Hi-Fi Personal Component System

SERVICE MANUAL

For U.S. & Canada model

MODEL

D-107

PERSONAL AUDIO SYSTEM

Some illustrations using in this service manual are slightly different from the actual set.

16-11, YUSHIMA 3-CHOME, BUNKYOU-KU, TOKYO 113-0034 JAPAN

Telephone: 03 (3837) 5321

X0133 205 NC 0112

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

SPECIFICATIONS

Amplifier Section

Practical maximum output: Satellite: 25W + 25W (6Ω/ohms, 1kHz, T.H.D. 0.9%)

Receiver Section

Audio input/output jacks: AUX input/output jacks, Optical digital out jacks

Receive frequency bands: FM: 87.50MHz to 108.00MHz

Receive sensitivity: FM: 1.5µV/75Ω/ohms

FM stereo separation: 35 dB (1 kHz)

Subwoofer: 50W (12Ω/ohms, 100Hz, T.H.D. 0.9%)

AM: 520kHz to 1710kHz

AM: 20µV

D-107

CD Section

Wow and flutter: Below measurement limits (±0.001% W peak)

Sampling frequency: 44.1kHz

Light source: Semiconductor laser

Clock and Timer Section

Clock: Crystal oscillation synchronizing system

Timers: Everyday timer (1 setting)

Common Section

Power supply: 80W

Power consumption: (In the standby mode: 1.5W or less when the eco-mode is set, 20W normally)

Maximum external dimensions: D107: 204 (W) × 293 (H) × 157 (D) mm (Including stand)

Mass: D-107: 2.6kg (5lbs 11.7oz)

(Within one minute per month)

Once timer (1 setting)

Sleep timer (maximum 60 min.)

(8-1/32″ × 11-17/32″ × 6-3/16″)

* With stand removed 204 (W) × 267 (H) × 82 (D) mm

(8-1/32″ × 10-33/64″ × 3-15/64″)

USC-107: 162 (W) × 293 (H) × 149 (D) mm (Including stand)

(6-3/8″ × 11-17/32″ × 5-55/64″)

* With stand removed 162 (W) × 267 (H) × 72 (D) mm

(6-3/8″ × 10-33/64″ × 2-53/64″)

USW-107: 447 (W) × 210 (H) × 205 (D) mm (Including net)

(17-19/32″ × 8-17/64″ × 8-5/64″)

USC-107: 1.4kg (3lbs 1.74oz) (each)

USW-107: 7.9kg (17lbs 6.7oz)

Remote Control (RC-909)

Remote control system: Infrared pulse

Power supply: 3V DC (using two R03/AAA type batteries)

Maximum external dimensions: 48 (W) × 210 (H) × 29 (D) mm

(1-57/64″ × 8-17/64″ × 1-9/64″)

Mass: 120g (4.2oz) (including batteries)

* For improvement purposes, specifications and functions are subject to change without advanced notice.

2

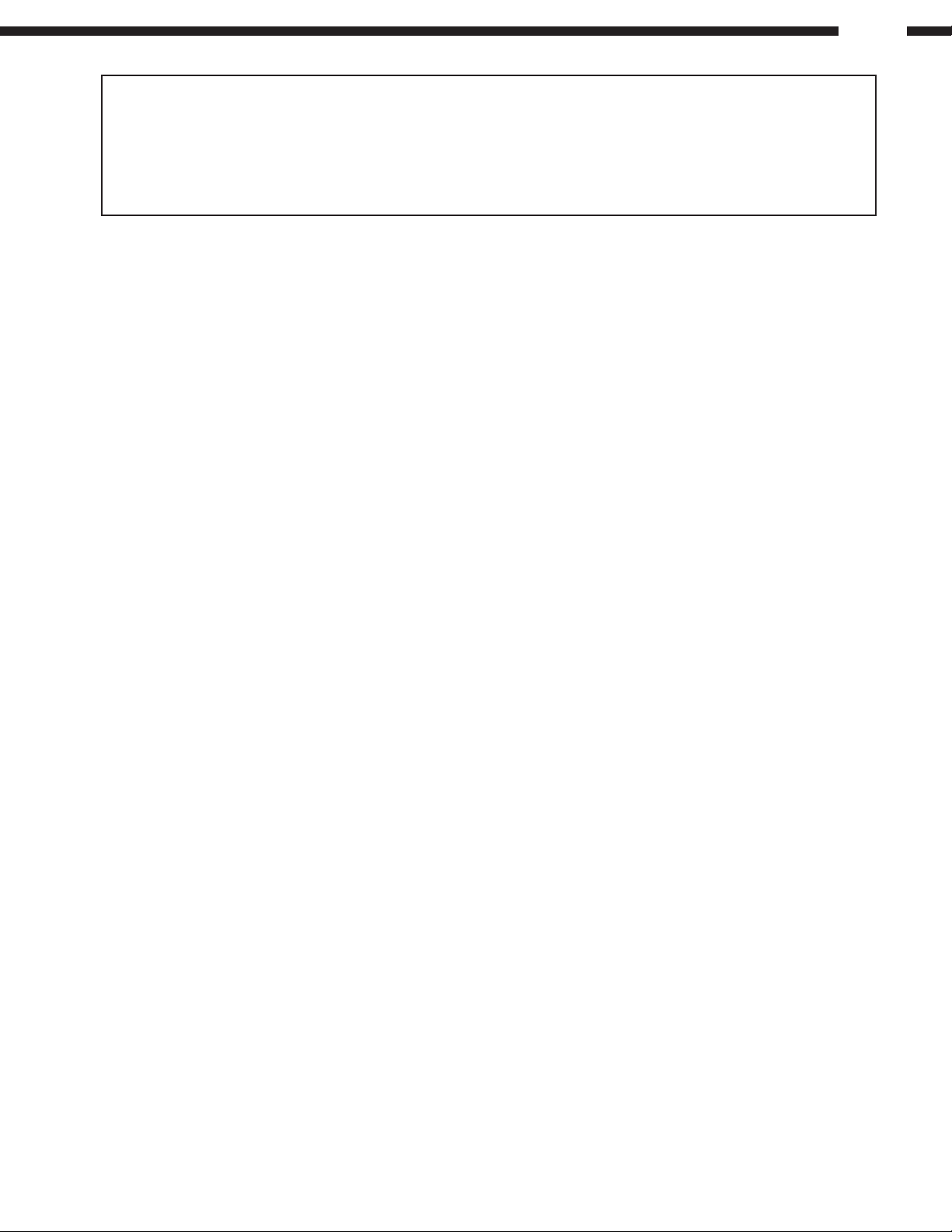

DISASSEMBLY

(Follow the procedure below in reverse order when reassembling)

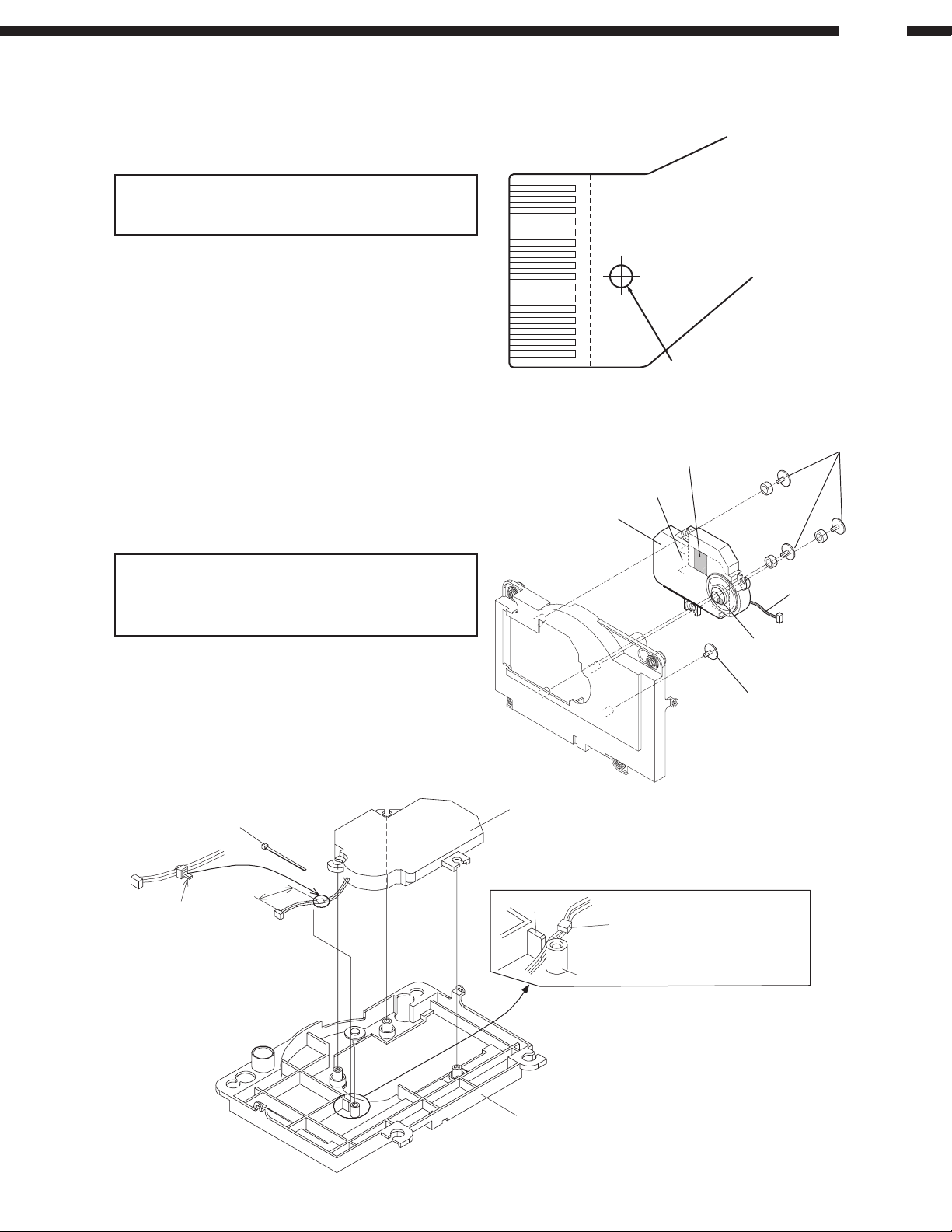

Note:This system has a feature to back-up various settings such as function selected, volume level, etc. By performing

disassembly or checking of the system, this back-up function can be a cause of error, and the system may not work

normally when power on after re-assembling.

To avoid this error, short-circuit both leads (+ and - terminals) of C110 on 1U-3398-1 (Main PWB) for more than 60

sec., and check that the voltage between the terminals is lowered less than 1V before re-assembling. (The back-up

function is deactivated and various settings are reset to factory settings, default values, if short-circuited.)

D-107

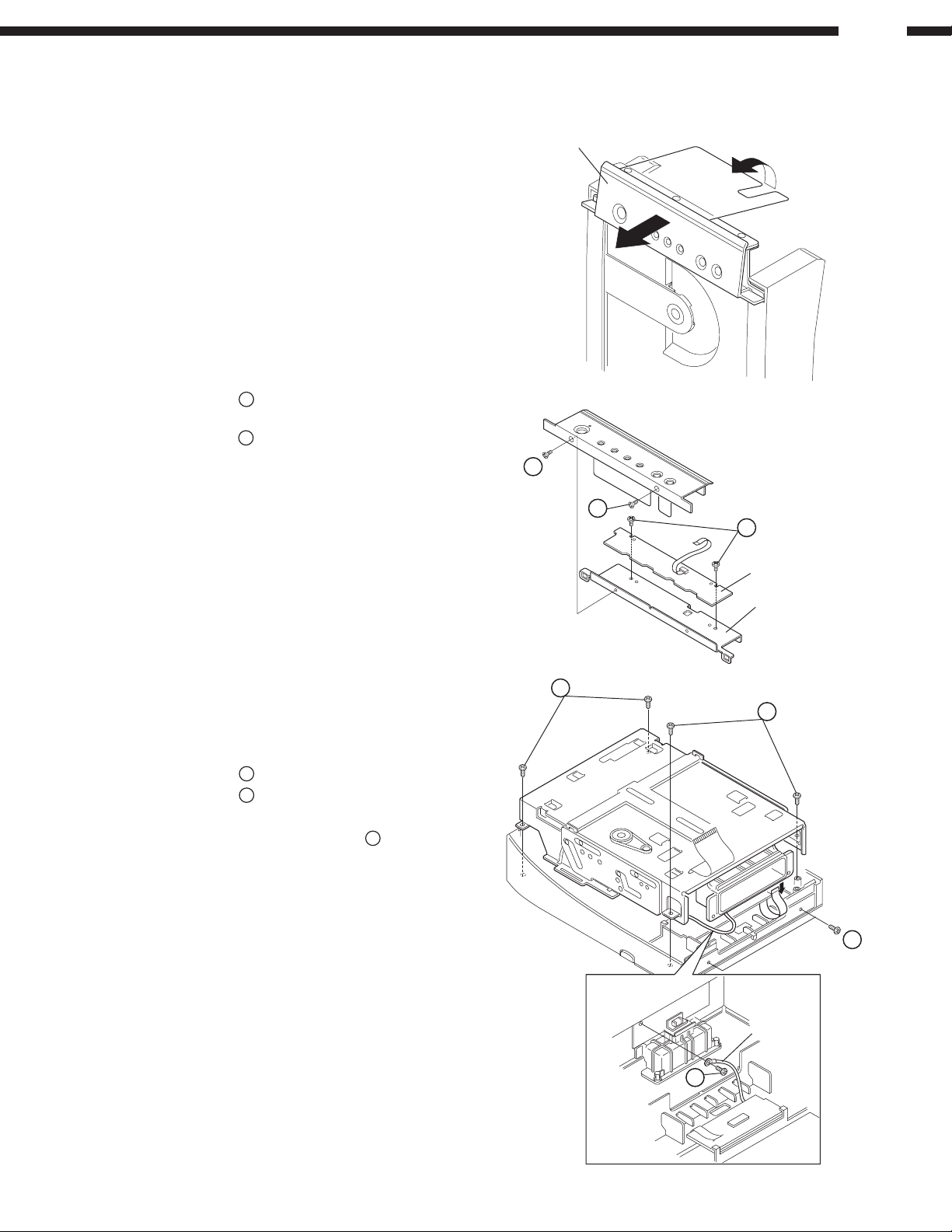

1. Rear Panel

1) Remove 4 screws 1 to detach the Stand Bracket.

2) Remove 3 screws

3) Lift up bottom end of the Rear Panel and disconnect

the cable

A

2

and 2 screws 3 on the Rear Panel.

.

1

2

3

3

4) Open the Rear Panel, and solder the Shorting Land on

the PWB to short-circuit.

Note:The Shorting Land must be short-circuited to

protect laser diode of the optical pick-up. Be sure

to short-circuit before disconnecting the cable

B

Also, remove solder on the Shorting Land after

inserting the cable

5) Disconnect 3 cables

B

.

B, C, D

.

.

A

Cable

B

Cable

C

Cable

D

Cable

3

D-107

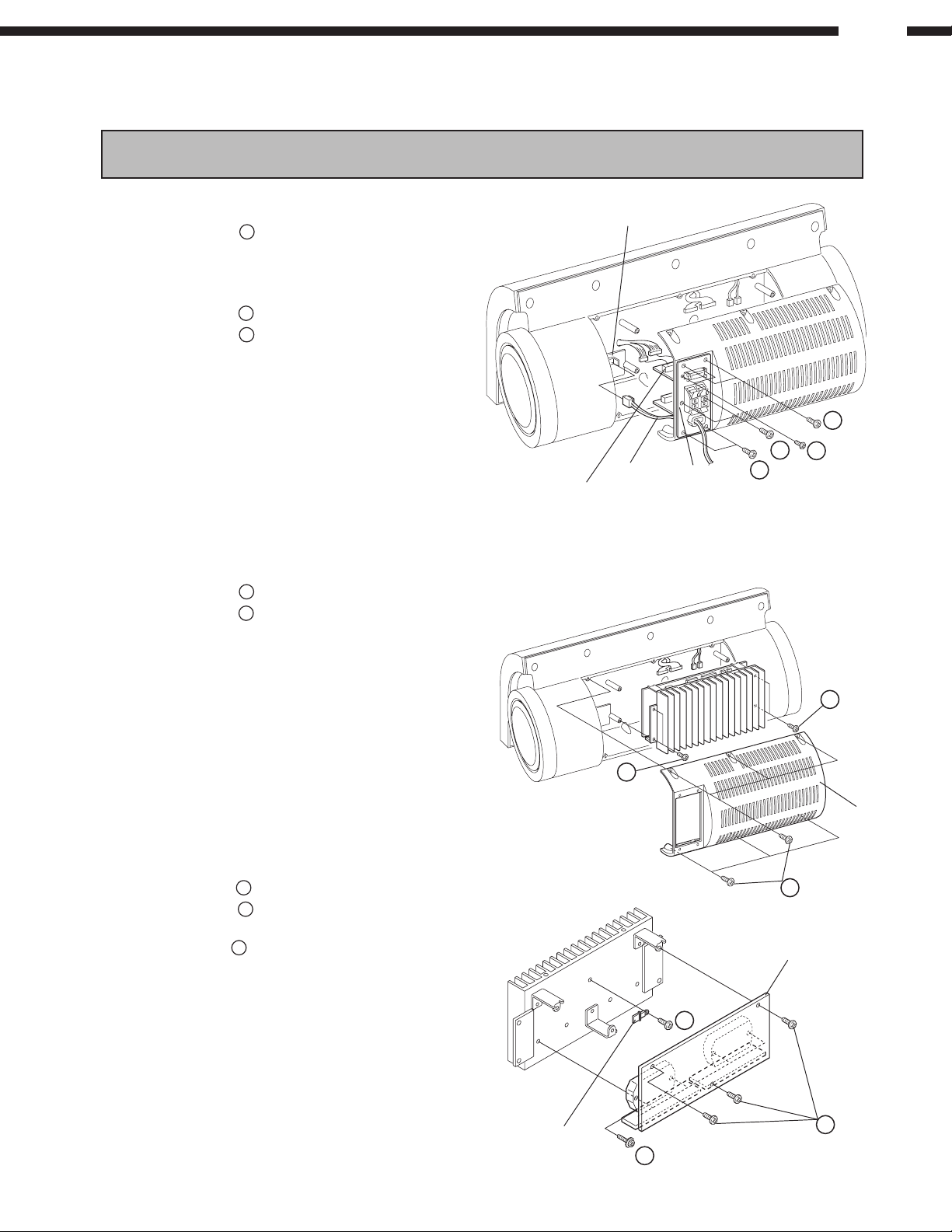

2. Main P.W.B.

1) Disconnect connector A and cable E.

2) Remove 4 screws

4

.

3. I/O P.W.B.

1) Remove 2 screws 5.

Cable

4

E

4

Connector

4

A

4

5

I/O P.W.B.

