Denon DCD-500AE Service manual

SERVICE MANUAL

For Europe &

Taiwan R.O.C. model

Ver. 1

MODEL

DCD-500AE

CD PLAYER

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

Denon Brand Company, D&M Holdings Inc.

●

●

●

●

TOKYO, JAPAN

本機の仕様は性能改良のため、予告なく変更すること

があります。

補修用性能部品の保有期間は、製造打切後8年です。

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

X0303 V.01 DE/CDM 0608

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Do not stare into beam or view directly with optical instruments, class 3A laser product.

DCD-500AE

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such as

the cabinet, parts, chassis, etc., have cautions indicated on

labels or seals. Be sure to heed these cautions and the cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching inter-

nal metal parts when the set is energized could cause

electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when

servicing while the set is energized, unplugging the power

cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra care

when the set is energized.

◎

Caution concerning disassembly and assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are moved

across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked ! on wiring

diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange the

wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the

surface of printed circuit boards. Care is also taken with the

positions of the wires inside and clamps are used to keep

wires away from heating and high voltage parts, so be sure to

set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety is

ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the

antenna, plugs, etc., and turn the power switch on. Using a

500V insulation resistance tester, check that the insulation resistance between the terminals of the power plug and the externally exposed metal parts (antenna terminal, headphones

terminal, microphone terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and structural parts used in the set have

special safety properties. In most cases these properties are

difficult to distinguish by sight, and using replacement parts

with higher ratings (rated power and withstand voltage) does

not necessarily guarantee that safety performance will be preserved. Parts with safety properties are indicated as shown

below on the wiring diagrams and parts lists is this service

manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the ! mark.

(2) Parts lists ... Indicated by the ! mark.

Concerning important safety parts

Using parts other than the designated parts

could result in electric shock, fires or other

dangerous situations.

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所についてはキャ

ビネット、部品、シャーシなどにラベルや捺印で注意事項を

表示しています。これらの注意書きおよび取扱説明書などの

注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電時

に内部金属部に触れると感電することがあります。従っ

て通電サービス時には、絶縁トランスの使用や手袋の着

用、部品交換には、電源プラグを抜くなどして感電にご

注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱に

は十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をして

おりますが、板金端面は鋭利となっている箇所が有りますの

で、部品端面に触れたまま指を動かすとまれに怪我をする場

合がありますので十分注意して作業して下さい。手の保護の

ために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持った

ものとなっています。従って交換部品は、使用されていたも

のと同じ特性の部品を使用してください。特に配線図、部品

表に

!印で指定されている安全上重要な部品は必ず指定の

ものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、プ

リント基板から浮かして取付けた部品があります。また内部

配線は引きまわしやクランパーによって発熱部品や高圧部

品に接近しないように配慮されていますので、これらは必ず

元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元どお

りになっているか、またサービスした個所の周辺を劣化させ

てしまったところがないかなどを点検し、外部金属端子部

と、電源プラグの刃の間の絶縁チェックをおこなうなど、安

全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグな

どを外し、電源スイッチを入れます。500V 絶縁抵抗計を用

いて、電源プラグのそれぞれの端子と外部露出金属部[アン

テナ端子、ヘッドホン端子マイク端子、入力端子など]との

間で、絶縁抵抗値が1 MΩ 以上であること、この値以下の

ときはセットの点検修理が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安全

上、特別な特性を持っています。この特性はほとんどの場合、

外観では判別つきにくく、またもとの部品より高い定格(定

格電力、耐圧)を持ったものを使用しても安全性が維持され

るとは、限りません。安全上の特性を持った部品は、この

サービスマニュアルの配線図、部品表につぎのように表示し

ていますので必ず指定されている部品番号のものを使用願

います。

(1) 配線図…!マークで表示しています。

(2) 部品表…!マークで表示しています。

安全上重要な部品について

指定された部品と異なるものを使用した場合に

は、感電、火災などの危険を生じる恐れがあり

ます。

2

DCD-500AE

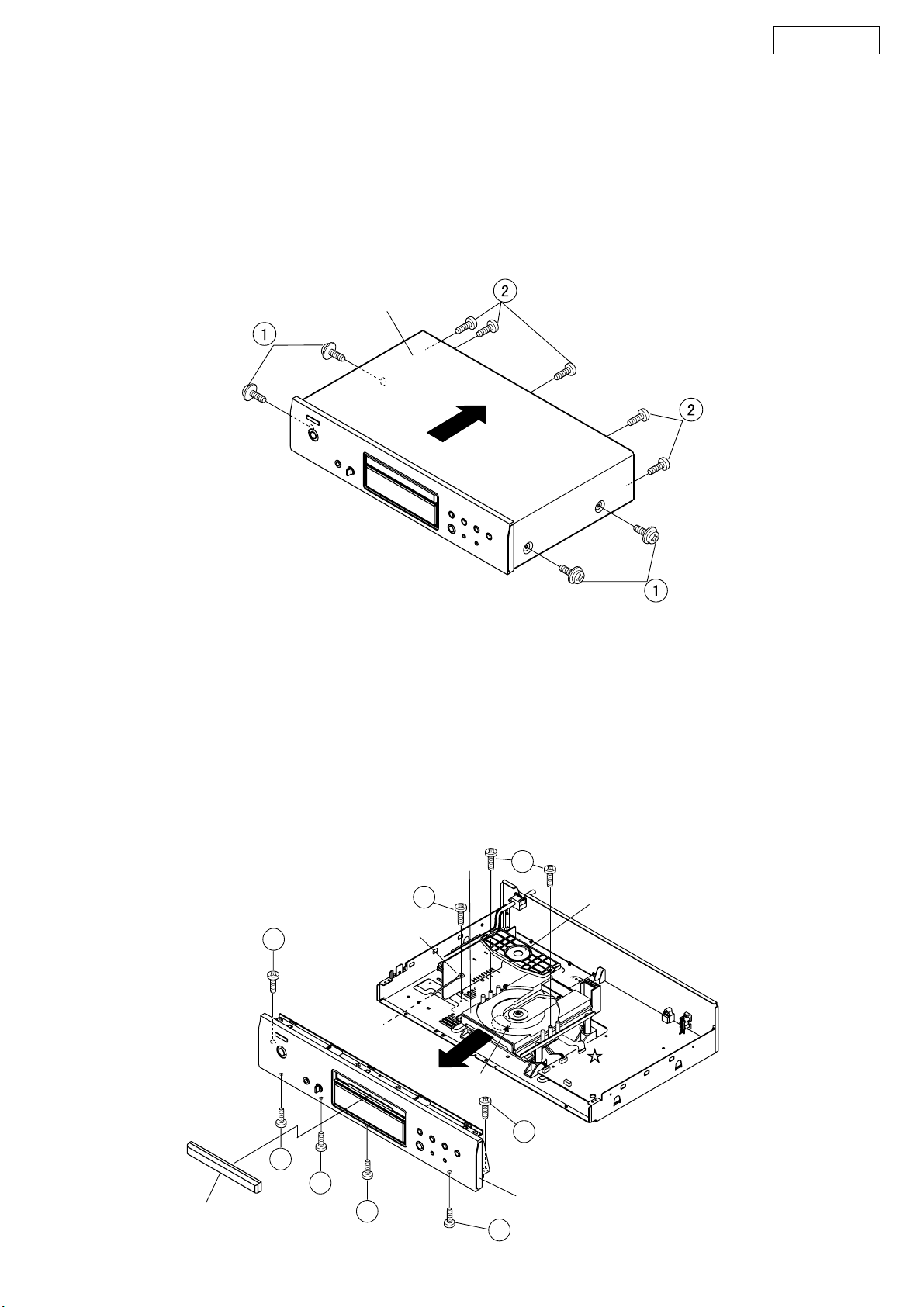

DISASSEMBLY

(Follow the procedure below in reverse order when reassembling.)

1. Top Cover

(1) Remove 4 screws ① on both sides.

(2) Remove 5 screws ② on rear side.

(3) Detach the Top cover as shown in the fig.

Top cover

各部のはずしかた

(組み立てるときは、逆の順序でおこなってください。)

1. トップカバーのはずしかた

(1) 側面のねじ① 4 本をはずします。

(2) 後面のねじ② 5 本をはずします。

(3) トップカバーを矢印の方向へはずします。

2. Front Panel

(1) Take off the Chucking plate after removing 2 screws ③ .

Open the CD tray by turning the Drive gear (a) clockwise,

then detach the Loader panel.

(2) Remove 1 screw ④ fixing the Ring wire.

(3) Remove 4 screws ⑤on the bottom edge of the Front pan-

el.

(4) Remove 2 screws ⑥ , at L/R ends of the Front panel.

(5) Detach the Front panel.

Note : Do not yet exclude FFC(

☆ mark).

