Page 1

Page 2

V E 0 5

5011608405

2016-04

Page 3

Page 4

VFD-V Series

Preface

Thank you for choosing DELTA’s high-performance VFD-V Series. VFD-V Series

are manufactured by adopting high-quality components, material and incorporating the

latest microprocessor technology available.

Getting Started

This manual will be helpful in the installation, parameter setting, troubleshooting, and daily

maintenance of the AC motor drives. To guarantee safe operation of the equipment, read

the following safety guidelines before connecting power to the AC drives. Keep this

operating manual handy and distribute to all users for reference.

!

WARNING

!

Always read this manual thoroughly before using VFD-V series AC Motor Drives.

!

DANGER! AC input power must be disconnected before any maintenance. Do not

connect or disconnect wires and connectors while power is applied to the circuit.

Maintenance must be performed by qualified technicians.

!

CAUTION! There are highly sensitive MOS components on the printed circuit boards.

These components are especially sensitive to static electricity. To avoid damage to

these components, do not touch these components or the circuit boards with metal

objects or your bare hands.

!

DANGER! A charge may still remain in the DC-link capacitor with hazardous voltages

even if the power has been turned off. To avoid personal injury, please ensure that

power has turned off before operating AC drive and wait ten minutes for capacitors to

discharge to safe voltage levels.

!

CAUTION! Ground the VFD-V using the ground terminal. The grounding method must

comply with the laws of the country where the AC drive is to be installed. Refer to Basic

Wiring Diagram.

!

DANGER! The AC drive may be destroyed beyond repair if incorrect cables are

connected to the input/output terminals. Never connect the AC drive output terminals

U/T1, V/T2, and W/T3 directly to the AC main circuit power supply.

!

CAUTION! The final enclosures of the AC drive must comply with EN50178. (Live parts

shall be arranged in enclosures or located behind barriers that meet at least the

requirements of the Protective Type IP20. The top surface of the enclosures or barrier

that is easily accessible shall meet at least the requirements of the Protective Type

IP40). (VFD-V series corresponds with this regulation.)

CAUTION! Heat sink may heat up over 70oC (158oF), during the operation. Do not

touch the heat sink.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 5

VFD-V Series

CHAPTER 1 RECEIVING AND INSPECTION

1.1 Nameplate Information ...........................................................................................1 - 1

1.2 Model Explanation..................................................................................................1 - 1

1.3 Serial Number Explanation.....................................................................................1 - 2

CHAPTER 2 STORAGE AND INSTALLATION

2.1 Storage...................................................................................................................2 -1

2.2 Installation ..............................................................................................................2 -2

CHAPTER 3 WIRING

3.1 Basic Wiring Diagram .............................................................................................3 - 2

3.2 External Wiring .......................................................................................................3 - 5

3.3 Main Circuit Terminal Explanations.........................................................................3 - 6

3.4 Control Terminal Explanations ................................................................................3 - 6

3.5 Component Explanations .......................................................................................3 - 8

3.6 Wiring Notice ..........................................................................................................3 - 1 4

CHAPTER 4 DIGITAL KEYPAD (VFD-PU05) OPERATION

4.1 Description of the Digital Keypad VFD-PU05 .........................................................4 - 1

4.2 Explanations of Display Messages.........................................................................4 - 1

4.3 Operation steps of the Digital Keypad VFD-PU05 ..................................................4 - 3

CHAPTER 5 DESCRIPTION OF PARAMETER SETTINGS

5.1 Group 0: System Parameter...................................................................................5 - 1

5.2 Group 1: Basic Parameter ......................................................................................5 - 1 3

5.3 Group 2: Digital Output/Input Parameter ................................................................5 - 1 8

5.4 Group 3: Analog Output/Input Parameter ...............................................................5 - 2 7

5.5 Group 4: Multi-Step Speed and Procedural Operation Parameter..........................5 - 3 5

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 6

VFD-V Series

5.6 Group 5: Motor Modulation Parameter ...................................................................5 - 4 0

5.7 Group 6: Protection Parameter...............................................................................5 - 4 5

5.8 Group 7: Special Parameter ...................................................................................5 - 5 2

5.9 Group 8: High-Performance Parameter..................................................................5 - 5 8

5.10 Group 9: Communication Parameter....................................................................5 - 6 2

5.11 Group 10: Speed Feedback Parameter ................................................................5 - 7 3

CHAPTER 6 MAINTENANCE AND INSPECTIONS.......................................................6 - 1

CHAPTER 7 TROUBLESHOOTING...............................................................................7 - 1

CHAPTER 8 PARAMETER SUMMARY.........................................................................8 - 1

APPENDIX A SPECIFICATIONS ...................................................................................A - 1

APPENDIX B ACCESSORIES .......................................................................................B - 1

B.1 Fuse Specification Chart ........................................................................................B - 1

B.2 Braking Resistors...................................................................................................B - 3

B.3 AMD - EMI Filter Cross Reference.........................................................................B - 7

B.4 PG Card .................................................................................................................B - 1 3

B.5 Zero Phase Reactor...............................................................................................B - 17

APPENDIX C DIMENSIONS...........................................................................................C - 1

APPENDIX D EC DECLARATION OF CONFORMITY ..................................................D - 1

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 7

Page 8

1

VFD-V Series

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

1-1

CHAPTER 1 RECEIVING AND INSPECTION

This VFD-V AC drive has gone through rigor ous quality control tests at the factory before

shipment. After receiving the AC dr ive, pleas e check f or th e follow ing:

Receiving

Check to make sure that the package includes an AC drive, the User Manual, dust

covers and rubber bushings.

Inspect the unit to insure it was not damaged during shipment.

Make sure that the part number indicated on the nameplate corresponds with the part number

of your order.

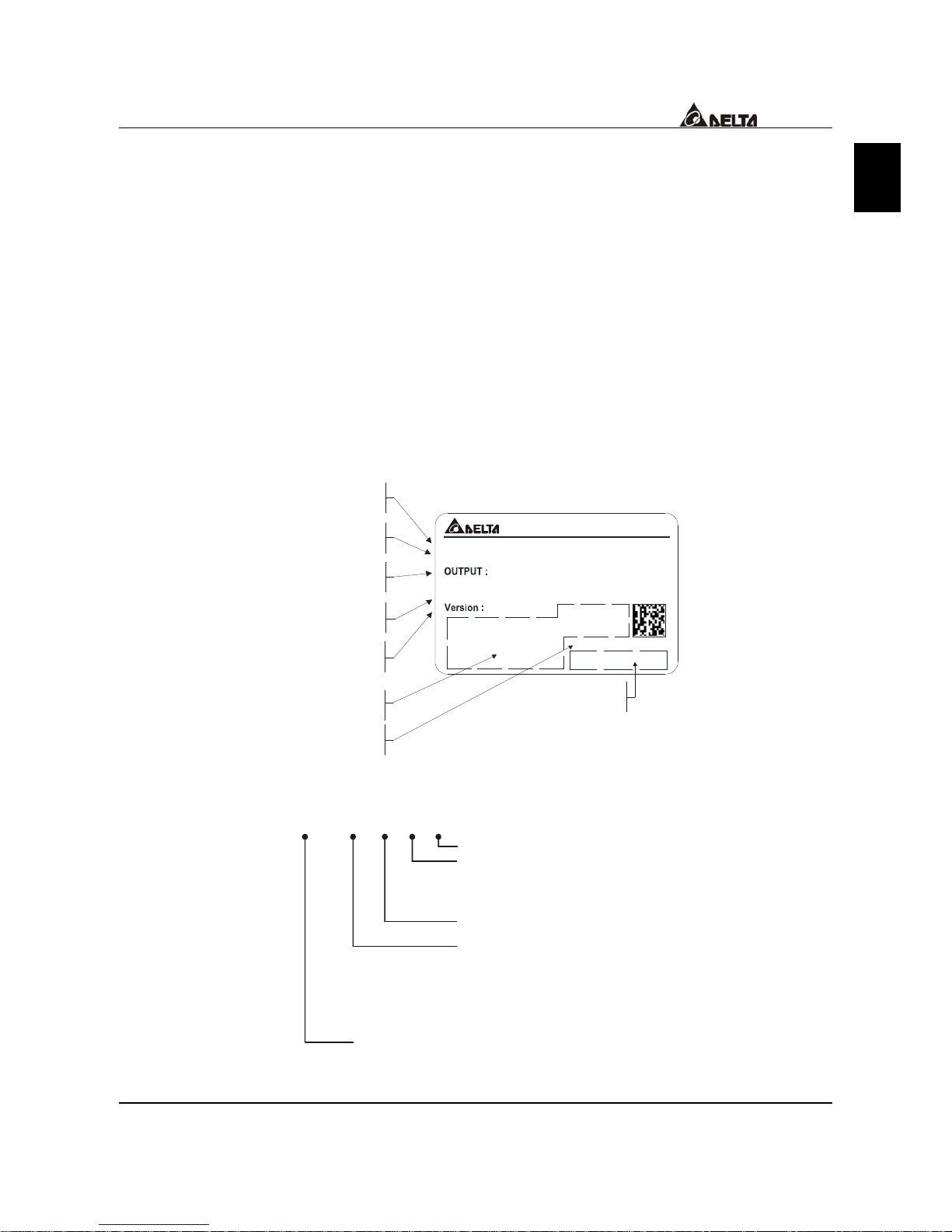

1.1 Nameplate Information → Example for 5HP/3.7kW 230V 3-Phase

037V23A0T00010123

DELTA ELE CTRONI CS, INC.

MODEL: VFD037V23A-2

3PH 200-24 0V 50/60 Hz 21.2A

INPUT:

3PH 0-240V 17A 6.5KVA 5HP

0-600H z

XX.XX

國際認證標示區;

國際認證標示區;

Certifications

序號;

序號;

Ser

ia l num be

r

機種名稱;

機種名稱;

Model name

輸入端電壓/電流範圍;

輸入 端電 壓/電流範 圍;

Input voltage/current

輸出端電壓/電流範圍;

輸出端電壓/電流範圍;

Output voltage/current

頻率範圍;

頻率範圍;

Frequency range

韌體版本;

韌體版本;

Firmware version

生產識別;

生产识别;

Product identi ficatio n

FREQUENCY RANGE:

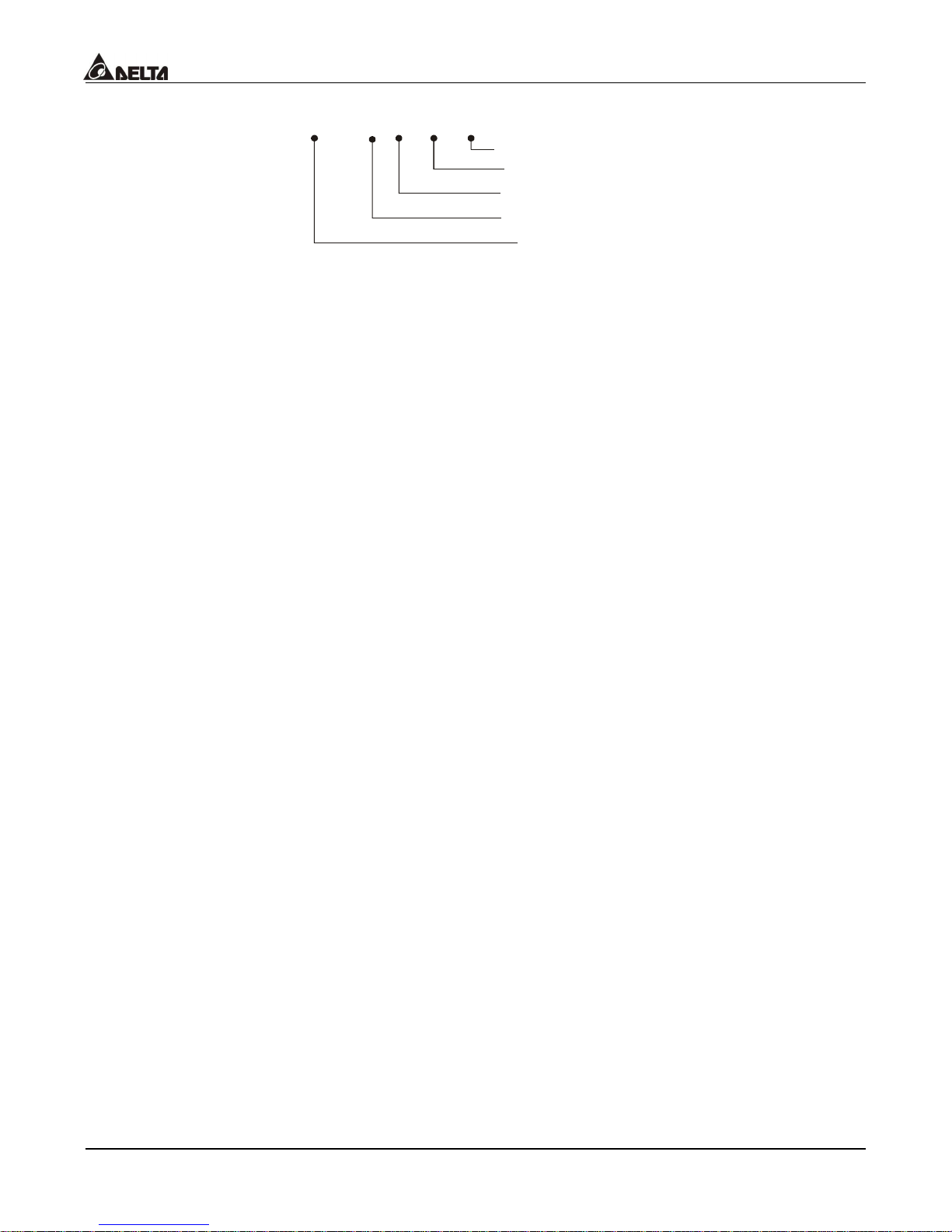

1.2 Model Explanation

VFD 037 V 23 A

Version Type

Input Voltage

23: 230 V 3- PHASE

43: 460 V 3- PHASE

VFD-V Series

Series Name

Applicable Motor Capacity

007:1 HP(0.75kW) 015:2HP(1.5kW)

022:3 HP(2.2kW) 037:5HP(3.7kW)

055:7 .5HP(5.5kW) 075:10HP(7.5kW)

110:15HP(11kW) 150:20HP(15kW)

185:2 5 HP(18.5kW) 220:30HP(22kW)

300:40HP(30kW) 370:50HP(37kW)

450:6 0 HP(45kW) 550: 75HP(55kW)

750:100H P(75kW)

Page 9

VFD-V Series

2

1.3 Serial Number Explanation

037V23A0T 0 10 9999

Production Number

Production Week

Production Year

Production Factory

Production Model

30V 3-PHASE 5HP(3.7kW)

●Please contact the dealers immediately should any discrepancy occurred.

1-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 10

VFD-V Series

CHAPTER 2 STORAGE AND INSTALLATION

2.1 Storage

The AC drive should be kept in the shipping carton before installation. In order to retain the

warranty coverage, the AC drive should be stored properly when it is not to be used for an

extended period of time.

Ambient Conditions:

2

Operation

Storage

Transportation

Air Temperature: -10

o

C to +40oC (14oF to 104oF)

+50oC (122oF) without dust cover.

