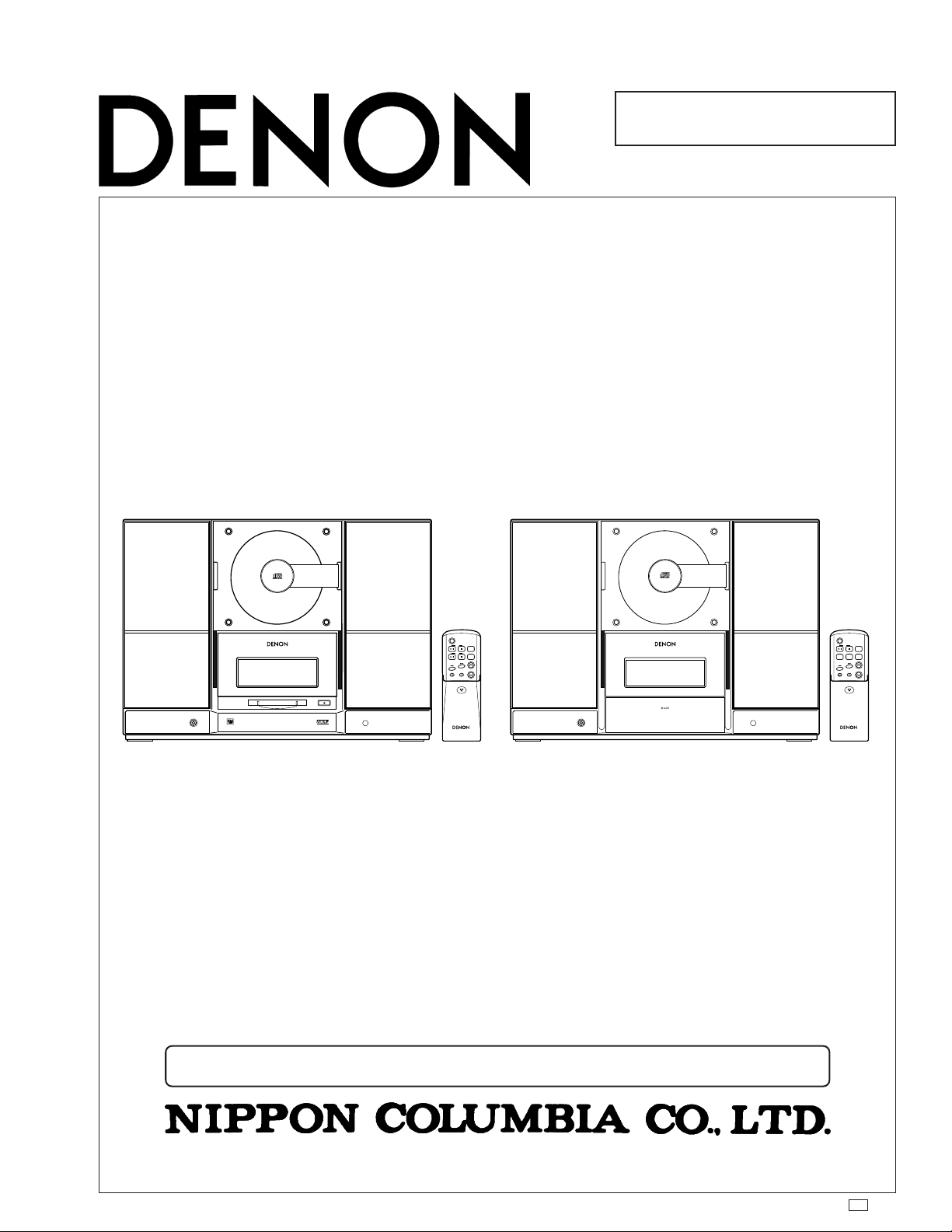

Denon D-A03 Service Manual

Hi-Fi Personal Audio System

EQ

AUXFM/AM

C D

POWER

VOLUME

SDB

TUNING/

PRESET

REMOTE

SENSOR

PHONES

VERTICAL LOADING SYSTEM

COMPACT DISC PLAYER

PERSONAL AUDIO SYSTEM / CD STEREO RECEIVER

40-STATION PRESET MEMORY

6-MODE PRESET EQUALIZER

REMOTE CONTROL UNIT

SERVICE MANUAL

For Hong Kong,

U.S.A. and Canada model

MODEL

D-A03

PERSONAL AUDIO SYSTEM

VERTICAL LOADING SYSTEM

COMPACT DISC PLAYER

POWER

PERSONAL AUDIO SYSTEM/CD-MD RECEIVER

D-A03

MENU TUNING

SLEEP TIMER OFF TOTAL

RANDOM INTOR SCAN ROCK POP JAZZ DANCE FLATT

PHONES

power loading mechanism

REMOTE

SENSOR

Hong Kong model U.S.A. and Canada model

C D

FM/AM

M D

AUX

VOLUME

TUNING/

PRESET

SDB

N.SPEED

HI.SPEED

REC MODE

REC

E Q

TOC/NAME

CLEAR

ENTER

DISPLAY

TIMER/DELETE

PLAY MODE

PROG.

REMOTE CONTROL UNIT

●●

● Some illustrations using in this service manual are slightly different from the actual set.

●●

14-14, AKASAKA 4-CHOME, MINATO-KU, TOKYO 107-8011 JAPAN

Telephone: 03 (3584) 8111

X0130 337 NC 0112

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

SPECIFICATIONS (There is no MD Section in the U.S.A. and Canada model)

Amplifier Section

Practical maximum output: Front speaker 11W (5.5W + 5.5W EIAJ)

Audio input/output jacks: MONO output terminal, AUX input terminal, 3.5mm headphone jack

Tuner Section

Receive frequency bands: FM: 87.50MHz to 108.00MHz

Receive sensitivity: FM: 1.5µV/75Ω/ohm

FM stereo separation: 35 dB (1 kHz)

AM: 520kHz to 1710kHz (U.S.A. and Canada model)

522kHz to 1611kHz (Hong Kong model)

AM: 20µV

D-A03

CD Player Section

Wow and flutter: Below measurement limits (±0.001% W peak)

Sampling frequency: 44.1kHz

Light source: Semiconductor laser

MD Section (Hong Kong model)

Format: MiniDisc digital audio system

Wow and flutter: Below measurement limits (±0.001% W peak)

Sampling frequency: 44.1kHz

Recording method: Magnetic modulation overwrite method

Light source: Semiconductor laser

Clock and Timer Section

Clock system: Within one minute per month

Timers: Everyday timer (One)

Recording timer (One)

Sleep timer (120 minutes, MAX)

Common Section

Power supply: 120V AC, 60Hz (U.S.A. and Canada model)

115/230V AC, 50/60Hz (Hong Kong model)

Power consumption: 29W

Maximum external dimensions: 390 (W) × 280 (H) × 165 (D) mm (Including feet, knobs and terminals)

Mass: 5.3kg

Approximately 0.8W during standby

Remote Control (RC-910: Hong Kong model, RC-911: U.S.A. and Canada model)

Remote control system: Infrared pulse

Power supply: 3V DC (using two R6P/AA type batteries)

Maximum external dimensions: 49 (W) × 140 (H) × 30 (D) mm

Mass: 120g (including batteries)

* For improvement purposes, specifications and functions are subject to change without advanced notice.

Licensed product based on U.S. and overseas patents of Dolby Laboratories Licensing Corporation.

2

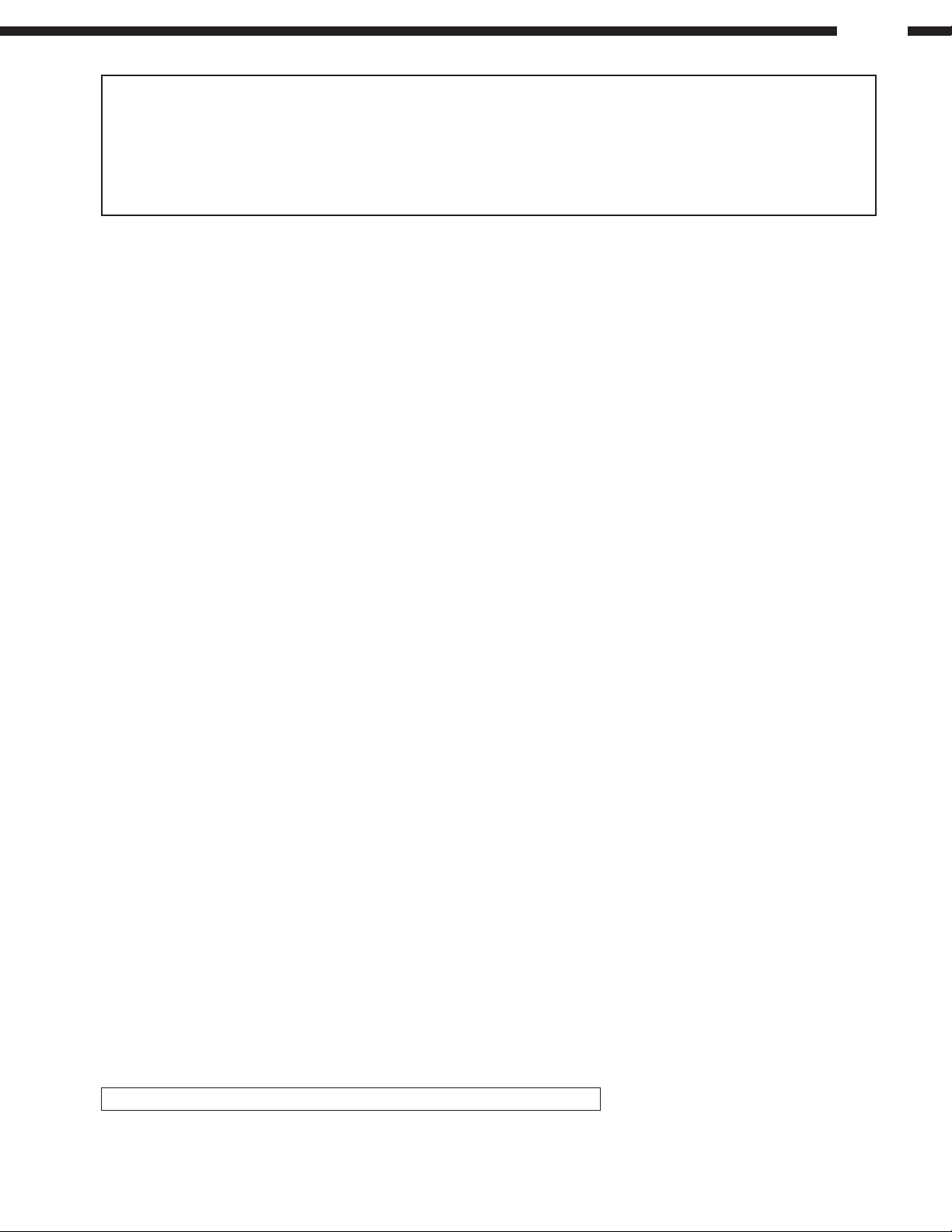

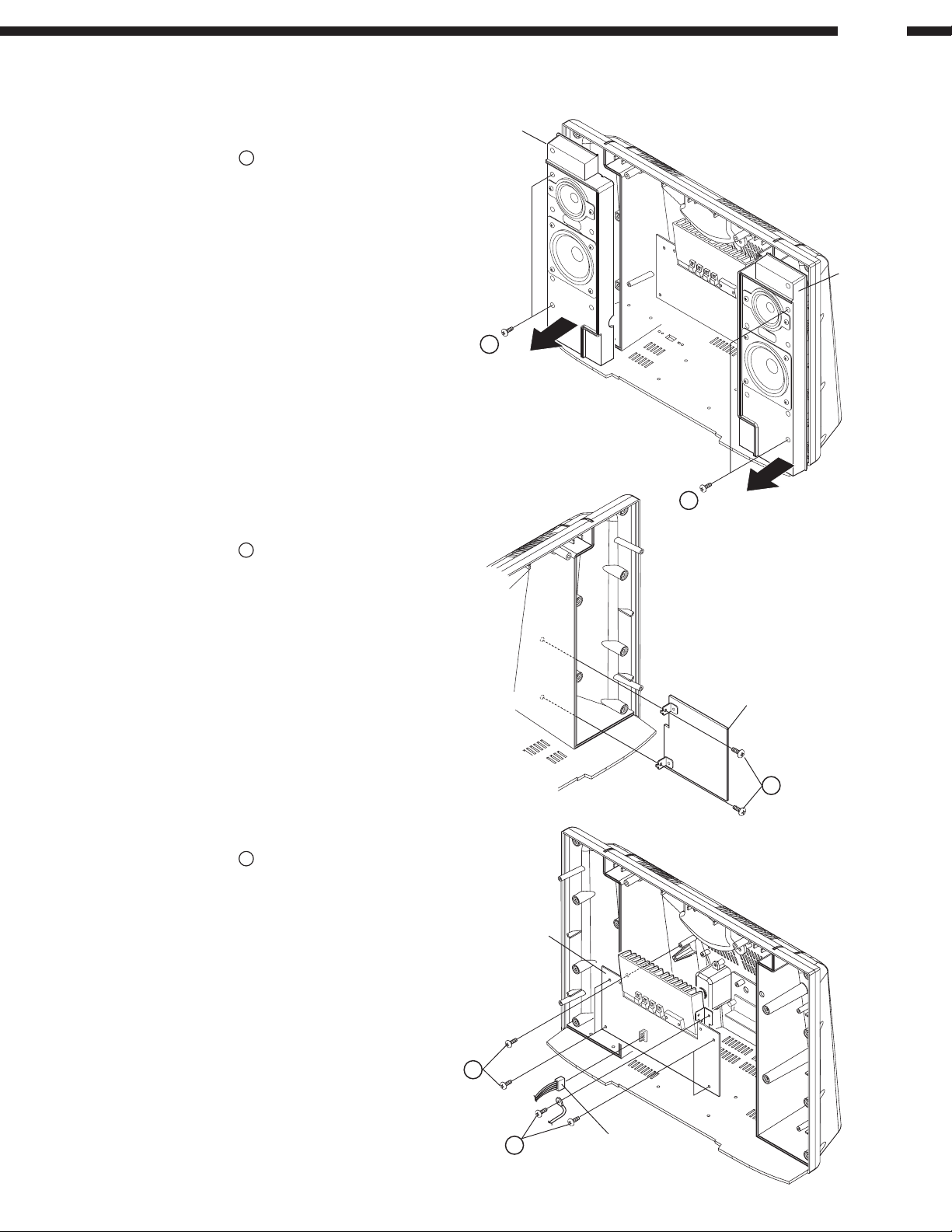

DISASSEMBLY

(Follow the procedure below in reverse order when reassembling)

1. Rear Cover & Front Panel

1) Remove 14 rear screws 1 and 4 (E3: 2) bottom screws

2

on the Rear Cover.

