Denon PMA-710AE Service Manual

D&M Holdings lnc.

e

Copyright 2011 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver. 8

●

For purposes of improvement, specifications and design are subject to change without notice.

●

Please use this service manual with referring to the operating instructions without fail.

●

Some illustrations using in this service manual are slightly different from the actual set.

Please refer to the

MODIFICATION NOTICE.

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E1C E1K EUT

PMA-710AE

33

INTEGRATED STEREO AMPLIFIER

S0279-0V08DM/DG1105

Please heed the points listed below during servicing and inspection.

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

CAUTION

CAUTION

◎ Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energize d, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle wi th extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise ch eck that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

2

PMA-710AE

DIMENSION

344

434

60

102.520

26520.5

23

max

50.5 165.5 49

344

3

PMA-710AE

WIRE ARRANGEMENT

Front Panel side

Back Panel side

If wire bundles are untied or moved to perform adjustment or parts replacement etc.,be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

Wire arrangement viewed from the top

4

PMA-710AE

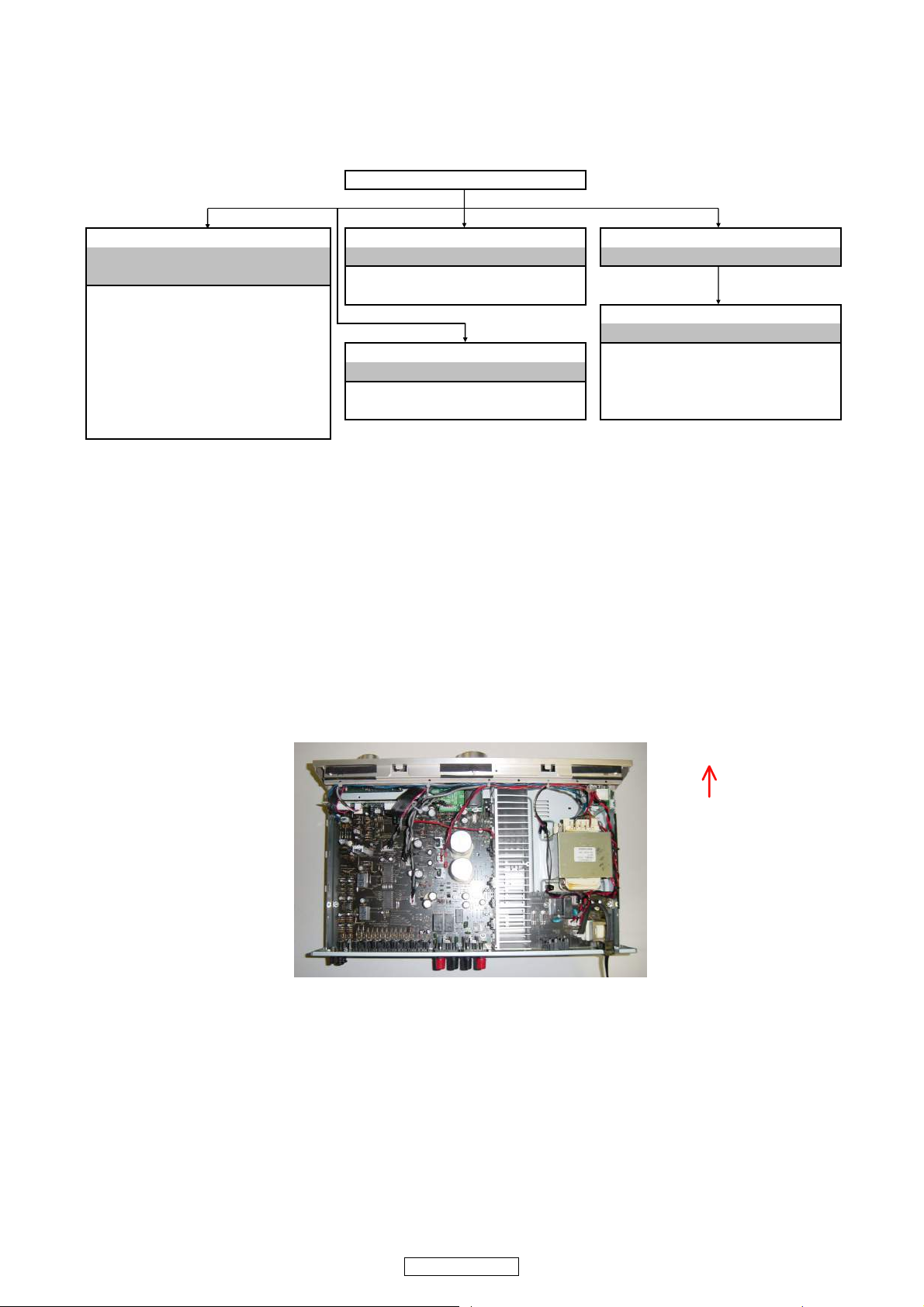

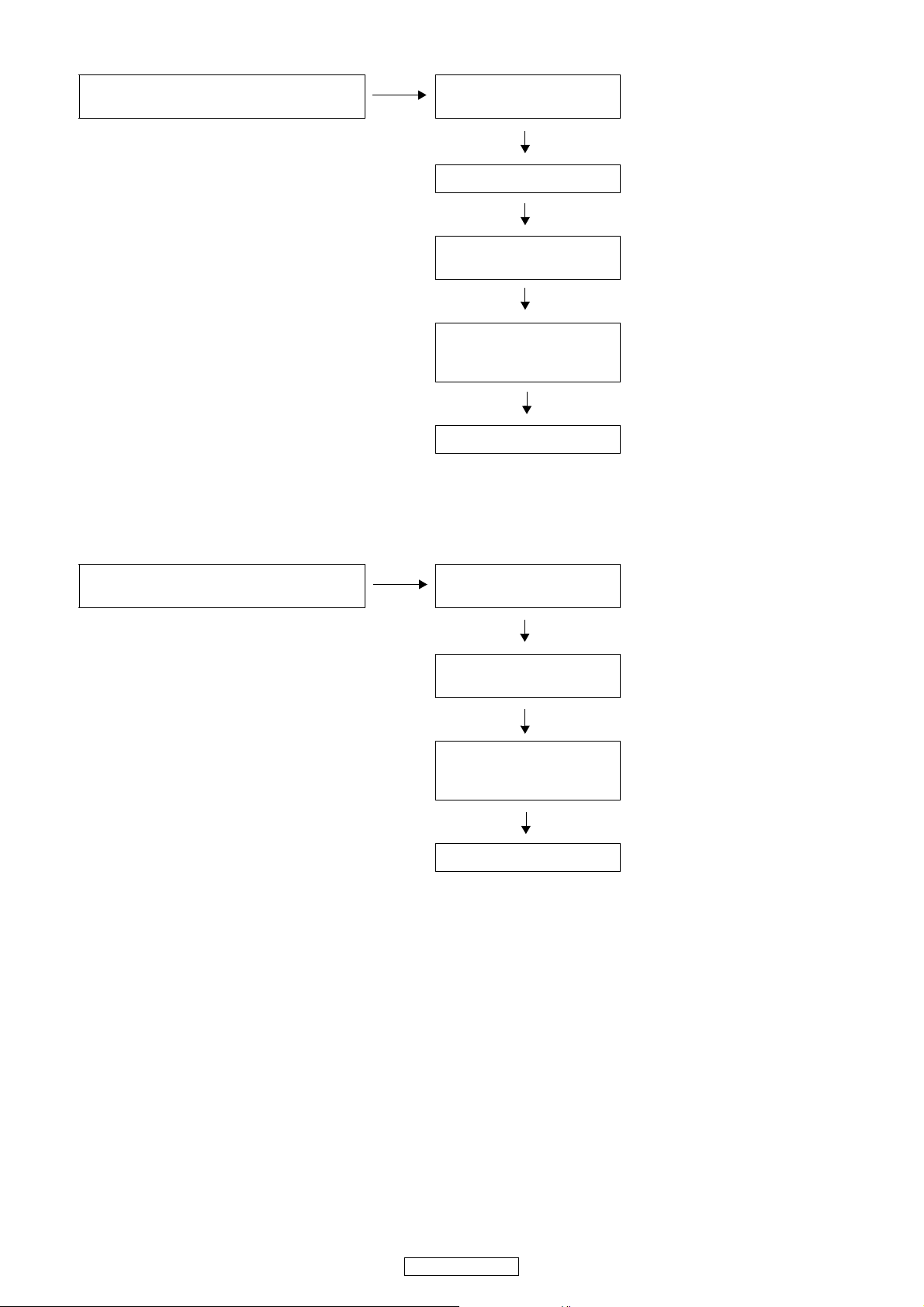

DISASSEMBLY

TOP CABINET

FRONT PANEL ASSY POWER PCB REAR PANEL

Refer to "DISASSEMBLY 1.FRONT PANEL ASSY" Refer to "EXPLODED VIEW" Refer to "EXPLODED VIEW"

and "EXPLODED VIEW" POWER PCB

FRONT PCB (Ref. No. of EXPLODED VIEW : 1-2)

(Ref. No. of EXPLODED VIEW : 2-1)

MAIN PCB ASSY

FUNCTION PCB Refer to "EXPLODED VIEW"

(Ref. No. of EXPLODED VIEW : 2-3)

POWER TRANSFORMER

MAIN PCB ASSY

VOLUME PCB Refer to "EXPLODED VIEW" (Ref. No. of EXPLODED VIEW : 1-1)

(Ref. No. of EXPLODED VIEW : 2-4) POWER TRANSFORMER MCU PCB ASSY

SW/HP PCB (Ref. No. of EXPLODED VIEW : 28) (Ref. No. of EXPLODED VIEW : 2-2)

(Ref. No. of EXPLODED VIEW : 2-5)

The viewpoint of each photograph

(Photografy direction)

[View from above]

Front side

• Disassemble in order of the arrow of the figure of following flow.

• In the case of the re-assembling, assemble it in order of the reverse of the following flow.

• In the case of the re-assembling, observe "attention of assembling" it.

