Denon D-AJ03 SM, D-AJ03 Service Manual

For U.S.A. & Canada model

SERVICE MANUAL

Ver. 1

MODEL

D-AJ03

PERSONAL AUDIO SYSTEM

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

For purposes of improvement, specifications and

●

design are subject to change without notice.

Please use this service manual with referring to

●

the operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

16-11, YUSHIMA 3-CHOME, BUNKYOU-KU, TOKYO 113-0034 JAPAN

● 本機の仕様は性能改良のため、予告なく変更すること

があります。

● 補修用性能部品の保有期間は、製造打切後

●

修理の際は、必ず取扱説明書を参照の上、作業を行って,

ください。

● 本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

X0178V.01 DE/CDM 0307

8年です。

D-AJ03

SAFETY PRECAUTIONS

Thefollowingcheckshouldbeperformedforthecontinuedprotectionofthecustomerandservicetechnician.

LEAKAGE CURRENT CHECK

Beforereturningtheunittothecustomer,makesureyoumakeeither(1)aleakagecurrentcheckor(2)alinetochassis

resistancecheck.Iftheleakagecurrentexceeds0.5milliamps,oriftheresistancefromchassistoeithersideofthe

powercordislessthan460kohms,theunitisdefective.

LASER RADIATION

Donotstareintobeamorviewdirectlywithopticalinstruments,class3Alaserproduct.

500V

1M

2

(1)

(2)

(1)

(2)