CD tray

4

6

Ring wire

2. フロントパネルのはずしかた

(1) ねじ③ 2 本をはずしチャッキングプレートをはずしま

す。ドライブギア(a)を時計回りに廻して CD トレイ

を引き出して、ローダーパネルをはずします。

(2) リングワイヤーを止めているねじ④1本をはずします。

(3) フロントパネル底部のねじ⑤ 4 本をはずします。

(4) フロントパネル左右側部のねじ⑥ 2 本をはずします。

(5) フロントパネルをはずします。

( 注)まだ FFC( ☆マーク ) は抜かないこと。

3

Chucking plate

Loader panel

(a)Drive gear

6

5

5

Front panel

5

5

3

DCD-500AE

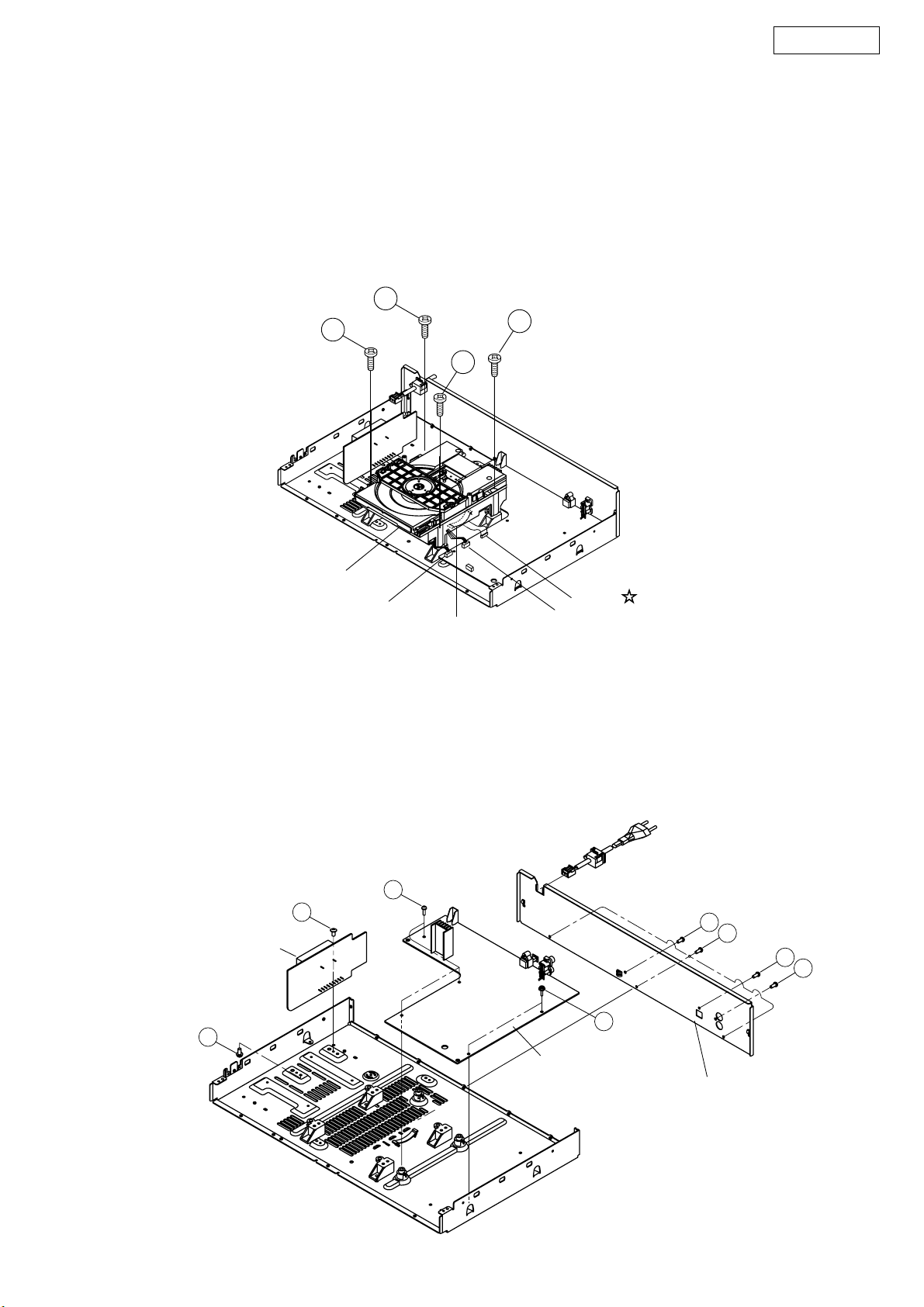

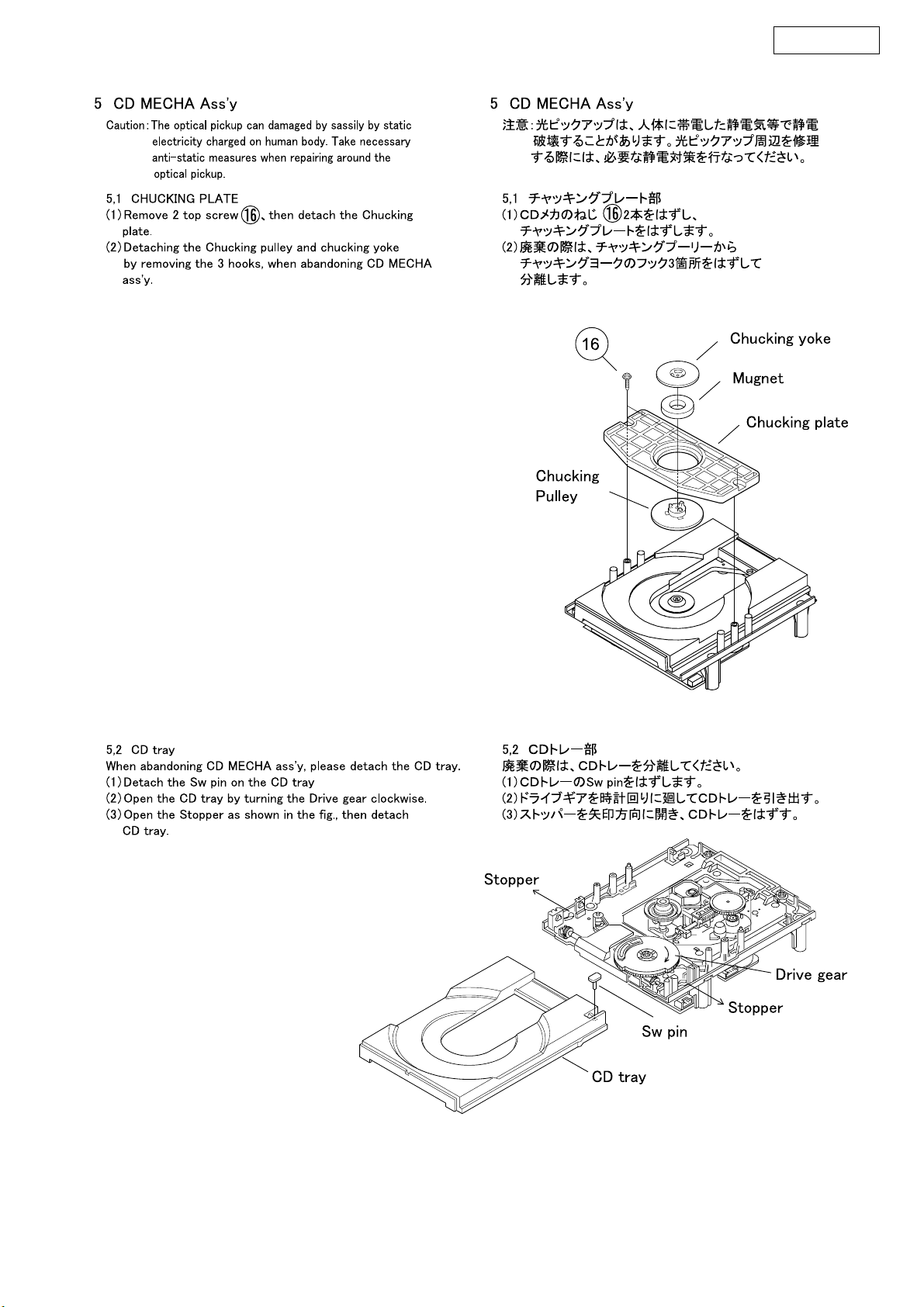

3. CD Mecha. Unit

(1) Remove 4 screws ⑦ fixing the CD Mecha..

(2) Unplug Connectors (b),(c) .

※ Do not yet exclude FFC( ☆ mark).

(3) Laser short-circuit in Pick-up of CD Mecha..

(4) Unplug Connector FFC from socket.

(5) Release the FFC from the Clamper.

7

7

3. CD メカのはずしかた

(1) CDメカを取り付けているねじ⑦4本をはずします。

(2) コネクター (b),(c) をソケットから抜きます。

※まだ FFC は抜かないこと(☆マーク)

(3) ピックアップのLD回路パターンの一部を半田付け

でショートします。

(4) FFC ケーブルをソケットから抜きます。

(5) FFC ケーブルをクランパーからはずします。

7

7

CD Mecha.

(b)

Clamper

4. Main P.W.B. and Power P.W.B.

(1) Remove 3 screws ⑧ ,1 screw ⑨〜⑪ of the Rear

panel and detach it.

(2) Remove 2 screws ⑫ ,3 screws⑬ fixing the Main

P.W.B..

(3) Remove 1 screw ⑭ ,1 screw⑮ fixing the Power

transformer with Power P.W.B..

13

15

Power transformer

with Power P.W.B.

14

FFC

(c)

4. Main 基板 ,Power 基板のはずしかた

(1) リアパネルを取り付けているねじ⑧ 3 本と端子を

取り付けているねじ⑨〜⑪各 1 本をはずして、リ

アパネルをはずします。

(2) ねじ⑫ 2 本とねじ⑬ 3 本をはずして、Main 基板

をはずします。

(3) ねじ⑭ 1 本とねじ⑮ 1 本をはずして、Power 基板

とパワートランスをはずします。

9

8

10

11

12

Main P.W.B.

