Page 1

www.delta.com.tw/industrialautomation

ASIA

Delta Electronics, Inc.

Taoyuan1

31-1, Xingbang Road, Guishan Industrial Zone,

Taoyuan County 33370, Taiwan, R.O.C.

TEL: 886-3-362-6301 / FAX: 886-3-362-7267

Delta Electronics (Jiang Su) Ltd.

Wujiang Plant3

1688 Jiangxing East Road,

Wujiang Economy Development Zone,

Wujiang City, Jiang Su Province,

People's Republic of China (Post code: 215200)

TEL: 86-512-6340-3008 / FAX: 86-769-6340-7290

Delta Electronics (Japan), Inc.

Tokyo Office

Delta Shibadaimon Building, 2-1-14 Shibadaimon,

Minato-Ku, Tokyo, 105-0012, Japan

TEL: 81-3-5733-1111 / FAX: 81-3-5733-1211

Series

HMI Connection Manual

Series HMI Connection Manual

Delta Electronics (Korea), Inc.

Donghwa B/D 3F, 235-6, Nonhyun-dong,

Kangnam-gu, Seoul 135-010, Korea

TEL: 82-2-515-5303/5 / FAX: 82-2-515-5302

Delta Electronics (Singapore) Pte. Ltd.

8 Kaki Bukit Road 2, #04-18 Ruby Warehouse Complex,

Singapore 417841

TEL: 65-6747-5155 / FAX: 65-6744-9228

AMERICA

Delta Products Corporation (USA)

Raleigh Office

P.O. Box 12173,5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3813 / FAX: 1-919-767-3939

EUROPE

Deltronics (The Netherlands) B.V.

Eindhoven Office

De Witbogt 15, 5652 AG Eindhoven, The Netherlands

TEL: 31-40-2592850 / FAX: 31-40-2592851

*We reserve the right to change the information in this manual without prior notice

