Page 1

http://www.delta.com.tw/industrialautoma tion/

Extension Ethernet Module

Instruction Sheet

Warning

3 Please read this instruction carefully before use.

3 This instruction provides the information of specifications, installation and basic operation and settings.

Regarding the Ethernet Networking protocols supported by DOP-EXLNHJ1AE, there is no detailed

information available on this instruction. If the users need complete information of Ethernet Networking

protocols, please refer to relevant professional articles and books.

3 DOP series Extension Ethernet Module should be used with DOP-AE series HMI product. Ensure to

switch off the power before wiring.

3 Please install this DOP series Extension Ethernet Module in an enclosure free of airborne dust, humidity,

electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the

device (e.g. key or specific tools are required for opening the enclosure) in case danger and damage on

the device may occur.

3 DO NOT touch any internal circuit in 1 minute after the power is switched off. Do NOT touch any

terminal when the power is switched on.

3 Make sure the ground terminal

interference.

3 DO NOT place any heavy objects on the connection port of DOP series Extension Ethernet Module.

Doing so may damage the product.

is correctly grounded in order to prevent electromagnetic

X Introduction

1.1 Model Explanation

1.2 Product Outline

1

DOP - EXLNHJ 1 AE

(1) (2) (3) (4)

(1) Product Name DOP: Delta Operation Panel

(2) Series EXLNHJ: Extension Ethernet Module

(3) Version

(4) Applicable HMI Series AE: DOP-AE Series HMI

3

4

Z Installation & Wiring

3.1 Installtion

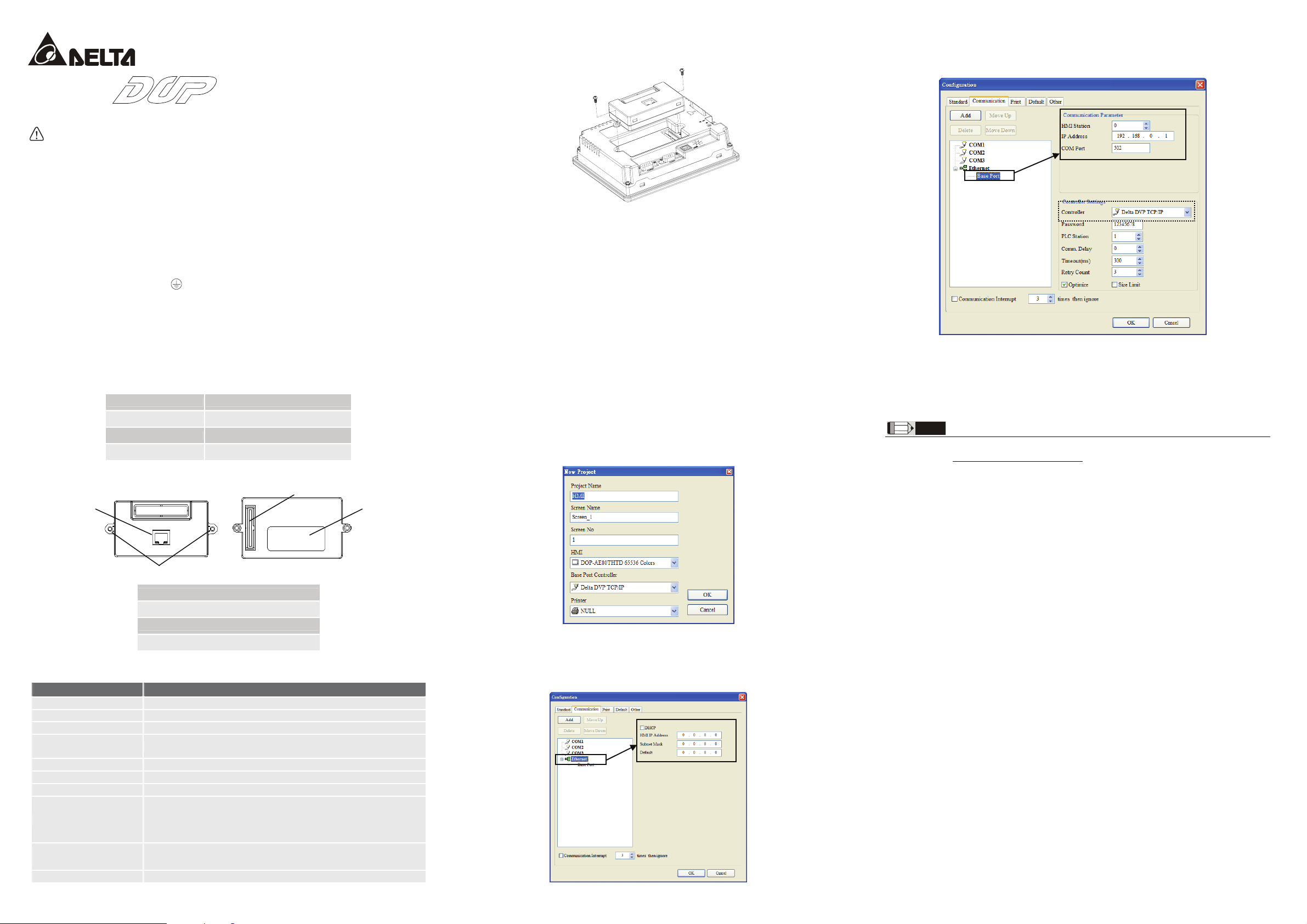

2. Clicking Base Port option can set IP address of the connecting controller on right side of the window. If

the connecting controller is not Delta DVP series PLC, the users can change Delta DVP TCP/IP to

Modbus TCP/IP by using the Controller drop-down list.

Wiring Note

1. Please avoid any conductive debris and tiny metal materials enter the Extension Ethernet Module when

screwing and wiring.

2. Allow a minimum space of 50mm between the Extension Ethernet Module and other control devices, and

keep the Extension Ethernet Module away from the high-voltage lines or any power equipment.

3.2 Caution

Environment