3

2) Disconnect connectors and wire

The Rear Cover and Front Panel can be detached

respectively.

~ 7 on the Front Panel.

D-A03

1

1

2

4

5P Connector

6P Connector

2. Main P.W.B.

1) Remove 5 screws 8.

2) Disconnect 2 FFCs, 10 connectors on the Main P.W.B.

5

3

4P Connector

Connectors

11P Connector

6

1P Earth Lug

7

8

FFC

1

8

3P Connector

Main P.W.B.

Connectors

10P Connector

FFC

3

3. MD Mecha.

1) Remove 3 screws 9.

2) Disconnect 1 each FFC and connector on the Main P.W.B.

4. CD Mecha. Chassis

1) Remove 4 each screws and from the front side to

detach the CD Door Lens and CD Door Bracket.

2) Remove 6 screws

and take off the Main Chassis.

D-A03

9

Connector

MD Mecha.

FFC

CD Door Bracket

CD Door Lens

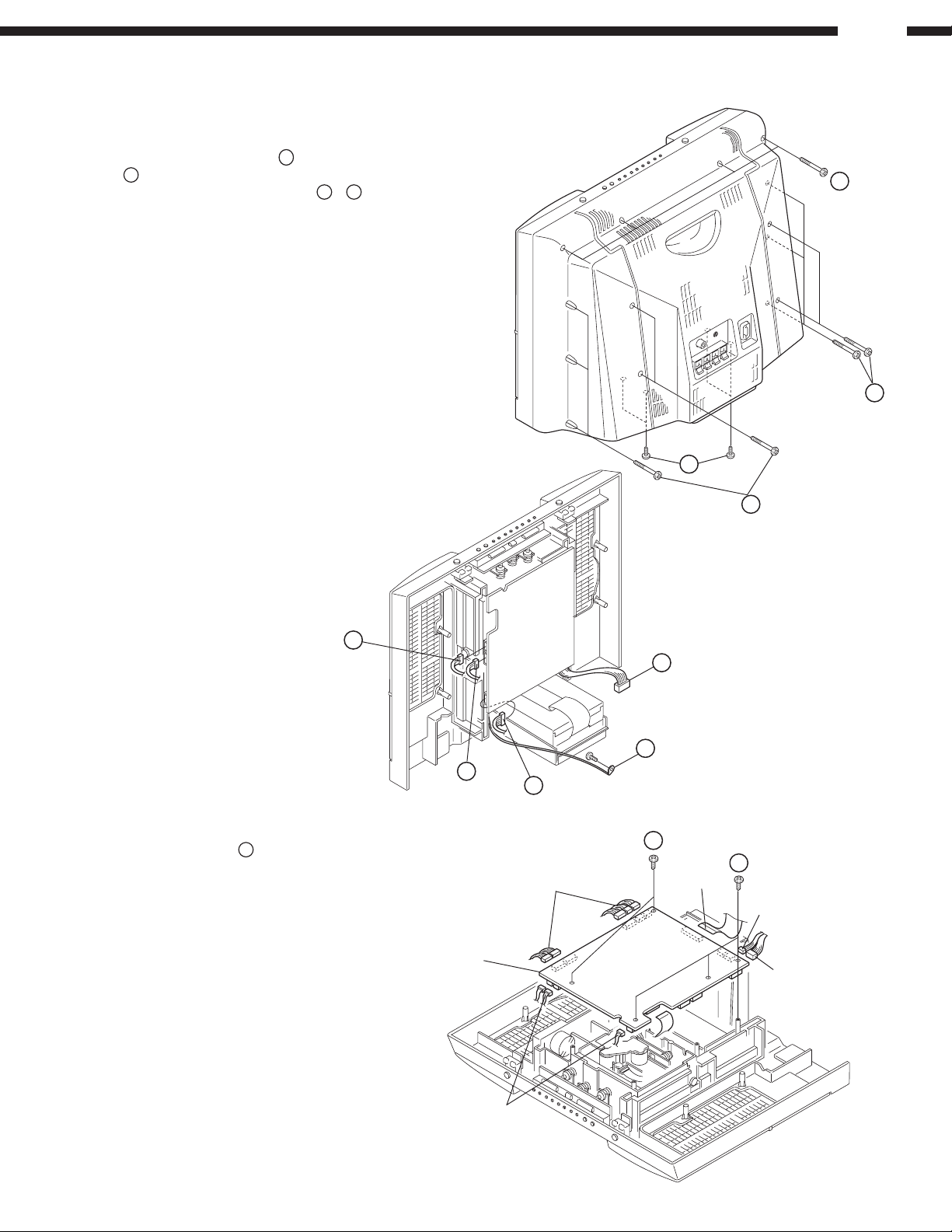

5. CD Mecha.

1) Remove 4 screws ! fixing the Bracket.

2) Detach the CD Mecha. upward as shown to the arrow

direction.

Rubber

(Green)

Collar

(White)

!

Main Chassis

!

Rubber

(Blue)

Rubber

(Green)

4

6. Speaker Box (L & R)

1) Remove 4 screws ".

2) Disconnect 2 connectors.

D-A03

Speaker

Box (L)

Speaker

Box (R)

"

7. Tuner P.W.B.

1) Remove 2 screws #.

8. Power P.W.B.

1) Remove 6 screws $.

2) Disconnect 1 connector.

"

Tuner P.W.B.

#

Power P.W.B.

$

$

Connector

5

ADJUSTMENT

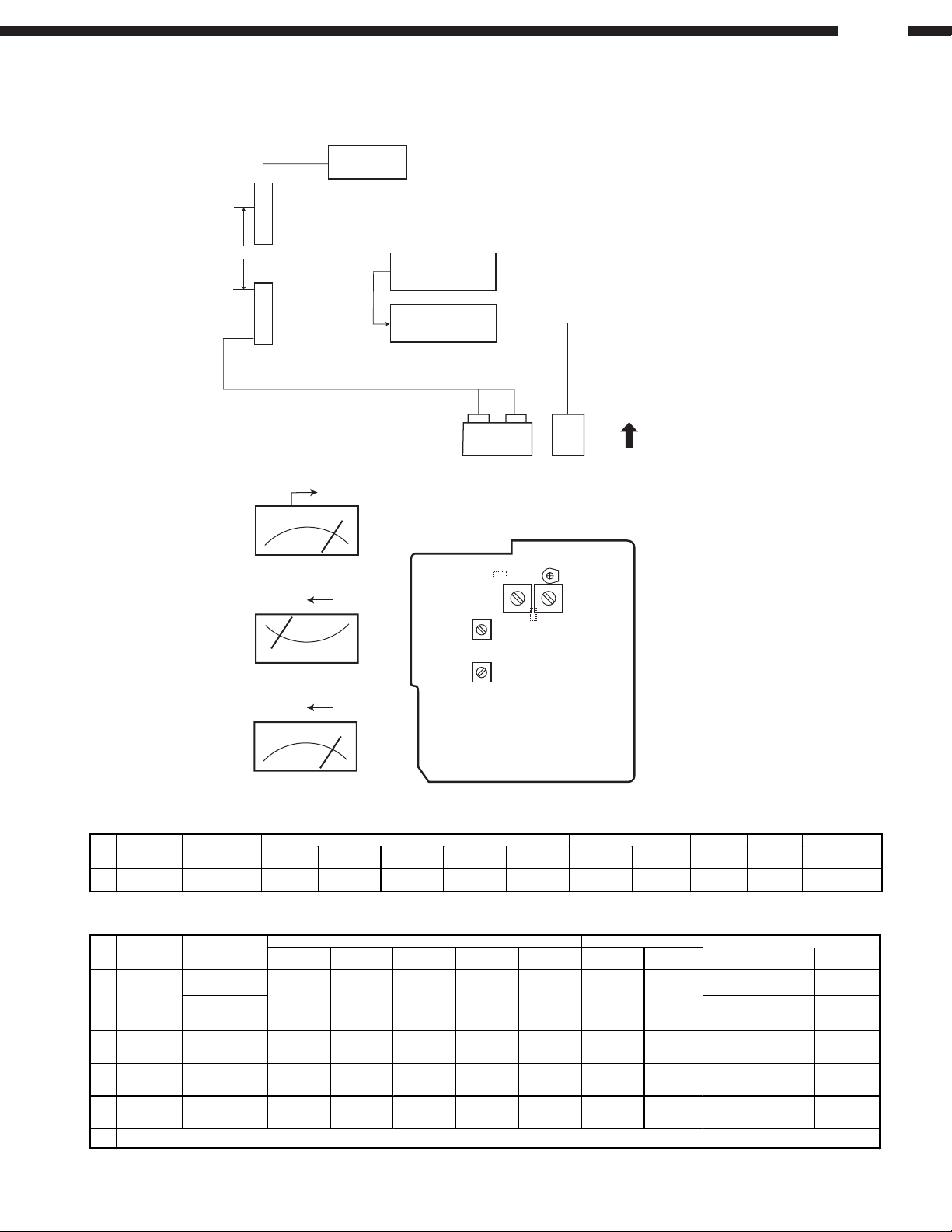

TUNER SECTION

Connections and adjustment point

AM SG

Modulation frequency: 400Hz

Modulation factor: 30%

D-A03

Test loop antenna

60cm

Loop antenna

Digital Voltmeter

To Output Terminal

Distortion Meter

To Output Terminal

To TP

Modulation frequency: 1kHz

L+R: 90% (67.5kHz Dev.)

Pilot: 10% (7.5kHz Dev.)

75kHz Dev.: 100%

FM stereo modulator

FM SG

Antenna Terminal

AM FMG

TUNER PWB

T403 T402

T401

T404

75 ohms

Coaxial Cable

TC401

RA25

R419

Rear Panel Side

Separation Meter or

Electronic Voltmeter

FM ALIGNMENT (BAND BUTTON: FM, AUTO)

Step

1

Alignment

Item

FM DC

Balance

Tune-in Point

(Channel Setting)

98 MHz FM SG 98 MHz

Measuring

Equipment

Frequency Level Modulation Connect to

Input Output

60 dB

µ

1 kHz

75 kHz dev

FM Ant

Te r m i n a l

AM ALIGNMENT (BAND BUTTON: AM)

Alignment

Step

Item

1 Band Edge

2 IF No Broadcast Area AM SG (900 kHz)

3Tracking

4Tracking

5 Repeat Steps 3 and 4, and set the output to maximum.

Tune-in Point

(channel Setting)

E1:522kHz

E3:520 kHz

E1:1611kHz

E3:1710 kHz

E1:603 kHz

E3:600 kHz

E1:1404 kHz

E3:1400 kHz

Measuring

Equipment

AM SG

AM SG

Frequency Level Modulation Connect to

E1: 603 kHz

E3: 600 kHz

E1: 1404 kHz

E3: 1400 kHz

Input Output

No AGC

Effects

No AGC

Effects

No AGC

Effects

400 Hz 30% Loop Ant

400 Hz 30% Loop Ant

400 Hz 30% Loop Ant

Measuring

Equipment

Digital

Vol tm et er

Measuring

Equipment

Digital

Vol tm et er

Electronic

Vol tm et er

Electronic

Vol tm et er

Electronic

Vol tm et er

Connect to

Both Leads

of R425

Connect to

Both Leads

of R419

LINE 1

Output

Te r m i n a l

LINE 1

Output

Te r m i n a l

LINE 1

Output

Te r m i n a l

Align Part Set Value Remarks

T404

Align Part Set Value Remarks

T403

T401

T402

TC401

±

E1: 1.3±0.2V

E3: 1.0±50mV

E1: (7.6±0.5V)

E3: (8.3±0.5V)

20mV

Approx.