20080122

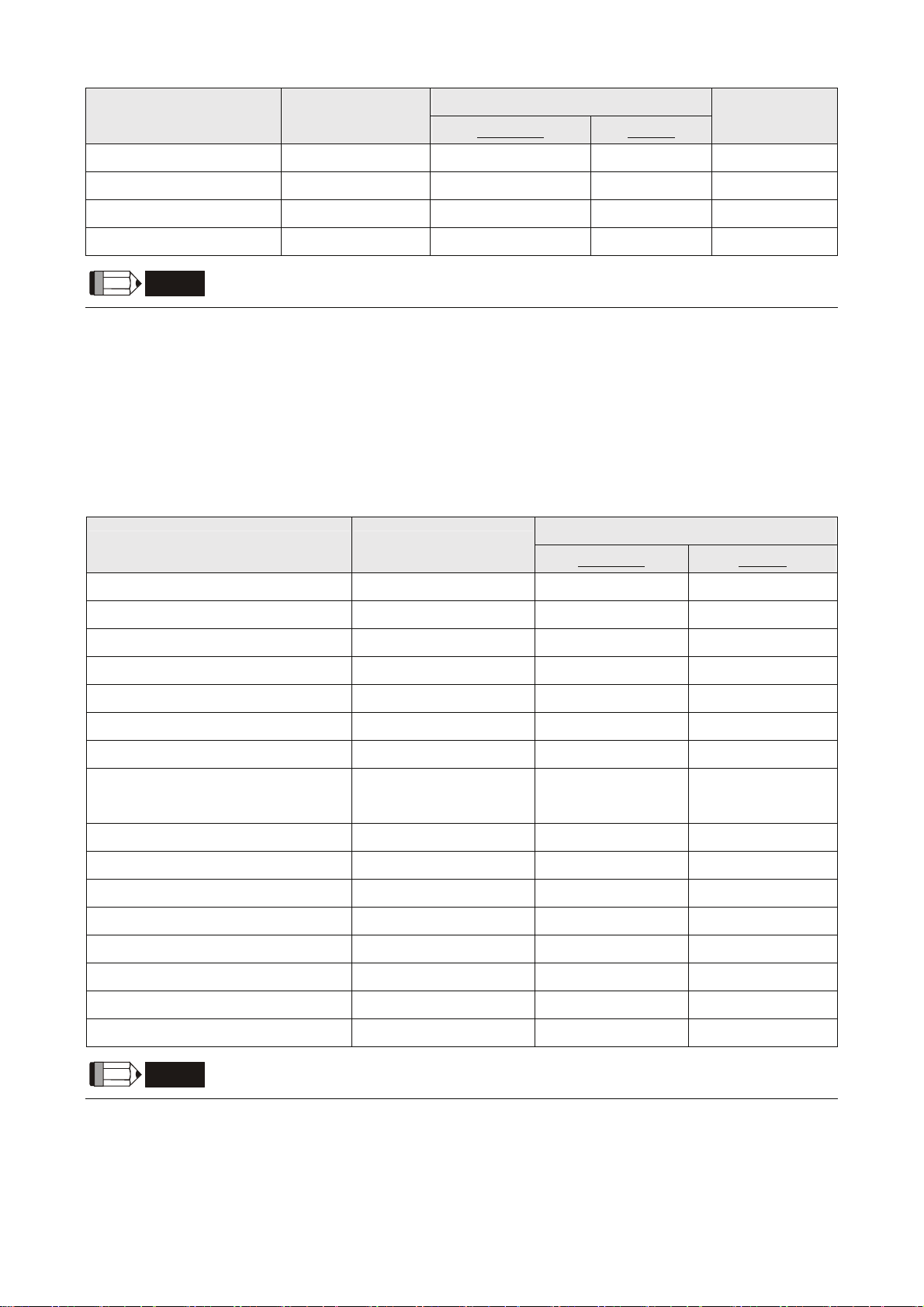

Page 2

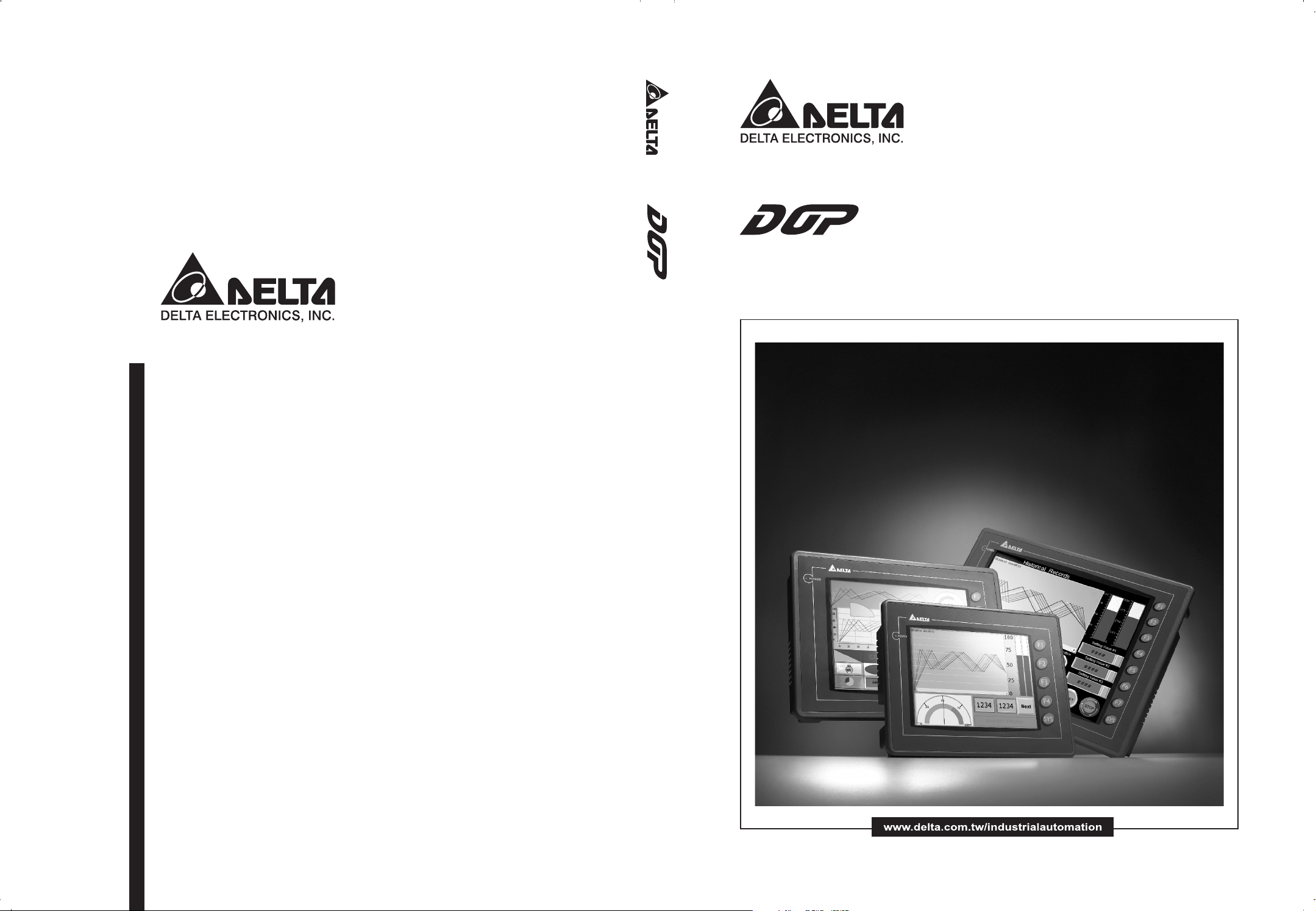

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

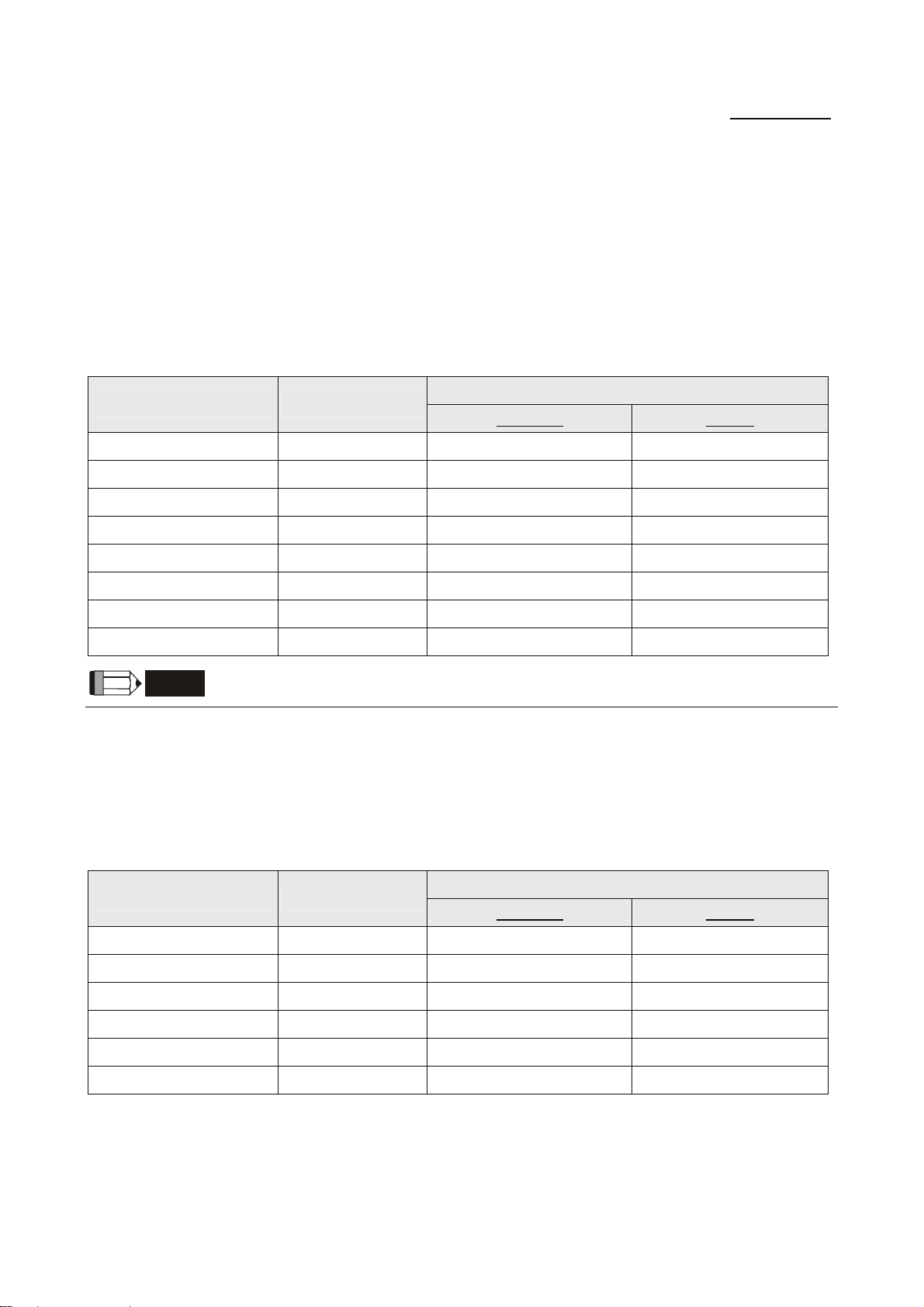

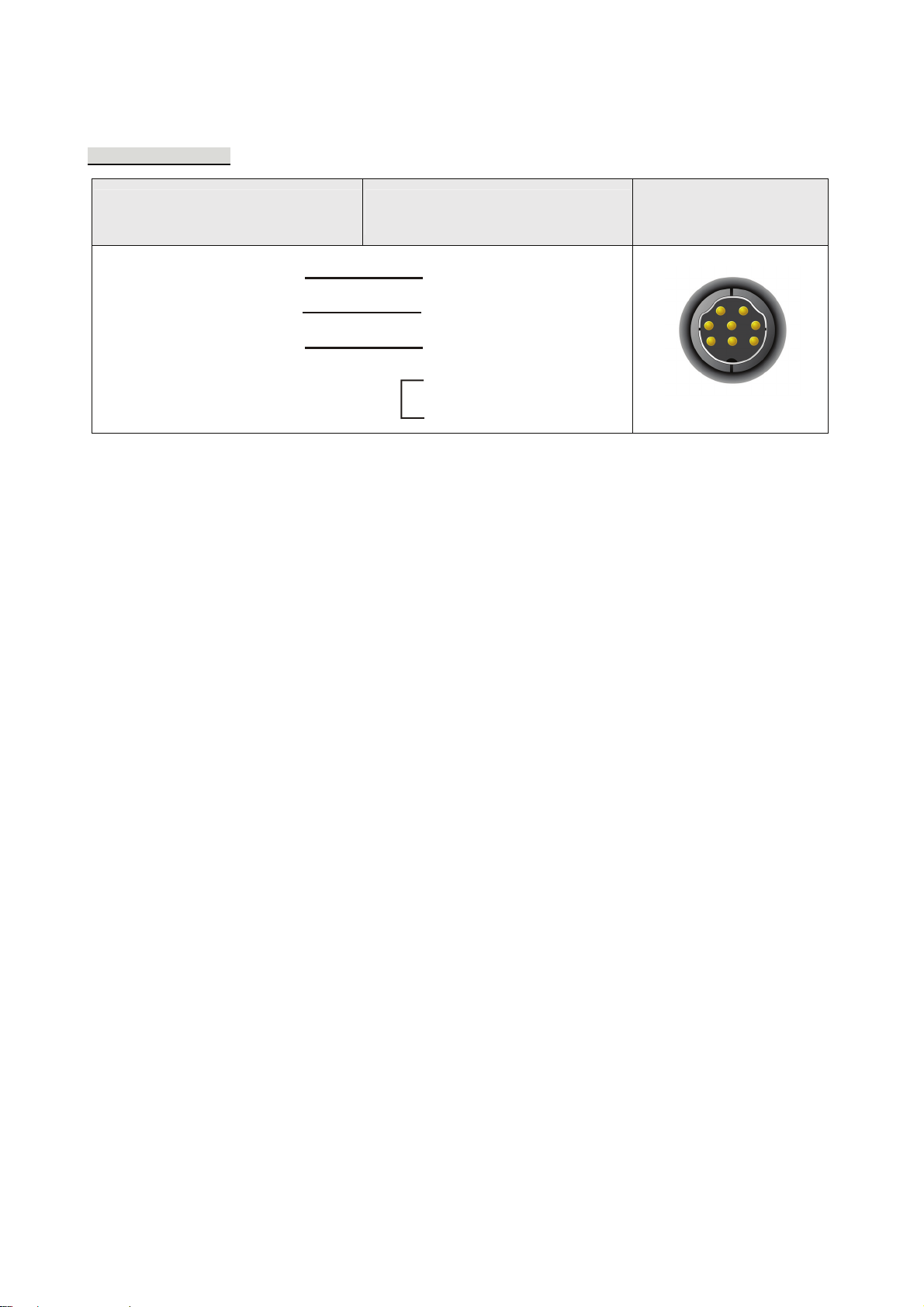

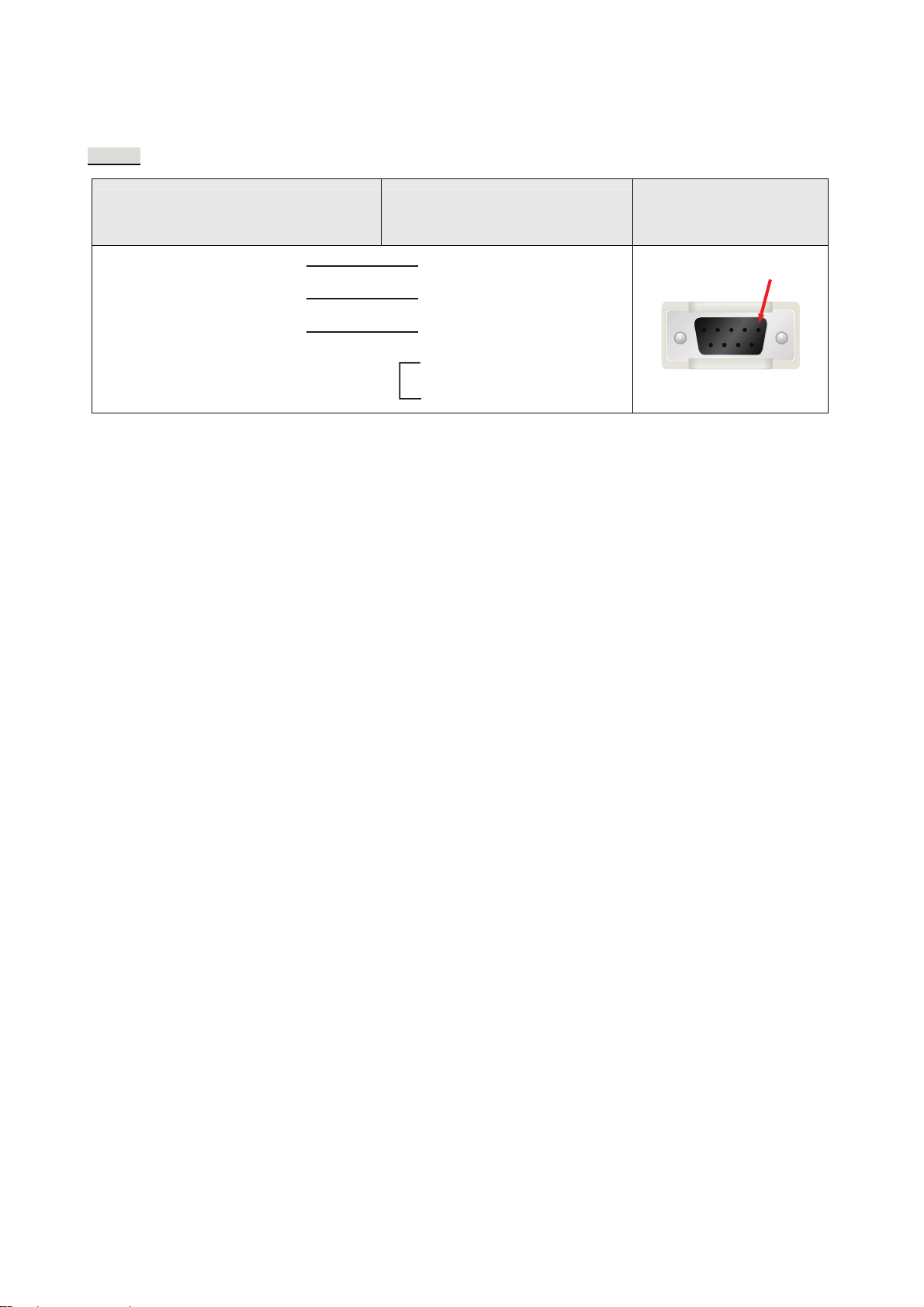

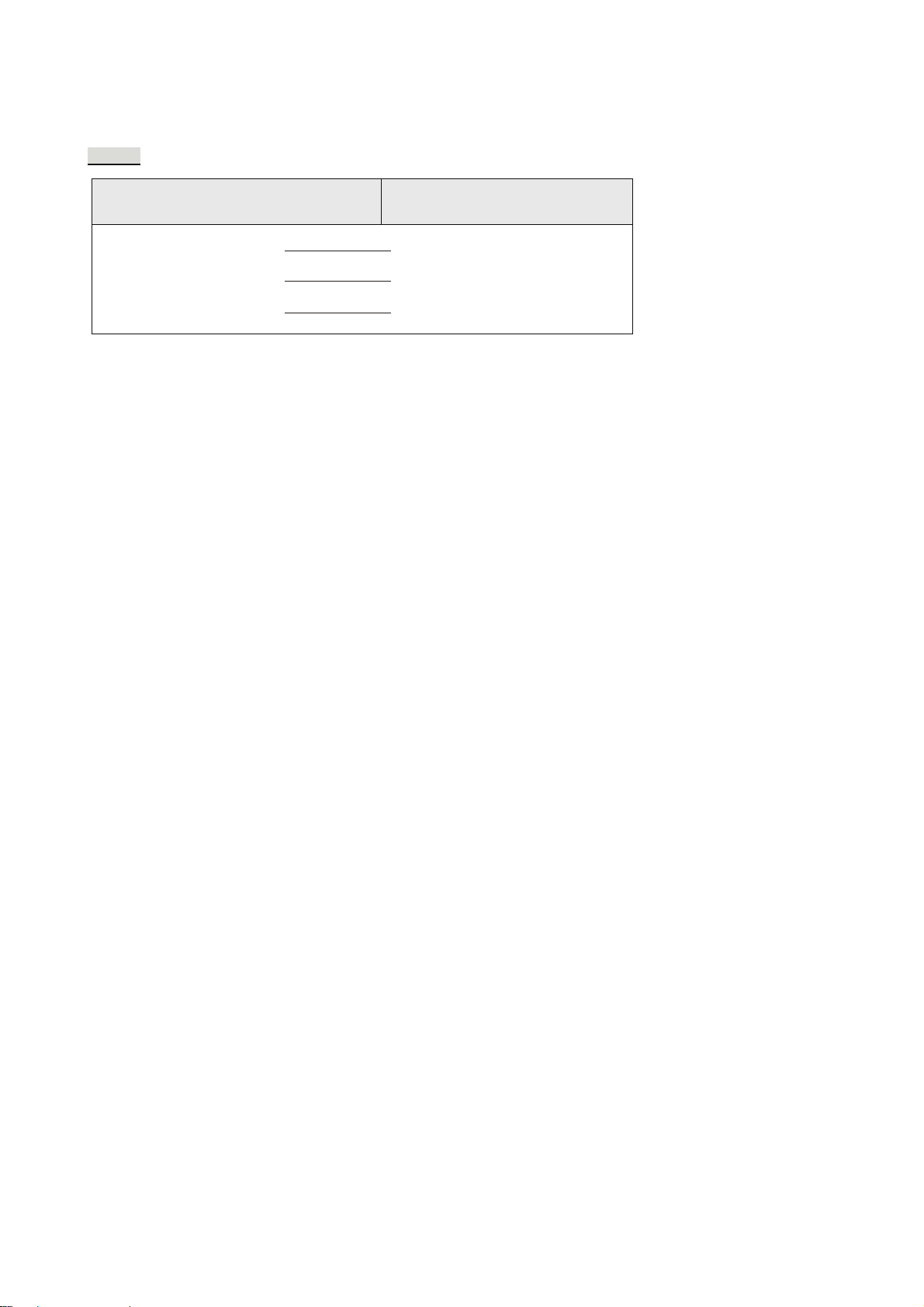

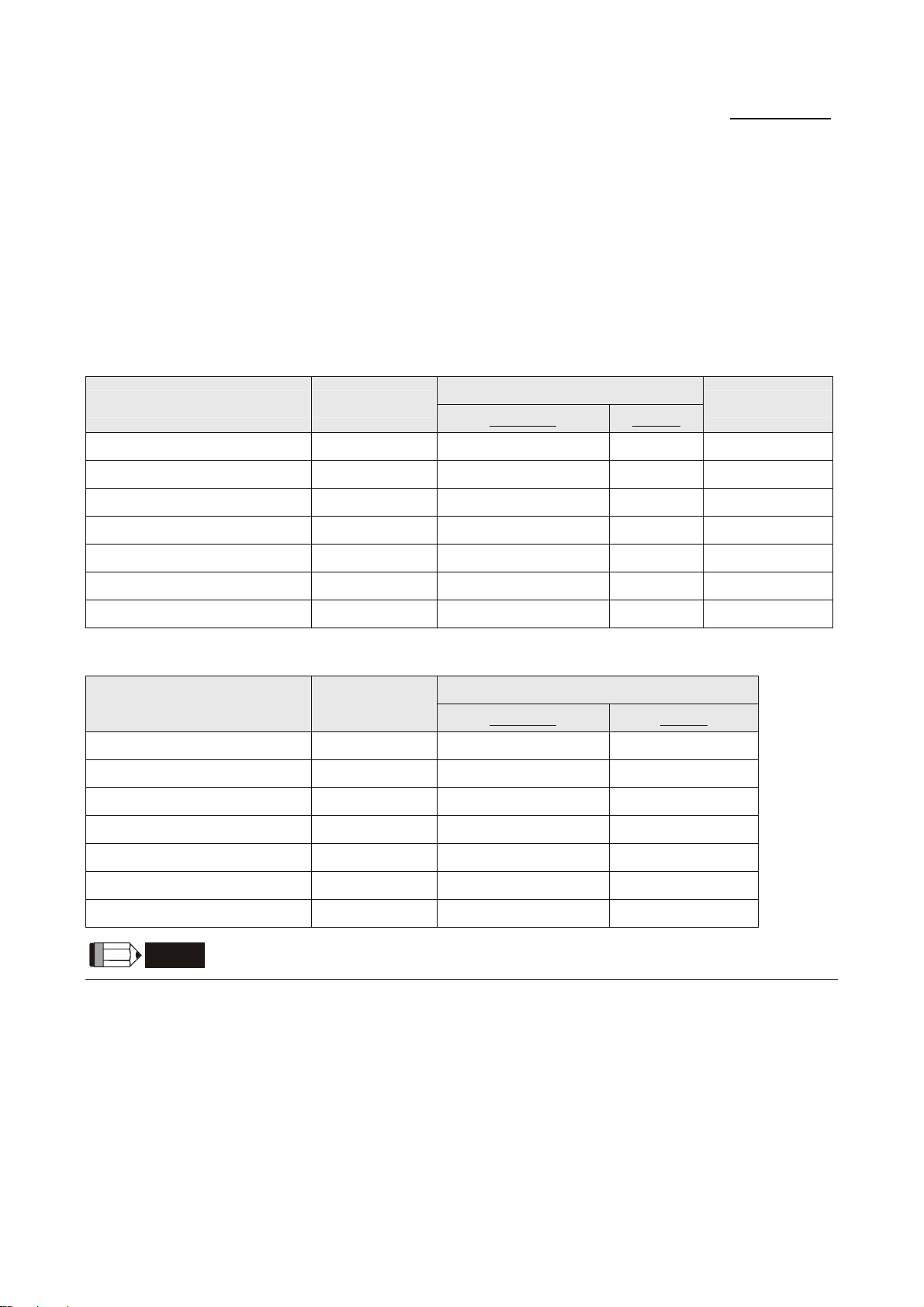

1.1 Pin Definition of Serial Communication

DOP-A Series

COM1

COM2

Pin1

PIN

1 N.C RXD- D-

PIN

1 N.C

2 RXD

3 TXD

4 N.C

5 GND

6 N.C

7 RTS

8 CTS

9 N.C

Mode 1 Mode 2 Mode 3

RS-232 RS-422 RS-485

Mode

RS-232

Pin1

2 RXD RXD+ D+

3 TXD TXD+ D+

4 N.C TXD- D-

5 GND GND GND

6 N.C RTS- N.C

7 RTS RTS+ N.C

8 CTS CTS+ N.C

9 N.C CTS- N.C

NOTE

1) Mode 3 is for RS-485. Pin 2 & 3 are D+ and pin 1 & 4 are D-.

2) Grounding is highly recommended if RS-485 & RS-422 are used for long transmission.

3) DO NOT connect Frame Ground (FGND) to GND. Please connect FGND to the outer covering of

connector.

4) Transmission speed is relevant to distance and baud rate.