Atmosphere pressure: 86 to 106 kPa

Installation Site Altitude: below 1000m

Vibration: Maximum 9.80 m/s2 (1G) at less than 20Hz

Maximum 5.88 m/s2 (0.6G) at 20Hz to 50Hz

Temperature: -20oC to +65oC (-4oF to 149oF)

Relative Humidity: Less than 90%, no condensation allowed

Atmosphere pressure: 86 to 106 kPa

Temperature: -20oC to +60oC (-4oF to 140oF)

Relative Humidity: Less than 90%, no condensation allowed

Atmosphere pressure: 86 to 106 kPa

Vibration: Maximum 9.80 m/s2 (1G) at less than 20Hz, Maximum 5.88

2

(0.6G) at 20Hz to 50Hz

m/s

Pollution Degree 2: good for a factory type environment.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

2-1

Page 11

VFD-V Series

A

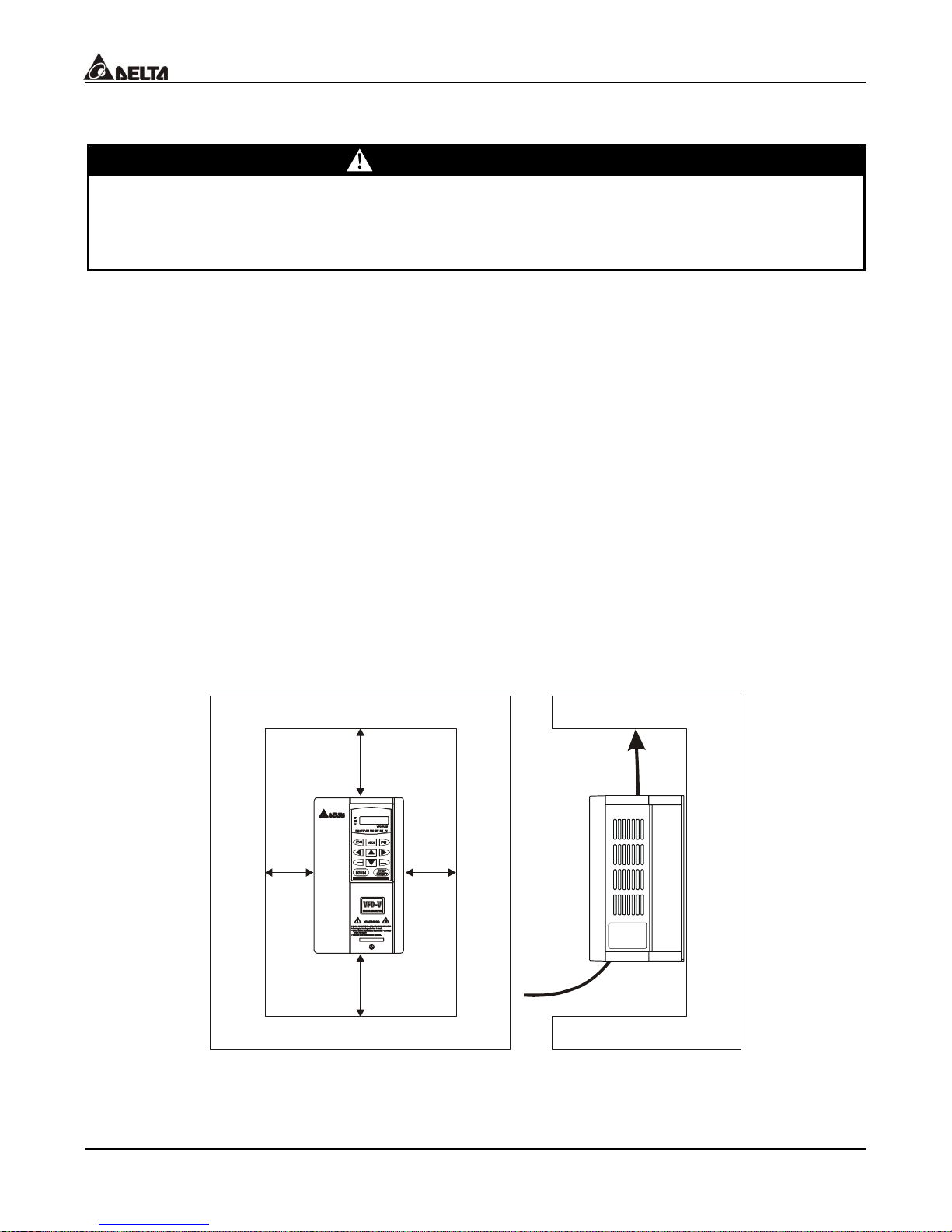

2.2 Installation

CAUTION

The control, power supply and motor leads must be laid separately. They must not be

fed through the same cable conduit / trunking.

High voltage insulation test equipment must not be used on cables connected to the

drive.

Improper installation of the AC drive will greatly reduce its life. Be sure to observe the

following precautions when selecting a mounting location.

Failure to observe these precautions may void the warranty!

Do not mount the AC drive near heat-radiating elements or in direct sunlight.

Do not install the AC drive in a place subjected to high temperature, high humidity,

excessive vibration, corrosive gases or liquids, or airborne dust or metallic particles.

Mount the AC drive vertically and do not restrict the air flow to the heat sink fins.

The AC drive generates heat. Allow sufficient space around the unit for heat dissipation.

120mm

5

0

m

m

FWD

PROG

REV

DATA

120mm

5

0

m

m

ir Flow

2-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 12

VFD-V Series

CHAPTER 3 WIRING

DANGER

Hazardous Voltage

Before accessing the AC drive:

Disconnect all power to the AC drive.

Wait five minutes for DC bus capacitors discharge.

Any electrical or mechanical modification to this equipment without prior written

consent of Delta Electronics, Inc. will void all warranties and may result in a safety

hazard in addition to voiding the UL listing.

Short Circuit Withstand:

The rated voltage must be equal to or less than 240V (460V model is 480Volts) and the current

must be equal to or less than 5000A RMS. (the model of 51HP or above is 10000A RMS)

3

General Wiring Information

Applicable Codes

VFD-V AC drives (007V23/43A, 015V23/43A, 022V23/43A, 037V23/43A, 055V23/43A,

075V23/43A, 110V43B, 110V23/43A, 150V23/43A, 185V23/43A, 220V23/43A, 300V23/43A,

370V23/43A, 450V43A) are Underwriters Laboratories, Inc. (UL) and Canadian Underwriters

Laboratories (cUL) listed, and therefore comply with the requirements of the National Electrical

Code (NEC) and the Canadian Electrical Code (CEC).

Installation intended to meet the UL and cUL requirements must follow the instructions

provided in “Wiring Notes” as a minimum standard. Follow all local codes that exceed UL and

cUL requirements. Refer to the technical data label affixed to the AC drive and the motor

nameplate for electrical data.

The "Line Fuse Specification" in Appendix B, lists the recommended fuse part number for each

V-Series part number. These fuses (or equivalent) must be used on all installations where

compliance with U.L. standards is a required.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-1

Page 13

VFD-V Series

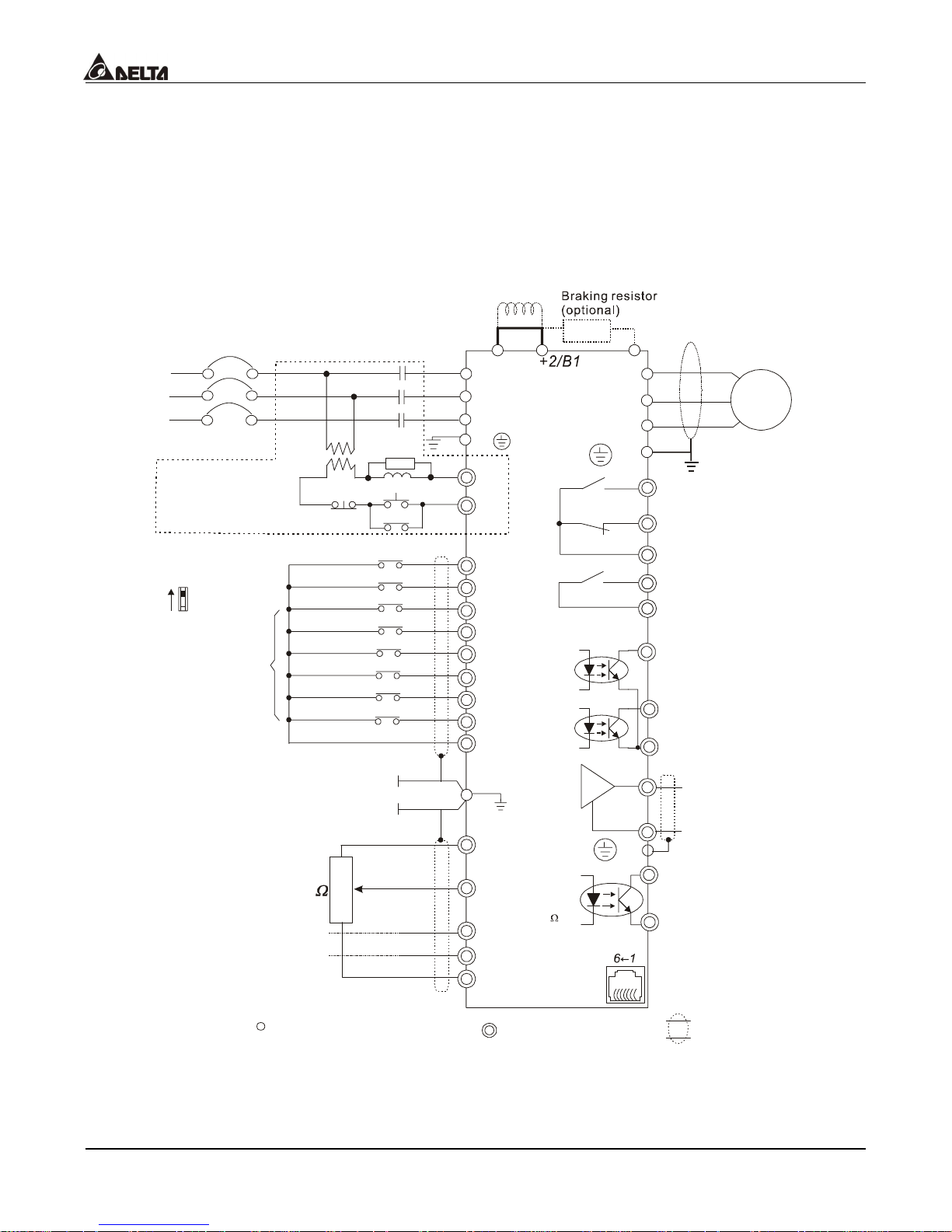

3.1 Basic Wiring Diagram

For wiring of the inverter, it is divided into the main circuit and the control circuit. Users

could open the case cover, and could inspect the main circuit terminal and the control circuit

terminal; users connect the circuit in compliance with the following wiring method.

The following diagram is the standard wiring diagram for the VFD-V inverter.

Wiring Diagram 1

10HP(7.5kW) and below

DC choke

(optional)

MC

Jumper

R/L1

S/L2

T/L3

E

RB

RC

MC

+24V

FWD

REV

MI1

MI2

MI3

MI4

MI5

MI6

DCM

Shield terminal

Power supply

+10V 20mA

Master Frequency

0 to 10V 47 K

ACI

AUI

ACM

+1

+10V

AVI

MO1

MO2

B2

U/T1

V/T2

W/T3

E

RA

RB

RC

MRA

MRC

MCM

AFM

ACM

DFM

DCM

Motor

IM

3~

Please refer to ontrol

Terminal Explanation?

Factory setting:

Operation Indication

Multi-function Photocoupler

Output 48VDC 50mA

Factory default:

Frequency-Achieving Indication

Factory default:

Driver-Ready Indication

Photocoupler Common

Output Terminal

Multi-function Analog Output

Te r mi na l

Factory default: Output

Frequency 0~ 10VDC/2mA

Analog Signal common

E

Digital Frequency Output

Te r mi na l

Factory default: 1:1

Duty=50% 10VDC

Digital Signal Common

RS-485

Serial interface

1: +EV 2: GND

5:NC

4: SG+

6: NC

3: SG-

Fuse/NFB(None Fuse Breaker)

R/L1

S/L2

T/L3

Recommended Circuit

when power supply

is turned OFF by a

fault output

Factory Default:

SINK Mode

Sink

Sw1

Source

Please refer to wiring

of SINK mode and

SOURCE mode.

Factory

default

* Don input voltage directly

to the above signals.

OFF

FWD/STOP

REV/STOP

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

Multi-step 5

Multi-step 6

Digital Signal Common

3

5K

Analog Signal Common

2

1

SA

ON

4~20mA

-10~+10V

Main circuit (power) terminals

Control circuit terminals

3-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Shielded leads & Cable

Page 14

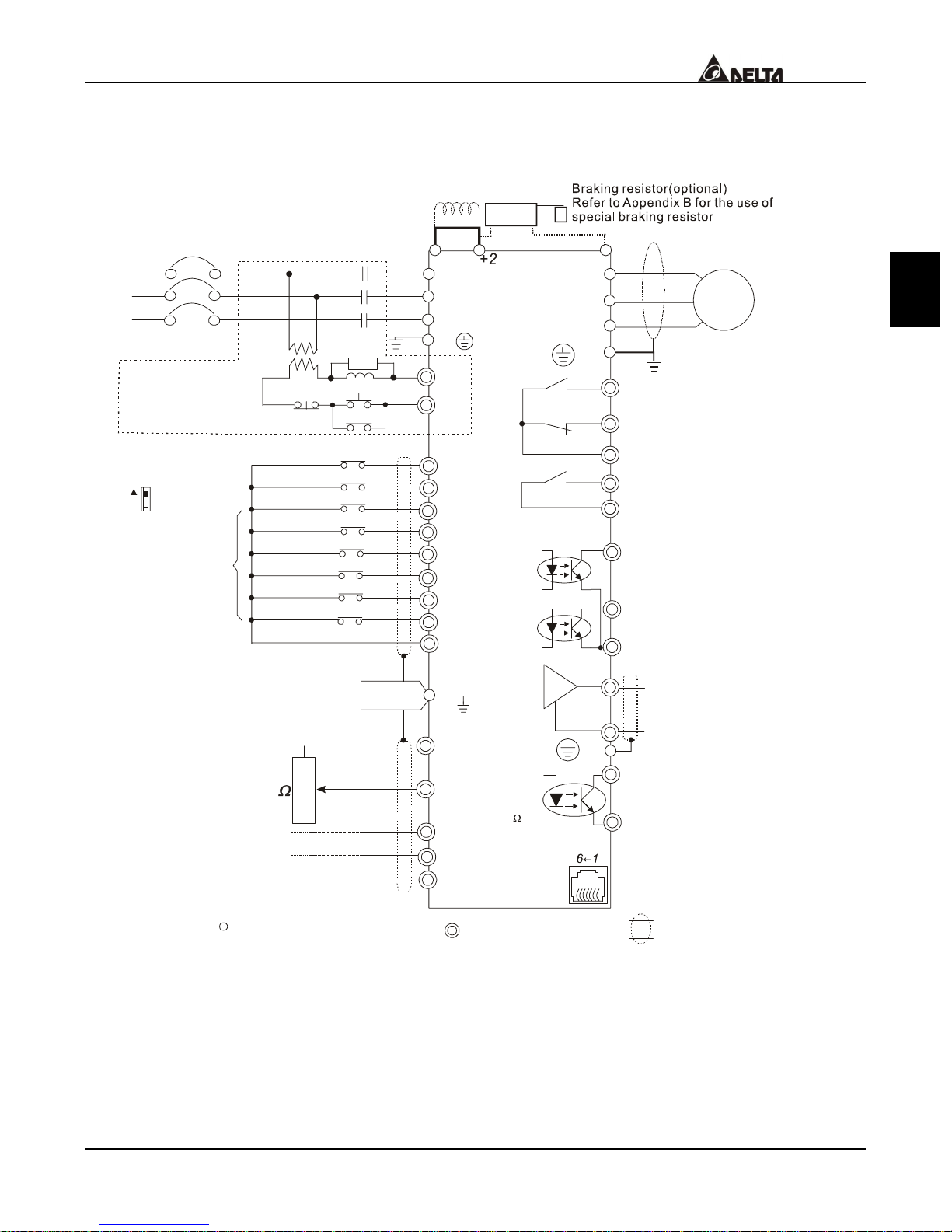

Wiring Diagram 2

15HP(11kW) and above

Fuse/NFB(None Fuse Breaker)

R/L1

S/L2

T/L3

Recommended Circuit

when power supply

is turned OFF by a

fault output

Factory Default:

SINK Mode

Sink

Sw1

Source

Please refer to wiring

of SINK mode and

SOURCE mode.

