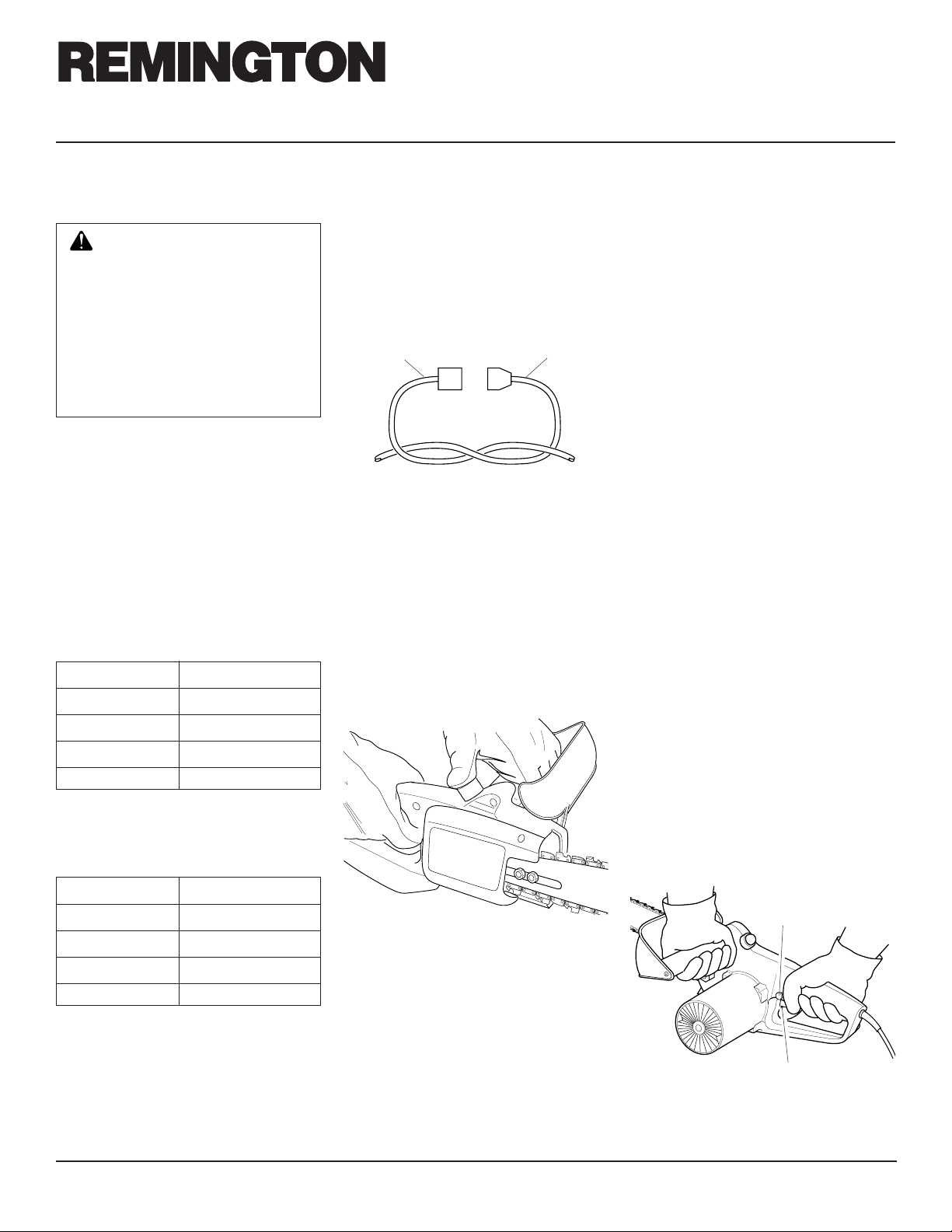

EXTENSION CORDS

Use proper extension cords with this saw.

Use only extension cords marked for outdoor use. The cord must be marked with

suffix W or W-A following the cord type

designation.

Use proper sized cord with this saw. Cord

must be heavy enough to carry current

needed. An undersized cord will cause voltage drop at saw. Saw will lose power and

overheat. Follow cord size requirements

listed below.

Cord Length AWG Cord Size

Models LNT-2: 076728K, 099178H,

100089-06, & 100089-08; Pole Saw Assy

104317 &106821; Pole Saw 104316-04 (8")

& 106890 (10")

Example:

25 feet 16 AWG

50 feet 16 AWG

100 feet 16 AWG

150 feet 14 AWG

, pages 2 and

SJTW-A or SJTW.

Keep cord away from cutting area. Make

sure cord does not catch on branches or logs

during cutting. Inspect cords often. Replace

damaged cords.

The extension cord may come undone from

the power cord during use. To avoid this,

make a knot with the two cords as shown in

Figure 7 below.

Extension

Cord

Figure 7 - Tying Extension Cord and

Power Cord in Knot

Chain Saw

Power Cord

OILING CHAIN

Always check oil level before using saw. To

oil chain, press squeeze bulb on oil cap. Do

not attempt to operate the oiler while cutting

with the saw. Oil will feed onto guide bar

and chain. Press squeeze bulb on oil cap at

least once before each cut. Check oil level

often by looking at oil sight level hole. Oil

sight level hole is on left side of saw, between front handle and front hand guard.

CUTTING WITH THE CHAIN

SAW

1. Connect saw to extension cord. Connect extension cord to power supply.

2. Make sure section of log to be cut is

not laying on ground. This will keep

chain from touching ground as it cuts

through log. Touching ground with

moving chain will dull chain.

3. Use both hands to grip saw. Always use

left hand to grip front handle and right

hand to grip rear handle. Use firm grip.

Thumbs and fingers must wrap around

saw handles (see Figure 9).

4. Make sure your footing is firm. Keep

feet apart. Divide your weight evenly

on both feet.

5. When ready to make a cut, press in

switch lockout with right thumb and

squeeze trigger (see Figure 9). This will

turn saw on. Releasing trigger will turn

saw off. Make sure saw is running at

full speed before starting a cut.

6. When starting a cut, place moving

chain against wood. Hold saw firmly

in place to avoid possible bouncing or

skating (sideways movement) of saw.

7. Guide saw using light pressure. Do not

force saw. The motor will overload and

can burn out. It will do the job better

and safer at the rate for which it was

intended.

8. Remove saw from a cut with saw running at full speed. Stop saw by releasing trigger. Make sure chain has

stopped before setting saw down.

9. Practice until you can maintain a steady,

even cutting rate.

Cord Length AWG Cord Size

25 feet 16 AWG

50 feet 16 AWG

100 feet 14 AWG

150 feet 12 AWG

Models EL-7: 075762J, 098013J, 099039J,

100089-04, 100089-05, & 100089-07

For more information, visit www.desatech.com

Figure 8 - Pressing Squeeze Bulb on Oil

Cap to Oil Chain

Switch

Lockout

Trigger

Figure 9 - Switch Lockout and Trigger

Location

8

107990

Page 9

OWNER’S MANUAL

OPERATING CHAIN

SAW

Continued

FELLING A TREE

(Cutting Down a Tree)

WARNING:

• Avoid kickback. Kickback can

result in severe injury or death.

See

Kickback,

risk of kickback.

• Do not fell a tree without ample

skill or expert help.

• Keep children, animals, and

bystanders away from area

when felling a tree.

