Page 1

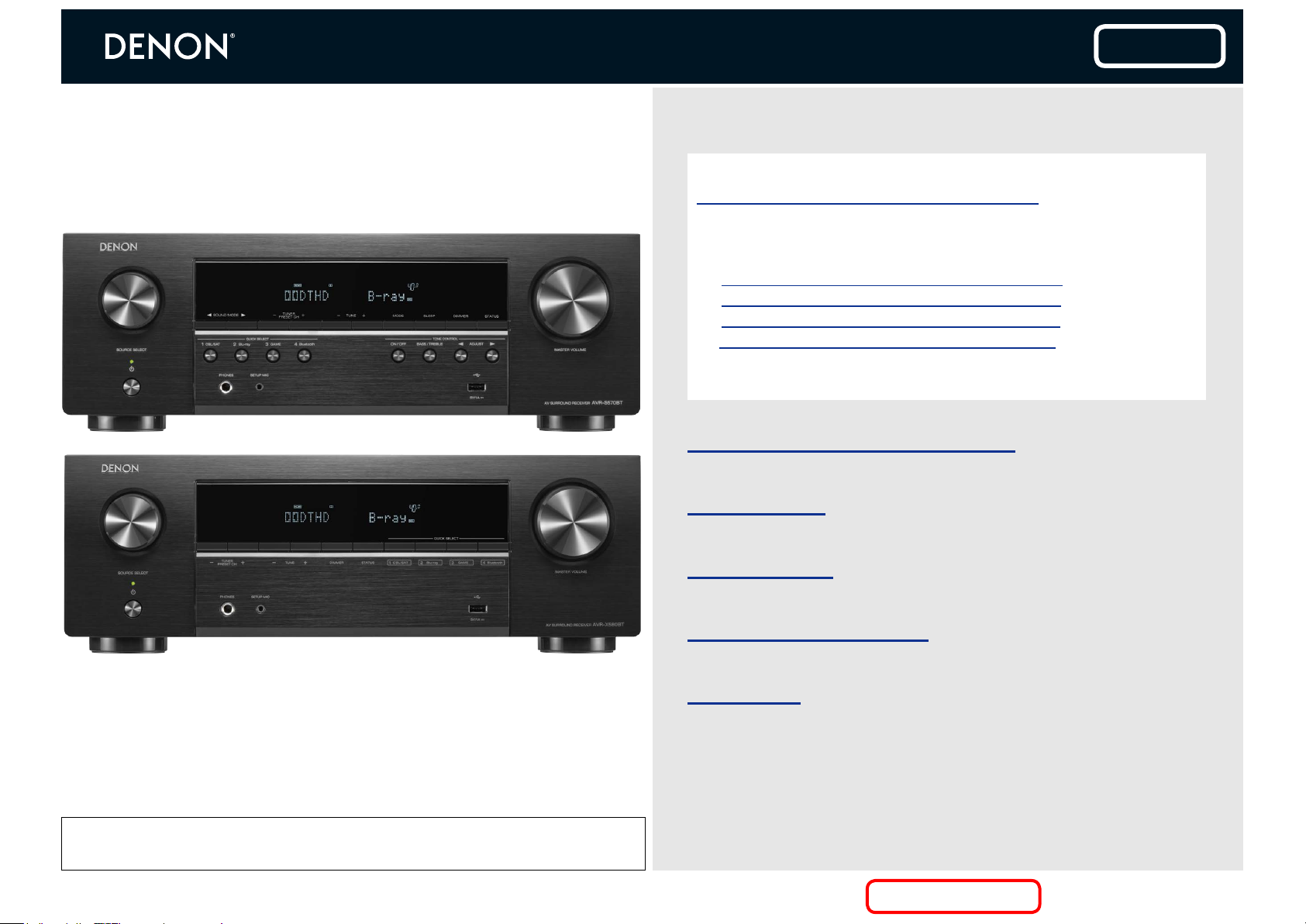

AV SURROUND RECEIVER

Service Manual

Ver. 2

AVR-S570BT

AVR-X580BT

Click here!

On-line service parts list

https://dmedia.soundunited.com/documents/details/29325

ONLINE PARTS LIST (P5)

WEB owner’s manual

NA: https://manuals.denon.com/AVRS570BT/NA/EN/index.php

EU: https://manuals.denon.com/AVRX580BT/EU/EN/index.php

AP: https://manuals.denon.com/AVRX580BT/AP/ZH/index.php

JP: https://manuals.denon.com/AVRX580BT/JP/JA/index.php

Upload is planned for the time of a future press release.

BEFORE SERVICING THIS UNIT

ELECTRICAL

MECHANICAL

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

•Forpurposesofimprovement,specicationsanddesignaresubjecttochangewithoutnotice.

•Pleaseusethisservicemanualwhenreferringtotheoperatinginstructionswithoutfail.

•Someillustrationsusedinthisservicemanualareslightlydifferentfromtheactualproduct.

REPAIR INFORMATION

UPDATING

Please refer to the MODIFICATION NOTICE.

Condential

Page 2

SAFETY PRECAUTIONS

BEFORE SERVICING THIS UNIT

NOTE FOR SCHEMATIC DIAGRAM

HANDLING THE SEMICONDUCTOR AND OPTICS

ONLINE PARTS LIST

Accessing the Parts List

Searching Part Numbers or Ref. Numbers

NOTE FOR PARTS LIST

SERIAL NUMBER

Serial Number Organization

SKU Code of this Unit

POST-SERVICE PRECAUTIONS

Initializing this Unit AVR-S570BT

Initializing this Unit AVR-X580BT

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

2

Page 3

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

Leakage current check

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from

chassis to either side of the power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state (on, off and standby mode), if applicable.

This Unit

CAUTION

Please heed the following cautions and instructions during

servicing and inspection.

◎ Heed the cautions!

Cautions which are delicate in particular for servicing are labeled on the cabinets, the parts and the

chassis, etc. Be sure to heed these cautions and the cautions described in the handling instructions.

◎ Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if you touch internal metal parts when the set is energized,

you may get an electric shock. Avoid getting an electric shock, by using an isolating transformer and

wearing gloves when servicing while the set is energized, or by unplugging the power cord when

replacing parts, for example.

(2) There are high voltage parts inside. Handle with extra care when the set is energized.

◎ Caution concerning disassembly and assembly!

Through great care is taken when parts were manufactured from sheet metal, there may be burrs on the

edges of parts. The burrs could cause injury if ngers are moved across them in some rare cases. Wear

gloves to protect your hands.

◎ Use only designated parts!

The set's parts have specic safety properties (re resistance, voltage resistance, etc.). Be sure to use

parts which have the same properties for replacement. The burrs have the same properties. In particular,

for the important safety parts that are indicated by the z mark on schematic diagrams and parts lists,

be sure to use the designated parts.

◎ Be sure to mount parts and arrange the wires as they were originally placed!

For safety seasons, some parts use tapes, tubes or other insulating materials, and some parts are

mounted away from the surface of printed circuit boards. Care should also be taken with the positions

of the wires by arranging them and using clamps to keep them away from heating and high voltage

parts, so be sure to set everything back as it was originally placed.

◎ Make a safety check after servicing!

Check that all screws, parts and wires removed or disconnected when servicing have been put back

in their original positions, check that no serviced parts have deteriorated the area around. Then make

an insulation, check on the external metal connectors and between the blades of the power plug. And

otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the antenna, plugs, etc., and on the power.

Using a 500V insulation resistance tester, check that the insulation resistance value between the inplug

and the externally exposed metal parts (antenna terminal, headphones terminal, input terminal, etc.) is

1M Ω or greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and the structural parts used in the set have special safety properties. In most

cases these properties are difcult to distinguish by sight, and the use of replacement parts with higher

ratings (rated power and withstand voltage) does not necessarily guarantee that safety performance

will be preserved. Parts with safety properties are indicated as shown below on the wiring diagrams and

the parts list in this service manual. Be sure to replace them with the parts which have the designated

part number.

(1) Schematic diagrams Indicated by the z mark.

(2) Parts lists Indicated by the z mark.

The use of parts other than the designated parts could cause electric shocks, res or other dangerous

situations.

Concerning important safety parts

Before Servicing

Electrical Mechanical Repair Information Updating

3

Page 4

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended

by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2)

a line to chassis resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from

chassis to either side of the power cord is less than 460 kohms, the set is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identied and remedied.

NOTICE:

(1) ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

(2) ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P

INDICATES MICRO-MICRO FARAD. N INDICATES NANO FARAD.

(3) EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION.

(4) CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

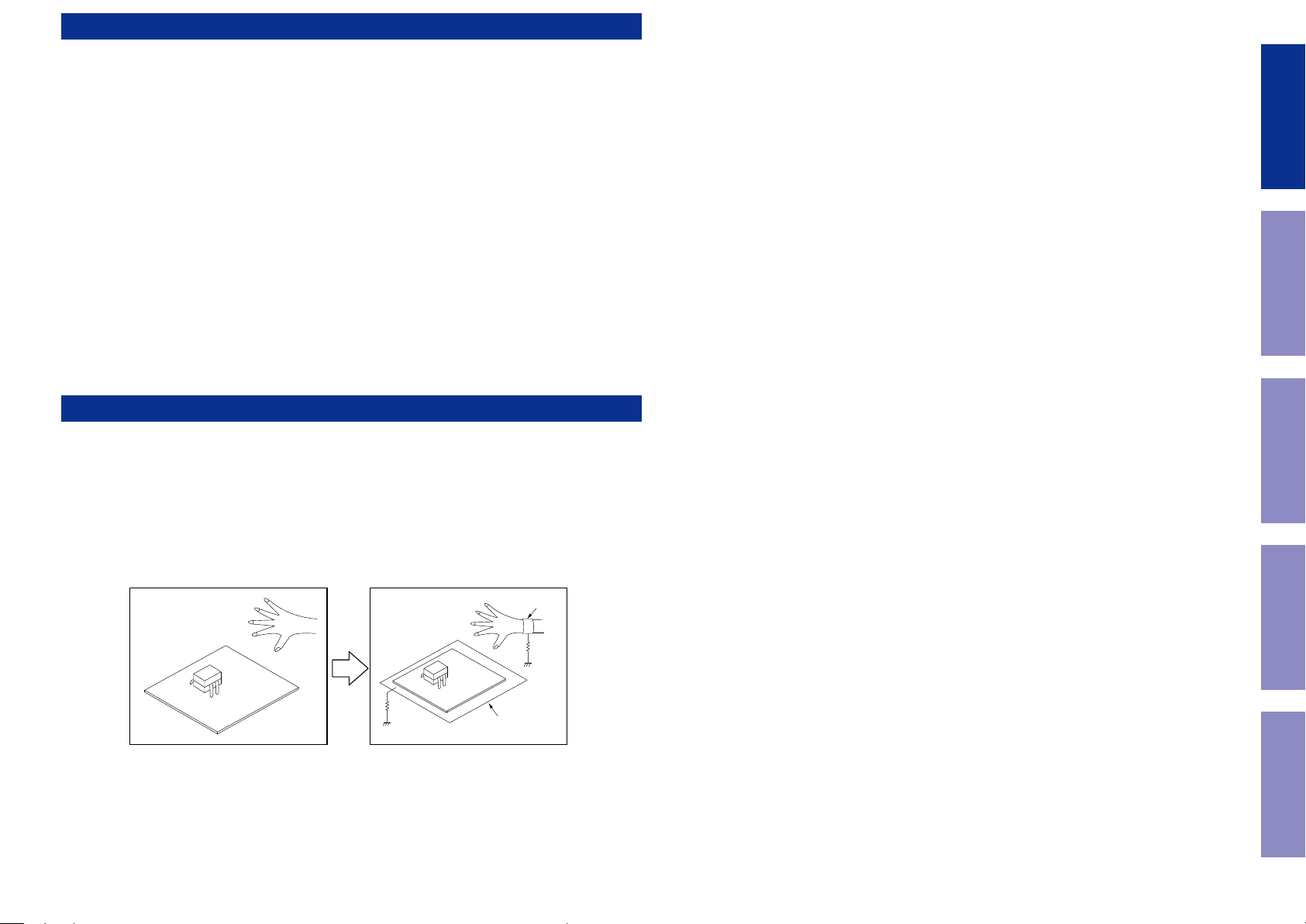

HANDLING THE SEMICONDUCTOR AND OPTICS

Electrostatic breakdown of the semi-conductors or optical pickup may occur due to a potential

difference caused by electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 M ohm) that is properly grounded to remove any static electricity

that may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate with proper grounding (1 M ohm) on the workbench

or other surface, where the semi-conductors are to be placed. Because the static electricity charge

on clothing will not escape through the body grounding band, be careful to avoid contacting semiconductors with your clothing

<Incorrect>

<Correct>

Grounding Band

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

PCB

1MΩ

PCB

Conductive Sheet or

Copper Plate

1MΩ

4

Page 5

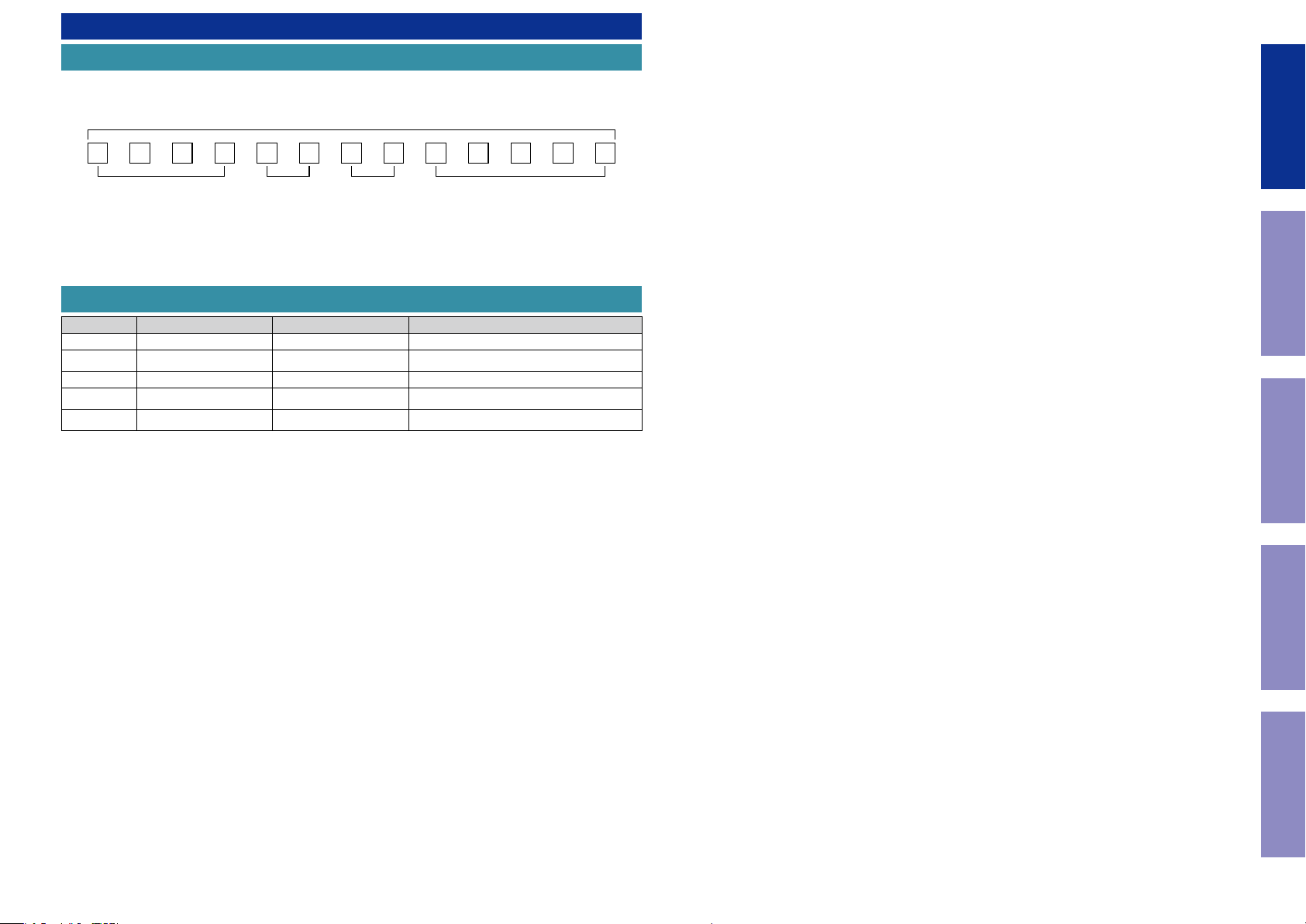

ONLINE PARTS LIST

A

sset No:Owner:Current Version:Status:Published By:Published On

:

k

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

32.2Major09-May-2019Vie

w

e

s

ve

Search Result(s) Found - 10

A

sset No:Owner:Current Version:Status:Published By:Published On

:

Search Result(s) Found - 10

A

sset No:Owner:Current Version:Status:Published By:Published On

:

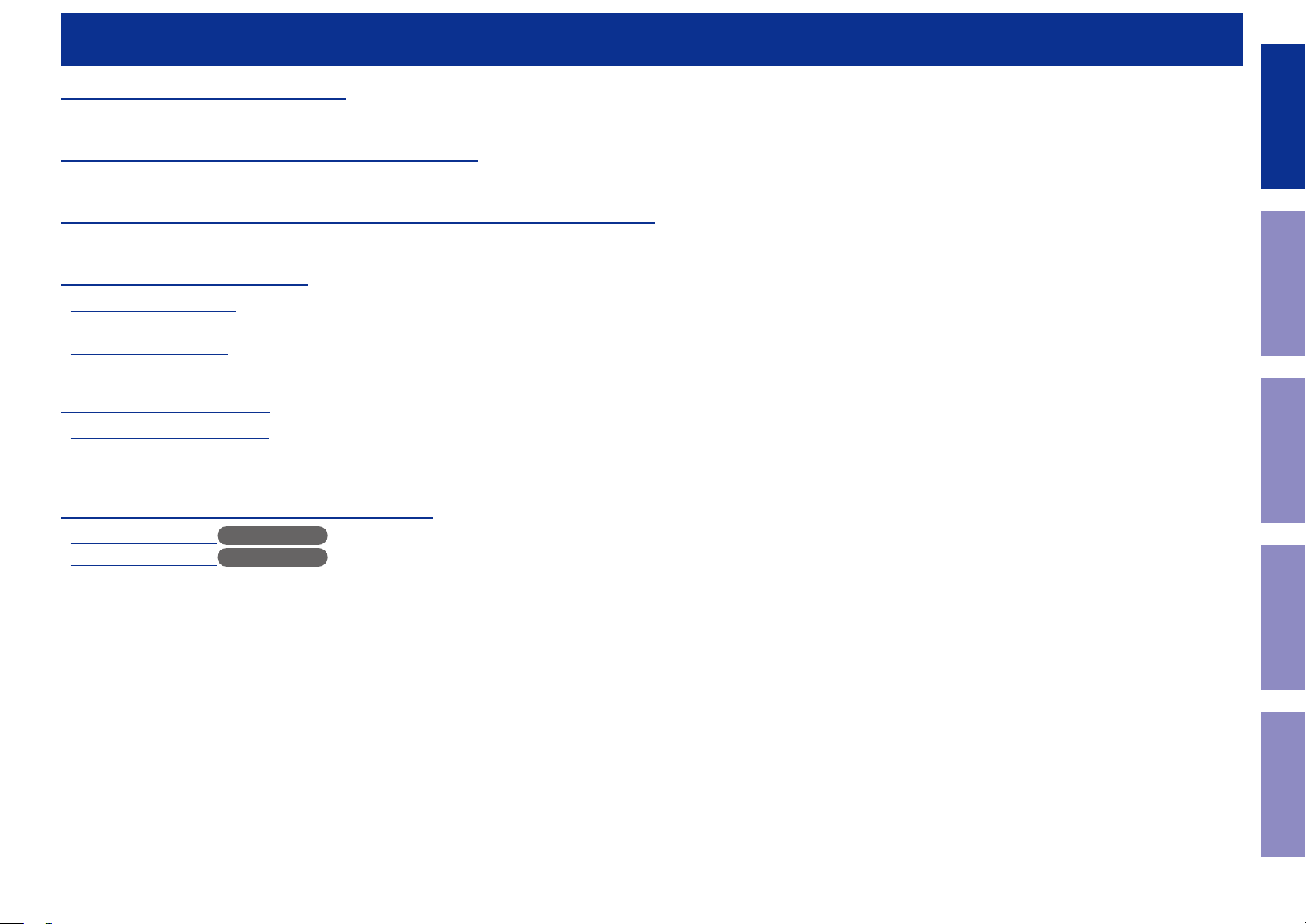

Accessing the Parts List

(1) Access from the Service Manual

・ Click the URL link on the cover of the service manual.

