Denon DCD-710 Service Manual

D&M Holdings lnc.

e

Copyright 2009 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver. 2

●

For purposes of improvement, specifications and design are subject to change without notice.

●

Please use this service manual with referring to the operating instructions without fail.

●

Some illustrations using in this service manual are slightly different from the actual set.

Please refer to the

MODIFICATION NOTICE.

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E1C E1K EUT

DCD-710AE

3

CD PLAYER

S0009-0V02DM/DG0911

Please heed the points listed below during servicing and inspection.

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Do not stare into beam or view directly with optical instruments, class 3A laser product.

CAUTION

CAUTION

◎ Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

2

DCD-710AE

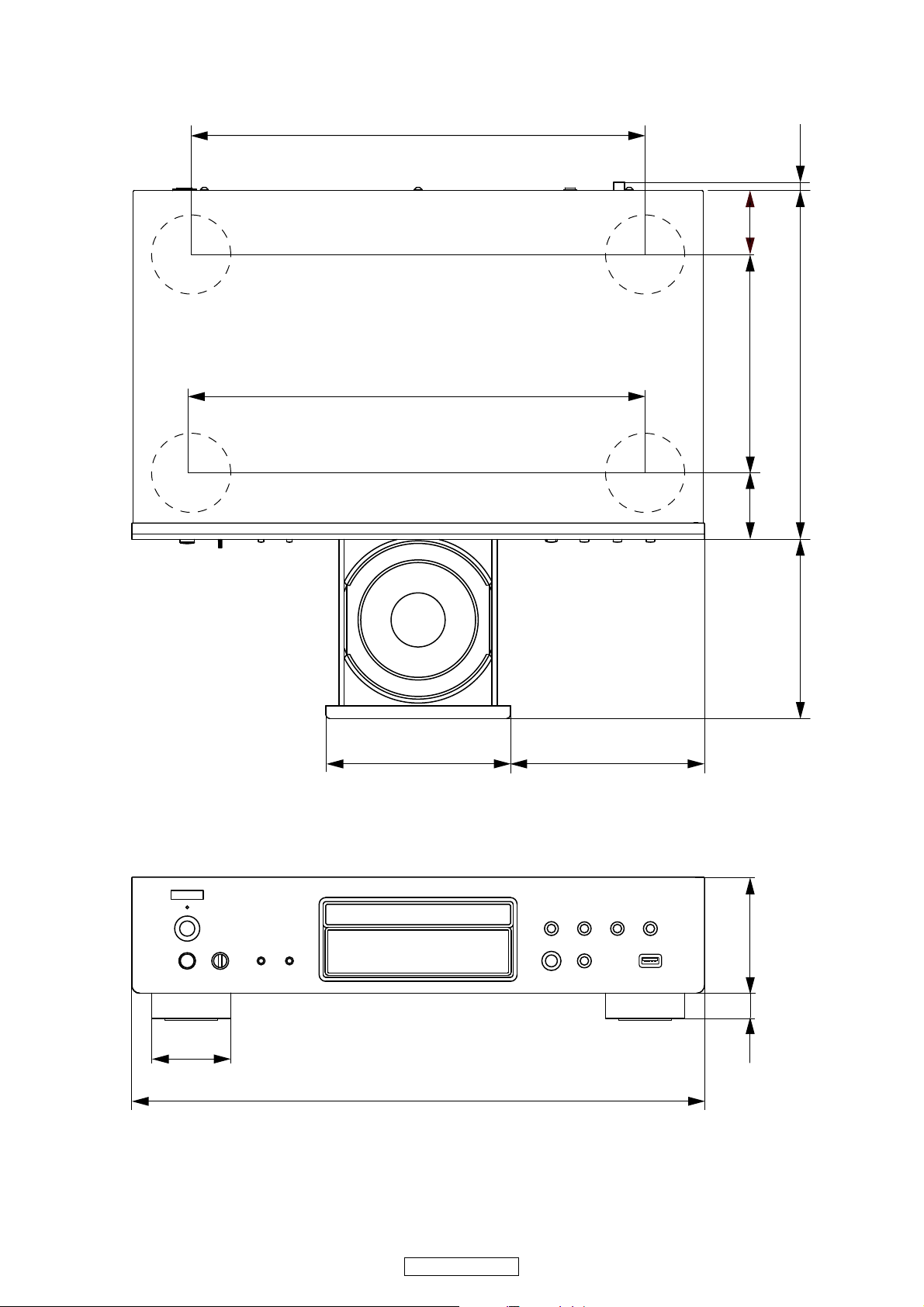

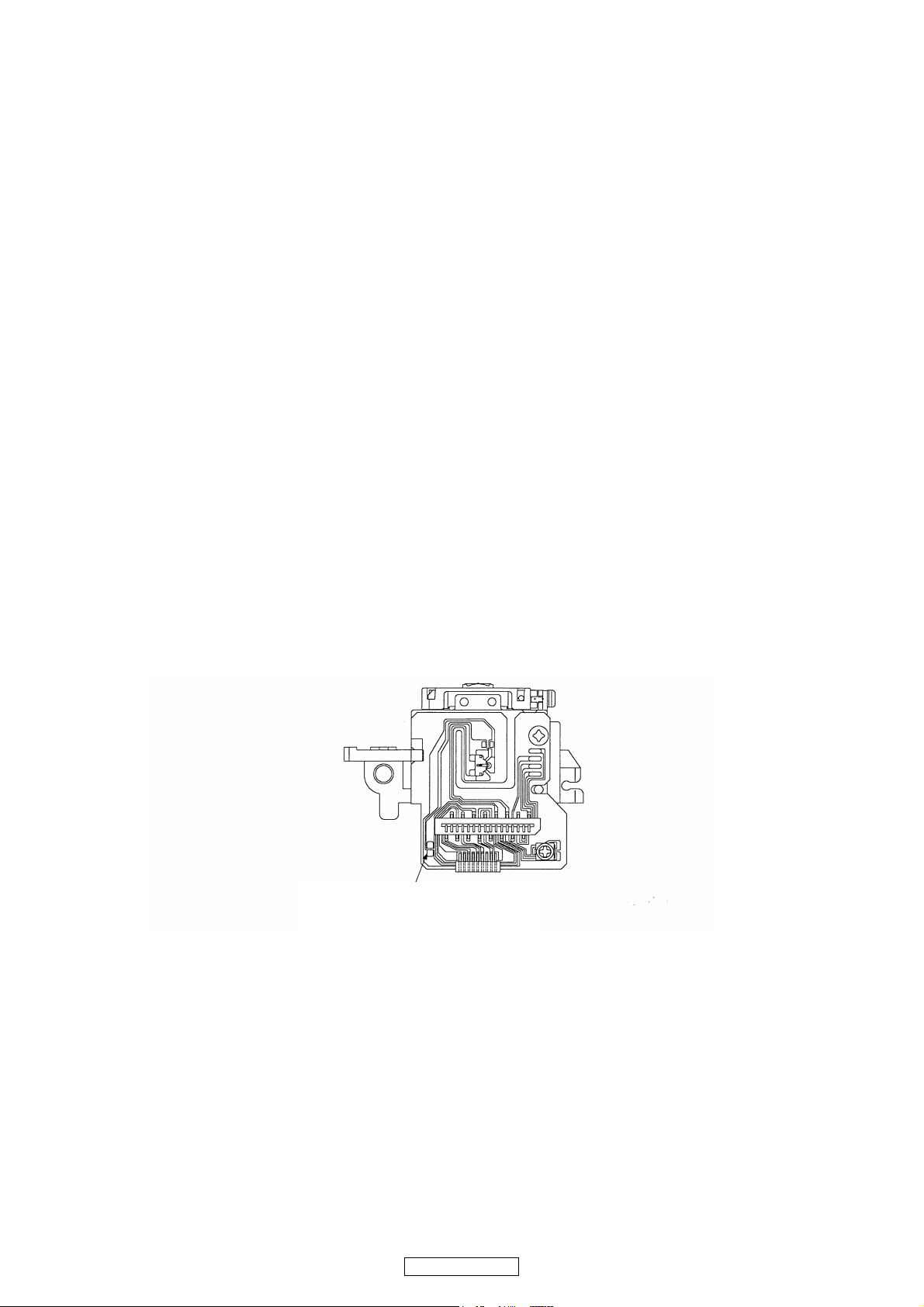

DIMENSION

344

434

140

147

60

8820

265136

7

max

50.5 165.5 49

344

3

DCD-710AE

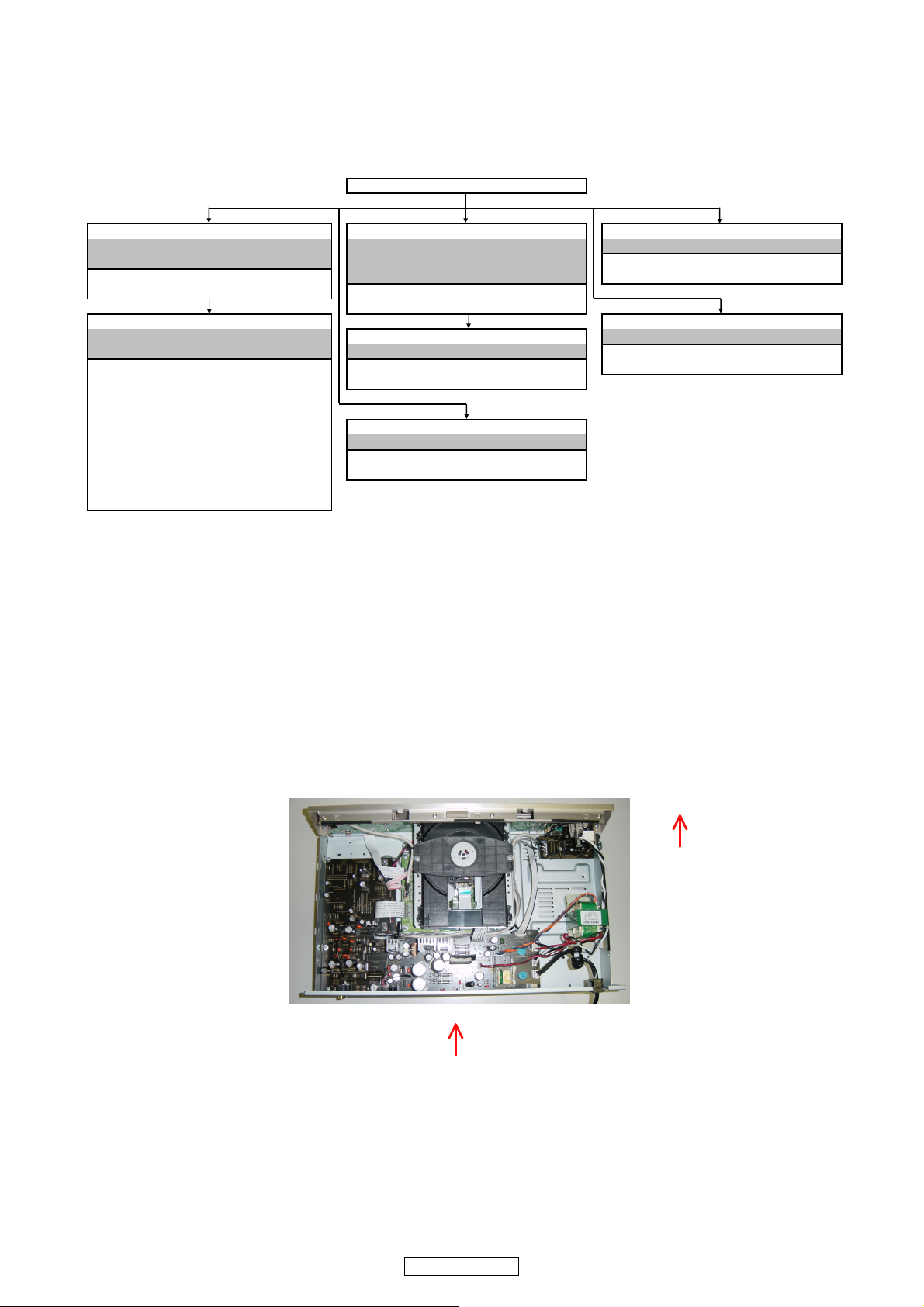

WIRE ARRANGEMENT

Front Panel side

Back Panel side

If wire bundles are untied or moved to perform adjustment or parts replacement etc.,be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

