Page 1

DENON

SERVICE MANUAL

MODEL DN-6OOF

STEREO CD PLAYER

-- TABLE OF CONTENTS --

SPECIFICATIONS ............................................................................ 2

NOTE FOR HANDLING OF LASER PICK-UP ..................................................... 3, 4

DISASSEMBLY .............................................................................. 5

ADJUSTMEN-[ .............................................................................. 6-- 9

HFAT RUN MODE FUNCTION ................................................................. 10

IC TERMINAL FUNCTION ................................................................... 11 - 14

NOTE FOR PARTS LIST ....................................................................... 14

PARTS LIST OF RW.BOARD .................................................................... 15

PACKING & ACCESSORIES ..................................................................... 16

PARTS LIST OF PACKING & ACCESSORIES ....................................................... t6

PARTS LIST OF EXPLODED VIEW ............................................................... 16

EXPLODED VIEW ............................................................................ 17

PARTS LIST C,F FG-70 MECHANISM UNIT ......................................................... 18

EXPLODED VIEW OF FG-70 MECHANISM UNIT .................................................... 18

P.W.BOARD .................................................................................. 19

WIRING DIAGRAM ............................................................................ 20

SCHEMATIC OIAGRAM ........................................................................ 21

SEMICONDUCTORS .......................................................................... 22

NIPPON COI_MBIA CO.. LTD.

Page 2

III DN-6OOF

SPECIFICATIONS

- -AUDIO ....

No.of.Chan_ neJs::.io_.._. ' _2channels-

Frequency Respon'_e: 2 - 20,000 Hz. .

--Dynamic Range: _ _ --98 dB "

Signa!rto-noise Ratio:- 107 dB:"

Harmonic Distortion 0.003 % (,1kHz) _

" SeparatiOn: ......... 103 dB (1 kHz)

Wow & Flutter: Below measurable limit:

(_+0.001% W.peak)

Output Voltage: 2 V

FUNCTIONS AND DISPLAY

Functions: Automatic search, progra.mmed

playback, repeat playback,

manual search, auto space,

time mode, auto edit.

Display: Track number, time, music caTendar,

emphasis feature and engaged

modes.

Others: Headphones jack

DISCS Compact Disc format

SUPPLIED ACCESSORIES Pin-plug connection cord

GENERAL CHARACTERISTICS

Power Supply: Voltage is shown on rating label

Power ConsumptionS-- _10W

Dimensions: 482 (19") W × 88 (3-15/32") H ×

-280 (11-1/32") Dmm

Weight: 4.2 kg

* Design and specifications are subject to change without notice in the course of product improvement.

Page 3

NOTE FOR HANDLING OF LASER PICK-UP

Caution for Handling the Laser Pick-up

The laser pick-up KSS-240A is assembled and precisely adjusted

using a sophisticated manufacturing process in our plant• Do not

disassemble or attempt to-readjust it. Please keep the following

instructions carefully in handling pick-up.

4. Metal Bearing

As the metal bearing of Cu-compound sintered alloy is impregnated

with FROIL946P (*Part No. 529 0054 007), never fail to supply the

bushing with the same lubricant at the time of replacing the pick-up.

1. Handle with Care

(1) Storage

Do not store the pick-up in dusty, high-temperatured or high-hu-

midity environments.

(2) Please take care for preventing from shock by falling down or

careless handling.

2. Laser Diode (LD)

(1) Protect your eyes

The laser beam may_lamage the human eye, since the intensity

of the focuseds:l_ot'm_i reach 7 x 103 W/cr_ 2even ifthe intensity

at the objective lens is 400 ,_W maximum. As the light beam

spreads alter focused through the objective lens, it does not effect

you in the place as far as more than 30 cms. However, do not

look at the laser light beam either through the objective Iens

directly nor another lens or a mirror.

(2) Poison of As

Since the LD chip contains As (Arsenic), as GaAs + GaAIAs, as

known as the poison, although the poison is relatively weak, in

comparing with others, e.g.As203, AsCI3 etc., and the amount is

small, avoid putting the chip in acid or an alkali solution, heating

it over 200°C or puttinc it into your mouth.

" (3) Avoid surge current or electrostatic discharge

The LD may be damaged or deteriorated by its own strong light

it a large current is supplied to it, even if only a short pulse.

Make sure that there is no surge current in the LD driving circuit

by switches or else. Be careful to handle pick-up as it may be

damaged in a moment by human electrostatic discharge. The

pins of the LD are short-circuited by solder for protection during

shipment.

For safety handling of an LD, grounding the human body, meas-

uring equipments and jig is strongly recommended. And still it is

further desirable to make use of mat on the platform and floor for

handling the LD.

To open the short-circuit, remove the soldering quickly with a

soldering iror_whose metal part is grounded.

The temperature of the; soldering iron should be less than 320°C

(30W).

5. Handling

Please handle the laser pick-up with holding the side base (rosin

molded part).

When either a part of human body or some other things may happen

to touch directly with the circuit part of F:W.Board, it may cause

deterioration, take careful attention in handling this base.

6. Deterioration

As KSS-240 comprises built-in RF Amp and APC curcuit, it resists

stronger against external electrostatJc damages than the former

typed pickup. However, there is possibility of pickup deterioration in

the following cases.

(1) Low HF level, or with great numbers of jitters.

(2) Tracking offset (EF Balance) is out of order (Refer to "Confirma-

tion Method of Adjustment" far cortirmation on (1) and (2)).

3. Actuator

(1) The performance of the actuator may be effected if magnetic

material is located nearby, since the actuator has a strong mag-

netic circuit. Do not permit dust to enter through the clearance of

the cover.

(2) Cleaning the lens

It may change.the specifications by attaching dust or ash on the

objective lens. Clean the lens with a cleaning paper dampened

with a little water, not pressing lens with so much strength by the

cleaning paper.

Page 4

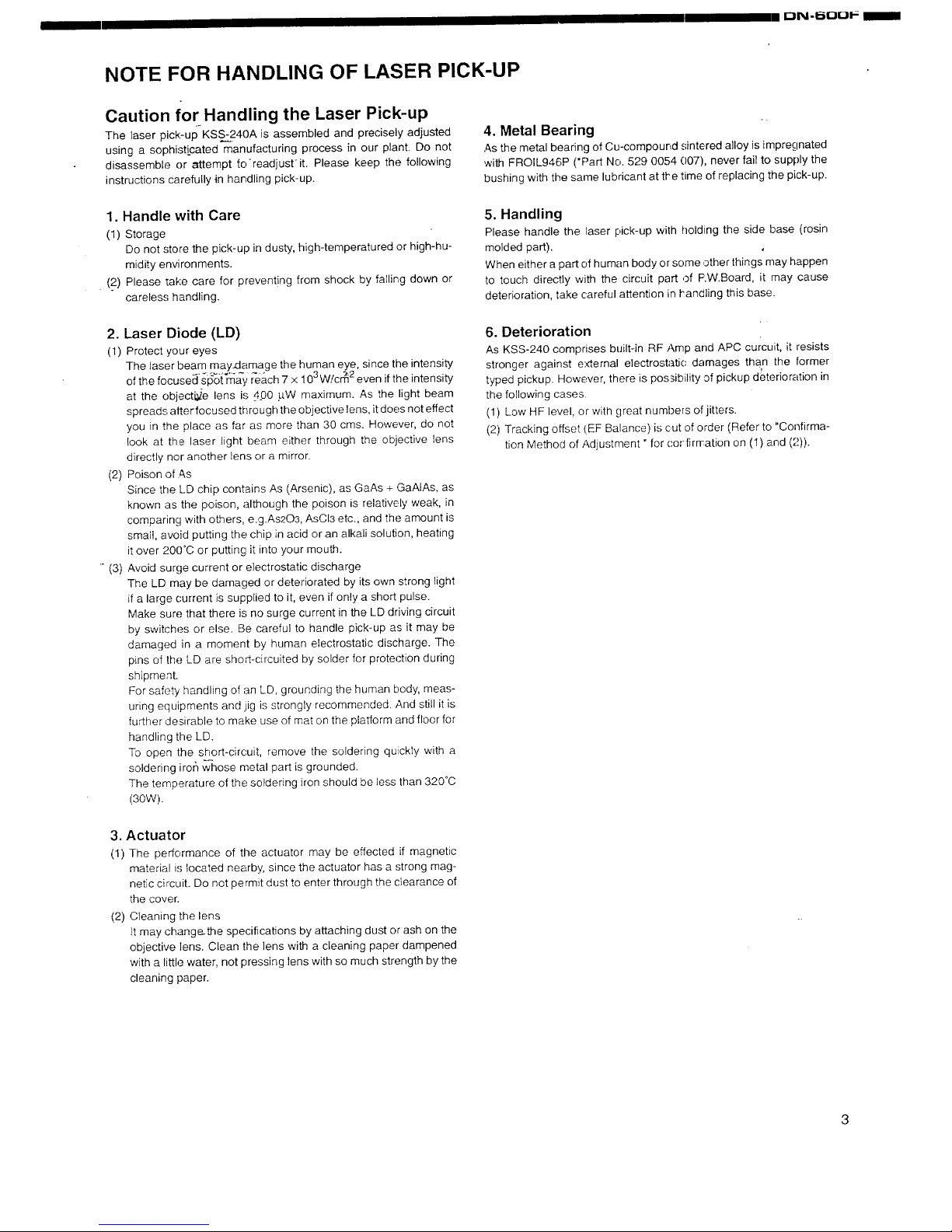

NOTE FOR HANDLING OF LASER PICK-UP

DESCRIPTION OF THE COMPONENTS

+X-axis direction

+Z-axis direction

Object lens

\

OP Slide base

\

Slide rack

Z-axis

A Y-axis

(Tangential direction)

X-axis

(Radial direction)