Rear panel

4

DCD-500AE

5

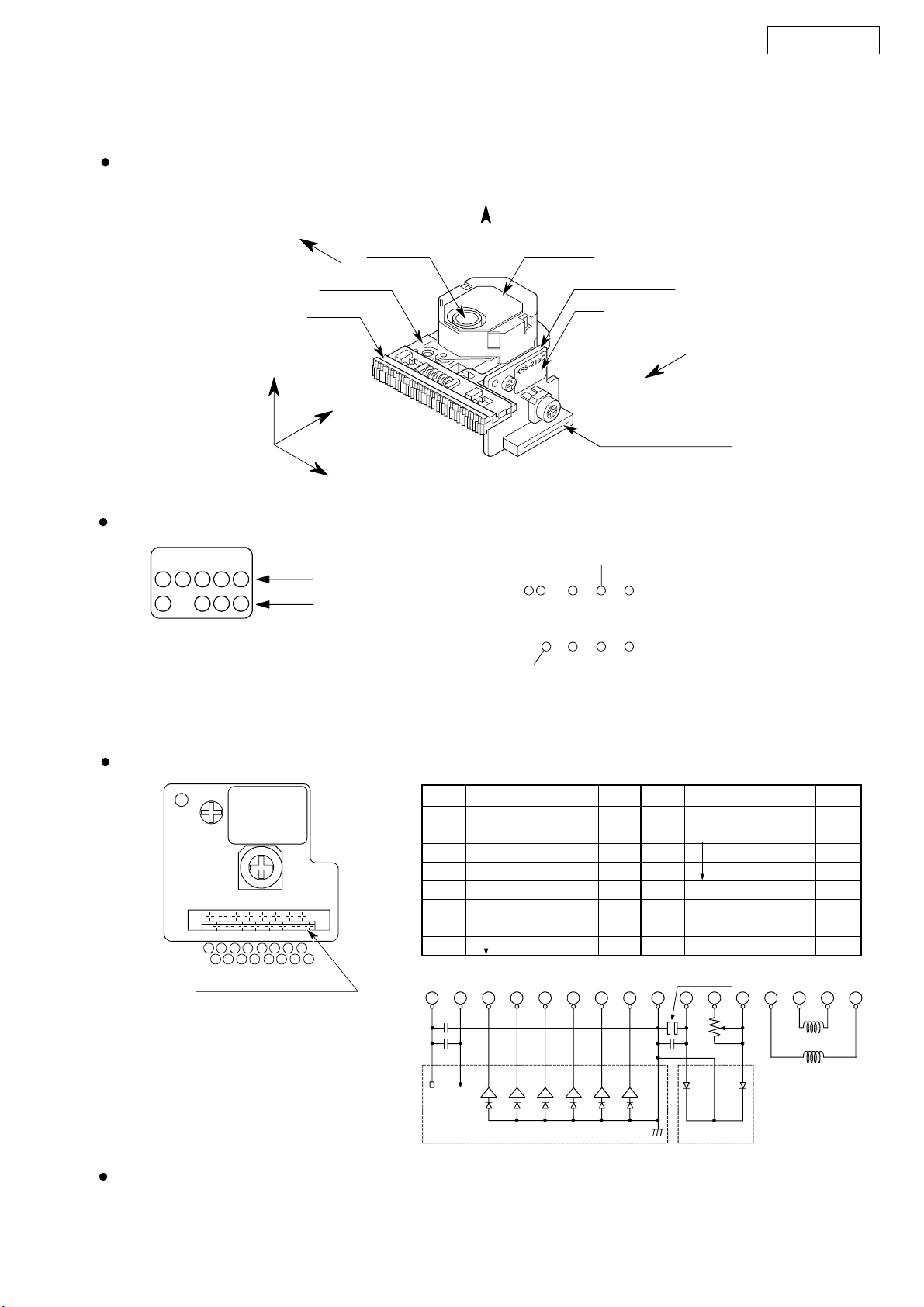

NOTE FOR HANDLING OF LASER PICK-UP

Description of the Components

+Z-axis direction

DCD-500AE

Label

+X-axis direction

KSS-213C

Z-axis

OP Slide base

Slide rack

Y-axis

(Tangental direction)

X-axis

(Radial direction)

Lot No.

lop

Object Lens

Actuator cover

PAL-2 Flexible board

Label

+Y-axis direction

Flexible flat cable connector

year

(last figure)

day month quality control No.

Lot No.

Oct. Nov. and Dec. are expressed by alphabetical letters

of X, Y and Z.

lop No.

10 1 10

LD drive currentquality control

The expressed unit is by mA, with omission of the

decimal point as for example, 56.5mA will be expressed as 565, but the head of English letter means

the control in the manufacturning plant.

-1

Pin Connector

KSS-213C

Pin No. Description

1PDIC Vc IN

2 Vcc IN

3EOUT

4DOUT

5AOUT

6BOUT

7COUT

1 3 5 7 9 11 13 15

2 4 6 8 10 12 14 16

8FOUT

Flexible flat cable connector

+2.5V +5V

CAUTION: The soldered connecting portion must be bridged when removing CN54.

IN/OUT

Pin No. Description

LD

9GNDIN

PDIC

IN/OUT

10 LD LD IN

11 VR IN

12 PD OUT

13 FCS (+) IN

14 TRK (+) IN

15 TRK (- ) IN

16 FCS (- ) IN

SHORT LAND

10

987654321

11

LDPDIC

13

12

14

15

TRACKING

FOCUSING

16

6

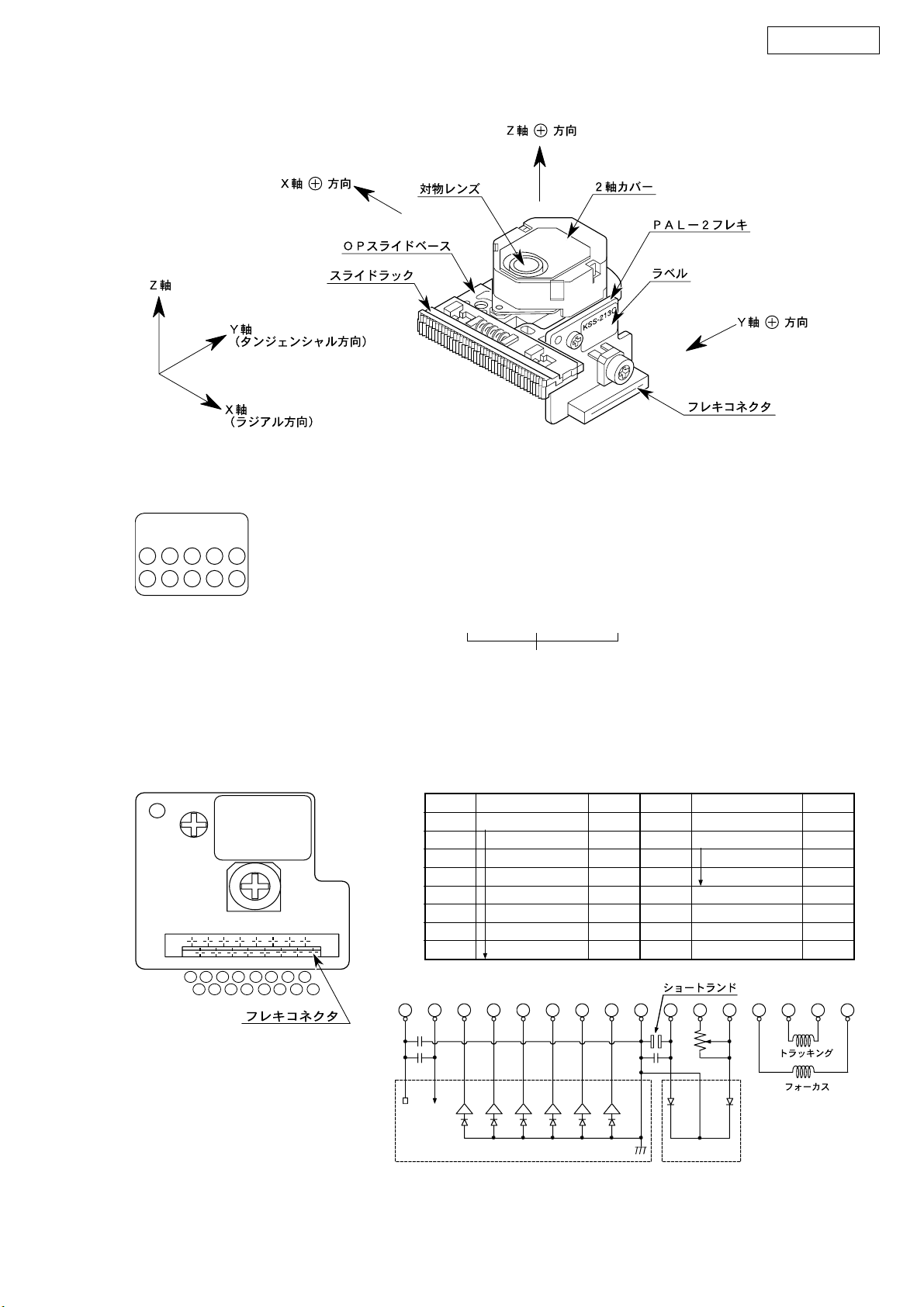

レーザピックアップ取扱い上の注意

各部の名称

ラベル表示

DCD-500AE

KSS-213C

コネクタ結線図

1 3 5 7 9 11 13 15

2 4 6 8 101214

KSS-213C

上段 日付 月 西暦年号の末尾 品質管理No.

Lot No. ○○ ○ ○ ○

但し、月表示の10、 11、 12はX、 Y、 Zで表わす。

下段 英字 10桁 1桁 小数点以下第1位

○○ ○ ○ ○

IOP表示

表示単位はmA、小数点は省略

頭の英字は、製造所の管理に用いる場合がある。但し、桁数は0〜2桁迄とする。

ピン No. 端子名 入出力

① PD IC Vc IN

② Vcc IN

③ E OUT

④ D OUT

⑤ A OUT

⑥ B OUT

⑦ C OUT

⑧ F OUT

16

5

4321

ピン No. 端子名 入出力

9

876

LD

⑨ GND IN

PDIC

⑩ LD LD IN

⑪ VR IN

⑫ PD OUT

⑬ FCS (+) IN

⑭ TRK (+) IN

⑮ TRK (-) IN

⑯ FCS (-) IN

10

11

141312

1615

(注意)

CN54 (16P FFC

+2.5V +5V

LDPDIC

ケーブル) をはずす前にハンダ接続部(ショートランド)をブリッジしてください。

7

DCD-500AE

Caution for Handling the Laser Pick-up

The laser pick-up KSS-213C is assembled and precisely

adjusted using a sophisticated manufacturing process in our

plant. Do not disassemble or attempt to readjust it. Please

observe the following instructions carefully in handling the

pick-up.