Examples of display

INTEGRATED NETWORK AV RECEIVER

Service Manual

AAA-AAAA

NOTE : If the web browser does not open automatically, copy the URL and paste it into the address bar

of the web browser and then press Enter.

(2) Accessing the Part List from the Model Asset Screen.

・ Display Model Asset from New SDI.

・ Click the section displayed as ▼ Link to Part Lists under the model name.

Click here!

On-line service parts list

AVR-X1700H: https://dmedia.soundunited.com/documents/details/28727

AVR-S760H: https://dmedia.soundunited.com/documents/details/28728

ONLINE PARTS LIST (P5)

WEB owner’s manual

NA: http://manuals.denon.com/AVRX1700H/NA/EN/index.php

EU: http://manuals.denon.com/AVRX1700H/EU/EN/index.php

AP: http://manuals.denon.com/AVRX1700H/AP/ZH/index.php

JP: http://manuals.denon.com/AVRX1700H/JP/JA/index.php

NA: http://manuals.denon.com/AVRS760H/NA/EN/index.php

EU: http://manuals.denon.com/AVRS760H/EU/EN/index.php

Upload is planned for the time of a future press release.

Ver. 1

Searching Part Numbers or Ref. Numbers

You can search a Parts List for part numbers or Ref. numbers.

(1) Enter the part number or Ref. number in the search window of the Parts List, and press the search

button.

(2) The search results are displayed.

The name of the sheet in which the search part is used and the part’s line are displayed.

(3) Next, click the "Sheet" section of the search results.

SR6014 Parts List

21095 Super Administrator 1.2 Published Kazuhiro Nakai 23-Jul-2019

FRONT INPUT VIDEO F.CNT S.CNT DIGITAL

1 SMPS D9001 943203500730S

2 SMPS D9002 943203500730S

SR6014 Parts List

21095 Super Administrator 1.2 Published Kazuhiro Nakai 23-Jul-2019

FRONT INPUT VIDEO F.CNT S.CNT DIGITAL

1 SMPS D9001 9432 03500730S

2 SMPS D9002 9432 03500730S

3 SMPS D9003 9432 03500730S

Download Package

Download Package

(525.24 KB)

(525.24 KB)

Create Public URL

DIODE, RECTIFIER,

AXIAL

DIODE, RECTIFIER,

AXIAL

Create Public URL

DIODE, RECTIFIER,

AXIAL

DIODE, RECTIFIER,

AXIAL

DIODE, RECTIFIER,

AXIAL

943203500730S

CVD1N4007SL 1

CVD1N4007SL 1

943203500730S

CVD1N4007SL 1

CVD1N4007SL 1

CVD1N4007SL 1

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

All Assets Tasks Drafts Notifications Deactivated Archived Advanced Search

XXXXXXXXXX

0000 XxxxxXxxxx 32.2 Published XxxxxXxxxx 09-May-2019

Download Packag

(392.35 MB)

Additional Classification

Brand

Region

Asset Type SDI

Category

Description ▼Link to Parts List

Denon

AP - JAPAN, NA, E

U, AP - CHINA

Version History

Version No. Type Created On

32.1 Major 23-Apr-2019 View

32.0 Major 07-Feb-2019 View

31.0 Major 07-Feb-2019 View

30.0 Major 24-Dec-2017 View

Search

Edit Thi

DeactivateArchi

Content

Search

Bac

NOTE FOR PARTS LIST

1. Parts indicated by "

nsp

" on this table cannot be supplied.

2. When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3. A part ordered without specifying its part number can not be supplied.

4. Part indicated by "@" mark is not illustrated in the exploded and packaging view.

WARNING: Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts

recommended by the manufacturer.

NOTE : If the ▼ Link to Parts List section is not displayed, download the parts table from the Asset list.

5

Page 6

SERIAL NUMBER

Serial Number Organization

The 13-digit serial number that contains the code of the manufacturing date.

13 digits

This Unit

SKU code Month

(01 ~ 12)

The last

2digit of year

Cumulative

serial number

SKU Code of this Unit

SKU Code NAV Number Product Name Description

DBZL 300614-01-00-101 AVRS570BTBKE3 Blk - - Pwr,NA-120V

DBZG 300613-01-00-201 AVRX580BTBKE2 Blk - - EU-Lmtd,220-240V

DBZK 300613-01-00-209 AVRX580BTBKEA Blk - - Australia/New Zealand Only

DBZJ 300613-01-00-206 AVRX580BTBKE1C Blk - - China Only

DBZH 300613-01-00-102 AVRX580BTK Blk - - Pwr,JP-100V

Before Servicing

Electrical Mechanical Repair Information Updating

6

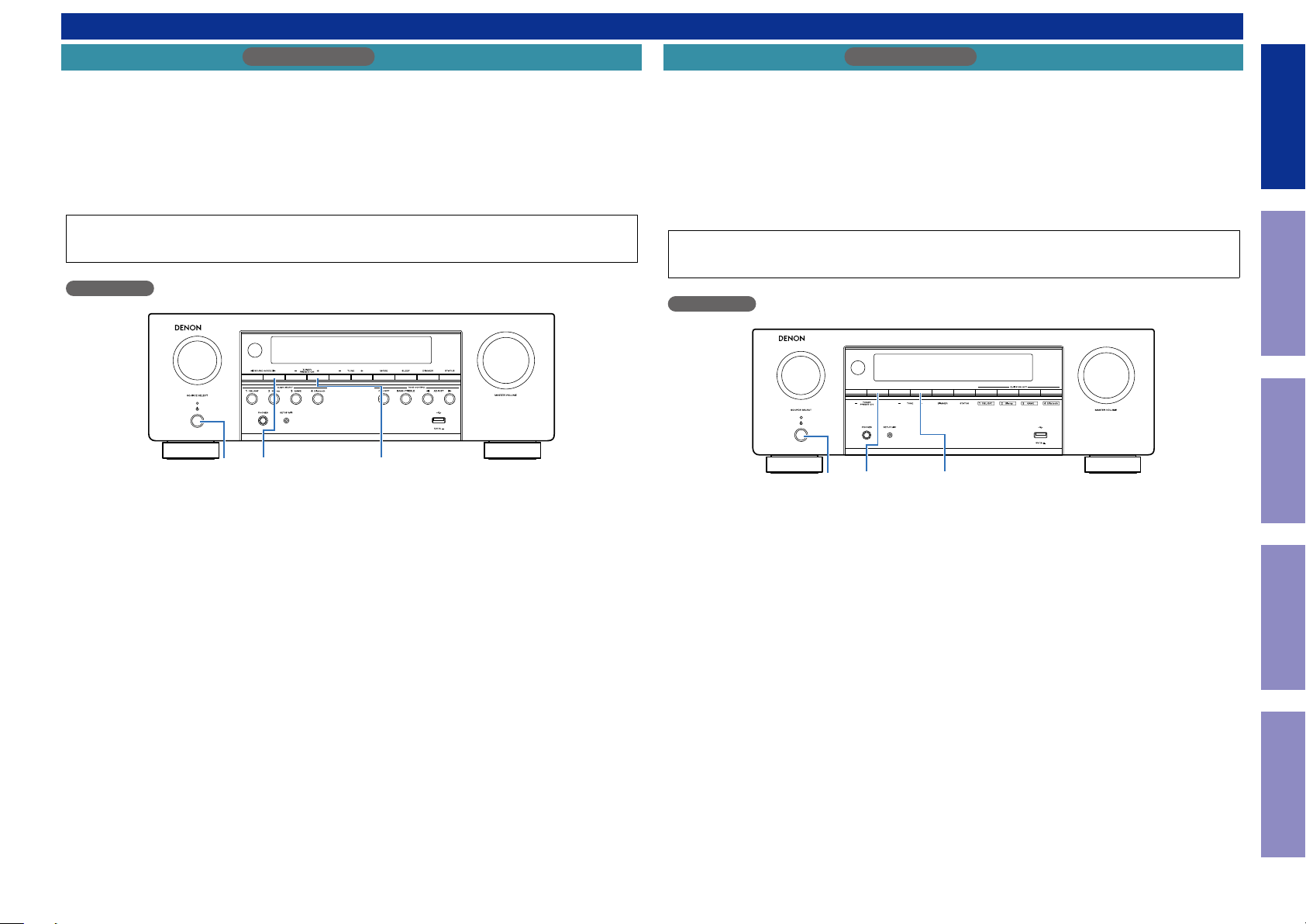

Page 7

POST-SERVICE PRECAUTIONS

Initializing this Unit

Make sure to initialize this unit after replacing the microcomputer or any peripheral equipment, or the

digital PCB.

1. Press the power button to turn off the power.

2. While holding down buttons "

the power button to turn on the power.

3. Release the buttons after conrming that the display ashes at 1-second intervals.

* The unit is initialized.

NOTE: • If the unit fails to enter the service mode in step 3, repeat the procedure from step 1.

• Initializing the device restores the customized settings to the factory settings. Write down

your settings in advance and recongure the settings after initialization.

AVR-S570BT

AVR-S570BT

SOUND MODE

SOUND

X

MODE

1

" and "

1

PRESET CH +

TUNER PRESET CH+

TUNER

" simultaneously, press

Initializing this Unit

Make sure to initialize this unit after replacing the microcomputer or any peripheral equipment, or the

digital PCB.

1. Press the power button to turn off the power.

2. While holding down buttons "

button to turn on the power.

3. Release the buttons after conrming that the display ashes at 1-second intervals.

* The unit is initialized.

NOTE: • If the unit fails to enter the service mode in step 3, repeat the procedure from step 1.

• Initializing the device restores the customized settings to the factory settings. Write down

your settings in advance and recongure the settings after initialization.

AVR-X580BT

AVR-X580BT

TUNER PRESET CH+

TUNER

X

PRESET CH +

TUNE +

" and "