Double axes cover

/

LO2 Flexible board

Label

//

+Y-axis direction

Flexible fiat cable

connecter

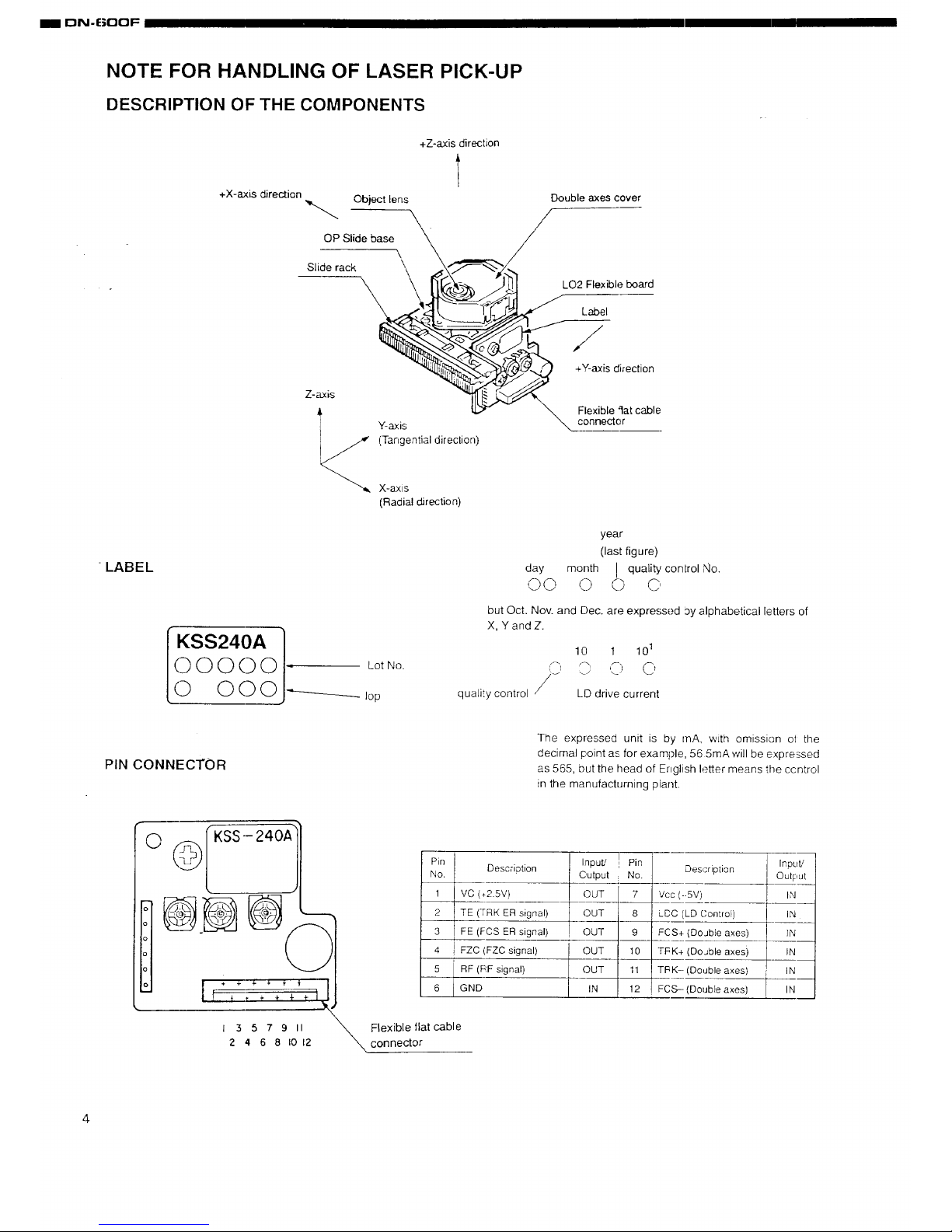

-LABEL

KSS240A

(D O O () O Lot No.

C_) O (_) O lop

year

(last figure)

day month I quality con[rol XIo.

O O 0 0 C'

but Oct. Nov. and Dec. are expressed ay alphabetical letters of

X, YandZ.

quality control /_

I 0 I 101

() _" C,

LD drive current

PIN CONNECTOR

The expressed unit is by mA, with omission ol the

decimal point as for example, 56 5mA will be expressed

as 565, but the head of English letter means tile ccntrol

in the manufacturning plant.

o

If t T t _ _ +

1357911

2 4 681012

Pin

No. Description

1 VC (+2.5V}

2 TE (TRK ER signal)

3 FE (FCS ER signal)

4 ! FZC (FZC signal)

5 RF (RF signal)

6 GND

I

InPut'/ l

Output i

OUT

OUT

QUT

OUT

OUT

! iN

Pin

No.

7 Vc

8 LC

9 FC

10 TF

11 TIq

12 FC

Input/

Description ! Output

l-- vi

(LD C.ontral) IN

(Doable axes) IN

(DoJble axes) IN

(Double axes)

(Double axes) IN

_, lexible flat cable

connector

Page 5

I I_llV-ldLlUl- I

IDISASSEMBLY

,DTOP COVER

Remove 4 screws from both sides and 1 screw from Back Panel.

Screw

Top Cover

t

Screw

• FRONT PANEL

1. Pull Loader frame frontward, and remove loader panel.

2. Remove 2 front panel upper screws.

3. Undo 2 front panel 5pper hooks.

4. Pull front panel and undo 3 lower hooks.

Loader Panel

Screw

Screw

• MECHANISM UNIT

Remove 4 screws.

• CLAMPER

Remove 2 screws.

Pull cJamper and undo 4 hooks.

Clamper

Mechanism Unit

Few

Front Panel

5

Page 6

I ON-6OOF

,ADJUSTMENT

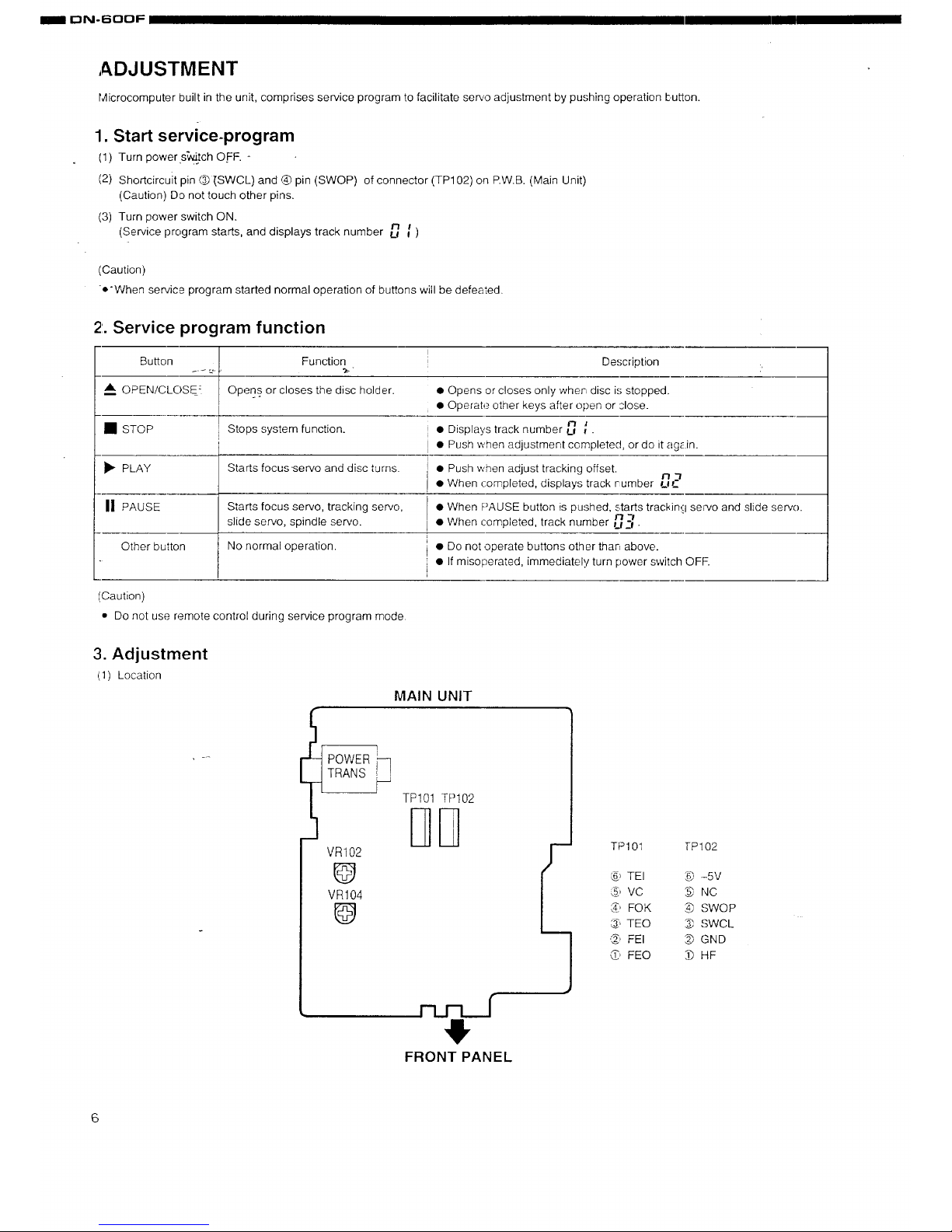

k,licrocomputer built in the unit, comprises service program to facilitate servo adjustment by pushing operation button.

1. Start service-program

(1) Turn power s_tch OFF. -

(2) Shortcircuit pin (_ [SWCL) and (_ pin (SWOP) of connector (TP102) on RW.B. (Main Unit)

(Caution) Do not touch other pins.

(3) Turn power switch ON.

(Service program starts, and displays track number D _)

(Caution)

o'When service program started normal operation of buttons will be defeated.

21.Service program function

_A

Button .... ..,

OPEN/CLOSE: [

Function

Opens or closes the disc holder.