2

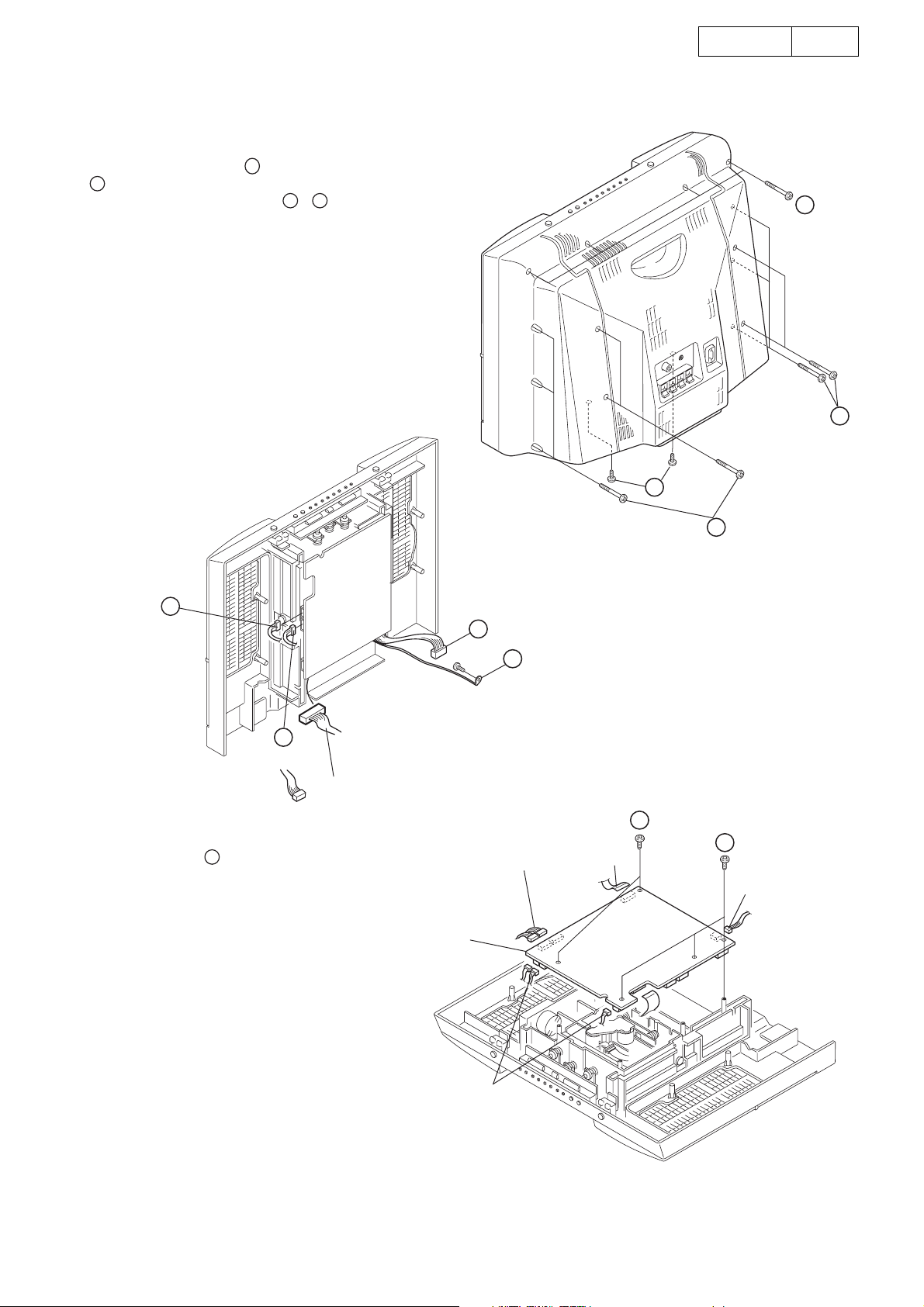

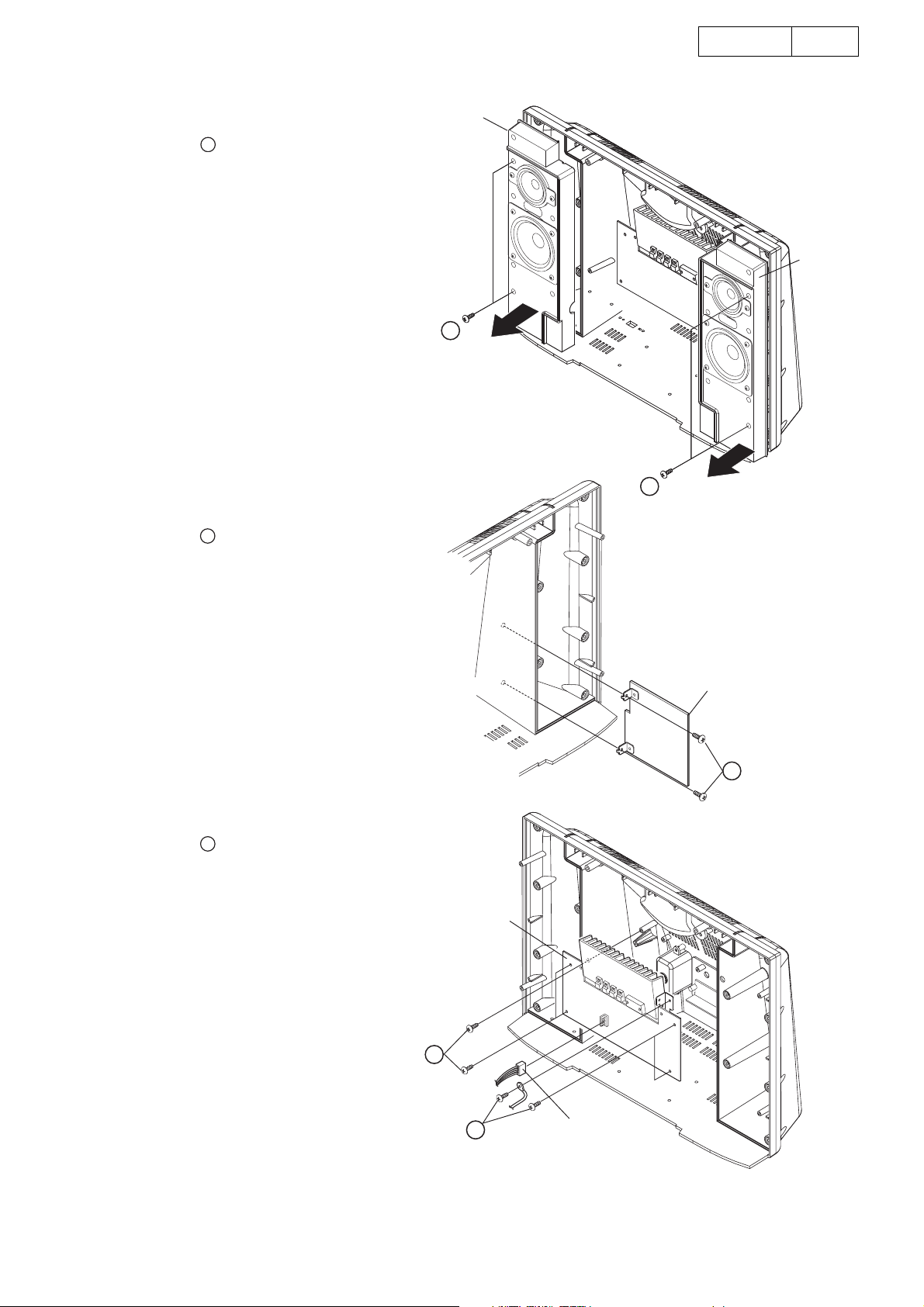

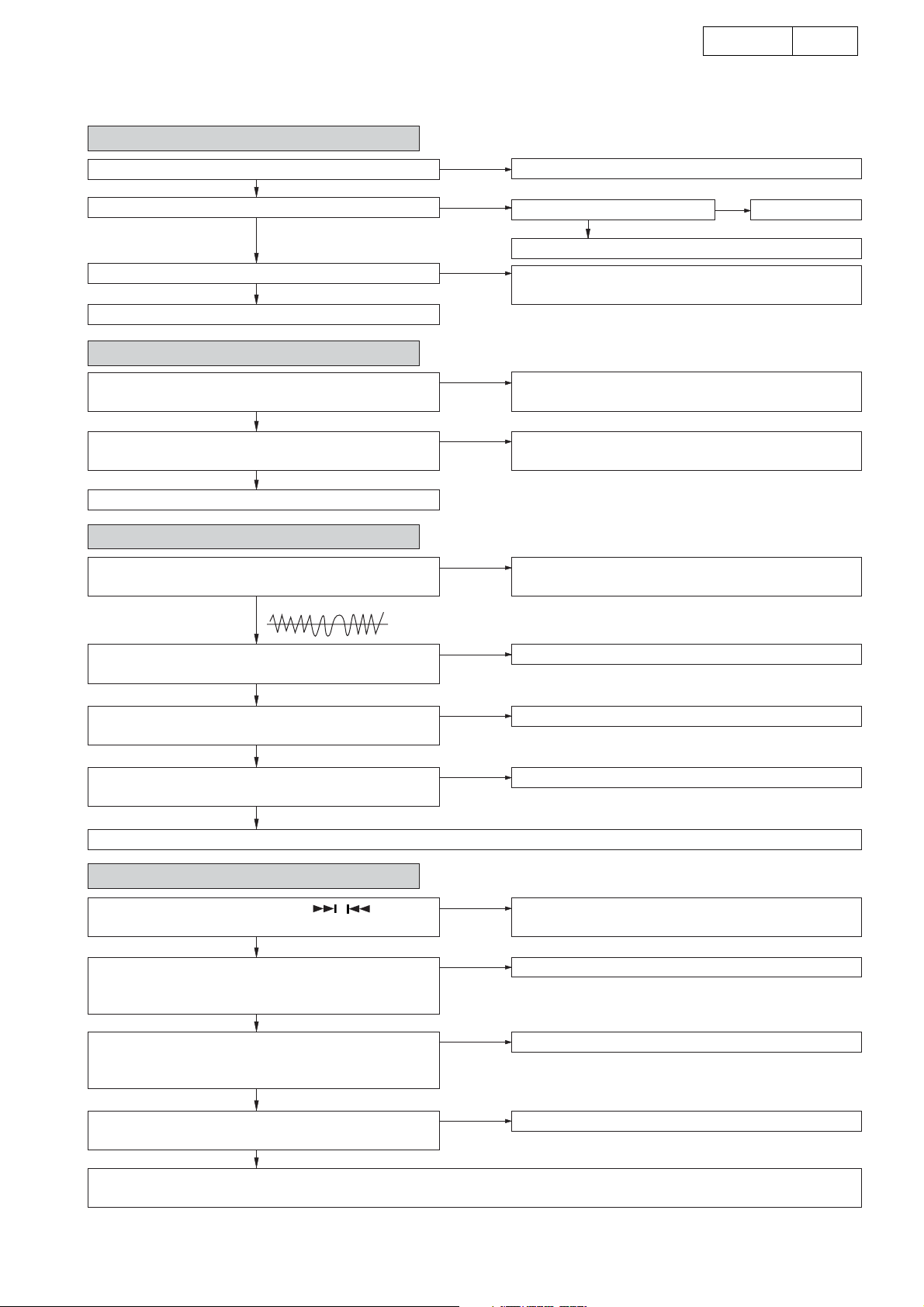

DISASSEMBLY

(Follow the procedure below in reverse order when reassembling)

1. Rear Cover & Front Panel

1) Remove 14 rear screws 1 and 4 (E3: 2) bottom screws

2

on the Rear Cover.

3

2) Disconnect connectors and wire

The Rear Cover and Front Panel can be detached

respectively.

~ 7 on the Front Panel.

D-AJ03

2

3

1

1

4

5P Connector

5

8P Connector

12P Connector

2. Main P.W.B.

1) Remove 5 screws 8.

2) Disconnect 2 FFCs, 8 connectors on the Main P.W.B.

Main P.W.B.

11P Connector

6

1P Earth Lug

7

Connectors

1

8

8

FFC

3P Connector

Connectors

3

FFC

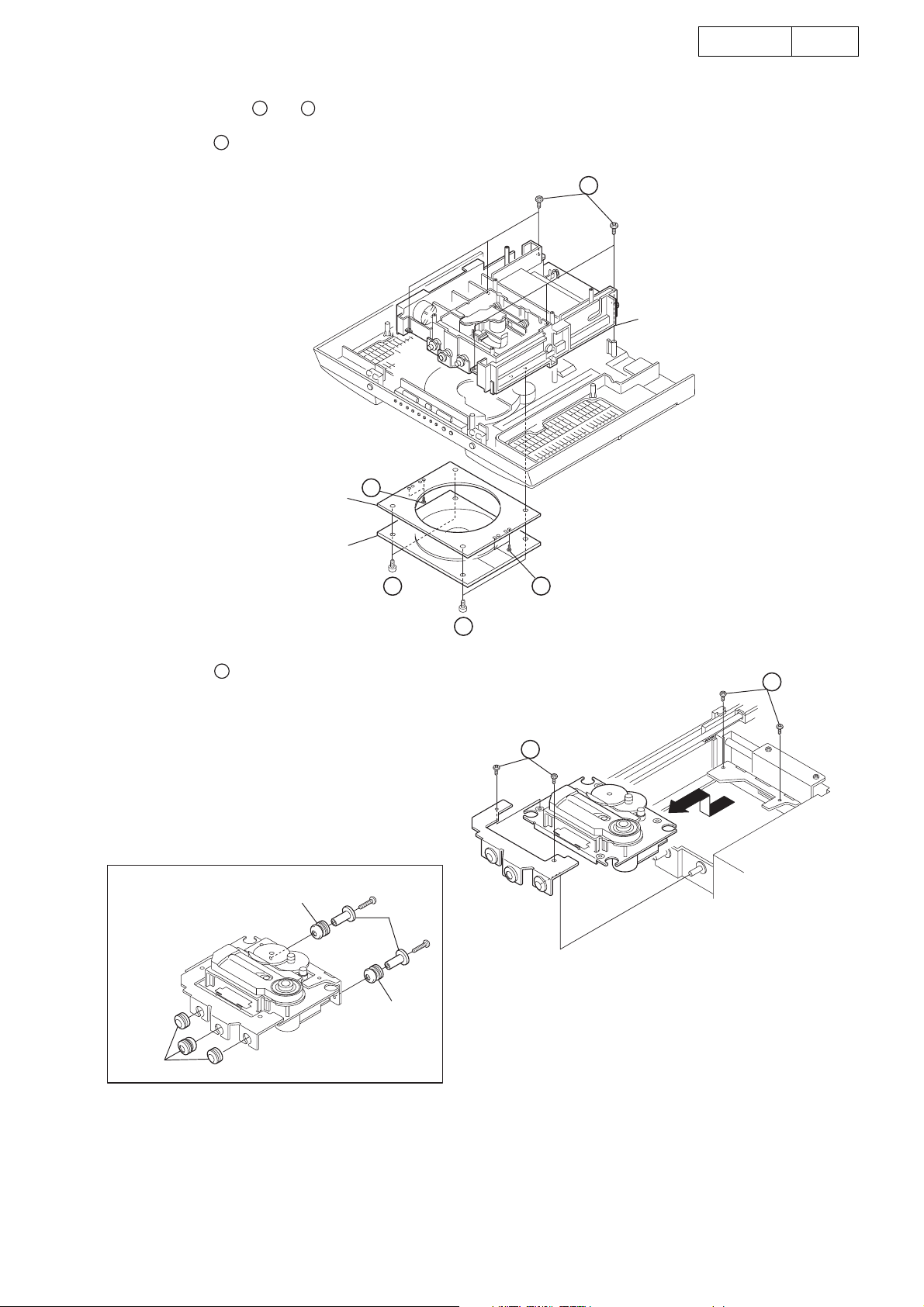

3. CD Mecha. Chassis

1) Remove 4 each screws ı and ıı from the front side to

10

detach the CD Door Lens and CD Door Bracket.

12

ıˇ

2) Remove 6 screws

and take off the Main Chassis.

CD Door Bracket

11

11

ıı

12

ıˇ

Main Chassis

D-AJ03

4

CD Door Lens

10

ı

4. CD Mecha.

1) Remove 4 screws ı fixing the Bracket.

2) Detach the CD Mecha. upward as shown to the arrow

direction.

13

Rubber

(Green)

Collar

(White)

10

11

ıı

ı

ı

13

ı

13

Rubber

(Blue)

Rubber

(Green)

4

5. Speaker Box (L & R)

1) Remove 4 screws ı.

2) Disconnect 2 connectors.

14

Speaker

Box (L)

ı

14

ı

14

D-AJ03

5

Speaker

Box (R)

6. Tuner P.W.B.

1) Remove 2 screws ı.

15

7. Power P.W.B.

1) Remove 6 screws ı.

2) Disconnect 1 connector.

16

Power P.W.B.

Tuner P.W.B.