Maximum

Output

Maximum

Output

Maximum

Output

Align with Mono

Modulation Signal

No Adjustment

Required

6

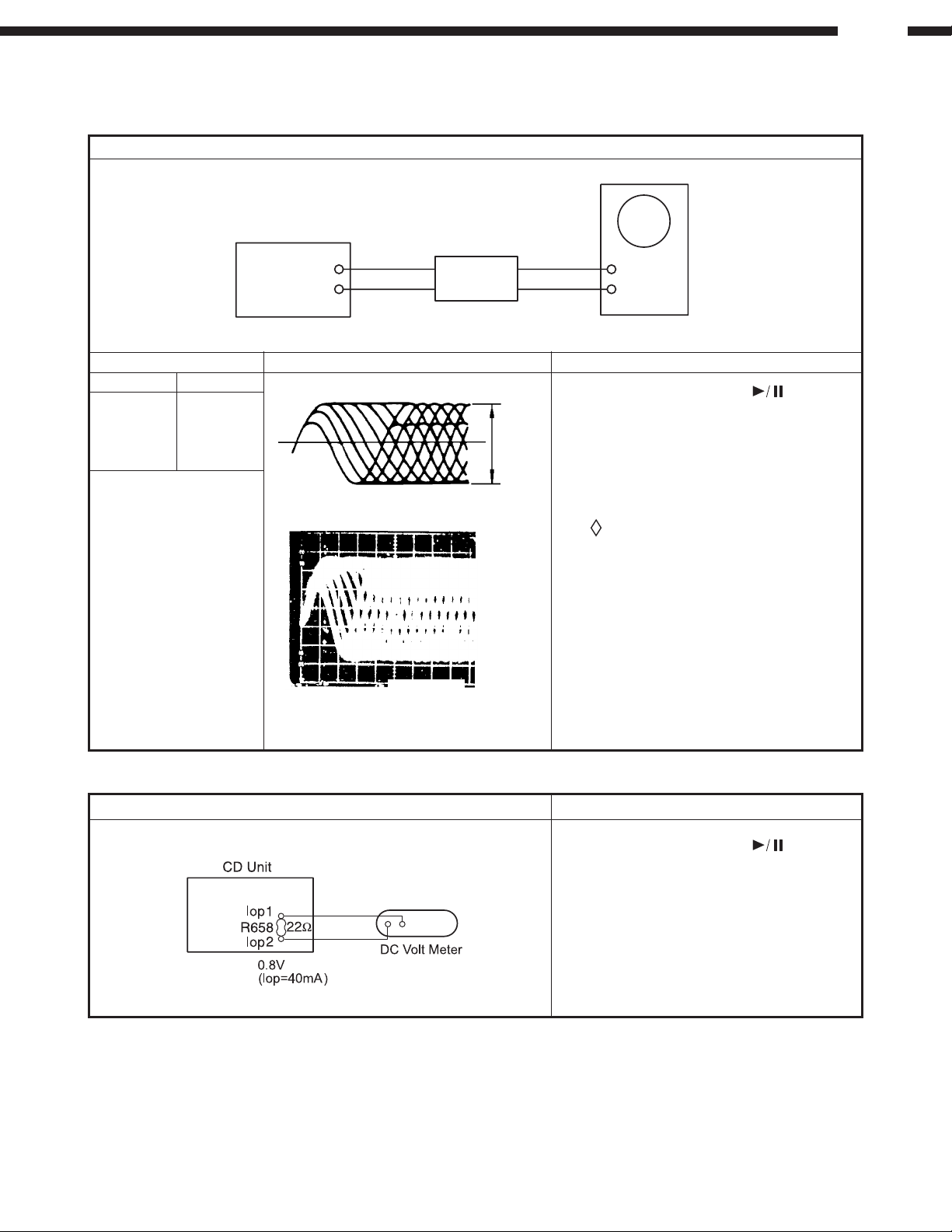

CD SECTION

1. RF level Confieming

D-A03

Connection

Oscilloscope

CD Servo Micon PWB

VH

0.2µs/div

50mV/div

• Set input mode to

ALTERNATE or

CHOPPER.

or

0.5µs/div

RF0

V

REF

Probe

10:1

CheckOscilloscope

+

−

Step

1. Press CD Play/Pause ( ) button

to make it playback state.

A

2. Check RF level with oscilloscope.

3. Confirm that the waveform is in good

A=0.8~1.2V

shape.

(

eye pattern in center must be

able to discriminate clearly.)

Eye Pattern

2. Pickup

Connection

Step

1. Press CD Play/Pause ( ) button

to make it playback state.

2. Measure Iop.

• Since this CD system has the built-in automatic adjustment function, re-adjustment is not necessary when replacing the

pickup.

Therefore, any combination of PWB and pickup can be made freely.

As the automatic adjustment is performed every time the disc is changed, each disc can be played in the most

appropriate condition.

7

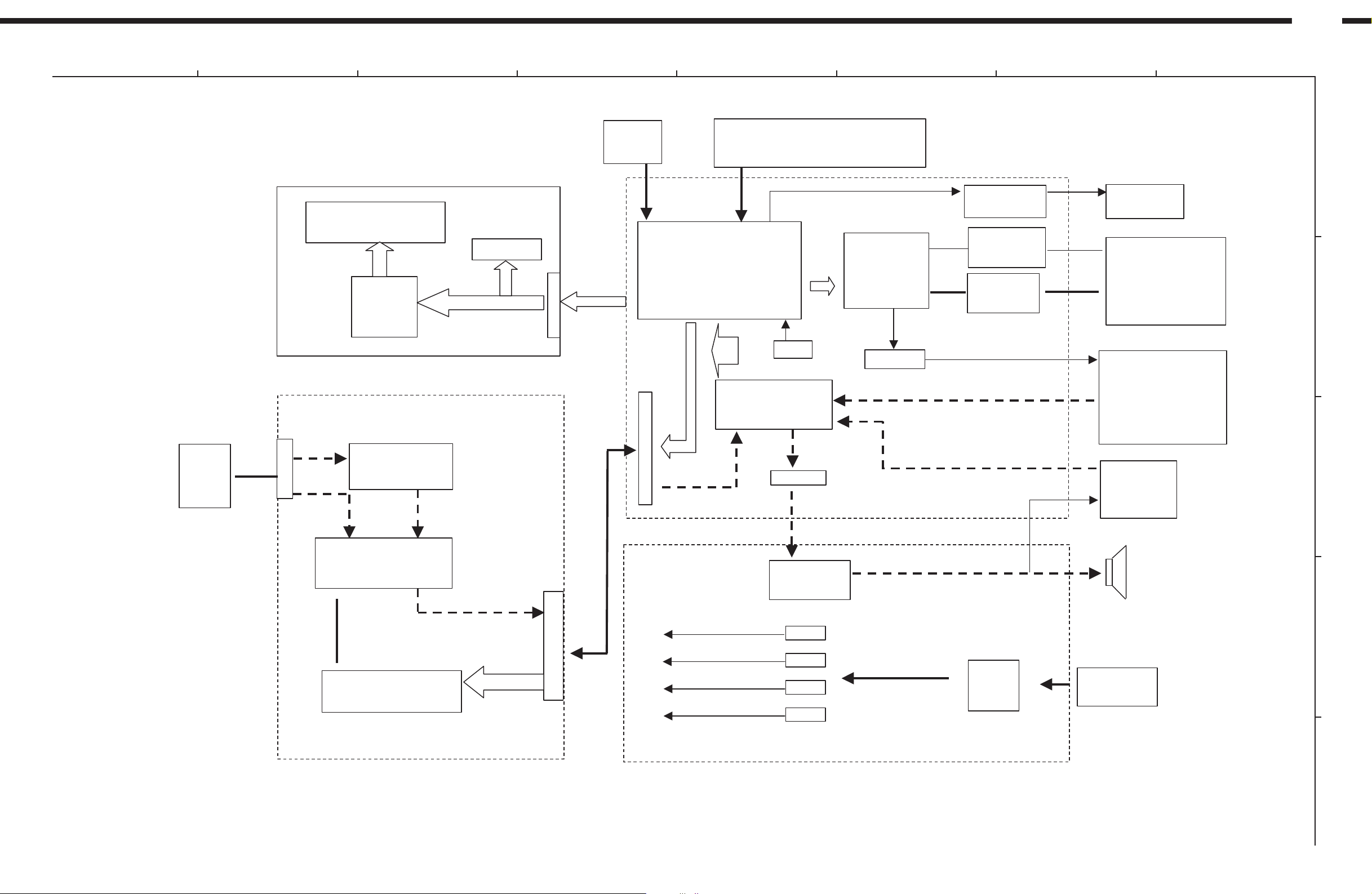

BLOCK DIAGRAM

1

D-A03

2

3

4

5

76

8

4p

Terminal

P.W.B.

LCD

8com,60seg

TUNER UNIT

LCD

Controller

LC75811W

FM FRONTEND

KCF216

DISPLAY UNIT

BACK light

REMOTE

Sensor

MICRO

COMPUTER

M38199

TACT KEY

Reset

ELE.VR SYSTEM

LC75342M

MUTING

MAIN UNIT

DSP

TC94A14FA

74VHC08

Door driver

BA6286

Motor driver

LA6558

RF AMP

TA2157F

A

CD DOOR

CD MECHA

CD4LXWNK

B

MD UNIT

MDM08AD

(Hong Kong Model)

AUX IN

C

SUB

WOOFER

FM IF/DET/MPX

AM RF/IF/DET

LA1844

PLL

LC72131

un5V(MICON)

(tuner,AUDIO)

(MD)

(CD)

(There is no MD Section in the U.S.A. and Canada model)

Power AMP

BA5415

6V

10V

6V

8V

- |<| Reg.