Revision January, 2008, Doc. Name: 2007PDD23000007 1-1

Page 3

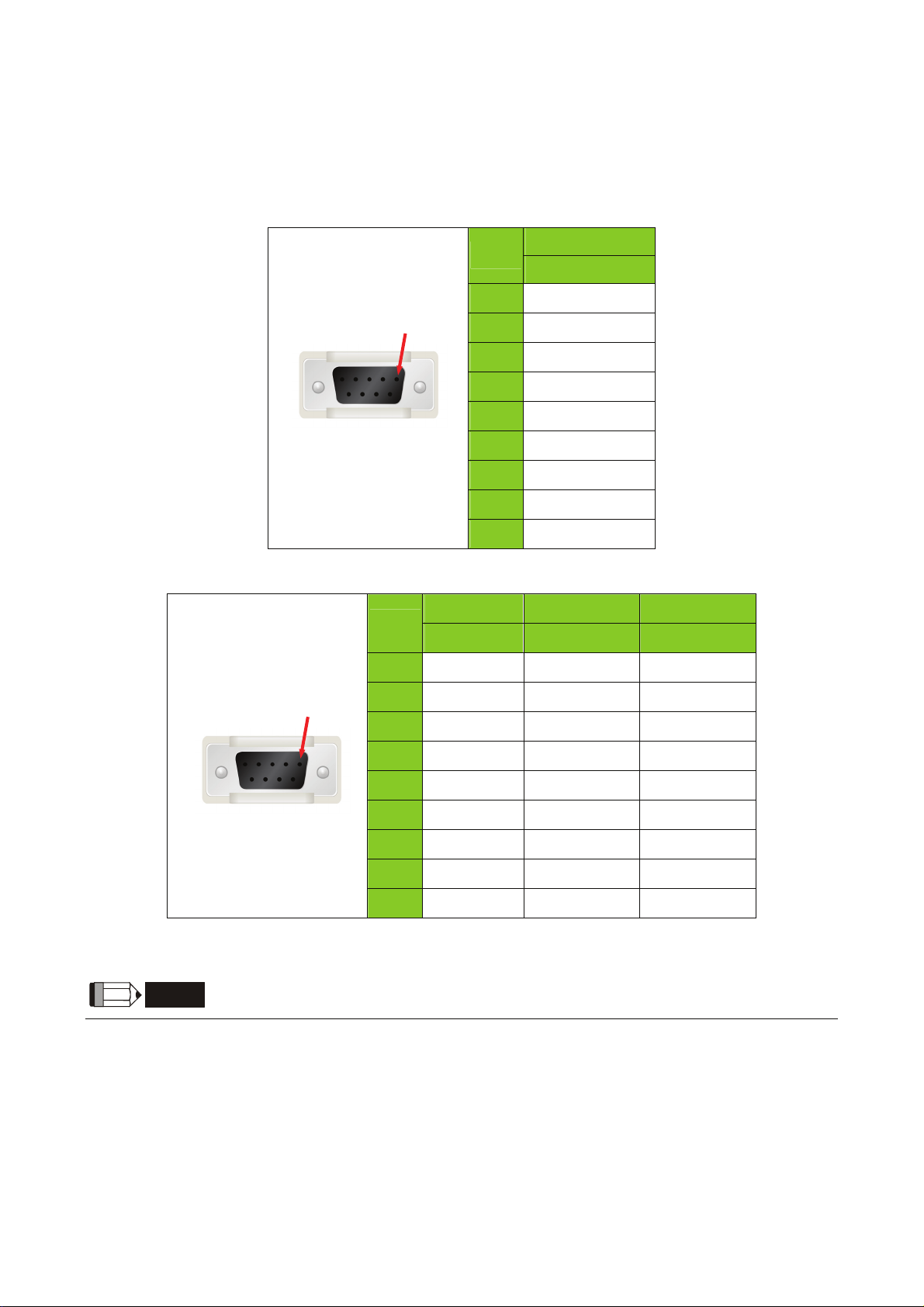

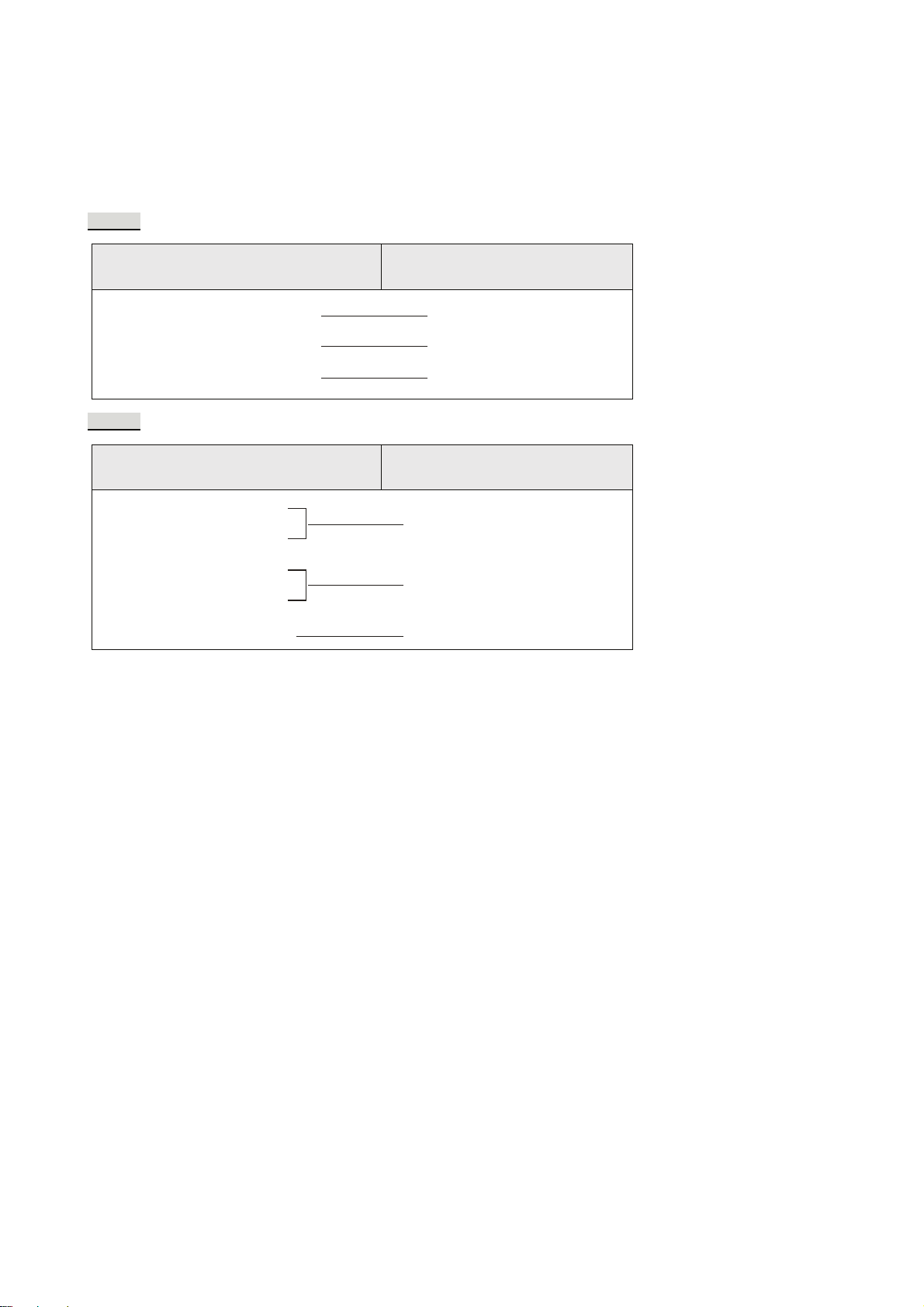

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

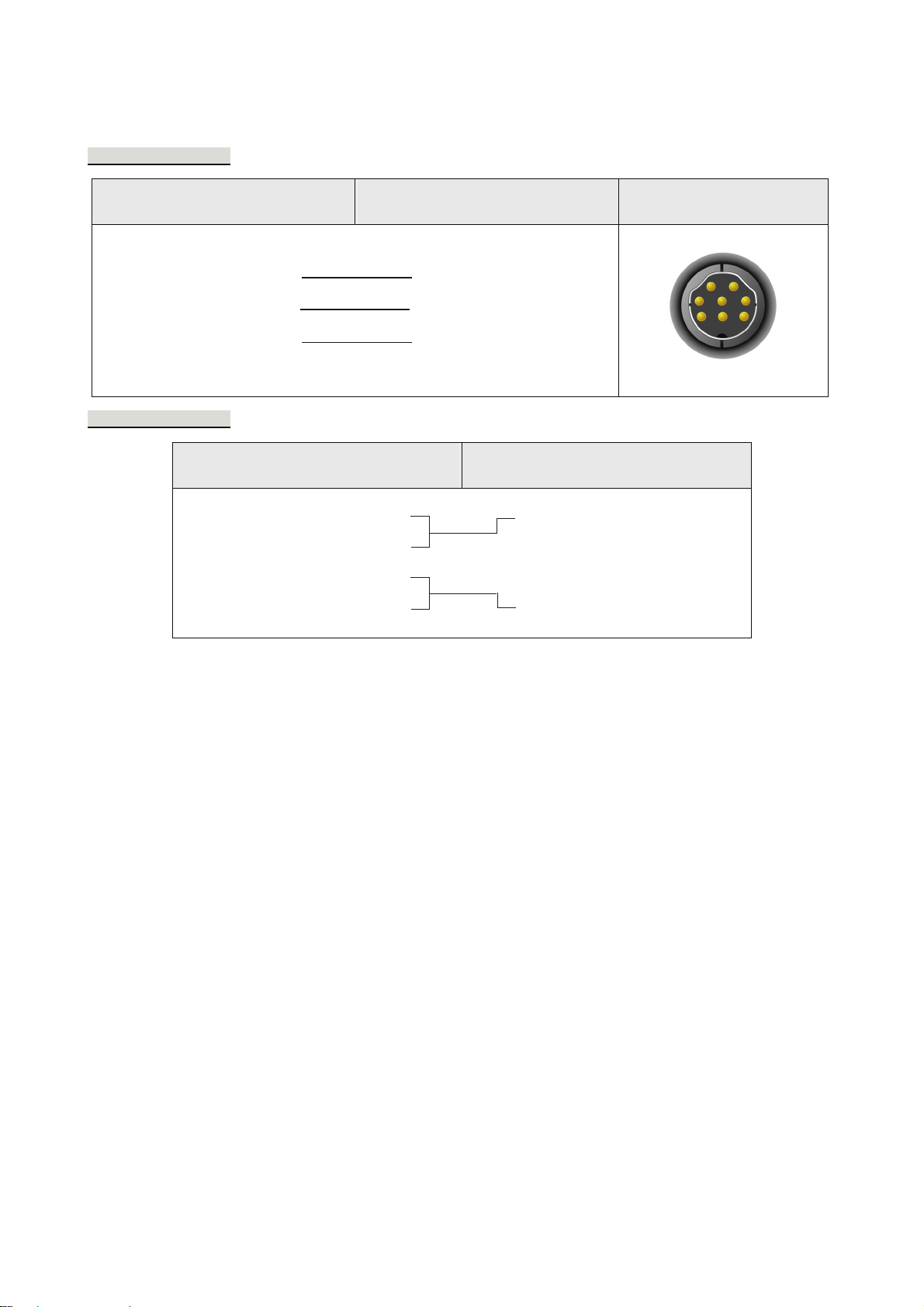

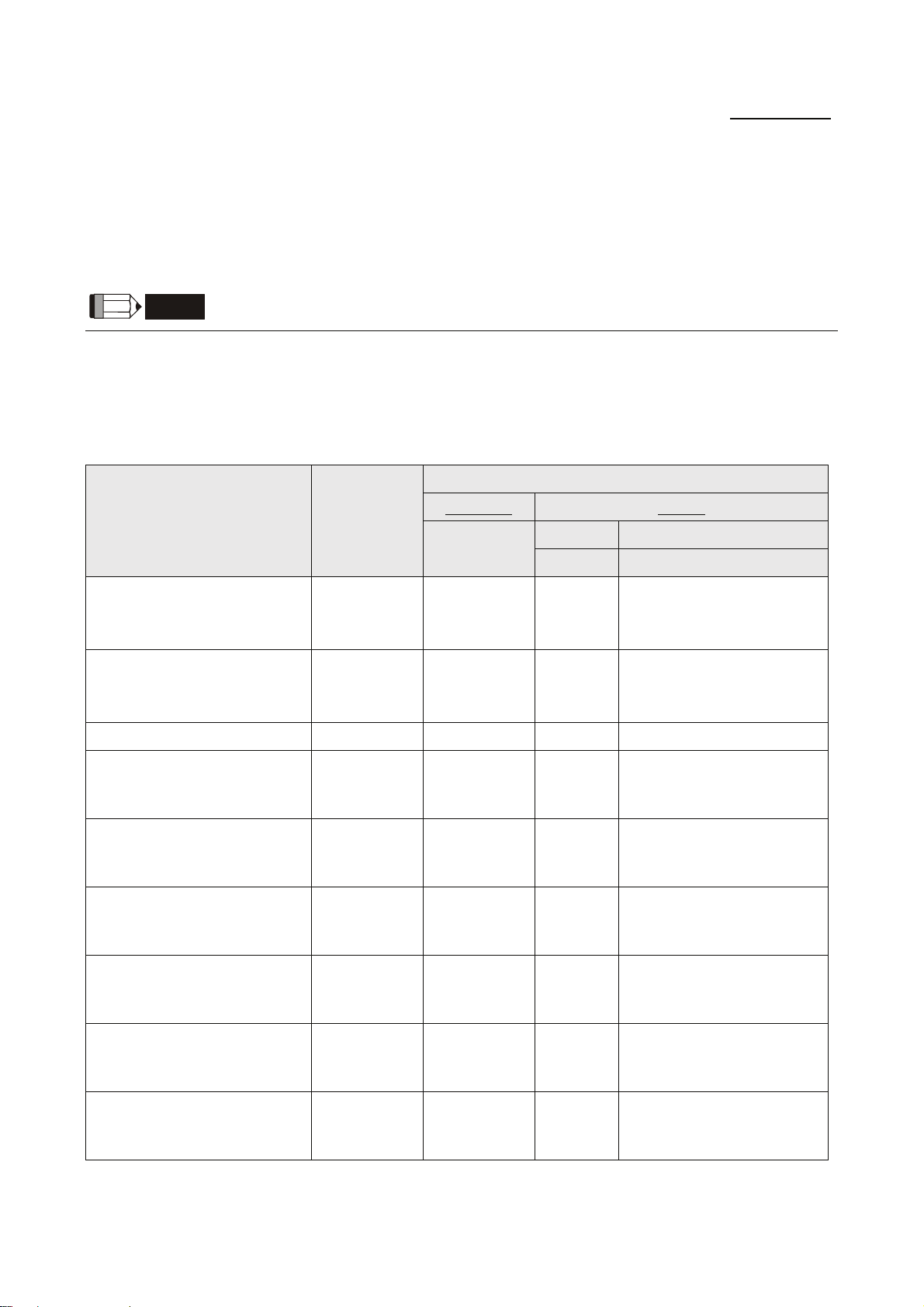

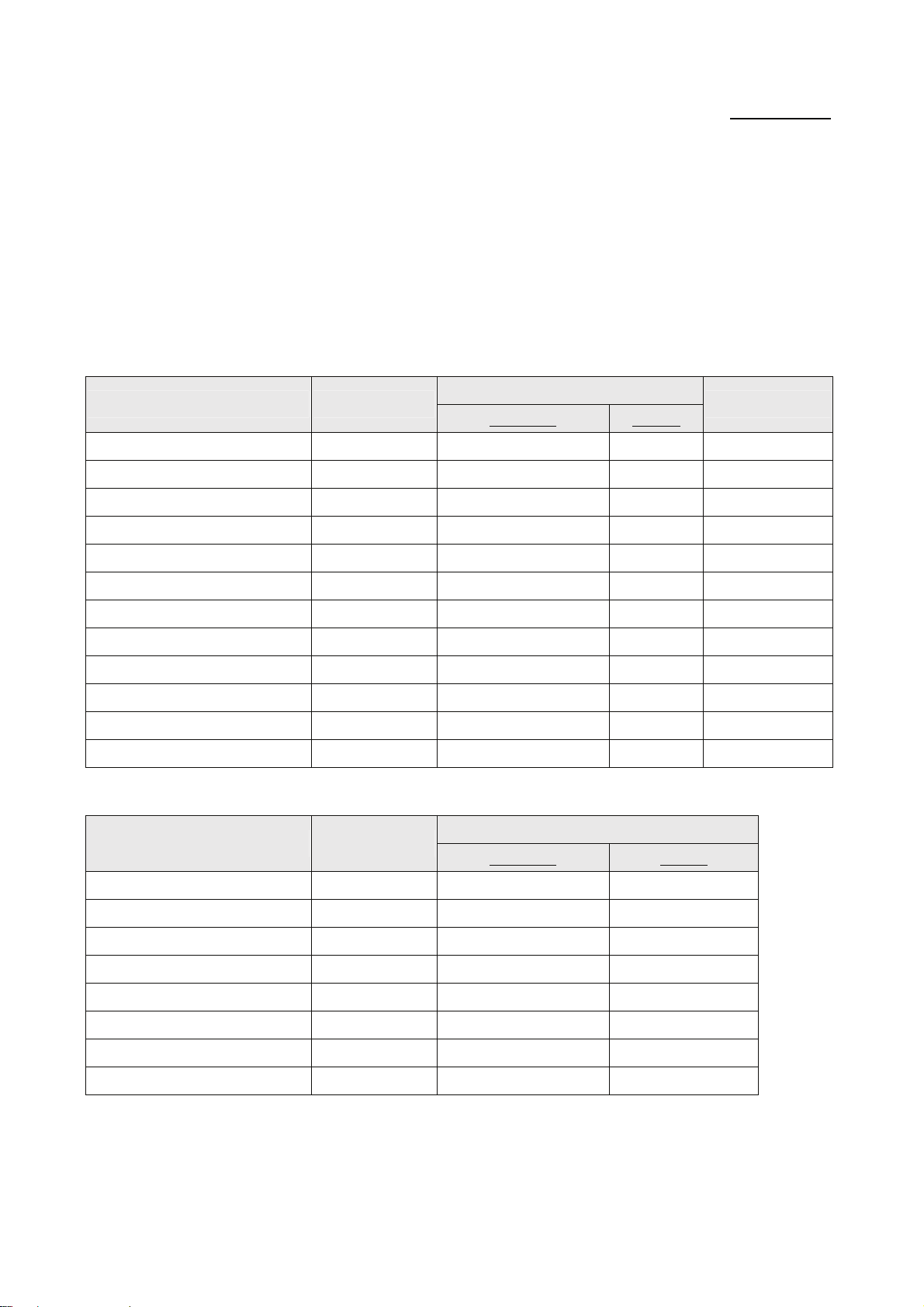

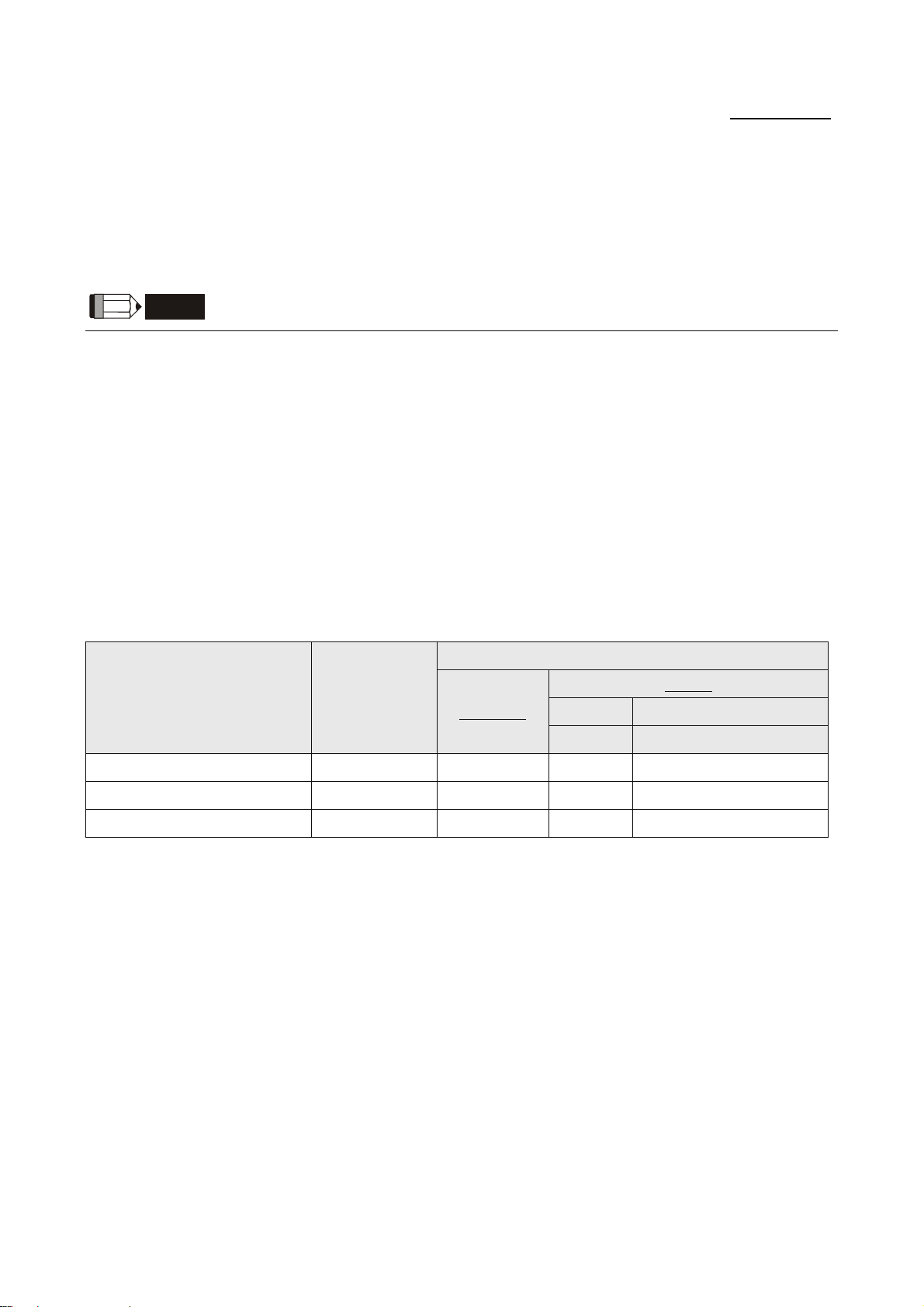

DOP-AE Series

COM1

COM2/COM3

PIN

Pin1

Mode 1 Mode 2 Mode 3 Mode 4 Mode 5 Mode 6

RS-232 RS-422 RS-485

1 N.C RXD- D- N.C RXD- D-

PIN

1 N.C

2 RXD

3 TXD

4 N.C

5 GND

6 N.C

7 RTS

8 CTS

9 N.C

Mode

RS-232

RS-232x2 RS-422x2 RS-485x2

Pin1

COM2

COM3

2 RXD RXD+ D+ RXD RXD+ D+

3 TXD TXD+ D+ TXD TXD+ D+

4 N.C TXD- D- N.C TXD- D-

5 GND GND GND GND GND GND

6 N.C RTS- N.C N.C TXD- D-

7 RTS RTS+ N.C TXD TXD+ D+

8 CTS CTS+ N.C RXD RXD+ D+

9 N.C CTS- N.C N.C RXD- D-

1-2 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 4

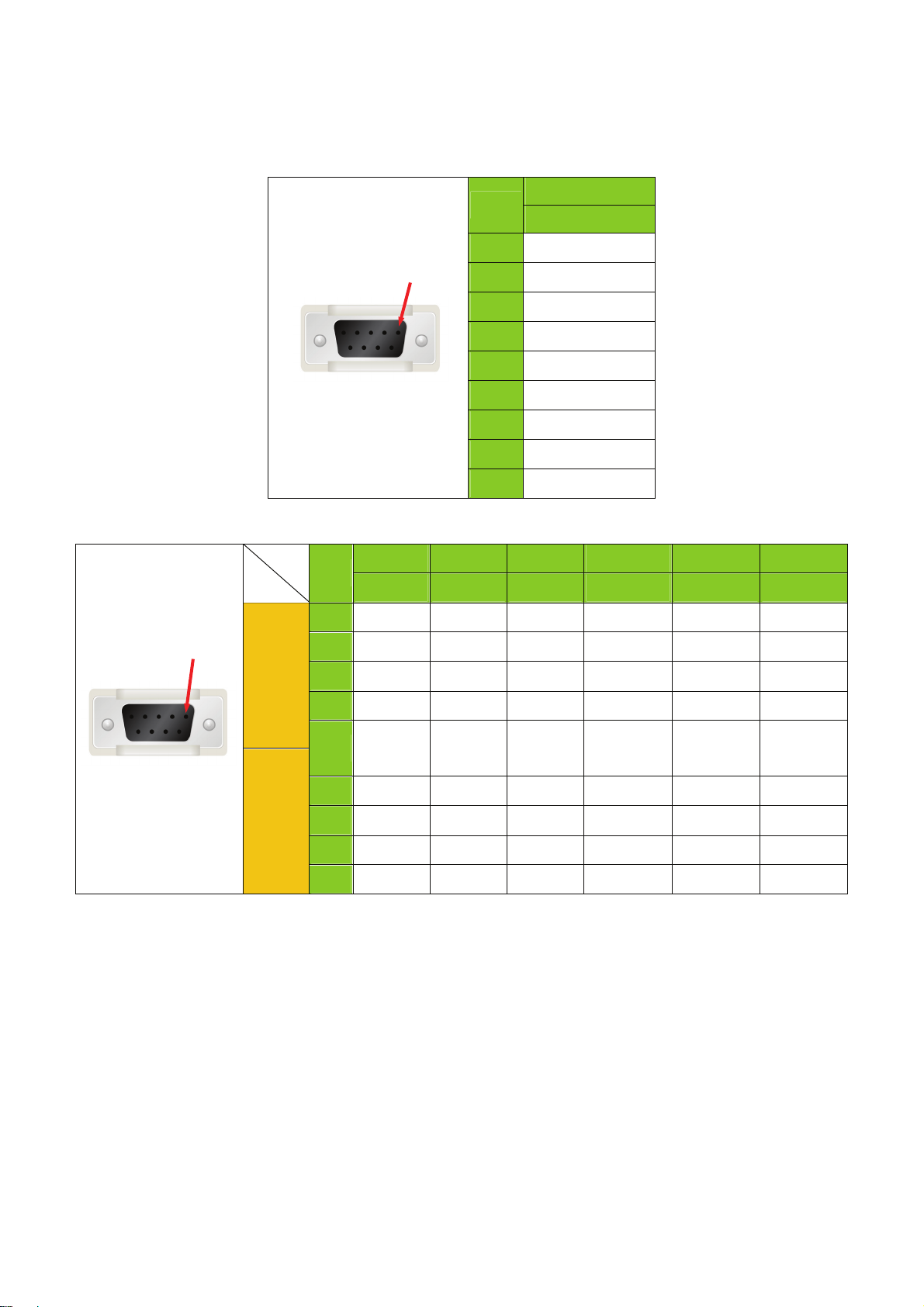

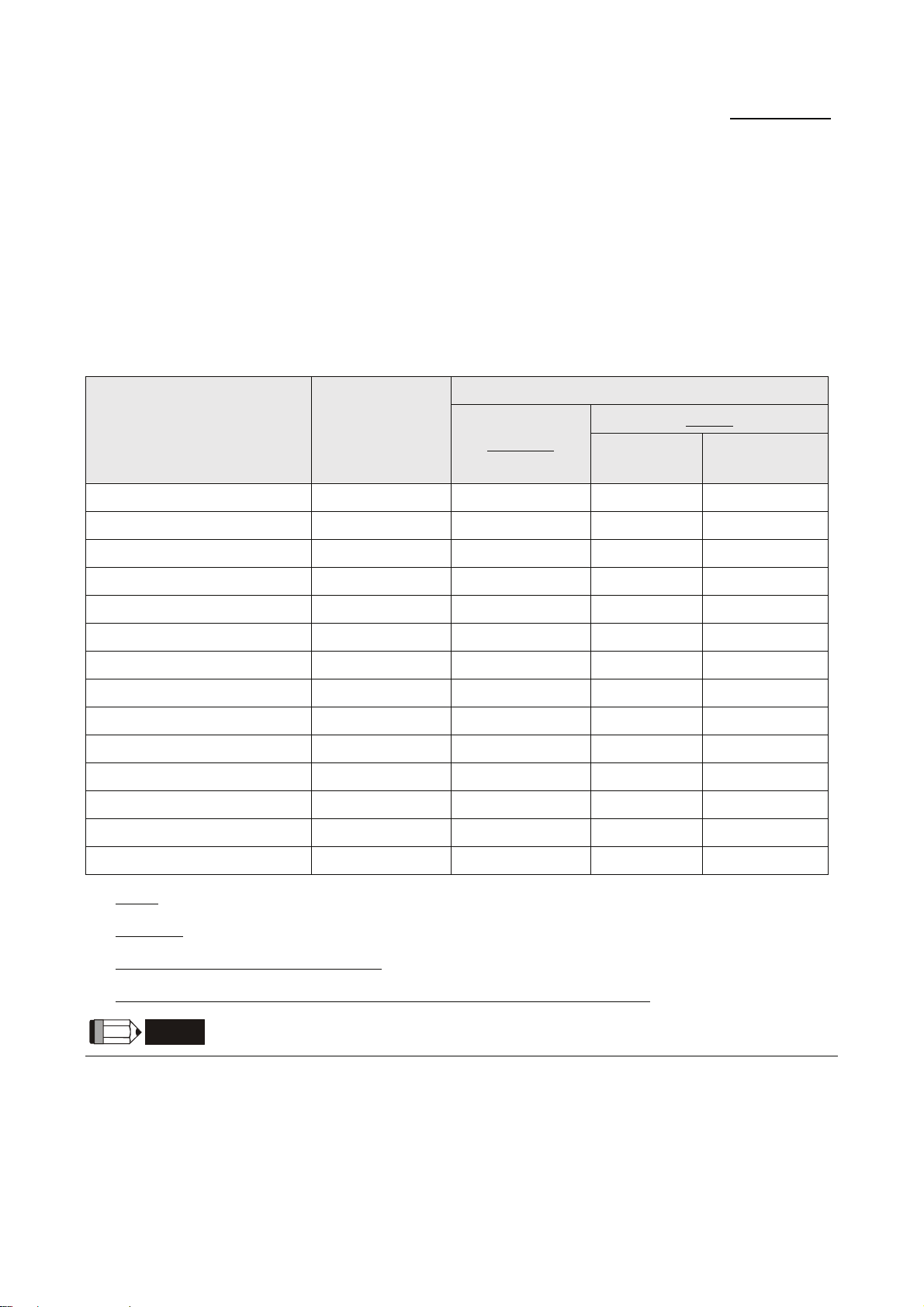

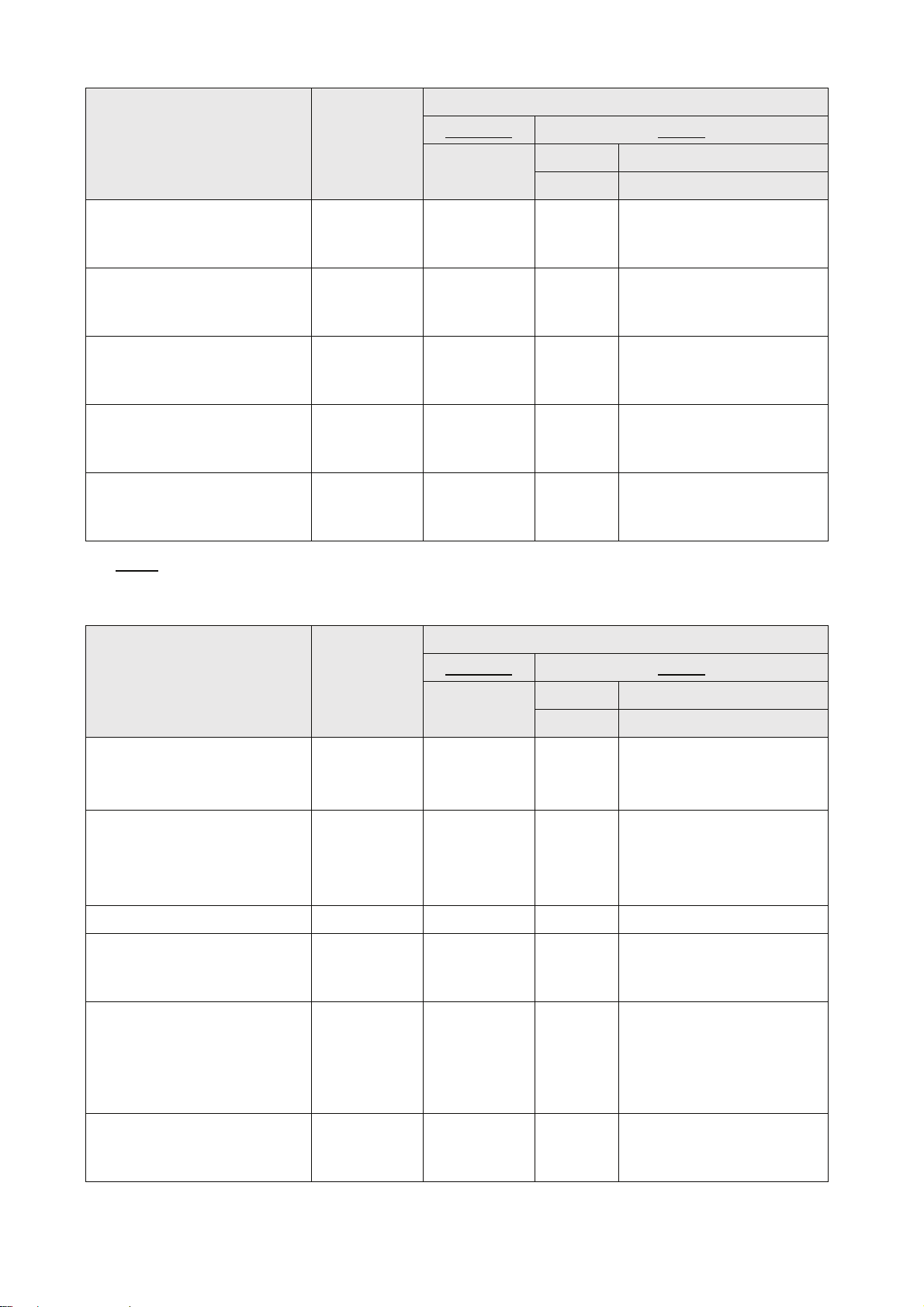

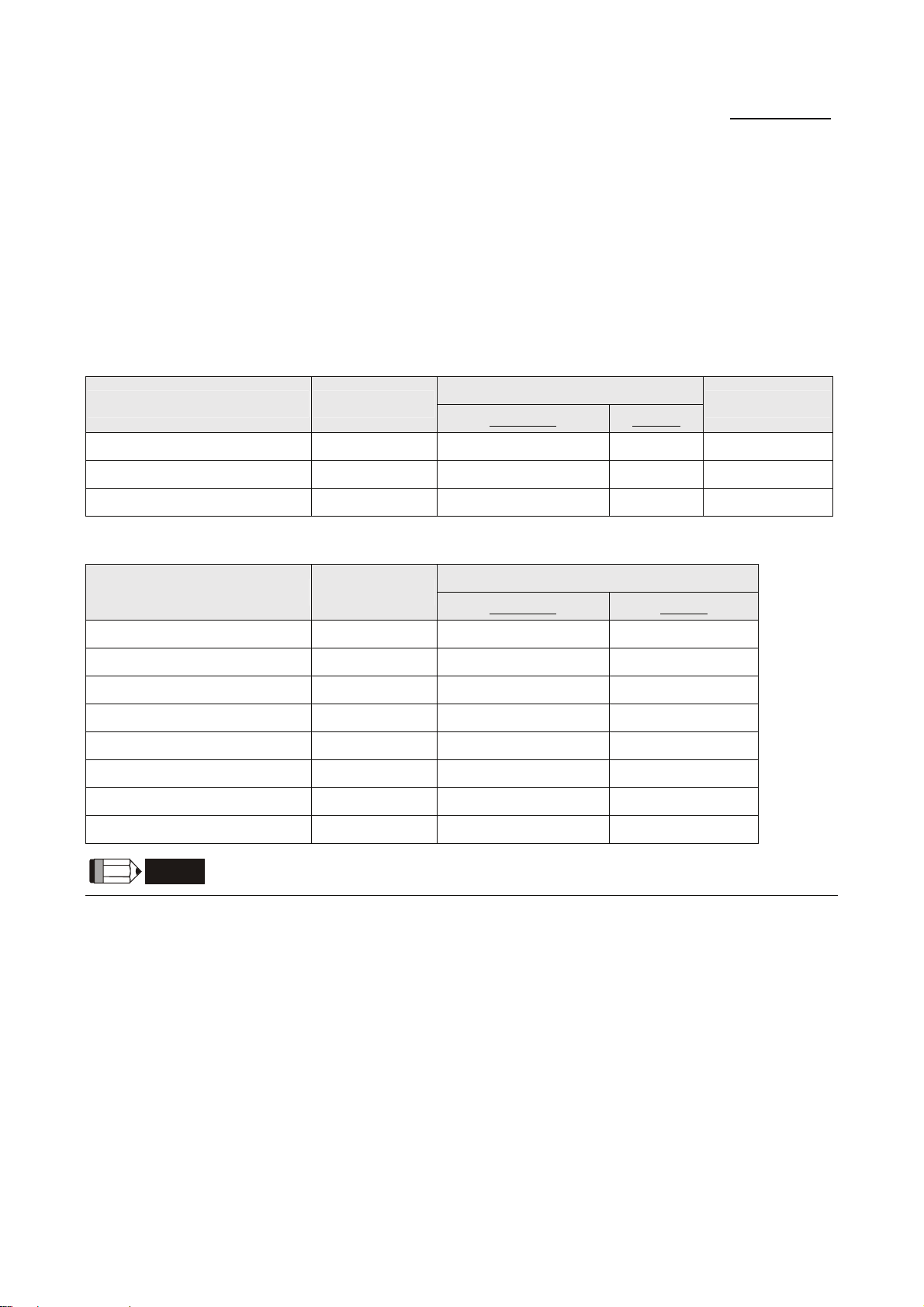

DOP AS Series

COM1/COM3

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

COM2

Mode 1 Mode 2

PIN

RS-232

RS-232x2

1 N.C N.C

2 RXD RXD

COM 1

3 TXD TXD

4 N.C N.C

5 GND GND

6 N.C N.C

COM 3

7 RTS TXD

8 CTS RXD

9 N.C N.C

Mode 1 Mode 2

PIN

RS-422 RS-485

R- RXD- D-

R+ RXD+ D+

T- TXD- D-

T+ TXD+ D+

GND GND

Revision January, 2008, Doc. Name: 2007PDD23000007 1-3

Page 5

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

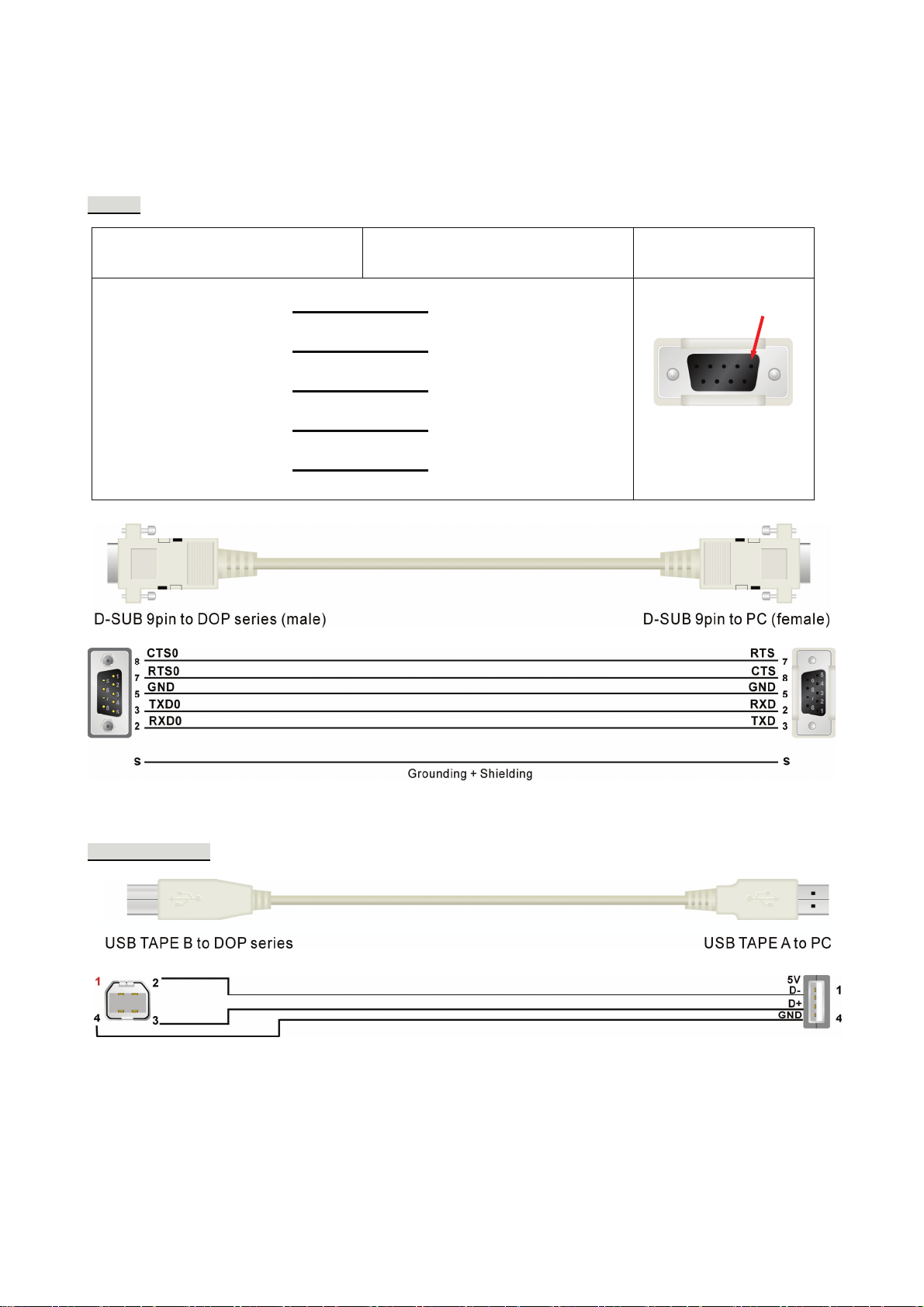

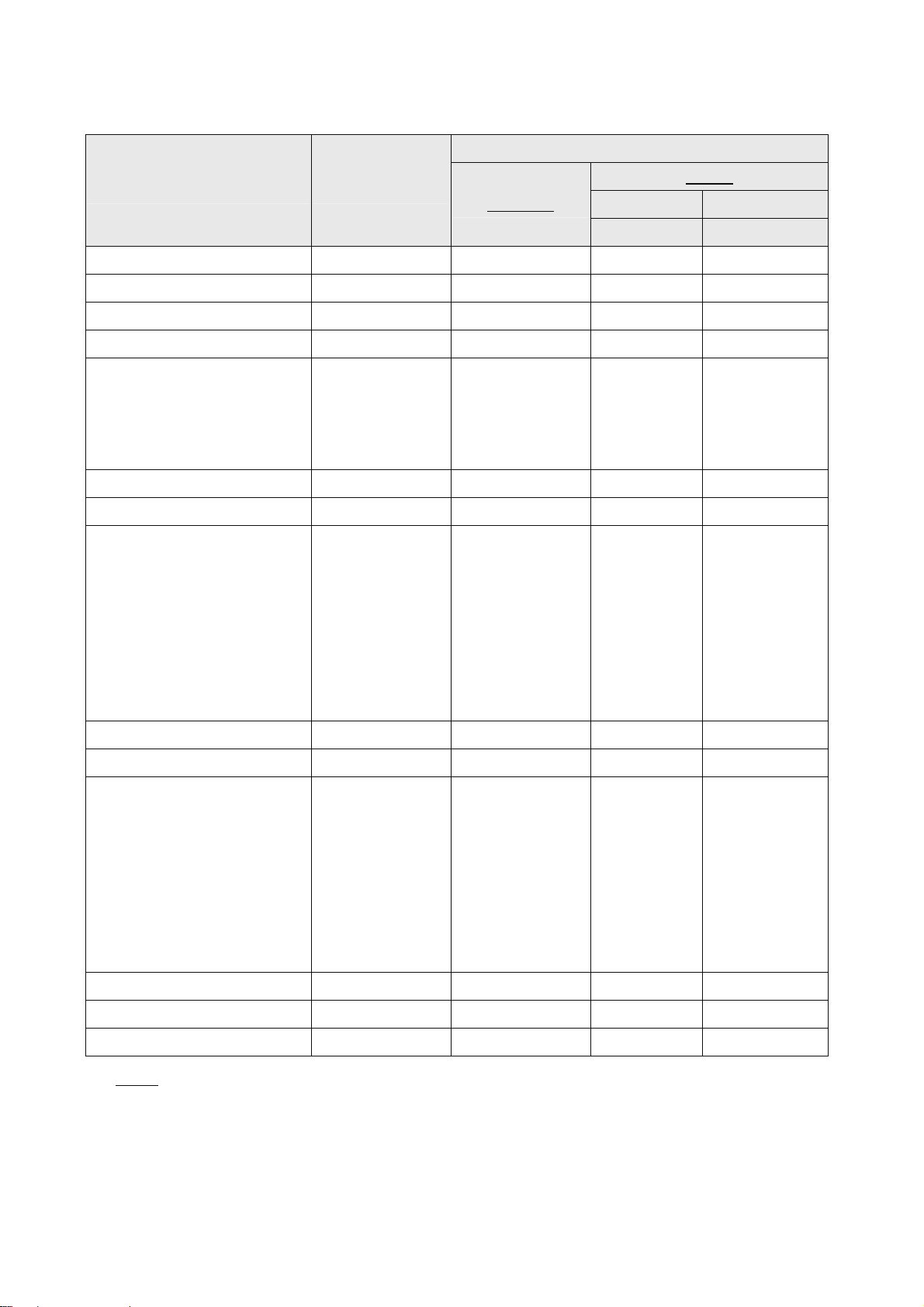

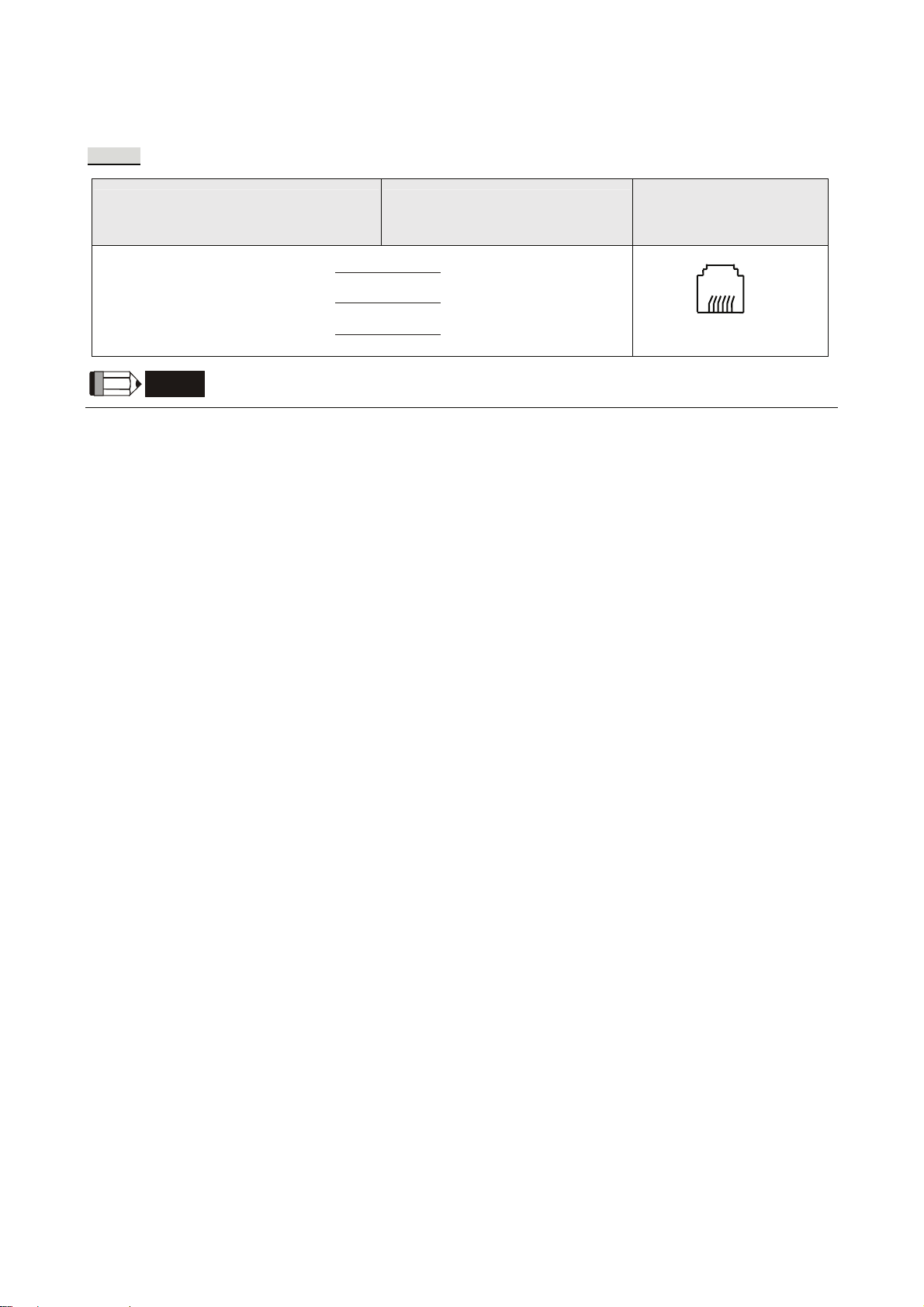

1.2 Cable for Download

Download via COM Port

RS-232

DOP series HMI

9 pin D-SUB male (RS-232)

RXD (2) (3) TXD

TXD (3) (2) RXD

GND (5) (5) GND

RTS (7) (8) CTS

CTS (8) (7) RTS

PC

9 pin D-SUB female (RS-232)

Controller

上視圖

Pin1

Download via USB Flash Drive

USB Connection