Factory

default

* Don input voltage directly

to the above signals.

FWD/STOP

REV/STOP

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

Multi-step 5

Multi-step 6

Digital Signal Common

5K

Analog Signal Common

OFF

3

2

1

-10~+10V

DC chock

(optional)

Jumper

SA

MC

ON

4~20mA

+1

R/L1

S/L2

T/L3

E

RB

RC

MC

+24V

FWD

REV

MI1

MI2

MI3

MI4

MI5

MI6

DCM

Shield terminal

+10V

Power supply

+10V 20mA

AVI

Master Frequency

0 to 10V 47 K

ACI

AUI

ACM

VFDB

-(minus sign)

MO1

MO2

U/T1

V/T2

W/T3

E

RA

RB

RC

MRA

MRC

MCM

AFM

ACM

DFM

DCM

Motor

IM

3~

Please refer to ontrol

Terminal Explanation?

Factory setting:

Operation Indication

Multi-function Photocoupler

Output 48VDC 50mA

Factory default:

Frequency-Achieving Indication

Factory default:

Driver-Ready Indication

Photocoupler Common

Output Terminal

Multi-function Analog Output

Te r mi na l

Factory default: Output

Frequency 0~ 10VDC/2mA

Analog Signal common

E

Digital Frequency Output

Te r mi na l

Factory default: 1:1

Duty=50% 10VDC

Digital Signal Common

RS-485

Serial interface

1: +EV 2: GND

5:NC

4: SG+

6: NC

3: SG-

VFD-V Series

3

Main circuit (power) terminals

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Control circuit terminals

3-3

Shielded leads & Cable

Page 15

VFD-V Series

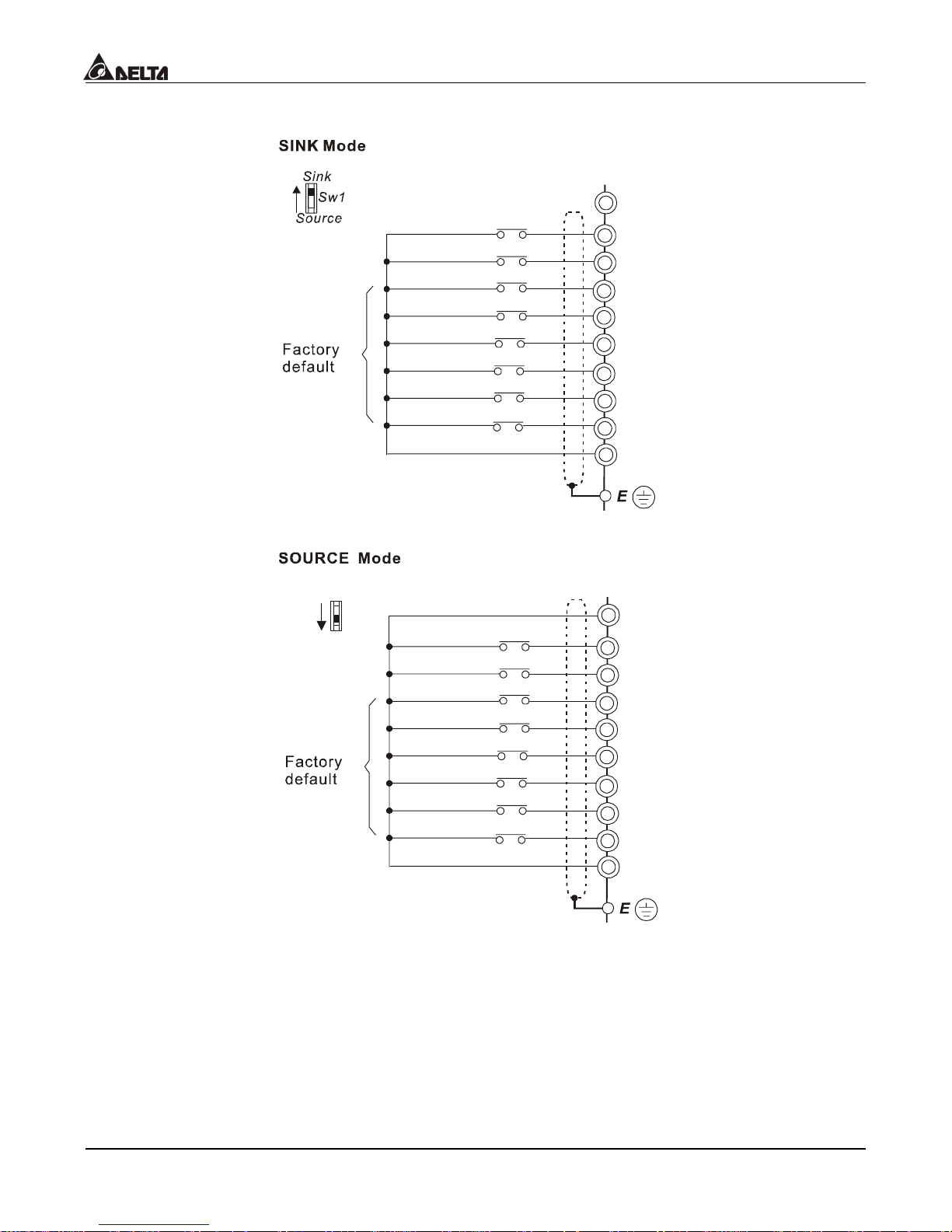

Wiring of SINK mode and SOURCE mode

FWD/STOP

REV/STOP

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

Multi-step 5

Multi-step 6

Digital Signal Common

+24V

FWD

REV

MI1

MI2

MI3

MI4

MI5

MI6

DCM

Sink

Sw1

Source

FWD/STOP

REV/STOP

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

Multi-step 5

Multi-step 6

Digital Signal Common

+24V

FWD

REV

MI1

MI2

MI3

MI4

MI5

MI6

DCM

3-4

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 16

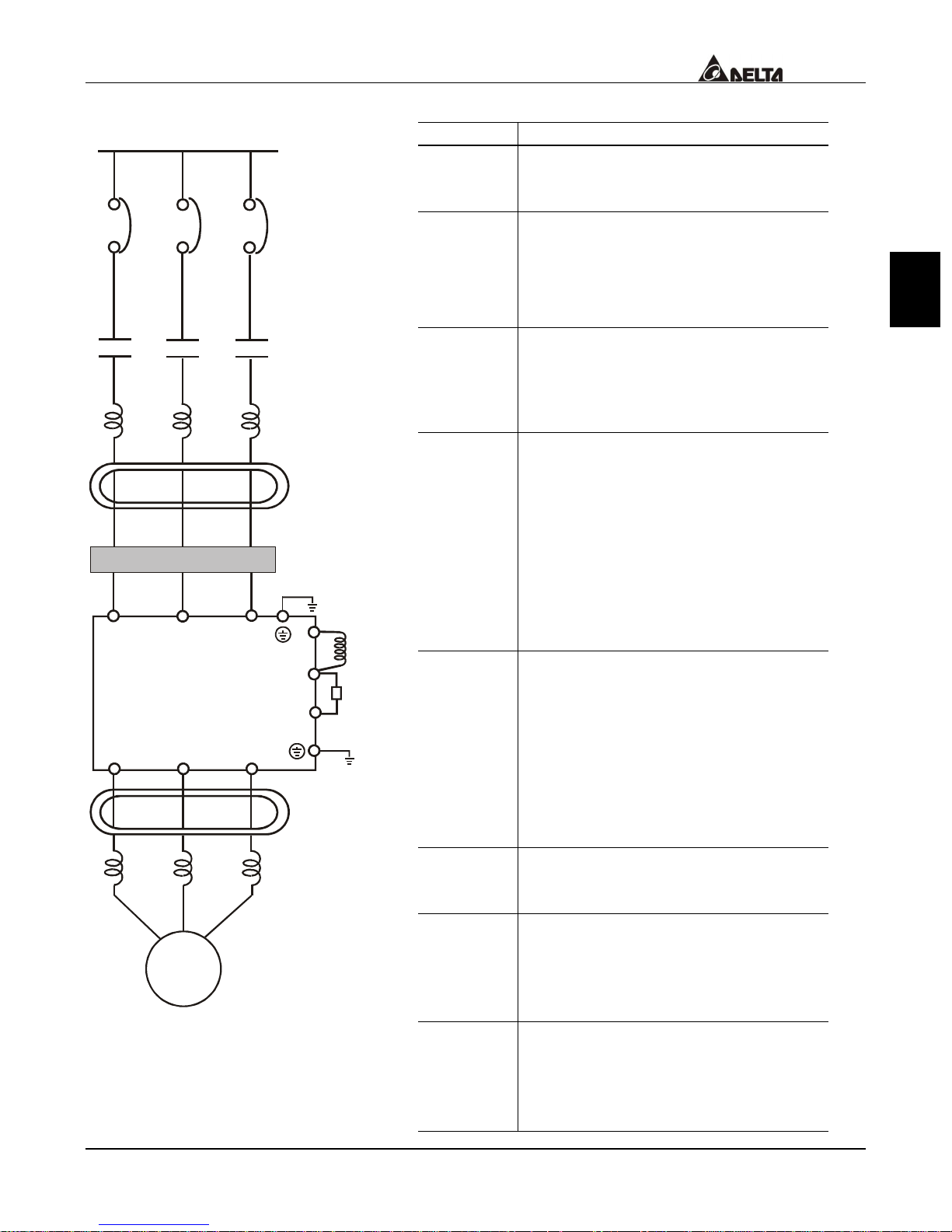

3.2 External Wiring

VFD-V Series

Power Supply

EMI Filter

R/L1 S/L2

U/T1 V/T2

T/L3

W/T3

FUSE/NFB

Magnetic

contactor

Input AC

Line Reactor

Zero-phase

Reactor

+1

+2/B1

B2

Zero-phase

Reactor

Output AC

Line Reactor

DC

Choke

Braking

Resistor

Items Explanations

Power

supply

Please follow the specific power

supply requirement shown in

APPENDIX-A.

There may be inrush current during

Fuse/NFB

power up. Please check the chart of

APPENDIX B and select the correct

(Optional)

fuse with rated current. NFB is

optional.

Magnetic

contactor

(Optional)

Please do not use a Magnetic

contactor as the I/O switch of the AC

drive, this will reduce the operating

life cycle of the AC drive.

In order to improve the input power

factor, reduces harmonics and

protection from AC line

Input AC

Line

Reactor

(Optional)

disturbances. (Surge, switching

spike, power flick, etc.) AC line

reactor should be installed when the

power supply capacity is 500kVA or

more and exceeds 6 times of the

inverter capacity, or the wiring

distance within 10m.

Zero phase reactors are used to

Zero-phase

Reactor

(Ferrite

Core

Common

Choke)

(Optional)

reduce radio noise specify when the

audio equipments installed near the

inverter. Good effective for noise

reduction on both the input and

output sides. Attenuation quality is

good in a wide range from AM band

to 10Mhz. Appendix B for specifies

zero phase reactors. (RF220X00A)

EMI filter

(Optional)

To reduce the electromagnetic

interference. Please refer to

Appendix B for detail.

3

Motor

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Braking

Resistor

(Optional)

Output AC

Line

Reactor

(Optional)

3-5

Used to reduce stopping time of the

motor. Please refer to the chart on

Appendix B for specific Braking

Resistors.

Motor surge voltage amplitudes

depending on the motor cable

length. For long motor cable

application, it is necessary installed

on the inverter output side.

Page 17

VFD-V Series

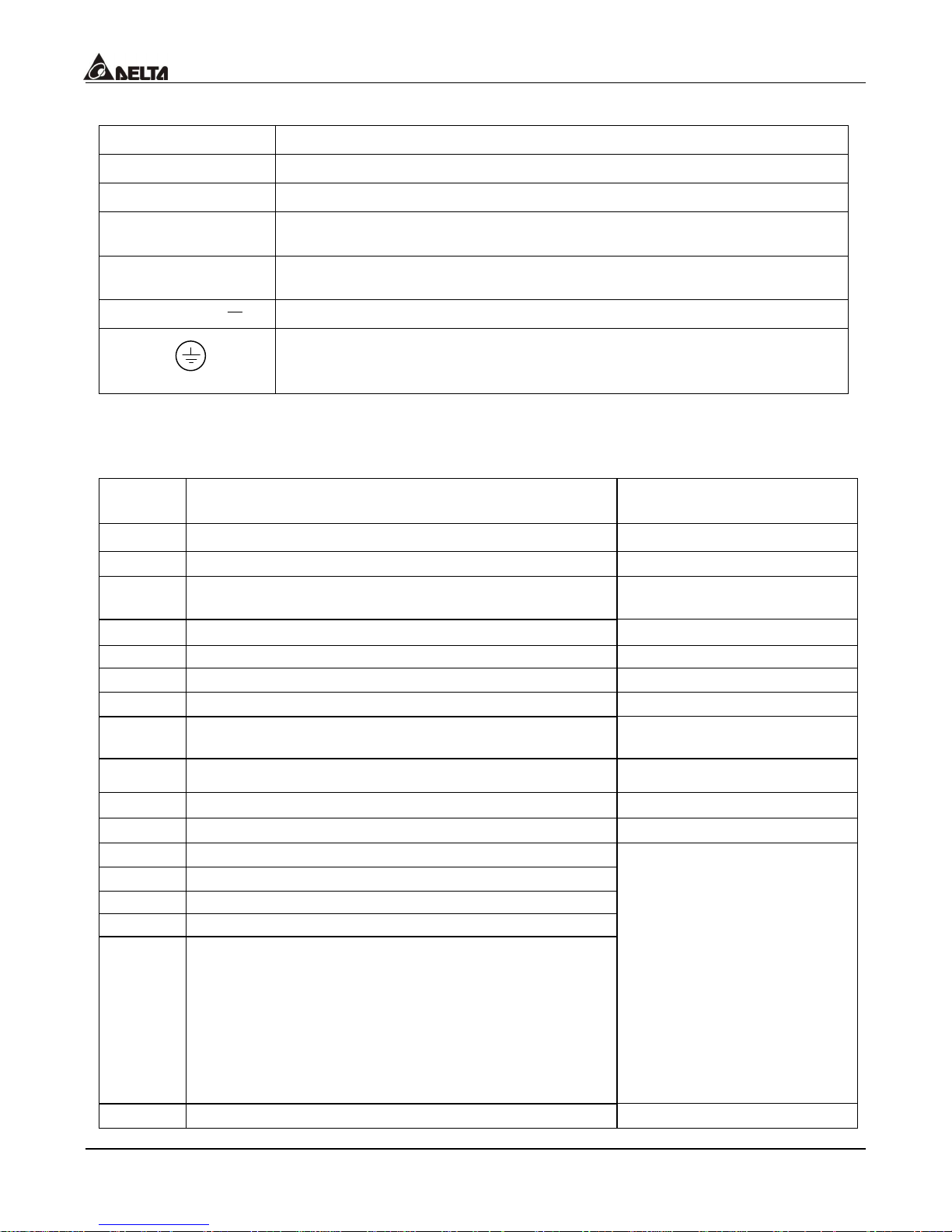

3.3 Main Circuit Terminal Explanations

Terminal Symbol Content Explanation

R/L1, S/L2, T/L3 Input terminals for business-used power supply

U/T1, V/T2, W/T3 Output terminals for the AC motor drivers (at the side of the motor)

+1~+2/B1

+2/B1~B2

Power-improved continuing terminals of the DC reactor; disconnect

the short-circuit piece when the device is installed

Connecting terminals of the braking resistor; purchase and install

these devices according to the selection chart

+2/B1~ Continuing terminals of the braking module (the VFDB series)

Ground terminals, please have these terminals grounded following

the third-type grounding of 230V series and the special grounding of

460V series within the electrician regulations

3.4 Control Terminal Explanations

Terminal

Symbol

Explanation on the Terminal Function Factory Setting

FWD FWD RUN-STOP command

REV REV RUN-STOP command

MI1 Multi-function input selection 1 (3-wire

Multi-step 1 command

STOP-designated terminal)

MI2 Multi-function input selection 2 Multi-step 2 command

MI3 Multi-function input selection 3 Multi-step 3 command

MI4 Multi-function input selection 4 Multi-step 4 command

MI5 Multi-function input selection 5 Abnormal reset command

MI6 Multi-function input selection 6 (TRG-designated

EF

terminal)

DFM Digital frequency signal output

1:1

+24V Digital control signal – the common end +24V 20mA

DCM Digital control signal – the common end

RA Multi-function relay output contact (NO a)

RB Multi-function relay output contact (NC b)

Resistive Load

5A(N.O.)/3A(N.C.) 240VAC

RC Multi-function relay output contact

MRA Multi-function relay output contact (NO a)

MRC Multi-function relay output contact – the common

end

5A(N.O.)/3A(N.C.) 24VDC

Inductive Load

1.5A(N.O.)/0.5A(N.C.)