ı

15

ı

16

ı

16

Connector

5

6

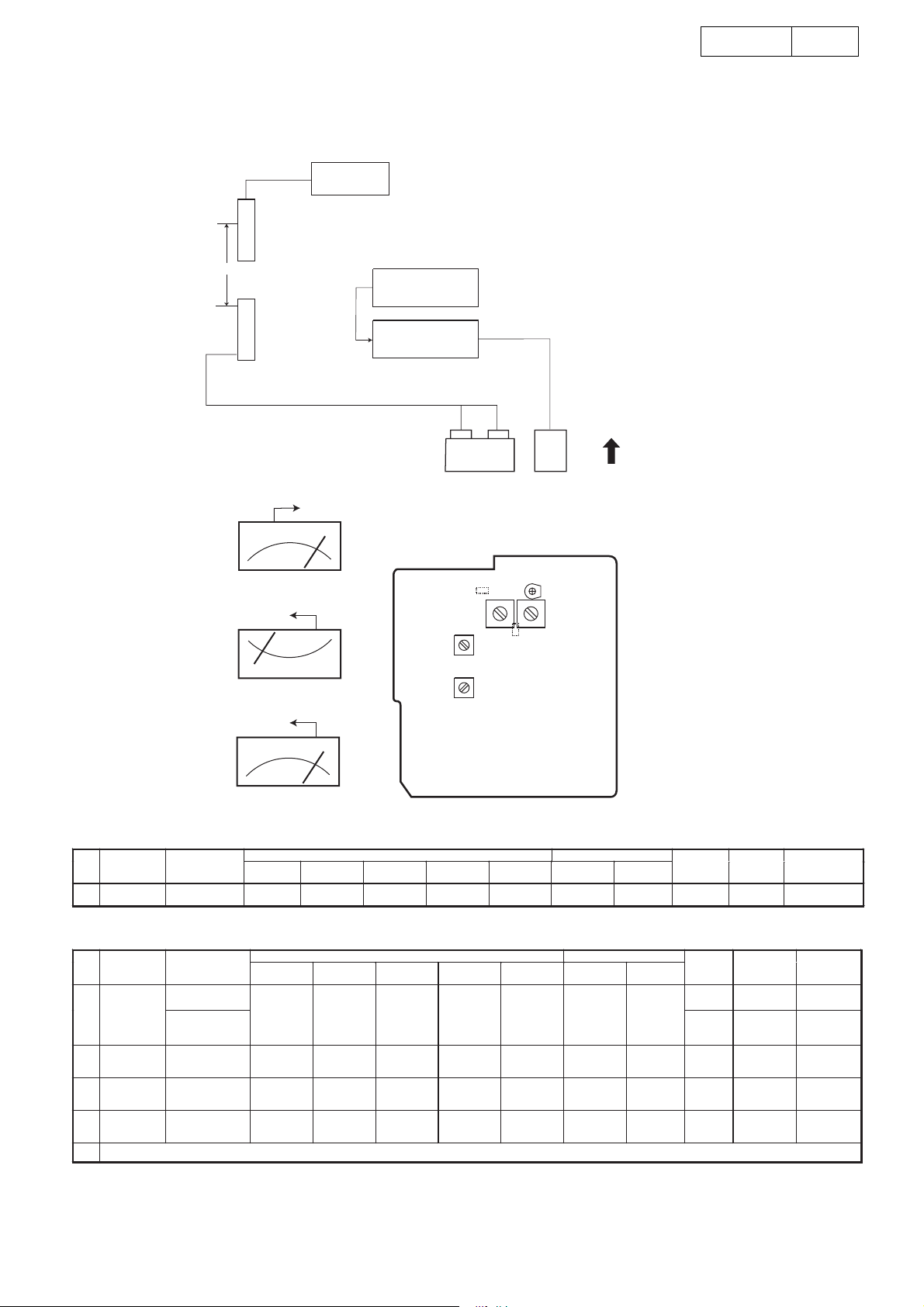

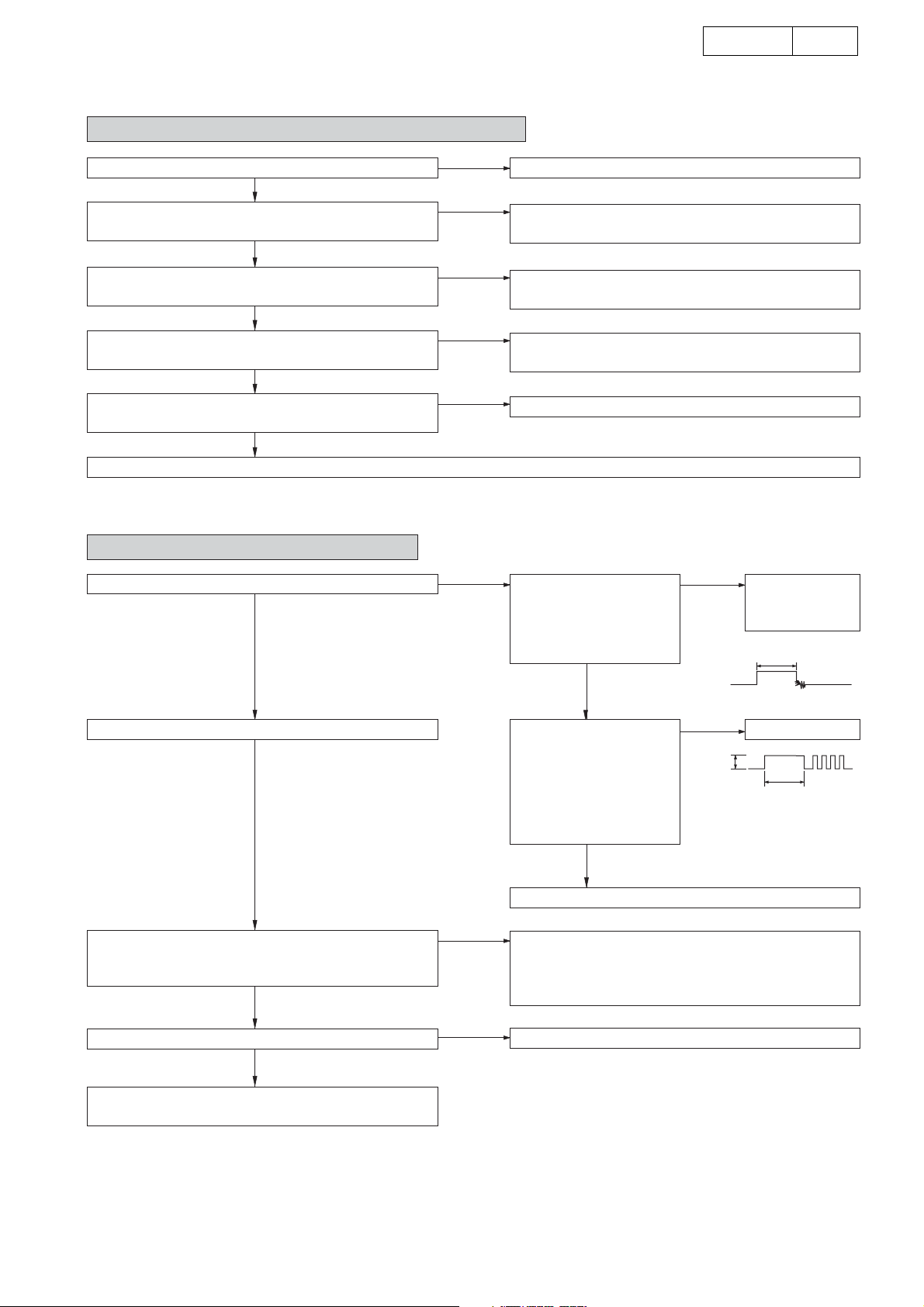

ADJUSTMENT

TUNER SECTION

Connections and adjustment point

AM SG

Modulation frequency:400Hz

Modulation factor:30%

D-AJ03

6

Test loop antenna

60cm

Loop antenna

Digital Voltmeter

To Output Terminal

Distortion Meter

To Output Terminal

To TP

Modulation frequency: 1kHz

L+R: 90% (67.5kHz Dev.)

Pilot: 10% (7.5kHz Dev.)

75kHz Dev.: 100%

FM stereo modulator

FM SG

Antenna Terminal

AM FMG

TUNER PWB

T403 T402

T401

T404

75 ohms

Coaxial Cable

TC401

R425

R419

Rear Panel Side

Separation Meter or

Electronic Voltmeter

FM ALIGNMENT (BAND BUTTON: FM, AUTO)

Step

1

Alignment

Item

FM DC

Balance

Tune-in Point

(Channel Setting)

98 MHz FM SG 98 MHz

Measuring

Equipment

Frequency Level Modulation Connect to

Input Output

60 dB

1kHz

75 kHz dev

FM Ant

Terminal

AM ALIGNMENT (BAND BUTTON: AM)

Alignment

Step

Item

1 Band Edge

2 IF No Broadcast Area AM SG (900 kHz)

3Tracking

4Tracking

5 Repeat Steps 3 and 4, and set the output to maximum.

Tune-in Point

(channel Setting)

E3:520 kHz

E3:1710 kHz

E3:600 kHz

E3:1400 kHz

Measuring

Equipment

AM SG

AM SG

Frequency Level Modulation Connect to

E3: 600 kHz

E3: 1400 kHz

Input Output

No AGC

Effects

No AGC

Effects

No AGC

Effects

400 Hz 30% Loop Ant

400 Hz 30% Loop Ant

400 Hz 30% Loop Ant

Measuring

Equipment

Digital

Voltmeter

Measuring

Equipment

Digital

Voltmeter

Electronic

Voltmeter

Electronic

Voltmeter

Electronic

Voltmeter

Connect to

Both Leads

of R425

Connect to

Both Leads

of R419

LINE 1

Output

Terminal

LINE 1

Output

Terminal

LINE 1

Output

Terminal

Align Part SetValue Remarks

T404

Align Part Set Value Remarks

T403

E3:1.0±50mV

E3:(8.3±0.5V)

T401

T402

TC401

20mV

Approx.