1-4 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 6

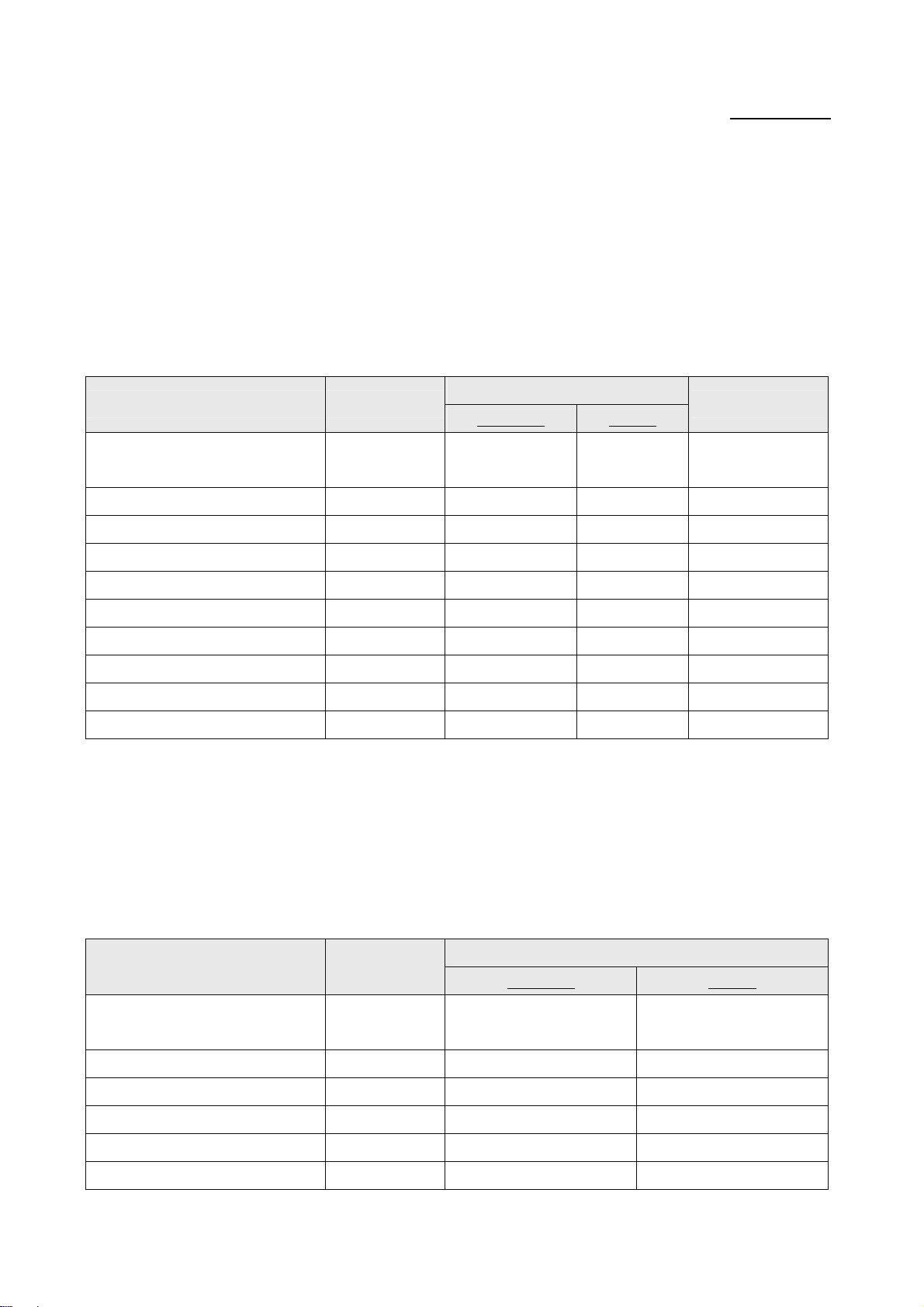

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

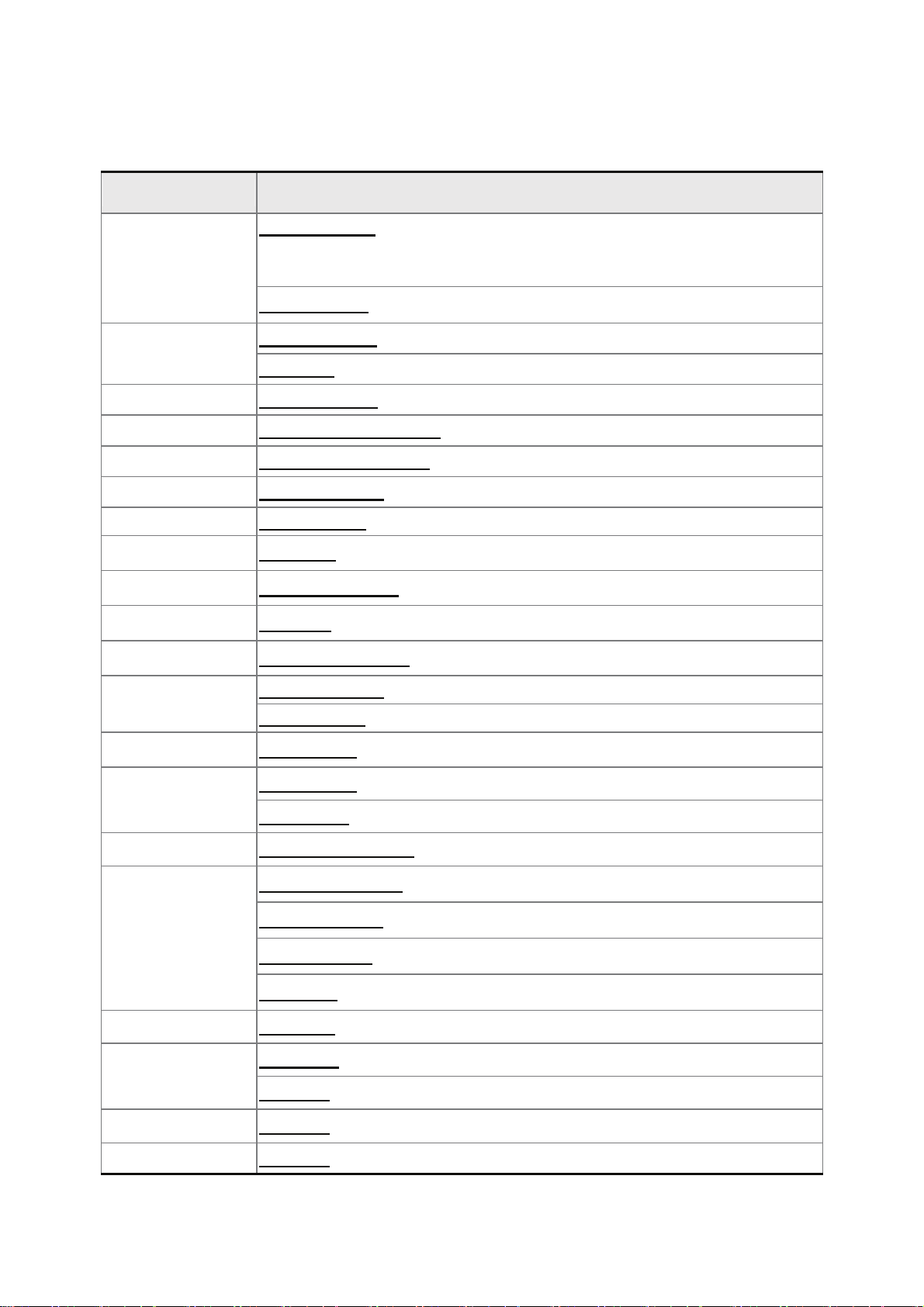

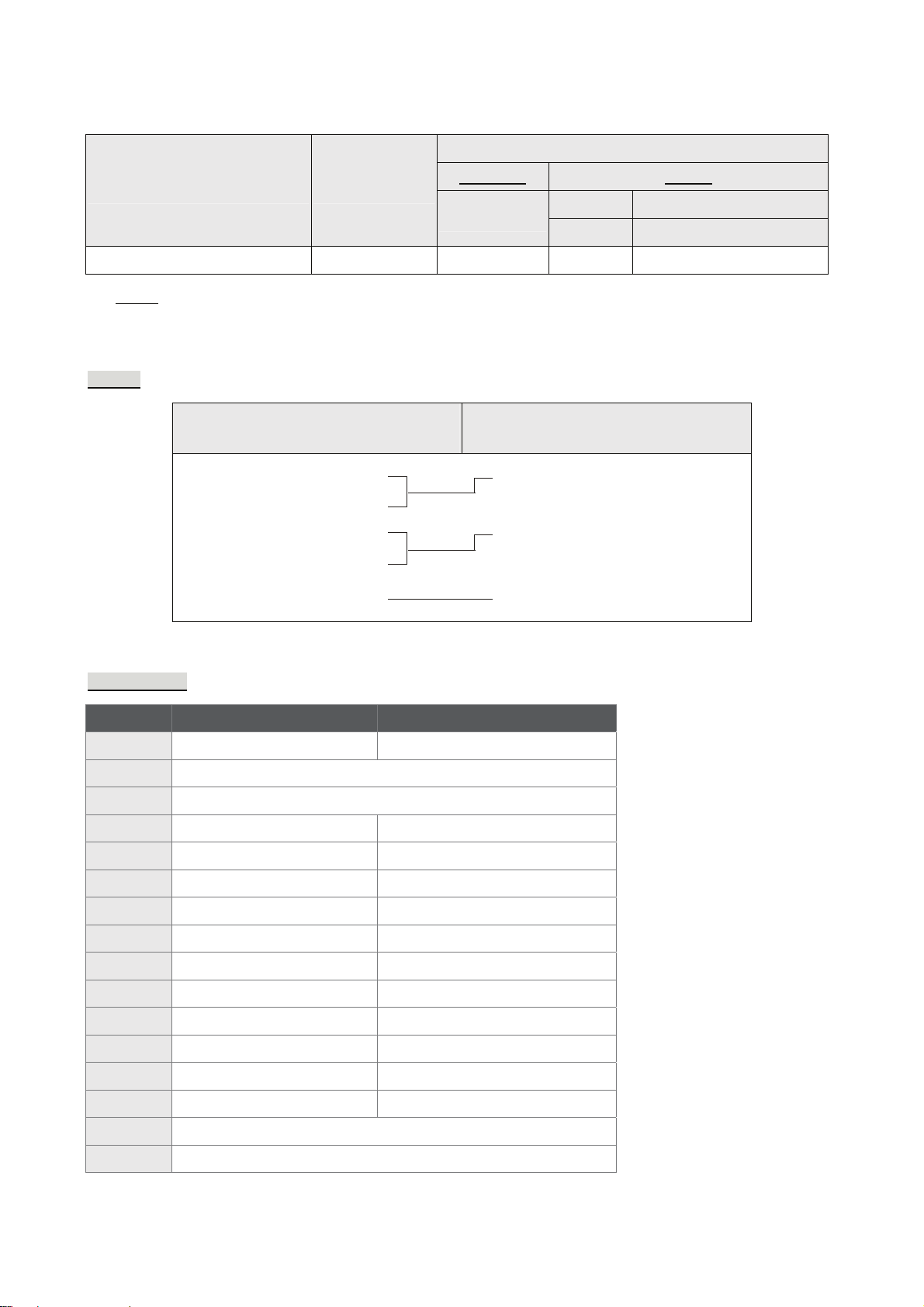

1.3 Supported Controllers and Devices

Please refer to the following table for supported controllers and devices provided by DOP series HMI.

Brand Controller Name / Series Name

Delta Controller

For Servo/AC drive/Temperature Controller/PLC

Delta

(984 RTU mode / ASCII mode)

Delta DVP PLC

MicroLogix PLC

Allen Bradley

SLC5 PLC

Cimon Loader Protocol

Copley Servo (Stepnet Protocol)

Danfoss VLT 2800 (FC Protocol)

Emerson EC20 Series PLC

Facon FB Series PLC

Festo Festo PLC

GE Fanuc 90 Series SNP PLC

Hitachi EH Series

Hust Hust CNC Controller

Nano Series PLC

Jetter

JC Series PLC

Keyence KV/KZ Series

SU/DL Series

Koyo

K-Sequence

Lenze LECOM-A/B Protocol

Master-K120S/200S

Glofa GM6 CNET

LG

Master-K CNET

XGT CNET

LI YAN LYPLC EX

M2i Master

M2i

M2i Slave

Matsushita FP Series

Mirle FAMA SC

Revision January, 2008, Doc. Name: 2007PDD23000007 1-5

Page 7

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

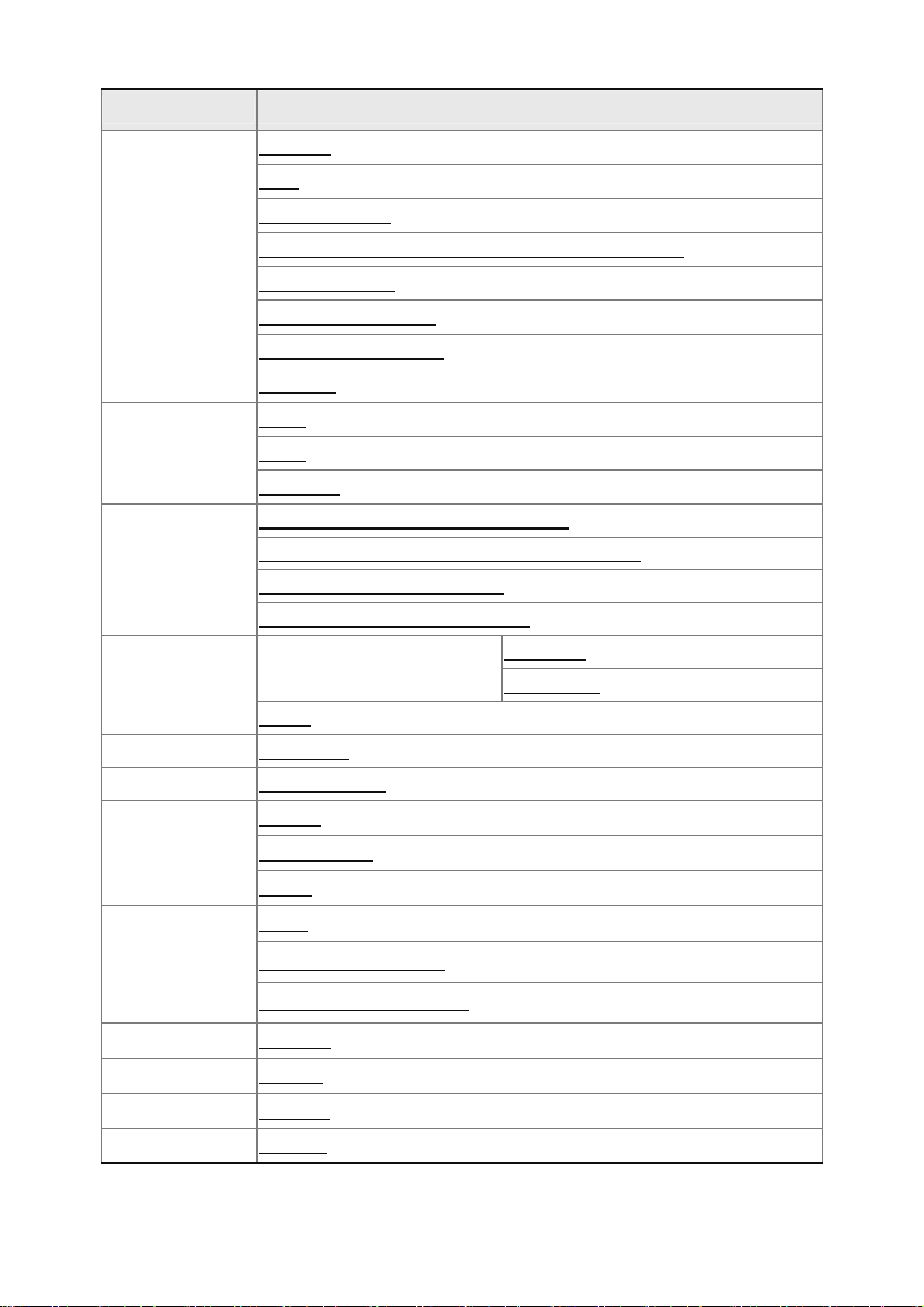

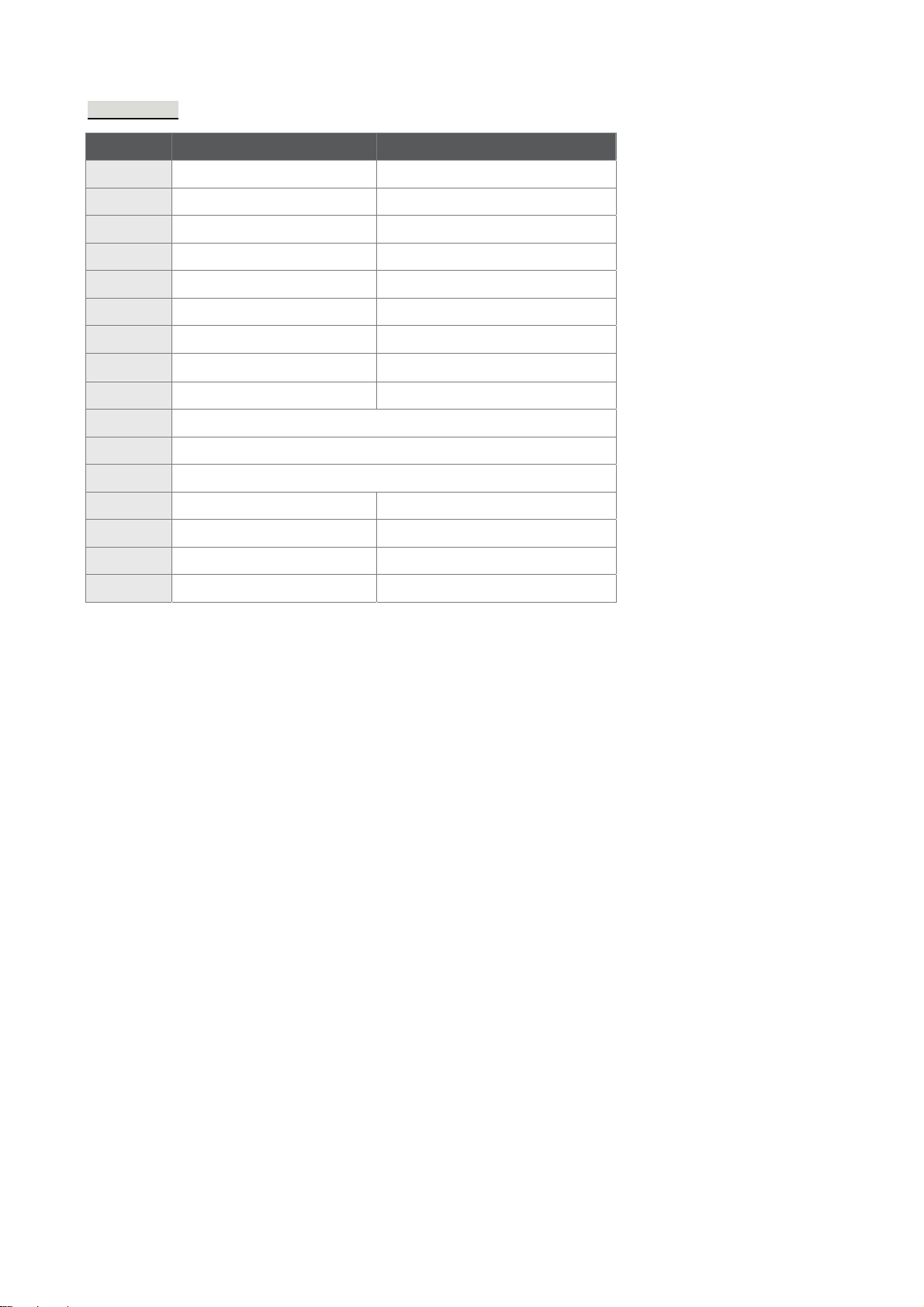

Brand Controller Name / Series Name

FX / FX2N

FX3U

A Series/J71UC24

Mitsubishi A2A/A2AS/A2USH A1SH/A3N/A2ASH CPU Port

Mitsubishi

Q Series CPU Port

Q Series Computer Link

FX Series Computer Link

J2s Series

BY125

MKS

Modbus

Modicon

Moeller Moeller PLC

NIKKI DENSO NCS-FI/FS Series

CT150

MC700/720

Modbus (Master) --- 984 RTU / ASCII mode

Hexadecimal Address (Master) --- RTU / ASCII mode

nW (Master) --- RTU / ASCII mode

Modbus (Slave) --- RTU / ASCII mode

TSX Micro

TWIDO

C Series

Uni-Telway

Modbus RTU

Omron

Siemens

Taian TP02 PLC

Vigor M Series

VIPA VIPA PLC

Yokogawa ACE PLC

CJ1/CS1 Series

TPM1A

S7 200

S7-300 (with PC Adaptor)