240VAC

MO1 Multi-function output terminal 1 (photo coupler) Instruction during operation

3-6

1.5A(N.O.)/0.5A(N.C.)

24VDC

Refer to Pr.02-11 to

Pr.02-12

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 18

VFD-V Series

(

A

Terminal

Symbol

MO2 Multi-function output terminal 2 (photo coupler)

(Max 48VDC 50mA)

MO3 Multi-function output terminal 3 (photo coupler)

Explanation on the Terminal Function Factory Setting

Set up the frequency

attained

Driver ready

Max 48VDC 50mA)

MCM Multi-function output terminal – the common end Max 48VDC 50mA

+10V Auxiliary reference power +10V 20mA

The greatest operation

AVI Analog voltage frequency command

frequency corresponding to

0~+10V

The greatest operation

ACI Analog current frequency command

frequency corresponding to

4~20m

The greatest operation

AUI Auxiliary analog voltage frequency command

frequency corresponding to

-10~+10V

The greatest operation

AFM Multi-function analog voltage output

frequency corresponding to

-10~10V

3

ACM Analog control signal – the common end

* Analog control signal wire specification: 18 AWG (0.8 mm2), cover the isolation

twisted wire.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-7

Page 19

VFD-V Series

3.5 Component Explanations

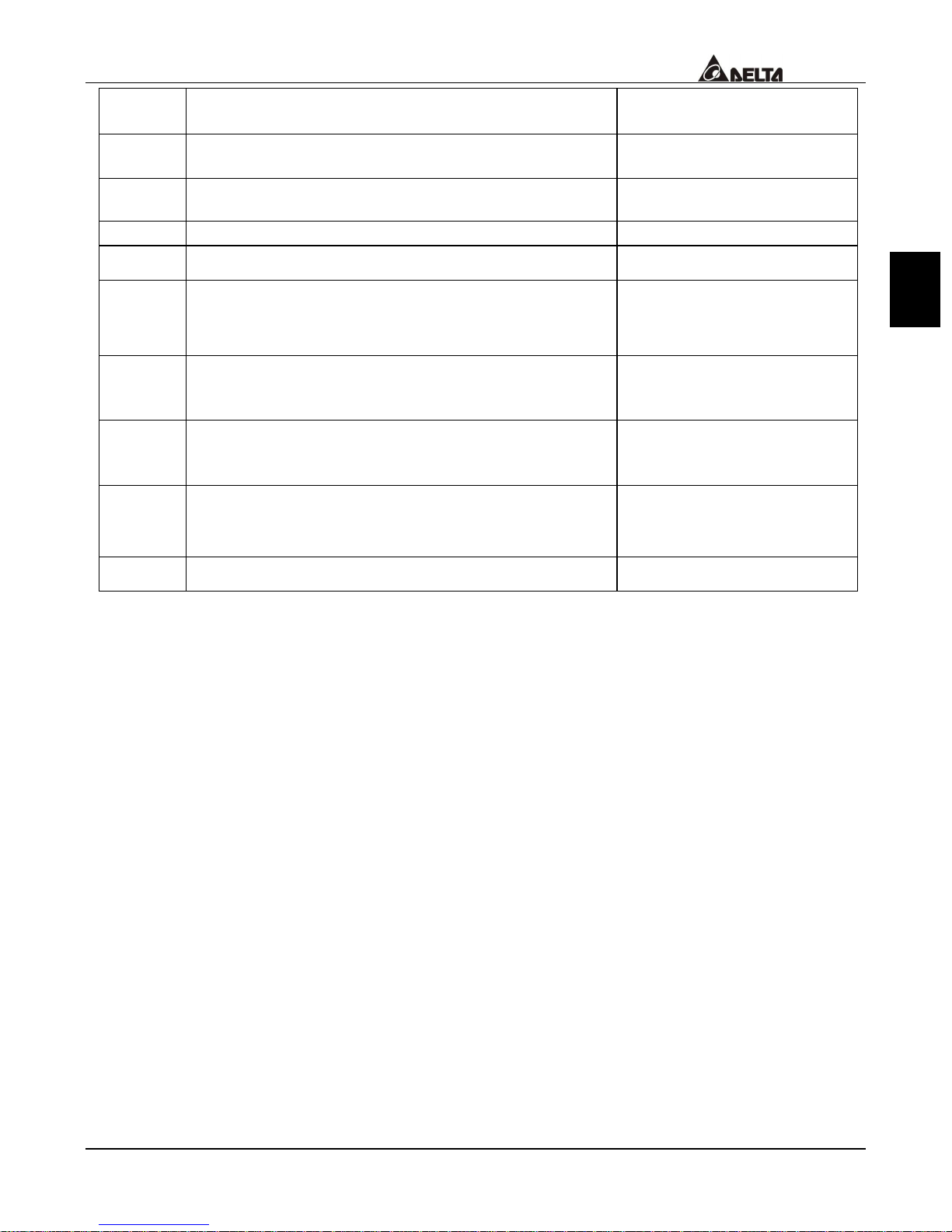

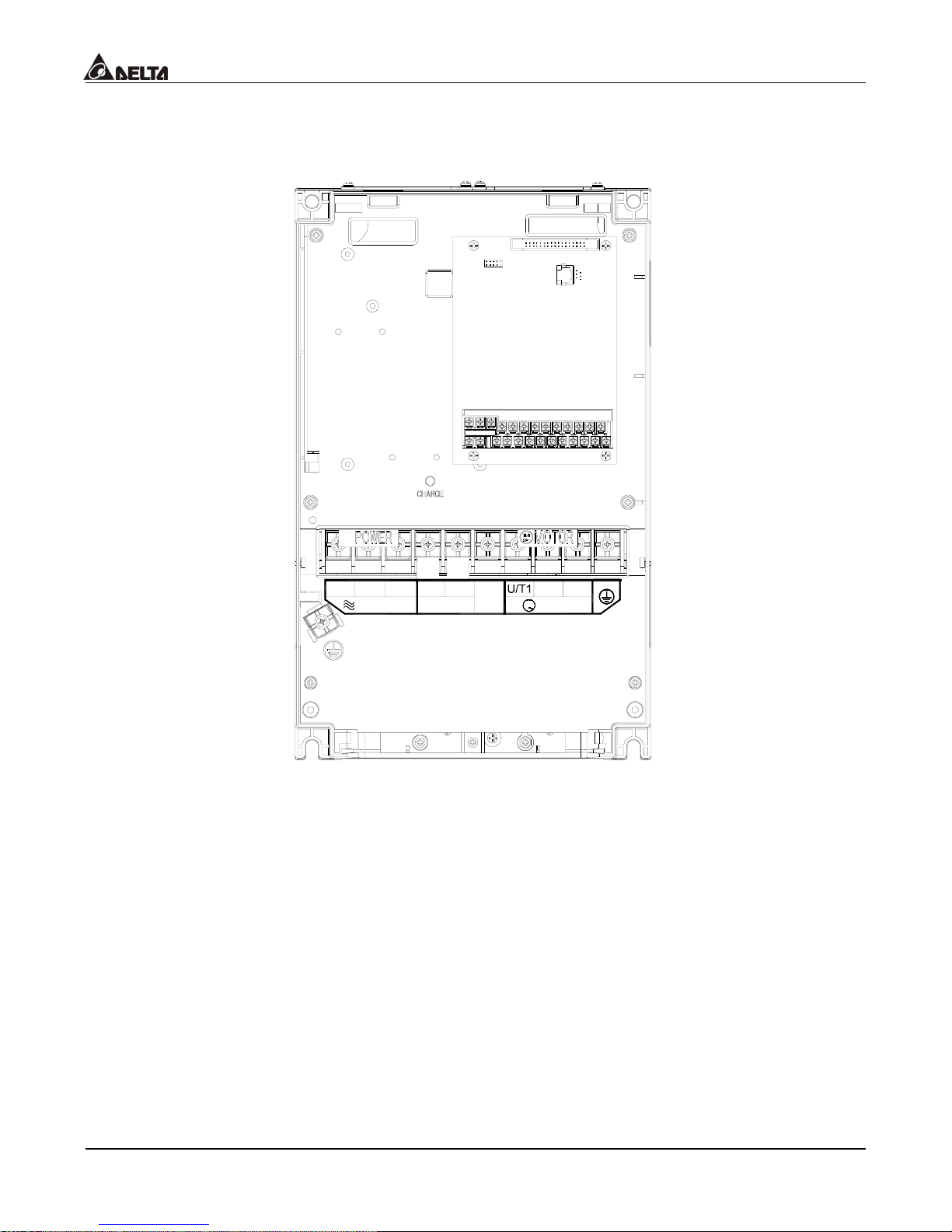

1 HP to 5 HP (VFD007V23A/43A, VFD015V23A/43A, VFD022V23A/43A, VFD037V23A/43A)

+2

+1

B

R/L1 S/L2 T/L3

Control Terminal

Torque: 8Kgf-cm (6.9 in-lbf)

Wire: 22-14 AWG

Power Terminal

Torque: 18 kgf-cm (15.6 in-lbf)

Wire Gauge: 18-10 AWG

Wire Type: Stranded Copper only, 75°C

1

Screw Torque :

18Kgf-cm

Wire Gauge :

18~10AWG

U/T1 V/T2 W/T3

B2

-

3-8

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 20

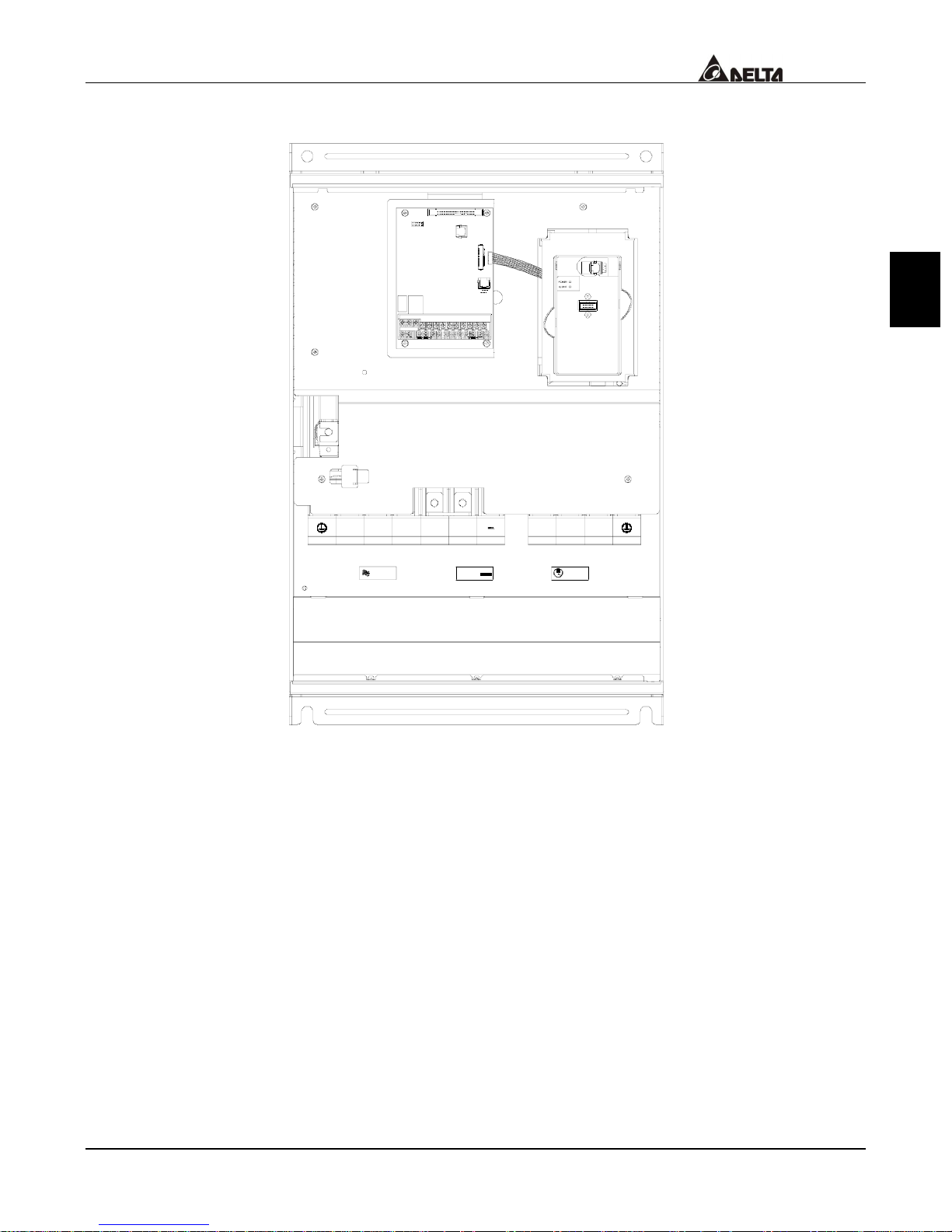

7.5 HP to 15 HP (VFD055V23A/43A, VFD075V23A/43A, VFD110V43B)

VFD-V Series

3

POWER

IM

MOTOR3

Control Terminal

Torque: 8Kgf-cm (6.9 in-lbf)

Wire: 22-14 AWG

Power Terminal

Torque: 30 kgf-cm (26 in-lbf)

Wire Gauge: 12-8 AWG

Wire Type: Stranded Copper only, 75°C

Note: If wiring of the terminal utilizes the wire with a 6AWG-diameter, it is thus

necessary to use the Recongnized Ring Terminal to conduct a proper wiring.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-9

Page 21

VFD-V Series

15HP to 30HP (VFD110V23A/43A, VFD150V23A/43A, VFD185V23A/43A,

VFD220V23A/43A)

R/L1

S/L2 T/L3

POWER

+1

( )

+2

-

DC DC +

( )

-

V/T2 W/T3

IM

MOTOR

3

Control Terminal

Torque: 8Kgf-cm (6.9 in-lbf)

Wire: 22-14 AWG

Power Terminal

Torque: 30 kgf-cm (26 in-lbf)

Wire Gauge: 8-2 AWG

Wire Type: Stranded Copper only, 75°C

NOTE: If wiring of the terminal of VFD220V23A utilizes the wire with a 1AWG-diameter, it

is thus necessary to use the Recognized Ring Terminal to conduct a proper

wiring.