TUNE +

" simultaneously, press the power

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

7

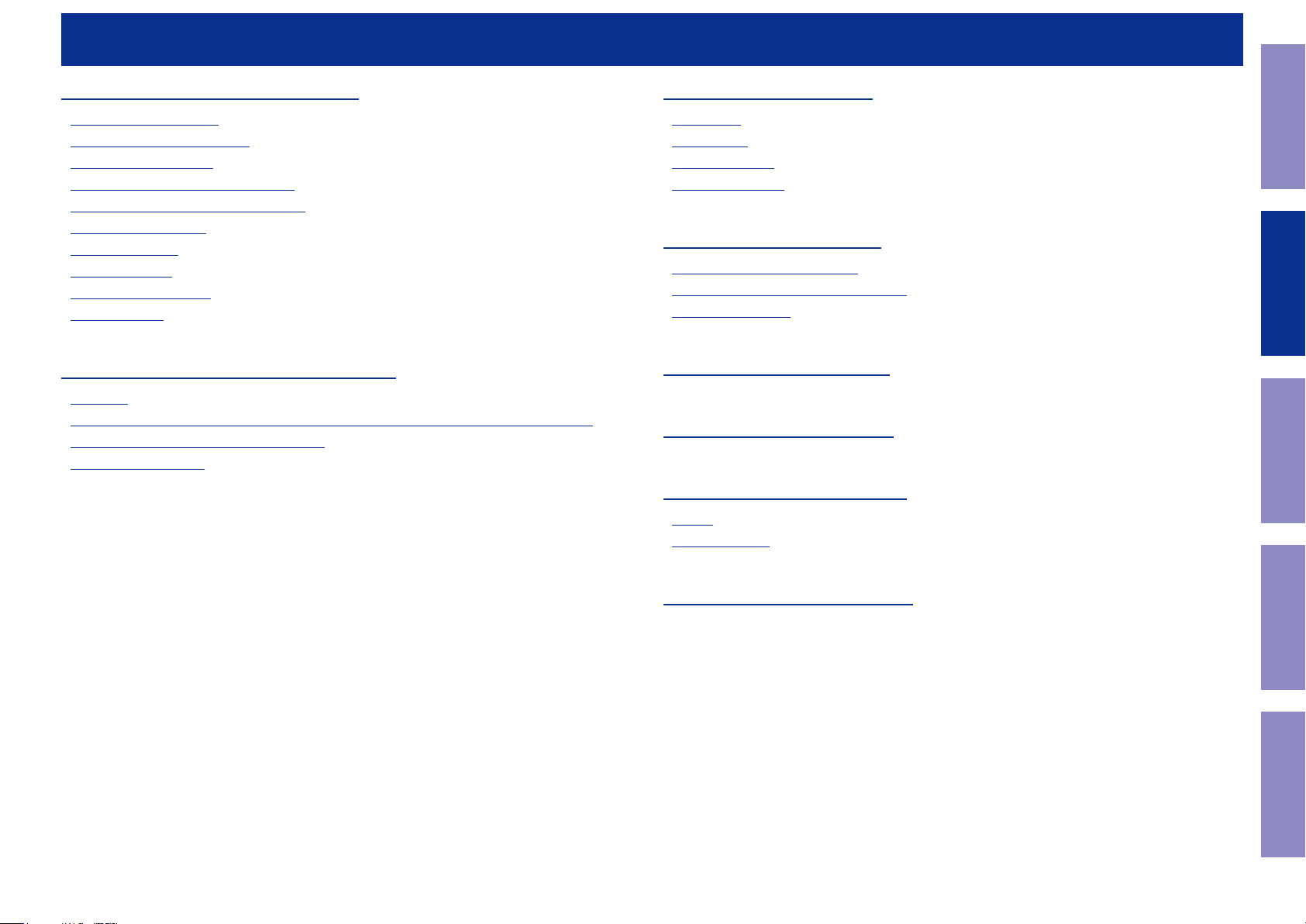

Page 8

ELECTRICAL

SCHEMATIC DIAGRAMS

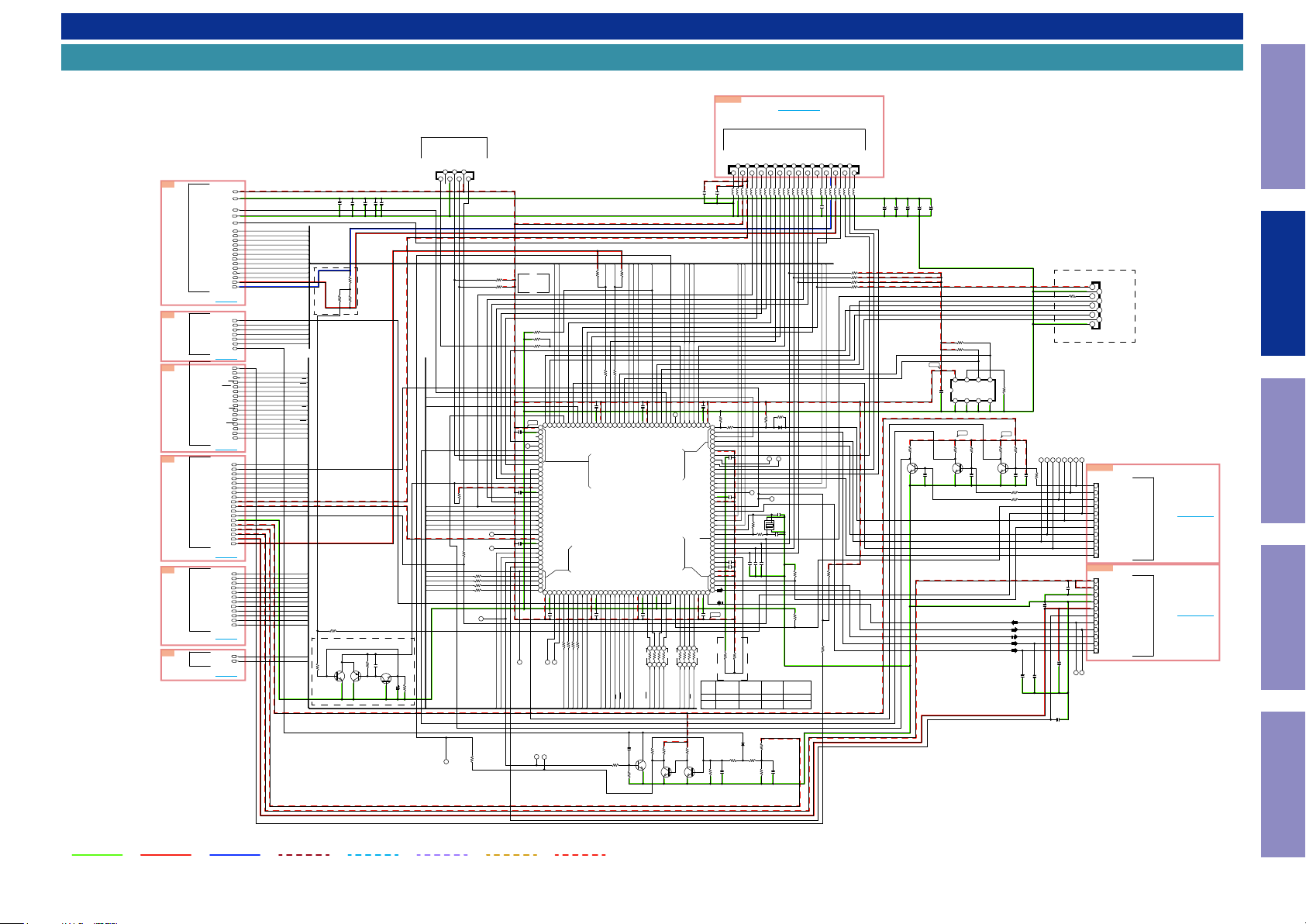

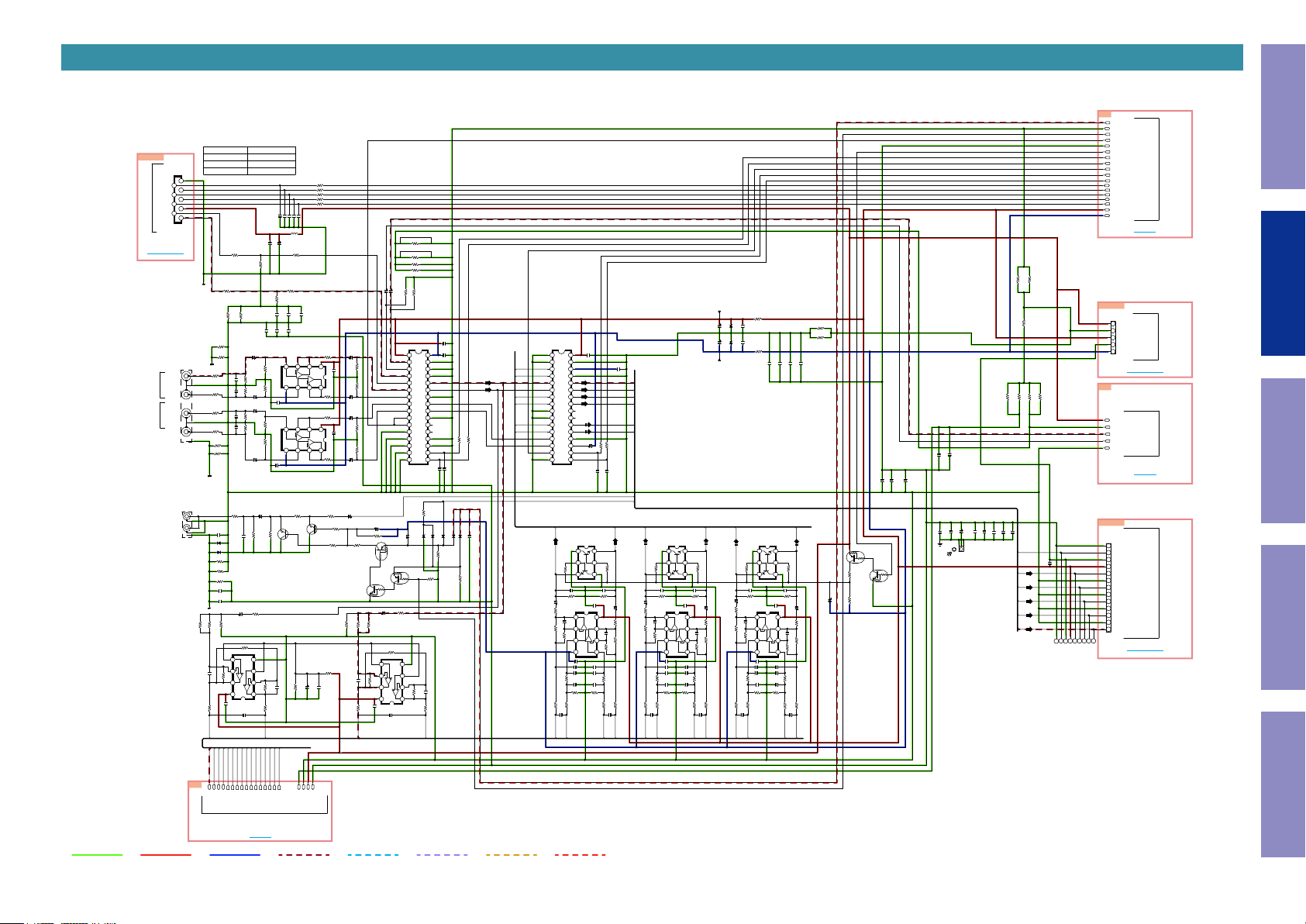

SCH01 DIGITAL MCU

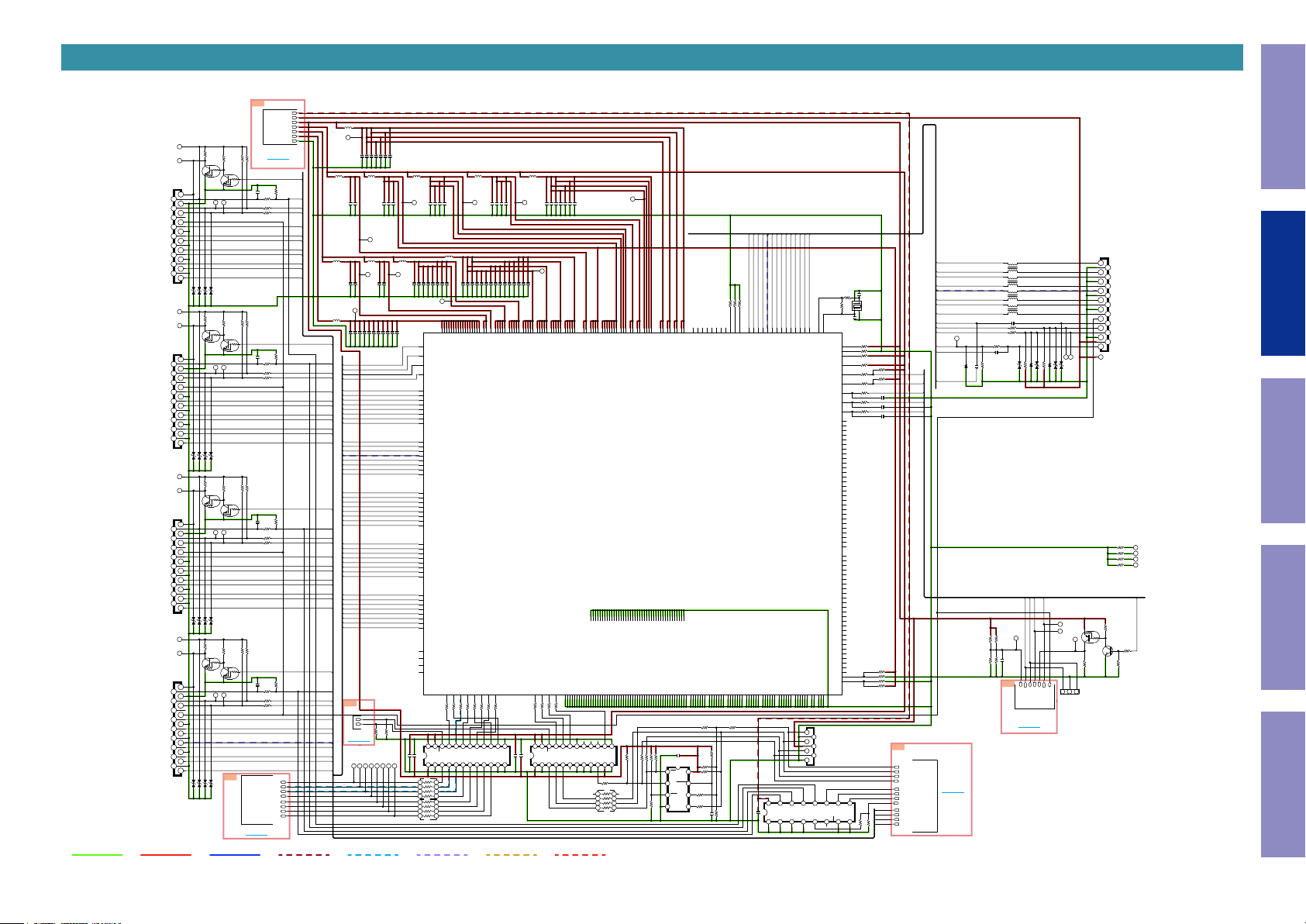

SCH02 DIGITAL HDMI TX

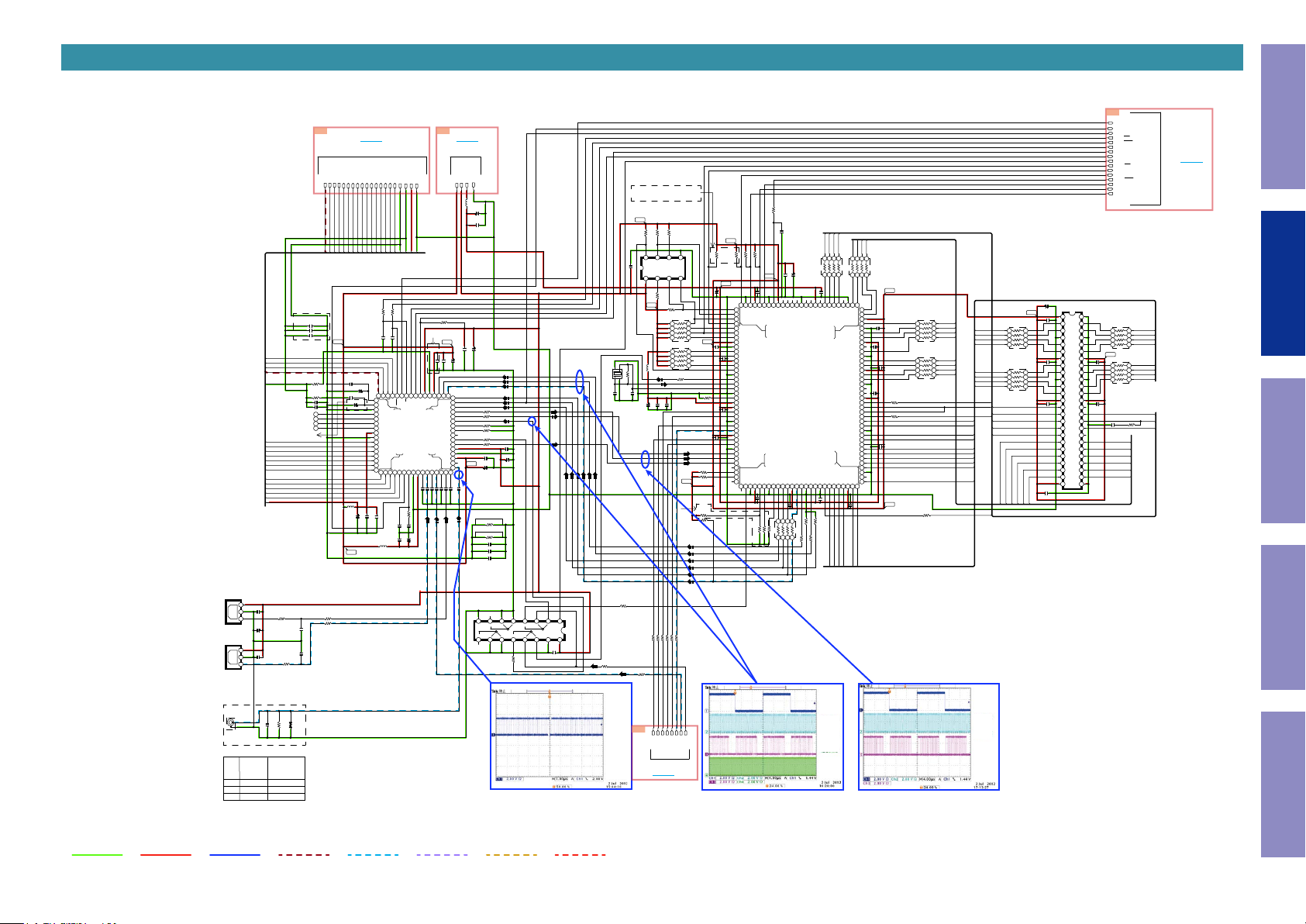

SCH03 DIGITAL DSP

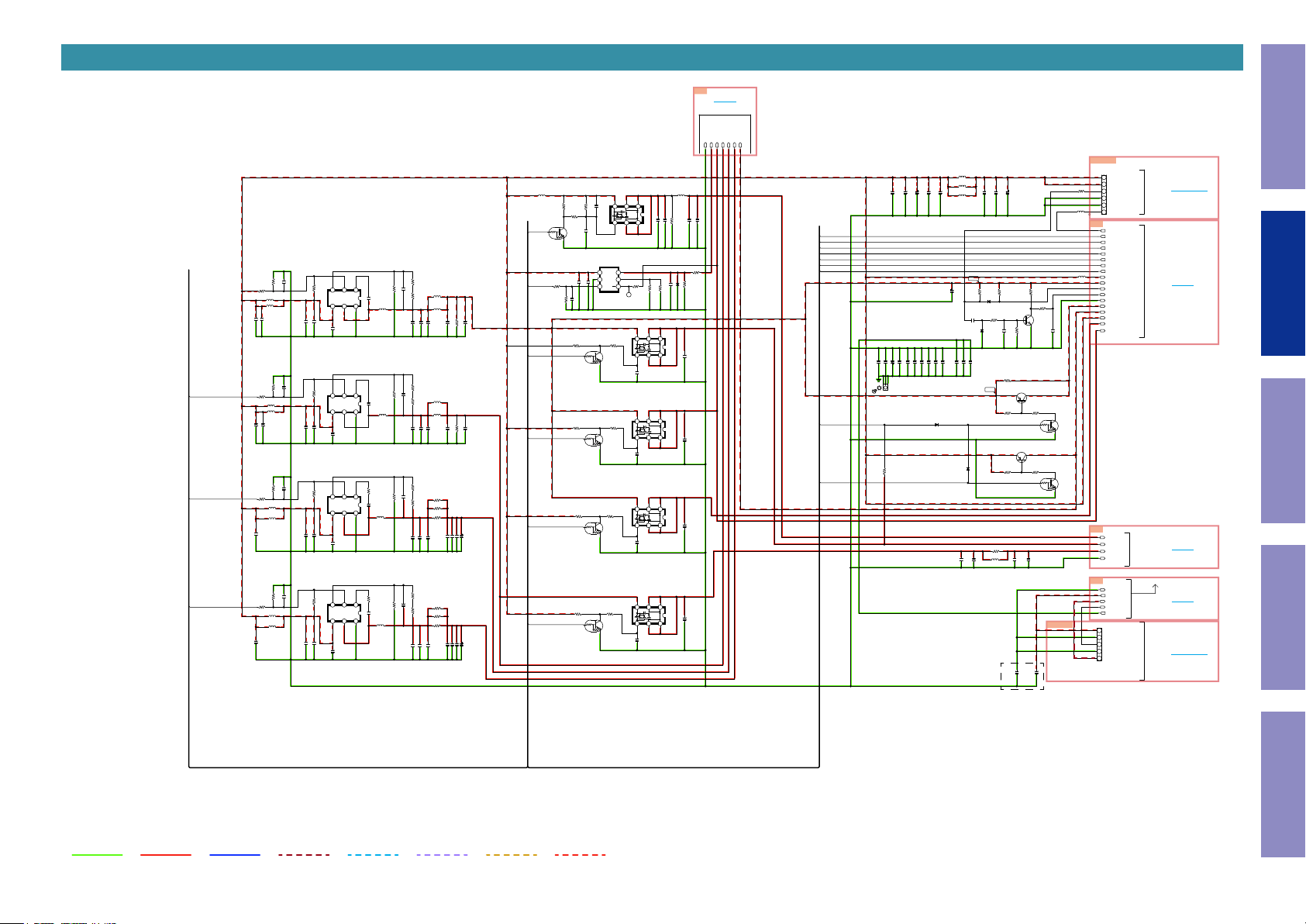

SCH04 DIGITAL INPUT VOLUME

SCH05 DIGITAL DIGITAL POWER

SCH06 MAIN AMP

SCH07 USB, BT

SCH08 FRONT

SCH09 REGULATOR

SCH10 SMPS

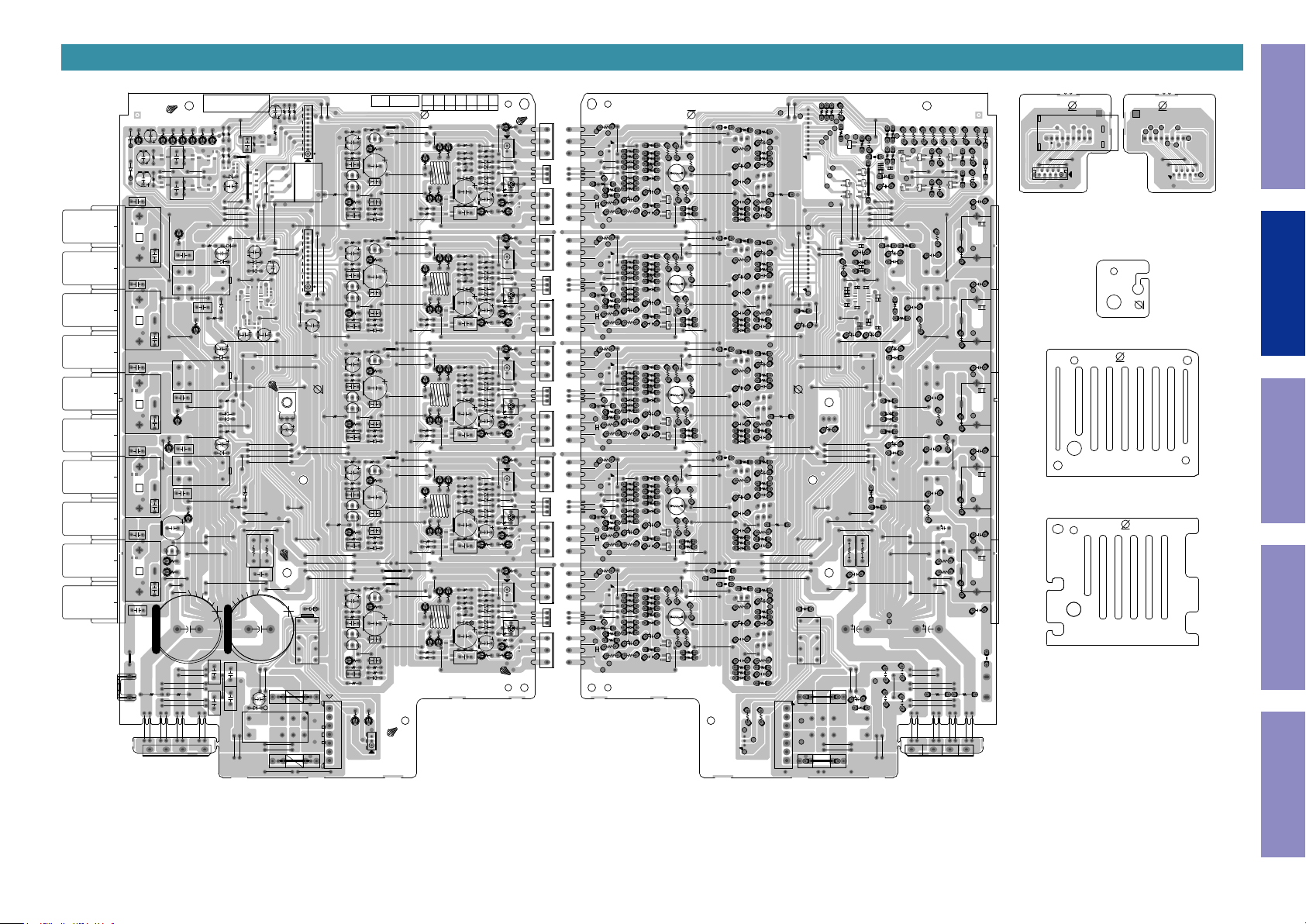

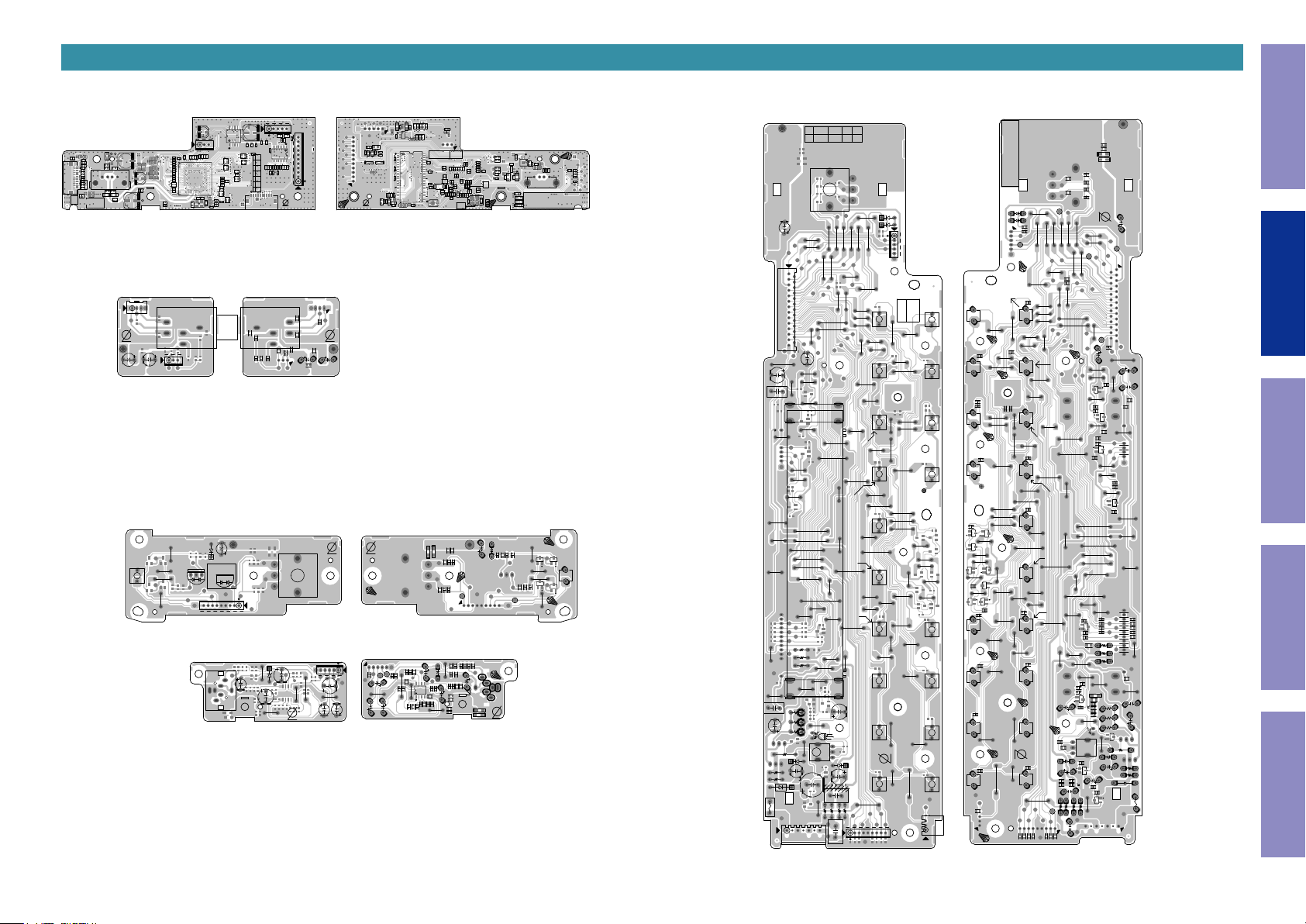

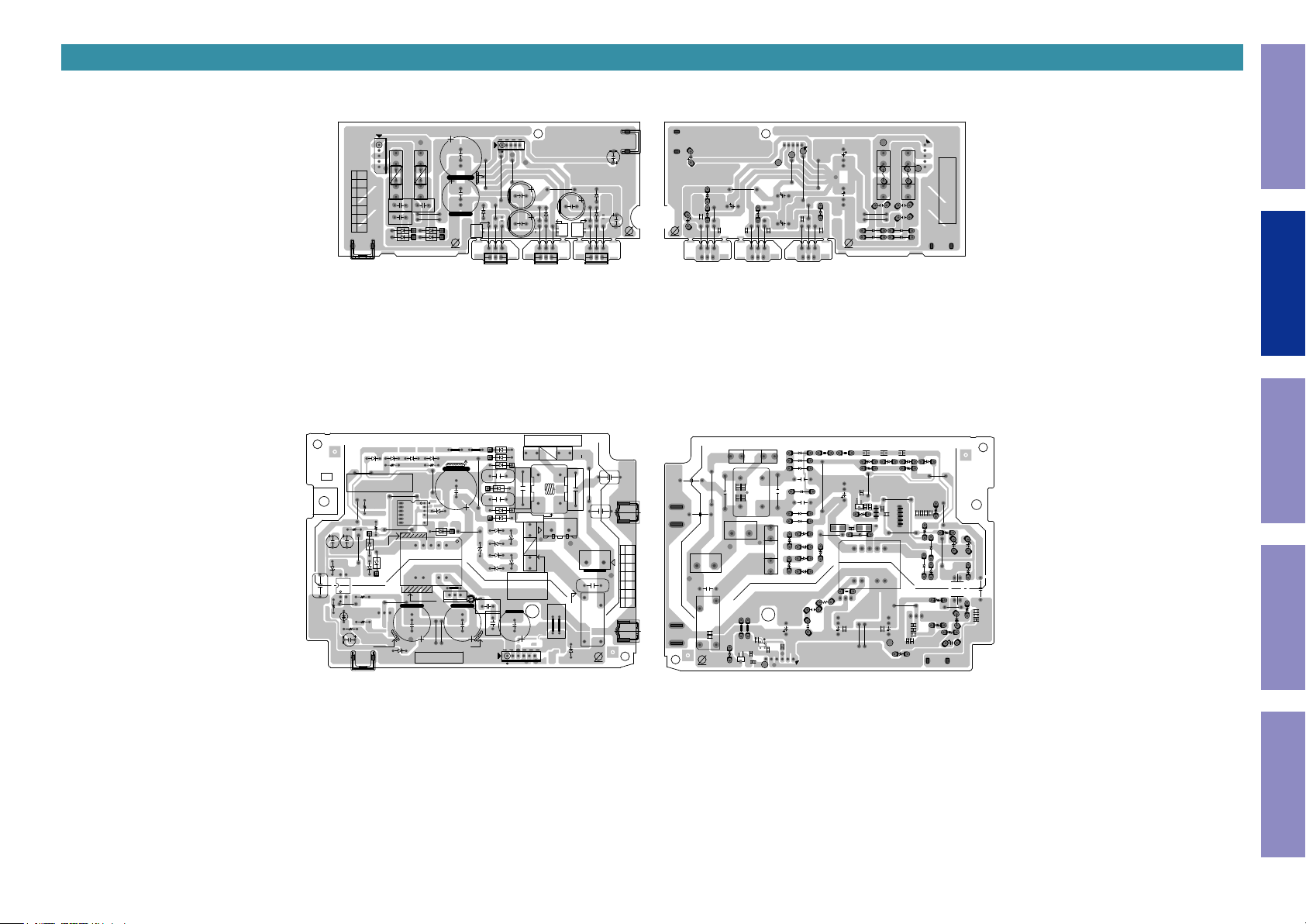

PRINTED CIRCUIT BOARDS

DIGITAL

MAIN, TUNER, PHONE WIRE GUIDE, FRONT CABLE GUIDE, USB WIRE GUIDE

USB, FRONT, PHONE, STANDBY, MIC

REGULATOR, SMPS

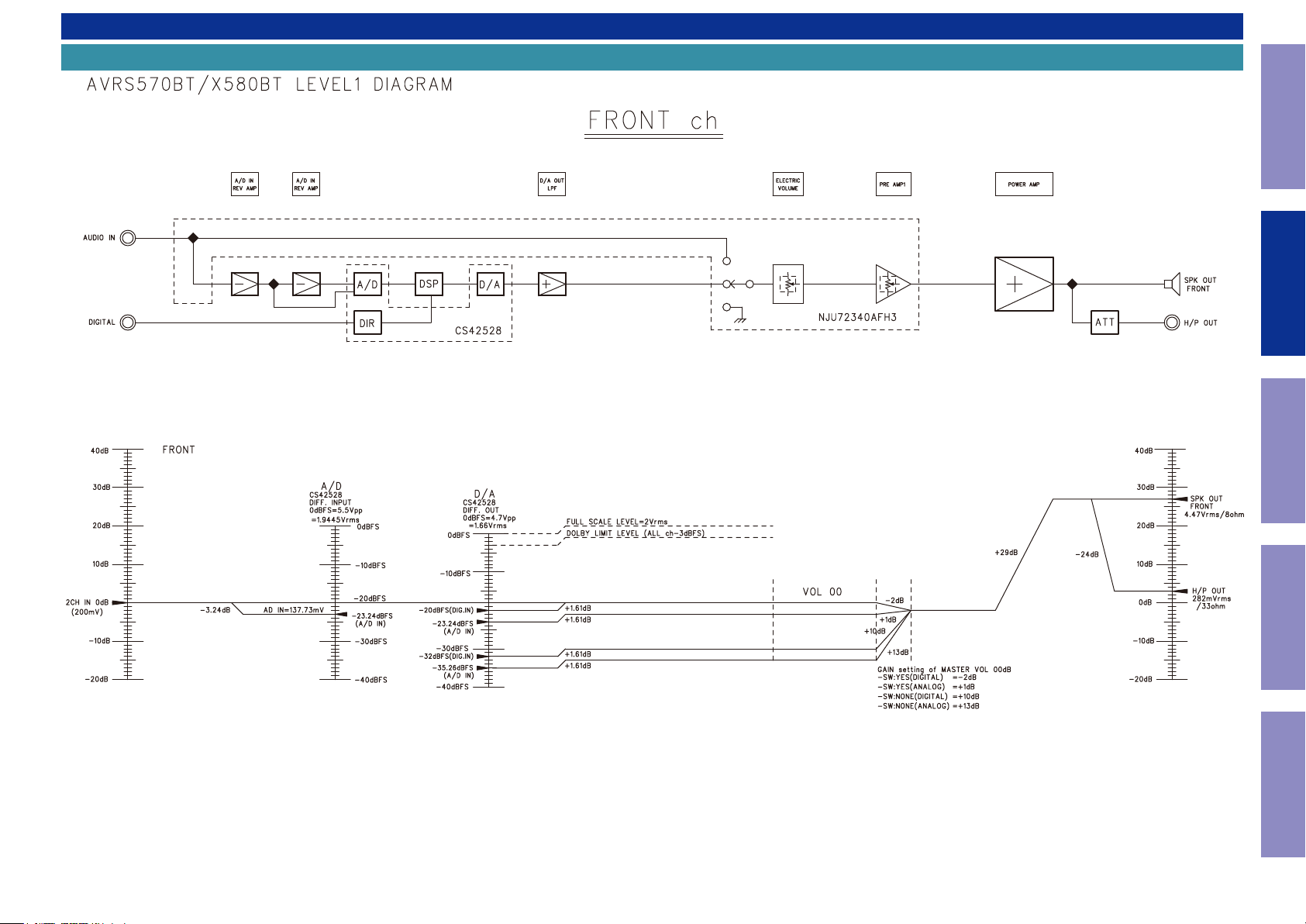

LEVEL DIAGRAM

FRONT ch

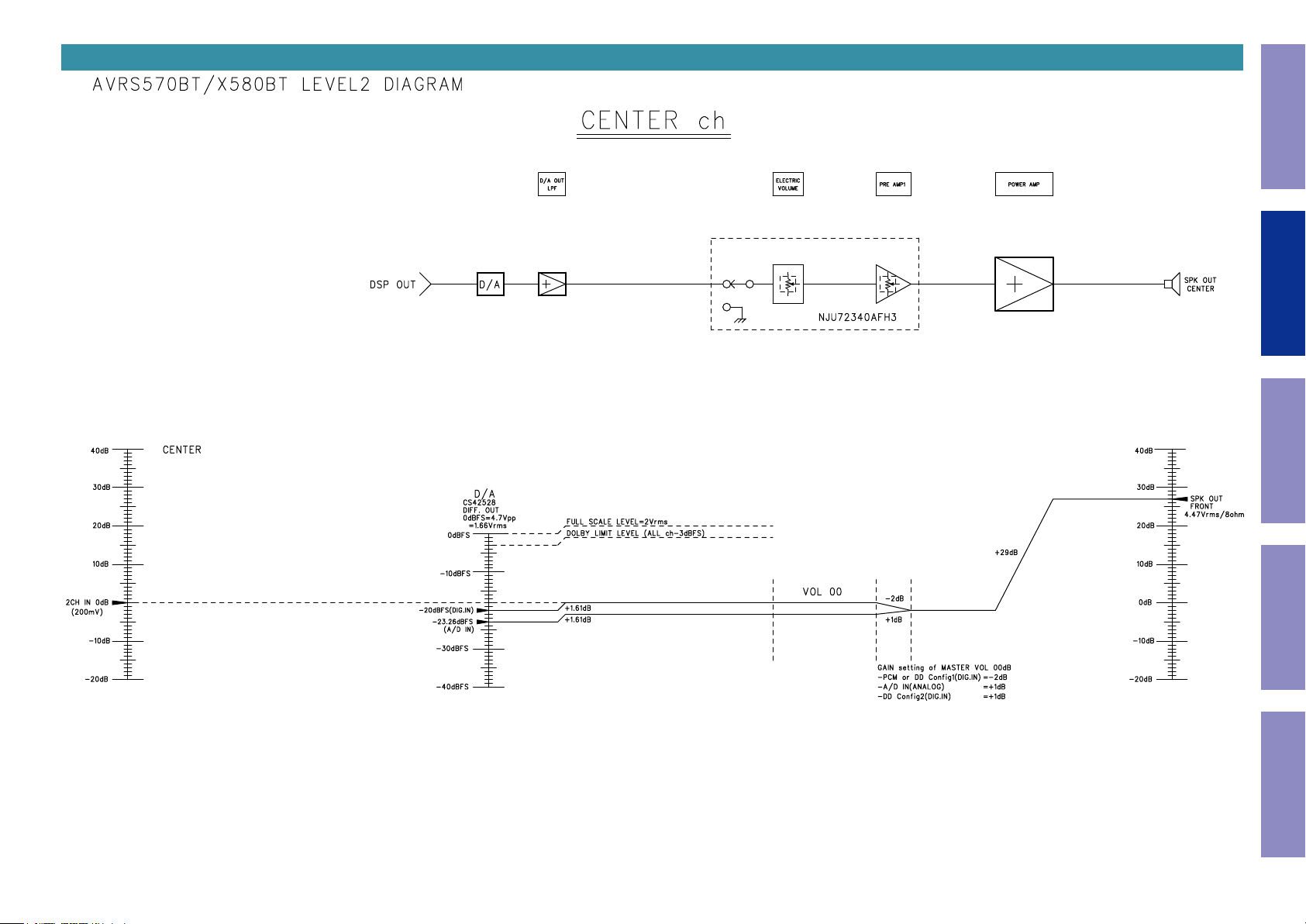

CENTER ch

SURROUND ch

SUBWOOFER ch

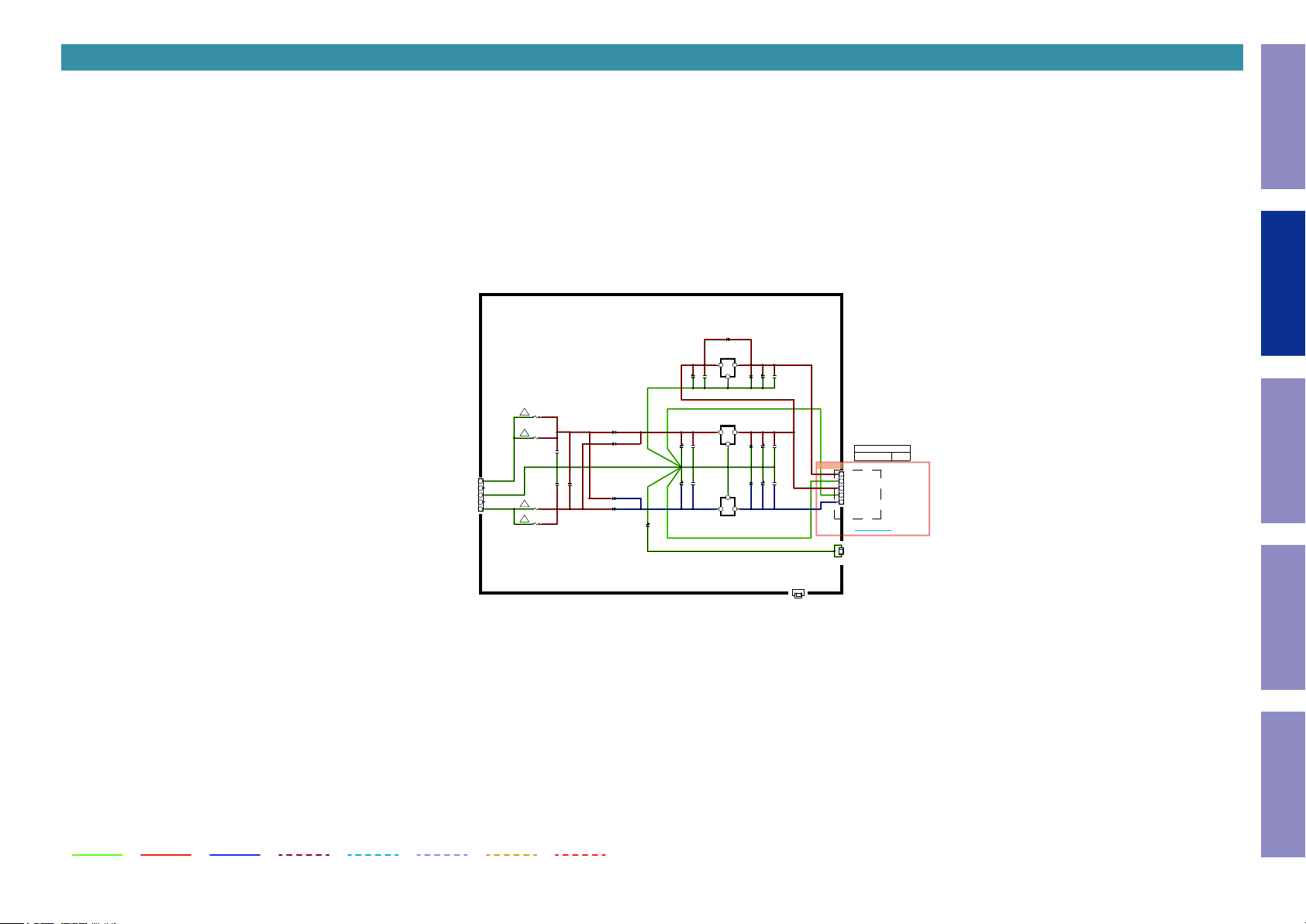

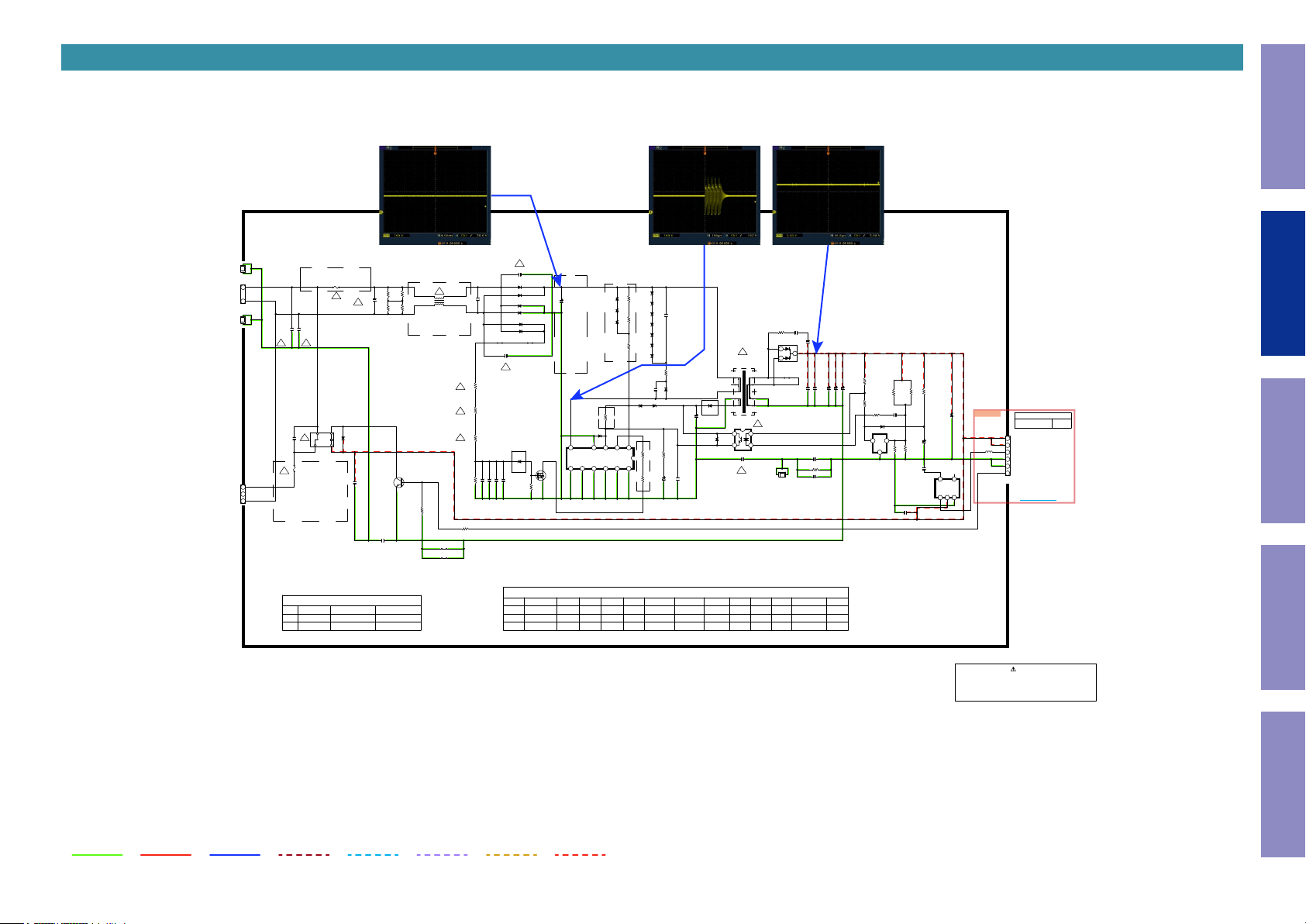

BLOCK DIAGRAM

ANALOG AUDIO DIAGRAM

DIGITAL AUDIO / HDMI DIAGRAM

VIDEO DIAGRAM

POWER DIAGRAM

WIRING DIAGRAM

SEMICONDUCTORS

1. IC's

2. FL DISPLAY

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

Remote Code Table

8

Page 9

SCHEMATIC DIAGRAMS

SCH01 DIGITAL MCU

A0

A1

A2

A3

A4

A5

MAIN_V OL_M UTE

MAIN_V OL_C LK

MAIN_V OL_D ATA

TO INPU T/VO LUM E PAR T

TO TX P ART

DSP _MOD E_S EL

TO DSP PART

H5V OUT _POW ER

FRO M/T O DIG ITAL POW ER PA RT

HD MI_OS D_S CLK

HD MI_OS D_M OSI

HD MI_OS D_M ISO

TO HD MI TX PAR T

DSP _SPC 1_IRQ

POW ER_D OWN

HD MI_OS D_C S

MCU PART

MCU +3V 3

AGND

SUB _MUT E

DGND

MIC_ SIGNAL

DAC _MU TE

SEL_ CLK

SEL_ DAT A

TUN ER_IN T

TUN ER_R ST

TUN ER_C E

TUN ER_S DIO

TUN ER_

SCL K

+12V

-12V

TO 0A

TX_ TEM P

HSC L

HSD A

TX_ HINT

TX_ HAIN T

TX_ RST

CEC _COM

TO 1A

DIR_ INT

COD EC_M UTE

DIR_ CE

DIR_ RST

DIR_ MOSI

DIR_ CLK

DIR_ MISO

HD MI_SW

DSP _CS

DSP _PCP _BSY

DSP _RST

DSP _MOS I

DSP _MISO

DSP _CLK

TO 2A

MAIN_P OWER

CEC_ POW ER2

CPU _POW ER

CEC_ POW ER

CEC_ POW ER3

DA_ POW ER

USB _POW ER2

MCU +5V

MCU +3V 3

MCU _RST

DGND

SWM 3V3

SWM 5V

D5V

USB 3V3

CEC3 V3

TO 3A

HINS EL_A

HINS EL_B

HINS EL_C

H5V _DE T

HPD 4

HPD 3

HPD 2

HPD 1

TO 4A

FLAS H_O E

AUD IO_O E

TO 5A

DAC_ MUT E

SEL_D ATA

MAIN_VO L_MU TE

MAIN_VO L_CL K

MAIN_VO L_DA TA

TUNER _INT

TUNER _RST

TUNER _CE

TUNER _SD IO

TUNER _SCL K

TX_H INT

TX_H AINT

CODE C_MU TE

DSP_ MOD E_SEL

DIR_R ST

DIR_M OSI

DIR_C LK

DIR_M ISO

HDMI _SW

DSP_ SPC1_IR Q

DSP_ PCP_ BSY

DSP_ RST

DSP_ MOSI

DSP_ MISO

DSP_ CLK

MAIN_PO WER

CPU_P OWE R

CEC_P OWE R

CEC_P OWE R3

DA_P OWE R

B_PO WER2

US

H5VO UT_ POW ER

POWE R_DO WN

HDMI _OSD _SC LK

HDMI _OSD _MO SI

HDMI _OSD _CS

HDMI _OSD _MIS O

HINSE L_A

HINSE L_B

HINSE L_C

H5V_ DET

F

LASH _OE

AUDIO _OE

SEL_C LK

DIR_C E

DSP_ CS

CN711

FOR UPD ATE (MP: OPEN )

7.BOOT

6.N.C

5.D GND

3.TX

4.RX

1.RE SET

2.MC U+3 V3

CN714

7654321

FFC 1mm P ITCH

0.1uF

0.1uF

0.1uF

0.1uF

C7142

C7141

C7120

22K

R7147

22K

22K

R7148

PO WER- FAIL

R7167

Q7109

KTA1504S YRT K

0.1uF

C7121

HSCL

HSDA

R7136 47K

R7137 47K

POWE R_DO WN

USB_ POWE R2

C7115

0.1uF

47K

R7127

CPU_P OWE R

MAIN_PO WER

HINSE L_C

HINSE L_B

HINSE L_A

H5V_ DET