Maximum

Output

Maximum

Output

Maximum

Output

Align with Mono

Modulation Signal

No Adjustment

Required

6

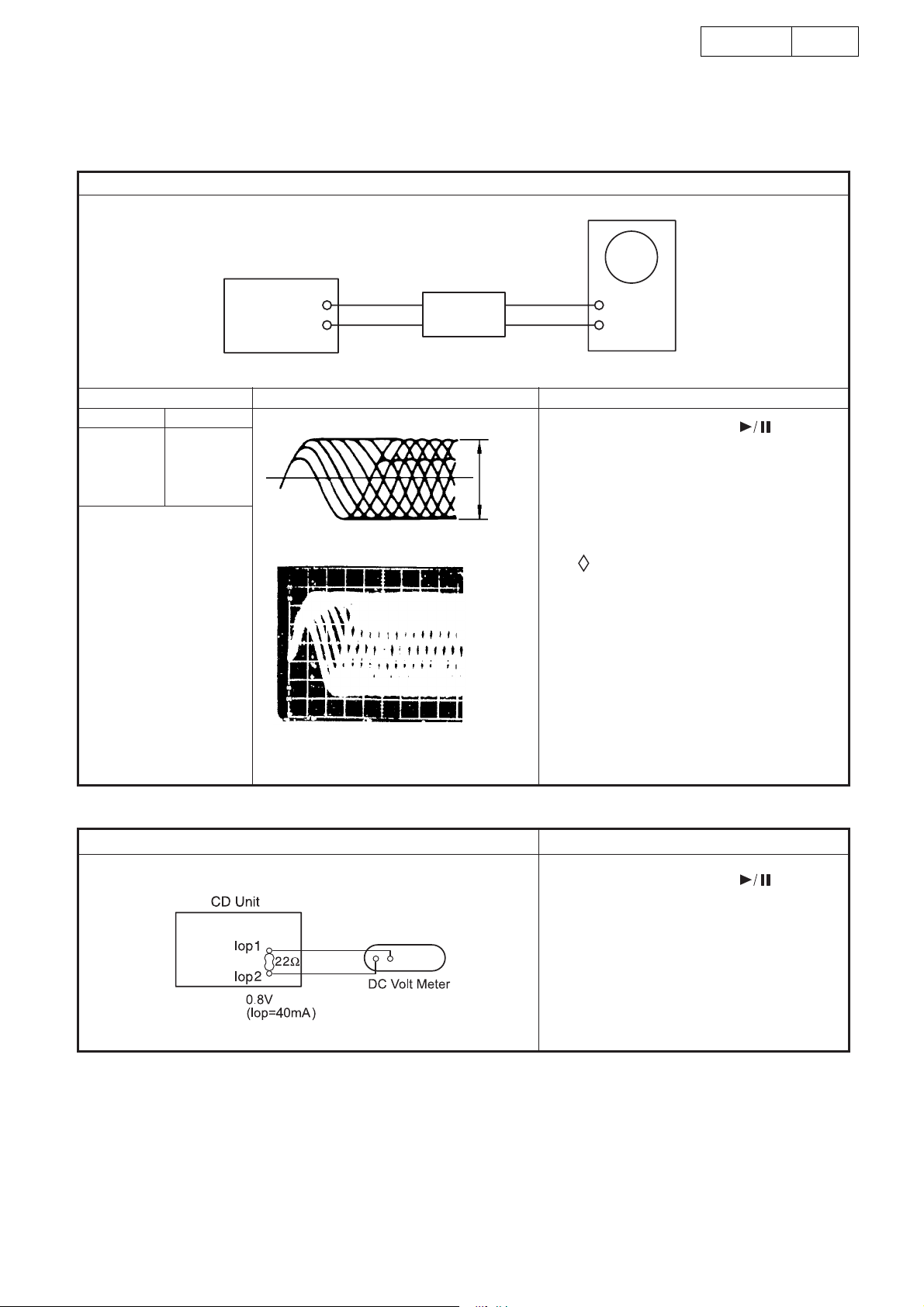

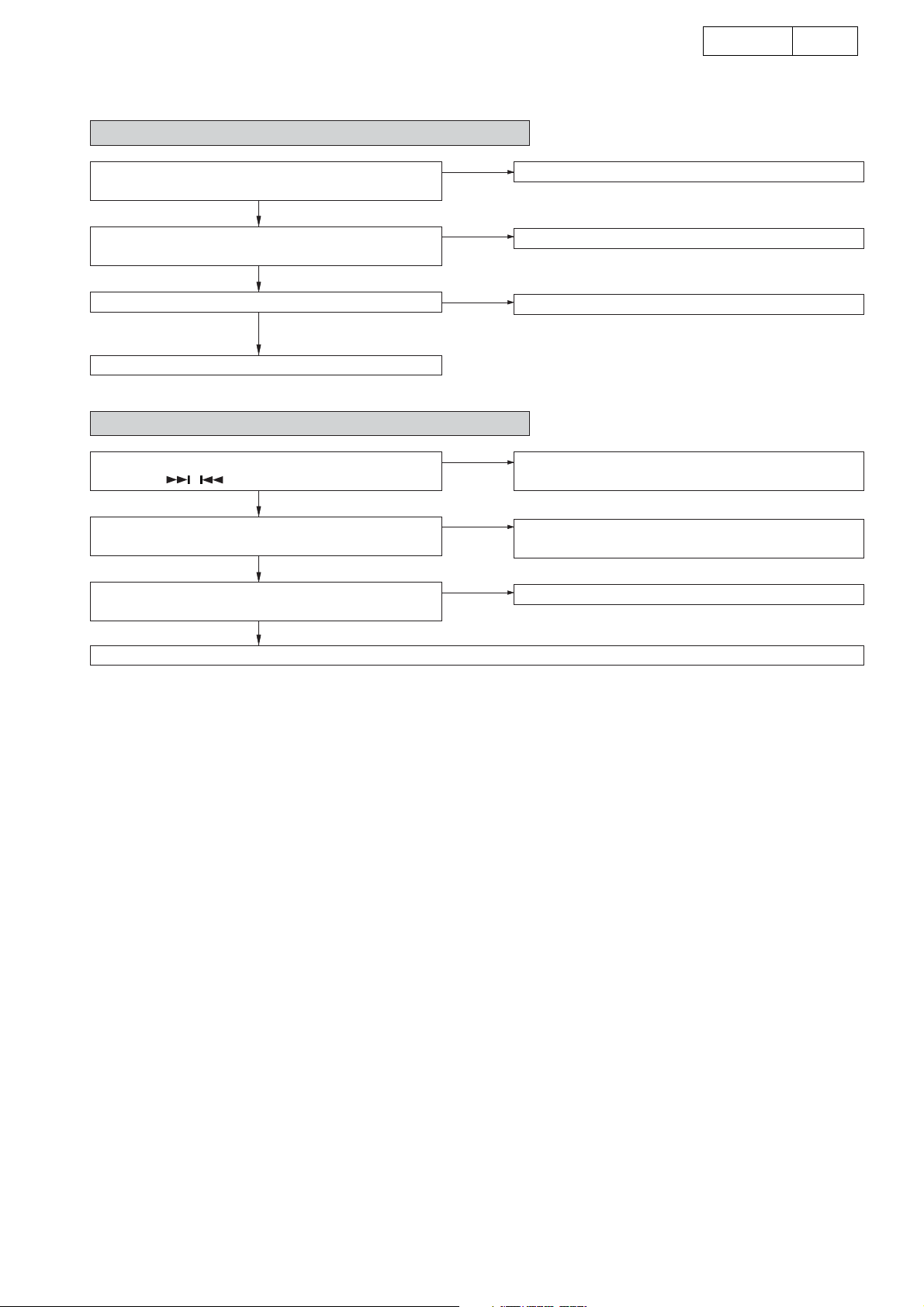

CD SECTION

1. RF level Confieming

Connection

Oscilloscope

D-AJ03

7

CD Servo Micon PWB

VH

0.2 s/div

50mV/div

• Set input mode to

ALTERNATE or

CHOPPER.

or

0.5 s/div

RF0

V

REF

Probe

10:1

CheckOscilloscope

+

Step

1. Press CD Play/Pause ( ) button

to make it playback state.

A

2. Check RF level with oscilloscope.

3. Confirm that the waveform is in good

A=0.8~1.2V

shape.

(

eye pattern in center must be

able to discriminate clearly.)

Eye Pattern

2. Pickup

Connection

Step

1. Press CD Play/Pause ( ) button

to make it playback state.

2. Measure Iop.

R108

• Since this CD system has the built-in automatic adjustment function, re-adjustment is not necessary when replacing the

pickup.

Therefore, any combination of PWB and pickup can be made freely.

As the automatic adjustment is performed every time the disc is changed, each disc can be played in the most

appropriate condition.