• If two or more persons perform

bucking and felling operations

WARNING: When felling a

tree, be aware of your surroundings. Do not endanger any person, strike utility lines, or cause

property damage. If tree strikes

utility lines, contact utility company at once.

Felling is the process of cutting down a tree.

Make sure your footing is firm. Keep feet

apart. Divide your weight evenly on both

feet. Follow directions below to fell a tree.

Before Felling a Tree

1. Before felling, inspect tree. Make sure

there are no dead limbs or branches that

may fall on you. Study natural lean of

tree, location of larger branches, and

wind direction. This will help you judge

which way tree will fall.

2. Clear work area around tree.

3. Plan and clear a retreat path before felling. Make retreat path opposite to

planned direction of fall of tree and at

45° angle (see Figure 10).

4. Remove dirt, stones, loose bark, nails,

staples, and wire from tree where you

will make felling cuts.

5. Stay on uphill side when felling tree.

Tree could roll or slide downhill after falling.

page 3 to avoid

Retreat

Path

Direction

of Fall

45°

Retreat

Path

Figure 10 - Retreat Path From Tree

Tree

Felling Procedure

A) Felling Notch

A properly placed felling notch will determine direction tree will fall. Place felling

notch on side of tree in direction you want

tree to fall (see Figure 11). Follow directions below to create a felling notch.

1. Make lower notch cut as close to

ground as possible. Hold saw so guide

bar is horizontal. Cut 1/3 the diameter

of tree trunk (see Figure 11).

ways make this horizontal lower notch

cut first. If you make this cut second,

tree can pinch chain or guide bar.

2. Start upper notch cut the same distance

above first cut as first cut is deep.

Example: If lower notch cut is eight

inches deep, start upper notch cut eight

inches above it. Cut downward at 45°

angle. The upper notch cut should meet

end of lower notch cut (see Figure 11).

3. Remove tree trunk wedge created by

notching cuts.

Note:

Al-

B) Felling Cut

1. Make felling cut two inches higher than

lower notch cut and on opposite side

of tree (see Figure 11). Keep felling cut

parallel to lower notch cut.

2. Cut towards notch.

WARNING: Do not cut all the

way through tree. Leave about

two inches of tree diameter uncut directly behind felling notch

(see Figure 11). This uncut portion acts as a hinge. The hinge

helps keep tree from twisting and

falling in wrong direction.

Direction

of Fall

3rd Cut Felling Cut

2

Inches

2"

Figure 11 - Felling A Tree

3. As felling cut nears hinge, tree should

begin to fall.

wedges into felling cut to control direction of fall. If tree settles back and pinches

chain, drive wedges into felling cut to

remove saw. Only use wedges made of

wood, plastic, or aluminum. Never use

wedge made of steel. This could cause

kickback and damage to chain.

4. When tree begins to fall, quickly

• remove saw from felling cut

•release trigger to turn saw off

• put saw down

• exit area using retreat path

WARNING: Be alert for falling

overhead limbs. Watch your footing while exiting area.

Hinge

Note:

If needed, drive

2nd Cut Upper

Notch Cut

1st Cut Lower

Notch Cut

107990

Continued

9

For more information, visit www.desatech.com

Page 10

®

ELECTRIC CHAIN SAW

OPERATING CHAIN

SAW

Continued

LIMBING A TREE

WARNING: Avoid kickback.

Kickback can result in severe injury or death. See

3 to avoid risk of kickback.

WARNING: When cutting limb

that is under tension, use extreme

caution. Be alert for wood springing back. When wood tension is

released, limb could spring back

and strike operator causing severe injury or death.

Limbing is removing branches from a fallen

tree. Make sure your footing is firm. Keep

feet apart. Divide your weight evenly on

both feet. Do not remove larger limbs under

tree that support log off ground. Remove

each limb with one cut (see Figure 12).

Clear cut limbs from work area often. This

will help maintain a safe work area.

Make sure you start your cut where limb

will not pinch saw during cutting. To avoid

pinching, start cut on freely hanging limbs

from above limb. Start cut on limbs under

tension from under limb. If pinch occurs,

turn saw off, lift limb, and remove saw.

Kickback

, page

BUCKING A LOG

WARNING: Avoid kickback.

Kickback can result in severe injury or death. See

3 to avoid risk of kickback.

WARNING:

• If on slope, make sure log will

not roll down hill. Secure log

by using wooden stakes. Drive

wooden stakes into ground on

downhill side of log. Stand on

uphill side of log while cutting.

Log may roll after cutting.

• Never try cutting through two

logs at same time. This could

increase the risk of kickback.

• While cutting log, never hold

log with your hand, leg, or foot.

• While cutting log, never allow

another person to hold log.

• Turn off and unplug saw be-

fore moving from one place to

another.

Bucking a log is cutting a log into sections.

Make sure your footing is firm. Keep feet

apart. Divide your weight evenly on both feet.

When possible, raise log or section off ground.

Do this by using limbs, logs, chocks, etc.

When cutting through log, maintain control

by reducing cutting pressure near end of cut.

Do not relax your grip on chain saw handles.

Do not let moving chain touch ground.

Ground will dull moving chain. After cutting through log, release trigger to turn saw

off before moving saw.

Follow directions below to buck a log.

Kickback

, page

Entire Length Of Log On

Ground

Cut log from top (see Figure 13).

Figure 13 - Bucking Log With Entire

Length On Ground

Log Supported On One End

1. Make first cut on underside of log (see

Figure 14). Use top of guide bar to

make this cut. Cut 1/3 through diameter of log. This cut will keep section

from splintering when cut.

2. Make second cut directly above first

cut. Cut down to meet first cut. This

cut will keep log from pinching guide

bar and chain.

2nd Cut

Figure 12 - Limbing A Tree

For more information, visit www.desatech.com

10

1st Cut

Figure 14 - Bucking Log When Log Is

Supported On One End

107990

Page 11

OWNER’S MANUAL

OPERATING CHAIN

SAW

Continued

Log Supported On Both Ends

1. Make first cut from above log (see Figure 15). Cut 1/3 through diameter of

log. This cut will keep section from

splintering when cut.

2. Make second cut on underside of log,

directly under first cut. Use top of guide

bar to make this cut. Cut up to meet

first cut. This will keep log from pinching guide bar and chain.

1st Cut

2nd Cut

Figure 15 - Bucking Log When Log Is

Supported On Both Ends

TRIMMING A TREE (Pruning)

WARNING: Avoid kickback.

Kickback can result in severe injury or death. See

3 to avoid risk of kickback.

WARNING: Do not operate

chain saw while

• in a tree

• on a ladder or any other un-

stable surface

• in any awkward position

You may lose control of saw causing severe injury.

WARNING: Do not cut limbs

higher than your shoulders.

CAUTION: Seek professional

help if facing conditions beyond

your ability.

Trimming a tree is the process of cutting

limbs from a living tree. Make sure your

footing is firm. Keep feet apart. Divide your

weight evenly on both feet. Follow directions below to trim a tree.

1. Make first cut six inches from tree trunk

on underside of limb. Use top of guide

bar to make this cut. Cut 1/3 through

diameter of limb (see Figure 16).

2. Move two to four inches farther out on

limb. Make second cut from above limb.

Continue cut until you cut limb off.