3-10

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 22

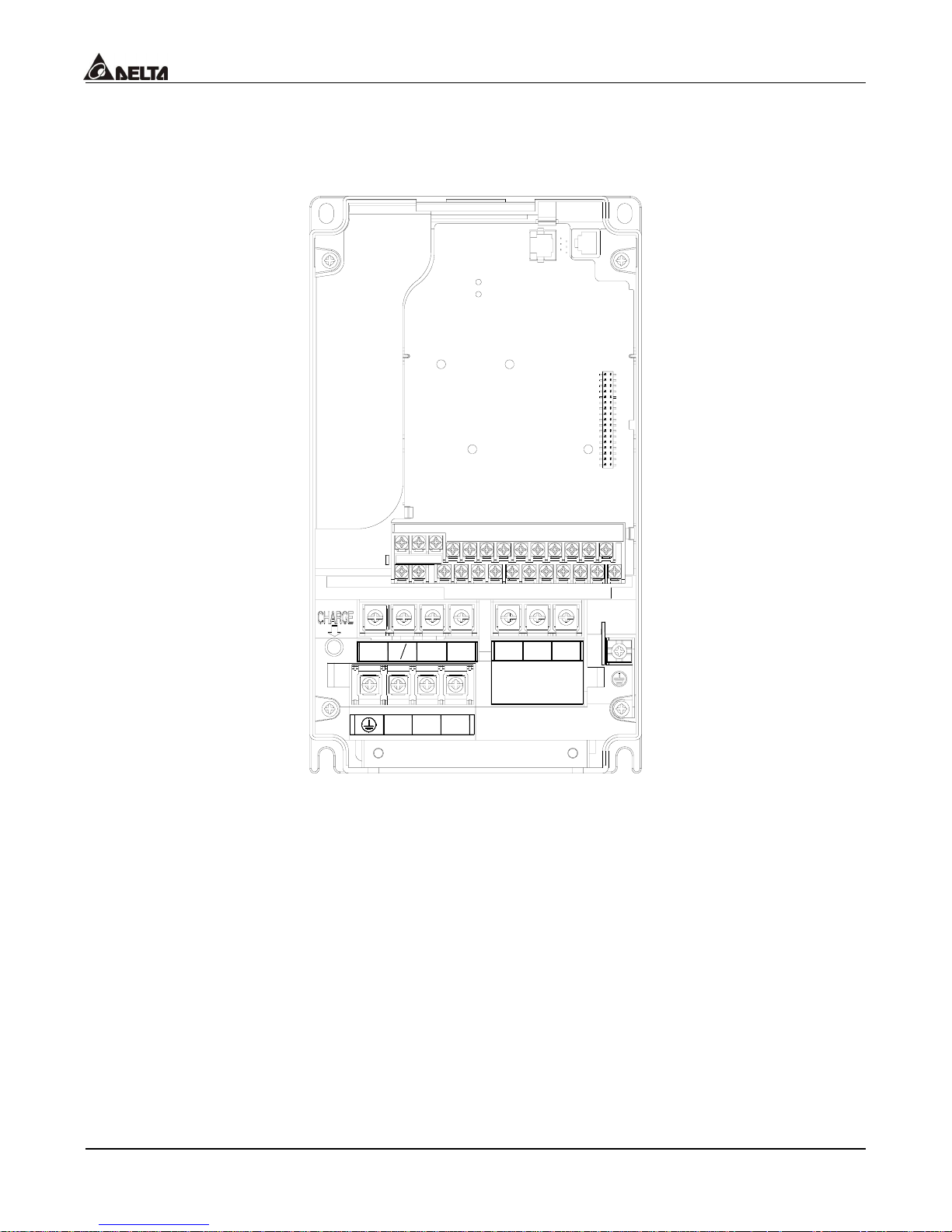

40 to 50 HP 230V (VFD300V23A, VFD370V23A)

VFD-V Series

POWER

CHARGE

Screw Torque:

200kgf-cm

(173in-lbf)

POWER

ALARM

W/T3S/L2R/L1 T/L3 +2+1 U/T1 V/T2

IM

MOTOR

3

3

Control Terminal

Torque: 8Kgf-cm (6.9 in-lbf)

Wire: 22-14 AWG

Power Terminal

Torque: 200 kgf-cm (173.6 in-lbf)

Wire Gauge: 1/0 – 4/0 AWG

Wire Type: Stranded Copper only, 75°C

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-11

Page 23

VFD-V Series

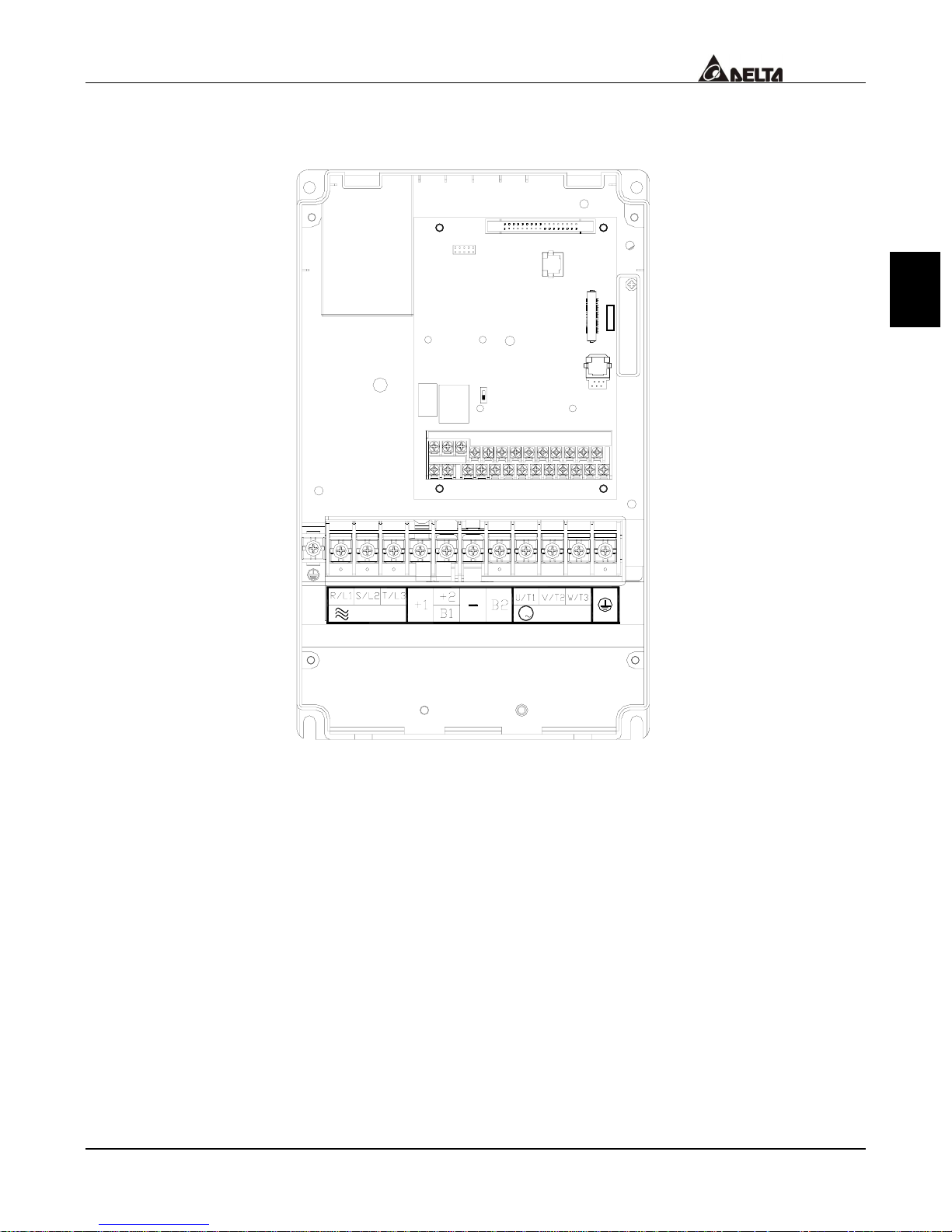

40HP to 60HP 460V (VFD300V43A, VFD370V43A, VFD450V43A)

POWER

ALARM

CHARGE

Control Terminal

Torque: 8Kgf-cm (6.9 in-lbf)

Wire: 22-14 AWG

Power Terminal

Torque: 57 kgf-cm (49.5 in-lbf)

Wire Gauge: 4-2 AWG

R/L1

S/L2 T/L3 U/T1 V/T2 2/T3

POWER

+1

-

+2

IM

3

MOTOR

Wire Type: Stranded Copper only, 75°C

3-12

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 24

75-100 HP 460V (VFD550V43A, VFD750V43A)

VFD-V Series

3

Control Terminal

Torque: 8Kgf-cm (6.9 in-lbf)

Wire: 22-14 AWG

Power Terminal

Torque: 200 kgf-cm (173.6 in-lbf)

Wire Gauge: 1/0 – 4/0 AWG

POWER

Screw Torque:

200kgf-cm

V/T2U/T1+2+1R/L1 S/L2 T/L3 W/T3

MOTOR

Wire Type: Stranded Copper only, 75°C

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-13

Page 25

VFD-V Series

3.6 Wiring Notice

1. There are corresponding ring terminals which will be included with each unit (15-30HP),

and please use the proper crimping tool by KST INC. P/N: KST-HDC38A for securing

the conductor.

2. When wiring up, and that the wiring route specifications are settled, please conduct the

wiring following the electrician regulations.

3. The connection between the three-phase AC input power and the main circuit terminal

R/L1, S/L2, T/L3 has to set up a none-fusing switch in between. The best is to series

connect with an electro-magnetic contactor (MC) so as to cut off the power supply at the

same time when the inverter protection function acts. (The two ends of the

electro-magnetic contactor should have the R-C Varistor).

4. There is no phase-order differentiation in the input power R/L1, S/L2, T/L3 and users

could connect with either one of use.

5. The ground terminal E is grounded with the third-type grounding method (with the

grounding impedance under 100Ω).

6. The grounding wire of the inverter could not be grounded at the same time with

machinery with grand current loading, like that of the electric soldering machine and of

the motor with grand horsepower; they have to be grounded individually.

7. The shorter the ground wire, the better it is.

8. When several inverters are grounded at the same time, be sure not to make it into a

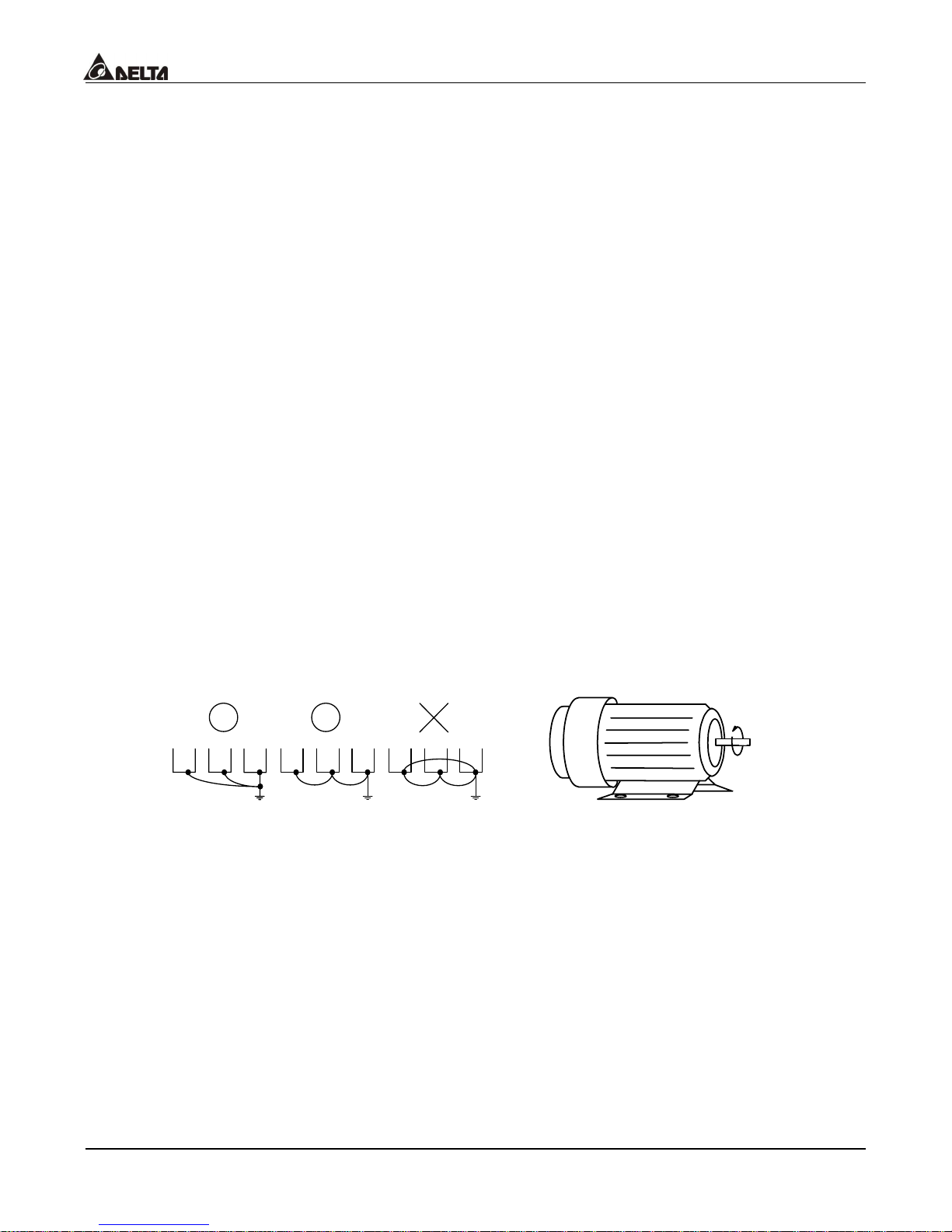

ground circuit. Please refer to the following diagram:

FWD RUN

9. If the output terminals U/T1, V/T2 and W/T3 of the inverter are connecting relatively to

the U, V, and W terminals of the motor, the FWD indicator located on the digital control

panel of the inverter will be lit, and that means the inverter is running forward, and the

rotation direction of the motor will be shown as the right hand side diagram above; if the

REV indicator is lit, it means that the inverter is running in reverse direction, and the

rotation direction will be of the opposite direction compared with the above diagram. If

users are not sure of whether the connection between output terminals U/T1, V/T2 and

W/T3 of the inverter is of one-to-one connection with U, V, and W terminals of the motor,

simply swap either two wires among the U, V, and W terminals of the motor for

correction if the inverter is running forward while the motor is running at reverse

direction.