I

• STOP Stops system function.

_" PLAY Starts focusservo and disc turns.

Hi PAUSE Starts focus servo, tracking servo,

slide servo, spindle servo.

Other button No normal operation.

Description

• Opens or closes only when disc is stopped.

• Operate other keys after open or close.

• Displays track number _j _.

• Rush when adjustment completed, or do it ag_.in.

• Push when adjust tracking offset.

rl-i

• When completed, displays track rumber LI C

• When PAUSE button is pushed, starts tracking se_vo and slide servo.

n-t

• When completed, track number U-'#.

• Do not operate buttons other than above.

• If misoperated, immediately turn power switch OFF--.

(Caution)

• Do not use remote control during service program mode.

3. Adjustment

(1) Location

MAIN UNIT

!

POWER_

TRANS

VR102

@

VR104

@

TP101 TP102

SD

FRONT PANEL

TP10I ]-P102

L_ TEl _ -5V

_, VC _, NC

_, FOK _ SWOP

,_, TEO _ SWCL

._, FEI _ GND

_, FEO _ HF

Page 7

ii_P i _il. L.--JLj LJ it- mmmm

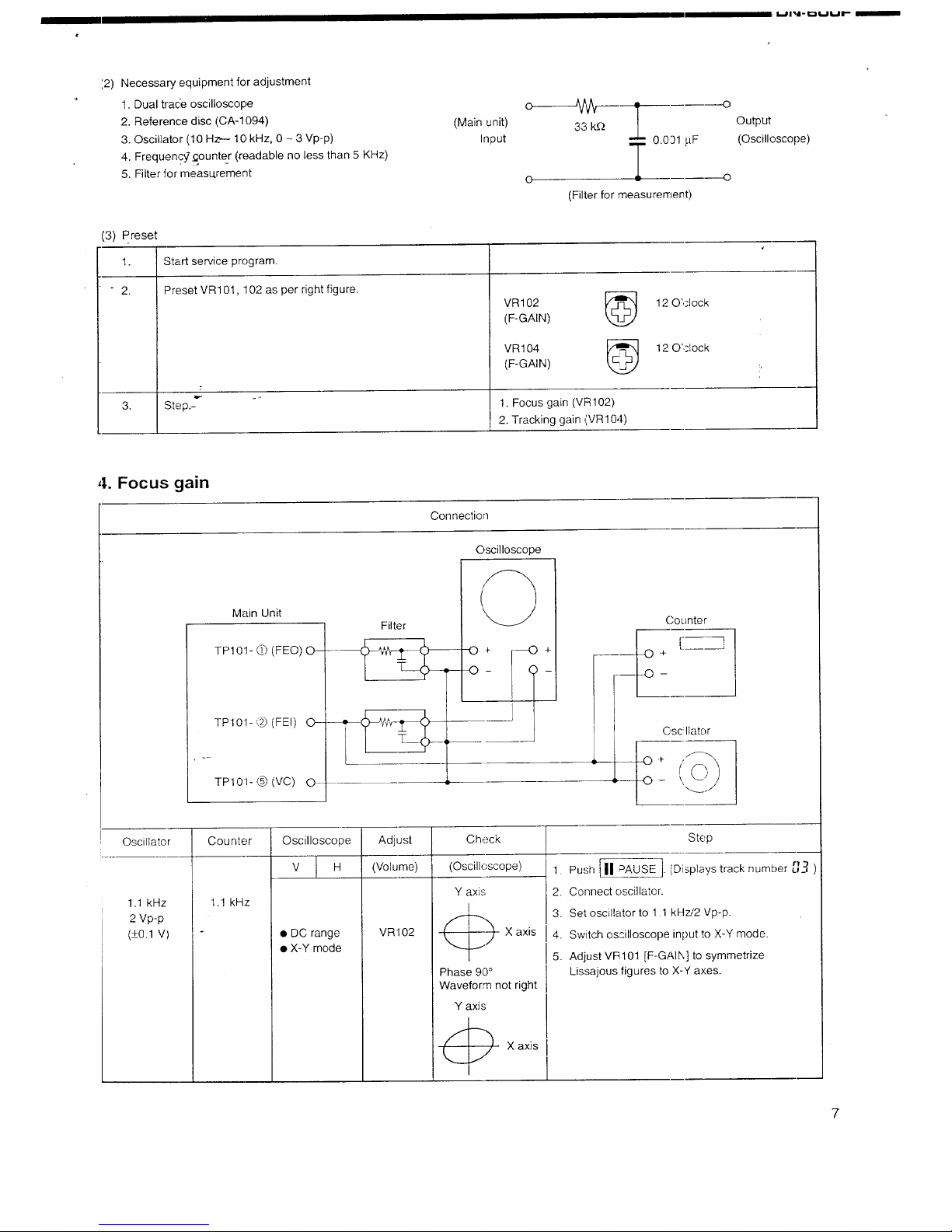

:2) Necessary equipment for adjustment

1. Dual tracie oscilloscope

2. Reference disc (CA-1094)

3. Oscillator (10 Hz,-- 10 kHz, 0 - 3 Vp-p)

4. Frequen,?_._ounte_r (_r_adable no less than 5 KHz)

5. Filter for measu.rement

(Main unit)

Input

33 k_Q Output

0.091 pF (Oscilloscope)

T o

o

(Filter for measuren'lent)

(3) Preset

1.

" " 2,

Start service program.

Preset VR101, 102 as per right figure.

VR102

(F-GAIN)

3. Step.- 1. Focus gain (VR 102)

2. Tracking gain (VR104)

VR104

kL2J

(F-GAIN)

12 O'clock

12 O'ciock

4. Focus gain

Connection

Main Unit

TP101- L[-')(FEO) O--

TP101- (_ (FEI) 0--

TPI01- @ (VC) 0

Filter

Oscilloscope

C'ounter

! C'sc Ilator

Oscillator

1.1 kHz

2 Vp-p

(_+0.1V)

Counter

Oscilloscope

V H

Adjust

(Volume)

Check

(Oscilloscope)

1.1 kHz

• DC range

• X-Y mode

VR102

Y axis

C)

Phase 90°

X axis

Step

1. Push [11#AUSE '1(Displays track number

2. Connect oscillator.

3. Set oscillator to 1.1 kHz/2 Vp-p.

4. Switch oscilloscope input to

X-Y mode.

5. Adjust VR101 [F-G to symmetrize

: Lissajous figures tc X-Y axes.

Waveform not right

Y axis

7

Page 8

I I1,_11| %11,, Q II,,,JU It--

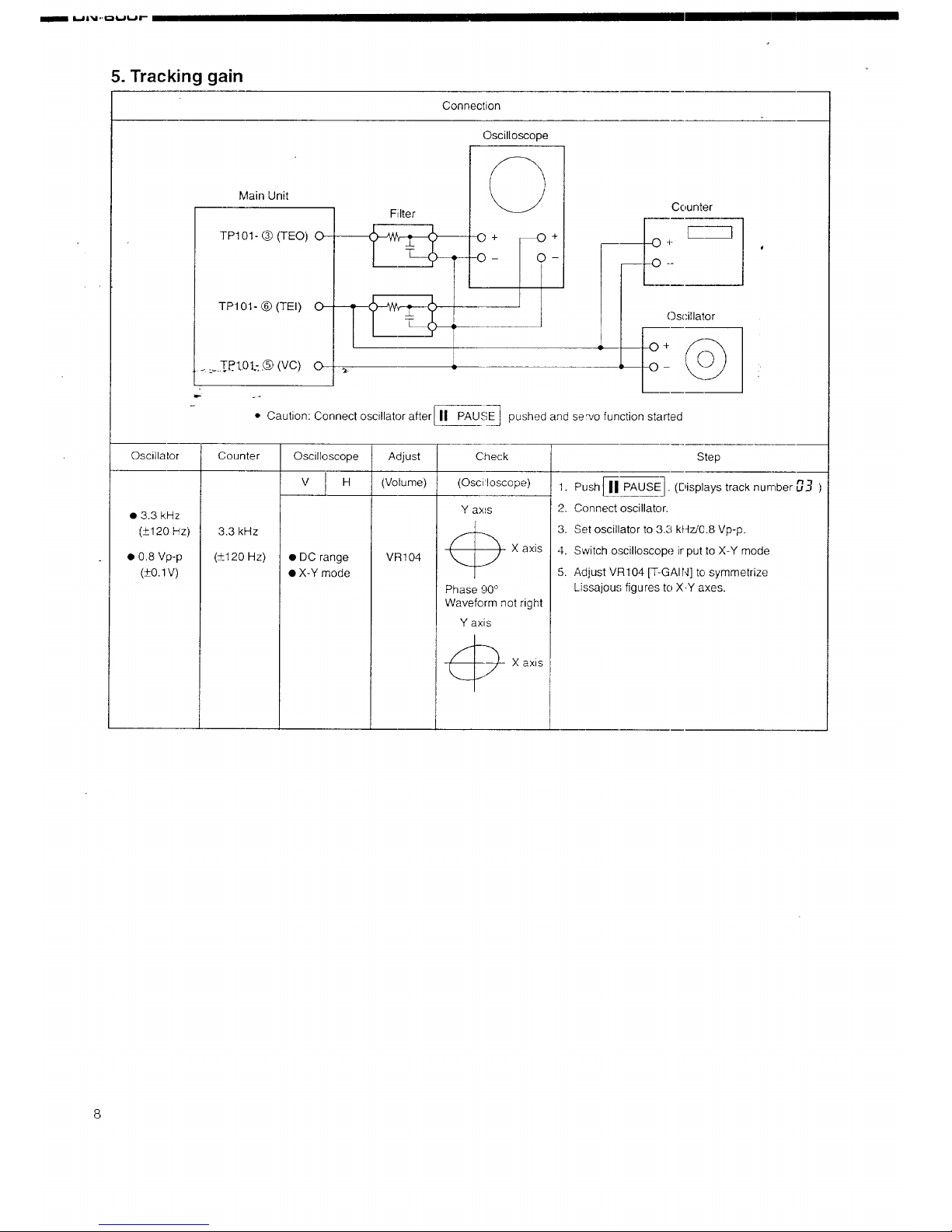

5. Tracking gain

Connection

Oscilloscope

Main Unit

TP101- (_) (TEO) O_

TP101- 0 (TEl) O--

......T,P.t01.:.®(VC) 0

Filter

Counter

Oscillator

• Caution: Connect oscillator afterhl PAUSE] pushed and sewo function started

Oscillator Counter Oscilloscope Adjust

V H (Volume)

• 3.3 kHz

(_+120Hz)

• 0.8 Vp-p

(±011V)

3.3 kHz

(+_120Hz) • DC range

• X-Y mode

VR 104

Check

(Osci !oscope)

Y ax_s

'_ x axis

Phase 90°

Waveform not right

Y axis

Step

1. Push [_ PAUSE I . (Displays track number _.._ )

2. Connect oscillator.

3. Set oscillator to 3,3 kHz/0.8 Vp-p.

4. Switch oscilloscope ir put to X-Y mode

5. Adjust V [T-GAIN] to symmetrize

Lissajou figures to X-Y axes.