5

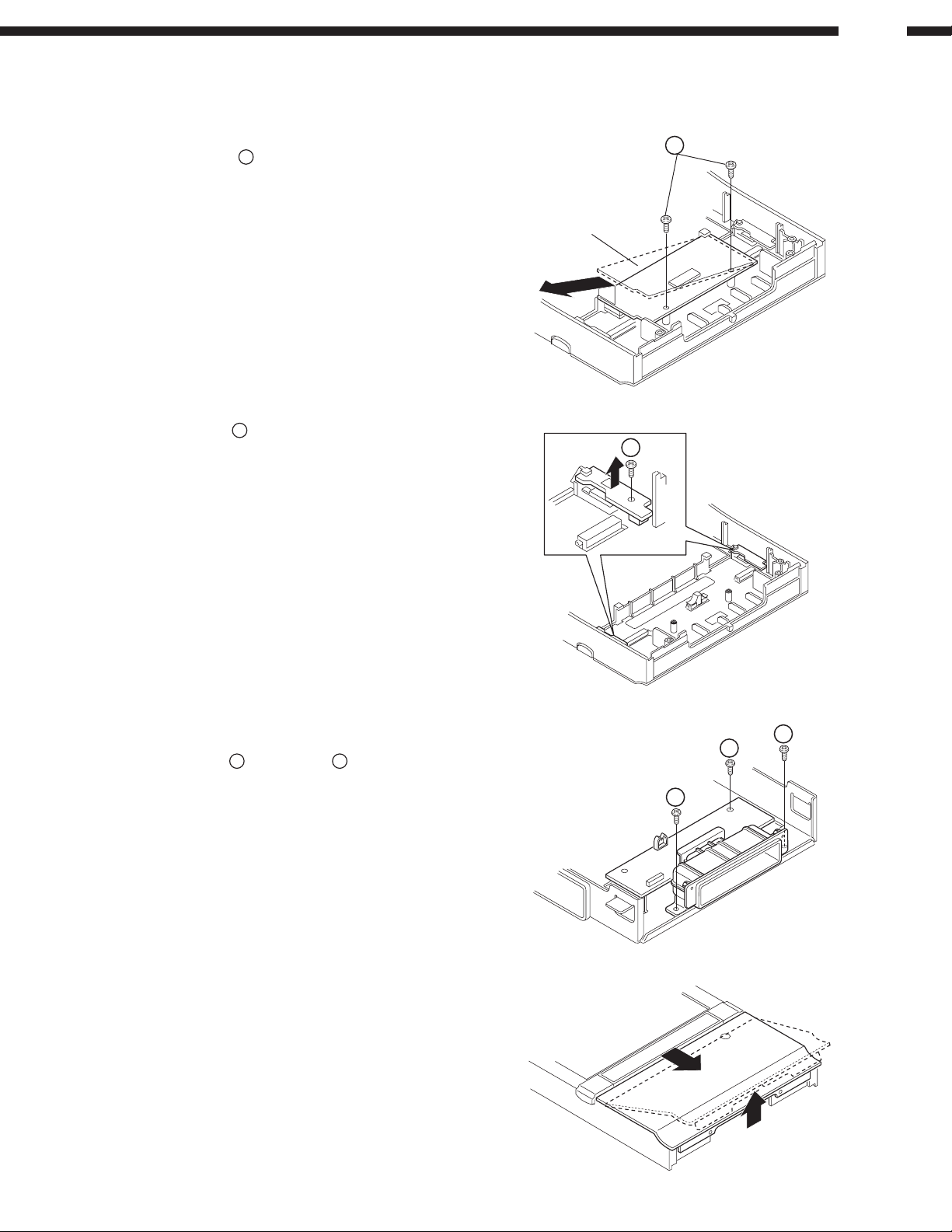

4. Door Panel

1) Turn the pulley counter-clockwise to open the Door

about 10mm horizontally.

Note:Be careful not to disengage or twist the belt.

6

2) Remove 2 screws

direction.

Note:In order not to scratch the silver part of the display

window, cover its surface with a thin sheet

beforehand.

, and detach by lifting in the arrow

10mm

Belt

6

4

D-107

5. Top Panel

1) Open rear of the Top Panel in the arrow direction (A).

2) Pull it out horizontally as shown in the arrow direction (B).

6. Control P.W.B.

1) Remove 2 screws 7 to separate the Top Panel and Tact

Knob Bracket.

2) Remove 2 screws 8.

Top Panel

7

(A)

(B)

7

8

Control P.W.B.

7. Mecha. Unit

1) Remove 4 screws 9.

2) Remove 2 screws

3) Lift up the Mecha. and disconnect the cable.

4) Open the Mecha. and remove 1 screw

.

fixing the wire.

Tact Knob Bracket

9

9

Wire

5

D-107

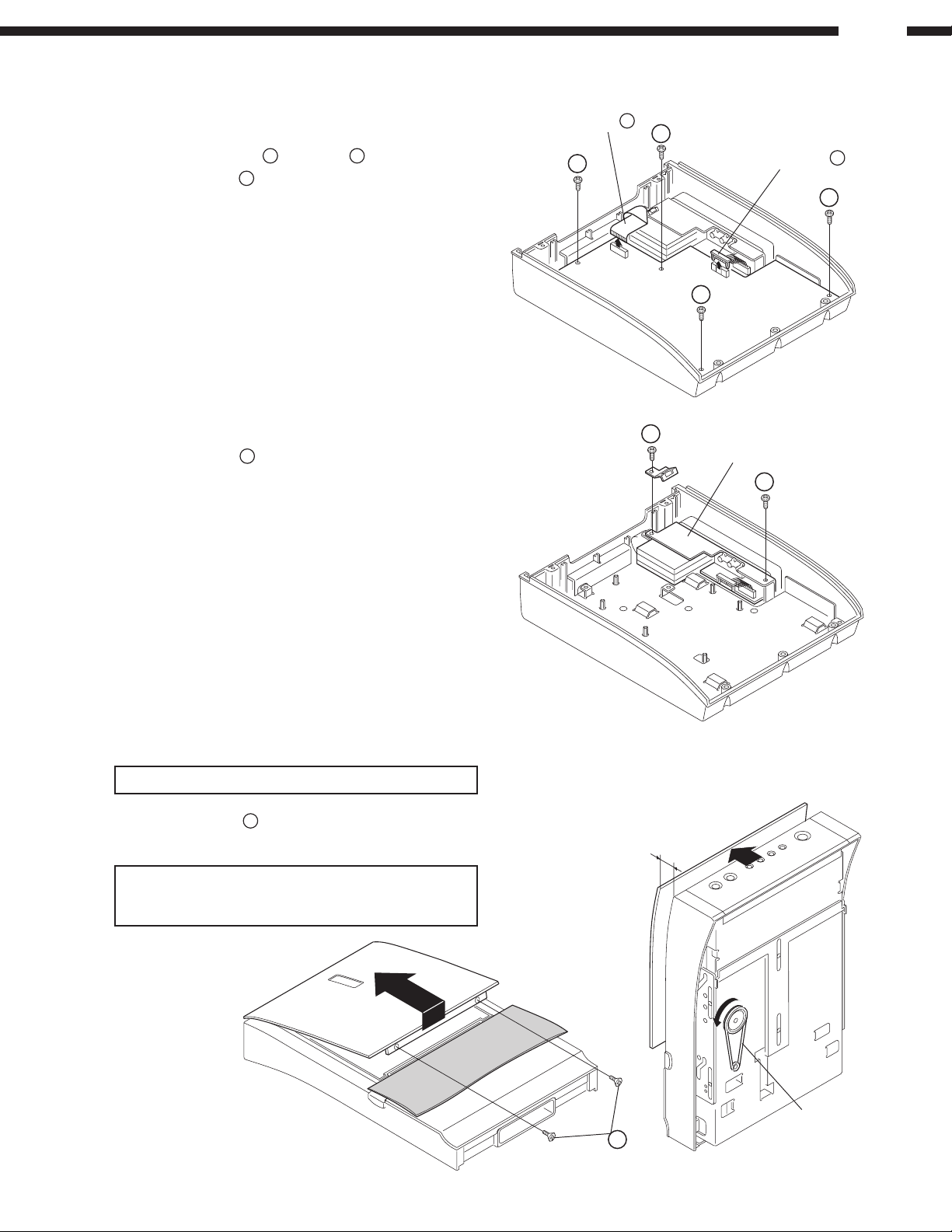

8. Display P.W.B.

1) Remove 2 screws .

2) Detach the P.W.B. with lifting as shown and sliding in the

arrow direction.

9. OP/CL SW P.W.B., Play P.W.B.

1) Remove 1 screw !.

2) Detach the P.W.B. by moving to the arrow direction.

(The same for the other P.W.B., right and left symmetrical.)

Display P.W.B.

!

10. Interface P.W.B.

1) Remove 1 screw " and 2 screws #, and release the wire

from its clamper.

11. Front Panel

1) Move the Front Panel to the arrow direction (A).

2) Detach the Front Panel with lifting its bottom and sliding in

the arrow direction (B).

"

#

#

(A)

(B)

6

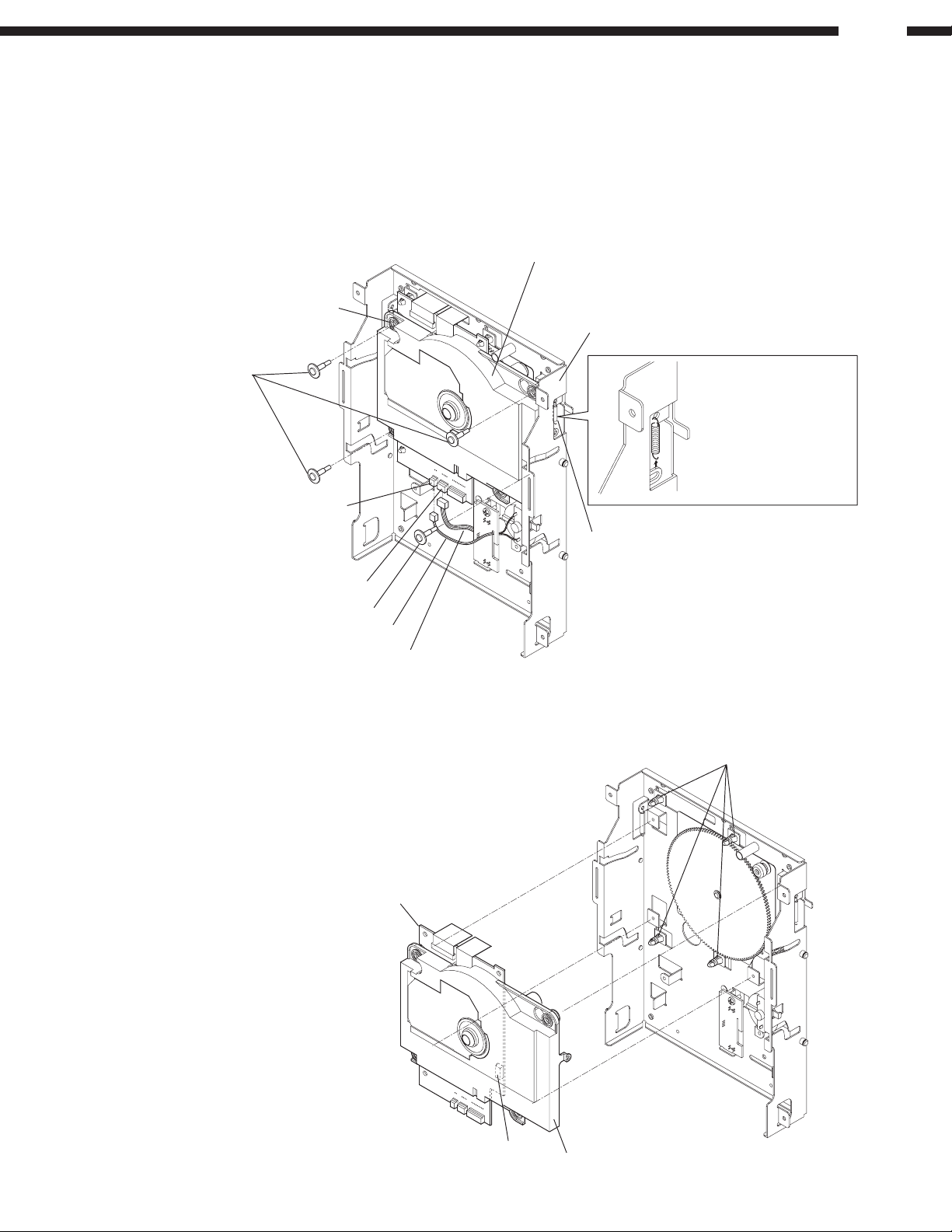

TR MECHA SUB ASS'Y DISASSEMBLY

1. Remove 4 Cut Washers and 2 Slide

Cams on both sides of the Mecha.

Slide Cam

Cut Washer

D-107

Slide Cam

Cut Washer

2. Disconnect 10P ZH-ZH Connector Cord from CX101, then

detach the Door Ass’y.

Note:When re-assembling Door Ass'y, align the groove

on Door Shaft P with the slit of Mecha Chassis

respectively.

Door Shaft P

CX101

10P ZH-ZH Conn. Cord

Door Ass'y

7

3-1. Disengage one each side of 2 TR Springs. Only TR

Holder side, don’t disengage Mecha Chassis side.

3-2. Disconnect 2P ZR Connector Cord from CX021, and

4P ZH-ZH Connector Cord from CX042.

3-3. Remove 4 pcs of Special Screw fixing the TR Holder.

TR Spring

Special Screw

D-107

TR Holder

Mecha Chassis

Disengage TR Holder

side (lower hook) only

CX021

CX042

Special Screw

2P ZR Conn. Cord

4P ZH-ZH Conn. Cord

4-1. Release 4 PWB Holders for IF Unit.

4-2. Detach IF Unit and TR Holder from the Mecha.

4-3. Disconnect 6P Wire of CD Traverse from CX064.

IF Unit

TR Spring

P.W.B. Holder (H=6.35)

CX064

TR Holder

8

5. Short-circuit the Shorting Land on FPC of TR Mecha Sub

Ass'y by soldering on the pattern.

D-107

Note:Be sure to short-circuit while FPC is still connected

with IF Unit. Also, remove solder on the Shorting

Land after connecting it with IF Unit.

6-1. Detach FPC of TR Mecha Sub Ass'y from IF Unit, then

disconnect it from CX162.

6-2. Remove 4 pcs of 2.6×6 Screw on the back of the TR

Holder, then detach the TR Mecha Sub Ass'y.

Note:When re-assembling the TR Mecha Sub Ass'y, tie

6P wire with a wire clamper and position it between

boss and rib as shown below, then fix with 2.6×6

Screw(p)-Z.

Pick-up

SF-P200R FPC

Seen from the

pattern side

Shorting Land

2.6×6 Screw(P)-Z

FPC

FPC

TR Mecha Sub Ass'y

6P Wire

Short Patter

Wire Clamper

Uncut length: 1~2mm

2.6×6 Screw(P)-Z

TR Mecha Sub Ass’y

38±2

Rib

Arrange the wire so that the

wire clamp comes to the

TR Mecha side.

Boss

TR Holder

9

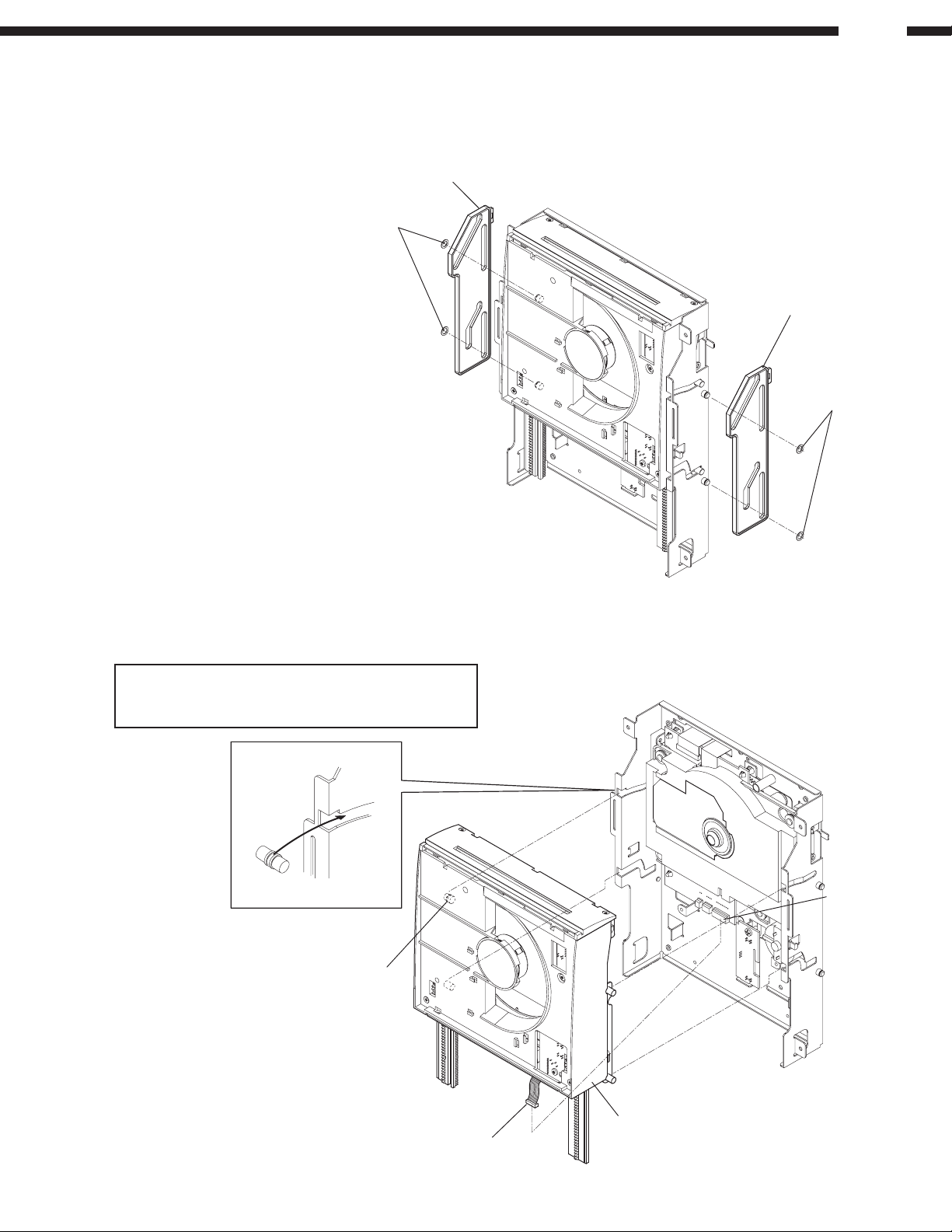

SUB WOOFER DISASSEMBLY

Caution:Be sure to check that there is no jarring sound from sub-woofer or no air-leak through joints of parts after

reassembling by playing CD source (ordinary music source) with volume indication level 30.