3-14

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 26

VFD-V Series

10. Be sure of the power voltage and the greatest current possible supplied.

11. When the “Digital Hand-held Programming Panel” is displayed, please do not

disconnect or dissemble any wiring.

12. No braking resistor is installed within the VFD-V inverter (selective purchasing item),

therefore, be sure to purchase and install the braking resistor if to be used on occasions

when the loading inertia is great or that it is of frequent start/stop.

13. Be sure not to connect the AC power with the terminals U/T1, V/T2 and W/T3 on the

power-generating side of the inverter.

14. Please tightly fasten the screws of the main circuit terminals so as to prevent sparks

generated due to the vibration and loosening of the screws.

15. Wiring of the main circuit and of the control circuit should be separated so as to prevent

erroneous actions. If the interlock connection is needed, please make it an

intersection of 90°.

16. If terminals U/T1, V/T2 and W/T3 on the power-generating side of the inverter is in need

of the noise wave-filter, it is then necessary to use the induction-type L-Varistor, but be

sure not to add in the phase-carrying capacitor or the L-C- and R-C-type wave filters.

3

17. Please use the separating wire as much as possible during control wiring, and be sure

not to expose the peeled-off separation net in front of the terminal to the external.

18. Please use the separating wire or tube as much as possible during power wiring, and

ground these two ends of the separating layer or tube to the ground.

19. If the installation site of the inverter is sensitive to interferences, please have the RFI

wave filters installed, and the nearer the inverter to the installation site, the better. In

addition, the lower the carrier wave frequency of, the less the interferences.

20. If the electric-leakage circuit breaker is installed in the inverter, it could serve as the

protection for the electric-leakage error, and as the prevention on the erroneous actions

of the electric-leakage circuit breaker; please select the sensor current above 200mA

with the action time of more than 0.1 second to have these actions accessible.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-15

Page 27

Page 28

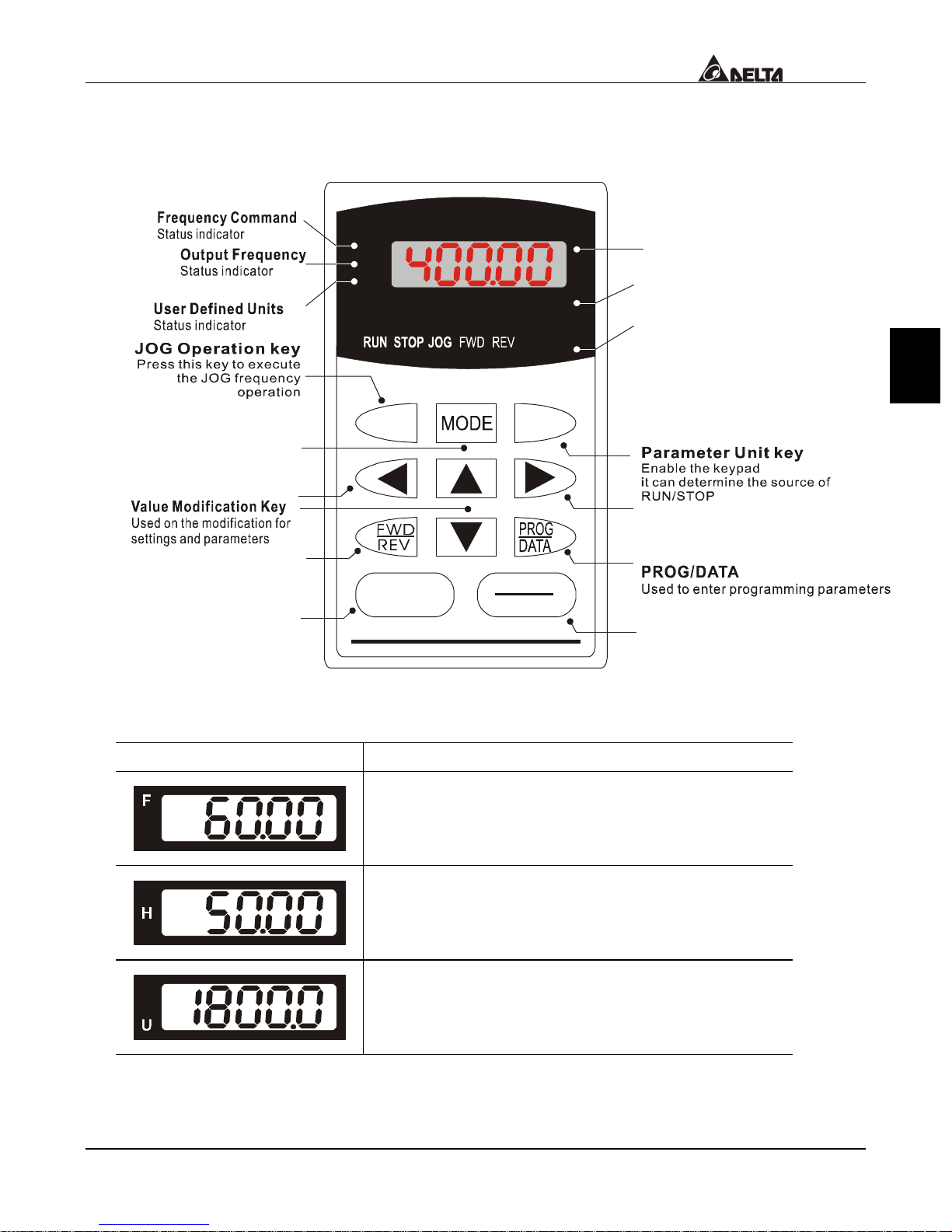

CHAPTER 4 DIGITAL KEYPAD (VFD-PU05) OPERATION

A

4.1 Description of the Digital Keypad VFD-PU05

LED Display

Display frequency, current, voltage

and error, etc.

Part Number

Status Display

Display the driver's current status

When "PU" lights, RUN/STOP is

controlled by PU05. When "PU" is

dark, RUN/STOP is set by 00-21.

When "EXT" lights, frequency

command and torque command

is set by 00-20. When "EXT" is dark,

it is controlled by PU05.

Right key

Moves the cursor right

MODE Selection key

Press this key to view different

operating values

Left key

moves cursor to the left

F

H

U

JOG

VFD-PU05

EXT PU

PU

VFD-V Series

4

FWD/REV Direction key

RUN

RUN key

4.2 Explanations of Display Messages

Messages Displayed Descriptions

Master frequency of the drive

ctual operation frequency output to the motor from

the drive

User-selected content (the side DC-BUS voltage)

STOP

RESET

STOP/RESET

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

4-1

Page 29

VFD-V Series

Messages Displayed Descriptions

Output current

Parameter duplication function: press

PROG/DATA and hold still for about 2~3 seconds,

it will start blinking and will duplicate the parameter

to PU-05.

Press the “Up” or “Down” key to switch to the

“SAVE” function

Parameter duplication function: press

PROG/DATA and hold still for about 2~3 seconds,

it will start blinking and will write the parameter into

the drive.

Press the “Up” or “Down” key to switch to the

“READ” function

The specified parameter item

Value of the parameter content

If the “End” message is displayed (as shown in the

figure), for about 1 second, it is an indication that

the data has been accepted and saved to the

internal memory automatically.

Displayed when the preset data is not accepted or

that the value goes over the limit

4-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 30

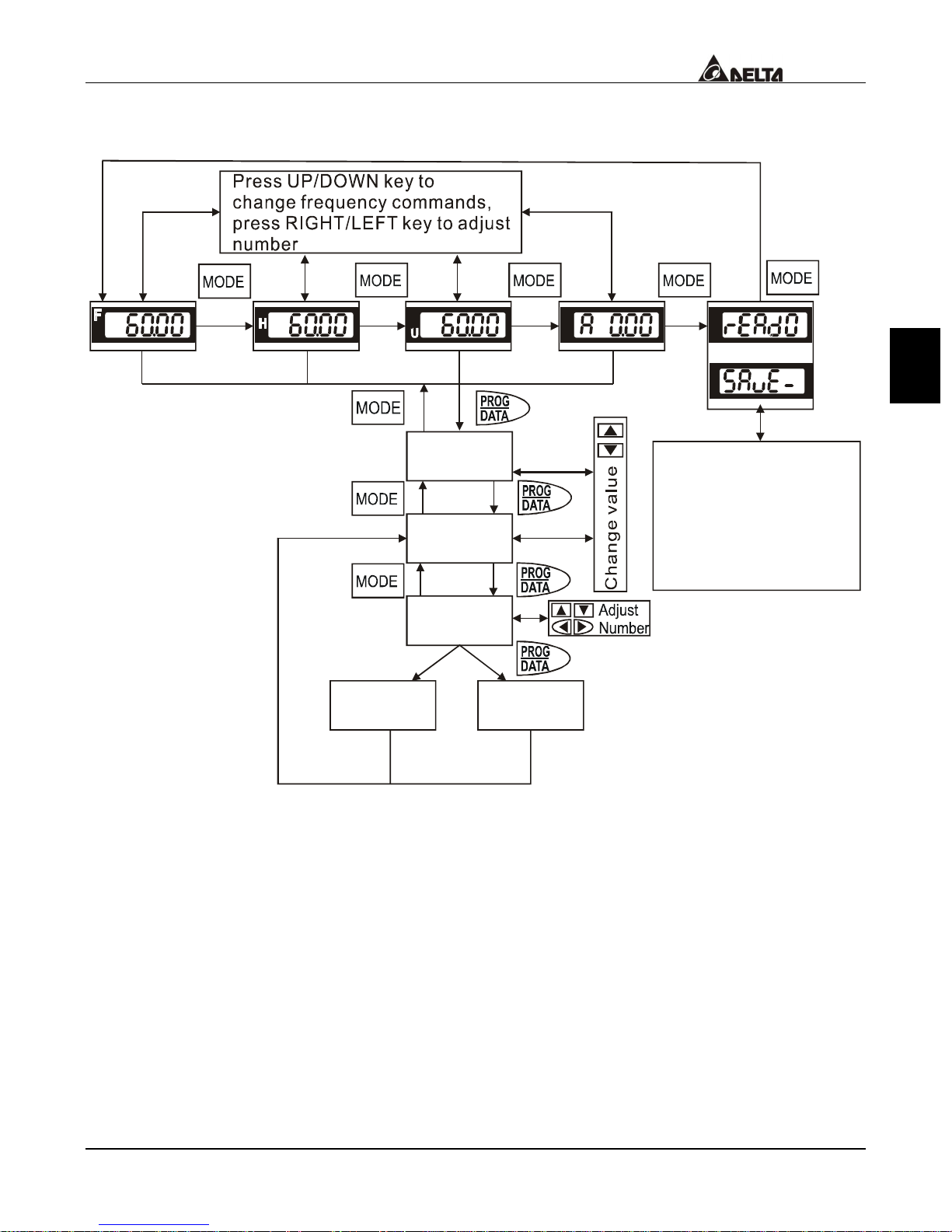

4.3 Operation steps of the Digital Keypad VFD-PU05

X

VFD-PU05 Operation Flow Chart

VFD-V Series

-ERR-

Cannot

write in

XX

XX-XX

XXXX

-END-

Succeed to

Write in

Or

Press UP key to select

SAVE: save parameters

READ: copy parameters

Press PROG/DATA for

about 2 seconds or until

it is flashing, then save/copy

data from AC drive to PU05.

4

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

4-3

Page 31

Page 32

CHAPTER 5 DESCRIPTION OF PARAMETER SETTINGS

5.1 Group 0: System Parameter

00-00 Identity Code Factory setting Read Only

Settings Based on the model type

00-01 Rated Current Display Factory setting Read Only

Settings Based on the model type

VFD-V Series

230V Series

Power [HP]

0.75

[1]

1.5

[2]

2.2

[3]

3.7

[5]

5.5

[7.5]

7.5

[10]11[15]15[20]

18.5

[25]

22

[30] 30[40]37[50]

Model Code 4 6 8 10 12 14 16 18 20 22 24 26

Rated Current of the

5 7.5 11 17 25 33 49 65 75 90 120 146

Fixed Torque

Rated Current of the

Variable Torque

6.25 9.375 13.75 21.25 31.25 41.25 61.25 81.25 93.75 112.5 150 182.5

The Greatest Carrier

15KHz 10KHz

Wave Frequency

460V Series

Power [HP]

0.75

[1]

1.5

[2]

2.2

[3]

3.7

[5]

5.5

7.5

[7.5]

[10]11[15]15[20]

18.5

[25]22[30]30[40]

37

[50]

45

[60] 55[75]

Model Code 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33

Rated Current

of the Fixed

3 4.2 6 8.5 13 18 24 32 38 45 60 73 91 110 150

Torque

5

75

[100]

Rated Current

of the Variable

3.75 5.25 7.5 10.625 16.25 22.5 30 40 47.5 56.25 75 91.25 113.75 137.5 187.5

Torque

The Greatest

Carrier Wave

Frequency

Pr. 00-00 and Pr. 00-01 offer the user the ability to verify the drive’s capacity and current

rating which has been preset by the factory.

Note 1: This parameter is read only.

Note 2: The factory setting is a constant torque rating. If a variable torque rating is desired,

please refer to Pr. 00-12.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

15KHz 10KHz 6KHz

5-1

Page 33

VFD-V Series

00-02 Parameter Reset Factory setting 0

Settings

10 Parameter reset (for 60Hz input)

9 Parameter reset (for 50Hz input)

Bit

settings

Bit 0 1 Parameters are read only 201

Bit 1 1 Disable Frequency and Torque Command changes. 212

Bit 2 1 Keypad disable 224

This parameter offers several functions.

1) The user may reset all parameters to their original factory settings.

2) The user may disable the keypad function.

3) The user may lock the parameters and allow them to be read only.

4) The user may disable the drive from accepting frequency or torque command

changes.

Throughout this manual, there are parameters such as this one, which use a term called

Bit Setting. This is simply the ability to have one parameter conduct multiple functions.

Example 1: Assume the function of Pr. 00-02 is set for “Disable Frequency and Torque

Command changes.” By referring to the above chart, we know Bit 1 is equal to “2”,

because the hex to decimal conversion is (2 ^ the bit = the decimal value). Therefore

21 = 2, and the decimal “2”, should be set in Pr. 00-02 to disable the frequency and

torque commands.

Example 2: Assume Pr. 00-02 is set for “Disable Frequency and Torque Command

changes” + “Keypad Disabled”. If we follow what we have learned, “Disable

Frequency and Torque Command changes” must be set to decimal “2”; and “Keypad

Disable” must be set to decimal “4”. The summation of the two decimal numbers gives

us 6. By entering the number 6 in the parameter, both functions are enabled.

A setting of 1 enables the “Parameters are Read Only” feature, but Pr. 00-00~00-23,

continue to be accessed.

If users would like to reset the parameters to original factory-settings, simply set the Pr.

00-02 to “9” or “10”. If a password was entered, this must first be decoded to allow the

parameters to be reset.

5-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 34

VFD-V Series

00-03 Start-up Display of the Drive

Factory setting 0

a

Settings 0 F (Master frequency command)

1 H (Output frequency)

2 U (multi-function display of Pr. 00-04)

3 Output current

This parameter allows the start-up display to be customized. The display may still be

changed, but during each power on, the display will default to the setting in this

parameter.