Wire arrangement viewed from the top

4

DCD-710AE

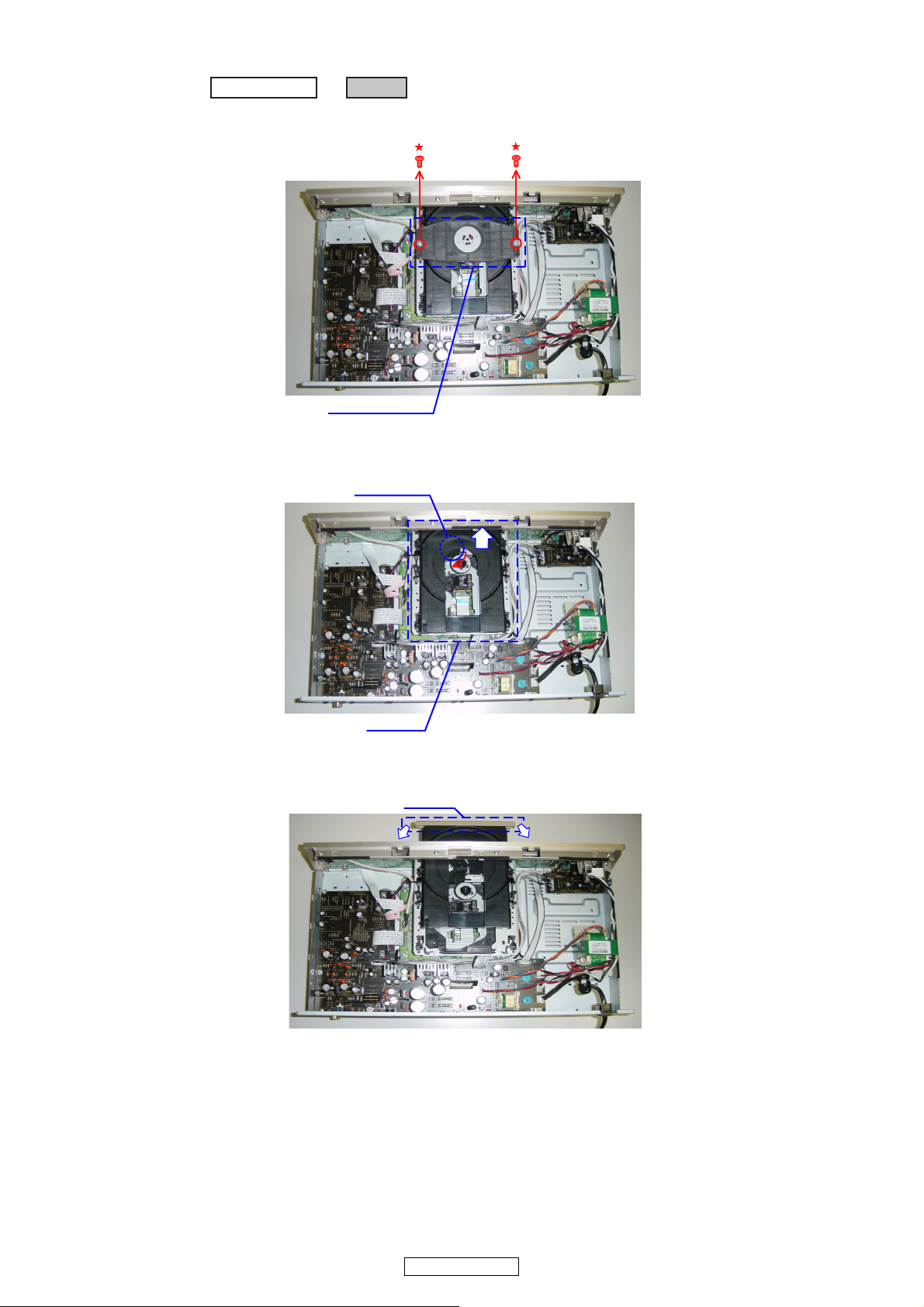

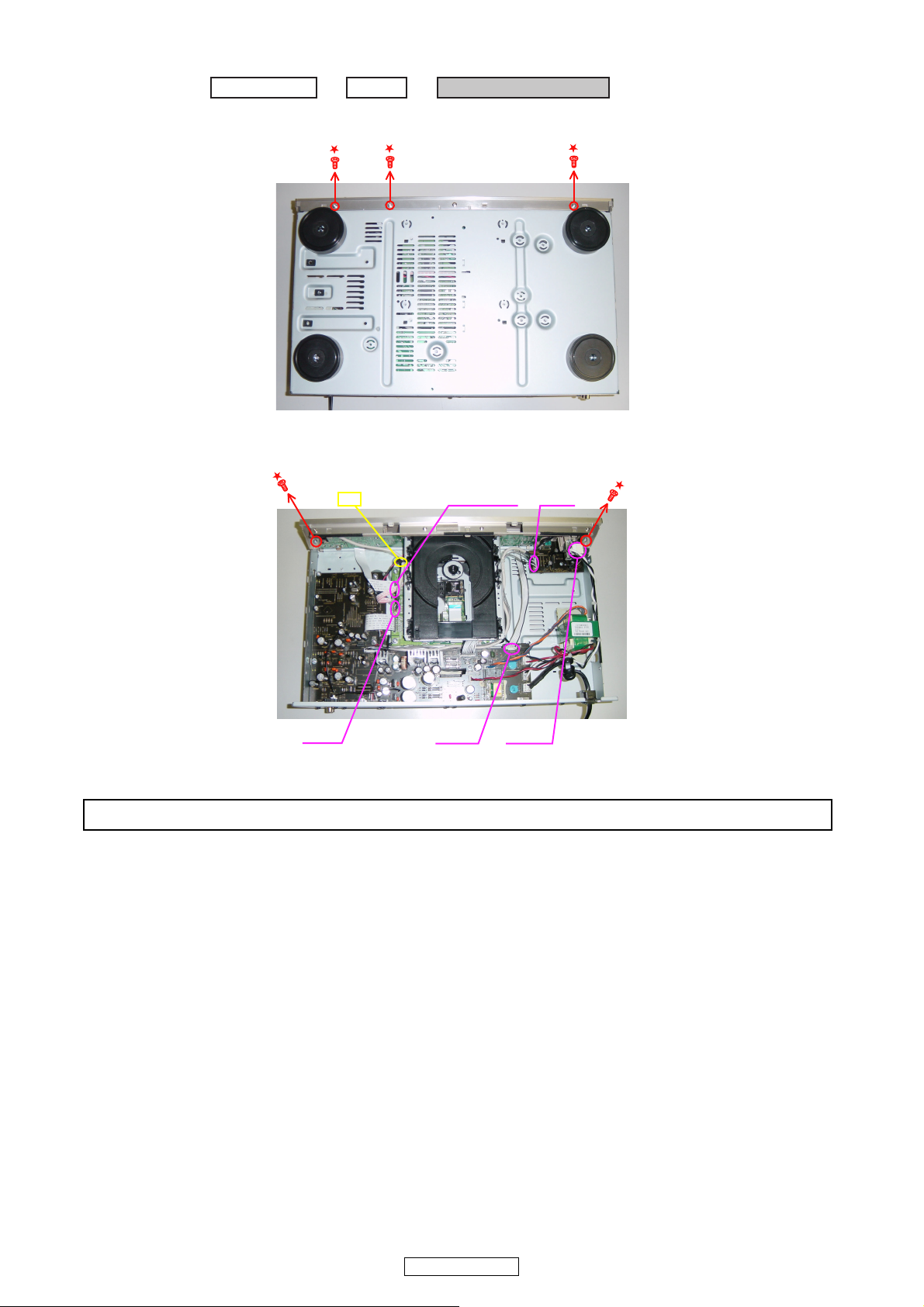

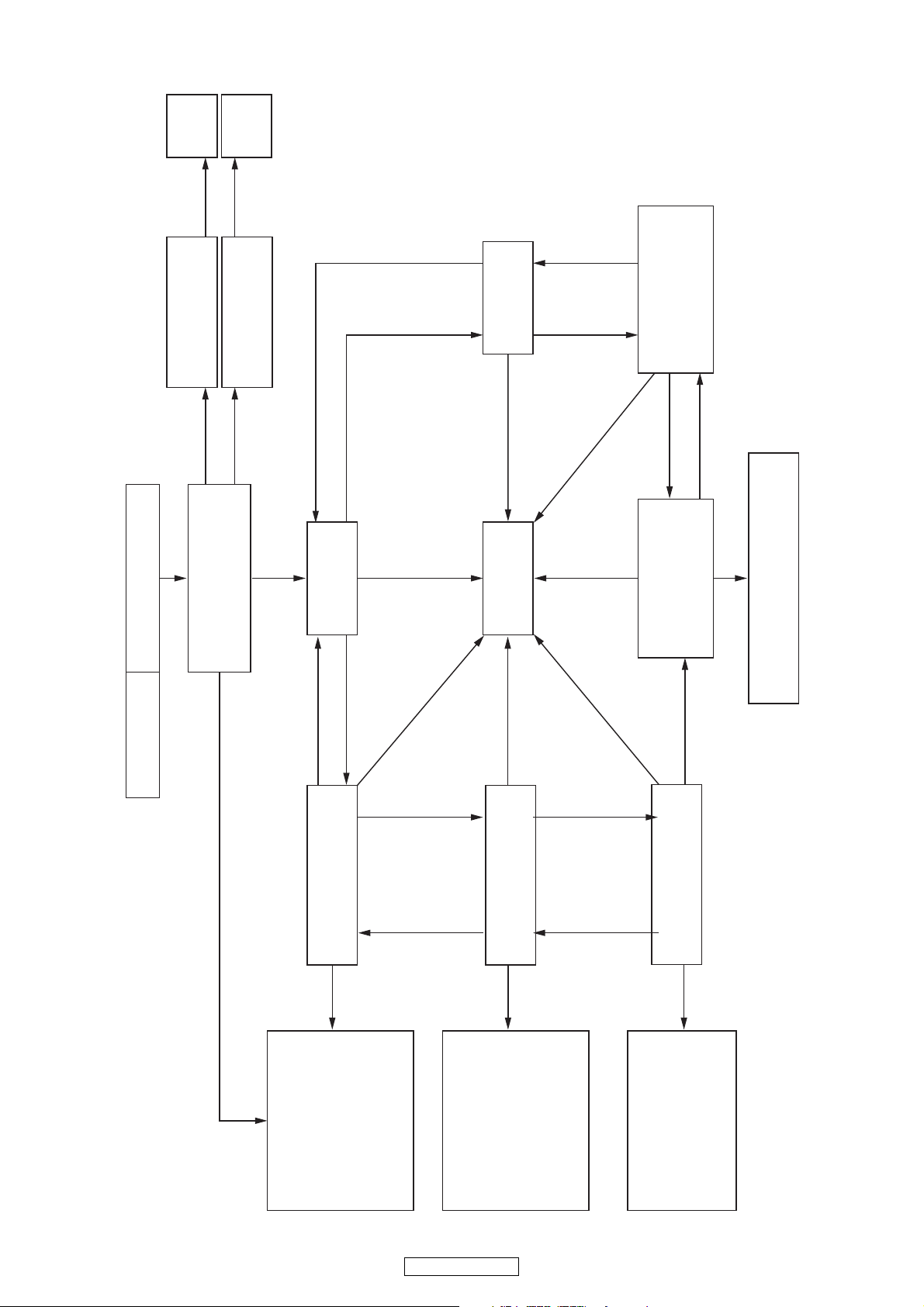

DISASSEMBLY

TOP COVER

DOOR CD MECHANISM ASSY AUDIO/POWER PCB

Refer to "DISASSEMBLY 1.DOOR" Refer to "DISASSEMBLY Refer to "EXPLODED VIEW"

Refer to "EXPLODED VIEW" 3.CD MECHANISM ASSY" AUDIO/POWER PCB

DOOR Refer to "EXPLODED VIEW" (Ref. No. of EXPLODED VIEW : 1-1)

(Ref. No. of EXPLODED VIEW : 9) CD MECHANISM ASSY

(Ref. No. of EXPLODED VIEW : 16)

FRONT PANEL ASS

Y

REAR PANE

L

Refer to "DISASSEMBLY 2.FRONT PANEL ASSY"

MAIN PCB ASS

Y

Refer to "EXPLODED VIEW"

Refer to "EXPLODED VIEW" Refer to "EXPLODED VIEW" REAR PANEL

DISPLAY PCB MAIN PCB ASSY (Ref. No. of EXPLODED VIEW : 12)

(Ref. No. of EXPLODED VIEW : 1-2) (Ref. No. of EXPLODED VIEW : 2)

H/P PCB

(Ref. No. of EXPLODED VIEW : 1-3)

MOMS PCB

POWER TRANS

(Ref. No. of EXPLODED VIEW : 1-4) Refer to "EXPLODED VIEW"

USB PCB POWER TRANS

(Ref. No. of EXPLODED VIEW : 1-5) (Ref. No. of EXPLODED VIEW : 21)

LED PCB

(Ref. No. of EXPLODED VIEW : 1-6)

The viewpoint of each photograph

(photography direction)

[View from above]

Front side

Direction of photograph: A

• Disassemble in order of the arrow of the figure of following flow.