D-107

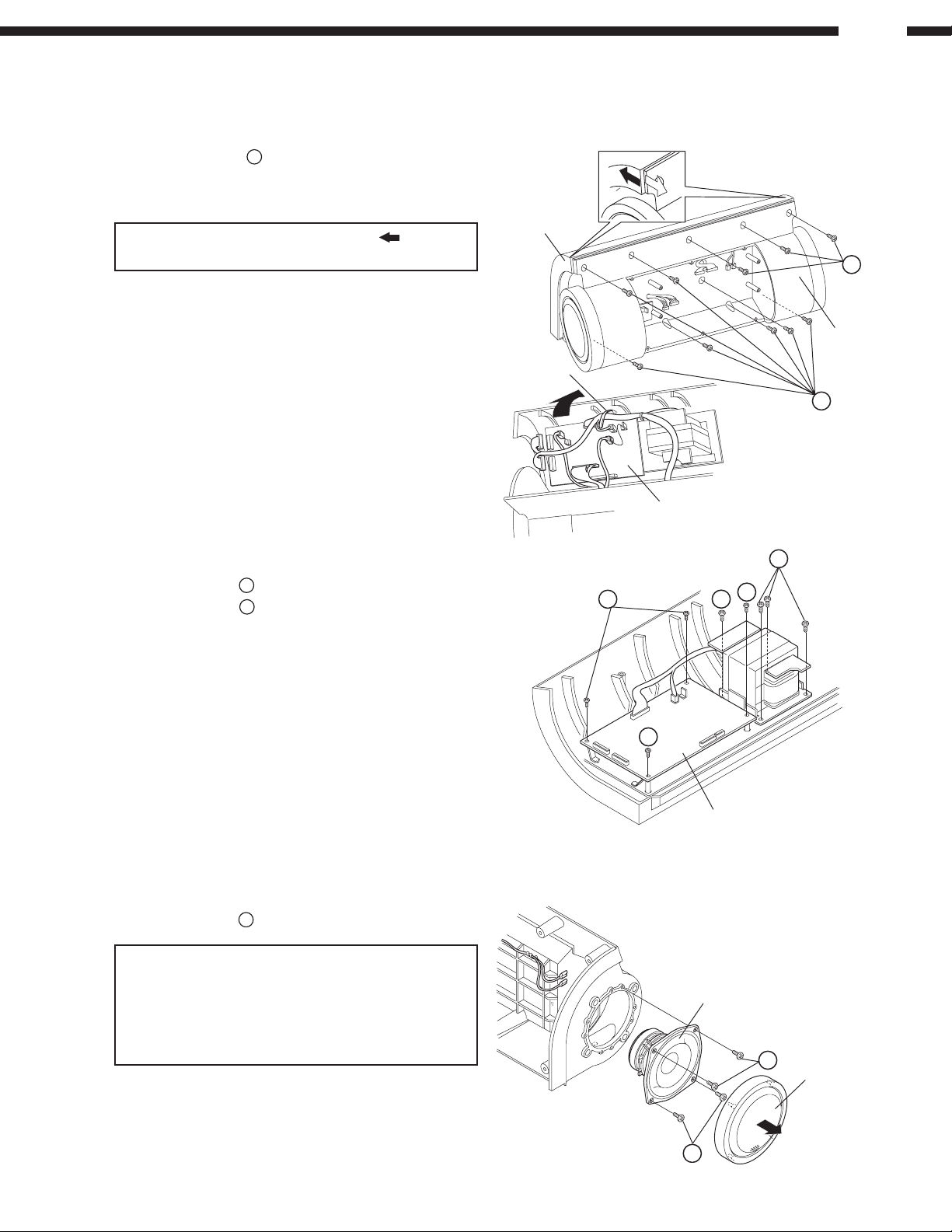

1. SP Terminal Unit, System Conn. Unit

1) Remove 4 screws 1 to detach the Rear Plate.

2) Disconnect 1 cable from the AC Conn. Unit and 3 cables

from the System Conn. Unit.

3) Disengage fasten terminal on SP Terminal right.

4) Remove 2 screws

5) Remove 2 screws

2

to detach the System Conn. Unit.

3

to detach the SP Terminal Unit.

2. Radiator Sub Ass'y

1) Remove 6 screws 4 to detach the Amp Cover.

5

2) Remove 4 screws

3) Lift up the Radiator Sub Ass’y and disconnect 4 cables

from the Power Amp Unit.

fixing the Radiator Sub Ass’y.

AC Conn. Unit

System Conn. Unit

Connect

Rear Plate

1

3

2

1

4) Remove 3 screws

5) Remove 4 screws

Amp Unit.

6) Remove 1 screw

6

and separate the Power Supply Unit.

7

and separate the L/R Amp Unit, SW

8

and separate the PTH Unit.

5

5

Amp Cover

4

Power Supply Unit

8

6

PTH Unit

7

10

3. Back Cabinet, Front Cabinet

1) Remove 10 screws 9.

2) With holding the Back Cabinet, pull both sides of the Front

Cabinet in the arrow direction.

D-107

Note:Use a rubber hammer etc. to hit the

of the Front Cabinet if it’s hard to remove.

3) Push the Front Cabinet to the arrow direction to make a

gap between the Back Cabinet.

4) Cut the wire clamp band near the Front Cabinet, and

disconnect 4 cables on the Pre Amp Unit.

5) Disconnect 2 cables on the bottom of the Pre Amp Unit,

and separate the Back and Front Cabinet.

arrow part

4. Pre Amp Unit, Transformer

1) Remove 4 screws to detach the Pre Amp Unit.

2) Remove 4 screws

to detach the Transformer.

Front Cabinet

Wire Clamp

Band

Pre Amp Unit

9

Back Cabinet

9

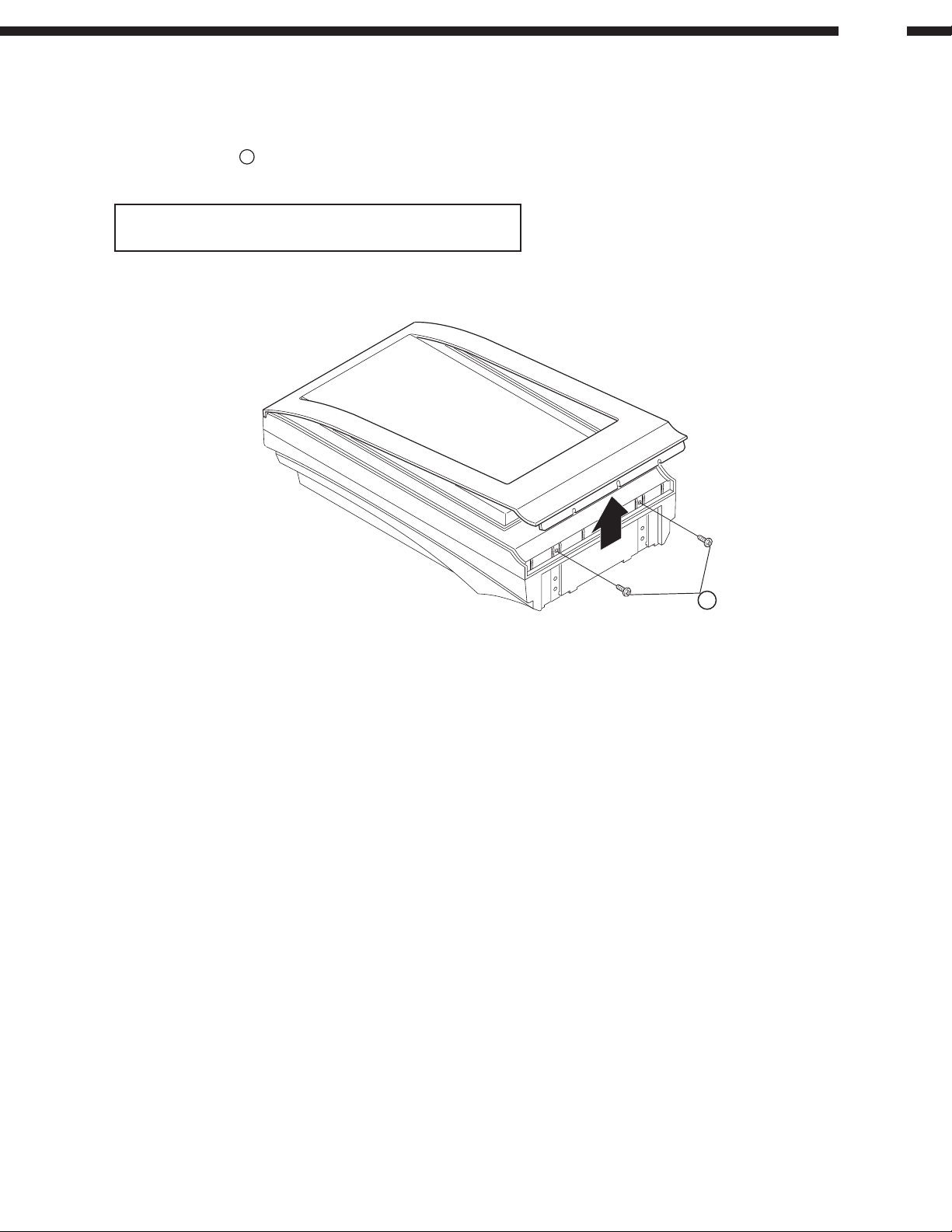

5. Speaker Unit

1) Pull out the Decoration Ring in the arrow direction.

2) Remove 4 screws

Note:When disconnecting the cables from terminals of

the Speaker Unit, make it at the position where the

terminals of the Speaker Unit can be seen from the

Back Cabinet. The clamp part of the internal

speaker cables will be disengaged if separated

farther.

to detach the Speaker Unit.

Speaker Unit

Pre Amp Unit

Decoration Ring

11

SPEAKER DISASSEMBLY

1. Front Panel

1) Remove 2 screws 1.

2) Lift up bottom end of the Front Panel as shown to release the hook.

Note: Unit change will be necessary if farther disassembling is

needed.

D-107

1

12

D-107

NOTE IN HANDLING FOR LASER PICK-UP

Caution for Handling the Laser Pick-up

The laser pick-up is assembled and precisely adjusted using a sophisticated manufacturing process in our plant. Do not

disassemble or attempt to readjust it. Please observe the following instructions carefully in handling the pick-up.

1. Handle with Care

(1) Storage

Do not store the pick-up in dusty, high-temperatured or high-humidity environments.

(2) Please take care for preventing from shock by falling down or careless handling.

2. Protection of the LD

Short a part of the LD circuit by soldering. After connection to a circuit, remove the short solder.

Pick-up

SF-P200R FPC

Seen from the

pattern side

Shorting Land

3. Precautions when handling the CD mechanism

Handle the laser pick-up so that it is not exposed to dust.

Do not leave the laser pick-up bare. Be sure to cover it.

If dust adheres on lens of the pick-up, blow it off with a blower brush.

Do not shock the laser pick-up.

Do not watch the light of the laser pick-up.

4. Cautions on assembling and adjustment

Be sure that to the bench, jig, head of soldering (with ceramic) iron and measuring instruments are well grounded.

Workers who handle the laser pick-up must be grounded.

The finished mechanism (prior to anchoring in the set) should be protected against static electricity and dust.

The mechanism must be stored so that damaging outside forces are not received.

When carrying the finished mechanism, hold it by the chassis body.

For proper operation, storage and operating environment should not contain corrosive gases. For example H

NO2, CL2 etc. In addition storage environment should not have materials that emit corrosive gases especially from

silicic, cyanic, formailn and phenol group. In the mechanism or the set, existence of corrosive gases may cause no

rotation in motor.

2S, SO2

13

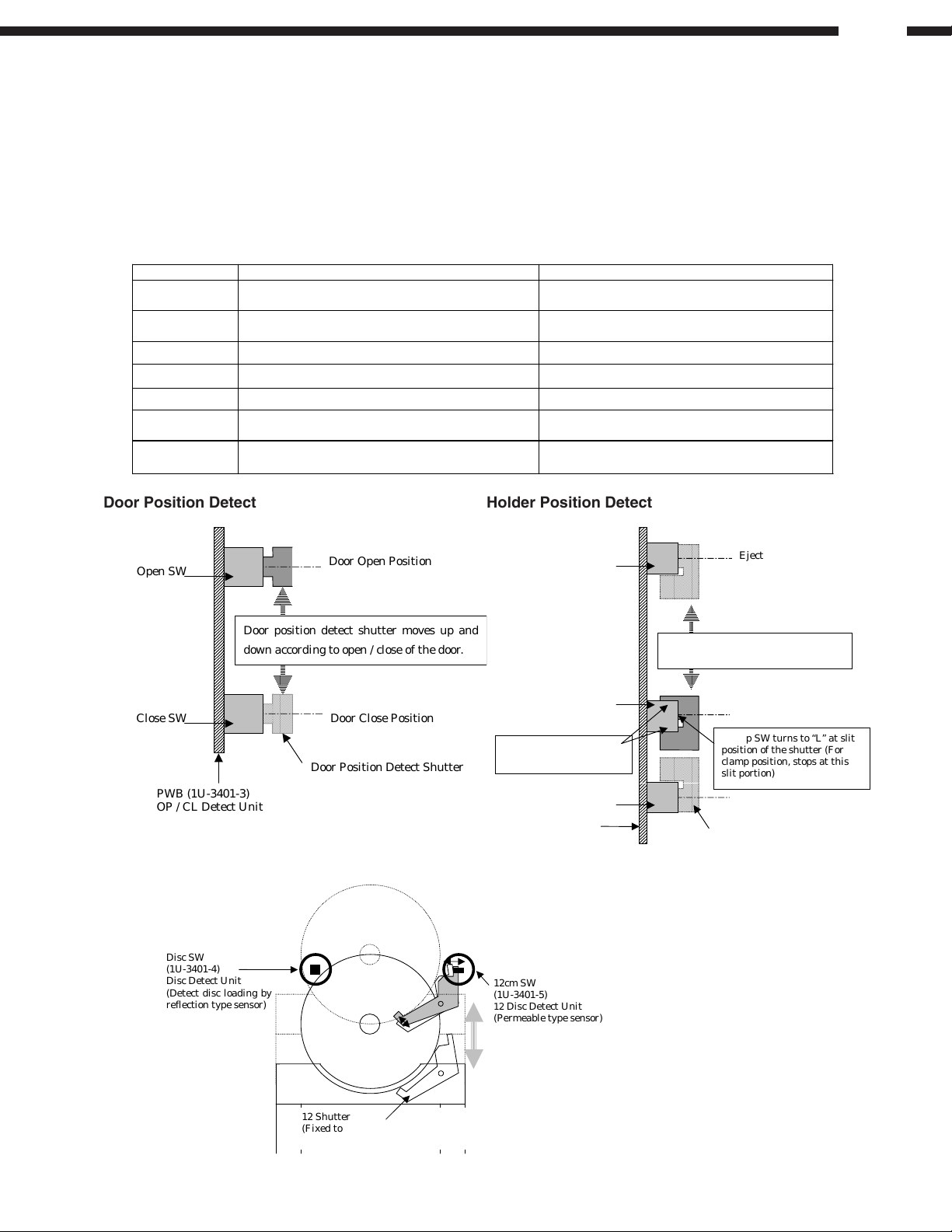

MECHANISM AND FUNCTION OF CD MECHA

Name Function Remarks

Disc SW Disc insertion detect

Monitors at holder (Door Open),

With disc : “L”, without disc : “H”

12cm SW 12cm Disc detect

Monitors at holder eject position,

12cm disc load : “L”, others : “H”

Open SW Door open position detect Door open stop position : “H”, others : “L”

Close SW Door close position detect Door close stop position : “H”, others : “L”

Out SW Holder (disc transfer part) eject position detect Eject position : “H”, others : “L”

Clamp SW Holder (disc transfer part) clamp position detect

Clamp position : “L”, Near Clamp position : “H”

Others : “L”

In SW

(Holder’s disc release position after clamping)

Retract position : “H”, others : “L”

Eject Position

Clamp Position

Out SW

Clamp SW

Holder position detect shutter moves

according to up / down of the holder.

Retract PositionIn SW

Holder Position Detect Shutter

PWB (1U-3401-2)

Disc Up / Down Unit

Near clamp position,

Clamp SW turns to “H”

Clamp SW turns to “L” at slit

position of the shutter (For

clamp position, stops at this

slit portion)

1. Traverse Mecha :

TR Mecha Sub Ass’y (GEN5327)

2. Door Open/Close Mechanism:

Driven by the door open/close motor, Open SW and Close SW are equipped for checking stop position.

3. Disc Transfer Mechanism:

Driven by the holder up-down motor, Out SW, Clamp SW, and In SW are equipped for checking stop position.

Description

Holder (disc transfer part) retract position detect

D-107

Door Position Detect Holder Position Detect

Open SW

Close SW

PWB (1U-3401-3)

OP / CL Detect Unit

Door position detect shutter moves up and

down according to open / close of the door.

Door Open Position

Door Close Position

Door Position Detect Shutter

Disc Detect

Disc SW

(1U-3401-4)

Disc Detect Unit

(Detect disc loading by

reflection type sensor)

12 Shutter

(Fixed to holder, actuates 12cm SW when pushed by 12cm

disc’s edge, immovable with 8cm disc)

12cm SW

(1U-3401-5)

Disc Detect Unit

12

(Permeable type sensor)

14

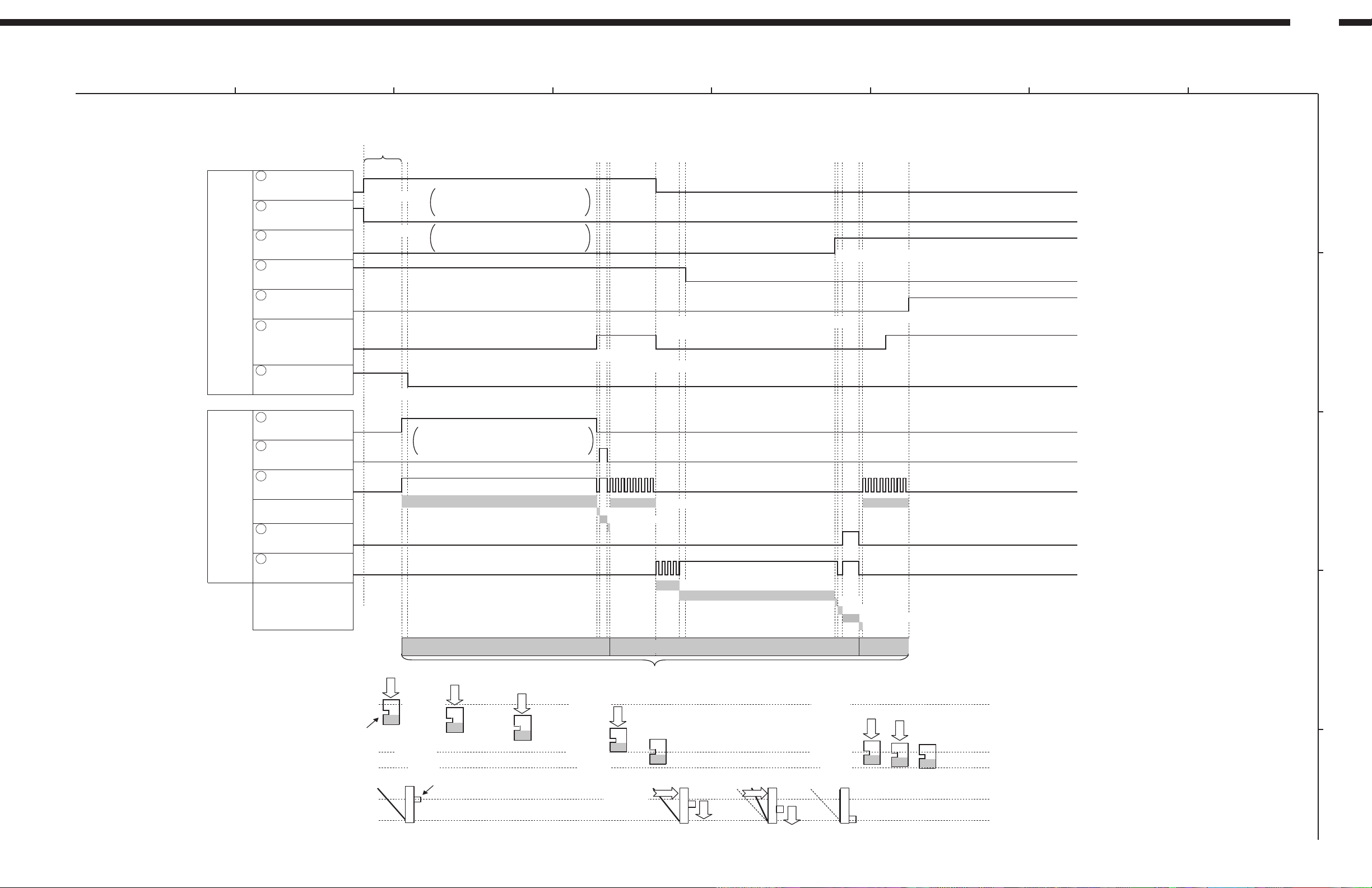

D-107

1 5678

Loader Mecha Timing Chart

Timing Chart when close

49 pin

DISC_SW

50 pin

12cm_SW

46 pin

CLOSE_SW

IC101

µcom

Input

Port

47 pin

OPEN_SW

43 pin

IN_SW

(Retract Position)

44 pin

CLAMP_SW

(Clamp Position)

45 pin

OUT_SW

(Eject Position)

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

1 sec.