Page 9

nN-6OOF

6. Tracking offset (E/F Balance)

Connection

Oscilloscope

Osciloscope

V H

0.1v/div : 1-2

ms/div

Main Unit

/

TP101- O (TEO) O I

1

TP101- O (VC)

Check

(Oscilloscope)

k

A-B

< 20%

A+B

Filter

O

O +

O-

A

B

Step

1. Push _ OPENICLOSE] and load dsc hoMer referrence disk.

2. Push Am OPEN/CLOSE ] and close, holder.

3. Push I • PLAY Ito turn disc. (Displays tracknumber r_-iuC )

4. Short (+)(-) of oscilloscope and check the base line.

5. Confirm that upper and Iower amplituc of the waveform is

symmetric against 0V.

7. HF level

Connection

Main Unit

Probe

TP102- d_ (HF) O 10 1

TP101- @ (VC) O_

J

Oscilloscope

© +

Oscilosc ,op,e

v

50mv/div

o_

20mV/div

H

0.2p/div

or

0.5(_L/ally

• Set input mode to

ALTERNATE or

CHOPPER.

Check

(Oscilloscope)

-/ iA

L

A=l.2±0.3Vp-p

II WJm

S p

I i

1. Push[ II PAUSEJ.(D _aystracknumberu_n_)

2. Check HF level of osc llcscope.

3. Confirm that the wave is in good shape.

(0 pattern ia center must be able to discriminate

clearly.)

mmlL . _..m.i mllll ,llmlll .....

. mmmiiimm_!

9

Page 10

I ON-6OOF

HEAT RUN MODE FUNCTION

Heat Run Mode

1)

To activate

While hold pushin"-g DH_, _1_, _ and _ keys simultaneously, turn the unit power on. The remote control sensor indicator will light to

show that _e unit i¢ shifted in Heat Run mode.

Be sure to Ioadthe disc previously.

Press the disc holder open/close button ( ,,A.AOPENICLOSE) to cancel Heat Run mode.

This mode functions only for a disc with 21 pieces of music or more. For a disc with 20 pieces of music or lesser, please

do not use.

2) Operation

During the Heat Run mode to shift the unit in Play mode makes the unit replays from the first music after opens the loader once and

re-closes it when finish playing the last track (comes into lead out).

Hereafter, operates open/close of loader, servo on, reading of TOC, and playing repeatedly, and repeats playing the two tracks; the first

and the last ones.

3) Error Message

When the system error occurs While in Heat Run mode, the following error message will display on the Track No. indicator and stops

operation ....

1.E1 -

At the time of Focus Servo does not activate.

2. E2

When unable to detect synchronous pattern however the disc is in rotating. (GFS does not drive.)

3. E3

No synchronous pattern can be detected while in Play mode. (No GFS drives.)

4. E4

When TOC is unreadable in despite of servo is activated.

5. E5

In case of loader malfunctions. (Unable to turn on the switch.)

6. E6

The inner circle switch of Pick-up does not turn off.

7. E7

The inner circle switch of Pick-up does not turn on.

-JrThe number of operation up to the stop will be displayed on the minute and second portion of the indicator.

10

Page 11

I I I I ON-6OOF n

IC TERMINAL FUNCTION LIST

CXD2500BQ Terminal Function

Terminal Symbol

No.

1 FOK -

Fsw "

2

3 MON

4 MDP

5 MDS

6 LOCK

7 NC

8 VCOO

9 VCOI

10 TEST

11 PDO

12 Vss

13 NC

14 NC _

15 NC -

16 VPCO

17 VCKI

18 FILO

19 FILl

20 PCO

21 AVss

22 CLI_7

23 AVDD

24 RF

25 TEST2

26 TEST3

27 ASYO

28 TEST4

29 NC

30 PSSL

31 WDCK

32 LRCK

33 VDD

34 DA16. "--

35 DA15

36 DA14

37 DA13

38 DA12

39 DA11

4O DA10

41 DA09

42 D_08

43 DA07

44 DA06

45 DA05

46 DA04

47 DA03

48 DA02

49 DA01

50 APTR

51 APTL

I/O

I

O

O

O

O

O

O

I

I

O

Terminal Function

lnp.ut terminal for OK focussing. Use for Servo-autosequencer.

Output to shift time constant of output filter for spindle motor.

ON/OFF control output for spindle motor.

Servo control for spindle motor.

Servo control for spindle motor..

Sampling GFS by 460 Hz and if it is "H", delivers "H" ; if it is continuously "L" 8 times, deliw;rs "1_".

Oscillation current output for analog EFM PLL.

Oscillation current output for analog EFM PLL. f LOCK=8.6436MHz.

TEST output. Normally GND.

Charge pump output for analog EFM PLL.

GND.

[

0

0

0

I

0

I

I

I

0

I

I

0

0

o

o

o

o

o

0

o

o

o

o

o

0

0

0

0

o

0

o

Charge pump output for variable pitch PLL.

Clock input from extemal VCO lot vadabTe pitch, fc center=16.9344MHz.

Filter output for master PLL. (slave-digital PLL)

Filter input for master PLL.

Charge pump output for master PLL.

Analog GND.

Control voltage output for master VCO.

Analog power supply (+5V).

EFM signal input.

Put to GND.

Put to GND.

Full swing output for EFM. (L=Vss, H:VDD).

Put to GND.

Input to shift output mode of audio data. Serial output at L; parallel output at H.

DiA Interface for 48 bit slot. Word-clock f-2 Fs.

D/A Inlerface for 48 bit slot. LR-dock f- Fs.

Power supply ( _SV ).

At PSSL=I for DA16 (MBS) output: PSSL=0 for serial data of 48 bit slot. (2s'COMP, MSB first).

At PSSL=t for DA15 output; PSSL 0 for bit clock of 48 bit slot.

At PSSL=I

At PSSL=I

At PSSL=I

At PSSL=I

At PSSL-1

At PSSL-1

At PSSL=I

At PSSL=I

At PSSL=I

At PSSL=I

At PSSL=I

At PSSL=I

At PSSL=I for DA02 output; PSSL=0 for MNT1 output.

At PSSL=I for DA01 output; PSSL=0 for MNT0 output.

Control output for aperture compensation. In H for R-oh.

Control output for aperture compensation. In H for L-oh.

for DA14 output; PSSL-0 for serial data of 64 bit slot. (_4s'COMP, LSB first',.

for DA13 output; PSSL:0 for bit clock of 64 bit slot.

for DA12 output; PSSL-0 fDr LR clock of 64 bit slot.

for DA11 output; PSSL=0 for GTOP output.

for DA10 output; PSSL=0 for XUGF output.

for DA09 output; PSSL=0 for XPLCK output.

for DA08 output; PSSL=0 for GFS output.

for DA07 output; PSSL=0 for RFCK output.

for DA06 output; PSSL=0 for C2PO output.

for DA05 output; PSSL=0 for XRAOF output.

for DA04 output; PSSL=0 for MNT3 output.

for DAO3 output; PSSL=0 for MNT2 output.

11

Page 12

ON-BOOF

rminal Symbol

No.

52 Vss

53 XTAI

54 XTAO _

55 XTSL

56 FS-Ui-

57 C4M

58 C16M

59 MD2

60 DOUT

61 EMPH

62 WFCK

63 SCOR

64 SBSO

65 EXCK

66 SQSO

67 SQCK ,_

68 MUTE

69 SENS

70 XRST

71 DATA

72 XLAT

73 Voo

74 CLOK

75 SEIN

76 CNIN

77 DATe

78 XLTO

79 CLKO

80 MIRR

I/O

O-

I

O

O

O

I

O

O

O

O

O

I

I

I

I

I

I

I

I

I

o

o

0

I

Terminal Function

GND.

X'tal oscillation circuit input. By selecting of mode, f=16.9344MHz or 33.8688MIqz.

X'tal oscillation circuit input, f=t6.9344MHz.

Selection input terminal of X'tal. "L" for X'ta116.9344MHz; H for 33.8688MHz.

2/3 Dividing output of 53 and 54 terminal. No change by variable pitch.

4.2336MHz output. When variable pitched, simultaneously changes.

16.9344MHz output. When variable pitched, simu Itaneously changes.

Digital-out ON/OFF control. ON at H; OFF at L.

Digital-out output terminal.

When playback disc emphasized, outputs H; otherwise outputs h

WFCK ( Write Flame Clock) output.

Output of subcode sync. S0+S1. H output when either one detected.

Serial output of Sub P-W.

Clock iutput for SBSO read-out.

I-Output for Sub Q_O bits and PCM peak level 16 bits.

i. Clock input for SQSO read-out.