• In the case of the re-assembling, assemble it in order of the reverse of the following flow.

• In the case of the re-assembling, observe "attention of assembling" it.

About the photos used for descriptions in the “DISASSEMBLY” section.

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***" at

the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

5

DCD-710AE

1. DOOR

TOP COVER

DOOR

→

Proceeding :

Chucking plate

Drive gear

CD tray

DOOR

(1) Take off the Chucking plate after removing screws.

(2) Open the CD tray by turning the Drive gear clockwise.

(3) Detach the DOOR.

6

DCD-710AE

2. FRONT PANEL ASSY

TOP COVER

DOOR

→

FRONT PANEL ASSY

→

Proceeding :

View from bottom

cut

CX73

BN31

FFC Cable BN33

CN51

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in FRONT PANEL ASSY.

(1) Remove the screws.

(2) Cut the clamp bands, disconnect the connector wires and FFC Cable Remove the screws..

7

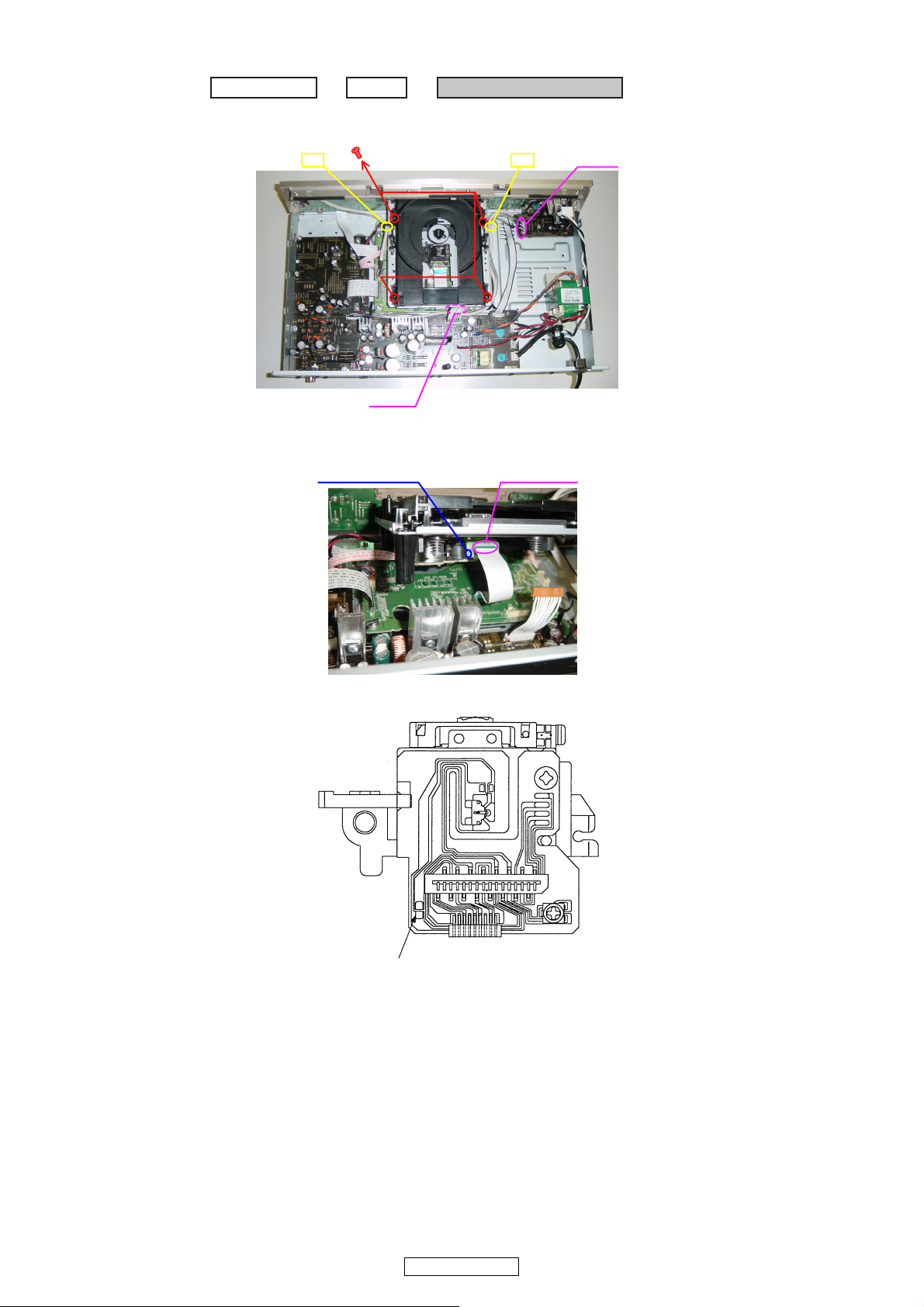

DCD-710AE

3. CD MECHANISM ASSY

TOP COVER

DOOR

→

CD MECHANISM ASSY

→

Proceeding :

cutcut

CN53

BN33

ً

Soldering place

FFC Cable

Direction of photograph: A

Laser short-circuit

(1) Cut the clamp bands, disconnect the connector wires. Remove the screws.