↑ 1. Disc Detect

↑ 1. Disc Detect

↑ 2. Holder Down Start

32

Descends holder after 1sec. when

DISC_SW(H) and 12cm_SW (L)

conditions are satisfied.

Defines as 8cm disc insertion in case of

DISC_SW(H) and 12cm_SW (H), and

repeats holder up/down 10 times.

4

↓ 6. Door Close Start (pulse open 4 times + door open)

↓ 5. Holder Slowdown End (pulse decline stop)

↑ 3. Holder Down Stop

↑ 4. Holder Slowdown Start (pulse decline start)

A

↑ 7. Door Close Stop

↓ 9. Holder Retract End (pulse decline stop)

↑ 8. Holder Retract Start (pulse decline start)

B

IC101

µcom

Output

Port

33 pin

DISC_DOWN

54 pin

Holder Motor (up)

(F. IN)

53 pin

Holder Motor (down)

(R. IN)

56 pin

Door Motor (open)

(FWD)

57 pin

Door Motor (close)

(REV)

Holder

Door

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

OUT_SW→

Holder Position

Detect Shutter

CLAMP_SW→

IN_SW→

OPEN_SW→

DISC_DOWN signal: Voltage control terminal

of holder motor which becomes "H" when

descending holder (disc) and "L" when others.

↑ Holder Down (While CLAMP_SW: Lo)

1. Disc Down Section (open corrective period)

(Monitor timer: 6sec.)

DOWN

OUT_SW→ OUT_SW→ OUT_SW→

CLAMP_SW→ CLAMP_SW→ CLAMP_SW→

IN_SW→

DOWN

Door Position

Detect Shutter

DOWN

↑ 20msec, 20msec Pulse Decline (while CLAMP_SW: Hi)

↑ STOP

↑ BRAKE (80msec)

↑ STOP

↑ Close with 20msec, 20msec Pulse (4 times)

↑ Door Close (while CLOSE_SW: Lo)

2. Slowdown Period

(Monitor timer: 2sec.)

Close Monitor Timer: 12sec.

* When monitor time-out, it reverts to open motion

DOWN

IN_SW→

OPEN_SW→

CLOSE

3. Door Close

(Monitor timer: 5sec.)

CLOSE

DOWN

↑ STOP

IN_SW→

DOWN

↑ 10msec, 10msec Pulse Decline (while IN_SW: Lo)

↑ 50msec Wait

↑ BRAKE (200msec)

↑ STOP

4. Retract Section

(Monitor timer: 2sec.)

DOWN

DOWN

C

D

E

15

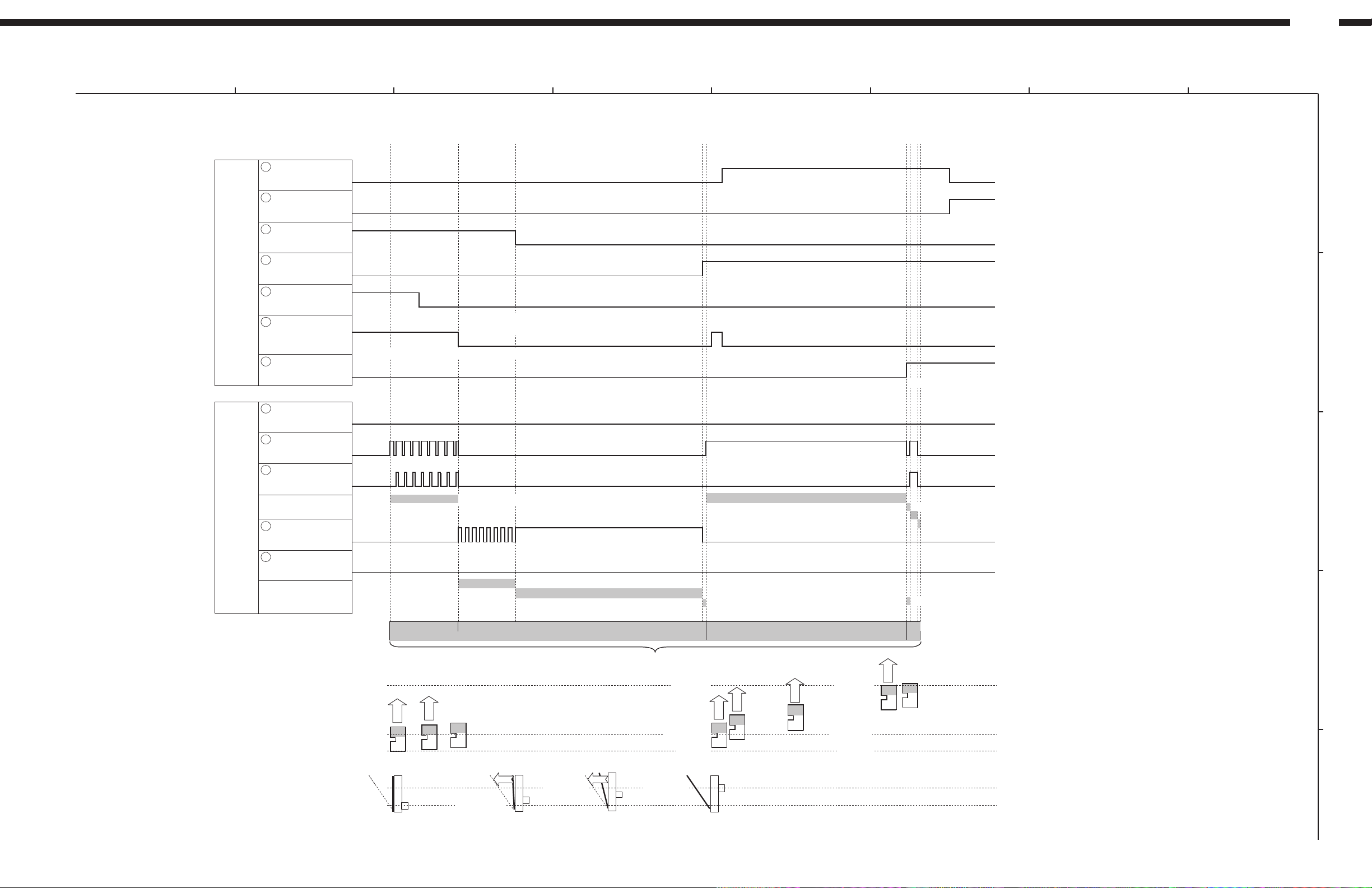

D-107

1 5678

Loader Mecha Timing Chart

Timing Chart when open

IC101

µcom

Input

Port

IC101

µcom

Output

Port

49 pin

DISC_SW

50 pin

8cm_SW

46 pin

CLOSE_SW

47 pin

OPEN_SW

43 pin

IN_SW

(Retract Position)

44 pin

CLAMP_SW

(Clamp Position)

45 pin

OUT_SW

(Eject Position)

33 pin

DISC_DOWN

54 pin

Holder Motor (up)

(F. IN)

53 pin

Holder Motor (down)

(R. IN)

56 pin

Door Motor (open)

(FWD)

57 pin

Door Motor (close)

(REV)

32

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

Hi

Lo

↓ Open Key Press

↑ 4. Door Open Start

↓ 3. Door Pulse Open Start (pulse open)

↓ 2. Holder Receiving End (pulse rise stop)

↑ 1. Holder Receiving Start (pulse rise start)

↑ 20msec, 10msec Pulse Rise (while CLAMP_SW: Hi)

(10msec BREAK)

↑ 20msec, 20msec Pulse Open (while CLAMP_SW: Hi, or 15 times)

↑ Door Open (while OPEN_SW: Lo)

4

↓ Unload Disc

A

↑ 5. Door Open Stop

↑ 6. Holder Up Start

B

↑ 7. Holder Up End

↑ Holder Up (while OUT_SW: Lo)

↑ STOP

↑ STOP

↑ BREAK (200ms)

↑ STOP

↑ STOP

C

Holder

Door

OUT_SW→

CLAMP_SW→

IN_SW→

OPEN_SW→

CLOSE_SW→

1.

Receiving Period

(Monitor timer: 2sec.)

UP

UP

CLOSE_SW→

2. Door Open Section

(Monitor timer: 5sec.)

OPEN

OPEN_SW→

Close Monitor Timer: 12sec.

* It stops when monitor time-out

OPEN

OPEN_SW→

OUT_SW→

CLAMP_SW→

IN_SW→

3. Disc Up Section (open corrective period)

(Monitor timer: 6sec.)

UP

UP

UP

OUT_SW→

CLAMP_SW→

IN_SW→

4. Open Finish Section

D

UP

E

16

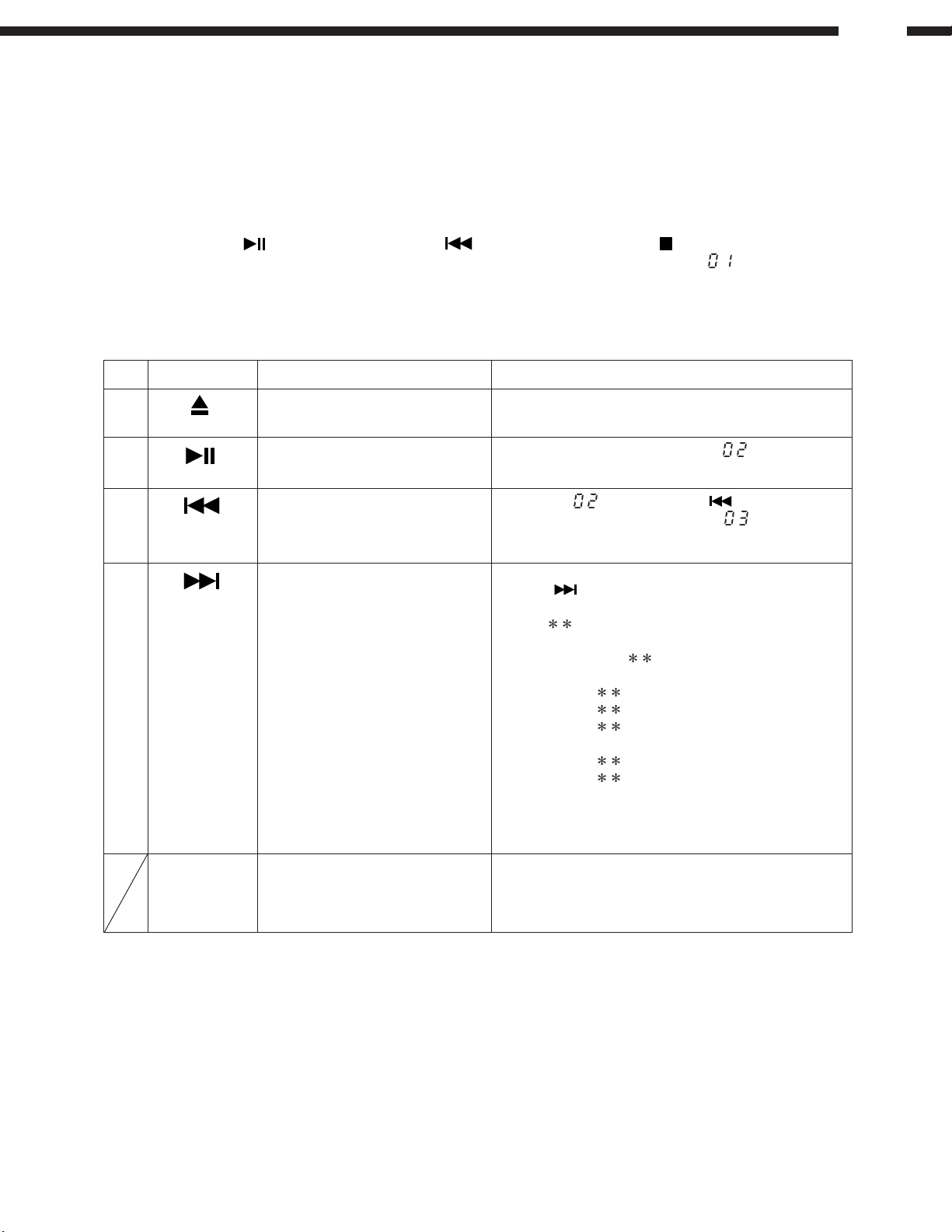

CONFIRMATION METHOD OF ADJUSTMENT

In the µcom of this system, there is a built-in function “adjustment confirmation mode” to

check various servo control easily with CD operation buttons.

Also, focus offset, tracking offset, tracking balance, focus gain, and tracking gain are all

adjusted automatically as the digital servo control is built in the system.

1. Activating Adjustment Confirmation Mode

(1) Load the test disc TCD-784 or Mozart (CO-74176) at the function CD.

(2) After pressing the button (PLAY/PAUSE) and button simultaneously, press button (STOP) within 3 sec.

(The adjustment confirmation mode is activated and the track number of the display turns to

Note: Normal control is disabled with the operation buttons when the adjustment confirmation mode is activated.

To cancel this mode, simply unplug the AC cord.

2. Function of Adjustment Confirmation Mode

.)

D-107

Step

(0)

(OPEN/CLOSE)

(1)

(PLAY/PAUSE)

(2)

(3)

Button Function

Load / unload of disc. Open/close while disc is no rotation.

Activates focus servo, and

starts disc rotation.

Activates all servo, and starts

auto-adjustment.

Displays each

auto-adjustment result.

Description

Press other button after finishing open/close mode.

Track number display turns to .

When displayed, press after 3 sec.

Track number display turns to .

After auto-adjustment, it stops.

After finishing auto-adjustment, every pressing of

the button displays each adjusted value of

auto-adjustment as follows. Check that the value

of portion falls within the range shown Table 1

on page18.

(The value of

Fdoffset h (Focus offset adjusted value)

Tdoffset

Tbal h

Fbal 0 0 h (Focus balance adjusted value)

Fogain

Trgain h (Tracking gain adjusted value)

Focus balance adjusted value is always fixed to 00h.

portion is hexadecimal)

h (Tracking offset adjusted value)

(Tracking balance adjusted value)

h (Focus gain adjusted value)

Other Button

May not operate normally.

Do not operate with other buttons other than

described above during this mode.

17

D-107

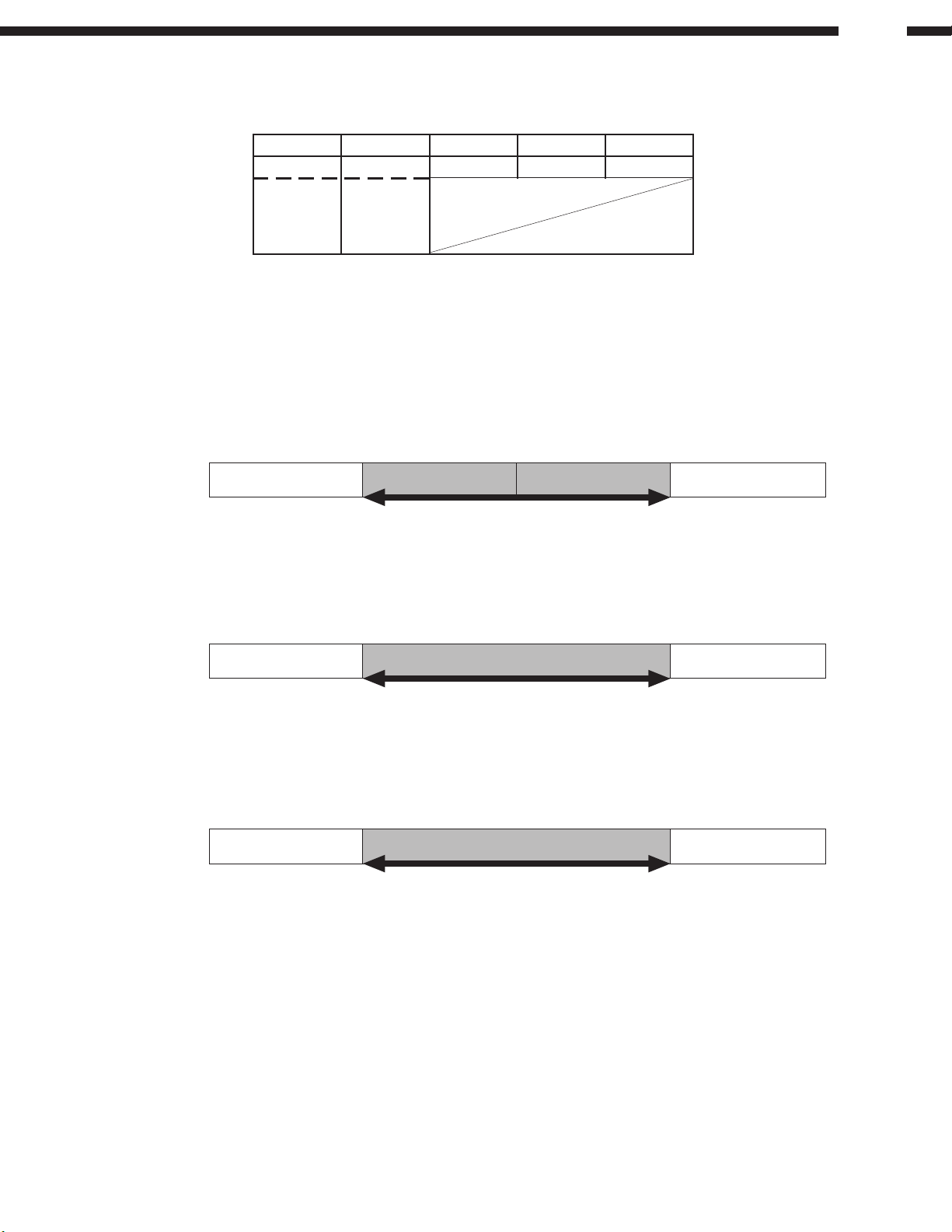

Table1 Servo Adjust Value Confirmation List

Fdoffset Tdoffset Tbal Fogain Trgain

EAh~0Eh EAh~0Eh 6Bh~9Ah 28h~56h 28h~56h

EAh~FFh EAh~FFh

or or

00h~0Eh 00h~0Eh

Fbal value indicated fourth in the item of adjusted value check will be displayed always as 00h because no adjustment is made.