Mute at H; remove mute at L.

SENS output. Outputs to CPU.

System reset input. Resets at "1._".

Input of serial data from CPU.

Input for latch from CPU. Latches serial data at release.

Power supply (+5V).

Serial data transfer clock input from CPU.

SENS input from SSR

Input of tracking pulse.

Serial data output to SSR

Serial data latch output to SSP.

Serial data transfer clock output to SSR

Mirror signal input. Use for track jump for over 128 tracks, using autosequencer.

CXD2500BQ

C 4M

(:i 6')

PDO

VCOl

VCOO

_CO

FILl

FPL(?

CLTV

Rf

ASY()

WFC<

seer

EXCK

5'350

EMPH

SQCK

SQSO

MON

FSW

MDP

MDS

TEST

NC

32k RA_

91G:TALPLL i

i

i

ERROR CORRECTER

!

SERVC DA re

AUTO CLKO

SEQUENCER XL_O

?-

Ca g _ #

12

Page 13

nN.6OOF

C;XA1372S Terminal Function

l-erminal

No.

1

2

3

4

5

6

7

-8

9

10

11

12

13

14

15

17

18

19

20

21

22

23

24

26

27

28

29

30

31

32

33

35

36

37

38

39

40

41

43

44

45

46

48

Symbol

TE -;

TDFCT

ATSC

FZC

FE

FDFCT

Vc

FGD

FS3

FLB

FEO

FE-

SRCH

TGU

TG2

TAO

TA-

SL+

SLQ

SL-

FSET

ISET

SSTOP

DIRC

LOCK

CLK

XLT

DATA

XRST

C.OUT

SENS

MIRR

DFCT

ASY

EFM

FOK

C(" 1

CC2

CB

CP

RF:I

RFO

]_C

I/O

I

I

I

I

I

I

I

I

I

C,

I

I

C,

I

I

0

I

I

I

I

I

I

I

I

I

I

0

0

0

0

I

O

0

0

I

I

I

1

0

I

Terminal Function

Tracking error signal input terminal.

Capacitor connecting terminal for time constant at the time of defect

Input terminal of ATSC detecting window comparator.

Input terminal of focus zero-cross comparator.

Focus error signal input terminal. "

Capacitor connecting terminal for time constant at the time of defect.

Mid-point voltage input terminal.

In case of reducing higher range gain of focus servo, connect a capacitor between this te

Shifts higher range gain of focus servo by FS3 ON/OFF.

Terminal for external time constant to increase lower range of focus servo.

Focus drive output.

Reverse input terminal for locus amplifier.

Terminal for external time constant to make focus search waveform.

Terminal for external time constant to shift higher range gain of tracking.

Terminal for external time constant to shift higher range gain of tracking.

Tracking drive output.

Reverse input terminal for tracking amplifier.

Non-reverse input terminal for sled amplifier.

Sled drive output.

Reverse input terminal for sled amplifier.

Terminal to compensate peak in locus/tracking phase.

Delivers a current to set the height of focus search, track jump, and sled kick

Terminal for limit switch ON/OFF to detect disc innermost circle.

Terminal is used at the lime of 1 track jump. A 4.7 kohm pull up resistor is included.

Reckless drive protection circuit of sted; activates at "L'. A 47k ohm pull up resistor is inc

Serial data transfer clock input from CPU.

Latch input from CPU.

Serial data input from CPU

Reset input terminal. Resets at "L".

Terminal to output signal lor track number cou:-4.

Terminal to oulput FZC, AS, TZC, SSTOP by cammand from CPU.

Oulput terminal for MIRR camparator.

Output terminal for DEFECT comparator

Input terminal for auto-symmetric control.

Output terminal for EFM comparator

Output terminal for focus OK (FOK) comparator

DEFECT bottom hold output terminal.

Input terminal to input DEFECT bottom held o_t_ut by capacitance combination.

Capacitor connecting terminal for DEFECT bo:tom hold.

MIRR hold capacitor connec:ing terminal. A non-reverse input terminal for MIRR comparator.

Input terminal to input RF summing amplifier output by capacitance combination.

Output terminal for RF summing amplifier. Check point for eye pattern.

Tracking zero-cross comparator input terminal

and terminal number (9).

13

Page 14

ON,.6OOF

€

CXA1372S

XRST

C OUT

SEN S

D G,_D

MIRF'

DFCI"

ASY (

EFkl !

FOK !

cc 2 1

D VCC I

,

_ g° _= < _ __ _ _,d,

-Ill: I:Z- I

TA--

TAO

A VCC

TG:!

,TGU

,SRCH

, FEO

J FS5

FCD

I VC

NOTE FOR PARTS LIST

• Part indicated with the mark " _') " are not always in stock and possibly to take a long period of time for supplying, or nn

some case supplying of part may be refused.

• When ordering of part, clearly indicate "1" and '1" (i) to avoid rots-supplying.

• Ordering part without stating its part number can not be supplied.

• Part indicated with the mark "-k" is not illustrated in the exploded view.

• Not including Carbon Film _+5%, 1/4W Type in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol _ _ have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

• Resistors • Capacitors

Ex.:

and per- I ance 7rror

I forrnance

RD : Carbon 2B : 1/8W F : _t%.

RC : Cornpostion 2E l_4W G : z2%

RS : Melal oxide lilm 3H2H fiWI'2W J : :5%

RW : Wincing 3A : 1W K : ±10%

RN : Metal tim 3D 2W M : _20%

RK : Metal mixlure 3; 3W

RN 14K 2E 182 G FR Ex.: CE

Type Shape Power Resist- Allowable Others Type

1 1

P : Pulse-resislanl :ype

NL : Low noise lype

NB : Non-bLIrning lype

FR : Fuse-resislor

F : Lead wire forming

* Resistance

1 8 2 = 1800 ohr,'n = 1.8 kohm

T [---- Indicates number of zeros after effective number.

2-digit effective number.

•Units: ohm

1 R 2 ==. 1.2 ohm

-- ---- 1-digit effective number.

2-digit effective number, decimal poinl indicated by R.

• Units: ohm

* Capacity (electrolyte only)

2 2 2 _ 2200_F

_[_ T..___ Indicates number of zeros after effective number.

2-digit effective number.

• Units: pF.

2 R 2 =::, 2.2pF

T -___ 1-digit effective number.

2-digit effective number, decimal point indicated by R.

• Units: HF.

CE : Aluminum foil

eleclrolytic

CA : Aluminum sol,d

ele¢lrolylic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM : Mica

CF Metat_ized

CH Metallized

04W 1 H 2R2 M BP

Shape Dielectric Capacity A Iowable Olhers

and per- strength euror I

formance l ['---J 1

F : =1%

0J : 6 3V I

1A : 13V I

1C 15V I

1E 25V I

tV 35V

1H 53V

2A 130V

2B 125V

2C lS0V

2D 230V

2E 250V

2H 530V

2J : 630V

G :2%

J -5%

K :10%

M ::20%

Z +8C %

20%

P +1C0%

-0%

C :0 25pF

D ::0 5pF

- Oelers

HS : High stability typ,_=

BP : Non-polar type

HF : Ripple resistant type

DL : For charge al_d cischar(je

HF : For assubng high

frequency

U : UL part

C : CSA part

W : UL-CSA lype

F Lead wire forming

* Capacity (except electrolyte)

2 2 2 _ 2200pF = 0.0022pF

- T.---(More than 2)-- Indicates numbe_ of ;:eros after effective nurnber.

2-digit effective number.

• Units: #F.

2 2 1 =_,2_OpF

T T"--"(0 or 1)----

• Units: pF.

Indicates number of zeros after effective number.

2-digit effective number.

• When the dielectric strength is indicated in AC. "AC" is included afterthe dieelectric

strength value

14

Page 15

QN.6OOF

PARTS LIST OF P.W.BOARD

3U-2599 MAIN UNIT

Ref. No. I Part No. I

SEMICONDUCTOR GROUP

{C102

IC103

IC105,106

IC201

1(;202

IC203

IC204

IC300

IC302,303

IC501

IC502,503

IC701

IC705

TR109

TR110

TR111

TRl12

TRl13

TRl14

TRl15

TRl16

TRl17

TR118

TR501

TR502

TR503

TR600,601

TR702

TR703

TR704

TR706,707

D207

D501-506

D507

D508

D601-608

D701

Part Name I Remarks

2621305 001

2630223 006

2630223 006

262 1846007

2621819 005

2620824 004

262 1352009

262 1761001

262 1409004

2630693 005

2680073905

2620591007

2630223 006

2740036 905

2720025 907

2740036 905

272OO25907

2740036 905

2720025 907

2740136 009

2720025 907

2740036 905

2720025 907

2740136 009

2720093 007

2710192 905

2740160 907

2690014 909

2690020 906

2710192 905

2740160 907

2760503 900

2"/60613 900

2760483 907

2760464 900

2760432 903

2760432 903

ICCXA1372S

ICTL4558P-B

ICTL4558P-B

ICM38173M6-161FP

ICCXD25OOBQ

ICSN74LS624N

ICTC74HCT04AP

ICSM5841BP

IC PCM61P-L

IC M5290P

IC ProtectorICP-N15T

IC HD74HC00P

ICTL4558P-B

Transistor2SD468(C)TF

Transistor2SB562(C)TF

Transistor2SD468(C)TF

Transistor2SB562(C)TF

Transistor2SD468(C)TF

Transistor2SB562(C)TF

Transistor2SD1913

Transistor2SB562(C)TF

Transistor2SD468(C)TF

Transistor2SB562(C)TF

Transistor2SD1913

Transistor2SB1274

Transistor2SA933(S)TP

Transistor2SD2144STPU

TransistorDTA124XS(22K-47K)'r

TransistorDTC114ES(1OK-10K)T

Transistor2SA933(S)TP

Transistor2SD2144STPU

Diode1SS198TE

Diode1A3-1

ZanerDiodeHZS30-1TD

ZonerDiodeHZS7A-1TD

Diode1SS270ATE

Diode1SS270ATE

BuiltinResistor

Builtin Resistor

RESISTORS GROUP

(Not included Carbon film +5%, 1/4W "_jpe)

VR102,104 2116093954 / Adjust22kohm +V06PB223(IM)

VR300,301 2116093970 1Adjust100kohm V06PB104(IM)

CAPACITORS GROUP

C106

C107

C108

C109-112

C113

Cl14

Cl16

2539030 934

2539035 926

2539030 921

2561034 979

2544337 910

2561035 910

2539030 963

CeramicO.O0331.tFt25V

CeramicO.027pF/25V

CeramicO.O022pFt25V

MetallizedO.IHF/50V

Electrolytic6.8pF/50V

Metatlized0.22pF/50V

Ceramic0.01uFI25V

CK45=1E332KT

CK45=1E273KT

CK45=1E222KT

CF93A1HlO4JT

CE04W1H6R8MT

CF93A1H224JT

CK45=1E103KT

Ref. No.