(2) Laser short-circuit in Pick-up of CD MECHANISM, then disconnect the FFC Cable.

8

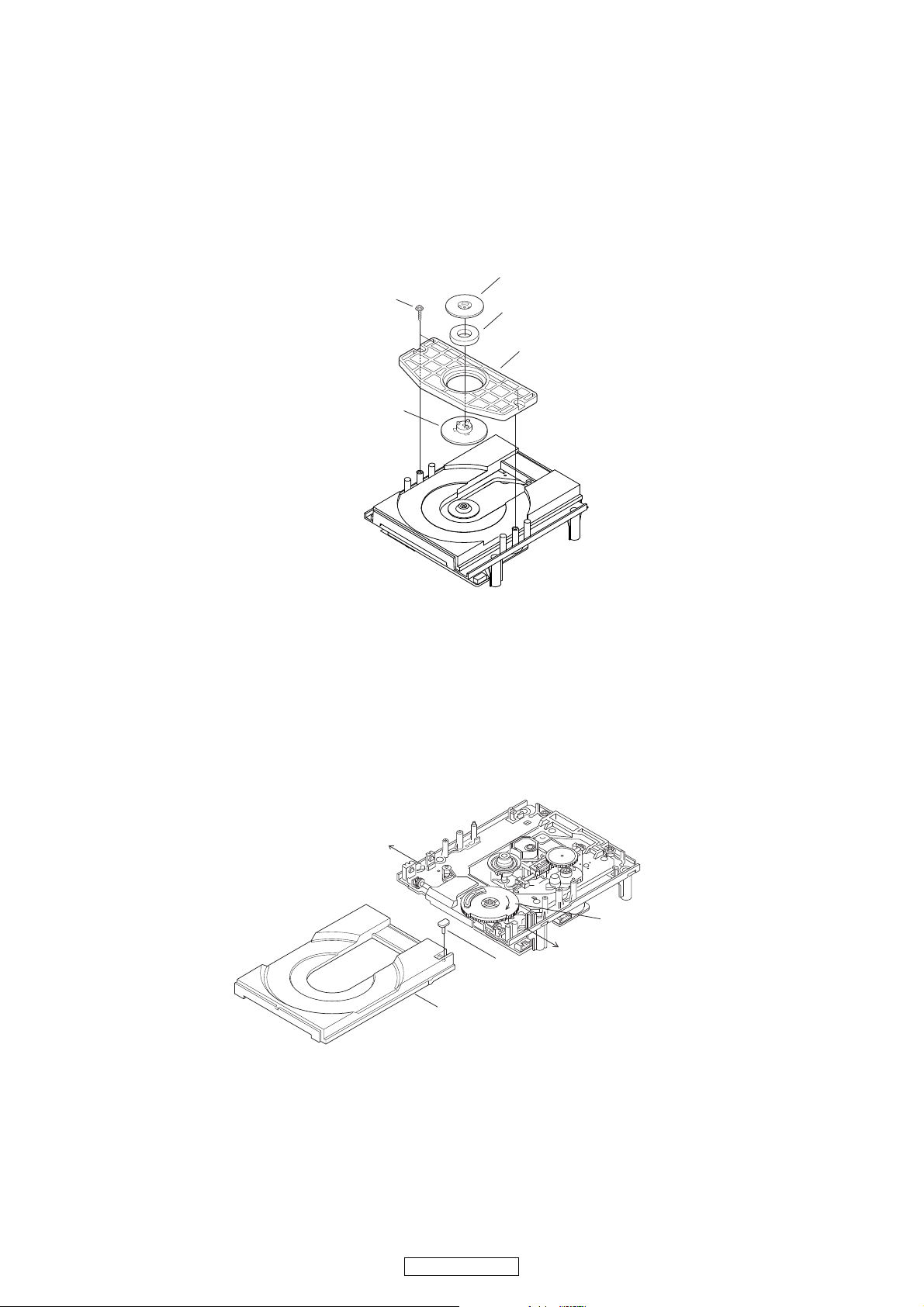

DCD-710AE

DISASSEMBLY OF MECHANIC

Chucking yoke

Chucking plate

Chucking pulley

Screws

Mugnet

Stopper

Stopper

Sw pin

CD tray

Drive gear

(Follow the procedure below in reverse order when reassembling.)

Caution : The optical pickup can damaged by sassily by static electricity charged on human body. Take necessary anti-static

measures when repairing around the optical pickup.

1. Chucking plate

(1) Remove 2 top screws, then detach the Chucking plate.

(2) Detaching the Chucking pulley and chucking yoke by removing the 3 hooks, when abandoning CD MECHA ass’y.

2. CD tray

When abandoning CD MECHA ass’y, please detach the CD tray.

(1) Detach the Sw pin on the CD tray.

(2) Open the CD tray by turning the Drive gear clockwise.

(3) Open the Stopper as shown in the fig., then detach CD tray.

9

DCD-710AE

Note Handling and Replacement of the Laser pick-up

Protective soldering place for laser diode.

1. Protection of the LD

Short a part of the LD circuit by soldering. After connection to a circuit, remove the short solder.

2. Precautions when handling the laser CD mechanism

• Handle the laser pick-up so that it is not exposed to dust.

• Do not leave the laser pick-up bare. Be sure to cover it.

• If dust adheres on lens of the pick-up, blow it off with a blower brush.

• Do not shock the laser pick-up.

• Do not watch the light of the laser pick-up.

3. Cautions on assembling and adjustment

• Be sure that to the bench, jig, head of soldering iron (with ceramic) and measuring instruments are well grounded.

• Workers who handle the laser pick-up must be grounded.

• The finished mechanism (prior to anchoring in the set) should be protected against static electricity and dust. The mechanism must be stored that damaging outside forces are not received.

• When carrying the finished mechanism, hold it by the

chassis body

• For proper operation, storage and operating environment should not contain corrosive gases. For example H

CI2 etc. In addition storage environment should not have materials that emit corrosive gases especially from silicic, cyanic,

formalin and phenol group. I the mechanism or the set, existence of corrosive gases may cause no rotation in motor.

2S, SO2, NO2,

4. Determining whether the laser pick-up is defective

•

Measure the waveform at RFO-VC on "MCU P.W.B. Unit ".

( For measuring points and waveforms, see pages 21.)

• The laser pick-up is OK if the amplitude level of the measured RFO waveform is between 0.4 and 1.1 Vp-p, defective otherwise.

10

DCD-710AE

SPECIAL MODE

DCD-710AE

Ver ****

USB_Ver ****

P

LAY/PAUSE

M

AIN KEY

O

PEN/CLOSE

R

EMOCON KEY

00 CD TEST MODE

01 LD ON

02 Focus ON

03 CLV ON

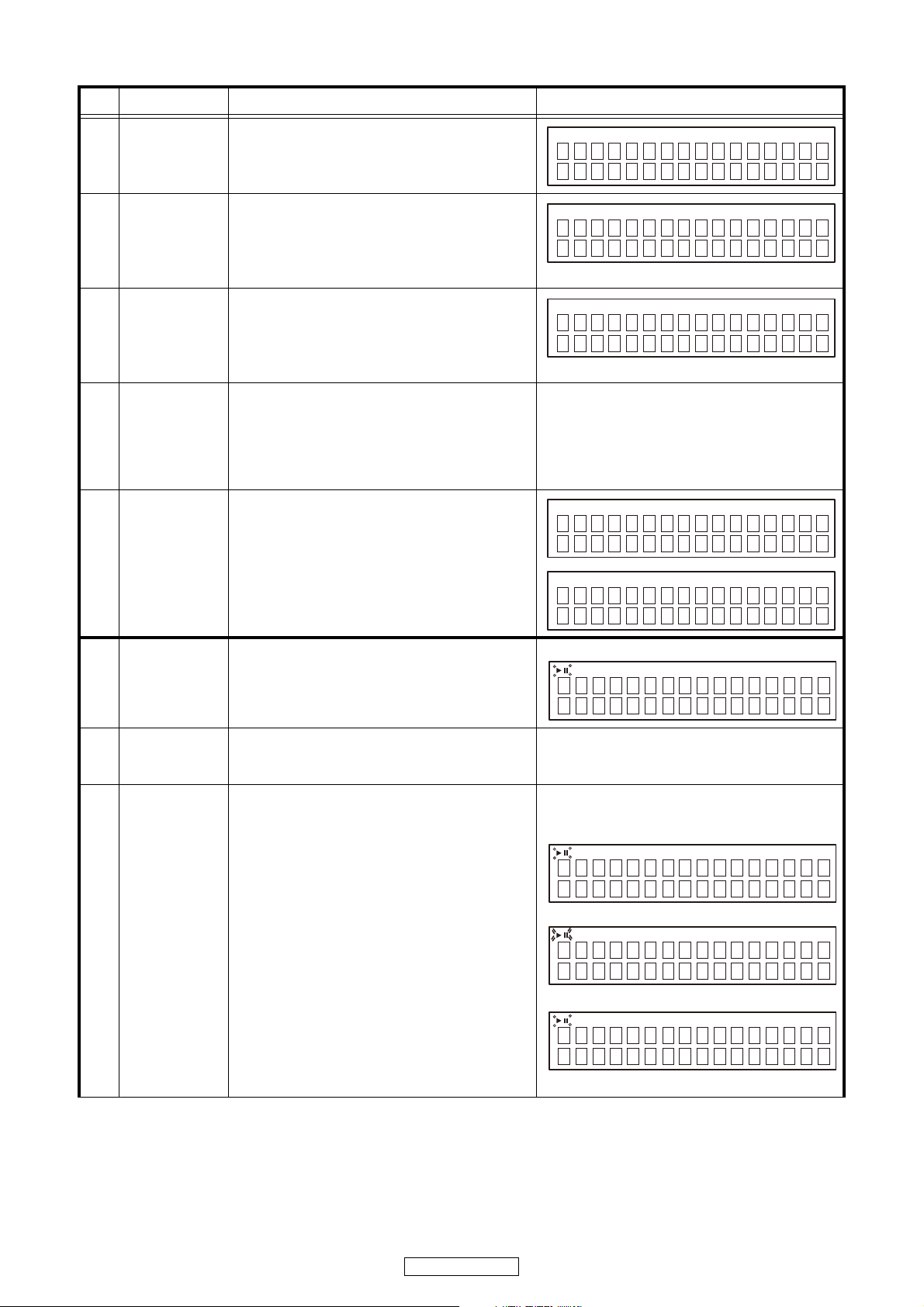

No Key name Function Display

• POWER switch is turned to on while pressing the

1

Service mode

5 and 2 button same time on DCD710AE.(Model name display)

Version No. of

1.1

main μ-com

Display mode

Version No. of

1.2

USB μ-com

Display mode

1.3 FLD check mode

Input button

1.4

name Display

mode

2 CD test mode

2.1 Disc loading

• Press the 9 button.