DA_P OWE R

HDMI _OSD _MO SI

HDMI _OSD _MIS O

HDMI _OSD _SC LK

HDMI _OSD _CS

100K

0.1uF

Q7110

C7132

KTC3875S YRT K

33K

R7168

C7133

10V/100uF

T7102

C7114

T7109

0.1uF

R7129 1K

R7131 33

R7132 33

R7133 33

R7134 33

T7104

AUDIO _OE

FLASH _OE

0

R7170

T7108

BOOT M ODE

HIGH :UP DAT E

LOW :NOR MAL

T7125

T7103

R7141 10K

R7138 10K

R7139 100

MCU+3V 3

C7116

0.1uF

T7105

TX_H INT

111

109

110

108107106105104103102101100

DEBU G

DEBU G

TX_H INT

VFD_ DAT A

999897969594939291908988878685848382818079787776757473

THER MALDE T_B

VFD_ CLK

VFD_ CE

PWR_ FAIL_ PROT ECT

VDD_9

VSS_9

VOL_ DOW N

VOL_ UP

CPU_ POW ER

MAIN_PO WER

HINSE L_C

HINSE L_B

HINSE L_A

H5V_ DET

NC

VDD_8

VSS_8

HDM I_TES T_N C

FLASH _OE

AUDI O_OE

CEC_ OUT

USB_ POW ER1

VDD_1

VSS_1

NCNCHPD 4

7271706968

0.1uF

C7113

T7123

T7124

T7106

TX_H AINT

112

TX_H AINT

113

ASO_ DET

R7174 33

R7173 33

HPD3

HPD4

115

116

114

H/P_ RLY

VFD_ RST

USB_ POW ER2

77.DA_ POW ER

76.HDM I_OS D_M OSI

75.HDM I_OS D_M ISO

74.HDM I_OS D_SC LK

73.HDM I_OS D_C S

HPD 3

HPD 2

HPD 1

67

66

65

R7175 33

R7176 33

HPD2

H5VO UT_ POW ER

HPD1

R7140 10K

R7143

0.1uF

C7117

121

119

117

120

118

VDD_10

VSS_10

H/P_ DET

GRN_L ED

WAK E_UP

108.VDD

107.VSS_2

106.PCAP _2

105.DEB UG/JT MS

104.NC

103.THE RMALDE T_A

102.UPD ATE_ RX

101.UPD ATE_ TX

ST M32F101ZG

H5VO UT_ POW ER

VDD_7

HDM I_SW

CEC_ POW ER3

VSS_7

64

63

62

616059

0.1uF

C7112

HDMI _SW

CEC_P OWE R3

CEC_ OUT

CEC_ IN

TX_R ST

DAC_ MUT E

R7142 10K

TUNER _SCL K

33

33

R7144

128

126

124

122

127

125

123

HSD A

HSCL

DAC_ MUT E

REMO TE_IN

TUNE R_SC LK

EEPROM _SCL

EEPROM _SDA

TUNER _CE

TUNER _SD IO

0.1uF

T7126

C7118

134

137

135

133

131

129

138

136

132

130

DEBU G

BOOT0

DEBU G

VDD_11

VSS_11

TX_R ST

CEC_ CTL

SW_M UTE

TUNE R_SD IO

CP_R ESET _NC

1.DC _PRO TECT

2.USB _DA C_M UTE

3.POW ER_ DOW N

4.FRO NT_R LY

5.C/S _RLY

IC711

MC U

33.VDDA

34.AMPSIG_ DET _NC

35.USB_ RST

36.USB_ RX

DIR_C LK

CODE C_M UTE

DIR_M OSI

DIR_M ISO

CURREN T_D ET_N C

DSP_ MOD E_SE L

VSS_6

CEC_ POW ER

DSP_ SPC1_IR Q

DIR_R ST

DSP_ RST

BOOT1

TX_T EMP

DSP_ MOSI

VDD_6

DSP_ PCP_ BSY

DIR_C E

58

57

56

55

54535251504948

47

46

45

44

434241

0.1uF

C7111

1 2 3 4

1 2 3 4

100x4

RN712

5 6 7 8

5 6 7 8

DSP_ PCP_ BSY

DIR_C E

DSP_ SPC1_IR Q

CODE C_MU TE

DIR_R ST

DSP_ MOD E_SEL

DSP_ RST

DIR_M OSI

DIR_C LK

DSP_ MISO

DSP_ MOSI

CEC_P OWE R

10K

R7178

DIR_M ISO

SWM 3V3

OPEN

C7134

4.7K

2.2M

R7180

R7181

Q7112

Q7113

3875SYRT K

100K

R7179

Q7111

KTC2875A S

KTC

KTC3875S YRT K

C7143

R7145

POW ER-FA IL

HSCL

HSDA

TX_R ST

HPD4

HPD3

HPD2

HPD1

R7196

0

2.2K

Q7108

R7166

KTC3875S YRT K

TUNER _INT

TUNER _RST

141

140

139

TUNE R_CE

TUNE R_INT

TUNE R_RS T

MIC_D ET

OSC32_IN

OSC32_O UT

HI-B_ RELY

SEL_C LK

SEL_D ATA

CP_S DA_N C

CEC_ POW ER2

MAIN_VO L_MU TE

MAIN_VO L_D ATA

MAIN_VO L_CL K

XTAL _IN

XTAL _OU T

DSP_ CS

DSP_ MISO

DSP_ CLK

40

DSP_ CLK

DSP_ CS

47K

R7182

27

OPEN

OPEN

OPEN

L7101

C7122

C7123

0.1uF

C7119

470K

R7101

R7102

144

142

143

0

VSS_3

VDD_3

RED_ LED

VBAT

C7101

0.1uF

9 8 7 6 5 4 3 2 1

ISEL_ B

ISEL_ A

VSS_5

C7102

VDD_5

0.1uF

USB_ EN

24 23 22 21 20 19 18 17 16 15 14 13 12 11 10

RESET

KEY1

KEY2

KEY3

OPTIO N

0.1uF

C7105