00-04 Definitions of the Multi-Function Display

Factory setting 0

a

Settings

0 output voltage 1 DC-BUS voltage

2 voltage command 3 multi-step speed

Speed command for the Process

4

Control Operation step

Remaining number of times for the

6

Time remaining for the Process Control

5

Operation step

7 counter value

“restart after fault” feature

8 torque loading 9 power factor ±1.000

10 Power factor angle (0~180 degrees) 11 Output power (Kw)

12 Output power (Kva) 13 Motor speed (rpm)

14 IGBT module temperature 15 Braking resistor temperature

16 Digital terminal input status 17 PID output command

18 PID feedback value 19 the q axis voltage (V/F and vector)

20 the d axis voltage (Vector only) 21 Magnetic flux

22 Overload accumulated time 23

Electronic thermal relay accumulated

time

Execution time of the multi-step

24

25 quiescence stage

speed

26 over-torque accumulated time 27 DC braking time

28 Compensated voltage 29 Slip compensation frequency

Running number of Encoder

30

31 PG position (position control)

(Channel 1)

Remaining pulses to reach position

32

control (home position)

33 DC voltage upon a fault

34 The output AC voltage upon a fault 35 The output frequency upon a fault

36 The current value upon a fault 37 the frequency command upon a fault

38 day (power-up time) 39 hour, minute

40 The upper bound frequency value 41 Over-torque level

42 Stall level limitation 43 Torque compensation gain

5

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-3

Page 35

VFD-V Series

44 torque limit (Pr. 06-12) 45 the q axis current (V/F and vector)

46 Frequency of Encoder (Channel 1) 49 PID error value

51 AVI input voltage 52 ACI input current

53 AUI input voltage 55 Auxiliary frequency value

60 Input state of digital terminals 61 Output state of digital terminals

84 Input frequency of pulse (Channel 2) 85 Input position of pulse (Channel 2)

86 OL3 timer

This parameter defines the display content the User Defined setting. The User Defined

setting may be displayed upon power up (Pr. 00-03) or by pressing the Mode key on the

keypad and scrolling until the “U” is illuminated.

00-05 User-Defined Coefficient Setting

Factory setting 0

a

Settings 4 digit 0-3: the number of the decimal places

3-0 digit 40~9999

This parameter allows the user to define a special value relative to the output frequency.

4th digit: Setting of the decimal places; 0 means that there is no decimal place and 3

stands for three decimal places.

3~0 digit: The actual value the maximum output frequency should correspond to.

Example: To display rpm’s for a 4-pole 60Hz motor with a base speed 1800rpm and no

slip, Pr 00-05 must be set as follows.

Set the 4th bit = 0, 3rd bit = 1, 2nd bit = 8, 1st bit = 0, 0 bit = 0.

The result of setting 01800 in Pr. 00-05 determines the value at 60Hz (Maximum Output

Frequency).

After this parameter is set, all functions relative to the frequency (except for the V/F

Curve frequency parameters) will automatically be changed to an RPM sale. RPM,

instead of Hz, will now be the unit for the keypad, and thus, if it is displayed as 60.00

before the setup, it will now display 1800 after the setup. Other parameters such as the

multi-step speed and JOG will be automatically changed also.

00-06 Software Version

Settings Read-only

00-07 Password Input

Settings 0~9999

00-08 Password Setting

Settings 0~9999

5-4

Factory setting 0

a

Factory setting 0

a

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 36

VFD-V Series

Pr. 00-07: This parameter allows the user to input their password and disable the

parameter lockout. An incorrect password may be entered 3 times and then a “Pcode”

will flash on the display, alerting the user the password is incorrect. The drive must be

powered off and then powered on again to clear the Pcode display.

Pr. 00-08: This parameter allows the user to input their password to lock out the

parameters from further changes.

To enter a password, the same password must be input twice within two minutes. To

verify the password was entered correctly, display the content of Pr. 00-08. If the

content is “1”, the password is entered. If the content is “0”, no password is entered.

To permanently disable the password. Enter the password in Pr. 00-07, then enter 0

into Pr. 00-08 twice within two minutes.

To re-activate the password, either enter an incorrect password into Pr. 00-07 or power

down and then re apply power to the AC drive.

00-09 Frequency and the Operation Method of PU05

Settings Bit 0 0 Frequency via the up/down keys

Frequency command enabled after pressing the

1

Factory setting 00000

a

0

0

2

1

data/prog key

Bit 1 0 PU05&RS485 frequency memorized 0

1 PU05&RS485 frequency not memorized

Bit 2 0 Up/down pin frequency memorized 0

1 Up/down pin frequency not memorized

Bit 3 0 FWD/REV direction memorized 0

1 FWD/REV direction not memorized

1

2

2

2

2

4

3

2

8

5

Bit 4 0 Parameter memorized 0

1 Parameter not memorized

This parameter allows the user to define the PU05 function. It also allows the user to

determine if the drive retains the direction and speed command after power has been

removed.

Pr. 00-09 = Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 = xxxxx

Bit0 = This setting determines if it is necessary to press the PROG/DATA key first, to

enable the frequency/torque commands via up/down keys on the PU05.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-5

4

2

16

Page 37

VFD-V Series

Bit1 = This setting allows the frequency/torque commands of PU05 and RS485 to either

be retained or forgotten after power has been removed.

Bit2 = This setting allows the frequency/torque commands of the UP/DOWN external

terminals to either be retained or forgotten after power has been removed.

Bit3 = This setting allows the FWD/REV direction to either be retained or forgotten after

power has been removed.

Bit4 = This parameter does not have to be memorized into EEPROM; its original value

will be recovered after the power is turned back on.

Example: If the frequency is to be controlled by the UP/DOWN keys (bit 0 = 0) and the

frequency is to be retained after power off (bit 1 = 1) and the direction is also to

be retained (bit3=1) then Pr. 00-09 must be set to 01010.

00-10 Control Methods Factory setting 0

Settings 0 V/F Control

1 V/F Control + PG

2 Vector Control (open loop)

3 Vector Control + PG (closed loop)

4 Torque Control

5 Torque Control + PG

This parameter determines the control mode for the AC motor drive

0: V/F control: Drive will follow the V/F curve described by Pr. 01-00 to 01-08.

1: V/F control + PG: Drive will follow the V/F curve described by Pr. 01-00 to 01-08, but will

have more speed accuracy.

2: Vector Control: Enables Open Loop Vector control. To acquire the best results, it is

recommended to use the auto-tuning feature of the drive Pr. 05-00. By using this

feature, 200% rated torque may be obtained at 0.5Hz. For more open loop vector

control, refer to group 5 parameters. While in Vector Control, Pr. 01-03 to 01-08 and Pr.

05-04 are not used.

3: Vector control + PG: Enables the Closed Loop Flux Vector Control. The Closed Loop

Flux Vector Control will offer the highest torque and speed accuracy control. 200%

torque at 0Hz and a 1:1000 turn down ratio. While in Vector Control, Pr. 01-03 to 01-08

and Pr. 05-04 are not used.

5-6

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 38

VFD-V Series

y

4: Torque control: Enables Torque (current) Control. Torque control allows the user to run

the AC drive based on current instead of frequency.

5: Torque control + PG: Enables the Closed Loop Torque Control. This will increase the

torque accuracy throughout the speed range and disabled Pr. 05-04.

Note: PI values for PG (closed loop), vector control (open loop) and torque control are

determined by Pr. 05-21~05-25.

00-11

Forward Reverse transition in V/F mode

Follow Pr. 01-00 to

Settings 0

Do not skip the start-up frequency

01-08 Settings

Follow Pr. 01-00 to

1

Skip the start-up frequency

01-08 Settings

2 V/F1.5 power curve Do not skip the start-up frequency

3 V/F1.5 power curve Skip the start-up frequency

4 2 power curve Do not skip the start-up frequency

5 2 power curve Skip the start-up frequency

Frequenc

FWD RUN

01-09

Startup

Frequency

FWD RUN

Factory setting 0

5

Going through point 0

REV RUN

FWD RUN

01-09

Startup

Frequency

This parameter selects the transition mode between Forward and Reverse. By

skipping the start up frequency range, there will be a short time where the motor has not

flux and very little power. It is recommended for all non-horizontal movement to

choose “do not skip the start up frequency”.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

FWD RUN

REV RUN

V/F Mode bit=0

Not going through point 0

-01-09

REV RUN

V/F Mode bit=1

5-7

REV RUN

STOP

STOP

Time

Page 39

VFD-V Series

This parameter may also be used in Vector control to determine if the drive will skip the

zero point. If the drive skips the zero point, it will stop at the frequency determined by

Pr.01-09 and then start again in the opposite direction at Pr.01-09. The Vector control

will generate its own V/F curve, therefore please select 0 or 1 for this parameter setting

when in Vector mode.

00-12 Constant Torque Operation Selection

Factory setting 0

a

Settings 0 oL (100%) Constant torque operation

1 oL (125%) Variable torque operation

When “1” is selected, the oL fault level is 125% of rated drive current. All other over load

ratings will not change, example: 150% of rated drive current for 60 sec.

00-13 Optimal Acceleration/Deceleration Setting

Factory setting 0

a

Settings 0 Linear acceleration/deceleration (follow Pr. 01-12 to 01-21)

1 Auto acceleration (follow Pr. 07-09), Linear deceleration

2 Linear acceleration, Auto deceleration (follow Pr. 06-02)

Auto acceleration (follow Pr. 07-09), Auto deceleration (follow Pr.

3

06-02)

Linear acceleration/deceleration, but conduct the stall prevention

4

throughout the auto acceleration/deceleration function.

Optimal Acceleration/Deceleration settings could ease the drive’s vibration during loaded

starts and stops. Also if the detected torque is small, the processor will speed up the

acceleration time and reach the set frequency at the fastest and smoothest startup

possible. At deceleration, the processor will monitor regenerated voltage and

automatically stop the drive at the fastest and smoothest time possible. Pr. 07-09

(Maximum Current Level for Speed Search) is regarded as the target of the output

current upon acceleration.

00-14 Time Unit for Acceleration/Deceleration and S Curve Factory setting 0

Settings 0 Unit: 0.01 sec

1 Unit: 0.1 sec

This parameter determines the time unit for the Acceleration/Deceleration setting. This

allows the user to choose either high resolution or long acceleration/deceleration times.

Refer to parameters (Pr. 01-12~01-19), the 1st to the 4th Acceleration/Deceleration Time,

(Pr. 01-20, 01-21) the JOG Acceleration/Deceleration Time and (Pr. 01-24~01-27) the S

Curve Acceleration/Deceleration Time.

5-8

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 40

VFD-V Series

00-15 Carrier Frequency Upper Bound

a

Factory setting 10

Settings 0: soft pwm

1~15KHz

00-16 Carrier Frequency Lower Bound

a

Factory setting 10

Settings 1-15KHz (disabled during soft PWM)

00-17 Center Frequency of Soft pwm

a

Factory setting 3

Settings 1~7KHz

This parameter is utilized in setting the carrier frequency of the PWM output.

Carrier

Frequency

Electromagnetic

Noise

Maximum

Interference,

Leakage Current

Minimum

Heat

Dissipation

Minimum

1kHz

8kHz

15kHz

Minimum

Maximum

Maximum

5

00-15

00-16

PWM Carrier Frequency

01-00

Operation

Frequency

The PWM carrier frequency has a direct effect on the electromagnetic noise of the motor

and heat dissipation of the drive. Therefore, if the surrounding noise is greater than the

electromagnetic noises of the motor, it is suggested to lower the carrier frequency, to

decrease the temperature of the drive. Although a quiet operation may be achieved with

a higher carrier frequency, it is necessary to take into consideration the relative wiring

length between the motor and drive and the effect this high frequency may have on the

motor windings.

During SOFT PWM, the electromagnetic noises are less annoying at the same carrier

frequency for standard operation.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-9

Page 41

VFD-V Series

If the carrier frequency’s lower bound (Pr. 00-16) > the carrier frequency’s upper bound

(Pr. 00-15), then the carrier frequency will be operated at the upper bound level.

00-18 Auto Voltage Regulation (AVR) Function

Factory setting 0

a

Settings 0 AVR function enabled

1 AVR function disabled

2 AVR function disabled during deceleration

This parameter selects the AVR mode. AVR is used to regulate the output voltage to

the motor.

The input voltage to the AC motor drive could range from AC180V-264V at, 50Hz/60Hz.

When this occurs, the output voltage to the motor will also vary from 180 to 264 unless

the AVR function is enabled. When enabled, the AVR function will limit the voltage to the

motor, based on Pr. 01-02.

00-19 Automatic Energy-Saving Operation

Factory setting 00010

a

Settings Bit 0 0 Disable automatic energy-saving operation

1 Enable automatic energy-saving operation

Bit 1 0 Maximum output voltage equals to the input power voltage

Maximum output voltage could be greater than the input power

1

voltage (over-modulation available)

When the Auto Energy-Saving function is enabled, the drive will operate with full voltage

during acceleration and deceleration. At constant speed the AC drive will calculate the

optimal output voltage value for the load. It is possible for the output voltage to be 25%

below Maximum Output Voltage during auto energy saving operation. This function

should not be used with variable loads or continuous rated output loads. During these

types of conditions, the operation will cycle on and off, giving poor energy saving results.

Output Voltage

100%

75%

The maximum output voltage

reduction is 25%.

5-10

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 42

VFD-V Series

00-20 Source of the Frequency Command

Factory setting 0

a

Settings 0 The digital keypad

1 The RS485 communication input

2 The external analog input

3 The external up/down pins (multi-function input terminals)

4 The pg (encoder) input or clock

5 The RS485 and PU05 at the same time (dual source)

6 The clock and direction (set by 10-12)

This parameter determines the drive’s master frequency source and Master torque

source.

00-21 Source of the Operation Command

Factory setting 0

a

Settings 0 The RS485 communication

1 The external terminal operation (2 wire or three wire)

2 The digital keypad operation

5

This parameter sets the drive’s operation command source, which may also be switched

via the PU key on the digital keypad. When the PU led on the keypad is illuminated the

Keypad has control over the drives operation.

00-22 Stop Methods

Factory setting 0

a

Settings 0 Ramp to stop

1 Coast to stop

When a “STOP” command is received, the drive will follow the stop method programmed

this parameter.

Frequency

Output

Frequency

Output

Frequency

Operation

Command

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

RUN

STOP

Time

5-11

Operation

Command

RUN

Free running

to stop

STOP

Time

Page 43

VFD-V Series

Ramp to stop: The drive will ramp down from maximum output frequency (Pr. 01-00) to

minimum output frequency (Pr. 01-09) based on the deceleration time (Pr. 01-13).

Coast to stop: the drive will stop the output instantly upon a STOP command and the

motor will coast to stop according to its inertia (time unknown).

(1) In applications where the motor must stop after the drive is stopped, please select

“Ramp to Stop”. This is often a safety consideration.

(2) If the inertial load is large, it is recommended to set the drive for “Coast to Stop” to

eliminate nuisance Over Voltage faults.

00-23

Reverse Operation

a

Factory setting 0

Setting 0 REV enabled

1 REV disabled

2 FWD disabled

This parameter enables the AC drives ability to run in the Reverse Direction. It may be

used to prevent a motor from running in a direction that would consequently injure

humans or damage the equipment.

5-12

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 44

VFD-V Series

5.2 Group 1: Basic Parameter

01-00 Maximum Output Frequency Factory setting 60.00/50.00

Settings 50.0~400.00Hz

This parameter determines the drive’s maximum output frequency.

01-01 Maximum Voltage Frequency (Base Frequency) Factory setting 60.00/50.00

Settings 0.00~400.00 Hz

This parameter must be set to the motor’s nameplate frequency rating.

01-02 Maximum Output Voltage

Settings 230V: 0.0~255.0V Factory setting 220.0

460V: 0.0~510.0V

Factory setting

440.0

5

This parameter must be set to the motor’s nameplate voltage rating.