7

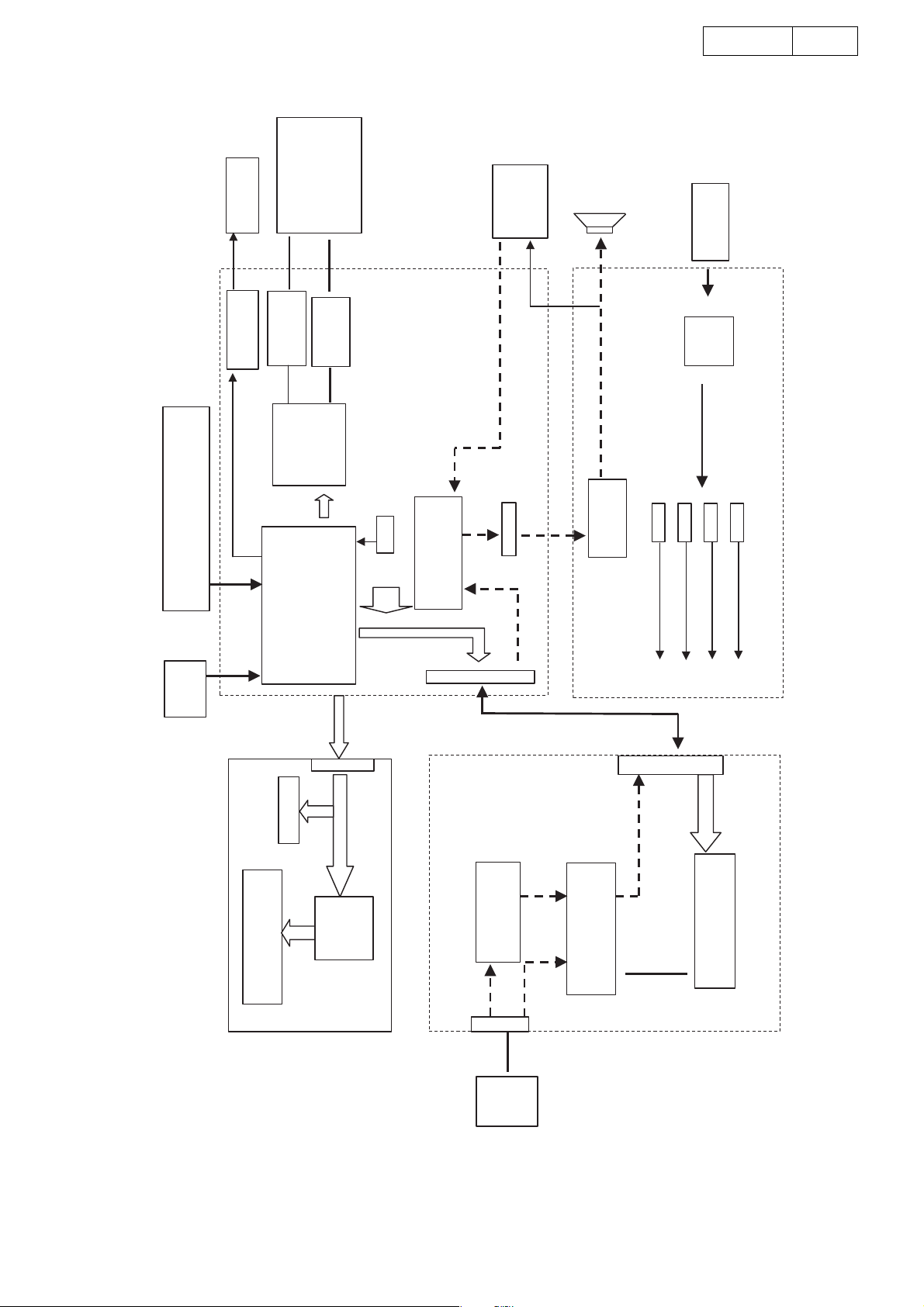

BLOCKDIAGRAM

CD DOOR

Motor driver

Door driver

BA6286

MAIN UNIT

CD MECHA

CD4LXWNK

LA6558

RF AMP

DSP

TC94A14FA

TA2157F

AUX IN

SUB

WOOFER

AC IN

- |<| -

D-AJ03

Reg.

8

TACT KEY

REMOTE

Sensor

MICRO

COMPUTER

M38199

LCD

8com,60seg

BACK light

DISPLAY UNIT

LCD

Controller

LC75811W

Reset

ELE.VR SYSTEM

LC75342M

MUTING

FM FRONTEND

KCF216

Power AMP

BA5415

un5V(MICON)

FM IF/DET/MPX

AM RF/IF/DET

LA1844

6V

10V

(tuner,AUDIO)

(MD)

PLL

6V

8V

(CD)

LC72131

(There is no MD Section in the U.S.A. and Canada model)

BLOCK DIAGRAM

TUNER UNIT

4p

Terminal

8

P.W.B.

D-AJ03

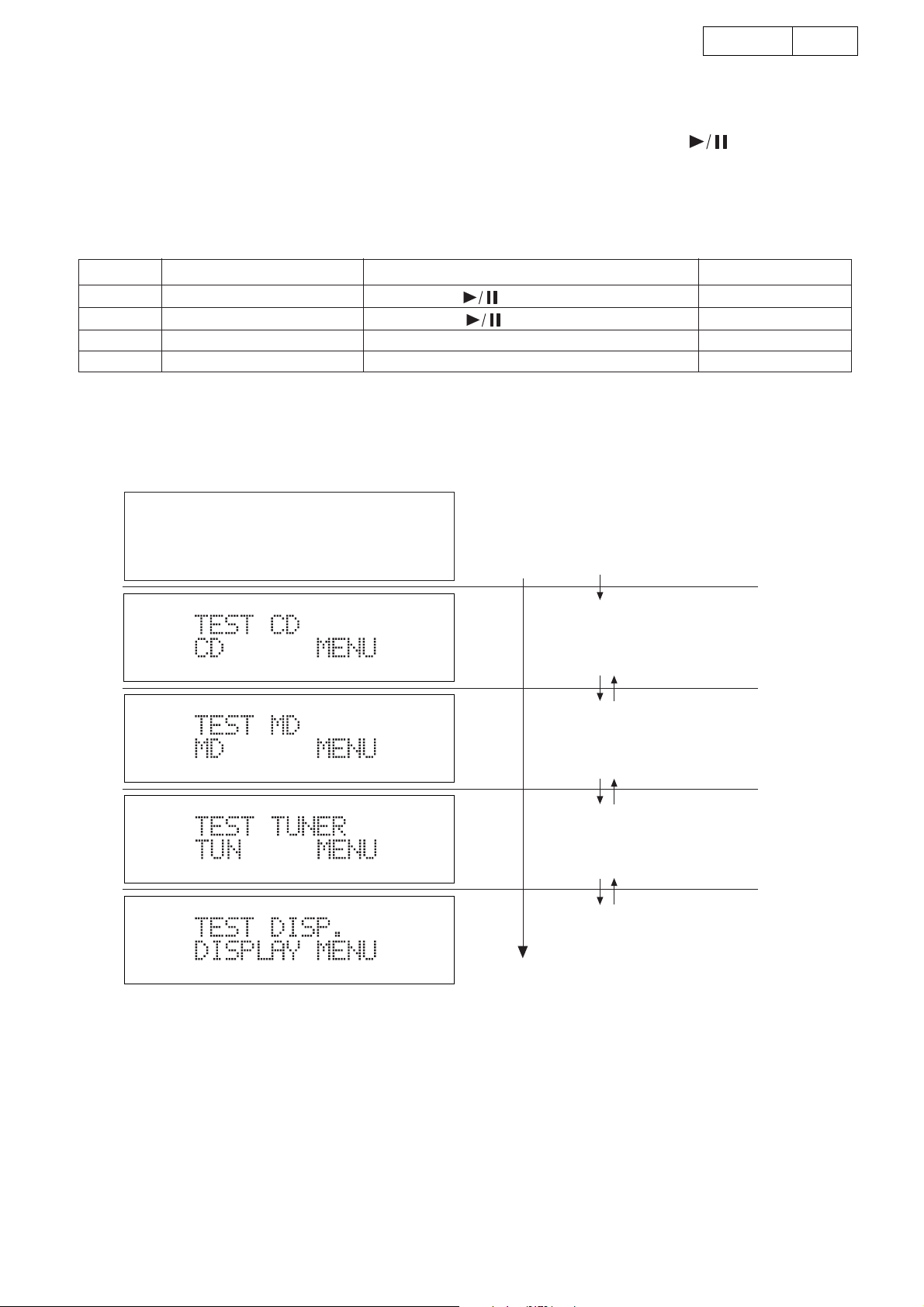

TEST MODE

From power off state to TEST mode

To enter into the TEST mode, plug the AC cord to the wall outlet while pressing the CD PLAY (CD ) button and

TUNER button simultaneously.

The version information is displayed initially.

Thereafter press the SKIP UP/DOWN button to select the TEST mode and then press the CD STOP button to determine it.

Press the DIRECT key during version display to obtain the designated TEST mode directly.

TEST MODE

No. TEST MODE DIRECT DISPLAY

1 CD TEST CD PLAY (CD ) CD MENU

2 MD TEST MD PLAY (MD ) MD MENU

3

4

Cancelling the TEST Mode

In each TEST mode, press the POWER button to display COMPLETE for 1 second and then cancel the TEST mode.

In the MD TEST mode, press the POWER button again.