D

AC IN

E

8

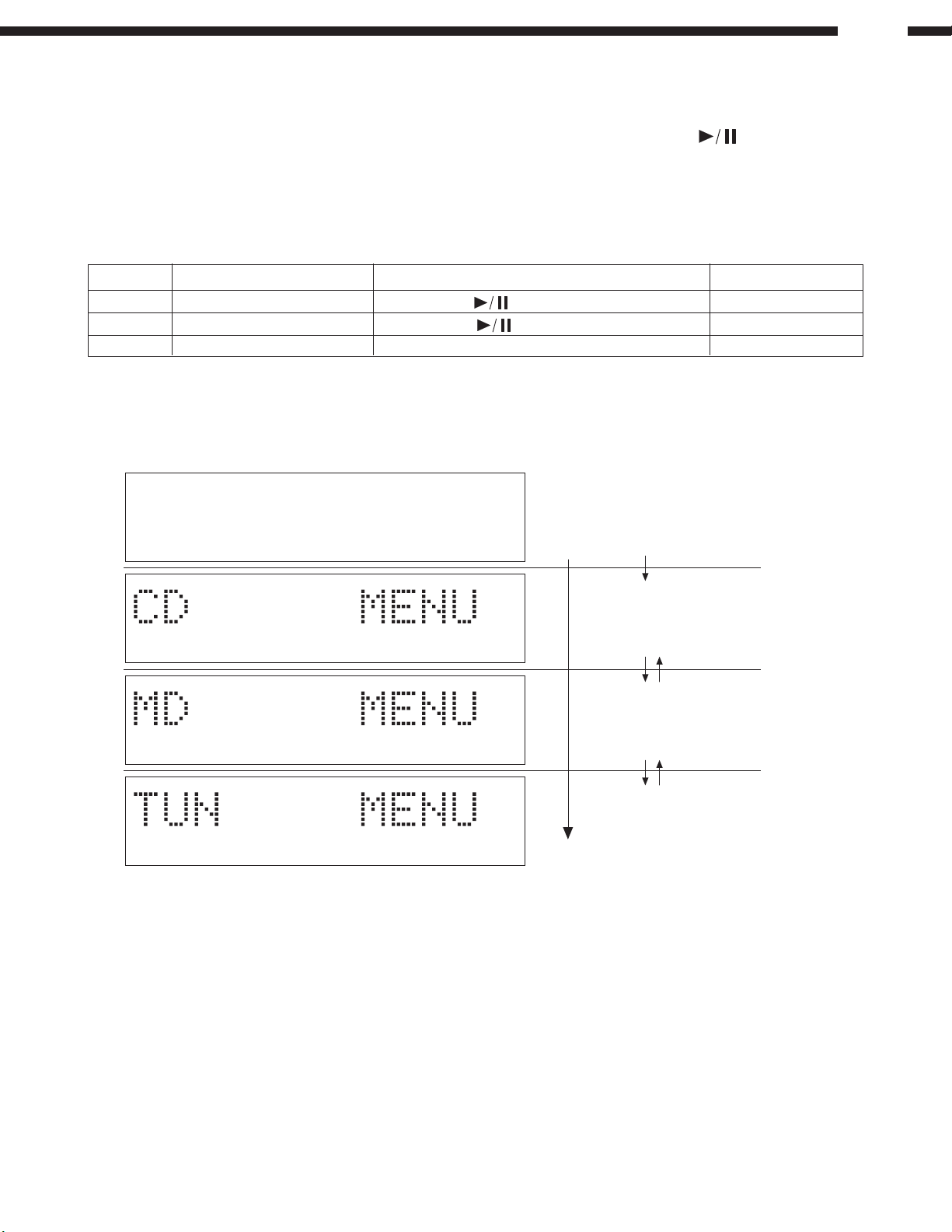

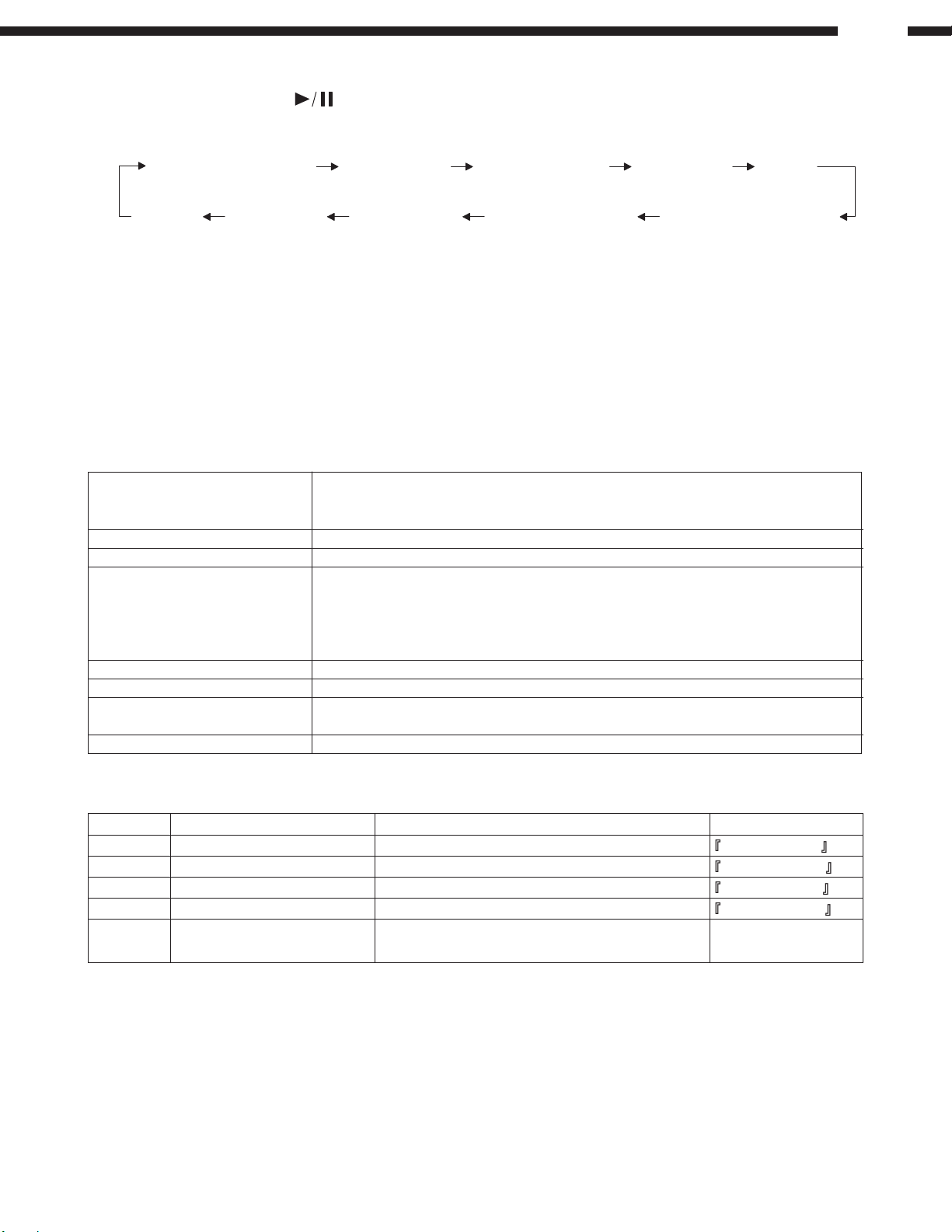

TEST MODE (There is no MD Section in the U.S.A. and Canada model)

From power off state to TEST mode

To enter into the TEST mode, plug the AC cord to the wall outlet while pressing the CD PLAY (CD ) button and

TUNER button simultaneously.

The version information is displayed initially.

Thereafter press the SKIP UP/DOWN button to select the TEST mode and then press the CD STOP button to determine it.

Press the DIRECT key during version display to obtain the designated TEST mode directly.

TEST MODE

No. TEST MODE DIRECT DISPLAY

1 CD TEST CD PLAY (CD ) CD MENU

2 MD TEST MD PLAY (MD ) MD MENU

3 TUNER TEST TUNER TUN MENU

Cancelling the TEST Mode

In each TEST mode, press the POWER button to display COMPLETE for 1 second and then cancel the TEST mode.

In the MD TEST mode, press the POWER button again.

D-A03

Version display

SKIP-DOWN

SKIP-UP

SKIP-UP

Test mode

With SKIP-UP button

Version display

to CD-PLAY

SKIP-DOWN

Version display

to MD-PLAY

SKIP-DOWN

Version display

to TUNER

9

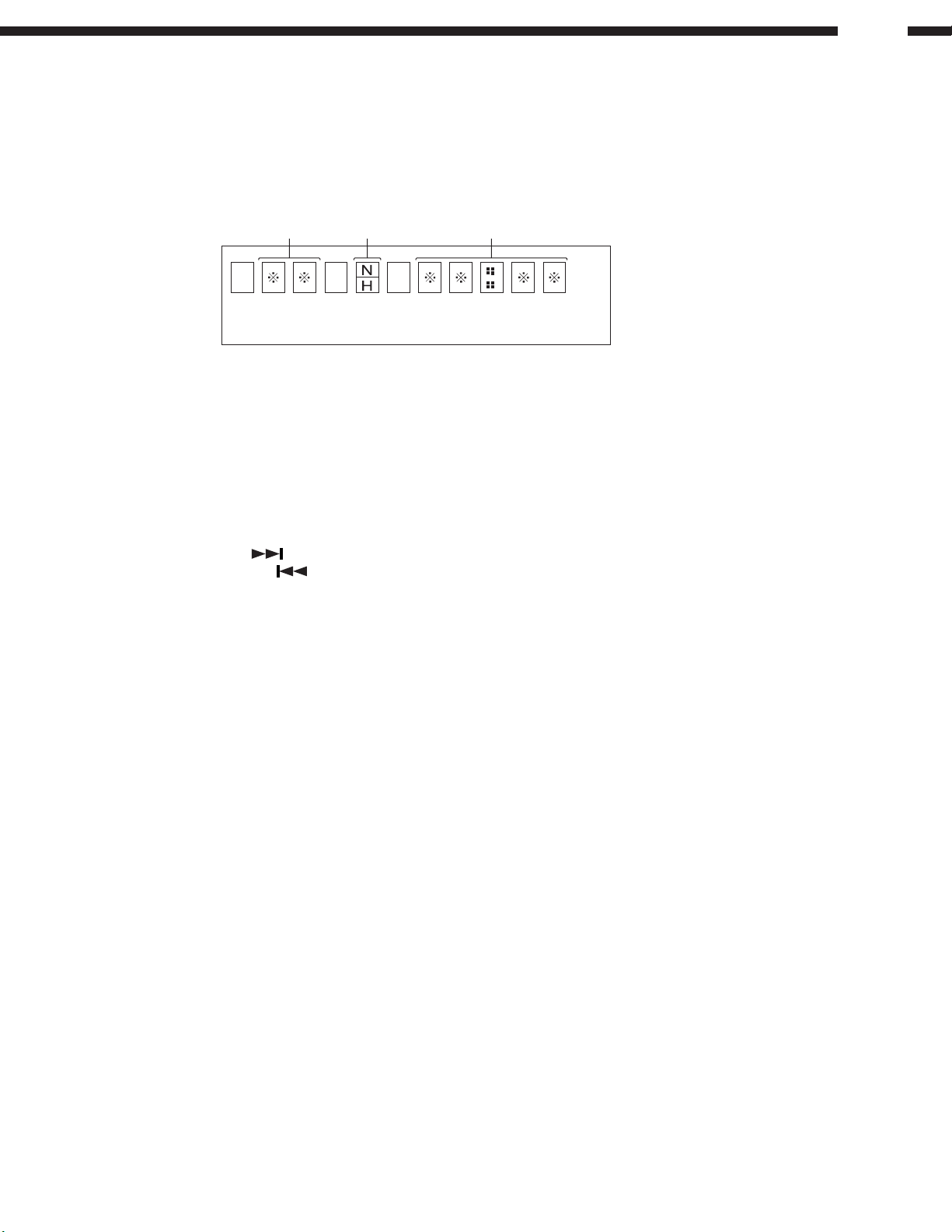

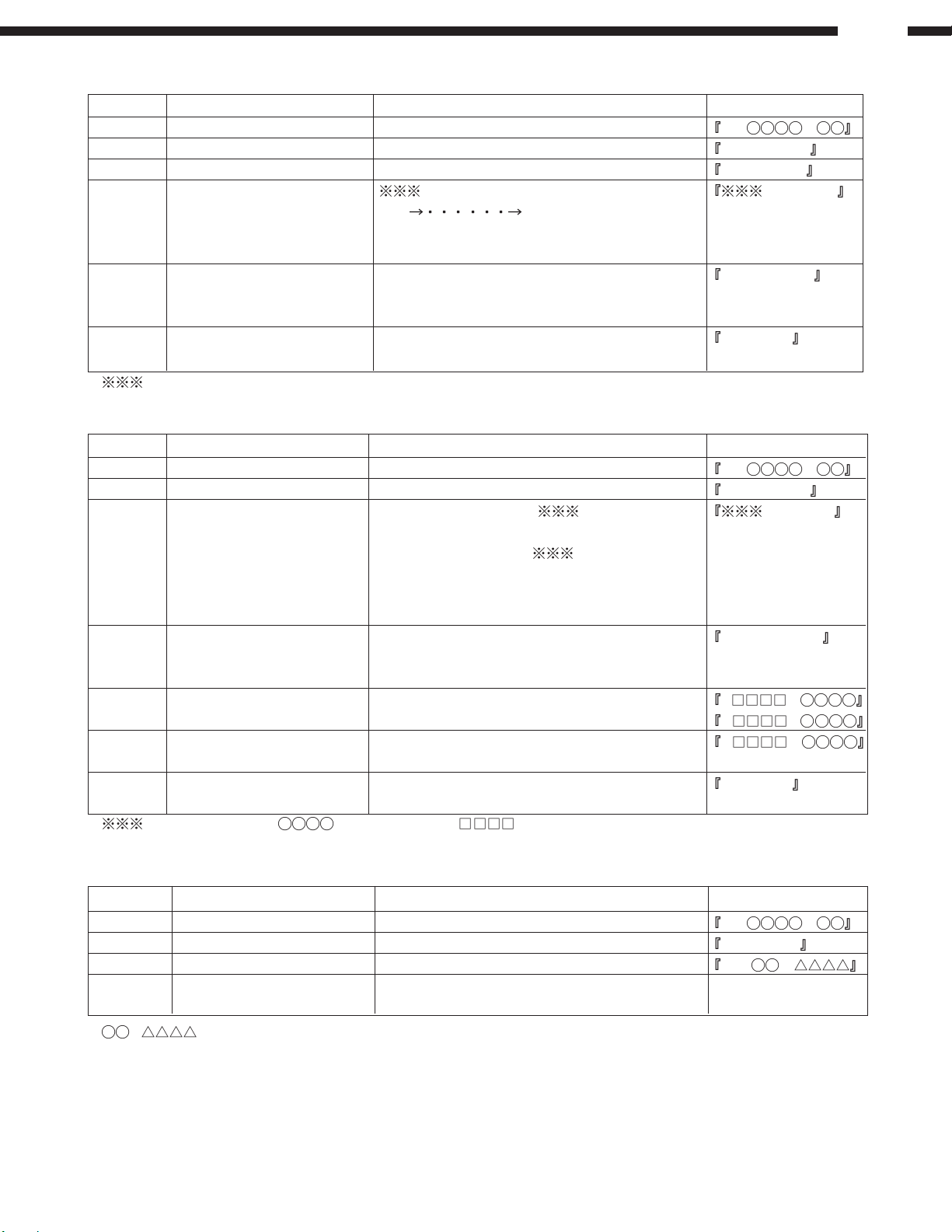

1. CD test

Outline: Readout of the set value after automatic adjustment (for judging difference from initial value)

Forced operation of pickup (Inner/Outer circumference feed)

During the PLAY mode, the number of errors accumulated for 10 seconds (750 frames) is displayed.

Basic CD operation by CD-PLAY button

During the TEST mode, the display is turned on and the following buttons become effective.

N: Normal speed

TNO Display

Operation

1. CD-PLAY: CD operation according to steps

STEP 1: LD ON by pressing CD PLAY button in the stop mode

STEP 2: Focus On by pressing CD PLAY button in STEP 1

STEP 3: CLV servo ON by pressing CD PLAY button in STEP 2

STEP 4: Tracking servo ON by pressing CD PLAY button in STEP 3

STEP 5: Sub-code readout/display by pressing CD PLAY button in STEP 4

* Keep pressing the CD PLAY button for more than 1 second to shift to STEP 5 directly.

2. CD STOP : To stop the playback operation (shifting from each step to the stop

3. CD SKIP-UP (

4. CD SKIP-DOWN ( ) : Forcible shift in the pickup REV direction

5. TUNER : Automatic adjustment (at the present pickup position)

6. POWER : Canceling the test mode

7. VOLUME UP/DOWN : To read the coefficient register while the CD operation is stopped/

8. CD OPEN/CLOSE : Normal open/close operation

) : Forcible shift in the pickup FWD direction

H: Double speed Time Display

mode) / To reset display (during display of coefficient)

Sliding is stopped when the PU_IN switch is turned on.

To display the error number during CD playback

D-A03

Readout of the adjusted value

Press the VOL.UP/DOWN button during the stop mode to read the following items.

Press the CD-STOP button to return to the normal display.

Item Display Max Type Min

Focus balance _ _ F B : x x 7 F 0 0 8 0

Focus gain _ _ F G : x x 1 F 0 0 E 0

Tracking balance _ _ T B : x x 7 F 0 0 8 0

Tracking gain _ _ T G : x x 1 F 0 0 E 0

Foucus offset F O F F : x x 7 F 0 0 8 0

Tracking offset T O F F : x x 7 F 0 0 8 0

RFRP R F R P : x x 7 F 0 0 8 0

Even if the CD-PLAY button is pressed initially, automatic adjustment is not obtained. Press the TUNER button in

the stop mode to gain CD-PLAY for automatic adjustment. Thereafter press the CD-STOP button to stop automatic

adjustment.