• Press the 9 button while version No. of main

μ-com is displayed.

• When display is version No. of USB μ-com and

the 9 button is pressed, turn on the entire display is flashing with an interval of about 1 second.

• Press the 9 button again in the turn on each

grid of FLD. (Each grid is displayed at interval of 1

second.)

• When display is each grid of the FLD check mode

and the 9 button is pressed, display name of

the pressing button.

• Turn off the POWER switch to clear this mode.

• POWER switch is turned to on while pressing the

5 and 2 button same time on DCD710AE.(Entering the Service mode)

• Press the

service mode.(CD TEST MODE display)

• Press the 5 button to open the tray.

• Set a disc on the tray, then press the 5 button

again to close the tray.

• Press the

steps.

q LD ON (with servo still stopped)

/

13 and 2 button same time while

/

13 button. Execute the following

"****" : Version number of main μ-com

"****" : Version number of USB μ-com

13 flashing

・13 flashing

q

w FOCUS ON (disc rotation, tracking off)

2.2 Servo check

e CLV ON

If no disc loaded, retry then stop.

w

e

11

DCD-710AE

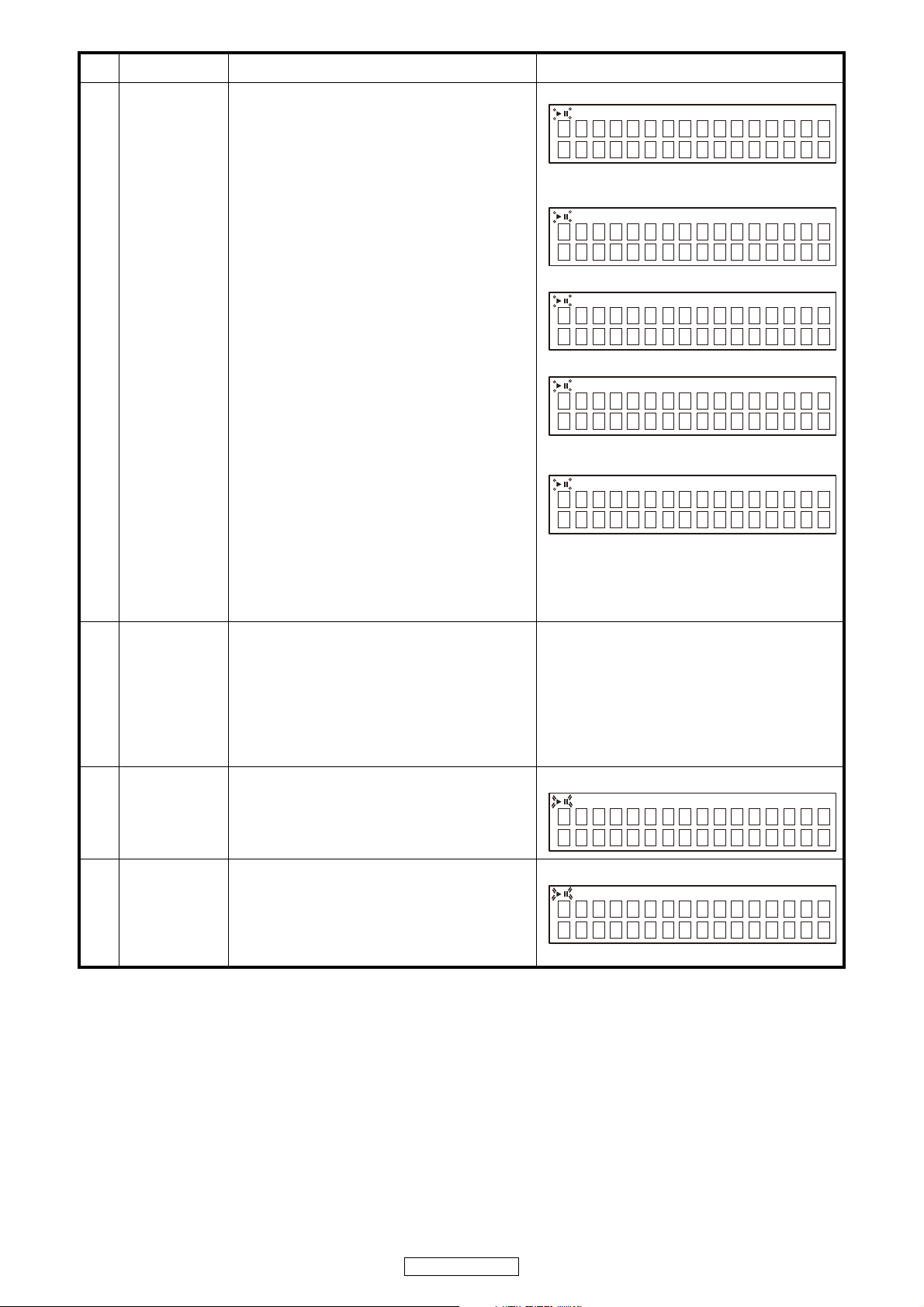

No

04 Tracking ON

I

NERR######

05 @@

Tr

XX:XX

M

ID ERR ######

05 @@

Tr

XX:XX

O

UT ERR ######

05 @@

Tr

XX:XX

P

PP ERR ######

ERR *** ***

00 CD TEST MODE

@@

Tr

XX:XX

2.2 Servo check

2.3

Key name

Pickup

movement

Function Display

r TRACKING ON

t SUB CODE readout (playback sound output)

• The BER (Block Error Rate) generated in 1

second's time is displayed on the upper tier of

the display.

• The playback position (IN/MID/OUT) can be

changed by pressing the 8 or 9 button.

• The count of the errors that could not be

corrected with the C1 error correction system is

displayed.

y When display is as in t and the

pressed, conduct BER (Block Error Rate)

display for 2 seconds.

• The BER (Block Error Rate) generated in 10

second's time is displayed of the display.

bPress

second to switch directly to SUB CODE readout

in step

・In the stop mode, pickup moves in REV (inwards)

or FWD (outwards) direction when 8 or 9

button pressed.

・When 8 button pressed, move to stop

operation after detection that inner switch has

turned on.

・Pickup movement stops when button released.

(Pickup moves while button is pressed.)

/

13 button continuously for over 1

t.

/

13 button is

r

t

[IN]

[MID]

[OUT]

###### : B.E.R., @@ : T.No, XX:XX : Time

y

PPP : Playback position (IN/MID/OUT)

###### : 1

Continuous display of previous time

second's B.E.R.

, *****:

10 second's B.E.R.

2.4 Stop

2.5 All servo on

・When 2 button is pressed, play operation and

servo stop.

・After stopping, conduct reading of auto adjust

values.

・When 2 and 5 button is pressed, all servos turn

on, auto adjustment is performed and switch to

playback operation. (Playback sound output)

(NOTE)When the 2 button is pressed for over 1

second while the laser turns on and the laser

current is measured.