S7-300 (without PC Adaptor)

1-6 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 8

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

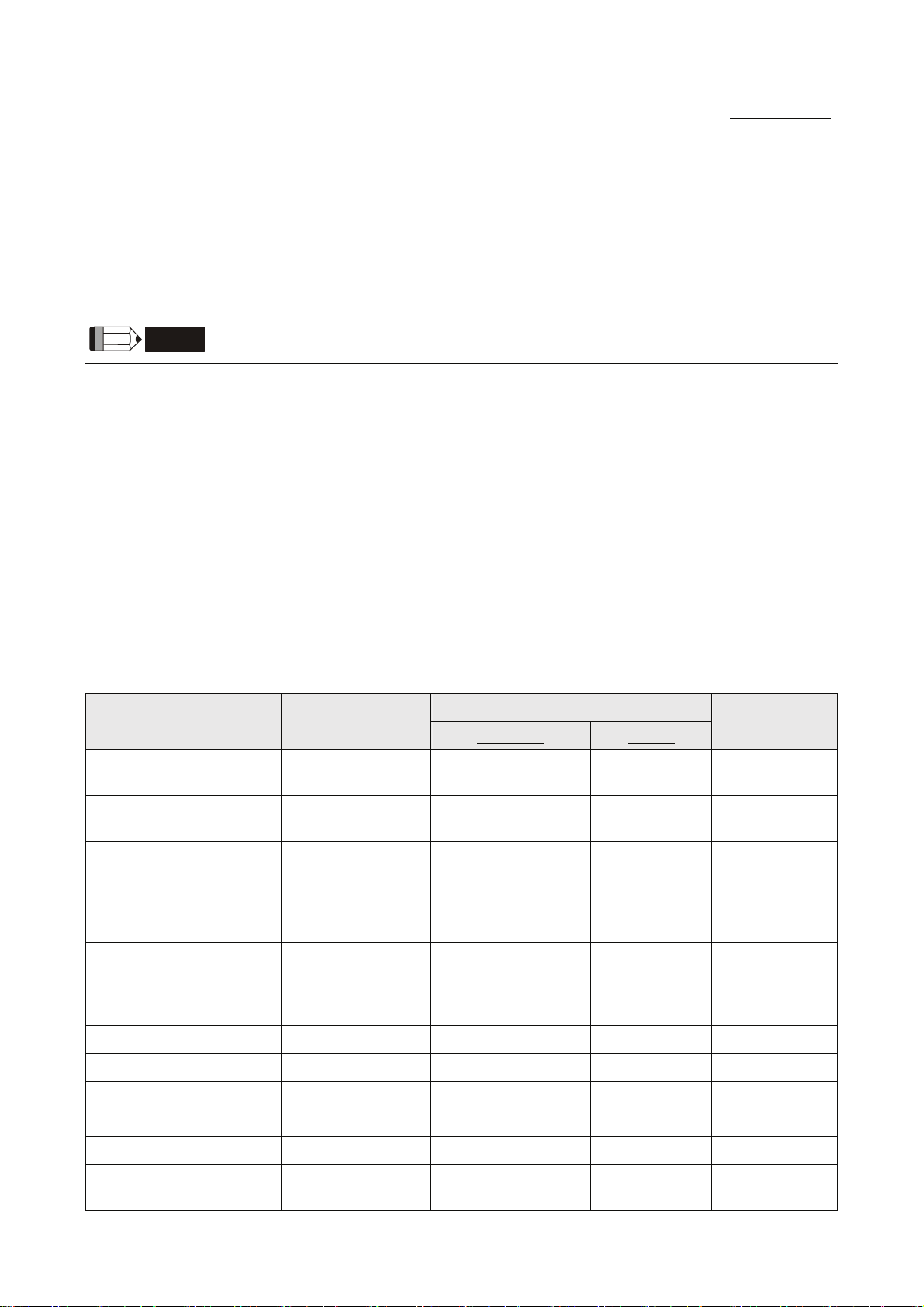

Delta (Servo/AC Drive/PLC/Temperature) Controller Back to Table

A. HMI factory setting

Baud rate: ASCII: 9600, 7, None, 2.

RTU: 9600, 8. None, 2.

Controller station number: 1.

Control area/status area: None.

NOTE

1) This driver can support all Delta products, i.e. AC drive, PLC, Servo, Temperature Controller and

Modbus standard connection. The users can easily set and communicate with these devices via using

this driver.

2) For people who are using Modbus standard connection:

Modbus / ASCII (Master), Modbus / 984 RTU (Master), Modbus / ASCII Hex Address (Master) and

Modbus / RTU Hex Address (Master) can be compatible with the new Delta controller ASCII and Delta

controller RTU. To change the driver settings, the user only needs to change the “Controller” Option

which is used to set the controller, then the new driver can be used immediately.

B. Definition of controller Read/Write address

Registers

Register Type Format

Servo communication

address

AC drive communication

address

TCntrl communication

address

WORD_DEVICE_X PLC_Xn n: 0 ~ 360(octal) N/A Word

WORD_DEVICE_Y PLC_Yn n: 0 ~ 360(octal) N/A Word

WORD_DEVICE_M PLC_Mn n: 0 ~ 1520, N/A Word

1536 ~ 4080 N/A Word

WORD_DEVICE_S PLC_Sn n: 0 ~ 1008 N/A Word

SERVO-n n: 0 ~ 0700h N/A Word

INVERTER-n n: 0 ~ 2299h N/A Word

TEMP_CTRL-n n: 0 ~ 6000h N/A Word

Read/Write Range

Data Length

Word No. Bit No.

WORD_DEVICE_T PLC_Tn n: 0 ~ 255 N/A Word

WORD_DEVICE_C PLC_Cn n: 0 ~ 199 N/A Word

WORD_DEVICE_D PLC_Dn n: 0 ~ 4095, N/A Word

4096 ~ 9999 N/A Word

WORD_DEVICE_HC PLC_HCn n: 200 ~ 255 N/A Double Word

PLC communication

address Module

Revision January, 2008, Doc. Name: 2007PDD23000007 1-7

PLC_Modulen n: 4000 ~ 4499h N/A Word

Page 9

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Register Type Format

Output Registers RW-n n: 0 ~ FFFFh N/A Word

Input Registers R-n n: 0 ~ FFFFh N/A Word

Output Registers Wn n: 40001 ~ 50000 N/A Word

Input Registers Wn n: 30001 ~ 40000 N/A Word

NOTE

1) The above addresses of Servo, AC drive, Temperature controller and PLC Module are in hexadecimal

format. PLC Word Device X and Y are in octal format. Other PLC Word Device M, S, T, C, D and HC are

in decimal format.

2) WORD_DEVICE_ X / WORD_DEVICE_Y / WORD_DEVICE_M / WORD_DEVICE_S: Address must be

0 or the multiple of 16.

Contacts

Contact type Format

Read/Write Range

Data Length

Word No. Bit No.

Read/Write Range

Word No. Bit No.

Servo communication address SERVO-n.b n: 0 ~ 0700h b: 0 ~ f

AC drive communication address INVERTER-n.b n: 0 ~ 2299h b: 0 ~ f

TCntrl communication address TEMP_CTRL-n.b n: 0 ~ 6000h b: 0 ~ f

Servo Digital Input SERVO_DI-n N/A n: 1 ~ 8

Servo Digital Output SERVO_DO-n N/A n: 1 ~ 5

WORD_DEVICE_X PLC_Xn N/A n: 0 ~ 377(octal)

WORD_DEVICE_Y PLC_Yn N/A n: 0 ~ 377(octal)

WORD_DEVICE_M PLC_Mn N/A n: 0 ~ 1535

1536 ~ 4095

WORD_DEVICE_S PLC_Sn N/A n: 0 ~ 1023

WORD_DEVICE_T PLC_Tn N/A n: 0 ~ 255

WORD_DEVICE_C PLC_Cn N/A n: 0 ~ 255

TCntrl Bit communication address TEMP_CTRLB-n N/A n: 800 ~ 8FFh

Discrete Outputs RWB-n N/A n: 0 ~ FFFFh

Discrete Inputs RB-n N/A n: 0 ~ FFFFh

Discrete Outputs Bn N/A n: 1 ~ 10000

Discrete Inputs Bn N/A n: 10001 ~ 20000

NOTE

1) The above addresses of Servo, AC drive, Temperature controller and PLC Module are in hexadecimal

format.

1-8 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 10

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

2) PLC Word Device X and Y are in octal format. Other PLC Word Device M, S, T, C, D and HC are in

decimal format.

3) Servo Digital Input and Servo Digital Output are only for Servo.

Pay close attention to the following important notes:

4) For Delta AC drive:

Communication address for HMI read/write address uses hexadecimal format. For detailed information

about communication address of Delta AC drive, please refer to Delta AC drive “User Manual”.

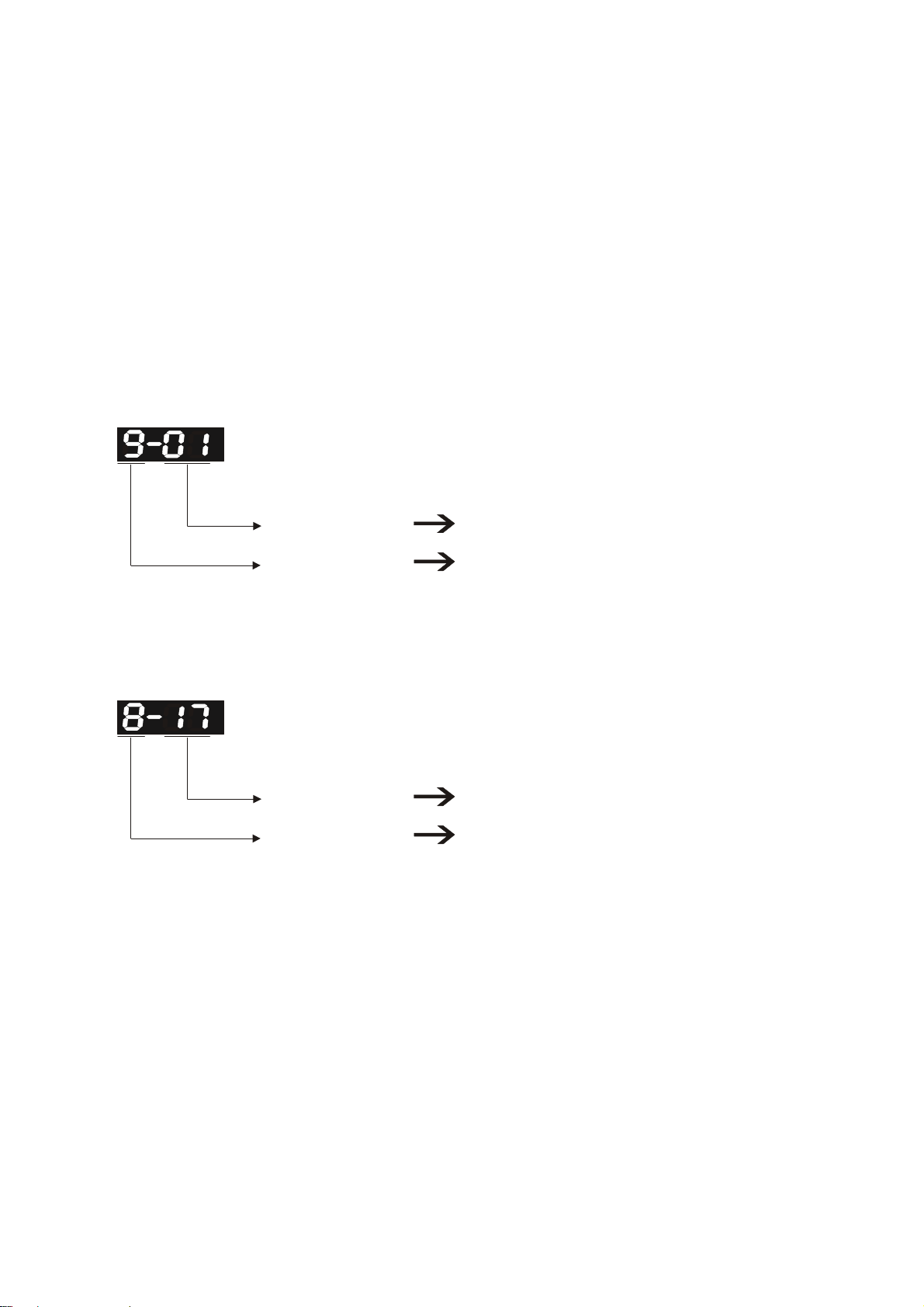

Example 1: Parameter 9-01 of Delta VFD-S drive Transmission Speed needs to be set to INVERTER901

in HMI. (Decimal 9 is converted to 09 in hexadecimal and 01 is converted to 01 in hexadecimal.

Therefore, setting INVERTER901 to HMI will discard the first 0)

Decimal value

Hexadecimal value

The communication address of parameter 9-01 is 0901H.

Example 2: if setting of parameter 8-17 (Lower Bound of DC Braking Start-up Frequency) of Delta VFD-

S drive is desired, user needs to set INVERTER811 in HMI. (8 is converted to 08 in hexadecimal and 17

is converted to 11 in hexadecimal. Therefore, setting the INVERTER811 to HMI will discard the first 0)

Decimal value

Hexadecimal value

The communication address of parameter 8-17 is 0811H.

5) For Delta Servo drive:

01

(Hexadecimal value)

09

(Hexadecimal value)

11

(Hexadecimal value)

08

(Hexadecimal value)

y HMI Read/Write address setting needs to input the communication address listed in SERVO “User

Manual”.

y Servo Digital Input and Servo Digital Output are only for Servo.

6) For Delta Temperature Controller (DTA series):

HMI can be set up to connect to several Delta A series temperature controllers on standard Modbus

networks by using RTU transmission mode. However, the communication delay time may need to

increase. Therefore, 5ms or longer is highly recommended.

Revision January, 2008, Doc. Name: 2007PDD23000007 1-9

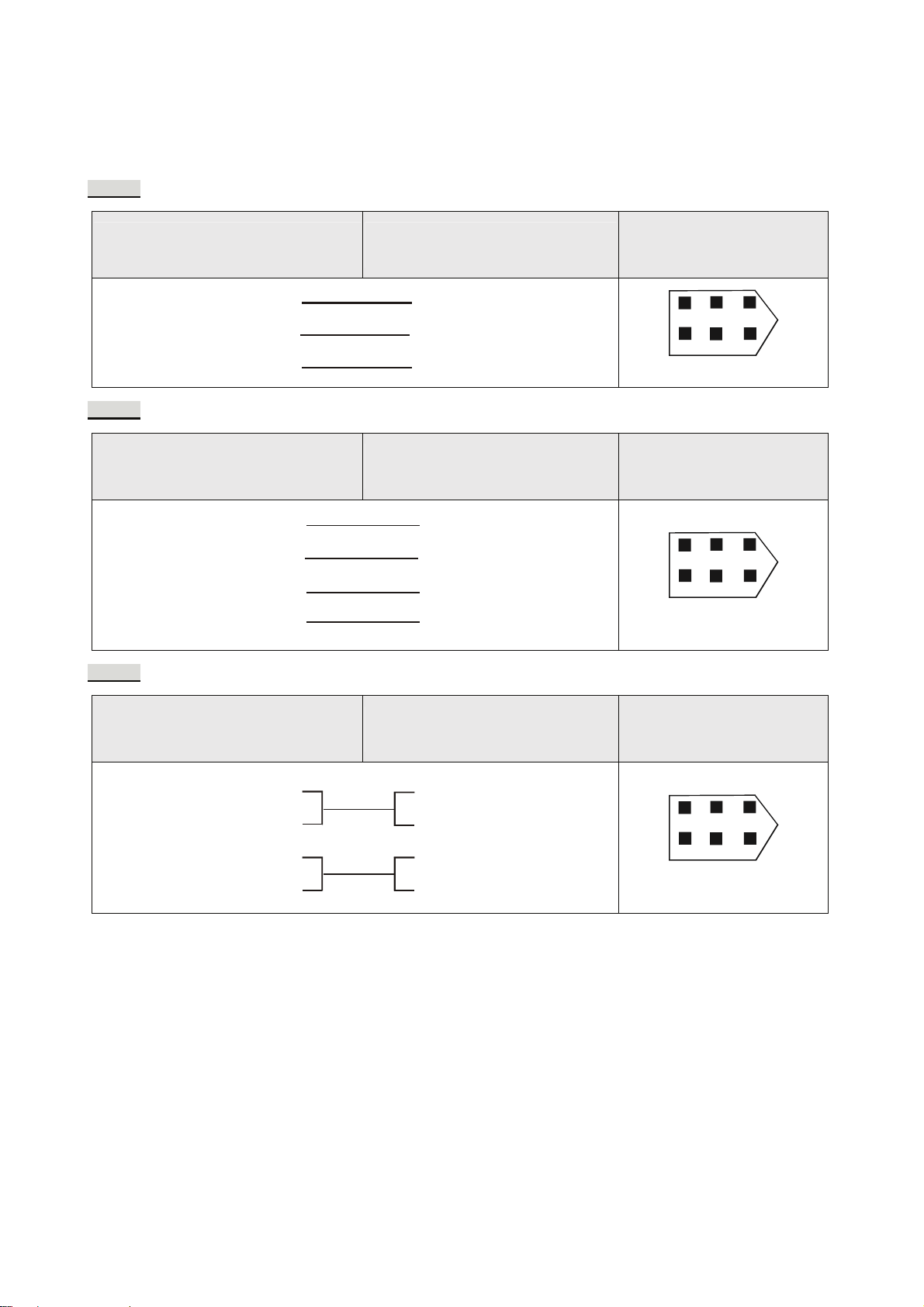

Page 11

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

(2)

C. Connections (Connector Pinouts)

Delta Servo

RS-232

DOP Series

9 pin D-SUB male (RS-232)

RS-422

DOP Series

9 pin D-SUB male (RS-422)

RS-485

RXD (2)

TXD (3)

GND (5)

RXD+ (2)

RXD- (1)

TXD+ (3)

TXD- (4)

Controller

CN3 cable connector (RS-232)

TX

(4) RX

(1) GND

CN3 cable connector (RS-422)

Controller

(5) TX+

(6) TX-

(3) RX+

(4) RX-

Controller

CN3 cable connector

(RS-232)

CN3 cable connector

3 5

1

2

4 6

Top V ie w

Controller

(RS-422)

3 5

1

2

4 6

Top V ie w

DOP Series

9 pin D-SUB male (RS-485)

RXD+ (2)

TXD+ (3)

RXD- (1)

TXD- (4)

Controller

CN3 cable connector (RS-485)

(3) 485+

(5) 485+

(4) 485-

(6) 485-

Controller

CN3 cable connector

(RS-485)

3 5

1

2

4 6

Top V ie w

1-10 Revision January, 2008, Doc. Name: 2007PDD23000007

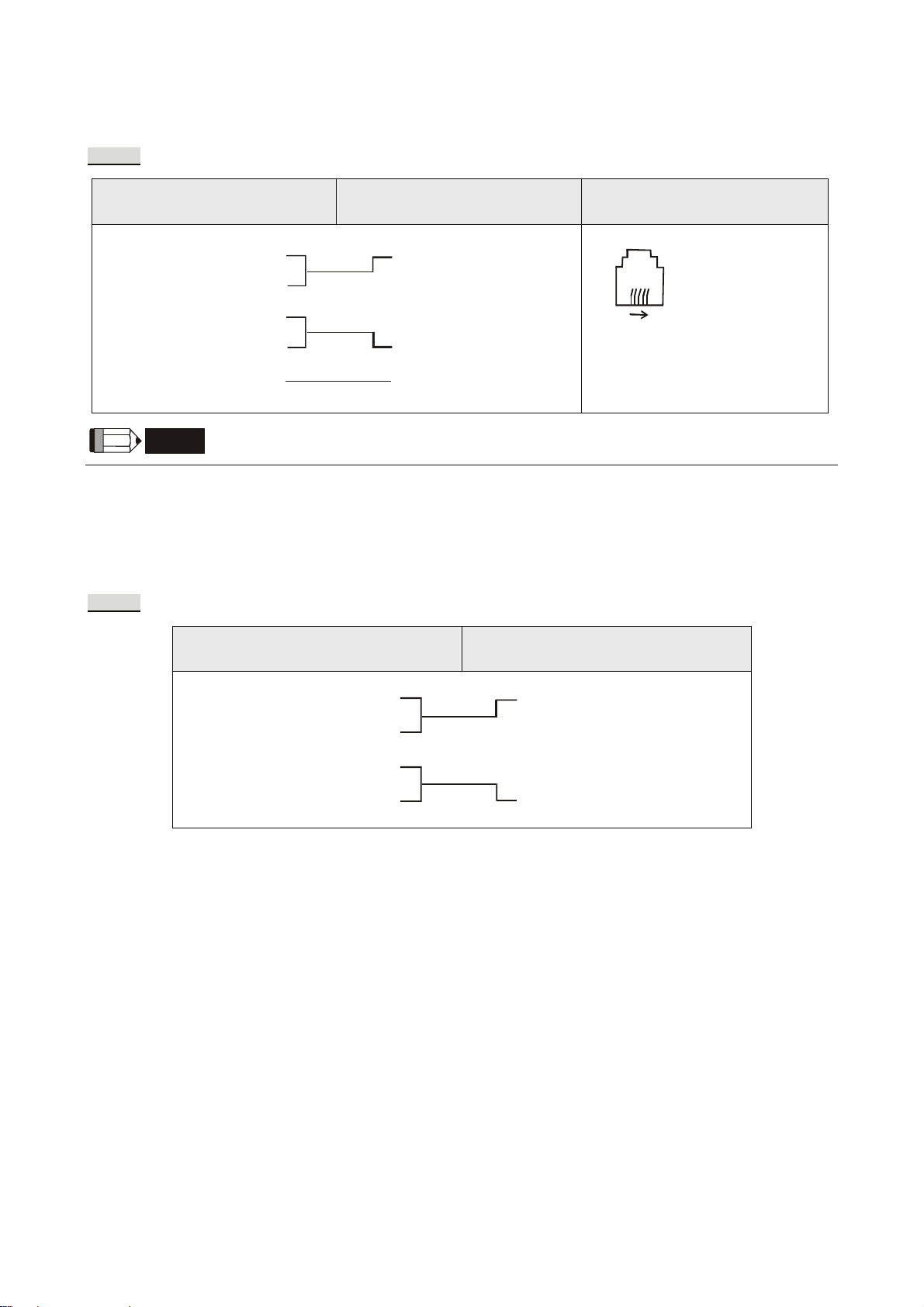

Page 12

Delta AC drive

)

RS-485

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

DOP Series

9 pin D-SUB male (RS-485)

RXD+ (2

TXD+ (3)

RXD- (1)

TXD- (4)

GND (5) (2) GND

NOTE

1) When connecting to a Delta VFD-M series AC drive, please connect Pin 5 (GND) of the Delta HMI and

Pin 2 (GND) of the Delta VFD-M AC drive.