Press the VOL. UP/DOWN button to display automatically adjusted values.

Readout of error numbers

Press the VOL.UP/DOWN button during playback to display the number of errors accumulated for 10 seconds

(750 frames).

Press the CD-STOP button during ERR display to return to the normal TEST mode display.

10

Double-speed mode

Press the MD-REC button in the stop mode to switch to the double/constant-speed mode cyclically.

During the double-speed mode,

lights up.

CD TEST

D-A03

STEP NO Display

TNO Display

N:NORMAL SPEED

H:HIGH SPEED

Time Display

N

H

STEP NO Display

TNO Display

Time Display

Coefficient name Coefficient

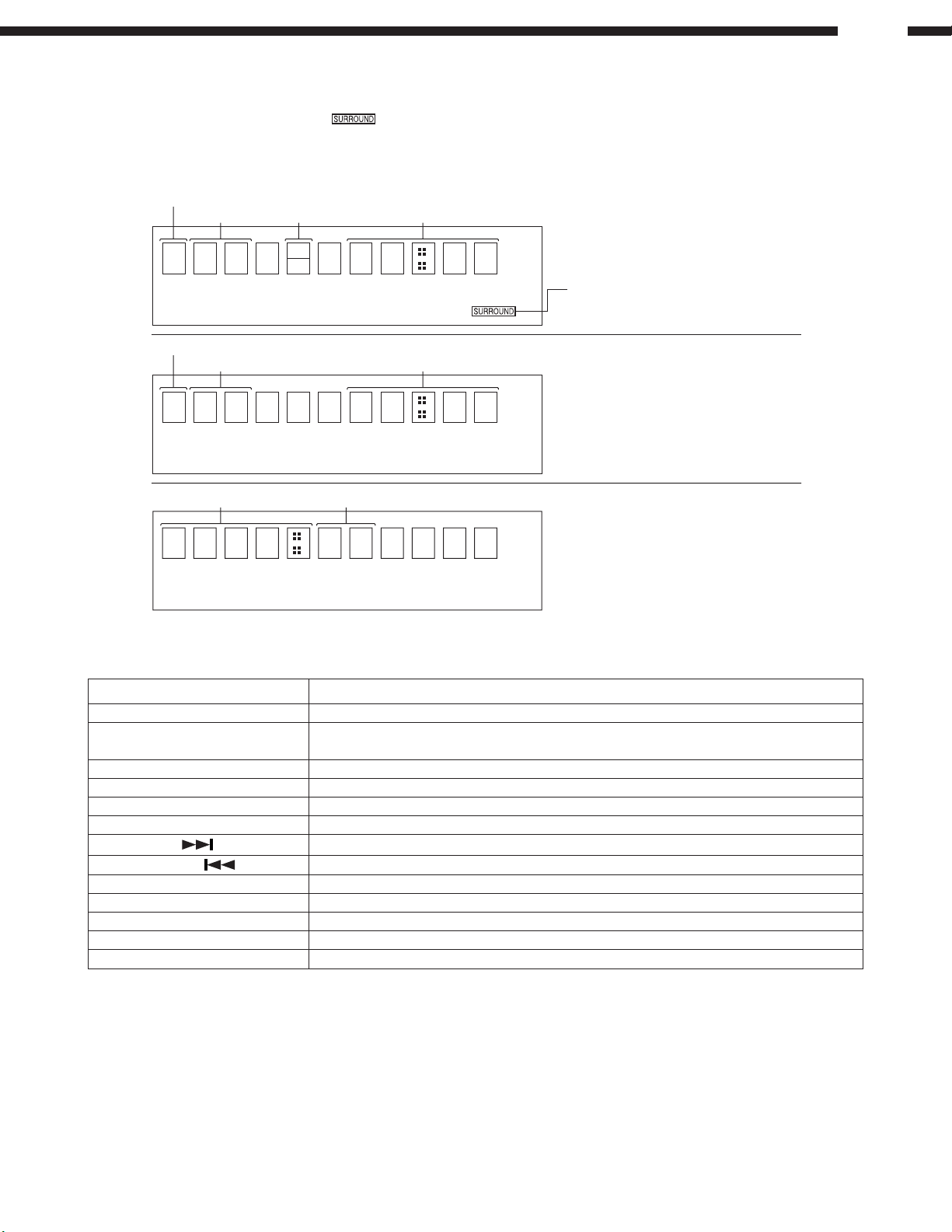

2. MD test mode (Refer to page 12 and after.)

Button used during MD test mode

Lights when double-speed mode

1.STEP NO. : 0 when stopped

2.Time display: Blank from the stop

mode to STEP 4

Readout of coefficient

Button Name Function

CD-PLAY To feed the menu of the TEST mode (1) (to feed the menu relating to adjustment and EEPROM)

TUNER To feed the menu of the TEST mode (2) (to feed the menu mainly relating to continuous

playback and recording)

AUX To feed the menu of the TEST mode (3) (to feed the menu of INNER and JUMP SELECT, etc.)

MD REC To feed the menu of the TEST mode in reverse (to feed the menu in each test mode in reverse)

MD-PLAY To select, determine and start the menu

MD-STOP To stop each test item and to select the next upper menu.

(M-) SKIP-UP ( ) 1. Forced slide feeding (FWD) 2. JUMP operation 3. Address setting value up, etc.

(M-) SKIP-DOWN ( ) 1. Forced slide feeding (REV) 2. JUMP operation 3. Address setting value down, etc.

VOL-UP Set value UP

VOL-DOWN Set value DOWN

CD-STOP 1. To switch laser by EJECT 2. To switch display during continuous playback, etc.