3. Make third cut as close to tree trunk as

possible on underside of limb stub. Use

top of guide bar to make this cut. Cut

1/3 through diameter of stub.

4. Make fourth cut directly above third

cut. Cut down to meet third cut. This

will remove limb stub.

Kickback

, page

2nd Cut -

4th Cut Final Stub

Cut

3rd Cut - Stub Undercut

(to avoid splintering)

Figure 16 - Cutting A Limb

Pruning Cut

(to avoid pinching)

6"

2" to 4"

1st Cut Pruning Undercut

(to avoid splintering)

107990

11

For more information, visit www.desatech.com

Page 12

®

ELECTRIC CHAIN SAW

CLEANING AND

MAINTENANCE

NOTICE: Below are instructions

for servicing your chain saw. Any

servicing not mentioned below

should be done by an authorized

service center.

CLEANING SAW BODY

WARNING: Unplug chain saw

from power source before servicing. Severe injury or death could

occur from electrical shock or

body contact with moving chain.

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

WARNING: When cleaning

saw body,

• do not submerge saw in any

liquids

• do not use products that con-

tain ammonia, chlorine, or

abrasives

• do not use chlorinated clean-

ing solvents, carbon tetrachloride, kerosene, or gasoline

Keep saw body clean. Use a soft cloth dampened with a mild soap and water mixture.

Wipe saw body to clean.

CARE OF GUIDE BAR

Uneven bar wear causes most guide bar

problems. Incorrect sharpening of chain

cutter and depth gauge settings often cause

this. When bar wears unevenly, it widens

guide bar groove (see Figure 17). This causes

chain clatter and rivet popping. Saw will not

cut straight. Replace guide bar if this occurs.

Inspect guide bar before sharpening chain.

A worn or damaged guide bar is unsafe. A

worn or damaged guide bar will damage

chain. It will also make cutting harder.

Guide Bar

Groove

Guide Bar

Normal Guide

Bar

Figure 17 - Guide Bar Cross Section Showing Uneven Bar Wear

Guide Bar

With Uneven

Wear

Normal Guide Bar Maintenance

1. Remove guide bar from chain saw.

2. Remove sawdust from guide bar

groove periodically. Use putty knife or

wire.

3. Clean oil slots after each day of use.

4. Remove burrs from sides of guide bar.

Use flat file to make side edges square.

Replace guide bar when

• bar is bent or cracked

• inside groove of bar is badly worn

Note:

When replacing guide bar, see Re-

placement Parts and Accessories, page 19,

for proper bar.

Burr

Flat File

Guide Bar

Cleaning Groove With

Putty Knife

For more information, visit www.desatech.com

12

Oil Slot

Figure 18 - Guide Bar Maintenance

107990

Page 13

OWNER’S MANUAL

CLEANING AND

MAINTENANCE

Continued

SHARPENING SAW CHAIN

WARNING: Unplug chain saw

from power source before servicing. Severe injury or death could

occur from electrical shock or

body contact with moving chain.

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

Keep chain sharp. Your saw will cut faster

and more safely. A dull chain will cause

undue sprocket, guide bar, chain, and motor

wear. If you must force chain into wood and

cutting creates only sawdust with few large

chips, chain is dull.

Items Needed to Sharpen Chain

Purchase these items from your local dealer,

hardware store, or chain saw supplies outlet.

• 5/32" round file

• Depth gauge tool

• File guide

•Vise

• Medium sized flat file

Sharpening Cutters

Use file guide for 30° filing.

1. Adjust chain for proper tension (see Saw

Chain Tension Adjustment, page 7).

2. Clamp guide bar in vise to hold saw

Note:

steady.

3. Press 5/32" round file (attached to file

guide) into groove between top plate

and depth gauge on chain. File guide

should rest on both top plate and depth

gauge (see Figures 19 and 20).

File at midpoint of guide bar.

Figure 19 - File and File Guide Placement On Chain

Do not clamp chain.

Note:

Filing

Direction

30° Guide

Mark

FILE HOLDER

4. Hold file guide level. Make sure 30°

mark on file guide is parallel to center

of guide bar (see Figure 19). This will

insure that you file cutters at 30° angle.

5. File from inside towards outside of cutter until sharp. Only file in this one direction (see Figure 19).

strokes with file should sharpen cutter.

6. After each cutter is sharpened, move

chain forward to sharpen next cutter.

File all cutters on one side of chain.

7. Move to other side of chain and repeat

process.

File

Guide

5/32"

Round File

This illustration

Note:

shows file guide

placement and filing

direction for sharpening cutters on left side

of chain.

Note:

Two or three

107990

Depth Gauge

(left side of chain)

Left Side of

Chain

Groove

Top Plate

(left side of chain)

Figure 20 - Chain Part Locations

13

Groove

Depth Gauge

(right side

of chain)

Top Plate

(right side of chain)

Right Side of

Chain

Continued

For more information, visit www.desatech.com

Page 14

®

ELECTRIC CHAIN SAW

CLEANING AND

MAINTENANCE

Continued

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced

as cutters are sharpened. After every second

or third sharpening, reset cutter depth gauges.

1. Place depth gauge tool (.025") firmly

across top of two cutters. Make sure

depth gauge enters slot in depth gauge

tool (see Figure 21).

2. Use medium flat file. File depth gauge

level with depth gauge tool.

3. Remove depth gauge tool. With flat file,

round off front corner of cutter depth

gauge (see Figure 22).

After several hand filings, have authorized

service center or sharpening service machine

sharpen chain. This will insure even filing.

Flat File

Depth Gauge

Depth

Gauge

Tool

Depth

Gauge

Slot

Figure 21 - Depth Gauge Tool On Chain

Front Corner

.025"

Figure 22 - Round Off Front Corner Of

Depth Gauge

REPLACING SAW CHAIN

Replace chain when cutters are too worn to

sharpen or when chain breaks. Only use

replacement chain noted in this manual.

Always include new drive sprocket when

replacing chain. This will maintain proper

driving of chain.

drive sprocket, see Replacement Parts and

Accessories, page 19.

Note:

For proper chain and

STORAGE

If storing saw for more than 30 days, follow

steps below.

1. Drain oil tank.

2. Remove and clean guide bar and chain.

Clean guide bar and chain by soaking

in petroleum based solvent or mild soap

and water mixture.

3. Dry guide bar and chain.

4. Place chain in container filled with oil.

This will prevent rust.

5. Wipe a thin coating of oil over surface

of guide bar.

6. Wipe off outside of saw body. Do this

with soft cloth dampened with a mild

soap and water mixture.

7. Store chain saw

• in a high or locked place, out of

children’s reach

• in a dry place

• in a carrying case or with scabbard

over guide bar

TECHNICAL

SERVICE

You may have further questions about assembling, operating, or maintaining this saw.

If so, contact DESA International’s Technical Service Department at 1-800-858-8501.

You can also visit DESA International’s

technical service web site at

www.desatech.com.

SERVICE

PUBLICATIONS

You can receive an illustrated parts list free

of charge. Send a self-addressed stamped

envelope to address on back page of this

manual.

When writing, include model number and

serial number of saw. You will find these

numbers on saw motor housing decal.

For more information, visit www.desatech.com

14

107990

Page 15

OWNER’S MANUAL

TROUBLESHOOTING

Note:

For additional help, visit DESA

International’s technical service web site

at www.desatech.com.