C117

C118,119

C120

C121

C122,123

C124

C125

C126

C127

C128

C129

C130

C131

0132

C1&3

0134

C135

C136

C140

C141

C142

C164

C166

C168

C170,171,

173

C174

C202-204

(:;2O5

C210

C211

C212,213

C214

C215,216

C217

C220

C222

C223,224

C227

C256

C257,258

C259

C300,30t

C302

C304

C306,307

C308,309

C311

C327

C328

C350

C353

C501

C502

C503

C505

C507

C508

Part No.

2539039 906

2531180921

2539039 906

2531181904

2544260 919

2539030 963

2539030 992

2539030 963

2539030 934

2539031 962

2539039 906

2531179 990

2539031 988

2534538 910

2534536 909

256 1034979

2543055918

2534538 949

2534538 910

2539030 934

2539039 906

2534536 941

2534536 941

2534538 910

2544254 938

Part Name

Ceramic0.1p.F/25V

Ceramic0.001pF/50V

Ceramic0.1pR25V

Ceramic0.01p.F/50V

Electrolytic0.22pF/50V

Ceramic0.01p_F/25V

Ceramic0.038pF/25V

Ceramic0.01p.F/25V

Ceramic0.OO33pF/25V

Ceramic0.0027pF/25V

Ceramic0.1p.F/25V

Ceramic560pF/50V

Ceramic0.0056pF/25V

Ceramic75pF/50V

Ceramic10pF/50V

Metallized0.1pF/50V

Electrolytic10pF/35VBipolar

Ceramic100pF/50V

Ceramic75pF/50V

Ceramic0.0033_F/25V

Ceramic0.1pF/25V

Ceramic15pF/50V

Ceramic15pF/50V

Ceramic75pF/50V

Electrolytic47pF/16V

2539039 906 Ceramic0.1pF/25V

2531181 904 _,eramicO.01mFl50V

2539039 906 Ceramic0.1pF/25V

2539031 904 CeramicO.047p_F/25V

253 1180947 CeramicO.O015uF/50V

2539039 906 CeramicO.lpF/25V

2544250932 Electrolytic220pF/6.3V

2539039 906 CeramicO.lpF/25V

2544254 941 Electrolytic100pF/16V

2544260 922 ElectrolyticO.33#F/50V

2534537937 Ceramic36pF/50V

2534536941 Ceramic15pF/50V

2531181904 CeramicO.01p.F/50V

2531180921 CeramicO.011JF/50V

2531180921 CeramicO.O01pF/50V

2531181904 CeramicO.01_.=F/50V

2544254954 Electrolytic220pF/16V

2539039 906 Ceramic0.1pF/25V

2539039 906 Ceramic0.1pF/25V

2531180905 Ceramic680pF/50V

2531121906 CeramicO.O056pF/50V

2544254 941 Electrolytic100pF/16V

2539039 906 CeramicO.lpF/25V

2544254 925 Electrolytic33BFI16V

2539039 906 Ceramic0.1pF/25V

2539039 906 CeramicO.lp.F/25V

2544254 792 i Electrolytic2200pF/16V

2644255 717 Electrolytic4700pF/16V

2544254 954 i Electrolytic220p.F/16V

2544260 948 ElectrolyticlpF/50V

2544262 946 I Electrolytic47p.F/63V

2544261 921 I ElectrolyticIO0,uF/50V

Remarks

CK45=1EIO4ZT

CK45B1HIO2KT

CK45=1E104ZT

CK45F1HIO3ZT"

CEO4W1HR22MT

CK45=1E103KT

CK45=1E333KT

CK45=1E103KT

CK45=1E332KT

CK45=1E272KT

CK45=1EIO4ZT

CK45BlI"1561KT

CK45=1E562KT

CK45SL1H750JT

CC45SL1H100DT

CF93A1Hi04JT

CE04D1V100MBP'[

CCA5SL1H101JT

CC45SL1H750JT

CK45=1E332KT

CK45=1E104Z1"

CC45SL1H150JT

CC45SL1H150JT

CC45SL1H750JT

CEO4W1C470MT

CK45=1E104ZT

GK45F1H103ZT

CK45=1EIO4ZT

CK45=1E473KT

CK45B11,1152KT

GK45=1EIO4ZT

CEO4WOJ221MT

CK45=1E104z'r

CEO4W1C101MT

CE04W1HR33MT

CC45SL1H360JT

CC45SL1H150JT

CK45F1H103ZT

CK45B1H102KT

CK45B1H102KT

CK45F1H103ZT

CE04W1C221MT

CK45=lE104ZT

CK45=1E104ZT

CK45B1H631KT

CK45B1H562KT

CE04W1C101MT

CK45=1EIO4ZT

CEO4W1C330MT

CK45=1EIO4ZT

CK45=1EIO4ZT

CEO4W1C222MC

CE04W1C472MC

CEO4W1C221MT

CEO4W1HOIOMT

CEO4W1J470MT

CEO4W1HIO1MT

Ref. No. Part Name Remarks

C509,510

C511

C512

C600,601

C704

C710,711

C716,717

C718,719

C720,721

C730

C731

C732

C733

C800

Part No.

2544258 934

2544260 964

2531122905

2531181904

2544254 954

2544368 934

2534537 982

2544250 929

2544254 941

253 1181904

2534538 949

2539039 906

2539039 906

2539039 906

Electrotytic33pF/35V

Electrolytic3.3pF/50V

CeramicO.O068pF/50V

CeramicO.01pF/50V

Electrolytic220p.F/16V

Electrolytic100p.F/25V

Ceramic56pF/50V

ElectrolyticIOOp.F/6.3V

Electrolytic100p.F/16V

Ceramic0.01pF/50V

CeramicIOOpF/50V

Ceramic0.1pF/25V

CeramicO.lpF/25V

Ceramic0.1p.F/25V

CE04W1V330MT

CE04W1H3R3MT

CK45B1H682KT

CK45F1H103Zi-

CE04W10221MT

CE04W1E101MT

CC45SL1H560JT

CE04W0J101MT

CE04W1C101MT

CK45F1H103ZT

CCA5SL1H101JT

CK45=1E104ZT

CK45=1E104ZT

CK45=lE104ZT

OTHER PARTS

)(200 399 0165007

X201 399 0111006

RM601 499 0264004

4123951016

PT300 2318063 009

HJ601 204 8364007

JK701 204 8262002

JK702 2048311021

SW600 212 1039000

LCD601 3934110005

CB101 205 0321054

CB102 205 0343058

CB103 205 0683006

CB2O3 205 0736021

CB500 2050581 001

CB601 2050535 060

cB602 2050736021

cs601 2050837007

TP101,102 2050190065

+++++++++ii++ +++

iiiii ! ii i+ ! i+i

i+,iiii+,+++,ii iii iiiii!iiiiiiiii+ i++i+ +,

X'Tal(16.9344MHz)

CST4.23MGW040

RemoteSensor

(GP1U571)

Reflector

PulseTrans

HeadPhonejack

1PPinJack (Digitalout)

2PPinJack(FIXout)

1PPushSwitch

(PowerON-OFF)

FLTube(FIPBNM6A)

5PConnectorBase(Red)

5PConnectorBase

(KR-PH)

FFCConnectorBase(12P)

31PFFC ConnectorBase

2PVHConnectorBase

4PConnectorBase

31P FFCConnectorBase

4PConnectorSocket

6PNHConnectorBase

+iiii ! @ iiii+,iii+!ii'+i+',+i

iiiii!!!!iii iii iii iiiii!!ii+!

15

Page 16

I UNI_U_ llIllll II I IIIIIIIIIII

PACKING & ACCESSORIES

Multi-Voltage (Asia) Only

r....

16

!