VSSA

C7106

VREF-

0.1uF

VREF+

34 33 32 31 30 29 28 27 26 25

VDD_4

VSS_4

USB_ TX

36 35

39

38

37

MCU+3V 3

0.1uF

C7110

100x4

R7113

RN711

OPTIO N

*OP TION

S570BT E3

R7113

4K7

R7114

R7184

220K

100K

220P

R7183

C7135

CEC -PAR T

23.CPU _POW ER

25.MCU _3V3

27.NC

24.MCU +5V

26.DGND

24 22

23 21

L7105

L7103

L7106

L7102

L7104

0

FCM601T0 5

FCM601T0 5

FCM601T0 5

MAIN_VO L_CL K

MAIN_VO L_DA TA

MAIN_VO L_MU TE

T7120

R7107

R7108

OPEN

C7108

C7107

R7114

OPTIO N

X580BT E2

X

10K

D7102

KDS160R TKP

R7185

27K

TO BN12B1

TO FRON T B'D

FFC W AFER /27P/1 .25mm

18.RC_ IN

16.RED _LED

17.W/G _LED

19.FL_ RST

20.FL_ CE

21.FL_ CLK

22.FL_ DAT A

14.KEY _2

15.KEY _1

1618

2026

1517

1925

L7114

L7111

L7113

L7115

L7110

L7112

L7108

L7107

L7109

0

0

0

0

0

0

0

0

0

0

R7104

1K

47K

R7103

D7101

OPEN

T7118

T7119

T7101

C7103

33pF

34

1M

8MHz

X7111

1 2

C7104

0

33pF

OPEN

OPEN

C7109

OPEN

R7192

OPEN

R7195

*O PTIO N TAB LE

X580BT E1C

X580BT K

10K

10K

10K10K

X

SWM 5V

1.2K

R7186

3.3K

0.1uF

R7187

C7136

DGND

13.KEY _3

L7116

0

2.ISE L_B

8.MIC _GND

3.MIC _DE T

4.PO WER _KEY

6.-12V

10.H/P _DE T

12.VSE L_B

L7117

0

1.ISE L_A

9.NC

1011121314

L7119

L7120

L7122

L7130

0

0

0

OPEN

C7149

FCM601T0 5

SEL_C LK

SEL_D ATA

R7194

OPEN

R7193

L7123

OPEN

L7124

0

0

L7126

L7125

0

0

R7149 10K

R7150 10K

R7151 10K

R7188 10K

P

FFC 27

123456789

L7127

0

0.1uF

0.1uF

0.1uF

0.1uF

C7124

0.1uF

C7127

C7125

C7126

C7144

CN715

9PIN WAFE R

1

1.MC U+3 V3

2

2.D GND

R7152 1K

3

3.RE SET

4

4.JTD O

5

5.JTC K

6

6.JTM S

7

7.JTD I

8

8.NJT RST

9

9.D GND

USE ONL Y DE BUG

T7110

T7111

T7112

T7113

T7114

T7115

T7116

T7117

CN712

100

OPEN

R7163

C7154

OPEN

C7155

0.1uF

CN712

CA2005-WV 11-K

11

11.TH ERMALD ET_B

10

10.TH ERMALD ET_A

987654321

9.AS O_D ET

8.NC (CURRE NT_D ET)

7.+ /-B D ETEC T

6.D C_PR OT

5.NC (AMPSIG _DE T)

4.C/ S_RL Y

3.FRO NT_ RLY

2.H /P_RL Y

1.H I-B_R LY

CN713

CN713

CA2005-WV 11-K

1.D 5V

2.D 5V

C7153

0.1uF

3.D GND

4.D GND

5.US B3V 3

6.US B_PO WER 1

7.MC S_T X

RX

8.MC S_

9 8 7 6 5 4 3 2 1

9.MC S_RS T

10.USB _DA C_MU TE

11 10

11.USB _EN

C7156

0.1uF

T7131

T7132

C7157

0.1uF

TO MAIN B' D

WA FER/ 9P/2 .0mm

WA FER/ 11P/2.0 mm

FRO M/T O USB /BT B'D

TO BN502

TO BN212

47K

R7156

KTC3875S YRT K

R7153

2.7K

R7154

2.7K

MCU+3V 3

5678

WP

SDA

SCL

VCC

IC712

0.1uF

C7128

1 2 3 4

M24C32WM N6T P

SWM3V3

47K

R7158

TK

Q7105

Q7106

0.01uF

C7129

KTC3875S YR

47K

R7155

GND

A2A1A0

SWM3V3

47K

120K

120K

R7161

R7162

R7159

Q7107

0.01uF

C7146

C7131

0.01uF

C7130

KTC3875S YRT K

R7164 100

R7165 100

C7152

0.1uF

CN711

5.+ 12V

7.MIC _SIGNA L

11.VSE L_A

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

GND LINE

POWER+ LINE

POWER- LINE

ANALOG AUDIO

DIGITAL AUDIO

TMDS SIGNAL

ANALOG VIDEO

STBY POWER

9

Page 10

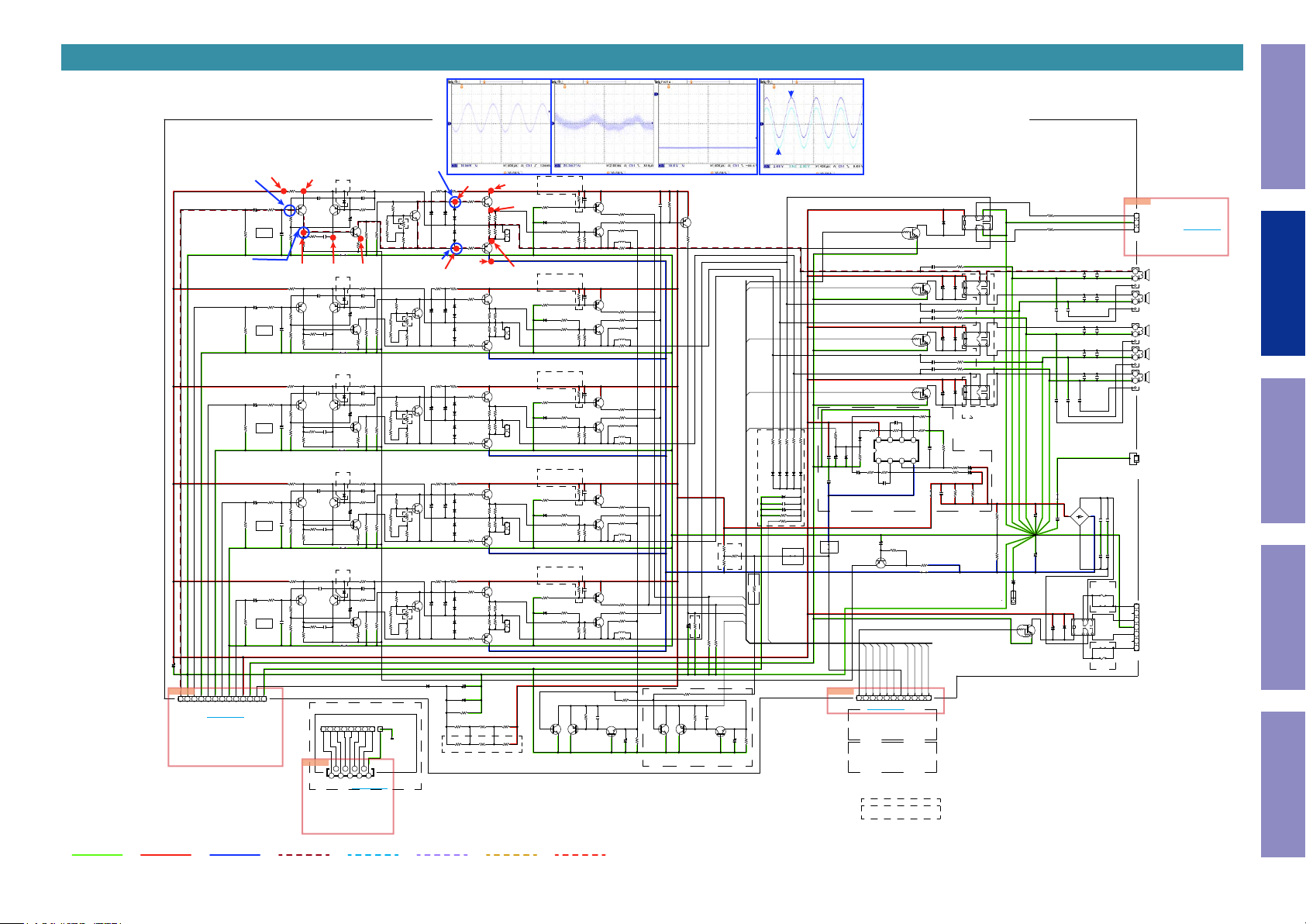

SCH02 DIGITAL HDMI TX

A6

TX PART

+5V_ 4

HPD4

JK794

CJJ9H036Z

19

19.HP DET

18

18.+5 V

17

17.GND

16

16.DDC S DA

5

1

15.DDC C LK

14

14.UT L/HEAC +

13

13.CE R EMOT E

12

12.CK-

11

11.CK SHIE LD

10

10.CK+

9

9.D 0-

8

8.D 0 SH IELD

7

7.D 0+

6

6.D 1-

5

5.D 1 SH IELD

4

4.D 1+

3

3.D 2-

2

2.D 2 SH IELD

1

1.D 2+

H DM I_ INP UT-4 (G ame)