・13 flashing

・13 flashing

@@ : T.No, XX:XX : Time

12

DCD-710AE

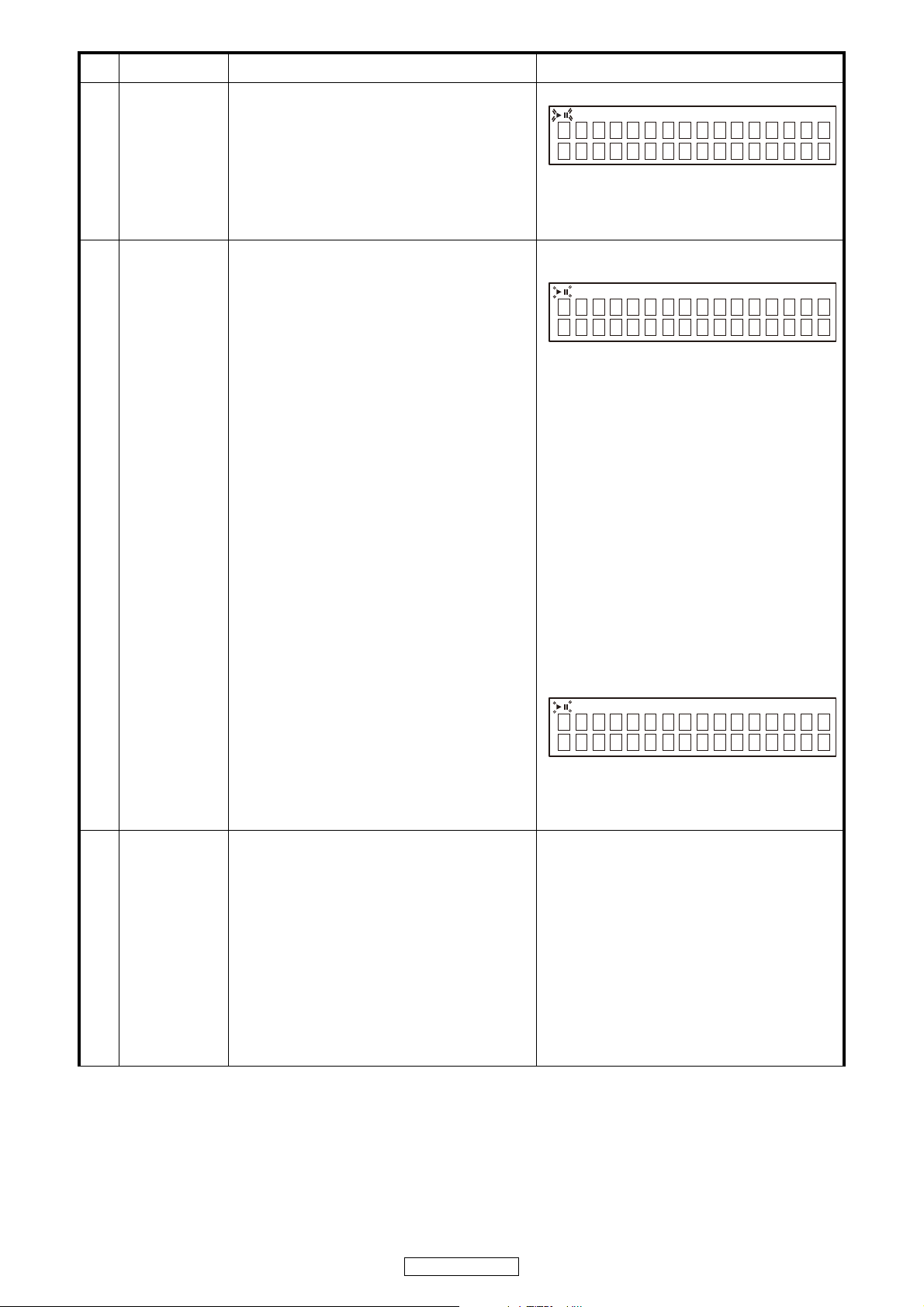

No

S

/C: XXmA/ YYmA

L

ASER CURRENT

S

TORED

L

ASER CURRENT

X

X

F

OCUS BALANCE

X

X

F

OCUS GAIN

X

X

T

RACKING BALANCE

X

X

T

RACKING GAIN

X

X

F

OCUS OFFSET

X

X

T

RACKING OFFSET

Key name

Function Display

Laser current is

2.6

display

・When the 2 button is pressed for over 1 second

while the DCD-710AE is in the stop mode, the

laser turns on and the laser current is measured.

・The laser drive current undergoes A/D

conversion for calculation. Decimal values are

discarded.

・The first current value is measured 3 seconds

after the laser turns on.

・The current value is updated every 3 seconds.

・Press the 2 button, CD test mode display (2)

reappears.

・Stored data is not cleared, even when the DCD-

710AE is reset.

q Overwriting the stored data

・When the

seconds while the laser current is displayed, the

current value is stored in the EEPROM

(overwriting the stored data).

・Once rewriting is completed, the display in 2.6

reappears.

・Press the 2 button after executing the servo auto

adjustment.

・When 9 button is pressed, the adjustment

values are displayed in the following order.

q FOCUS BALANCE

/

13 button is pressed for over 5

・ 13 flashing

XX : Stored data : EEPROM Stored value

YY : Current value

q

・13 flashing

q

Adjustment value

2.7

display

w FOCUS GAIN

e TRACKING BALANCE

r TRACKING GAIN

tFOCUS OFFSET

y TRACKING OFFSET

XX : Adjustment value

w

XX : Adjustment value

e

XX : Adjustment value

r

XX : Adjustment value

t

XX : Adjustment value

y

XX : Adjustment value

13

DCD-710AE

No

X

X

R

FRP

X

XXXX hour

L

ASER ON TIME

C

LEAR

L

ASER ON TIME

Key name

Function Display

Adjustment value

2.7

display

Accumulated

2.8

laser on time

display

u RFRP

i Return to q.

(Note)If auto adjustment is not completed, proper

values are not displayed.

・When the DISC/USB and 5 button is pressed

while the DCD-710AE is in the stop mode, the

accumulated laser on time is displayed.

・The laser drive times are added and the result is

displayed.

・One count corresponds to 10 minutes. (Values

under 10 minutes are discarded.)

・Count values are stored in the EEPROM every 10

minutes.

・The accumulated laser on time is displayed in

hours.

・Laser ON/OFF is monitored and counted.

・Press the 2 button, CD test mode display (2)

reappears.

・The count values are not cleared, even when the

set is reset.

・Minimum display specification

• No. dig its stored in EPROM: 4, 0xFFFF

• No. digits displayed: 5

• When the time exceeds 10922 hours, the

stored data is not updated and the value is

fixed to 0xFFFF.

(The display is fixed to 10922 hours.)

u

XX : Adjustment value

・13 flashing

CD heat run

3

mode

q Count value is reset

・When the

seconds while the accumulated laser on time is

displayed, the count value is reset.

・After resetting is completed, the display in 2.8

(00000 hours on the top line) reappears, and

after 5 seconds the model name display

reappears.

・Count value is reset upon shipment from the

factory and when the mechanism is replaced.

・AC is turned on while pressing the 5 and 2 button

same time on Main Unit.

・Switches to mode according to button input.

・Press a reverse button to switch the mode while

displaying the version of the main μcom.

(Normal heat run mode, Heat run short mode,

Automatic mounting mode.)

・If an error occurs, display the error and stop

operation at that point.

・Number of operations held.

・While heat run, the operation of each button is not

valid except the ON/STANDBY button and

pressing the 5 and 2 button same time.

/

13 button is pressed for over 5

q

14

DCD-710AE

No

H

.R.NORMAL

XXXX

XXXX

H

.R.SHORT

XXXX

XXXX

Key name

Function Display

Normal heat run

3.1

mode

/

・Press the

displayed or H.R.NORMAL is displayed.

・Count this as the 0th heat run repetition.

q Play from the first to last track on disc.

w After disc playback has finished, move pickup

e When loader open status detected, close tray

r The heat run repetition no. is incremented

13 button while name of the model is

to innermost position and open tray.

again, re-read TOC and start playback from the

first track on the disc.

(increased by 1) when the tray is opened.

※If the 2 and 5 button is pressed while operat-

ing, number of heat run is displayed for 3 seconds.

・Model Name display

・H.R.NORMAL display

・Normal heat run mode

Normal display except when 1 light, 3 flashing

q Normal display except when 1 light, 3 flashing

w

XXXX : No. of heat run repetitions

e Normal display except when 1 light, 3 flashing

r

XXXX : No. of heat run repetitions

Heat run Short

3.2

mode

t Conduct q to e repeatedly.

/

・Press the

H.R.SHORT is displayed.

・Count this as the 0th heat run repetition.

q Play the last track only on disc.

w After disc playback has finished, move pickup

to innermost position and open tray.

e When loader open status detected, close tray

again, re-read TOC and start playback from the

first track on the disc.

r The heat run repetition no. is incremented

(increased by 1) when the tray is opened.

※If the 2 and 5 button is pressed while oper-

13 button while name of the

ating, number of heat run is displayed for 3

seconds.

・H.R.SHORT display

・Heat run Short mode

Normal display except when 1 light, 3 light

q Normal display except when 1 light, 3 light

w

XXXX : No. of heat run repetitions

e Normal display except when 1 light, 3 light

r

XXXX : No. of heat run repetitions

t Conduct q to e repeatedly.

15

DCD-710AE

No

H

.R.CHACKING

XXXX

XXXX

CD EX-XX

Key name

Function Display

Automatic

3.3

mounting mode

3.4 Error display

/

・Press the

H.R.CHACKING is displayed.

・Count this as the 0th heat run repetition.

q Play the last track only on disc.

w The heat run repetition no. is incremented

(increased by 1) when the tray is opened.

※If the 2 and 5 button is pressed while oper-

e Conduct q repeatedly.

E1-00:Disc cannot be detected

E1-01:Tracking offset adjustment not possible

E1-02:Focus offset adjustment not possible

E2-00:Focus servo dropped during playback.

E2-01:Focus servo dropped during searching.

E2-03:Focus servo dropped during TOC reading.

E2-05:Focus servo dropped during manual

E2-10:Subcode can no longer be read during

E2-11:Subcode can no longer be read during

E2-12:Subcode can no longer be read during

E2-14:Subcode cannot be read during pause

E2-15 :Subcode cannot be read during manual

E3-00: TOC could not be read within specified

E3-01:PVD/SVD analysis could not be

E4-04:Search time out

E4-05:Error in communications with CD decoder

E5-00:Inner switch not on

E6-00:Inner switch not off

E8-00:Tray is not opened by the specified time.

E8-01:Tray is not closed by the specified time.

E9-01:Other error

13 button while name of the

ating, number of heat run is displayed for 3

seconds.

search.

playback

searching

TOC reading

search

time

completed within specified time

・H.R.CHACKING display

・Heat run short mode

Normal display except when 1 flashing, 3 flashing

qNumber of heat run is display

XXXX : No. of heat run repetitions

・READING, CLOSEdisplay

Normal display except when 1 flashing, 3 flashing

wNumber of heat run is display

XXXX : No. of heat run repetitions

,

・

13 with mode light or flashing

X-XX : Error cord

16

DCD-710AE

No

XXXX

01 01: 47

V

ersionUp Main

S

etDisc -> Close

V

ersionUp

F

ileSearch

V

ersionUp

F

ileCheck

V

ersionUp

E

rasig

V

ersionUp

W

riting

V

ersionUp

I

NVALID DISC

V

ersionUp Main

C

omplete

INITIALIZE

V

ersionUp USB

S

etDisc -> Close

Key name

Function Display

3.4 Error display

Main μ-com

Version u p

4

mode

q Number of heat run is display

・Press the 9 button while the error is displayed.

・ No. heat runs is displayed for 5 seconds, the error

display reappears.

w The track no. and time when the erro r occurred is

displayed

・Press the 8 button while the error is displayed.

・ The track no. and time when the error occurred is

displayed for 5 seconds, then error display

reappears.

・POWER switch is turned to on while

simultaneously pressing 5 and 2 button.

・ While displaying model name, when 2 and the

PITCH- button are pressed simultaneously, the

tray opens.