About the photos used for descriptions in the “DISASSEMBLY” section.

• The direction from which the photographs used herein were photograph ed is indicated at "Direction of photograph: ***" at

the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

PMA-710AE

5

1. FRONT PANEL ASSY

Proceeding : CABINET TOP FRONT PANEL ASSY

→

View from bottom

Style pin : Loose

cut

CN52 CN53 CN95

CN92

CN94CN50CN55

CN51

CN93

CN94

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in FRONT PANEL ASSY.

(1) Remove the screws.

(2) Cut the wire clamp bands, then loose the style pins.

(3) Disconnect the connector wires, then remove the screws.

6

PMA-710AE

2. POWER PCB

Proceeding : TOP CABINET POWER PCB

→

Please refer to "EXPLODED VIEW" for the disassembly method in POWER PCB.

Proceeding : TOP CABINET REAR PANEL

→

Please refer to "EXPLODED VIEW" for the disassembly method in REAR PANEL.

Proceeding : TOP CABINET REAR PANEL

→

MAIN PCB ASSY

→

Please refer to "EXPLODED VIEW" for the disassembly method in MAIN PCB ASSY.

Proceeding : TOP CABINET POWER TRANSFORMER

→

Please refer to "EXPLODED VIEW" for the disassembly method in POWER TRANSFORMAER.