-@

501 1739 174: (U.S.A., Canada, Europe and Multi-Voltage Model)

501 1739 187: (U.K. Model)

PARTS LIST OF

PACKING & ACCESSORIES PARTS LIST OF EXPLODED VIEW

Ref. No. PartNo. Part Name

101 504 0092060 STYRENEPAPER

101 504 0170005 PROTECTORSHEET

102 505 0102092 STYRENEPAPER

103 503 1130009 CUSHION

104 503 1152003 SUBCUSHION

105 501 1739174 CARTONCASE

105 501 1739187 CARTONCASE

106 5050038 030 POLYCOVER

107 5112683 006 INST,MANUAL

108 2032360 004 2P PINCORD

Remarks

ForACCord

U.K.onty

U.K.only

U.S.A.,Canada,

Europe,Multi-

Voltage(Asia)

U.K.only

ForAcc_sories

O'ty

1

1

1

2

2

1

1

1

1

1

1!0 5150692 004 DELWARRANTYCOM U.S.A.only 1

Ref. No, Part No. Part Name Remarks

r-- 1 3u-2599 MAINUNITASS'Y

[

- 1-1 -- MAIN UNIT

1-2 -- DISPLAY/ KEYUNIT

1-3 -- HEAD PHONEUNIT

-1-4 -- POWER SWITCHUNIT

2 2048364007 HEADPHONEJACK HJ601

3 3934110005 FLTUBE(FIP8NM6A)

4 2121039000 1PPUSHSWITCH SW600

6 3870028007 CDMECHA.UNIT(FG-70)

® 7 1220187113 TOPCOVERSPACER

® 9 144 2411104 FRONTPANEL

® 10 146 1392408 SUB PANELAss'y

11 1131540195 SERIESKNOB

12 1139245285 TENKEY

13 1131541055 FUNCTIONKNOB

14 1131561051 MANUALSEARCHKNOB

15 0090011012 31P FFCCORD

17 1131357281 POWERSWITCHKNOB

18 1461394147 LOADERPANEL

21 4737508017 3x10 CBTS(P)-B

22 4737002 021 3x8 CBTS(S)-B

24 4737002 005 3x6 CBTS(S)-Z

25 4737007 071 4x12 CBTS(S)-ZNB

27 2048262002 1P PINJACK JK701

® 28 461 0740002 SHEET

29 4610706 114 FOOTSHEET

30 4110962801 CHASSIS

31 1051139039 REARPANEL(E3) U.S.A.,Canada

@ 1051139042 REARPANEL(E2,EK) Europe,U.K.

® 1050993 111 REARPANEL(El) Mulit-Voltage(Asia)

® 33 441 1132204 BO'FrOMPLATE

34 4430518003 P.C.B.HOLDER

37 2048311021 2P PIN JACK JK 702

Nii i

® 4,3 102 0425 224 TOP COVER

=® 44 4123901 008 MOUNTBRACKET

45 4111143001 SELECTORBRACKET Multi-Voltage(Asia)only

WARNING:

• Parts marked with ",A, "and/or shading have special characteristics important

to safety.

Part indicated with the mark "®" are not always in stock and possibly to take a

long pedod of time for supplying, or in some case supplying of part may be

refused.

Page 17

1

EXPLODED VIEW

i 2

3 4 5 6 7

\

I

L____

MultiVoltage

Model0nly

8

i °

I

I

I

L

WARNING:

Parts marked withthis symbol z_ _ have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

8

1

Multi Voltoge

Model Only

DN-6OOF

A

B

C

D

E

17

Page 18

DN-6OOF

18

PARTS LIST OF FG-70 MECHANISM UNIT

Ref.No. Part .No

2 9KA90H006

3 9KA9OH005

7 9KA80G017

8 9KA80G018

9 4990191009

12 9KS01Wl 47

13 9KA85P009

15 0090051 001

16 443 1093006

17 9KA82G253

18 9KM20S004

19 9KA85G026

20 9KA85G020

21 9KA85G021

22 9KA85G004

23 9KA85G022

24 9KA85G006

25 9KA85G007

26 9KA85G008

27 9KA85G009

28 9KA85G010

29 9KA85G030

30 9KA85P001

31 9KA85H001

34 9KA82G057

35 9KA91H002

36 9KB30B0 08

37 9KM26B004

39 9KA82G308

40 9KA85G027

41 9KS01Wl 48

42 9KA85S001

43 9KA85S002

44 9KA85S003

45 9KA85G033

46 9KA85G036

47 9KB20B005

48 9KS21W604

50 9KA85S005

60 9KA85A007

61 9KA85A008

62 9KA85A008

62-1

Part Name Remarks

FSFIXING SCREW

FEEDSHAFT

DRIVEGEAR(A)

DRIVEGEAR(B)

LASERP.U

LEAFSWITCH

MOTORP.W.B.

12P FFCCABLE

FFCBUSH

SEB-PHCONNECTORBASE

2x4SCREW

MECHA.PLATE(FG70)

MECHA.FRAME(FG70)

CDTRAY(FG70)

CLAMPERFRAME

UDPLATEGEAR(FG70)

CLAMPER(F)

RELAYGEAR(A)

RELAYGEAR(B)

RELAYGEAR(C)

GEARBELT(F)

DAMPER(FG40)

CLAMPERPLATE(F)

SCREW(F)

MAGNET

3x8 (W-10)SCREW

3x8 BAINDSCREW

2.6x4BAINDSCREW

SEB-PH(RED)

CNW2(FG70)

OP/CLSWITCH(SSS12)

SPRING(A)

SPRING(B)

SPRING(C)

GEARGUIDE

TRAYSTOPPER

2x5 BAIND(B)

STW2.1x6x0.4

HOLDSPRING

SPINDLEMOTORASS'y

FEEDMOTORASS'y

LOADINGMOTORASS'y

MOTORP.W.B.

KSS-240A

EXPLODED VIEW OF FG-70 MECHANISM UNIT

1 I 2 I

3 4.

A

B

C

D

E

Page 19

, ,......................................................................................... nN.6OOF

P.W.BOARD

1

I

3U-2599 MAIN UNIT

2 3 4

$608

!

5 6 7 8

A

B

C

D

E

19

Page 20

ON-6OOF

WIRING DIAGRAM

1 2

3

4 5

6

7

8

A

B

C

D

E

IN MOST

SW

LOADING

MOTOR _

OPEN/CLOSE _o._

sw

SPINDLE

MOTOR

SLIDE

MOTORk,____FI2J

OPTICAL PICK UP

KSS-240A

LASER DIODE

MONITOR DIODE

PHOTO DETECTOR

DIODE

I

I HF AMP

I ALPC

CXAIO81S

M

I

FOCUS I

TRACKING

COIL

VC

TE

FE

FZC

RF

GND

VCC

LDC

FCS+

TRK+

TRK-

FCS-

3U-2599-2

KEYDISPLAYUNIT

SBX1610-52

I REMOTE

UNIT

COAXIAL

DIGITAL

OUT

CB101

(RED)

CB102

111

4: 7126

_ ,.,,p _ z__> !

I,.L- _, r,__ .,'r' 4.-

'[31130129128127126

,._ SERVO }

CONTROL

0XA13725

EFM DEMODULATOR

ERROR CORRECTION

INTER PORA_ON

32K RAM

I CXD2500BQ

PITCH JCONTROL

o.;R

I-_ FE1

_wc,m _oO

SWOP

+_C_J _J_C 1

1"P102 T'PlOl

G1 G2 G3 G4 G5 G6 07 G8 G9 CC604

_'J _J _'_ "" "" "/ "" " " ") "' l FL DISPLAY _l-

r_ r', _', ,,", ,,',, r,, t",, ,",, r', l FIPBNM6A

_.) (.) (,) () () () (._ () (.) K3

!

!

11rrlrfrFrl

312

o1,.1oo1-;

517[_31_21111_0'i9[?[i71 ?'?1 ? ?li2]i1'T[i ' i 1_

1111

Ill CB601

C0603

#-COM

M3817,.3M6-161FP

DIGITAL

ATT.

DIGITAL

FILTER

SM5841BP

DAC

PCM61P-L

ACTIVE

L.P.F

ACTIVE

LP.F

]

/

I

L

ON/OFF

t

RESET "_ ANALOGAssP

+SV,-SV

REGULATE I

t M529OP POWER

I 7V _TRANS

I 30V _ (

5V

I _v o}

±SV

UNREOOULATE

-3OV

FOR DISPLAY

5V AC

FOR DISPLAY

GND

ON/OFF

F1 IN

F1 OUT

CC605

_=_

3U-2599-4

POWERSW UNIT

I

I

I

HP L

GND

HPR

MUTE

CB602

H/P

3U-2599-3

./P JACKUNIT

L-- 1

AUDIO OUTPUT

R _

AC PLUG

3U-2599-1

MAINUNIT

20

Page 21

I DN-6OOF i

SCHEMATIC DIAGRAM

11 I

OPEN

OPEN/CLOSE

SW

SPINDLE

MOTOR

IN MOST SW

SLIDE

MOTOR

FCS

TRK+

/ I

I,OV o.3v

ID __. -03V

I TRACK JUMP

(PAUSE )

10

3U - 259 8 - I

IC203

SN74LS624N

I

ICI03B

R248 TL455SP PLAY: 5V

STOP: OV

R247

33k

IC204A

TC74HCT04

6.8k

C211

C212

)FSW

MON

CBIOI

C800

MDS

LOCK

NC

VCO 0

I

TEST

PDO

Vss

NC

)NC

VPCO

VCXI

FIEO

FILl

PCO

9 I 8 I 7

SCOR

WFCK_

$21

PLAY: . V DOUTI

STOP:OV 544.SEC MD2

CI6M_

FST_

IC202 XTSLI

CXD2500BQ XTAOI

XTAII

VSSl

DAI

DA2 q

O.7JJ$_

OA3

SV DA4

OV DA5

O.23psw=c OA6

DA7

DA8

I C103A I

TL4558P

r-_qA_- _ I

I 4 7k

RIS8 75p "

220 RI54

4.3k 4.7k

( 8V

TRill

IF I _0468 RI50 ilOk (+BY)

" - 18k RI44

_, i __ ,_o_ OREN

RI4 - -CI74

751(8 TR 12 "- 0.1

I 'l" I .2_o I T _,'_OTT'.''5°

II/ -- , I 11

EYE PATERN

o.3v_ 2.5v

STOP : 2.5V

,/

/

TPI02 TPIOI

<CLOSE SW>

< OPEN SW >

2.5V

CHASS

0,01 GND

(F/P SIDE)

ICi058

TR113 TL45.SG P

2S0_.68

\_ PLAY;SV

STOP :O V

VRI04

All3

lOW

RI66 RII2 RI67

lOOk S6k IOk

w.