Temperature Controller

RS-485

DOP Series

9 pin D-SUB male (RS-485)

RJ-11 cable connector (RS-485)

Controller

(4) SG+

(3) SG-

Controller

RJ-11 cable connector (RS-485)

2: GND

3: SG4: SG+

6

1

To p V ie w

DO NOT use Pin 1, 5 and 6 while

RS-485 cable connector

using RS-485 communication.

Controller

RXD+ (2)

D+

TXD+ (3)

RXD- (1)

TXD- (4)

D-

Revision January, 2008, Doc. Name: 2007PDD23000007 1-11

Page 13

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Delta DVP PLC Back to Table

A. HMI factory settings

Baud rate: 9600, 7, Even, 1.

Controller station number: 1.

Control area/status area: D0 / D10.

B. Definition of controller Read/Write address

Registers

Register Type Format

X_Data Xn n: 0 ~ 360(octal) N/A

Y_Data Yn n: 0 ~ 360(octal) N/A

M_Data Mn n: 0 ~ 1520, 1536 ~ 4080 N/A

S_Data Sn n: 0 ~ 1008 N/A

T_Register Tn n: 0 ~ 255 N/A

C_Register Cn n: 0 ~ 199 N/A

D_Register Dn n: 0 ~ 4095, 4096 ~ 9999 N/A

HC_Register Cn n: 200 ~ 255 N/A

NOTE

1) (W) is “Word”.

2) (DW) is “Double Word”.

3) X_Data / Y_Data / M_Data / S_Data: Address must be 0 or the multiple of 16.

Word No. Bit No.

Read/Write Range

Contacts

Contact type Format

Word No. Bit No.

X_Data Xn N/A n: 0 ~ 377(octal)

Y_Data Yn N/A n: 0 ~ 377(octal)

M_Data Mn N/A n: 0 ~ 1520, 1536 ~ 4080

S_Data Sn N/A n: 0 ~ 1023

T_Coil Tn N/A n: 0 ~ 255

C_Coil Cn N/A n: 0 ~ 255

1-12 Revision January, 2008, Doc. Name: 2007PDD23000007

Read/Write Range

Page 14

C. Connections (Connector Pinouts)

)

RS-232 Connection

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

DOP Series

9 pin D-SUB male (RS-232)

RS-485 Connection

9 pin D-SUB male (RS-485)

RXD (2)

TXD (3)

GND (5)

DOP Series

Controller

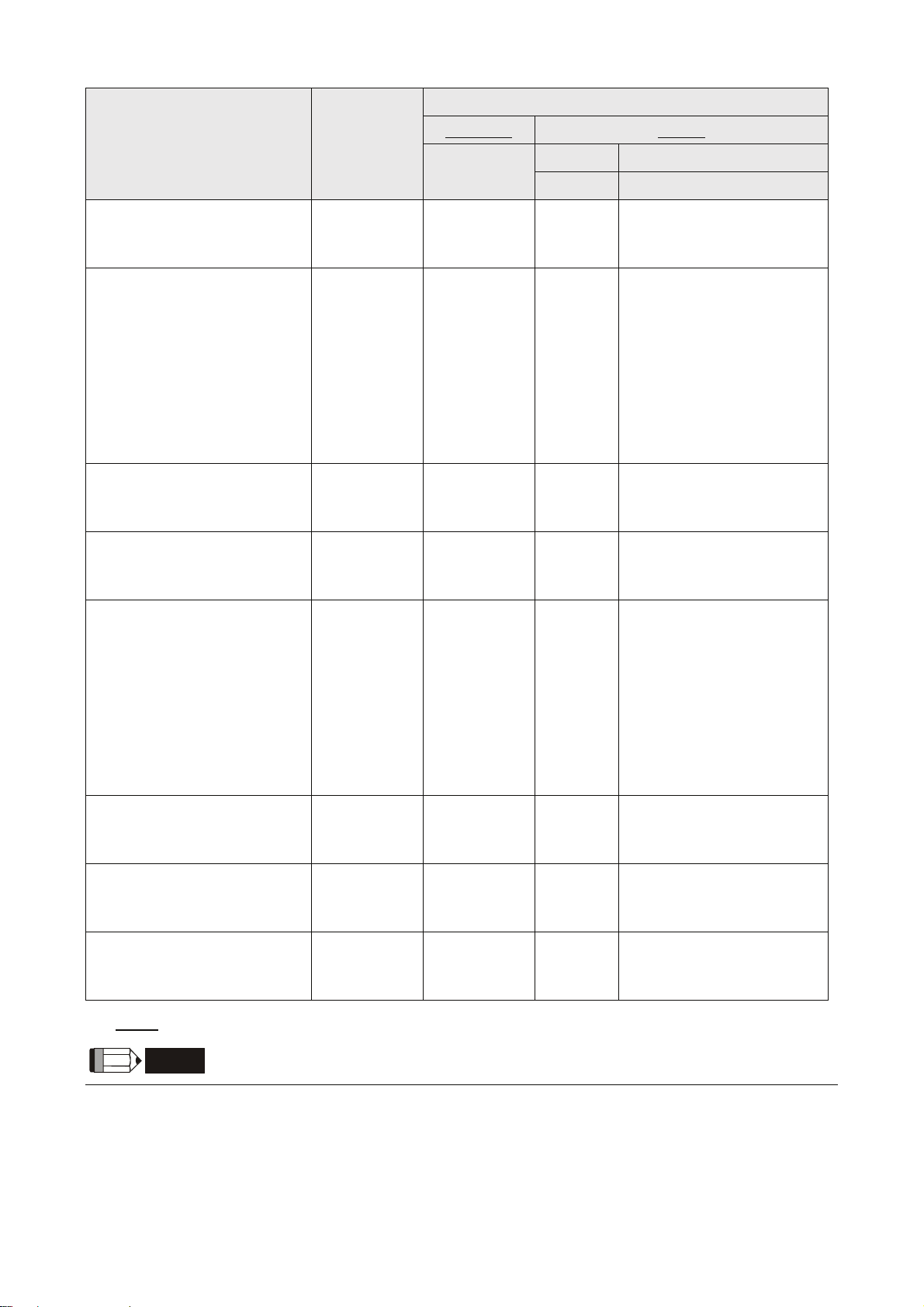

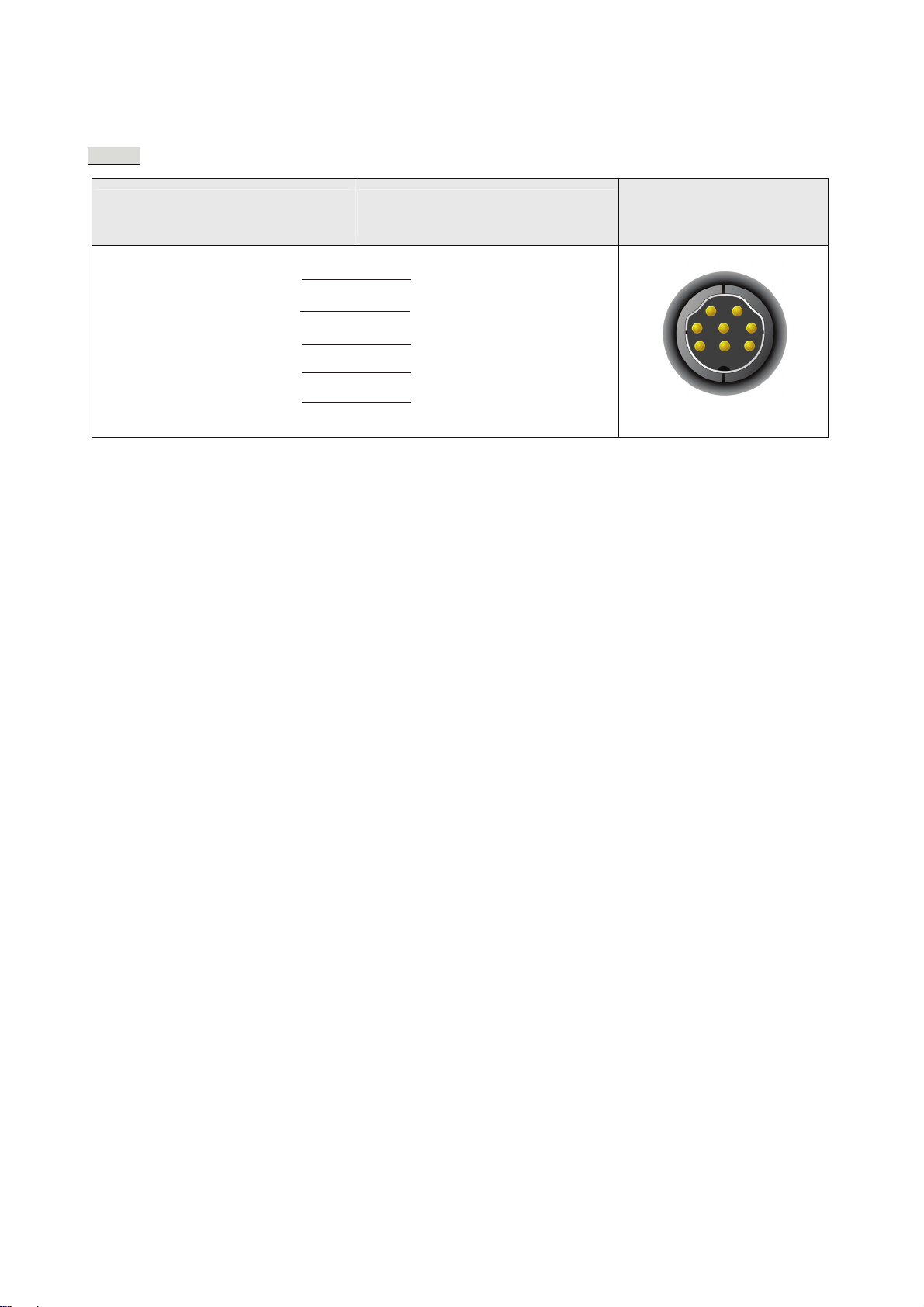

8 pin Mini DIN male (RS-232)

(5) TXD

(4) RXD

(8) GND

RXD+ (2

TXD+ (3)

RXD- (1)

TXD- (4)

8 pin Mini DIN male (RS-232)

Controller

RS-485 cable connector

D+

D-

Controller

1

5

4

8

Top View

Revision January, 2008, Doc. Name: 2007PDD23000007 1-13

Page 15

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

AllenBradley MicroLogix PLC Back to Table

A. HMI factory setting

Baud rate: 19200, 8, None, 1.

PLC station number: 1.

Control area/status area: B3:0/B3:10.

B. Definition of controller Read/Write address

Registers

Read/Write Range

Register Type Format

Word No.

Low Byte

Output File O:n n: 0 ~ 3 N/A 0

Input File I:n n: 0 ~ 3 N/A 1

Status File S2:n n: 0 ~ 65 N/A 2

Bit File B3:n n: 0 ~ 255 N/A 3

Timer Flag T4:n n: 0 ~ 255 N/A 4

Timer Preset Value T4:n.PRE n: 0 ~ 255 N/A 4

Timer Accumulator Value T4:n.ACC n: 0 ~ 255 N/A 4

Counter Flag C5:n n: 0 ~ 255 N/A 5

Counter Preset Value C5:n.PRE n: 0 ~ 255 N/A 5

Counter Accumulator Value C5:n.ACC n: 0 ~ 255 N/A 5

Control File R6:n n: 0 ~ 255 N/A 6

Control Size of Bit Array R6:n.LEN n: 0 ~ 255 N/A 6

Control Reserved File R6:n.POS n: 0 ~ 255 N/A 6

Integer File N7:n n: 0 ~ 255 N/A 7

Bit No.

High Byte

File No.

Bit No

¾

¾

¾

¾

1) After last communication data has been memorized by PLC (PLC will send 0x10 0x05 consecutively),

1-14 Revision January, 2008, Doc. Name: 2007PDD23000007

: Low byte is not used, so the value is 0. High byte stores file number.

Data Size

T4, C5 and R6 only read 1 Word once.

If reading multiple Words once, the communication speed of PLC will be slow.

communication may fail. At this time, power off and power up HMI or power off and power up PLC once.

: Word.

NOTE

Page 16

Contacts

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Read/Write Range

Contact Type Format

Bit No.

Word No.

Low Byte High Byte

Bits File No.

Output O:n/b n: 0 ~ 3 b: 0 ~ 15 0

Input I:n/b n: 0 ~ 3 b: 0 ~ 15 1

Status S2:n/b n: 0 ~ 65 b: 0 ~ 15 2

Bit B3:n/b n: 0 ~ 255 b: 0 ~ 15 3

Timer T4:n/b n: 0 ~ 255 b: 0 ~ 15

4

T4:n/EN n: 0 ~ 255 15

T4:n/TT n: 0 ~ 255 14

T4:n/DN n: 0 ~ 255 13

Timer Preset Value T4:n.PRE/b n: 0 ~ 255 b: 0 ~ 15 4

Timer Accumulator Value T4:n.ACC/b n: 0 ~ 255 b: 0 ~ 15 4

Counter flag C5:n/b n: 0 ~ 255 b: 0 ~ 15

5

C5:n/CU n: 0 ~ 255 15

C5:n/CD n: 0 ~ 255 14

C5:n/DN n: 0 ~ 255 13

C5:n/OV n: 0 ~ 255 12

C5:n/UN n: 0 ~ 255 11

C5:n/UA n: 0 ~ 255 10

Counter Preset Value C5:n.PRE/b n: 0 ~ 255 b: 0 ~ 15 5

Counter Accumulator Value C5:n.ACC/b n: 0 ~ 255 b: 0 ~ 15 5

Control R6:n/b n: 0 ~ 255 b: 0 ~ 15

R6:n/EN n: 0 ~ 255 15

R6:n/DN n: 0 ~ 255 13

R6:n/ER n: 0 ~ 255 11

R6:n/UL n: 0 ~ 255 10

R6:n/IN n: 0 ~ 255 9

R6:n/FD n: 0 ~ 255 8

Control Size of Bit Array R6:n.LEN/b n: 0 ~ 255 b: 0 ~ 15 6

Control Reserved R6:n.POS/b n: 0 ~ 255 b: 0 ~ 15 6

Integer N7:n/b n: 0 ~ 255 b: 0 ~ 15 7

Bit No

¾

: Low byte stores Bit address. High byte stores file number.

6

Revision January, 2008, Doc. Name: 2007PDD23000007 1-15

Page 17

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

C. Connections (Connector Pinouts)

RS-232 Connection

DOP Series

9 pin D-SUB male (RS-232)

RXD (2)

TXD (3)

GND (5)

Controller

8 pin Mini DIN male (RS-232)

(7) TXD

(4) RXD

(2) GND

(3) RTS

(6) CTS

Controller

8 pin Mini DIN male

(RS-232)

2

1

3

4

6

7

Top View

1-16 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 18

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

AllenBradley SLC5 PLC Back to Table

A. HMI factory setting

Baud rate: 19200, 8, None, 1.

PLC station number: 1.

Control area/status area: B3:0/B3:10.

NOTE

1) Error Check uses CRC (Cyclical Redundancy Check).

B. Definition of controller Read/Write address

Registers

Register Type Format

Read/Write Range

Word No. Bit No.

Low Byte High Byte

Element No.

Slot or File No.

Output File O:n

O:s.n

Input File I:n

I:s.n

Status File S2:n n: 0 ~ 255 N/A File No. = 2

Bit File Bf:n n: 0 ~ 255 N/A f: 10 ~ 255

Timer Flag Tf:n n: 0 ~ 255 N/A f: 10 ~ 255

Timer Preset Value Tf:n.PRE n: 0 ~ 255 N/A f: 10 ~ 255

Timer Accumulator Value Tf:n.ACC n: 0 ~ 255 N/A f: 10 ~ 255

Counter Flag Cf:n n: 0 ~ 255 N/A f: 10 ~ 255

n: 0 ~ 30 N/A Slot No. s = 0

s: 0 ~ 255

File No. = 0

n: 0 ~ 30 N/A Slot No. s = 0

s: 0 ~ 255

File No. = 1

If f is ignored, file no. will be

default setting 3.

If f is ignored, file no. will be

default setting 4.

If f is ignored, file no. will be

default setting 4.

If f is ignored, file no. will be

default setting 4.

If f is ignored, file no. will be

default setting 5.

Counter Preset Value Cf:n.PRE n: 0 ~ 255 N/A f: 10 ~ 255

If f is ignored, file no. will be

default setting 5.

Revision January, 2008, Doc. Name: 2007PDD23000007 1-17

Page 19

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Read/Write Range

Register Type Format

Word No. Bit No.

Low Byte High Byte

Element No.

Slot or File No.

Counter Accumulator Value Cf:n.ACC n: 0 ~ 255 N/A f: 10 ~ 255

If f is ignored, file no. will be

default setting 5.

Control File Rf:n n: 0 ~ 255 N/A f: 10 ~ 255

If f is ignored, file no. will be

default setting 6.

Control Size of Bit Array Rf:n.LEN n: 0 ~ 255 N/A f: 10 ~ 255

If f is ignored, file no. will be

default setting 6.

Control Reserved File Rf:n.POS n: 0 ~ 255 N/A f: 10 ~ 255

If f is ignored, file no. will be

default setting 6.

Integer File Nf:n n: 0 ~ 255 N/A f: 10 ~ 255

If f is ignored, file no. will be

default setting 7.

Bit No

¾

: Low byte is not used, so the value is 0. High byte stores file number.

Contacts

Read/Write Range

Word No. Bit No.

Contact Type Format

Low Byte High Byte

Element No.

Bits Slot or File No.

Output O:n/b

O:s.n/b

n: 0 ~ 30 b: 0 ~ 15 Slot No. s = 0

s: 0 ~ 255

File No. = 0

Input I:n/b

I:s.n/b

n: 0 ~ 30 b: 0 ~ 15 Slot No.

s = 0

s: 0 ~ 255

File No. = 1

Status S2:n/b n: 0 ~ 31 b: 0 ~ 15 2

Bit Bf:n/b n: 0 ~ 255 b: 0 ~ 15 f: 10 ~ 255

If f is ignored, file no. will be

default setting 3.

Timer Tf:n/b n: 0 ~ 255 b: 0 ~ 15

Tf:n/EN n: 0 ~ 255 15

f: 10 ~ 255

If f is ignored, file no. will be

default setting 4.

Tf:n/TT n: 0 ~ 255 14

Tf:n/DN n: 0 ~ 255 13

Timer Preset Value Tf:n.PRE/b n: 0 ~ 255 b: 0 ~ 15 f: 10 ~ 255

If f is ignored, file no. will be

default setting 4.

1-18 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 20

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Read/Write Range

Contact Type Format

Timer Accumulator Value Tf:n.ACC/b n: 0 ~ 255 b: 0 ~ 15 f: 10 ~ 255

Counter Flag Cf:n/b n: 0 ~ 255 b: 0 ~ 15

Cf:n/CU n: 0 ~ 255 15

Cf:n/CD n: 0 ~ 255 14

Cf:n/DN n: 0 ~ 255 13

Cf:n/OV n: 0 ~ 255 12

Cf:n/UN n: 0 ~ 255 11

Cf:n/UA n: 0 ~ 255 10

Counter Preset Value Cf:n.PRE/b n: 0 ~ 255 b: 0 ~ 15 f: 10 ~ 255

Counter Accumulator Value Cf:n.ACC/b n: 0 ~ 255 b: 0 ~ 15 f: 10 ~ 255

Word No. Bit No.

Low Byte High Byte

Element No.

Bits Slot or File No.

If f is ignored, file no. will be

default setting 4.

f: 10 ~ 255

If f is ignored, file no. will be

default setting 5.

If f is ignored, file no. will be

default setting 5.

If f is ignored, file no. will be

default setting 5.

Control Rf:n/b n: 0 ~ 255 b: 0 ~ 15

Rf:n/EN n: 0 ~ 255 15

Rf:n/DN n: 0 ~ 255 13

Rf:n/ER n: 0 ~ 255 11

Rf:n/UL n: 0 ~ 255 10

Rf:n/IN n: 0 ~ 255 9

Rf:n/FD n: 0 ~ 255 8

Control Size of Bit Array Rf:n.LEN/b n: 0 ~ 255 b: 0 ~ 15 f: 10 ~ 255

Control Reserved Rf:n.POS/b n: 0 ~ 255 b: 0 ~ 15 f: 10 ~ 255

Integer Nf:n/b n: 0 ~ 255 b: 0 ~ 15 f: 10 ~ 255

Bit No

¾

: Low byte stores Bit address. High byte stores file number.

NOTE

f: 10 ~ 255

If f is ignored, file no. will be

default setting 6.

If f is ignored, file no. will be

default setting 6.

If f is ignored, file no. will be

default setting 6.

If f is ignored, file no. will be

default setting 7.

1) Device O and I need to assign Slot No. (s). If not assign Slot No., it will use default setting 0.

Revision January, 2008, Doc. Name: 2007PDD23000007 1-19

Page 21

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

C. Connections (Connector Pinouts)

RS-232

DOP series

9 pin D-SUB male (RS-232)

RXD (2)

TXD (3)

GND (5)

9 pin D-SUB female (RS-232)

(3) TXD

(2) RXD

(5) SG

Controller

(7) RTS

(8) CTS

Controller

9 pin D-SUB female

(RS-232)

Pin1

Top View

1-20 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 22

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Cimon PLC (Loader Protocol) Back to Table

A. HMI factory setting

Baud rate: 38400, 8, None, 1, RS-232.

PLC station number: 1.

Control area/status area: D00000 / D00010.

B. Definition of controller Read/Write address

Registers

Read/Write Range

Register Type Format

Data Length

Word No. Bit No.

Input Xn n: 000-512 N/A Word

Output Yn n: 000-512 N/A Word

General Purpose Relay Mn n: 000-999 N/A Word

General Purpose Relay Ln n: 000-999 N/A Word

Latch Relay Kn n: 000-999 N/A Word

Flags Fn n: 000-127 N/A Word

Timer (Set) TSn n: 0000-4095 N/A Word

Timer (Current) TCn n: 0000-4095 N/A Word

Counter (Set) CSn n: 0000-4095 N/A Word

Counter (Current) CCn n: 0000-4095 N/A Word

General Purpose Word Data Dn n:00000-31999 N/A Word

Step Controller Sn n: 0-99 N/A Byte

Contacts

Read/Write Range

Contact Type Format

Word No. Bit No.

Input Xnb n: 000-512 b: 0-F

Output Ynb n: 000-512 b: 0-F

General Purpose Relay Mnb n: 000-999 b: 0-F

General Purpose Relay Lnb n: 000-999 b: 0-F

Latch Relay Knb n: 000-999 b: 0-F

Flags Fnb n: 000-127 b: 0-F

Timer Status Tb N/A b: 0-4095

Counter Status Cb N/A b: 0-4095

Revision January, 2008, Doc. Name: 2007PDD23000007 1-21

Page 23

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

C. Connections (Connector Pinouts)

RS-232

DOP series

9 pin D-SUB male (RS-232)

RXD (2 )

Controller

6 pin RJ11

2

Controller

9 pin D-SUB female

(RS-232)

TXD (3)

GND (5)

NOTE

1) Device S

The unit of PLC internal memory is byte and Device S is read by the unit of byte. Therefore, we

recommend the user do not use two consecutive devices S as the read addresses or the interference will

occur. For example, when choosing two numeric input device, please use S24 and S26, do not use S24

and S25.