• If an the 5 or

closed, a disc will be loaded and V ersi on up will be

started.

• " INVALID DISC" is displayed when not found

upgrade file and the tray is opened.

/

13 button is pushed and a tray is

,

q

13 with mode light or flashing

XXXX : No. of heat run repetitions

・Error display reappears after 5 seconds. See 3.4.

,

13 with mode light or flashing.

w

・Error display reappears after 5 seconds. See 3.4.

q During a file search

w During a file check

4.1

4.2

5

6

Start version up

End version up

Initialize

USBμ-com

Version u p

mode

e During deletion

r Writing

t When a file is not found

・After Version UP is completed, a tray is opened

and it stops in

・Press POWER SW while simultaneously pressing

5 and 9 button.

・The system is reset, and once this is completed

the unit is set to the normal mode.

DIMMER : 100%

PURE DIRECT : OFF

DISC/USB : DISC

REMOTE/BROWSE : REMOTE

・The laser current initial value and laser

accumulated on time is not cleared.

・Press POWER SW while simultaneously pressing

5 and 2 button.

・ While displaying model name, when 2 and the

PITCH- button are pressed simultaneously, the

tray opens.

17

DCD-710AE

No

V

ersionUp

F

ileSearch

V

ersionUp

F

ileCheck

V

ersionUp

E

rasig

V

ersionUp

W

riting

V

ersionUp

I

NVALID DISC

V

ersionUp USB

C

omplete

Key name

Function Display

Start version up

6.1

End version up

6.2

/

• If an the 5 or

closed, a disc will be loaded and Version up will

be started.

• " INVALID DISC" is displayed when not found

upgrade file and the tray is opened.

・After Version UP is completed, a tray is opened

and it stops in

13 button is pushed and a tray is

q During a file search

w During a file check

e During deletion

r Writing

t When a file is not found

EEPROM TEST

7

mode

・Press POWER SW while simultaneously pressing

PITCH- and DISC/US button.

・POWER LED lights to the orange (TEST start).

・MUTING ON

・After EEPROM TEST, in the case of OK, LED

lights to the green.

・After EEPROM TEST, in the case of NG, LED

lights to the red.

・Mode is cancelled with POWER OFF.

18

DCD-710AE

Special mode transition diagram

5+2+POWER SW_ONService mode

μ-com

Ver.display

USB μ-com

Ver.display

CD test mode

Model Name display

“DCD-700AE”

Key input mode

The name of the key is displayed.

USB Ver UP mode

“Ver UP USB” display

Main Ver UP mode

“Ver UP Main” display

1/3

1/3

1/3

8 or 9

9 + PITCH-

2

+ PITCH-

2+1/3

2+1/3

1/3 or

5

1/3 or

5

2+1/3

2+1/3

2+1/3

2+1/3

2+1/3

9

9

9

9

9

8

9

9

8

8

8

8

8

8

1/3

Start

Ver UP

Start

Ver UP

H.R.NORMAL display

H.R.SHORT display

H.R.CHACKING display

FL tube

The display for each grid.

(It displays at intervals

of 1 second.)

FL all light

The entire display is

flashing with an interval

of about 1 second.

H.R.NORMAL operation

TOC read → playback

title-all of the disc. →

OPEN → CLOSE →

TOC read

It displays repeatedly.

H.R.SHORT operation

TOC read → playback

title-end of the disc. →

OPEN → CLOSE →

TOC read

It displays repeatedly.

H.R.CHACKING operation

TOC read → OPEN →

CLOSE → TOC read

It displays repeatedly.

19

DCD-710AE

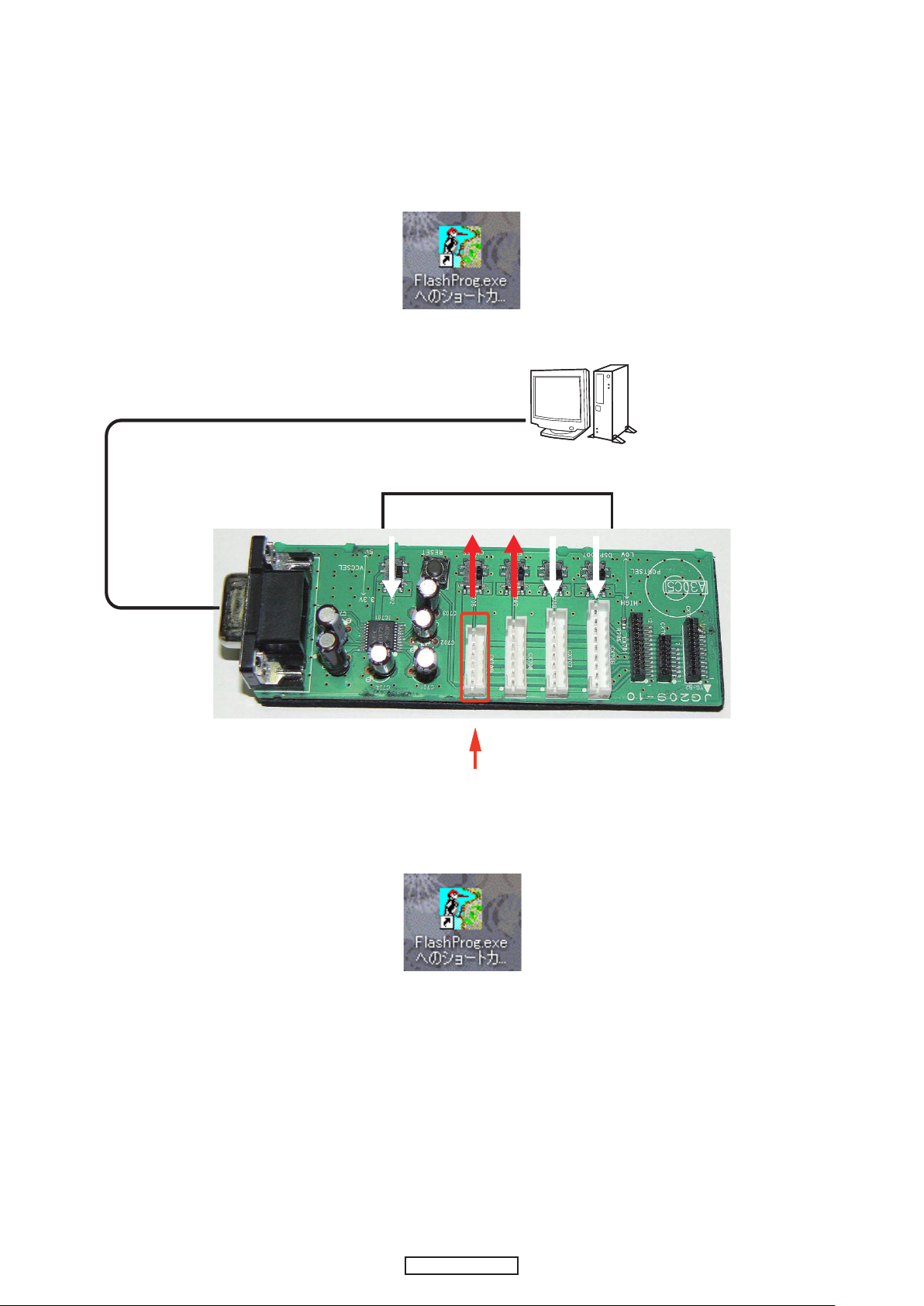

VERSION UPGRADE PROCEDURE OF FIRMWARE

PC

①Connect windows PC with RS-232C cable.

②Switch to the direction of the arrow.

③Connect CN52 on the CUP12202Z-1 board

with 6P PH-PH CON.CORD(00D2040572004).

CX709

PC

①Connect windows PC with RS-232C cable.

②Switch to the direction of the arrow.

③Connect CN52 on the CUP12202Z-1 board

with 6P PH-PH CON.CORD(00D2040572004).

CX709

Initial Version No.of main μ-com and USB μ-com.

Main μ-com Ver 0035

①

USB μ-com USB Ver 0014

②

When update Firmware, please conrm a last version in SDI.

※

1. Update for IC15(TMP92FD28AFG)

(1) Prepare the windows PC that installed the FlashProg.EXE.

(2) Connect SPK-581 as forrows.

s

(3) Double click FlashProg.exe, and launch the FlashProgrammer.