POWER To operation mode without automatic adjustment

MD-EJECT Normal EJECT operation

11

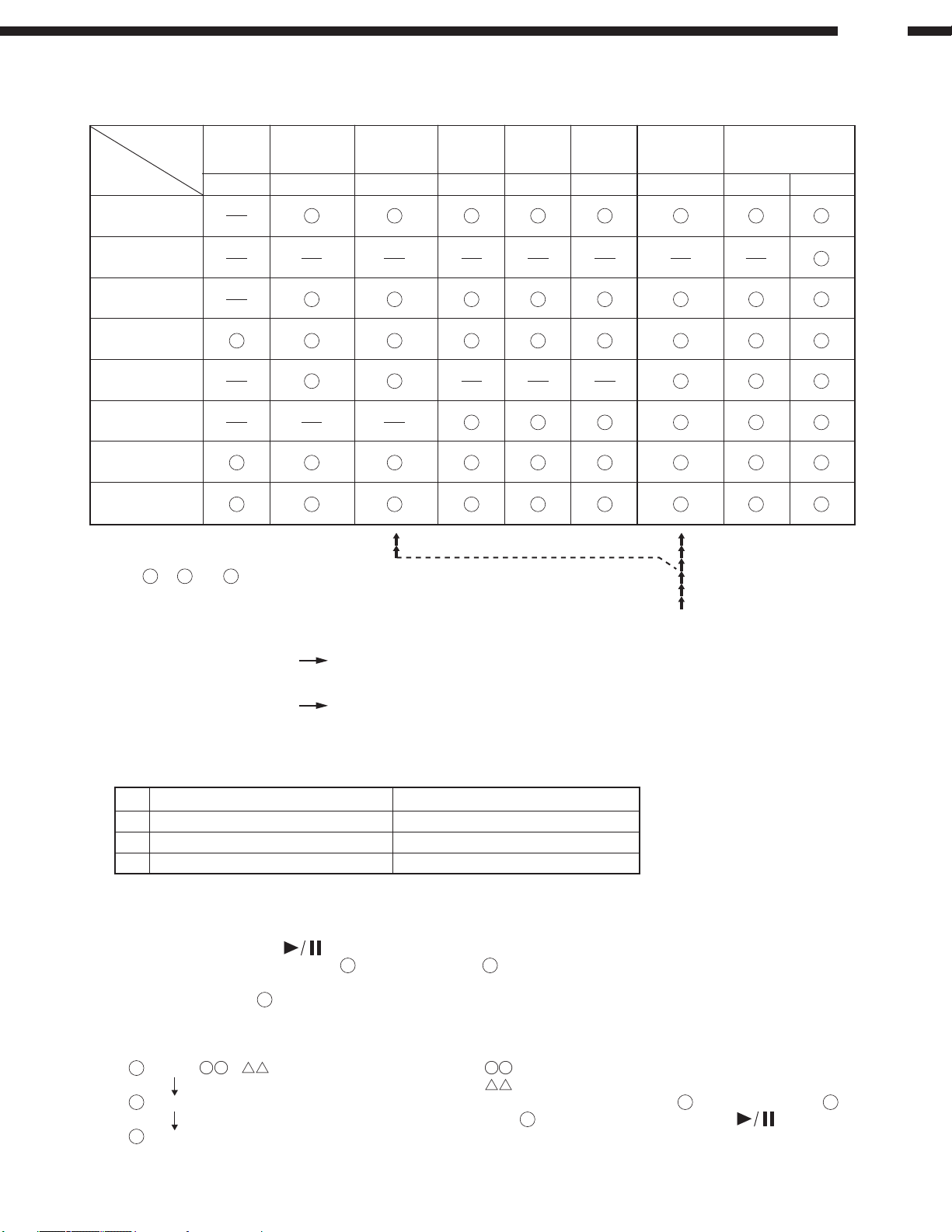

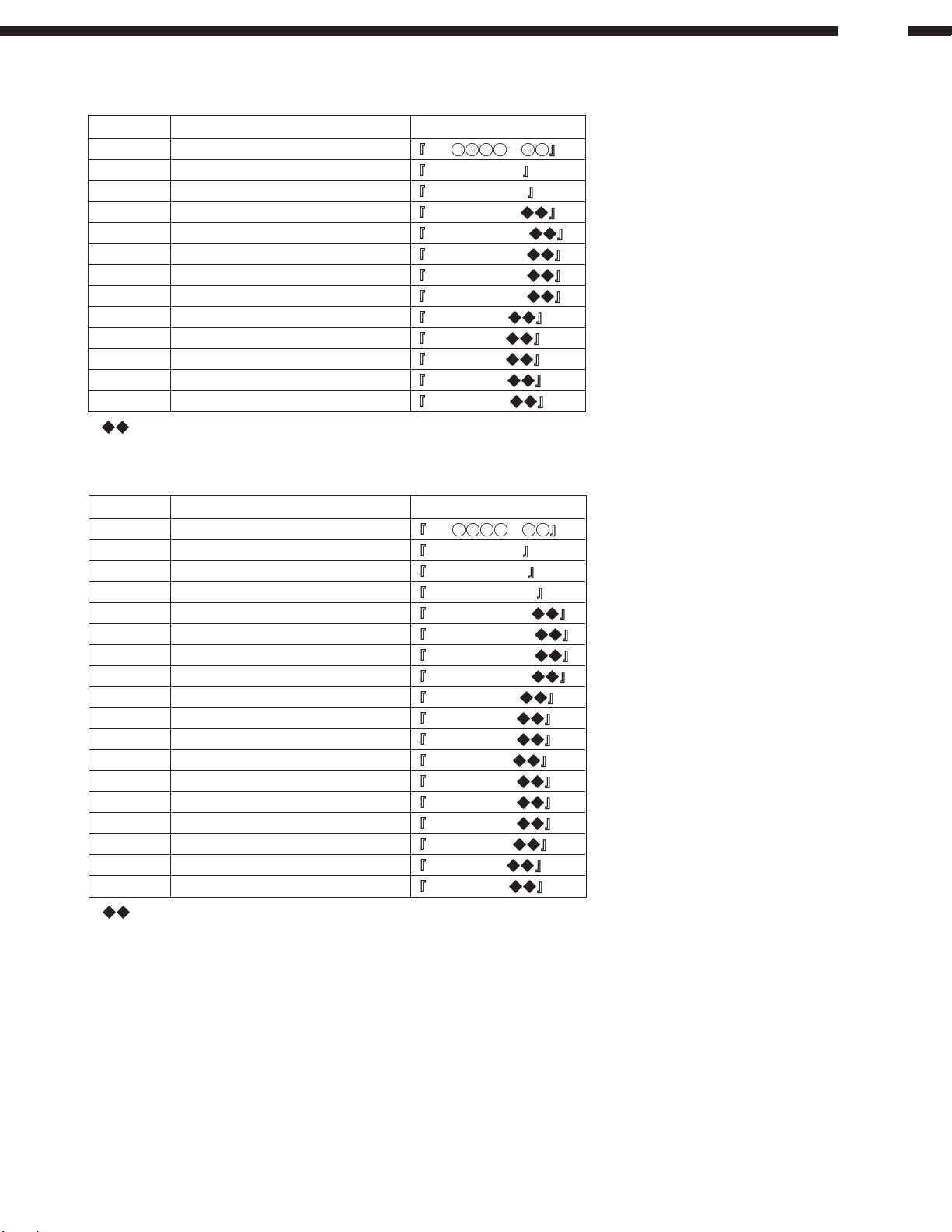

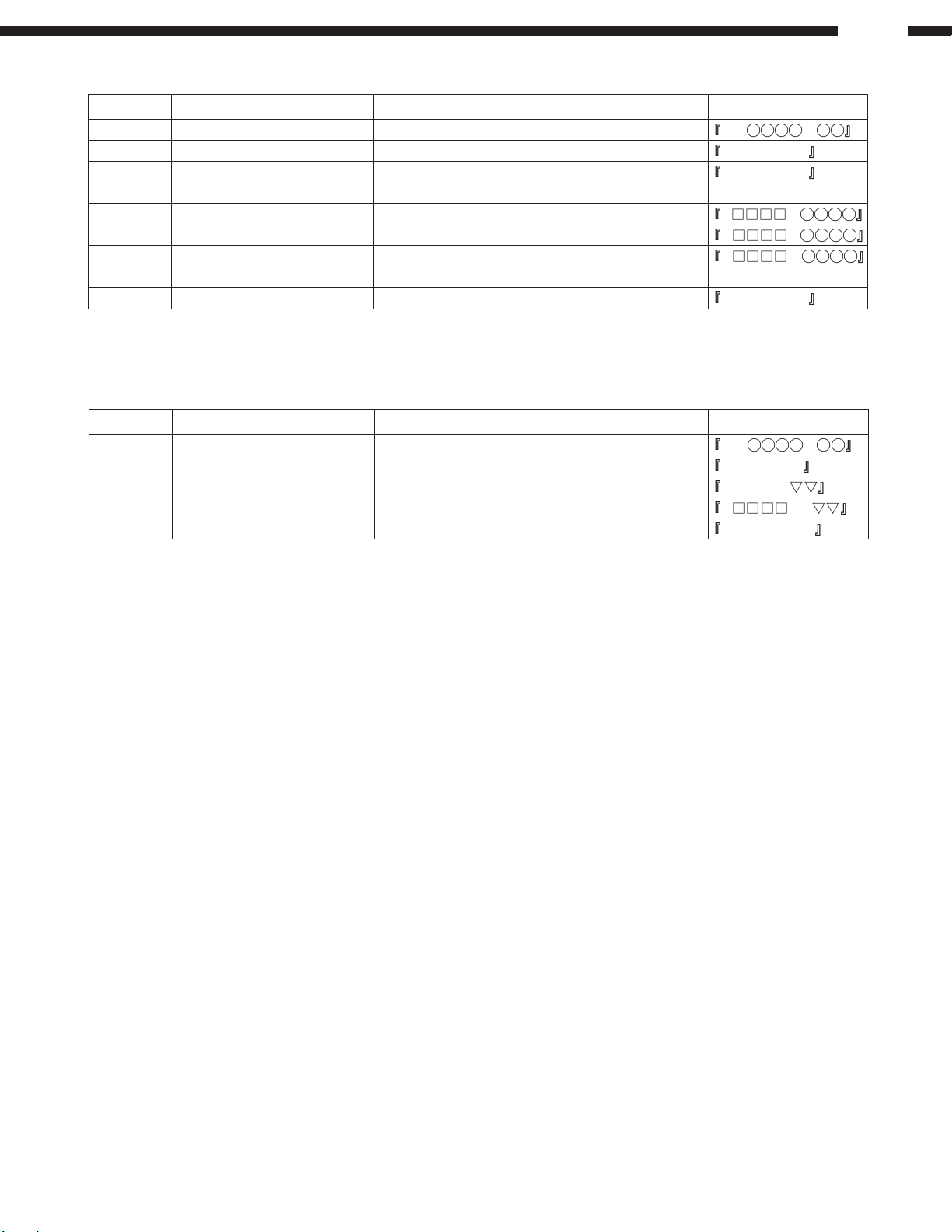

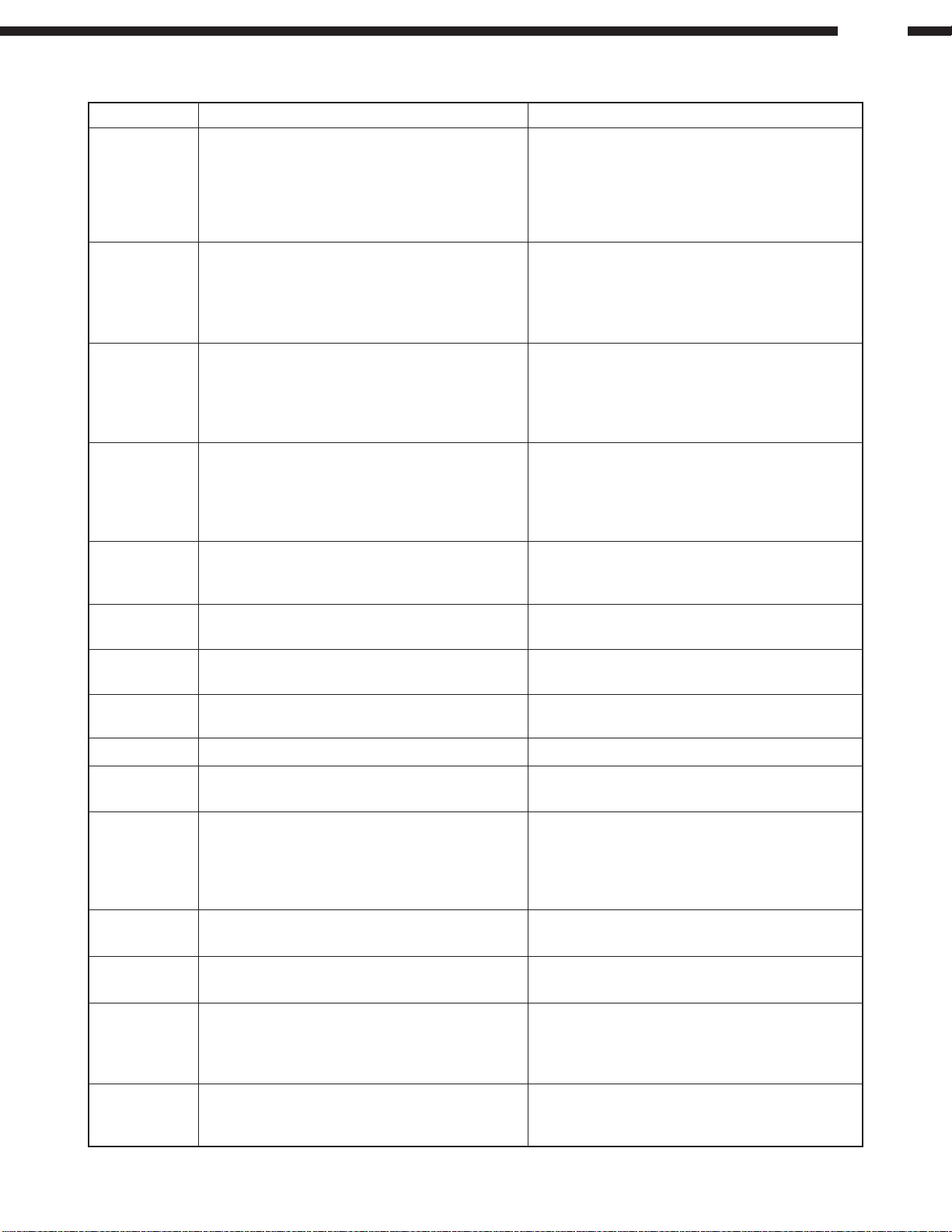

MD SECTION

Enter the test mode, adjust or set as shown in the following table according to the repair operations.

D-A03

Execution item

required

Repair

Operations

PICK replacement

HEAD replacement

MECHANISM

replacement

MAIN PWB

replacement

MD microcomputer

replacement

MD LSI

replacement

RF IC replacement

EEPROM IC

replacement

number to and indicate the order of inplementation.

1 8 9

TEMP

basic

setting

TEMP EEPROM_SET TEST-CANCEL AUTO-YOBI AUTO-ADJ AUTO-AFB TEST-CANCEL TEST-PLAY TEST-REC

1

1

1

Checking

EEPROM

setting

1

1

2

1

2

2

Writing the

EEPROM

setting

2 3 4 5 6 7 8

2

3

2

3

3

AUTO-YOBI

adjustment

"−" is an item that you don’t have to execute.

The EEPROM writing result is shown at the end of the test mode

OK_EEPROM: "SET" and "YOBI COMPLETE" were wirtten normally

WR_EEPROM: Although "SET" was written normally, it was not written in the "YOBI COMPLETE" state

Perform "AUTO-YOBI" adjustment. After making a normal adjustment.

Write the preliminary adjustment into the EEPROM.

NG_EEPROM: "SET" could not be written.

Check the connection between the MD microcomputer and the EEPROM.

AUTO-

adjustment

3 4 5 6 7 8

4 5 6 7 8 9

1 3 4 5 62

4 5 6 7 8 9

4 5 6 7 8 9

AUTO-AFB

adjustment

Writing the

EEPROM

setting

Operation check

3 42

1

1. Preparation for adjustment

Test disc

Type Test Disc

1 High reflection disc TGYS1 (SONY) for playback

2 Low reflection disc Mini disc for recording

3 Transparent disc for head alignment

2. Test Mode

Test mode setting method

1. While the CD PLAY (CD

and then MD PLAY button. (State A is changed to state B.)

2. Insert the playback-only disc 1 (high reflection disc) or the recordable disc 2 (low reflection disc).

C

(State is changed to

.)

Above procedures will set the unit to the test mode.

A

tsm 22 e : TEST MODE represents version of MD microcomputer.

STOP state

B

EJECT (When the MD STOP button is pressed in the C state, the indication A is

C

AUT AJST

) button and the TUNER button are pressed down together, press the POWER button

represents version of EEPROM data.

restored. To restore C again, press the CD PLAY (CD ) button.)

12

Entering the specific mode

Whenever the CD PLAY (CD ) button is pressed, the mode is changed.

If the REC button is pressed instead, the mode will change in the opposite order.

D-A03

(AUTO prelimiraty adjustment)

ERR DATA

(ERR DATA)

Cancel of test mode

AUT YOBI

EEPROM_SET

(EEPROM setting)

AUTO AJST

(AUTO adjustment)

MAN AFB

(MANUAL advanced

AFB adjustment)

AUT AFB

(AUTO AFB adjustment)

MNU AJST

(MANUAL AFB adjustment)

RST YOBI

(RESULT YOBI)

(MANUAL prelimiraty adjustment)

RESULT

MNU YOBI

The mode is written on EEPROM by pressing the POWER button. If the POWER button is pressed again, the unit

returns to the normal state.

* Before pressing the POWER button, make sure that the AUTO pre-adjustment, AUTO adjustment, and AUTO AFB

adjustment have been completed.

* After the value of EEPROM is changed or the AUTO pre-adjustment, AUTO adjustment, and AUTO AFB adjust-

ment are performed again, write on EEPROM by pressing the POWER button. (When the POWER button is

pressed, data is written on EEPROM.)

* When the value of EEPROM has been changed, write the data on EEPROM once. To preform adjustment using

the data, set the unit to the TEST mode again, perform AUTO pre-adjustment, AUTO adjustment, and AUTO AFB

adjustment, and then write the data again on EEPROM.

• Test mode

1. Laser Measurement Mode • To Temp Setting (EEPROM_SET)

• To Control Setting (EEPROM_SET)

• Laser power measuring (Rec/Play power)

2. Auto Adjust Mode • Performs automatic adjustment (after adjustment, grating adjust mode)

3. AFB Adjust Mode • Performs focus adjustment

RST YOBI • Not necessary in servicing, do not enter in these modes

RESULT

MNU YOBI

MNU AJST

ERR DATA

4. EEPROM Setting Mode • Changes various digital parameters manually

5. Auto Pre-adjust Mode • Performs automatic pre-adjustment

6. Test-play Mode • Performs continuous play from the address defined

• C1 error rate, ADIP error rate measurements

7. Test-rec Mode • Performs continuous recording from the address defined

1. EJECT mode

Step No. Setting Method Remarks Display

Step 1 Test mode eject status _ _ EJECT_ _ _

Step 2 Press CD STOP button Playback power output status ppw_ _ _ _ _ _ _

Step 3 Press CD STOP button Recording power output status rpw_ _ _ _ _ _ _

Step 4 Press CD STOP button Not for service, don't enter xpw_ _ _ _ _ _ _

Step 5 Press TUNER button To Temp Setting of EEPROM_SET

(Refer to Temp Setting of EEPROM)

Pickup Laser Power Check

The laser power in recording/playback can be checked with a laser power meter. However, only confirmation should be

performed as the measurement might be inconstant. Change the pickup only when it is largely out of spec.

Reference value (at the room temperature 25°C)

At playback (ppw): 0.72±0.1 mW

At recording (rpw): 5.5±0.5 mW

Note: Be careful not to stare at laser emission as your eyesight may be damaged.

13

2. AUTO pre-adjustment mode (Low reflection disc only)

Step No. Setting Method Remarks Display

Step 1 Test mode stop status tsm e

Step 2

Step 3 Press REC button Auto pre-adjust menu _AUT_YOBI_

Step 4 Press ENTER button change as follows during auto-adjust :_ _ _ _ _ _

Step 5 Grating adjustment _COMPLETE_

Step 6 Adjust value output Can’t_ADJ.

3. AUTO adjustment mode

Step No. Setting Method Remarks Display

Step 1 Test mode stop status tsm e

Step 2 Press CD PLAY button Auto adjust menu AUTO_AJST_

Step 3 Press MD PLAY button With high reflection disc, change as follows : _ _ _ _ _

Step 4 Adjust value output For grating adjustment _ COMPLETE _

Step 5 Continuous play (pit part) C1 error check s c

Step 6 Press CD STOP button ADIP error check a a

Step 7 Adjust value output Can’t_ADJ.