3. REAR PANEL

4. MAIN PCB ASSY

5. POWER TRANSFORMER

7

PMA-710AE

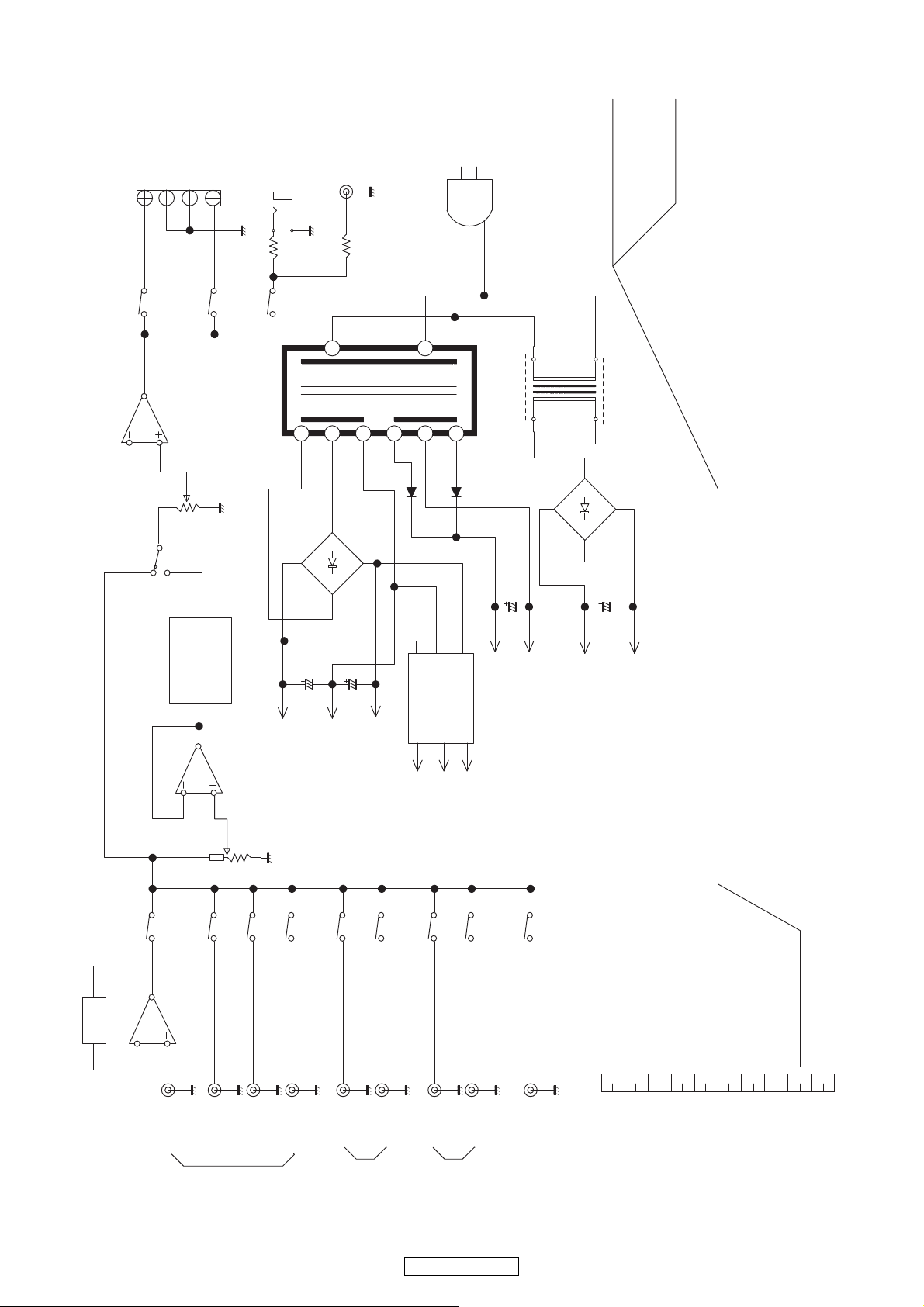

BLOCK AND LEVEL DIAGRAM

EQ

TONE

&

LOUDNESS

SOURCE DIRECT

BALANCE

BUFFER

MAIN VOLUME

POWER AMP

SPEAKER A

SPEAKER B

PHONO

CD

TUNER

LINE

44dB

HEADPHONE

35.5dB(MM)