When out of the range value appears, open and close the door once, then check the value again.

Value indicated are hexadecimal

(HEX)

Summary of Adjustment Range

Adjustment and confirmation range of Fdoffset, Tdoffset

Adjustment range: 9Ah ~ 66h

Confirmation range: EAh ~ 0Eh

9Ah EAh FFh

Adjustment and confirmation range of Tbal

Adjustment range: 00h ~ FFh

Confirmation range: 6Bh ~ 9Ah

00h 6Bh

Adjustment and confirmation range of Fogain, Trgain

Adjustment range: 14h ~ 7Fh

Confirmation range: 28h ~ 56h

14h 28h

00h 0Eh

9Ah

56h

66h

FFh

7Fh

18

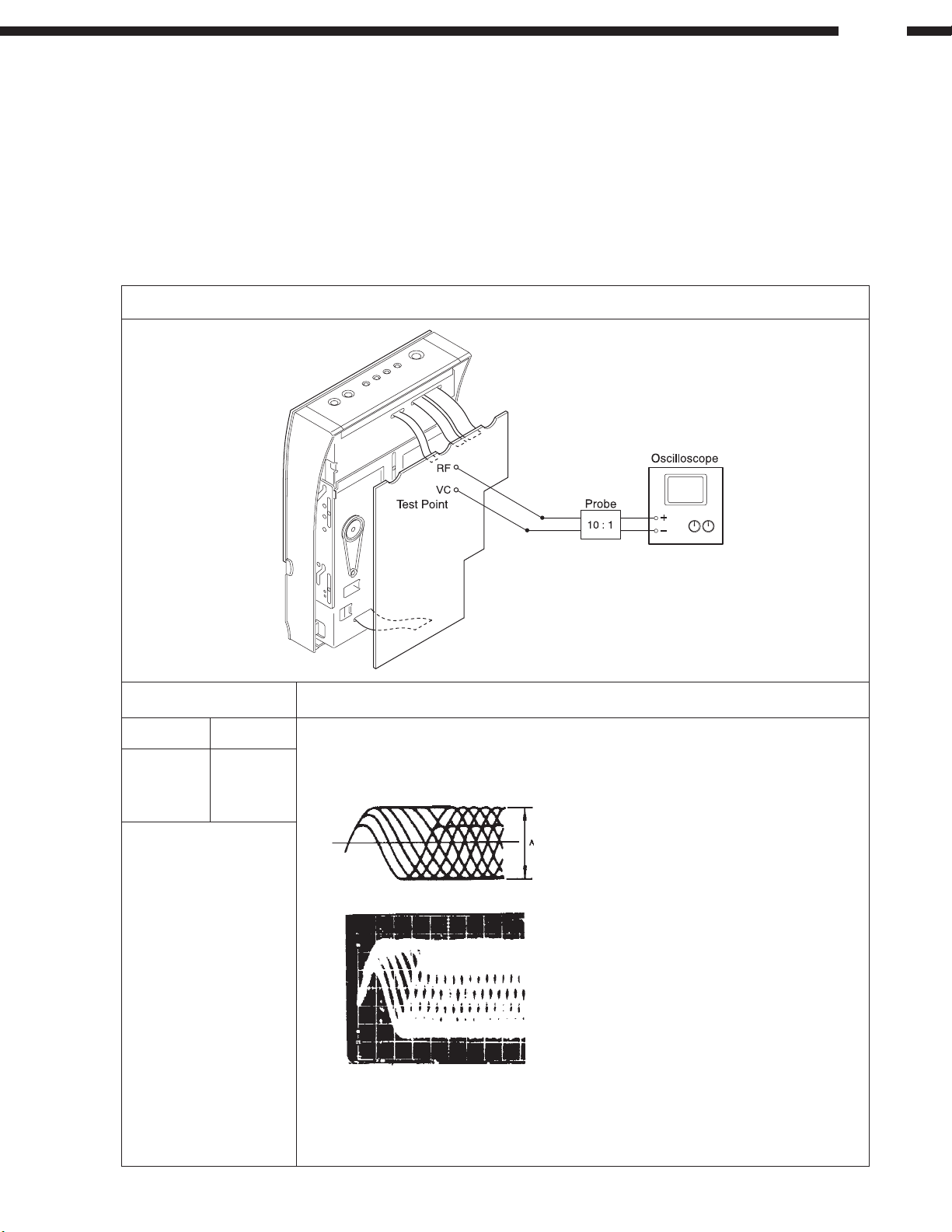

3. How to Check HF Level

(1) Measuring instruments required

a) Oscilloscope

b) Test disc: TCD-784 (A-BEX) or Mozart (CO-74176)

(2) Attaching connection wire for checking HF level

a) Disassemble 1U-3398-1 (Main PWB) → Refer to “DISASSEMBLY” on page 3, 4.

b) Solder wires to RF and VC test points for connecting the probe of oscilloscope.

(Length of the wires should be less than 20 cm) → Refer to 1U-3398-1 drawing on page 32.

c) Assemble 1U-3398-1, see the diagram below.

Wiring Diagram

D-107

Oscilloscope

VH

50mV/div

or

20mV/div

0.2µs/div

or

0.5µs/div

Check Item

1. Playback the test disc.

2. Check HF level on the oscilloscope.

A=0.7V~1.3V

Eye-pattern

3. Check that the wave-form is not deformed

(The center 2 shapes must be discernible.)

19

)

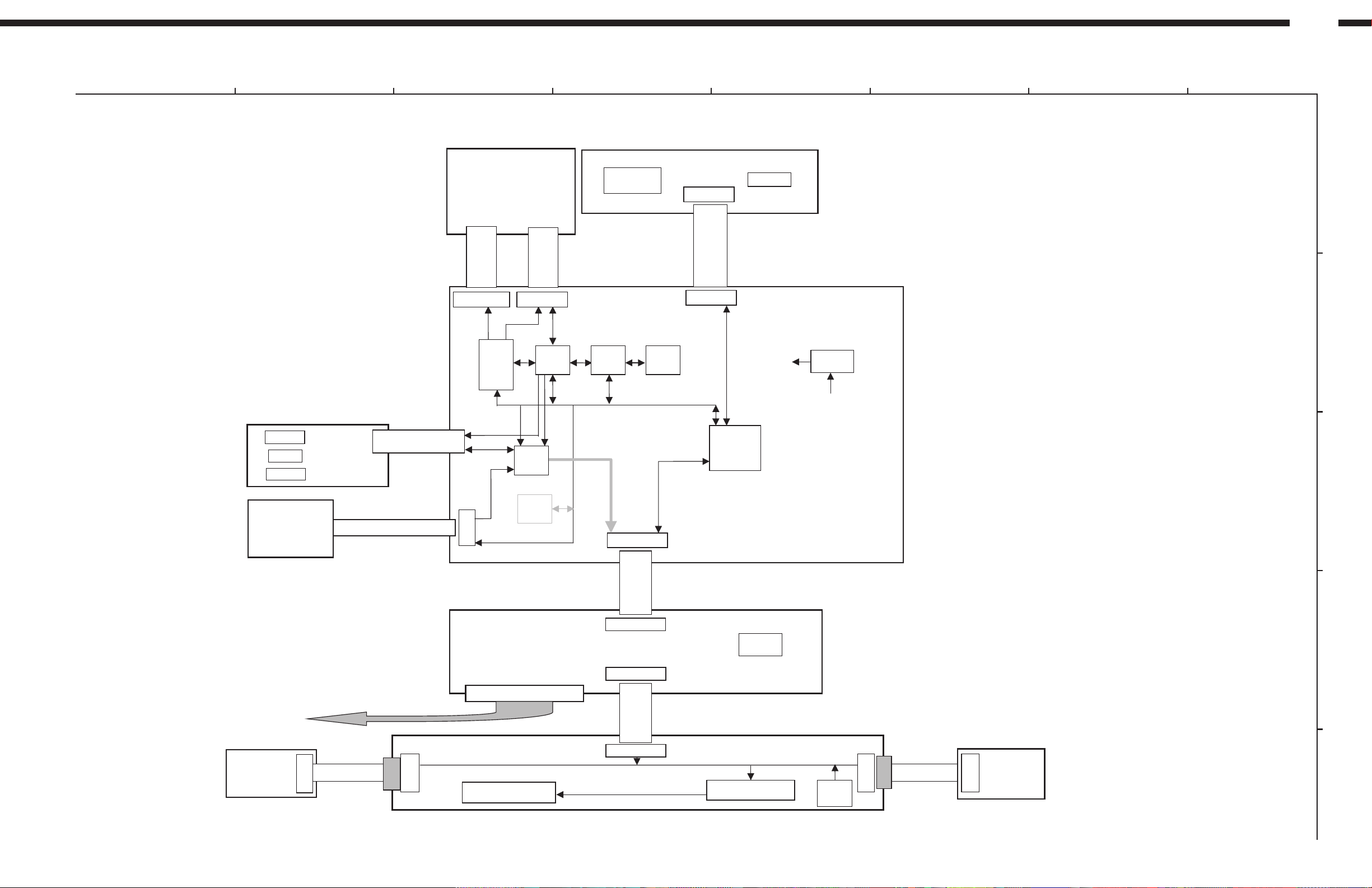

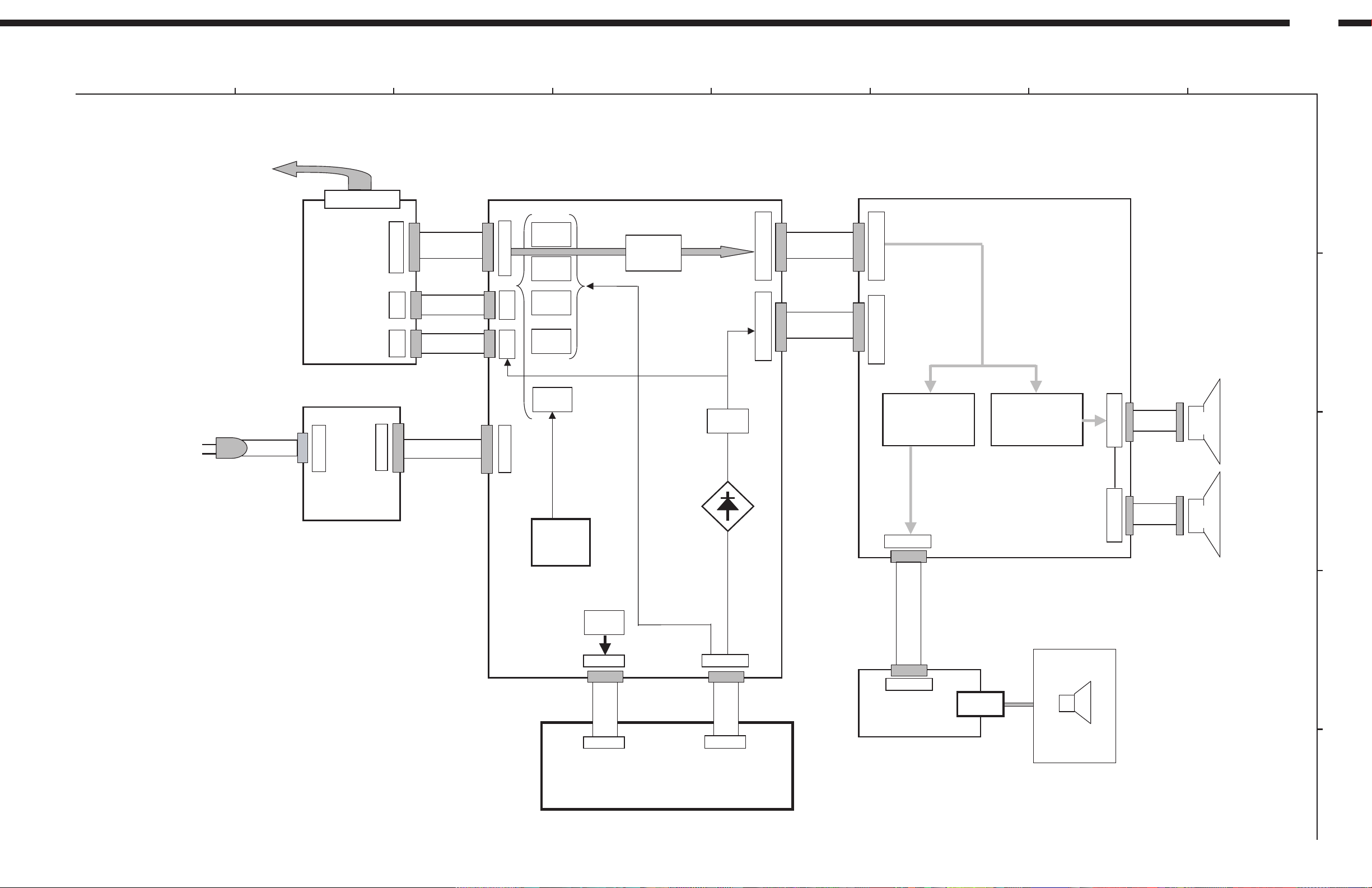

BLOCK DIAGRAMS

D-107

1

32

4

5678

UD-107 BLOCK & WIRING DIAGRAM

FG350

(Mecha side inserted)

21P FFC (P=1)

CX161 CX211

IC201

IC202

MOTOR

DRIVER

(Mecha side inserted)

16P FFC (P=1)

IC204

DSP

POWER ON/

STANDBY LED

MAIN UNIT

IC203

MP3

1U-3398-7

CONTROL UNIT

1U-3398-8

IC208

DRAM

CY051

5P FFC (P=1)

CX051

TACT SW

IC204

IC203

IC208

IC207

Reg. +3.3V

VVV

+5V-D1

A

B

OPT.OUT

AUX IN

AUX OUT

TUNER PACK

USW-107

1U-3398-5

OP/CL SW UNIT

1U-3398-4

AUDIO I/O UNIT

CW031

3P KR-DS(WHT)

11P TWGP

15P FFC (P=1.25)

CX031

CX151

IC305

EQ&VR

IC302

RDS

20P DISM

FL701 (VFD)

CX291

CY291

1U-3398-3

INTERFACE UNIT

CY131

13P FFC (P=1)29P FFC (P=1)

CX131

1U-3398-2

DISPLAY UNIT

IC101

µ

COM

IC501

Reg. +6V

IC701 VFD DRIVER

IC703

REMOCON

SENSOR

CX032

3P KR-DS (RED)

CW032

1U-3398-6

PLAY SW UNIT

C

D

E

20

D-107

1 5678

32

4

USW-107 BLOCK & WIRING DIAGRAM

UD-107

A

AC CORD

20P DISM

1U-3445-1

SYSTEM CONN

UNIT

1U-3417-6

AC CONN

CX025

UNIT

CY121 CY061 CX031

CY022

12P PH-PH

6P PH-PH

6P PH-PH

2P VH-VH (BLU)

CX121

CX061

CY031

CX022

IC201

Reg. +12V

IC202

Reg. +6V

TR201

Reg. -30V

DC

+/-F

IC203

Reg. +6V

1U-3400-1

POWER SUPPLY UNIT

AUDIO SIG.