1. DO NOT install the Extension Ethernet Module in a place subjected to corrosive or flammable gases, liquids,

or airborne dust or metallic particles.

2. DO NOT install the Extension Ethernet Module in a location high temperature and high humidity (where

temperature and humidity will exceed specification).

3. DO NOT install the Extension Ethernet Module in a location where vibration and shock will exceed

specification.

[ Software Settings

Activate Delta Screen Editor software program. Under Application Name choose a name to save.

Under HMI choose a AE series HMI. Under Base Port Control choose Delta DVP TCP/IP.

3. After completing all settings, please click Ok button to save the settings and start to edit the screen data

of HMI.

NOTE

1) The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the most

updated version at http://www.delta.com.tw/industrialautomation.

2

1. Connection Port for Ethernet

2. Direct Mounting Hole

3. Connection Port for Extension Module

4. Nameplate

Y Function Specifications

Item DOP-EXLNHJ1AE

Power Supply Voltage DC 5V +/-10%, 1A (provided by HMI)

Interfaced Supported RJ-45 with Auto MDI/MDIX

Number of Ports 1 Port

Transmission Method

(Standard Conformance)

Transmission Cable Category 5e (TIA/EIA-568-A, TIA/EIA-568-B)

Transmission Speed 10/100 Mbps Auto Detection

Ethernet Protocol ICMP, IP, TCP, UDP, DHCP, Modbus TCP

Noise Immunity

Operation / Storage

Environment

Vibration / Shock Resistance Standards: IEC61131-2, IEC 68-2-6 / IEC61131-2 & IEC 68-2-27

IEEE 802.3, IEEE 802.3u

ESD (IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge

EFT (IEC 61131-2, IEC 61000-4-4): Power Line: 2KV, Communication I/O: 1KV

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV

RS (IEC 61131-2, IEC 61000-4-3): 26MHz ~ 1GHz, 10V/m

Operation: 0 oC~50 oC (Temperature), 10%~85% (Humidity), Pollution Degree 2

Storage: -40 oC~85 oC (Temperature), 5%~85% (Humidity)

Settings of DOP-EXLNHJ1AE

1. Select Options > Configuration and click Communication tab. The users can choose Ethernet option

and set HMI IP address on right side of the window. If connecting to a DHCP Server, the users can select

DHCP to get network configuration automatically when the DHCP console starts. If Static IP address is

used, the users need to complete network configuration manually.

Loading...

Loading...