C108

102 RIO9 ,022

22k IOk

ICI06A

TRI IT TL4558P

2SD_68

RI?I

RIBS:

lOOk'

220 (CI69) :

(CI65]

T ( RI99 )

x2OO

16.9344MHz

TPI03

GFS

CI07

O.02TT

B.P

TRII5 ICI06B

2SDI913 TL4_8P

CI66 15p

RI80 (R_78)

220

(CI67)"

JACK701

IT°°Llj.Zm o• T •

II I_ 1TRANSJ__c_oI /

I I I _ _ I _,,ov I c_,J.

6 IO0'p

> I ' ,c_o,i_

I

MO741..ICOOP

-F5V > I

CL,lJmtlJlJlJlJ_."--,_V

XLT L_ 5V

ova>

DATA 5V

I

C718

I00/6.3

C130 "

560p

RI74

47k

6 I 5 I 4

3 j 2

C716 56p

R746

R750

RT44

3.9k

)NC

)NC CLOSE: OV

)NC OPEN,

)KI OPeN :OV

)K 2 OTHER: 5V NCI

)K3 NC'

)NC it201

M38173M6-161FP NC_

+SV GNDI

XOUTI

)GND C4M_

)t-5V

CLOSE :OV )NC PLAY :5V

OThWER: 5V I NG STOP: OV

R740

30k

C720 f

t_O/16

C719

C721,

I00/16'

C205

0. I

R359 Ik

( BCK

R358 ik

R30B

Ik

R_05 Ik

..,_R3p§_j_ ......................................

,_C3H

I00/16

÷ x

R255

Ik

<C,OM>--_1-

C255 "=" C256

47p Z IOOOp

F DATA >-

" _ FCLK >-

" _ MLE

XRST

031

0.0056

CI09

0.1

)1,111

CII2

113

150=

CII4 0.22

IC102

CXAI372S

TE TZC

TDFCT DVEE

FOF,CT I CB

VC DVcc

FGD CSI

FS3

FLB

FEO

FE - ASY

SRCH OFCT

TGU MIRR

TG2 DGND

AV¢c SENSE

TAO LOUT

TA- XRST

SL'P DATA

SLO XLT

SL- ELK

FSET LOCK

ISET DIRC

S STOP AVEE

Ril6

:40k

Ell7

0.1

RI41

9.1k

D207 ISS198

lOOk

C203.

o.oi

lOk

_CLK COM

)LEE

IC302

PCM61P

)DGND

)VL

IC303

PCM61P

ANALOG GNO

RIm7 Ik

..1-]__:

iool

R206

IOk

MD2

OPEN

4.23MHz I

_L ...... J

LRCK

C202 O.Oi

VR300

R310 4TOk

VR301

)lOOk

R315

IM

RSII 470k

_2T..L

.01_

SS

)

C122

DATA

TRACKI'1n n 5v

• JUMP JUULov '

PLAY, STOP :OV

+

29.8V

43130292'8272625242'3222 20 9 8 T 6 5 4 312 II10 9 8 T 6 5 4 3 2 I

" [ CB602 COIRI) u Lv_L> Ir'

lli_..K_ ,kl,k,t_,k_,k.t..t..k_.,k,k,L,',,ti_,i,L..k,kI,.,,,,,_ 2.1....

_ _ _ _ z_> - o.,,.,., _ ® ,._ ,.,_ _ ,..,_ ,_ _..

_z o '" LlUU U

ov

u- __ LED601 _ ,,N RIN

FIPSNM6A

............ _,_,_,__ ,__ _ _

r i;T,,,,,,,,,, I_,_,,,I ooo,-ooo _Cll

\!LLLLL(!-.

G ;8 G! ,,-I4 I 3 I Z I I I,,_,_...--

ooo, o.o2: .o,:DOO., o.oT o.oo,;COOT:£

S601 $604 SE07 ' "S610 " $613 $616 " " $619 ' " S622

PLAY A.REV TIME _ROCY01R IO 7 I CC605

'1 _--, o- o--_ o--, o-- o

,_ y o_,y _ _ _L_°d'? Y _ t? _ I Lt--t------

t soo21s.o5.oo so,,so,.Iso,Ts .oso2.Fso2.1 I

1,T,-STOP I AFF OP/CL AED lid I 8 s z I-reTCHI I I I

L,._n..l,_n_,,_r,._,,-,'L.'-"-'I"-"-'_ '-"-'l'-"'-"I I,',',_ I

soo, soo,s0,2so,s.sss s,, .2,rSO2T. o

1~1PAUSE I M.REV M.FF A-SP DISP I 9 6 3 A-B I [ ....

._17 _ o- o- ? o- ? o= o- o-l_ swooo

- _ _ 'i _ . c,_ 2 2 o_

POWER SW

°i'

o RGOI_ 603

lOOk

3U-2598- 2 ON

3U -2598 -4

I R606 JACK6Ol

_ JVSI I 56

H.P JACK

$2

- 8 V _ TR5OI IO.IV 0501 _504(

2SDI94_ ISR35

JV540

RSOI

4,7k

Jr505

9.BY

C503 C505

t'220/6.3 1/50m

}' ICSOI

M52_P

.(C504)

X

0501

'503

5O4

,.2V

+

I:C511

$,3/50

R502

4.7k

TRS02

2SBI274

D505,506

15R35

; R!

' I

JVSlO R609

RG08

47k

.C60t C600

_D506 _,0505

.100150

( Ft > L

R506

I00

. RS05

iO0

F2 >

+5V:

+BY),

RTIO

IW

C3S01

O'i T

L

L [ R22,

lOW

C732 R222

"OI ]iOk

R720

680

C710

100/16 R724

50k

C711

100/16 R72S

30k

TR704

2SA933

TR702

DTAI24X

TR703

DTCII4ES

O701

ISS27OA

R708

91

9.IV

DIG GND

i r

1

ACI20V I

GOHz

I

CN_OO _ I

I

- -- AC PLUG J

Europe,U.K. Model I ACz_v I

iiii:i:i:i_i_.Z_[I7 I 50/60HZ i

I

c.sooT -- __ _uLj

PGSO0

AC PLUG

SW500 ACI20/220/240V

MULT. SW 50Hz/6Oib

Multi -Voltage

Model

+ B LINE

B LINE

SIGNAL LINE

)L

I

JAGK 702

I

R

WARNING:

Pans marked with this symbol Z_ _ have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the unit to the customer, make sure you make either (1) aleakage current check or (2) a line to chassis resistance check• If

the leakage current exceeds 0.5 milliamps, or if the resistance fromchassis to either side of the power cord is less than 240 kohms, the unit is

defective.

WARNING:

DO NOT return theunit tothe customer until the problem is located and corrected.

NOTES

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM, M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD. P=MICRO-MICRO FARAD

EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION.

CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

A

m

B

C

D

E

F

G

H

21

Page 22

I DN-6OOF I

SEMICONDUCTORS

• IC's

TL4558P

:RC4558P

1

A OUTPUT I_v I[_] V+

A-,NPUT X--I BOUTPUT

A+,NPOT__ B-,NPUT

v-H =--p ÷,NPUT

SM5841BP

1

OKSL IT"

XTI I-_

XTO I_-

CKOI-Z

vss E

MOTE

MCKi-7

MLE I-@-

RS--_I_

"_DIN

BCKI

LRCI

[] BCKO

[] VDD

WCKO

DOL

___ DOR

DG

M5290P

PCM61P-L

-vcc Iq-

CollectorOut(-) r2

EmitterOut(-)

NC1"-4-

-5V OUT I_"

BALANCE

DELAY

RESET

M5290P

'_1 +Vcc

EmitterOut(+)

1-_ CollectorOut(+)

NC

+5VOUT

REFERENCE

ON/OFF

GND

-Vcc E

DIG. GND

+VL I_"

NC

CLK

LEC 16"

DATA

-VL

PCM61 P-L

z

_I I_I _

5_z

:p,o

+Vcc

VPOT

1-T1 MSB ADJ

IOUT

ANA. GND

1--_ S.J

RF

VOUT

CXA1372S

TE

TDFCT

ATSC

FZC

FE

FDFCT

VC

FGD

FS3

FLB

FEO

FE-

SRCH

TGU

TG2

AVCC

TAO

TA-

SL+

SLO

SL-

FSET

ISET

SSTOP

IT

FZ

E

IT

rT

FT

rT

lnT

E

E

E

E

TZC

DVEE

RFO

4-_ RFI

cP

CB

DVCC

4-_ CC2

CCl

FOK

EFM

3-71 ASY

DFCT

MIRR

DGND

_'_ SENS

3-_ C.OUT

31--7 XRST

DATA

2-_ XLT

2-_ CLK

LOCK

DIRC

AVEE

CXD2500BQ

M38173M6-161 FP

HflHRn flflflflflflAH flHflflflH H

64

65

i1_11=:

_1=:=

¢=z==:

=_==:

= © ©

=::=m:

o

,HHHHHHHHHHHHHHHHHHHHHH

41

40

=

:=E=_

=

=

=

=

=

=

=

=

=

=

::=E==

=

=

25

.M

• IC PROTECTOR

or

• TRANSISTOR

2SD1913

2SB1274

2SD1762

2SB 1185

E (Emitter)

C (Collector)

B (Base)

2SA933(Q)

2SD2144

:C557A/B

E( B

• IC DIODE

___=

lSS198

1SS270A

lSR35

1A3-1

L,=

HZS6B-1

HZS7A-1

HZS30-1

2SB562

2SD468(C)

:BC369

:BC368

ECB

DTC114ES(10K)

DTA124XS(22K-47K)

E CB

INPUT

(B) (C)

31_1_E) OUIPUI

III GND

22

Page 23

DN-6OOF

Page 24

NIPPON COLUMBIA CO.. LTD.

14-14, AKASAKA 4-CHOME, MINATO-KU, TOKYO 107-I 1, ,JAPAN

Telephone: 03 (3584) 8111

Cable: NIPPON COLUMBIA TOKYO Telex: JAPANOLA J22591

Printed Jr,Japan 407 _B_ 0438

Loading...

Loading...