HPF/LPF

ALC

MAIN AMP

±

V

CX111 CX101

11P PH-PH

10P EH-EH

CY111 CY101

1U-3417-2

L/R AMP UNIT

IC500

STK402-050

1U-3417-1

POWER AMP UNIT

1U-3417-3

SW AMP UNIT

IC700

STK402-050

CX023 CX024

2P EH

B

SW

T202

MINI

TRANS

PRIMARY

RELAY

CX021

2P VH-VH

CW021

1U-3400-2

PRIMARY UNIT

MAIN POWER TRANS

T201

CX131

13P SCN-EH

CW131

1U-3400-3

SECONDARY UNIT

CX041

4P EH-EH

CY041

1U-3417-4

SP TERMINAL

UNIT

JK500

USC107 L/R

2P EH

SW

C

D

E

21

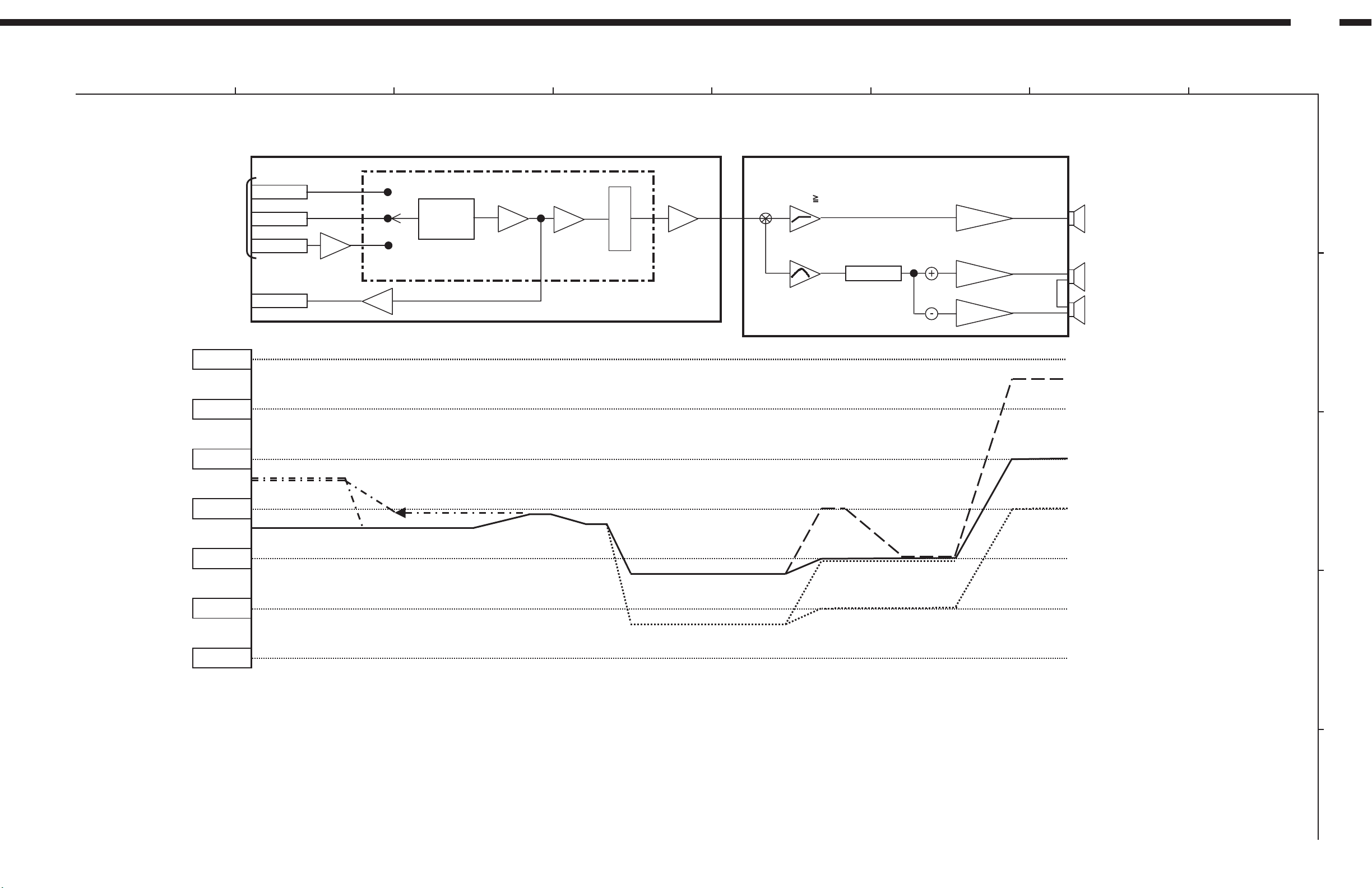

LEVEL DIAGRAM

D-107

1

32

4

5678

D-107 LEVEL DIAGRAM

SOURCE

UD107

TUNER

CD

AUX IN

AUX OUT

LC75396NE

FUNCTION

SWITCH

INPUT

EQ

V

O

L

U

M

E

USW107

HPF 200Hz

BPF PEAK 70Hz

ALC

L/R

POWER AMP

SUB

WOOFER

A

L/R SPEAKER

SUB

WOOFER

B

+30dBV

SUB WOOFER

+20dBV

+10dBV

0dBV

-10dBV

-20dBV

-30dBV

AUX INPUT 2V

CD 0dB

AUX

VOLUME -10dB

STEP54

VOLUME -20dB

STEP44

ALC ON

ALC OFF

L/R

L/R

C

D

E

22

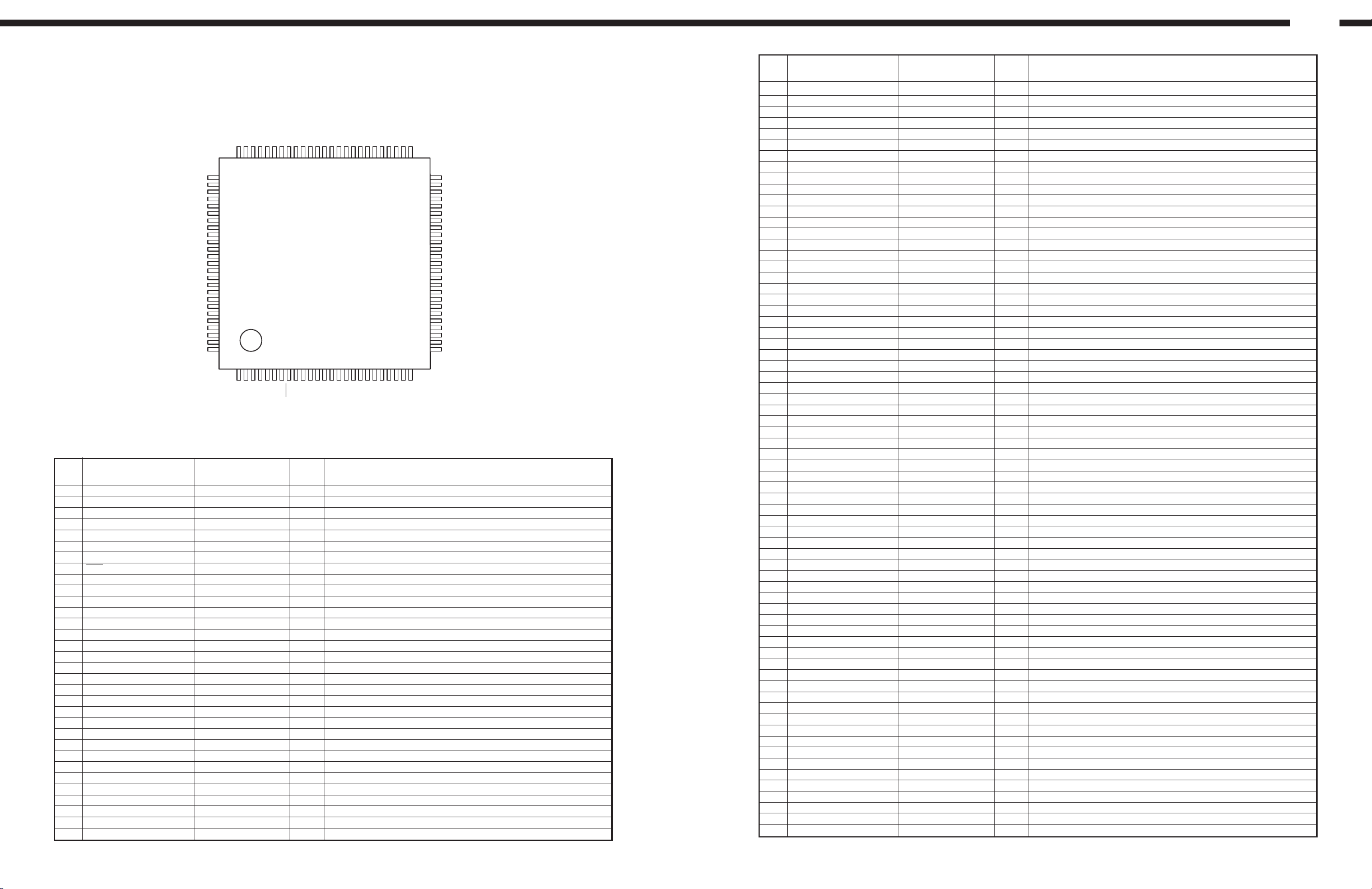

D-107

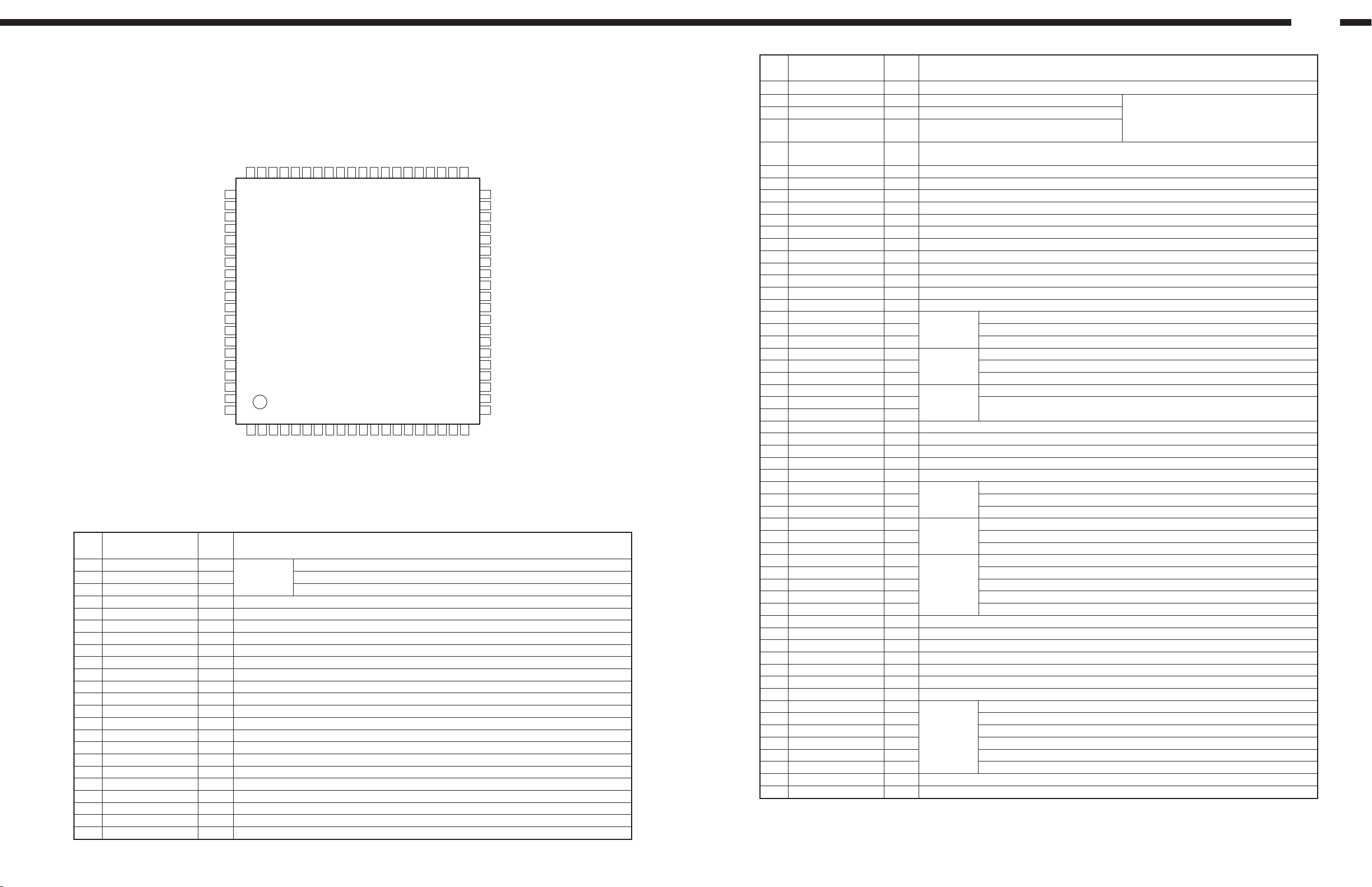

SEMICONDUCTORS

IC’s

Note: Indication before IC No. (SW) denotes “USW-107”.

LC877296B

(IC101)

S47/PF7

V3/PL6

V2/PL5

V1/PL4

COM0/PL0

COM1/PL1

COM2/PL2

COM3/PL3

P30

P31

VSS3

VDD3

P32

P33

P34

P35

P00

P01

P02

P03

P04

P05

P06

P07

P10/SO0

M877296B Terminal Function

Pin

No.

1 P11/SI0/SB0 645DO I LC78645, LC78683 serial

2 P12/SCK0 645CK O LC78645, LC78683 serial

3 P13/SO1 SDI O Other PLL, RDS, VR, DISP serial, LC2720, LC72131

4 P14/SI1/SB1 SDO I Other PLL, RDS, VR, DISP serial, LC2720, LC72131

5 P15/SCK1 SCK O Other PLL, RDS, VR, DISP serial, LC2720, LC72131

6 P16/T1PWML 645CE O LC78645CE

7 P17/T1PWMH/BUZ 683CE O LC78683CE

8 RES

9 XT1/AN10 Clock 32.768kHz

10 XT2/AN11

11 VSS1

12 CF1 Main Clock 10MHz

13 CF2

14 VDD1 Back up HOLD mode use

15 P80/AN0 AD0 Operation button input

16 P81/AN1 AD1 Operation button input

17 P82/AN2 AD2 PWB check mode control

18 P83/AN3 AD3 PWB check mode control

19 P84/AN4 ROM CLK I FLASH Write

20 P85/AN5 TUNER1 I Tuner type E20, E31, J1, E10

21 P86/AN6 TUNER2 I Tuner type E20, E31, J0, E11

22 P87/AN7/MICIN OP/CL I Sensor OP/CL input (A/D input)

23 P70/INT0/T0LCP/AN8 FSYNC I LC78683

24 P71/INT1/T0HCP/AN9 INTB I LC78683

25 P72/INT2/T0IN P.DOWN I Power-down detect→HOLD mode

26 P73/INT3/T0IN REMOCON I Remote control input

27 S0/PA0

28 S1/PA1

29 S2/PA2

30 S3/PA3

31 S4/PA4

32 S5/PA5 DISC LED O DISC LED ON output, Hi: ON

Pin Name

S46/PF6

S45/PF5

S44/PF4

S43/PF3

S42/PF2

S41/PF1

S40/PF0

S39/PE7

S38/PE6

S37/PE5

S36/PE4

S35/PE3

S34/PE2

S33/PE1

S32/PE0

S31/PD7

S30/PD6

S29/PD5

S28/PD4

S27/PD3

S26/PD2

S25/PD1

S24/PD0

VSS2

75747372717069686766656463626160595867565554535251P72/INT2/T0IN

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

1P11/SI0/SB0

Symbol

2P12/SCK0

3P13/SO1

4P14/SI1SB1

TOP VIEW

5P15/SCK1

6P16/T1PWML

7P17/T1PWMH/BUZ

8RES

9XT1/AN10

10XT2/AN11

11VSS1

I/O

12CF1

13CF2

14VDD1

15P80/AN0

16P81/AN1

17P82/AN2

18P83/AN3

19P84/AN4

20P85/AN5

21P86/AN6

22P87/AN7/MICIN

23P70/INT0/T0LCP/AN8

24P71/INT1/T0HCP/AN9

VDD2

S23/PC750

49 S22/PC6

48 S21/PC5

47 S20/PC4

46 S19/PC3

45 S18/PC2

44 S17/PC1

43 S16/PC0

42 S15/PB7

41 S14/PB6

40 S13/PB5

39 S12/PB4

38 S11/PB3

37 S10/PB2

36 S9/PB1

35 S8/PB0

34 S7/PA7

33 S6/PA6

32 S5/PA5

31 S4/PA4

30 S3/PA3

29 S2/PA2

28 S1/PA1

27 S0/PA0

26 P73/INT3/T0IN

25

Function

Pin

No.