VOLATAGE

REGULATOR

POWER AMP

OUTPUT STAGE

±16V

±16V

±16V

PHONO EQ

TONE

POWER AMP

FIRST STAGE

CONTROL

&

RELAY

STANDBY

30dB

20dB

10dB

0dB

-10dB

-20dB

-30dB

-40dB

-50dB

-60dB

-70dB

CD etc. 100mV(-20dB)

MM 1.7mV(-55.4dB)

50W/8ohm 20.0V(25.5dB)

AC CORD

PRE OUT

0.7V/10k ohm(-3dB)

INPUT

RECODER-1RECODER-2

PREOUT

PB

REC

PB

REC

2

4

3

1

2

4

3

1

PMA-710AE

8

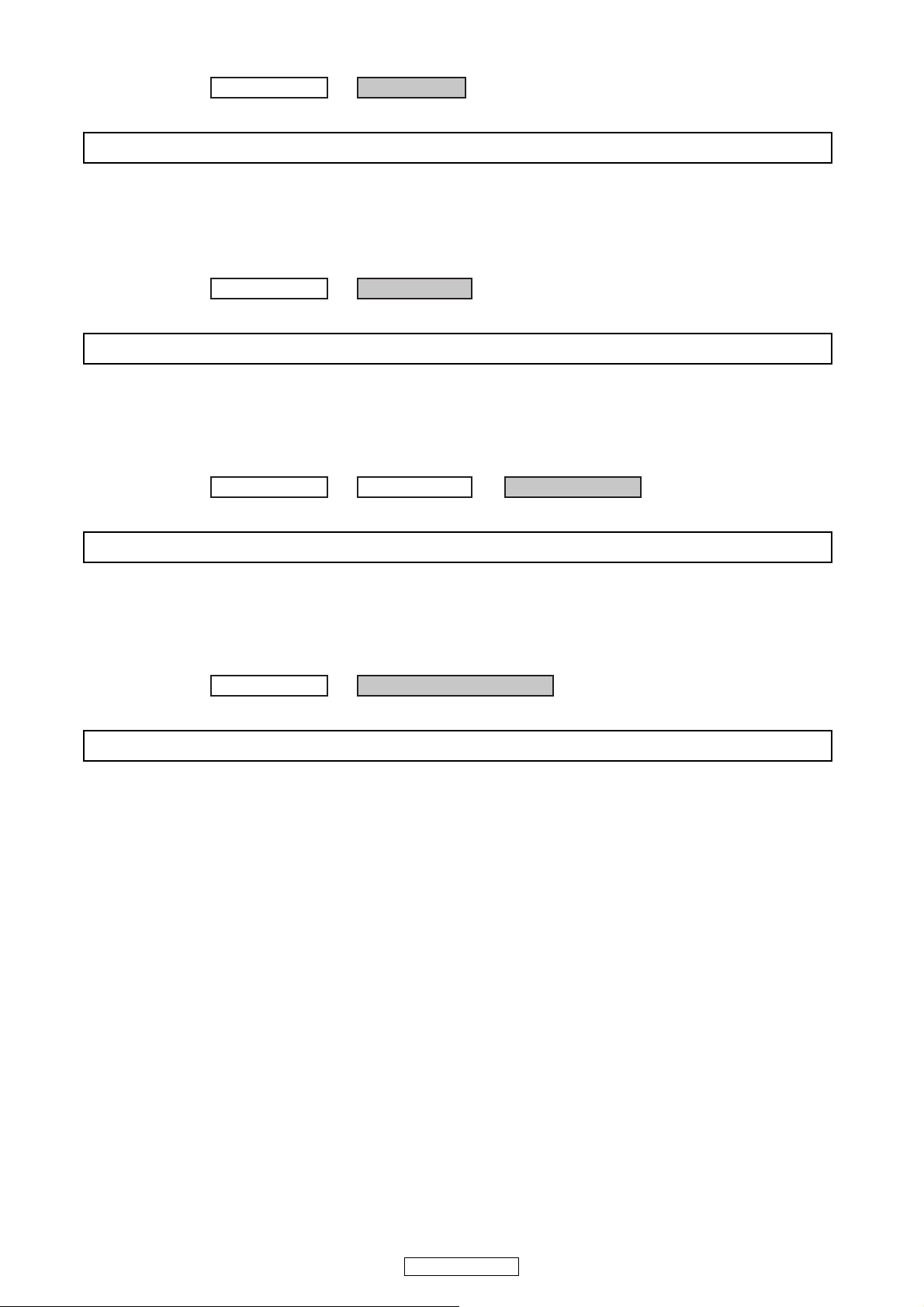

ADJUSTMENT

VR31

CN31

CN32

VR32

Volume

DC Voltmeter

Power

Trans

Idling Current

Required measurement equipment: DC Voltmeter

1. Setup

(1) Place the unit at an ordinary position avoiding direct air flow from an air-conditioner or fan. Do the adjustment at a tem-

perature between 15 °C (59 °F) and 30 °C (86 °F).

(2) Set control as follows.

• POWER switch → OFF (j).

• VOLUME control → fully counterclockwise ( c min.)

• SPEAKER terminals → open: do not connect the speakers, dummy load etc.

2. Adjustment

(1) Remove top cover. And then connect DC Voltmeter to the test points CN31 and CN32 of CUP12196B Main PCB.

(2) Connect power cord to AC wall outlet, and turn POWER switch "ON" ( h ).

(3) Right after power on, adjust VR31 and VR32 so that the DC voltmeter reads 10 ±1mV.

(4) Then after 2 minutes warm up adjust VR31 and VR32 so that the DC voltmeter reads 10 ±1mV.

(5) And after 10 minutes warm up adjust VR31 and VR32 so that the DC voltmeter reads 10 ±0.5mV.