1. Handle with Care

(1) Storage

Donotstorethepick-upindusty,0or

high-humidity environments.

(2) Please take care for preventing from shock by falling

down or careless handling.

2. Laser Diode (LD)

(1) Protect your eyes

The laser beam may damage the human eye, since the

intensity of the focused spot may reach 7x10

W/cm2even if the intensity at the objective lens is 400µW

maximum. As the light beam spreads after focused

through the objective lens, it does not effect you in the

place as far as more than 30 cms. However, do not look

at the laser light beam either through the objective lens

directly nor another lens or a mirror.

(2) Poison of As

Since the LD chip contains As (Arsenic), as GaAs +

GaAlAs, as known as the poison, although the poison is

relatively weak, in comparing with others, e.g. As

etc., and the amount is small, avoid putting the

AsCl

3

chip in acid or an alkali solution, heating it over 200 °C

or putting it into your mouth.

(3) Avoid surge current or electrostatic discharge

The LD may be damaged or deteriorated by its own

strong light if a large current is supplied to it, even if only

a short pulse.

Make sure that there is no surge current in the LD driving

circuit by switches or else. Be careful to handle pick-up

as it may be damaged in a moment by human

electrostatic discharge. The pins of the LD are shortcircuited by solder for protection during shipment.

For safety handling of an LD, grounding the human body,

measuring equipments and jig is strongly recommended.

And still it is further desirable to make use of mat on the

platform and floor for handling the LD.

To open the short-circuit, remove the soldering quickly

with a soldering iron whose metal part is grounded.

The temperature of the soldering iron should be less than

320°C (30W).

2O3

4. Metal Bearing

As the metal bearing of Cu-compound sintered alloy is

impregnated with FROIL946P, never fail to supply the

bushing with the same lubricant at the time of replacing the

pick-up.

5. Handling

Please handle the laser pick-up with holding the slide base.

(resin molded part).

When either a part of human body or some other things may

happen to touch directly with the circuit part of P.W.Board, it

may cause deterioration, take careful attention in handling

this base.

6. Deterioration

As KSS-213C comprises built-in RF Amp and APC circuit,

resists stronger against external electrostatic damages than

the former typed pickup. However, there is possibility of

3

pickup deterioration in the following cases.

(1) Low HF level, or with great numbers of jitters.

(2) Tracking offset (EF Balance) is out of order (Refer to

“Confirmation Method of Adjustment” for confirmation (1)

and (2)).

,

3. Actuator

(1) The performance of the actuator may be affected if

magnetic material is located nearby, since the actuator

has a strong magnetic circuit. Do not permit dust to enter

through the clearance of the cover.

(2) Cleaning the lens

It may change the specifications by attaching dust or

ash on the objective lens. Clean the lens with a cleaning

paper dampened with, not pressing lens with so much

strength by the cleaning paper.

8

取扱い上の注意事項

レーザーピックアップ

安易に分解、調整等を行わないでください。取扱いに関して次の点に注意してください。

KSS-213C

は専門工場にて精密に組立調整されております。

1. 一般事項

(1) 保管

高温高湿下、ほこりの多い所での保存はさけてください。

(2) 精密に調整されていますので落下や不用意な取扱いによる衝撃がかからない様に注意してください。

2. 半導体レーザー(LD)