20

DCD-710AE

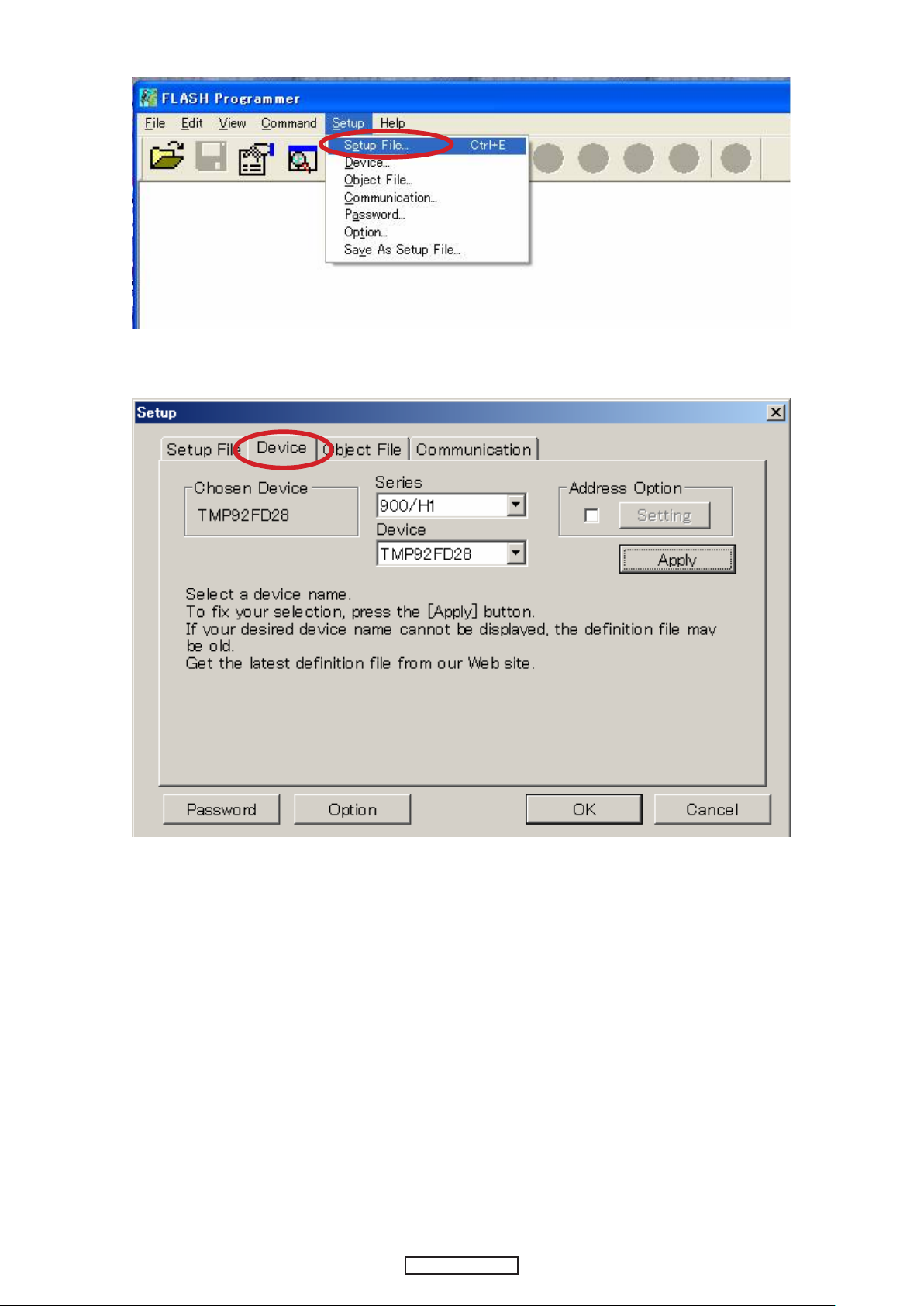

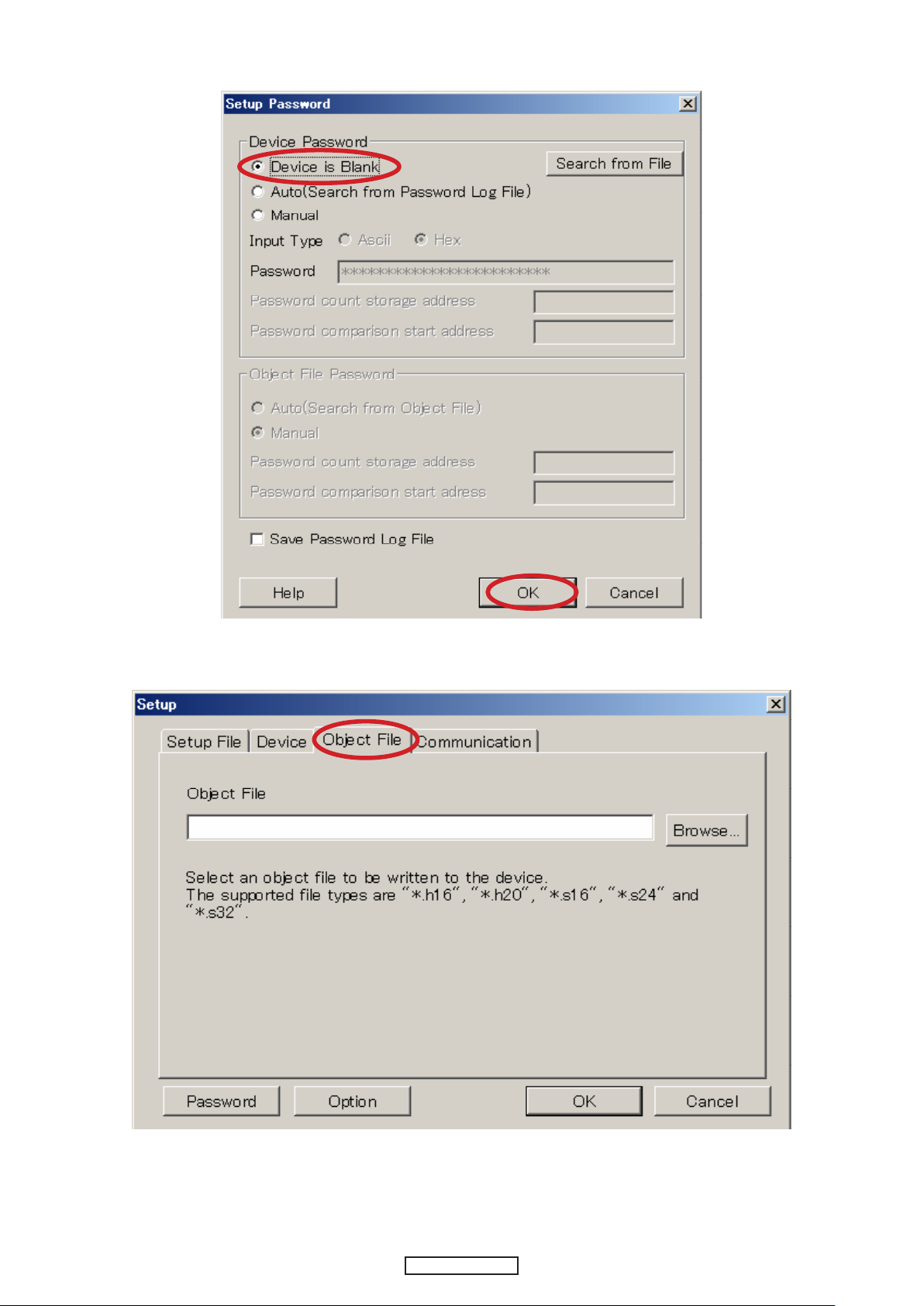

(4) Click the Setup in the menu bar and select the Setup File.

(5) Click Device tab.

21

DCD-710AE

(6) Choose the TMP91FD28 in the Device, and choose the 900/H1 in the Series.

Click Apply, and display the chosen Dvice.

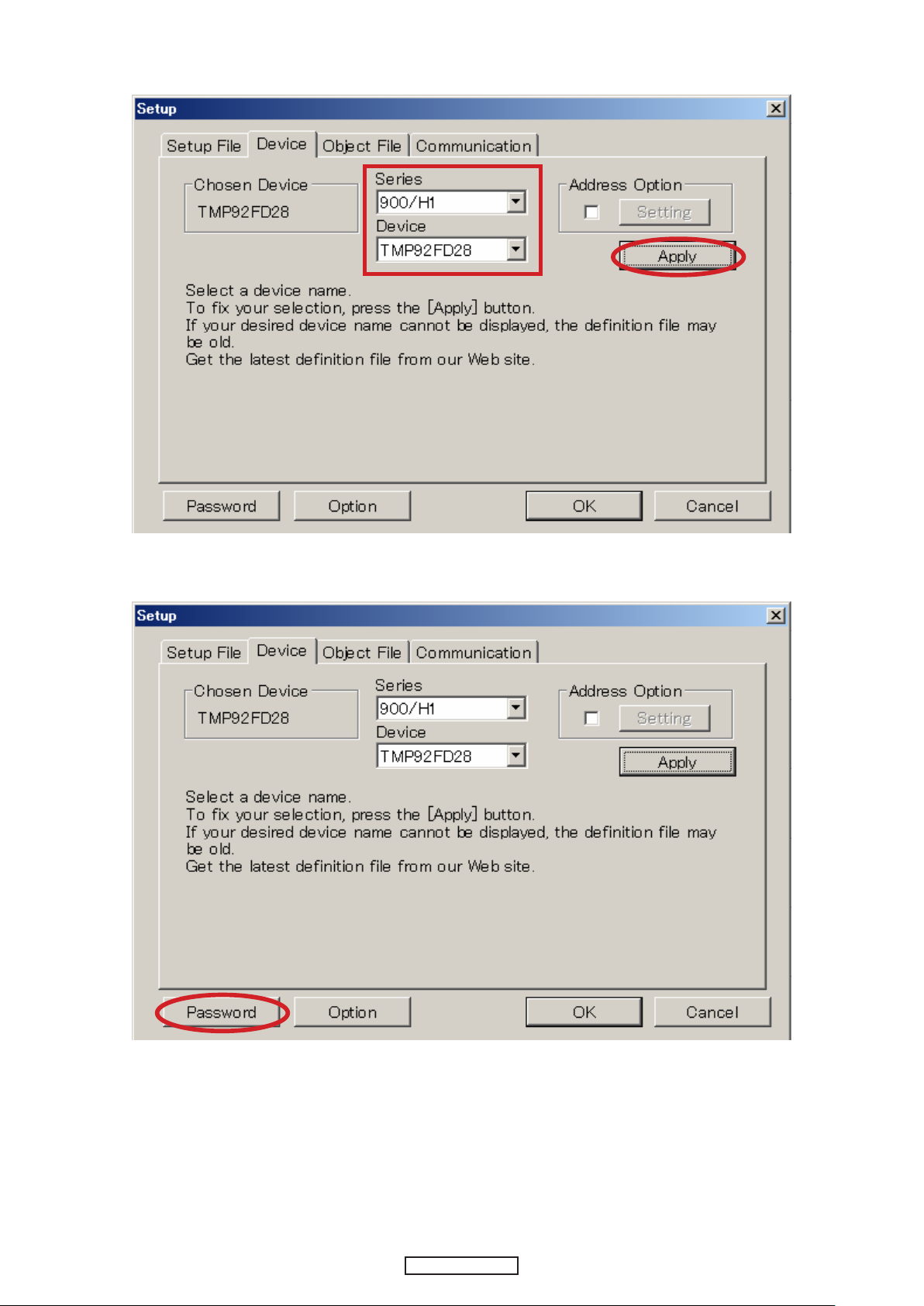

(7) Click Password.

22

DCD-710AE

(8) Choose the Device is Blank.

And Click OK.

(9) Click Object File tab.

23

DCD-710AE

Loading...

Loading...