01-03 Upper Midpoint Output Frequency Factory setting 0.50

Settings 0.00~400.00Hz

01-04 Upper Midpoint Output Voltage

Settings 230V: 0.0~255.0V

460V: 0.0~510.0V

Factory setting 5.0

a

Factory setting 10.0

a

01-05 Lower Midpoint Output Frequency Factory setting 0.50

Settings 0.00~400.00Hz

01-06 Lower Midpoint Output Voltage

Settings 230V: 0.0~255.0V

460V: 0.0~510.0V

Factory setting 5.0

a

Factory setting 10.0

a

01-07 Minimum Output Frequency Factory setting 0.00

Settings 0.00~400.00Hz

01-08 Minimum Output Voltage

Settings 230V: 0.0~255.0V

460V: 0.0~510.0V

Setting of the V/F curve figure is usually based upon the motor’s allowable loading

characteristics. Pay special attention to the motor’s heat dissipation, dynamic balance,

and bearing lubricity, if the loading characteristics exceed the loading limit of the motor.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-13

Factory setting 0.0

a

Factory setting 0.0

a

Page 45

VFD-V Series

When setting the V/F curve, please follow this hierarchy for frequency:

01-01≥01-03≥01-05≥01-07. There is no hierarchy for the voltage setting, but a high

voltage at low output frequencies may cause motor failure. At low frequencies, always

use the lowest voltage necessary for the application.

01-09 Startup Frequency

Factory setting 0.50

a

Settings 0.00~400.00Hz

The Start-up Frequency is the initial frequency output upon a RUN command. If the

startup frequency setting is greater than the Maximum Output Frequency (Pr. 01-00), the

drive will default to Pr. 01-00 as the start point.

When the Pr. 07-12 (Speed-Tracing Function) is enabled, Pr. 01-09 (Start-up frequency)

is disabled.

01-10 Upper Bound Frequency

Factory setting 100.0

a

Settings 0.0~110.0%

01-11 Lower Bound Frequency

Factory setting 0.0

a

Settings 0.0~100.0%

These parameters set the upper and lower limits of the output frequency. If the

command frequency is lower than the Lower Bound frequency, the motor will be

operating at ZERO speed; if the command frequency is greater than the Upper Bound

frequency, the motor will then operate at the Upper Bound frequency.

Vol tag e

1st Voltage

01-02

2nd Voltage

01-04

3rd Voltage

01-06

4th Voltage

01-08

4th Freq.

01-11 01-10

Lower Bound Frequency

Frequency output

ranges limitation

01-07

01-09

Startup Freq.3rd Freq.

01-05

Upper Bound Frequency

01-03

2nd Freq.

Regular V/F Curve

Special V/F Curve

01-01

1st Freq.

Maximum Operation

Frequency

V/F Curve

This function is disabled if the Lower Bound > the Upper Bound.

01-00

5-14

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 46

VFD-V Series

01-12 1st Acceleration Time

01-13 1st Deceleration Time

01-14 2nd Acceleration Time

01-15 2nd Deceleration Time

01-16 3rd Acceleration Time

01-17 3rd Deceleration Time

01-18 4th Acceleration Time

01-19 4th Deceleration Time

01-20 JOG Acceleration Time

01-21 JOG Deceleration Time

Factory setting 10.00/60.00

a

Factory setting 10.00/60.00

a

Factory setting 10.00/60.00

a

Factory setting 10.00/60.00

a

Factory setting 10.00/60.00

a

Factory setting 10.00/60.00

a

Factory setting 10.00/60.00

a

Factory setting 10.00/60.00

a

Factory setting 10.00/60.00

a

Factory setting 10.00/60.00

a

Settings 0.00~600.00 Sec/0.0~6000.0 Sec

The Acceleration Time the time needed for the drive to ramp from 0.0Hz to Maximum

Output Frequency (Pr. 01-00). The Deceleration Time is the time needed for the drive

to ramp down from Maximum Output Frequency (Pr. 01-00) to 0.00Hz.

The acceleration/deceleration times will be disabled if Pr. 00-13 (Auto

acceleration/deceleration Selection) is set for automatic operation.

5

Acceleration/Deceleration times 2 to 4 are enabled by using a multi-function terminal

(Pr.02-01 to 02-06) set to 8 or 9. Acceleration/Deceleration time 4 may also be

selected via Pr. 01-23.

Acceleration/Deceleration time 1 are the factory default for out-of-the-box operation.

The acceleration time has a direct effect on the rise of current upon a RUN command.

If the application load is large and the acceleration time is short (1 second) it is possible

the drive will fault with an “oc”. Similarly if the deceleration time is short (1 second) it is

possible the drive will fault with an “ov” due to motor regeneration.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-15

Page 47

VFD-V Series

Set Point of

the Operation

Frequency

01-00

Maximum

Operation Frequency

Time

01-12 01-14

01-16 01-18

01-20

Definition of the Acceleration/Deceleration Time

01-13 01-15

01-16

01-21

01-19

01-22 JOG Frequency

Factory setting 6.00

a

Settings 0.00Hz~400.00Hz

This parameter determines the Jog frequency. The Jog function may be selected by

the JOG key on the PU05 keypad or the external I/O terminals. When the drive is

operating under a RUN command, the JOG operation is disabled. Likewise, the drive

will not accept a RUN command while the JOG command is enabled.

01-23 1st/4th Acceleration/Deceleration Frequency

Factory setting 0.00

a

Settings 0.00Hz~400.00Hz

This parameter selects the frequency point for transition from acceleration/deceleration

time 1 to acceleration/deceleration time 4.

The transition from acceleration/deceleration time 1 to acceleration/deceleration time 4,

may also be enabled by the external terminals (Pr. 02-01 to 02-06). The external

terminal has priority over Pr. 01-23.

5-16

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 48

Frequency

01-23

1st/4th

Acceleration

/Deceleration

Freq.

1st Acceleration

Time

4th Acceleration Time

VFD-V Series

1st Deceleration

Time

4th Deceleration

Time

1st/4th Acceleration/Deceleration Switching

01-24 S-Curve for Acceleration Departure Time

01-25 S-Curve for Acceleration Arrival Time

01-26 S-Curve for Deceleration Departure Time

01-27 S-Curve for Deceleration Arrival Time

Factory setting 0.00

a

Factory setting 0.00

a

Factory setting 0.00

a

Factory setting 0.00

a

Settings 0.00~25.00 Sec/0.0~250.0 Sec

This parameter determines the S curve strength. A large S curve time will give the

smoothest transition between speed changes. Please note the S curve settings

increase the actual acceleration/deceleration times as follows:

Actual acceleration time = [½(Pr.01-24) + ½(Pr.01-25) + Pr.01-12]

The S curve is disabled when Pr. 00-13 (Auto Acceleration/Deceleration Speed

Selection) is set to Auto or Pr 01-12 to 01-19 (acceleration/deceleration times) is set to

0.

Frequency

01-25 01-26

5

01-24

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-17

01-27

TIME

Page 49

VFD-V Series

01-28 Skip Frequency 1 (upper limit) Factory setting 0.00

01-29 Skip Frequency 1 (lower limit)

Factory setting 0.00

01-30 Skip Frequency 2 (upper limit) Factory setting 0.00

01-31 Skip Frequency 2 (lower limit)

Factory setting 0.00

01-32 Skip Frequency 3 (upper limit) Factory setting 0.00

01-33 Skip Frequency 3 (lower limit)

Factory setting 0.00

Settings 0.00~400.00Hz

These parameters determine the skip frequencies of the AC drive.

Please use the following hierarchy when setting these parameters: Pr. 01-28 > Pr. 01-29 >

Pr. 01-30 > Pr. 01-31> Pr. 01-32 > Pr. 01-33. The Skip frequency will be disabled if this

rule is not followed.

The Skip Frequencies are useful when a motor has vibration at a specific frequency

bandwidth. By skipping this frequency, the vibration will be avoided.

5-18

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 50

5.3 Group 2: Digital Output/Input Parameter

V

V

V

02-00 2-Wire/3-Wire Operation Control Factory setting 0

0

Settings

FWD/STOP, REV/STOP

1

FWD/STOP, REV/STOP (Line Start Lockout)

2

RUN/STOP, REV/FWD

3

RUN/STOP, REV/FWD (Line Start Lockout)

4

3-wire (momentary push button)

5

3-wire (momentary push button and Line Start Lockout)

The VFD-V drive offers six types of external operation control.

VFD-V Series

Three of

six methods include a “Line Start Lockout” feature. When Line

the

start lock out is enabled, the drive will not recognize a RUN command upon

power up. The VFD-V must see the terminal state change from low to high.

This is a safety feature for applications where applying power does not

determine a RUN command.

The Line Start Lockout feature does not guarantee the motor will never start under this

condition. It is possible the motor may be set in motion by a malfunctioning switch.

02-00 Control Circuits of the External Terminal

0, 1

2-wire operation control (1)

FWD/STOP

REV/STOP

2, 3

2-wire operation control (2)

RUN/STOP

REV/FWD

FWD/STOP

REV/STOP

RUN/STOP

FWD/REV

FWD:("OPEN":STOP)

("CLOSE":FWD)

REV:("OPEN": STOP)

("CLOSE": REV)

DCM

FWD:("OPEN":STOP)

("CLOSE":RUN)

REV:("OPEN": FWD)

("CLOSE": REV)

5

FD-V

4, 5

3-wire operation control

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

STOP RUN

RUN/FWD

5-19

DCM

FWD "CLOSE":RUN

EF/MI1 "OPEN":STOP

REV/FWD "OPEN": FWD

"CLOSE": REV

DCM

FD-V

FD-V

Page 51

VFD-V Series

02-01 Multi-Function Input Command 1 (MI1) (NOTE 1) Factory setting 1

02-02 Multi-Function Input Command 2 (MI2) Factory setting 2

02-03 Multi-Function Input Command 3 (MI3) Factory setting 3

02-04 Multi-Function Input Command 4 (MI4) Factory setting 4

02-05 Multi-Function Input Command 5 (MI5) Factory setting 5

02-06 Multi-Function Input Command 6 (MI6) (NOTE 2) Factory setting 10

02-23 Multi-Function Input Command 7

02-24 Multi-Function Input Command 8

02-25 Multi-Function Input Command 9

02-26 Multi-Function Input Command 10

02-27 Multi-Function Input Command 11

02-28 Multi-Function Input Command 12

02-29 Multi-Function Input Command 13

02-30 Multi-Function Input Command 14

Factory setting

Factory setting

Factory setting

Factory setting

Factory setting

Factory setting

Factory setting

Factory setting

0

0

0

0

0

0

0

0

Settings 0 to 44

This parameter selects the functions for each multi-function terminal.

Note 1: If Pr.02-00 is set to 3-wire operation control. Terminal MI1 is needed for the third

wire position. Therefore MI1 is not allowed for any other operation.

Note 2: Multi-Function Input Commands 7-14 are the extension terminals of 02-01-02-06.

There are 14 terminals but the terminals 7-14 are virtual terminals and you can set

the state of bit 8-15 of 02-10 to ON or OFF by PU05 or communication.

Full List of the Functions

Settings Functions Explanations

0 No Function

1 Multi-step Speed Command 1

15 step speeds could be conducted through the

2 Multi-step Speed Command 2

digital statuses of the 4 terminals, and 17 in total if

3 Multi-step Speed Command 3

the master speed and JOG are included.

4 Multi-step Speed Command 4

5

After the error of the drive is eliminated, use this

Reset

terminal to reset the drive

6 JOG Command JOG operation

5-20

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 52

Settings Functions Explanations

VFD-V Series

7

When the acceleration/deceleration speed

inhibition function is executed, the drive will stop

Acceleration/deceleration

Speed Inhibit

the acceleration/deceleration immediately; the

drive will go on with the acceleration/deceleration

from where it stopped earlier after this command is

removed

8 The 1st, 2

nd

acceleration or

deceleration time selection

9

The 3

rd

, 4

th

acceleration or

The acceleration/deceleration time of the drive

could be selected from this function or the digital

statuses of the terminals; there are 4

acceleration/deceleration speeds in total for

deceleration time selection

selection.

10 EF Input External fault input terminal

11 Disable Vector(stop)

If the ON/OFF function of the terminal is

pre-determined, output of the drive will be cut off

12

B.B. traces from the bottom

upward

immediately, and the motor will then be of the B.B.

status. And once the ON/OFF function is

5

restored, the drive will then trace from the bottom

upward to catch up with its mutual rotation speed

with the same frequency before B.B., then speed

13

B.B. traces from the top

downward

up to the pre-set frequency. Even if the motor is

of a complete stop after B.B., as long as the

ON/OFF status is restored, the speed-tracing

function could still be operated.

14 Cancel the setting of the optimal acceleration/deceleration time

Switch between drive settings

Used in the vector control

15

1 and 2

Operation speed command

16

form AVI

Operation speed command

17

from ACI

Operation speed command

18

from AUI

19

20

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Emergency Stop

Digital Up command

Refer to Pr. 02-07

5-21

Page 53

VFD-V Series

Settings Functions Explanations

21

22

23

24

25

26

27

28

29

30

31

Digital Down Command

Auto procedural operation function disabled

Auto procedural operation suspended

PID function disabled

When this terminal is functioning, the currently

displayed counter value will be cleared and “0” is

Clear counter

then displayed; the drive could only accept the

trigger signals to keep counting upward after this

signal disappeared.

Input the counter value (multi-function input command 6)

FWD JOG command

REV JOG command

Accommodating the braking module breakdown

Braking Module Breakdown

output

Position Control

PG feedback control function

Use with PG03/PG04

disable

32 Torque/Speed Switch

EEPROM write function

33

disable

Zero speed is replaced by DC

34

current control

35 04-35,04-36 disable

36 Position control 2 (PG2 input)

37 Dwell function disable

38 Pause Stop

39 P2P Position Control

It is a zero speed command and it is valid during

running. It is used to improve the vibration by using

DC mode at zero speed when AC drive is not

matched with motor or parameter settings of motor

is not very well.

It can be used as position function of clock input

when using with CH2 of PG04.

AC drive stops at this moment and it will run after

closing the function of this terminal.

It can be used to control the 8 default positions

when using with PG03/PG04. But sub-function will

be valid when d36 is set.

5-22

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 54

Settings Functions Explanations

P2P is pause. AC drive keeps outputting at this

VFD-V Series

40 P2P Hold

moment. It will keep on unfinished jog after

terminal is closed.

In speed mode, it will do FWD home search

41 FWD Home Search

according to the setting of 10-09.

In P2P mode, it is used with FWD limit sensor.

42 P2P FWD Limit

When it reaches FWD limit during running, it will

stop free running.

In P2P mode, it is used with REV limit sensor.

43 P2P REV Limit

When it reaches REV limit during running, it will

stop free running.

In speed mode, it will do REV home search

44 REV Home Search

according to the setting of 10-09.

02-07 UP/DOWN Key Mode

Factory setting 00000

a

Settings Bit 0 0 UP/DOWM following the acceleration/deceleration time

UP following the constant speed, and DOWN following the

1

deceleration time

5

Bit 1 0

UP following the acceleration time, and DOWN following the

constant speed

1 UP/DOWN following the constant speed

The maximum Up/Down acceleration/deceleration speed is 10.00Hz/Sec.

02-08 The Acceleration/Deceleration Speed of the

Factory setting 0.01

a

UP/DOWN Key with Constant Speed

Settings 0.01~1.00Hz/msec

02-09 Digital Input Responding Time

Factory setting 0.005

a