Pin Name

Symbol

I/O

Function

33 S6/PA6 DISC DOWN O Drive V switching at DISC DOWN, Hi: ON

34 S7/PA7 DSP OSC OFF O XTI OFF other than CD FUNCTION

35 S8/PB0 DRF I LC78645

36 S9/PB1 WRQ I LC78645

37 S10/PB2 EMPH O LC78645

38 S11/PB3 645RST O LC78645

39 S12/PB4 OVF I LC7868

40 S13/PB5 CNTOK I LC7868

41 S14/PB6 WOK O LC7868

42 S15/PB7 683RST O LC7868

43 S16/PC0 IN SW I HOLDER part SW input

44 S17/PC1 CLMP SW I HOLDER part SW input

45 S18/PC2 OUT SW I HOLDER part SW input

46 S19/PC3 DOOR CL SW I DOOR part SW input

47 S20/PC4 DOOR OP SW I DOOR part SW input

48 S21/PC5 LIMIT SW I PU in-circle SW

49 S22/PC6 DISC I DISC insert detect input, L: Detect

50 S23/PC7 12cm I 12cm DISC detect input, H: Detect

51 VDD2

52 VSS2

53 S24/PD0 R.IN O LIFT Motor drive

54 S25/PD1 F.IN O LIFT Motor drive

55 S26/PD2 M.MUTE O LA6559 MUTE

56 S27/PD3 FWD O LA6559 FWD (DOOR Motor)

57 S28/PD4 REV O LA6559 REV (DOOR Motor)

58 S29/PD5 LED RED O Power LED RED

59 S30/PD6 LED GRN O Power LED GRN

60 S31/PD7

61 S32/PE0

62 S33/PE1

63 S34/PE2

64 S35/PE3

65 S36/PE4

66 S37/PE5

67 S38/PE6

68 S39/PE7

69 S40/PF0

70 S41/PF1

71 S42/PF2

72 S43/PF3

73 S44/PF4

74 S45/PF5 396CE O LC75396NE CE

75 S46/PF6 396DI O LC75396NE DI

76 S47/PF7 396CL O LC75396NE CL

77 V3/PL6

78 V2/PL5

79 V1/PL4

80 COM0/PL0

81 COM1/PL1

82 COM2/PL2

83 COM3/PL3

84 P30 ROM DATA0 I/O FLASH Write

85 P31 ROM DATA1 I/O FLASH Write

86 VSS3

87 VDD3

88 P32 DISP RESET Display Driver reset

89 P33 PROTECTION I Power Amp Protection act., L: Detect

90 P34 TUNED I LA1837 Tuned

91 P35 STEREO I LA1837 Stereo

92 P00 SP.RELAY O Speaker Relay, Lo: Mute

93 P01 PRE.MUTE O PRE AMP Mute

94 P02 TU.MUTE O LA1837 Mute

95 P03 DISP.CS O DISPLAY Driver CS

96 P04 AUX MUTE O Mute at AUX Function, Hi: Mute

97 P05

98 P06

99 P07 720CE O LC72720, LC72131 CE

100 S10/SO0 645DI O LC78645, LC78683 serial

39

23

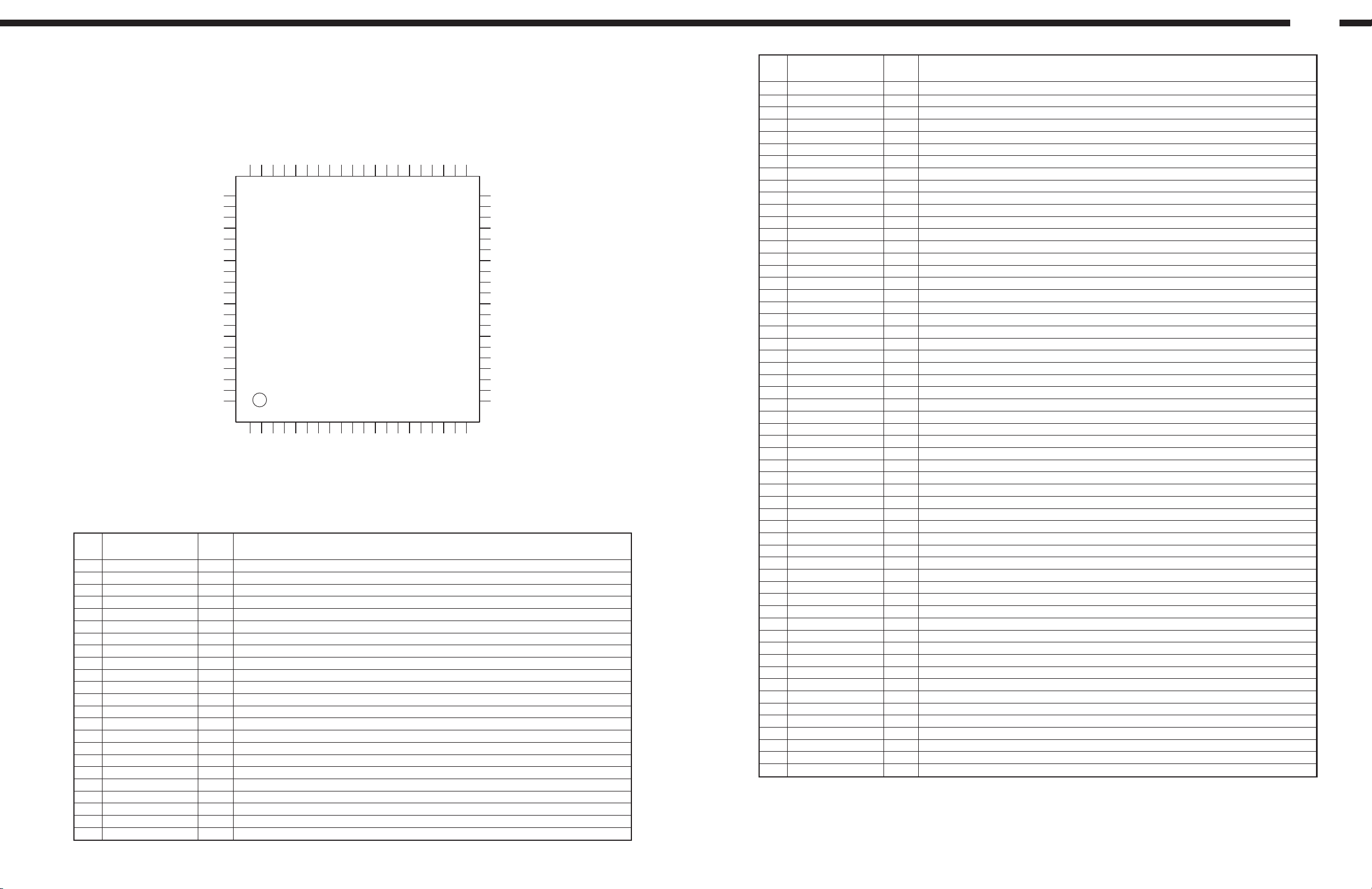

D-107

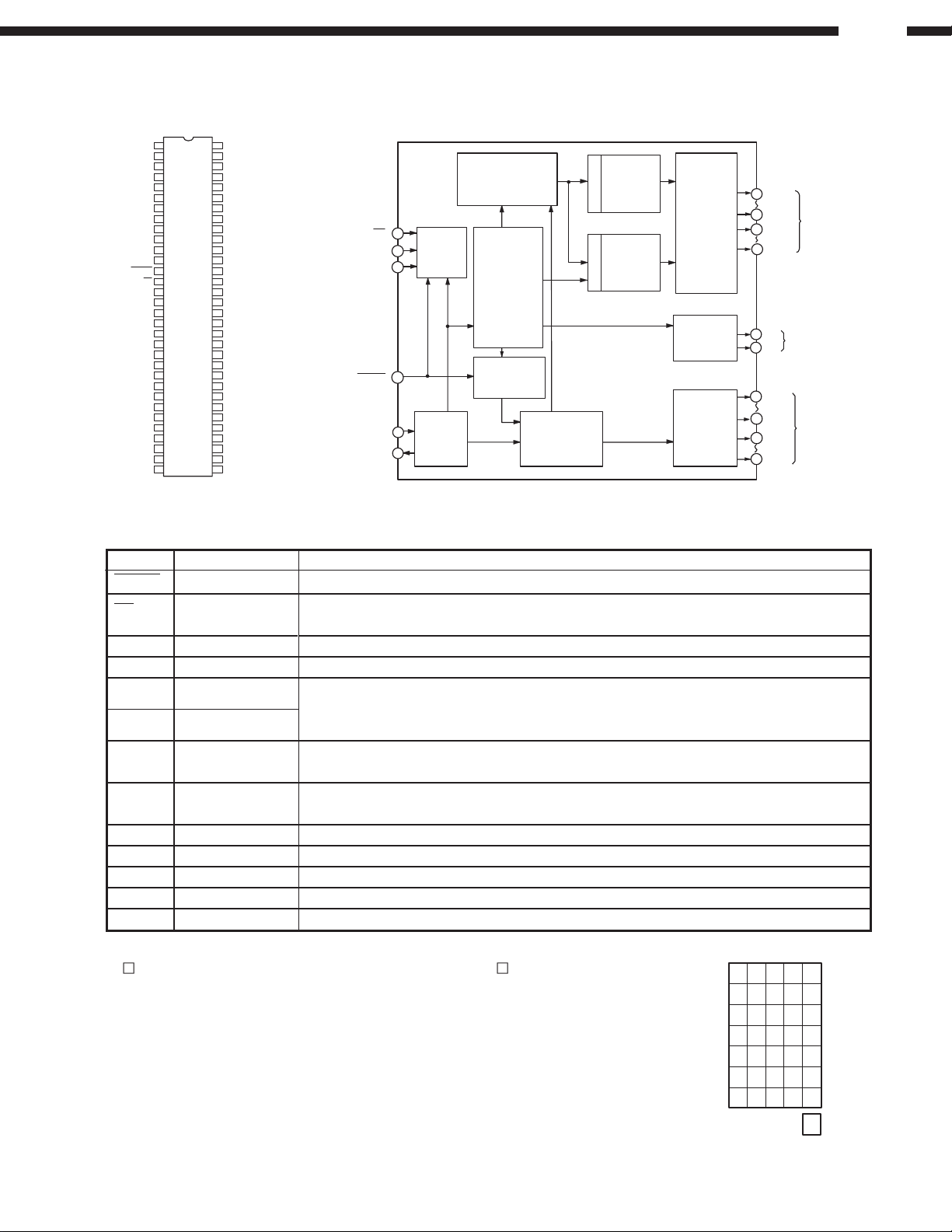

LC78683E (IC203)

MADRS0

MADRS1

MADRS2

MADRS3

MADRS4

MADRS5

MADRS6

MADRS7

60595857565554535251504948

CL

CE

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

12345678910111213141516171819

LRSY

ADBCK

ADDATA

ADLRCK

TOP VIEW

VSS

CKIN

C2FIN

VSS

DVDD5

VSS

STREQ

STCK

STDAT

FSYNC

CRCF

DVDD6

VSS

WOK

CNTOK

OVF

CMDOUT

CMDIN

INTB

RESB

DATAIN

DATACK

LC78683E Terminal Function

Pin

No.

Symbol

1 LRSY I CD L/R clock input

2 ADDATA O Audio data output

3 ADBCK O Audio bit clock output

4 ADLRCK O Audio L/R clock output

5 C2FIN I CD C2 flag input

6 VSS GND

7 CKIN I System clock (16.9344MHz) input

8 VSS GND

9 CKOUT O Clock (384Fs) output

10 VSS GND

11 DVDD1 I/O power (3.3V)

12 PW I Sub-code data serial input

13 SBSY I Sub-code block sync sig. input

14 SFSY I Sub-code frame sync sig. input

15 SBCK O Sub-code serial clock output

16 AVDD Analog (PLL) power (3.3V)

17 VPRFR VCO osc. range setting pin

18 VCOC VCO control V input

19 VPDO VCO charge pump output

20 AVSS Analog (GND)

21 DVDD2 Internal power (1.7V)

22 VSS GND

23 MDATA0 I/O DRAM data bus

I/O

VSS

CKOUT

DVDD4

MADRS8

VSS

DVDD1

MADRS9

MADRS10

MADRS11

474546

PW

SFSY

SBSY

OEB

MADRS12

CASUB

444342

SBCK

AVDD

VPRFR

Function

CASLB

WEB

VPDO

VCOC

RASB

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

AVSS

MDATA15

MDATA14

MDATA13

MDATA12

MDATA11

MDATA10

MD ATA9

MD ATA8

VSS

DVDD3

MD ATA7

MD ATA6

MD ATA5

MD ATA4

MD ATA3

MD ATA2

MD ATA1

MD ATA0

VSS

DVDD2

Pin

No.

Symbol

I/O

Function

24 MDATA1 I/O DRAM data bus

25 MDATA2 I/O DRAM data bus

26 MDATA3 I/O DRAM data bus

27 MDATA4 I/O DRAM data bus

28 MDATA5 I/O DRAM data bus

29 MDATA6 I/O DRAM data bus

30 MDATA7 I/O DRAM data bus

31 DVDD3 DRAM I/F power (3.3V)

32 VSS GND

33 MDATA8 I/O DRAM data bus

34 MDATA9 I/O DRAM data bus

35 MDATA10 I/O DRAM data bus

36 MDATA11 I/O DRAM data bus

37 MDATA12 I/O DRAM data bus

38 MDATA13 I/O DRAM data bus

39 MDATA14 I/O DRAM data bus

40 MDATA15 I/O DRAM data bus

41 RASB O DRAM RAS output

42 WEB O DRAM WE output

43 CASLB O DRAM CAS output (Lower Byte)

44 CASUB O DRAM CAS output (Upper Byte)

45 OEB O DRAM OE output

46 MADRS12 O DRAM Address output

47 MADRS11 O DRAM Address output

48 MADRS10 O DRAM Address output

49 MADRS9 O DRAM Address output

50 MADRS8 O DRAM Address output

51 DVDD4 DRAM I/F power (3.3V)

52 VSS GND

53 MADRS7 O DRAM Address output

54 MADRS6 O DRAM Address output

55 MADRS5 O DRAM Address output

56 MADRS4 O DRAM Address output

57 MADRS3 O DRAM Address output

58 MADRS2 O DRAM Address output

59 MADRS1 O DRAM Address output

60 MADRS0 O DRAM Address output

61 DVDD5 Internal power (1.7V)

62 VSS GND

63 STREQ I/O MP3 data request flag in/output

64 STCK I/O MP3 data transfer clock in/output

65 STDAT I/O MP3 data serial in/output

66 FSYNC O MP3 frame sync sig.

67 CRCF O CRC flag out / MP3 data out enable flag

68 DVDD6 µcom I/F power (3.3V)

69 VSS GND

70 WOK I DRAM write act. flag / MP3 data req. flag input

71 CNTOK O Data link chk-end flag / MP3 data serial output

72 OVF O DRAM write off flag / MP3 data trans. clock output

73 CMDOUT O Command serial data output

74 CMDIN I Command serial data input

75 CL I Command serial clock input

76 CE I Command enable input

77 INTB O Interrupt sig. output

78 RESB I System reset

79 DATAIN I CD serial data input

80 DATACK I CD bit clock input

25

24

D-107

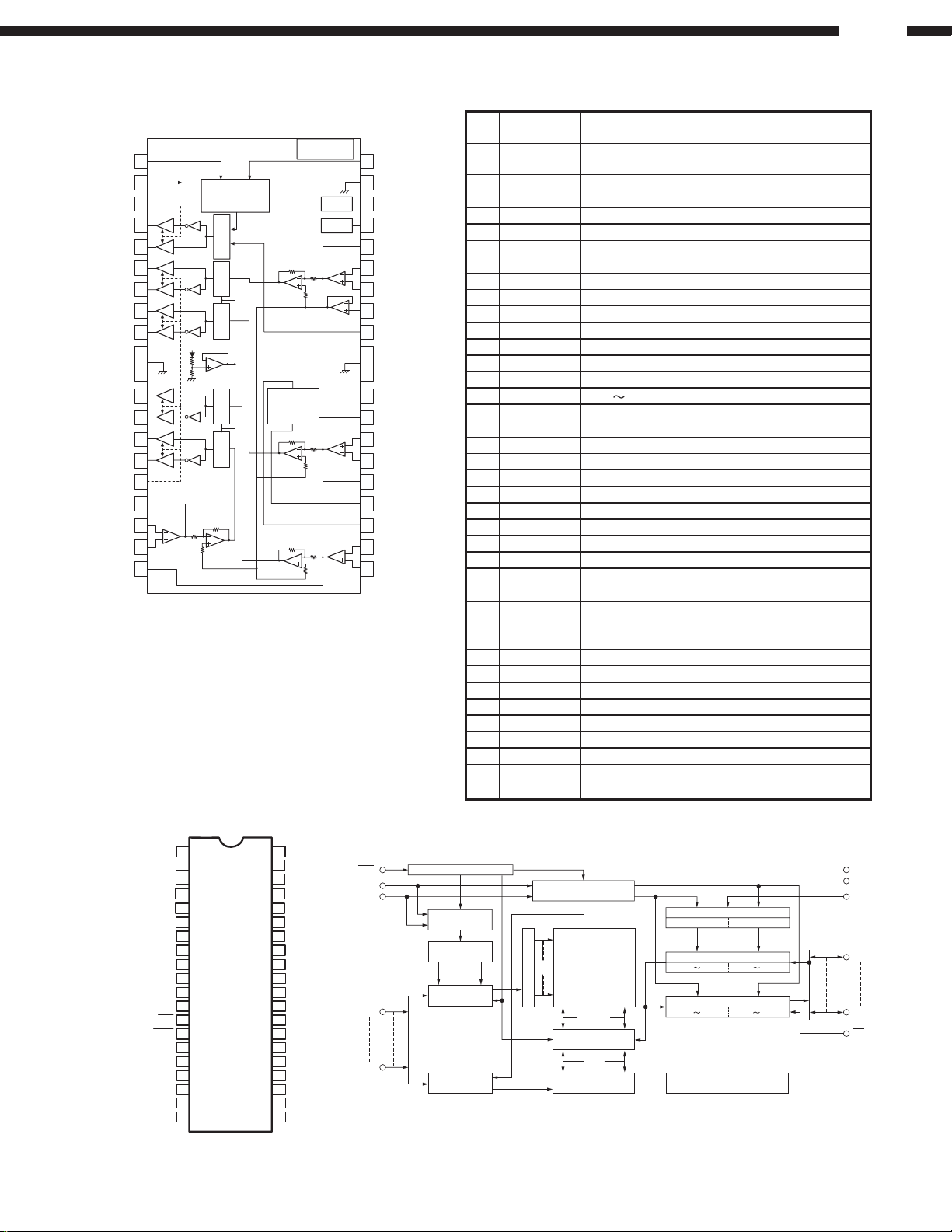

LC78645E (IC204)

DATA

DATACK

LRSY

ASDFIN

ASDACK

ASLRCK

16MOUT

EFLG

C2F

XVSS

FSX/16MIN

XIN

XOUT

XVDD

RVDD

60595857565554535251504948474645444342

61

CE

62

CL

63

DI

64

DO

65

∗WRQ

∗RES

66

DRF

67

VDD5

68

69

VSS

CONT3

CONT2

CONTI

PDOI

PDO2

VVSS

PCKIST

VVDD

FR

LDS

LDD

70

71

72

73

74

75

76

77

78

79

80

123456789

SLCO

EFMIN

SLCIST

RF

TOP VIEW

FIN1

RFVSS

RFVDD

1011121314151617181920

FE

TE

FIN2

TIN1

TIN2

REFI

VREF

TEC

LC78645E Terminal Function

Pin

No.

Symbol

1 SLCO O Control output

2 SLCIST AI R con. pin for current setting of SLCO

3 EFMIN I RF sig. input pin

I/O

For slice

level control

4 RF AO RF sig. monitor pin

5 RFVDD Power pin for RF

6 RFVSS GND pin for RF, connect to 0V

7 FIN1 AI A+C sig. input pin

8 FIN2 AI B+D sig. input pin

9 TIN1 AI E sig. input pin

10 TIN2 AI F sig. input pin

11 VREF AO Vref volt output pin

12 REFI AI Vref volt setting pin

13 FE AO FE sig. monitor pin

14 TEC AO LPF cap. for TE sig. connect pin

15 TE AO TE sig. monitor pin

16 REMON AO RF internal sig. monitor pin

17 JITTC A Cap. connect pin for jitter detect

18 ADAVDD Power pin for servo A/D & D/A

19 ADAVSS GND pin for servo A/D & D/A, connect to 0V

20 TDO AO Output pin for tracking control, D/A output

21 FDO AO Output pin for focus control, D/A output

22 SPDO AO Output pin for spindle control, D/A output

23 SLDO AO Output pin for sled control, D/A output

Function

RCHO

RVSS

JITTC

RFMON

LVS S

ADAVDD

LCHO

LVDD

41

TDO

ADAVSS

40

TEST

39

DOUT

38

VDD

37

(3.3V) VSS

36

MONI5

MONI4

35

MONI3

34

MONI2

33

32

MONI1

FSEQ

31

30

V/∗P

DEFECT

29

28

SBCK/FG

27

SBCK/CONT6

26

CONT5

25

CONT4

24

GPDAC

23

SLDO

22

SPDO

21

FDO

Pin

No.

Symbol

I/O

Function

24 GPDAC AO Servo D/A general output pin

25 CONT4 I/O General output pin 4

26 CONT5 I/O General output pin 5

27 SBCK/CONT6 I/O

28 SBCK/FG I

General output pin 6

or sub-code read out clock input pin

Sub-code read out clock input pin / FG sig. input pin / External emphasis set pin

Function decided by command, connect to 0V when not in use

Control from µcom command, connect to 0V

or open when not in use

29 DEFECT O Defect pin

30 V/*P O Auto switching monitor output pin of rough/phase servo control, H: Rough, L: Phase

31 FSEQ O Sync sig. detect output pin, H: When sync sig. of detected EFM and external are equal

32 MONI1 O Internal sig. monitor pin 1

33 MONI2 O Internal sig. monitor pin 2

34 MONI3 O Internal sig. monitor pin 3

35 MONI4 O Internal sig. monitor pin 4

36 MONI5 O Internal sig. monitor pin 5

37 VSS Digital block GND pin, connect to 0V

38 VDD Digital block power pin

39 DOUT O Digital OUT pin (EIAJ format)

40 TEST I Input pin for test, connect to 0V

41 LVDD Power pin for Lch

42 LCHO AO Output pin for Lch

43 LVSS GND pin for Lch, connect to 0V

44 RVSS GND pin for Rch, connect to 0V

45 RCHO AO Output pin for Rch

Lch D/A

converter

Rch D/A

converter

46 RVDD Power pin for Rch

47 XVDD Power pin for x’tal osc.

48 XOUT O

49 XIN I

For x’tal osc.