TUNER TEST

DISPLAY TEST

TUNER

VOL DOWN

TUN MENU

DISPLAY MENU

9

Version display

SKIP-DOWN

SKIP-UP

SKIP-UP

SKIP-UP

Test mode

With SKIP-UP button

Version display

to CD-PLAY

SKIP-DOWN

Version display

to MD-PLAY

SKIP-DOWN

Version display

to TUNER

SKIP-DOWN

Fig.20 Test Mode Menu

9

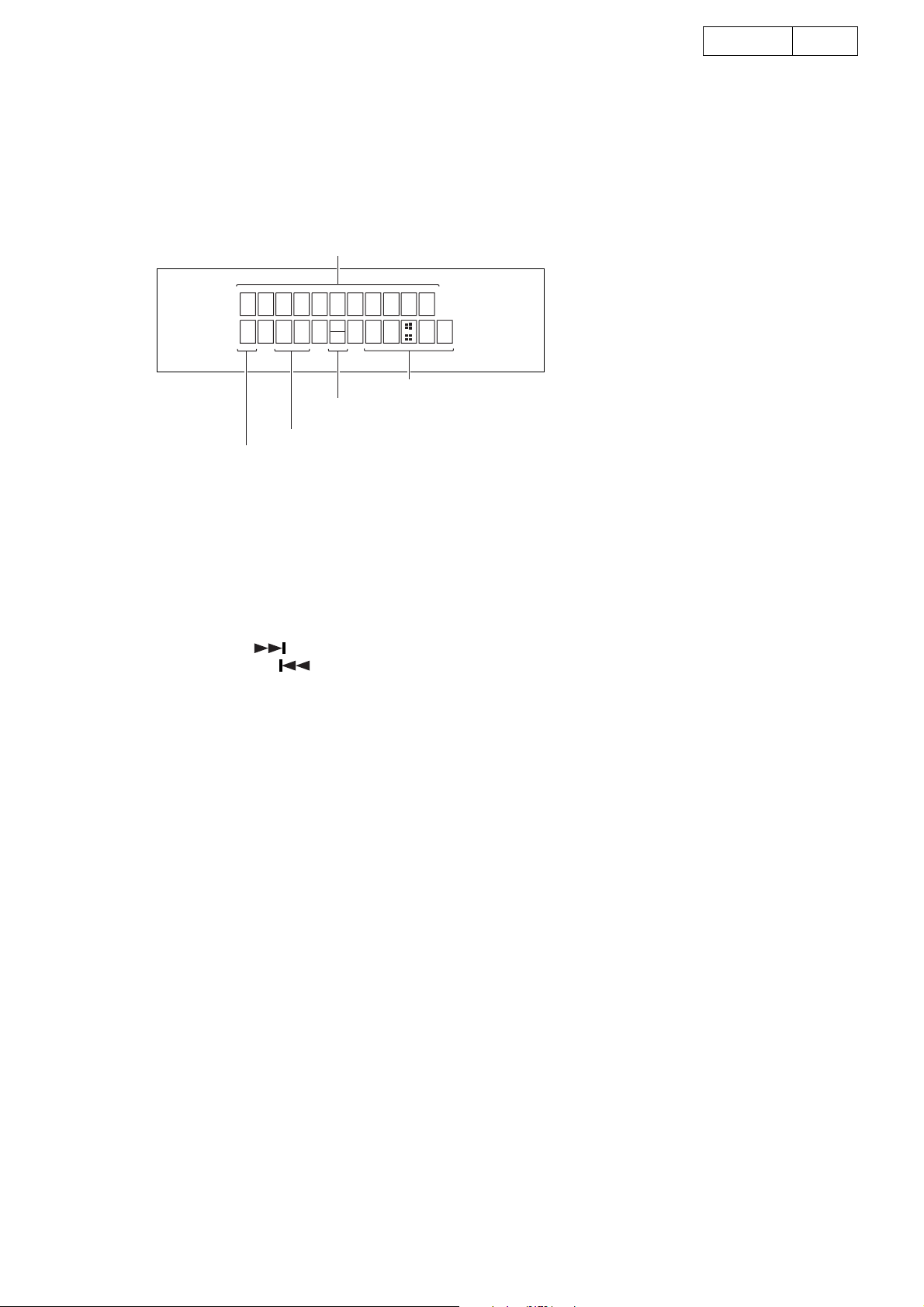

1. CD test

Outline: Readout of the set value after automatic adjustment (for judging difference from initial value)

Forced operation of pickup (Inner/Outer circumference feed)

During the PLAY mode, the number of errors accumulated for 10 seconds (750 frames) is displayed.

Basic CD operation by CD-PLAY button

During the TEST mode, the display is turned on and the following buttons become effective.

Error Display

N

H

Time Display

N:NORMAL SPEED

TNO Display

STEP NO Display

Operation

1. CD-PLAY: CD operation according to steps

STEP 1: LD ON by pressing CD PLAY button in the stop mode

STEP 2: Focus On by pressing CD PLAY button in STEP 1

STEP 3: CLV servo ON by pressing CD PLAY button in STEP 2

STEP 4: Tracking servo ON by pressing CD PLAY button in STEP 3

STEP 5: Sub-code readout/display by pressing CD PLAY button in STEP 4

* Keep pressing the CD PLAY button for more than 1 second to shift to STEP 5 directly.

2. CD STOP : To stop the playback operation (shifting from each step to the stop

3. CD SKIP-UP (

4. CD SKIP-DOWN (

5. TUNER : Automatic adjustment (at the present pickup position)

6. POWER : Canceling the test mode

7. VOLUME UP/DOWN : To read the coefficient register while the CD operation is stopped/

8. CD OPEN/CLOSE : Normal open/close operation

H:HIGH SPEED

mode) / To reset display (during display of coefficient)

) : Forcible shift in the pickup FWD direction

) : Forcible shift in the pickup REV direction

Sliding is stopped when the PU_IN switch is turned on.

To display the error number during CD playback

D-AJ03

10

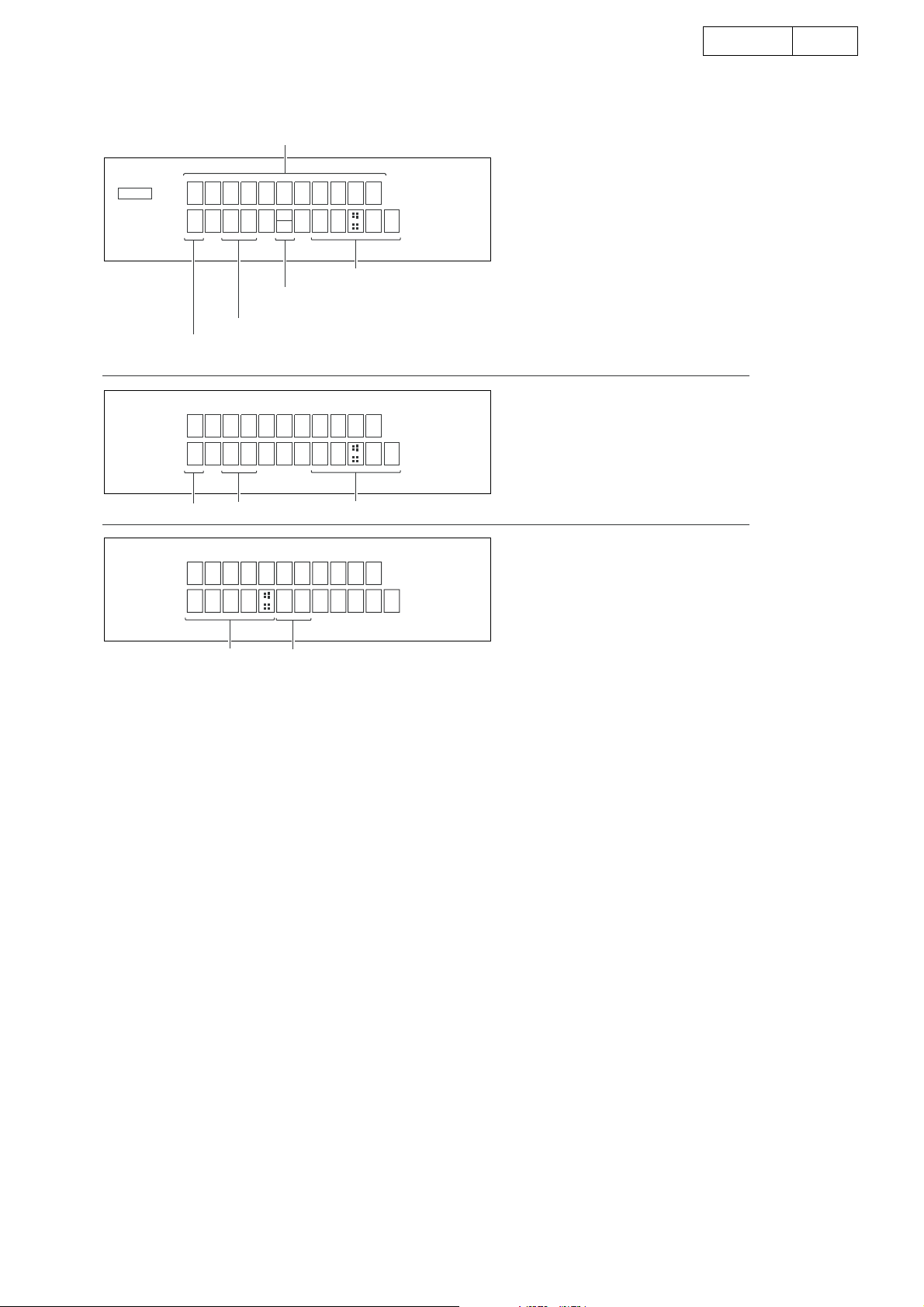

Readout of the adjusted value

Press the VOL.UP/DOWN button during the stop mode to read the following items.

Press the CD-STOP button to return to the normal display.

Item Display Max Type Min

Focus balance _ _ F B : x x 7 F 0 0 8 0

Focus gain _ _ F G : x x 1 F 0 0 E 0

Tracking balance _ _ T B : x x 7 F 0 0 8 0

Tracking gain _ _ T G : x x 1 F 0 0 E 0

Foucus offset F O F F : x x 7 F 0 0 8 0

Tracking offset T O F F : x x 7 F 0 0 8 0

RFRP R F R P : x x 7 F 0 0 8 0

Even if the CD-PLAY button is pressed initially, automatic adjustment is not obtained. Press the TUNER button in

the stop mode to gain CD-PLAY for automatic adjustment. Thereafter press the CD-STOP button to stop automatic

adjustment.

Press the VOL. UP/DOWN button to display automatically adjusted values.

Readout of error numbers

Press the VOL.UP/DOWN button during playback to display the number of errors accumulated for 10 seconds

(750 frames).

Press the CD-STOP button during ERR display to return to the normal TEST mode display.