OBSERVED FAULT

Saw runs, but does not cut

Saw does not cut unless heavily forced.

Cutting produces only sawdust with few

large chips

Saw runs slow. Saw stalls easily

Motor of saw does not run when you squeeze

trigger

Motor of saw runs, but chain does not move

Chain does not get oil

WARNING: Unplug chain saw from power source before servicing.

Severe injury or death could occur from electrical shock or body contact

with moving chain.

POSSIBLE CAUSE

Chain assembled backwards on guide bar

Chain is dull

Low power supply voltage

1. Switch lockout not pressed in to release

trigger

2. Extension cord connections loose

3. Open line fuse or circuit breaker

4. Bad motor brushes

5. Open wiring circuit on saw

Gear train failure

1. Clogged oil slot in guide bar

2. Oil is too thick

REMEDY

See Assembly, page 6

See Sharpening Saw Chain, page 13

Extension cord wire size too small. See

Extension Cords, page 8

1. Press in switch lockout before squeezing trigger

2. Check cord connections

3. Check line fuse or circuit breaker

4. See authorized service center

5. See authorized service center

See authorized service center

1. Remove guide bar and clean oil slot

2. Use correct weight of oil. See Filling Oil

Tank, page 7

Chain comes off guide bar

Saw smokes

Saw leaks oil

1. Chain is loose

2. Guide bar and chain not assembled right

Saw damaged. Do not use saw

Oil cap is not secure

1. Tighten chain. See Saw Chain Tension

Adjustment, page 7

2. See Assembly, page 6

See authorized service center

Tighten oil cap.

not in use

Note:

Empty oil tank when

107990

15

For more information, visit www.desatech.com

Page 16

®

ELECTRIC CHAIN SAW

ILLUSTRATED

PARTS

BREAKDOWN

LNT-2

19

21

14

13

5

24

10

6

9

7

3

16

18

21

17

22

11

1

4

12

2

20B

26

23

15

20

22

20

Shoulder Screw Installation E-Ring Installation

Installing Shoulder Screw or E-Ring

Depending On Model

For more information, visit www.desatech.com

20B

16

22

8

25

107990

Page 17

OWNER’S MANUAL

PARTS LIST

LNT-2

KEY PART 100089-06 107709-01

NO. NO. DESCRIPTION 099178H 100089-08 076728K

1 097568-01 Guide Bar, 12"

2 091373-02 Saw Chain

3 107481-01 Armature Assembly 1 1 1

4 075676 Sprocket Roller Bearing 1 1 1

5 076744 Hex-Head Bolt 2 2 2

6 107512-01 Cap & Bulb Assembly 1 1 1

7 099829-01 Cord 1 1 1

8 077399-02 Side Cover, Black

9 076105 Thrust Disk 1 1 1

10 107482-01 Field & Brush Assembly 1 1 1

11 059606 Drive Gear 1 1 1

12 075752 Internal Gear 1 1 1

13 106809-01 Front Hand Guard 1 1 1

14 079089-02 Motor Housing, Black 1 1 1

15 NPC-4C Hex Nut 2 2 2

16 077115 Adjusting Plate Assembly 1 1 1

17 075887 Bearing Plate 1 1 1

18 079086-02 Oil Reservoir 1 1 1

19 097403-01 Pan-Head Screw 1 1 1

20 076905 Pan-Head Shoulder Screw 1 1 1

20B 109920-01 E-Ring 1 1 1

21 076906 Flat-Head Tap Screw 2 2 2

22 059046 Pan-Head Tap Screw 10 10 10

23 077143 Sprocket Support 1 1 1

24 077525S Lock-Off Switch 1 1 1

25 106810-01 Sprocket Cover, Black 1 1 1

26 079963-02 Scabbard

This list contains replaceable parts used in your chainsaw. When ordering parts, be sure to provide the correct

model and serial numbers (from the model plate), then the part number and description of the desired part.

QTY.

__ __

097570-01 Guide Bar, 14" 1 1

__ __

091374-02 Saw Chain 1 1

__

__ __

079963-04 Scabbard 1 1

1

1

__

1

__

__

1

__

107990

17

For more information, visit www.desatech.com

Page 18

®

ELECTRIC CHAIN SAW

ILLUSTRATED

PARTS

BREAKDOWN

EL-7

14

25

22

5

9

3

21

13

26

6

17

18

21

2

1

15

24

20B

20

Shoulder Screw Installation E-Ring Installation

Installing Shoulder Screw or E-Ring

Depending On Model

4

10

27

7

19

11

23

8

12

16

20B

20

19

For more information, visit www.desatech.com

18

107990

Page 19

OWNER’S MANUAL

PARTS LIST

EL-7

This list contains replaceable parts used in your chainsaw. When ordering parts, be sure to provide the correct

model and serial numbers (from the model plate), then the part number and description of the desired part.

QTY.

098031J

099039J

KEY 075762J 100089-05

NO. PART NO. DESCRIPTION 100089-07 107714-02

1 097570-01 Guide Bar, 14" 1

097572-01 Guide Bar, 16"

2 091374-02 Saw Chain 1

091375-02 Saw Chain

3 100933-01 Armature 1 1

4 075676 Sprocket Roller Bearing 1 1

5 076744 Hex-Head Bolt 2 2

6 107512-01 Oil Reservoir Cap 1 1

7 099829-01 Cord 1 1

8 077399-02 Side Cover, Black 1 1

9 098042-01 Field 1 1

10 059606 Drive Gear 1 1

11 075752 Internal Gear 1 1

12 106810-01 Sprocket Cover 1 1

13 106809-01 Front Hand Guard 1 1

14 076053 Motor Housing Assembly 1 1

15 097034-02 Housing Assembly 1 1

16 NPC-4C Hex Nut 2 2

17 077115 Adjusting Plate Assembly 1 1

18 079086-02 Oil Reservoir 1 1

19 059046 Pan-Head Tap Screw 6 6

20 076905 Pan-Head Shoulder Screw 1 1

20B 109920-01 E-Ring 1 1

21 076906 Flat-Head Tap Screw 2 2

22 097403-01 Pan-Head Screw 1 1

23 077143 Sprocket Support 1 1

24 077525S Lock-off Switch 1 1

25 058059 Thrust Washer 1 1

26 079963-04 Scabbard 1 1

27 059045 Pan Head Tap Screw 4 4

__

__

__

1

__

1

107990

PARTS AVAILABLE - NOT SHOWN

079882-09 Hardware Package 1 1

Includes: 2 - NPC-4C Nuts

2 - 076744 Bolts

1 - 097403-01 Screw

19

For more information, visit www.desatech.com

Page 20

®

ELECTRIC CHAIN SAW

PARTS DEALERS

Ray’s Portable Heater Service

3191 Myers Road

Camino, CA 95709-9550

530-644-7716

Baltimore Electric

1348 Dixwell Avenue

Hamden, CT 06514-0322

203-248-7553

1-800-397-7553

Eckley’s Small Engine

31617 Spruce Drive

Eustis, FL 32726-9592

352-357-6764

Parts Company of America

1657 Shermer Road

Northbrook, IL 60062-5362

708-498-5900

1-800-323-0620

www.grainger.com

Portable Heater Parts

342 North County Road 400 East

Valparaiso, IN 46383-9704

219-462-7441

1-800-362-6951

www.portableheaterparts.com

sales@portableheaterparts.com

techservice@portableheaterparts.com

FBD

1349 Adams Street

Bowling Green, KY 42103-3414

270-846-1199

1-800-654-8534

franktalk@aol.com

Lyons & Lyons Sales Co. Inc.