33.8688MHz x’tal resonater connect pin

50 FSX/16MIN I/O 7.35kHz sync sig. output pin or external clock input pin for DF, DAC

51 XVSS GND pin for x’tal osc., connect to 0V

52 C2F O C2 flag output pin

53 EFLG O Correction monitor pin of C1, C2

54 16MOUT O 16.9344MHz output pin

55 ASLRCK I L/R clock input pin (connect to 0V when not in use)

56 ASDACK I Bit clock input pin (connect to 0V when not in use)

57 ASDFIN I L/Rch data input pin (connect to 0V when not in use)

58 LRSY O L/R clock output pin

59 DATACK O Bit clock output pin

60 DATA O L/Rch data output pin

For anti-

shock mode

For digital

data output

61 CE I Chip enable sig. input pin

62 CL I Data transfer clock input pin

63 DI I Data input pin

For µcom I/F

64 DO O Data output pin (Nch open drain output)

65 *WRQ O Interrupt sig. output pin

66 *RES I Reset input pin, set to “L” once when power ON

67 DRF O Focus ON detect pin

68 VDD5 Power pin for µcom I/F

69 VSS Digital block GND pin, connect to 0V

70 CONT3 I/O General output pin 3

71 CONT2 I/O General output pin 2

72 CONT1 I/O General output pin 1

73 PDO1 O Phase compare out pin 1 for built-in VCO control

74 PDO2 O Phase compare out pin 2 for built-in VCO control

75 VVSS GND pin for built-in VCO control

76 PCKIST AI R con. pin for PDO1, 2 output current setting

For PLL

77 VVDD Power pin for built-in VCO control

78 FR AI R con. pin for built-in VCO frequency range setting

79 LDS AI Laser power detect sig. input pin

80 LDD AO Laser power control sig. output pin

41

25

M66004FP (IC701)

DIG

11

1

2

DIG

10

3

DIG

09

DIG

08

4

DIG

07

5

DIG

06

6

DIG

05

7

DIG

04

8

9

DIG

03

DIG

02

10

DIG

01

11

DIG

00

12

13

RESET

CS

14

15

SCK

SDATA

16

PI

17

PO

18

19

Vcc1

20

X

out

21

X

in

22

Vss

SEG

23

35

24

SEG

34

SEG

33

25

SEG

32

26

SEG

31

27

28

SEG

30

SEG

29

29

SEG

28

30

SEG

27

31

Vp SEG

32

DIG

64

63

DIG

62

DIG

DIG

61

60

Vcc2

59

SEG

SEG

58

SEG

57

56

SEG

55

SEG

54

SEG

53

SEG

52

SEG

51

SEG

50

SEG

49

SEG

48

SEG

47

SEG

46

SEG

45

SEG

SEG

44

43

SEG

42

SEG

41

SEG

SEG

40

39

SEG

38

SEG

SEG

37

SEG

36

35

SEG

34

SEG

33

12

13

14

15

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

C hip Select Input

S h ift C lo c k In p u t

S e r ia l D a ta In p u t

R e s e t In p u t

C lo c k In p u t

C lock O u tput

CS

SCK

SDATA

RESET

XIN

XOU T

14

15

16

13

21

20

Serial

Reception

Circuit

Clock

G eneration

Circuit

D isplay C ode R eg ister

(8 -b it x 1 6 )

code

write

C o d e /

C om m and

Control Circuit

Display Control

R egister

D is p la y C o n t ro lle r

RAM

write

code select

CGROM

(35-bit x 160)

DecoderDecoder

CGROM

(35-bit x 16)

Segm ent

O utput

Circuit

O u tp u t P o rt

(2 -bit)

D igit O utput

Circuit

D-107

SEG

00

59

26

SEG

33

31

23

18

17

12

1

64

61

SEG

SEG

P0

P1

DIG

DIG

DIG

DIG

Segm ent

27

O utput

35

O u tp u t P o rt

00

11

D igit O utput

12

15

M66004FP Terminal Function

Symbol Name Function

RESET Reset Input

CS Chip Select Input

SCK Shift Clock Input

SDATA Serial Data Input

X

IN Clock Input

OUT Clock Output

X

DIG 00~

DIG 15

SEG 00~

SEG 35

Digit Output

Segment Output

P0, P1

VCC1

VCC2

Vss

Vp

(Forwarding connection of segment output terminal.)

in the right figure indicates 1 dot of segment, the figure in shows the segment output

terminal number (00~35) to be connected.

Initialzes internal state of M66004.

Able to communicate with MCU in "L" mode.

Command from MCU will be disregareded in "H" mode.

Shifts input data at rise from "L" to "H".

Inputs character code or command data needed to display from MSB.

Sets oscillation frquency by connecting external resistor and capacitor (maximum

oscillation frequency fosc (max)=1MHz). Also feasible to apply external clock. In this case,

inject external clock to Xin terminal and open Xout terminal.

Connect to digit terminal of VFD. DIG00~DIG15 correspond to the 1st figure to 16th figure

respectively.

Connect to segment terminal of VFD. For corresponding SEG00~SEG35 to segment

terminal of VFD, refer to the figure right.

Output port (static operation).

Positive power supply terminal for internal logic.

Positive power supply terminal for high tension output port.

GND terminal.

Negative power supply terminal for VFD drive.

00 01 02 03 04

05 06 07 08 09

10 11 12 13 14

15 16 17 18 19

20 21 22 23 24

25 26 27 28 29

30 31 32 33 34

35

26

D-107

)

LA6559 (IC201)

1

REV

Signal System VCC

2

S-VCC

VCC2

VLO-

VLO+

VO4+

VO4-

VO3+

VO3-

VO2+

VO2-

VO1+

VO1-

VCC1

VIN1

VIN1-

VIN1+

VIN2

FR

3

4

5

6

7

8

9

Power

System

GND

FR

10

11

12

13

14

15

16

17

18

Power Supply

(LOADING)

(Forward/Reverse/

Power Supply

(CH1 to CH4)

11k

LC32V4265T-25

(IC208)

Input

Break/OFF)

Control

Output

Level

Shift

Level

Shift

Level

Shift

Level

Shift

33k

Signal System GND

CH2 to CH4

Output

CH1 Output

ON/OFF

33k

Power System GND

3.3VREG

(External PNP)

33k

3.3VREG GND

3.3VREG

Power Supply

33k

Thermal

Shutdown

MUTE2

MUTE1

11k

PNP Tr

Collector

11k

11k

PNP Tr

Base

36

FWD

35

S-GND

34

MUTE2

33

MUTE1

32

VIN4

31

VIN4-

30

VIN4+

29

VREF-IN

28

VCONT(LOADING

FR

FR

27

REG-OUT

26

REG-IN

25

VIN3+

24

VIN3-

23

VIN3

22

GND-VREG

21

VCC-VREG

20

VIN2+

19

VIN2-

Pin

No.

Name

1 REV

2 S-Vcc

Function

5CH output change terminal, logic input of

loading block

signal system power supply

(BTL-AMP:CH1~4)

3 Vcc2 Power supply for loading block

4 VL0− Loading output (−)

5 VL0+ Loading output (+)

6 VO4+ Output terminal (+) for channel 4

7 VO4− Output terminal (−) for channel 4

8 VO3+ Output terminal (+) for channel 3

9 VO3− Output terminal (−) for channel 3

10 VO2+ Output terminal (+) for channel 2

11 VO2− Output terminal (−) for channel 2

12 VO1+ Output terminal (+) for channel 1

13 VO1− Output terminal (−) for channel 1

14 Vcc1 CH1 CH4(BTL-AMP) output stage power supply

15 VIN1 Input terminal for channel 1

16 VIN1− OP-AMP input AMP-A input terminal (−)

17 VIN1+ OP-AMP input AMP-A input terminal (+)

18 VIN2 Input terminal for channel 2, input AMP output

19 VIN2− Input terminal (−) for channel 2

20 VIN2+ Input terminal (+) for channel 2

21 Vcc-VREG 3.3VREG power supply

22 GND-VREG 3.3VREG GND

23 VIN3 Input terminal for channel 3, input AMP output

24 VIN3− Input terminal (−) for channel 3

25 VIN3+ Input terminal (+) for channel 3

26 REG-IN PNP transistor base connected

27 REG-OUT

3.3V power output to which the PNP transistor

collector connected

28 VCONT Loading output voltage set terminal

29 VREF-IN Reference voltage applied terminal

30 VIN4+ Input terminal (+) for channel 4

31 VIN4- Input terminal (−) for channel 4

32 VIN4 Input terminal for channel 4, input AMP output

33 MUTE1 Output ON/OFF for channel 1 (BTL AMP)

34 MUTE2 Output ON/OFF for channel 2 to 4 (BTL AMP)

35 S-GND Signal system GND

36 FWD

Output change terminal (FWD) for loading

output (VLO+−), logic input of loading block

V

1

CC

2

I/O1

3

I/O2

4

I/O3

5

I/O4

6

V

CC

7

I/O5

8

I/O6

9

I/O7

TOP VIEW

10

I/O8

11 30

N.C.

12 29

N.C.

13 28

WE

14 27

RAS

15 26

N.C.

16 25

A0

17 24

A1

18 23

A2

19 22

A3

20

V

CC

40

VSS

39

I/O16

38

I/O15

37

I/O14

36

I/O13

35

V

SS

34

I/O12

33

I/O11

32

I/O10

31

I/O9

RAS Vcc

UCAS

LCAS

N.C.

LCAS

UCAS

A0

OE

A8

A7

A6

A8

A5

Clock Generator No.1

Mode Control

Refresh Counter

Row Address

Buffer

Column Address

Buffer

Clock Generator No.2

Row Decoder

262144 Memory Cell

512

Column Decoder

x16 Bit

512x16

Sense Amp

I/O Gate

512

Pre-Decoder

Clock Generator No.3

Lower Byte Upper Byte

Data Input Buffer

I/O1

I/O8 I/O9 I/O16

Data Output Buffer

I/O1

I/O8 I/O9 I/O16

PWB Bias Generator

Vss

WE

I/O1

I/O16

OE

A4

V

SS21

27

LC75396NE (IC305)

LTIN

LF1C1

LF1C2

LF1C3

LF2C1

LF2C2

LF2C3

LF3C1

LF3C2

LF3C3

LF4C1

LF4C2

LF4C3

LF5

LTOUT

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

D-107

LFIN

LSELO

LINVIN1

V

R1

R2

R3

R4

R5

RINVIN1

RSELO

RTIN

LFCOM

RFCOM

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

LFOUT

LRIN

LRCOM

LROUT

LVref

SS

V

CE

DI

CL

Vref

RVref

RROUT

RRCOM

RRIN

RFOUT

49

50

L5

51

L4

52

L3

53

L2

54

L1

55

DD

56

57

58

59

60

61

62

63

64

1

34

RF1C12RF1C2

RF1C35RF2C1

TOP VIEW

67

RF2C2

RF2C3

89

RF3C1

RF3C2

10 11 12 13 14 15 16

RF5

RF3C3

RF3C1

RF3C2

RF3C3

RTOUT

RFIN

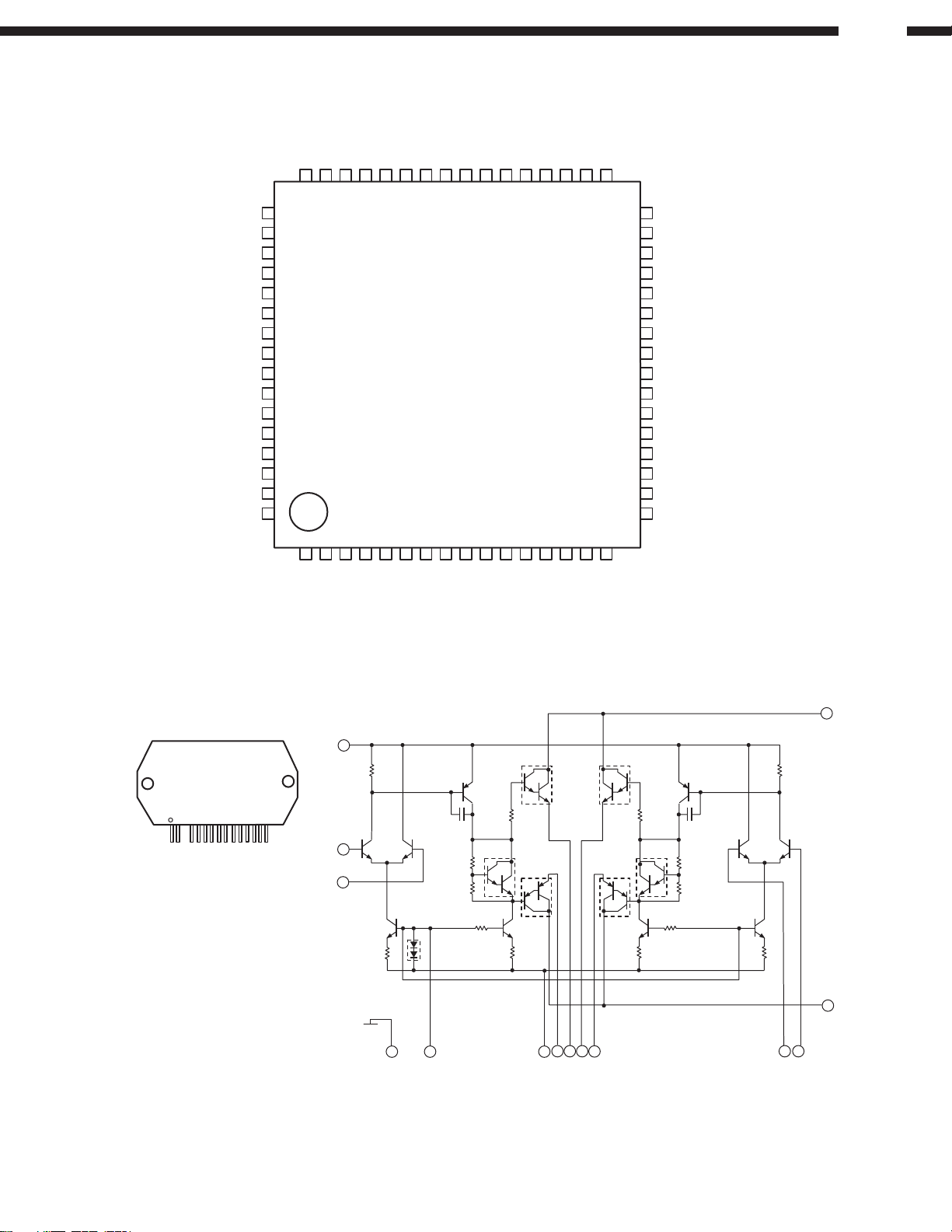

STK402-050 (SW: IC500, 700)

FRONT VIEW

1

15

4

R1

1

TR1 TR2

2

TR3

R2

SUB

8

TR7

TR4

C1

R3

R4

D1

13

5

R6

TR5

TR8

TR6

R5

R7

7610

12

TR9

TR11

R8

C2

TR14

TR12

TR13

R9

R11

R12

R10

TR10

11

R13

TR15

TR16

R14

9

14 15

28

D-107

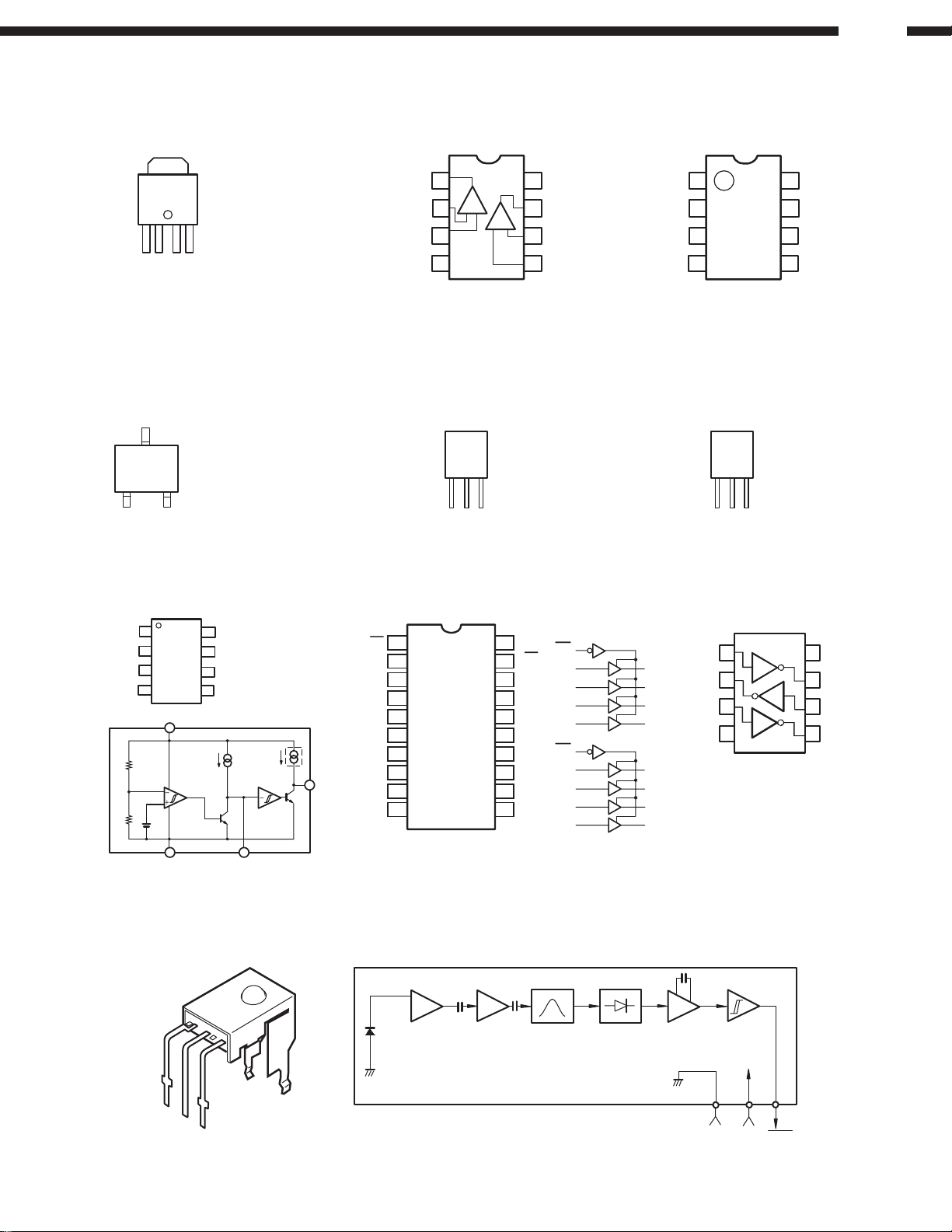

BA033S (IC207) BA6417F (IC202)

BA15218F

(IC301, 303, 401)

(SW: IC101, 102, 105, 106, 401 )

3

1

245

1.CTL

2.Vcc

3.GND

4.OUT

5.N. C.

MN13821C (IC102)

VDD

TOP

VIEW

OUT Vss

NJM7806FA(S) (IC501)

1

1ch

−

+

2

IN1

3

+IN1

45

V

EE

+

2ch

8 OUT1

7

−

6

(SW: IC202, 203)

FRONT

VIEW

GND

Input

Output

Vcc

OUT2

IN2

+IN2

1

2

VM

3

Vcc

45

FIN

NJM7812FA(S) (SW: IC201)

FRONT

VIEW

GND

Input

Output

8 OUT1

7

6

GND

OUT2

VRFF

RIN

M51953AFP (IC103)

NC NC

1

NC

2

3

NC

GND

4

R1

R2

1.25V

Vcc

GND

7

4

8

Vcc

7

OUTPUT

6

DELAY-CAP

5

A

5µ

Typ Typ

DELAY-CAP

25µ

A

5

SN74LVC244APW (IC205)

6

OUTPUT

GP1U271X (Remote Control Sensor)

1OE

1A1

2Y4

1A2

2Y3

1A3

2Y2

1A4

GND

GND

10

TC7WU04F

Vcc

Limiter

Amp

20

19

18

17

16

15

14

13

12

11

1OE

2OE

1A1

1Y1

1A2

2A4

1A3

1Y2

1A4

2A3

2OE

1Y3

2A1

2A2

2A2

1Y4

2A3

2A1

2A4

BPF Integrator

Detector &

Comparator

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

1A

3Y

2A

GND

1

2

3

4

5

6

7

8

9

Head

Amp

(IC206)

1

2

3

4

Hysteresis

Comparator

8

Vcc

7

1Y

6

3A

5

2Y

V

OUT

Vcc

GND

GND Vcc

Vout

29

Loading...

Loading...