(1) レーザー光に対する目の保護

LDの出力は対物レンズ出射出力で最大

は光束が広がりますので

して光束を観察すると危険ですから絶対に行わないでください。

(2) Asの毒性

LDのチップは GaAs+ GaAlAsで毒物として良く知られている Asを含んでいます。

毒性は他の化合物、例えばA

題ありませんが、チップを取り出し、酸やアルカリ溶液へ入れたり、200 ℃以上に加熱したり、口に入れたりするこ

とは絶対に行わないでください。

(3) サージ電流、静電気による破壊

LDに大電流を流すときわめて短時間であっても自身が発する強い光によって劣化が促進され、或は破壊します。

LD駆動回路にはスイッチ、その他によるサージ電流が流れない様にしてください。又、不注意に取り扱うと人体から

の静電気が加わって瞬時に破壊されてしまいます。

LDの端子は出荷時に輸送による静電気破壊防止の為半田でショートされています。

更に、安全を期するため、取付時人体アース、計測器及び治工具のアースを必ず行ってください。又作業台、床には

アースマットを用いて接地してください。

ショート部の開放はLD コネクター差し込み後、半田ゴテで行ってください。半田ゴテは金属部分が接地されたものを

使用してください。

半田ゴテ先温度は 320℃以下(30W)のものを使用し、すみやかに行ってください。

30cm

以上離れれば大丈夫ですが動作中のLDを直視したり、あるいは他のレンズやミラーを介

S2 O3、AS Cl3等に比較し、はるかに弱い毒性で素子1ヶ当たりは少量ですのでほとんど問

400 W

ですが集光された所では約

3

7×10

W/cm2に達します。対物レンズ集光後

DCD-500AE

3. 2軸アクチュエータ

(1) アクチュエータ部は強力な磁気回路を有していますので磁性体が近づくと特性が変化します。

又、カバーのすきまから異物が入ることの無い様にしてください。

(2) レンズ清掃

対物レンズにゴミ、ホコリ等の汚れがついたとき性能が変化します。

清掃に当たってはレンズペーパーに水を少量つけ無理な力がレンズに加わらない様にして拭いてください。

4. 軸受

軸受けにはフロイル946P(関東化成工業)を塗布して有りますので、ピックアップ交換時は、必ずフロイル946Pを塗布

してください。

5. 取扱い

光学ピックアップの取扱いはスライドベース(樹脂モールド部)を持って行ってください。プリント基板の回路部に人

体、又は他の物体が直接触れると劣化の原因になることが有りますので、充分ご注意ください。

6. レーザーピックアップの劣化

トラッキング及びフォーカス調整が困難になったり、まったく不可能となった場合には、レーザーピックアップの劣化が

考えられます。この場合はレーザーダイオードの電流値を測定して判定を行ってください。

9

DCD-500AE

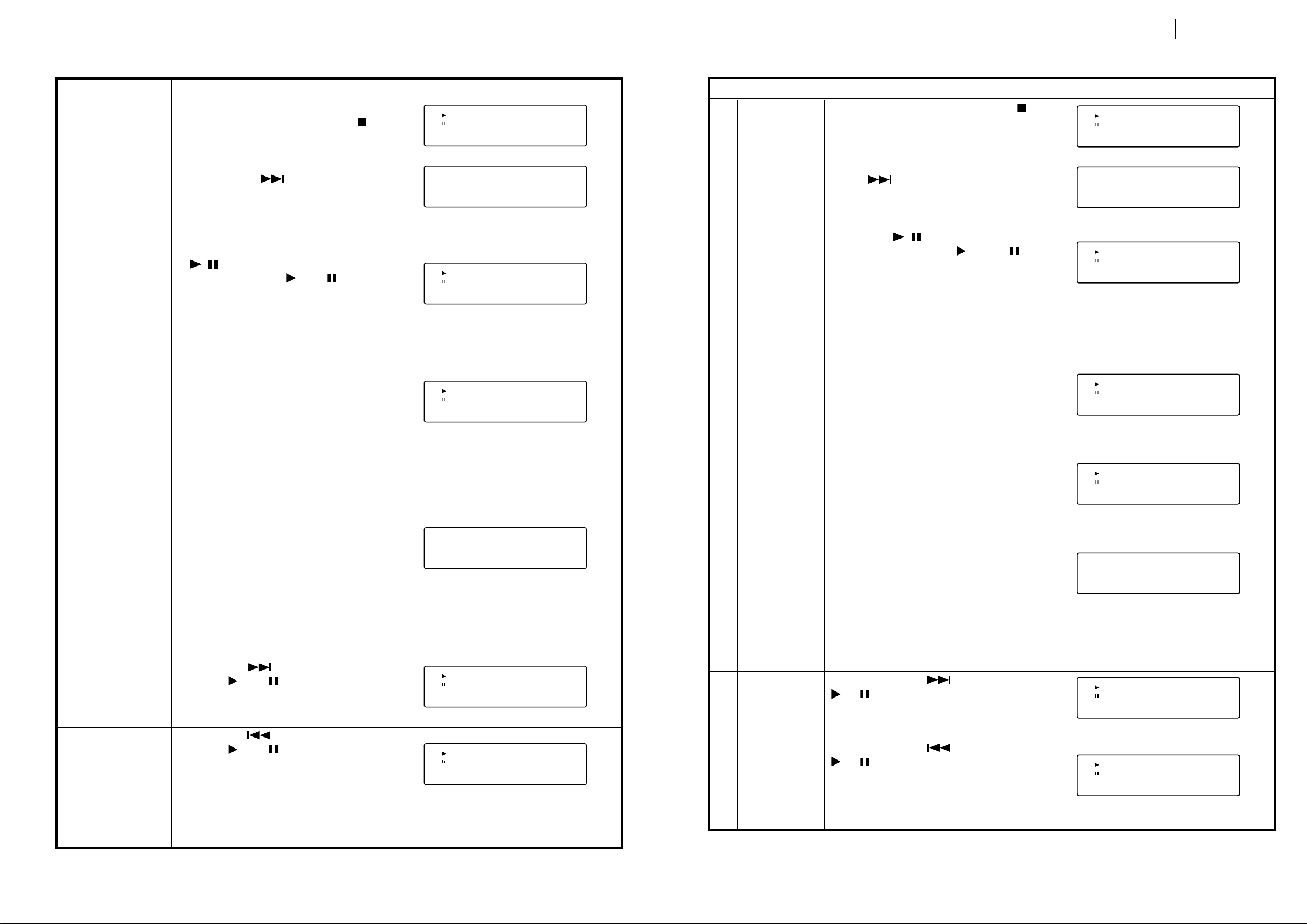

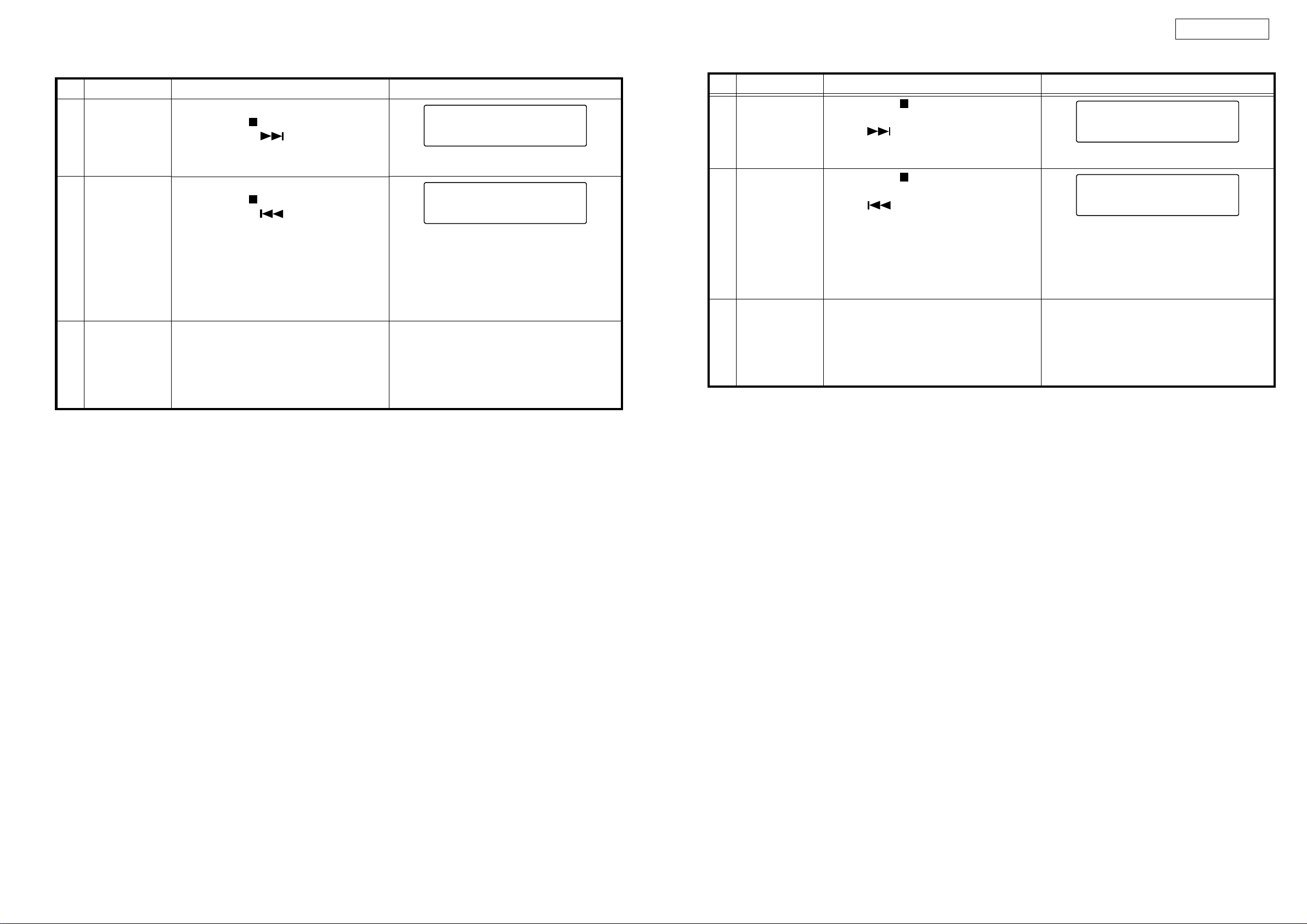

HEAT RUM MODE

No Mode Operation and Function Display

① When DISC is attached, POWER switch is

1 Heat Run Mode

Number of Heat

2

Run Repetition

Display Mode

Number of Track

and Elapsed Time

3

of Track being

played Display

Mode

turned to ON while pressing the Stop ( )

button on Main Unit.

“DCD500DNC100” is displayed.

② Press the Skip ( ) button continuously

for over 3 seconds to display the version number of main micro computer.

③ While the version number of main micro com-

puter is displayed, press the Play/Pause

( ) button continuously for over 3 sec-

/

onds to start heat run. is lit, is flashing and the other part of the FL tube is

displayed in the same way as normal play

mode. Count this as the 0th heat run repetition.

1)Play from the first to last track on disc.

2)After disc playback has finished, pickup is

moved to innermost position.

3)The tray is opened and the heat run repetition number is incremented (increased by 1).

4)The tray is closed.

5)TOC is re-read. Conduct 1) to 5) repeatedly.

・If the TIME button is pressed while operating,

number of heat run is displayed for 1 second.

・While heat run, the operation of each button is

not valid except the TIME button.

・POWER switch is turned to OFF to clear heat

run mode.

・If an error occurs, display the error and stop

operation at that point. Number of operations

held.

Press the Skip ( ) button while the error is

displayed. and are lit. And number of

heat run repetition is displayed for 5 second and

then the error display reappears.

Press the Skip( ) button while the error is

displayed. and are lit. And Number of

track and elapsed time of track being played in

time when error occured are displayed for 5

second and then the error display reappears.

xx-xxxx-xx :The version number of main micro

xx : Number of music being played

mm:ss : Elapsed time of music being played

xxxx : Number of heat run repetition

Error Code Content

E1-00 Disc cannot be detected.

E2-00 Focus servo could not follow dur-

E3-00 TOC could not be read within

xxxx : Number of heat run repetition

xx : Number of track in time when error

mm:ss : Elapsed time of track being played in

5

C

D

x

computer

D

C

D

C

occured

time when error occured

0

D

x

xxx

-

x

x

x

E

ing playback.

specified time.

x

x

0

-

DCN

x

m

0

0

m

-

m

x

x

m

ヒートランモード

No モード 操 作 と 機 能 表 示

① DISC をセットした状態で本体の Stop( )

0

0

1

x

x

s

s

:

1 ヒートランモード

x

x

x

x

x

x

s

s

:

エラー時のヒート

2

ラン回数表示モー

ド

エラー時の曲番と

3

時間表示モード

ボタンを押しながら、POWER スイッチを ON

にします。モデル名DCD500DNC100を表示

します。

② Skip( )ボタンを3秒以上押し、マイコ

ンのバージョン番号を表示させます。

③マイコンのバージョンが表示されている間に

Play/Pause( ) ボタンを3秒以上押して

ヒートランを開始します。 が点灯、 が

点滅します。他は通常再生モードと同じで

す。

以下の動作を繰り返し行います。最初のヒー

トラン回数を0回目とします。

1) ディスクの先頭曲から最終曲までを再生し

ます。

2) ディスクの最終曲再生終了後、PU を再内

周に移動させます。

3) トレイをオープンし、ヒートラン回数をカ

ウントアップします。

4) トレイをクローズします。

5)TOC リードを行い、1) の動作から再度開始

します。

・ヒートラン動作中に TIME ボタンを押すと、1

秒間ヒートラン回数が表示されます。

・ヒートラン時は TIME ボタン以外受け付けま

せん。

・ヒートランモードを解除するときは、POWER

スイッチを OFF にします。

・ヒートラン動作中にエラーが発生すると、エ

ラーを表示し、その時の状態で停止します。

動作回数は保持されます。

エラー表示中に Skip( )ボタンを押すと、

と が点灯し、ヒートラン回数を 5 秒間

表示して、エラー表示に戻ります。

エラー表示中に Skip( )ボタンを押すと、

と が点灯し、エラー発生時の曲番と再

生時間を 5 秒間表示して、エラー表示に戻りま

す。

/

0

5

C

D

x

xx-xxxx-xx :メインマイコンのバージョン番号

xx :再生中トラック番号

mm:ss :再生時間

D

C

xxxx :ヒートラン回数

D

C

xxxx :ヒートラン回数

エラーコード 内容

E1-00 ディスクの検出ができない。

E2-00 再生中にフォーカスが追従できな

E3-00 TOC が規定時間内に読めない。

D

C

xxxx :ヒートラン回数

xx :エラー発生時のトラック番号

mm:ss :エラー発生時の再生時間

0

D

x

x

かった時があった。

x

-

x

E

x

xxx

x

-

DCN

x

m

0

0

m

-

m

x

x

x

m

0

0

1

x

x

s

s

:

x

x

x

x

x

x

x

x

x

s

s

:

10

DCD-500AE

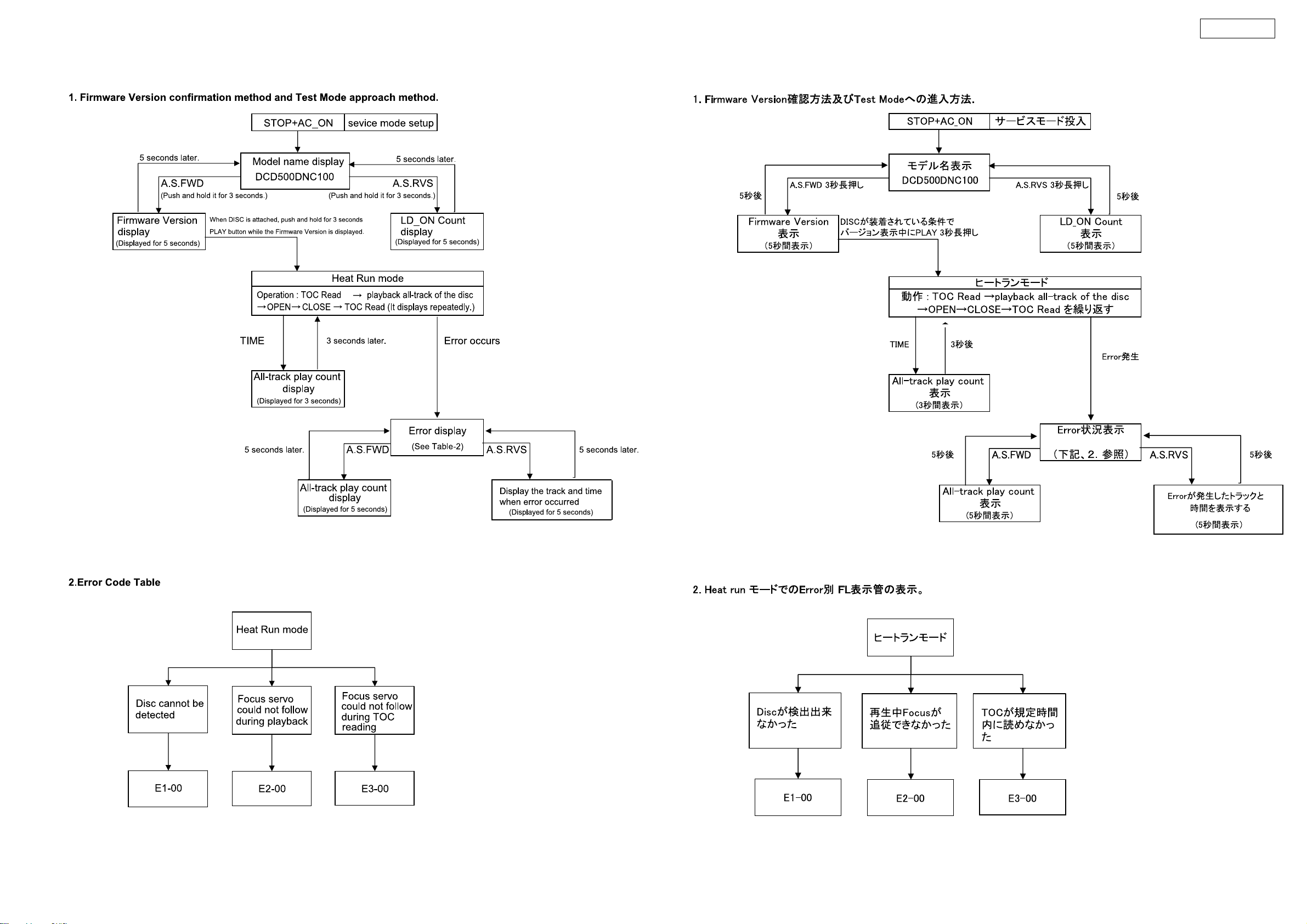

SERVICE MODE

No Mode Operation and Function Display

Version Number

of Micro Com-

1

puter Display

Mode

Number of Laser

2

ON Time Count

Display Mode

3

Initialize Mode

① POWER switch is turned to ON while press-

ing the Stop ( ) button on Main Unit.

② Press the Skip ( ) button continuously

for over 3 seconds to display the version number of main micro computer.

① POWER switch is turned to ON while press-

ing the Stop ( ) button on Main Unit.

② Press the Skip( )button continuously

for over 3 seconds to display number of Laser

ON time count.

・The number of time when the normal playback

time the Laser is turned to ON is incremented

(increased by 1) in every 15 minutes. The

accumulation number of times is recorded to

memory whenever count it.

POWER switch is turned to ON while pressing

the TIME button on Main Unit.

・Brightness setting of display becomes 100%

(default).

・The accumulation number of laser on time is

cleared, and a count becomes 0000.