Press once the CD PLAY button

End of adjustment If the adjust OK, go to Step 5

Adjust value output

Press STOP button Step 3

Press STOP button Return to Step 3

: Adjustment name

End of adjustment If the adjust OK, go to Step 4

Press MD PLAY button Step 5

Press MD STOP button Step 2

Continuous play (groove part) a c

Press MD STOP button Returns to Step 2

Press MD STOP button Returns to Step 2

: Adjustment name, : Measured value, : Address

Auto adjustment menu AUTO_AJST_

HAo TCO

If the adjust NG, go to Step 6

PEG---HAG

With low reflection disc, change as follows

PEG---LAG

If the adjust NG, go to Step 7

D-A03

4. AFB Adjust Mode

Step No. Setting Method Remarks Display

Step 1 Test mode stop status tsm e

Step 2 Press CD PLAY button 2 times AFB adjust menu _AUT_AFB_

Step 3 Press MD PLAY button FAB _

Step 4 Adjust value output

Press MD STOP button Returns to Step 2

, : Measured value

14

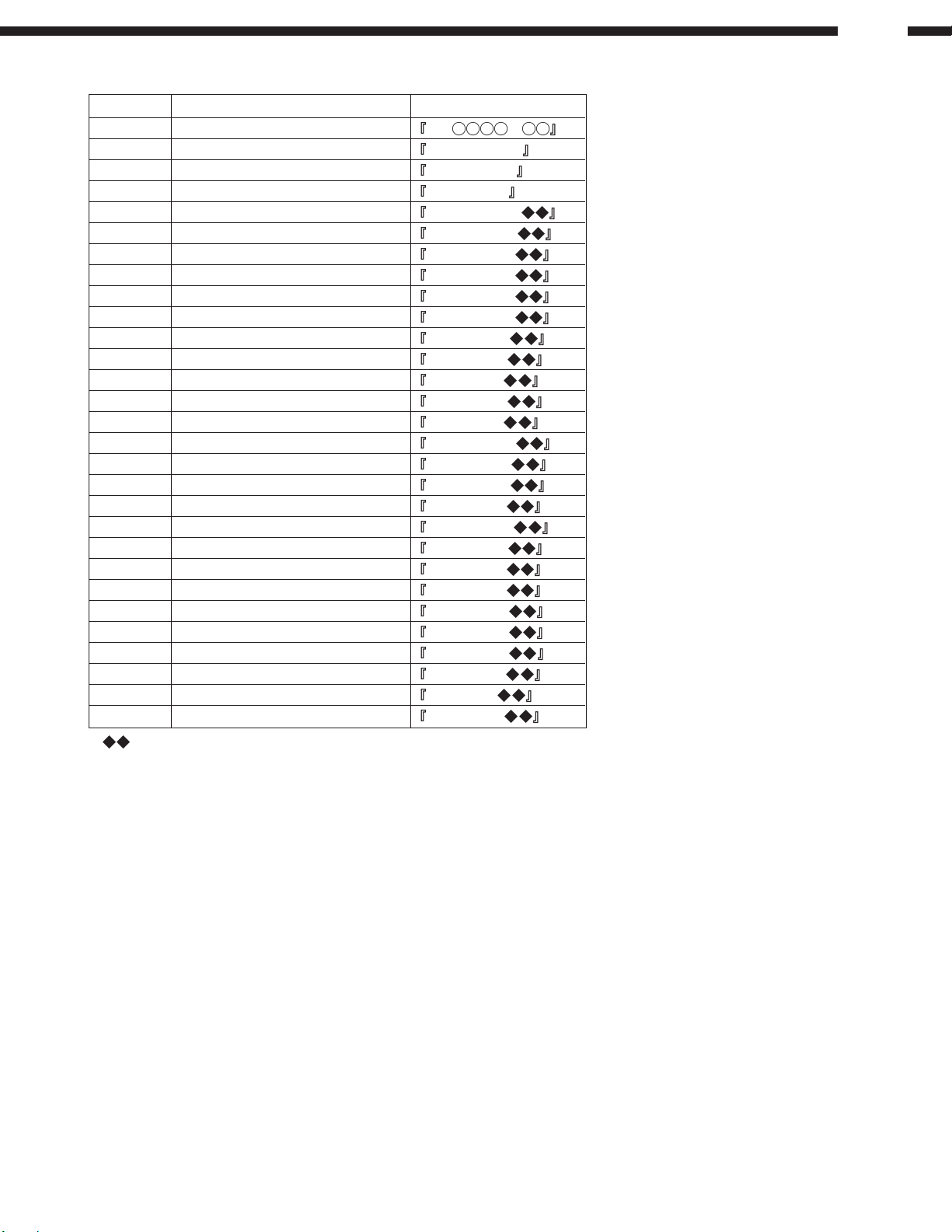

5. EEPROM Setting Mode

A) Focus Setting

Step No. Setting Method Display

Step 1 Test mode stop status tsm e

Step 2 Press CD PLAY button 8 times EEPROM_SET

Step 3 Press MD PLAY button _ _Focus_ _ _ _

Step 4 Press MD PLAY button FG _ _ _ _ _ _

Step 5 Press CD PLAY button FG2 _ _ _ _ _ _

Step 6 Press CD PLAY button FF0 _ _ _ _ _ _

Step 7 Press CD PLAY button FF1 _ _ _ _ _ _

Step 8 Press CD PLAY button FF2 _ _ _ _ _ _

Step 9 Press CD PLAY button FZHLEV _ _

Step 10 Press CD PLAY button FOKLEVh _

Step 11 Press CD PLAY button FOKLEVL _

Step 12 Press CD PLAY button FOSTn_ _ _

Step 13 Press CD PLAY button DSCJG_ _ _

: Setting value

D-A03

B) Spindle Setting

Step No. Setting Method Display

Step 1 Test mode stop status tsm e

Step 2 Press CD PLAY button 8 times EEPROM_SET

Step 3 Press MD PLAY button _ _Focus_ _ _ _

Step 4 Press CD PLAY button 1 time _ _ Spindle _ _ _

Step 5 Press MD PLAY button SPG _ _ _ _ _ _

Step 6 Press CD PLAY button SPG _ _ in _ _ _

Step 7 Press CD PLAY button SPG _ _ mid _ _

Step 8 Press CD PLAY button SPG _ _ out _ _

Step 9 Press CD PLAY button SPGM _ _ _ _

Step 10 Press CD PLAY button SP1 _ _ _ _ _

Step 11 Press CD PLAY button SP2 _ _ _ _ _

Step 12 Press CD PLAY button SP22 _ _ _ _

Step 13 Press CD PLAY button SP3 _ _ _ _ _

Step 14 Press CD PLAY button SP4 _ _ _ _ _

Step 15 Press CD PLAY button SP5 _ _ _ _ _

Step 16 Press CD PLAY button SP52 _ _ _ _

Step 17 Press CD PLAY button SPDLIM _ _

Step 18 Press CD PLAY button SPKLEVm _

: Setting value

15

C) Tracking Setting

Step No. Setting Method Display

Step 1 Test mode stop status tsm e

Step 2 Press CD PLAY button 8 times EEPROM_SET

Step 3 Press MD PLAY button _ _Focus_ _ _

Step 4 Press CD PLAY button 2 times _ Tracking _

Step 5 Press MD PLAY button TG _ _ _ _ _ _

Step 6 Press CD PLAY button TG2 _ _ _ _ _

Step 7 Press CD PLAY button TF0 _ _ _ _ _

Step 8 Press CD PLAY button TF1 _ _ _ _ _

Step 9 Press CD PLAY button TF2 _ _ _ _ _

Step 10 Press CD PLAY button FT3 _ _ _ _ _

Step 11 Press CD PLAY button SVCNT4 _ _

Step 12 Press CD PLAY button TRBLVo _ _

Step 13 Press CD PLAY button TRBLVt _ _

Step 14 Press CD PLAY button TRKLVo _ _

Step 15 Press CD PLAY button TRKLVt _ _

Step 16 Press CD PLAY button TDPWo _ _ _

Step 17 Press CD PLAY button TDPWt _ _ _

Step 18 Press CD PLAY button SLCTo _ _ _

Step 19 Press CD PLAY button SLCTt _ _ _

Step 20 Press CD PLAY button SLCTm _ _ _

Step 21 Press CD PLAY button TCRSC1P _

Step 22 Press CD PLAY button TCRSC0h _

Step 23 Press CD PLAY button TCRSC0L _

Step 24 Press CD PLAY button TCRSCHh _

Step 25 Press CD PLAY button TCRSCHL _

Step 26 Press CD PLAY button COTLVp _ _

Step 27 Press CD PLAY button COTLVr _ _

Step 28 Press CD PLAY button JPint _ _ _

Step 29 Press CD PLAY button KIK10 _ _ _

: Setting value

D-A03

16

D) Slide Setting

Step No. Setting Method Display

Step 1 Test mode stop status tsm e

Step 2 Press CD PLAY button 8 times EEPROM_SET

Step 3 Press MD PLAY button _ _Focus_ _ _ _

Step 4 Press CD PLAY button 3 times _ _ _ Sled _ _ _

Step 5 Press MD PLAY button SLG _ _ _ _ _

Step 6 Press CD PLAY button SL2 _ _ _ _ _

Step 7 Press CD PLAY button SLDLIM _ _

Step 8 Press CD PLAY button SLDLEV _ _

Step 9 Press CD PLAY button SLKLVk _ _

Step 10 Press CD PLAY button SLKLVt _ _

Step 11 Press CD PLAY button SLKLVm _ _

Step 12 Press CD PLAY button SLBKm _ _ _

Step 13 Press CD PLAY button SLKrio _ _

Step 14 Press CD PLAY button SLKroi _ _

Step 15 Press CD PLAY button SLKlio _ _

Step 16 Press CD PLAY button SLKloi _ _

Step 17 Press CD PLAY button INNER1 _ _

Step 18 Press CD PLAY button INNERu _ _

Step 19 Press CD PLAY button EJ _ WAIT _

: Setting value

E) Temp Setting

Step No. Setting Method Display

Step 1 Eject status (or without Mecha.) _ _ EJECT_ _ _

Step 2 Press TUNER button TEMP_ _

: Setting value, : Measured value

F) Control Setting

Step No. Setting Method Display

Step 1 Test mode stop status tsm e

Step 2 Press CD PLAY button 8 times EEPROM_SET

Step 3 Press MD PLAY button _ _Focus_ _ _

Step 4 Press CD PLAY button 5 times _ Control _ _

Step 5 Press MD PLAY button CONTRL1 _

Step 6 Press CD PLAY button CONTRL2 _

Step 7 Press CD PLAY button ADJTTM _ _

Step 8 Press CD PLAY button HDEQAD _ _

Step 9 Press CD PLAY button LDEQAD _ _

Step 10 Press CD PLAY button GDEQAD _ _

Step 11 Press CD PLAY button GDEQAD2 _

Step 12 Press CD PLAY button HDEQBC _ _

Step 13 Press CD PLAY button LDEQBC _ _

Step 14 Press CD PLAY button GDEQBC _ _

Step 15 Press CD PLAY button GDEQBC2 _

Step 16 Press CD PLAY button HALSG_ _ _

Step 17 Press CD PLAY button LALSG_ _ _

Step 18 Press CD PLAY button GALSG_ _ _

Step 19 Press CD PLAY button HALSOFS _ _

Step 20 Press CD PLAY button LALSOFS _ _

Step 21 Press CD PLAY button GALSOFS _ _

: Setting value

D-A03

17

G) Adjust Setting

Step No. Setting Method Display

Step 1 Test mode stop status tsm e

Step 2 Press CD PLAY button 8 times EEPROM_SET

Step 3 Press MD PLAY button _ _Focus_ _ _

Step 4 Press CD PLAY button 6 times ADJSET _ _ _ _

Step 5 Press MD PLAY button COK _ _ _ _ _

Step 6 Press CD PLAY button FAT _ _ _ _ _

Step 7 Press CD PLAY button TAT _ _ _ _ _

Step 8 Press CD PLAY button CAT _ _ _ _ _

Step 9 Press CD PLAY button FAB _ _ _ _ _

Step 10 Press CD PLAY button STR _ _ _ _ _

Step 11 Press CD PLAY button SFS _ _ _ _ _

Step 12 Press CD PLAY button STC _ _ _ _ _

: Setting value

H) REC bit setting

Step No. Setting Method Display

Step 1 Test mode stop status tsm e

Step 2 Press CD PLAY button 8 times EEPROM_SET

Step 3 Press MD PLAY button _ _Focus_ _ _

Step 4 Press CD PLAY button 7 times RECbit _ SET

Step 5 Press MD PLAY button SP _ WR50 _

Step 6 Press CD PLAY button SP _ WR56 _

Step 7 Press CD PLAY button SP _ WR44 _

Step 8 Press CD PLAY button SP _ WR53 _

Step 9 Press CD PLAY button LP2WR50 _

Step 10 Press CD PLAY button LP2WR56 _

Step 11 Press CD PLAY button LP2WR44 _

Step 12 Press CD PLAY button LP2WR53 _

Step 13 Press CD PLAY button LP4WR50 _

Step 14 Press CD PLAY button LP4WR56 _

Step 15 Press CD PLAY button LP4WR44 _

Step 16 Press CD PLAY button LP4WR53 _

Step 17 Press CD PLAY button RVD _ _ _ _

: Setting value

D-A03

18

6. Test-play Mode (For checking playback performance at the address defined.)

Step No. Setting Method Remarks Display

Step 1 Test mode stop status tsm e

Step 2 Press TUNER button Test-play menu TEST_PLAY_

Step 3 Press CD STOP button Address setting (displays address initial value) ADRES_0032

Press MD PLAY button

Step 4 Continuous play (pit part) (Address + C1 error display) s c

Continuous play (groove part) (Address + C1 error display) a c

Step 5 Press CD STOP button (Address + ADIP error display) a a

Continuous play (groove part)

Step 6 Press MD STOP button Test-play menu TEST_PLAY_

7. Test-rec Mode

Use a disc for recording function check. (For checking recording performance at the address defined.)