10

CD TEST

ANA

STEP NO Display

STEP NO Display

Error Display

N

H

N:NORMAL SPEED

TNO Display

H:HIGH SPEED

TNO Display

Time Display

Time Display

D-AJ03

1.STEP NO. : 0 when stopped

2.Time display: Blank from the stop

mode to STEP 4

11

Coefficient name Coefficient

Readout of coefficient

11

D-AJ03

12

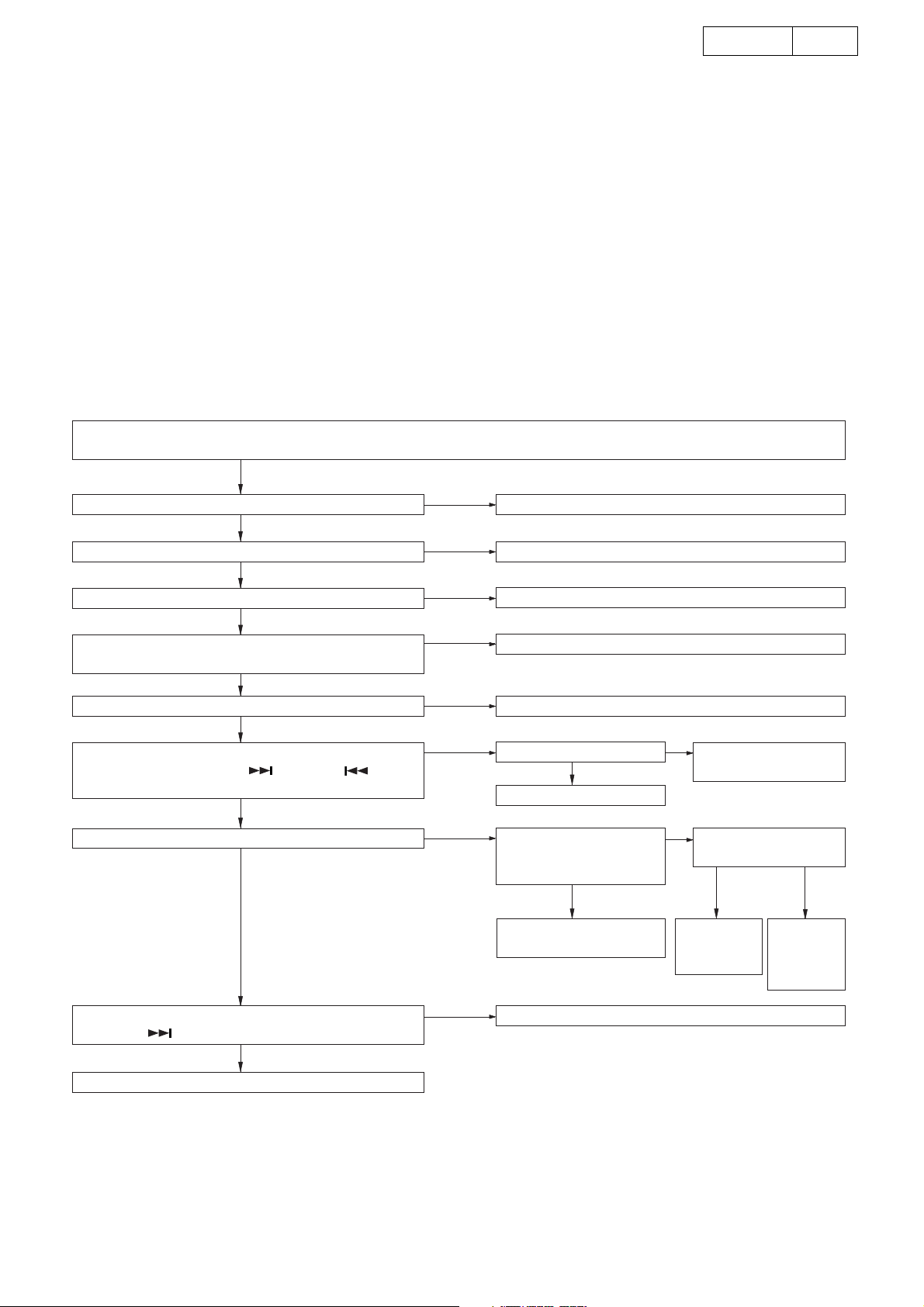

TROUBLESHOOTING OF CD

CD SECTION

When the CD does not function

When the CD section does not operate when the objective lens of the optical pickup is dirty, this section may not operate.

Clean the objective lens, and check the playback operation. When this section does not operate even after the above step

is taken, check the following items.

Remove the cabinet and follow the trouble shooting instructions.

“Track skipping and/or no TOC (Table of Contents) may be caused by build up of dust other foreign matter on the laser

pickup lens. Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below.”

Turn off the power, and wipe the lens softly using a cleaning paper moistened with commercially available cleaning solution

so as not to damage it.

Be careful not to touch the lens with bare hands.

Dust gradually accumulates on the objective lens during use, and it may degrade performance. To avoid this problem, use

a cleaning disc designed for CD optical pickup lenses.

When a disc is loaded, the power is turned on, and the CD (stop) button is pressed, is +7.2V applied to the collector of TR102 and +5.0V to

the emitter ? Is +3.3V applied to pin 22 on IC145 ?

Is the voltage applied as shown in the wiring diagram ?

Yes

Is the laser lit in the CD test mode 1 ?

Yes

Does the unit switch from the CD test mode 1 to 2 ?

Yes

When the CD test mode is changed from 2 to 3, does the

disc motor rotate properly ?

Yes

Is the output at pin 19(HF) of IC146 flat in the CD test mode 4 ?

Yes

Is sound output when the pickup lens is moved to where a

track is located by pressing the

in the CD test mode 5 ?

When the unit is turned off and on again, is it initialized ?

(button) and (button)

Yes

Yes

No

No

No

No

No

No

No

Check the power circuit in the main unit.

Refer to "The laser does not light up".

Refer to "Out of focus".

Refer to "The disc motor CLV servo is defective".

Refer to "HF is abnormal".

Does the sled motor run ?

Yes

Refer to "No sound is heard".

Has the optical pickup

returned to the inner

periphery position ?

Yes

The optical pickup in-switch

is defective (ON state).

No

Refer to "The sled motor

does not run".

No

Is the optical pickup in

switch in the OFF state ?

OFF

Check the

microcomputer

PWB.

ON

The optical

pickup in

switch is

defective.

Are tracks played from the track 1 in ascending order by

pressing the

Normal

(button) ?

Yes

No

12

Refer to "Track search is impossible".

The laser does not light up

Is 1.5V applied to the LDO terminal of pin 7 of IC146 ?

Yes

Is +1.8V applied to the collector of TR101 ?

Yes

Is +1.8V applied to pin 10 of CX151 ?

Yes

The optical pickup is defective if CX151 is normal.

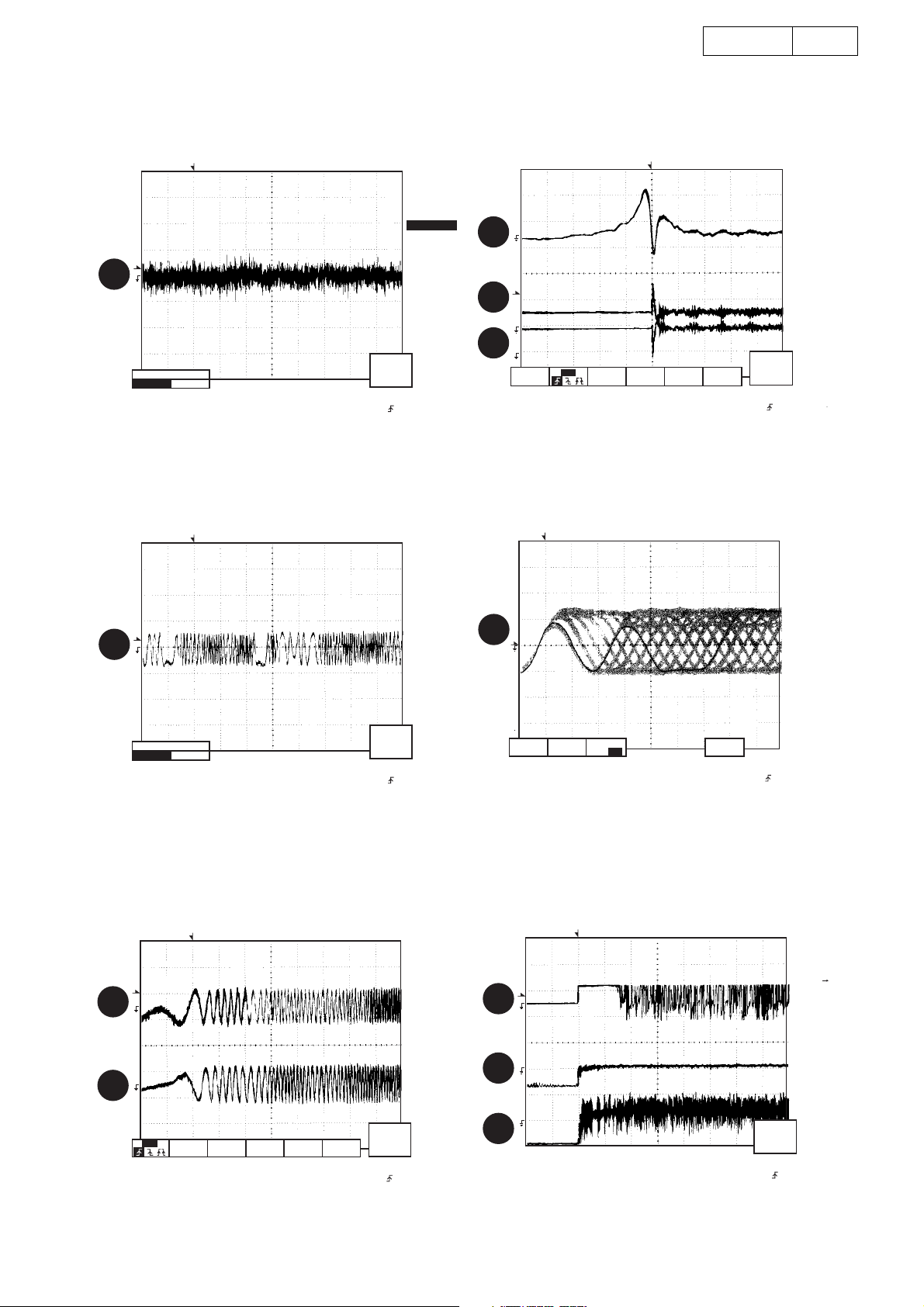

Out of focus

Does the pickup lens go up and down when removing the

disc ?

Yes

Is the waveform inputted at pin 15 on IC146 when loading a

disc ? <Refer to the waveform diagrams on page 31.>

Yes

IC146 is defective.