x

x

xxx

-

xx-xxxx-xx : The version number of main micro

computer

L

D

-

xxxx : Number of Laser ON time count

Not special display

xxx

サービスモード

No モード 操 作 と 機 能 表 示

①本体の Stop( )ボタンを押しながら、

マイコンのバー

x

-

x

x

1

ジョン番号表示

モード

x

レーザー ON 時間

2

カウント回数表示

モード

3 初期化モード

POWER スイッチを ON にします。

② Skip( )ボタンを3秒以上押し、マイコ

ンのバージョン番号を表示させます。

①本体の Stop( )ボタンを押しながら、

POWER スイッチを ON にします。

② Skip( )ボタンを3秒以上押し、レー

ザーON 時間カウント回数を表示させます。

・通常再生時にレーザーを ON にしている時間

を15分毎にカウントアップします。カウン

ト時に累積回数を記憶します。

本体 TIME ボタンを押しながら、POWER スイッ

チを ON にします。

・FL 管の輝度設定を 100%( デフォルト ) にし

ます。

・レーザーON 時間カウントの累積回数をクリ

アします。

x

xxx

-

x

x

x

x

x

xxx

-

xx-xxxx-xx :メインマイコンのバージョン番号

L

D

-

xxxx :レーザー ON 時間カウント回数

なし

11

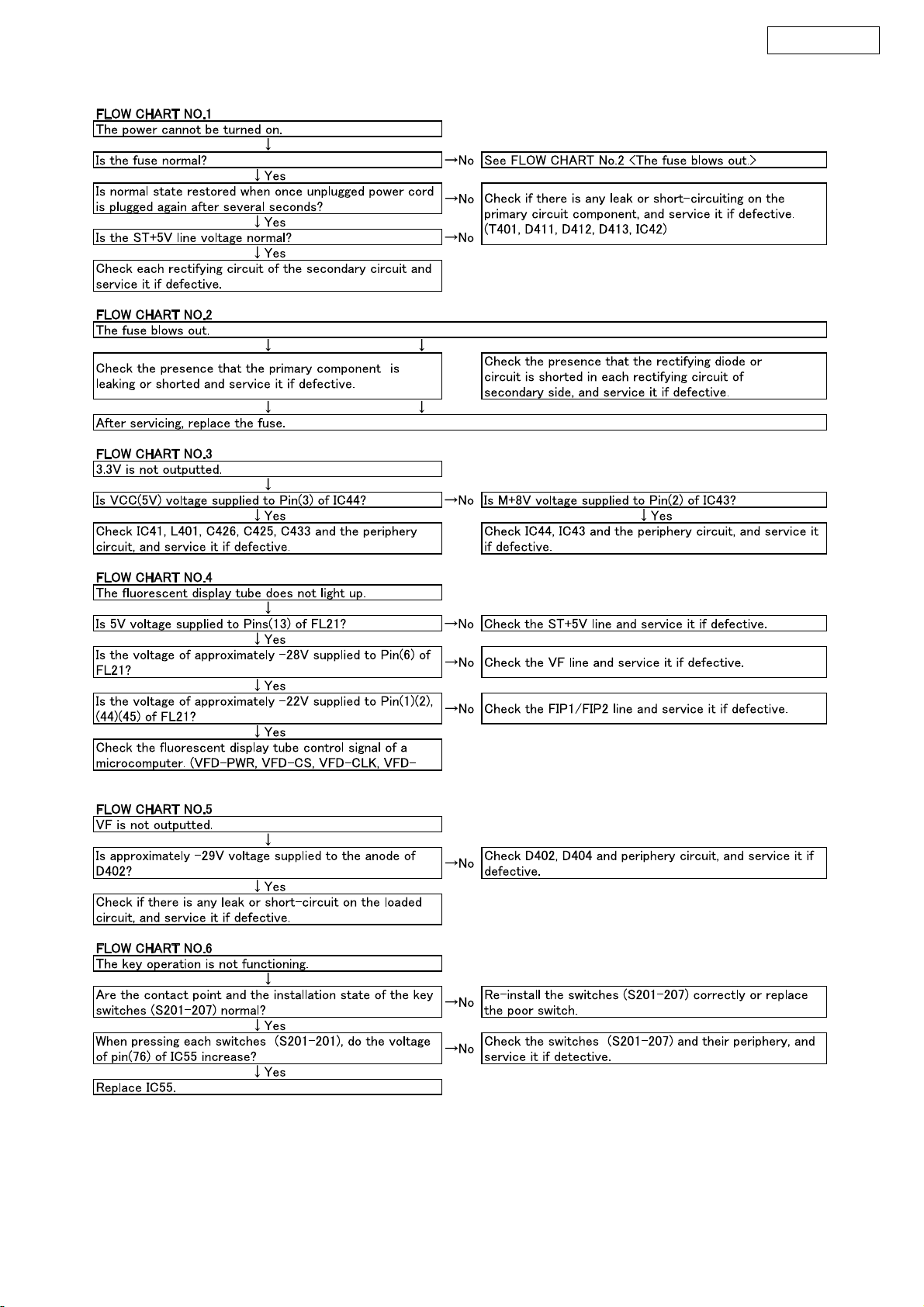

CD TEST MODE & SERVICE MODE

DCD-500AE

12

TROUBLE SHOOTING

DCD-500AE

13

DCD-500AE

14

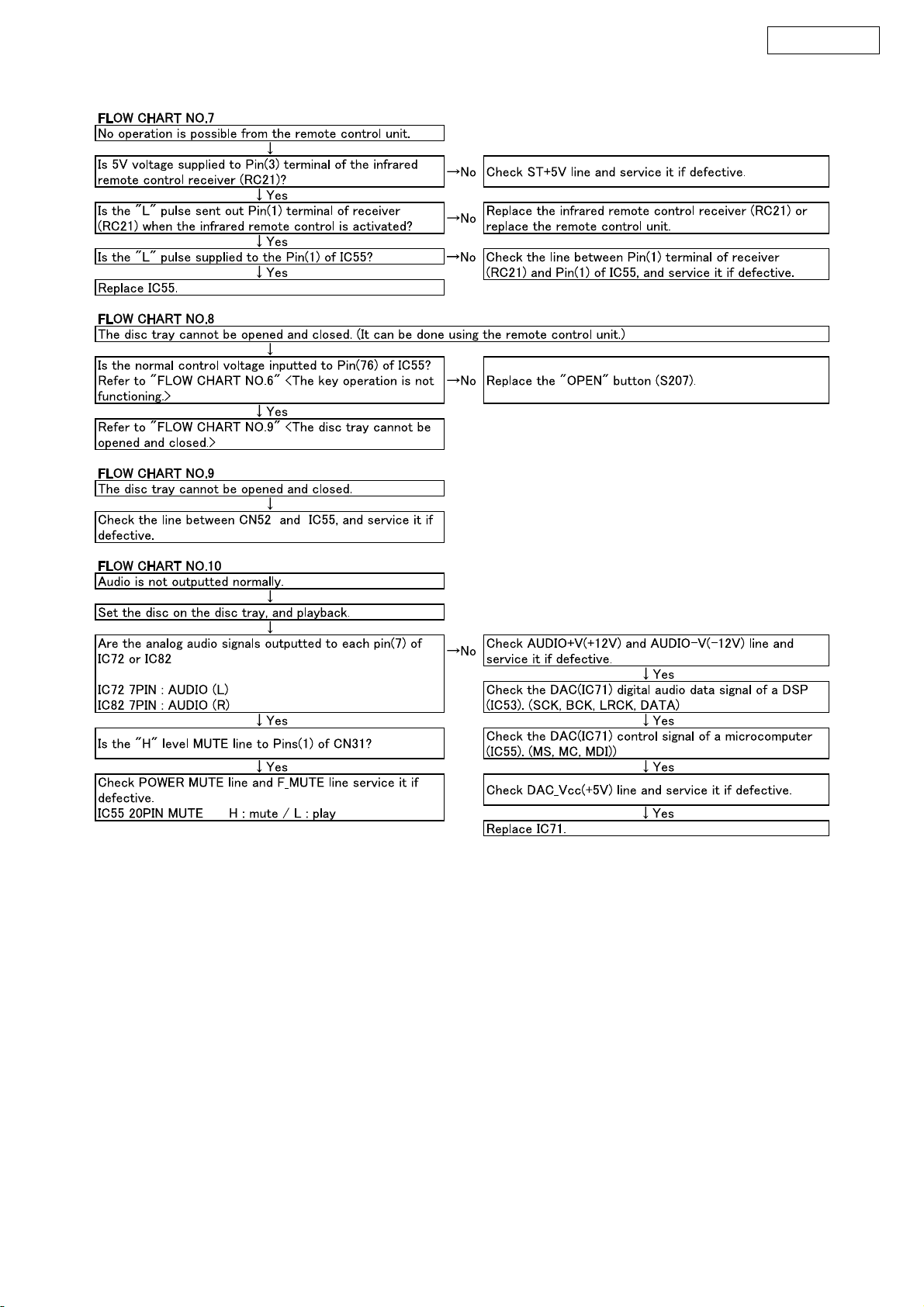

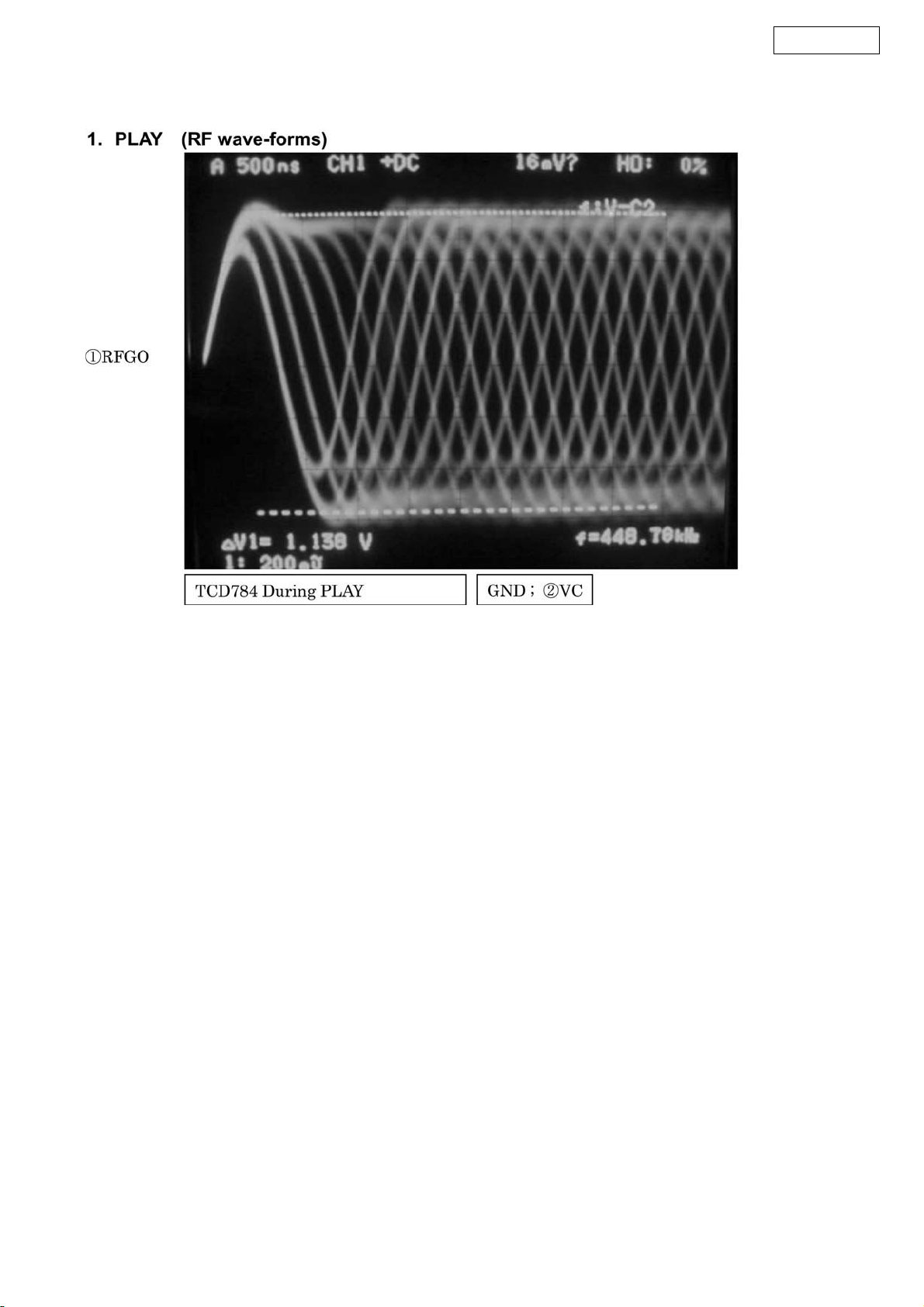

WAVEFORMS

DCD-500AE

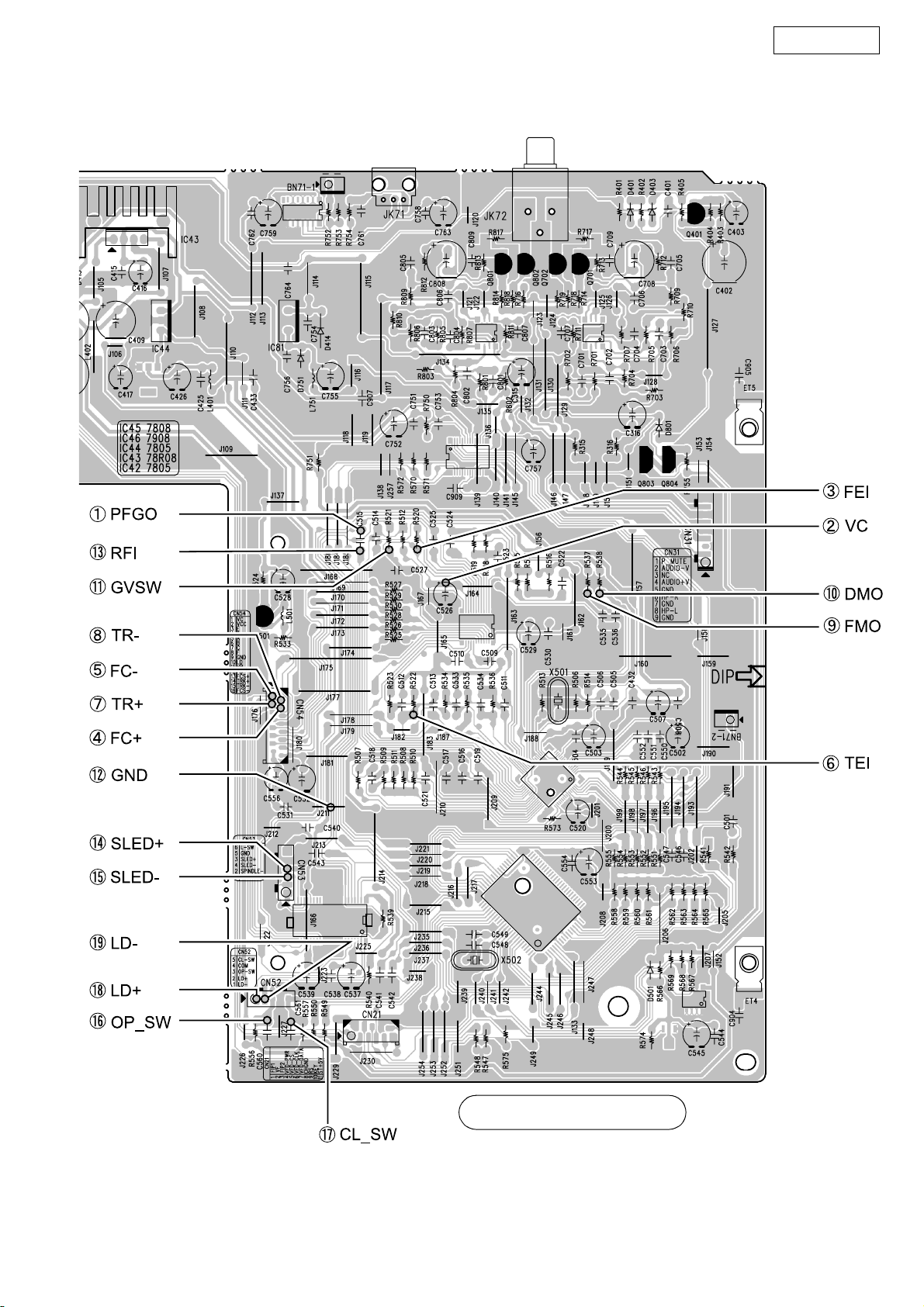

MAIN P.W.B. UNIT

15

WAVE-FORMS OF EACH POINT

DCD-500AE

16

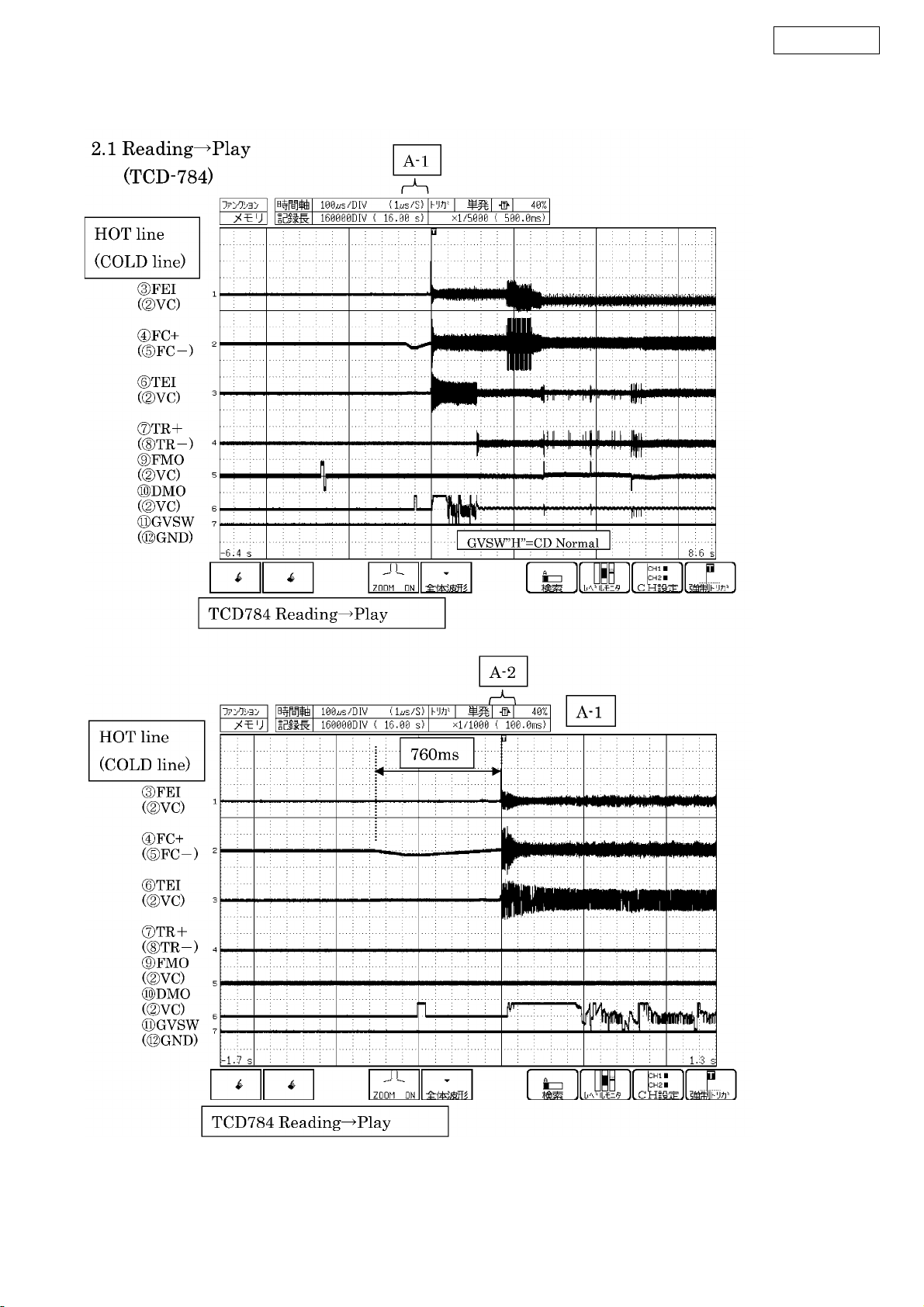

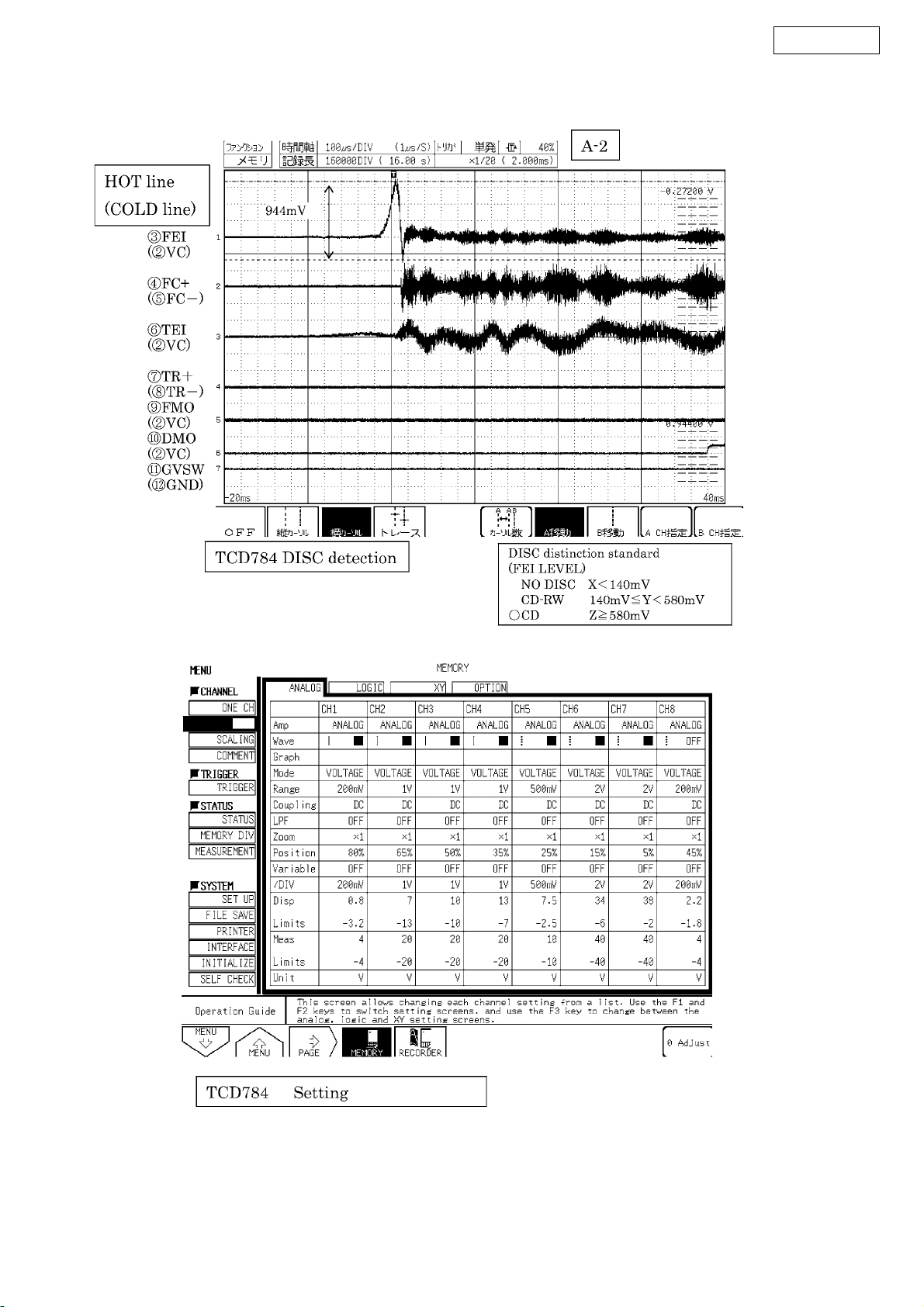

2. READING

DCD-500AE

17

DCD-500AE

18

Loading...

Loading...