3

5

1 ~ 6

Top View

1-22 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 24

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Copley Servo (Stepnet Protocol) Back to Table

A. HMI factory setting

Baud rate: 9600, 8, None, 1.

PLC station number: 0.

Control area/status area: None.

B. Definition of controller Read/Write address

Registers

Register Type Format

RAM memory Rn n: 00-FF (Hex) N/A DWord

Flash memory Fn n: 00-FF (Hex) N/A DWord

Internal Register IRn n: 0-31 N/A Word

Contacts

Read/Write Range

Data Length

Word No. Bit No.

Contact Type Format

BIT_DEVICE_RB RBn.b n: 00-FF (Hex) b: 0-31

BIT_DEVICE_FB FBn.b n: 00-FF (Hex) b: 0-31

BIT_DEVICE_T0 T0n N/A n: 0

BIT_DEVICE_T1 T1n N/A n: 0

BIT_DEVICE_T2 T2n N/A n: 0

BIT_DEVICE_RST RSTn N/A n: 0

BIT_DEVICE_CPR CPRn n: 00-FF (Hex) N/A

BIT_DEVICE_CPF CPFn n: 00-FF (Hex) N/A

NOTE

1) RB and FB are the bit access of Ram/Flash memory. Therefore, RB0x21.14 indicates bit 14 of Ram

memory 0x21.

2) T0, T1 and T2 is virtual device for simulating Trajectory Generator Command. The number of 0, 1 and 2

indicates the subcommand of that command, so only bit 0 is acceptable.

Read/Write Range

Word No. Bit No.

3) RST is for simulating Reset Command, so only bit 0 is acceptable.

4) CPR and CPF are for simulating Copy Command of Ram and Flash individually. The address (n) after

CPR and CPF is just the copy address for Ram/Flash memory. For example, CPRCA indicates that the

content of Ram memory 0xCA will be copied into Flash memory 0xCA and CPFA6 indicates that the

content of Flash memory 0xA6 will be copied into Ram memory 0xA6.

5) T0, T1, T2, RST, CPR, CPF are all write-only and they can not be used on Reset button.

Revision January, 2008, Doc. Name: 2007PDD23000007 1-23

Page 25

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

D

C. Connections (Connector Pinouts)

RS-232

DOP series

9 pin D-SUB male (RS-232)

RXD (2 )

TXD (3)

GND (5)

9 pin D-SUB female (RS-232)

RS-232 Tx

RS-232 RxD

Signal Ground

Controller

1-24 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 26

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Danfoss VLT 2800 (FC Protocol) Back to Table

A. HMI factory setting

Baud rate: 9600, 8, Even, 1, RS-485.

PLC station number: 1.

Control area/status area: None / None.

NOTE

1) Delta HMI can be connected to for VLT-2800, 5000, 6000, 7000 controllers.

2) Each data length format of Danfoss AC drive parameter is not fixed, therefore, “Multiple Duplicate”

function is not provided.

3) Max. supported alarm number is 16. If the alarm number is over 16, a fault will occur.

4) Does not support “optimum read/write” characteristic.

5) If the selected element is a string, the minimum data length should be more than 2.

B. Definition of controller Read/Write address

Registers

Read/Write Range

Register Type Format

Parameter Pn:I n: 0 ~ 999 0 I: 0 ~ 31

Control Word CTRWD 0 N/A N/A

Status Word STAWD 0 N/A N/A

Index No : If the index No. is not used, its default setting will be 0. The default setting of index No. for

¾

parameter P606 ~ P617 is 1.

Please notice that it is necessary to input the index No. when using some parameters of Danfoss

¾

controllers. At this time, please pay close attention on the setting range of index number. If the setting

range is not started from 0, the parameter read & write failure will occur. For example, the index No.

setting range of the parameter P615 is from 1 to 20, if the users do not input the index No., the system

Word No.

Low Byte High Byte

Index No.

Bit No.

will assume the index number is 0 (default setting) and the a fault will occur when the users read or write

the parameter.

CTRWD: Write-only. (Can not be used on the devices which can display the value or input value. It is

¾

recommended to be used on the setting value/setting constant (button), or marco function.)

STAWD: Read-only.

¾

Control & Status Word: Please refer to the explanation on the next page.

¾

Revision January, 2008, Doc. Name: 2007PDD23000007 1-25

Page 27

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

)

Contacts

Read/Write Range

Contact Type Format

Word No. Bit No.

Low Byte High Byte

Element No.

Bits Index No.

Parameter Pn:I.b n: 0 ~ 999 b: 0 ~ 31 I: 0 ~ 31

Bit No

¾

: Low byte stores Bit address. High byte stores index number.

C. Connections (Connector Pinouts)

RS-485

DOP Series

9 pin D-SUB male (RS-485)

RXD+ (2

TXD+ (3)

RXD- (1)

TXD- (4)

Shell Shell

RS-485 cable connector

68 TXD/RXD+

69 TXD/RXD-

Controller

Explanation of Control Word & Status Word

Control Word

Bit Bit = 0 Bit = 1

15 No Function Reversing

14 Choice of Setup 2 (msb)

13 Choice of Setup 1 (lsb)

12 No Function Relay 04 activated

11 No Function Relay 01 activated

10 Data Not Vaild Vaild

9 Ramp 1 Ramp2

8 Jog 1 OFF ON

7 No Function Reset

6 Ramp Stop Start

5 Hold Ramp Enable

4 Quick-Stop Ramp

3 Coasting Enable

2 DC Brake Ramp

1 Preset reference choice msb

0 Preset reference choice msb

When Bit 10 = 1 (Data Valid), the Control Word is valid.

¾

1-26 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 28

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Status Word

Bit Bit = 0 Bit = 1

15 Timer OK Above limit

14 Torque OK Above limit

13 Voltage OK Above limit

12 Temperature OK Over-Temp, auto-start pending

11 Not Running Running

10 Out of Range Frequency OK

9 Local Control Bus Control

8

Speed ≠ reference Speed = reference

7 No Warning Warning

6 Reserved

5 Reserved

4 Reserved

3 No Fault Trip

2 Coasting Enabled

1 VLT not ready Ready

0 Control not ready Ready

Revision January, 2008, Doc. Name: 2007PDD23000007 1-27

Page 29

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Emerson EC20 Series PLC Back to Table

A. HMI factory setting

Baud rate: 19200, 8, Even, 1 (RS-232).

PLC station number: 0.

Control area/status area: D0 / D10.

B. Definition of controller Read/Write address

Registers

Register Type Format

Data Word Dn n: 0-7999 N/A Word

Special Data Word SDn n: 0-255 N/A Word

Data Word Zn n: 0-15 N/A Word

Timer Tn n: 0-255 N/A Word

Counter Cn n: 0-199 N/A Word

DoubleWord Counter CDWn n: 200-255 N/A DWord

DoubleWord Data Word DDWn n: 0-7998 N/A DWord

Contacts

Contact Type Format

External Output Relay Yb N/A b: 0-377(Octal)

External Input Relay Xb N/A b: 0-377(Octal)

Internal Relay Mb N/A b: 0-1999

Special Internal Relay SMb N/A b: 0-255

Read/Write Range

Data Length

Word No. Bit No.

Read/Write Range

Word No. Bit No.

Status Relay Sb N/A b: 0-991

Timer Tb N/A b: 0-255

Counter Cb N/A b: 0-255

NOTE

PLC Communication Settings:

1) Emerson EC20 series PLC has two communication ports, COM0 and COM1. They are provided for the

communication protocol for connecting to PC, Modbus communication protocol and user-defined

protocol. The default setting is COM0 to be enabled only, so the user needs to set the communication

mode as Modbus RTU via PC software before using it.

2) COM1 supports RS-232 and RS-485.

1-28 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 30

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

D

)

3) Please note that not all of the addresses can be written when reading SM and SD device. We

recommend the user not to set all of the addresses as write address except when setting parameters.

C. Connections (Connector Pinouts)

RS-232

RS-485

DOP series

9 pin D-SUB male (RS-232)

RXD (2 )

TXD (3)

GND (5)

DOP series

9 pin D-SUB male (RS-232)

D- (1

D- (4)

D+ (2)

D+ (3)

G ND (5)

Controller

TX

RXD

GND

Controller

(3) RS485+

(4) RS485-

GND

COM1

COM1

Revision January, 2008, Doc. Name: 2007PDD23000007 1-29

Page 31

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Facon FB Series PLC Back to Table

A. HMI factory settings

Baud rate: 9600, 7, Even, 1.

Controller Station number: 1.

Control area/status area: R0 / R10.

B. Definition of controller Read/Write address

Registers

Register Type Format

Data length

Word No. Bit No.

Input Relay WXn n: 0 ~ 9992 N/A Byte

Output Relay WYn n: 0 ~ 9992 N/A Byte

Internal Relay WMn n: 0 ~ 9992 N/A Byte

Step Relay WSn n: 0 ~ 9992 N/A Byte

Data Register Rn n: 0 ~ 65534 N/A Word

Data Register Dn n: 0 ~ 65534 N/A Word

Timer Present Value RTn n: 0 ~ 9999 N/A Word

Counter Present Value RCn n: 0 ~ 9999 N/A Word

Data Register DRCn n: 200 ~ 255 N/A Double Word

Read/Write range

Input Relay / Output Relay / Internal Relay / Special Relay: Address must be the multiple of 8.

¾

Contacts

Read/Write range

Contact type Format

Word No. Bit No.

Input Relay Xn N/A n: 0 ~ 9999

Output Relay Yn N/A n: 0 ~ 9999

Internal Relay Mn N/A n: 0 ~ 9999

Step Relay Sn N/A n: 0 ~ 9999

Timer Flag Tn N/A n: 0 ~ 9999

Counter Flag Cn N/A n: 0 ~ 9999

1-30 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 32

C. Connections (Connector Pinouts)

RS-232

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

DOP Series

9 pin D-SUB male (RS-232)

RXD (2)

TXD (3)

GND (5)

(2) TXD

(1) RXD

(6) SG

Controller

15 pin male (RS-232)

(3) RTS

(4) CTS

RS-232

Connecting to CB (Communication Board) or CM (Communication Module)

FBs Series Port 1

9 pin D-SUB male (RS-232)

DOP Series

9 pin D-SUB male (RS-232)

Controller

RXD (2) (2) TXD

TXD (3)

(3) RXD

Controller

15 pin male (RS-232)

Pin1

9 pin D-SUB male (RS-232)

Top View

Controller

Pin1

RS-232

FBs Series Port 0

DOP Series

9 pin D-SUB male (RS-232)

GND (5)

(5) GND

(8) RTS

(7) CTS

4 pin Mini DIN male (RS-232)

RXD (2) (4) TXD

TXD (3)

GND (5)

(2) RXD

(1) GND

(3) +5V

Controller

Controller

4 pin Mini DIN male

(RS-232)

2

1

3

4

Revision January, 2008, Doc. Name: 2007PDD23000007 1-31

Page 33

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Festo PLC Back to Table

A. HMI factory settings

Baud rate: 9600, 8, None, 1.

Controller Station number: 0. (no PLC station number in protocol)

Control area/status area: R0 / R10.

NOTE

1) Connectable PLC: FEC-FC Model

B. Definition of controller Read/Write address

Registers

WORD_DEVICE_IW Iwn n: 0 ~ 255 N/A Word

WORD_DEVICE_OW Own n: 0 ~ 255 N/A Word

WORD_DEVICE_FW FWn n: 0 ~ 9999 N/A Word

WORD_DEVICE_TW TWn n: 0 ~ 255 N/A Word

WORD_DEVICE_CW CWn n: 0 ~ 255 N/A Word

WORD_DEVICE_R Rn n: 0 ~ 255 N/A Word

WORD_DEVICE_TP TPn n: 0 ~ 255 N/A Word

WORD_DEVICE_CP CPn n: 0 ~ 255 N/A Word

Contacts

Register Type Format Word No. Bit No. Data Size

Register Type Format Word No. Bit No.

BIT_DEVICE_I In.b n: 0 ~ 255 b: 0 ~ 15

BIT_DEVICE_O On.b n: 0 ~ 255 b: 0 ~ 15

BIT_DEVICE_F Fn.b n: 0 ~ 9999 b: 0 ~ 15

BIT_DEVICE_T Tn N/A n: 0 ~ 255

BIT_DEVICE_C Cn N/A n: 0 ~ 255

BIT_DEVICE_TON TONn N/A n: 0 ~ 255

BIT_DEVICE_TOFF TOFFn N/A n: 0 ~ 255

BIT_DEVICE_T / BIT_DEVICE_C / BIT_DEVICE_TON / BIT_DEVICE_TOFF: Only 1 Bit can be

¾

transferred for each communication.

Only 1 Bit or 1 Word can be transferred for each write command.

¾

1-32 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 34

C. Connections

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

NOTE

1) Communication port of PLC: COM port

2) It needs to use the dedicated cable for FESTO controllers Æ Cable for transferring TTL to RS-232 and it

is 6 pin RJ-12 connector at PLC side.

Revision January, 2008, Doc. Name: 2007PDD23000007 1-33

Page 35

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

GE Fanuc 90 Series SNP PLC Back to Table

A. HMI factory settings

Baud rate: 19200, 8, ODD, 1.

Controller Station number: 0. (no PLC station number in protocol, therefore, only 1(HMI) to 1 (PLC)

communication is allowed.)

Control area/status area: %R1 / %R10.

NOTE

1) Please notice that no PLC station number in protocol, therefore, only 1(HMI) to 1 (PLC) communication

is allowed.

2) If the PLC enabled “Check Password” function, the user needs to set the password by clicking Option >

Configuration > Communication. The user can find Controller Settings and set PLC password on

Communication Tab in the Configuration dialog box. Please enter a 4-digit password (If entering a

password that exceeds 4-digit number, only the first 4-digit number is valid).

B. Definition of controller Read/Write address

Registers

Register Type Format

Discrete Inputs %In n: 1 ~ 12288 N/A Word (the multiple of 16 + 1)

Discrete Outputs %Qn n: 1 ~ 12288 N/A Word (the multiple of 16 + 1)

Discrete Temporaries %Tn n: 1 ~ 256 N/A Word (the multiple of 16 + 1)

Read/Write range

Data length

Word No. Bit No.

Discrete Internals %Mn n: 1 ~ 12288 N/A Word (the multiple of 16 + 1)

%SA Discretes %SAn n: 1 ~ 128 N/A Word (the multiple of 16 + 1)

%SB Discretes %SBn n: 1 ~ 128 N/A Word (the multiple of 16 + 1)

%SC Discretes %SCn n: 1 ~ 128 N/A Word (the multiple of 16 + 1)

%S Discretes %S-n n: 1 ~ 128 N/A Word (the multiple of 16 + 1)

Genius Global Data %Gn n: 1 ~ 7680 N/A Word (the multiple of 16 + 1)

Registers %Rn n: 1 ~ 16384 N/A Word

Analog Inputs %AIn n: 1 ~ 8192 N/A Word

Analog Outputs %AQn n: 1 ~ 8192 N/A Word

1-34 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 36

Contacts

)

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Contact Type Format

Discrete Inputs %In N/A n: 1 ~ 12288

Discrete Outputs %Qn N/A n: 1 ~ 12288

Discrete Temporaries %Tn N/A n: 1 ~ 256

Discrete Internals %Mn N/A n: 1 ~ 12288

%SA Discretes %SAn N/A n: 1 ~ 128

%SB Discretes %SBn N/A n: 1 ~ 128

%SC Discretes %SCn N/A n: 1 ~ 128

%S Discretes %-Sn N/A n: 1 ~ 128

Genius Global Data %Gn N/A n: 1 ~ 7680

C. Connections (Connector Pinouts)

RS-232

DOP

9 pin D-SUB male

(RS-232)

Word No. Bit No.

Controller

RJ-45 cable connector

(RS-232)

Read/Write range

RJ-45 cable connector

Controller

(RS-232)

RS-422

RXD (2) (5) TXD

TXD (3)

GND (5)

DOP Series

9 pin D-SUB male (RS-232)

RXD- (1

RXD+ (2)

TXD+ (3)

TXD- (4)

(1 2 ) SD ( A')

(13) SD( B')

(11) RD(B)

(10 ) RD(A)

(9 ) RD ( *)

(6 ) RT S(A)

(15 ) CTS(A')

(8 ) CT S(B)

(6) RXD

(4) GND

15 pin male (RS-232)

Controller

(NOTE 1 )

8

1

Top V iew

Controller

15 pin male (RS-232)

Pin1

Top View

(14 ) RTS(B')

NOTE

1) (9) RD(*) should be connected to 10(RD)(A) in serial. But if connecting PLC model is Series 90-70 PLC

IC697CPU731 and IC697CPU771, (9) RD(*) needs to be connected to 11(RD)(B).

Revision January, 2008, Doc. Name: 2007PDD23000007 1-35

Page 37

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Hitachi EH Series PLC Back to Table

A. HMI factory settings

Baud rate: 19200, 7, EVEN, 1.

Controller station number: 0.

Control area/status area: WR0 / WR10.

B. Definition of controller Read/Write address

Registers

Read/Write Range

Register Type Format

Data Length

Word No. Bit No.

External Input WX WXrusn Word

s: 0-A n: 0-7

External Output WY WYrusn

r: 0-4

u: 0-4

N/A

Word

Internal Output WR WRn n: 0-C3FF N/A Word

Special Internal Output WR WRn n: F000-F1FF N/A Word

Shared Internal Output WM WMn n: 0-3FF N/A Word

CPU Link Area 1 WL WLn n: 0-3FF N/A Word

CPU Link Area 2 WL WLn n: 1000-13FF N/A Word

Timer/Counter TC TCn n: 0-511 N/A Word

Contacts

Read/Write Range

Register Type Format

Word No. Bit No.

External Input X Xrusb

s: 0-A N/A

External Output Y Yrusb

r: 0-4

u: 0-4

b: 0-95

Internal Output R Rb N/A b: 0-7FF

Shared Internal Output M Mnb n: 0-3FF b: 0-F

CPU Link Area 1 L Lnb n: 0-3FF b: 0-F

CPU Link Area 2 L Lnb n: 1000-13FF b: 0-F

On Delay Timer TD TDb N/A b: 0-255

Single-shot Timer SS SSb N/A b: 0-255

Up Counter CU CUb N/A b: 0-511

Up-down Counter up input CTU CTUb N/A b: 0-511

Up-down Counter down input CTD CTDb N/A b: 0-511

Up-down Counter down output CT CTb N/A b: 0-511

Progress Value Clear CL CLb N/A b: 0-511

Rising Edge Detection DIF DIFb N/A b: 0-511

Falling Edge Detection DFN DFNb N/A b: 0-511

1-36 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 38

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

NOTE

1) Communication Settings:

y In Hitachi EH series PLC, only port 1 can be used for communication through procedure 2. The

user can select procedure type via DIP switch and specific Special Internal Input (WR).

y In Hitachi EH-150 series PLC, only EH-CPU***A/448/516/548 can use procedure 2.

y It needs to set the external I/O (WX, WY, X, Y) of EH series PLC first or HMI cannot read and write

their addresses.

y Hitachi EH series PLC and PC can be connected only by procedure 1 (@19200bps)

2) CPU Relevant Notice:

EH-150

y DIP5 should be set to ON.

y If DIP5 is set to ON, PLC will determine the proper procedure (1 or 2) by the value of WRf037.

When setting the address, the highest bit of write value must be 1 and then PLC can write the value

into other seven bits. The data will not lost even when the power of PLC is cut off. Therefore,

i) Write the value 0x8000 into the address. After restart PLC, the address value will become

0x0000 and perform communication by procedure 1.

ii) Write the value 0xC000 into the address. After restart PLC, the address value will become

0x4000 and perform communication by procedure 2.

y Use DIP3 and DIP4 to set the communication speed of port 1.

i) When DIP3 is ON and DIP4 is OFF, the communication speed is 19200bps.

y Use DIP6, PHL to set the communication speed of port 2.

i) When DIP6 is ON and PHL is OFF, the communication speed is 19200bps.

ii) The EH-150 PLC is a “Base Unit” which has a built-in CPU module. This unit allows easy

connection of extension module, such as “External I/O”.

MicroEH

y DIP5 is used to set communication speed.

i) When SW1 is ON, the communication speed is 19200bps.

y MicroEH PLC will determine the proper procedure (1 or 2) by the value of WRf01a. Different than

EH-150, when setting the address, the highest bit of write value does not need to be 1. But the data

will lost even the power of PLC is cut off. However, if set the value of R7f6 to 1, the data of WRf01a

will be saved into Flash memory.

i) 0x0000 for procedure 1.

ii) 0x8000 for procedure 2.

iii) If the PLC uses procedure 2 and saves the data into Flash memory, it cannot connect to

the peripheral devices and programs (Ladder Editor) that only support procedure 1.

iv) Standard External I/O built in MicroEH PLC are listed as below:

Digital Type

Revision January, 2008, Doc. Name: 2007PDD23000007 1-37

Page 39

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

)

slot 0: X48

slot 1: Y32

slot 2: empty16

Analog Type

slot 3: X4W

slot 4: Y4W

3) Communication Protocol:

External I/O (X, Y, WX, WY)

y Address rules:[r][u][s][n/b].

i) Word no/Bit no [n/b]

ii) Slot number [s]

iii) Unit number [u]

iv) Remote number [r]

Only support EH-150

v) ex1: WX103 represents unit 1, word 3 of slot 0

vi) ex2: X103 represents bit 3 of slot 1

vii) ex3: X113 represents bit 13 of slot 1

viii) ex4: Y2004 represents unit 2, bit 4 of slot 0

ix) ex5: Y2104 represents unit 2, bit 4 of slot 1

y External I/O (X, Y, WX, WY) cannot read and write several addresses one time so they do not

support “optimum read/write” characteristic.

Internal Output

y Shared Internal Output (M, WM) read and write the same address. For example,

i) M3ab and WM3a: the read and write address of M3ab is the bit b of WM3a.

y CPU Link Area (L, WL) are the same as Shared Internal Output (M, WM). CPU Link Area (L, WL)

also read and write the same address.

i) Only support EH-150.

C. Connections (Connector Pinouts)

RS-232

DOP Series

9 pin D-SUB male (RS-232)

RX D (2

TXD (3)

GND (5)

RTS (7) (7) DR1

CT S (8) (8 ) RS1

9 pin D-SUB male (RS-232)

(5) SD1

(6) R D1

(1) SG1

Controller

Controller

9 pin D-SUB male (RS-232)

Pin1

Top View

1-38 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 40

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

HUST CNC Controller Back to Table

A. HMI factory settings

Baud rate: 9600, 7, EVEN, 2.

Controller station number: 0.

Control area/status area: W0 / W10.

B. Definition of controller Read/Write address

Registers

Read/Write Range

Register Type Format

Word No. Bit No.

Word Register Wn n: 0 ~ 13500 N/A Word

Double Word Register Dn n: 0 ~ 13500 N/A Double Word

NOTE

Data Length

1) The unit for Hust CNC controller is D Word and Wn is the low word of Dn.

Contacts

Contact Type Format

BIT_DEVICE_B Bm.n m: 0 ~ 13500 n: 0 ~ 31

BIT_DEVICE_I In N/A n: 0 ~ 255 (8 DW)

BIT_DEVICE_O On N/A n: 0 ~ 255 (8 DW)

BIT_DEVICE_C Cn N/A n: 0 ~ 255 (8 DW)

BIT_DEVICE_S Sn N/A n: 0 ~ 255 (8 DW)

BIT_DEVICE_A An N/A n: 0 ~ 1023 (32 DW)

C. Connections (Connector Pinouts)

RS-232

DOP Series

9 pin D-SUB male (RS-232)

RXD (2)

TXD (3)

GND (5)

9 pin D-SUB male (RS-232)

(2) TXD

(3) RXD

(5) SG

Word No. Bit No.

Controller

(8) RTS

Read/Write range

9 pin D-SUB male

Controller

(RS-232)

Pin1

(7) CTS

Revision January, 2008, Doc. Name: 2007PDD23000007 1-39

Top View

Page 41

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Jetter Nano Series PLC Back to Table

A. HMI factory settings

Baud rate: 9600, 8, EVEN, 1 (RS-232).

Controller station number: 0. (no PLC station number in protocol, therefore, only 1(HMI) to 1 (PLC)

communication is allowed.)

Control area/status area: WR0 / WR10.

NOTE

1) Please notice that no PLC station number in protocol, therefore, only 1(HMI) to 1 (PLC) communication

is allowed.