Glen Arm Road

Glen Arm, MD 21057-9454

410-665-6500

1-800-333-5966

lyonsco@erols.com

Master Part Distributors

1251 Mound Avenue NW

Grand Rapids, MI 49504-2672

616-791-0505

1-800-446-1446

Hance Distributors, Inc.

12795 16th Avenue North

Plymouth, MN 55441-4556

763-559-2299

www.hanceco.com

Automotive Equipment Service

3117 Holmes

Kansas City, MO 64109-1716

816-531-9144

1-800-843-3546

www.aes-lawnparts.com

Bowden Electric Motor Service

1681 S. Wesleyan Blvd.

Rocky Mount, NC 27803

252-446-4203

East Coast Energy

707 Broadway

West Long Branch, NJ 07764-1542

1-800-755-8809

Forrest Lytle and Sons, Inc.

740 West Galbraith Road

Cincinnati, OH 45231-6002

513-521-1464

Bortz Chain Saw Shop

Road #2, Box 64A

Oley, PA 19547-9412

610-987-6452

21st Century

2950 Fretz Valley Road

Perkasie, PA 18944-4034

215-795-0400

1-800-325-4828

Laportes

2444 N 5th Street

Hartsville, SC 29550-7704

843-857-0222

MTA Distributors

(Generators ONLY)

555 Hickory Hills Blvd.

Nashville, TN 37189-9244

615-259-8777

1-800-264-0225

Webbs Appliance Center

1519 Church Street

Nashville, TN 37203-3004

615-329-4079

1-800-899-4079

Industrial Hardware

4109 Bainbridge Blvd.

Chesapeake, VA 23324-1403

804-543-2232

1-800-788-0008

catatem@erols.com

Mills Lawn and Garden

928 Commonwealth Place

Virginia Beach, VA 23464

757-361-9293

www.mills-parts.com

Tuco Industrial Products

5223 180th Street SW

Suite 4A-1

Lynnwood, WA 98037-4506

425-743-9533

1-800-735-1268

www.tucoheat.com

ALABAMA (AL)

A & O General Repair Service

1470 Opelika Road

Auburn, AL 36830

334-821-7022

Southern Power Tool

2824 Cottage Glen Dr.

Mobile, AL 36693

334-639-8188

ARIZONA (AZ)

Best Brothers Lawnmower Repair

5549 W. Glendale Avenue

Glendale, AZ 85301

602-939-9170

D & L Small Engines, Inc.

10023 North 19th Ave.

Phoenix, AZ 85021

602-861-1978

Power Tool Service Center

660 East 19th Street

Tucson, AZ 85719

520-884-8974

CALIFORNIA (CA)

Ray’s Portable Heater Service

3191 Meyers Road

Camino, CA 95709

530-644-7716

California Electric Service

612 South Shoppers Lane

Covina, CA 91723

818-915-4935

California Electric Company

1208 East Ash Avenue

Fullerton, CA 92631

714-870-0900

J & N Garden Equipment

4460 W. Imperial Hwy.

Inglewood, CA 90304

310-671-0079

Shamay's Enterprises

P. O. Box 3714

58643 Knox-Niman Lane

Landers, CA 92285

760-364-2046

AUTHORIZED SERVICE CENTERS

California Electric Service

2594 East Colorado Blvd.

Pasadena, CA 91107

626-792-3194

West Coast Contractors Supply

#28 13th Street

San Francisco, CA 94103

415-861-6124

Leete Electric Company

930 Petaluma Hill Road

Santa Rosa, CA 95404

707-545-0484

Rincon Valley Yard & Garden

4972 Sonoma Hwy

Santa Rosa, CA 95409

707-593-4124

California Electric Service

14753 Oxnard Street

Van Nuys, CA 91411

818-997-8855

Power Outdoor Equipment

3160 Industrial Drive

Yuba City, CA 95993

530-671-1871

COLORADO (CO)

McGuckin Power Equipment Center

2845 Valmont Road

Boulder, CO 80302

303-443-9317

Ace Mower and Small Engines

4718 Chromium Drive

Colorado Spring, CO 80918

719-593-0862

Bartell Tool Service

1448 W. Cedar Avenue

Denver, CO 80223

303-777-5463

Metrogas Equipment Company

790 West 64th Ave.

Denver, CO 80221

303-428-3036

Winfrey’s Jones LLP

317 8th Street

Greeley, CO 80631

970-353-9576

AAA Electric Company, Inc.

24 South Main Street

Longmont, CO 80501

330-776-6031

Dales Electric Motor Repair

932 Coffman Street

Longmont, CO 80501

303-651-6907

CONNECTICUT (CT)

Baltimore Electronics

5 Manila Ave.

Hamden, CT 06514

203-248-7553

1-800-397-7553

Utility Electric Service

53 Main Street

Hartford, CT 06106

860-246-7271

Goodies Sales and Service

133 Hamilton Street

New Haven, CT 06515

203-865-1470

FLORIDA (FL)

301 Mower Shop

5724 15th Street E.

Bradenton, FL 34203

941-758-7844

Eckley’s Small Engine

31617 Spruce Drive

Eustis, FL 32736

352-357-6764

Al’s Small Engine, Inc.

2496 Blanding Blvd.

Middleburg, FL 32068

904-282-5472

Lindle & Sons Electric Motor Repair

7016 Hwy. 22

Panama City, FL 32401

850-871-1722

Eustis and Sons, Inc.

7035 66th Street North

Pinellas Park, FL 34665

727-544-1486

A1A Small Engines & Equipment

420 S. Dixie Hwy. E.

Pompano Beach, FL 33060

954-946-5044

Mulvaney’s Inc.

2148 W. Tennessee Street

Tallahassee, FL 32304

850-576-5578

A-1 Tool Rental, Inc.

2509 South State Road 7

West Hollywood, FL 33023

954-961-9250

GEORGIA (GA)

Hamilton Hardware

5300 Veterans Pkwy.

Columbus, GA 31904

706-322-6545

Cowan Ace Hardware

1264 Green Street

Conyers, GA 30207

770-483-8818

Able Tool Rental

3360 Fairburn Road

Douglasville, GA 30135

770-949-1932

Douglasville Ace Hardware

6530 Church Street

Douglasville, GA 30133

770-942-7044

ASAP Equipment Services

3560 C Buford Hwy

Duluth, GA 30096

678-584-5462

Fayette Mower & Appliance

395 S. Glynn St.

Fayetteville, GA 30215

770-461-9400

S & P Rental & Supply Co.

259 Grayson Hwy

Lawrenceville, GA 30245

770-963-0392

Spray Solutions

476 Flowing Wells Rd. D-1

Martinez, GA 30907

706-855-1293

Tifton Electric Motors

1265 US Hwy. 82E

Tifton, GA 31794

912-382-4040

IDAHO (ID)

Rossiter Electric

1501 S. Capitol Ave.

Idaho Falls, ID 83403

208-529-3665

Steam Store Rocky Mountain, Inc.