H DM I_ INP UT-3 (B lu -ra y)

H DM I_ INP UT-2 (M e dia P la ye r)

H DM I_ INP UT-1 (C B L/SA T)

19.HP DET

18.+5 V

17.GND

16.DDC S DA

15.DDC C LK

14.UT L/HEAC +

13.CE R EMOT E

12.CK-

11.CK SHIE LD

10.CK+

9.D 0-

8.D 0 SH IELD

7.D 0+

6.D 1-

5.D 1 SH IELD

4.D 1+

3.D 2-

2.D 2 SH IELD

1.D 2+

19.HP DET

18.+5 V

17.GND

16.DDC S DA

15.DDC C LK

14.UT L/HEAC +

13.CE R EMOT E

12.CK-

11.CK SHIE LD

10.CK+

9.D 0-

8.D 0 SH IELD

7.D 0+

6.D 1-

5.D 1 SH IELD

4.D 1+

3.D 2-

2.D 2 SH IELD

1.D 2+

19.HP DET

18.+5 V

17.GND

16.DDC S DA

15.DDC C LK

14.UT L/HEAC +

13.CE R EMOT E

12.CK-

11.CK SHIE LD

10.CK+

9.D 0-

8.D 0 SH IELD

7.D 0+

6.D 1-

5.D 1 SH IELD

4.D 1+

3.D 2-

2.D 2 SH IELD

1.D 2+

+5V_ 3

HPD3

CJJ9H036Z

+5V_ 2

HPD2

CJJ9H036Z

+5V_ 1

HPD1

CJJ9H036Z

OPEN

D7941

JK793

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

OPEN

D7931

JK792

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

OPEN

D7921

JK791

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

OPEN

D7911

1k

R7941

Q7941

KRC102S

DA_4 CK_ 4

OPEN

OPEN

OPEN

D7942

D7943

D7944

1k

R7931

Q7931

KRC102S

DA_3 CK_ 3

OPEN

OPEN

OPEN

D7932

D7933

D7934

1k

R7921

Q7921

KRC102S

DA_2 CK_ 2

OPEN

OPEN

OPEN

D7922

D7923

D7924

1k

R7911

Q7911

KRC102S

DA_1 CK_ 1

OPEN

OPEN

OPEN

D7912

D7913

D7914

CEC 0V9C ORE

TO 6A

10k

R7942

FRO M DIG ITAL POW ER

Q7942

R7943 47K

R7944 47K

KRC102S

0.1uF

C7914

R7946

0

R7947 0

R7948 0

10k

R7932

Q7932

R7933 47K

R7934 47K

KRC102S

0.1uF

C7913

R7936

0

R7937 0

R7938 0

10k

R7922

Q7922

R7924 47K

R7923 47K

KRC102S

0.1uF

C7912

R7926

0

R7927 0

R7928 0

10k

R7912

Q7912

R7914 47K

R7913 47K

KRC102S

0.1uF

C7911

R7916

0

R7917 0

R7918 0

A7

HD MI_MC LK

HD MI_SP DIF

HD MI_SD ATA 0

HD MI_SD ATA 2

HD MI_LR CLK

HD MI_SD ATA 3

TO DSP

HD MI_SD ATA 1

HD MI_B CLK

TO 7A

SWM 5V

CEC 5V

CEC 3V3

CEC 1V8

CEC 0V9

DGND

R7945

R7935

R7925

R7915

L7921

FBMJ3216H L160NT

AVDD33RX

HPD4

L7922

BLM21PG 221SN1

47K

RX0P5 V

RX0SD A

RX0SC L

P0_C-

P0_C+

P0_D0-

P0_D0+

P0_D1-

P0_D1+

L7927

P0_D2-

BLM21PG 221SN1

P0_D2+

L7931

FBMJ3216H L160NT

HPD3

47K

RX1P5 V

RX1SD A

RX1SC L

P1_C-

P1_C+

P1_D0-

P1_D0+

P1_D1-

P1_D1+

P1_D2-

P1_D2+

HPD2

47K

RX2P5 V

RX2SD A

RX2SC L

P2_C-

P2_C+

P2_D0-

P2_D0+

P2_D1-

P2_D1+

P2_D2-

P2_D2+

HPD1

47K

RX3P5 V

RX3SD A

RX3SC L

P3_C-

P3_C+

P3_D0-

P3_D0+

P3_D1-

P3_D1+

P3_D2-

P3_D2+

6.3V/ 10uF

C7921

BLM21PG 221SN1

0.1uF

6.3V/ 10uF

0603

C7928

C7929

AVDD18EA

BLM21PG221S N1

VDD09STB V DD09EA

0.1uF

6.3V/ 10uF

06030603

C7949

C7948

VDD09

0.1uF

0.1uF

0.1uF

0603

6.3V/ 22uF

C7978

C7977

C7976

C7975

RX3P

5V

RX2P5 V

RX1P5 V

RX0P5 V

RX3SC L

RX3SD A

RX2SC L

RX2SD A

RX1SC L

RX1SD A

RX0SC L

RX0SD A

P0_C-

P0_C+

P0_D0-

P0_D0+

P0_D1-

P0_D1+

P0_D2-

P0_D2+

P1_C-

P1_C+

P1_D0-

P1_D0+

P1_D1-

P1_D1+

P1_D2-

P1_D2+

P2_C-

P2_C+

P2_D0-

P2_D0+

P2_D1-

P2_D1+

P2_D2-

P2_D2+

P3_C-

P3_C+

P3_D0-

P3_D0+

P3_D1-

P3_D1+

P3_D2-

P3_D2+

5A

FLASH _OE

AUDIO _OE

FROM MCU

TO A5

HDMI _MCK

HDMI _SPD IF

0.1uF

0.1uF

0.1uF

0.1uF

0603

0603

0603

0603

6.3V/ 10uF

6.3V/ 10uF

C7927

C7926

C7925

C7924

C7923

C7922

0.1uF

6.3V/ 10uF

C7934

C7933

FBMJ3216H L160NT

0.1uF

0.1uF

0.1uF

0603

0603

C7957

C7956

C7955

L7925

FBMJ3216H L160NT

0.1uF

0.1uF

0603

0603

0603

PVDD18VDD18

C7936

C7935

L7930

0.1uF

0.1uF

0.1uF

0.1uF

6.3V/ 10uF

6.3V/ 10uF

6.3V/ 10uF

0603

0603

0603

0603

C7959

C7958

C7964

C7963

C7962

C7961

C7960

L7924

L7923

BLM21PG 221SN1

0.1uF

0.1uF

6.3V/ 22uF

0603

0603

C7930

C7932

C7931

L7929

L7928

FBMJ3216H L160NT

0.1uF

0.1uF

6.3V/ 10uF

6.3V/ 10uF

6.3V/ 10uF

0603

0603

C7951

C7950

C7953

C7952

C7954

AVDD09TX

G14

G13

G12

G11

G10

G16

G7

G15

J7

H7

U13

U14

P17

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0603

0603

0603

0603

0603

0603

0603

0603

C7985

C7984

C7983

C7982

C7981

C7980

C7979

HDMI _DA TA0

HDMI _DA TA2

P2

RX3P5V

P1

RX2P5V

N5

RX1P5V

N4

RX0P5V

Y20

RX3SCL

Y19

RX3SDA

E19

RX2SCL

E20

RX2SDA

D20

RX1SCL

D19

RX1SDA

E6

RX0SCL

D4

RX0SDA

A10

P0RX3M

A9

P0RX3P

A8

P0RX0M

A7

P0RX0P

A6

P0RX1M

A5

P0RX1P

A4

P0RX2M

A3

P0RX2P

A21

P1RX3M

A20

P1RX3P

A19

P1RX0M

A18

P1RX0P

A17

P1RX1

A16

P1RX1P

A15

P1RX2M

A14

P1RX2P

K23

P2RX3M

J23

P2RX3P

H23

P2RX0M

G23

P2RX0P

F23

P2RX1M

E23

P2RX1P

D23

P2RX2M

C23

P2RX2P

AA23

P3RX3M

Y23

P3RX3P

W23

P3RX0M

V23

P3RX0P

U23

P3RX1M

T23

P3RX1P

R23

P3RX2M

P23

P3RX2P

D15

CH1SPD IF

D8

CH1BCL K

E9

CH1LRC LK

D9

CH1ASD 0

OPEN

OPEN

R7239

R7238

RCK

HDMI _DA TA3

HDMI _BCK

HDMI _DA TA1

HDMI _L

24 23 22 21 2 0 19 18 17 16 1 5 14 13

0.1uF

0.1uF

VCCB

IC721

VCCA

C7217

C7216

SN74AX C8T245P WR

1234

1234

VDD09_01G8VDD09_02G9VDD09_03

M

OE

VCCB

DIR1A1A2A3A4

56

RN723

78

100x4

56

RN722

100x4

78

R17

09_08

VDD

VDD09_07

VDD09_06

VDD09_05

VDD09_04

VDD09_10

VDD09_09

VDD09_17

VDD09_11H8VDD09_12

VDD09_13

VDD09_16

VDD09_14

VDD09_15

CH0ASD 1

CH0MCL K

CH0SPD IF

CH0BCL K

CH0ASD 0

F19

E16

E15

D16

D17

D18

R7980 33

R7979 33

R7978 33

R7977 33

R7976 33

R7975 33

4

B2B1B3B5B

A5

A6A7A8

54321

L7926

FBMJ3216H L160NT

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

6.3V/ 10uF

6.3V/ 10uF

0603

0603

C7940

C7939

C7938

C7937

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0603

0603

0603

0603

0603

0603

0603

C7970

C7969

C7968

C7967

C7966

C7965

C7971

T7

U7

U8

Y11

Y13

W11

W13

AB8

AB9

AB10

AVDD09EA

VDD09STB_01

VDD09STB_02

AVDD09TX1_02

AVDD09TX0_02

AVDD09TX1_01

AVDD09TX0_01

AVDD09TX1_03

AVDD09TX1_04

AVDD09TX1_05

CH0ASD 3

CH0ASD 2

CH0LRC LK

F20

E18

R7982 33

R7981 33

B7

B6

B8

GND

GND

DIR2

12

1110

9876

0.1uF

6.3V/ 10uF

6.3V/ 10uF

6.3V/ 10uF

AVDD18TX

C7944

C7943

C7942

C7941

AVDD09RX

0.1uF

0.1uF

0.1uF

0603

0603

0603

0603

C7974

C7973

C7972

L19

L20

N19

N20

T22

R22

J22

K22

H22

E13

D13

P22

B14

B15

B16

AB14

AB15

AB16

AVDD09RX2_04

AVDD09RX2_05

AVDD09RX3_01

AVDD09RX3_02

AVDD09RX3_05

AVDD09RX3_04

AVDD09RX2_03

AVDD09RX2_01

AVDD09RX2_02

AVDD09RX1_05

AVDD09RX1_04

AVDD09RX3_03

AVDD09RX1_01

AVDD09RX1_02

AVDD09TX0_03

AVDD09RX1_03

AVDD09TX0_04

AVDD09TX0_05

NCS

SCLK

MISOD7MOSI

E7

E8

D6

33

R7986

R7985 33

R7984 33

R7983 33

24 23 22 21 2 0 19 18 17 16 1 5 14 13

OE

0.1uF

0.1uF

VCCB

VCCB

IC722

A2

VCCA

DIR1

A1

C7215

C7214

SN74AX C8T245P WR

0603

C7945

B8

A1

B2B1B3

A3A4A5

54321

0603

0603

C7947

C7946

E11

D11

B9

B10

AVDD09RX0_05

AVDD09RX0_04

AVDD09RX0_01

AVDD09RX0_02

AVDD09RX0_03

VSS_03

VSS_01A2VSS_02

VSS_04

VSS_05B2VSS_06

B1

A22

A23

AVDD18RX

0603

P

ARCIN

EARCP

EARCM

P1TX 0P

P1TX 3

P1TX 1P

TX1S CL

P1TX 2P

P1TX 0M

TX1S DA

P1TX 1M

P1TX 2M

P1TX 3M

TX1H PD

P1TX 2P

P1TX 2M

P1TX 1P

P1TX 1M

TX_H AINT .