9

PMA-710AE

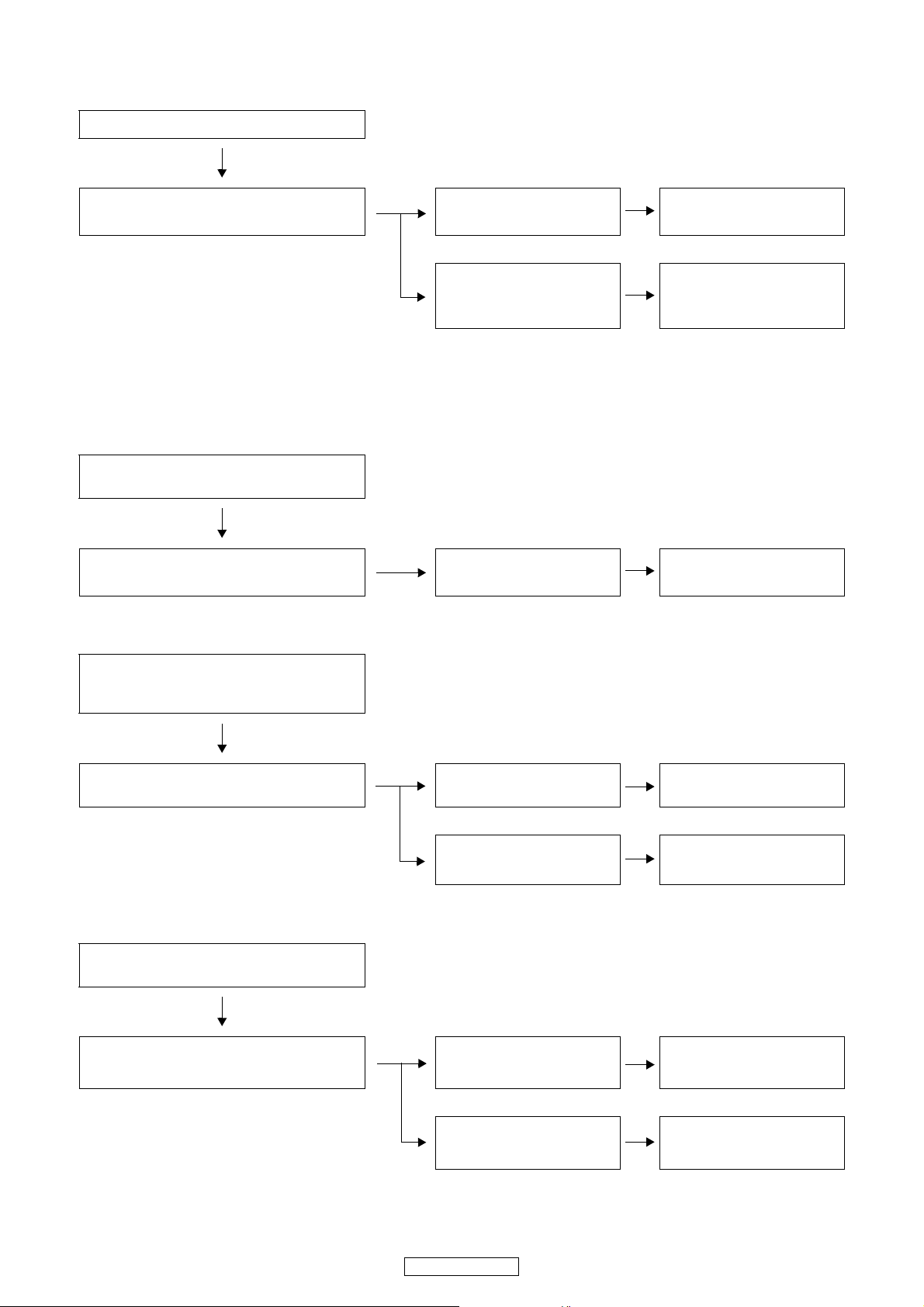

TROUBLE SHOOTING

1. The power can not be turned on. (Power indication LED does not light.)

Check the insertion of the Power Part.

Check whether power is being supplied to the coil

of the standby transformer (T901).

Power not supplied.

Power supplied.

Broken wire in standby transformer (T901)

Malfunction of D941-944, C941

or C943.

2. The power turned on, but a sound does not output normally. (Both channels)

2.1.

Set remains in standby mode with power indicator

LED lit red.

Check each connector.

2.2.

The connectors are inserted

completely.

Malfunction of RC71 or IC41.

Power indicator LED remains flashing red and

muting mode is not canceled (protection mode is

set).

Check the power amplifier output's offset voltage.

2.3.

Set operates, but then power indicator LED

flashes red (protection mode is set).

Check the power amplifier output's offset voltage.

Offset voltage output is 1V or

greater.

No offset voltage is output.

Offset voltage output is 1V or

greater.

Damaged power amplifier circuit.

Damaged temperature detection circuit or protection circuit.

Damaged power amplifier circuit.

No offset voltage is output. Check the bias current.

10

PMA-710AE

2.4.

Power indicator LED is lit normally (green or

orange).

Check each connector.

Is the fuse (F901) normal?

Check the voltage of each

department.

Check the operation of the

switching relay, switching IC

and speaker relay.

Check the Signal line.

3. The power turned on, but a sound does not output normally. (Single channel)

Power indicator LED is lit normally (green or

orange).

Check each connector.

Check the voltage of each

department.

Check the operation of the

switching relay, switching IC

and speaker relay.

Check the Signal line.

11

PMA-710AE

Loading...

Loading...