155 North Gate Mile

Idaho Falls, ID 83401

208-522-0609

J & J Enterprises

1704 Addison Avenue East

Twin Falls, ID 83301

208-733-2001

ILLINOIS (IL)

Uline Lawn Equipment

290 W. Squk Trail

Chicago Heights, IL 60411

708-755-2227

708-755-1533 (Fax)

Lange Electric

912 E. Fayette

Effingham, IL 62401

217-347-7626

Carter’s Small Engine Repair

206 N. Hickory Street

Galatia, IL 62935

618-268-4814

H & R Pump Company, Inc.

2111 E. Washington Street

Joliet, IL 60434

815-726-2950

INDIANA (IN)

Hutchens Sales and Service

R.R. #5, Box 550

Bloomfield, IN 47424

812-876-1891

Nichols Ice & Oil

2018 Park Road

Connersville, IN 47331

765-825-3741

For more information, visit www.desatech.com

20

107990

Page 21

OWNER’S MANUAL

B & W Repair Service

213 N. Main Street

Dale, IN 47523

812-937-2576

Industrial Motor & Electrical

Supply, Inc.

64466 State Road 19

Goshen, IN 46526

219-862-4044

Tyrie Mower Repair

110 South 16th Street

Lafayette, IN 47905

765-742-7886

Kabelin True Value Hardware

512 Andrew Avenue

Laporte, IN 46350

219-362-7917

Lear Lawn & Garden

2204 N. Wolfe Street

Muncie, IN 47303

765-282-6273

Li’l Engine Sales & Service, Inc.

1428 Vincennes Street

New Albany, IN 47150

812-944-1377

Portable Heater Parts

342 North County Road, 400 East

Valparaiso, IN 46383

219-462-7441

D W Handy’s

217 West 15th St.

Vincennes, IN 47591

812-886-0172

New Paris Farm Store

68443 W. Main Street

P. O. Box 96

New Paris, IN 46553

219-831-4823

IOWA (IA)

Beal’s Motor Rewinding

600 West Beach

Cherokee, IA 51012

712-225-6173

Blink Electric Motors

Rear 116 N. 1st Ave.

Marshalltown, IA 50158

641-752-3036

Northeast Iowa Motor Service

24665-150th Street

Sumner, IA 50674

563-578-5883

Black Hawk Rental

324 West 15th Street

Waterloo, IA 50702

319-234-4421

KANSAS (KS)

Abilene Rent-All & Sales

1701 West 1st Street

Abilene, KS 67410

785-263-7668

NAAB Electric, Inc.

2013 W. Jones

Garden City, KS 67846

316-276-8101

Morris Electric Repair

2423 5th Street

Great Bend, KS 67530

316-792-2919

McPherson Rental Center

911 West First Street

McPherson, KS 67460

620-241-3333

KENTUCKY (KY)

Gillum’s Service & Repair

8611 Rt. US 60

Ashland, KY 41102

606-928-4932

E-Z Rent It Inc.

1428 U.S. 31-W By-Pass

Bowling Green, KY 42101

270-782-9462

Roman’s Repair Shop

601 College Street

Bowling Green, KY 42101

270-746-0857

Hopkinsville Electric Motor

704 W. 15th Street

Hopkinsville, KY 42240

270-886-7585

Maury’s Fluorescent Appliance

1521 Bardstown Road

Louisville, KY 40205

502-456-1671

Rental World, Inc.

9509 Dixie Hwy.

Louisville, KY 40272

502-935-8853

All States Industrial Repair

728 E. Center Street

Madisonville, KY 42431

270-821-6555

LOUISIANA (LA)

Triangle Bicycle and Lawnmower

5433 Crowder Road

New Orleans, LA 70127

504-241-3239

Wayne’s Heat & Air

1605 W. Vine Street

Opelousas, LA 70570

337-948-4246

Evans of LA, Inc.

907 Cypress Street

West Monroe, LA 71291

318-322-6180

MAINE (ME)

Richard’s Electric Motor

549 Main Street

Caribou, ME 04736

207-498-8950

Roger’s Electric Motor Shop

823-West Main Street

Madawaska, ME 04756

207-728-4253

Rent-N-Save

28 Allen Avenue

Portland, ME 04103

207-797-2223

MARYLAND (MD)

Center Supply Company

6802 Industrial Drive #208

Beltsville, MD 20705

301-595-0860

Lehmans Hardware, Inc.

5921 Belair Road

Baltimore, MD 21206

410-483-5888

Norris Taylor Contractors, Inc.

8480 Ocean Gateway

Easton, MD 21601

410-822-2050

Lyons & Lyons Sales Co. Inc.

Glen Arm Road

Glen Arm, MD 21057-9454

410-665-6500

1-800-333-5966

lyonsco@erols.com

Chesapeake Rent All

210 N. Stokes Street

Havre De Grace, MD 21078

410-939-1720

B & M Sharpening & Repair

8614 Church Lane

Randalstown, MD 21133

410-655-0801

MASSACHUSETTS (MA)

Ormond’s Inc.

115R Dean Ave.

Franklin, MA 02038

508-528-2013

Beacon Lumber/Beacon Rental

513 Church Street

New Bedford, MA 02745

508-995-1766

Mott’s Tool Repair Service

92 Rayber Road

Orleans, MA 02653

508-240-0764

Utility Electric Service #2

810 Main Street

Springfield, MA 01105

413-781-1635

MICHIGAN (MI)

R & A Service

12900 Haggerty Road

Belleville, MI 48111

734-697-1144

Thompson’s Rental Resale Repair

11973 New Lothrop Road

Byron, MI 48418

810-266-4969

Hendricks Sales

7876 Division

Grand Rapids, MI 49548

616-455-8220

Chicago Drive Rentals, Inc.

11298 Chicago Drive

Holland, MI 49424

616-396-9575

Fowler’s Farm City Sales

2876 West Washington Road

Ithaca, MI 48847

989-875-3976

Superior Industrial Sales & Service

116 N. State Street

Jackson, MI 49201

517-784-0539

Norm’s Electric Motor Repair

414 Walbridge Street

Kalamazoo, MI 49007

616-382-5054

A & J Rentals

550 S. 11th Street

Niles, MI 49120

616-684-3200

Bob’s Service Shop

2537 W. Drahner Road

Oxford, MI 48371

248-628-2601

Bid’s Service, Inc.

11276 E. Ten Mile

Warren, MI 48089

586-759-3040

MINNESOTA (MN)

Perry’s Electrical Rebuilders

24664 Hale Avenue

Forest Lake, MN 55025

651-464-8054

Andy’s Small Engine City

2408 Pearl Ct. SE

Rochester, MN 55904

507-280-0373

Reed’s Sales & Service

1260 Payne Ave.

St. Paul, MN 55101

651-774-9515

MISSISSIPPI (MS)

Handy Man Rentals

1904 Shiloh Road

Corinth, MS 38834

662-287-2460

MISSOURI (MO)

Stewarts Enterprises

7631 NW Salebarn Road

Cameron, MO 64429

816-632-6578

Northwest Power Sales

26848 Haultain Drive

Maryville, MO 64468

660-582-5080

Buchheit, Inc.