Step No. Setting Method Remarks Display

Step 1 Test mode stop status tsm e

Step 2 Press TUNER button 2 times Test-rec menu TEST_REC_

Step 3 Press CD STOP button Address setting (displays address initial value) a0032_pw

Step 4 Press MD PLAY button Continuous recording a pw

Step 5 Press MD STOP button Test-rec menu TEST_REC_ _

D-A03

19

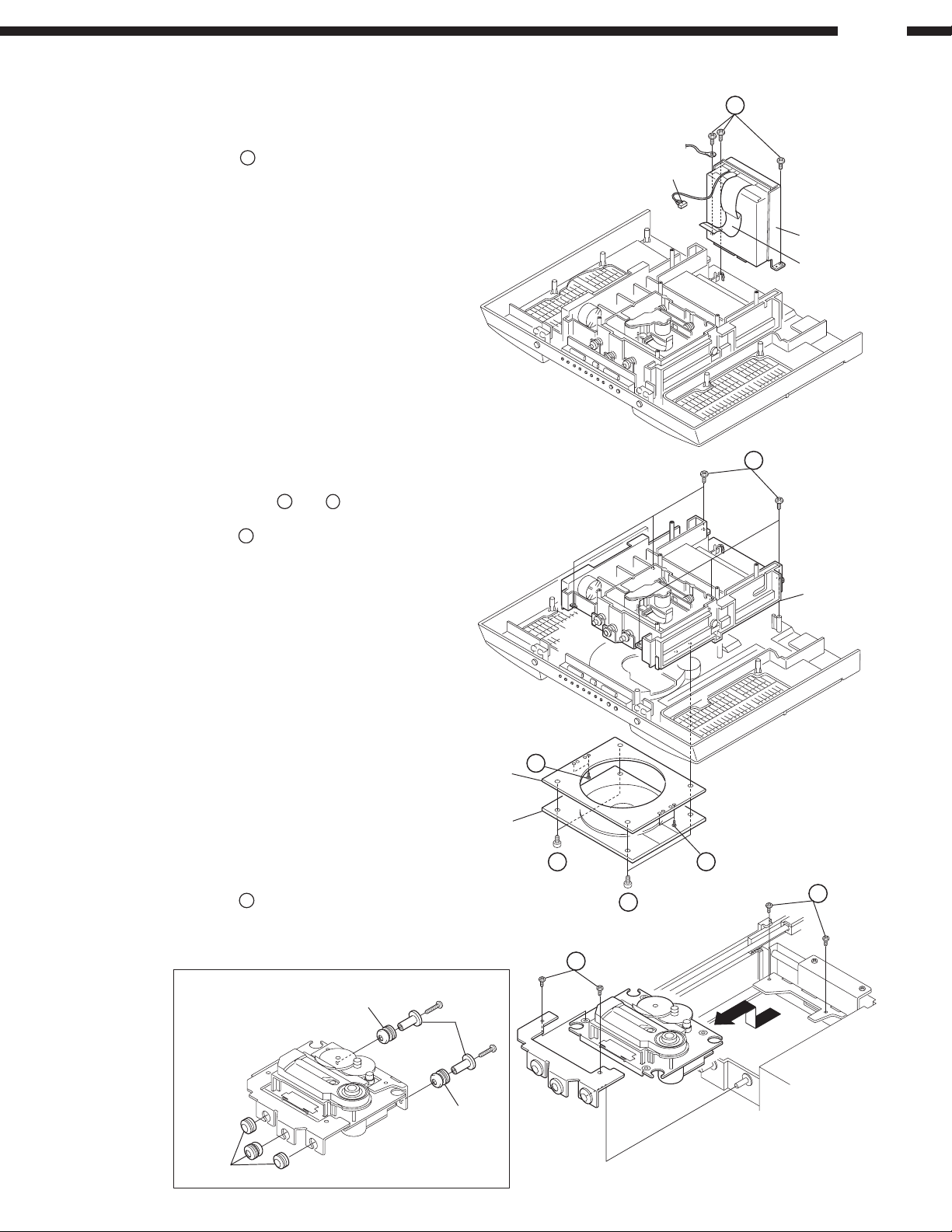

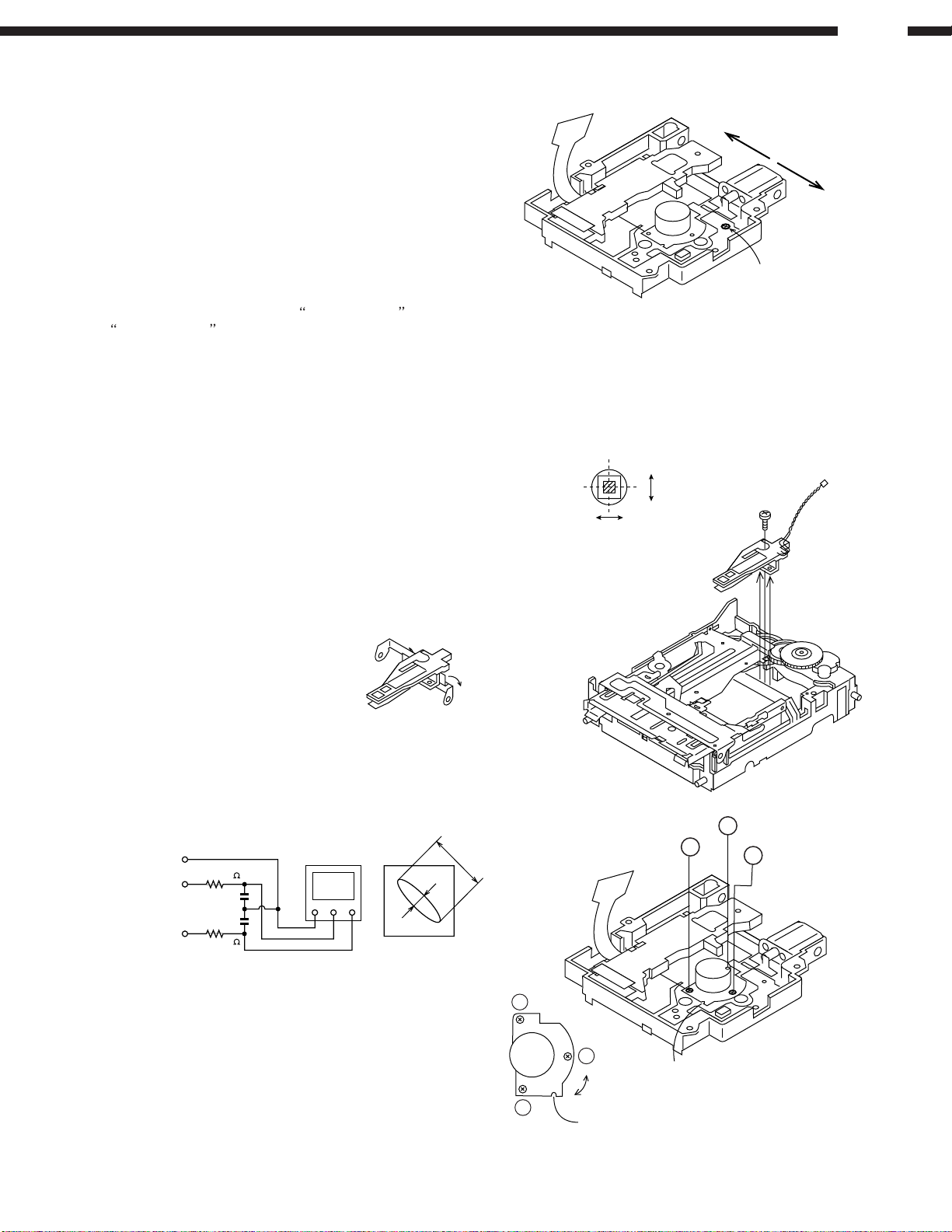

Lead-in SW Position Measurement Mode

1. Adjustment

Load the high reflection test disc TGYS1.

Note: Adjust the lead-in switch position to FF85 ~ FFD2.

1. Loosen 1 screw (A1) fixing the Mecha. SW P.W.B.

2. Loosen the screw once and retighten it with pushing the

P.W.B. to the A direction if the lead-in switch position is

less than FF85 before loosening the screw, or with

pushing to the B direction if the position is more than

FFD2.

Then measure the lead-in switch position again, and

tighten the screw (A1) firmly if it's within the spec.

2. Confirmation

Check that the display shows

_COMPLETE_ instead of

#COMPLETE_ in step 4 of the AUTO adjustment mode.

• Rotating the loading motor forcibly

The loading motor can be rotated forcibly by rotating the VOL

UP/DOWN button while STOP or EJECT in the test mode

appears on the display

Magnetic Head Mounting Position Check

• Check the mounting position of the magnetic head

without fail when replacing the head or optical pickup.

• To adjust the mounting position easier, move the optical

pickup to the center position beforehand.

Object Lens

D-A03

A

B

(A1) × 1

Magnetic Head

Tangential Direction

1. Load the transparent test disc for head alignment.

2. Lower the magnetic head up-shift arm manually to lift up

the magnetic head.

3. View the unit from the above and check that the object

lens of the pickup aligns with the magnetic head.

4. Check whether the magnetic head moves up or down

smoothly.

Mechanism Adjustment

• How to check optical pickup grating

IC1201 4pin

(GND) (TP1202)

IC1201 11pin

(EOUT)

IC1201 12pin

(FOUT)

100k

470p

470p

100k

Oscilloscope

GND CH1 CH2

XY

Lissajous Wave-form

(a:b=4:1 or less)

b

Lower with finger

a

Radial Direction

2

3

1

Optical Pickup Grating Deviation Measuring Method

Adjust the Lissajous Wave-form (x-y) of EOUT against FOUT

after performing automatic adjustment at Auto Adjust Mode

(COMPLETE indication) using the high reflection test disc.

1. Loosen 3 screws fixing the spindle motor a little, and

adjust with watching the Lissajous Wave-form.

2. Tighten the screws in the order 1, 2, and 3 after the

adjustment.

2

1

Slide the mounting position of

the spindle motor with inserting

3

Adjusting

Cutout

a screwdriver etc. in the

adjusting cutout, and check the

Lissajous Wave-form.

20

Detailed Description of Error Indication

Error Indication Content of Error Remedy

Can't REC

DEFECT occured continuously for 10 times during

REC-PLAY

Record enable cluster become 0 due to DEFECT

occurrence during REC-PLAY.

Unable to read address. However repeating try, unable

to enter REC mode in 20 seconds.

Is there any scratch, dust, finger print, black spot, etc. on

the disc? Check for eccentricity, warp, etc. of disc.

D-A03

Can't COPY

NO SIGNAL

TOC FULL

Can't u READ

TOC FROM a

TOC FROM L0~4

NOT AUDIO

With the channel status of input digital signal from D-IN

during REC-PAUSE or RE-PLAY, it is judged as follows.

(1) Except audio.

(2) Except public use.

(3) Copy NG by reverse of CD COPY bit.

Becomes as follows against the digital signal input from

D-IN during REC-PAUSE, REC-PLAY or CD FUNC

playback.

(1) Digital IN PLL is UNLOCKED.

(2) Locked other than FS=44.1 kHz

No registering area for character information. (music

name, disc name, etc..)

No recording area in UTOC remained when entering

REC-PAUSE.

No remaining program area for music data.

FTNO > LTNO.

FTNO ≠ 0 or 1.

Unable to read UTOC recorded on the disc.

Start address > End address when TOC read. Replace with the other disc as abnormality exists in data

One of UTOC 0~4 data is looped when TOC read. Replace with the other disc as abnormality exists in data

Other than audio data is recorded in TNO track mode

with oresently selected music.

Check if the copy inhibit.

(Example: CD-R, etc.)

Check for abnormality in D-IN signal line.

Replace with another disc having record area remained.

Replace with the other disc as abnormality exists in data

of UTOC.

of UTOC.

of UTOC.

Select other TNO or replace with other disc.

? DISC

DISC FULL

PROTECTED

Can't EDIT

TEMP OVER

Can't r READ ∗

(∗ is the symbol of

number)

Can't READ s

Can't READ r

Not a MD format disc is inserted. Out of spec disc, replace with others and check.

When entering REC-PAUSE or edit, found that the disc

is for playback only.

Attempted to record or edit as the mis-erasure

preventive knob of REC/PLAY disc set to preventive

position.

Attempted to edit the write protect track by information

written in UTOC.

At each edit function, editing conditions are not satisfied. Operating method is wroug. Try it again with correct

The temperature inside (MD unit) is too high due to

abnormality.

As a result of reading data, the data is not correct.

Unable to read correctly.

As abnormality occurred while recording music data,

unable to perform correct recording.

Attempted to read TOC, but couldn’t.

As a result of reading TOC, data is not correct.

As the disc is playback only, replace with a recording

disc.

Set the mis-erasure preventive knob back to the former

position and retry.

As the track attempted to edit is write protect, try it in the

other track.

manner.

Check according to the troubleshooting.

Avoid using in a high temperature.

Abnormality in data of TOC, UTOC, disc scratch, etc.

Replace with the other disc.

TOC information recorded on disc is not met with the MD

spec requirement. Replace with the other disc.

Scratch, etc. on the disc, Replace with the other disc.

21

Loading...

Loading...