TX_H INT

TX_R ST

HSCL

HSDA

4A

FRO M CP U

HD MI_OS D_S CLK

HD MI_OS D_M OSI

HD MI_OS D_C S

HD MI_OS D_M ISO

HIN SEL_A

HIN SEL_B

HIN SEL_C

H5V _DE T

HPD 4

HPD 3

HPD 2

HPD 1

P1TX 0P

P1TX 0M

P1TX 3P

P1TX 3M

EARCP

TX1S CL

TX1S DA

TX1H PD

EARCM

ARCIN

TO A4

C7992

R7991

10pF

1k

1M

R7992

X7201

R7962 10k

R7963 10k

L17

N17

L5

M17

L7

H5

J5

N7

Y9

K5

K7

H19

M7

W9

18IO_04

VDD18_03

VDD18_07

VDD18_05

VDD18_02

VDD18_06

VDD18_01

VDD18_04

PVDD18PCR

VDD

VDD18IO_01

VDD18IO_02

VDD18IO_03

AVDD18EA_02

AVDD18EA_01

L23

N23

M23

M22

C22

U15

J19

AB12

AC11

PVDD18_1

PVDD18_2

AVDD18TX1_01

AVDD18TX1_02

A11

A13

AA22

B3

B12

B21

AC12

AC13

AVDD18RX2

AVDD18RX3

AVDD18RX0

AVDD18RX1

DD18TX0_02

AVDD33RX2_01

AVDD33RX3_02

AVDD33RX3_01

AVDD33RX2_02

AVDD33RX1_01

AVDD33RX1_02

AVDD18TX0_01

AV

R7961 10k

T4

W4

A12

AVDD33RX0_01

V5

AC14

AC15

AC16

AC17

AC18

AC19

AC20

AC21

P0TX1P

P0TX2P

P0TX1M

P0TX2M

AVDD33RX0_02

AC8

AC9

AC10

TX0SCL

P0TX3P

P0TX0P

P1TX2P

TX0SDA

P0TX3M

P0TX0M

P1TX2M

TX0HP D

Y1

T1

U2

W5

Y7

AA1

Y4

AC3

AC4

AC5

AC6

AC7

P1TX1P

P1TX1M

ARCIN

EARCP

EARCM

XO_NC

TX1SCL

P1TX3P

P1TX0P

TX1SDA

P1TX3M

P1TX0M

TX1HP D

IC791

MN 864807A

L15

N15

L14

N14

L13

N11

N12

N13

L11

L12

L10

N9

K9

J10

J11

J13

J14

NC_01

NC_02

NC_03

NC_04

VSS_13

VSS_14

VSS_15

VSS_12

VSS_11

VSS_07

VSS_08

VSS_09

VSS_10

J9

E12

B11

B13

B23

B22

G17

H17

H20

D12

B5B4B7

B6

A6A7A8

9876

R7236

7 8

5 6

N10

K10

K11

K12

K13

K14

K15

L9

M14

M13

M11

M12

M10

P10

P11

P12

P13

P14

P15

P9

R11

R13

R14

R10

NC_18

NC_30

NC_17

NC_29

NC_16

NC_15

NC_26

NC_27

NC_28

NC_13

NC_14

NC_25

NC_23

NC_12

NC_24

NC_05

NC_06

NC_07

NC_08

NC_09

NC_10

NC_11

NC_22

NC_21

NC_19

NC_20

NC_32

NC_34

NC_35

NC_36

NC_37

NC_39

NC_41

NC_31

NC_33

NC_38

NC_40

VSSRX1_05

VSS_20

VSS_25

VSS_23

VSS_24

VSS_22

VSS_16

VSS_18

VSS_32U5VSS_33

VSS_34

VSS_35

VSS_37

VSS_17

VSS_19

VSS_36

VSS_21

VSS_38

VSS_30

VSS_39

VSS_26

VSS_28R9VSS_29

VSS_31

VSS_27

17

P7

R1

V1

R7

U4

U9

M9

J12

J15

J20

B8

DIR2

1110

W8

L22

R15

R12

N22

U

U10

U11

U12

M19

M20

M15

GND

GND

12

R7233 0

R7232 10k

R7234 33

R7231 10k

R7235 10k

33

1 2 3 4

RN721

100x4

R7230

VSS_42

VSS_43

VSS_44

VSS_40

VSS_45

VSS_41

Y8

Y12

AB1

AB2

W12

C7213

MX25L3233FM 2I-08G

4 3 2 1

OPEN

VSSIO_06N2VSSIO_07

AVSSTX1_02

VSSIO_04

VSSIO_02

VSSIO_03

VSSIO_05

AVSSTX0_02

VSSIO_01

AVSSTX0_01

VSS_52

VSS_53

VSS_46

VSS_47

VSS_48

VSS_49

VSS_50

VSS_51

F5

E5

N1

D5

M4

M5

Y14

AC1

AC2

W14

AC22

AC23

AB11

AB13

AB22

AB23

R7229 33

0.1uF

10k

R7228

R7227

IC725

10k

8765

CS

VCC

R7226

10k

SO

HOL D

R7225

WP

SCLK

0

R7224

VSS

SI

0

OPEN

C7212

AVSSTX0_03

AB17

AB18

AVSSTX0_04

AVSSTX0_05

AVSSTX0_06

AB19

AB20

R7237 33

R7223

AVSSRX0_06

AVSSRX0_05

AVSSTX1_01

AVSSTX1_03

AVSSTX1_04

AVSSRX0_01

AVSSTX1_05

AVSSRX0_02

AVSSRX0_03

AVSSTX1_06

AVSSRX0_04

AVSSTX1_07

AVSSTX0_07

B4

B5

B6

B7

E10

Y10

AB3

AB4

AB5

AB6

AB7

D10

W10

AB21

C7211

OPEN

VSSRX3_06

AVSSRX2_05

AVSSEA_02

AVSSRX2_06

AVSSEA_01

AVSSRX3_05

AVSSRX3_01

AVSSRX3_02

AVSSRX3_03

AVSSRX2_01

AVSSRX2_04

AVSSRX1_06

AVSSRX3_04

AVSSRX2_02

A

A

AVSSRX2_03

AVSSRX1_01

AVSSRX1_02

AVSSRX1_03

AVSSRX1_04

Y2

F22

P19

E22

P20

E14

K19

K20

Y22

V22

B17

B18

B19

B20

AA2

U22

G22

D22

D14

W22

1

2

3

4

5

6

7

16 1 5 14 1 3 12 11 10

B6

B7

B5

VCC

IC723

0.1uF

CVIS N74CBT 3251PWR

B3

B4

B1

ANCOE

B2

PVSS_1

PVSSPCR

J17

U16

SCK

GND

MOS I

VCC

/CS

MISO

GND

B8

25.0MHz

C7993

12pF

U1

XI_SYSC LK

R7964 47K

P5

CEC

R7965 47K

T5

PTEST

R7966 47K

P4

NTEST

R7967 4 k7

G19

NOSDIRQ

R7968 1k

R7969 10

E17

NIRQA

R7970 4 k7

R7971 10

T2

NIRQ

R7972 1k

R4

NRESET

C7994

1000pF

R7973 47

R2

HSCL

C7995

OPEN

R7974 47

R5

HSDA

C7996

OPEN

C2

PCLKOU T

D2

HSYNCO UT

G5

VSYNCO UT

C1

DEOUT

D1

Q23

E4

Q22

E2

Q21

E1

Q20

F1

Q19

F4

Q18

G4

Q17

F2

Q16

G2

Q15

G1

Q14

H4

Q13

H2

Q12

H1

Q11

J2

Q10

J4

Q9

J1

Q8

K2

Q7

K4

Q6

K1

Q5

L4

Q4

L2

Q3

M2

Q2

L1

Q1

M1

Q0

G20

PCLKIN

R19

HSYNCI N

T20

VSYNCIN

R20

DEIN

U20

D23

T19

D22

T17

D21

U19

D20

V20

D19

W20

D18

V19

D17

W19

D16

W17

D15

Y17

D14

W18

D13

W16

D12

Y18

D11

Y16

D10

W15

D9

Y15

D8

W6

D7

W7

D6

Y5

D5

Y6

D4

V4

D3

R7987 OP EN

W2

D2

R7988 47K

V2

D1_LPSA1

R7989 47K

W1

D0_LPSA0

R7990 OP EN

PVSS_2

K17

CN721

CJP07GA 333ZR

MP :O PEN

1.00mm FFC

9

S1

S0

S2

HPD4

HPD3

0

2

HPD

GND

R7222

HPD1

87654321

OPEN

R7211

L7951

4ohm /0605

EXCX 4CZ040X

L7952

4ohm /0605

EXCX 4CZ040X

L7953

4ohm /0605

EXCX 4CZ040X

L7954

4ohm /0605

EXCX 4CZ040X

C7915

1uF

R7951 0

R7952 0

H1_HP

R7953 1 k2

C7916

1uF

1k8

OPEN

OPEN

OPEN

1uF

OPEN

D7951

R7954 47K

C7917

OPEN

R7956 1k 8

R7955

D7952

D7955

D7953

D7954

HSCL

HSDA

TX_R ST

TX_H INT

TX_T EMP

TH791

(OVER 88'C)

NTC T HER MISTO R 10K

0.1uF

R7905 10k

R7906 OPENR7907 OPEN

R7908

1A

HSC L

HSD A

TX_ RST

TX_ HINT

TX_ TEM P

CEC _COM

TX_ HAIN T

FRO M CP U

TO A1

OPEN

OPEN

H1_CK

H1_DA

D7957

D7956

TX_R ST

TX_H INT

TX_H AINT

R7904

321

BN791

PIN HE ADE R (2. 0mm Pit ch)

MP:O PEN

KRA102S

JK795

CJJ9H036Z

1

1.TX 2+

2

2.TX 2 SH IELD

3

3.TX 2-

4

4.TX 1+

5

5.TX 1 SH IELD

6

6.TX 1-

7

7.TX 0+

8

8.TX 0 SH IELD

9

9.TX 0-

10

10.TX C+

11

11.TX C SH IELD

12

12.TX C-

13

13.CE R EMO TE

14

14.UT L/HEAC +

15

15.DDC S CK

16

16.DDC S DA

17.GND

18.+5 V

19.HP DET

H DM I_ OU TPU T

17

18

19

H1_5V

FRO M HD MI 4 K PA RT

R7996 0

HS1

R7997 0

HS2

R7998 0

HS3

R7999 0

HS4

10k

R7903

Q7902

2SC4617EB TLR

TX_H AINT .

R7902

47K

47K

R7901

Q7901

10k

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

GND LINE

POWER+ LINE

POWER- LINE

ANALOG AUDIO

DIGITAL AUDIO

TMDS SIGNAL

ANALOG VIDEO

STBY POWER

10

Page 11

SCH03 DIGITAL DSP

D SP PART

CJSJSR 1124

OP T2

CB L/SA T

(E3 Ver . AUX )

CJSJSR 1124

OP T1

TV

CB L/SA T

COAX IAL

OP TION

JK784

C7841

R7841

2A

DIR_ INT

COD EC_M UTE

DSP _MOD E_S EL

DIR_ CE

DIR_ RST

DIR_ MOSI

DIR_ CLK

DIR_ MISO

HD MI_SW

DSP _CS

DSP _SPC 1_IRQ

DSP _PCP _BSY

DSP _RST

DSP _MOS I

DSP _MISO

DSP _CLK

50

VSS

VDD

494847

DQ15

DQ0

VSSQ

DQ2

DQ3

VDDQ

DQ4

DQ5

VSSQ

DQ6

DQ7

VDDQ

_CAS

_RAS

_CS

BA

A10/AP

A0

A1

A2

A3

VDD

RN751

1234

DQ14

VSSQ

464544434241403938373635343332313029282726

DQ13

DQ12

VDDQ

DQ11

DQ10

VSSQ

DQ9

DQ8

VDDQ

NC

UDQM

CLK

CKE

NC

A9

A8

A7

A6

A5

A4

VSS

5678

33x4

C7436

+3V3D

0.1uF

RN750

1234

5678

33x4

C7435

0.1uF

C7434

15P

R7430

AD9

AD8

AD7

AD6

AD5

AD4

TO A2

FRO M/T O MCU PAR T

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

SD3

SD6

SD7

75

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

AD[ 0:19]

DA_ GND1

D_S R-

DGND

+5V A

AGND

DSP _AUD IO

100

0.1uF

1011121314151 6

INT

RESET

AD0/CS

SCL/CCLK

AD1/CD IN

SDA/CDO UT

14.AINR+

16.AINL-

15.AINL+

IC744

CS 42528-CQ

DIR + CO DEC

33.AOUTA2 -

34.AOUTB1 -

35.AOUTB1 +

AGND

VARX

AOUTA1+

AOUTA1-

MUTEC

LPFLT

0.1uF

C7460

R7412

1.37K/F

1000P

C7456

0.022uF

C7457

C7459

0.1uF

C7458

10V/100uF

A9

TO DIGIT AL P OWE R PAR T

R7479

OPEN

* Cirru s Rec ommend

+5VD

OPEN

C7446

0.1uF

C7447

C7728

LRCK1

SCLK1

123456789

64

CX_SDIN 2

VD

VLC

CX_SDIN 3

63

DGND

CX_SDIN 4

62

SAI_SCLK

61

SAI_LRCK

60

2.CX_SCL K

3.CX_LRC K

1.CX_SD IN1

OMCK

59

ADCIN1

58

ADCIN2

57

CX_SDOU T

56

RMCK

55

SAI_SDOU T

54

VLS

53

48.RXP1/GP O1

47.RXP2/GP O2

46.RXP3/GP O3

DGND

52

VD

51

TXP

50

RXP0

RXP7/GPO 7

RXP6/GPO 6

RXP5/GPO 5

RXP4/GPO 4

49

0.01uF

0.01uF

0.1uF

0.1uF

0.1uF

0.01uF

C7464

C7466

C7465

C7463

C7462

C7461

TO 9A

DGND

+1V 8H

+3V 3D

+5V D

L7401

C7442

CB05YT YH221

10V/220uF

C7443

0.1uF

C7444

0.1uF

C7445

16V/100uF

10V/100uF

SCLK2

R7476 100

LRCK2

R7475 3 3

R7474 1K

R7473 1K

SDTO1

MCKO

R7472 220

SDTO2

R7471 33

C7471

0.1uF

C7469

0.1uF

+5VD

C7468

16V/100uF

0.01uF

C7467

Pattern

R7482 OP EN

Pattern

R7483 OPE N

C7475

OPEN

C7476

OPEN

C7480

OPEN

L : A OUT (HD MI off)

H : B OUT ( H DMI o n)

8 7 6 5 4 3 2 1

2Y

GND

3A4Y4B

3Y

3B

9

R7449

C7470

16V/100uF

100

*HD MI SP DIF M ODE : DIR MASTE R

*HD MI I2 S MO DE : H DM I MASTER

*AD C MO DE : DSP MASTER

*DIR MOD E : D IR MAST ER

1A1B1Y2A2B

SEL

4A

VCC

ST

IC745

16151413121110

C7437

0.1uF

* Ci rrus Re commen d

R7424, R7425: 10K -->3. 3K C hang e.

+3V3D

10K

10K

3.3K

R7427

R7428

R7426

4321

DO

WP#

CS#

0.1uF

C7428

CLKNCVCC

8 7 6 5

10K

R7429

+3V3D

R7401

3.3K

RN741

10Kx4

5 6 7 8

RN742

10Kx4

4

X741

R7403

1

2 3

24.576MHz

10pF

C7403

C7404

5 6 7 8

L7402

CB05YT YH221

1M

R7402 330

10pF

1uF

0.01uF

C7406

C7407

C7405

10V/220uF

+3V3D

3.3K

R7425

VSS

IC742

DI

+1V8

MX25L8006EM 2I-12G

C7427

OPEN

1 2 3 4

+3V3D

C7401

0.1uF

C7402

0.1uF

1 2 3 4

R7404

5.1K/ F

C7408

0.1uF

C7409

0.1uF

R7405

3.3K

R7406

+3V3D

3.3K

R7407

10K

R7408

10K

*HD MI AU DIO Count erm easu re

R7447

100

68

68

68

SN74AH C157PW R

R7448

0

68

R7445 0

R7446 0

R7431

R7432

R7444

R7443

R7484

0

(1) SPDIF input

CH1:RXIN0

7A

HDM I_BC LK

HDM I_MCL K

HDM I_SPD IF

HDM I_LRC LK

HDM I_SD ATA0

HDM I_SD ATA1

HDM I_SD ATA2

HDM I_SD ATA3

FROM HD MI_T X

TO A7

100

R7420

SD[ 0:7]

100P

C7425

SD5

SD0

SD1

SD2

AD0

AD1

114

EXT_A17

GNDIO1

5354555657

100

R7416

AD13

5 6 7 8

5 6 7 8

33x4

RN747

1 2 3 4

C7422

110

111

112

113

VDD5

SD_CS#

EXT_A15

EXT_A16

102.SD_A0,E XT_ A0

101.SD_A1,E XT_ A1

100.VDDIO5

99.SD_A2,E XT_ A2

68.SD_D0,E XT_ D0

67.GNDIO2

66.EXT_WE #

65SD_D1,E XT_ D1

DAO1_LRCL K

GND2

VDD2

SD_DQM 0

0.1uF

C7414

10K

10K

R7415

33x4

RN746

1 2 3 4

106

SD_BA1, EXT_ A14

SD_A11,EX T_A1 1

SD_A12,EX T_A1 2

SD_D10,EX T_D 10

SD_D11,EX T_D 11

SD_D12,EX T_D 12

SD_D13,EX T_D 13

SD_D14,EX T_D 14

SD_D15,EX T_D 15

SD_D4,E XT_ D4

616263

+3V3D

103

105

104

GNDIO5

100 101 102

SD_BA0, EXT_ A13

SD_A10,EX T_A1 0

C7420

GNDD4

0.1uF

SD_A3,EX T_A 3

SD_A4,EX T_A 4

C7419

VDD4

0.1uF

EXT_CS2 #

SD_A5,EX T_A 5

GNDIO4

SD_A6,EX T_A 6

SD_A7,EX T_A 7

C7418

VDDIO4

0.1uF

SD_A8,EX T_A 8

SD_A9,EX T_A 9

GND3

0.1uF

C7417

VDD3

R7419

SD_CLKE N

SD_CLKIN

SD_CLKO UT

R7418

SD_DQM 1

SD_D8,E XT_ D8

SD_D9,E XT_ D9

GNDIO3

C7416

VDDIO3

0.1uF

65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 8 5 86 87 88 89 90 91 92 93 94 95 96 97 98 99

SD_D3,E XT_ D3

VDDIO2

SD_D2,E XT_ D2

64

C7415

0.1uF

+3V3D

0.1uF

107

109

108

SD_RAS#

SD_CAS#

SD_WE#

SD_D5,E XT_ D5

SD_D6,E XT_ D6

SD_D7,E XT_ D7

59

60

58

33

DA12

DA11

DA10 AD12

DA14

DA13

DA15

3.3K

3.3K

3.3K

R7423

R7424

R7422

+3V3D

0.1uF

C7423

C7424

0.1uF

123

122

124

121

GNDIO6

RESET#

SCP1_MOSI

SCP1_MISO/ SDA

1.SCP2_CK

2.SCP2_MISO

3.SCP2_MOS I

4.SCP1_IRQ

CS 497024CVZ

35.DAO2_D3

36.DBDA

37.DBCK

38.DAO2_D2

DAO2_D0,H S3

DAO2_SCLK

GNDD1

DAO2_LRCL K

4647484950

44

45

0.1uF

5 6 7 8

RN743

1 2 3 4

R7411 OPE N

R7409 OPE N

R7410 OPE N

116

118

120

117

119

VDDIO6

EXT_OE#

EXT_A19

EXT_A18

EXT_CS1 #

IC741

AU DIO D SP

DAO1_DAT A1,H S1

DAO1_DAT A0,H S0

DAO1_D2,H S2

DAO1_D3

VDDIO1

51

0.1uF

C7412

33x4

R7413

16V/100uF

115

GND5

DAO1_SCLK

2

5

R7414

128

123456789

PCP/SCP2_I RQ#

SCP1_CS#

PCP/SCP2_C S#

VDDIO7

GNDIO7

GPIO3,DDAC

1011121314151617181920212223242526272829303132333435363738

GPIO2,UAR T_T XD

VDD7

GPIO1,UAR T_RX D

GPIO1,UAR T_C LK,EE_ CS#

GND7

XTAL_OU T

XTI

XTO

GNDA

PLL_REF_RES

VDDA(3.3V)

VDD8

DAI1_DATA 3,D SD3

DAI1_DATA 2,D SD2

GND8

DAI1_DATA 1,D SD1

DAI1_DATA 0,D SD0

VDDIO8

DAI1_BCLK ,DSD -CLK

DAI1_LRCK, DSD 4

GNDIO8

DAI2_LRCK

DAI2_SCLK

DAI2_DATA ,DSD 5

39

C7426

125

127

126

VDD6

GNDD6

SCP1_CLK

SCP1/PCP _BS Y

DAO2_D1,H S4

VDD1

TEST

DAO_MCL K

414243

40

C7410

(3) DAC input

CH1:LRCK

CH2:BCK

CH3:DIN1

AD[ 0:19]

IC743

C7429

M12L16161A5T G2R

10V/100uF

512K * 16B it * 2 Ban ks

SD7

SD6 S D4

SD3

SD4

+3V3D

C7430

RN748

0.1uF

1234

5

DQ1

678

33x4

C7431

0.1uF

RN749

1234

9 8 7 6 5 4 3 2 1

5

678

33x4

LDQM

SD2

SD1

SD0

SD5

C7432

0.1uF

_WE

25 2 4 23 2 2 21 20 19 18 1 7 16 15 14 13 1 2 11 1 0

C7433

0.1uF

AD2

AD3

AD13

AD12

AD0

AD1

RN745

AD2

AD3

DA8

AD4

DA9

AD5

1 2 3 4

5 6 7 8

33x4

RN744

5 6 7 8

33x4

DA10

DA11

AD6

AD7

AD8

DA12

AD9

1 2 3 4

DA13

DA14

DA15

33

33

DA0

DA1

DA2

DA3

DA4

DA5

DA6

DA7

DA8

DA9

R7417

33

DA[ 0:15]

(2) DIR output

CH1:FSDIR1

CH2:64FSDIR1

CH3:DATADIR1

CH4:MCLK

A8

TO 8A

FRO M/TO INPU T/V OLUM E PAR T

CTD_

D_F R-

D_F L-

D_F L+

D_F R+

AD_ RIN-

D_C T+

D_S W+

D_S L-

D_S L+

D_S R+

D_S W-

AD_ LIN+

AD_ RIN+

100

R7477

R7478

C7450

C7452

D_SB RD_SB R+

D_SB L+

D_SB L-

OPEN

0.1uF

0.1uF

L7403

C7453

50V/100uF

+5VD

C7454

C7455

35V/470uF

FCM601T0 5

100P

C7449

C7448

C7451

50V/22uF

VQ

17

AINR-

FILT+

18

REFGND

19

AOUTB4-

20

AOUTB4+

21

AOUTA4+

22

AOUTA4-

23

VA

24

AGND

25

AOUTB3-

26

AOUTB3+

27

AOUTA3+

28

AOUTA3-

29

B2-

AOUT

30

AOUTB2+

31

AOUTA2+

32

33 34 35 36 37 38 3 9 40 41 4 2 43 4 4 45 46 47 48

0.1uF

C7727

0.01uF

L7404

+5VD

AGND

AD_R INAD_R IN+

AD_L IN+

AD_L IN-

D_SR D_SR +

D_SL +

D_SL D_SW D_SW +

D_CT +

D_CT D_FR D_FR +

D_FL +

D_FL +5VA

C7477

C7478

C7479

C7473

0.1uF

C7474

OPEN

T7401

T7402

T7403

T7404

*SOUN D QU ALIT Y Cout erme asu re.

*EMI Cout erm easu re.