Route 7, Box 239

Perryville, MO 63775

573-547-1017

A K Small Engine Works

15726 Hwy C

Versailles, MO 65084

573-378-6339

MONTANA (MT)

Tom’s Service Repair

1111-6th Avenue North

Billings, MT 59101

406-259-6179

Mosch Electric Motors, Inc.

2513 - 17th St. NE

Black Eagle, MT 59414

406-453-2481

Sun Rental Center

1301 - 3rd St. NW

Great Falls, MT 59404

406-761-6688

NEBRASKA (NE)

Hatten’s Electric Service

130 S. Hastings, Box 843

Hastings, NE 68901

402-463-4596

Craft Specialties

201 Pine St.

Hadder, NE 68738

402-379-3129

Flohr Electric Motor

4356 South 90th Street

Omaha, NE 68127

402-331-6863

MSE Parts Unlimited

4935 South 136th Street

Omaha, NE 68137

402-895-0806

Ted’s Mower Sales and Service, Inc.

5155 Q. Street

Omaha, NE 68117

402-731-7058

LaVern Hass Repair

1204 - 1st Road

Wisner, NE 68791

402-529-6846

NEW HAMPSHIRE (NH)

Kingston Enterprises

85 North Road

Kingston, NH 03848

603-642-3506

NEW JERSEY (NJ)

Associated Industries

2433 Rt. 206

Eastampton, NJ 08060

609-267-8417

Woodchuck’s Lawnmower

and Appliance

220 Whitehorse Pike

Magnolia, NJ 08049

856-783-1111

Tep’s Power Equipment

1002 N. High Street

Millville, NJ 08332

856-825-8294

Richard’s Sharpening Service

824 Mill Road

Northfield, NJ 08225

609-641-9481

Capitol Service & Equipment

551 New Market Road

Piscataway, NJ 08855

732-968-5577

Air & Electric Tool Service, Inc.

130 W. 3rd Street

Roselle, NJ 07203

908-242-6930

NEW YORK (NY)

Valley Mower Service

2857 Ellis Creek Road

Barton, NY 13734

607-589-4825

White Tool Supply Inc.

3047 Atlantic Avenue

Brooklyn, NY 11208

718-227-8844

Lehman’s Farm & Home Supply

Route 26

Denmark, NY 13631

315-493-1151

M & S Repair Shop

303 Hilltop Drive

Elma, NY 14059

716-652-0311

Luther’s Outdoor Equipment

3676 State Route 5

Frankfort, NY 13340

315-894-4467

Crossbay Appliance Service

158-34 Crossbay Blvd.

Howard Beach, NY 11414

718-843-4422

Provenzano’s

84 E. Main Street

Kings Park, NY 11754

631-269-1080

Para-Deys Tools

708 Victor Road

Macedon, NY 14502

315-986-2520

P & C

12 East Street

Nunda, NY 14517

716-468-5050

Otega Repair

226 County Hwy 7

Otego, NY 13825

607-988-7859

Owego Agway Coop

38 West Avenue

Owego, NY 13827

607-687-2039

Jack-n-Heater Service

185 Beartown Road

Painted Post, NY 14870

607-962-1239

Larmon Small Engine

16353 Co. Rt. 91

Pierrepont Manor, NY 13674

315-465-6671

R & D Mower & Snowblower

Sales and Service

1632 Empire Blvd.

Webster, NY 14580

716-671-9409

Bedford Appliance, Inc.

1173 Yonkers Ave.

Yonkers, NY 10704

914-237-7575

NORTH CAROLINA (NC)

Harnett & Wake Sales & Service

44 N. Broad Street

Angier, NC 27501

919-331-0463

Leonard Electric Motor Repair, Inc.

531 N. Fayetteville St.

Asheboro, NC 27203

336-625-2375

107990

21

For more information, visit www.desatech.com

Page 22

®

ELECTRIC CHAIN SAW

Martin Equipment Company

4209-B US 70 E.

Goldsboro, NC 27534

919-778-5996

Hickory Home & Garden

336 HWY 321 NW

Hickory, NC 28601

704-327-3719

O’Mary’s Small Engine

220 W. Forlines Road

Winterville, NC 28590

252-355-4597

NORTH DAKOTA (ND)

Fix-It Shop

316 21st Street E.

Dickson, ND 58601

701-225-0766

Ted’s Saw Service

901 South 12th Street

Grand Forks, ND 58201

701-775-7343

Craig’s Small Engine Repair

508 East 2nd Street

Williston, ND 58801

701-774-0798

OHIO (OH)

Carter Electrical Repair

3448 Lunar Rd. NE

Carrollton, OH 44615

330-627-4061

North East Mower Service

412 East 156th Street

Cleveland, OH 44110

216-531-8197

Lefeld Welding & Steel Supply

600 N. Second Street

Coldwater, OH 45828

419-678-2397

Dayton Hardware & Supply

16-32 N. Irwin Street

Dayton, OH 45404

513-258-3721

1-800-762-3426 Ohio only

Ken’s Repair

3246 S. Sectionline

Delaware, OH 43015

740-369-4798

Anytool & Outdoor Power Equip.

21150 Lorain Road

Fairview Park, OH 44126

440-356-1920

Deep Run Mower Service

58781 Heil Addn. Deep Run

Martins Ferry, OH 43935

740-859-6131

Worcester Sales and Service

34200 Lorian Road

N. Ridgeville, OH 44039

440-327-2196

Leonard Hardware

145 North 15th Street

Sebring, OH 44672

330-938-6329

Sparks Sales & Service

5184 Fletcher Chapel Road

Springfield, OH 45502

937-323-5925

United Rentals of North America

5745 Angola Road

Toledo, OH 43615

419-865-5539

OKLAHOMA (OK)

Kay Electric Company

1101 W. Broadway

P.O. Box 635

Altus, OK 73522

580-482-1757

Sooner Distributors

3021 S. High Street

Oklahoma City, OK 73143

405-634-3391

H. L. Moss

1714 E. 15th Street

Tulsa, OK 74104

918-744-1305

OREGON (OR)

Turner’s Lawnmower and Saw

728 SE Robin Way

Gresham, OR 97080

503-665-5441

Pendleton Grain Growers

200 S. 1st Street

Hermiston, OR 97801

541-567-5591

Appliance Repair Central

3203 NE Sandy Blvd.

Portland, OR 97232

503-234-7339

PENNSYLVANIA (PA)

General Rental & Sales Center

Old Rt 1 & 41

Avondale, PA 19311

610-268-2825

Bud’s Tractor and Mower Sevice

21 Bock Lane

Baden, PA 15005

724-869-7142

Engine Doctors

20 Russell Blvd.

Bradford, PA 16701

814-362-3091

Pro-Fix

136 Narrows Road

Edwardsville, PA 18651

570-288-0476

Carson’s Hardware

637-43 Main Street

Hellertown, PA 18055

610-838-7741

Al Muccioli’s Service

2001 Bedford Street

Suite C

Johnstown, PA 15904

814-266-5734

0Valray Nurseries Inc.

R.D. #8, Box 362

Kittanning, PA 16201

724-548-1579

Hillyard Equipment Service Center

633 Lausch Lane

Lancaster, PA 17601

717-569-5768

Petrosky’s Hardware & Supply Co.