2) Only 1 Bit or 1 Word can be transferred for each communication.

3) In general, each register occupies max. 24 Bits. However, some registers occupies 8 Bits only.

4) Because the initial time of this controller is longer, it is recommended to set HMI startup delay time

(Recommended time is 10 seconds).

5) When the register R is used for Double Word device, please set its format as signed format. (The default

format in Screen Editor is signed format)

B. Definition of controller Read/Write address

Registers

Register Type Format

Read/Write Range

Word No. Bit No.

Data

Length

16 Bits Register WRn n: 0 ~ 32767 N/A 16 Bits

32 Bits Register Rn n: 0 ~ 32767 N/A 24 Bits

Only the first 16 bits are used for WRn registers.

Only the first 24 bits are used for Rn registers, the highest 8 bits (Bit 24 ~ 31) are set to 0 by default setting.

(24-bit Integer : If in decimal format, the range is -8388608 ~ +8388607. If in hexadecimal format, the range

is 0x000000 ~ 0xFFFFFF.)

NOTE

1) The difference between WRn and Rn:

y When using devices that the data length is in Word, only Bit 0 ~ 15 are valid for both of WRn and

Rn registers.

y When using devices that the data length is in Double Word,

if the read/write address format is set to WRn, the Bit 0 ~ 15 of WRn register is the low word of a

read/write value, the Bit 0 ~ 15 of WRn+1 register is the high word of a read/write value.

1-40 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 42

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

if the read/write address format is set to Rn, only Bit 0 ~ 23 are valid for Rn registers.

(Notice: As the Jetter controller is a 24-bit format controller, the valid setting range is 24 Bits.

If exceeds this range, HMI will stop read/write operation and show “…..Value is Incorrect”

on the screen. So, please do not set any bit on Bit24 ~ Bit31 (Bit24 ~ Bit31 cannot be written).

y When using devices that the data length is in m Words,

if the read/write address format is set to WRn, the Bit 0 ~ 15 of WRn register is the lowest word of a

read/write value and the Bit 0 ~ 15 of WRn+m-1 register is the highest word of a read/write value.

if the read/write address format is set to Rn, the Bit 0 ~ 23 of Rn register is the lowest word of a

read/write value and the Bit 0 ~ 23 of Rn+1 register is the highest word of a read/write value.

Each register is regards as a “Double Word”. The value of Bit24 ~ Bit31 is 0.

Contacts

Contact type Format

Input Relay Inbb n: 1 ~ 32 bb: 01 ~ 08

Output Relay Onbb n: 1 ~ 32 bb: 01 ~ 08

Flag Relay Fn N/A n: 0 ~ 32767

C. Connections (Connector Pinouts)

RS-232

DOP Series

9 pin D-SUB male (RS-232)

Word No. Bit No.

Controller

9 pin D-SUB male (RS-232)

Read/Write Range

RXD (2) (2) TXD

TXD (3)

GND (5)

(3) RXD

(7) GND

Controller

9 pin D-SUB male

(RS-232)

Pin1

Top View

The pin definition of the cable of Jetter controller is different than the general RS-232 cable. Please pay

¾

close attention.

Revision January, 2008, Doc. Name: 2007PDD23000007 1-41

Page 43

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Jetter JC Series PLC Back to Table

A. HMI factory settings

Baud rate: 9600, 8, EVEN, 1 (RS-232).

Controller station number: 0. (no PLC station number in protocol, therefore, only 1(HMI) to 1 (PLC)

communication is allowed.)

Control area/status area: WR0 / WR10.

NOTE

1) Please notice that no PLC station number in protocol, therefore, only 1(HMI) to 1 (PLC) communication

is allowed.

2) Only 1 Bit or 1 Word / 2 Words can be transferred for each read and write command.

B. Definition of controller Read/Write address

Registers

Register Type Format

16 Bits Register WRn n: 0 ~ 32767 N/A 16 Bits

32 Bits Register Rn n: 0 ~ 32767 N/A 24 Bits

The characteristics of WRn and Rn of JC series are the same as the Nano series. Please refer to the section

that introduces Jetter Nano Series PLC

Contacts

Read/Write Range

Word No. Bit No.

.

Data

Length

Contact type Format

Word No. Bit No.

Input Relay Inbb n: 1 ~ 32 bb: 01 ~ 16

Output Relay Onbb n: 1 ~ 32 bb: 01 ~ 16

Flag Relay Fn N/A n: 0 ~ 32767

Read/Write Range

1-42 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 44

C. Connections (Connector Pinouts)

RS-232

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

DOP Series

9 pin D-SUB male (RS-232)

RXD (2) (8) TXD

TXD (3)

GND (5)

Controller

8 pin Mini DIN male (RS-232)

(4) RXD

(2) GND

Controller

8 pin Mini DIN male (RS-232)

2

4

8

Top View

Revision January, 2008, Doc. Name: 2007PDD23000007 1-43

Page 45

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Keyence KV/KZ Series Back to Table

A. HMI factory settings

Baud rate: 9600, 8, EVEN, 1 (RS-232).

Controller station number: 0. (no PLC station number in protocol, therefore, only 1(HMI) to 1 (PLC)

communication is allowed.)

Control area/status area: DM-0 / DM-10.

NOTE

1) Please notice that no PLC station number in protocol, therefore, only 1(HMI) to 1 (PLC) communication

is allowed.

2) Only 1 Bit or 1 Word can be transferred for each communication. (Communication speed is slow.)

B. Definition of controller Read/Write address

Registers

Register Type Format

Timer T-nnn nnn: 0 ~ 199 N/A Word

Counter C-nnn nnn: 0 ~ 199 N/A Word

High-speed Counter CTH-n n: 0 ~ 1 N/A Word

High-speed Counter

Comparator

Data Memory DM-nnnn nnnn: 0 ~ 1999 N/A Word

Temporary Data Memory TM-nn nn: 0 ~ 31 N/A Word

Read/Write Range

Data Length

Word No. Bit No.

CTC-n n: 0 ~ 3 N/A Word

Timer Preset Value PT-nnn nnn: 0 ~ 199 N/A Word

Counter Preset Value PC-nnn nnn: 0 ~ 199 N/A Word

CTC Preset Value PCTC-n n: 0 ~ 3 N/A Word

Contacts

Contact type

Relay R-nnnbb nnn: 0 ~ 69 bb: 00 ~ 15

Timer T-nnn N/A nnn: 0 ~ 199

Counter C-nnn N/A nnn: 0 ~ 199

High-speed counter

comparator

1-44 Revision January, 2008, Doc. Name: 2007PDD23000007

Format

Word No. Bit No.

CTC-n N/A n: 0 ~ 3

Read/Write Range

Page 46

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

NOTE

When using the protocol format of KV series and connecting to KZ-80T PLC, some errors occur. Please refer

to the following description:

1) Readable Timer address is not continuous. For example, T-0 ~ T-9 can be read, T10 cannot be read,

T11 ~ T20 can be read, T21 ~ T50 cannot be read, …etc.

2) Counter cannot be read. For example,

Registers: C- (Counter), CTH- (High-speed counter), CTC- (High-speed counter comparator),

PC- (Counter preset value), PCTC- (CTC preset value) they all cannot be read.

Contacts: C- (Counter), CTC- (High-speed counter comparator) they all cannot be read also.

C. Connections (Connector Pinouts)

RS-232

KV Series

9 pin D-SUB male (RS-232)

DOP

RJ-11 cable connector (RS-232)

Controller

Controller

RJ-11 cable connector (RS-232)

RXD (2) (3) SD

TXD (3)

GND (5)

KZ Series

DOP

9 pin D-SUB male (RS-232)

RXD (2) (5) SD

(5) RD

(4) SG

RJ-11 cable connector (RS-232)

Controller

6 - 1

Top V iew

PLC side (Comm. Port)

Controller

RJ-11 cable connector (RS-232)

6 - 1

Top V iew

TXD (3)

GND (5)

(3) RD

(4) SG

PLC side (Comm. Port)

Revision January, 2008, Doc. Name: 2007PDD23000007 1-45

Page 47

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

NOTE

1) Communication Cable: The pins of SD and RD of KZ-80T and KV Series are reverse.

1-46 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 48

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Koyo SU/DL Series Back to Table

A. HMI factory settings

Baud rate: 9600, 8, ODD, 1 (RS-232).

Controller station number: 1.

Control area/status area: V1400 / V1410.

B. Definition of controller Read/Write address

Registers

Register Type Format

Read/Write Range

Word No. Bit No.

Data

Length

Timer Accumulated Vn n: 0 ~ 177 (octal) N/A Word

Counter Accumulated Vn n: 1000 ~ 1177 (octal) N/A Word

V Memory Vn n: 1400 ~ 7777 (octal) N/A Word

Linker Relays Vn n: 40000 ~ 40037 (octal) N/A Word

Input Status Vn n: 40400 ~ 40423 (octal) N/A Word

Output Status Vn n: 40500 ~ 40523 (octal) N/A Word

Control Relays Vn n: 40600 ~ 40635 (octal) N/A Word

Stage Vn n: 41000 ~ 41027 (octal) N/A Word

Timer Status Vn n: 41100 ~ 41107 (octal) N/A Word

Counter Status Vn n: 41140 ~ 41147 (octal) N/A Word

Spec. Relay 1 Vn n: 41200 ~ 41205 (octal) N/A Word

Spec. Relay 2 Vn n: 41216 ~ 41230 (octal) N/A Word

Contacts

Read/Write Range

Contact type Format

Word No. Bit No.

Linker Relays GXn N/A n: 0 ~ 777 (octal)

Input Status Xn N/A n: 0 ~ 477 (octal)

Output Status Yn N/A n: 0 ~ 477 (octal)

Control Relays Cn N/A n: 0 ~ 737 (octal)

Stage Sn N/A n: 0 ~ 577 (octal)

Timer Status Tn N/A n: 0 ~ 177 (octal)

Counter Status CTn N/A n: 0 ~ 177 (octal)

Spec. Relay 1 SPn N/A n: 0 ~ 137 (octal)

Spec. Relay 2 SPn N/A n: 320 ~ 617 (octal)

Revision January, 2008, Doc. Name: 2007PDD23000007 1-47

Page 49

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

C. Connections (Connector Pinouts)

RS-232

DOP

9 pin D-SUB male (RS-232)

RXD(2)

TXD(3)

GND(5)

Controller

RJ-11 cable connector (RS-232)

(4)TXD

(3)RXD

(1)GND

(6)GND

Controller

RJ-11 cable connector

(RS-232)

1 - 6

Top V iew

1-48 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 50

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Koyo K-Sequence Back to Table

A. HMI factory settings

Baud rate: 9600, 8, ODD, 1 (RS-232).

Controller station number: 1.

Control area/status area: R1400 / R1420.

NOTE

1) If read / write address exceeds the valid range, HMI will stop read/write operation and show “….Error

6….. Command Can Not be Executed….” on the screen.

B. Definition of controller Read/Write address

Registers

Register Type Format

Read/Write Range

Word No. Bit No.

Data

Length

Input Status Xnnnn nnnn: 0 ~ 1760 (octal) N/A Word

Output Status Ynnnn nnnn: 0 ~ 1760 (octal) N/A Word

Link Relays GXnnnn nnnn: 0 ~ 3760 (octal) N/A Word

Relays GQnnnn nnnn: 0 ~ 3760 (octal) N/A Word

Relays Mnnnn nnnn: 0 ~ 3760 (octal) N/A Word

Stage Snnnn nnnn: 0 ~ 1760 (octal) N/A Word

Timer Status Tnnn nnn: 0 ~ 360 (octal) N/A Word

Control Relays Cnnn nnn: 0 ~ 360 (octal) N/A Word

Special Relay 1 SPnnn nnn: 0 ~ 760 (octal) N/A Word

Register Rnnnnn nnnnn: 0 ~ 41237 (octal) N/A Word

Register Pnnnnn nnnnn: 0 ~ 37777 (octal) N/A Word

nnnn: Is in octal format and must be the multiple of 16 except for R and P.

¾

Contacts

Contact type Format

Word No. Bit No.

Input Status Xnnnn N/A nnnn: 0 ~ 1777 (octal)

Read/Write Range

Output Status Ynnnn N/A nnnn: 0 ~ 1777 (octal)

Linker Relays GXnnnn N/A nnnn: 0 ~ 3777 (octal)

Relays GQnnnn N/A nnnn: 0 ~ 3777 (octal)

Control Relays Mnnnn N/A nnnn: 0 ~ 3777 (octal)

Stage Snnnn N/A nnnn: 0 ~ 1777 (octal)

Timer Status Tnnn N/A nnn: 0 ~ 377 (octal)

Revision January, 2008, Doc. Name: 2007PDD23000007 1-49

Page 51

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Contact type Format

Counter Status Cnnn N/A nnn: 0 ~ 377 (octal)

Spec. Relay 1 SPnnn N/A nnn: 0 ~ 777 (octal)

C. Connections (Connector Pinouts)

RS-232

Port 0 Communication Cable

DOP

9 pin D-SUB male (RS-232)

RXD(2)

TXD(3)

GND(5)

RJ-11 cable connector (RS-232)

Word No. Bit No.

Controller

(4)TXD

(3)RXD

(1)GND

(6)GND

(Note 1)

Read/Write Range

Controller

RJ-11 cable connector

(RS-232)

1 - 6

Top V iew

If pin 6 is not grounded, a communication error may occur when connecting to a CKD SM 24R controller.

¾

Ensure that pin 6 is well grounded. This will not cause any problems when connecting to SN32DRA

controller.

DOP Series

9 pin D-SUB male (RS-232)

RXD (2)

TXD (3)

GND (5)

RS-485

Port 1 Communication Cable

DOP

9 pin D-SUB male (RS-485)

9 pin D-SUB male (RS-232)

D- (1)

Controller

(3) TXD

(2) RXD

(5) SG

Controller

9 pin D-SUB male (RS-232)

Pin1

DOP

9 pin D-SUB male (RS-485)

Top View

D-

D- (4)

D+ (2)

D+ (3)

1-50 Revision January, 2008, Doc. Name: 2007PDD23000007

D+

Page 52

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

The corresponding registers of CCM2 and K-Sequence

Address Corresponding Relationship:

CCM2 K sequence SN32DRA

V R R

X X I

Y Y Q

C M M

S S S

T T T

CT C C

SP SP SP

Revision January, 2008, Doc. Name: 2007PDD23000007 1-51

Page 53

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Lenze LECOM-A/B Protocol Back to Table

A. HMI factory settings

Baud rate: 9600, 7, EVEN, 1 (Baudrate: 1200/2400/4800/9600/19200).

Controller station number: 1 (1~99).

Control area/status area: None / None.

NOTE

1) Please pay close attention to each pin definition of cable connectors.

2) Ensure not to use the general RS-232 5-pin cable. This is because if pin 2, 3, 5, 7, 8 are all connected to

the drive, the drive can not recognize the communication signal and can not identify what kind of

communication it is.

3) For more detailed information of pin definition of cable connectors, please refer to the C. Connections

(Connector Pinouts) of Lenze LECOM-A/B Protocol controller.

4) Ensure the HMI communication data format (The communication data written into the drive) is correct.

The Word “m” in the following table is used to specify the HMI communication data format.

5) Ensure the HMI display data format (Property table/Setting value...etc.) is correct.

6) When using broadcast function, please check if device is available. This is because the broadcast

function can be activated only when the user chooses “write only” device for broadcast station number

(only choose setting value/setting constant (button) and then the broadcast function can be used). If

choosing other devices, the system will ask you to read back the drive setting value, so please ensure to

choose the correct device. If choosing the incorrect devices, a “Controller Station Number Error…” fault

message will display on HMI screen.

7) Support 82XX frequency inverters and 93XX servo inverters.

B. Definition of controller Read/Write address

Registers (n, m, y are in decimal)

Read/Write Range

Register Type Format

CWn n: 1 ~ 10000 N/A N/A Word Parameter without subcode

CWn.m n: 1 ~ 10000 m: 0 ~ 23 N/A Word

Parameter with subcode CWn/y n: 1 ~ 10000 N/A y:1 ~ 255 Word

CWn/y.m n: 1 ~ 10000 m: 0 ~ 23 y:1 ~ 255 Word

Word No. Bit No.

Data Length

LowByte HighByte

subcode

1-52 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 54

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Read/Write Range

Register Type Format

Parameter without subcode

Parameter with subcode CDn/y n: 1 ~ 10000 N/A y:1 ~ 255 DoubleWord

CDn/y.m n: 1 ~ 10000 m: 0 ~ 23 y:1 ~ 255 DoubleWord

NOTE

1) m : HMI communication data format

2) The value of m represents the different communication data format:

CDn n: 1 ~ 10000 N/A N/A DoubleWord

CDn.m n: 1 ~ 10000 m: 0 ~ 23 N/A DoubleWord

Word No. Bit No.

Data Length

LowByte HighByte

subcode

y If m value is undefined: ASCII hexadecimal format (VH). (4 or 8 numbers.)

y m >= 23 : ASCII hexadecimal format (VH). (4 or 8 numbers.)

y m = 0 ~10 : unsigned, ASCII decimal format (VD).

m represents decimal place, For example:

m=0 Æ no decimal place

m=1 Æ one decimal place (tenth)

m=2 Æ two decimal place (hundredth)

y m = 11 ~20 : signed, ASCII decimal format (VD).

m represents decimal place, For example:

m=11 Æ one decimal place (tenth)

m=12 Æ two decimal place (hundredth)

y m = 21 : signed, ASCII decimal format (VD).

without decimal place

y m = 22 : ASCII hexadecimal format (VH). 2 numbers.

when using this format, the write value will be limited within the range of 0~0xFF

(low byte).

For example: when entering 0x1234 during communication, the actual write value

is 0x34, not 0x1234.

Contacts (n, b, y are in decimal)

Read/Write Range

Register Type Format

Parameter without subcode CBn.b n: 1 ~ 10000 b: 0 ~ 31 N/A

Parameter with subcode CBn/y.b n: 1 ~ 10000 b: 0 ~ 31 1 ~ 255

Revision January, 2008, Doc. Name: 2007PDD23000007 1-53

Word No. Bit No.

LowByte HighByte

subcode

Page 55

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

Only VH type parameter can provide Bit read/write function (it is convenient for the user to read/write Bit No.

of parameters).

CBn.b, CWn (CWn.m), CDn (CDn.m): read/write address is the same (address n).

NOTE

1) Since the data format of this controller is complicated (a. VS (String format), b. VO (Octet string format

data blocks), c. VH (ASCII hexadecimal format)(1, 2, 4 bytes), d. VD (ASCII decimal format)(positive,

negative, decimal,..)) and the communication format is not compatible, therefore, it is needed to ensure

the HMI communication data format is correct, or an error may occur.

2) Registers: only can read/write the data of ASCII hexadecimal format (VH), ASCII decimal format (VD)

(i.e. Either VH or VD data format can be set via communication.)

Contacts: only can read/write the data of ASCII hexadecimal format (VH)

HMI display data format (Property table/Setting value...etc.) should also be correct.

Explanation:

y Registers: only can read/write the data of VH, VD. HMI needs to set communication data format

(please refer to 4), 5) and 6)). String format (VS), and Octet string format for data blocks (VO) can

not be used. If the controller returns the data in VS or VO format, HMI will show “……Value Is

Incorrect” on the screen.

y Contacts: only can read/write the data of ASCII hexadecimal format (VH). Only VH type parameter

can provide Bit read/write function. If the controller returns the data in other format, HMI will show

“……Value Is Incorrect” on the screen.

y Do not write the inexistent Bit address, or HMI will show “….Write …. Command Can Not be

Executed” on the screen.

For example: CW470/1. The valid value of CW470/1 is within the range of 0 ~ 0xFF. Therefore, Bit

8 ~31 is not existed. Although HMI will show the value of Bit 8 ~31 is 0, the user can not write or set

the value.

y The settings of ASCII hexadecimal format (VH) and ASCII decimal format (VD) should be correct. If

the VD data is set in VH format in HMI (m value is undefined, or m=22 or 23) or the VH data is set

in VD format in HMI (m=0 ~ 21), when HMI write the data, HMI will show “….Write …. Command

Can Not be Executed” on the screen or tell the user the write value is incorrect.

y The decimal place of ASCII decimal format (VD) should be set correctly, or the write value will not

be correct. The decimal place displayed on HMI should also be correct, or the display value will be

incorrect.

y ASCII hexadecimal format (VH), 2 numbers (m = 22). The value is limited to 2 numbers. Using this

format the write value will be limited within the range of 0 ~ 0xFF (low byte) automatically.

3) Station Number and Broadcast

y The valid station number is from 0 to 99. If exceeds this range, HMI will stop read/write operation

and show “Controller Station Number Error …”on the screen.

1-54 Revision January, 2008, Doc. Name: 2007PDD23000007

Page 56

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

y 00 indicates the global broadcasting number (1~99).

y 10, 20, 30, 40, 50, 60, 70, 80, 90 are local broadcasting number.

The affected ranges are: 11~19, 21~29, 31~39, 41~49, 51~59, 61~69, 71~79, 81~89 and 91~99

respectively. Only choose setting value/setting constant (button), and then the broadcast function

can be used. If choosing other devices, the system will be confused while reading back the drive

setting value via broadcast function, so please ensure to choose the correct device. If choosing the

incorrect devices, a “Controller Station Number Error…” fault message will display on HMI screen.

y Use in LECOM-A/B protocol. 82XX frequency AC drives and 93XX servo drives all use this protocol.

4) Explanation of communication error address

y Registers: display CW n, CWy n, CD n, CDy n in order

y Contacts: display CB n, CByn in order (n: address value)

5) HMI data format explanation

y Some controller parameters are in Word and some are in Double Word. Therefore, there are two

kinds of data format: Word ( CWn (CWn.m), CWn/y(CWn/y.m) ) and Double Word ( CDn (CDn.m),

CDn/y(CDn/y.m) ).

y Furthermore, regarding to Bit No., HMI only read/write 32Bit (Bit0 ~ Bit31) of parameters in VH

format.

y CWn(CWn.m), CDn(CDn.m), or CBn.b: read/write address is the same (address n), but

When symbol is set to CW, read/write value is the low word of parameters (n) only,

When symbol is set to CD, read/write value is the Double Word of whole parameters (n),

When symbol is set to CB, read/write value is the Bit (b) No. of parameters (n).

(m : HMI communication data format)

y (CWn/y(CWn/y.m), CDn/y(CDn/y.m), CBn/y.b: read/write address, which y subcode is the

same(address n), but

When symbol is set to CW, read/write value is the low word of parameters (n) only,

When symbol is set to CD, read/write value is the Double Word of whole parameters (n),

When symbol is set to CB, read/write value is the Bit (b) No. of parameters (n).

(m : HMI communication data format)

y Actually when using HMI,

i) When using devices that the unit is in Word (e.g. numeric devices (numeric value display,

numeric value input…)…), the read/write value will be the same no matter the read/write

address format is set to CWn or CDn as read/write value is the low word of parameters (n)

only.

ii) When using devices that the unit is in Double Word (e.g. numeric devices (numeric value

display, numeric value input…)…), if the read/write address format is set to CWn,

read/write value is coming from the low word of CWn and CWn+1 these two addresses.

(The low word of CWn is regarded as “low word” and the low word of CWn+1 is regarded

as “high word”, and then combining “low word” and “high word” to a Double Word.)

Revision January, 2008, Doc. Name: 2007PDD23000007 1-55

Page 57

Delta DOP Series HMI Connection Manual|DOP-A/AE/AS Series

If the read/write address format is set to CDn, read/write value is the whole Double Word

of CDn (1 address).

iii) When using character device (e.g. character display, character input…), if the read/write

address format is set to CWn, the read/write value is coming from the low word of CWn,

CWn+1, CWn+2, …every address.

If the read/write address format is set to CDn, read/write value is the whole Double Word

of CDn, CDn+1, CDn+2,…every address.

iv) When using “Multiple Duplicate” function, if the Word and Bit addresses exceed the valid

range, the Word and Bit addresses will be set to 0 automatically. Sometime error will

occur to remind the user when compiling.

v) CBn.b, CBn/y.b are added for the user to read and write Bit No. of parameters in VH

format more easily.

vi) Only can read or write 1 parameter for each communication.

C. Connections (Connector Pinouts)

Pin 2, 3, 5 are for RS-232 communication. Pin 7, 8 are for RS-485 communication.

RS-232

DOP

9 pin D-SUB male (RS-232)

9 pin D-SUB male (RS-232)

Controller

RXD (2) (3) TXD

TXD (3)

GND (5)

RS-485

DOP