R7480

OPEN

R7481

OPEN

AD_ LIN-

0.1uF

0.1uF

0.1uF

JK782

C7822

VCC

RX

0.1uF

GND

R7821 33

1 2 3

OUT

C7824

OPEN

JK783

VCC

C7832

RX

0.1uF

GND

1 2 3

OUT

JK784

C7841

S570BT /E3

O

100pF

O

R7833 33

100P

R7841

X580BT /ALL

R7824 33

R7834 33

33P

C7823

33P

C7833

75

OPEN

D7841

X

0.1u F

X

GND LINE

POWER+ LINE

POWER- LINE

ANALOG AUDIO

DIGITAL AUDIO

TMDS SIGNAL

ANALOG VIDEO

STBY POWER

11

Page 12

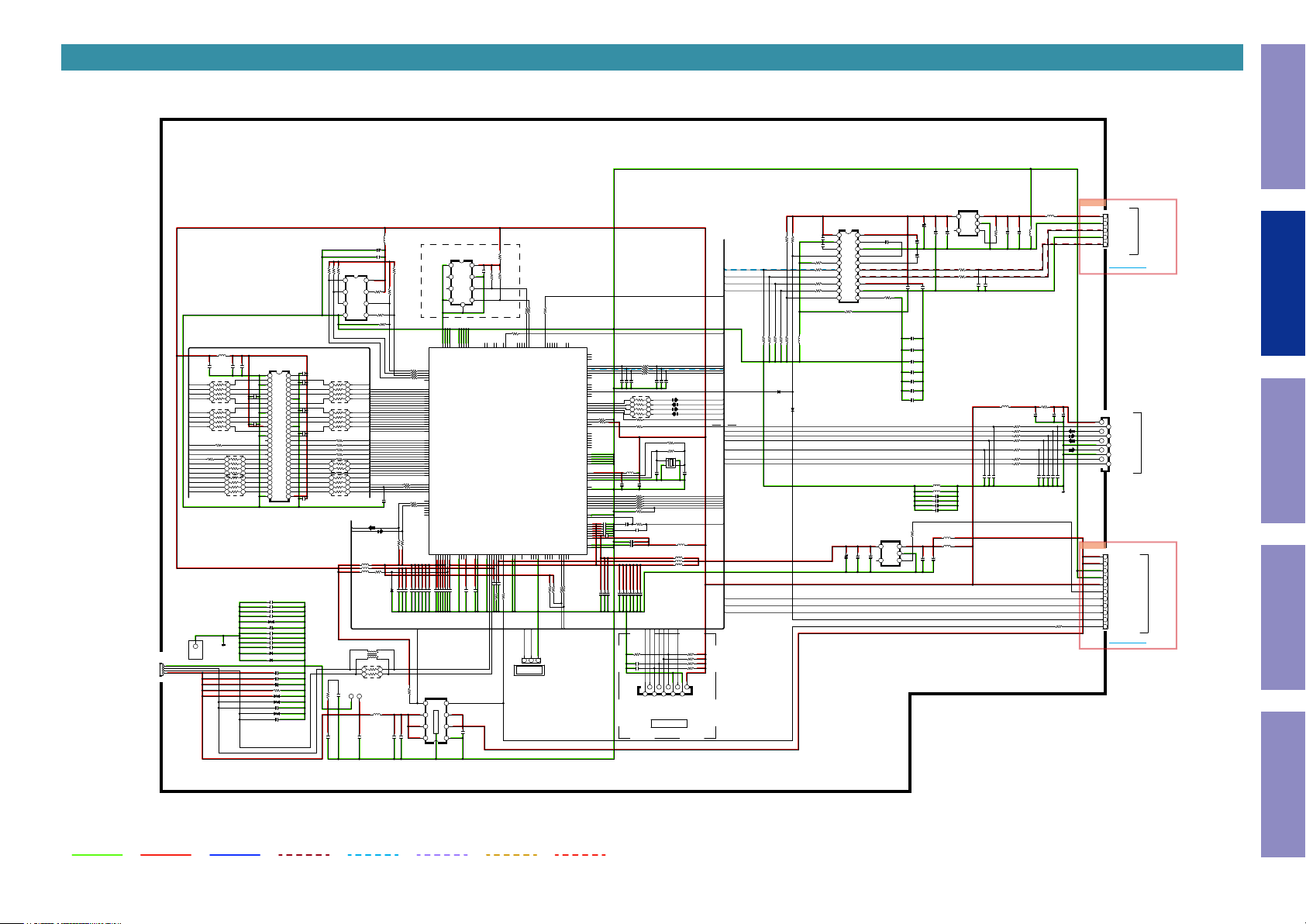

SCH04 DIGITAL INPUT VOLUME

D IGIT AL PO W ER PART

100K

C7511

R7512

0.1uF

CEC_P OWE R3

CEC_P OWE R

CEC_P OWE R

R7511

0.1uF

C7512

R7521

0.1uF

C7525

R7531

0.1uF

C7538

R7541

0.1uF

C7552

33

L7511

CB03YT YH600

L7512

OPEN

10uF

C7513

33

L7521

CB03YT YH600

L7522

OPEN

10uF

C7526

33

L7531

CB03YT YH600

L7532

OPEN

33

L7541

CB03YT YH600

L7542

OPEN

R7522

R7532

R7542

OPEN

R7513

C7515 16V/10uF

C7514 16V/10uF

100K

0.1uF

C7524

OPEN

R7523

C7527 16V/ 10uF

C7528 16V/ 10uF

100k

0.1uF

C7537

OPEN

R7533

C7539 16V/10uF

C7540 16V/10uF

100k

0.1uF

C7551

OPEN

R7543

C7553 16V/10uF

C7554 16V/10uF

VFB

EN

IC751

TPS563201DDC R

3 2 1

VIN

SW

0.1uF

C7516

VFB

EN

IC752

TPS563201DDC R

3 2 1

SW

VIN

0.1uF

C7529

VFB

EN

IC753

TPS563201DDC R

3 2 1

SW

VIN

0.1uF

C7541

VFB

EN

IC754

TPS563201DDC R

3 2 1

SW

VIN

0.1uF

C7556

6A

TO A6

TO HD MI TX PAR T

DGND

CEC 0V9C ORE

CEC 3V3

CEC 0V9

CEC 5V

SWM 5V

CEC 1V8

CN751

CN751

C7592

SWM 3.3V

CN752

CA2505-WV 06L

1.D 5.2V

2 1

2.D 5.2V

R7589

3

3.M_ RESE T

0

4.D _GND

5.D _GND

L7584

6 5 4

6.MAIN_ POW ER

CB03YT YH600

3A

MAIN_P OWER

CEC_ POW ER2

CPU _POW ER

CEC_ POW ER

CEC_ POW ER3

DA_ POW ER

USB _POW ER2

H5V OUT _POW ER

L7585

MCU +5V

CB03YT YH600

MCU +3V 3

POW ER_D OWN

MCU _RST

DGND

SWM 3V3

SWM 5V

D5V

USB 3V3

0.1uF

CEC3 V3

FRO M/T O SMP S B'D

FRO M/T O MCU PAR T

TO BN601

WA FER/ 6P/2 .5mm

TO A3

SWM 5V

9A

+5V D

B0

CN752

CA2005-WV 05-K

5 4 3 2 1

+3V 3D

+1V 8H

DGND

DA_ GND2

+5V A

USB /BT_ L

USB /BT_ R

AGND

1.+ 5VA

2.D A_GND

3.US B/BT _R

4.D A_GND

5.US B/BT _L

TO A9

TO DSP PART

FRO M/T O INP UT/V OLUM E PA RT

TO 0B

TO BN211

TO USB /BT B'D

WA FER/ 5P/2 .0mm

L7581

CB03YT YH600

L7582

CB03YT YH600

0.1uF

0.1uF

OPEN

0.1uF

C7597

L7583

0.1uF

OPEN

C7584

C7585

C7586

CB03YT YH600

16V/470uF

OPEN

C7158

1uF

1uF

0.1uF

0.01uF

0.01uF

0.01uF

C7598

C7599

C7510

C7509

C7508

C7801

D7562

OPEN

16V/470uF

C7589

C7588

C7587

MCU+3V 3

10K

10K

100K

D7591

KDS160

R7566

KDS160

MCU+3V 3

R7593 0

R7565

R7564

R7567

4.7K

L752

OPEN

100

Q7593

47K

0.1uF

R7598

C7591

KTC3875S YRT K

R7568

0

Q7563

OPEN

R7560

R7569

OPEN

OPEN

Q7564

KRC102S

KTA1504S YRTK

Q7585

R7585

R7584

3.3K

10K

Q7586

KRC102S

OPEN

OPEN

C7505

C7506

C7501

C7502

0.1uF

0.1uF

R7563

C7590

1uF

D7592

0.01uF

1000pF

C7802

C7803

OPEN

D7563

OPEN

OPEN

C7503

C7504

L7551

CB03YT YH600

R7551

Q7551

DA_P OWE R

KRC104S

VBST

654

0.1uF

C7517

L7513

(5040) 3.6 uH

GND

VBST

654

0.1uF

C7530

L7523

(5040) 3.6 uH

GND

VBST

0

R7530

654

0.1uF

C7542

L7533

2.2uH (5040)

GND

VBST

0

R7540

654

0.1uF

C7507

L7543

2.2uH (5040)

GND

D 3.3 V

R7516

33.2K/F

L7514

0

0

C7518 OPEN

R7515

R7514 10K/F

L7515

OPEN

0.1uF

6.3V/ 22uF

6.3V/ 22uF

6.3V/ 22uF

6.3V/ 22uF

C7522

C7521

C7520

R7517 47K

D 1.8 V

13K7/F

L7524

0

0

L7525

OPEN

6.3V/ 22uF

6.3V/ 22uF

C7533

C7534

CE C0 .9V

1k8/F

R7537

0

0

R7538

0

R7539

0

6.3V/ 22uF

6.3V/ 22uF

C7546

C7545

CE C0 .9V Core

1k8/F

R7547

0

0

R7548

0

R7549

0

C7560

C7559

6.3V/ 22uF

6.3V/ 22uF

C7523

0.1uF

C7535

R7527 47K

C7536 OPEN

OPEN

C7550

C7547 0.1 uFC7561 0.1 uF

C7549 OP EN

C7548 OP EN

OPEN

C7564

C7562 OP EN

C7563 OP EN

C7519

OPEN

R7526

R7524 10K/F

R7525

C7531

6.3V/ 22uF

C7532

R7536

OPEN

C7543

R7535

R7534 10k/F

6.3V/ 22uF

C7544

R7546

OPEN

C7557

R7545

R7544 10k/F

C7558

6.3V/ 22uF

H5VO UT_ POW ER

DA_P OWE R

CEC_P OWE R

USB_ POWE R2

DA_P OWE R

R7501

0

R7502 100k

S

D D

0.1uF

100K

OPEN

R7553

C7555

R7552

100K

3 2 1

G

D D

OPEN

C7565

IC761

1

IN

VOUT

6

542

GND

ILIM

R7503

1uF

10uF

C7571

C7572

3

EN

OC

OPEN

BD2222G-G TR

0.1uF

C7570

R7561

10K

R7571

10K

R7581

10K

R7591

10K

KRC104S

KRC104S

KRC104S

KRC104S

T761

R7562

33K

Q7561

R7572

10K

Q7571

R7582

10K

Q7581

R7592

33K

Q7591

654

S

3 2 1

G

0.1uF

C7574

S

3 2 1

G

0.1uF

C7576

S

3 2 1

G

0.1uF

C7578

S

3 2 1

G

0.1uF

C7580

Q7552

D D

D D

D D

D D

D D

D D

D D

D D

L7552

CB03YT YH600

OPEN

OPEN

0.1uF

OPEN

PDEQ 2309

R7554 47K

C7567

C7569

C7566

C7568

R7506 0

10uF

OPEN

R7504

R7505

100k/F

100k/F

C7573

D7561

R7507 10K

654

Q7562

PDEQ 2309

0.1uF

C7575

654

Q7572

PDEQ 2309

0.1uF

C7577

654

Q7582

PDEQ 2309

0.1uF

C7579

654

Q7592

PDEQ 2309

0.1uF

C7581

CEC_ POW ER2

CPU_ POW ER

CEC_ POW ER

CEC_ POW ER3

DA_P OWE R

USB_ POW ER2

H5VO UT_ POW ER

CPU_PO WER

CEC_PO WER2

OPEN

C7582

C7583

0.1uF

0.1uF

OPEN

50V/0.1 uF

C7595

C7593

C7596

C7594

ET751

OPEN

OPEN

R7583

This Unit

Before Servicing

Electrical Mechanical Repair Information Updating

*EMI Couter mea sure .

GND LINE

POWER+ LINE

POWER- LINE

ANALOG AUDIO

DIGITAL AUDIO

TMDS SIGNAL

ANALOG VIDEO

STBY POWER

12

Page 13

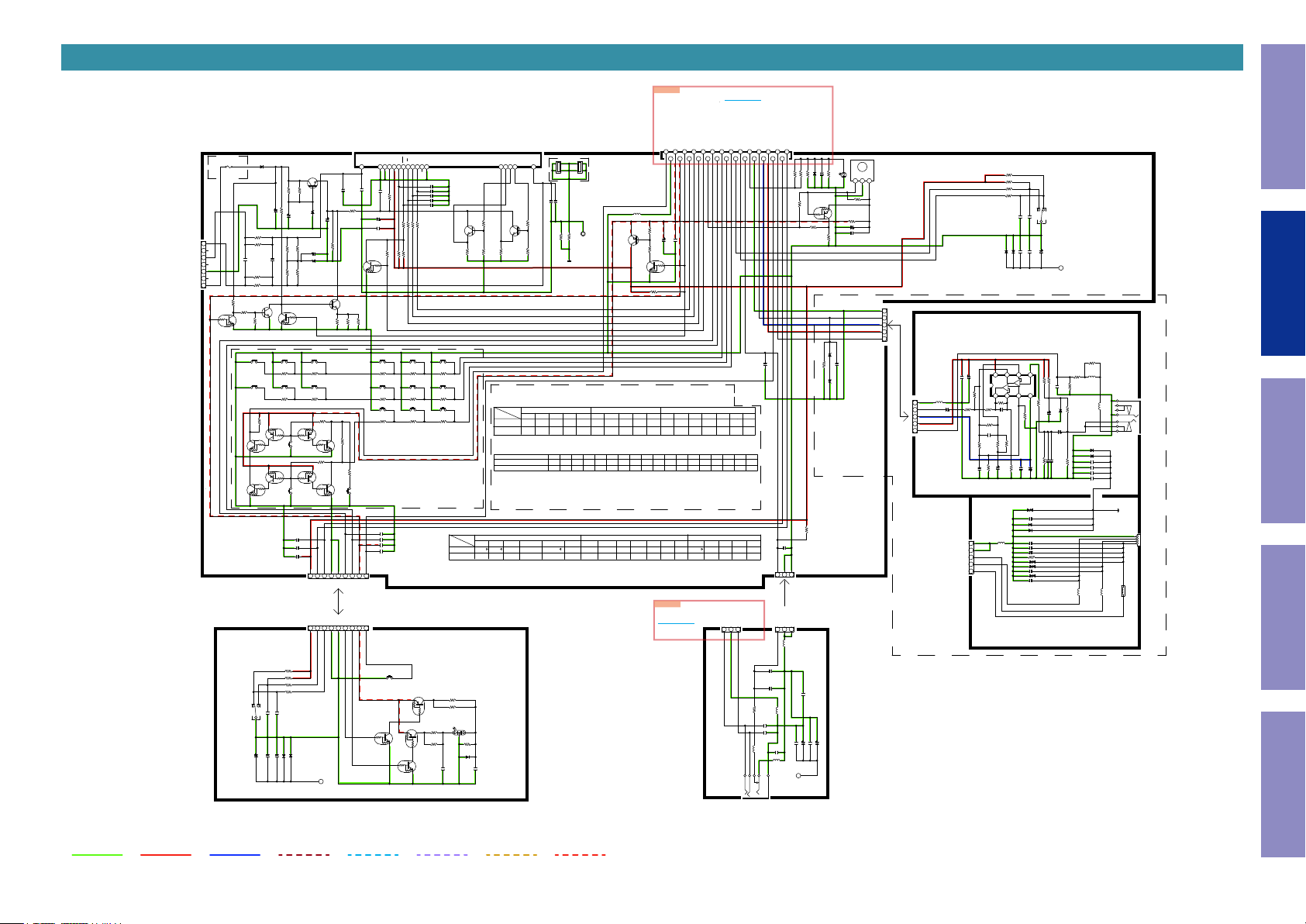

SCH05 DIGITAL DIGITAL POWER

WA FER/ 13P/2.0 mm

WI RE/7 P/2. 0mm

INPUT /VOLU ME PART

*TUN ER M ODU LE OP TION

TU771

1.CH _GND

2.INT

3./RS T

4./C E

5.SD IO

6.SCL K

7.VC C

8.R-O UT

9.L-O UT

FRO M TU NER M ODU LE

TO BN508

CB L/SAT

AU X

PRE OUT

TU771

CJP09H J282X

TUN ER MO DUL E

L CH

R CH

L CH

R CH

SW 2

SW 1

SU BWOOFE R

AVR-S 570BT E 3

AVR-X 580BT E2

AVR-X 580BT E1C

AVR-X 580BT K

13

2

46

57

8

9

CHGND

JK771

CHGND

CHGND

JK772

CHGND

150K

R7732

CNVY ST990-A 9U2

CNVY ST990-D 8E3

CNVY ST990-A 2J1

CNVY ST990-A 9U2

R7601

270

R7603

R7602

270

OPEN

OPEN

R7659

R7658

R7654

OPEN

C7753

R7740

OPEN

50V/22uF

R7611

100

220P

100K

C7751

R7613

R7612

C7754

220P

100K

R7614

C7752

100

50V/22uF

C7763

R7621

50V/22uF

100

220P

100K

C7761

R7623

R7622

220P

100K

C7762

R7624

100

R7655

0

R7738

C7764

0

50V/22uF

R7642

C7642

220

50V/22uF

C7638

0.1uF

100K

330P

R7660

D7603

C7639

OPEN

D7604

OPEN

R7764

OPEN

R7765

OPEN

R7664

0

C7702

OPEN

C7703

0.1uF

C7629

R7741

0

50V/22uF

15K

OPEN

R7742

R7743

R7746

4.7K

4321

220P

CM2

C7704

4.7K

R7744

CM1

8 7 6 5

IC766

NJM2740V

0.1uF

C7705

100

C7706

R7745

2700P

AD_R IN-

C7605

27K

C7736

R7615

R7616

R7625

R7626

R7747

R7748

0.1uF

91k

91k

91k

91K

R7652

4.7K

100

AD_R IN+

100P

C7611

CB03YT YH600

C7607

27K

R7604

0.1uF

C7621

0.1uF

0.1uF

C7737

IC768

NJM8080G

C7755

OPEN

IC769

NJM8080G

C7765

OPEN

100K

OPEN

C7708

R7637 100

R7651 100

R7653 100

R7656 100

R7657 100

100P

100P

0.1uF

100P

C7612

C7610

C7613

C7614

L7601

16V/470uF

R7605

0

R7606

0

0.1uF

0.1uF

C7622

C7739

0.1uF

C7738

-

B-INPUT

B

B+INPUT

+

V-

A+INPUT

4 3 2 1

-

B-INPUT

B

B+INPUT

+

V-

A+INPUT

4 3 2 1

R7643

470

Q7610

KTC2875A S

12K

C7707

R7757

A-INPUT

A-INPUT

B OUTPUT

+

A

-

B OUTPUT

+

A

-

KTC2875A S

AGND

16V/100uF

R7618

33

8765

V+

C7756

A OUTPUT

R7617

33

R7628

33

8765

V+

C7766

A OUTPUT

R7627

33

R7644

470

R7641

Q7611

10K

R7645

10K

R7758

10K

0.1uF

C7709

0A

MCU +3V 3

AGND

SUB _MUT E

MIC_ SIGNAL

DGND

DAC _MUT E

SEL_ CLK

SEL_ DAT A

MAIN_V OL_M UTE

MAIN_V OL_C LK

MAIN_V OL_D ATA

TUN ER_IN T

TUN ER_R ST

TUN ER_C E

TUN ER_S DIO

TUN ER_S CLK

+12V

-12V

Pattern

R7771

OPEN

Q7612

KRA104S

4.7K

CM2

IC767

R7772 OPEN

R7773 OPEN

R7774 OPE N

K

100V/10uF

C7721

R7720 100

V+NCV-

USB/B T_L

USB/B T_R

TUNER _L

TUNER _R

CBL/SA T_L