602 Alexandria Street

Latrobe, PA 15650

724-537-3541

Raymond, M. Nolt

290 S. Shirk Road

New Holland, PA 17557

717-354-0198

Snyder Electric Company

1500 Chateau Street

Pittsburgh, PA 15233

412-231-3100

Stamm’s Mower Repair

Rd. 5, Pine Lane Box 150

Selinsgrove, PA 17870

570-743-7651

SOUTH CAROLINA (SC)

Hall’s Small Motor Repair

225 Heathwood Drive

Aiken, SC 29803

803-649-6313

Todd’s Electric Motor Repair

110 Laurel Street

Conway, SC 29526

843-248-2444

Laportes

2444 N. 5th Street

Hartsville, SC 29550

843-857-0222

Turner Repair Service

3 E. Belvue Road

Taylors, SC 29687

864-244-1746

TENNESSEE (TN)

Vista Small Engine

1510 Vista Lane

Clarksville, TN 37043

931-552-6953

Master Repair Service

239 Elmore Road

Crossville, TN 38555

931-484-2061

The Speciality Shop

2300 East Magnolia Avenue

Knoxville, TN 37917

865-523-6894

Authorized Equipment Service

812 Polk Avenue

Memphis, TN 38126

901-774-0850

Webb’s Appliance Service Center

1519 Church Street

Nashville, TN 37203

615-329-4079

TEXAS (TX)

Sacate Vedre, Inc.

1906 N. Western

Amarillo, TX 79106

806-373-4409

Industrial Distributing Co.

9411 Neils Thompson Dr.

Austin, TX 78759

361-837-4122

Brunson Feed Mill

709 Sealy Ave.

Ballinger, TX 76821

915-365-2419

Bud’s LP Gas & Supply

225 Grand

Channelview, TX 77330

713-457-2456

Corpus Christi Power Tool & Rpr.

3701 Agnes

Corpus Christi, TX 78405

361-883-1117

Freel Enterprise

118 Elston

Dallas, TX 75232

214-376-9913

Southwest Electric Service

3008 Canton St.

Dallas, TX 75226

214-742-8211

Powell’s Small Engine Service

5906 Hwy 66

Greenville, TX 75402

903-454-1877

Home Appliance Services

1909 Reese Street

Liberty, TX 77575

409-336-8615

Ray DeSpain’s Inc.

P.O. Box 184, Loop 494 North

New Caney, TX 77357

281-689-2121

Service Department

UTAH (UT)

Roosevelt Service Center

133 South 300 East, Box 1546

Roosevelt, UT 84066

435-722-2119

Appliance Service Center

1475 S. Main Street

Salt Lake City, UT 84115

801-467-6361

VERMONT (VT)

Brown and Roberts

182 Main Street

Brattleboro, VT 05301

802-257-4566

VIRGINIA (VA)

Industrial Hardware

4109 Bainbridge Blvd.

Chesapeake, VA 23324

804-543-2232

Warren E. Smith Shops

406 Cambria Street

Christiansburg, VA 24073

540-382-5501

B & B Appliance & Lawn Equipment

71 Lawson Road SE Suite C

Leesburg, VA 22075

703-777-1093

Roberts Small Engine Repair

1109 Curve Road

Pearisburg, VA 24134

540-921-3255

American Power Equip. Ctr.

2381 Staples Mill Road

Richmond, VA 23230

804-354-5810

Outdoor Power Equipment

800 White Marsh Road

Suffolk, VA 23434

804-925-4933

Mills Repair Service

928 Commonwealth Place

Virginia Beach, VA 23464

757-361-9293

WASHINGTON (WA)

Action Small Appliance Service

1500 - 145th Place SE

Bellevue, WA 98007

425-643-9806

TUCO Industrial Products

5223 - 180th SW Suite 4A-1

Lynnwood, WA 98037

425-743-9533

Action Small Appliance

2125 Second Avenue

Seattle, WA 98121

206-448-2020

Lifficks Electric Shop

8239 S. Park Avenue

Tacoma, WA 98408

253-474-7403

WEST VIRGINIA (WV)

Beckley Mower Service

3695 Robert C. Byrd Drive

Beckley, WV 25802

304-253-5748

Raymond’s Service Center

Route 65

Delbarton, WV 25670

304-475-2855

Town and Country Supply

4117 First Avenue

Nitro, WV 25143

304-755-3520

WISCONSIN (WI)

Smith Petroleum Ltd.

217 N. Walworth

Darien, WI 53114

262-724-3206

Ohnstad Power Equipment

12012 Center Hill Road

Darlington, WI 53530

608-776-3802

Bob’s Engine Shop

513 S. Military Road

Fond Du Lac, WI 54935

920-921-2841

Reliance Electric Motors

1621 Livingstone Road

Hudson, WI 54016

715-386-3633

Kewaunee Small Engine

E2068 State Hwy 29

Kewaunee, WI 54216

920-388-2604

Ken’s Economy Sales

8887 Highway A

Marshfield, WI 54449

715-676-2143

Cliff’s Tractor Place

Hwy 35-133

P.O. Box 76

Patch Grove, WI 53817

608-994-2354

Barton Small Engine

1628 N. Main Street

West Bend, WI 53090

262-334-5373

For more information, visit www.desatech.com

22

107990

Page 23

OWNER’S MANUAL

REPLACEMENT

PARTS AND

ACCESSORIES

Purchase these accessories and parts from

your nearest dealer or service center. If they

can not supply these accessories or parts,

either contact your nearest Parts Dealer or

DESA International for referral information. Parts dealers are listed in this manual.

LNT-2

Part Number Description

104302-01S

104301S

097567-01S Guide bar, 10"

091371S Chain, 10"

097568-02S Guide bar, 12"

091373-02S Chain, 12"

075752 Drive sprocket

099178H, 100089-06, 100089-07,

100089-08, & EL-1

Part Number Description

097570-01S Guide bar, 14"

091374-02S Chain, 14"

075752 Drive sprocket

#

#

Guide bar, 8"

Chain, 8"

WARNING: Use only replacement parts and accessories described in

this manual. Use of other parts or accessories could damage saw or

injure operator.

You can also visit DESA International’s

technical service web site at

www.desatech.com.

EL-7, 098031J, 099039J, 100089-04,

100089-05

Part Number Description

097572-03S Guide bar, 16"

091375-02S Chain, 16"

075752 Drive sprocket

POLE SAW, 104316-04 (8")

POLE SAW ASSEMBLY, 104317

Part Number Description

104302-01S Guidebar, 8"

104301S Chain, 8"

075752 Drive Sprocket

DESA International

P.O. Box 90004

Bowling Green, KY 42102-9004

1-800-858-8501

POLE SAW, 106890-01 (10")

POLE SAW ASSEMBLY, 106821

Part Number Description

097567-01S Guidebar, 10"

091371S Chain, 10"

075752 Drive Sprocket

General

Part Number Description

079963-02 Plastic scabbard, 8" & 10"

079963-04 Plastic scabbard,

12", 14", & 16"

106809-01 Hand Guard

077155 Adjusting Plate Assy.

#

Must order both pieces.

107990

23

For more information, visit www.desatech.com

Page 24

REPAIR SERVICE

Note:

Only use original replacement parts.

This will protect your warranty coverage for

parts replaced under warranty.

Each authorized service center is independently owned and operated. For additional

service center or warranty information, call

WARRANTY SERVICE

If saw requires warranty service, return it to

nearest authorized service center. You must

show proof of purchase. If faulty materials