No

No

No

No

No

D-AJ03

IC146 is defective

Is +3.3V applied to C109 of R108 ?

Yes

Check the +3.3V stabilization circuit of IC145 and L103.

The PWB pattern has been cut between TR101 and pin 10

of CX151.

Refer to "The triangular wave for focus servo does not

appear".

Check the optical pickup wires. If OK, the optical pickup is

defective.

No

R108 is defective.

13

HF is abnormal

Is the output (tracking error signal) found at pin 4 and 5 on

IC145 in the CD test mode 3 ?

Normal

Is tracking input found at pin 11 of IC146 ?

<Refer to the waveform diagrams on page 31.>

Yes

Is the tracking output found at pin 34 in IC149 in the CD test

mode 4 ?

Yes

Is there the output between pin 5 and 6 on IC145 ?

Yes

Check the portion between IC145 and CX151 and connection of the optical pickup wires. If OK, the optical pickup is defective.

Abnormal

No

No

No

Check between IC145 and CX151. If OK, the optical pickup

is defective.

Check the parts around IC146. If OK, IC146 is defective.

Check the parts around IC149. If OK, IC149 is defective.

Check the parts around IC145. If OK, IC145 is defective.

Track search is impossible

Does the sled motor run by pressing the / button in

the test mode ?

Yes

Is the waveform outputted to pin 11 and 17 on IC146 when a

track is jumped ?

<Refer to the waveform diagrams on page 31.>

Yes

Is the waveform output found at pin 34 and 40 on IC149 when

a track is jumped ?

<Refer to the waveform diagrams on page 32.>

Yes

Is the slide output found at pin 25 and 26 on IC145, and the

tracking output at pin 5 and 6 ?

Yes

Check the portion between IC145 and CX151 and connection of the optical pickup wires. If OK, the optical pickup is defective.

Check the portion between IC145 and CX062, sires and periphery of the sled spin motor. If OK, the motor is defective.

No

No

No

No

Refer to "The sled motor does not run".

IC146 is defective.

IC149 is defective.

If the parts around IC145 are normal, IC145 is defective.

13

The triangular wave for focus servo does not appears

D-AJ03

14

Is +3.3V applied to pin 6 of IC149 ?

Yes

Does the triangular wave appear at pin 33 on IC149 ?

<Refer to the waveform diagrams on page 32.>

Yes

Does the triangular wave appear at pin 13 on IC145 ?

<The same waveform as above>

Yes

Does the saw tooth wave appear between pins 13 and 16 of

IC145 ? <Refer to the waveform diagrams on page 32.>

Yes

Does the saw tooth wave appear between pins 13 and 16 of

CX151 ? <The same waveform as above>

Yes

The connection of CX151 is poor or the optical pickup is defective.

This disc motor CLV servo is defective

Does the disc motor rotate in the CD test mode 3 ?

Yes

No

No

No

No

No

No

The +3.3V line of IC149 is defective.

Check the parts around pin 33 on IC149. If OK, IC149 is

defective.

The connection of signal lines between pin 33 on IC149

and pin 13 on IC145 is poor.

Check the parts around IC145 and the power supply line. If

OK, IC145 is defective.

The PWB pattern has been cut.

Is the voltage applied

between pins 27 and 28 of

IC1 for about 0.3-1.5 seconds

when switching from the CD

test mode 2 to 3 ?

No

Yes

The disc motor is

defective or wires

have broken.

0.3-1.5 seconds

Does the disc motor rotate too rapidly or slowly ?

Yes

Does the eye pattern appear at pin 19 on IC146 ?

<Refer to the waveform diagrams on page 31>

(It is OK even if the waveform is not clear.)

Yes

Is the eye pattern Vp-p 1.2V inputted to the pin 24 on IC149 ?

Yes

IC149 is defective.

(After checking the parts around it, replace it.)

No

No

Is the pin 41 on IC149 in the

high state for 0.3-1.5

seconds and does it pulse

when switching from the CD

test mode 2 to 3 ?

<Refer to the waveform

diagrams on page 31>

Yes

IC149 is defective or wires have broken.

Recheck whether the optical pickup objective is dirty.

If it is dirty, clean it.

Check the connection between pin 19 on IC146 and pin 24

on IC149. If OK, the optical pickup is defective.

Check the PWB pattern and C155.

No

IC149 is defective.

5V

0.3-1.5 seconds

14

No sound is heard

D-AJ03

15

Is the digital signal outputted from the pin 4 (digital OUT) of

IC149 ?

Yes

Is digital signal outputted from the pin 8 (digital OUT) of

IC150 ?

Yes

Is the digital signal sent to the pin 26 of CX281 ?

Yes

OK

No

No

No

Check the parts around IC149. If OK, IC149 is defective.

Check the parts around IC150. If OK, IC150 is defective.

Check the CD/MD connection sections.

The slide motor does not run

Is the slide feed signal outputted to pin 40 of IC149 by

pressing the

Is the slide feed signal outputted between pins 25 and 26 of

IC145 ?

Is the slide feed voltage applied to both edges of the sled

motor ?

Check the slide motor. If the sled motor does not run when the DV2.0V is applied to its terminal. It is defective.

/ button in the test mode ?

Yes

Yes

Yes

No

No

No

Check the connection of parts around IC149. If OK, IC149

is defective.

Check the connection between pin 20 of IC145 and pin 40 of

IC149. If OK, IC145 is defective.

Check the PWB pattern.

15

WAVEFORMS OF CD CIRCUIT

Tracking error

Stopped

T

1

1

IC146

11pin

TEO

Smoothing : ON

BW : 20MHz

CH1=200mV

CH1 V/DIV

CAL

=Filter=

T

DC 10:1

VAR

=Offset=

CH1 : 0.000V Main : 10K

CH3 : 0.00V

CH4 : 0.00V

=Record Length=

Zoom : 4KCH2 : 0.00V

2000/09/18 16:56:26

5ms/div

(5ms/div)

NORM:200kS/s

200mV

=Trigger=

Mode : AUTO

Type : EDGE CH1

Delay : 102.3ns

Hold off : MINIMUM

When there is no

wound in the disc.

CH1

V/DIV

Disc playback

Foucus servo on

Stopped

CH1=500mV

IC146

15pin

FEO

3

IC145

4pin

FO+

DC 10:1

1

T

CH2=2V

DC 10:1

T

CH3=2V

DC 10:1

4

2

5

3

IC145

3pin

FO

-

Smoothing : ON

BW : 20MHz

CH2

CH1 CH3 CH4 EXT LINE

=Filter= =Offset= =Record Length= =Trigger=

CH1 : 0.000V Main : 10K

CH3 : 0.00V

CH4 : 0.00V

Zoom : 5KCH2 : 0.00V

D-AJ03

2000/09/18 15:29:21

2ms/div

(2ms/div)

NORM:500kS/s

CH2

Level

2.48V

Mode : SINGLE

Type : EDGE CH2

Delay : 102.3ns

Hold off : MINIMUM

When a door

was closed,

disc dovetail

16

RF

T

Stopped

CH1=500mV

DC 10:1

6

T

1

IC146

19pin

RFGO

FileName

Format

BMP

=Filter= =Offset= =Record Length= =Trigger=

Smoothing : ON

BW : 20MHz

Stopped

CH1=1V

DC 10:1

T

1

7

IC149

41pin

DMO

2

8

IC146

12pin

RFDC

3

AutoFile

OFF ON

CH1 : 0.000V Main : 1K

CH3 : 0.000V

CH4 : 0.00V

T

CH2=1V

DC 10:1

Zoom : 400CH2 : 0.00V

CH3=1V

DC 10:1

2

IC146

17pin

RFRP

=Filter=

Smoothing : ON

BW : 20MHz

=Offset=

CH1 : 0.00V Main : 10K

CH3 : 0.00V

CH4 : 0.00V

=Record Length=

Zoom : 4KCH2 : 0.00V

1

IC146

11pin

TEO

Tracking

Stopped

T

1

Smoothing : ON

BW : 20MHz

CH1 V/DIV

CAL

=Filter=

T

CH1=1V

DC 10:1

VAR

=Offset=

CH1 : 0.00V Main : 10K

CH3 : 0.00V

CH4 : 0.00V

=Record Length=

Zoom : 4KCH2 : 0.00V

2000/09/18 16:55:04

5ms/div

(5ms/div)

NORM:200kS/s

CH1

V/DIV

=Trigger=

Mode : AUTO

Type : EDGE CH1

Delay : 102.3ns

Hold off : MINIMUM

1V

By the test

mode 3

During the tracking jump TEO, RFRP Disc motor and CD related signal

1

IC146

11pin

TEO

2

IC146

17pin

RFRP

Stopped

CH1=1V

DC 10:1

T

1

2

CH1

=Filter=

Smoothing : ON

BW : 20MHz

T

CH2=1V

DC 10:1

CH2 CH3 CH4 EXT LINE

=Offset=

CH1 : 0.00V Main : 10K

CH3 : 0.00V

CH4 : 0.00V

=Record Length=

Zoom : 5KCH2 : 0.00V

2000/09/18 17:01:23

2ms/div

(2ms/div)

NORM:500kS/s

CH1

Level

0.54V

=Trigger=

Mode : SINGLE

Type : EDGE CH1

Delay : 102.3ns

Hold off : MINIMUM

Track jump

2000/09/18 14:55:22

500ms/div

(500ms/div)

NORM:200kS/s

To

TopMenu

Mode : SINGLE

Type : EDGE CH1

Delay : 102.3ns

Hold off : MINIMUM

2000/09/18 16:45:07

500ms/div

(500ms/div)

NORM:2kS/s

=Trigger=

Mode : SINGLE

Type : EDGE CH1

Delay : 102.3ns

Hold off : MINIMUM

CH3

V/DIV

1V

Disc playback

CD test 2 3

upgrade

16

Loading...

Loading...